Tray, steel carrying box and steel carrying method

A pallet and box technology, applied in the field of assembly and transportation, can solve the problems of low loading and unloading efficiency, lack of versatility, and high loading and unloading frequency, and achieve the effects of saving loading time, improving setting reliability, and improving loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

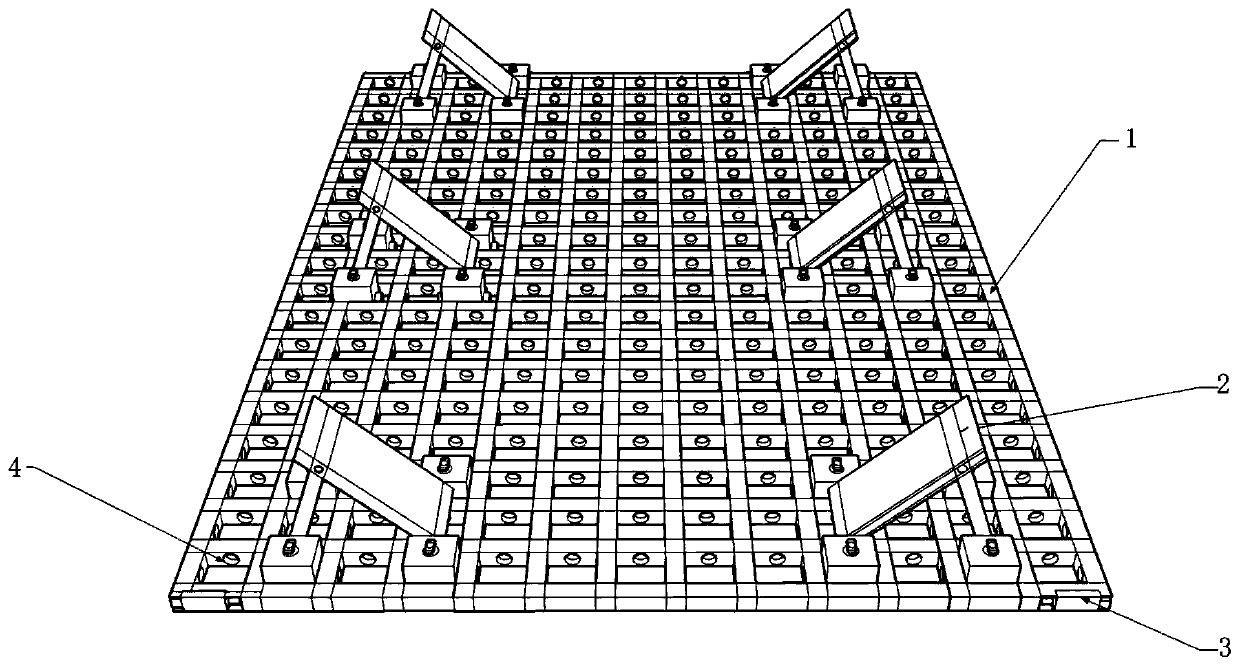

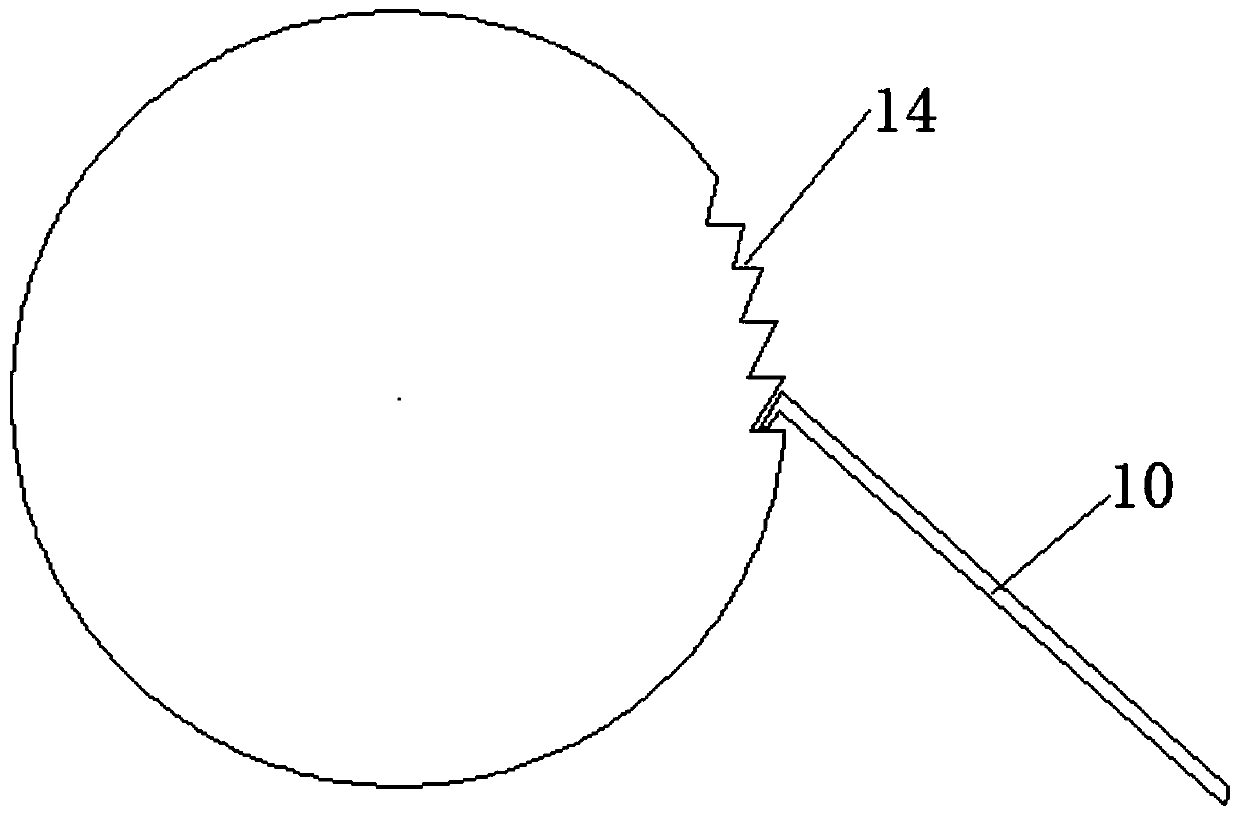

[0045] In a typical embodiment of the present invention, such as figure 1 As shown, a pallet includes a frame 1, an embedded bracket 2 and a fixed base 3. The frame 1 has a set length and width. The frame 1 is made of channel-shaped high-strength steel, which plays the role of carrying goods and integrating all components into a whole. The pallet has two functions, one function is as a bearing device for steel, fixing steel products on the steel pallet, which plays a role in fixing the steel products during transportation, solves the problems existing in the loading and unloading of steel boxes, and greatly improves the loading and unloading efficiency Another function is to use steel pallets to transport different steel products of different specifications. By changing the setting position of the embedded bracket, it can also be used to ship rolls or crankshafts, axles and commercial vehicles, etc., to achieve versatility and diversity.

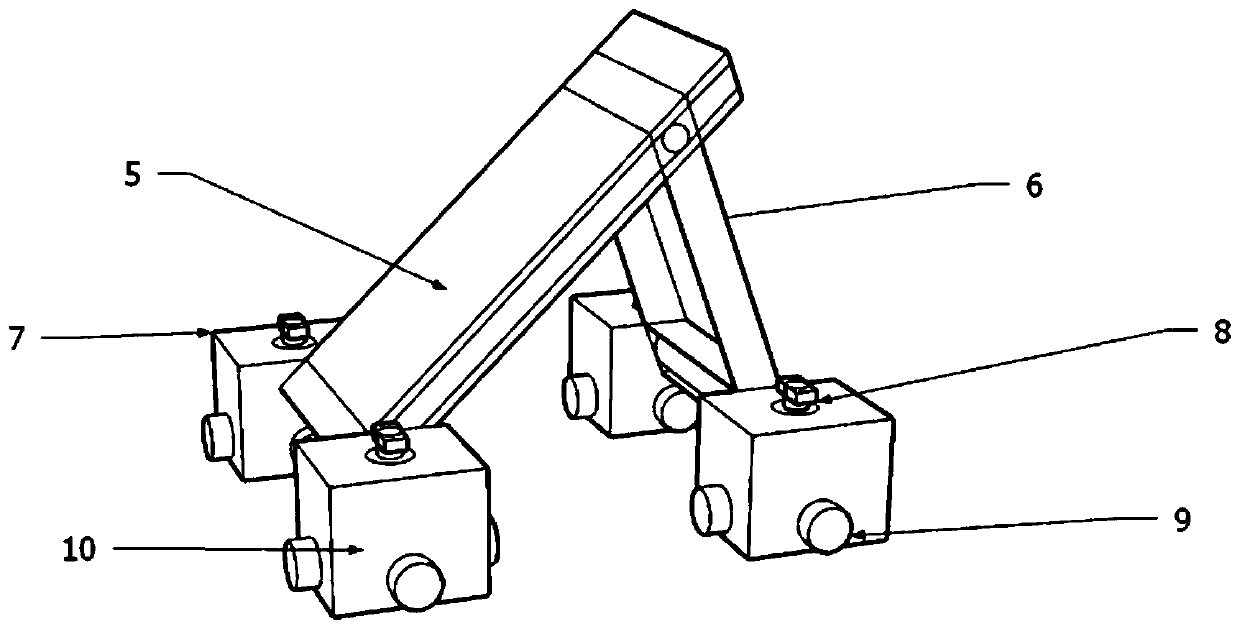

[0046] The fixed base 3 comprises a fra...

Embodiment 2

[0052] This embodiment provides a steel carrying case. The carrying case includes a case body and the tray described in Embodiment 1. The tray and the case together form a steel case 11. The tray can be arranged at the bottom of the case, and the top of the case is open. The box body includes a bottom plate, a front plate, a rear plate, a right side plate and a left door. The bottom plate supports the tray, and the box is opened through the side door. These parts can form a space for placing steel materials; among them, the front plate and the rear plate , The right side panel and the left door adopt the deep wave structure that meets the requirements of the air bag test, and the strength of the deep wave structure meets the requirements of the bulk container; the side of the box is equipped with a back beam structure, which greatly improves the strength of the box.

[0053] Among them, the front plate and the rear plate adopt deep wave structure, and the wave trough grooves of...

Embodiment 3

[0062] A method for carrying steel, using the steel carrying box described in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com