Patents

Literature

62results about How to "Reduce the difficulty of grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-pressure water jet punching-drilling-expanding-cutting integrated antireflection device for coal seam, and related method

ActiveCN106320985AHigh strengthExtended service lifeDrill bitsConstructionsPunchingHigh pressure water

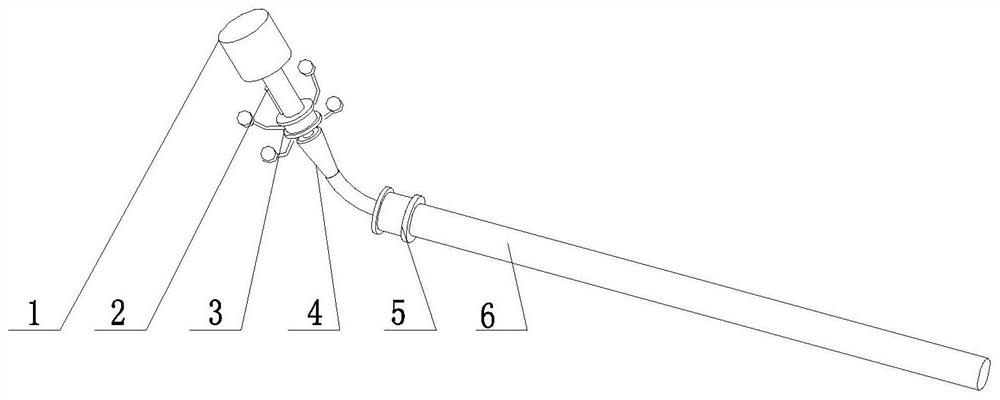

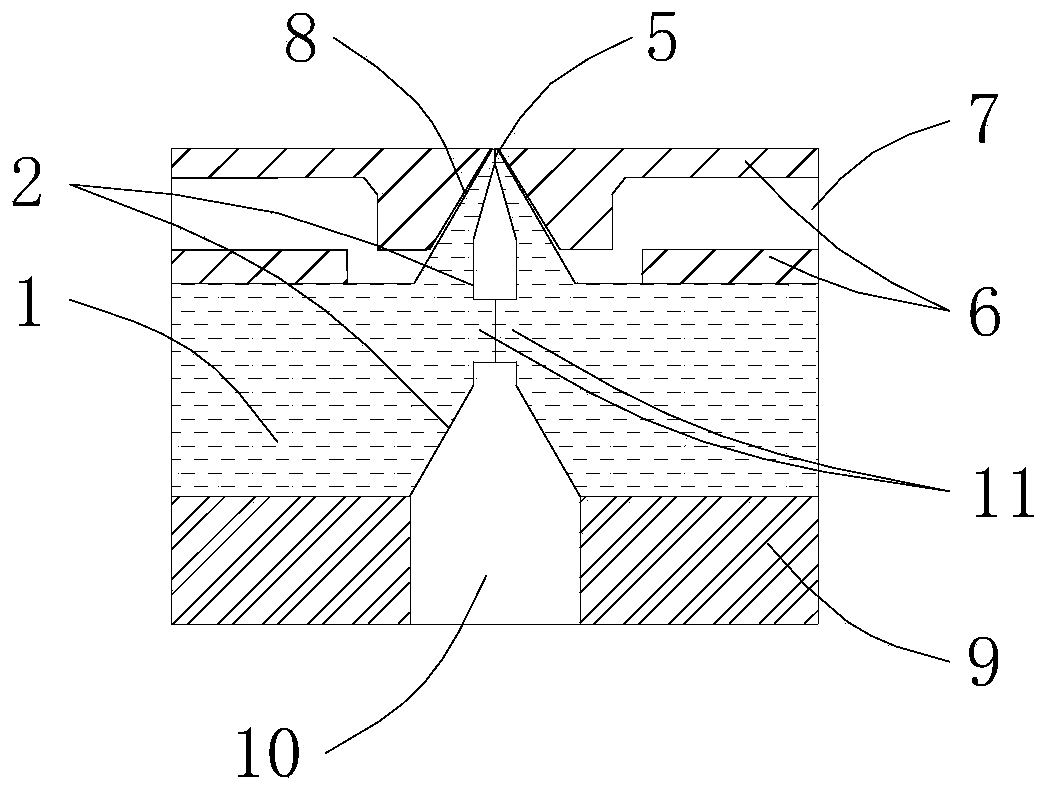

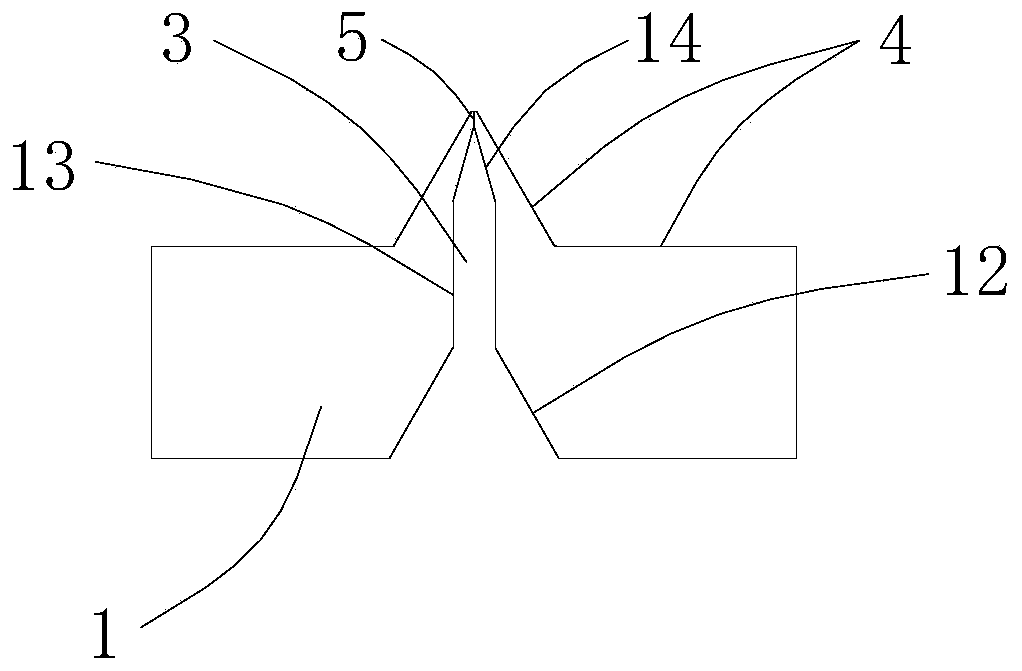

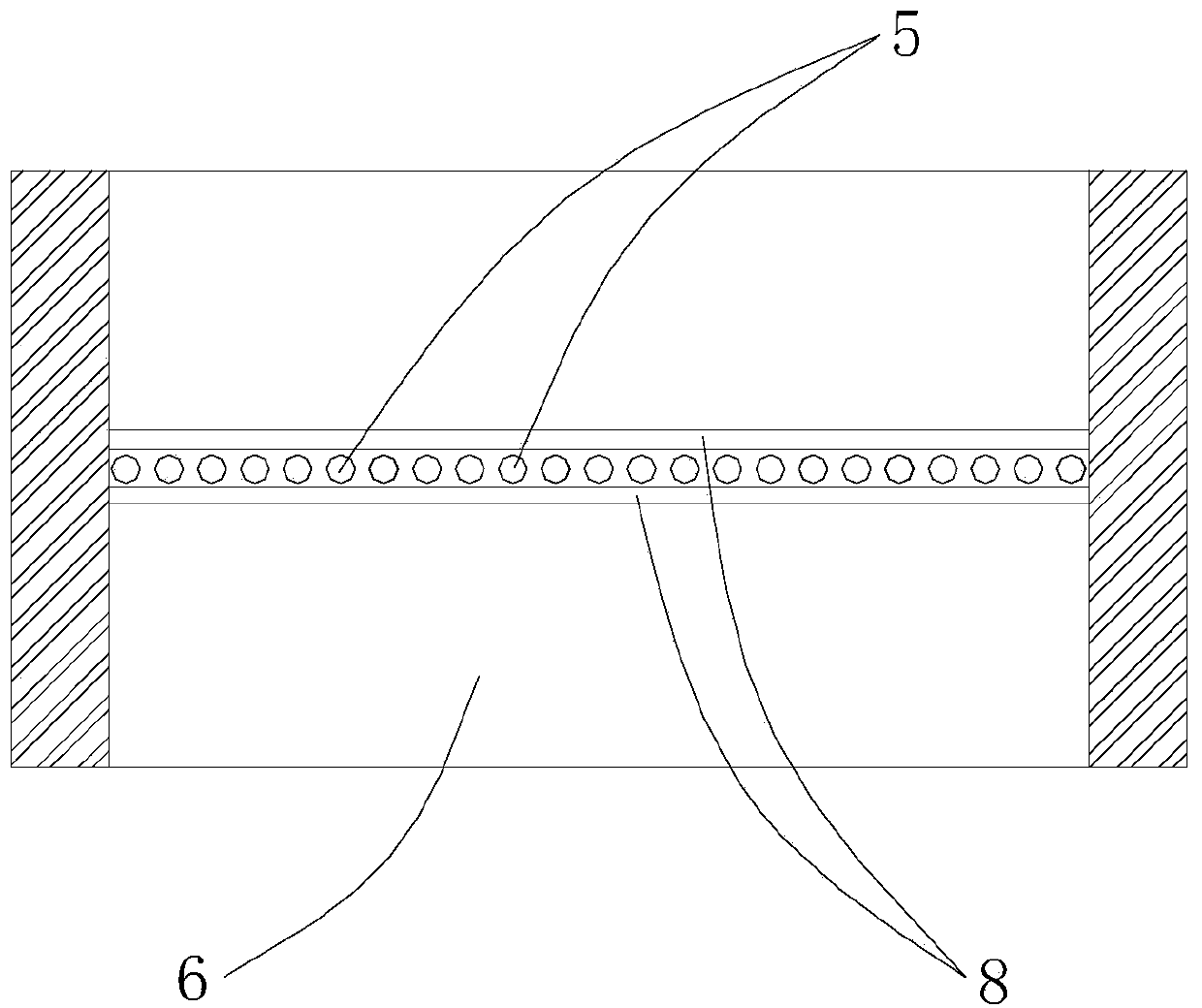

The invention discloses a high-pressure water jet punching-drilling-expanding-cutting integrated antireflection device for coal seam, which comprises a drilling machine, a drilling rod and a drill bit. The drill bit comprises a cylindrical body, wherein the front end of the body extends forward to form a cone-like reaming portion. A reaming cutter is fixed on the conical surface of the reaming cutter. The end face of the small head end of reaming portion extends forward to form a drilling cutter. The rear end of the body is extended backward to form a slitting portion, and the rear end of the slitting portion is fixedly connected with the drilling rod. Pore passages allowing liquid to pass through are provided in the reaming portion, the body and the slitting portion. The rear end of the pore passages is connected with the center hole of drilling rod. The front hole of the pore passages is provided with a punched hole nozzle. A horizontal slit nozzle is provided within the slitting portion, and the pore passages are also provided with a valve core. Therefore, the invention provides a punching-drilling-expanding-cutting integrated antireflection device for the coal seam, and also provides a method for the antireflection of the coal seam by using this punching-drilling-expanding-cutting integrated antireflection device, in order to effectively avoid the borehole deviation, improve the construction environment, reduce water waste and gas waste, and improve work efficiency.

Owner:CHONGQING UNIV

Efficient preparation method for nano-scale solid powder

ActiveCN104785349ALow viscosityNot easy to reuniteSilicaOther chemical processesMaterials preparationSlurry

The invention relates to the field of nano-material preparation, and particularly relates to a method for efficiently grinding a nano-material. The nano-scale solid powder prepared by an efficient preparation method for nano-scale solid powder is a nano-scale solid oxide powder for preparing a grinding aid, a grinding aid raw material is modified to improve the hydrophobicity and then is used as a grinding aid, and the grinding aid raw material and a target substance are the same substance; a raw material slurry to be grinded is configured; the raw material slurry is poured in a grinding machine and cyclically grinded in a manner of wet-method grinding, and finally separated, filtered, cleaned and dried to obtain the nano-scale solid oxide powder. According to the method disclosed by the invention, the modified nano-scale powder with the hydrophobicity is added as the grinding aid during the wet-method grinding, and thus the grinding efficiency is increased, meanwhile, the grinding aid and the grinded substance are the same, and an additional filtering and cleaning step is not needed, and thus further simplifying the whole processing technique, greatly shortening the time needed by production and processing, reducing the production cost, and increasing the yield.

Owner:浙江冠旗纳米科技有限公司

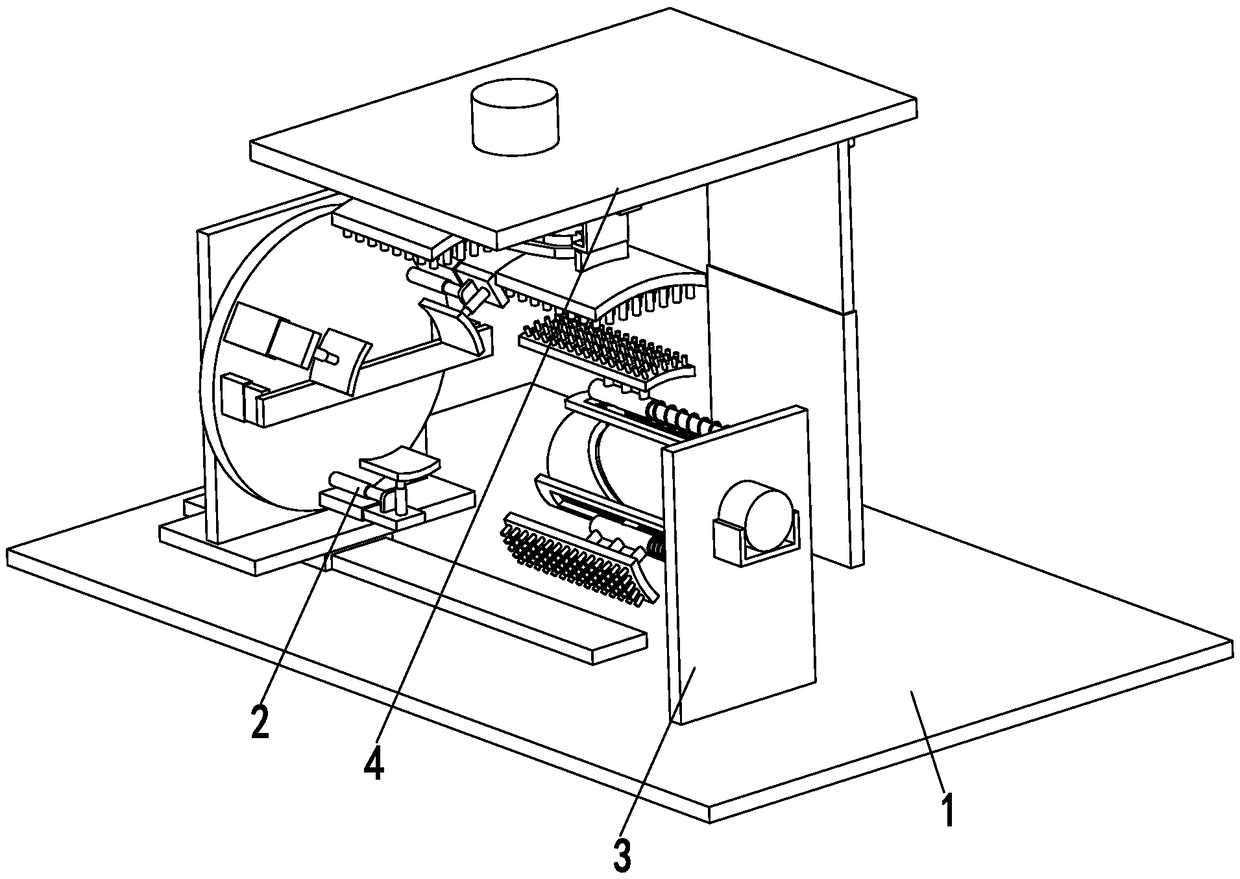

Workpiece grinding machine of numerical-control electric spark machine tool

InactiveCN108789046ASolve the costSolve labor intensityGrinding carriagesGrinding drivesNumerical controlEngineering

The invention relates to a workpiece grinding machine of a numerical-control electric spark machine tool. The workpiece grinding machine of the numerical-control electric spark machine tool comprisesa base plate, a fixing device, an inner wall grinding device and an outer wall grinding device. The fixing device and the inner wall grinding device are sequentially installed on the base plate from left to right. The outer wall grinding device is installed on the back side of the base plate. The inner wall grinding device comprises a fixing plate, a rotating motor, a rotating column, sliding blocks, limiting frames, telescopic rods, springs, adjusting air cylinders and first steel wire brushes. The outer wall polishing device comprises a lifting frame, a rotating motor, a rotating column, a cam, connection sliding blocks, connection frames, guide rails and second steel wire brushes. The workpiece grinding machine of the numerical-control electric spark machine tool can solve the problemsthat in an existing annular workpiece grinding process, the labor cost is high, the labor intensity is high, the work efficiency is low, the grinding difficulty is large, and the adjustability is poor; the automatic grinding function on the annular workpiece can be achieved; and the workpiece grinding machine of the numerical-control electric spark machine tool has the advantages of being low in labor cost, low in labor intensity, high in work efficiency, small in polishing difficulty, good in adjustability and the like.

Owner:浙江芊荷科技有限公司 +1

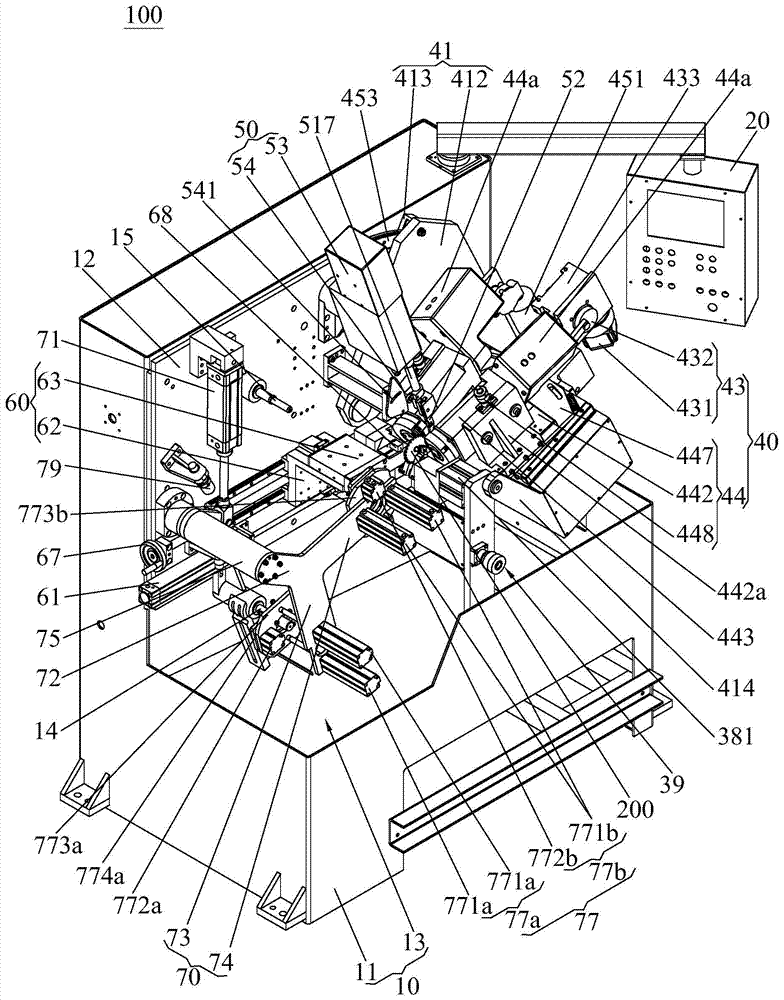

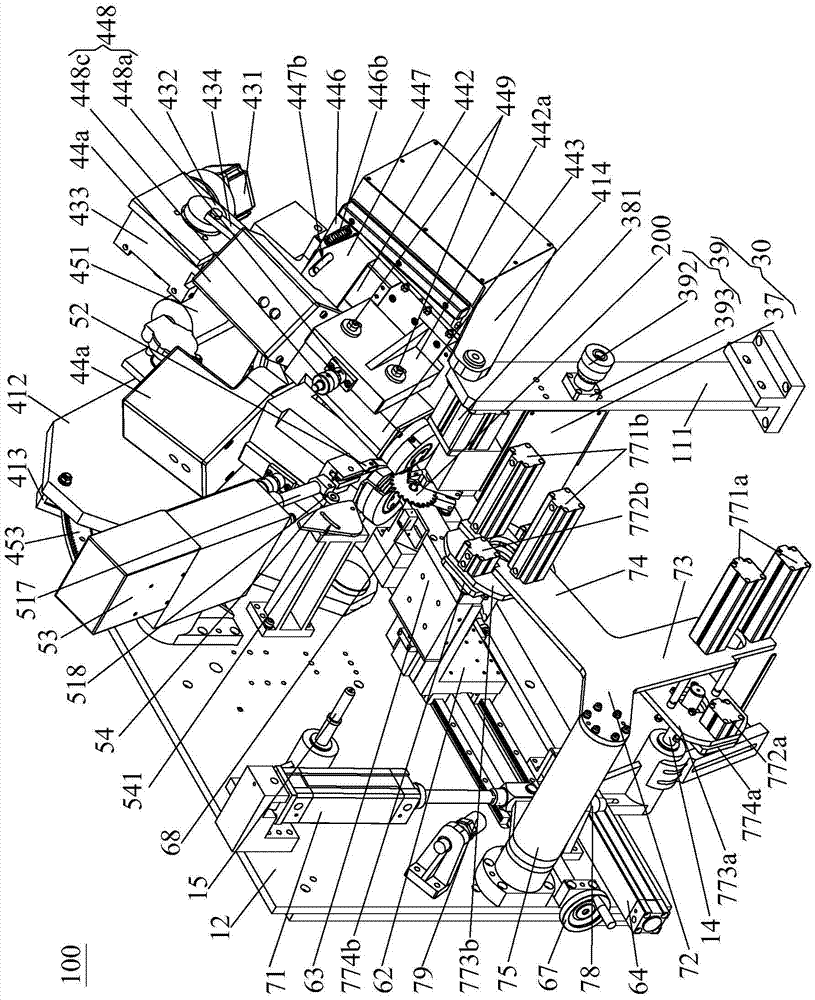

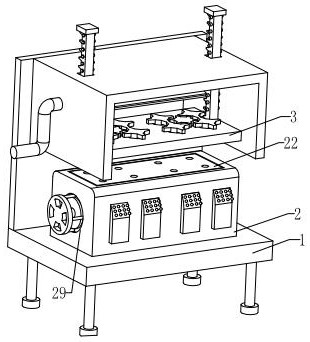

Bilateral discharge machine

ActiveCN103692018ACompact structureEasy to operateSawing tools dressing arrangementsTooth grindingEngineering

The invention provides a bilateral discharge machine, which comprises a housing, a controller, a clamping unit, a discharge tooth-grinding unit, a tooth-driving unit, a bearing unit and a feeding unit, the clamping unit comprises a first jaw and a second jaw which are oppositely arranged, so that a clamping area for clamping a saw blade is formed, the discharge tooth-grinding unit comprises a first mount, a first driving mechanism, a second driving mechanism and two discharge tooth-grinding mechanisms, the first driving mechanism can drive the two discharge tooth-grinding mechanisms to move close to or separate from each other, the second driving mechanism can drive the two discharge tooth-grinding mechanisms to synchronously reciprocate close to or away from the clamping area and in a direction intersecting the closing and separating direction, the tooth-driving unit can drive alloy welded pieces on the saw blade in the clamping area one by one, the bearing unit can move the borne saw blade into or out of the clamping area, and the feeding unit can feed a saw blade to be machined onto a carrier and take away a machined saw blade from the carrier. The bilateral discharge machine increases the efficiency of machining and the quality of grinding.

Owner:高邮市驿都小微企业服务管理有限公司

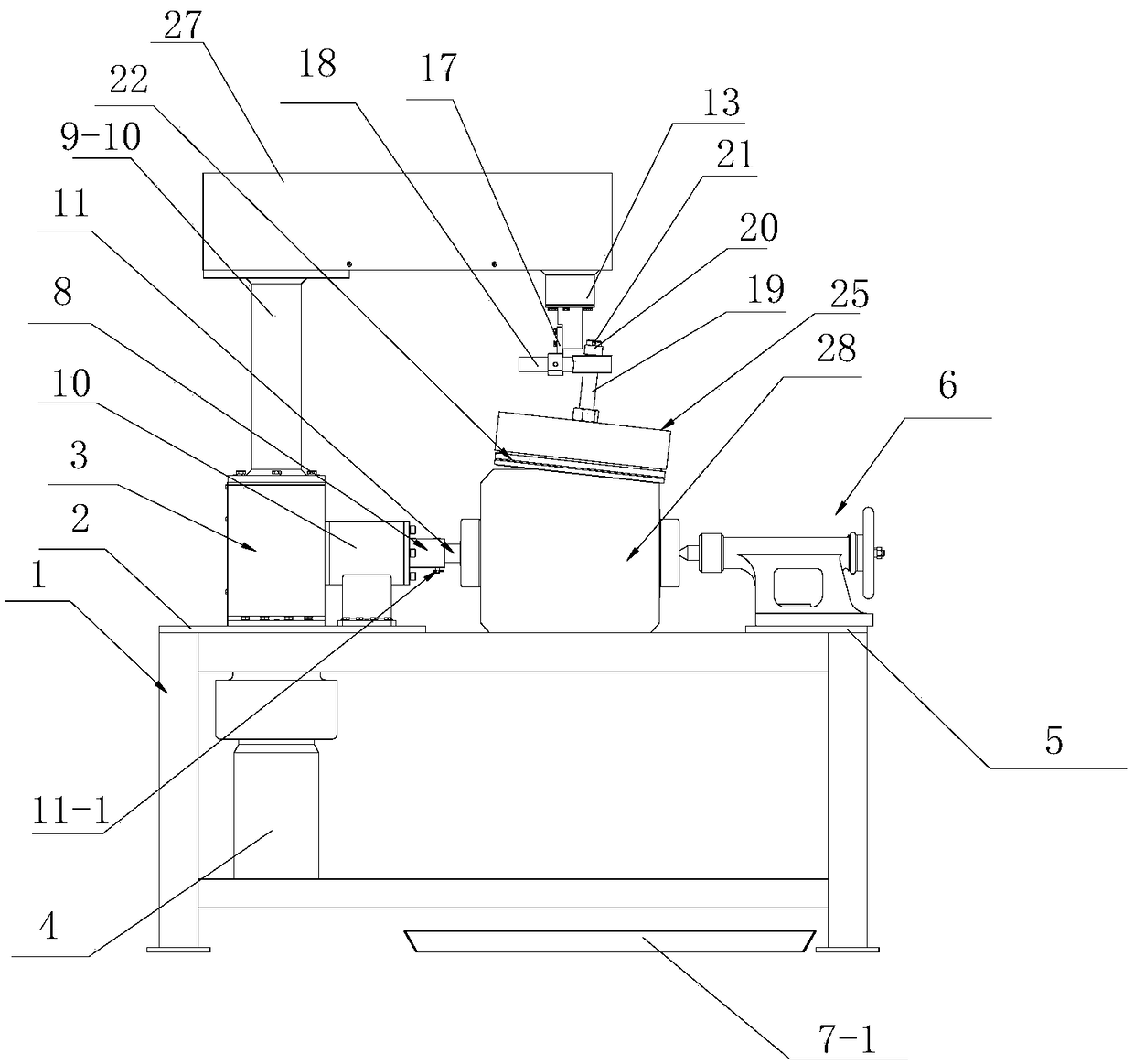

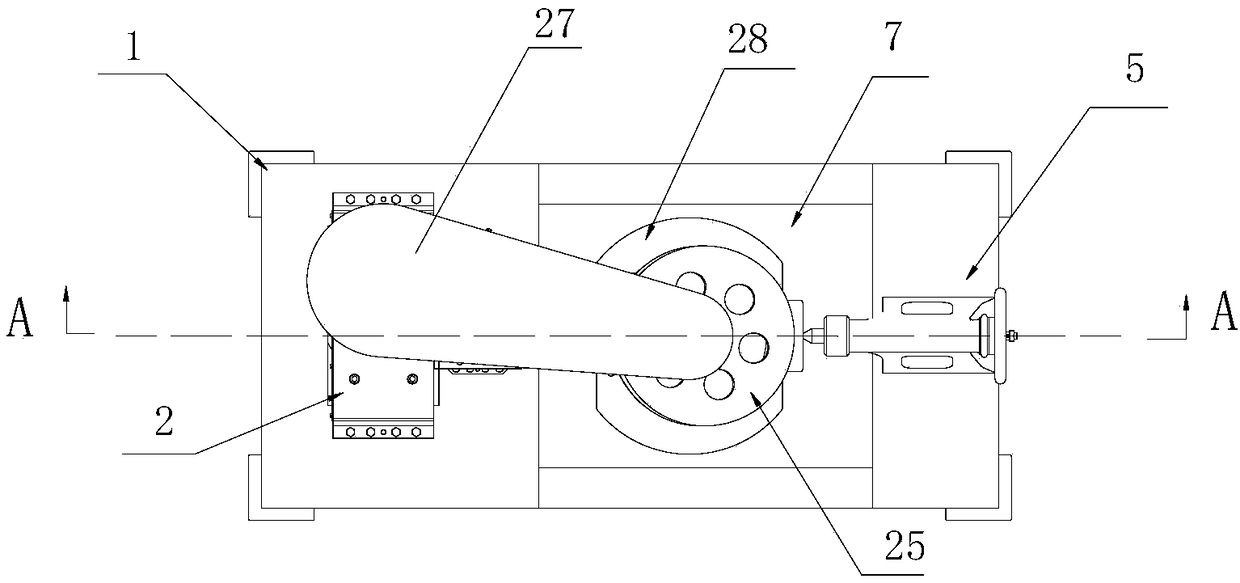

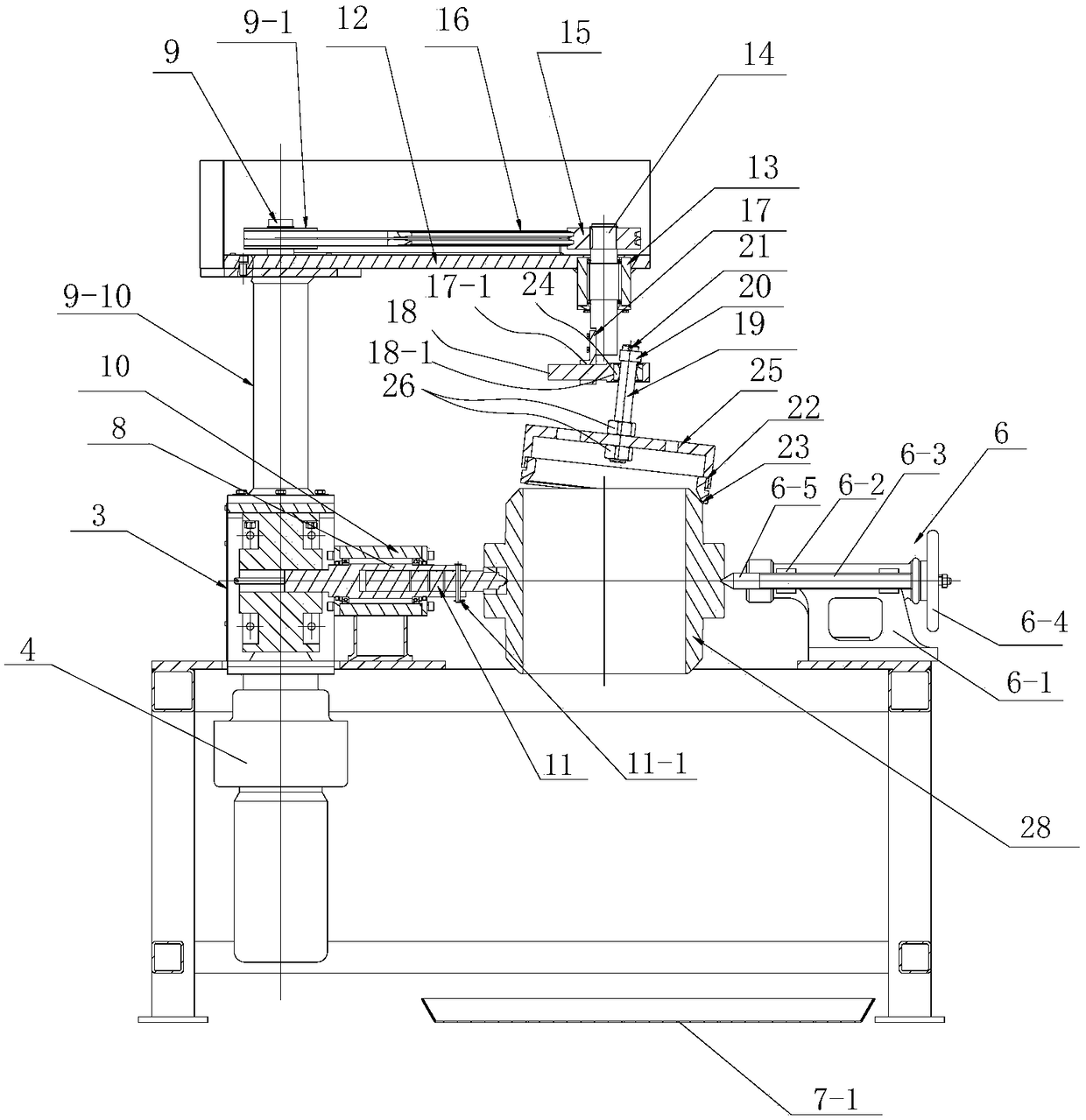

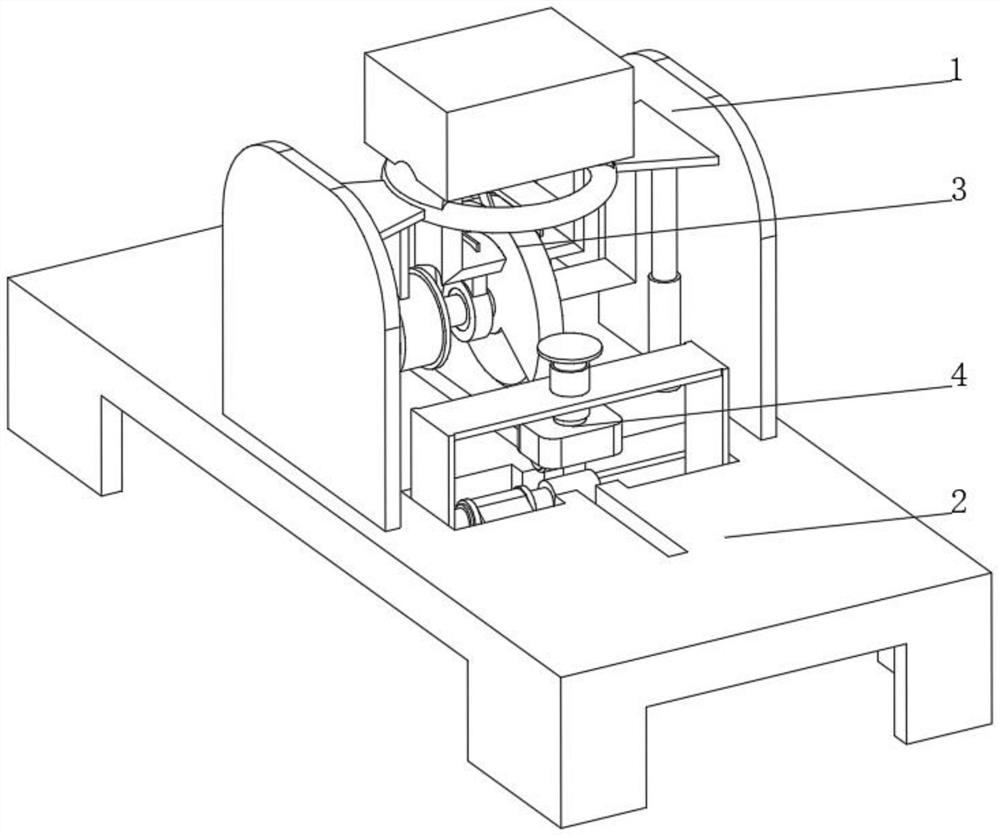

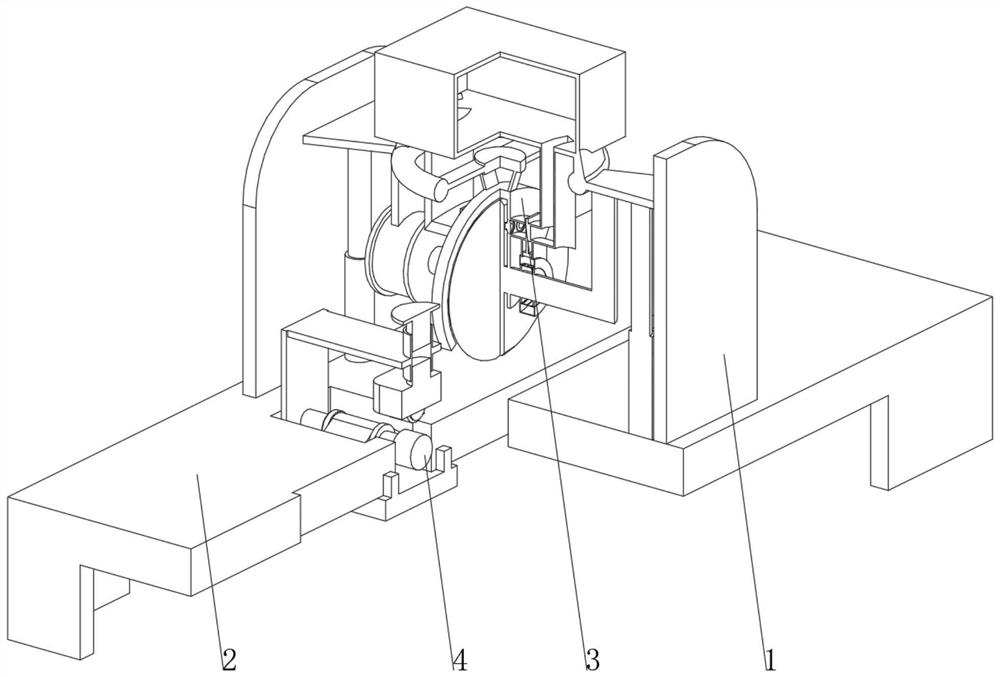

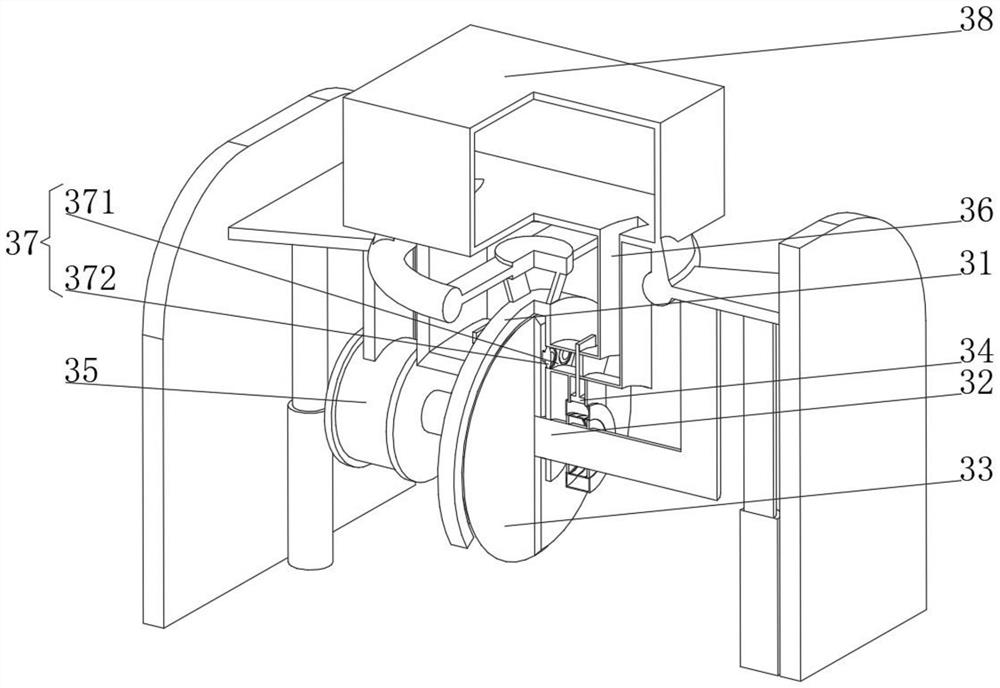

Grinding machine for grinding of ball valve ball body

PendingCN108500775AEasy to operateImprove transfer efficiencySpherical surface grinding machinesLapping machinesDrive wheelDrive motor

The invention relates to a grinding machine for grinding of a ball valve ball body. The grinding machine for grinding of the ball valve ball body is characterized in that the grinding machine for grinding of the ball valve ball body comprises a machine frame, a power supporting plate, a gear box, a driving motor, a tailstock supporting plate and a tailstock clamping mechanism; a ball body drivingshaft and a grinding power shaft are installed in the gear box; a telescopic shaft is connected to the end portion of the ball body driving shaft, a driving wheel is installed at the upper end portionof the grinding power shaft, a cantilever beam is arranged on the upper portion of a supporting sleeve, and a grinding shaft is installed at the end portion of the cantilever beam; a driven wheel isinstalled on the upper portion of the grinding shaft of the cantilever beam, and a transmission element is installed between the driving wheel and the driven wheel; and a suspension frame is installedat the lower end of the grinding shaft, a telescopic arm is installed on the suspension frame in a penetrating mode, a rocker is installed at the one end of the telescopic arm in the vertical direction in a penetrating mode, a grinding rack is connected to the lower end of the rocker, and a grinding tool of a valve seat sealing surface is arranged at the lower end of the grinding rack. The grinding machine for grinding of the ball valve ball body has the advantages that the conception is novel, the use is convenient, the machining efficiency and quality of the ball body are improved, good sealing performance is ensured after the grinding machine is matched with the valve seat, and the grinding difficulty of a ball body workpiece is reduced.

Owner:TIANJIN XIANGJIA FLUID CONTROL SYST CO LTD

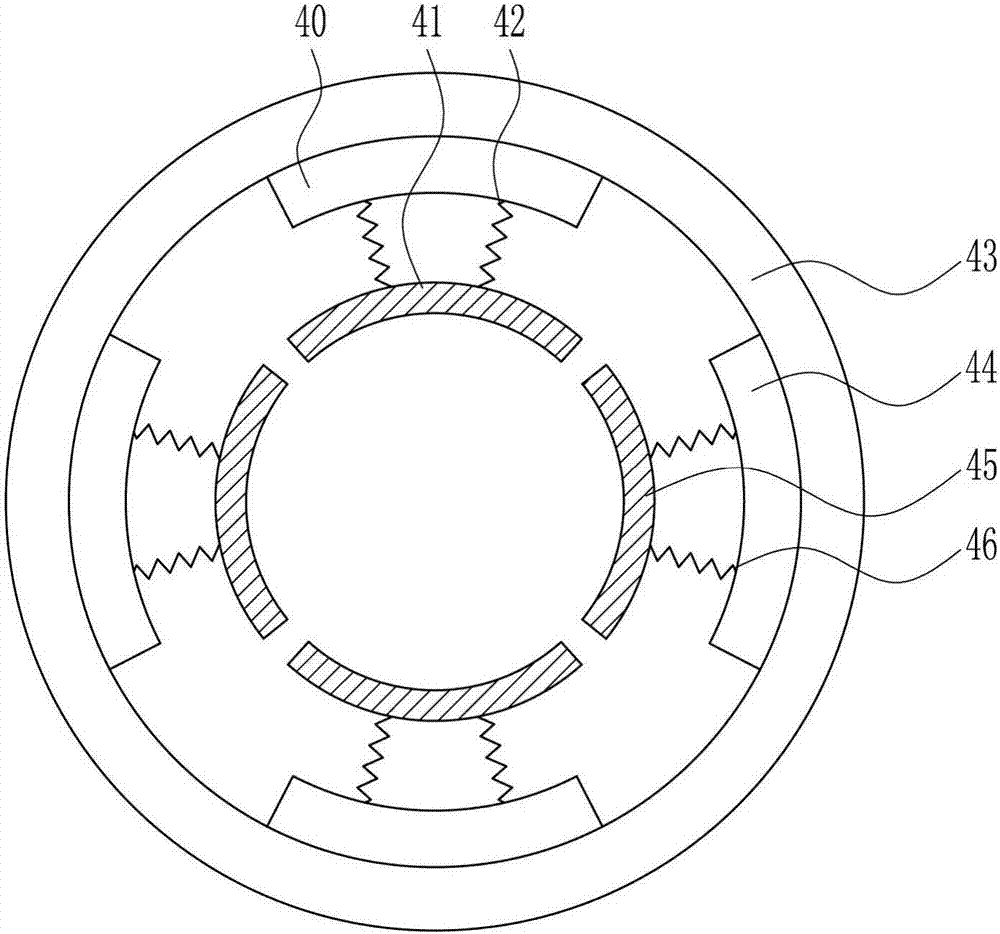

Carrier rocket guide pipe inner wall scratch detecting and polishing device and method

InactiveCN112059765AAchieve grindingRealize detectionRevolution surface grinding machinesGrinding feed controlUniversal jointElectric machinery

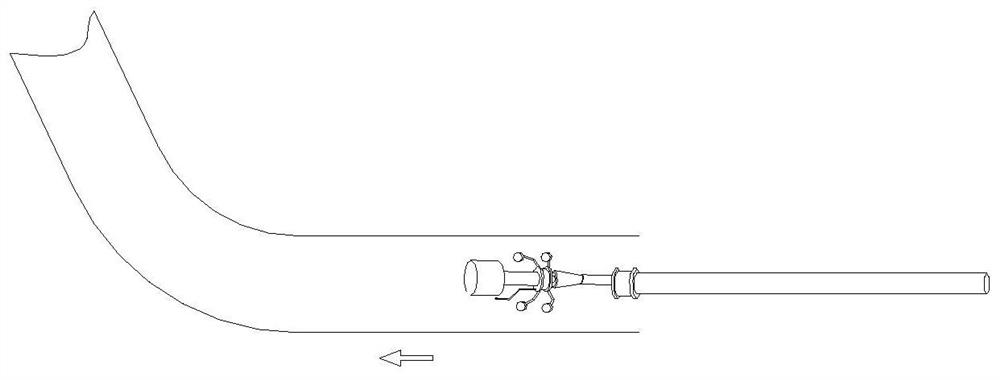

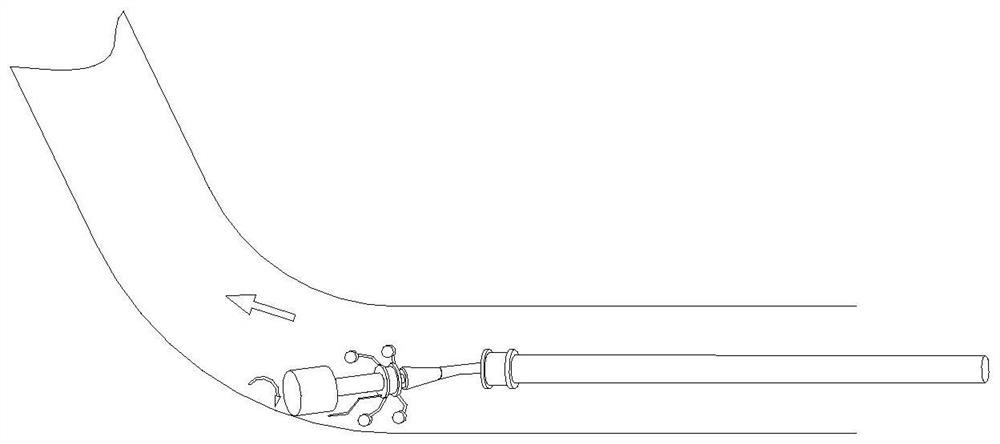

The invention provides a carrier rocket guide pipe inner wall scratch detecting and grinding device and method. The carrier rocket guide pipe inner wall scratch detecting and grinding device comprisesa grinding wheel, an endoscope probe, a planet wheel, a driving motor and a universal joint, wherein the grinding wheel is connected with the planet wheel through a connecting column; the endoscope probe is arranged on the connecting column; the planet wheel is connected with the driving motor; the driving motor is connected with the universal joint; and the universal joint is connected with a main pipe to realize movement turning at a pipe elbow. A grinding device and a detection device are integrated into an internal structure, a grinding head and endoscope detection are combined into a whole, linkage work is achieved, detection and grinding of a pipeline product with a bent pipe in a carrier rocket pressurization conveying system can be achieved, scrapping of the whole pipe caused by scratches generated in the machining process of the interior of the pipe and redundant objects is avoided, the machining cost of guide pipe parts is saved, and the material utilization rate is increased.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Grinding device convenient to clean for agricultural scientific research experiments

InactiveCN109499666ASlow down the feeding speedReduce shockHollow article cleaningGrain treatmentsAgricultureEngineering

The invention belongs to the technical field of agricultural scientific research, and particularly relates to a grinding device convenient to clean for agricultural scientific research experiments. The problems that the grinding difficulty of a grinding device is large and the efficiency is low are aimed, so that the technical scheme is provided as follows that the grinding device comprises a base, universal wheels are all arranged at four corners of the outer wall at the bottom of the base, four electric control hydraulic rods are arranged on the outer wall of the top of the base, and the topouter walls of the four electric control hydraulic rods are provided with the same tank body; and the tank body comprises an upper tank body, a lower tank body and a middle tank body, a feeding portis formed in the outer wall of the top of the upper tank body, a feeding hopper is arranged on the inner wall of the feeding port, a water tank is arranged on one side of the outer wall of the top ofthe base, and a water pump is arranged on the outer wall of one side of the water tank. According to the grinding device, the feeding speed can be reduced, a buffer table is of an obtuse-angle triangular structure, the buffer contact surface is added, and the impact on equipment during the feeding is greatly reduced; and a water spraying disc is moved to the position above the feeding hopper, namely the tank body can be sprayed and cleared, and the cleaning portability of the tank body is improved.

Owner:湖南全望信息科技有限公司

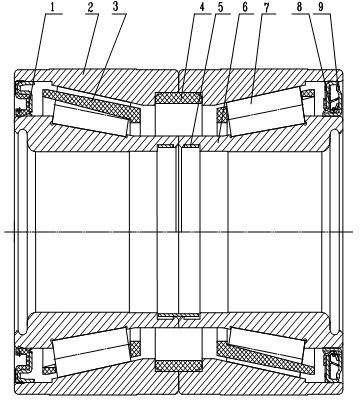

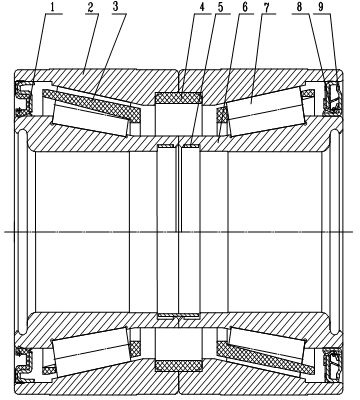

Novel truck hub bearing

InactiveCN102518657AReduce the difficulty of grindingReduce difficultyRoller bearingsBearing componentsEngineeringGrinding wheel

A novel truck hub bearing belongs to the technical field of automobile hub bearings, and both of each inner ring and each outer ring are in two-piece structures. The inner periphery of each outer ring is provided with a groove, a nylon lock ring is in interference connection with the two outer rings, the two inner rings are fixedly connected through a spring collar, a rolling element, the inner rings and a retainer form a component to be combined with the two outer rings, a first seal ring and a second seal ring are mounted on two sides of the combination, and a dust cover is mounted outside the second seal ring. The novel truck hub bearing has the advantages that the outer rings in the two-piece structure can be ground with common equipment, excess length of a grinding wheel shaft is not needed, and grinding difficulty is reduced; similarly, difficulty in grinding of notches for the seal rings on two sides is reduced greatly; and the two-piece structure of the outer rings is more adaptive to impact of shaft defection during use of the bearing.

Owner:WAFANGDIAN BEARING GRP CO LTD +1

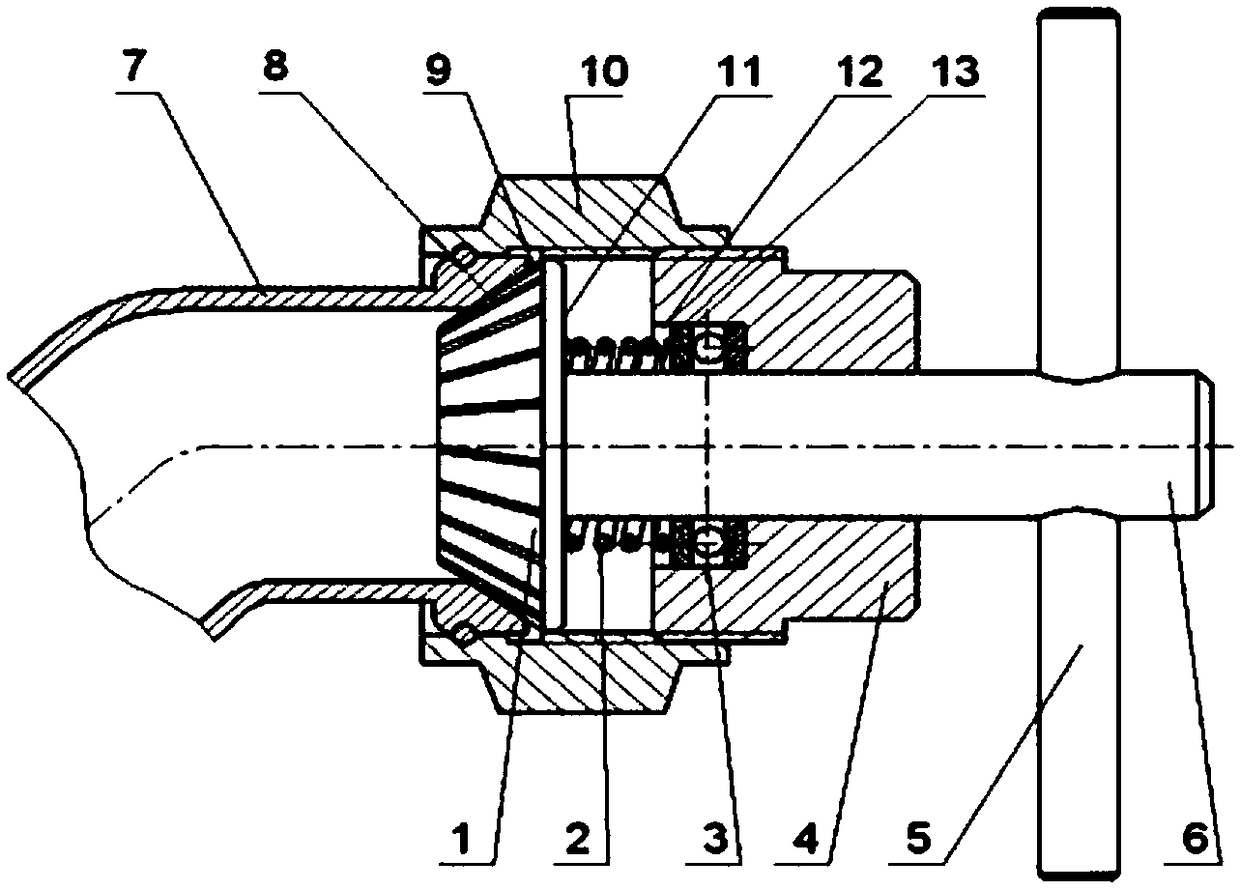

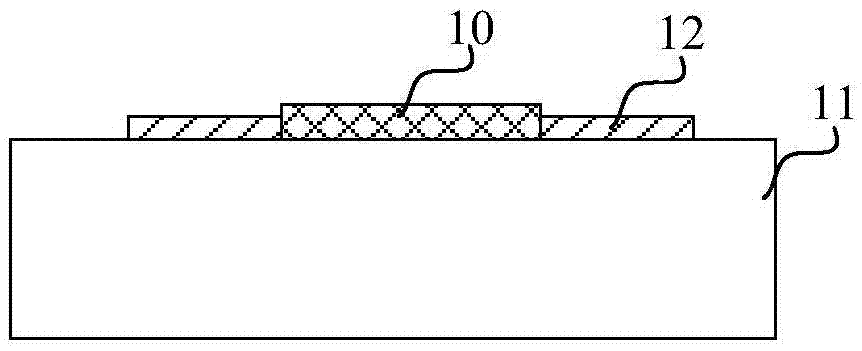

Grinding tool and grinding method for guide pipe orifice angle

PendingCN108068006AAvoid the phenomenon of angle deflectionReduce labor intensityLapping machinesLapping toolsEngineeringScrew thread

Provided are a grinding tool and a grinding method for a guide pipe orifice angle. The grinding tool comprises a grinding head, a guide rod, a compaction spring and a thread guide sleeve. The grindinghead is located at the front end of the guide rod, the grinding head is of a rigid structure with a tapered grinding surface, the angle of the tapered grinding surface is matched with the angle surface of an orifice of a guide pipe, the thread guide sleeve is a revolution body, a guide hole is formed in the center of the thread guide sleeve, a bearing is inlaid in the center of the thread guide sleeve, external threads are arranged on the outer side of the thread guide sleeve, the guide rod is inserted into the guide hole, and the compaction spring is located among the grinding head, the guide rod and the bearing. The thread guide sleeve of the grinding tool is connected with a cap nut of the orifice of a guide pipe part, the grinding head is pressed in the orifice of the guide pipe underthe action of the compaction spring, the grinding head is rotated through a handle at the tail of the guide rod to realize the purpose of rough grinding of the angle of the orifice of the grinded guide pipe.

Owner:XIAN AIRCRAFT IND GROUP

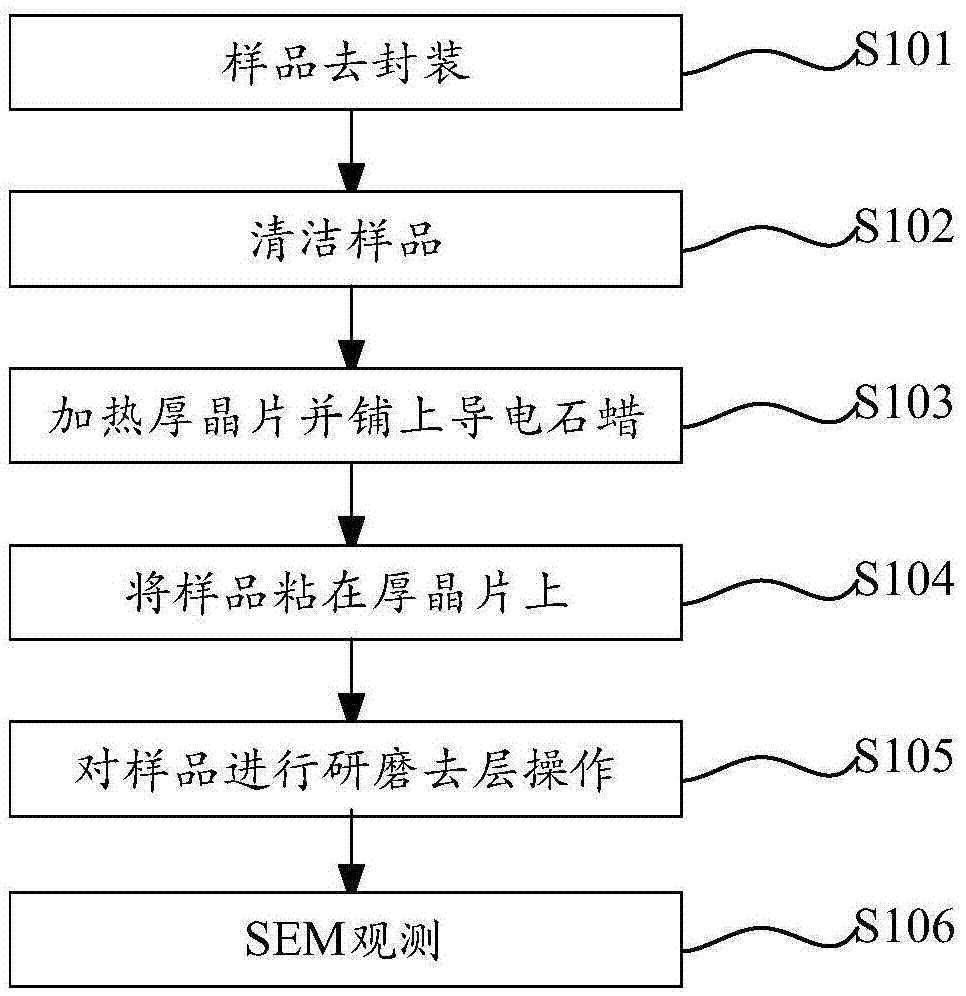

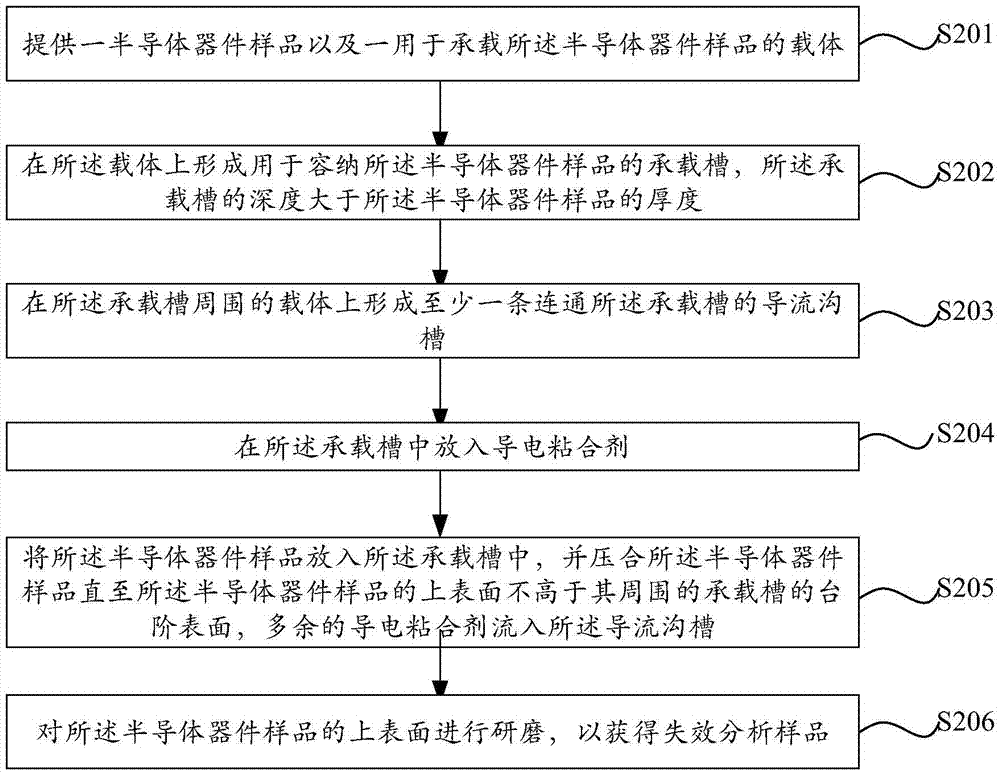

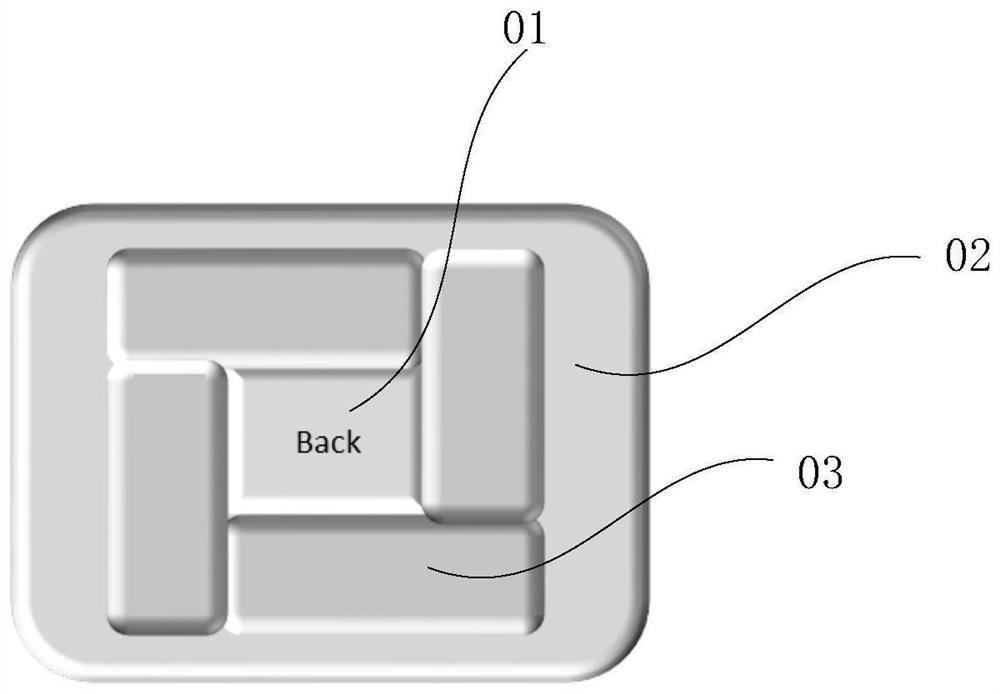

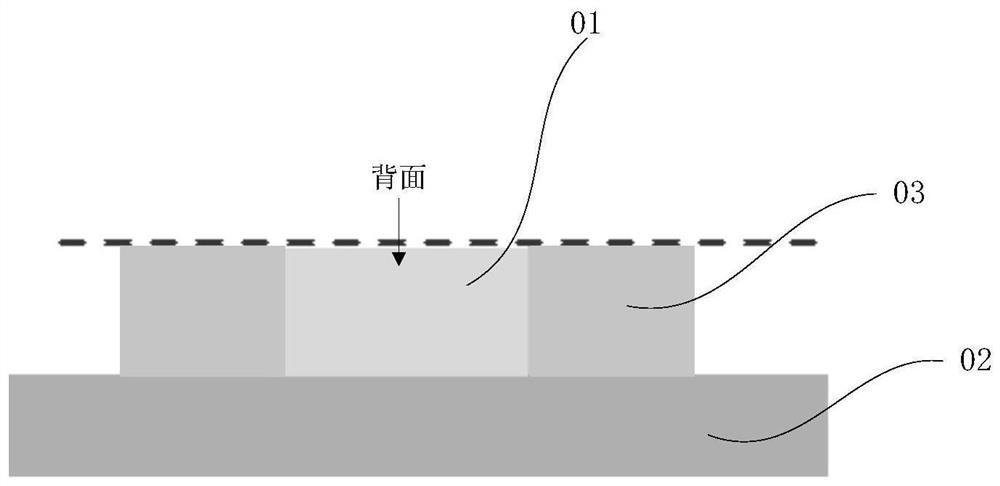

Semiconductor device failure analysis sample and preparation method thereof, and failure analysis method

ActiveCN106971952AFree from pollutionHigh success rate of preparationSemiconductor/solid-state device testing/measurementAdhesiveUltraviolet

The invention provides a semiconductor device failure analysis sample and a preparation method thereof, and a failure analysis method. A bearing groove fitting with a semiconductor device sample and at least one diversion trench communicating with the bearing groove are arranged in a carrier, a conductive adhesive is placed in the arranged bearing groove, the carrier is heated or is irradiated by ultraviolet to fuse the conductive adhesive, finally, the semiconductor device sample is placed in the bearing groove, the semiconductor device sample is lightly pressed so as to be flush with a step surface of a side wall of the bearing groove, thus pollution of the conductive adhesive to the sample surface is avoided, and more importantly, during grinding delayering, the occurrence of a phenomenon of nonuniform grinding of the sample surface is avoided.

Owner:SEMICON MFG INT TIANJIN +1

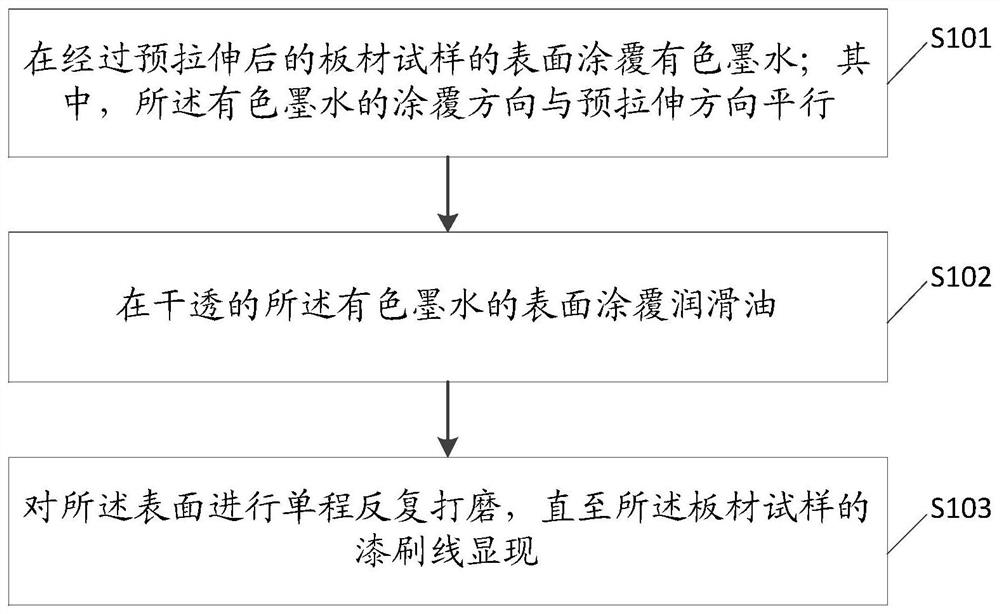

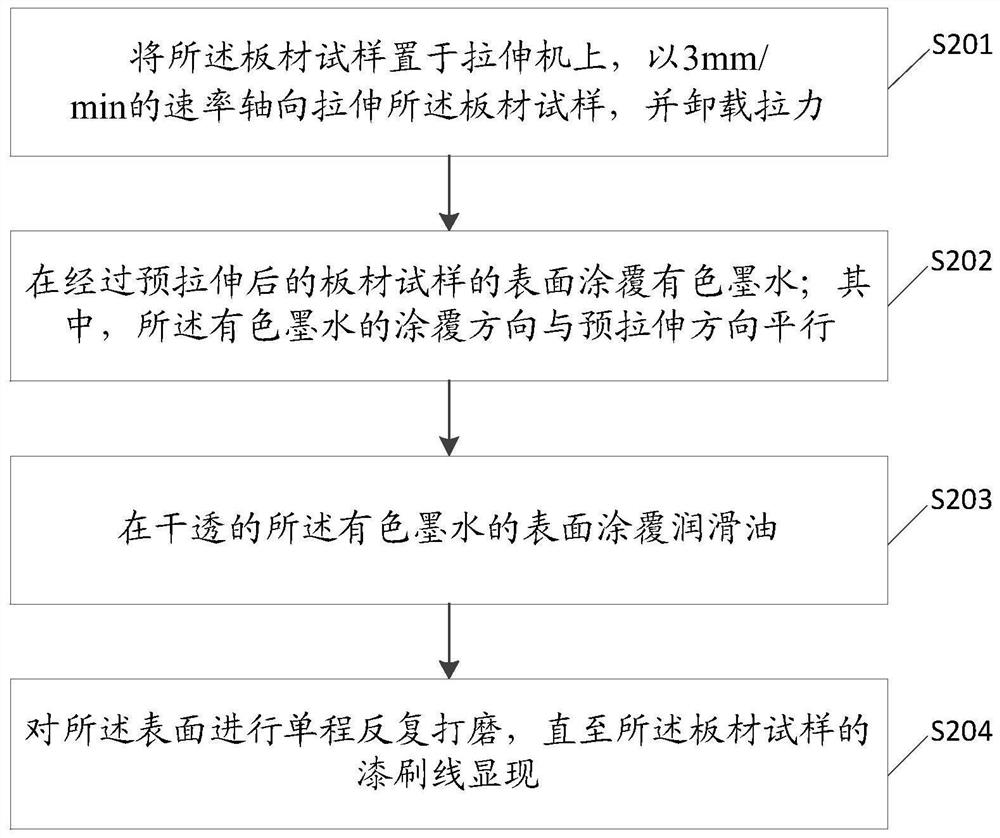

Paint brush line display method

PendingCN112461746AIncrease contrastImprove accuracyUsing mechanical meansMaterial analysisPolymer sciencePolishing

The invention discloses a paint brush line display method which comprises the steps: coating the surface of a pre-stretched plate sample with colored ink, wherein the coating direction of the coloredink is parallel to the pre-stretching direction; coating lubricating oil on the surface of the completely dried colored ink; and repeatedly polishing the surface in a single pass until the paint brushline of the plate sample appears. It can be seen that according to the paint brush line display method, the surface of the pre-stretched sample plate is coated with a layer of colored ink firstly, then the surface of the pre-stretched sample plate is coated with lubricating oil, then polishing is conducted, in the polishing process, the colored ink in the protruding area where the paint brush line is located is polished, the area is brightened, and the colored ink in the concave area is not polished away, and the area is still dark so that the concave-convex area contrast is obvious, the paint brush line contrast and the display accuracy are improved, and due to the existence of colored ink, the polishing degree is easy to judge, excessive polishing is avoided, and the polishing difficulty is reduced.

Owner:SOUTHWEST ALUMINUM GRP

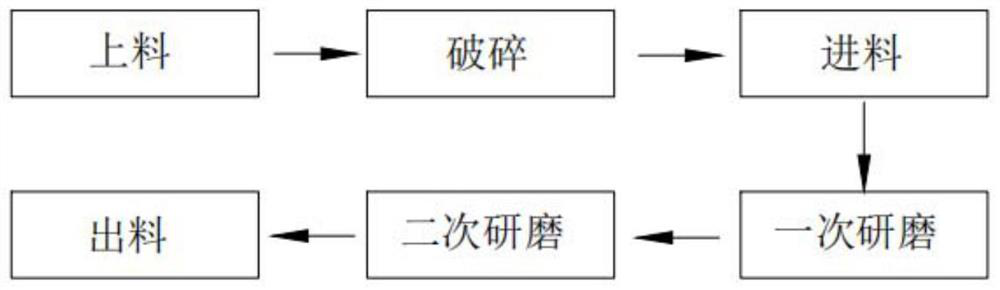

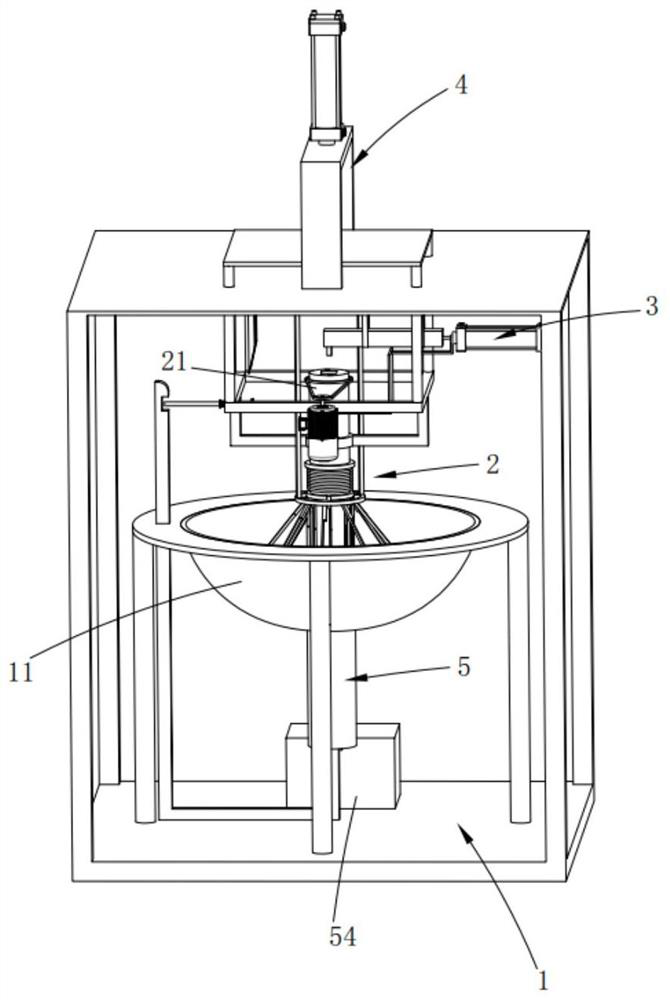

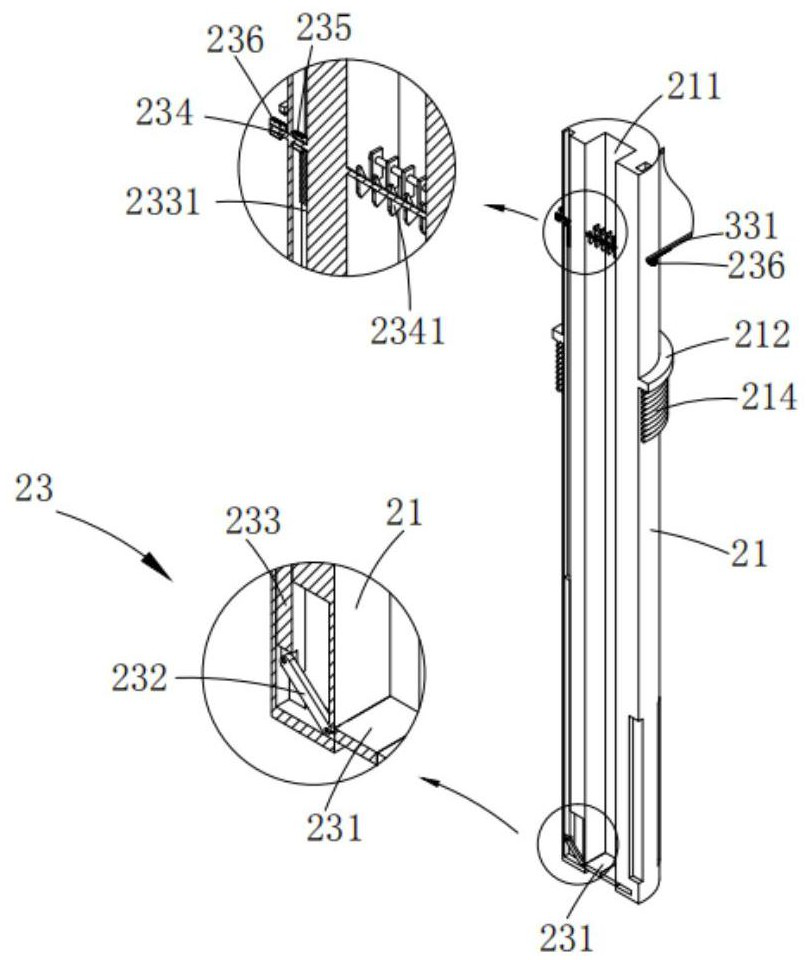

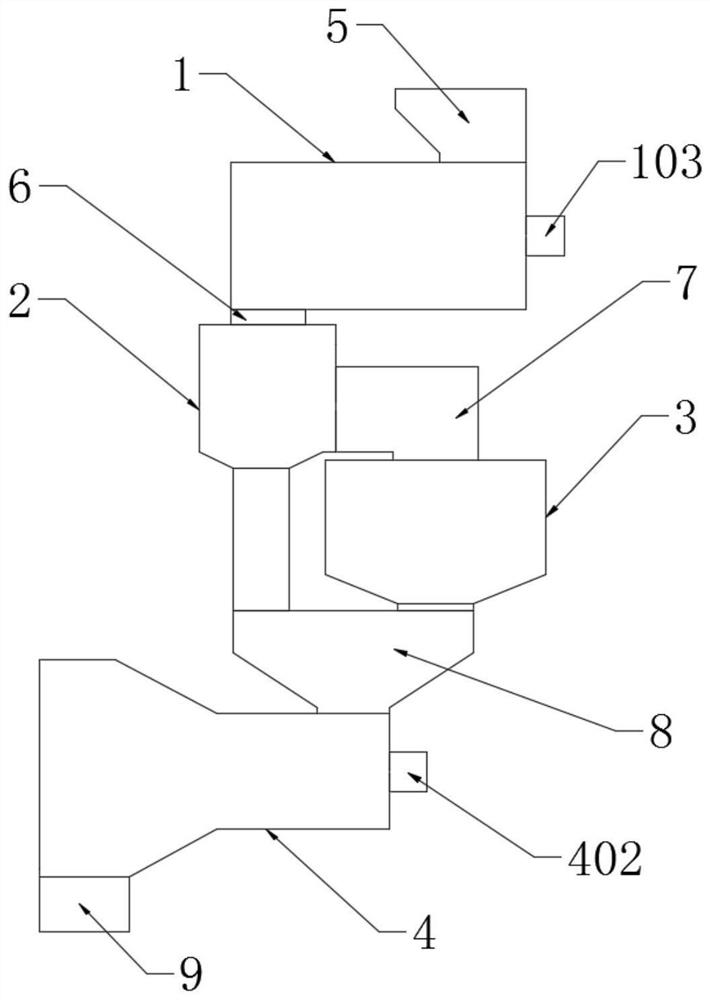

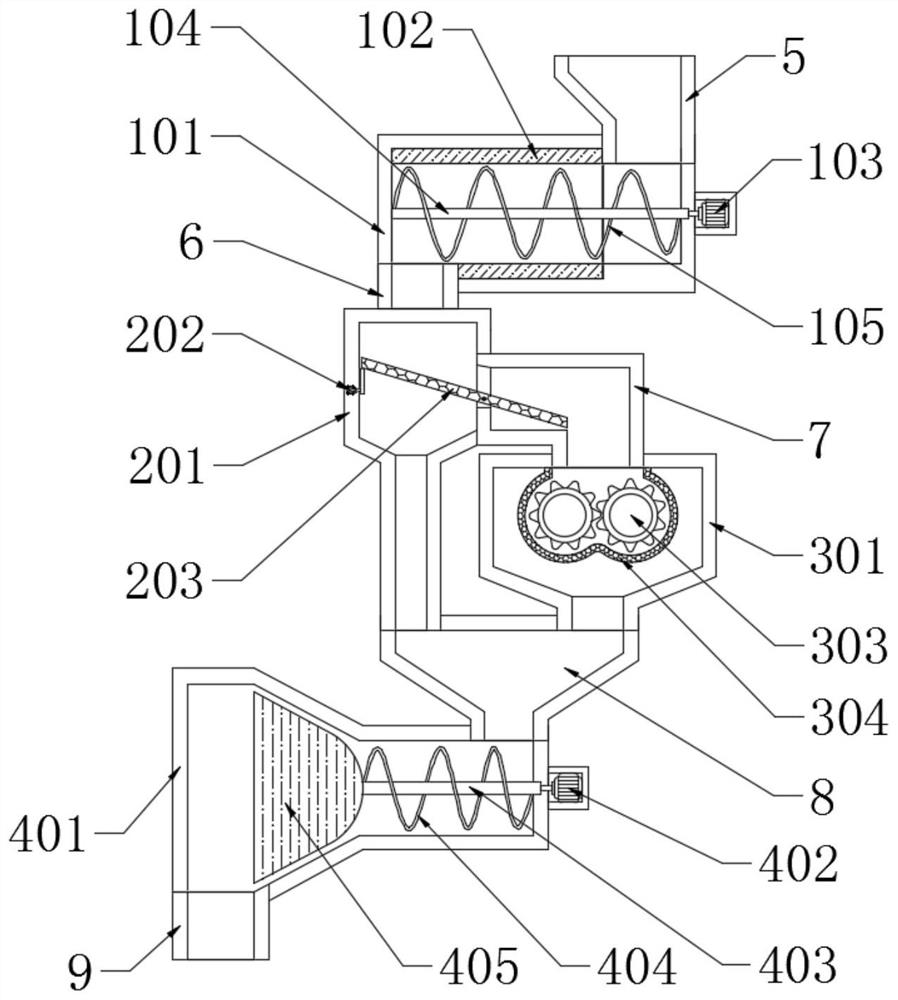

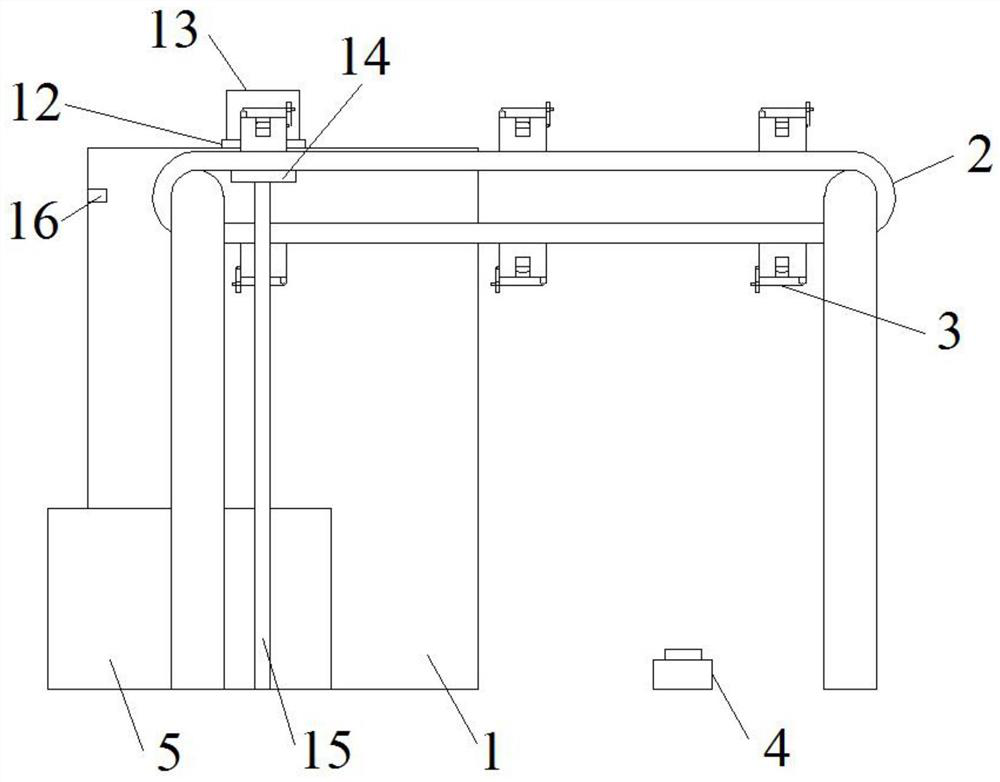

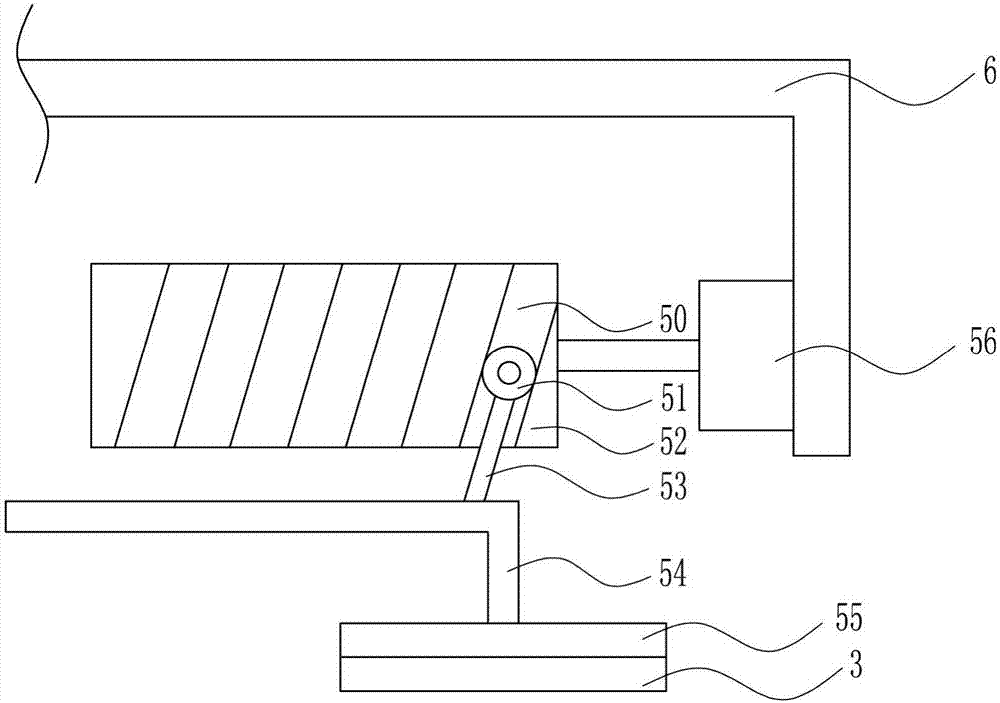

Automatic seasoning production process

InactiveCN112246313ARealize automated productionReduce the difficulty of grindingGrain treatmentsProcess engineeringCrushing procedure

The invention relates to the technical field of seasoning production equipment, in particular to an automatic seasoning production process. The automatic seasoning production process comprises the following steps: step 1, a feeding procedure; step 2, a crushing procedure which is carried out synchronously with the step 1; step 3, a feeding procedure which is synchronously carried out with the step2; step 4, a primary grinding procedure; step 5, a secondary grinding procedure which is synchronously carried out with the step 4; and step 6, a discharging procedure. A grinding shaft is driven bya driving mechanism to slide up and down, materials are driven to enter a second base for secondary grinding after being subjected to primary grinding in a first through hole, meanwhile, the materialsin the grinding shaft are driven to be crushed and fed at the same time through pushing of a first air cylinder, grinding is conducted after crushing, the grinding difficulty is reduced, automatic production of seasonings is achieved, and manual feeding and mashing are not needed.

Owner:ANHUI FUYANG FOREFRONT FOOD CO LTD

Method for improving activity of titanium-containing blast furnace slag

InactiveCN102249569AHigh activityReduce the difficulty of grindingCement productionMagnetic separationSlagMagnetic separator

The invention discloses a process method for improving the activity of titanium-containing blast furnace slag. The process method comprises the following steps of: A, screening the furnace slag into the furnace slag of more than 10 millimeters and the furnace slag of less than 10 millimeters; B, conveying the furnace slag of less than 10 millimeters into a coarse grinding machine, grinding coarsely to form the furnace slag of between 0.15 and 1 millimeter, conveying the furnace slag of between 0.15 and 1 millimeter into a magnetic separator, and performing magnetic separation to obtain strong-magnetic furnace slag and weak-magnetic furnace slag; and C, grinding the weak-magnetic furnace slag finely, conveying into a powder concentrator, and performing powder concentration, wherein the specific surface area of 400 square meters / kilogram is used as a limit, the weak-magnetic furnace slag of which the specific surface area is more than 400 square meters / kilogram is used as micro powder for cement. In the method, granules which are difficult to grind in the furnace slag are removed by a two-step separation method of the combination of screening before coarse grinding and after fine grinding; simple substance iron and iron oxides in the furnace slag are removed by utilizing the magnetic separator; and the furnace slag is divided into two parts to be grinded, so the grinding difficulty of the furnace slag is reduced, energy is saved, and the activity of the slag is enhanced.

Owner:王永伯

Waste tire rubber powder normal-temperature desulfuration method

ActiveCN105295089AReduce desulfurization costReduce energy consumptionPlastic recyclingBond energyAmmonia

The invention relates to the technical field of waste tire rubber powder normal-temperature desulfuration, in particular to a waste tire rubber powder normal-temperature desulfuration method. A waste tire is cut into granules, microwave radiation and magnetic separation are carried out three times, ultrasonic wave catalysis is carried out one time, and a desulfurizing agent is added, so that the waste tire can be desulfurized at normal temperature, and recycling and desulfuration cost and desulfuration energy consumption for the waste tire are lowered; in addition, the ammonia water soaking treatment technology is introduced, so that the bond energy of an S-S bond and an S-C bond are seriously damaged under the mixed treatment of microwave radiation, ultrasonic wave catalysis and desulfurizing agent adding, and meanwhile the bond energy of a C-C bond is protected, damage to the C-C bond in the desulfurizing process is reduced, and the rubber powder yield and quality are improved.

Owner:贵州华宇橡胶科技有限公司

Spinneret plate and processing method thereof

InactiveCN111455473AReduce processing difficultyReduce processing costsSpinnerette packsSpinningWire cutting

The invention discloses a processing method used for a spinneret plate. A first plate body is divided into two parts, a first groove and a second groove are processed, the processing difficulty and the processing cost are reduced, the processing efficiency is improved, the grinding difficulty is reduced, and the grinding precision and the inner wall smoothness are improved; holes are cyclically formed at intervals in a wire cutting manner, the situation that due to direct drilling, the processing difficulty is large and the processing precision is low is avoided, grinding is also convenient after separating, and the inner wall precision is improved; and finally a processed second branch plate is mounted in the second groove to form an air gap, and a processed third plate body with a feeding hole is mounted at the bottom of the first plate body. The spinneret plate manufactured through the method is uniform in spinning and high in spinning quality, meanwhile, cleaning is convenient, andthe service life is long.

Owner:江阴市合助机械科技有限公司

Marble corner processing device

ActiveCN108177043BPass smoothlyGuaranteed accuracyEdge grinding machinesGrinding work supportsEngineering

The invention relates to the field of stone processing, and particularly discloses a marble corner processing device. The marble corner processing device is provided with a limiting mechanism and a chamfering mechanism, a first limiting plate and a second limiting plate in the limiting mechanism can limit marble, a part, to be chamfered, of the marble can be conveniently located at the position ofthe chamfering mechanism, chamfering on the part to be chamfered is facilitated, and polishing balls can conduct quick and stable chamfering on the part to be chamfered in the chamfering process; andthe polished marble can be detected through an arc-shaped strip, and the chamfering accuracy of the marble can be detected conveniently.

Owner:苏州市振渭城镇建设发展有限公司

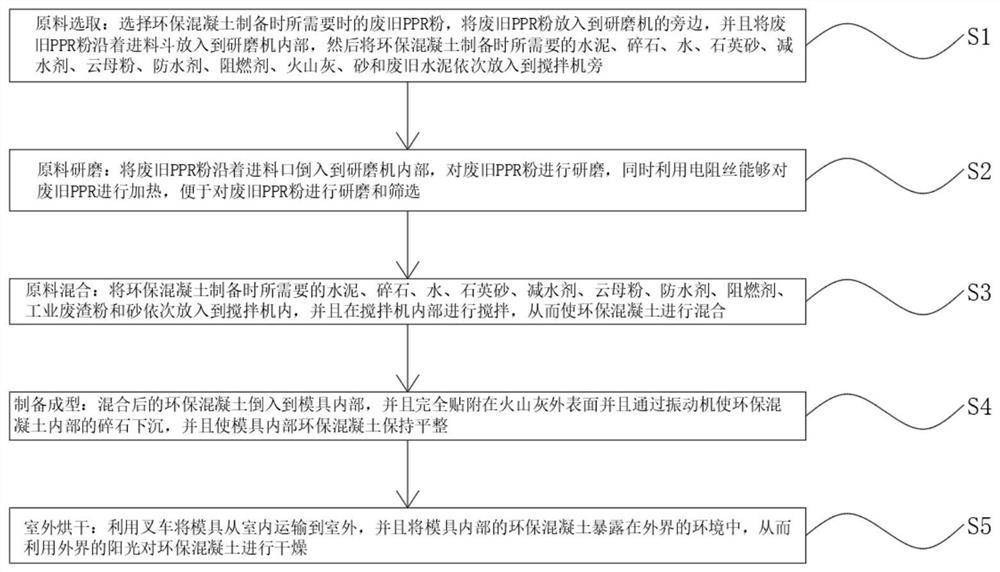

Processing method for high-strength environment-friendly concrete

ActiveCN111822080AReduce usageHigh hardnessSolid waste managementCeramic shaping apparatusSlagCompressive strength

The invention discloses a processing method for high-strength environment-friendly concrete. The environment-friendly concrete consists of the following components in parts by weight: 100-200 parts ofcement, 40-130 parts of water, 23.8-59 parts of quartz sand, 46.2-82.4 parts of broken stones, 1-2 parts of a water reducer, 10-30 parts of mica powder, 5-30 parts of a waterproof agent, 0.5-2 part of a flame retardant, 40-80 parts of cinerite, 10-30 parts of waste PPR powder, 245-490 parts of sand, 60-120 parts of an adhesive and 60-80 parts of industrial waste slag powder. Waste PPR powder andindustrial waste residue powder, which are added into concrete, are poured into a stirrer to stir, so that use amount of cement is reduced, and production cost is reduced; mica powder, quartz sand andcinerite are added, so that hardness, pressure resistance and water seepage resistance of concrete can be improved; and meanwhile, a heat conduction rate of the concrete is reduced, so that the concrete has highest hardness, highest compressive strength, low heat conduction rate and strong water seepage resistance; and meanwhile, production cost is reduced, waste PPR powder and industrial waste residue powder are recycled, so that the environment-friendly purpose is achieved.

Owner:舟山恒尊预拌混凝土有限公司

Marble corner processing device

ActiveCN108177043AGuaranteed accuracyImprove eligibilityEdge grinding machinesGrinding work supportsEngineering

The invention relates to the field of stone processing, and particularly discloses a marble corner processing device. The marble corner processing device is provided with a limiting mechanism and a chamfering mechanism, a first limiting plate and a second limiting plate in the limiting mechanism can limit marble, a part, to be chamfered, of the marble can be conveniently located at the position ofthe chamfering mechanism, chamfering on the part to be chamfered is facilitated, and polishing balls can conduct quick and stable chamfering on the part to be chamfered in the chamfering process; andthe polished marble can be detected through an arc-shaped strip, and the chamfering accuracy of the marble can be detected conveniently.

Owner:苏州市振渭城镇建设发展有限公司

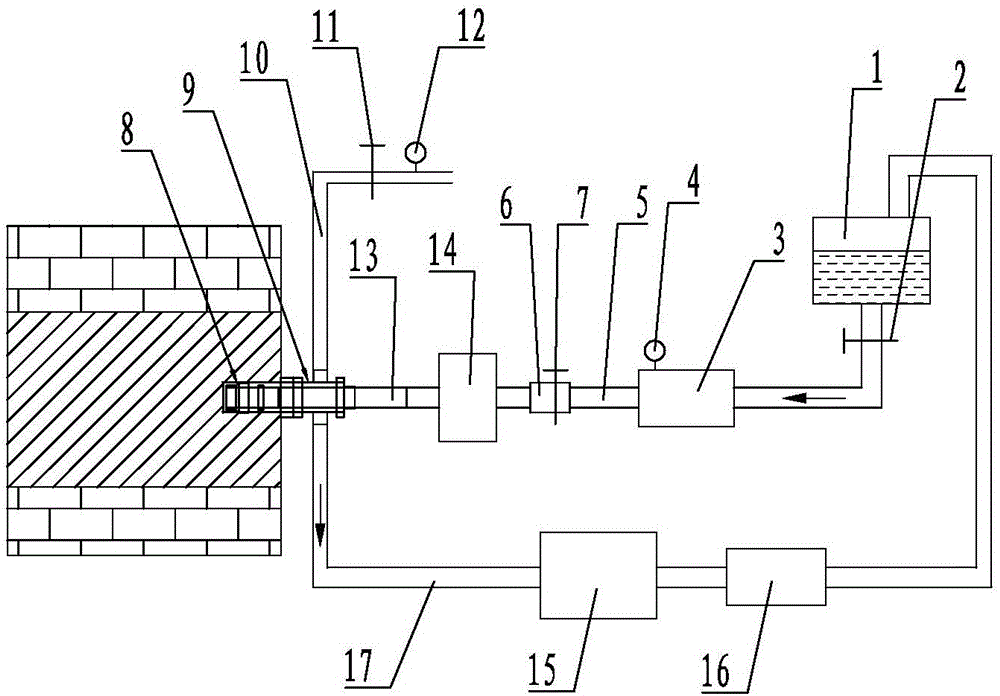

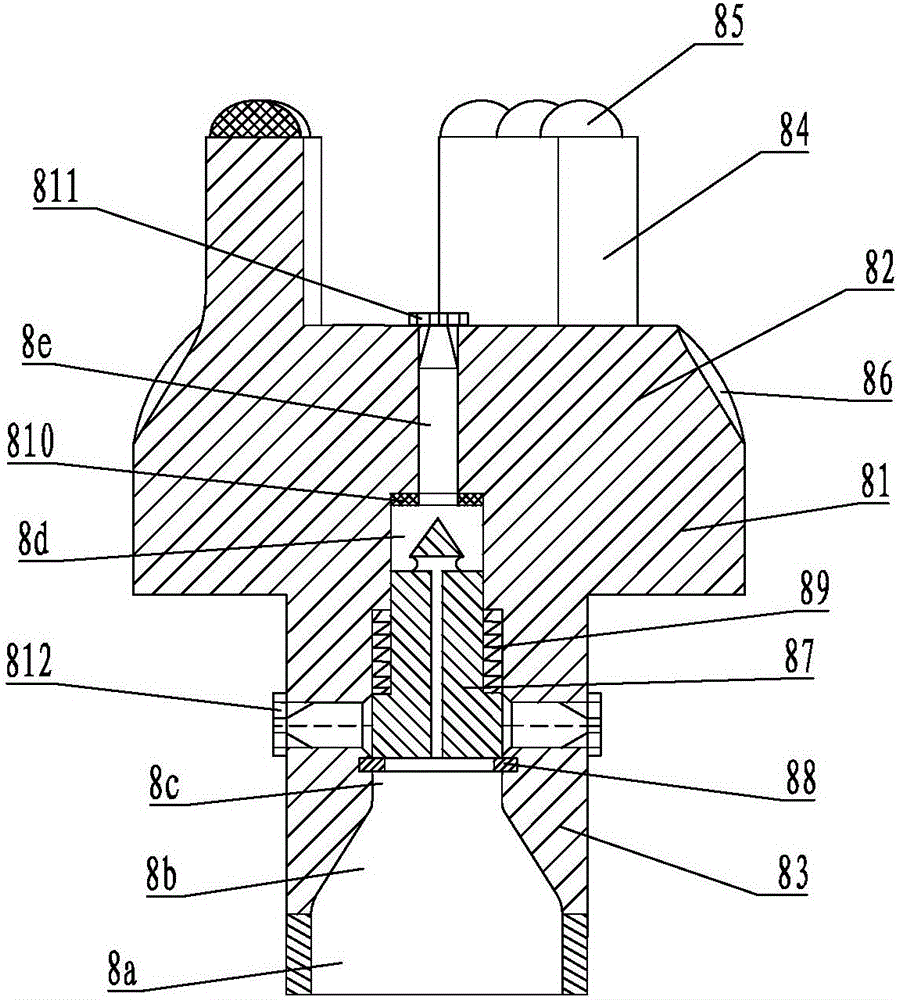

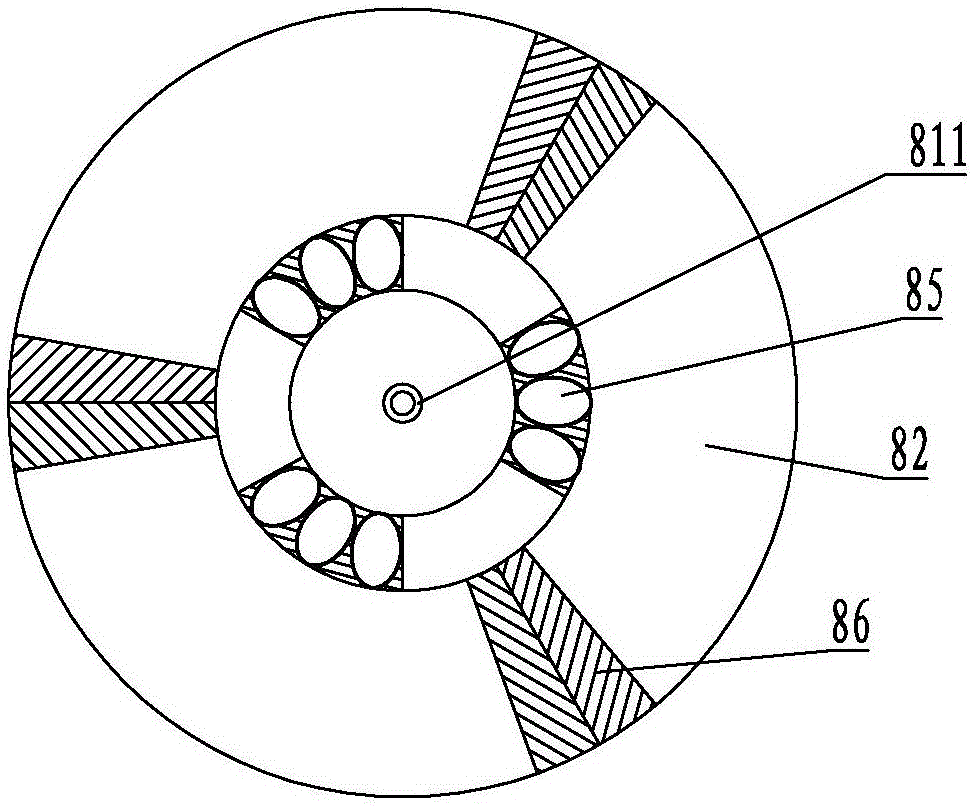

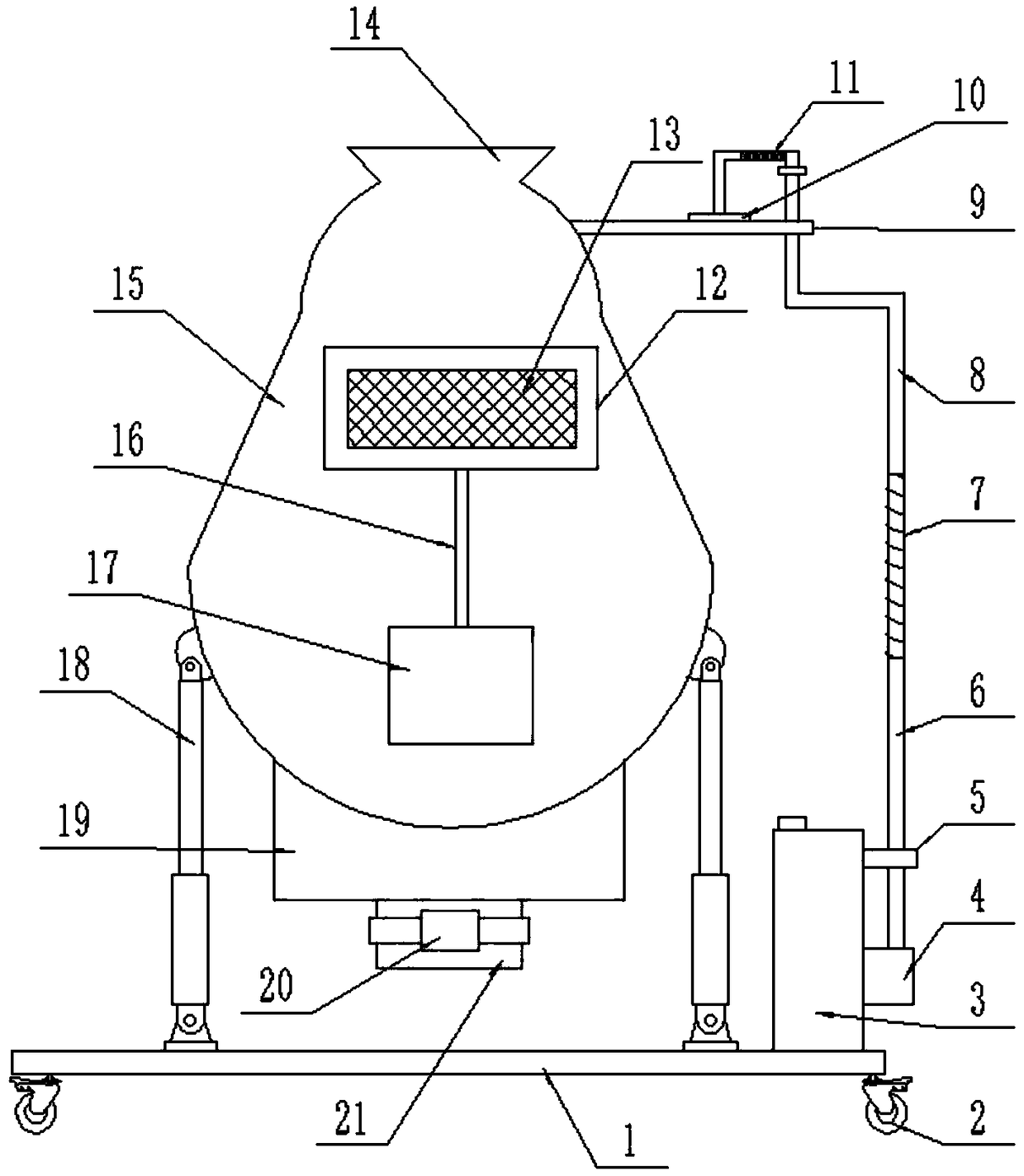

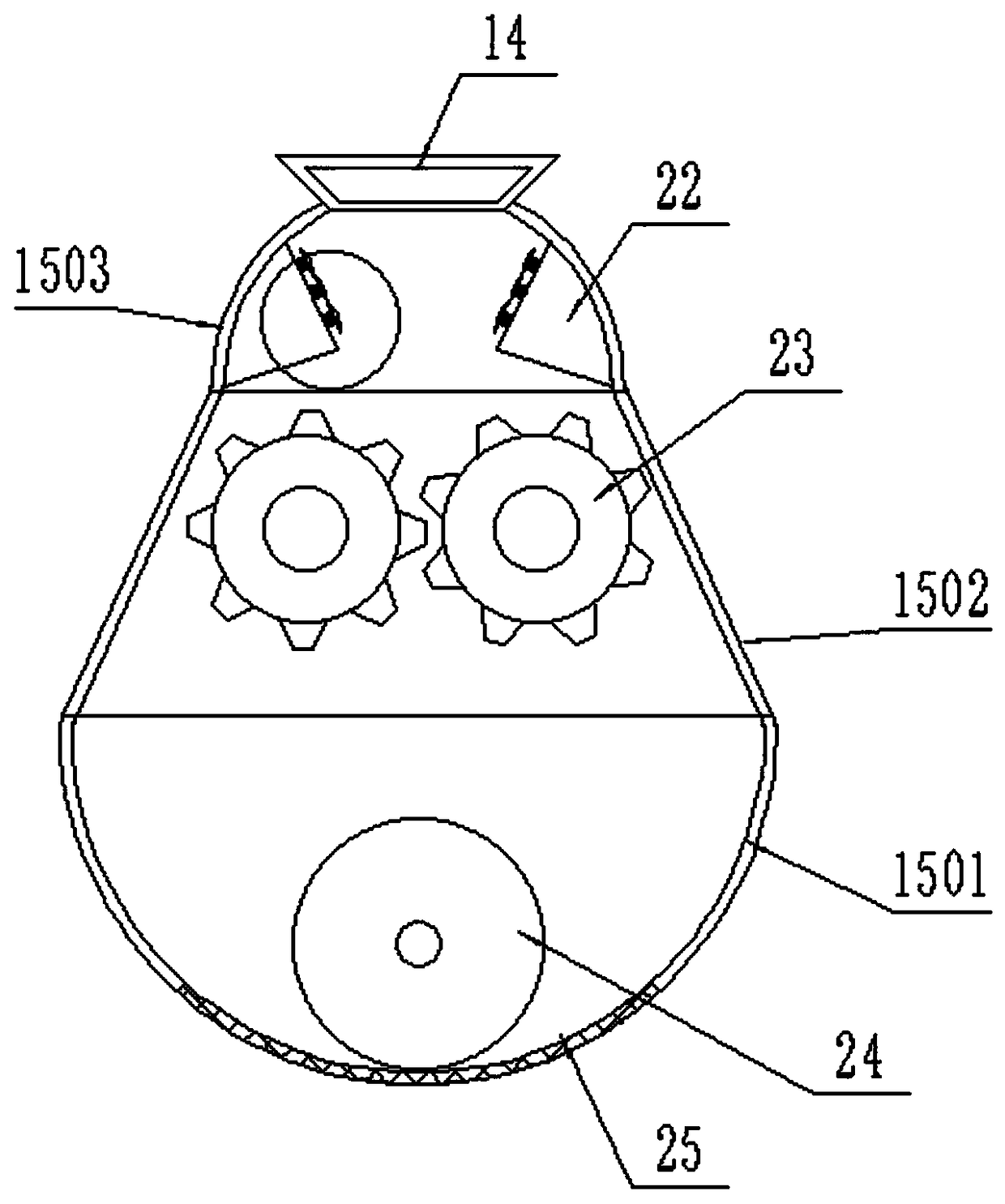

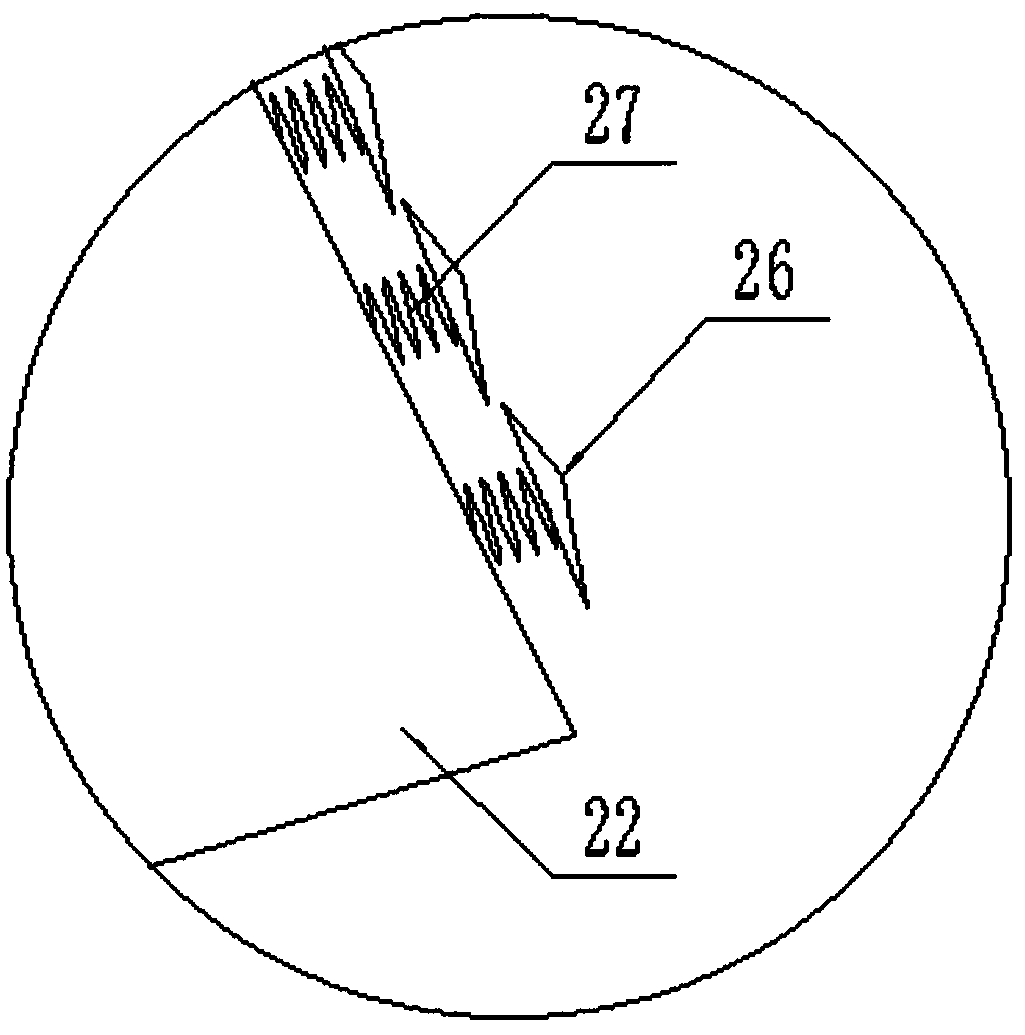

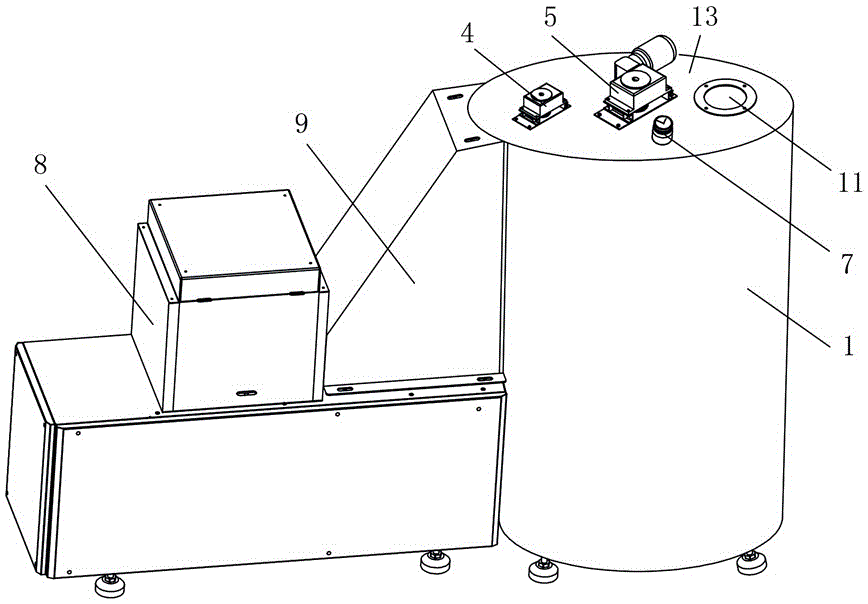

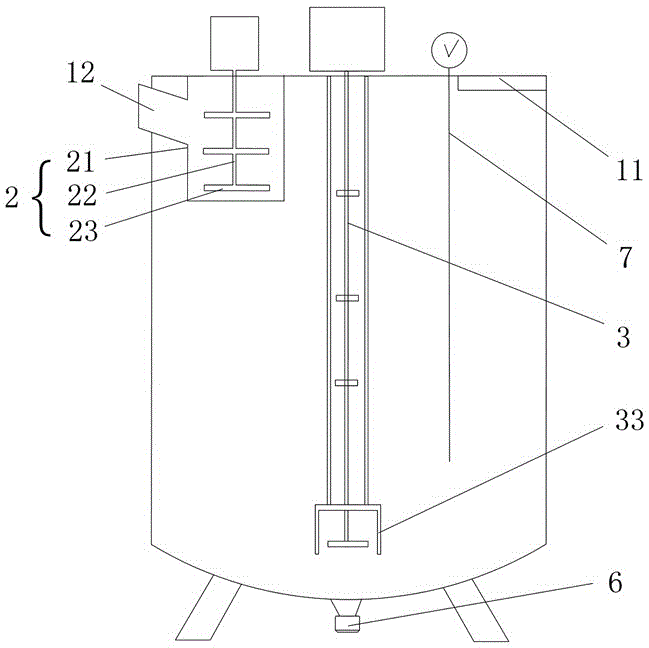

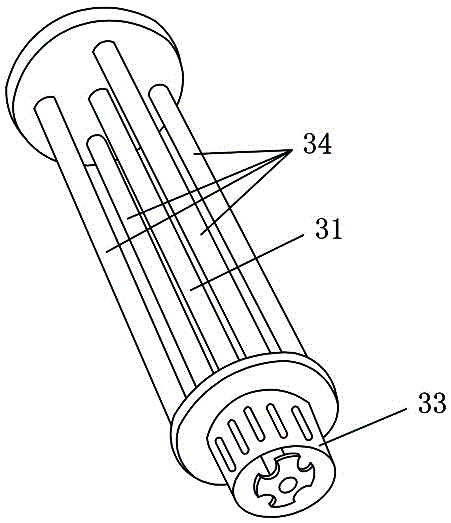

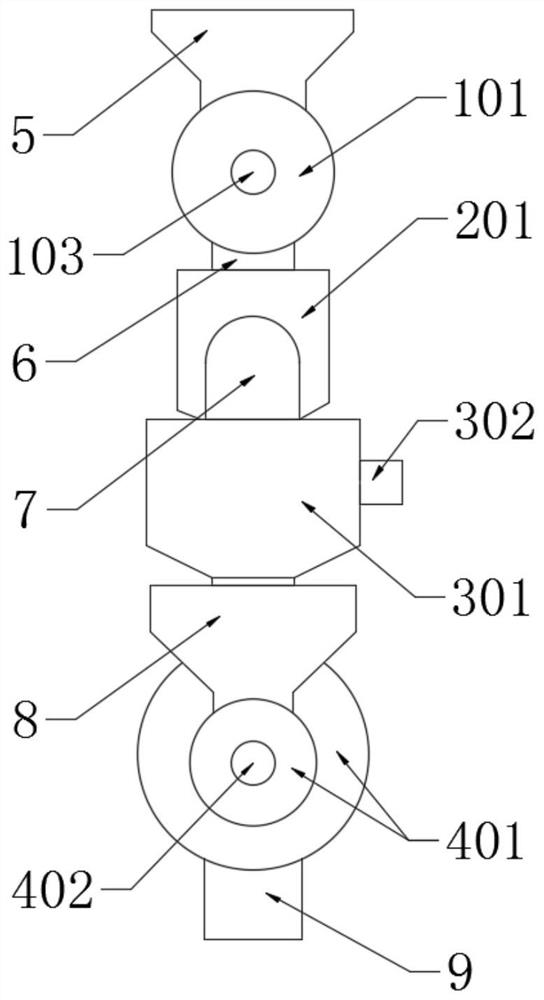

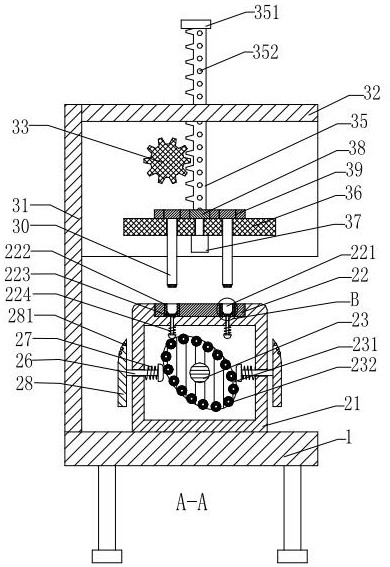

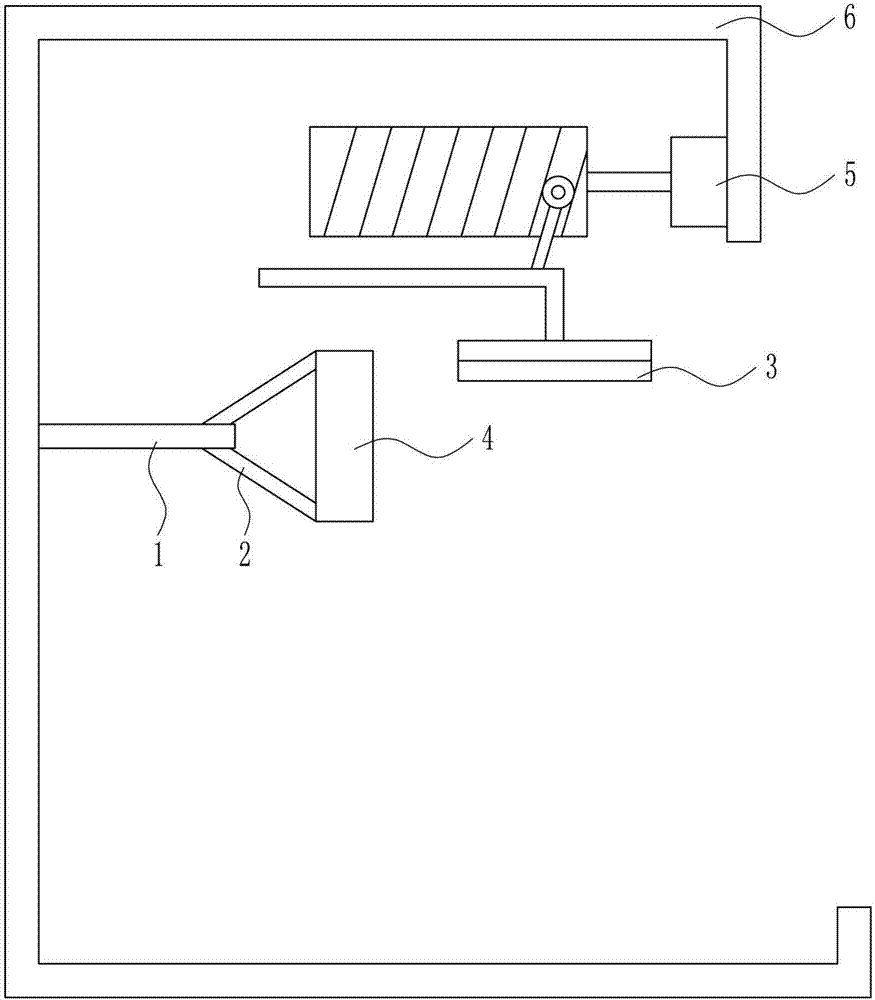

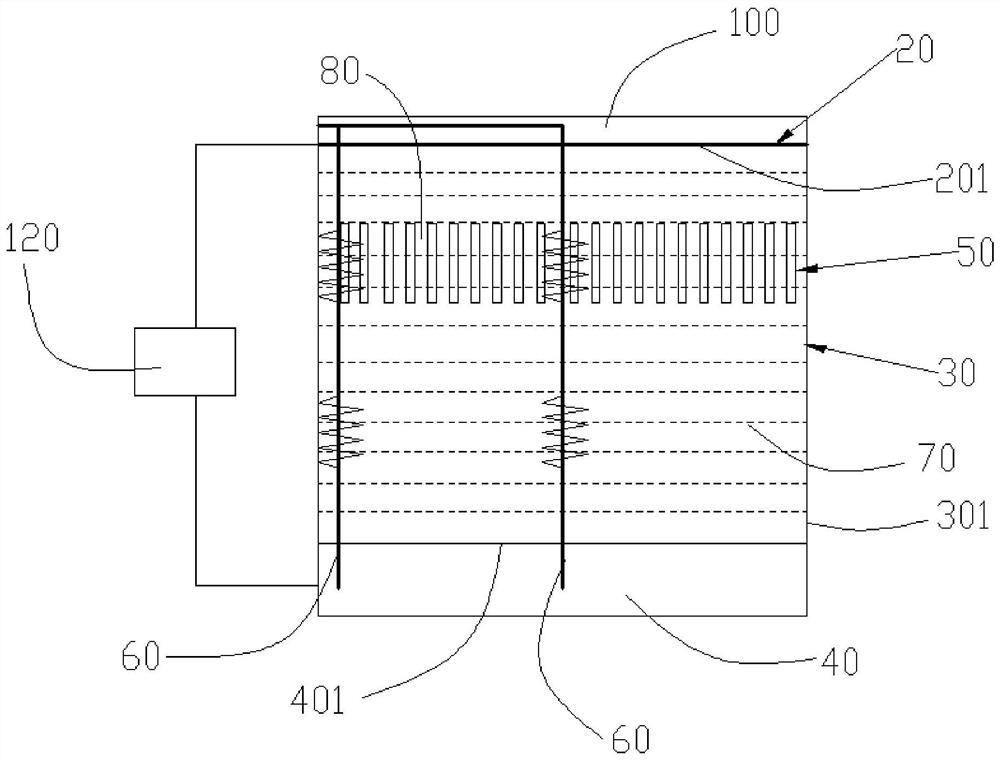

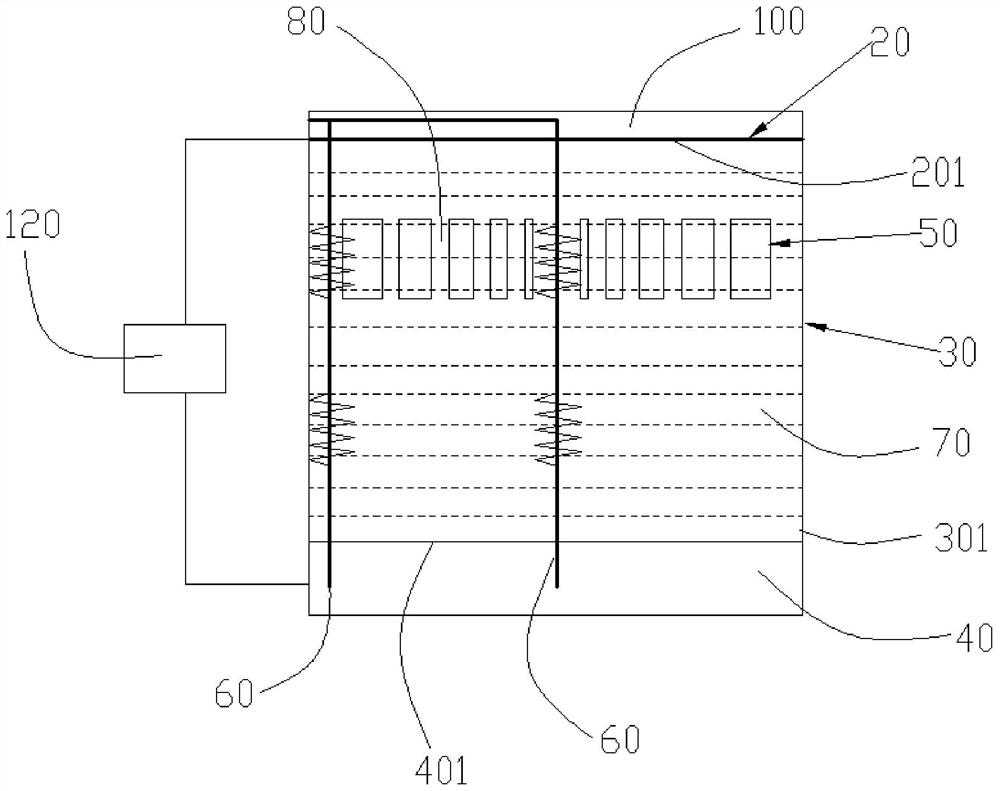

Production device for crystallized honey

PendingCN106722621AReduce grinding difficultyImprove qualityFood scienceOperational maintenanceLiquid phase

The invention discloses a production device for crystallized honey. The production device comprises a tank body, wherein a first feeding hole for injecting liquid-phase honey, and a second feeding hole for injecting crystal-phase honey are formed in the tank body; a pre-cutting mechanism and a conveyer belt mechanism in match are arranged outside the tank body; the pre-cutting mechanism is used for pre-cutting solid crystal-phase honey which is conveyed to the second feeding hole through the conveyer belt mechanism; the tank body is internally provided with a pre-grinding homogenization mechanism and a high-shearing emulsification stirring mechanism in match; the pre-grinding homogenization mechanism is arranged at the second feeding hole and is used for further grinding the cut crystal-phase honey and mixing with the liquid-phase honey; the high-shearing emulsification stirring mechanism is rotated to stir the liquid-phase honey and the grinded crystal-phase honey to uniformly mix the honey inside the tank body. The production device has the advantages of simple and compact structure, easy operation and maintenance, high automatic degree and high working efficiency and is capable of effectively improving the quality of crystallized honey.

Owner:湖南省明园蜂业有限公司

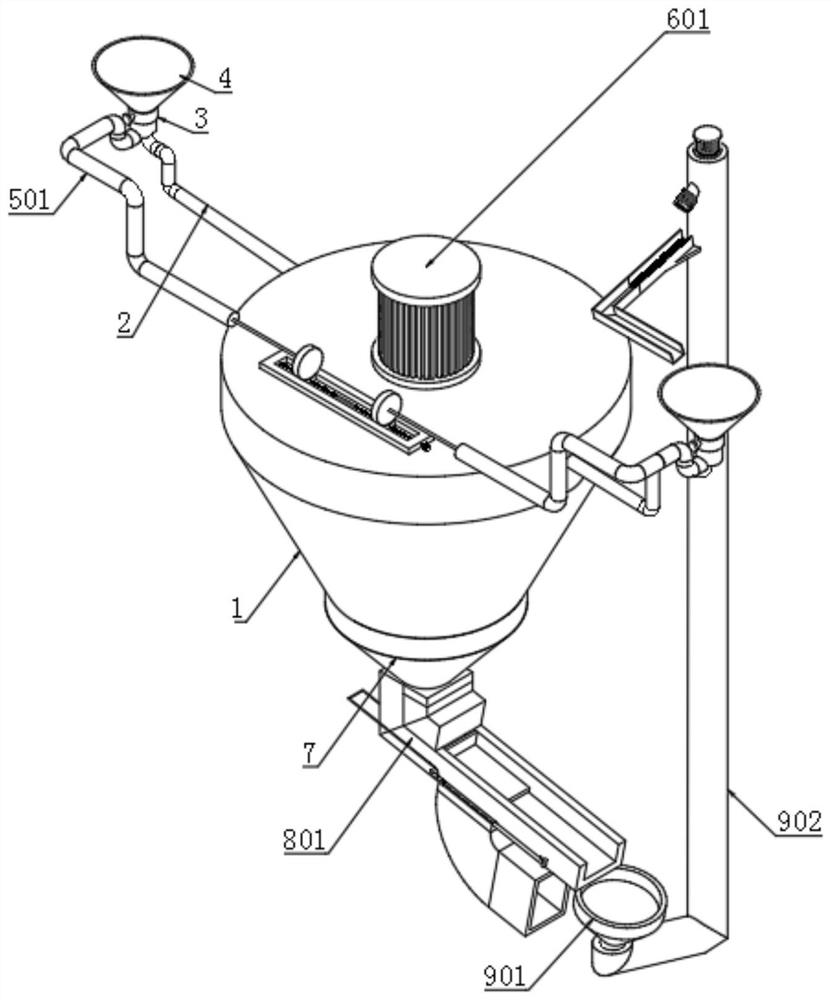

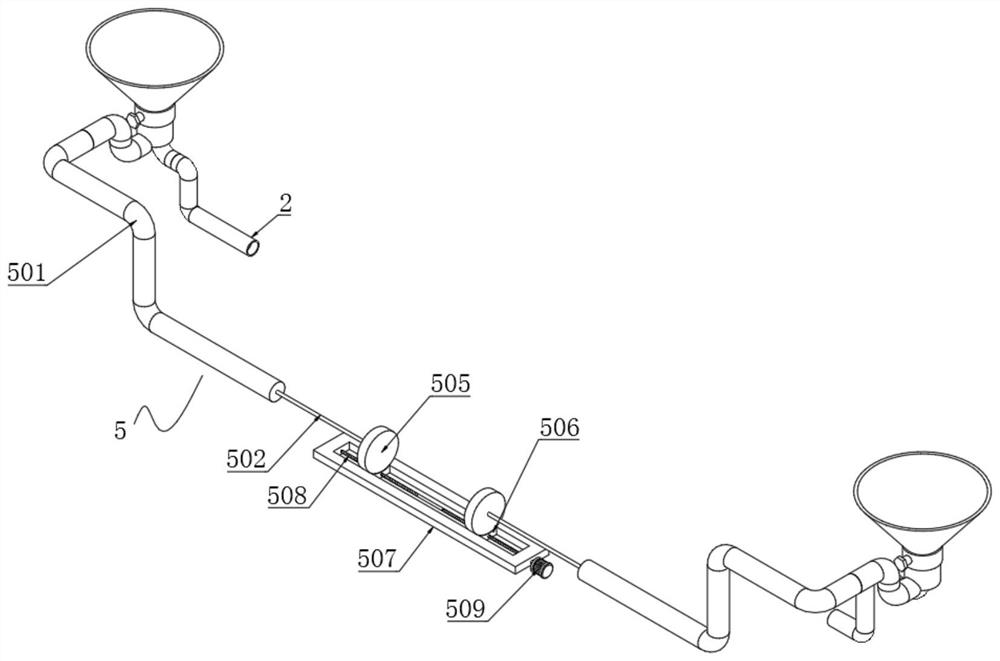

Production equipment for casting residue superfine slag powder and production method based on equipment

ActiveCN113578442AImprove drying effectReduce the difficulty of crushingSievingSolid waste managementSlagProcess engineering

The invention discloses production equipment for casting residue superfine slag powder and a production method based on the equipment. The production equipment comprises a drying mechanism, wherein a feeding hopper is arranged at the top end of the drying mechanism; a material guiding pipe is arranged at the end, away from the feeding hopper, of the drying mechanism; a screening mechanism is arranged on the side, away from the drying mechanism, of the material guiding pipe; a conveying pipe is arranged on the side wall of the screening mechanism; a smashing mechanism is arranged on the side, away from the screening mechanism, of the conveying pipe; a mixing tank is arranged on the side, away from the conveying pipe, of the smashing mechanism; and the mixing tank is connected with the bottom end of the screening mechanism. The production equipment for the casting residue superfine slag powder provided by the invention is novel in structure, high in automation degree, low in required labor intensity, good in grinding effect and high in working efficiency, the whole production process is simple and practical, casting residue slag drying and grinding are effectively integrated, and automatic production is achieved.

Owner:广东韶钢嘉羊新型材料有限公司

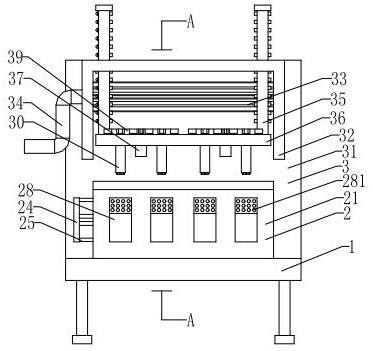

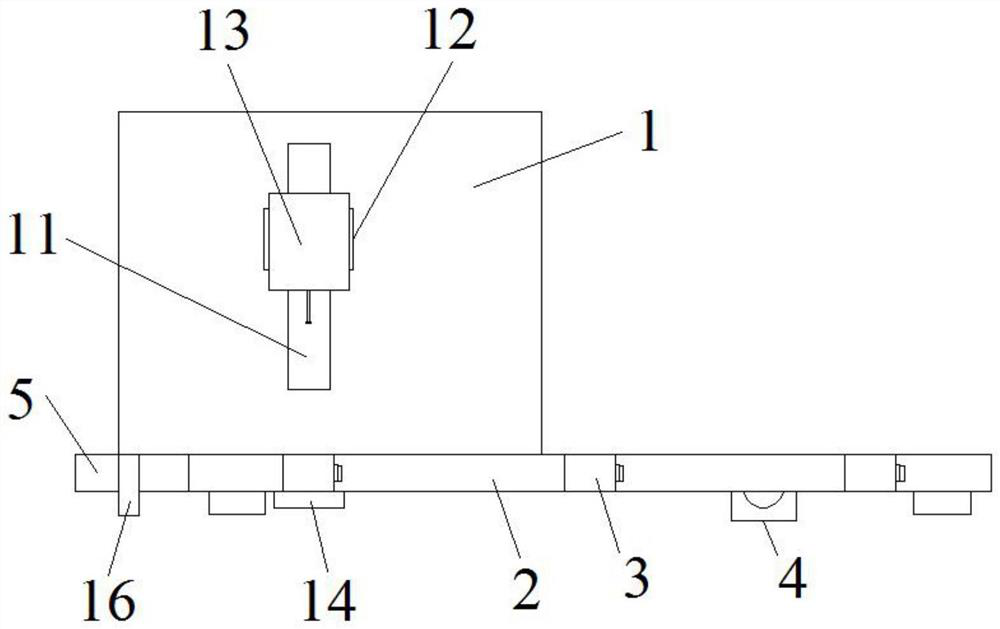

Automatic grinding and polishing machine

InactiveCN114473780AImprove grinding efficiencyReduce the difficulty of grindingGrinding carriagesRevolution surface grinding machinesPolishingEngineering

The automatic grinding and polishing machine comprises a supporting base, a fixing assembly and a polishing assembly, the fixing assembly is fixedly installed above the upper end face of the supporting base, the polishing assembly is arranged above the fixing assembly, and the polishing assembly is fixedly installed on the supporting base; the problems that when automobile parts are polished, the two sides and the inner wall of a through hole need to be manually polished when the through hole in the surface of the automobile parts is polished at present, the manual polishing difficulty is high, and the polishing efficiency is lowered are solved; and b, when existing automobile parts are subjected to polishing treatment, metal powder scraps are easily generated, the metal powder scraps are easily sucked into the respiratory tract of a human body so as to injure the human body, and waste scraps generated by polishing are difficult to clean.

Owner:徐州大业三维科技有限公司

DC plug polishing equipment

InactiveCN113894649AGrinding speed is fastReduce the difficulty of grindingGrinding machinesGrinding feedersPolishingControl engineering

The invention discloses DC plug polishing equipment which comprises a workbench, a pin type polisher, a conveying belt and a controller, the conveying belt is arranged on one side of the workbench, a sliding way is arranged on one side, away from the ground, of the workbench, the sliding way is perpendicular to the conveying belt, an electronic sliding seat is arranged on the sliding way in a sliding mode, and the pin type polisher is connected with the electronic sliding seat; the electronic sliding seat is used for driving the pin type polisher to slide along the sliding way; a plurality of clamping pieces are arranged on the conveying face of the conveying belt and arranged in the conveying direction of the conveying belt at intervals; and the controller is in signal connection with the electronic sliding seat, the pin type polisher and the conveying belt, and the controller is used for controlling the conveying belt to rotate so that the DC plug clamped by one clamping piece can be aligned and then controlling the pin type polisher to slide in the conveying direction so that the pin type polisher can polish the DC plug clamped by the clamping piece right opposite to the sliding way. According to the technical scheme provided by the invention, an operator does not need to operate a polisher to polish the DC plug, so that the polishing difficulty is reduced, the stability of the product quality is ensured, and the production capacity is improved.

Owner:湖南弘钧电子科技有限公司

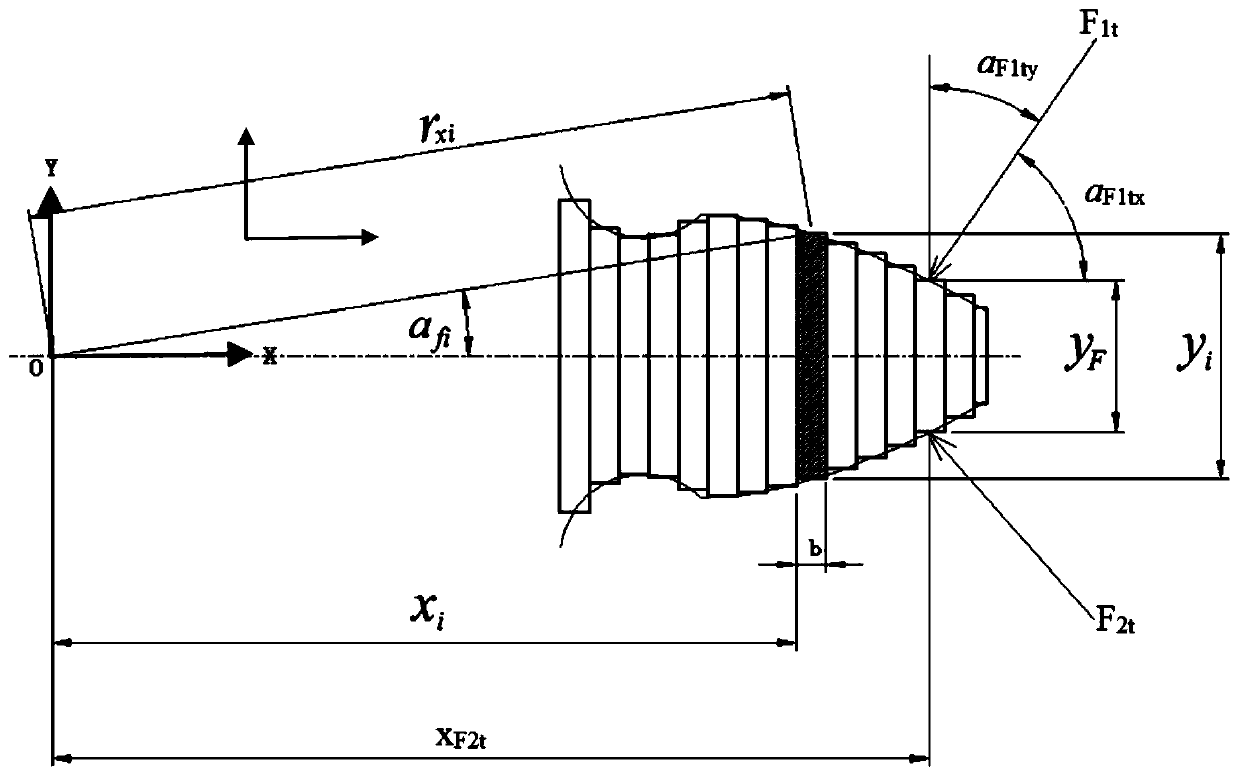

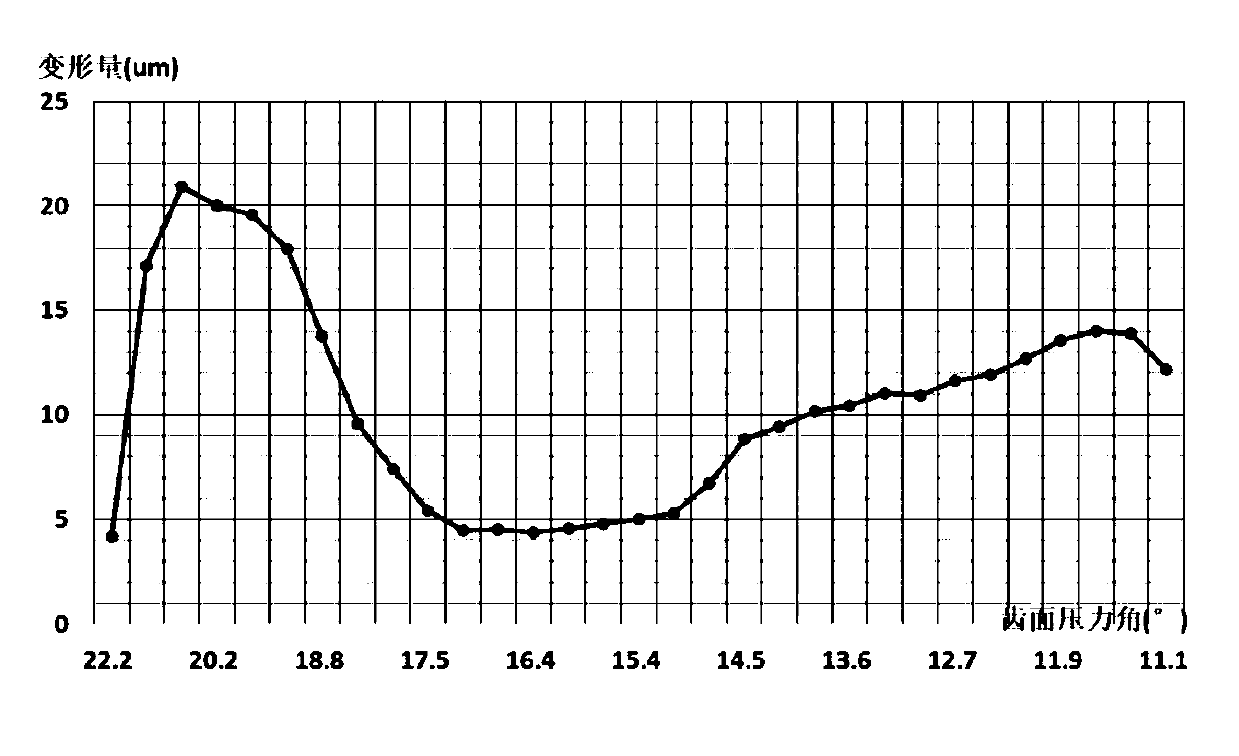

Elastic deformation optimization gear shaving cutter design method

ActiveCN111079233AReduce the difficulty of grindingImprove processing qualityGeometric CADSustainable transportationStress pointGear wheel

The invention relates to an elastic deformation optimization gear shaving cutter design method. The gear shaving concave phenomenon generated in existing gear shaving machining is restrained or relieved. The method comprises the following steps: 1) setting an initial meshing angle parameter a_nh0, and calculating an initial parameter of the gear shaving cutter through the a_nh0; 2) calculating theelastic deformation [delta]<0t> corresponding to each stress point at any moment of the gear part of the gear shaving cutter through the initial parameters of the gear shaving cutter in the step 1),and calculating the elastic deformation [delta]<1t> of each stress point at the corresponding moment on a gear meshed with the gear part; calculating the comprehensive elastic deformation [delta]<t> corresponding to each stress point; 3) drawing an elastic deformation dynamic distribution diagram between the comprehensive elastic deformation [delta]<t> and the pressure angle of the corresponding stress point, and calculating a comprehensive elastic deformation range R<delta>; and (4) adjusting the meshing angle parameter a_nh0, repeating the step (2) to the step (3), taking the a_nh0 when theR<delta> is smaller than or closest to 10 microns as a final design meshing angle parameter, and completing the design of other parameters of the gear shaving cutter according to the final design a_nh0 value.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

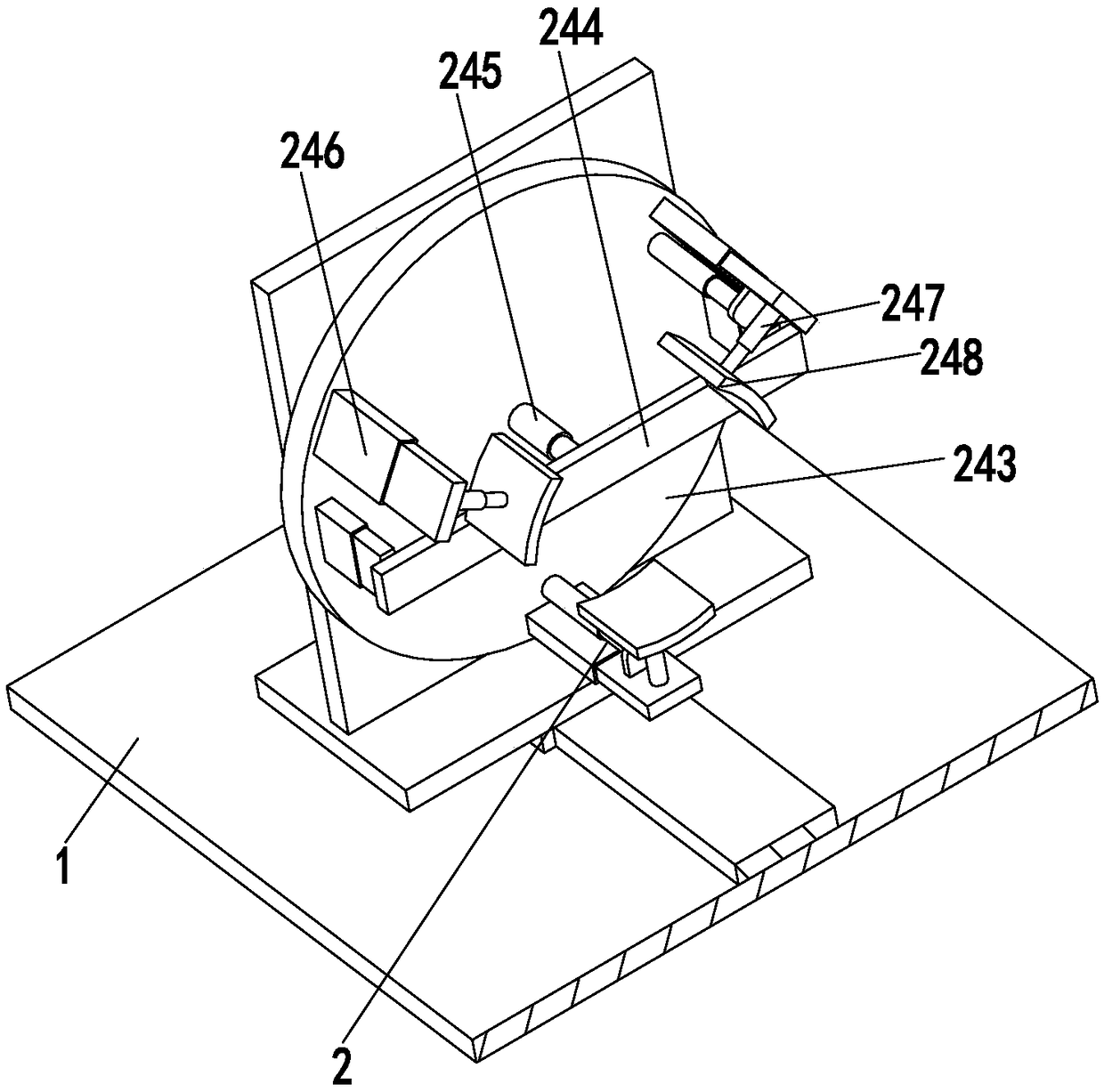

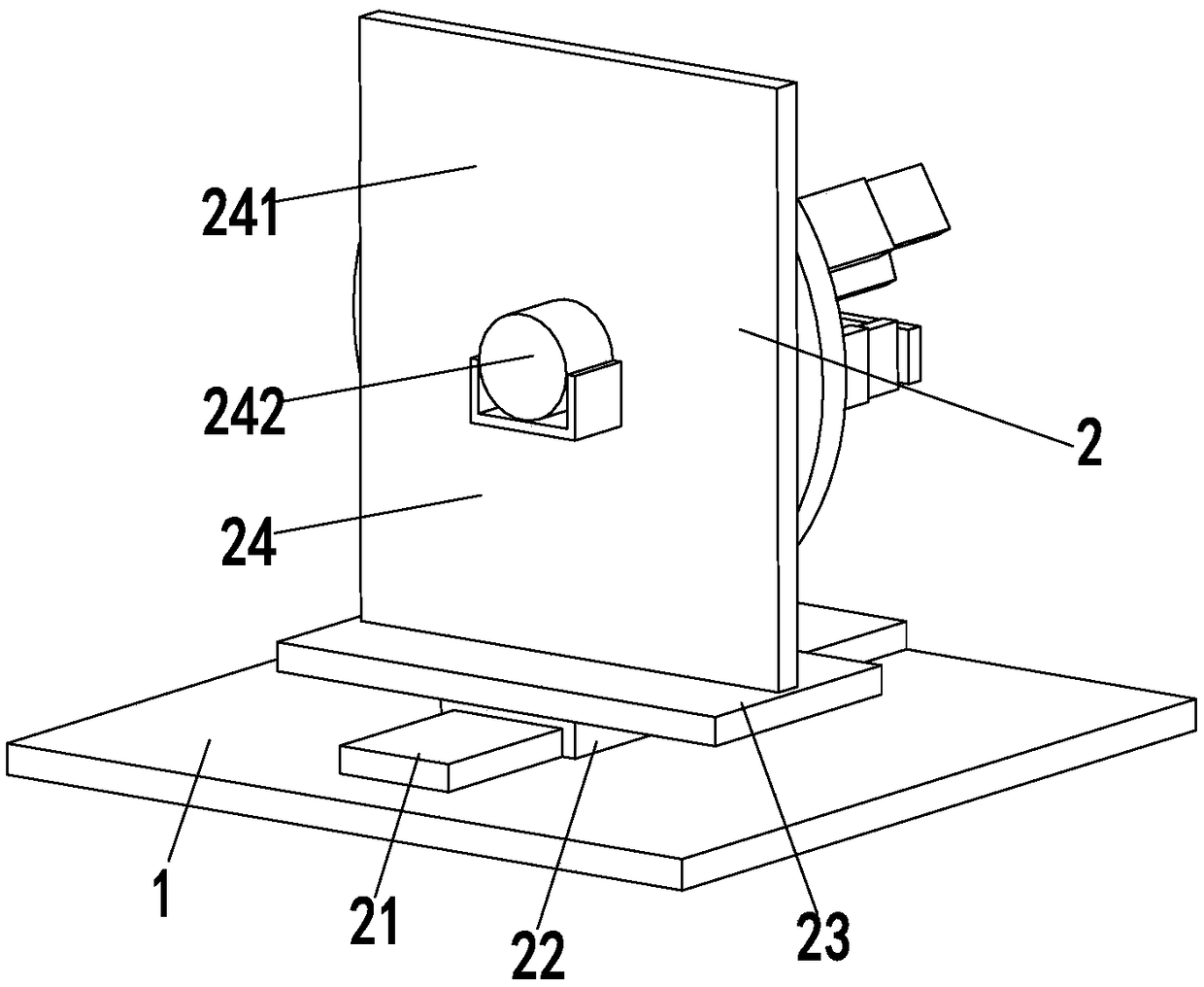

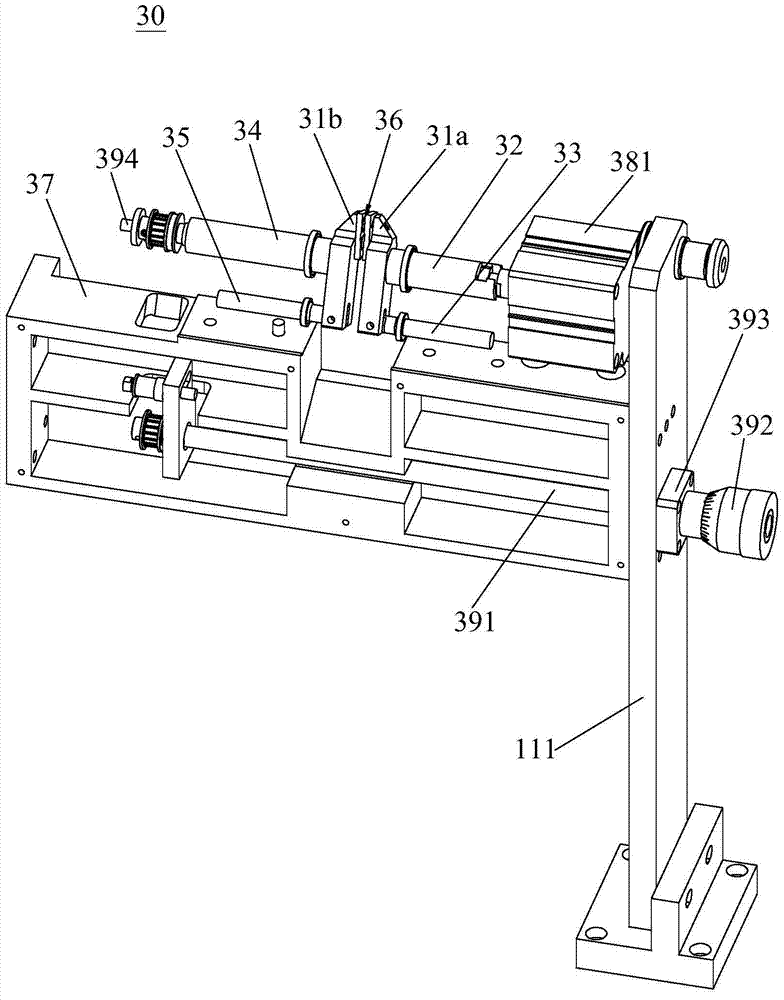

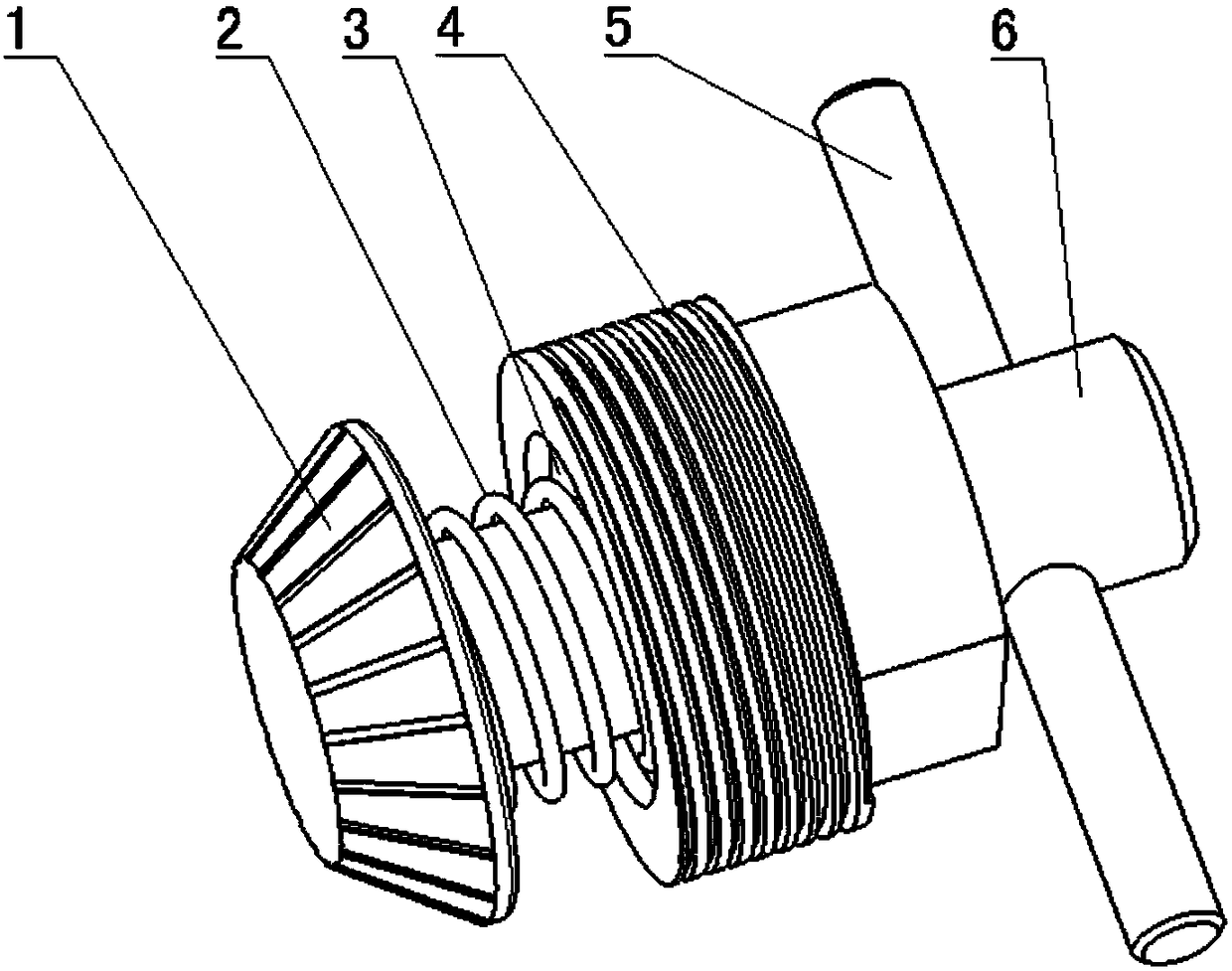

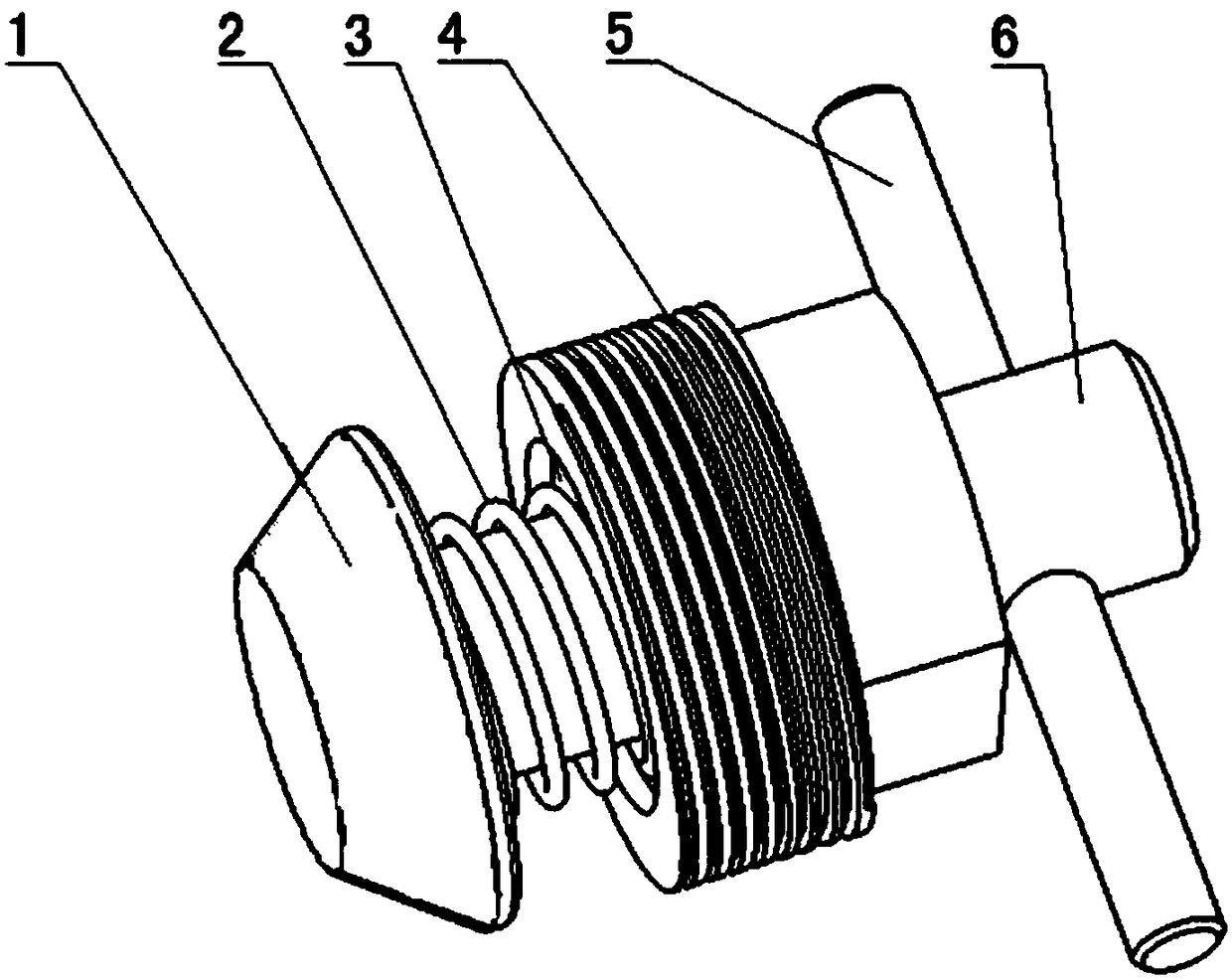

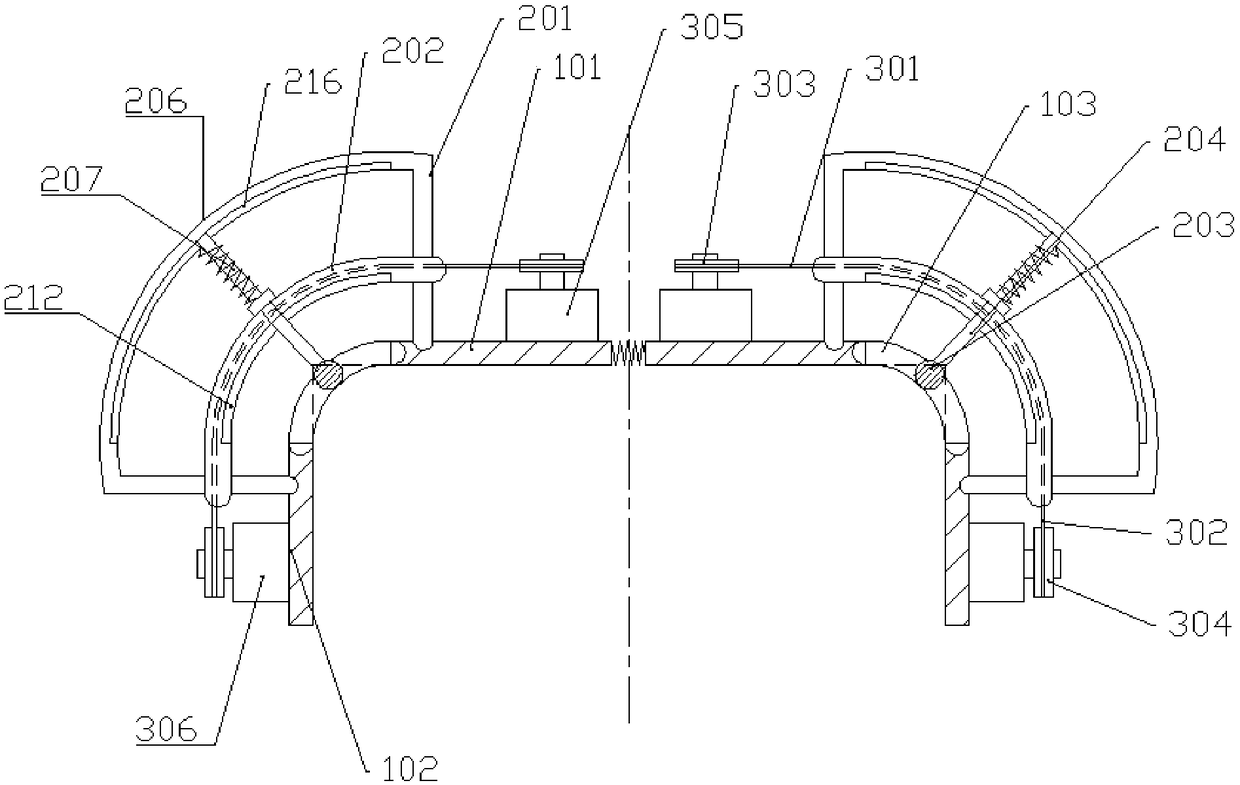

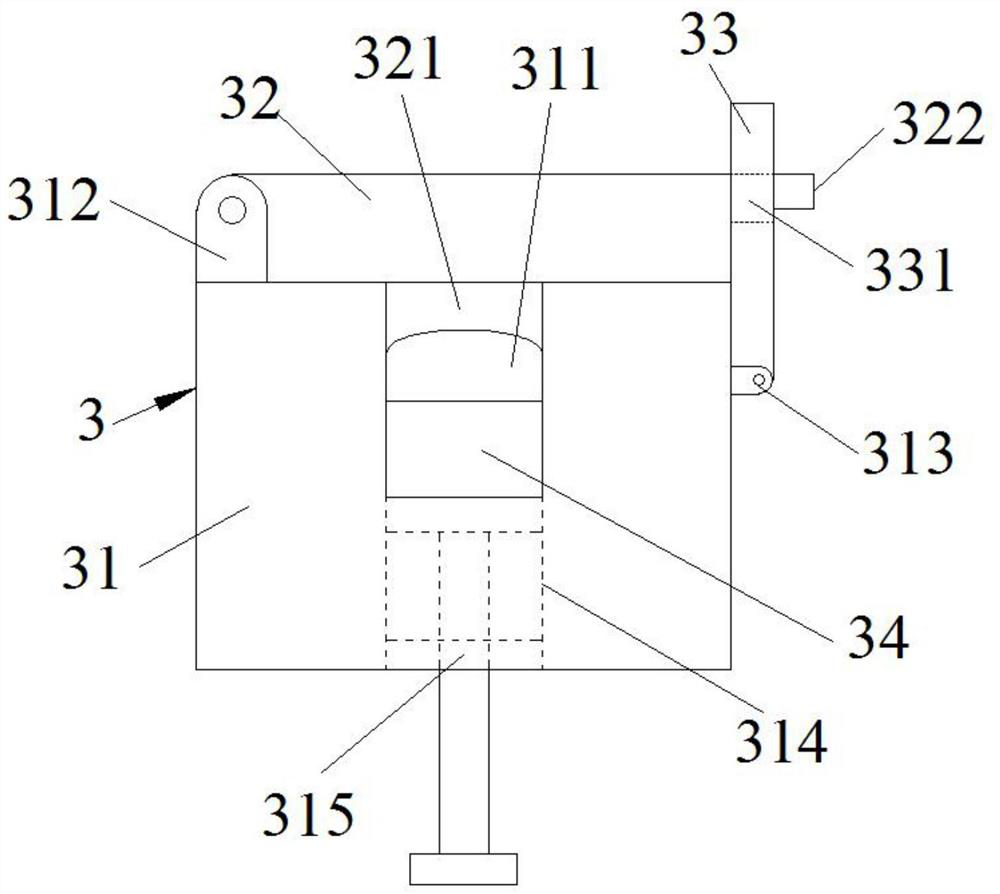

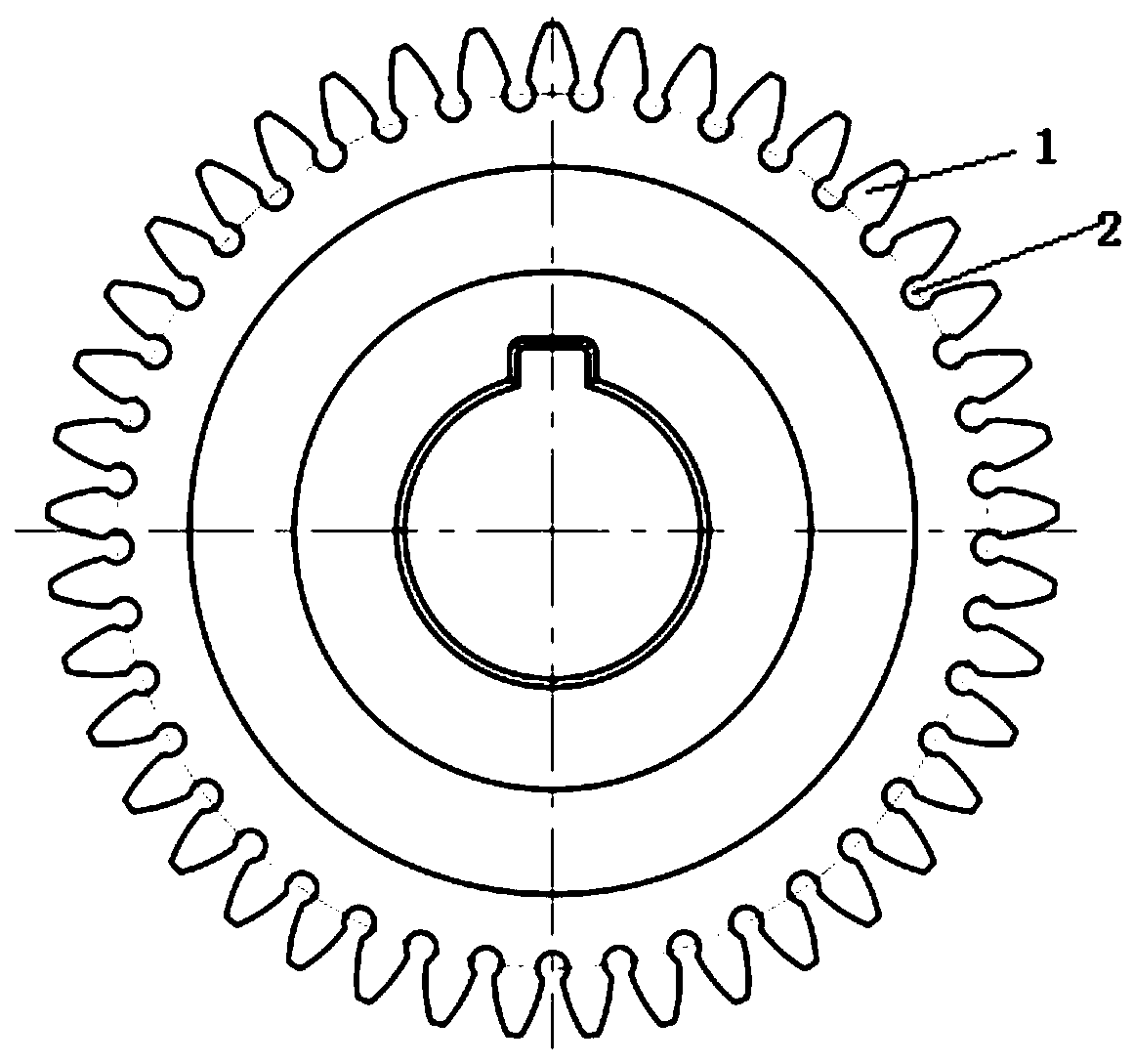

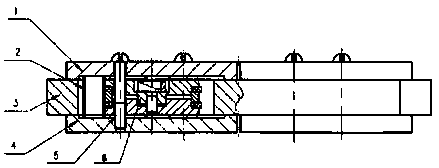

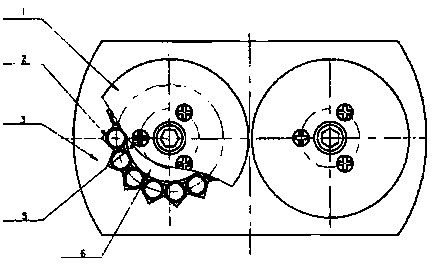

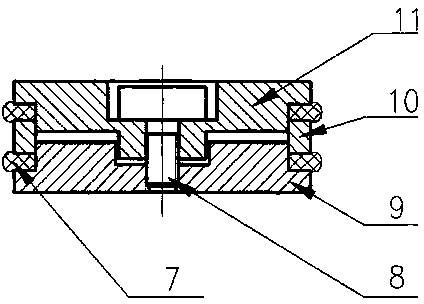

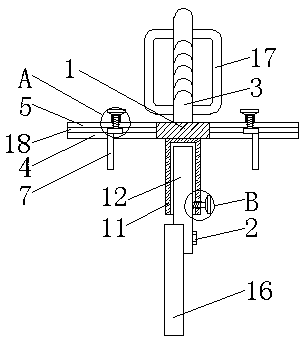

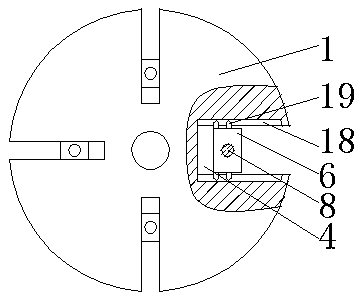

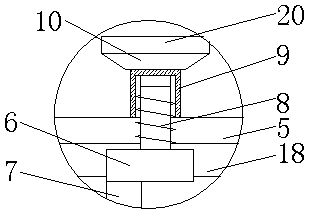

Star ring type multi-perforated expansion clamping device

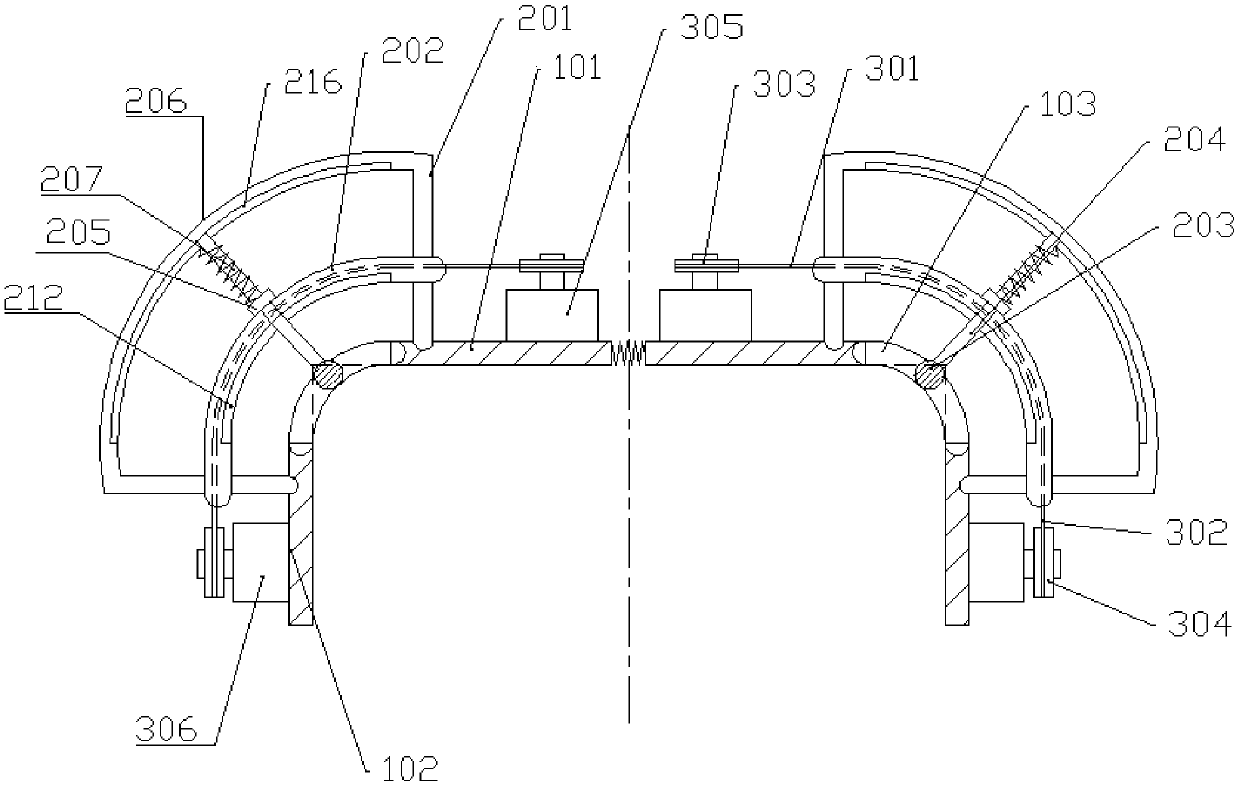

The invention provides a star ring type multi-perforated expansion clamping device, comprising a V-shaped slot star ring base frame and round expansion assemblies; the round expansion assemblies are placed in the V-shaped slot star ring base frame being a slab; star rings formed by a plurality of V-shaped slots are arranged in the slab; the round expansion assemblies are inserted in the V-shaped slot star rings; the round expansion assemblies can be radially, uniformly and circumferentially expanded and bulged under the axial force action so as to radially clamp a thin wall hollow tubular part placed between the V-shaped slot star rings and the round expansion assemblies. The thin wall hollow tubular part is positioned by the radial expanding and bulging of two rubber rings and the V-shaped slot star rings, the clamping force is uniform, the perpendicularity of the thin wall hollow tubular part can be ensured and the deviation in positioning is avoided. The machining efficiency is improved, the grinding difficulty is reduced and the precision of the end surface of the small-diameter thin wall hollow tubular part is ensured.

Owner:上海航天控制工程研究所

Grinding device for wooden shoe tree machining

ActiveCN106926091ALarge grinding areaImprove grinding efficiencyGrinding carriagesGrinding drivesEngineeringContinuous rotation

The invention relates to a grinding device, in particular to a grinding device for wooden shoe tree machining. In order to achieve the technical purpose, the grinding device for wooden shoe tree machining comprises a fulcrum bar, first connecting bars, a grinding plate, a clamping device, a moving device, a support and the like. The first connecting bars are arranged on the top and the bottom of the right end of the fulcrum bar, the clamping device is arranged at the right end of the first connecting bar, the moving device is arranged on the upper portion of the right wall in the support, and the grinding plate is arranged at the bottom of the moving device. Through the cooperation of the moving device and a swing bar and continuous rotation of the clamping device, the effect of improving the machining efficiency and reducing the grinding difficulty is achieved, and the grinding device is easy to operate, high in generalizability and high in efficiency.

Owner:温州市华利欧鞋服有限公司

Mechanical circular hole grinding tool

InactiveCN108311973AFor lateral movementReduce the difficulty of grindingGrinding carriagesRevolution surface grinding machinesThreaded pipeEngineering

The invention discloses a mechanical circular hole grinding tool which comprises a disc and bolts; the top of the disc is fixedly connected with a handle; transverse slots are formed in the bottom ofthe disc; the number of the transverse slots is four; long grooves communicating with the transverse slots are formed in the top of the disc; inner cavities of the transverse slots are connected withsliding blocks in a sliding manner; the bottoms of the sliding blocks are fixedly connected with clamping blocks; the bottoms of the clamping blocks extend to the exteriors of the transverse slots; the tops of the sliding grooves are fixedly connected with first threaded rods; the tops of the first threaded rods penetrate through the long grooves and extend to the exteriors of the long grooves; and the tops of the first threaded rods are sleeved with threaded pipes. According to the mechanical circular hole grinding tool, with the adoption of second threaded rods and the threaded pipes, a vertical rod can be fixed, and the distance between a cutter and the disc can be adjusted, so that the inner wall of a semicircular hole is ground conveniently, the grinding difficulty of the semicircularhole is lowered, the grinding precision is improved and people can use mechanical circular hole grinding tool conveniently.

Owner:李百冲

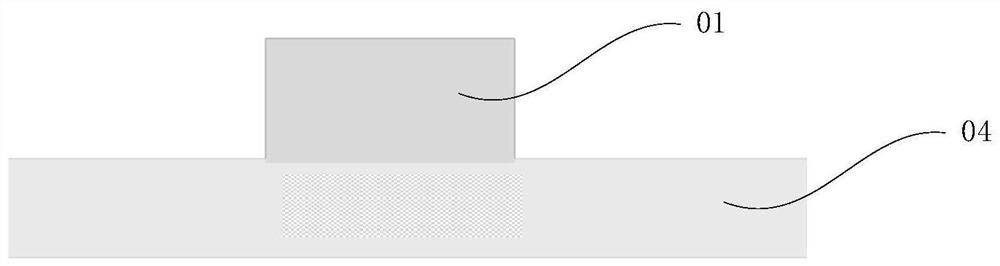

Method for polishing back surface of ultra-small sample

ActiveCN112345336AReduce difficultyReduce the difficulty of grindingPolishing machinesPreparing sample for investigationMechanical engineeringMaterials science

The invention provides a method for polishing the back surface of an ultra-small sample. The method comprises the following steps of sticking an ultra-small chip on a first gasket with the front surface facing downwards, splicing a splicing gasket at the periphery of the chip, cooling and fixing the chip, polishing the back surface of the chip, heating the first gasket and taking down the chip andthe splicing gasket for later use, sticking the chip on a glass slide with the front surface facing upwards, cooling and fixing, pricking needles on the front surface of the chip and obtaining hot spots on the back surface, heating the glass slide with the chip, and taking down the chip, putting the chip on a second gasket coated with AB glue in a manner that the front surface of the chip faces upwards, tightly jointing and splicing a ground splicing gasket with the same height as the chip around the chip, then heating, fixing and cooling, removing a layer from the front surface of the sample, and determining a failure position around the hot spot. According to the method, the difficulty of polishing the back surface of the ultra-small sample can be greatly reduced, subsequent analysis can be carried out, meanwhile, a splicing gasket with a proper height is provided for subsequent wafer grinding, and the wafer grinding difficulty is reduced. The success rate of sample preparation is greatly improved, the improvement of an online process is assisted and promoted, and the product yield is further improved.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

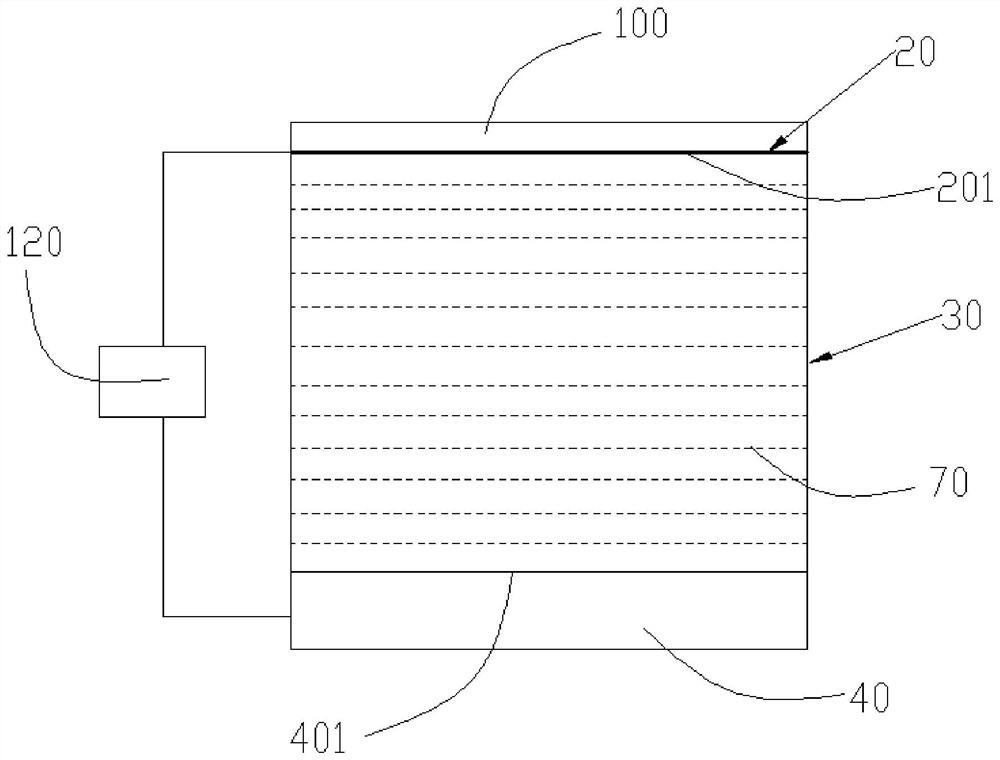

Wafer electroplating device and electroplating method

InactiveCN112831821AReduce grinding difficultyReduce current differenceSemiconductor devicesElectrodesPhysicsLiquid crystal

The invention provides a wafer electroplating device and electroplating method. The wafer electroplating device comprises an electroplating bath, an electroplating anode, a virtual anode and a power source. Electroplating liquid is arranged in the electroplating bath, a seed layer is arranged on the surface of a wafer, the electroplating anode comprises a first surface facing the seed layer, the seed layer comprises a second surface facing the electroplating anode, and at least part of the first surface and at least part of the second surface are immersed in the electroplating liquid. The power source comprises a positive electrode and a negative electrode, the electroplating anode is connected to the positive electrode of the power source, the seed layer is connected to the negative electrode of the power source, the virtual anode is immersed in the electroplating liquid and located between the electroplating anode and the seed layer, the virtual anode can enable ions in the electroplating liquid to pass through, and the resistance of the virtual anode is larger than the sum of the resistance of the electroplating liquid and the resistance of the seed layer. The wafer electroplating device and electroplating method solve the technical problem that the thickness of an electroplated layer formed on the wafer through electroplating is not uniform.

Owner:YANGTZE MEMORY TECH CO LTD

Plate cutting machine

PendingCN114505538AExpand the spraying rangeGood cooling effectEdge grinding machinesMetal sawing accessoriesPhysicsElectric machinery

The plate cutting machine specifically comprises a supporting frame, the bottom of the supporting frame is fixedly connected with a workbench, and the part, located above the workbench, of the top of the supporting frame is fixedly connected with a cutting device; the polishing device is arranged on the part, located on one side of the cutting device, of the workbench; the cutting device comprises a cutting disc, a rotating shaft is rotatably connected to the center of the inner wall of the cutting disc, a cutting knife penetrates through and is fixedly connected to the center of the rotating shaft, and the bottom of the cutting knife extends to the outside of the cutting disc; and the control device is arranged on one side of the cutting disc, and one end of the rotating shaft penetrates through the control device and is fixedly connected with a driving motor. According to the plate cutting machine, the situation that a cutting knife throws cooling water out to pollute a working table top can be avoided, the spraying range of the cooling water can be expanded through the multiple spraying head bodies, and the cooling effect is better.

Owner:沭阳县成基实业有限公司

Surface treatment method for sewage inspection well cover

ActiveCN107502126AMaintain metallic lusterHeating fastAntifouling/underwater paintsPretreated surfacesAdhesion forceSewage

The invention mainly relates to the technical field of machining and discloses a surface treatment method for a sewage inspection well cover. The surface treatment method for the sewage inspection well cover comprises the steps of polishing, cleaning, quenching and covering with a film. The method is simple and convenient to operate. The inspection well cover is polished after being frozen, so that polishing difficulty and high temperature generated by polishing are lowered, the metal luster of the inspection well cover is maintained and the polishing efficiency is improved; the inspection well cover is heated rapidly after cleaning and then put into a urea solution to perform quenching cooling and a protective film is formed on the surface, so that the corrosion of the inspection well cover is avoided, and the combining capacity of the inspection well cover and the film is improved; the inspection well cover is heated to the original temperature after quenching, so the combining capability of the coating film is improved; the inspection well cover is spray-coated with coating, the coating raw material is rich, safe, non-toxic and strong in adhesion force, so the wear resistance of the film is improved, the antibacterial property, the stability and the wear resistance of the film are enhanced, and the service life of the inspection well cover is prolonged by 23 to 25 percent.

Owner:FUNAN COUNTY FENJIN MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com