Grinding device for stone machining

A technology for stone processing and plate placement, which is used in grinding drive devices, grinding/polishing safety devices, metal processing equipment, etc. It can solve problems such as damage to the staff's hearing system, loud noise, etc., to improve the fixation effect and reduce noise. , good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

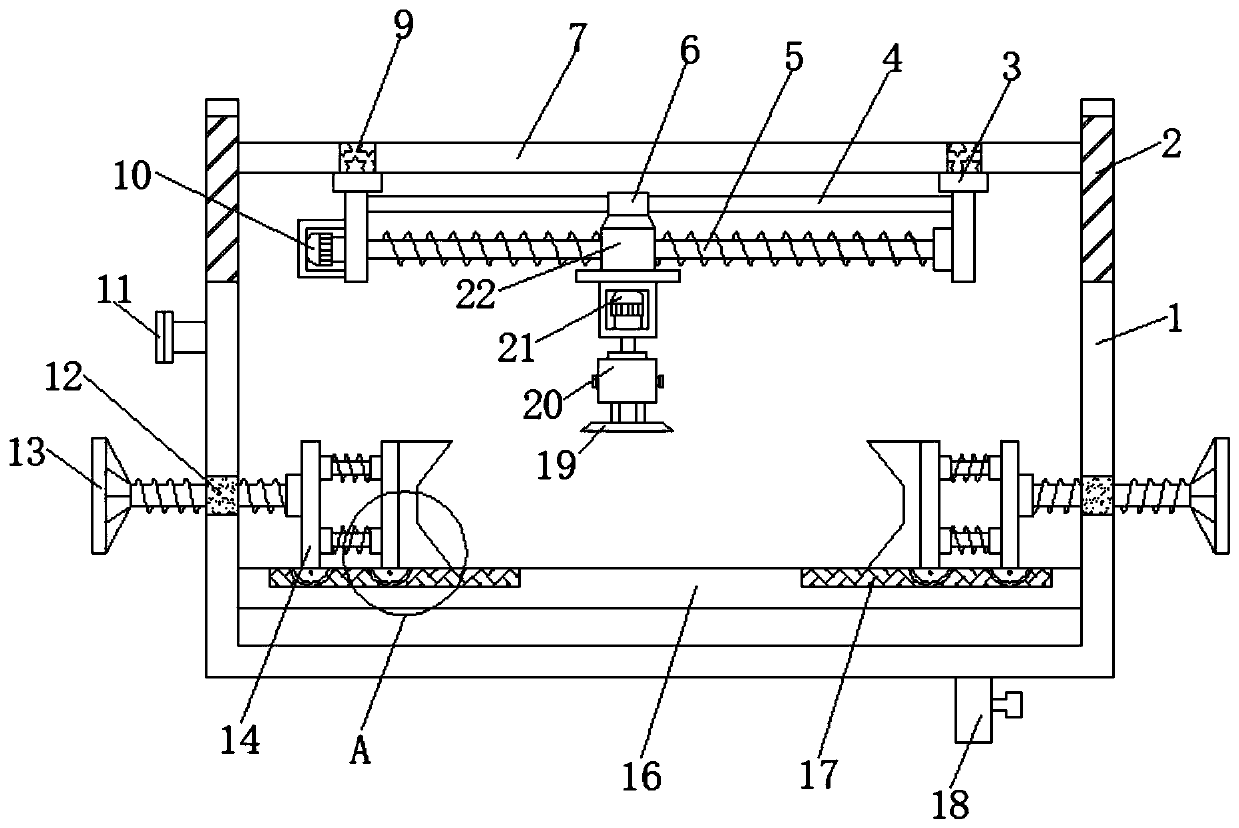

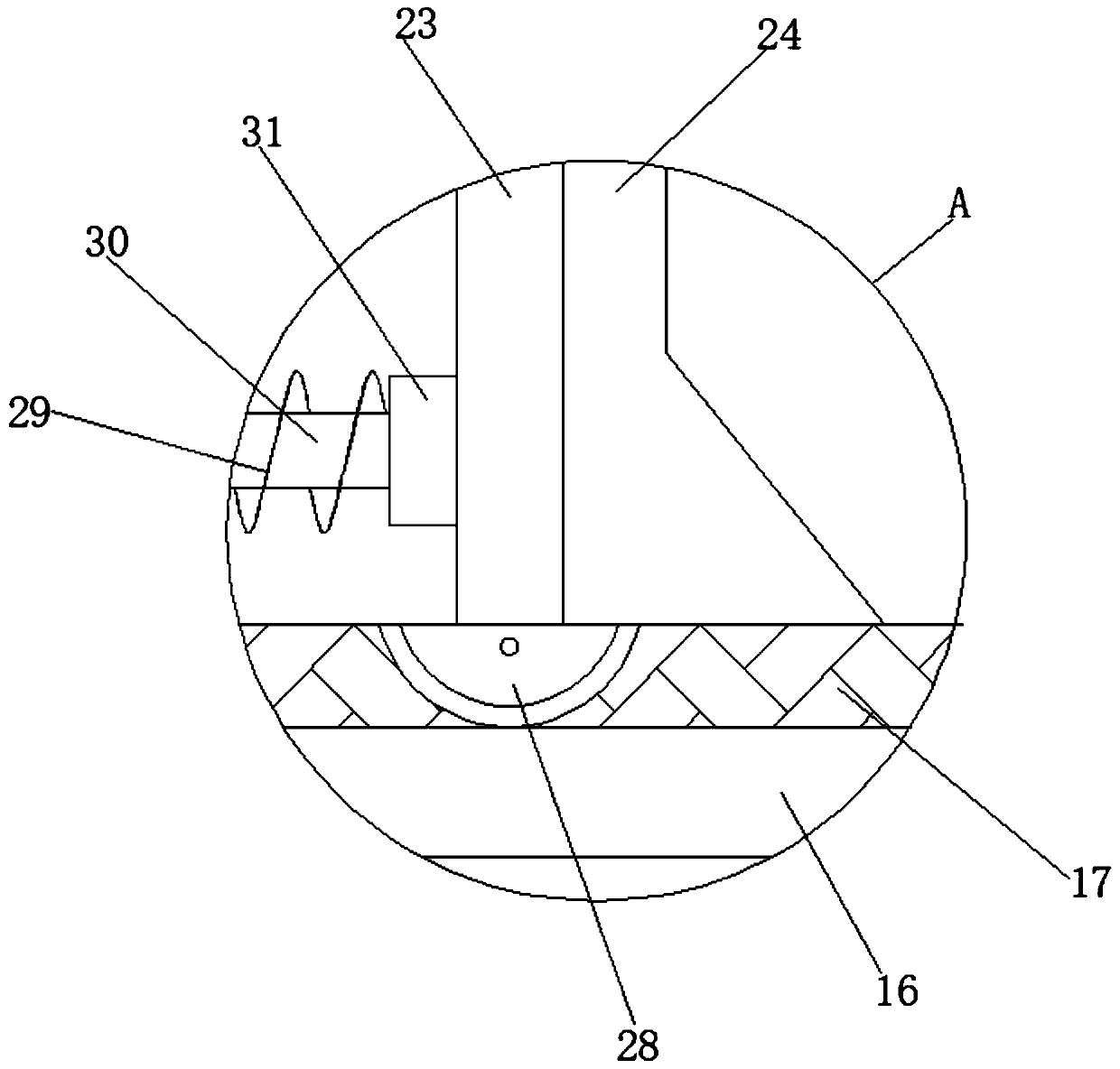

[0030] refer to Figure 1-3 , a grinding device for stone processing, comprising a box body 1, the inner walls of both sides of the box body 1 are connected with a placement plate 16 by bolts, and the top outer wall of the placement plate 16 is provided with a chute 17, the box body 1 The inner walls on both sides of the first electric slide rail 2 are connected by bolts, and the first electric slider is slidably connected to the inner wall on one side of the first electric slide rail 2, and the outer wall on one side of the first electric slider is connected by bolts. There is a connecting plate 7, and the bottom outer wall of the connecting plate 7 is connected with a second electric slide rail 9 by bolts, and the bottom inner wall of the second electric slide rail 9 is slidably connected with a second electric slide block, and the second electric slide block The bottom outer wall of the connecting rod 3 is connected with a connecting rod 3 by bolts, and the bottom outer wal...

Embodiment 2

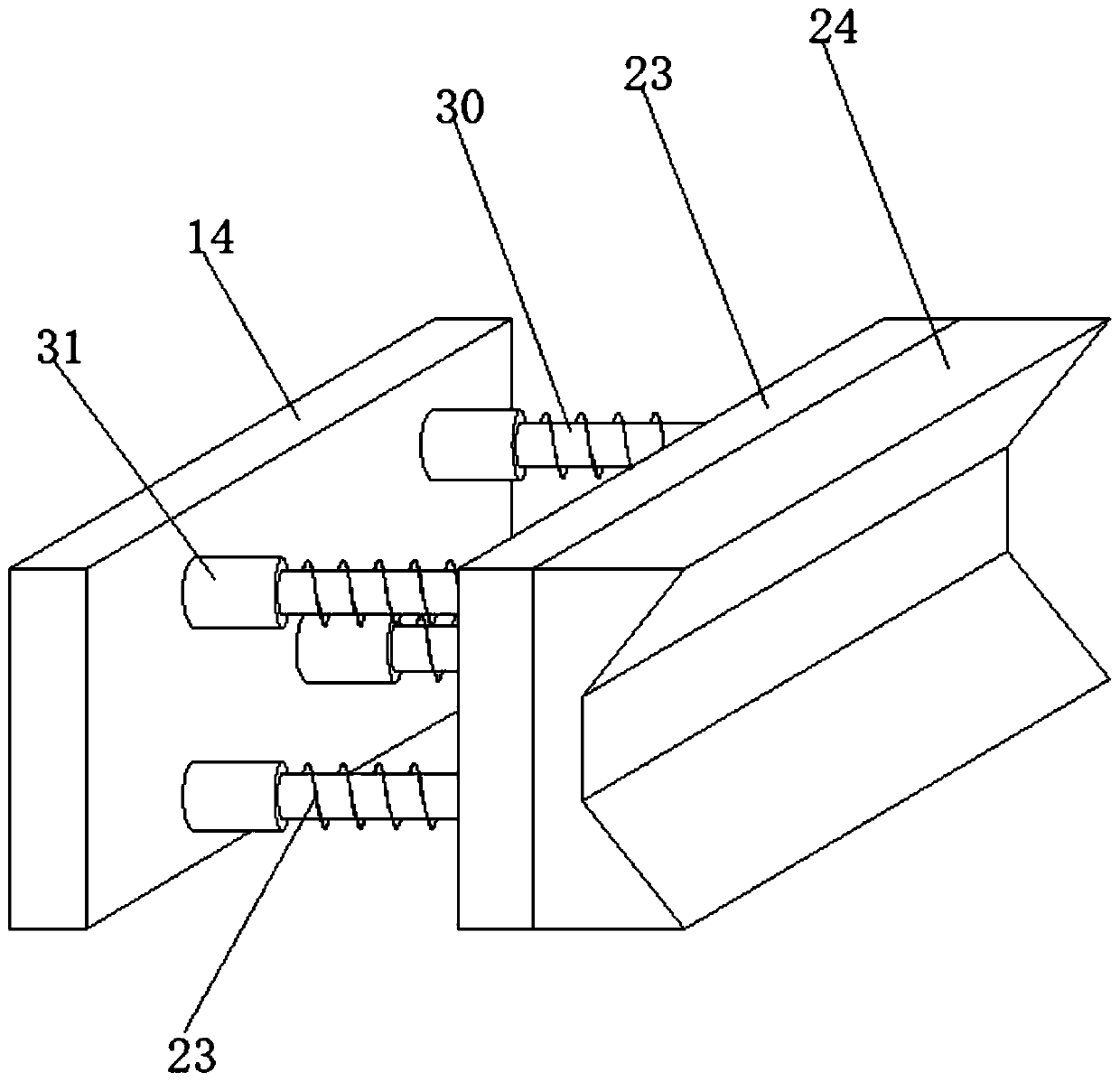

[0034] refer to Figure 4 , a grinding device for stone processing. Compared with Embodiment 1 in this embodiment, the outer wall of one side of the clamping block 24 is welded with bumps 25 distributed equidistantly, and the cross section of the bumps 25 is M-shaped.

[0035] Working principle: when in use, when people are grinding the stone, they can place the stone on the placement plate 16, and then pour water into the box 1 through the water inlet pipe 11 until the water submerges the top of the stone, and the grinding device grinds the stone in the water , not only can reduce the noise during grinding, but also avoid the dust generated during grinding from causing harm to people's bodies. Then people turn the screw body 13, and the screw body 13 drives the clamping block 24 to move until the stone body is fastened and fixed. The cross section of the protrusion 25 provided on the outer wall of one side of the holding block 24 is M-shaped, which can improve the fixing effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com