Patents

Literature

184results about How to "Large grinding area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for architectural decoration plastering construction

The invention provides a method for architectural decoration plastering construction. The method comprises the following steps: firstly, base treatment, secondly, screeding, thirdly, plastering, and fourthly, wall surface grinding; screeding in the second step means that construction positioning paying-off is performed according to required plastering height, screeding templates are longitudinally installed along a wall surface subjected to base treatment in the first step according to the paying-off height, and the lateral distance between adjacent screeding templates is 1.3 to 1.8 meters. Wall surface grinding in the fourth step means that the wall surface subjected to plastering in the third step is subjected to standing for 12 to 24 hours till plastering mortar on the wall surface is at a half-dried compact hardened state, and teeth of a saw blade are used for grinding the mortar along the two adjacent screeding templates through a rule till the mortar is even. Due to the method, the plastering construction efficiency can be improved, the construction quality is guaranteed, the large-area construction efficiency is further improved with the matching of mechanized construction, and the defects of low efficiency of traditional manual construction and high technical requirements on constructors are overcome.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

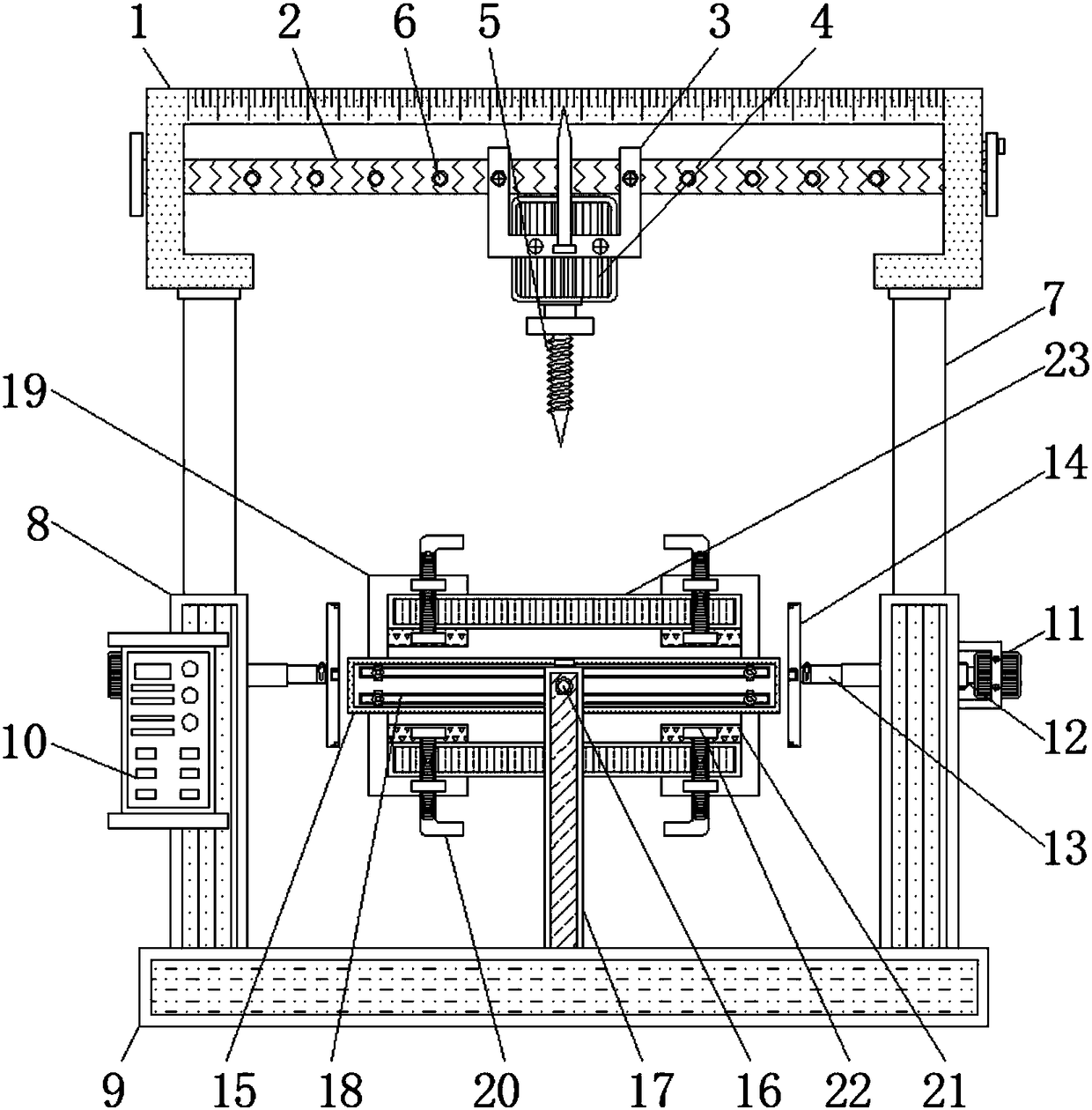

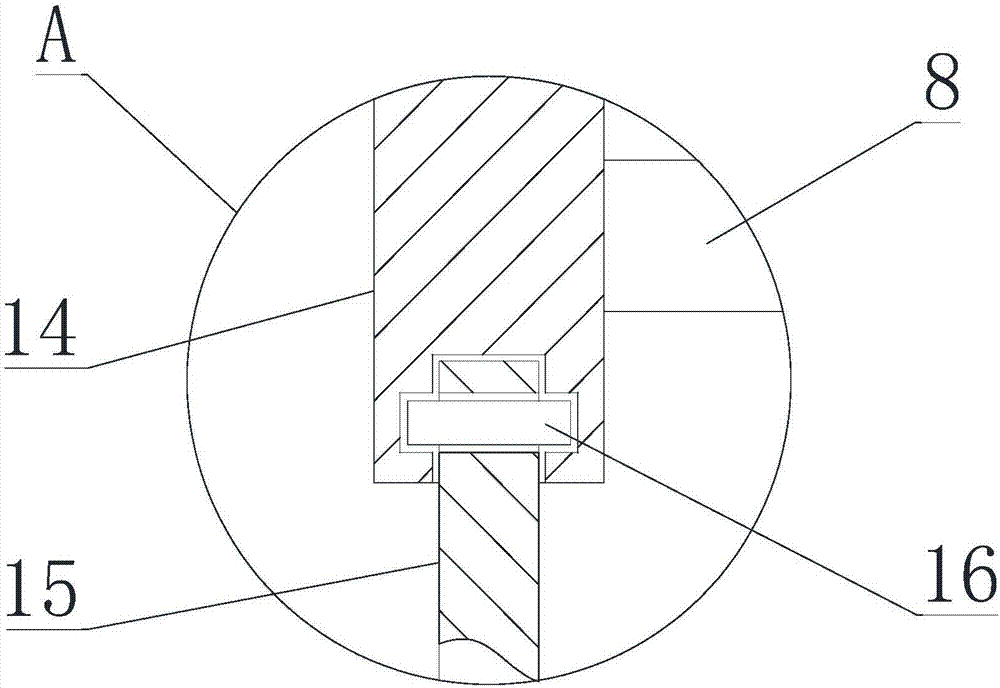

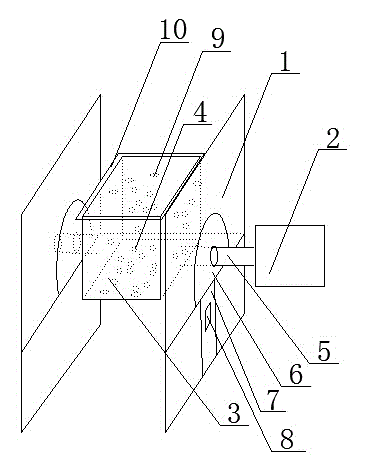

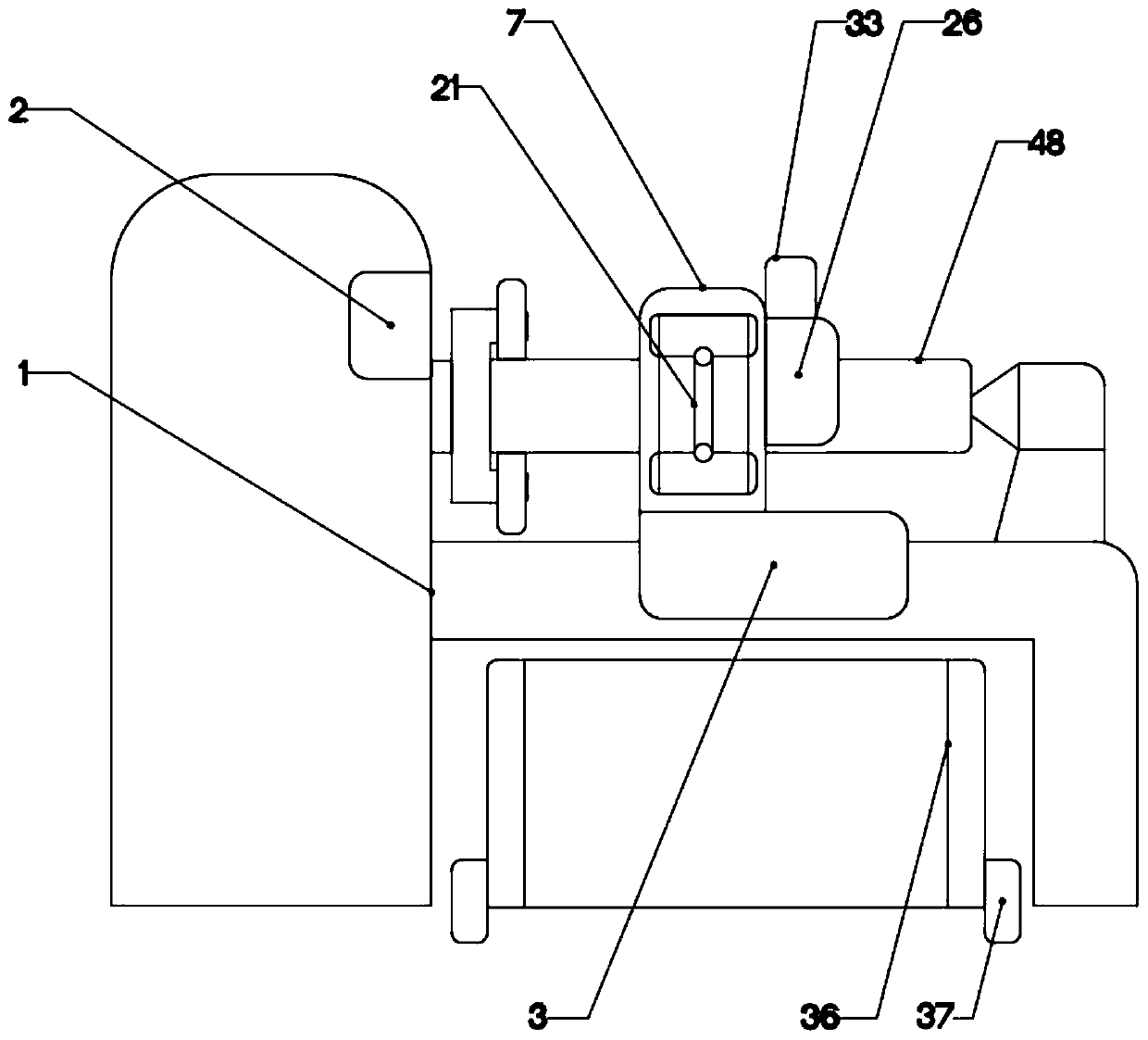

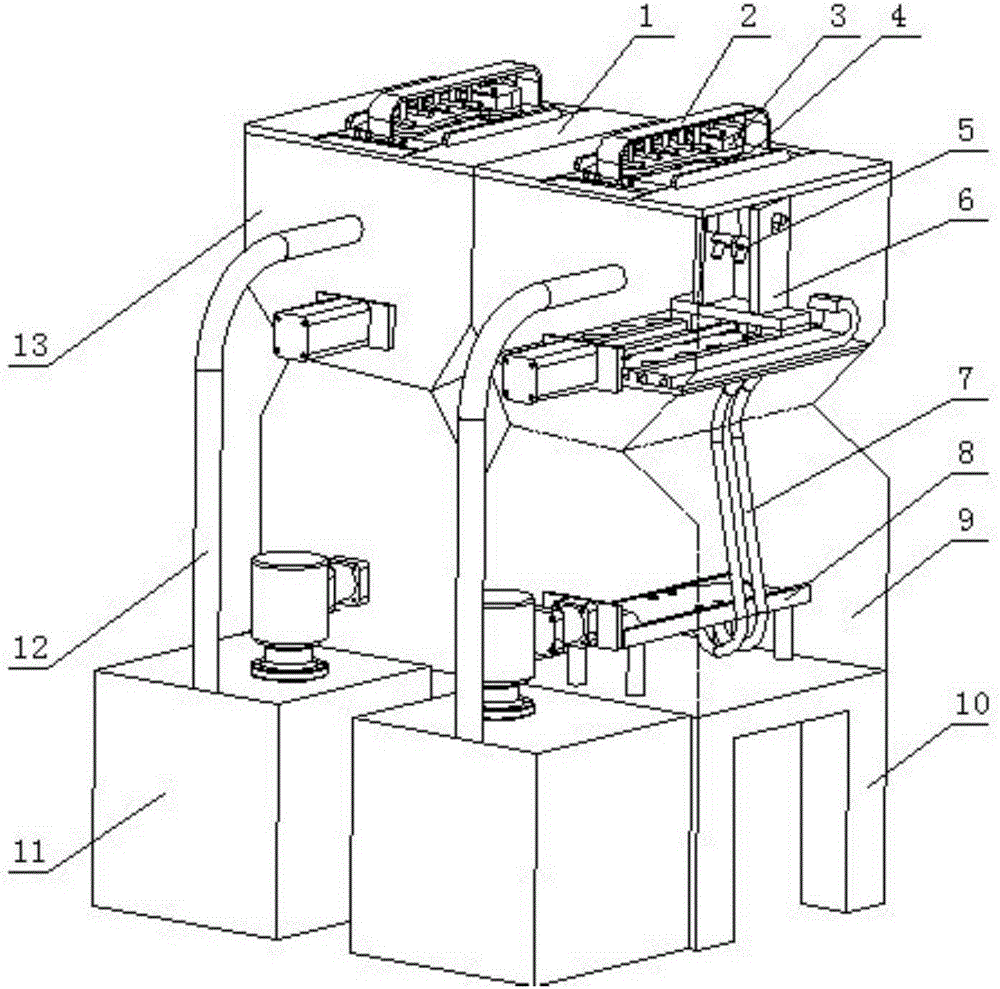

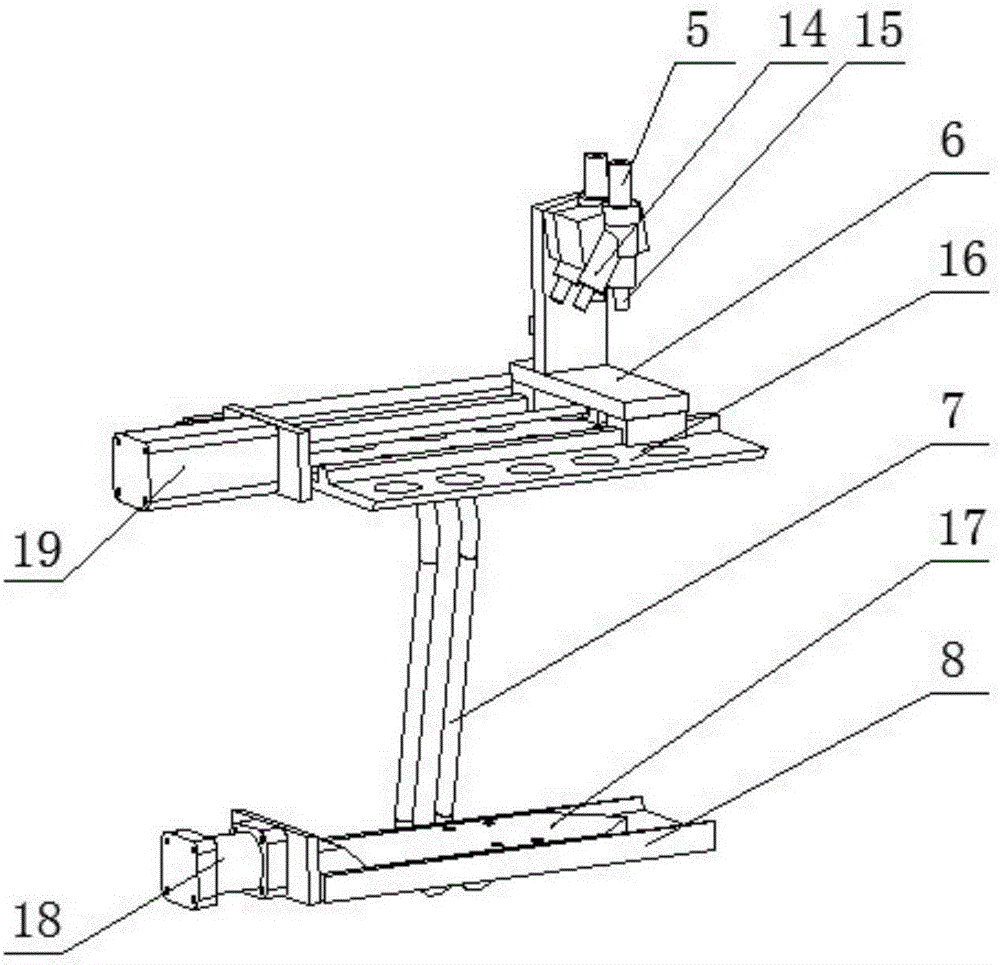

Drilling and grinding integrated machine for panel machining

ActiveCN108372405AIncrease flexibilityHigh precisionOther manufacturing equipments/toolsLarge fixed membersEngineeringMachining

The invention discloses a drilling and grinding integrated machine for panel machining. The drilling and grinding integrated machine comprises a top plate and a workbench. An installing base is arranged on a transverse rod installed below the interior of the top plate. The two sides of the lower portion of the top plate are connected with supporting plates through electric telescopic columns, wherein the supporting plates are symmetrically fixed to a base. A second motor fixed to one side of one supporting plate is connected with a manual telescopic rod through a connecting sleeve. The workbench is connected with a supporting rod through a connecting shaft. A grinding block is arranged in a groove formed in the surface of the grinding disc. One side of a first clamping plate and one side of a second clamping plate are connected through connecting springs. Surface sliding ways are reserved in the upper surface of the workbench. Movable grooves are symmetrically formed in the left side and the right side of the top plate, and inserting holes are reserved in the upper end, the lower end, the front face and the back face of the connecting shaft. The drilling and grinding integrated machine for panel machining can grind the surface of a panel after the panel is drilled, and accordingly later work proceeding is convenient.

Owner:杭州智安知识产权服务有限公司

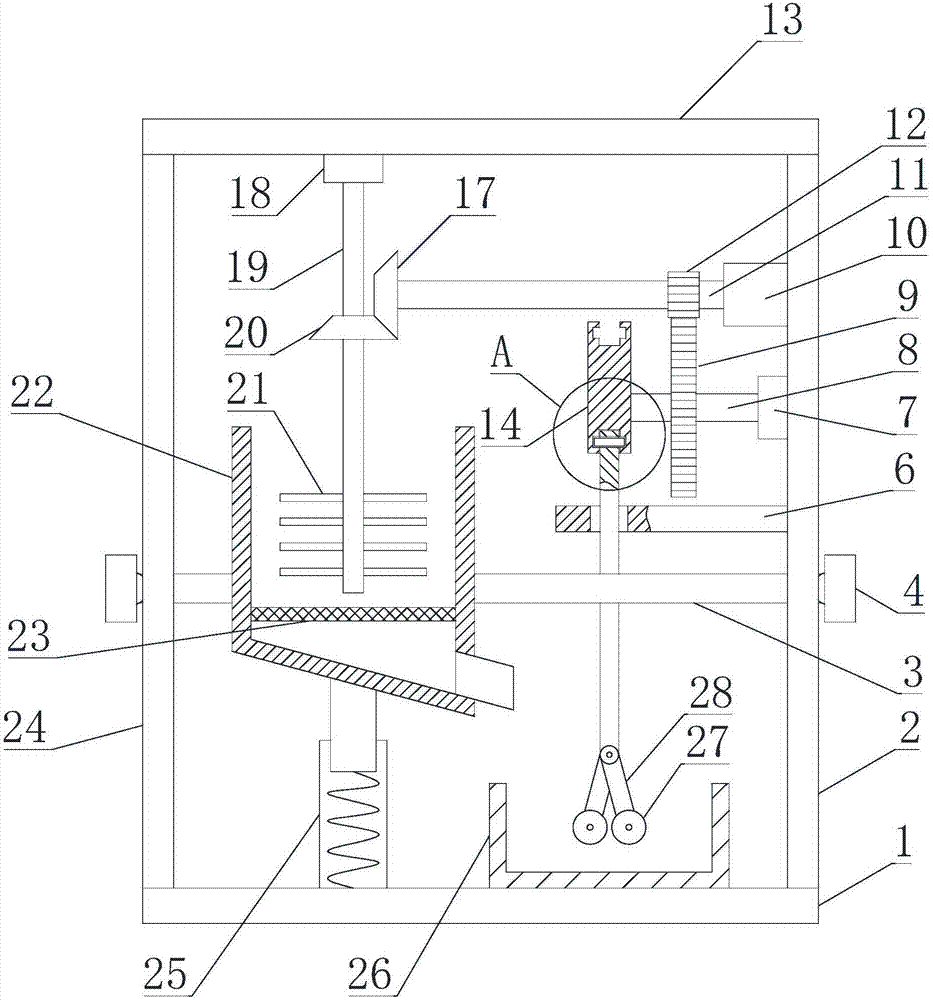

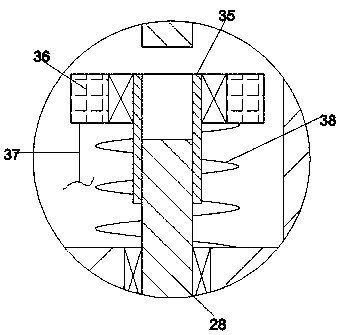

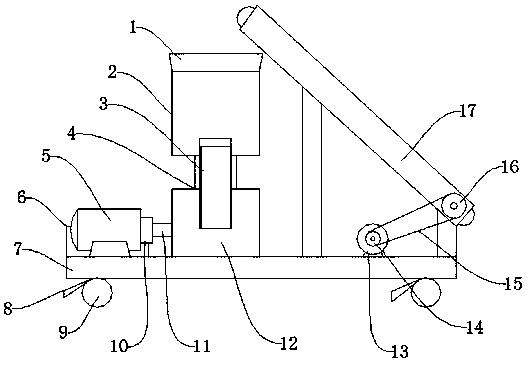

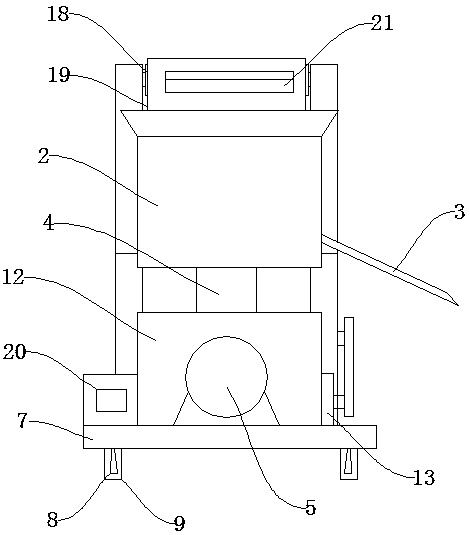

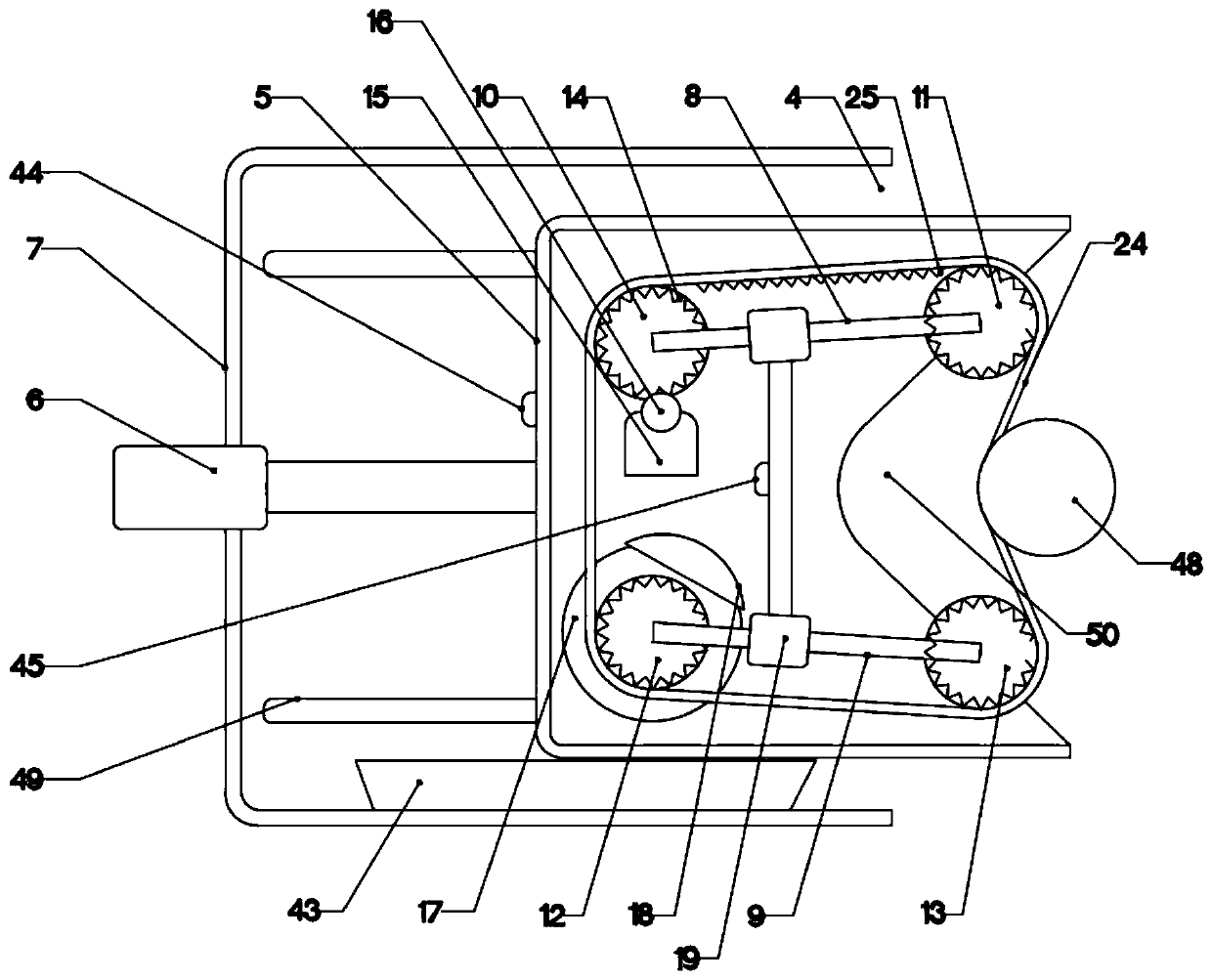

Integrated efficient traditional Chinese medicine smashing and grinding device

InactiveCN107127037AImprove processing efficiencyEasy to operateGrain treatmentsGear wheelEngineering

The invention discloses an integrated high-efficiency crushing and grinding device for Chinese medicinal materials, which comprises a bottom plate, a right support plate and a left support plate, the right support plate and the left support plate are arranged on the bottom plate, and the left side wall of the right support plate is arranged from top to bottom. The motor, the first bearing with seat and the limit plate, the motor shaft at the left end of the motor is connected with the second rotating shaft, the driving gear is installed on the second rotating shaft, and the first bevel gear is also connected at the left end of the second rotating shaft; the first bearing with seat is connected with The first rotating shaft, a driven gear is installed on the first rotating shaft, the driving gear meshes with the driven gear, a cam is installed at the left end of the first rotating shaft, a groove is arranged on the cam, and a lifting rod is connected to the groove through a roller; the support plate A crushing box is installed on the left side; a grinding box is also arranged on the bottom plate, two connecting rods are hinged at the bottom end of the lifting rod, and a grinding roller is connected at the bottom end of the connecting rods. The invention combines crushing and grinding to improve processing efficiency; a variety of motion modes can be completed through one driving device, and the operation is convenient and the cost is saved.

Owner:惠安县长信机电科技有限公司

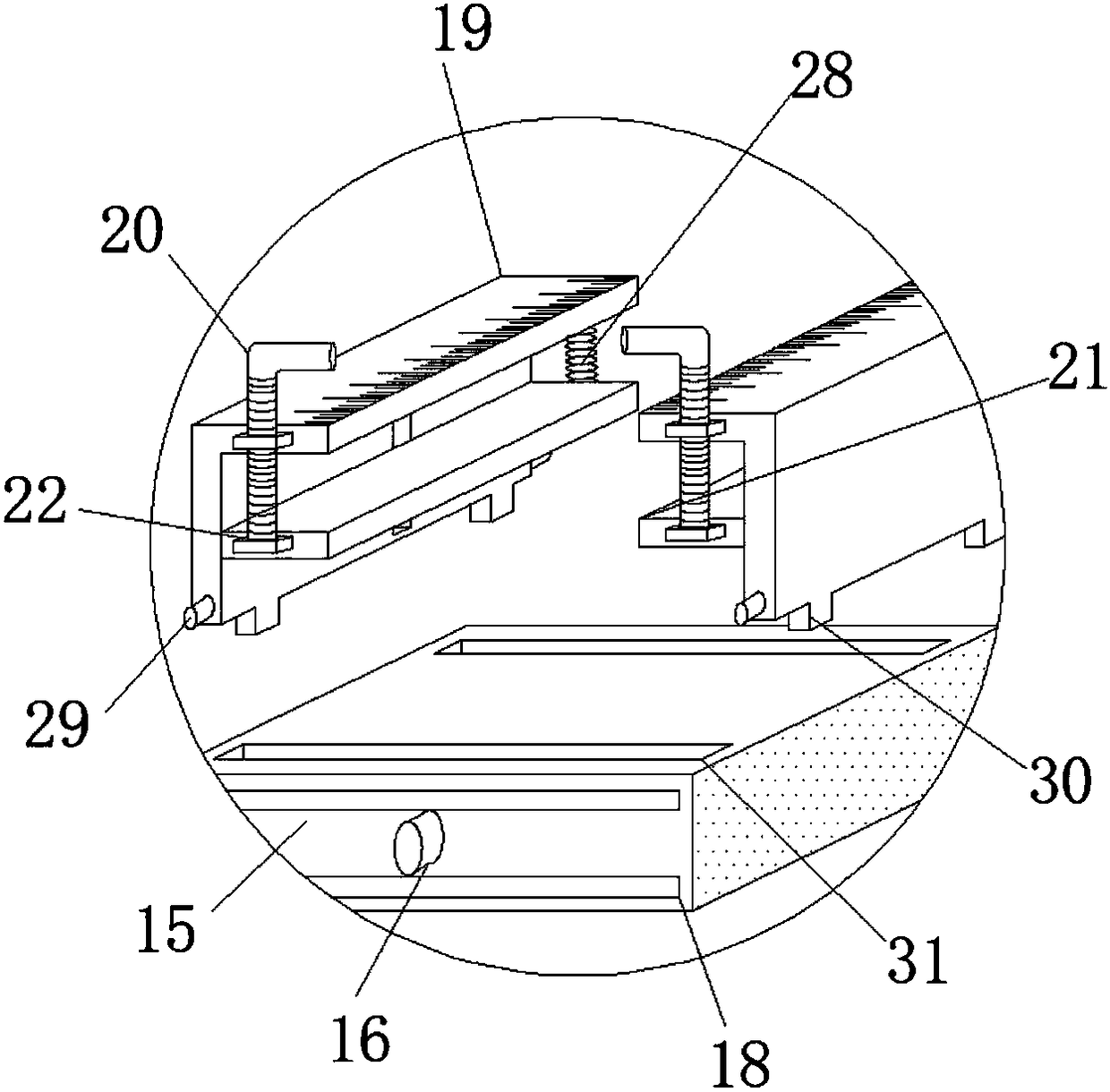

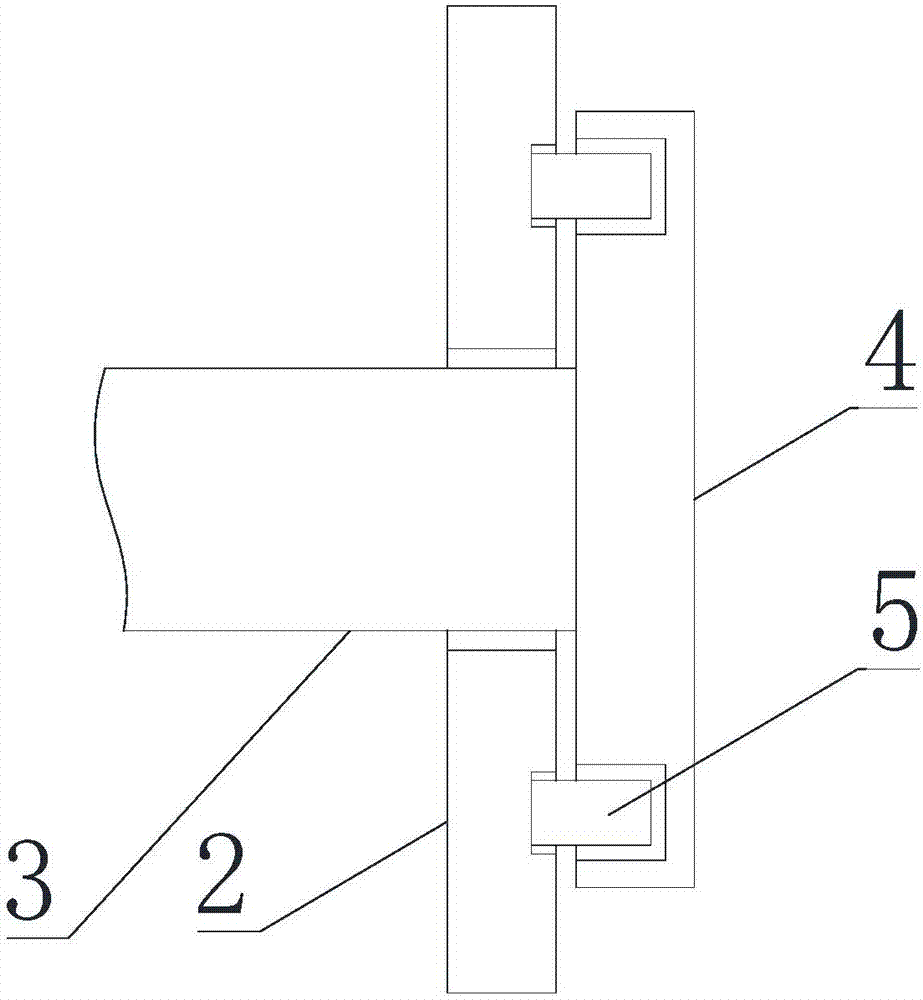

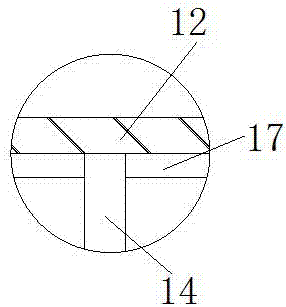

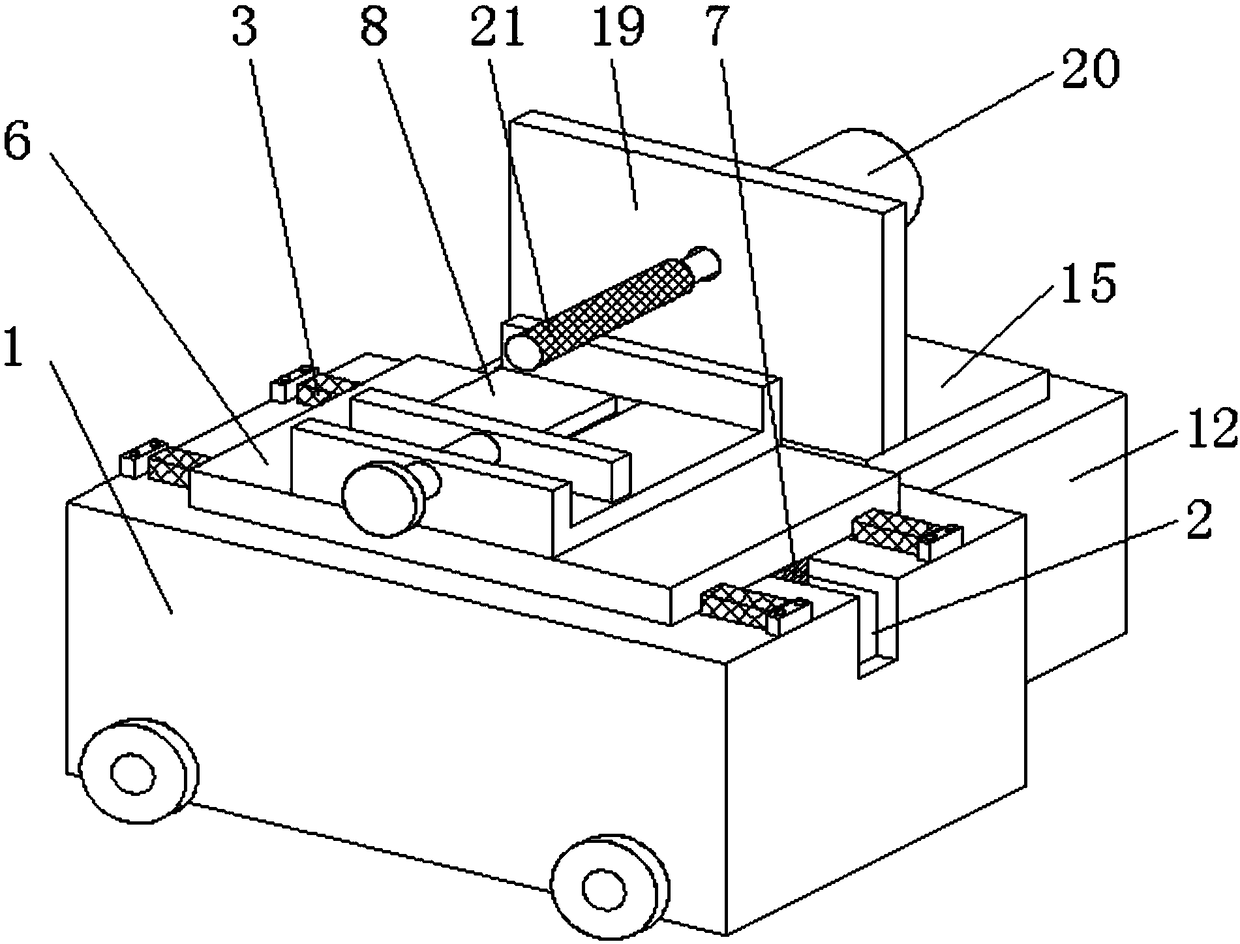

Grinding and dedusting device for hardware machining

InactiveCN107984358ALarge grinding areaImprove work efficiencyGrinding carriagesGrinding machinesEngineeringMachining process

The invention discloses a grinding and dedusting device for hardware machining. The grinding and dedusting device comprises a workbench. A support pillar is fixedly connected to the right side of thetop of the workbench. A support rod is fixedly connected to the top of the support pillar. A first electric extending-and-contracting rod is connected to the bottom of the support rod in a sliding manner. A motor box is fixedly connected to the bottom of the first electric extending-and-contracting rod. According to the grinding and dedusting device for hardware machining, the first electric extending-and-contracting rod, a motor and a grinding disc are arranged to jointly form a device which can ascend and descend for grinding; a dust cover, a dedusting pipe, a suction fan and a dust storagebox are arranged to jointly form a device capable of conducting dedusting; working boxes, second electric extending-and-contracting rods, first sliding blocks, push rods and clamping plates are arranged to jointly form a clamping and fixing device; by means of cooperation among the devices, the purposes that a great amount of dust generated in the machining process can be removed, and the environment cannot be affected are achieved; and the problems that the great amount of dust generated in the machining process cannot be removed, and the environment can be affected are solved.

Owner:湖南新融创科技有限公司

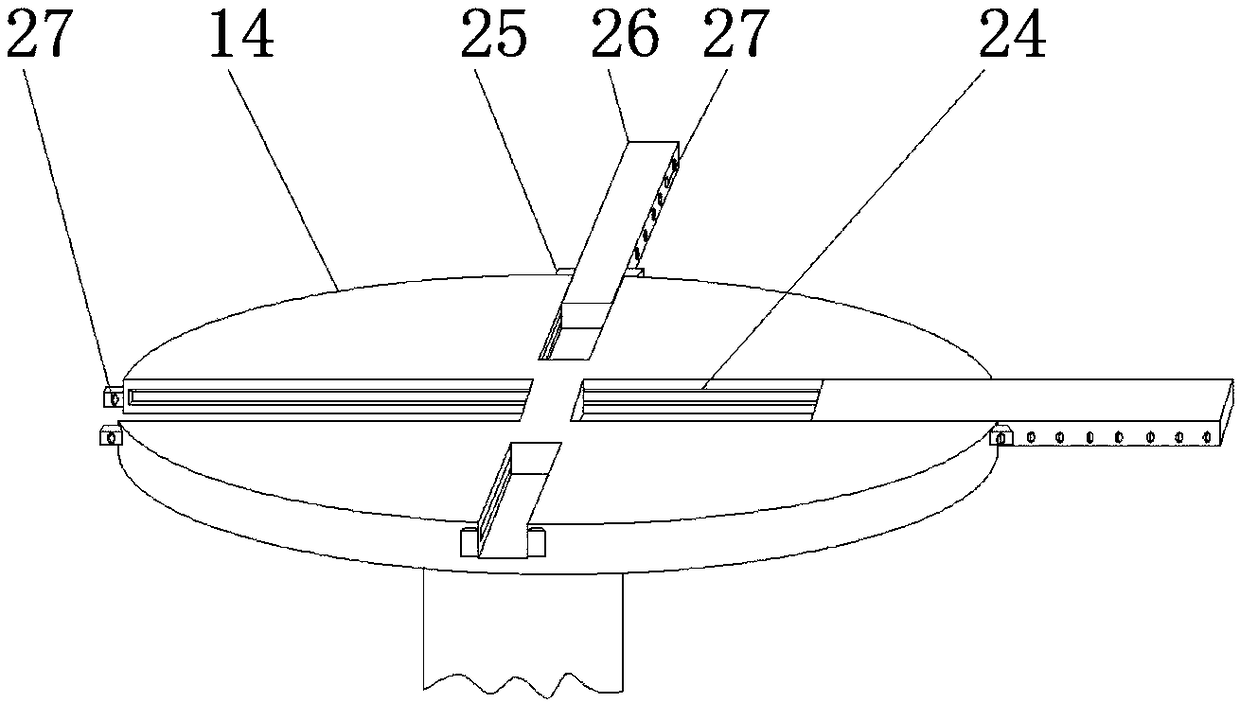

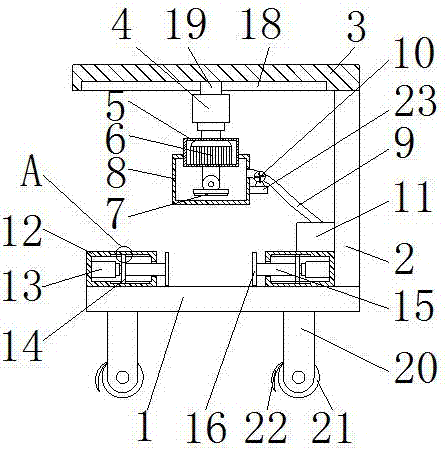

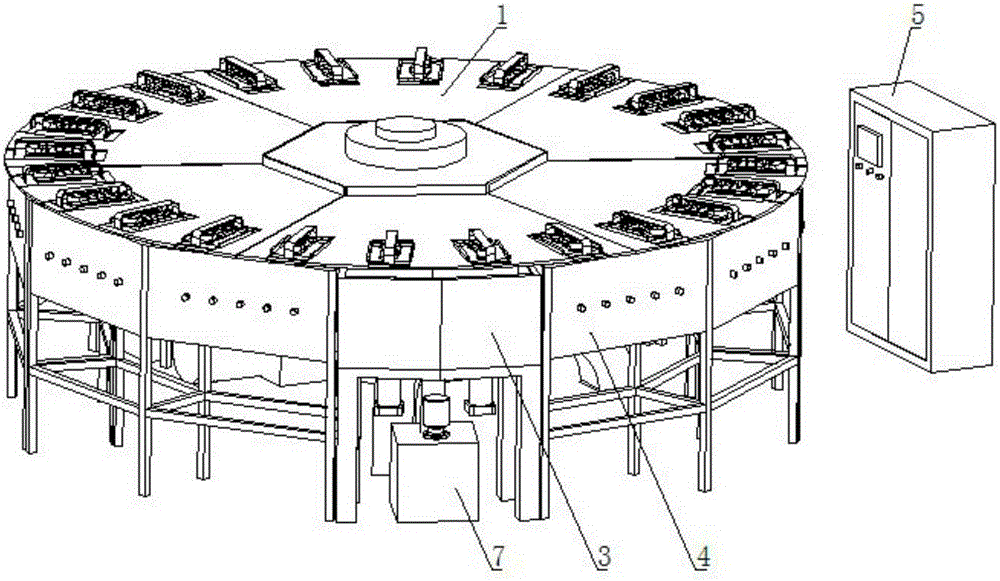

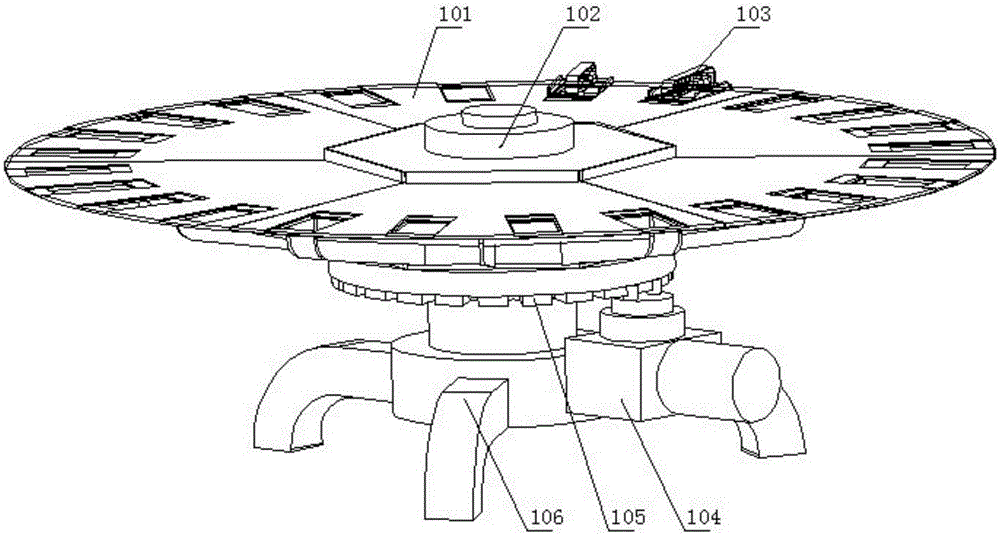

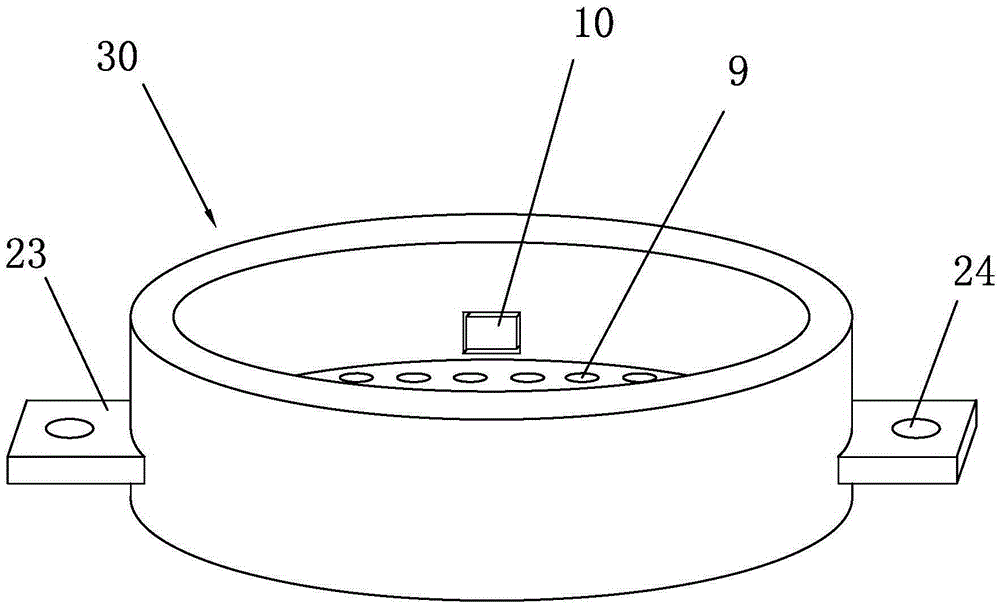

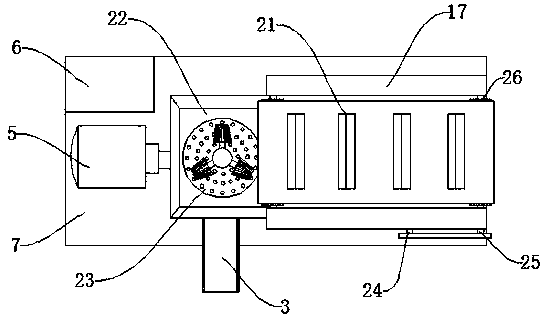

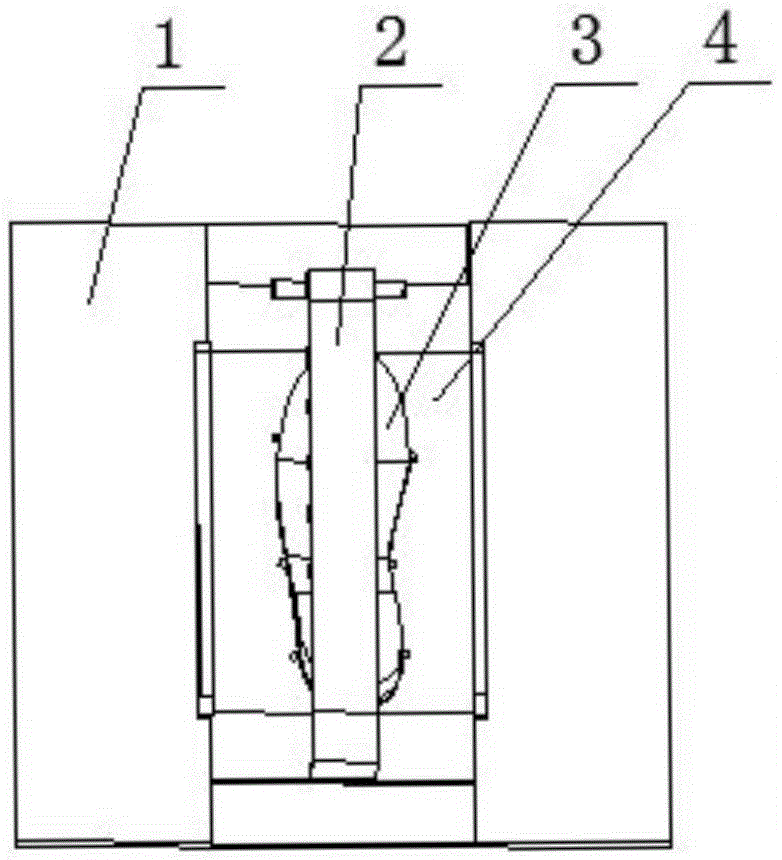

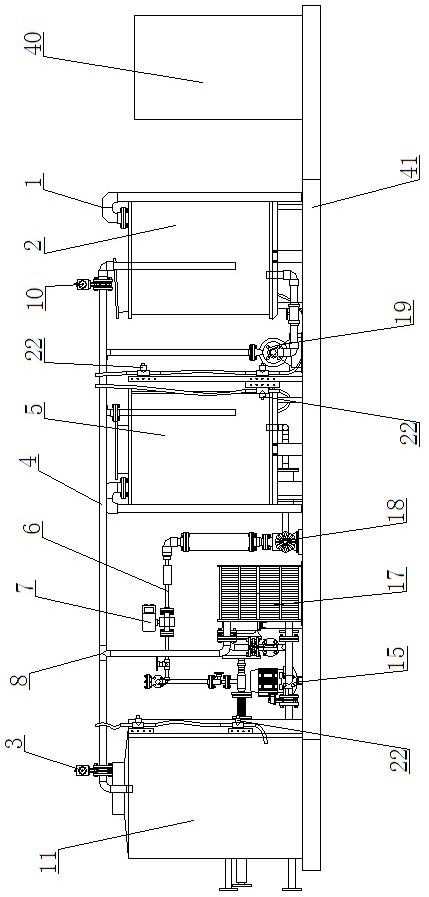

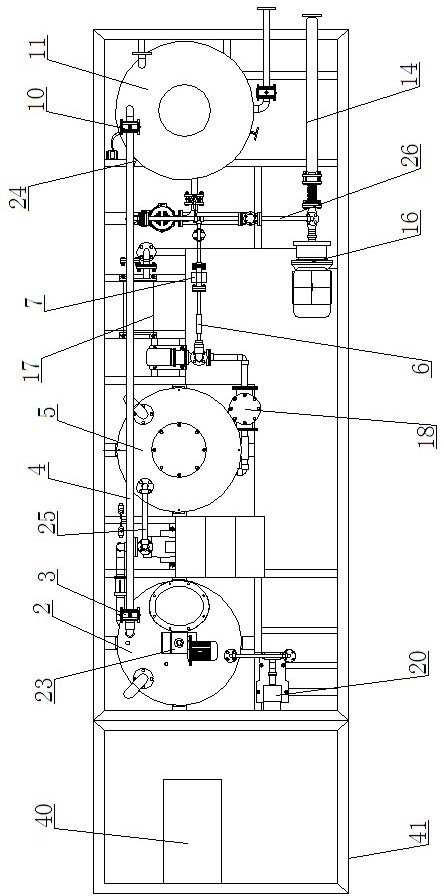

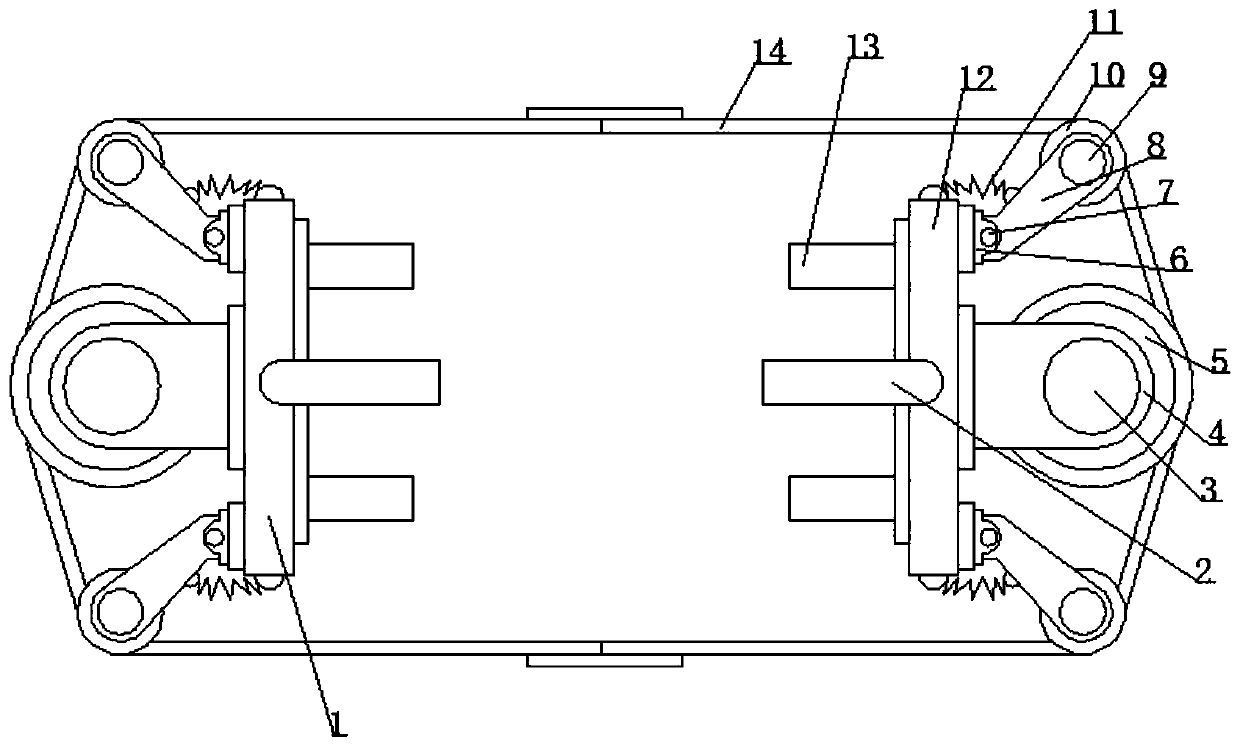

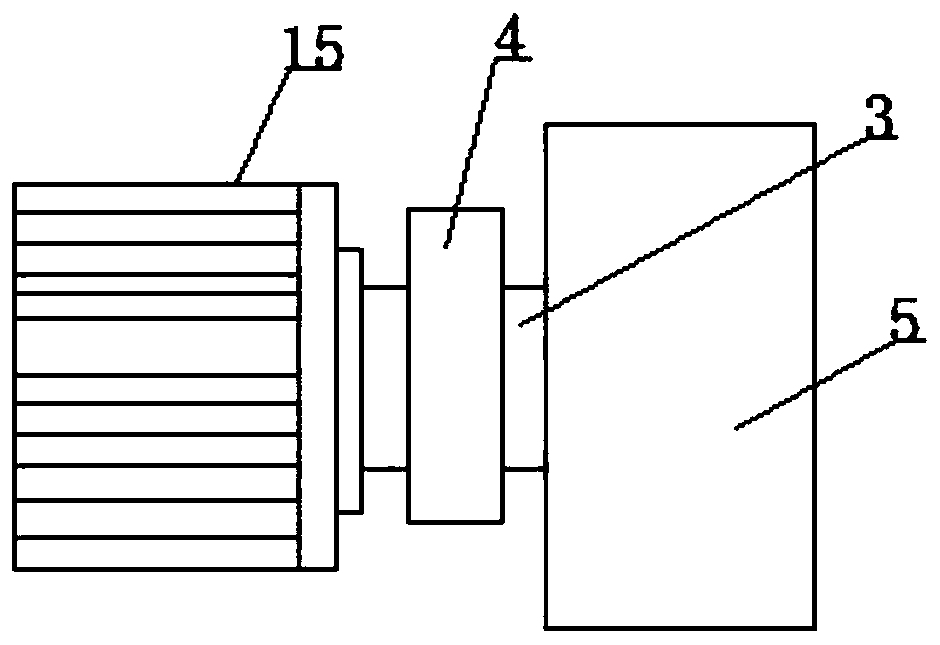

Multi-station full-automatic shoe sole sandblast polishing glue-spraying and drying disk machine

InactiveCN105212444AGood adhesionLarge grinding areaSolesAbrasive blasting machinesAbrasive blastingPulp and paper industry

The invention relates to a multi-station full-automatic shoe sole sandblast polishing glue-spraying and drying disk machine, comprising a rotating disk mechanism, a refrigeration mechanism, a polishing mechanism, a glue-spraying mechanism, drying mechanisms, and an electric control cabinet. The radial direction of the periphery of the rotating disk mechanism is uniformly distributed with a plurality of shoe sole fixing supports. The corresponding lower part of the rotating disk mechanism below the plurality of shoe sole fixing supports is provided with the refrigeration mechanism, a fluffing mechanism, the glue-spraying mechanism, and the plurality of drying mechanisms in sequence in an annular manner. The rotating disk mechanism, the fluffing mechanism, the glue-spraying mechanism, and the plurality of drying mechanisms are respectively connected with the electric control cabinet. The disk machine is reasonable in structure and high in automation degree, and the machine has high quality and high efficiency, and saves manpower, saves energy and protects environment, and effectively product processing efficiency and processing quality, and the products are reliable and durable.

Owner:马士通安全设备(天津)有限公司

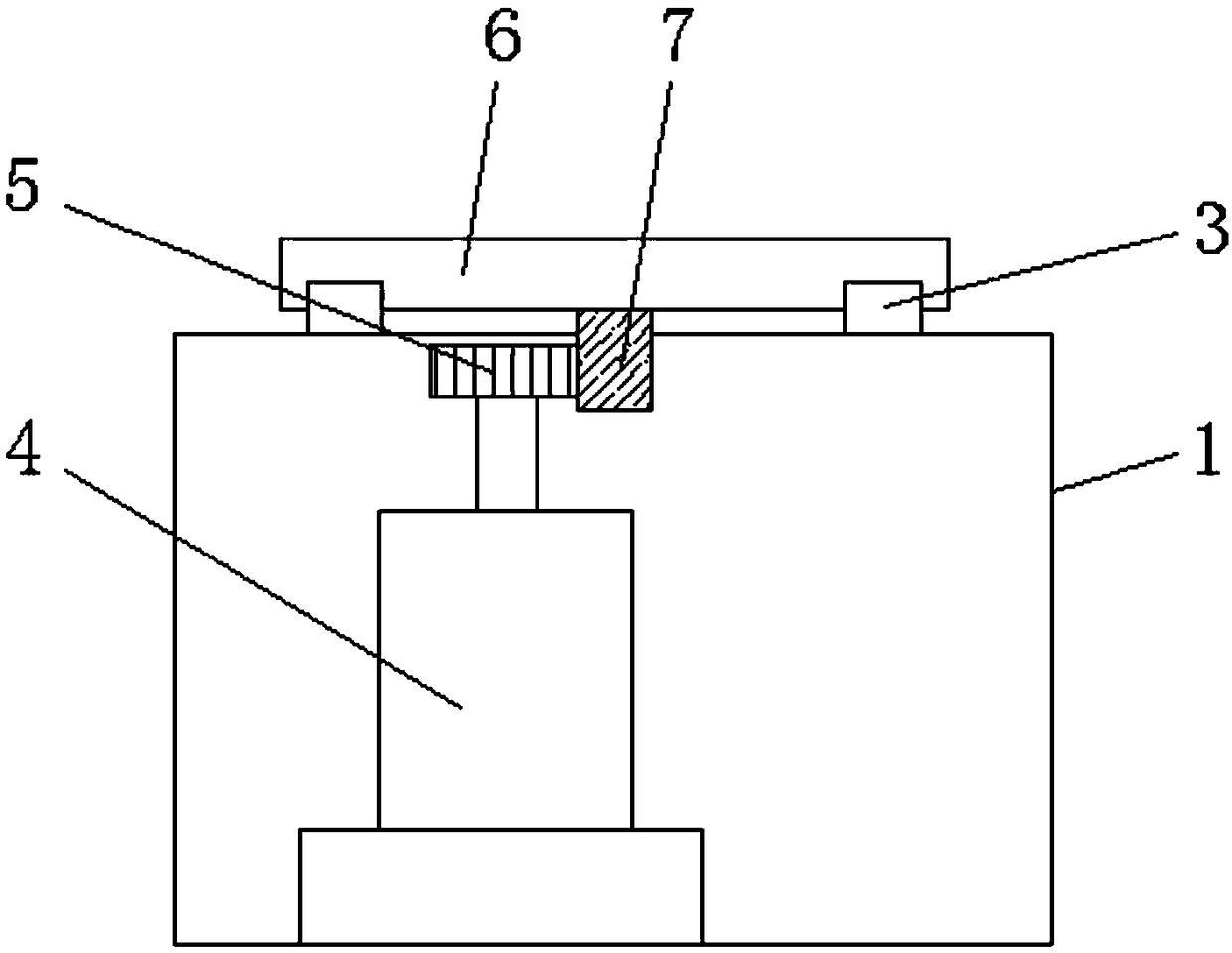

Grinding device and grinder using the same

ActiveCN101244530ANo gapsImprove processing efficiencyOptical surface grinding machinesEngineeringGrinding wheel

The invention discloses a grinding device, comprising a bowl-shape outer grinding wheel, a bowl-shape inner grinding wheel and a grinding wheel shaft, which is characterized in that: the outer grinding wheel is sleeved on the inner grinding wheel; two mutually independent grinding wheel positioning interfaces are arranged on the grinding wheel shaft, which are used to arranged the outer grinding wheel and the inner grinding wheel; the inner grinding wheel is fixed on the grinding wheel shaft to do fine grinding to the workpiece; the outer grinding wheel can move up on the shaft of the grinding wheel shaft to do coarse grinding to the workpiece. The grinding device has advantages that: the processing precision is improved; the abrasion of the grinding wheel is reduced; and the production efficiency is increased. The invention also discloses a grinder which uses the grinding device.

Owner:陈耀龙

Graded traditional Chinese herb grinding system

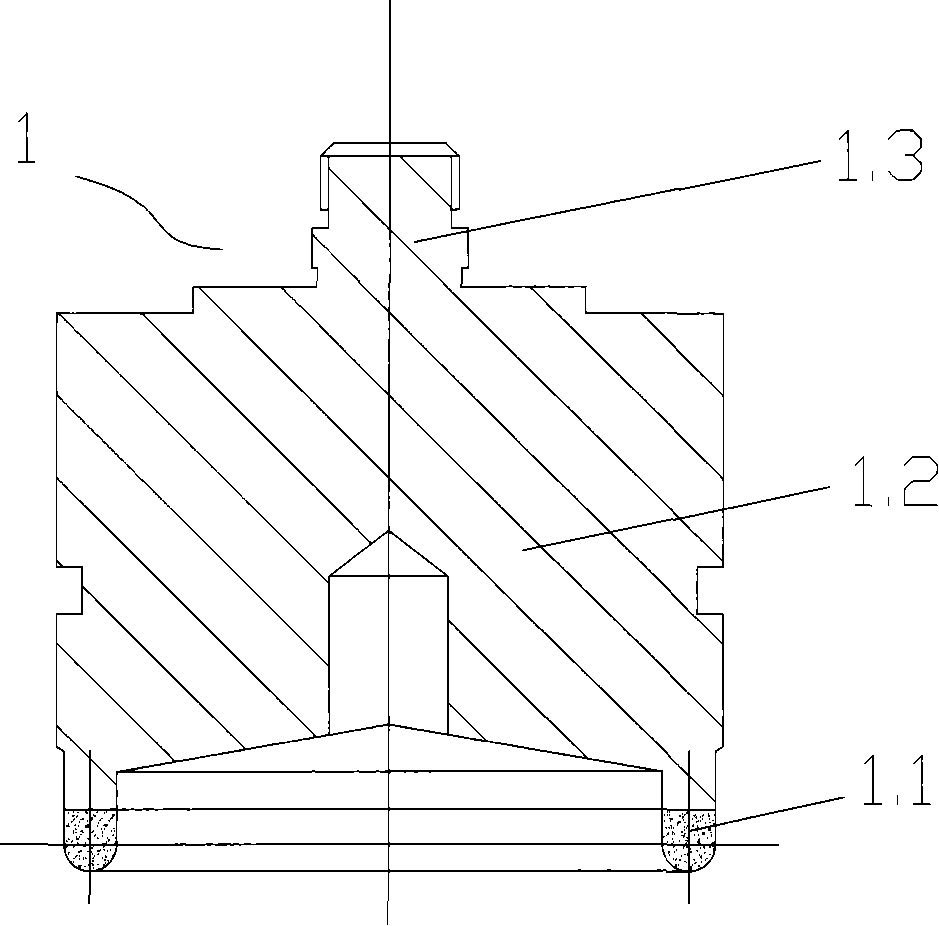

The invention discloses a graded traditional Chinese herb grinding system which comprises a base, a grinding ball and a grinding bowl. A half-circle limit groove is arranged in the surface of the base; a first rotating shaft is arranged at the top of the base and is rotatably connected with a branch pipe; a pressure lever and a spring are connected to the interior of the branch pipe in a sleeved manner; a bottom plate is welded to the bottom end of the spring; a sliding chute is arranged in the branch pipe; a support rod is welded to the side wall of the pressure lever, and a rotary motor is connected to the bottom of the support rod; the rotary motor is detachably connected with the grinding ball; the lower portion of the grinding ball is of a half-circle structure, the middle portion of the grinding ball is of a truncated cone-shaped structure, the upper portion of the grinding ball is provided with a connecting shaft, and the grinding ball is of a hollow-out structure; the grinding bowl is right under the grinding ball and is placed in the limit groove, the grinding bowl is of a half-circle structure, and the top of the grinding bowl extends upwards to form a ring wall. The grinding system is mainly used for grinding of traditional Chinese herbs, the traditional Chinese herbs can be crushed and ground by grade, and overall time in grinding is shortened; the graded traditional Chinese herb grinding system has the advantages of simpleness in structure and convenience in operation.

Owner:安徽普仁中药饮片有限公司

Polyvinyl chloride injection molding and polishing integrated device

ActiveCN110216547AImprove integrityQuality improvementGrinding drivesSpherical surface grinding machinesPolyvinyl chlorideEngineering

The invention discloses a polyvinyl chloride injection molding and polishing integrated device. The device comprises a box. A working cavity with a left opening is formed inside the box, the working cavity is communicated with a first rotating cavity in a vertical symmetry mode, a main rotating mechanism for transversely rotating and polishing a plastic ball is arranged between the first rotatingmechanism and a third sliding hole, the main rotating mechanism comprises the first rotating cavity, a disc is slidably arranged inside the first rotating cavity, a spline sleeve extending up and downis fixedly arranged on the disc, and a hollow hemisphere is fixedly arranged at the bottom end of the spline sleeve. After the device performs injection molding and solidification to form the plasticball, all-dimensional polishing is performed, the polishing area is large, the efficiency is high, few polishing scratches of the spherical mirror formed after polishing are caused, the mirror surface effect is good, the formed smooth plastic ball is high in quality, in addition, the device can collect plastic dust generated during polishing, the interior of the working cavity is clean and tidy,and meanwhile the device does not contaminate air and is environmentally friendly.

Owner:广东启智精密科技有限公司

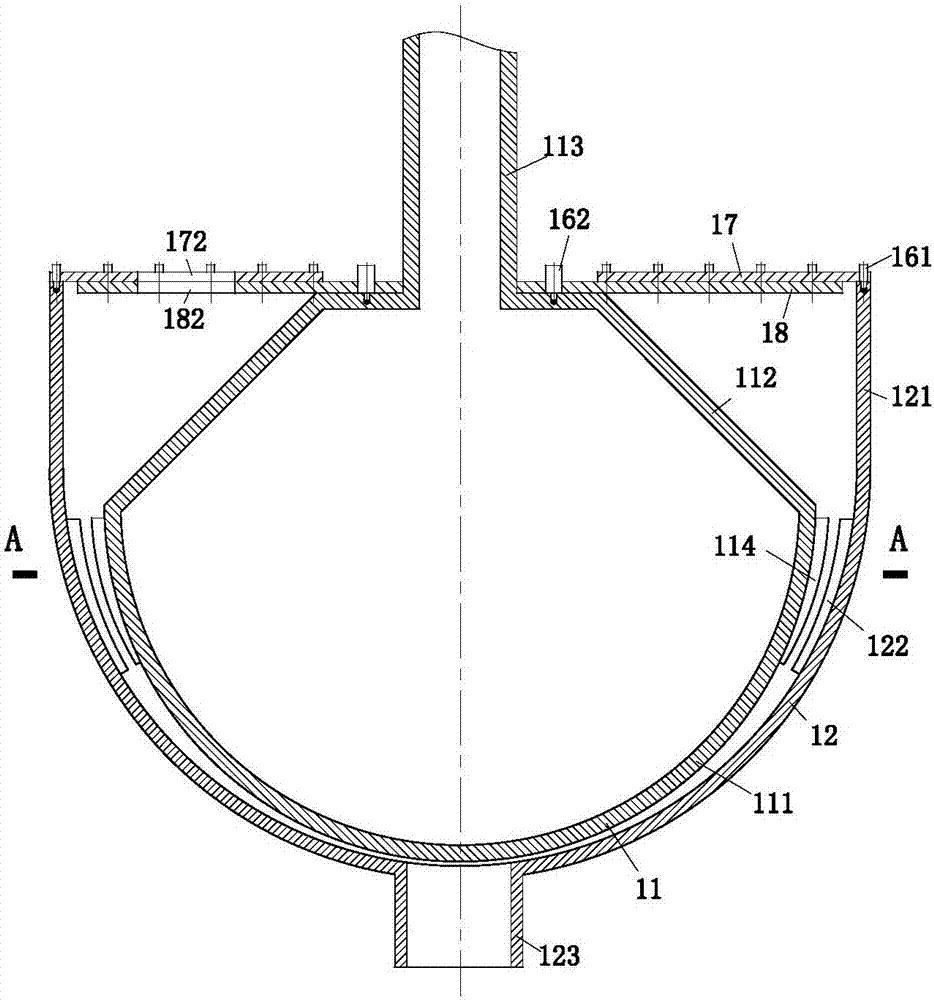

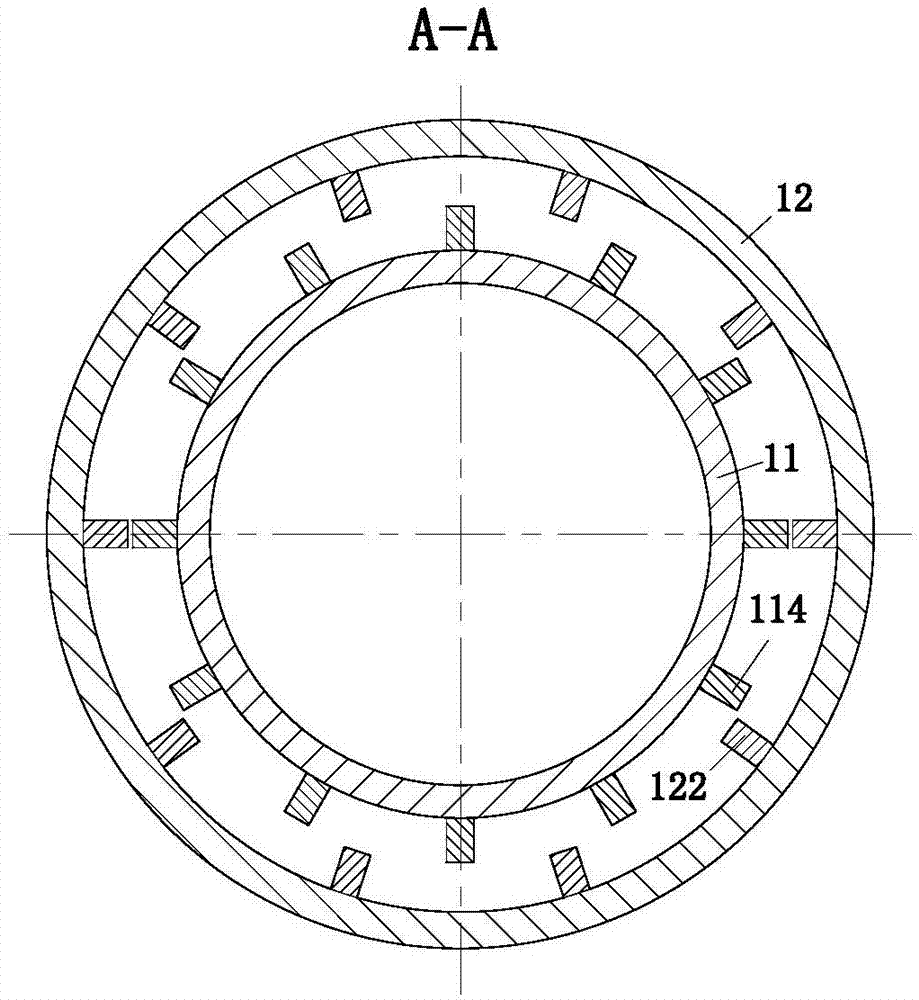

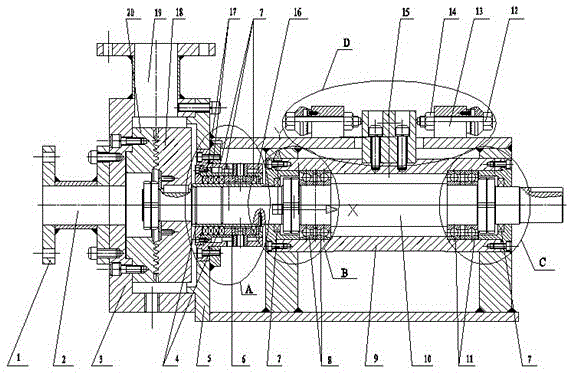

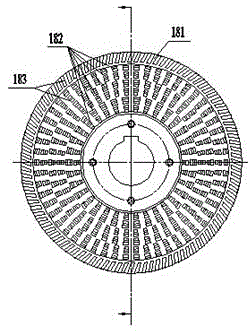

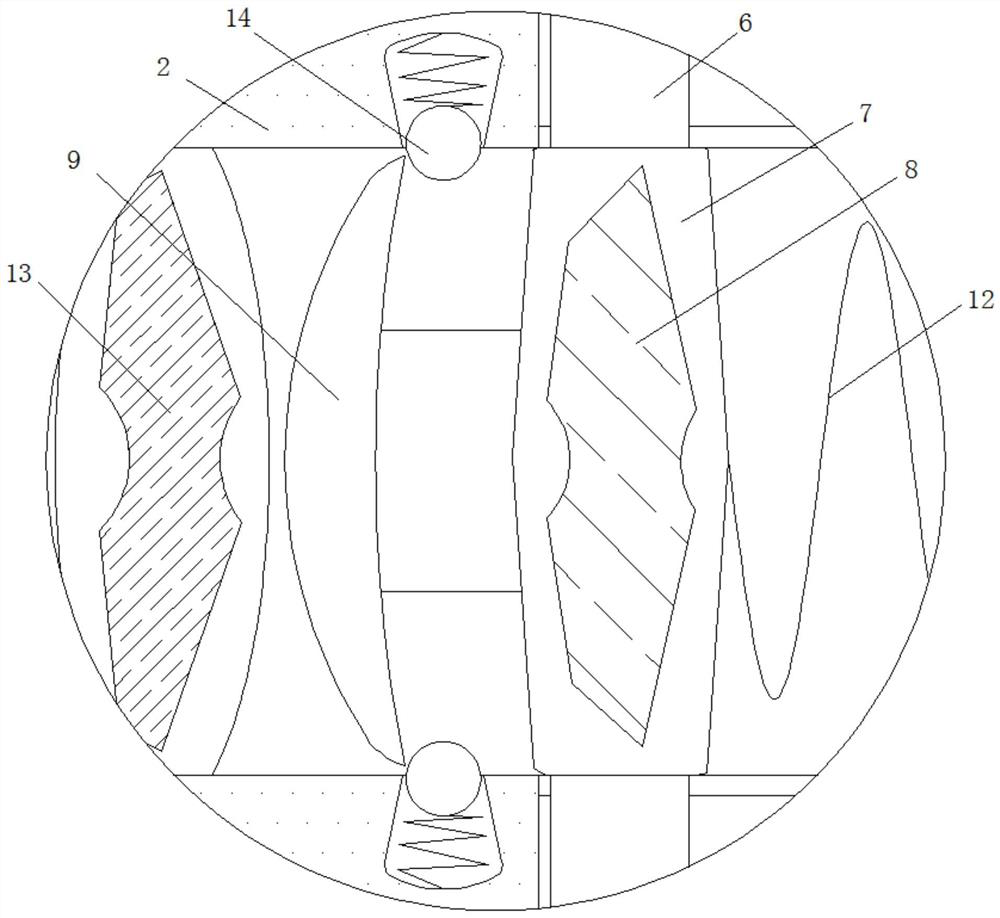

Colloid mill stator and rotor and colloid mill comprising stator and rotor

The invention discloses a colloid mill stator and rotor and a colloid mill comprising the stator and rotor, and belongs to the field of machinery. According to the colloid mill stator and rotor provided by the invention, the end surface of a stator disc and the end surface of a rotor disc are provided with concentric annular distribution toothed sections; a sluice channel is formed between adjacent toothed sections; straight teeth are arranged on the toothed section at the outermost layer of the end surface of the static disc; trapezoidal teeth are arranged on the toothed sections at the other layers of the end surface of the stator disc; the tooth height of each straight tooth is smaller than the tooth height of each trapezoidal tooth on the end surface of the stator disc; a blind groove is formed in the outer edge of the sluice channel between two adjacent straight teeth; inclined teeth are arranged on the toothed section at the outermost layer of the end surface of the rotor disc; trapezoidal teeth are arranged on the other various layers of the end surface of the rotor disc; the tooth height of each inclined tooth is smaller than the tooth height of each trapezoidal tooth of the end surface of the rotor disc; and a blind groove is formed in the inner edge of the sluice channel between two adjacent inclined teeth. The colloid mill comprising the stator and rotor disclosed by the invention is simple in structure, high in shearing efficiency and long in service life.

Owner:SHANDONG DASHAN ROAD & BRIDGE ENG

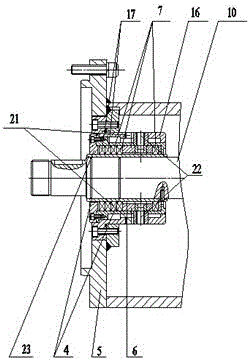

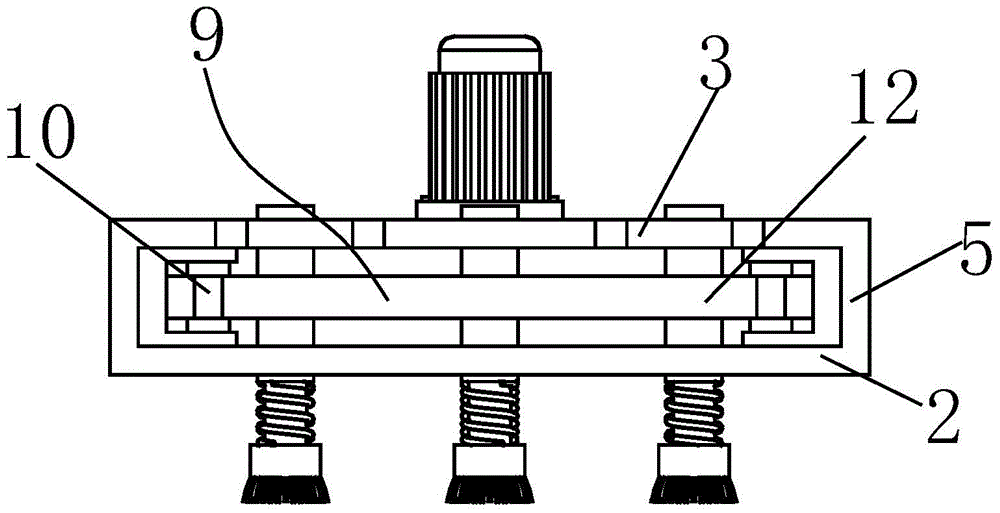

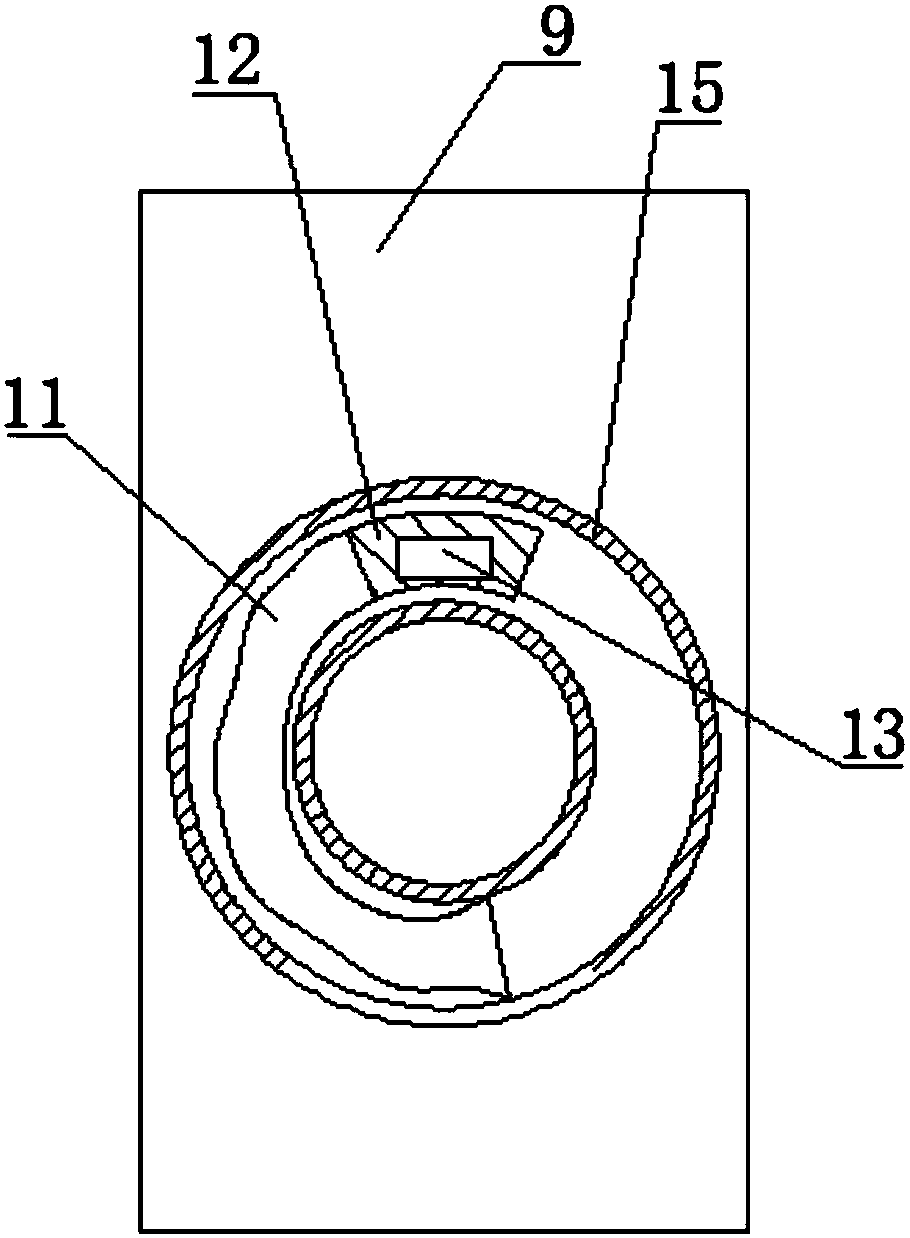

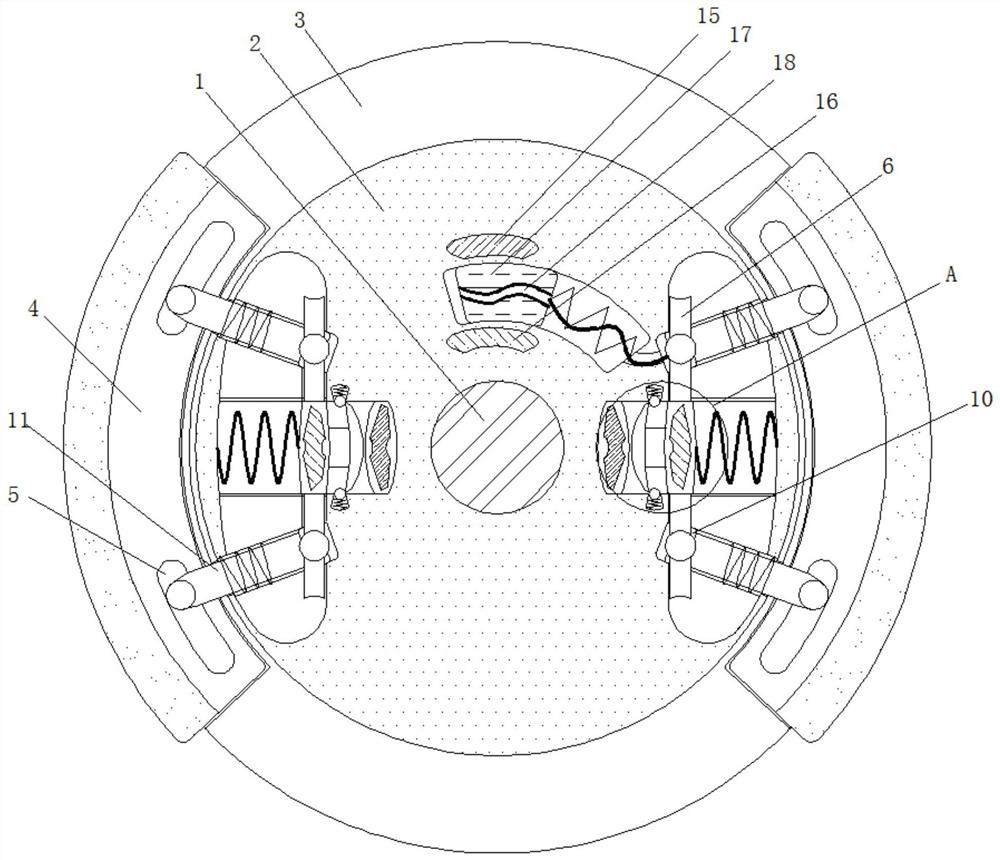

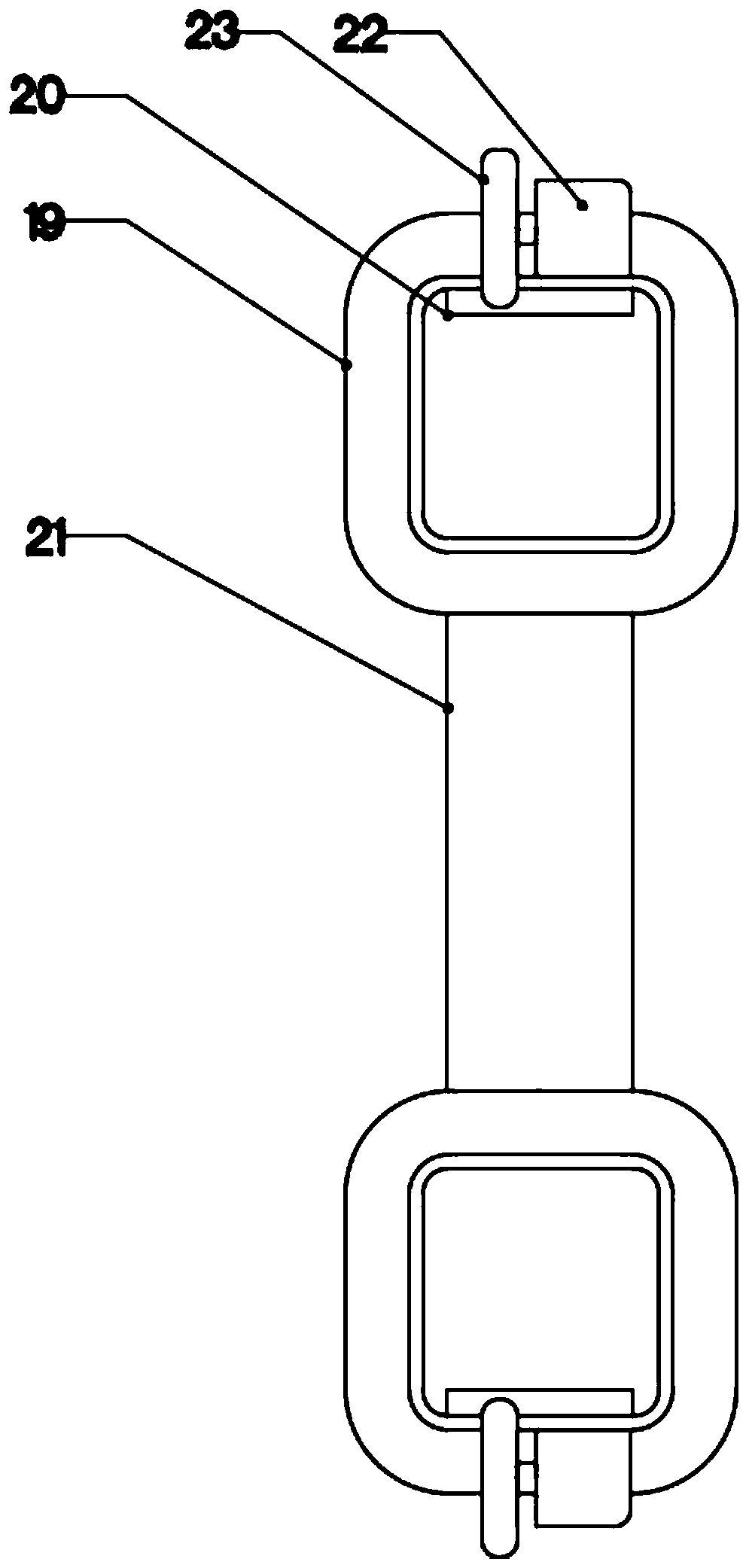

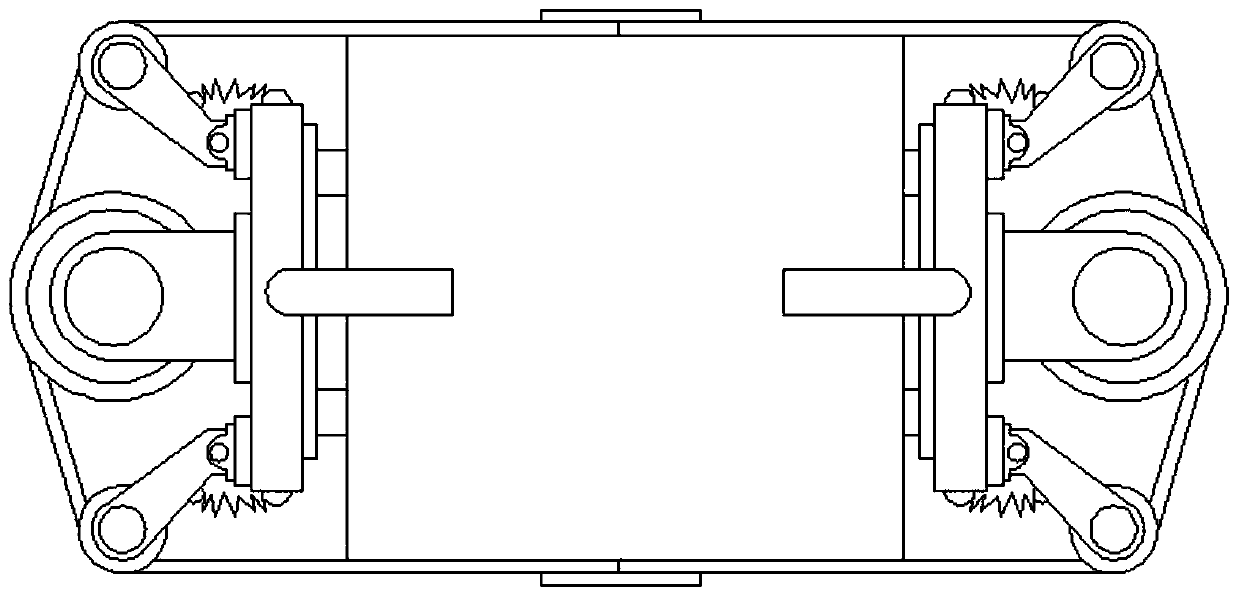

Planetary wheel type flexible abrasive disc

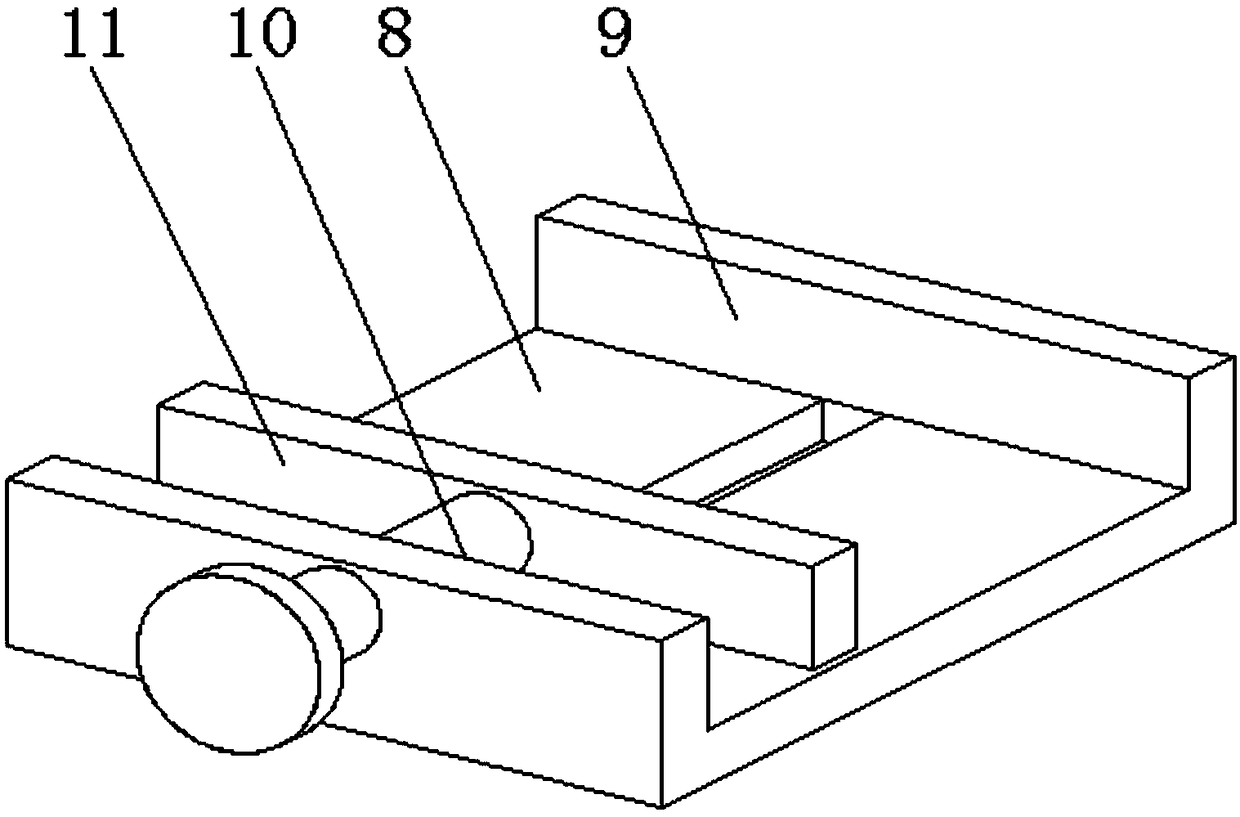

InactiveCN104440485AEasy to cleanLarge grinding areaGrinding machinesEngineeringMechanical engineering

The invention relates to a planetary wheel type flexible abrasive disc. The planetary wheel type flexible abrasive disc comprises a shell body, wherein the shell body is defined by a base plate, a top plate, a left side plate and a right side plate, a first hole and five second holes are formed in the top pate, five third holes are formed in the base plate, an abrasive disc set is fixed in the shell body, and four clamping wheels are evenly arranged between the shell body and the abrasive disc set; the abrasive disc set comprises an inner gear ring, a driving gear and driven abrasive bundles, a motor is arranged over the driving gear, the motor is fixed on the top plate, a shaft of the motor penetrates through the first hole to be fixedly connected to the driving gear, driven gears are arranged on the upper portions of the driven abrasive bundles respectively, square grooves are formed in the lower ends of the driven abrasive bundles respectively, a baffle ring is arranged at the lower end of each square groove, a square cleaning rod is arranged in each square groove, an end block is arranged at the upper end of each cleaning rod and is clamped in the corresponding square groove, the lower end of each cleaning rod penetrates through the corresponding third hole and is provided with an abrasive brush, and the lower portion of each cleaning rod is sleeved with a compression spring. According to the planetary wheel type flexible abrasive disc, self-adaptation can be achieved according to the shape of a part to be polished, polishing area is large, and polishing efficiency is improved.

Owner:WUHU JIENUO TECH

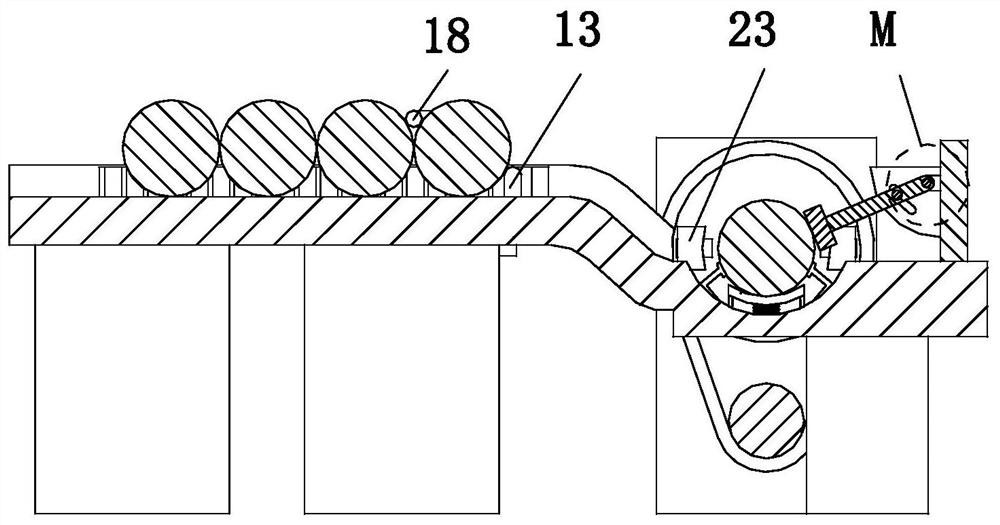

Novel pipeline polishing device

ActiveCN112059760AAffect the grinding areaLarge grinding areaGrinding carriagesRevolution surface grinding machinesRatchetGear wheel

The invention relates to the technical field of polishing devices, in particular to a novel pipeline polishing device. The novel pipeline polishing device is characterized in that a pipeline supporting mechanism is arranged at one end of a center shaft, a rotating seat is rotatably mounted at the other end of the center shaft, a supporting frame is slidably mounted on the rotating seat in the length direction of the center shaft, and a polishing mechanism is arranged on the supporting frame; a first small shaft is eccentrically and fixedly installed on a driving disc, a second small shaft parallel to the first small shaft is fixedly installed on the supporting frame, and a connecting rod is arranged between the first small shaft and the second small shaft. When the driving disc rotates, the connecting rod drives the polishing mechanism to reciprocate in the length direction of a pipeline so as to increase the polishing area of the polishing mechanism, when a driving gear rotates in thedirection opposite to the rotating direction of a ratchet wheel, the rotating seat is driven to rotate around the center shaft by a certain angle so as to increase the polishing process, and when thedriving gear rotates in the rotating direction of the ratchet wheel, the polishing area is increased. The rotating seat and the central shaft are kept in a relatively static state to prolong the contact time of the polishing mechanism and the same part of the pipeline.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

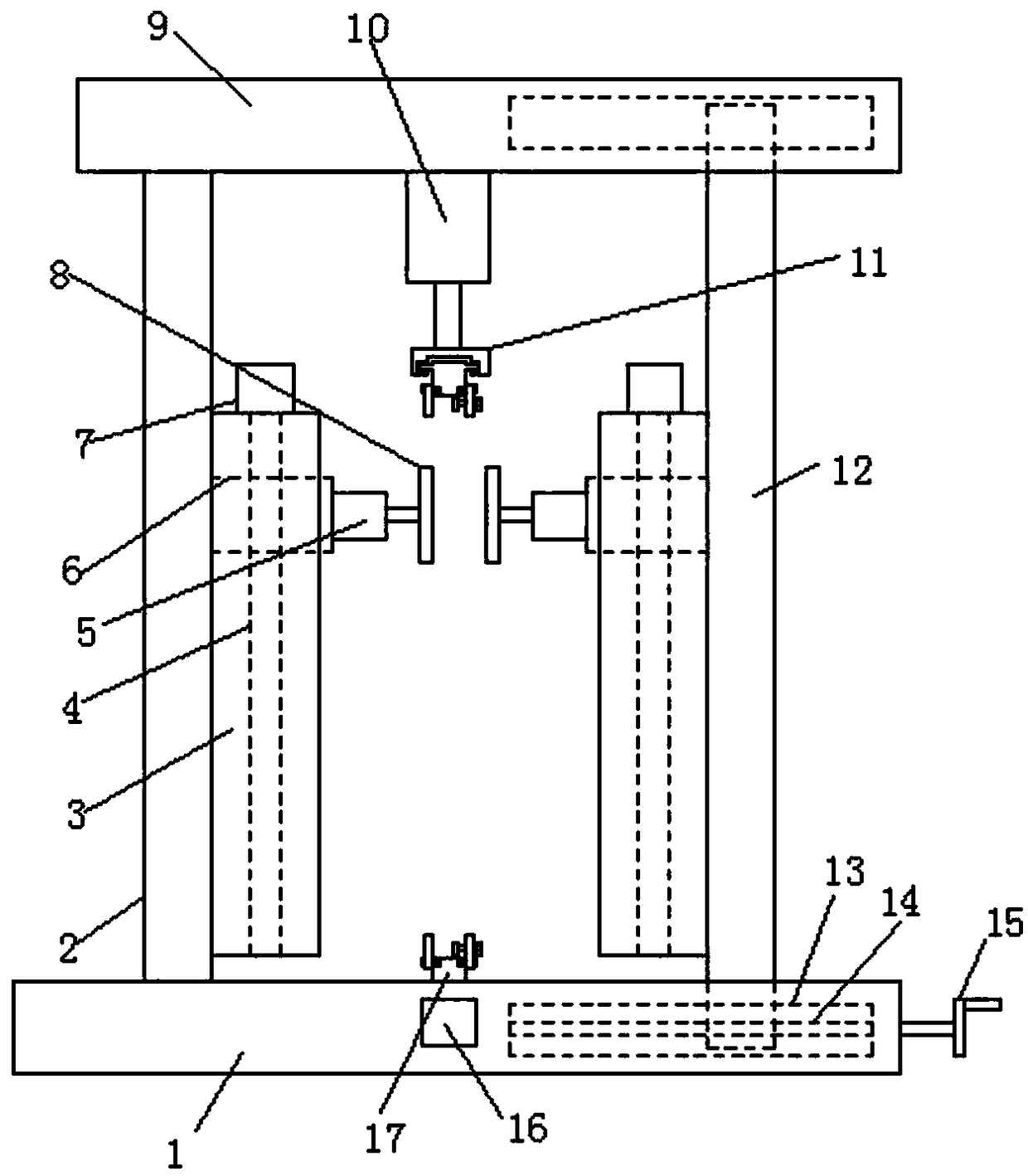

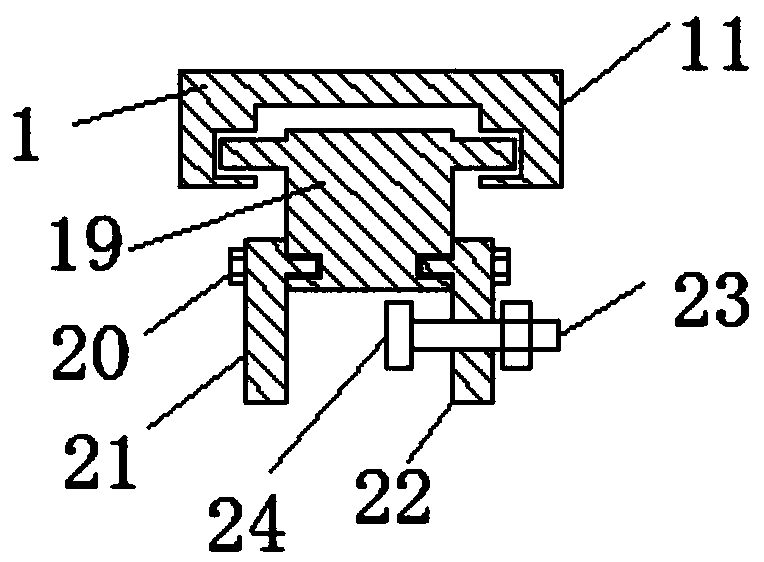

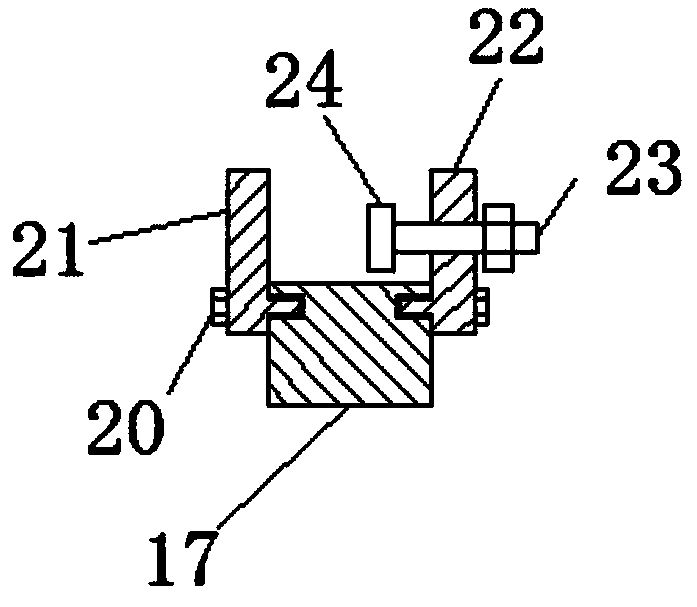

Steel plate grinding device

InactiveCN108637815AImprove grinding efficiencyLarge grinding areaGrinding drivesGrinding work supportsSheet steelEngineering

The invention discloses a steel plate grinding device and relates to the technical field of steel plate machining. The steel plate grinding device comprises a base and a cross beam; a first support and a second support are connected between the base and the cross beam; the second support is connected between the base and the cross beam in a sliding manner; the first support and the second supportare connected with a first grinding mechanism and a second grinding mechanism correspondingly; a clamping device is further arranged between the cross beam and the base; the first grinding mechanism and the second grinding mechanism are used for grinding a steel plate; and the clamping device is used for clamping the steel plate. According to the steel plate grinding device, the two end faces of the steel plate are ground at the same time through the first grinding mechanism and the second grinding mechanism, and the steel plate grinding efficiency is greatly improved; and the steel plate grinding device is simple in structure, the grinding area of a grinding wheel is greatly increased while operation is convenient, and the grinding effect and the grinding efficiency are further improved.

Owner:芜湖立普德机械科技有限公司

Grinding machine

InactiveCN105312998AEasy to controlSimple structureEdge grinding machinesPolishing machinesElectric machineryPulp and paper industry

The invention relates to a grinding machine and belongs to the technical field of grinding device design. The grinding machine comprises a machine frame and a motor and is characterized by further comprising a grinding barrel, grinding sand is arranged in the grinding barrel, and rotary shafts are arranged at two ends of the grinding barrel. Two bearings are arranged on the machine frame. The rotary shafts of the grinding barrel are supported on the bearings of the machine frame, and one end of a rotary shaft is connected with the motor. A switch control box is arranged at the lower portion of the machine frame, and a motor switch button is arranged on the wall of the control box. A plurality of protrusions are arranged on the inner wall of the grinding barrel. One end of the grinding barrel is open, and a cover is arranged at the open position. The grinding machine is reasonable and simple in structure, easy to produce and manufacture, convenient to use, reasonable in design, simple in structure and good in grinding effect.

Owner:王涛

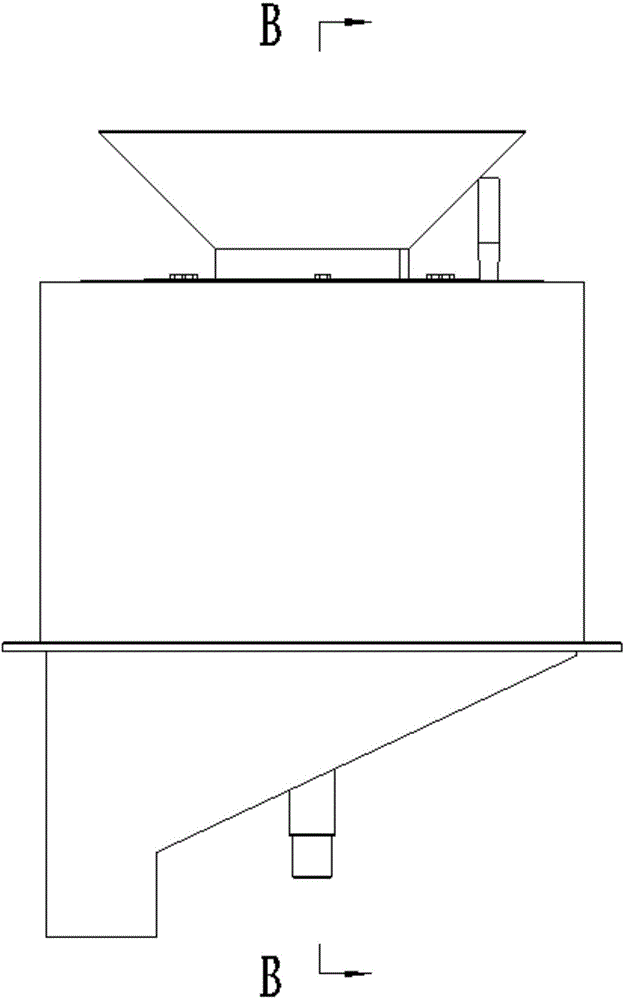

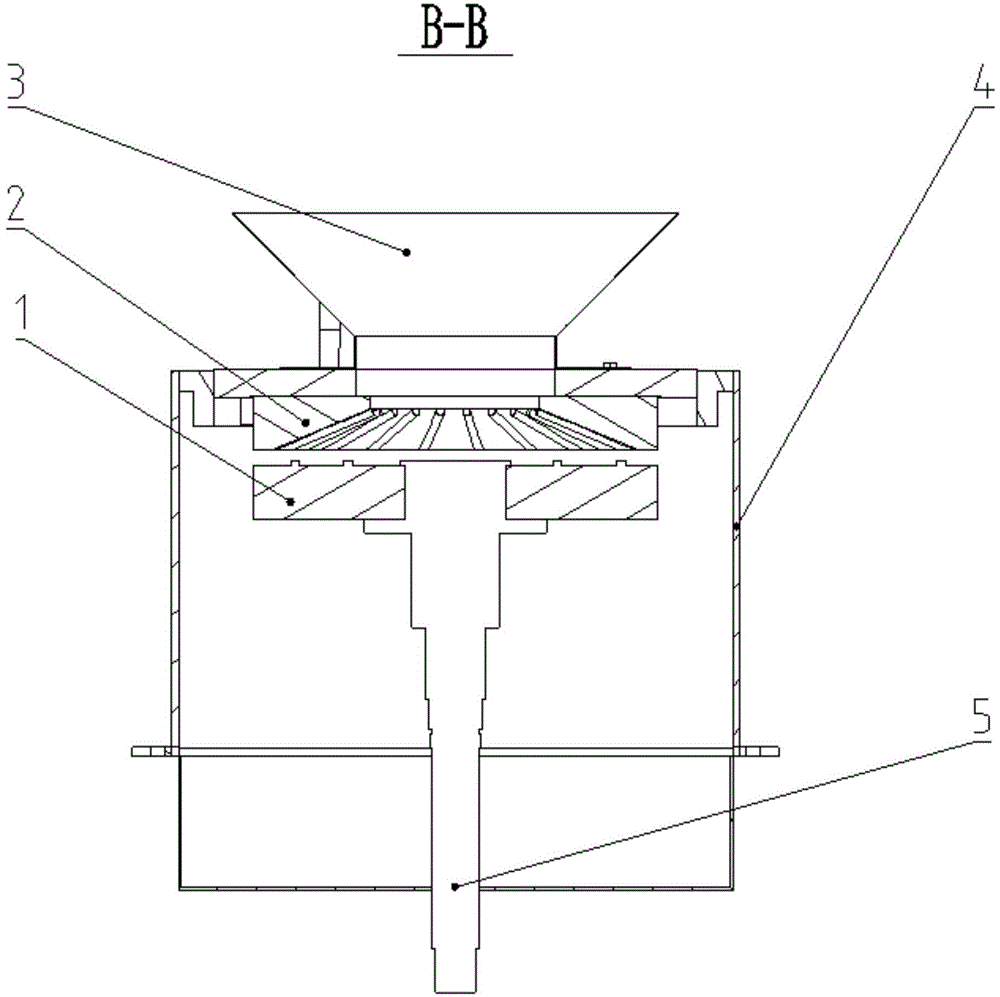

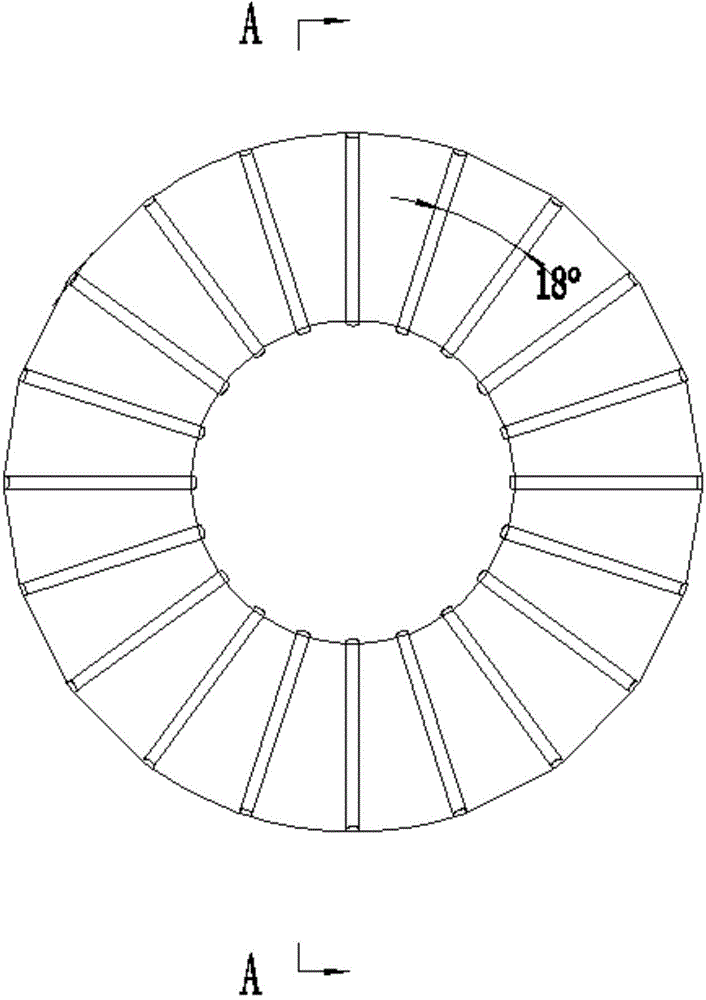

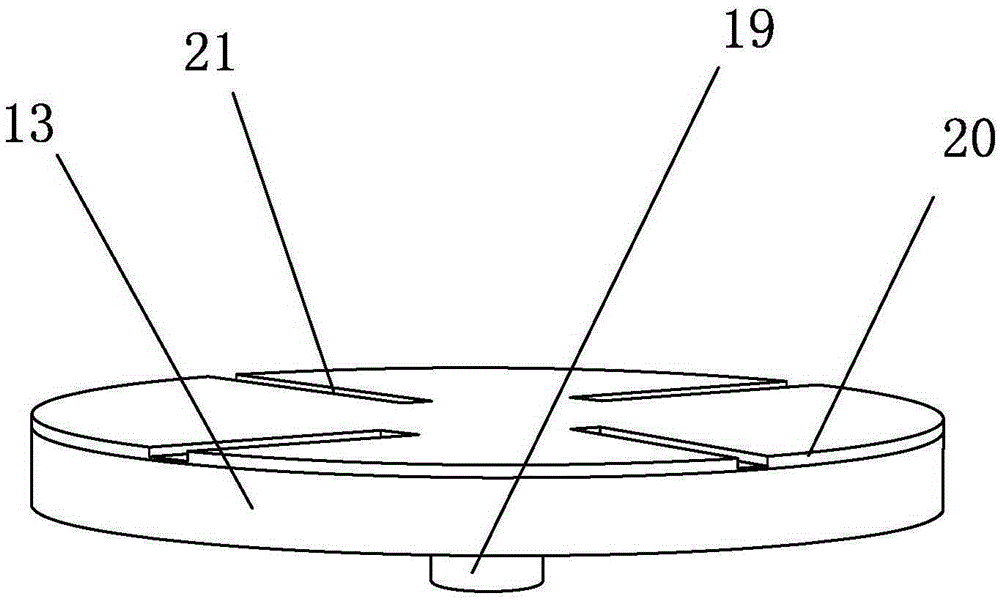

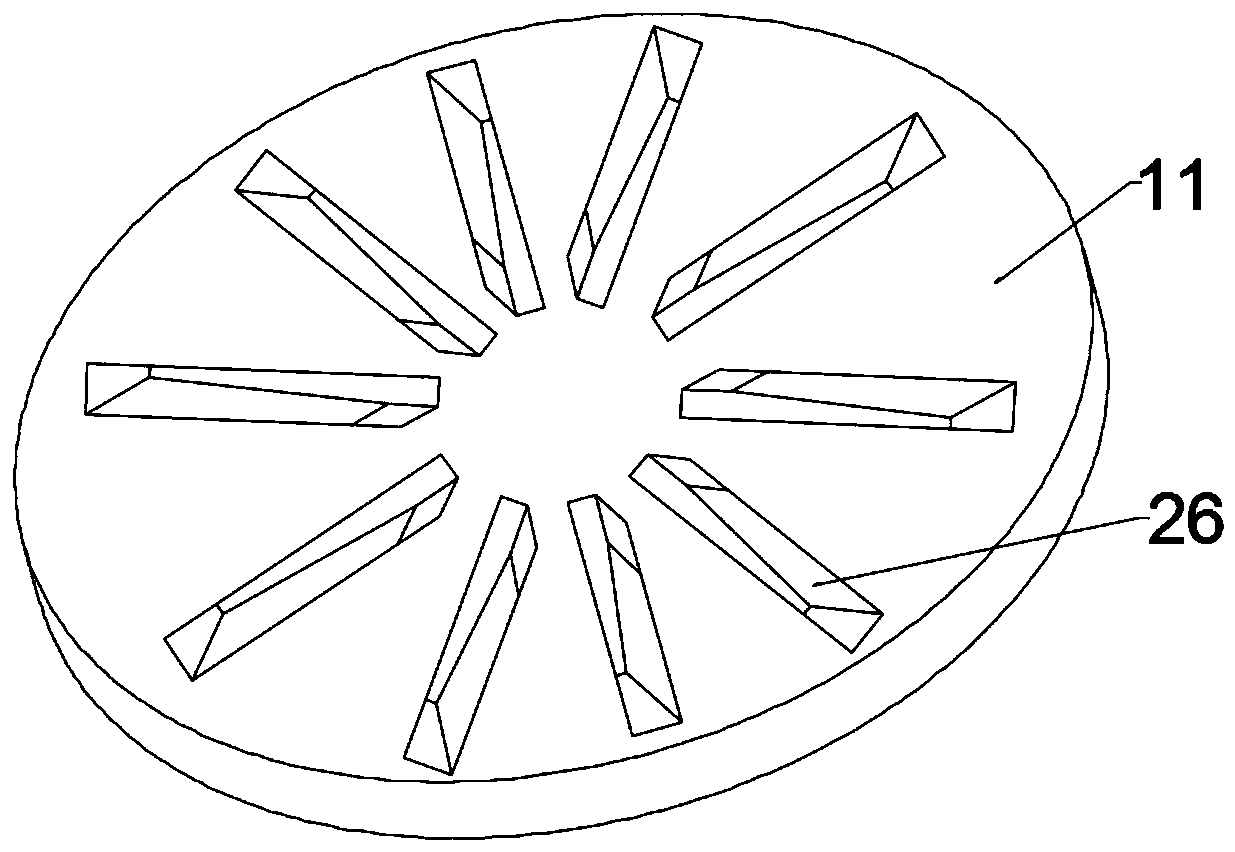

Sheller for barley or buckwheat

ActiveCN103816958ASeparate as soon as possibleAvoid damageGrain huskingGrain polishingPolygonum fagopyrumEngineering

The invention relates to corn sheller equipment, in particular to a sheller for barley or buckwheat, and belongs to the technical field of agricultural machinery and equipment. The sheller for barley or buckwheat comprising a hopper (3) and a material bin (4) is characterized in that a static disc (2) is arranged below the hopper (3), a feeding hole is formed at the center of the static disc (2) and coaxially corresponds to the hopper (3), a plurality of groove holes are formed on the static disc from the center to the outer diameter in a diverged manner, soft rubber rods are fixed in the groove holes, and the bottoms of the soft rubber rods and the bottom of the static disc (2) are located in a same height or almost in the same height; a movable disc (1) is arranged below the static disc (2); curved bars are arranged on the upper plane of the movable disc (1) and adopt the center of the movable disc as arc cores.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Grinding tool for spherical surface

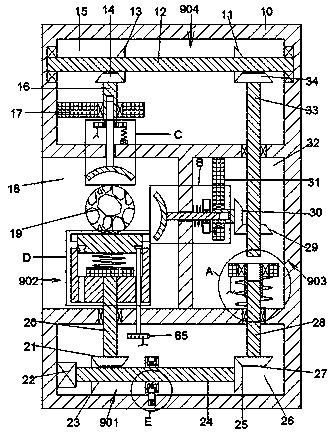

InactiveCN111230651AAutomatic automatic attractionLarge grinding areaSpherical surface grinding machinesElectric machineryEngineering

The invention provides a grinding tool for a spherical surface. The grinding tool comprises a shell and a grinding chamber located in the shell, an opening of the grinding chamber faces left, the lower side of the grinding cavity is provided with a power cavity, the right side of the grinding cavity is provided with a conversion cavity located on the upper side of the power cavity, an upper grinding cavity is disposed above the conversion cavity and the grinding cavity, a power device is arranged in the grinding cavity, the power device comprises a motor fixedly connected with the left end wall of the power cavity, a conversion device is arranged in the grinding cavity, and the conversion device can automatically attract a workpiece; meanwhile a rotating device is additionally arranged, sothat the maximum grinding area on the surface of the workpiece is achieved under the common action of the upper surface and the right surface; and meanwhile, the working quality is ensured, and compared with a manual mode, the grinding tool is time-saving and labor-saving, the quality of the machined workpiece can be ensured to be uniform.

Owner:HANGZHOU GANGHE MASCH TECH CO LTD

Efficient and comprehensive double-sided rapid grinding machine for dustproof steel plates

InactiveCN108436636APrevent slippingSimple structureGrinding work supportsPlane surface grinding machinesEngineeringPiston

The invention discloses an efficient and comprehensive double-sided rapid grinding machine for dustproof steel plates. The efficient and comprehensive double-sided rapid grinding machine comprises a first air cylinder, and the inner bottom wall of the first air cylinder is fixedly connected with a first motor. The efficient and comprehensive double-sided rapid grinding machine for dustproof steelplates is simple in structure, the steel plate is placed between four extrusion pads, under the action of the third spring, the steel plate is clamped, a protruding structure can prevent the steel plate from sliding down, a screw rod is manually rotated, at the moment, an external power supply is connected, the second motor is powered on, so as to drive a grinding piece to rotate; due to the action of a second spring, the grinding piece can also vibrate when the grinding piece is rotationally abrased, and the grinding area of the grinding piece is enlarged; the first motor is started to drivea cam to rotate, and the two pistons move back and forth under the action of a first spring, so that air bags expand and contract, the first sliding blocks can slide, and then the grinding pieces canmove; and the grinding range of the grinding piece is further increased, the steel plate is ground more comprehensively, and the working efficiency is improved.

Owner:陈永强

Large-diameter inner hole polishing device for castings

InactiveCN112123047ALarge grinding areaAutomatically adjust the diameter of the grinding inner holeRevolution surface grinding machinesGrinding drivesPhysicsPolishing

The invention relates to the technical field of polishing, and discloses a large-diameter inner hole polishing device for castings. The polishing device comprises a rotating shaft; a fixing chuck is fixedly connected to the outer side of the rotating shaft; a guide ring is fixedly connected to the outer side of the fixing chuck; polishing pieces are movably connected to the two sides of the guidering; and arc-shaped holes are formed in the polishing pieces. According to the large-diameter inner hole polishing device for the castings, a movable plug drives a pushing rod to operate, an electromagnet and a magnetic block are used in cooperation, when an arc-shaped clamping piece moves outwards, a guide rod pushes the pushing rod to move outwards under the action of the centrifugal force, meanwhile, a second sliding block is pulled to move rightwards, at the moment, the relative area of a positive plate and a negative plate is gradually increased, and the circuit voltage is gradually increased, so that the magnetism of the electromagnet is gradually increased, the effect of controlling the polishing pieces to move outwards through the magnetism is achieved, the polishing area of a polishing stone is increased, the purpose of automatically adjusting the diameters of polished inner holes is achieved, and the polishing efficiency is effectively improved.

Owner:苏建飞

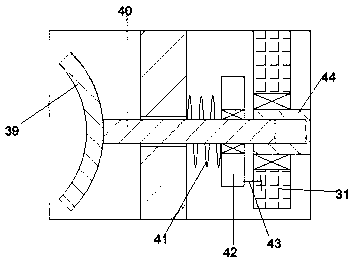

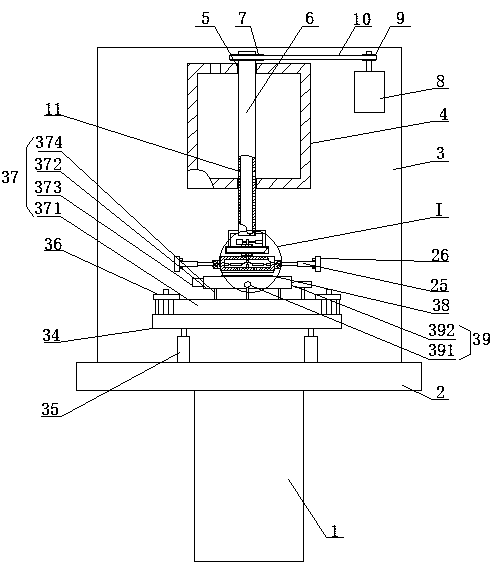

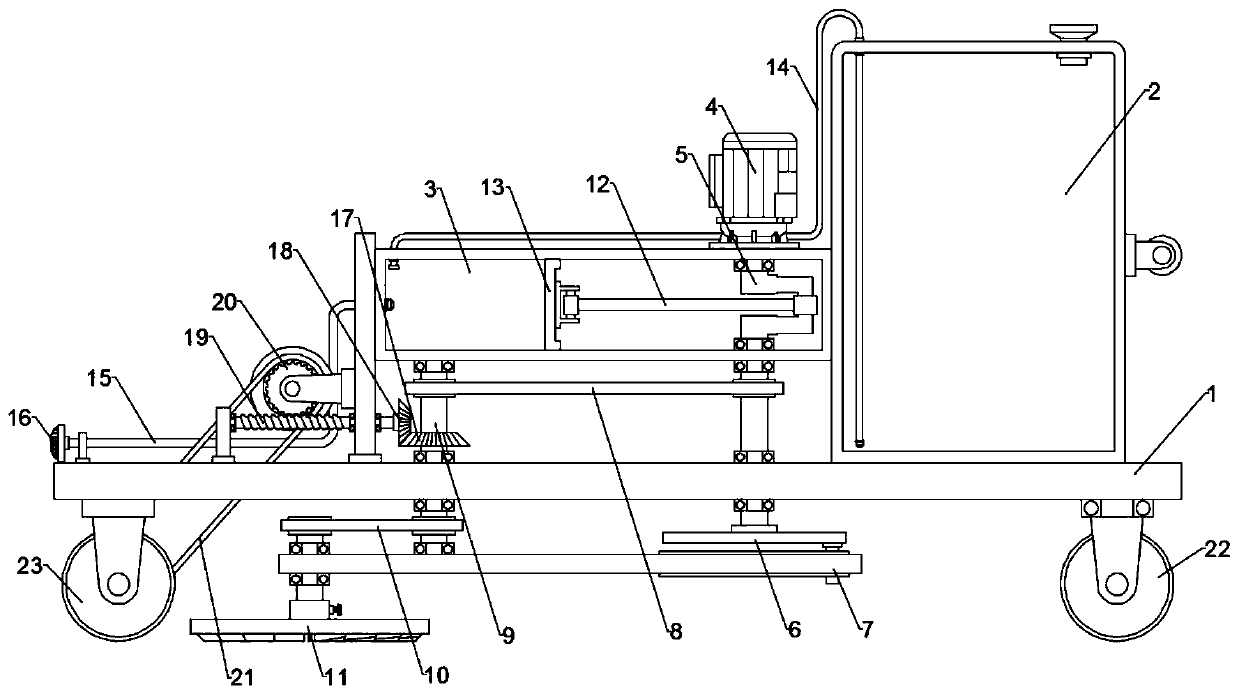

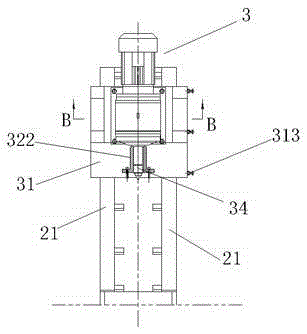

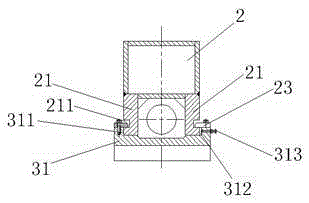

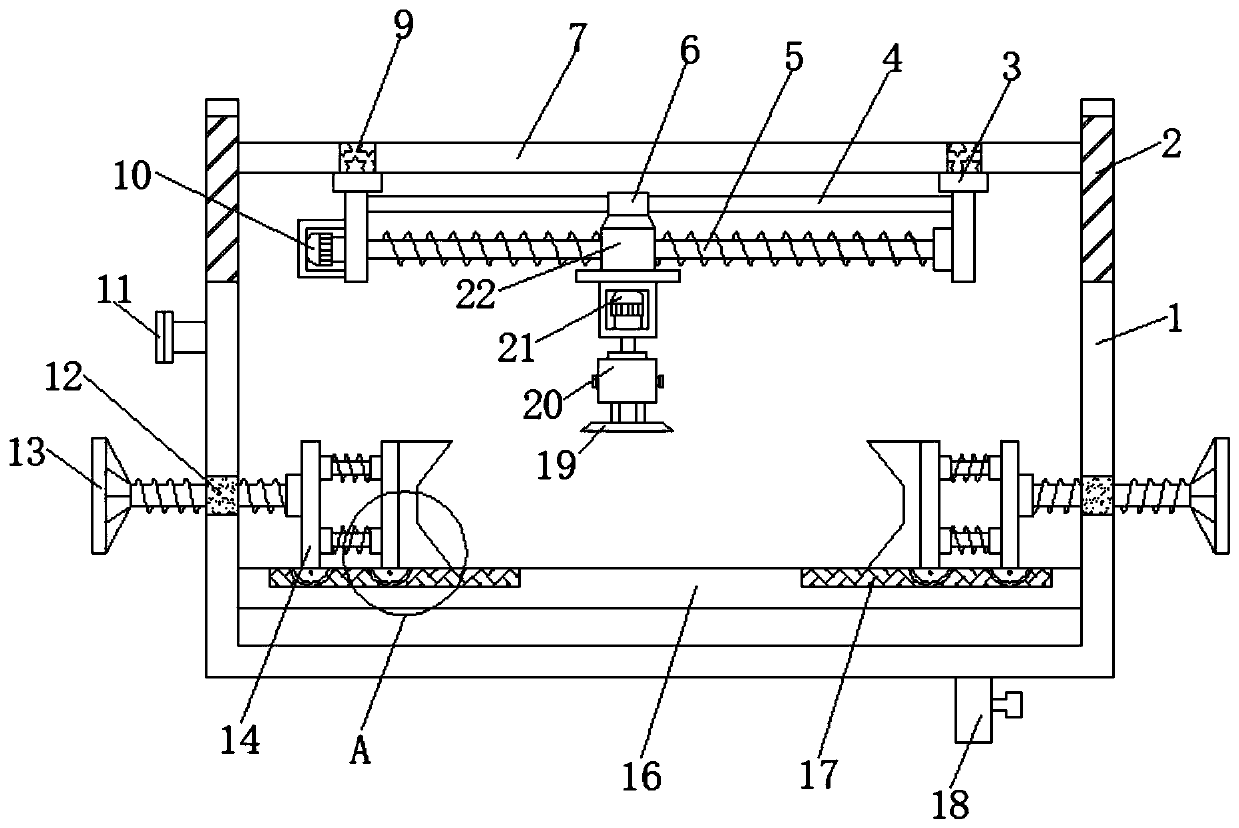

Machining device for ultrasonic grinding of sapphire lens

InactiveCN108381376AHigh precisionImprove grinding efficiencyOptical surface grinding machinesGrinding drivesUltrasonic vibrationEngineering

The invention discloses a machining device for ultrasonic grinding of a sapphire lens. The device comprises a support and an ultrasonic vibration loading system; a worktable and a machine tool lathe bed are fixedly arranged on the upper portion of the support, a grinding liquid box is fixedly arranged on the front side of the machine tool lathe bed, the middles of the upper end face and the lowerend face of the grinding liquid box are provided with first through holes, a vertical pipe is arranged in the first through holes through a seal bearing, the upper end and the lower end of the vertical pipe are closed, a driven belt wheel is fixedly arranged on the upper end of the vertical pipe, a vertical motor is fixedly arranged on the front side of the machine tool lathe bed, a driving belt wheel is fixedly arranged on an output shaft of the motor, and the driving belt wheel and the driven belt wheel are connected through a transmission belt. Compared with an existing lens machining device, the structure is simpler, multiple workpieces can be machined at the same time, a grinding liquid supply system is arranged, grinding liquid flowing out operation has the automatic rotating speed adjusting function, a rotating shaft of a grinding head can be automatically and slightly changed along with rotating speed changes of the motor, and the relative position of the grinding head can be changed at any time in the sapphire lens grinding process.

Owner:ZHONGBEI UNIV

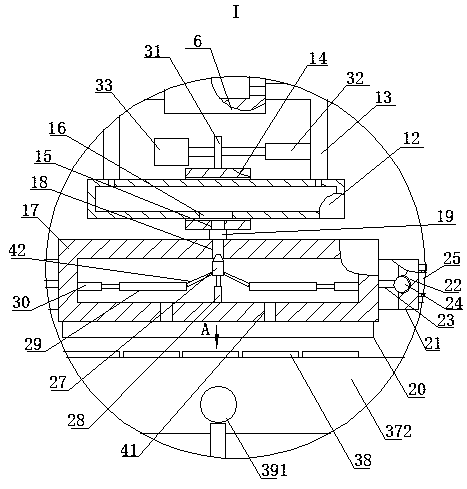

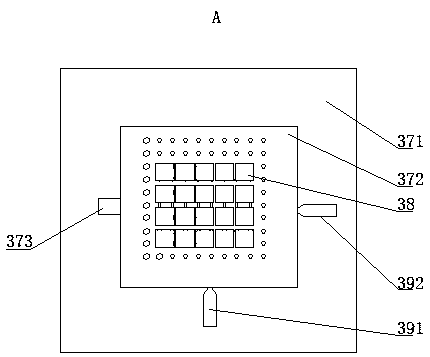

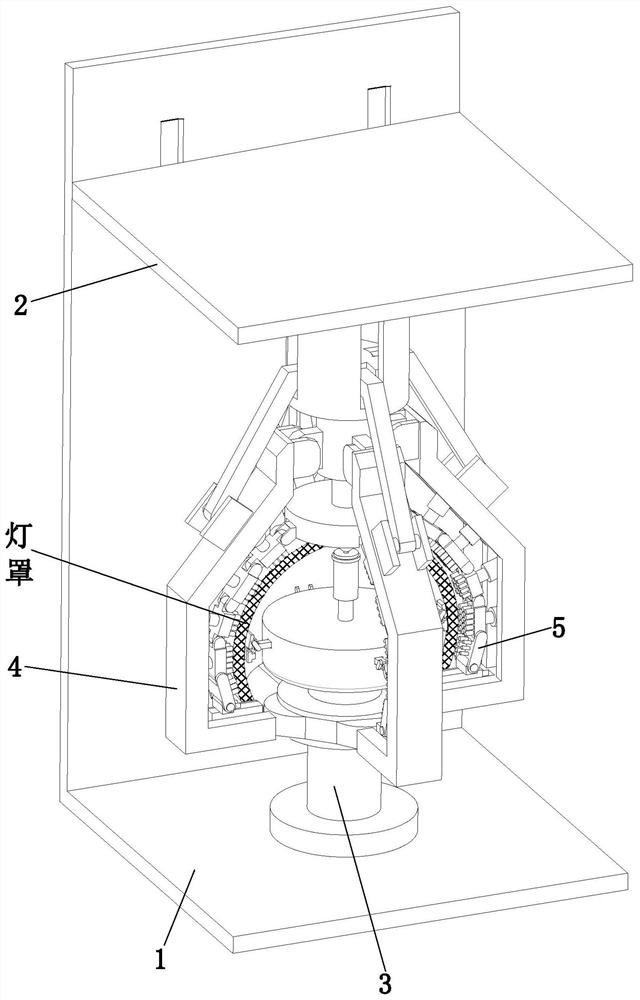

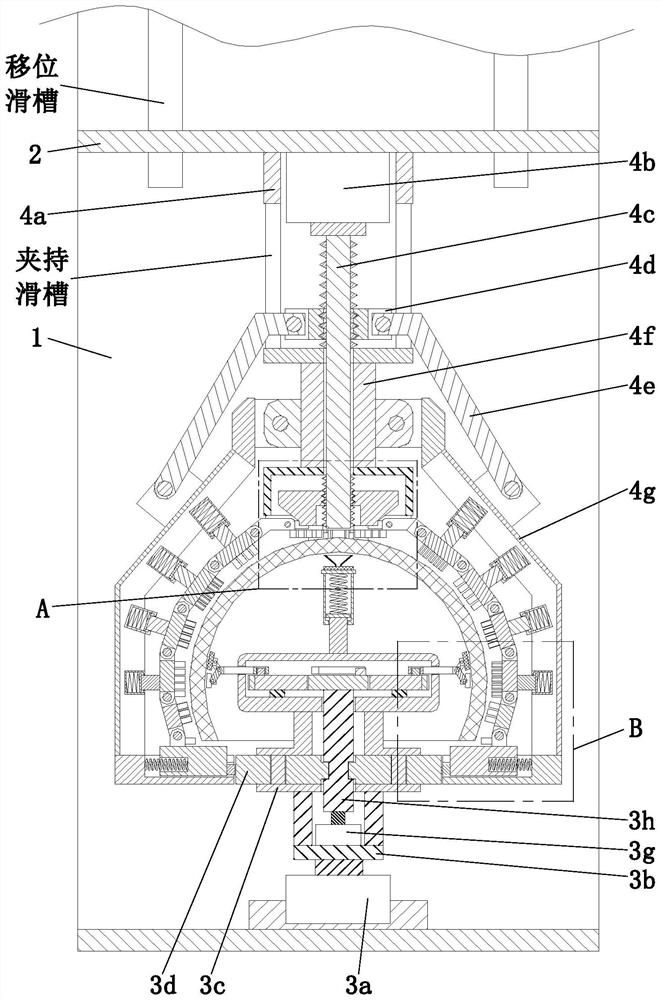

Production process of lampshade of LED energy-saving lamp

InactiveCN112059810ACause the surface to overheatPrevent springbackEdge grinding machinesGrinding carriagesMechanical engineeringIndustrial engineering

The invention provides a production process of a lampshade of an LED energy-saving lamp. The process is implemented by matching a mounting L-shaped plate, a lifting slide plate, a rotary support mechanism, a clamping mechanism and polishing mechanisms, the rotary support mechanism is mounted at the lower end of the mounting L-shaped plate, a shifting slide groove is formed in the mounting L-shapedplate, and the lifting slide plate is mounted in the shifting slide groove in a sliding fit manner. The clamping mechanism is installed at the lower end of the lifting slide plate, the clamping mechanism is located above the rotary support mechanism, and the polishing mechanisms are evenly installed on the clamping mechanism in a sliding fit manner. The production process can solve the problems that in the production process of lampshades of LED energy-saving lamps, the lampshades are difficult to align to be stably clamped and supported, common external supporting and clamping can influencethe effective working area of deburring in the production process of the lampshades of the LED energy-saving lamps, and in the deburring and polishing process, the arc-shaped surfaces of the lampshades of the LED energy-saving lamps are difficult to circumferentially and evenly grind.

Owner:郭玲艳

Grinding device applied to glass surface machining

InactiveCN105345645AImprove grinding effectExtended service lifeLapping machinesLapping toolsGlass chipEngineering

The invention discloses a grinding device applied to glass surface machining. The grinding device comprises a working platform, a grinding frame, grinding mechanisms and a grinding fluid mechanism. The grinding frame comprises a first grinding frame body and a second grinding frame body. The grinding mechanisms are arranged above the first grinding frame body and the second grinding frame body. The grinding mechanisms comprise grinding discs, telescopic rods and fixed rods. Pressurizing blocks are arranged above the grinding discs. Grinding skins are arranged at the bottoms of the grinding discs. Grinding grooves are formed in the grinding skins, and scale marks are arranged on the telescopic rods. The grinding device is simple in structure and high in practicality; due to the design of the grinding frame, the situation that glass chips generated in the glass grinding process are splashed out to hurt operators is effectively avoided; due to the design of the first grinding frame body and the second grinding frame body, working efficiency is improved; and due to the design of the pressurizing blocks, the number of the pressurizing blocks can be increased or decreased according to the glass machining sizes and machining requirements, so that grinding pressure is more suitable for current glass grinding, and working quality is further improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

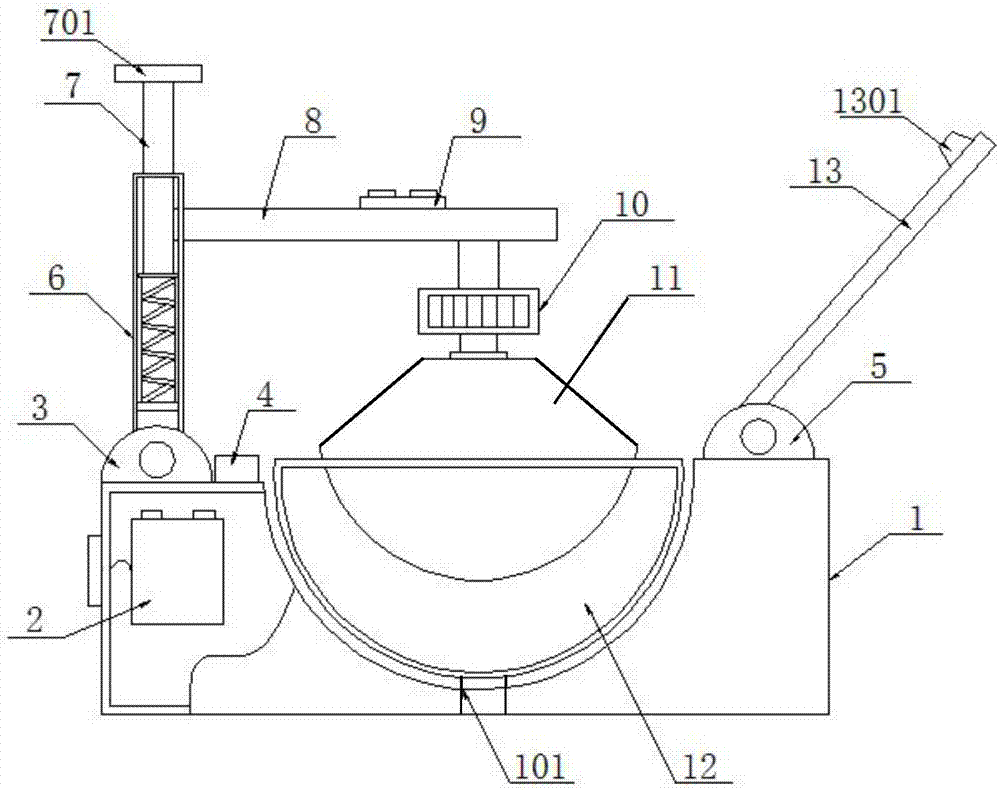

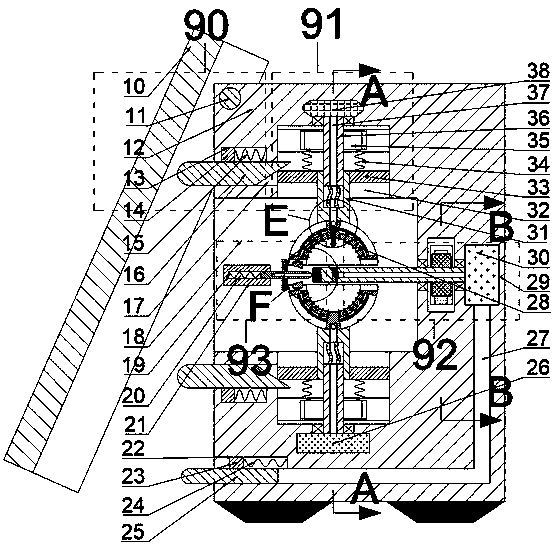

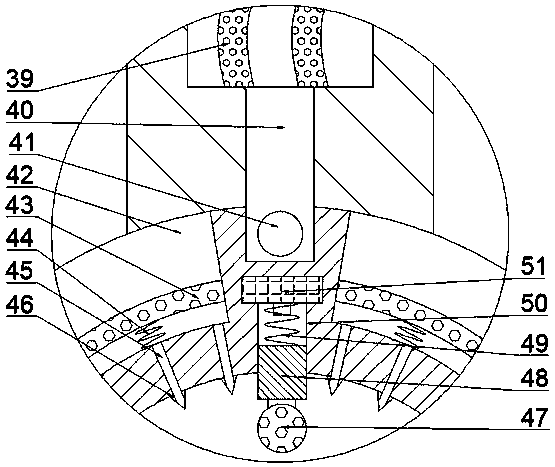

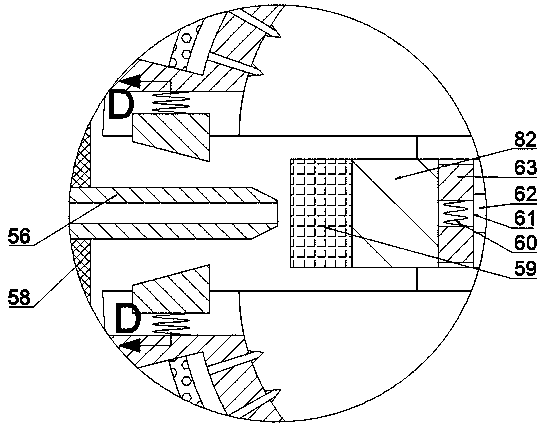

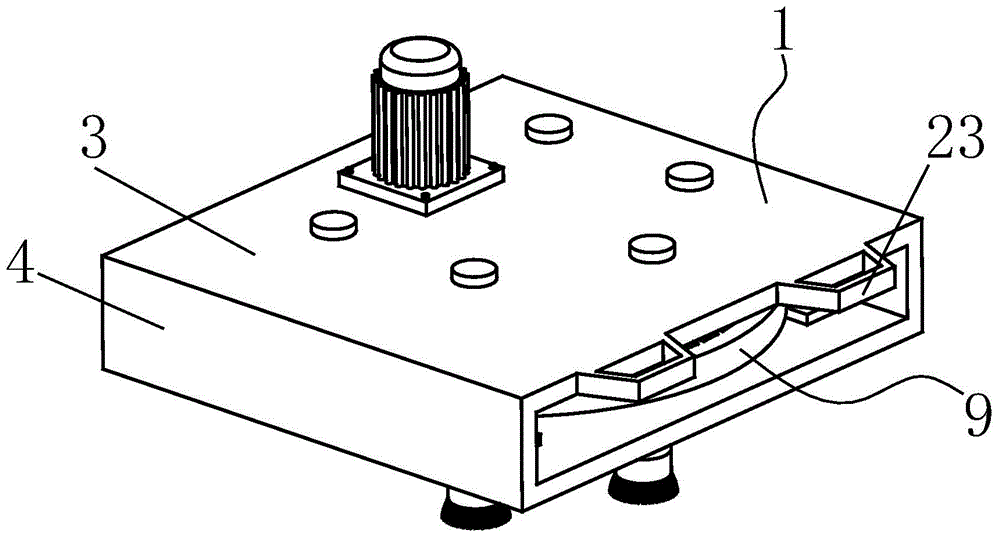

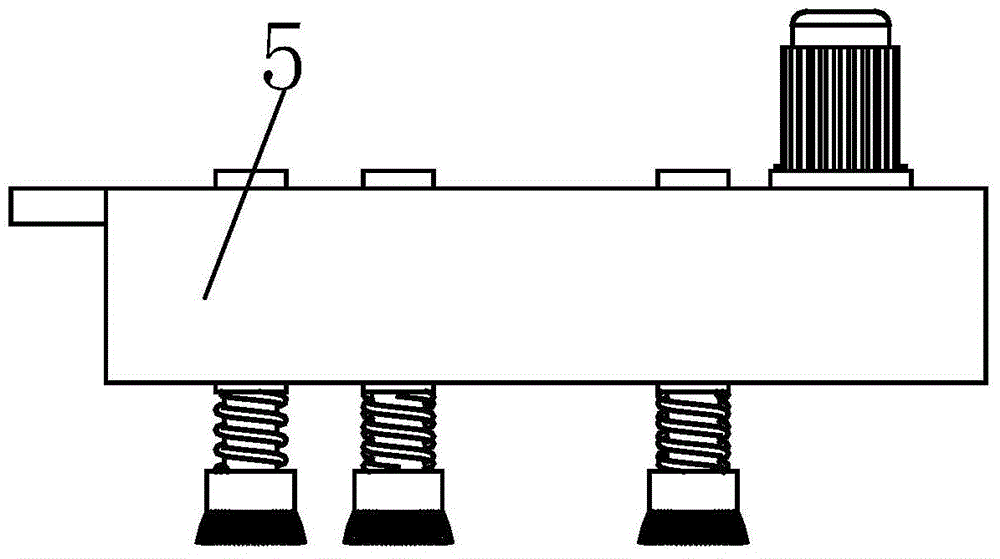

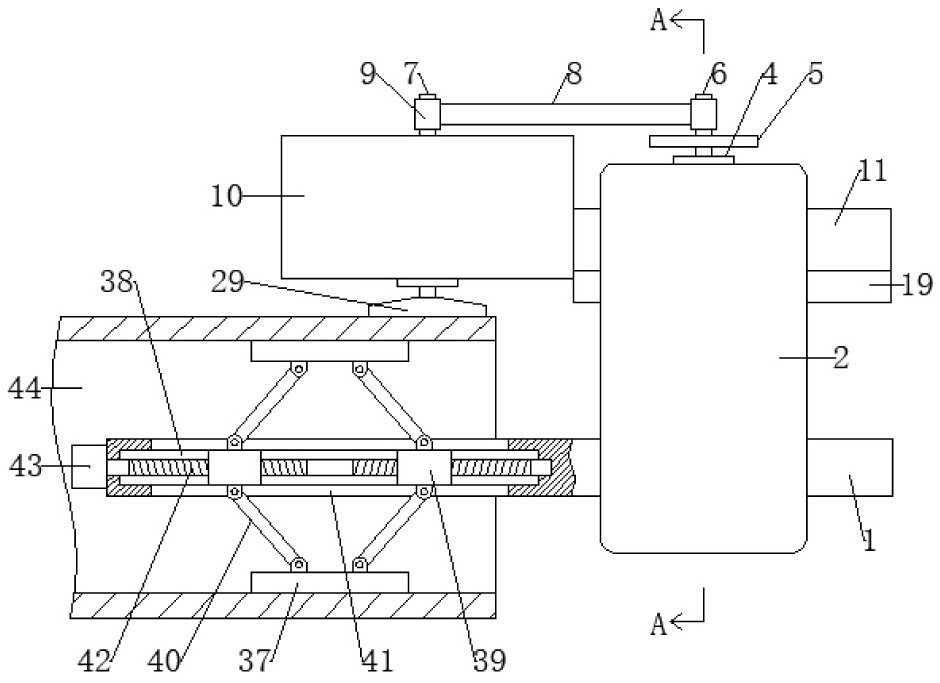

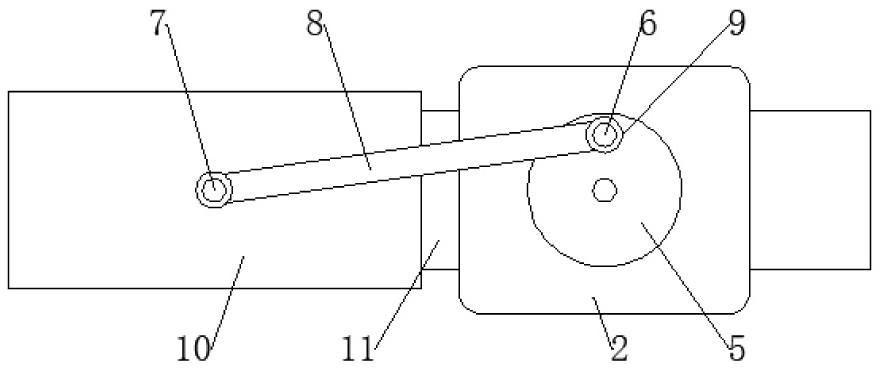

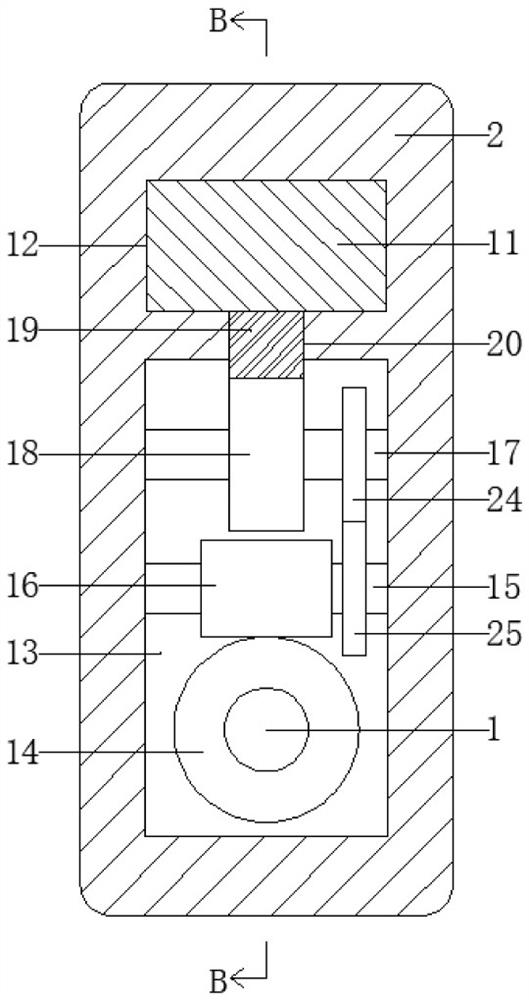

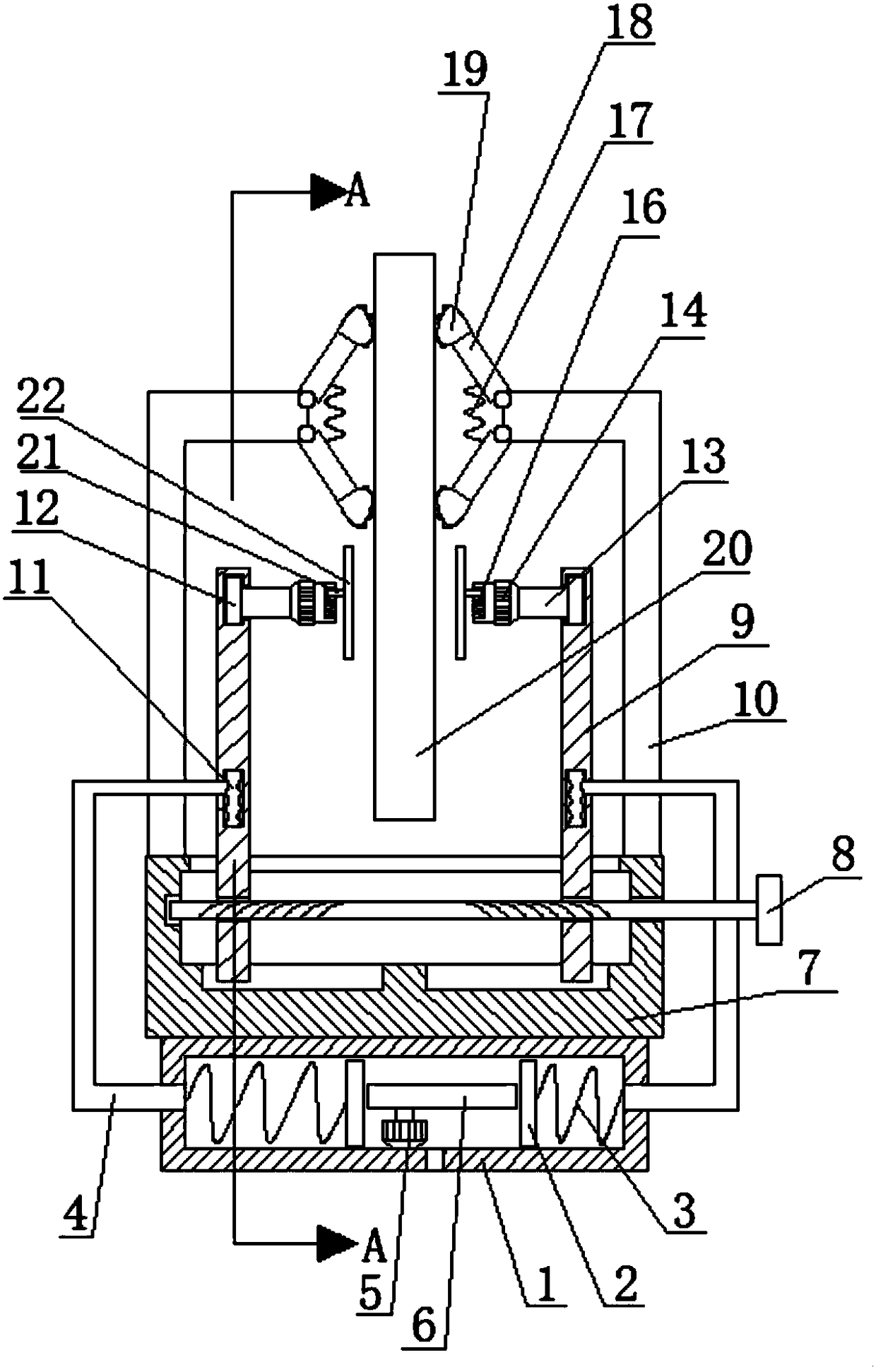

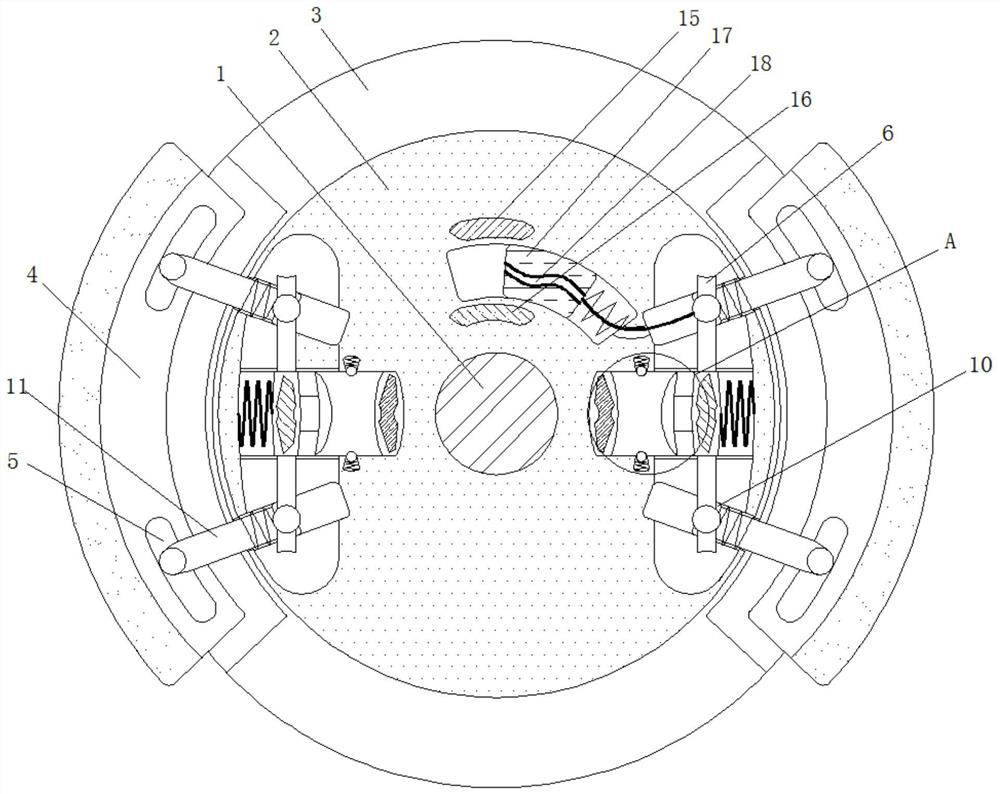

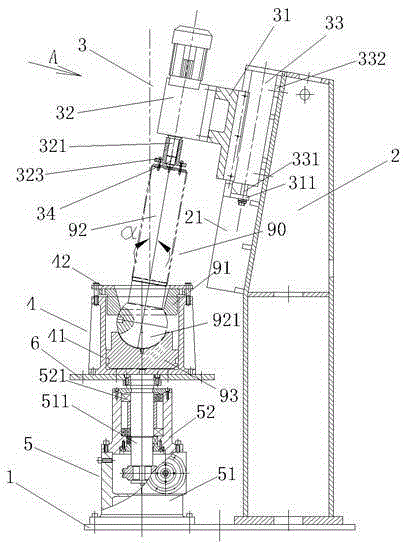

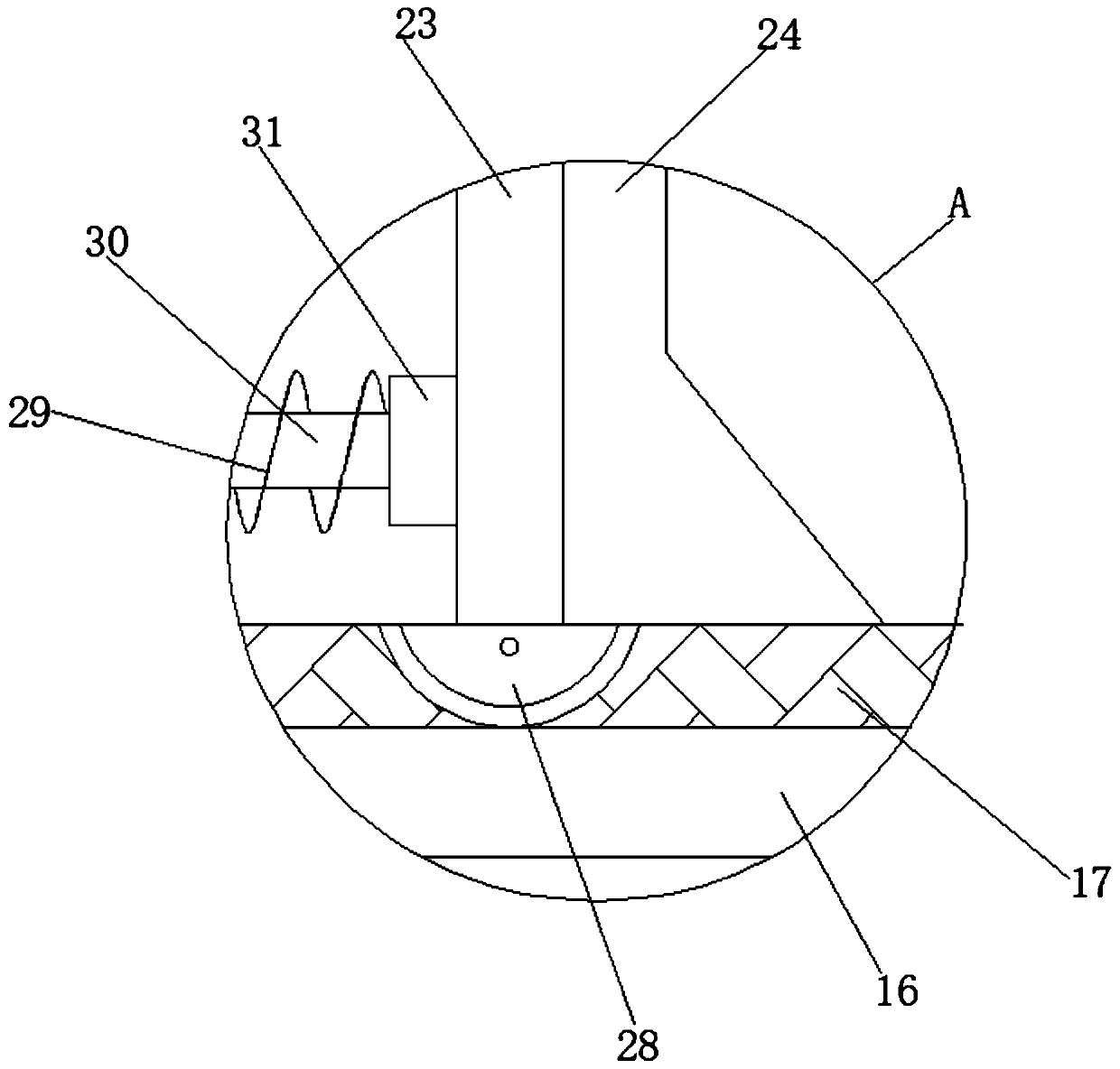

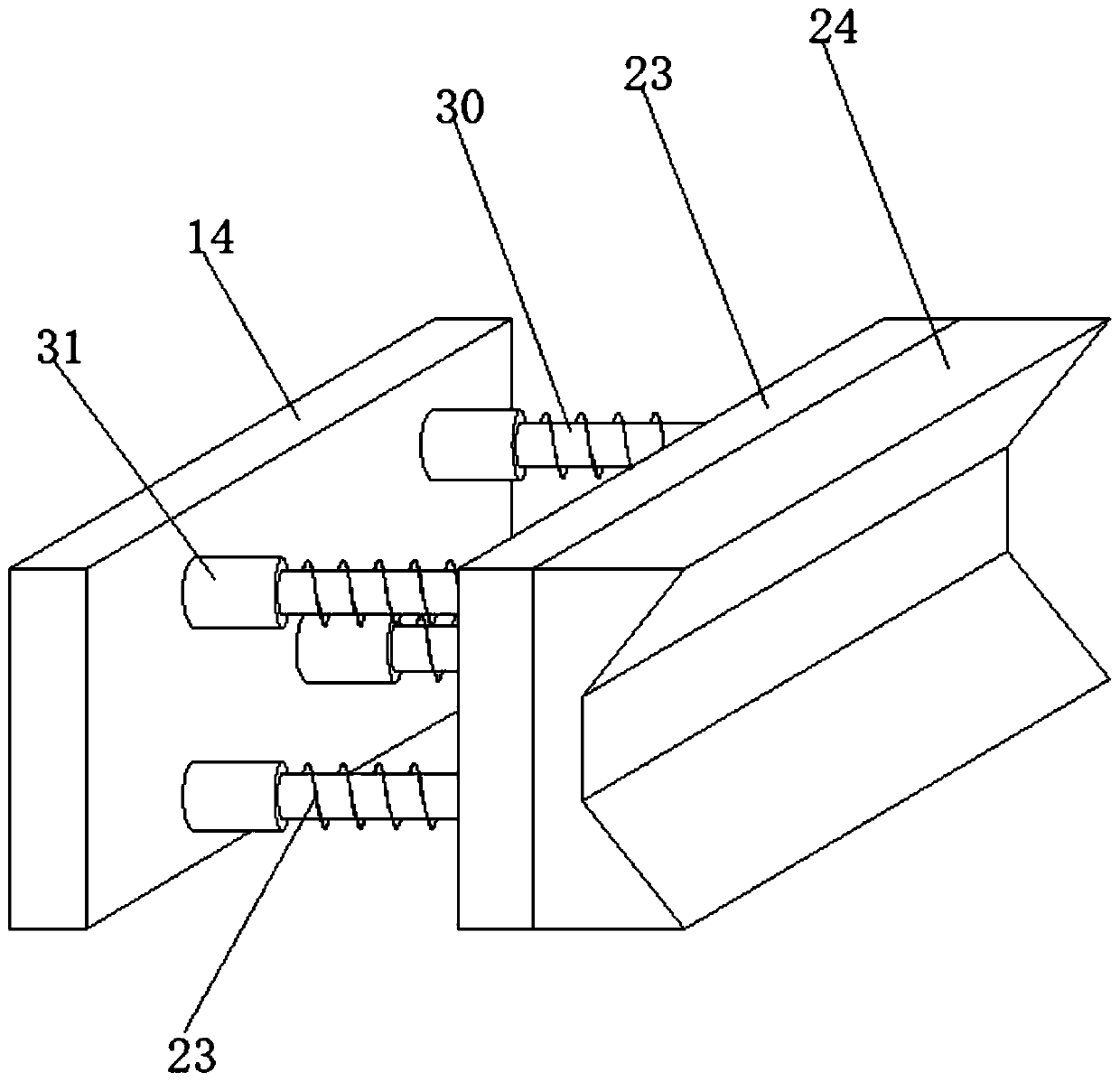

Terrazzo machine with swing function and for architectural decoration

InactiveCN110253359APlay the role of dustLarge grinding areaGrinding drivesPlane surface grinding machinesDrive shaftEngineering

The invention discloses a terrazzo machine with the swing function and for architectural decoration, in particular to a terrazzo machine with the function of swinging to enlarge the polishing area. Spray is carried out to reduce dust while polishing is carried out, and therefore, the terrazzo machine has the environmental protection function; and during polishing, the terrazzo machine can automatically travel, and then the problem that according to the prior art, the polishing area is small is solved. A power assembly comprises a flange, a motor and a crank shaft, wherein the motor is installed on a pump box, and the crank shaft is connected to an output end of the motor and is rotationally connected with the pump box in a penetration manner. A bent part on the upper part of the crank shaft is connected with a pumping unit arranged in the pump box. A rotary plate is fixed to the lower end of the crank shaft. A boss is fixedly connected with the outer edge of the lower surface of the rotary plate. The boss is arranged in a guide grooved formed in a swing rod in an oscillating rod in an embedded manner. The middle of the oscillating rod is rotationally connected to the lower end of a driven shaft. The upper part of the driven shaft is connected with the crank shaft through a first driving part. A polishing shaft is rotationally connected with the front end of the oscillating rod. The lower part of the polishing shaft is connected with an abrasive disk in a sleeved manner, and is fixed through an adjustable bolt. The polishing shaft is connected with the lower part of the driven shaft through a driving part.

Owner:滕以飞

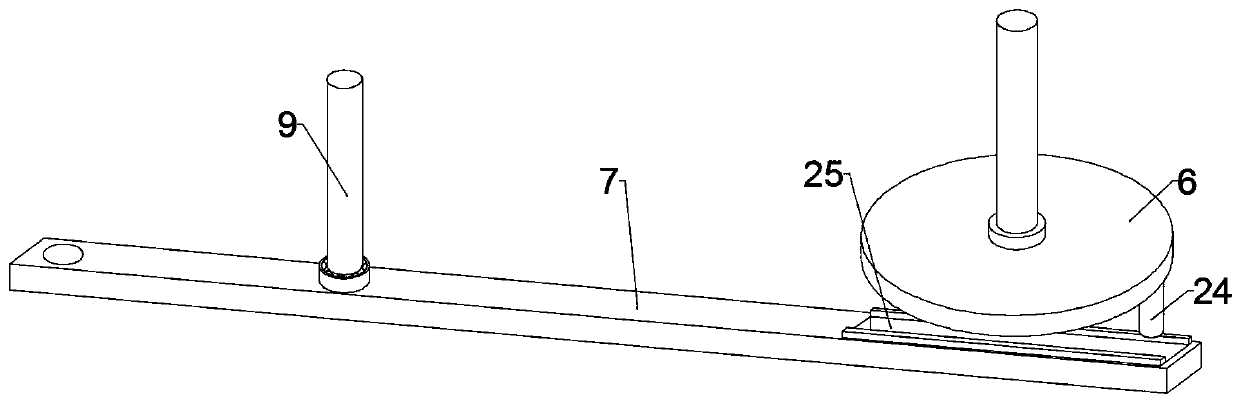

Granulating machine used for producing chicken feed and using method of granulating machine

InactiveCN109043619ASave human effortImprove the efficiency of feedingFeeding-stuffGrain treatmentsDischarge efficiencyCam

The invention discloses a granulating machine used for producing chicken feed and a using method of the granulating machine. The granulating machine comprises a bottom plate, a granulating bin and a support, universal wheels are fixed to the four corners of the lower end of the bottom plate and provided with wheel locks, and a first motor is arranged on one side of the upper end of the bottom plate. The granulating machine has the advantages that by arranging a second motor, a driving belt wheel, a belt, a second rotating shaft, a driven belt wheel, a third rotating shaft and a driving roller,a conveying belt can be driven to rotate to realize automatic feeding operation, in this way, labor can be saved, and the feeding efficiency can be improved; by arranging a conical press roll and a conical mold, the grinding area of materials can be effectively increased, the materials are ground more sufficiently, the utilization rate of the materials is increased, and the quality of the feed isensured; by arranging a vibrating motor, a fourth rotating shaft, a cam and a discharging plate, vibrating discharging can be realized, the feed can be effectively prevented from adhering during falling, and the discharging efficiency is improved.

Owner:徐巍

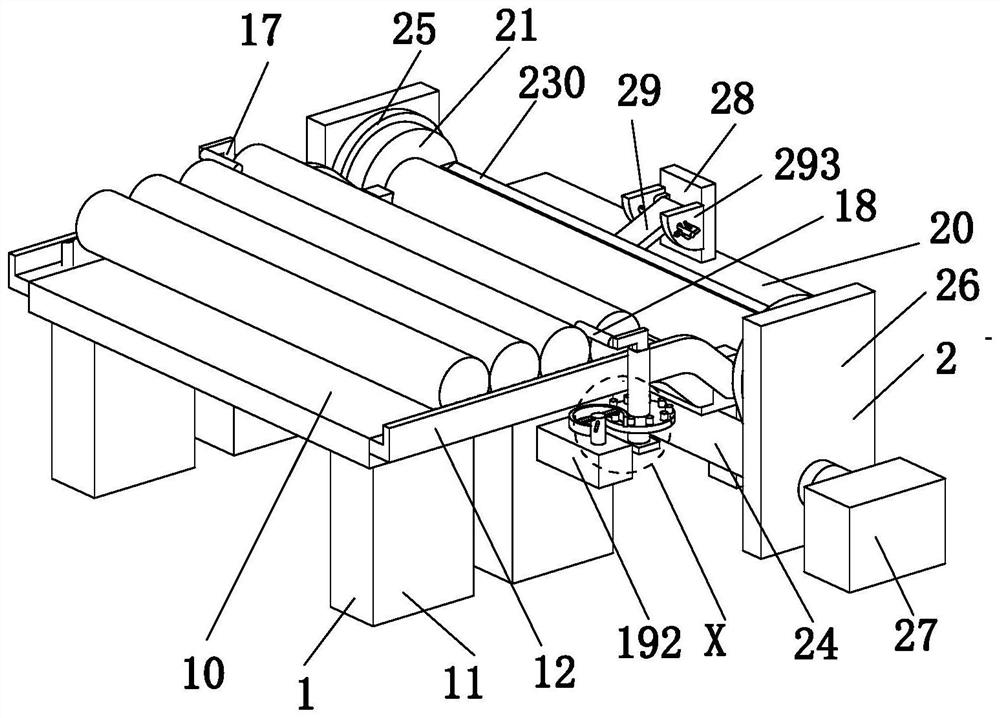

Multi-angle machining roller manufacturing device

ActiveCN110026867ALarge grinding areaImprove grinding efficiencyGrinding drivesSpraying apparatusBand shapePulley

The invention discloses a multi-angle machining roller manufacturing device. A lathe body is included. A roller buffering device is arranged on one side of the lathe body and is in sliding connectionwith the ground. A controller is arranged on the side surface of the lathe body. A strip-shaped grinding device is arranged above the lathe body. A circular oil applying device is arranged on one sideof the strip-shaped grinding device. The strip-shaped grinding device can make a strip-shaped grinding strip more attached to a roller through mutual cooperation of a fixed pulley and a movable pulley. The circular oil applying device can recycle surplus oil through the funnel collecting function. The multi-angle machining roller manufacturing device has the beneficial effects that operation is simple and convenient, and practicability is high.

Owner:TIANJIN SAIXIANG M&E ENG CO LTD

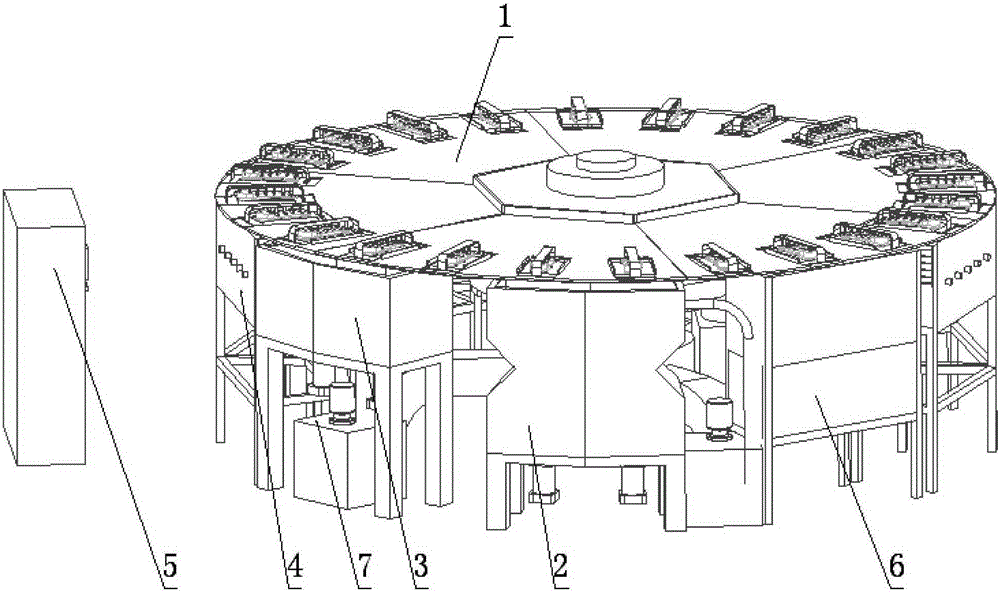

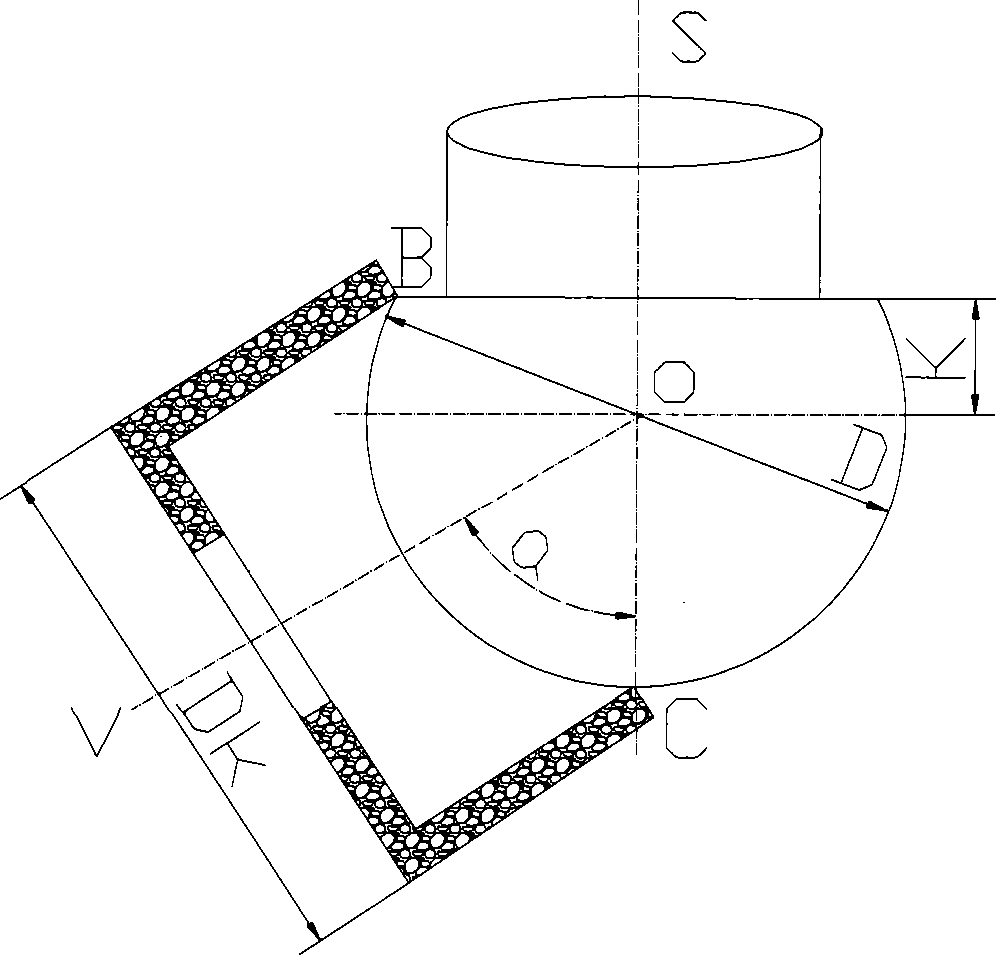

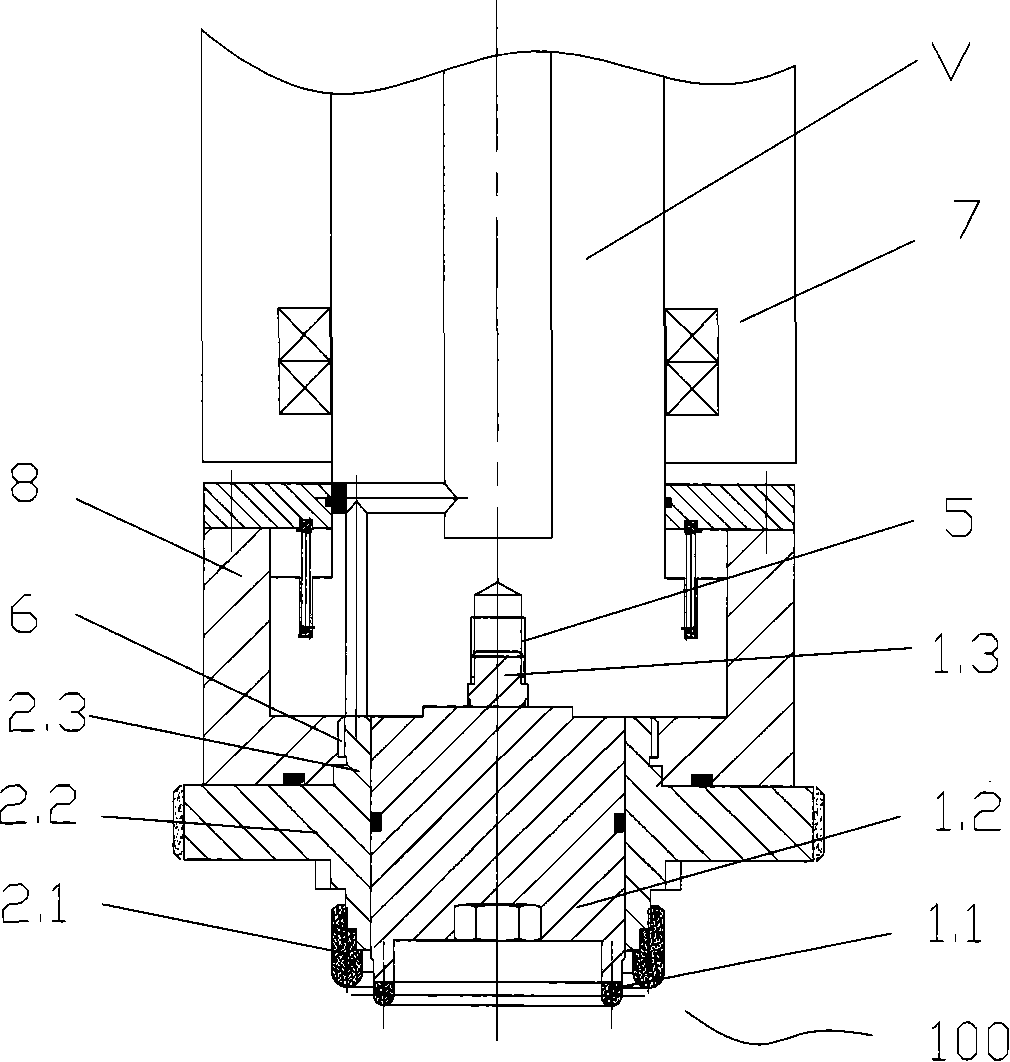

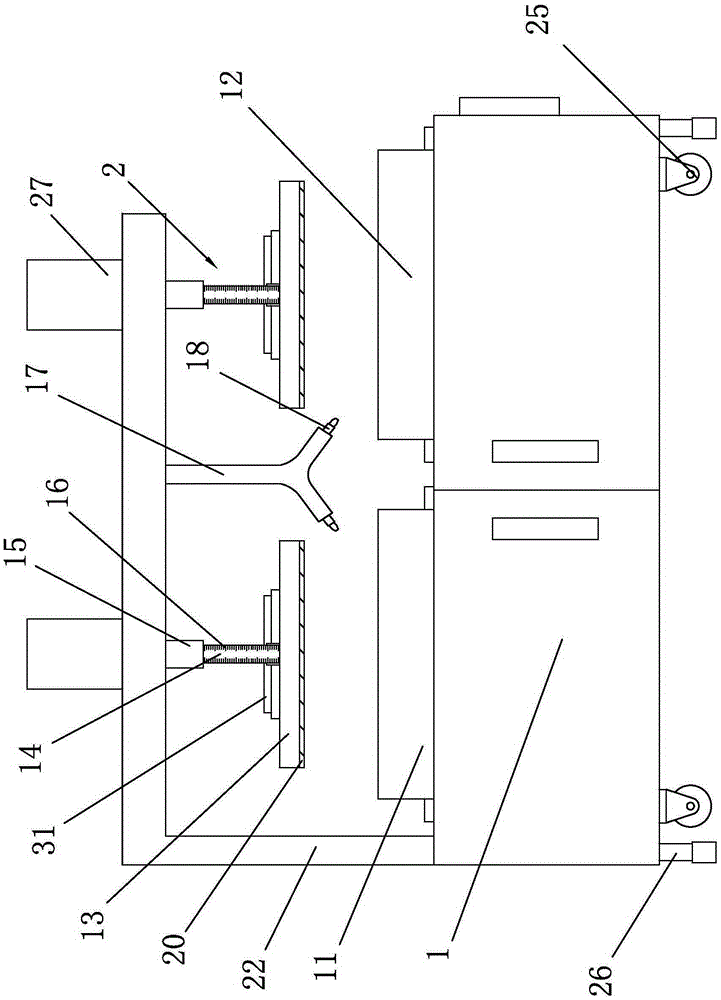

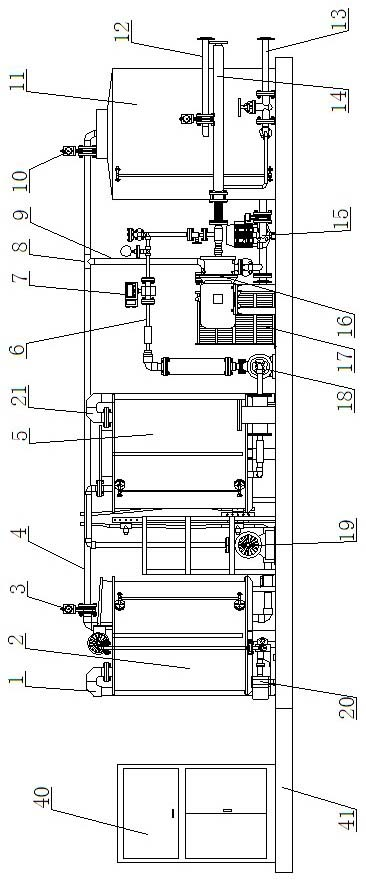

Full-automatic sole sandblast grinding machine and sandblast polishing technology

InactiveCN105212442ALarge grinding areaGood effectSolesAbrasive machine appurtenancesSurface levelEngineering

The invention relates to a full-automatic sole sandblast grinding technology. The specific steps comprise: (1) putting the innersole of a to-be-processed shoe undersole downward on a sole positioning bushing plate of a platform; (2) locking, that is, locking a shoe undersole fixing support to fix the shoe undersole; (3) sandblasting and polishing, that is, in fluffing, high-pressure gas spraying out from the nozzle of a spray gun, a sand pipe extending in sand in a sand box, sand grains being pumped out along the sand pipe, and with spraying of the high-pressure gas, sprayed high-pressure sand grains and the surface of the shoe undersole highly rubbing to roughen the surface; (4) cleaning, that is, at set polishing time, a blanking plate shutting down the inlet of the sand pipe, the spray gun spraying clean high-pressure gas to blow and clean sand grains residual on the surface of the shoe undersole; (5) the shoe undersole which completes polishing returning to an initial position, opening the sole fixing support, and taking down the shoe undersole. The grinding machine is rational in structure, and is in high quality and efficient, saves manpower, saves energy and is environmentally friendly, and the machine is high in automation degree. Processing efficiency of products and processing quality are effectively improved, and products are reliable and durable.

Owner:马士通安全设备(天津)有限公司

Emulsified asphalt production equipment

ActiveCN102627979AIncrease contact areaLarge grinding areaWorking-up pitch/asphalt/bitumenColloid millWater pipe

The invention provides emulsified asphalt production equipment, which comprises a colloid mill, a mixing tank, a hot water tank and a PLC (Programmable Logic Controller) control system, wherein the hot water tank is connected with the mixing tank through a hot water pipe which is provided with control valves at two ends; the outlet end of the mixing tank is connected with a liquid soap tank through a conveying pipe, so that mixed liquid soap is conveyed into the liquid soap tank for later use; meanwhile, the mixing tank can be used for mixing liquid soap continuously; the liquid soap tank is connected with the colloid mill through a liquid soap pipe to supply needed liquid soap to the colloid mill; the outlet end of the colloid mill is connected with a heat exchanger through a finished product conveying pipe; a water inlet pipe of the heat exchanger is connected with the hot water tank; a water outlet pipe of the heat exchanger is connected with the hot water pipe through a three-way valve; floating ball switches which are connected with the PLC control system are arranged in the hot water tank, the mixing tank and the liquid soap tank, and are used for transmitting acquired corresponding signals to the PLC control system; and the PLC control system is used for controlling the work of each tank. According to the emulsified asphalt production equipment, the automatic degree of entire equipment is raised, the working efficiency is increased, and production cost is lowered.

Owner:王经勃

Polishing equipment for aluminum alloy imitation wood grain materials

InactiveCN108908000AIncreased flexibility of useImprove practicalityGrinding machinesAluminium alloyWood grain

The invention discloses polishing equipment for aluminum alloy imitation wood grain materials. The polishing equipment comprises a main equipment body, wherein the main equipment body is provided witha groove, and sliding guide rails are fixedly installed at the upper end of the main equipment body; a first stepping motor is fixedly installed in the main equipment body, and a first gear is arranged at the upper end of the first stepping motor; and a moving plate is arranged on the sliding guide rails, a first rack is fixedly installed on the lower surface of the moving plate, and the first rack is located in the groove and is in meshing connection with the first gear. In conclusion, the polishing equipment has the beneficial effects that the polishing equipment for aluminum alloy imitation wood grain materials is provided with the moving plate, a detachable vice and a lifting rod and can move horizontally with the materials, the use flexibility of the polishing equipment is improved,materials needing to be polished can be fixed, the polishing accuracy is improved, the height of a polisher can also be adjusted, different sizes of materials can be polished conveniently, and convenience is realized.

Owner:四川鼎际恒荣金属材料有限公司

Grinder for ball head assembly

InactiveCN105269432AIncrease contact areaImprove grinding precisionGrinding drivesSeat surface grinding machinesFuselagePiston rod

The invention discloses a grinder for a ball head assembly. The grinder comprises a bottom plate, a body, an abutting head rotating device, a grinding tool and a grinding tool rotating supporting device. The abutting head rotating device is arranged on one side of the upper portion of the body in a slant mode and comprises a sliding seat, an upper motor and reduction box set, a sliding seat moving oil cylinder and an abutting head. The inner sides of the sliding seat are arranged on two guide rails in a slant bridging manner, wherein the guide rails are arranged on the two sides of the upper portion of the body. One side of the upper motor and reduction box set is fixed to the outer side of the sliding seat. A reduction box output shaft is fixedly connected to the inner end of the abutting head. The front end of the sliding seat is connected with the end of a sliding seat moving oil cylinder piston rod. The grinding tool comprises a grinding seat and an upper cover, wherein the bottom of the grinding seat is fixed to the top end of the grinding tool rotating supporting device. According to the grinder, the grinding area among a ball head cover, a ball head and a ball bowl is enlarged, and therefore the contact area between the ball head cover, the ball head and the ball bowl is increased to more than 85% after grinding and painting check among the ball head cover, the ball head and the ball bowl, and ball head assembly grinding precision and efficiency are greatly improved.

Owner:WORLD PRECISE MACHINERY CO LTD CHINA

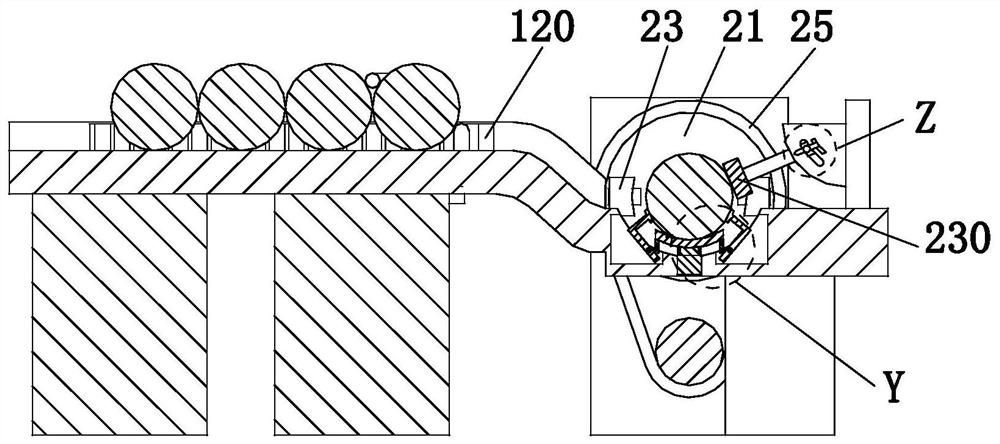

Polymer alloy bar forming treatment system

ActiveCN112372384AReduce complexityGuaranteed positive dockingRevolution surface grinding machinesGrinding drivesPolymer alloyButt joint

The invention relates to a polymer alloy bar forming treatment system. The system comprises a feeding mechanism and a polishing mechanism. The lower end of the feeding mechanism is installed on an existing working ground, the right right end of the feeding mechanism is connected with the polishing mechanism, and the lower end of the polishing mechanism is installed on the existing working ground.According to the polymer alloy bar forming treatment system, macromolecular alloy bar forming treatment is carried out by adopting the design concept of integrating a feeding structure and a polishingstructure, and the arranged feeding mechanism can achieve the function of automatic supply of one single bar, so that assembly line type operation with higher working efficiency can be carried out togreatly reduce the complexity of overall operation on the bar; and meanwhile, an auxiliary structure for quickly clamping and positioning the bar is arranged to ensure that the bar is in butt joint with a main clamping fixing mechanism.

Owner:BAOJI UNIQUE TITANIUNM IND CO LTD

Grinding device for stone machining

The invention discloses a grinding device for stone machining. The grinding device comprises a box body, placing plates are arranged on the inner walls of the two sides of the box body, a sliding groove is formed in the outer wall of the top of each placing plate; a first electric sliding rail is arranged on the inner walls of the two sides of the box body. The inner wall of one side of the firstelectric sliding rail is slidably connected with a first electric sliding block. A connecting plate is arranged on the outer wall of one side of the first electric sliding block, a second electric sliding rail is arranged on the outer wall of the bottom of the connecting plate, a second electric sliding block is slidably connected to the inner wall of the bottom of the second electric sliding rail, and a connecting rod is arranged on the outer wall of the bottom of the second electric sliding block. When people grind stone, the stone can be placed on the placing plate, then water is injected into the box body through a water inlet pipe until the water submerges the top of the stone, and the grinding device grinds the stone in the water, so that the noise during grinding can be reduced, andthe harm of dust generated during grinding to the health of people can be avoided.

Owner:周庆祥

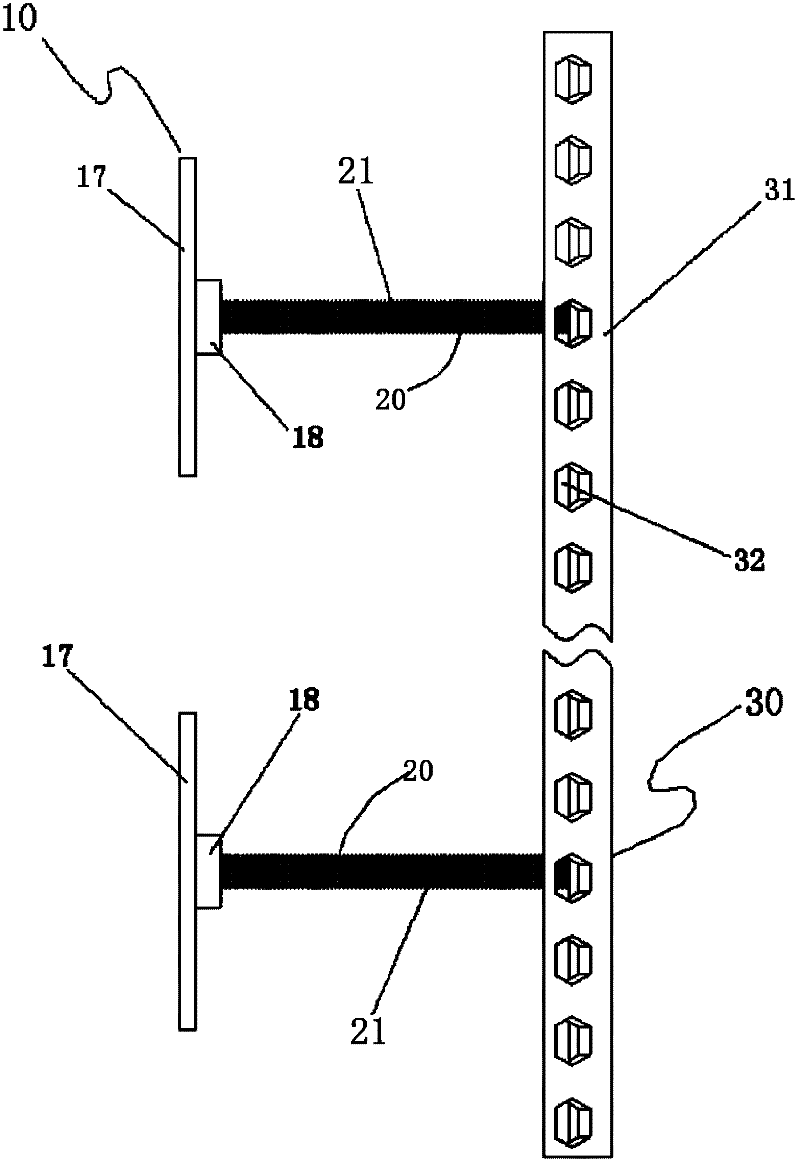

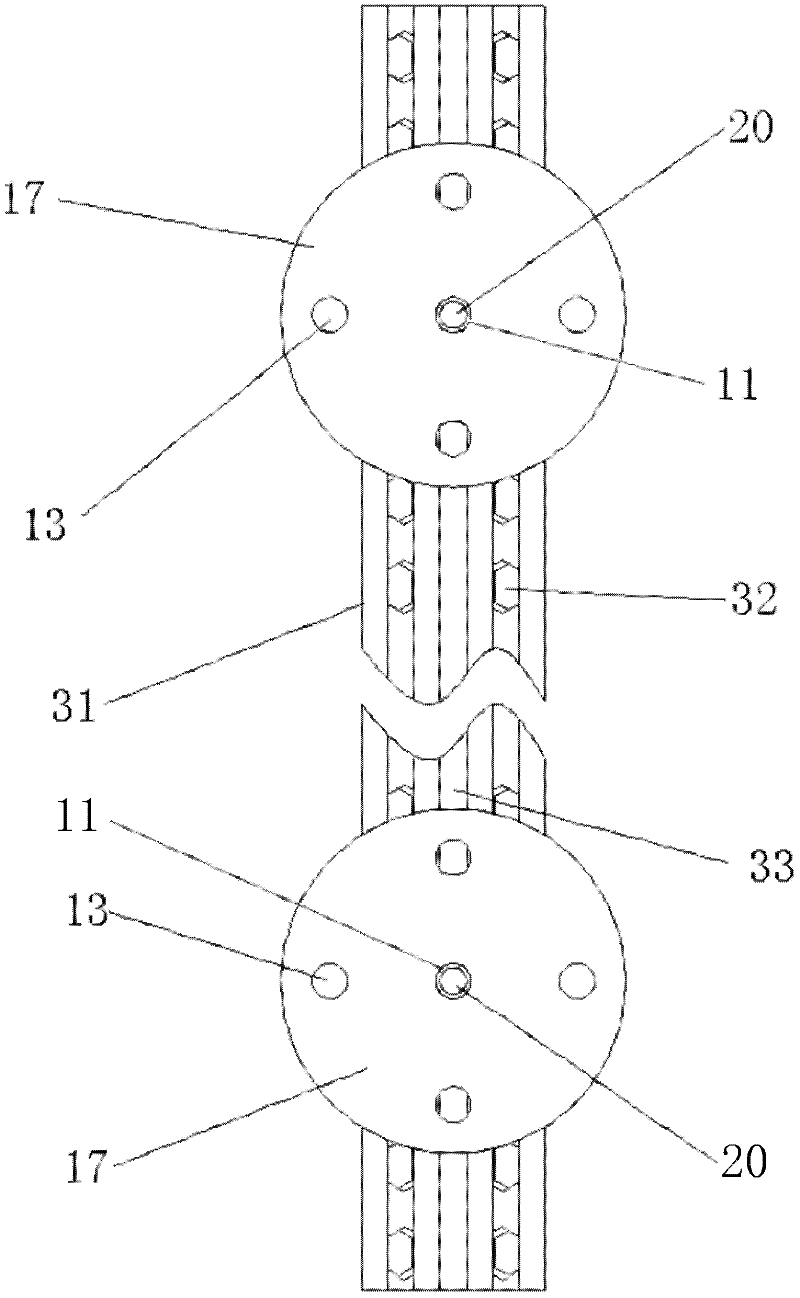

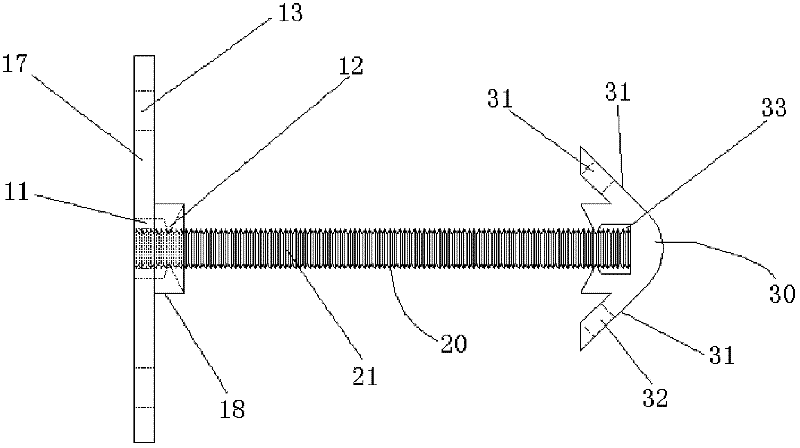

Sander for prefabricated slab laying

ActiveCN111571391ASmooth splicingFast full range sandingConstruction materialPortable grinding machinesSanderDrive wheel

The invention discloses a sander for prefabricated slab laying. The sander for prefabricated slab laying aims to solve the problem that in the prior art, the side faces of prefabricated slabs cannot be polished easily and rapidly. The sander for prefabricated slab laying comprises a first mounting plate and a second mounting plate. Inserting rods are evenly welded to the inner side face of the first mounting plate and the inner side face of the second mounting plate. Grips are fixedly mounted on the side faces of the first mounting plate and the second mounting plate, supporting rods are welded to the middles of the outer surfaces of the first mounting plate and the second mounting plate, driving wheels are mounted at the outer ends of the supporting rods, first rotating shafts are mountedbetween the driving wheels and the supporting rods, and motors are mounted at the outer ends of the first rotating shafts. Rotating blocks are welded to the two ends of the outer surface of the firstmounting plate and the two ends of the outer surface of the second mounting plate correspondingly, and rotating rods are sleeved with the rotating blocks. The motors are used for driving, a conveyingbelt is used for polishing the side faces of the prefabricated slabs, so that the prefabricated slabs are spliced more stably, the polishing area of the conveying belt is relatively large, the grinding efficiency is improved, and efficiency is relatively high.

Owner:广东南粤建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com