Patents

Literature

428results about How to "Increase internal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

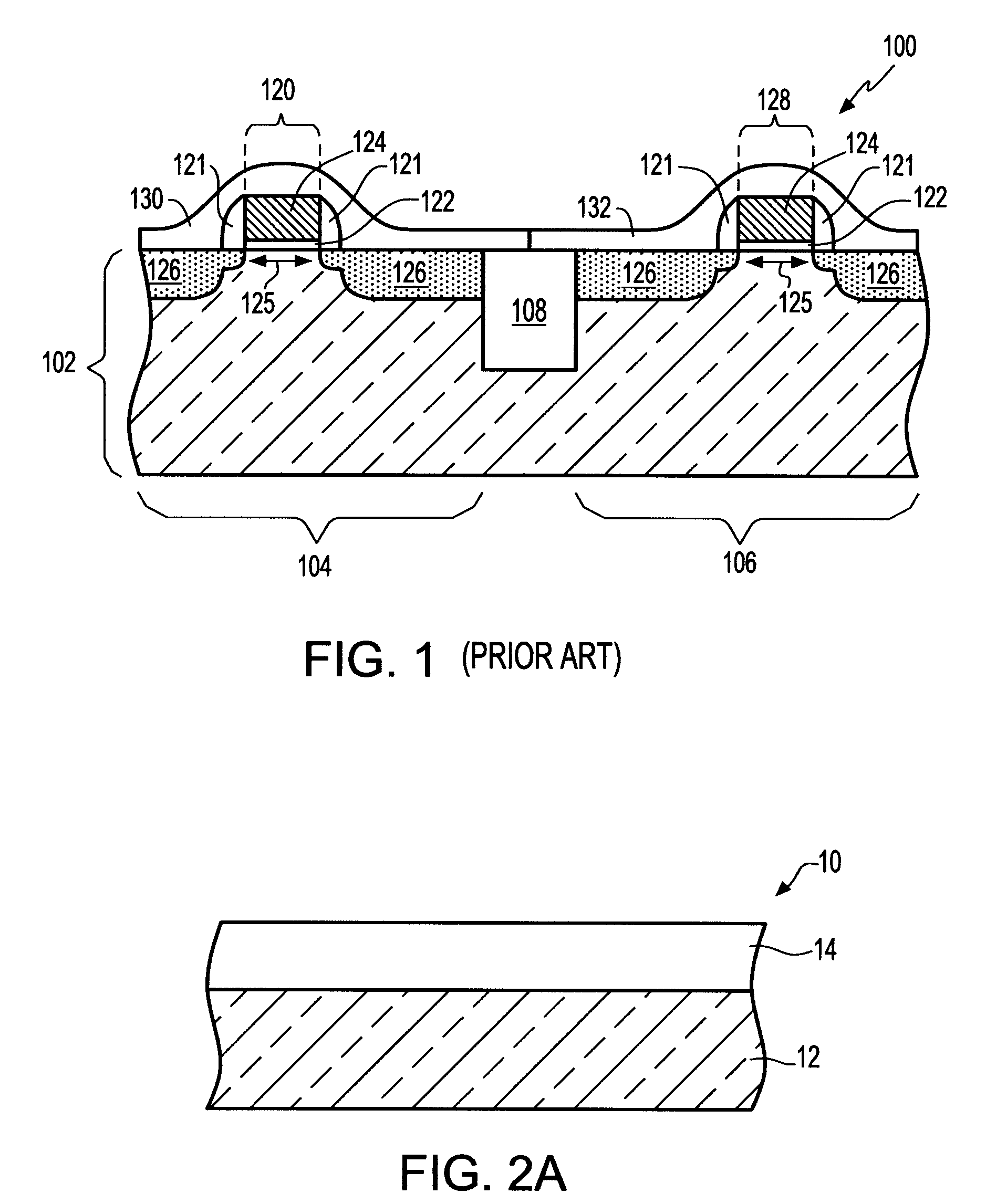

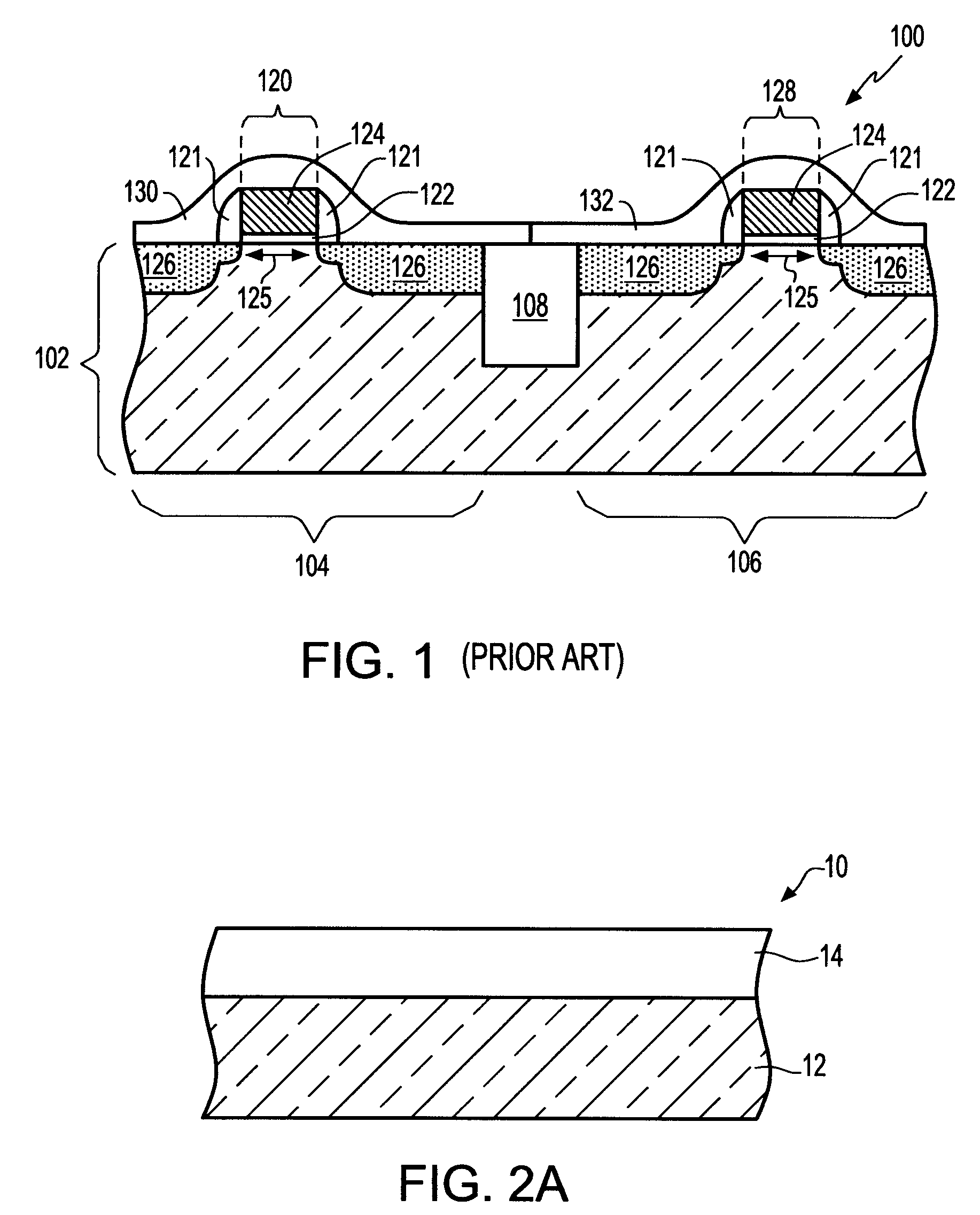

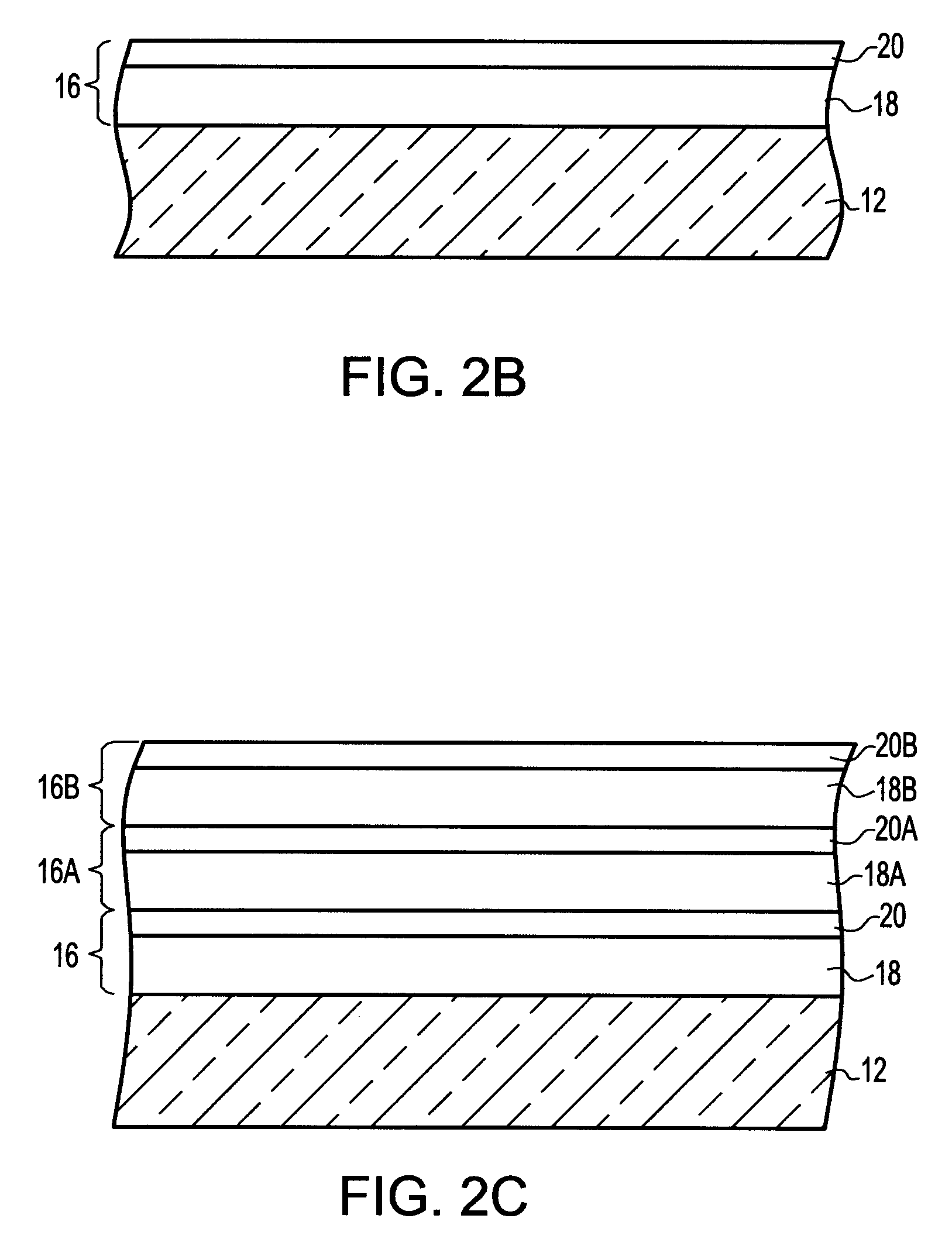

Method of producing highly strained pecvd silicon nitride thin films at low temperature

InactiveUS20060223290A1Increase pressureImprove stress conditionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingStressorMaterials science

A method for increasing the level of stress for amorphous thin film stressors by means of modifying the internal structure of such stressors is provided. The method includes first forming a first portion of an amorphous film stressor material on at least a surface of a substrate, said first portion having a first state of mechanical strain defining a first stress value. After the forming step, the first portion of the amorphous film stressor material is densified such that the first state of mechanical strain is not substantially altered, while increasing the first stress value. In some embodiments, the steps of forming and densifying are repeated any number of times to obtain a preselected and desired thickness for the stressor.

Owner:GLOBALFOUNDRIES INC

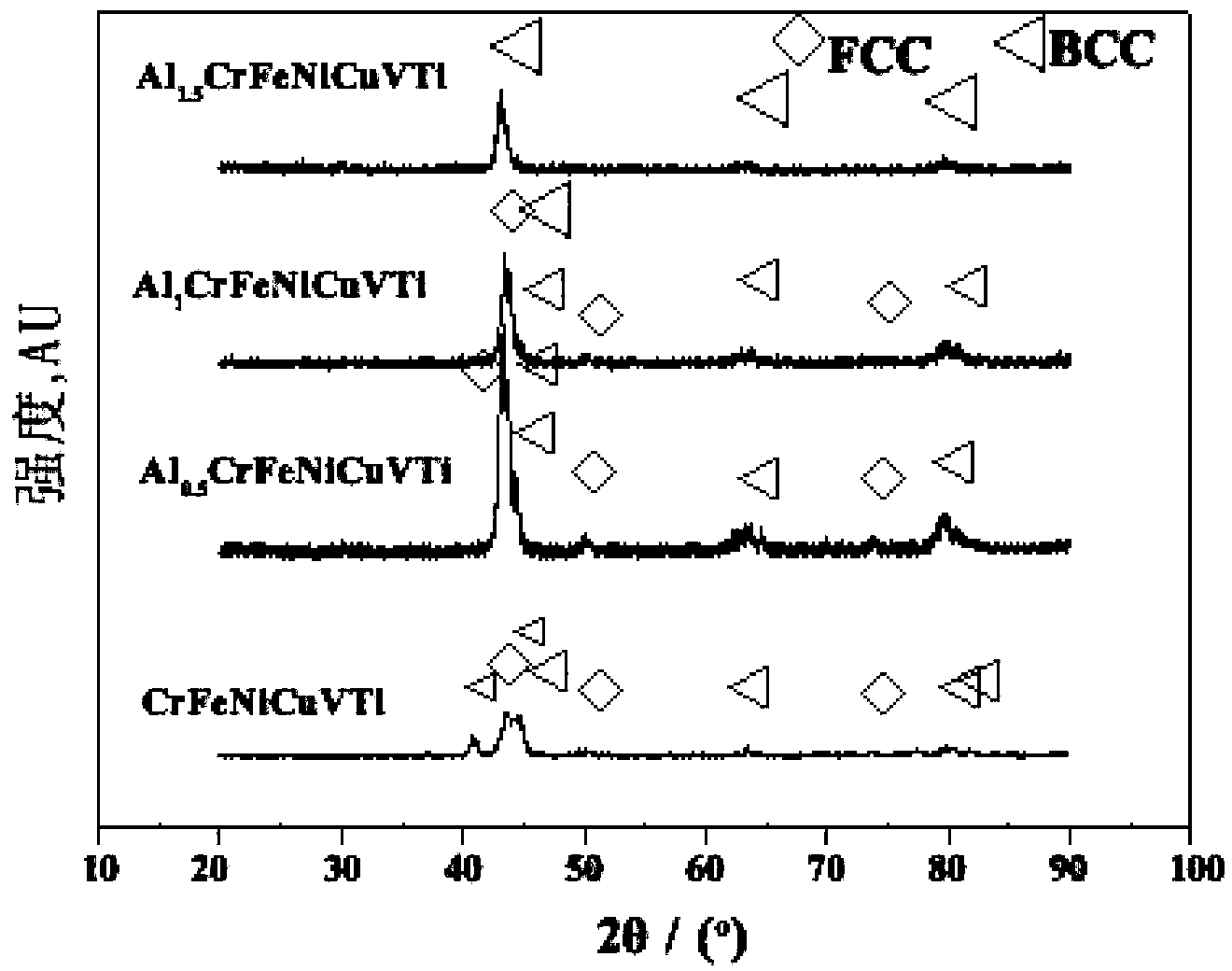

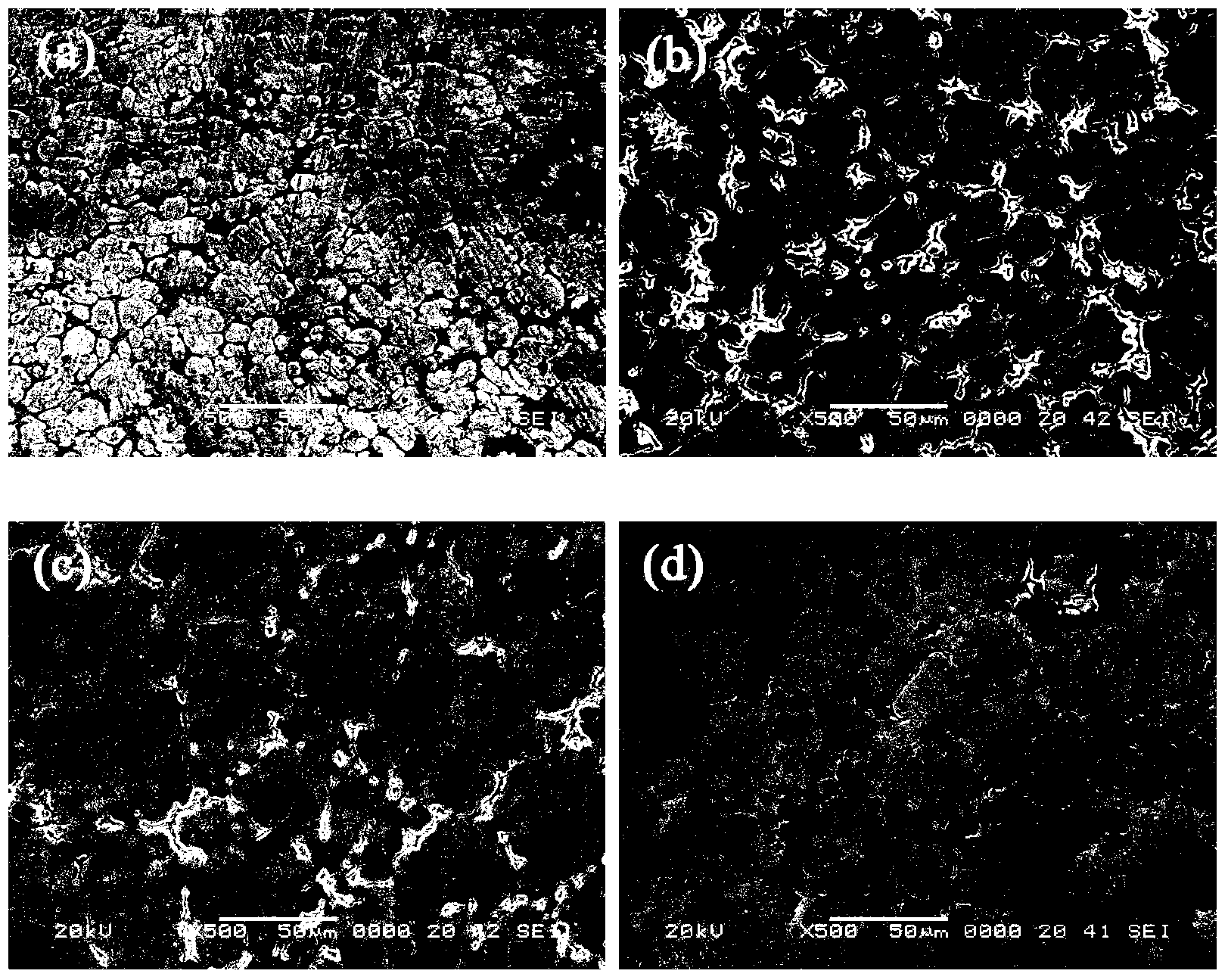

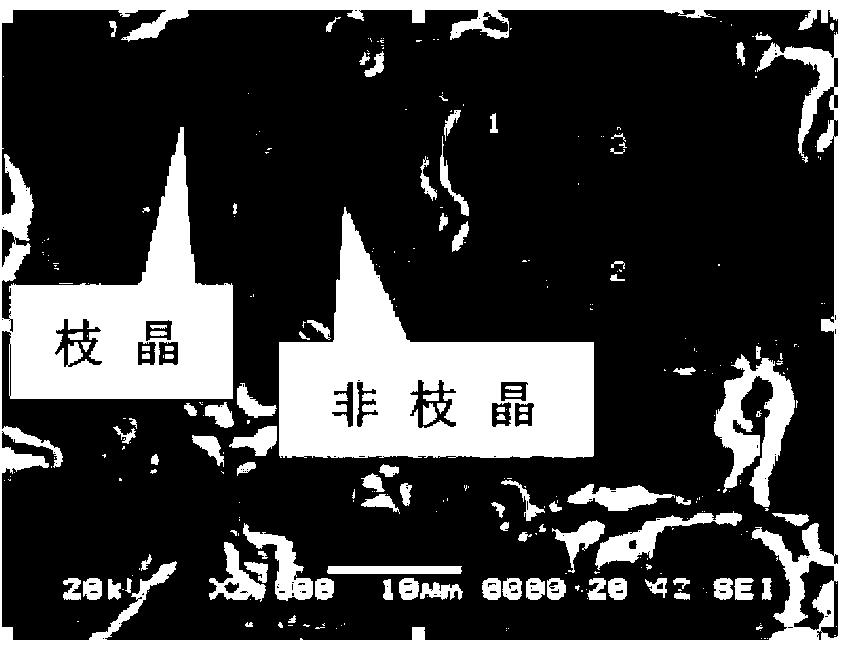

AlxCrFeNiCuVTi high-entropy alloy material and preparation method thereof

The invention relates to an AlxCrFeNiCuVTi high-entropy alloy material and a preparation method thereof. The high-entropy alloy comprises a component of AlxCrFeNiCuVTi, wherein x is a molar ratio, and the value range of x is 0.5-1.5. The preparation method of the alloy material comprises the following steps of: putting raw materials into a solution including acetone and ethanol, cleaning for 23-30 minutes by using an ultrasonic oscillator, and then drying in a 50DEG C drying oven for 6 hours; weighing alloys according to a molar ratio, and putting the alloys into a water-cooling copper crucible; when the air pressure in a furnace body reaches 3*10<-3>Pa, introducing high-purity argon to clean for 3-5 times; introducing high-purity argon to ensure that the air pressure in a furnace chamber is kept to be 0.8-0.9 atmospheric pressure, and then electrifying, wherein the smelting striking current is 30-40A, the current after stabilization is 90A, the time for smelting the alloys once is 10 seconds, and a sample needs to be smelted for 5 times repeatedly; and when the components of a smelted sample are uniformly cooled, taking the alloy out of the furnace. Compared with a conventional crystal alloy, the AlxCrFeNiCuVTi high-entropy alloy material has higher hardness, strength, high temperature stability, corrosion resistance and work hardening capacity.

Owner:梧州漓佳铜棒有限公司

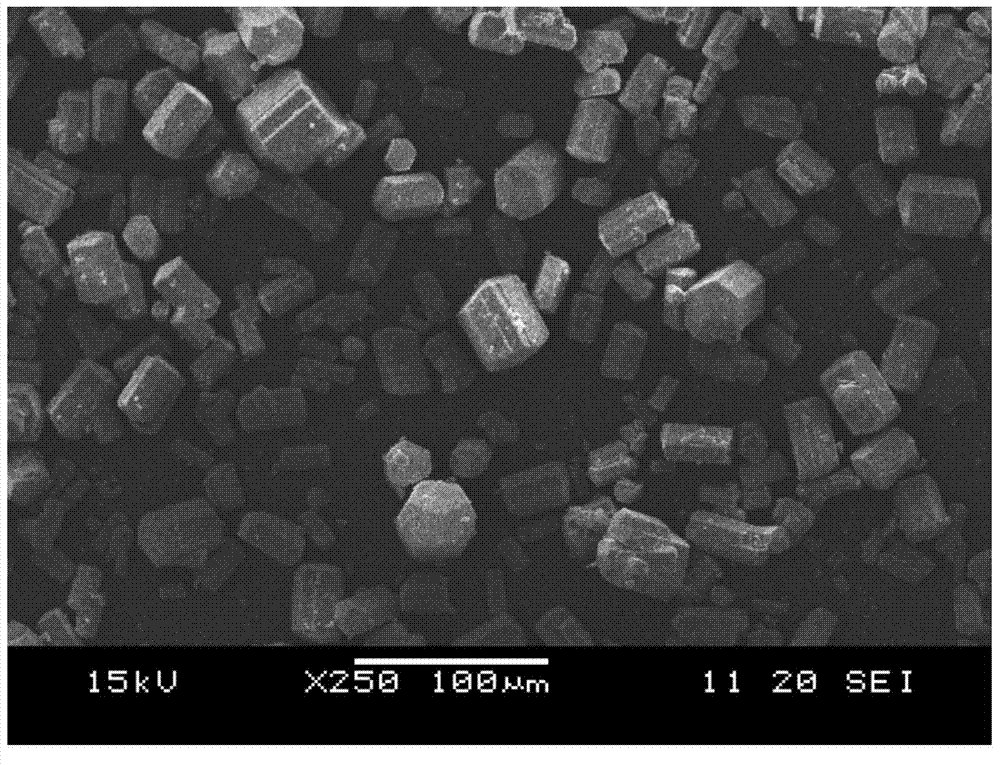

Gypsum material for 3D printing and preparation method thereof

ActiveCN104744000AHigh mechanical strengthGood dispersionAdditive manufacturing apparatusFilling materials3d printer

The invention discloses a gypsum material for 3D printing. The gypsum material is that a gypsum product is printed and formed through 1 part by mass of powder and 0.25 to 1 part by mass of liquid-phase material by a 3D printer, wherein the powder is prepared from the following raw materials in parts by mass: 90 to 98 parts of hemihydrate gypsum, 1 to 10 parts of filling material, and 0 to 2 parts of fibers; the liquid-phase material is prepared from the following raw materials in parts by mass: 80 to 90 parts of water, 5 to 15 parts of flexible adhering material, and 1 to 5 parts of coagulating material. The invention further discloses a preparation method of the gypsum material for 3D printing; the gypsum material is prepared by mixing and uniformly agitating all raw materials. The gypsum material for 3D printing and the preparation method have the advantage that the problems of small strength, poor fluidity, large fineness and poor flexibility in the prior art can be solved.

Owner:NANJING UNIV OF TECH

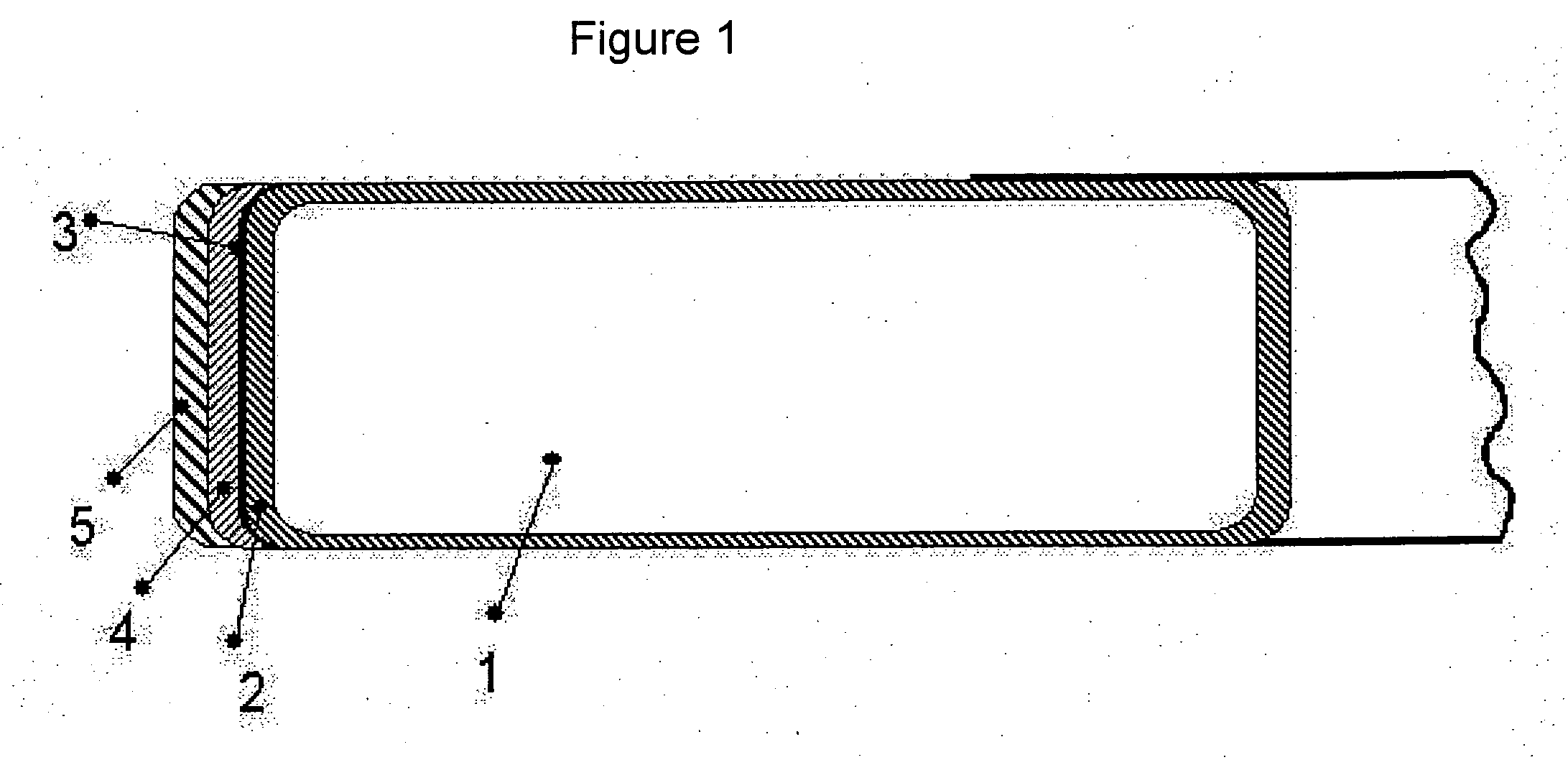

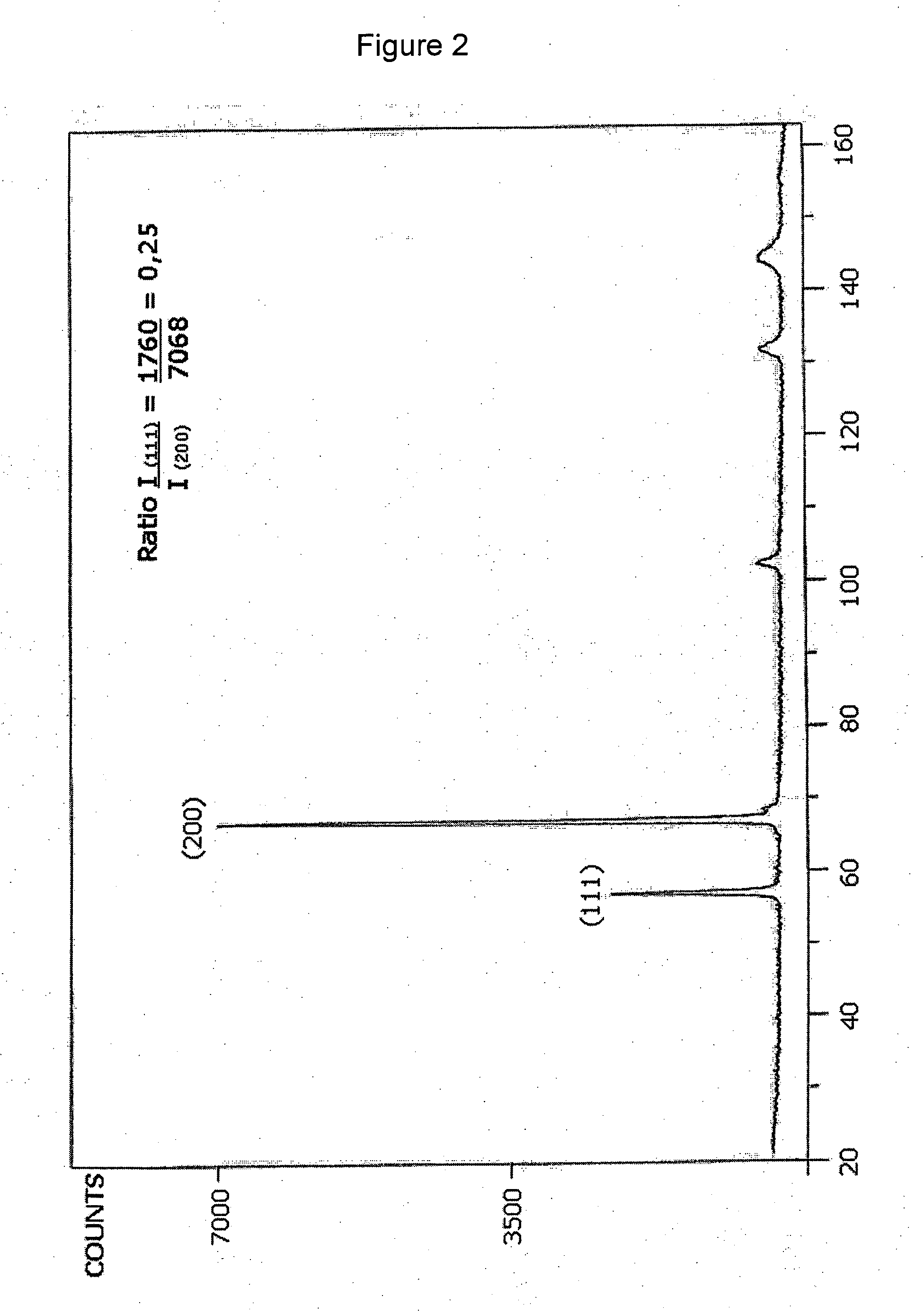

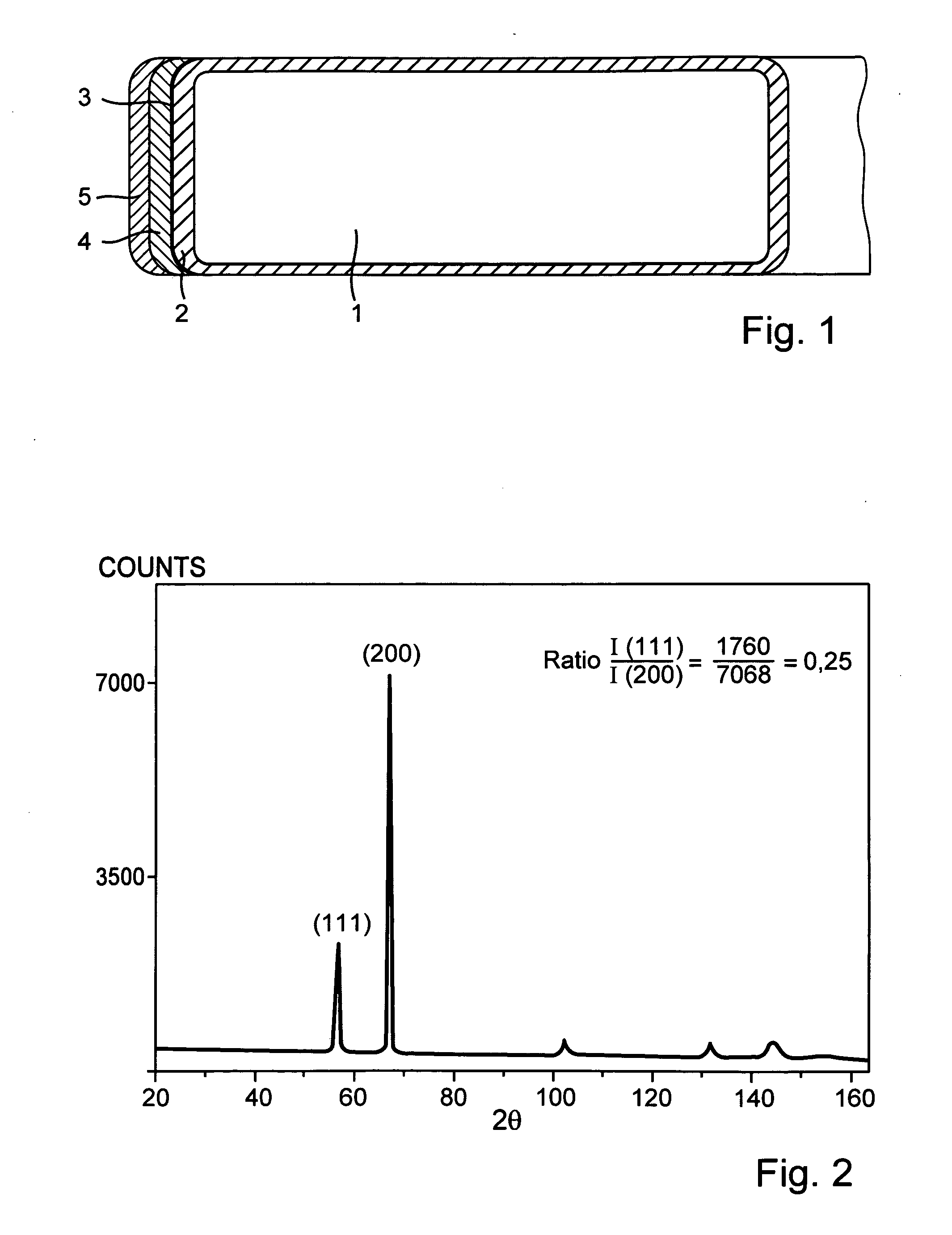

Piston ring for internal combustion engines

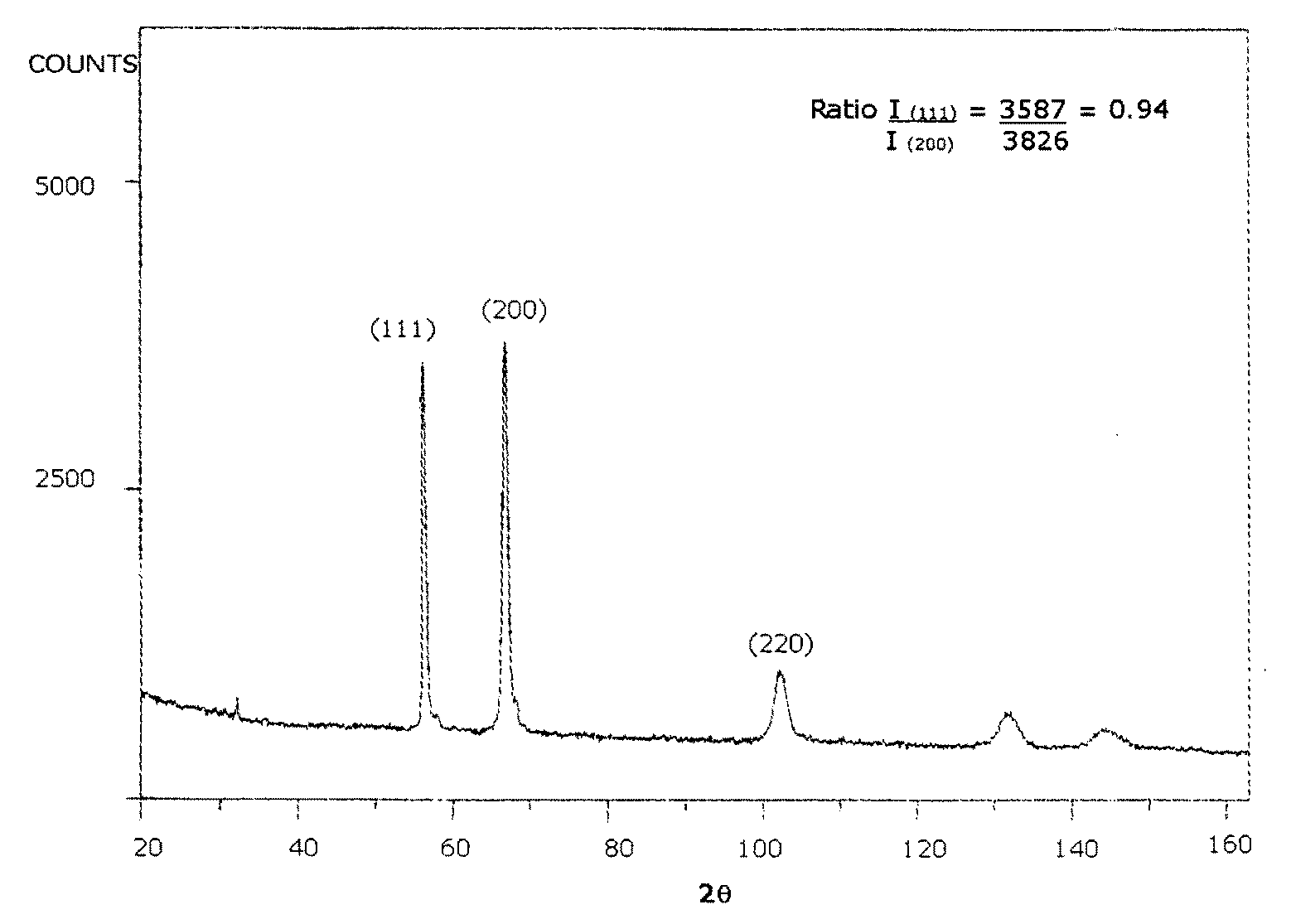

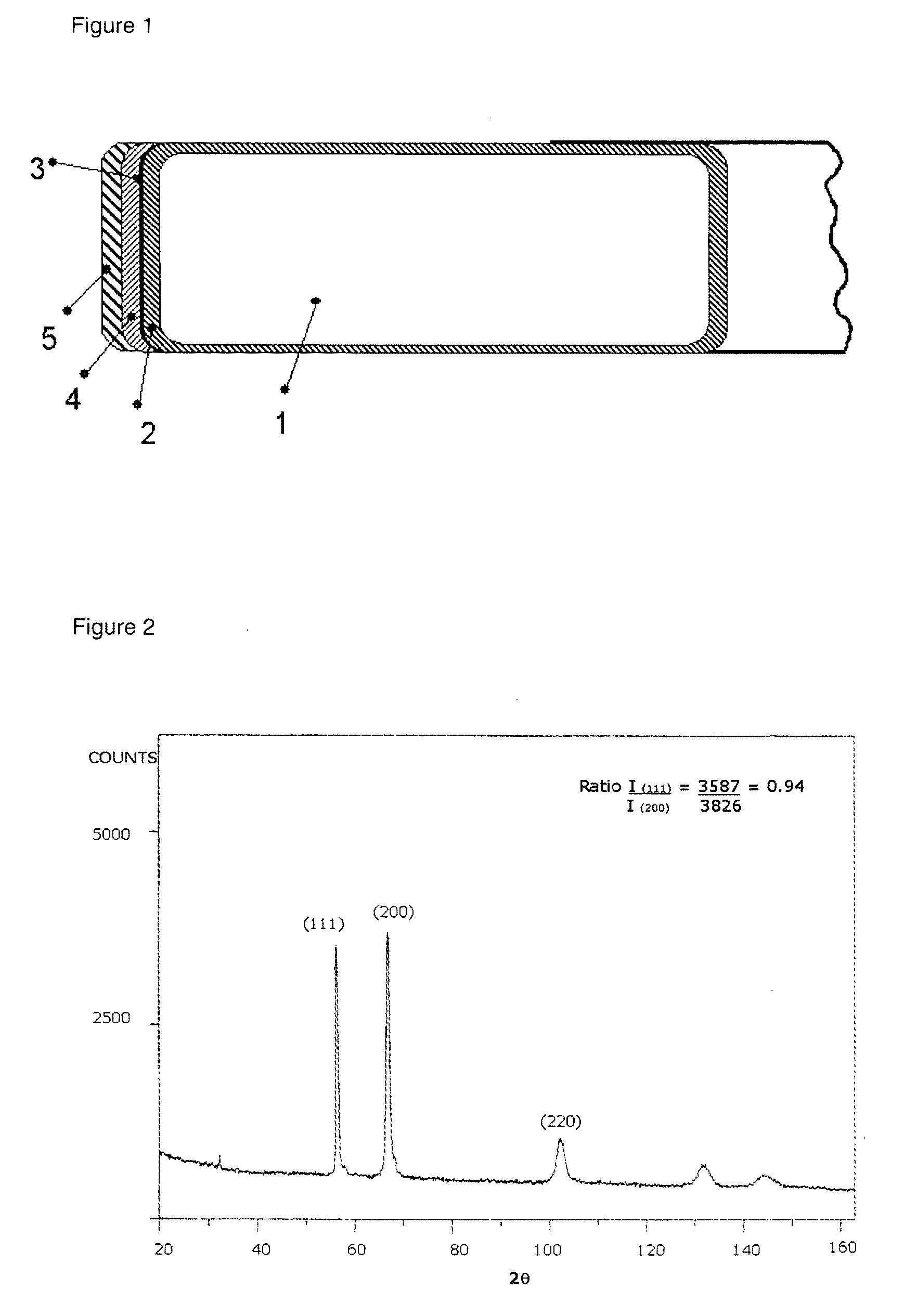

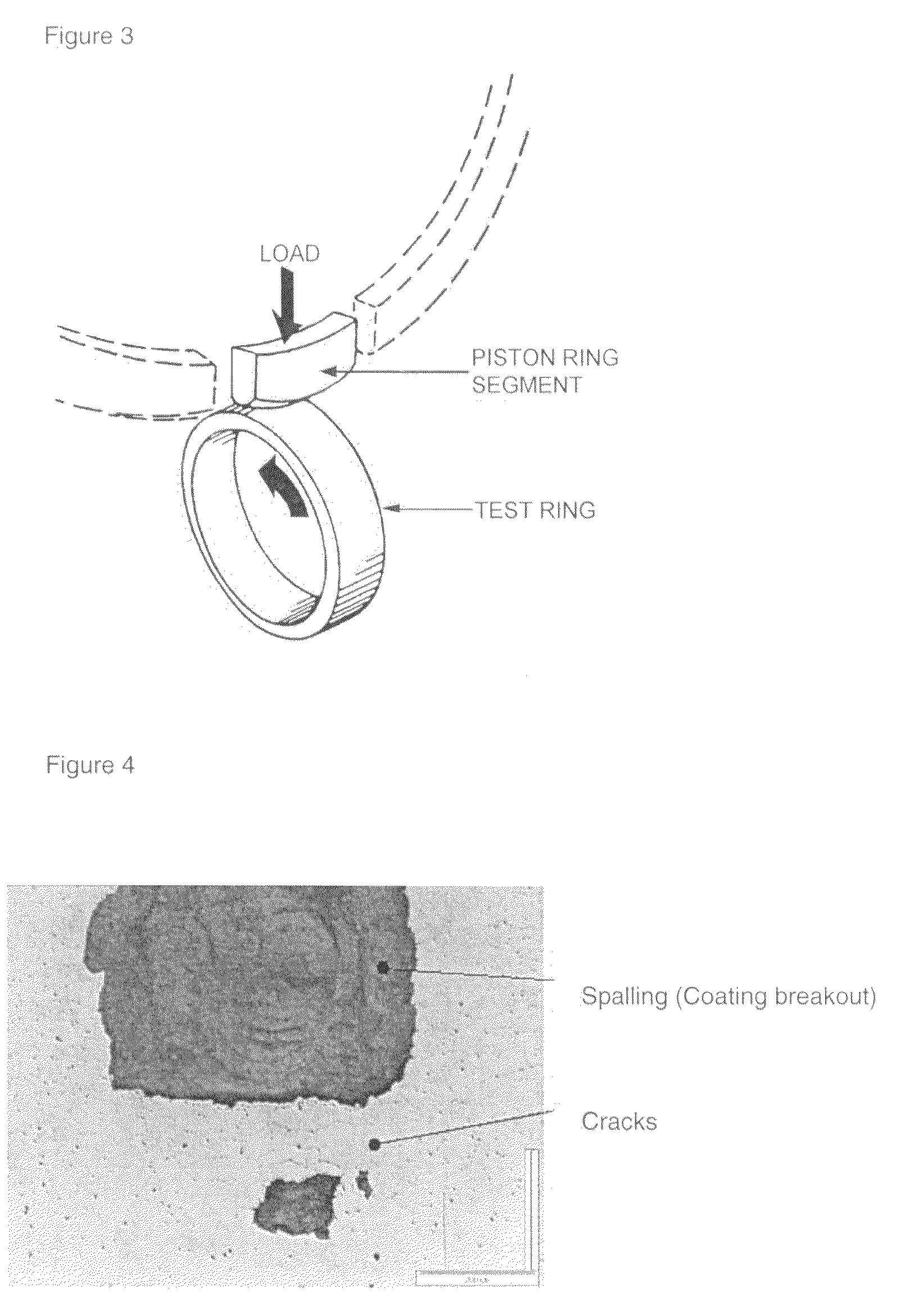

InactiveUS20060269790A1Promote absorptionReduce toughnessPiston ringsVacuum evaporation coatingCrazingEngineering

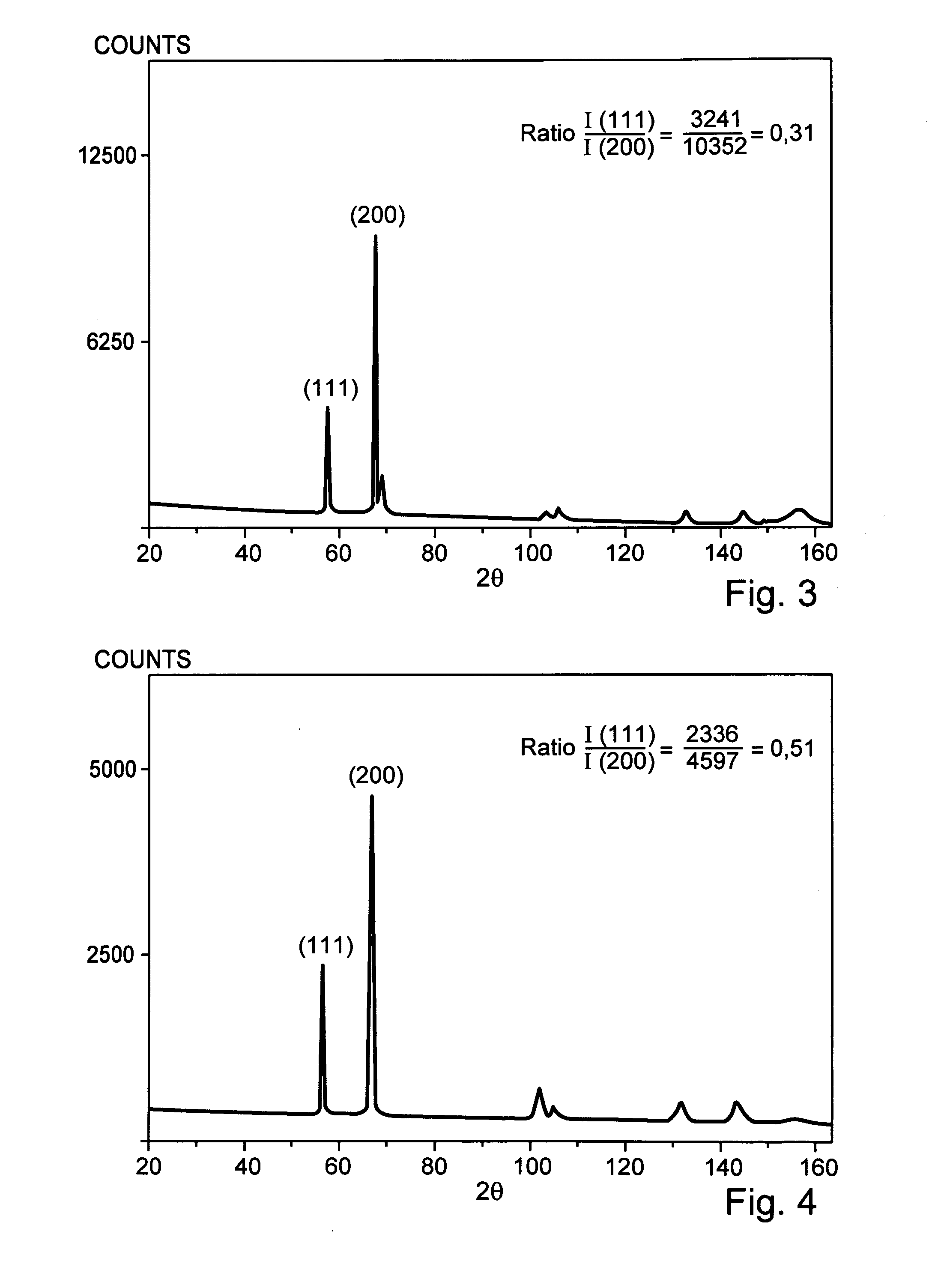

A piston ring for internal combustion engines with a coating of Chromium nitride (CrN) deposited by a physical vapor deposition process on a sliding surface with a typical crystal structure of CrN phase, has a high wear resistance and superior resistance to the generation of micro-cracks and consequent localized loss of pieces of the coating. The coating is a columnar crystalline coating of CrN having a dispersed pore content lower than 10% in volume and ratio of intensities, measured through x-ray diffraction, between the crystal planes (111) and planes (200), parallel to the surface, in the range of 0.40 to 0.70. This crystalline distribution is obtained through an oxygen content impregnated in the CrN coating between 1.0% in weight to 7.0% in weight. The Vickers hardness of the film ranges from 1,500 to 2,200 HV.

Owner:MAHLE METAL LEVE +1

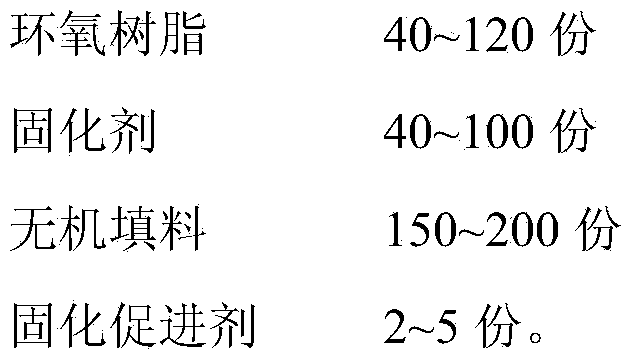

Outdoor electric-insulation modified epoxy resin composition

The invention discloses an outdoor electric-insulation modified epoxy resin composition which comprises an epoxy resin, a curing agent, a curing accelerator and an inorganic filler. The outdoor electric-insulation modified epoxy resin composition has the advantages of high weather resistance, favorable hydrophobicity, high volume resistivity, high tracking resistance, high arc resistance, low thermal expansivity and the like, and can be used for manufacturing suspension insulators for alternating current transmission lines as well as umbrella skirts of cross arms and other outdoor insulation parts. Compared with the silicon rubber umbrella skirt, the umbrella skirt prepared from the composition can prevent birds from damage, resist line walking trampling, avoid shipping damage and the like.

Owner:赛思迈(上海)新材料科技有限公司

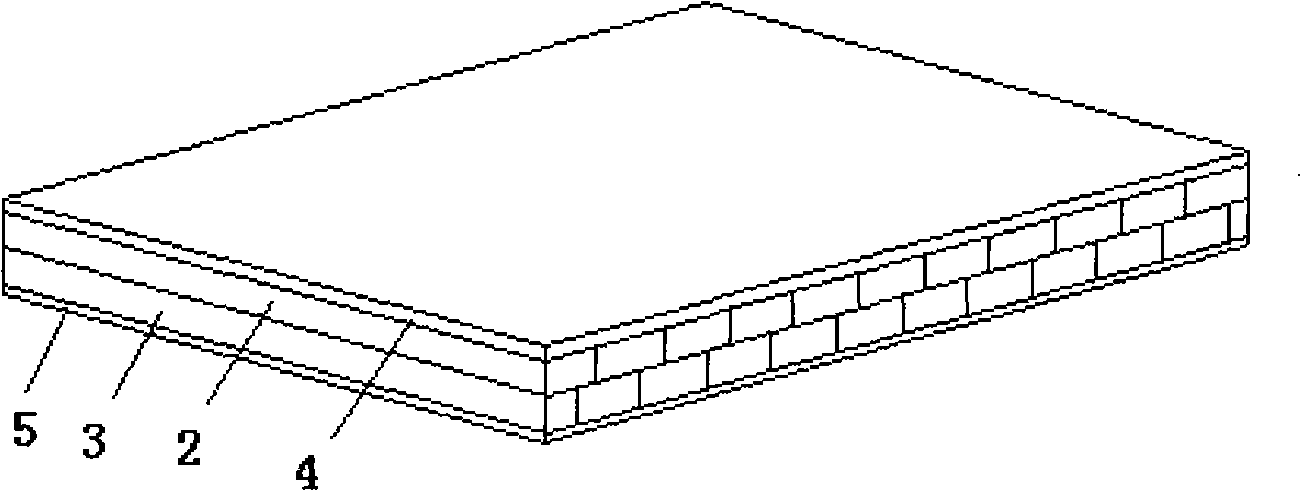

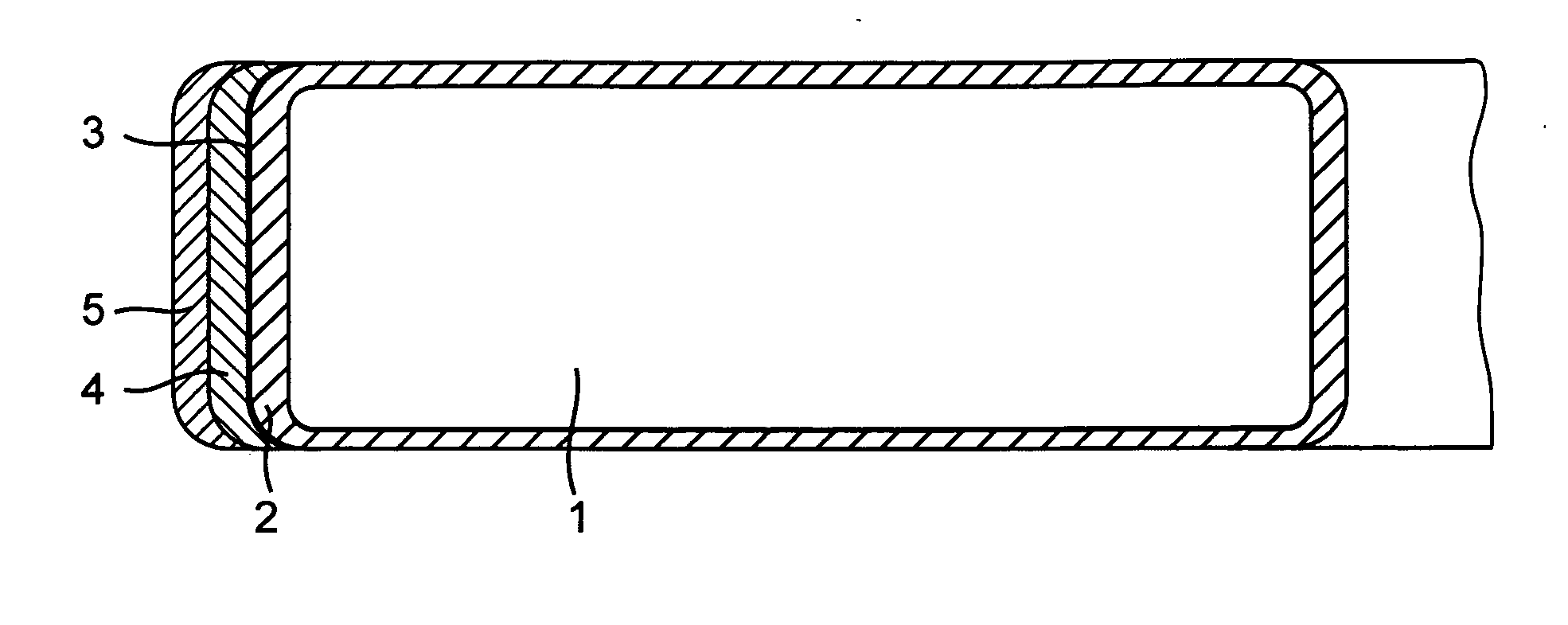

Piston ring with chromium nitride coating for internal combustion engines

ActiveUS20090278320A1Improve the immunityHigher absorption of internal compressive stressesPiston ringsBraking action transmissionGas phaseX-ray

The invention relates to a piston ring for internal combustion engines, the piston ring comprises a steel or cast iron base material with a coating of chromium nitride deposited by a physical vapor deposition process on a sliding surface of the piston ring, wherein the coating is composed of a columnar crystal structure of CrN with the following features:(a) an oxygen content in solid solution of 0.5 to 2.5 wt %;(b) a content of uniformly dispersed micro-pores of less than 10% in volume of the coating; and(c) an X-ray diffraction intensity ratio of (111) planes to (200) planes parallel to the surface in the range of 0.80 to 1.20.

Owner:MAHLE INT GMBH +1

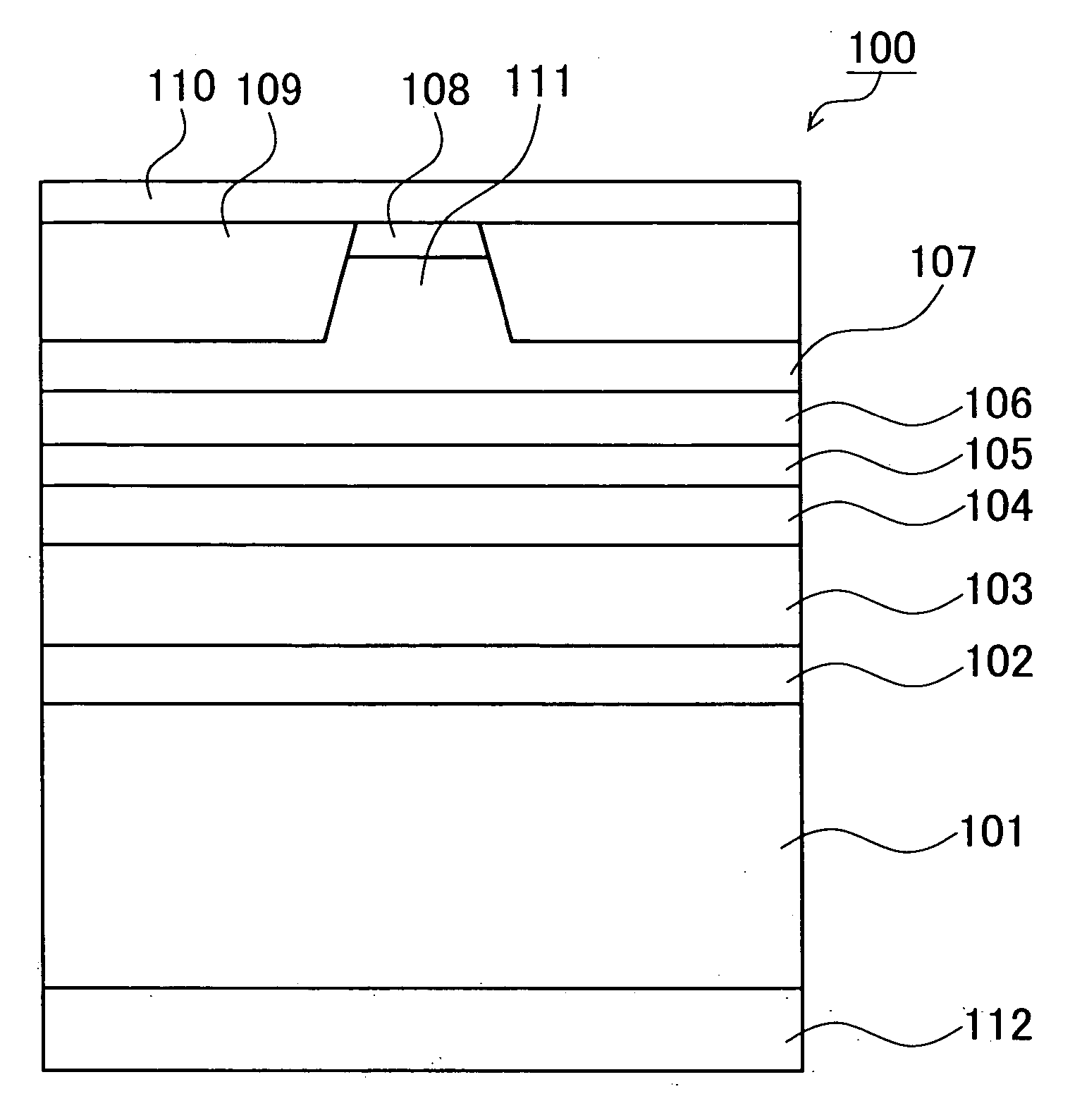

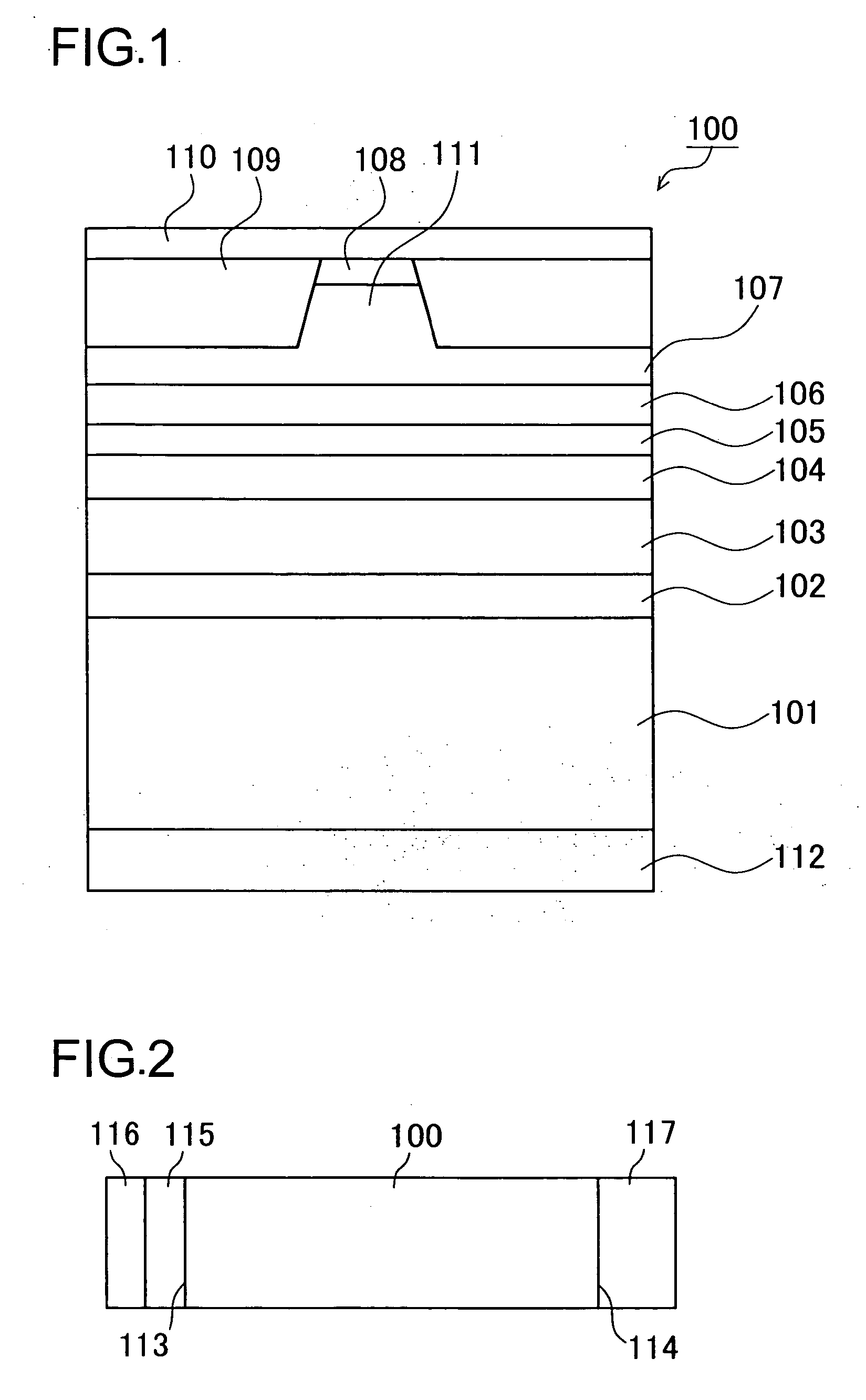

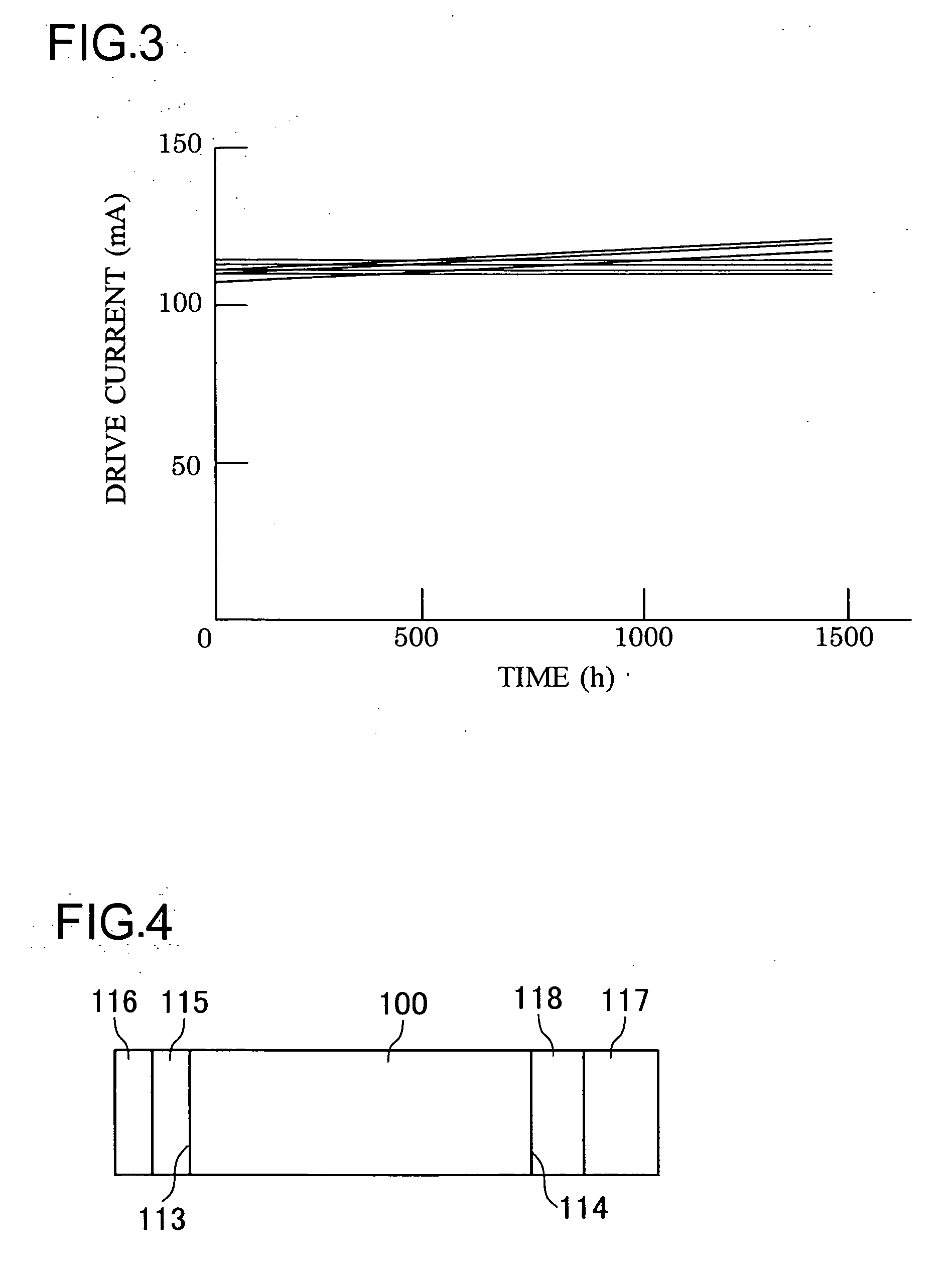

Nitride semiconductor light-emitting device and method of manufacture thereof

ActiveUS20070080368A1Improve adhesionImprove reliabilityLaser detailsSemiconductor/solid-state device manufacturingLight emitting deviceNitride semiconductors

In a nitride semiconductor laser bar including a group III-V nitride semiconductor layer, on the front-side cavity end face, a separation layer of aluminum nitride is laid, and further on the separation layer, an end face coating film of aluminum oxide is laid. Likewise, on the rear-side cavity end face, a separation layer of aluminum nitride is laid, and further on the separation layer, an end face coating film of an aluminum oxide / TiO2 multilayer film is laid.

Owner:SHARP FUKUYAMA LASER CO LTD

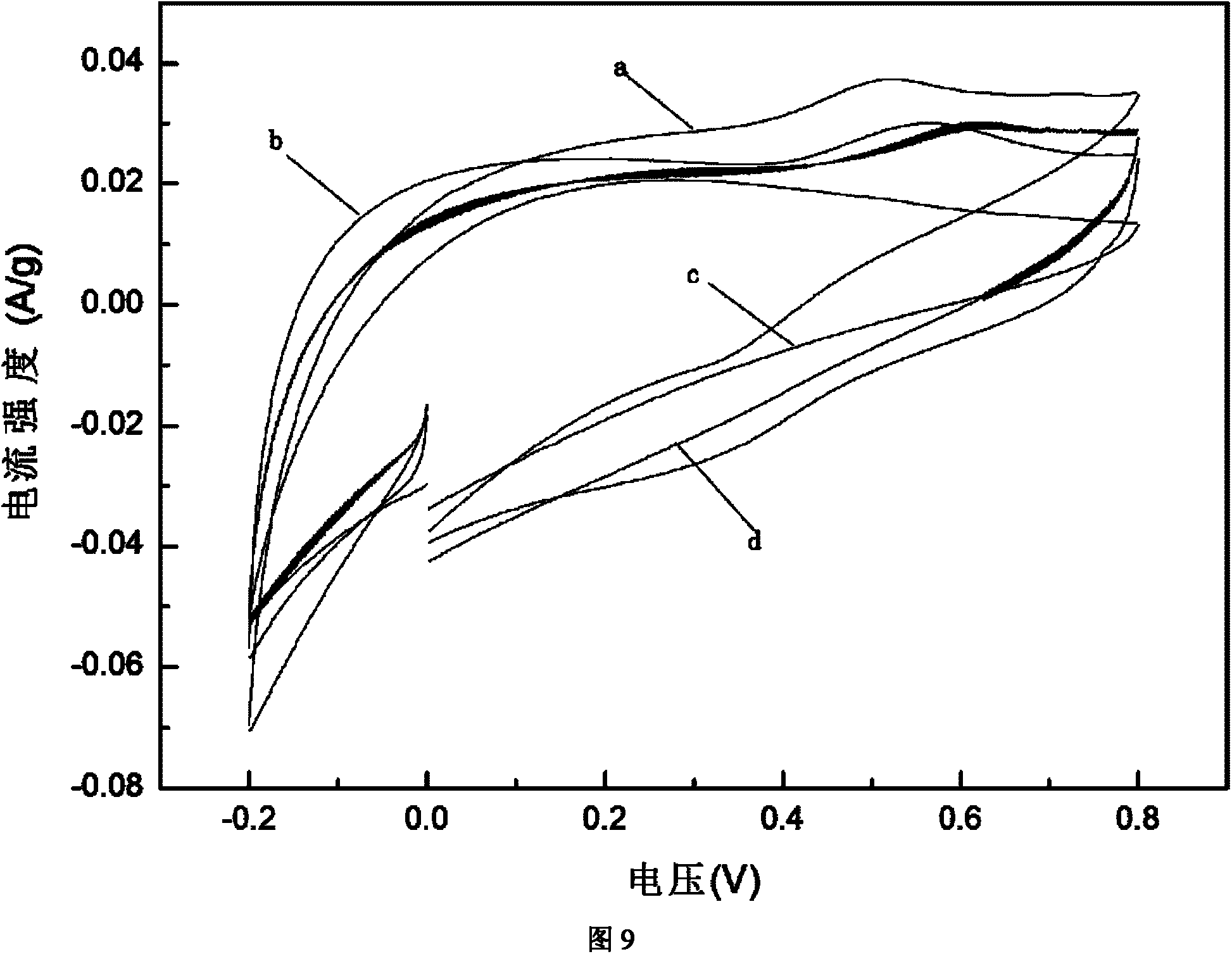

Method for preparing carbide film by carbonizing graphene reinforced polyimide resin

ActiveCN102560453AIncrease internal stressReduce brittlenessSolid/suspension decomposition chemical coatingCapacitancePolymer science

The invention discloses a method for preparing a carbide film by carbonizing graphene reinforced polyimide resin, and relates to a method for preparing a carbide film. The method solves the technical problems of high carbonizing temperature, high energy consumption, long carbonizing period and low carbonizing rate and low strength of the carbide film in the conventional method for preparing the carbide film. The method comprises the following steps of: 1, adding 4,4'-diamino diphenyl ether (ODA) and 3,3',4,4'-benzophenonetetracarboxylic dianhydride (BTDA) into N,N-dimethyl acetamide (DMAC), and performing mechanical stirring to obtain a polyamide acid (PAA) solution; 2, adding graphene into the PAA solution, and performing in-situ polymerization reaction to obtain a solution A; 3, spreading the solution A on a clean glass plate, heating to the temperature of 60 DEG C and preserving the heat for 2 hours, heating to the temperature of 100 DEG C and preserving the heat for 1 hour, heating to the temperature of 200 DEG C and preserving the heat for 1 hour, heating to the temperature of 300 DEG C and preserving the heat for 1 hour, and thus obtaining a composite film; and 4, carbonizing, naturally cooling to room temperature, and thus obtaining the carbide film. The carbide film has excellent mechanical properties; and because the adding proportion of the graphene is increased, the mechanical properties of the carbide film are improved, the specific capacitance of the graphene is also improved, and the carbide film is suitable to be used as an electrode material.

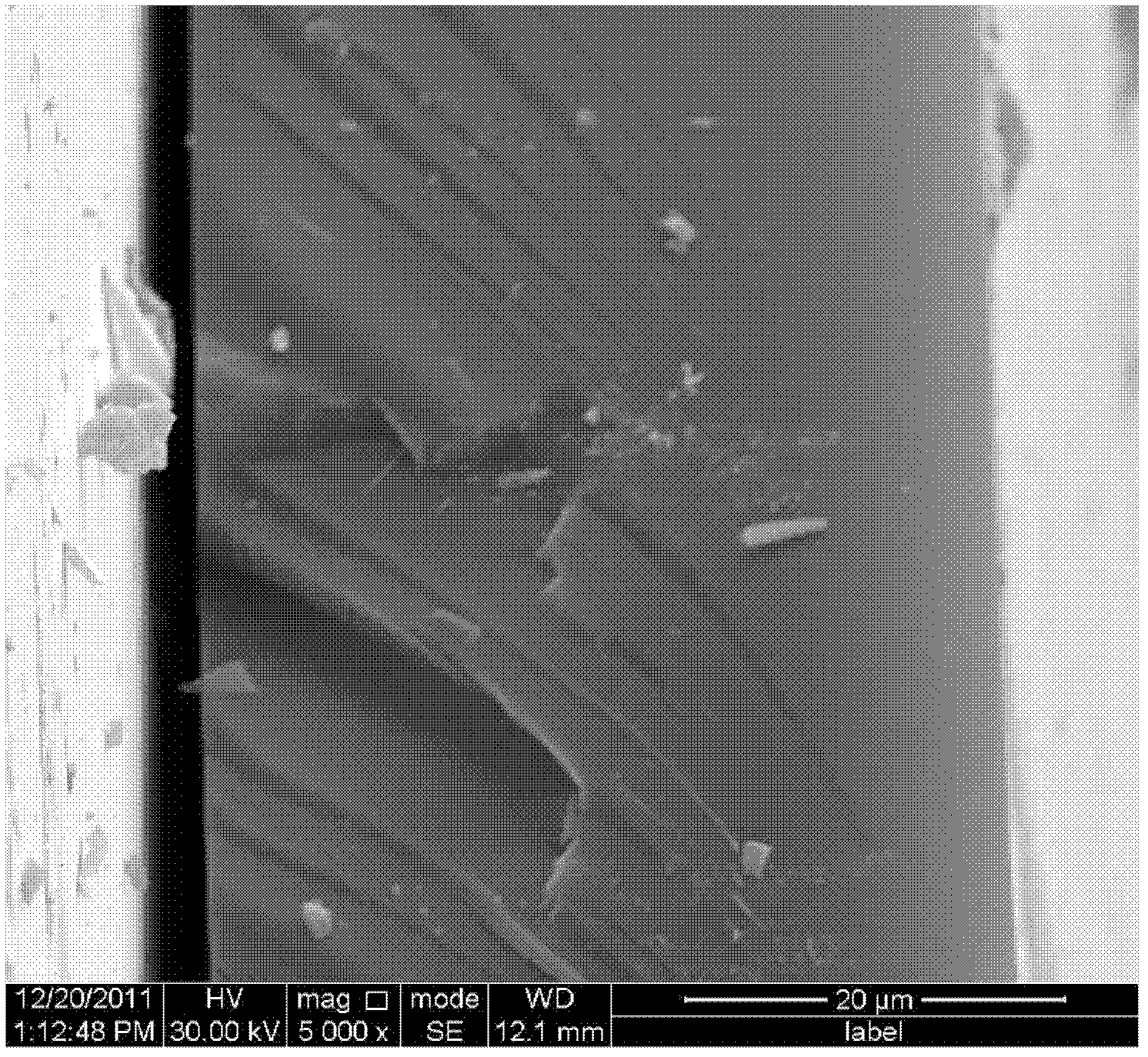

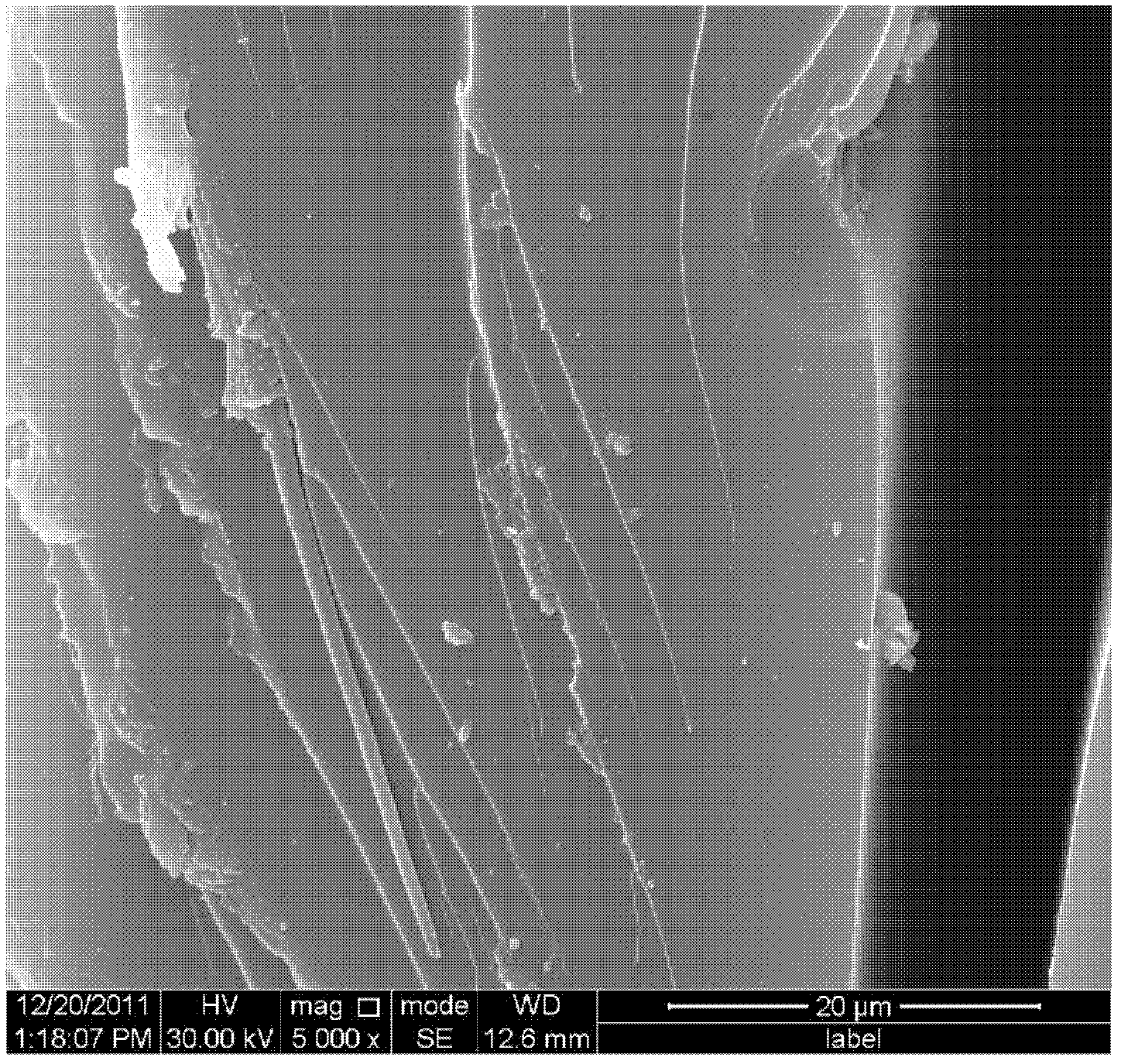

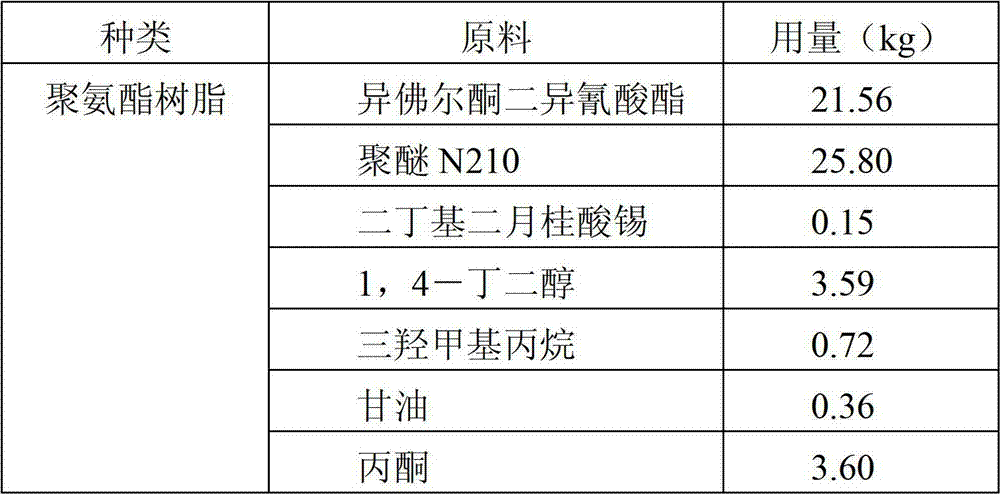

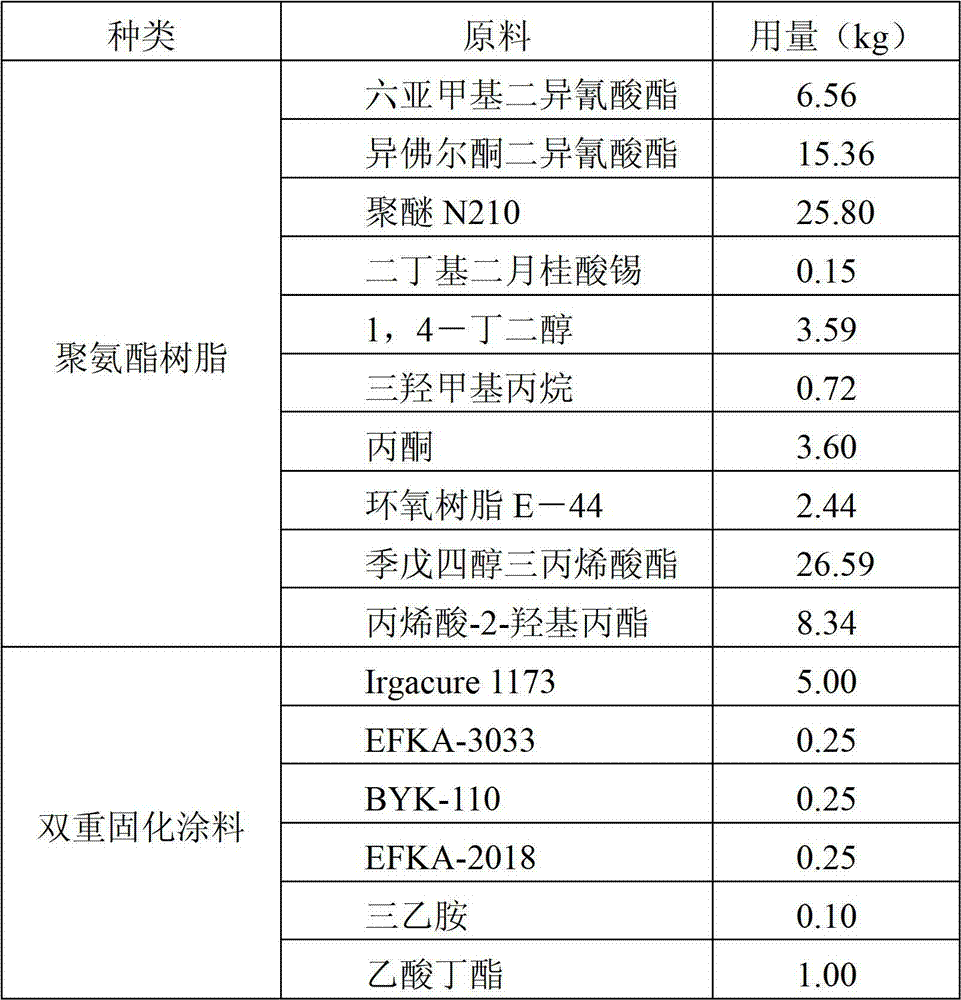

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

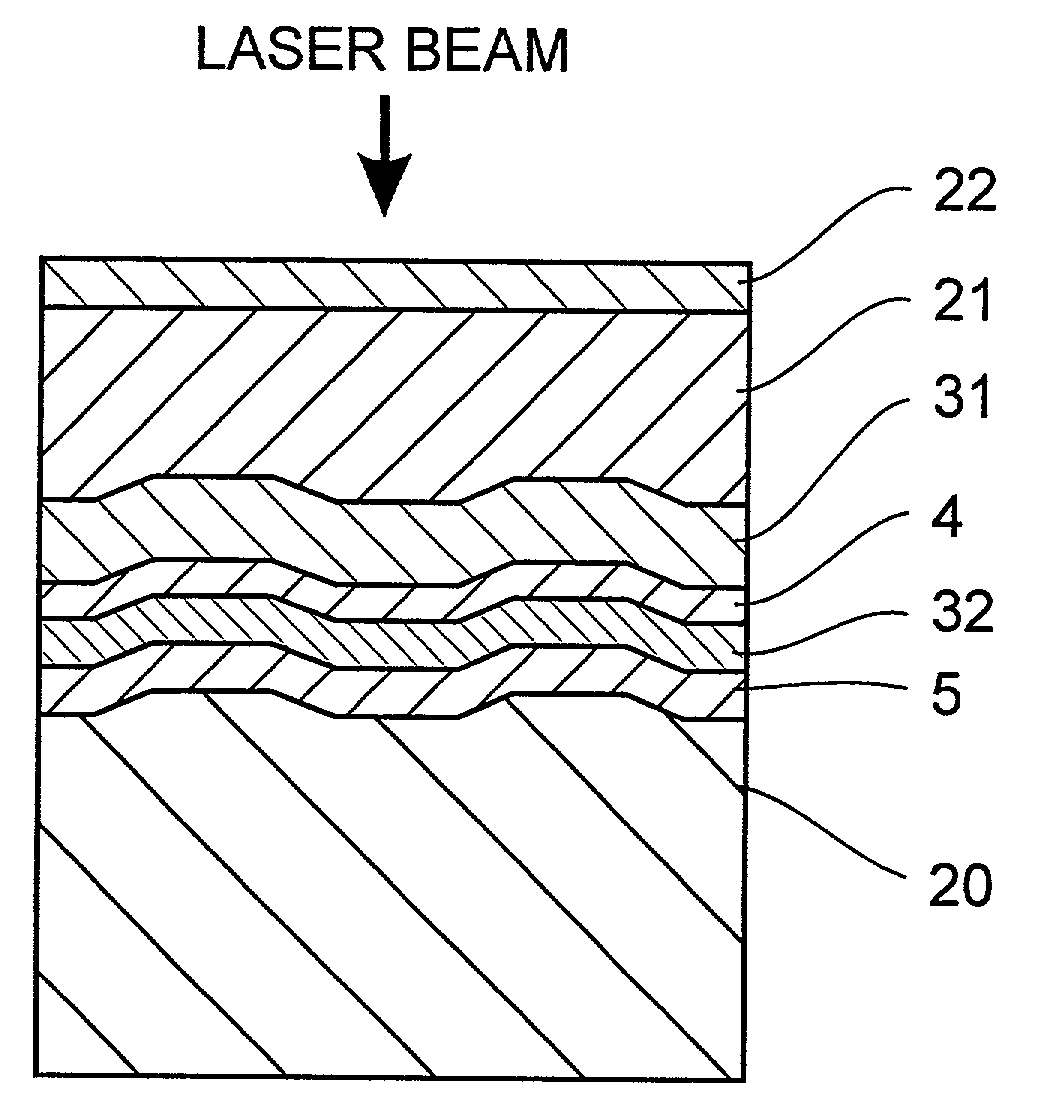

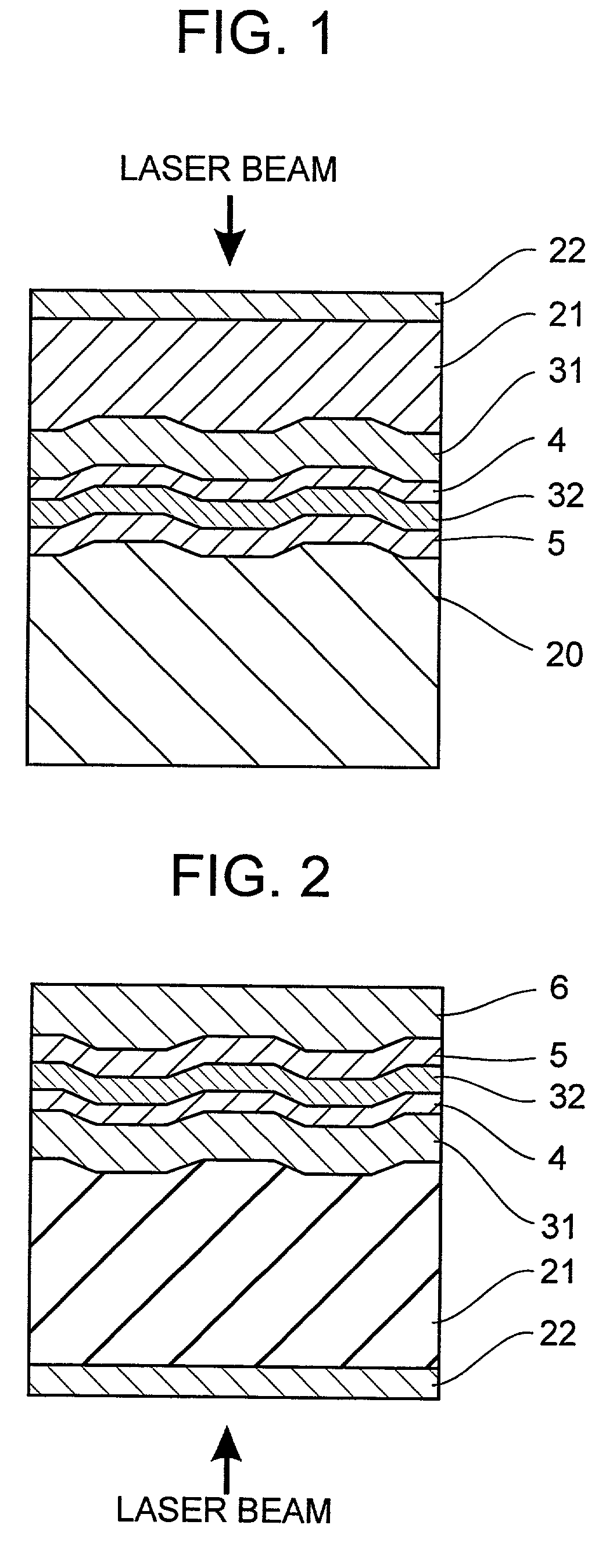

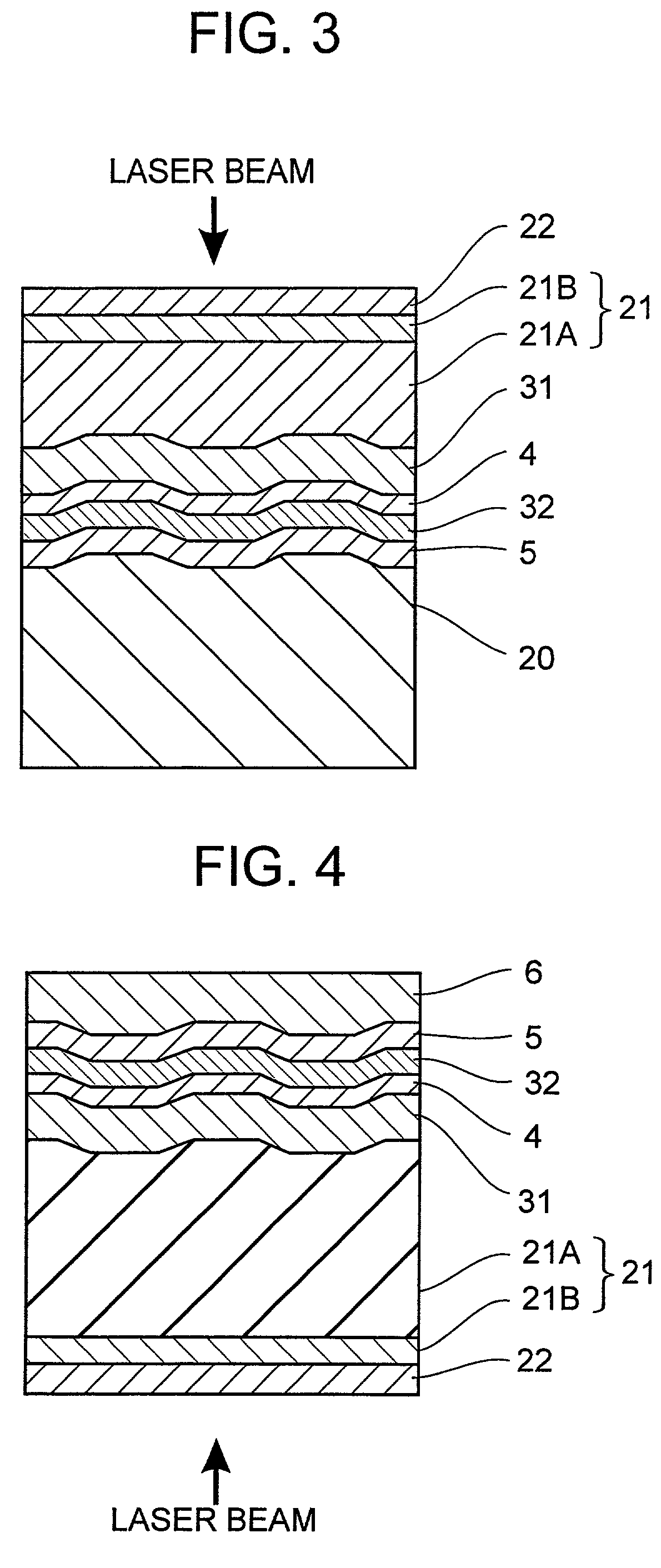

Optical information medium and evaluation method

InactiveUS20020054975A1Protect the surfaceExcellent abrasion resistanceRecord carriersInformation arrangementPolysilazaneOptical recording

An optical information medium has a light-transparent substrate and an information recording layer, wherein optical recording and / or reading is performed with a laser beam that enters the information recording layer from the light-transparent substrate side. A cured polysilazane film is disposed on the laser beam incident side of the light-transparent substrate, and the light-transparent substrate or the light-transparent substrate having the cured polysilazane film integrated thereon has a tensile modulus of at least 200 MPa. The medium on its laser beam incident side surface is improved in mar resistance.

Owner:TDK CORPARATION

Low-density ultrahigh-strength steel and preparation method thereof

ActiveCN106244927ALow costIn line with the development concept of energy saving and emission reductionChemical compositionCarbide

The invention relates to low-density ultrahigh-strength steel and a preparation method thereof, and belongs to the field of metal materials. The steel comprises the following chemical components in percentage by mass: 0.6 to 1.6 percent of C, 5 to 10 percent of Al, 15 to 30 percent of Mn, 0.01 to 0.2 percent of Nb, 0.1 to 3 percent of Mo, less than or equal to 5 percent of Cr, less than or equal to 0.5 percent of Ti, less than or equal to 2 percent of Si, less than or equal to 0.6 percent of B, and the balance of Fe and unavoidable impurity elements. According to the low-density ultrahigh-strength steel and the preparation method thereof, a NbMoC phase which is finely dispersed precipitates by compounding and adding the Nb and the Mo; precipitation is strengthened by cooperating with a kappa-carbide; the tensile strength reaches over 1,350 MPa, the elongation reaches over 10 percent and the density is 6.8 to 7.0 g / cm<3>; the low-density ultrahigh-strength steel is low in cost, is suitable for light weight of traffic transportation tools, such as vehicles and airplanes, and meets the development concept of energy conservation and emission reduction.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

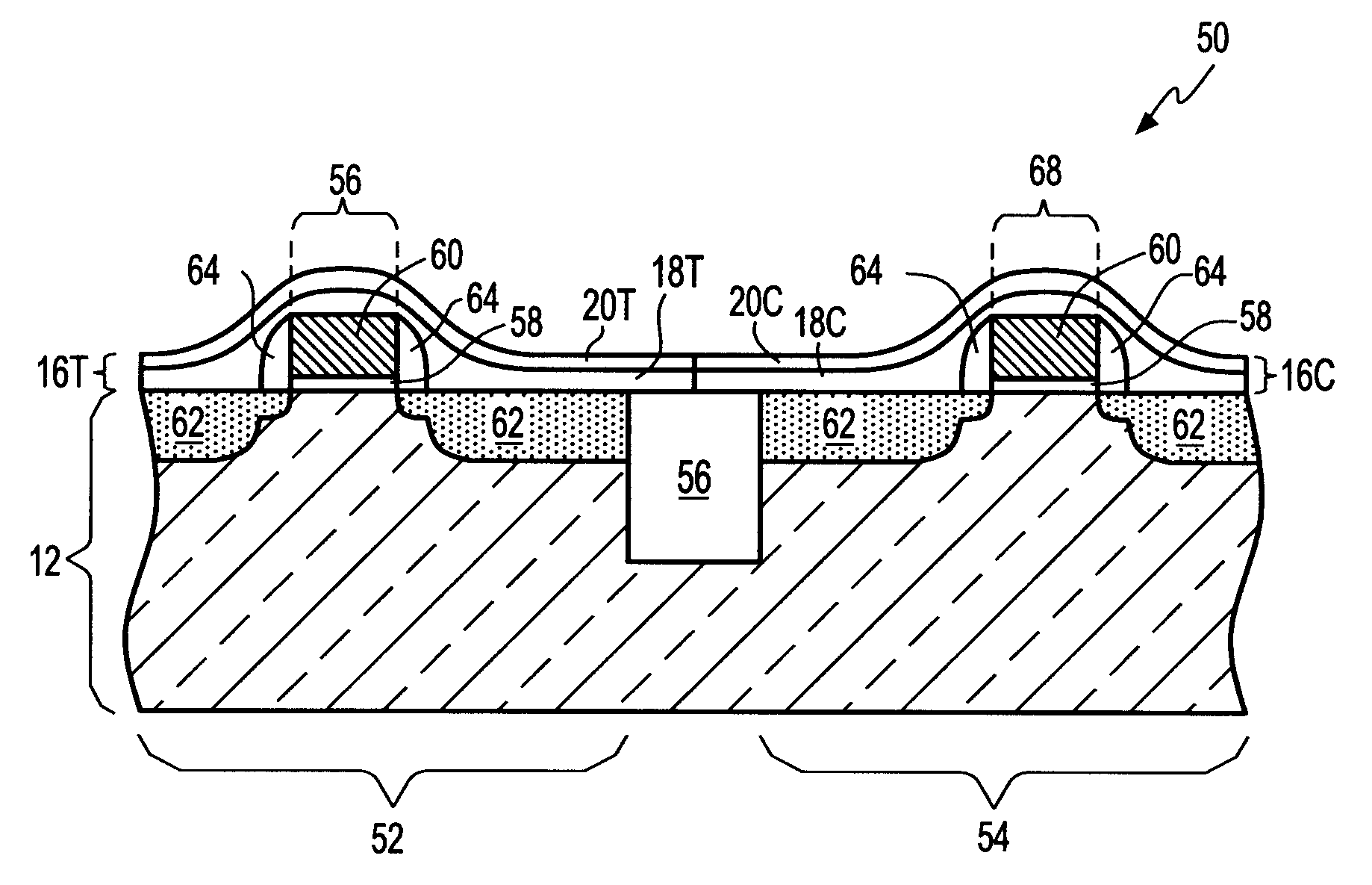

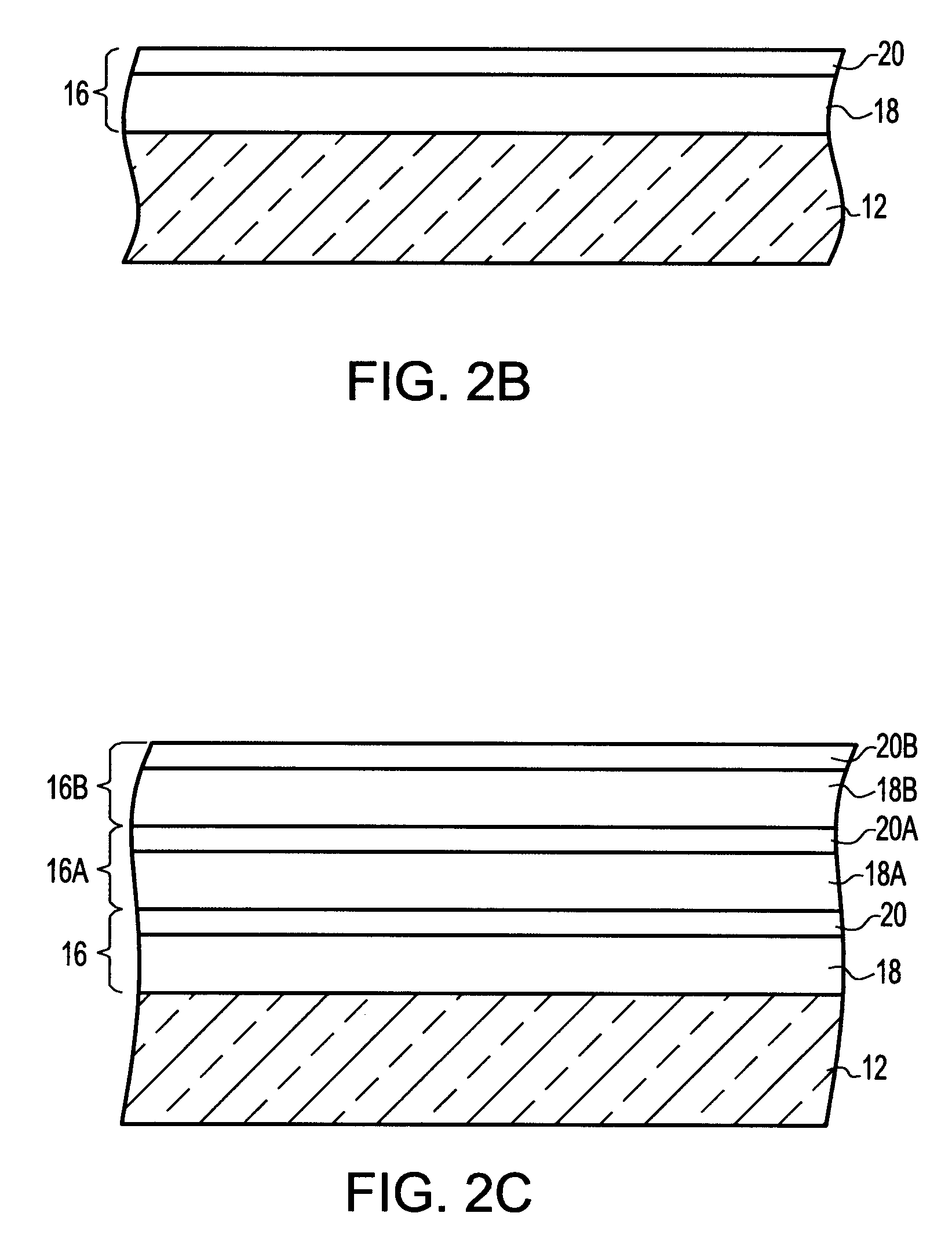

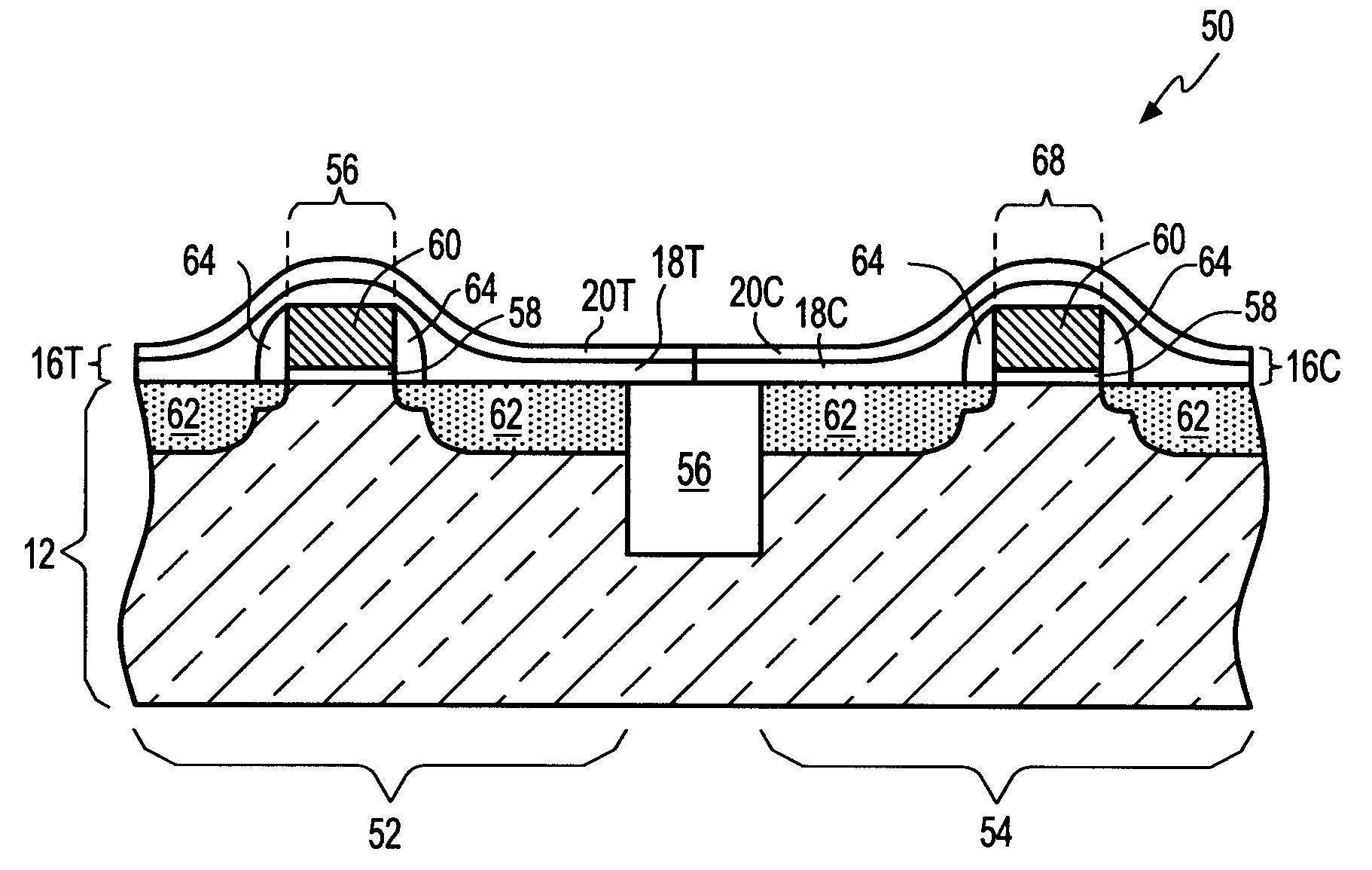

Method of producing highly strained PECVD silicon nitride thin films at low temperature

InactiveUS7585704B2Improve stress conditionIncrease the pressure valueSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThin membraneComposite material

A method for increasing the level of stress for amorphous thin film stressors by means of modifying the internal structure of such stressors is provided. The method includes first forming a first portion of an amorphous film stressor material on at least a surface of a substrate, said first portion having a first state of mechanical strain defining a first stress value. After the forming step, the first portion of the amorphous film stressor material is densified such that the first state of mechanical strain is not substantially altered, while increasing the first stress value. In some embodiments, the steps of forming and densifying are repeated any number of times to obtain a preselected and desired thickness for the stressor.

Owner:GLOBALFOUNDRIES INC

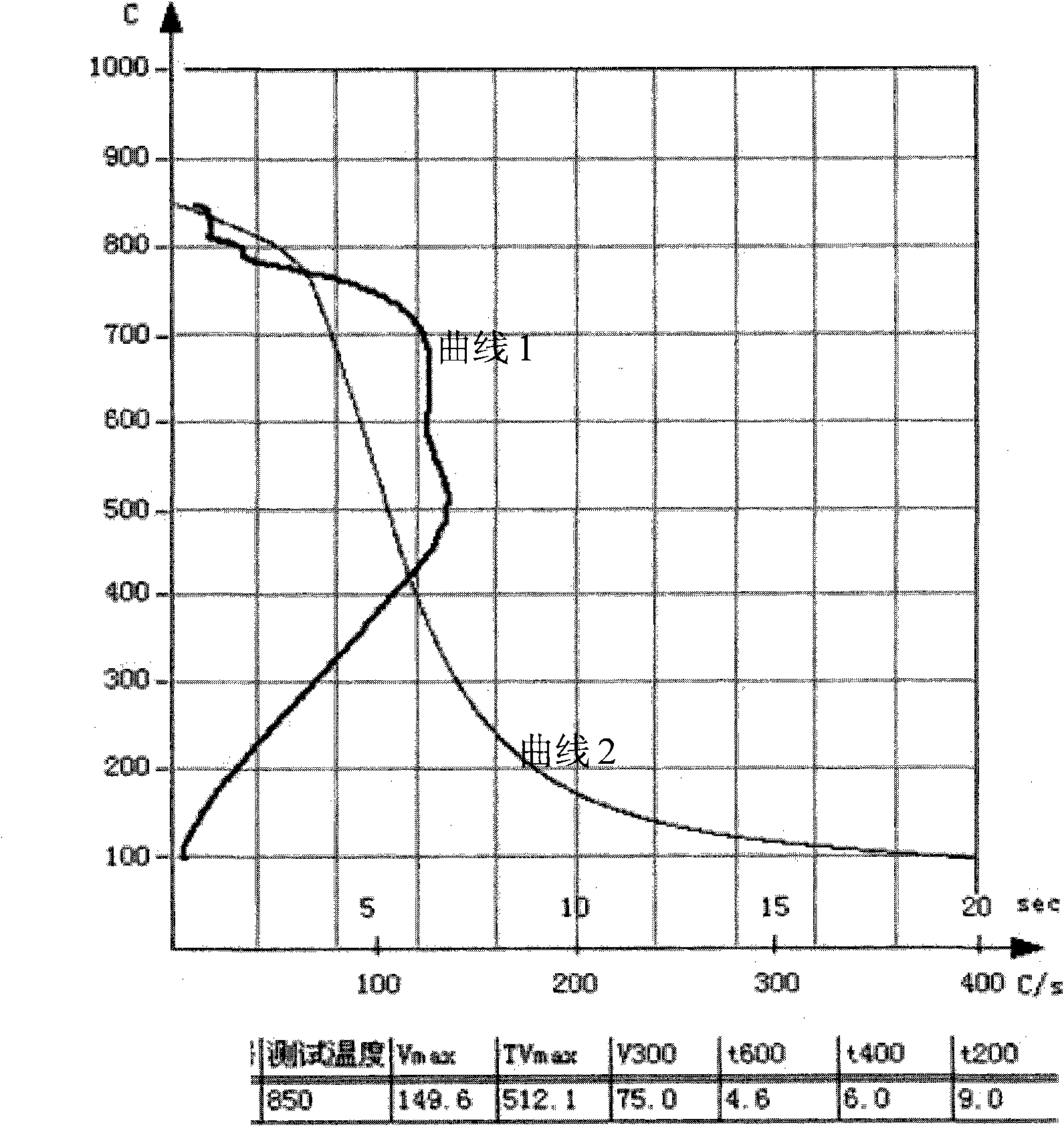

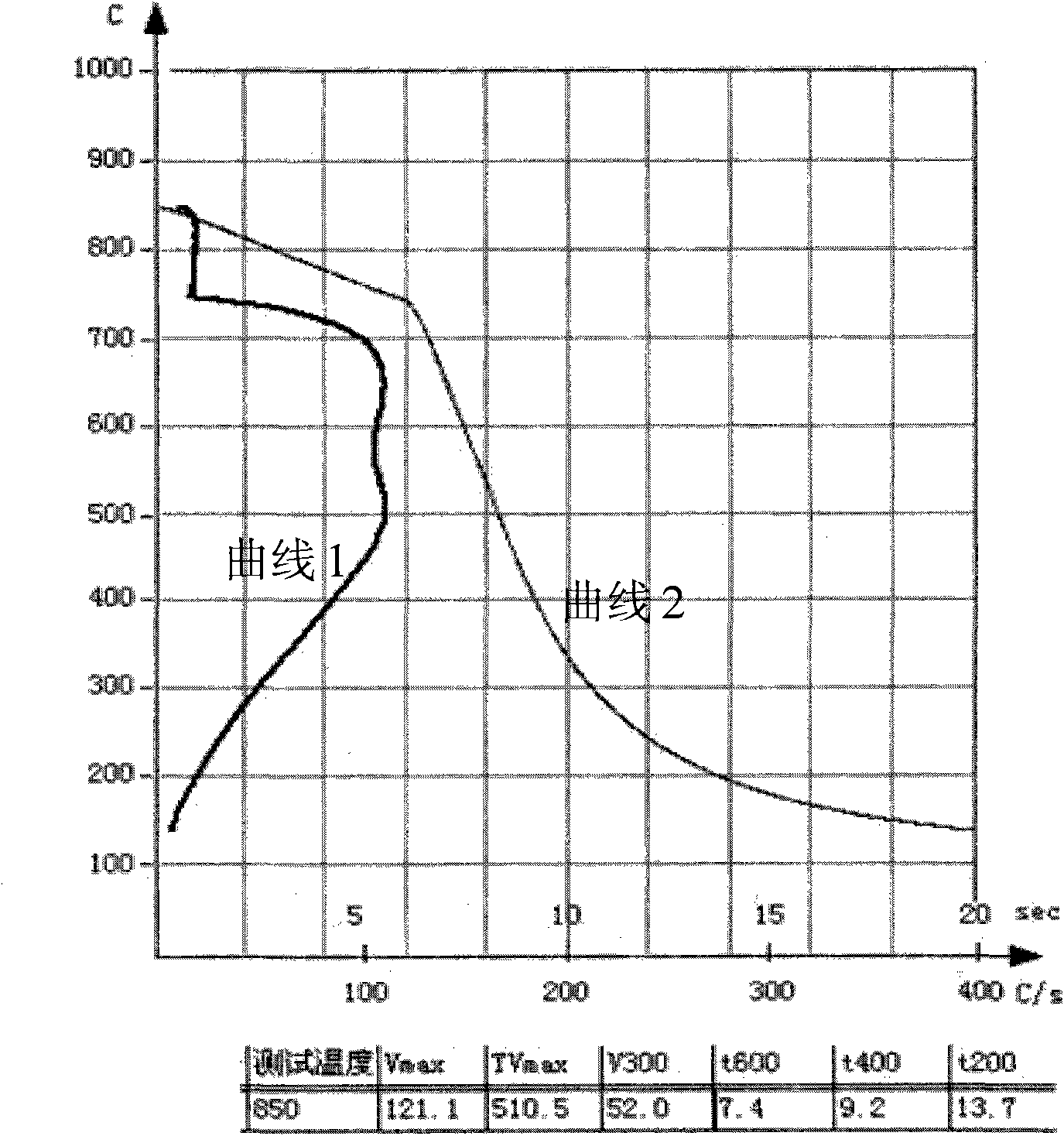

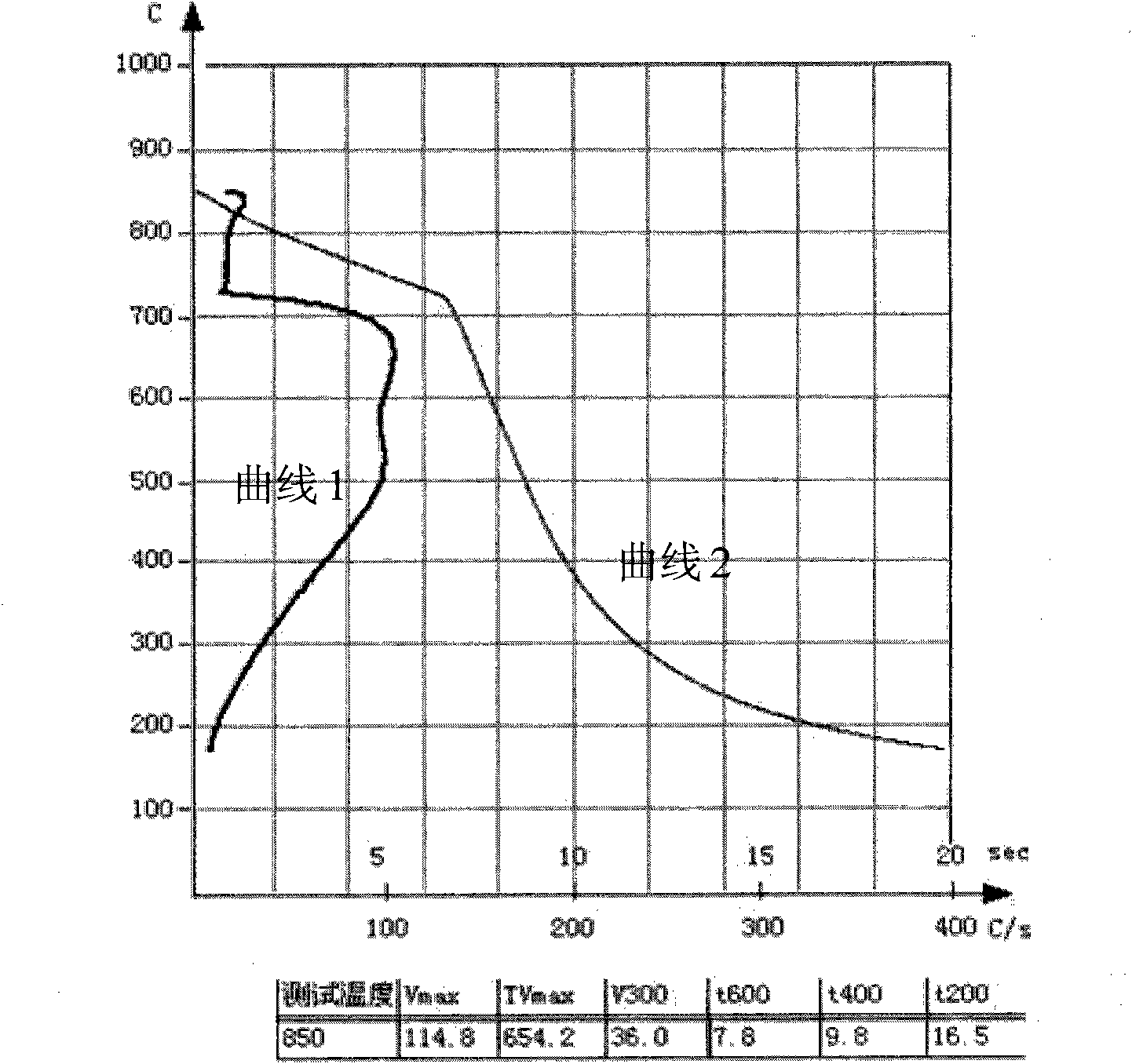

Quenching agent

The invention provides a quenching agent which is characterized by comprising the following components in percentage by weight: 13%-40% of polyether, 1%-5% of triethanolamine, 0.2%-1% of sodium benzoate, 0.05%-0.5% of defoaming agent and the balance of water. By preparing the quenching agent provided by the invention into different concentration for carrying out cooling experiment, the experiment result shows that the quenching agent provided by the invention has high cooling speed at the temperature higher than 400 DEG C, thereby obtaining fine workpiece grains and improving the performance of workpieces; and the quenching agent provided by the invention has lower cooling speed at the temperature lower than 400 DEG C, thereby preventing larger internal stress from forming in the workpieces to achieve the purpose of preventing the workpieces from cracking.

Owner:KASONG SCI & TECH

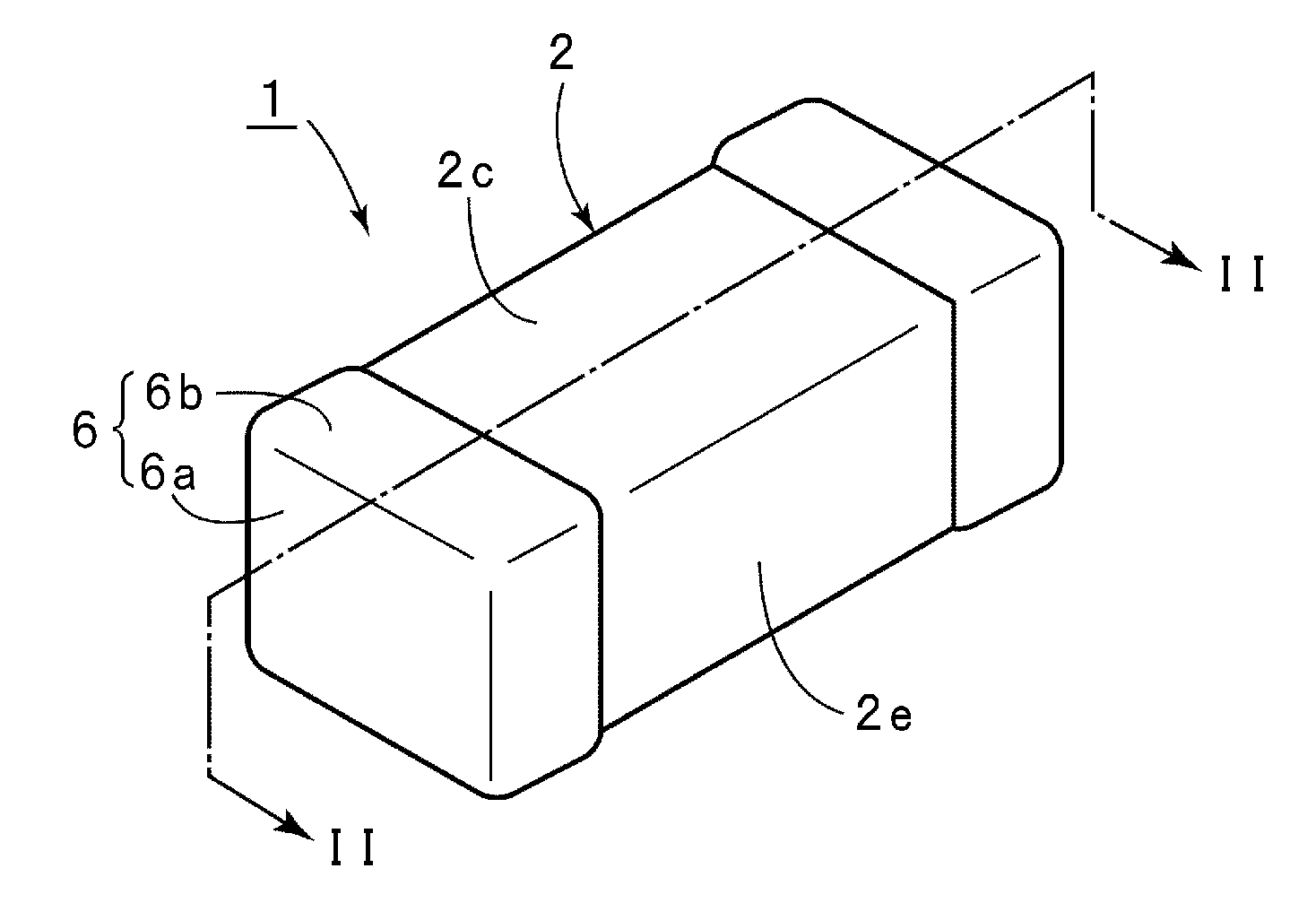

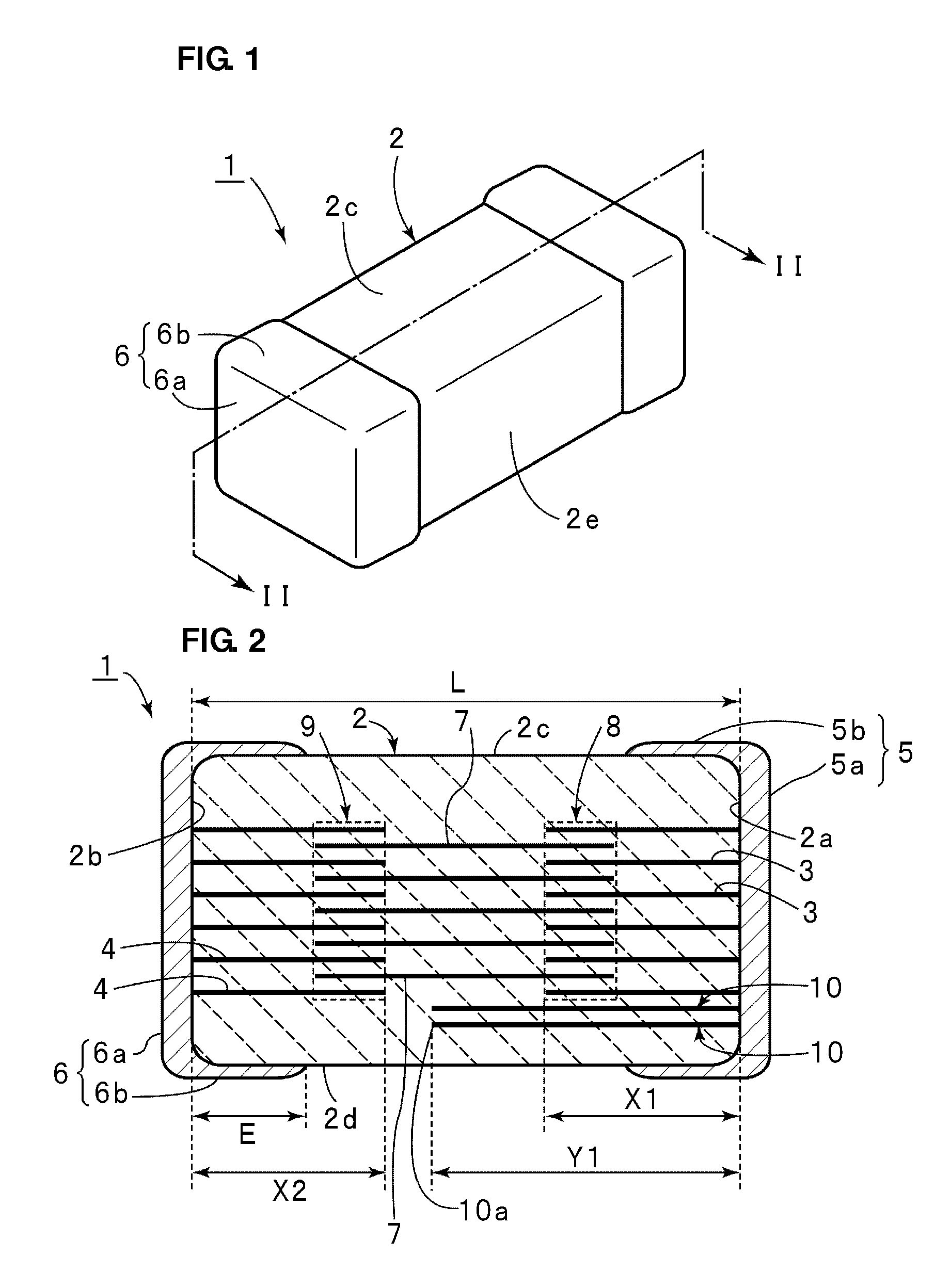

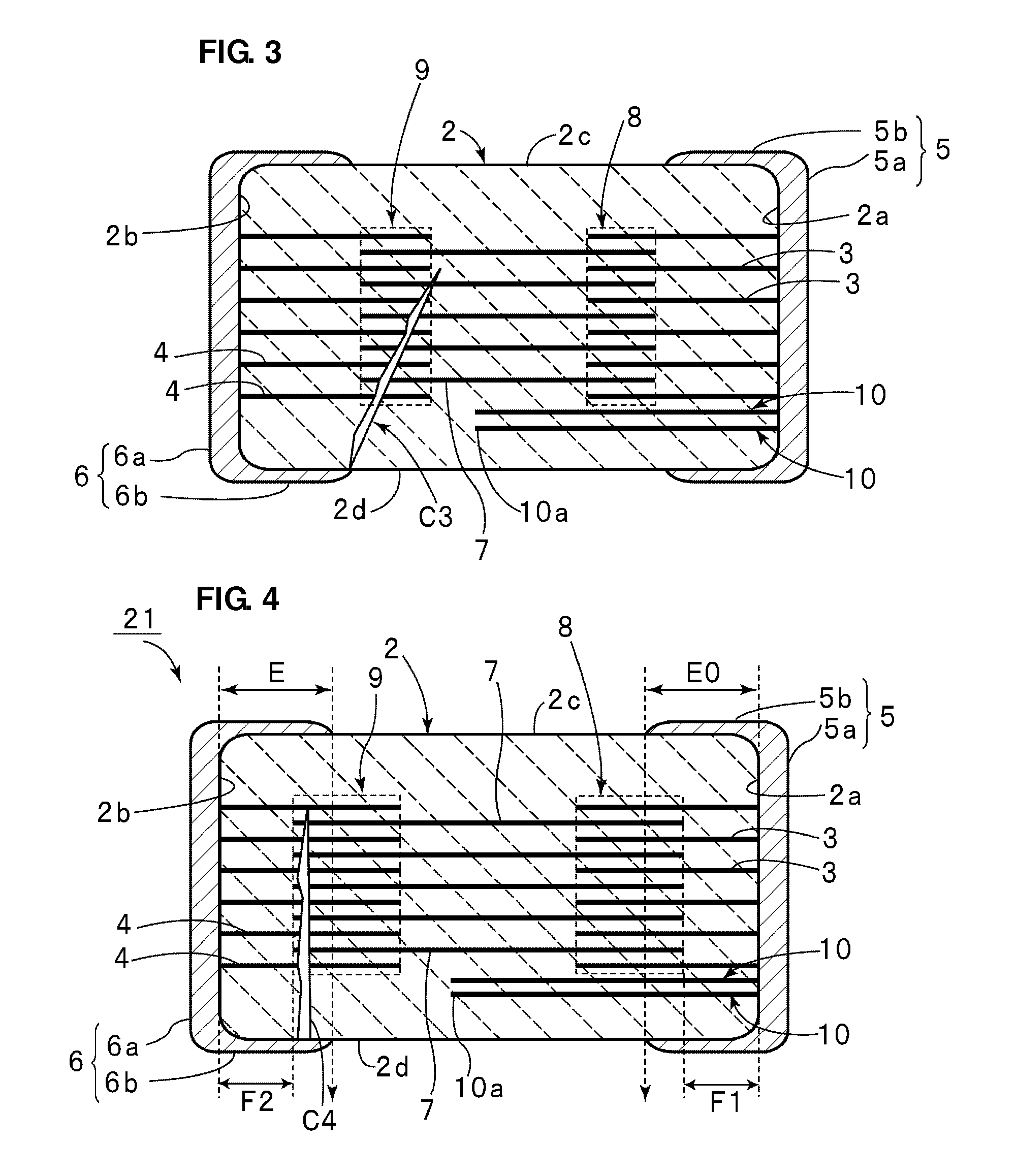

Multilayer ceramic electronic component

ActiveUS20100220426A1Increase internal stressPrevent short-circuitingFixed capacitor electrodesCurrent responsive resistorsElectrical conductorCeramic capacitor

A multilayer ceramic capacitor includes first internal electrodes extending to a first end surface of a ceramic element assembly, a plurality of second internal electrodes extending to a second end surface, floating internal electrodes arranged so as to overlap the first and second internal electrodes with ceramic layers disposed therebetween to define first and second effective regions, inner conductors that are elongated from the first end surface beyond a region that overlaps the first effective region in the direction of layering, and a relationship X1<Y1<(L−E) is satisfied where L is the dimension in the longitudinal direction extending from the first end surface to the second end surface, X1 is the longitudinal-direction dimension of each of the first internal electrodes, Y1 is the distance between the first end surface and an end of each of the first internal electrodes, and E is the distance between the second end surface and an end of the second extended section.

Owner:MURATA MFG CO LTD

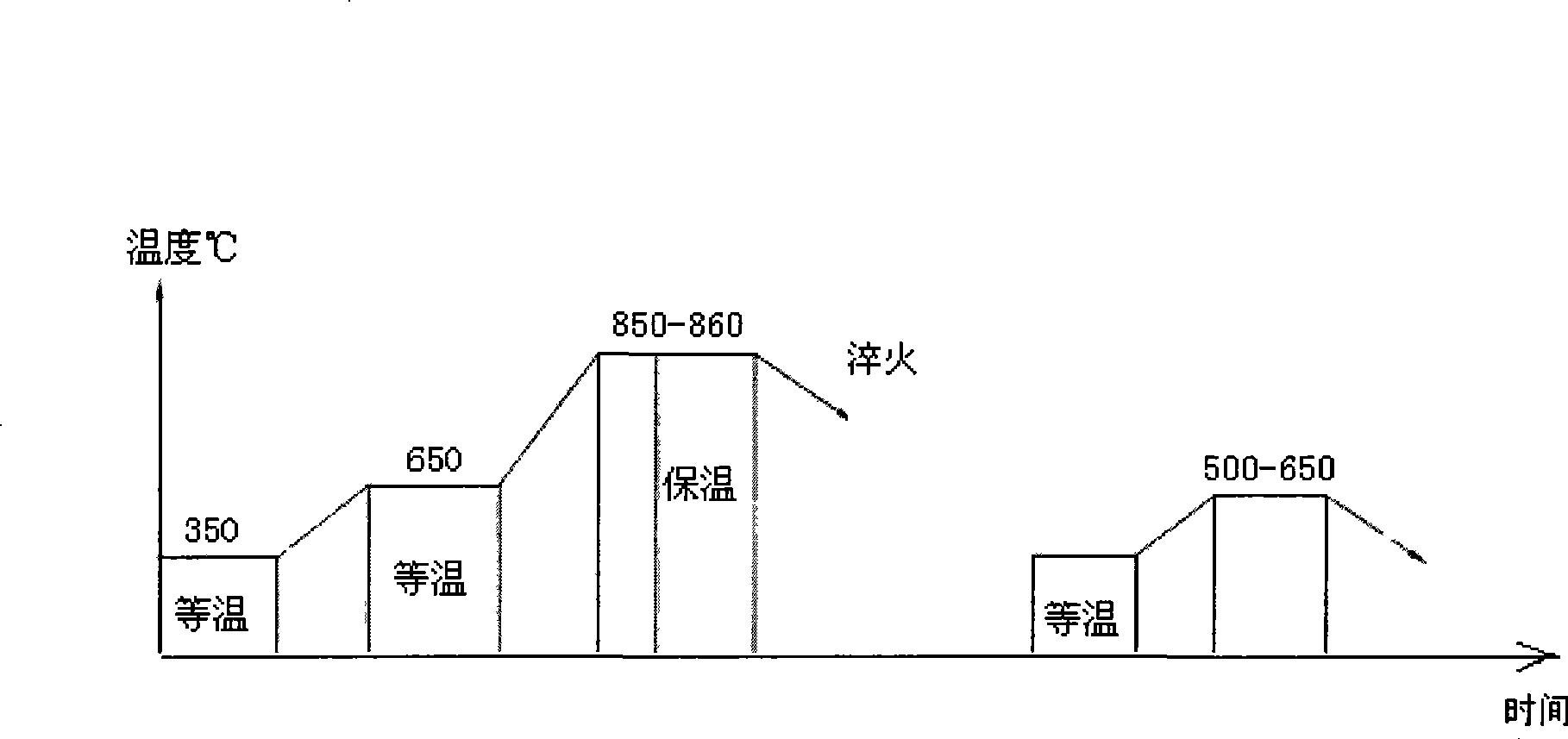

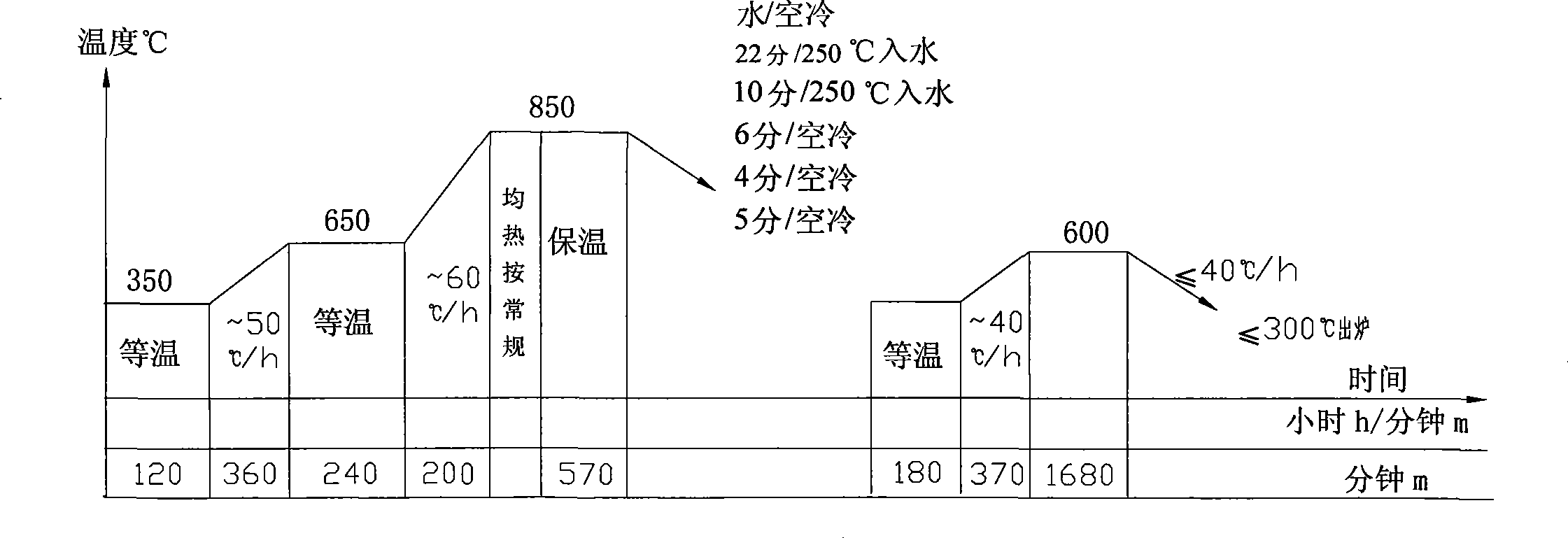

Water quenching and air cooling modified treatment technology of 42CrMo material

InactiveCN101363070APrevent cold crackingImprove overall performanceHeat treatment process controlQuenchingAir cooling

The invention discloses a hardening and tempering and quenching treatment process of a large 42CrMo forged piece, which comprises the steps of heating up, heat preservation, quenching, high temperature tempering, etc. Quenching is carried out by a water quenching and air cooling method. The process comprises the following specific steps: when quenching, the forged piece is cooled in water for a certain time, and then is taken out for air cooling and buffer; when the surface temperature returns to 200-300 DEG C, the forged piece is put into water for water cooling again, and then is taken out for air cooling and buffer; after a plurality of cycles of water cooling and air cooling, the temperature of the forged piece is stable and not over 300 DEG C, the quenching process is completed. The treatment process provides the hardening and tempering scheme of the forged piece under the quenching condition without an oil groove, quenching oil, and the like, and improves the comprehensive properties of the forged piece.

Owner:SHANGHAI HEAVY MACHINERY PLANT

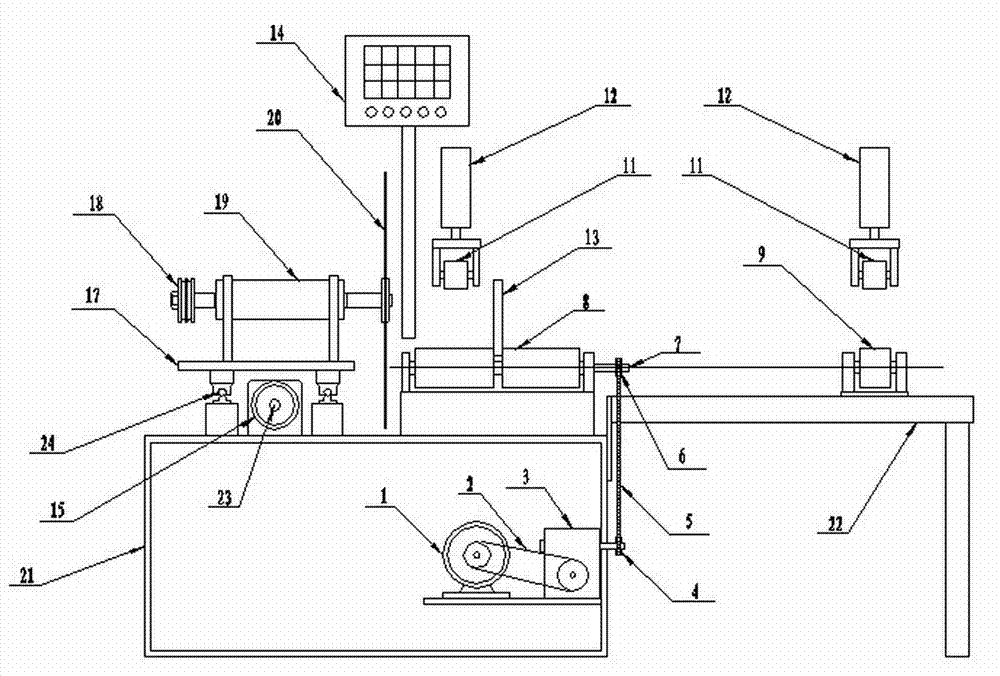

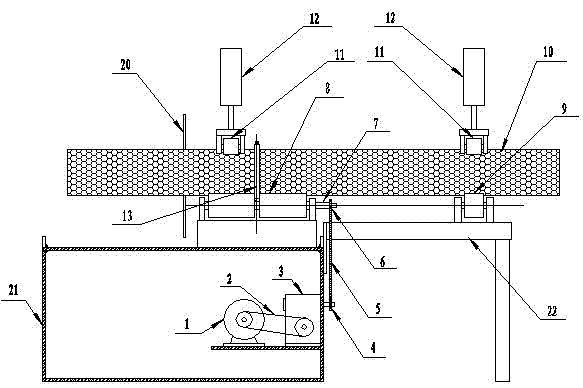

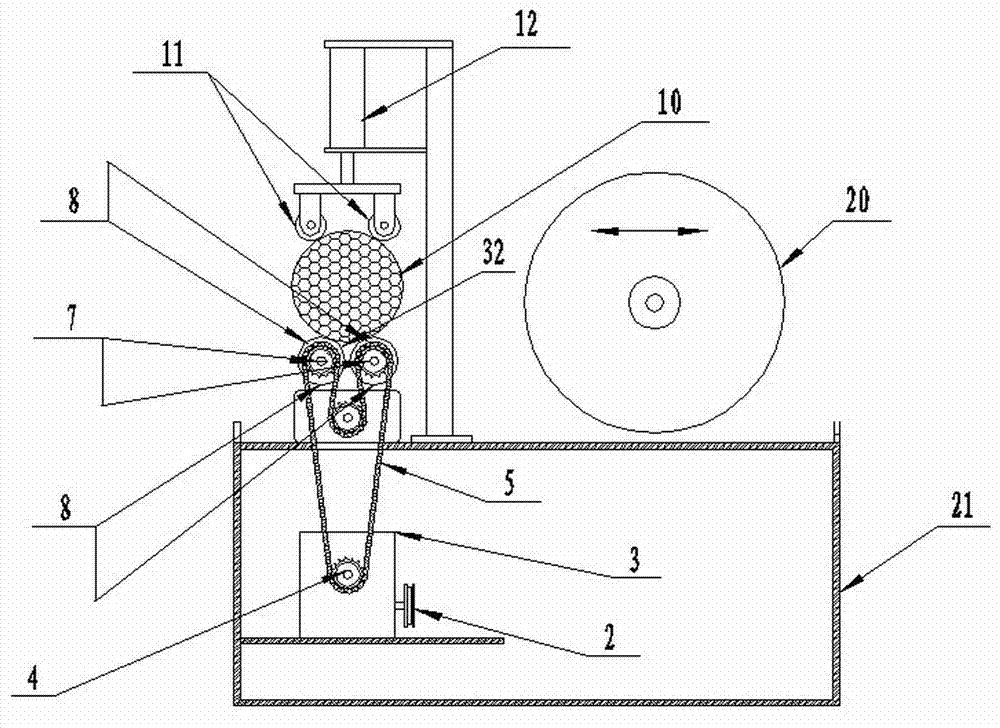

Rotary floating cutting numerical control machine tool for silicon rod

InactiveCN102862239AControl BrokenReduce vibrationWorking accessoriesFine working devicesNumerical controlEngineering

The invention discloses a rotary floating cutting numerical control machine tool for a silicon rod, and relates to a numerical control machine tool, in particular to a numerical control cutting machine for cutting the silicon rod. The rotary floating cutting numerical control machine tool comprises a numerical control box, a machine tool body, a transmission mechanism, and a cutting mechanism and a silicon rod clamping mechanism which are arranged on the machine tool body, and is characterized in that the silicon rod clamping mechanism comprises a driving rotation support wheel which clamps the silicon rod in a matching manner in the vertical direction, and a floating rotary pressing wheel; the floating rotary pressing wheel is connected with an elastic pressing device which drives the floating rotary pressing wheel to tightly press the silicon rod; and the transmission mechanism is connected with a shaft of the driving rotation support wheel. The rotary floating cutting numerical control machine tool can realize the non-concentric axial rotation floating radius cutting of polycrystalline silicon rods which have the characteristics that the material texture density is sparse, workpieces are bent in the axial direction, ovality exists in the diameter direction, the diameters are different, the appearances are not irregular, the breaking phenomenon is easy to generate, and the like in the floating rotation state, and is novel and capable of realizing the automatic radius cutting.

Owner:刘鸿彬

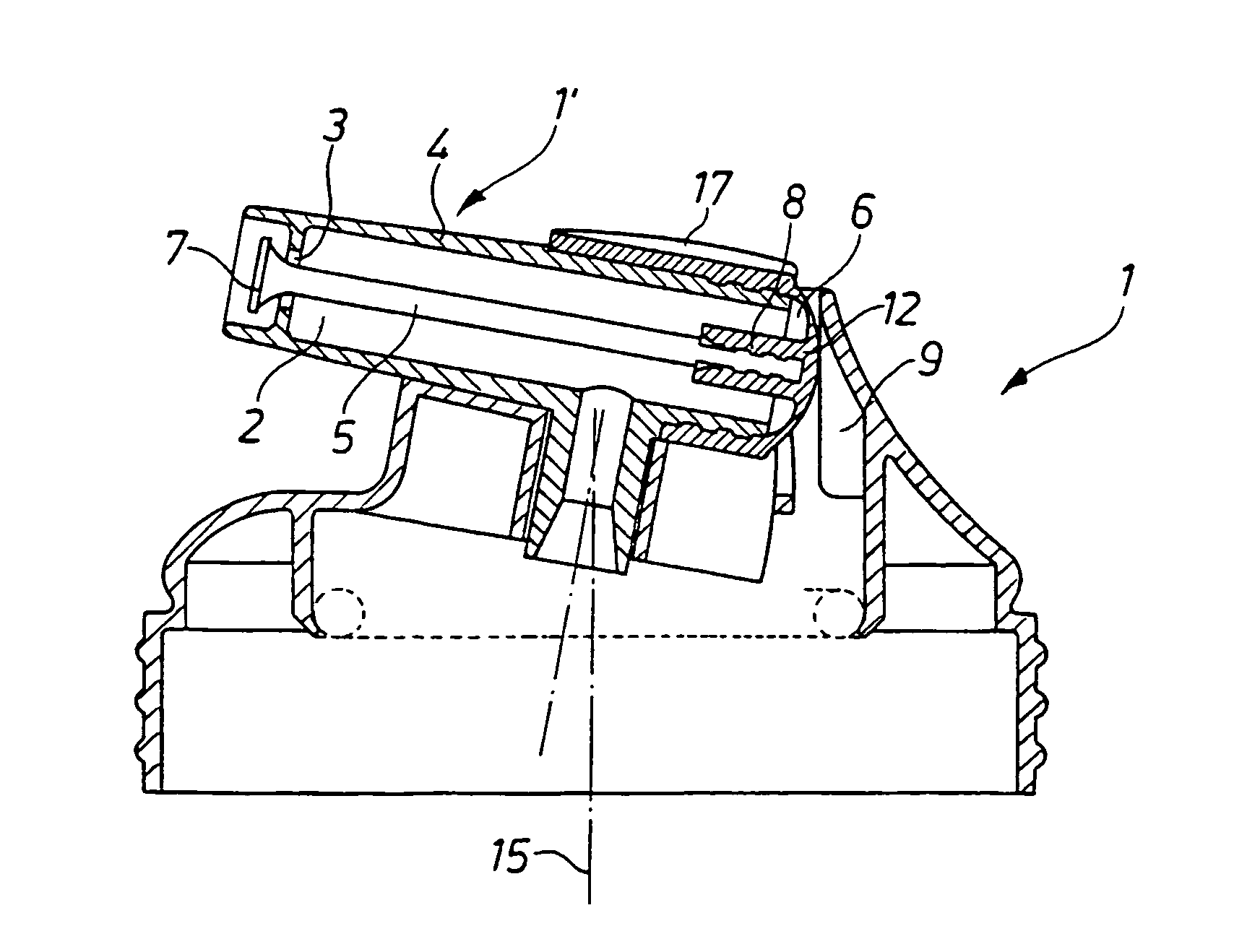

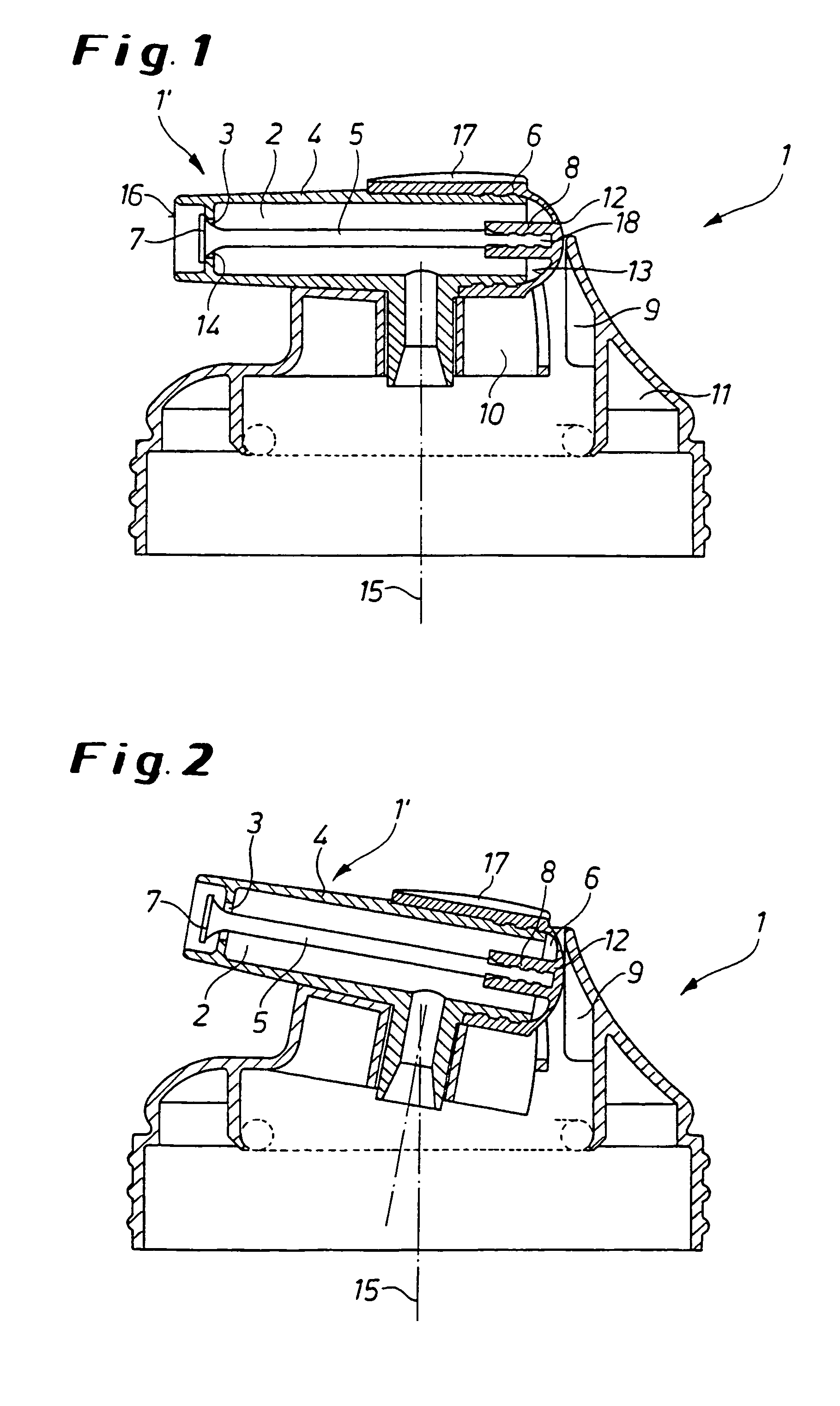

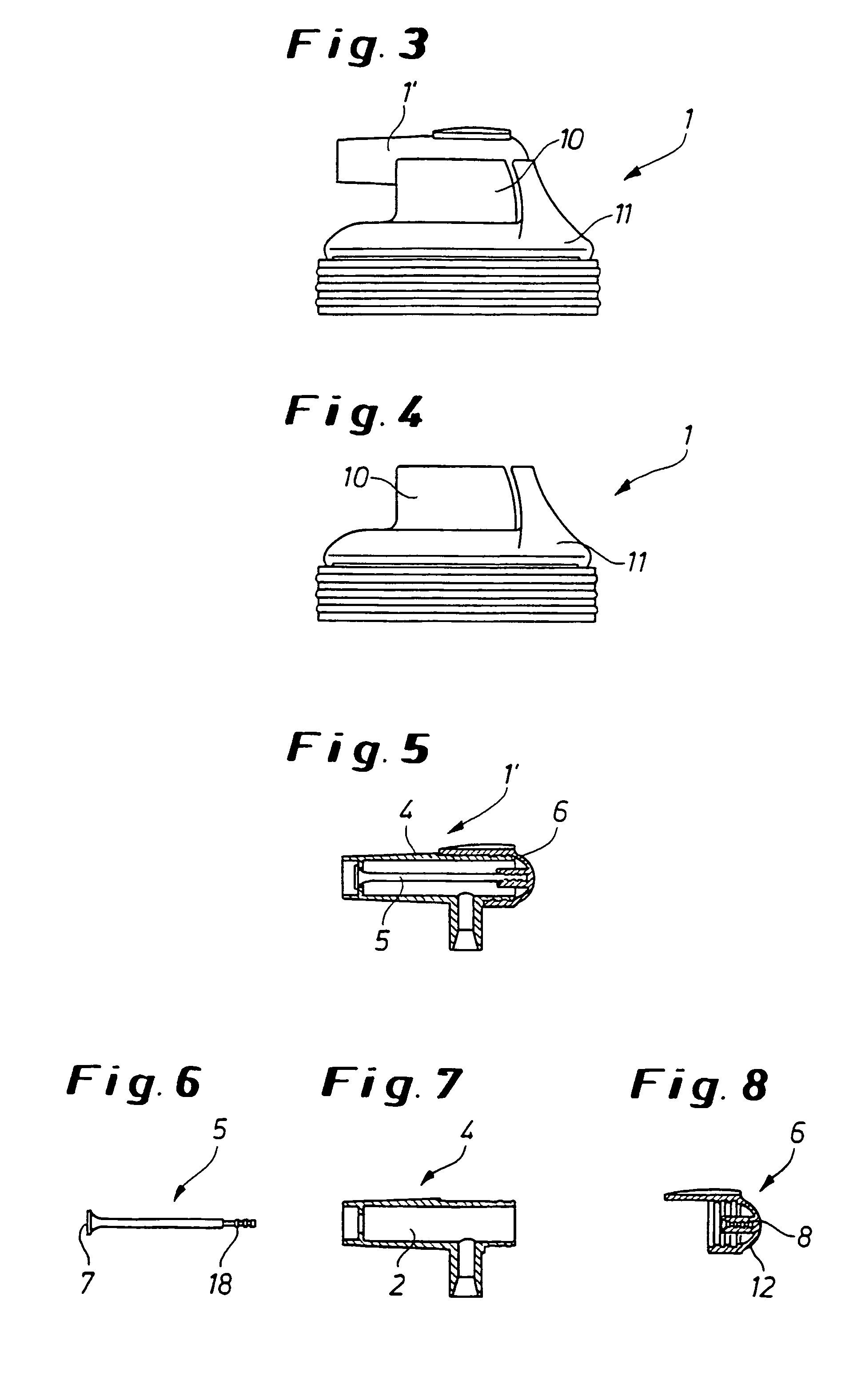

Dispenser head with a check valve

InactiveUS7464839B2Inhibition releaseExtra stressLarge containersSpray nozzlesEngineeringCheck valve

One disadvantage during delivery of products such as foams, for instance shaving foam or gel, self-foaming products and other products that are applied with a pressurized system from a conventional, pressurized dispenser container with the aid of known dispenser heads that can be inserted into the delivery valve of the dispenser container is that the pressurized product remaining in the delivery channel continues to be pressed out in small amounts in an uncontrolled manner after utilization despite the fact that the delivery valve is closed. In order to eliminate said disadvantage, the dispenser head (1) is configured with an additional closing device (1′) that automatically opens the delivery hole (3) and automatically closes it after the dispensing process is completed.

Owner:RPC WIKO

Fe-based amorphous alloy powder and preparation process thereof

The invention provides Fe-based amorphous alloy powder and a preparation method thereof. The specific alloy ingredient of the powder is 40-95 wt% of Fe, and alloy elements are one or combination of multiple elements, such as, P, Ni, Cr, Co, Mo, W and Re, which can be subjected to electro-deposition together with iron. The preparation process of the powder includes the steps that (1), pre-treatment of a metal substrate plated surface is performed; (2), electroplating liquor is prepared; (3), a constant-potential power source or a pulse power source can be adopted, current density of an electrode is 200-1000 mA / mm<2>, and electrolyte temperature is 30-70 DEG C; (4), a mechanical or physical method is adopted to make a plated layer fall off; (5) ball milling is performed under protection of vacuum or inert gases; (6), the amorphous alloy powder is sieved.

Owner:株洲红日新材料科技有限公司

3D printing gypsum ink and preparation method thereof

The present invention belongs to the technical field of 3D printing materials, and relates to a 3D printing gypsum ink, and the 3D printing gypsum ink is prepared from the following components by weight: 60% to 93% of gypsum powder, 2% to 20% of filler, 4% to 18% of a modifying solvent and 0.5% to 5% of a coagulant. The present invention also discloses a preparation method of the 3D printing gypsum ink, and all the raw materials are mixed and stirred evenly to obtain the 3D printing gypsum ink. The problems of low strength, poor mobility, coarse particles, poor toughness and high cost in the prior art can be solved, and an economical 3D printing forming material with industrial potential, high speed, good precision and low use cost is developed.

Owner:QINGHAI MINGYANG ENVIRONMENTAL TECH GRP CO LTD

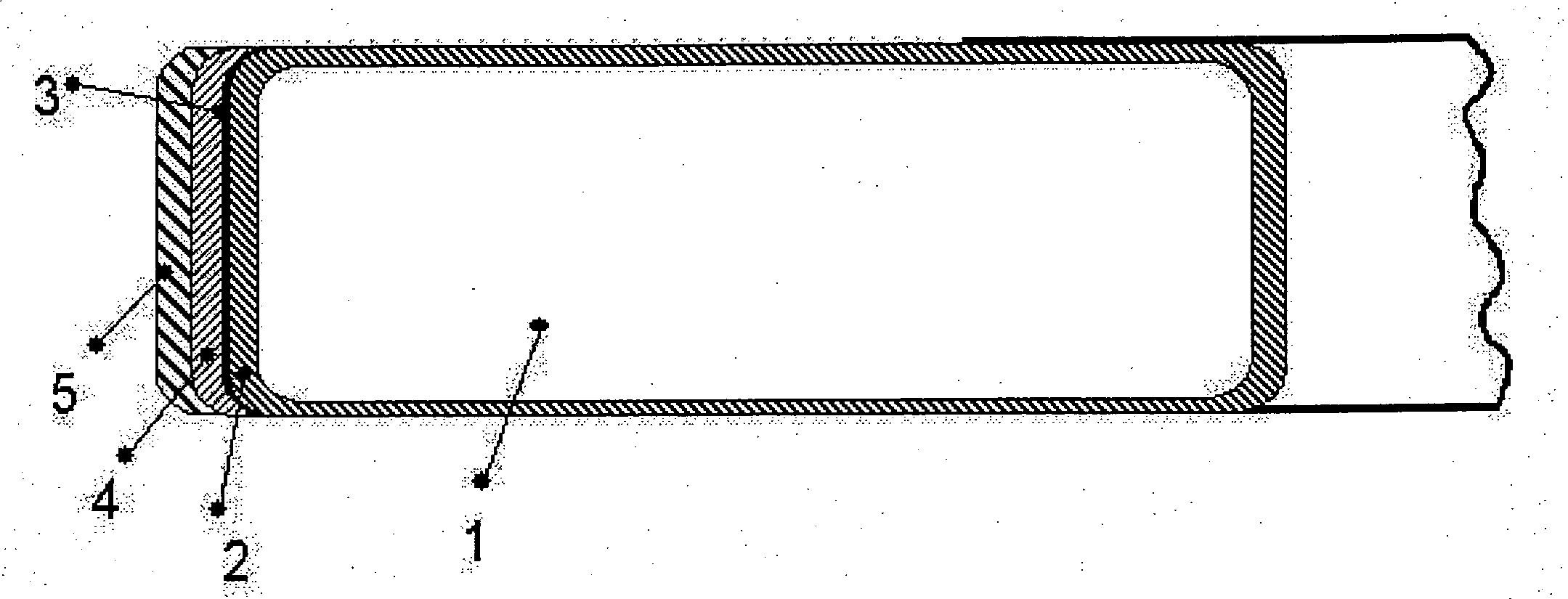

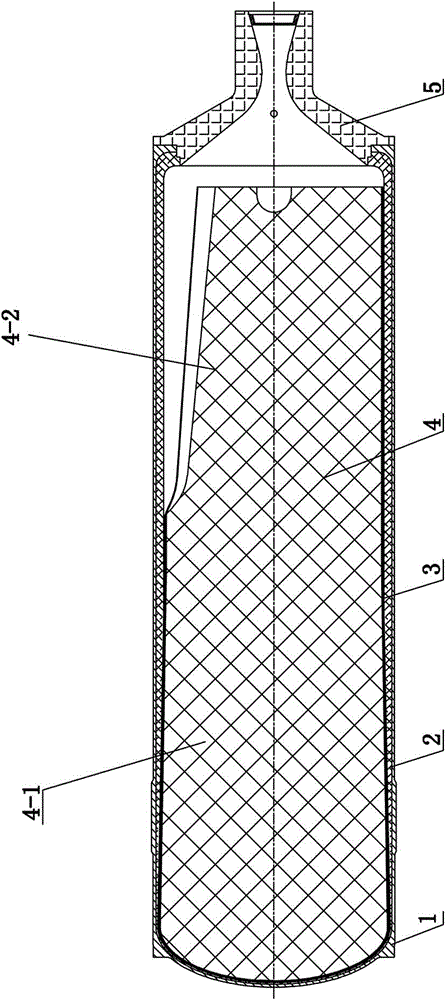

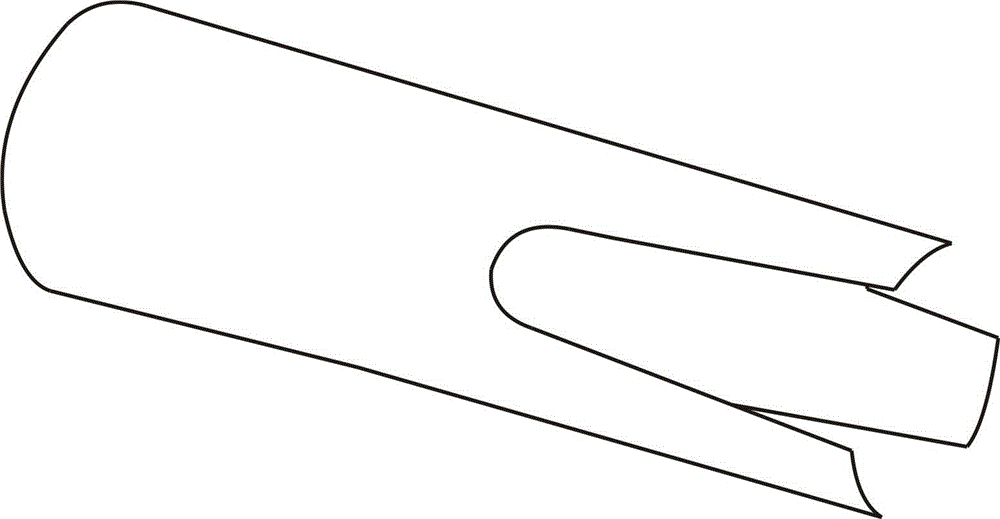

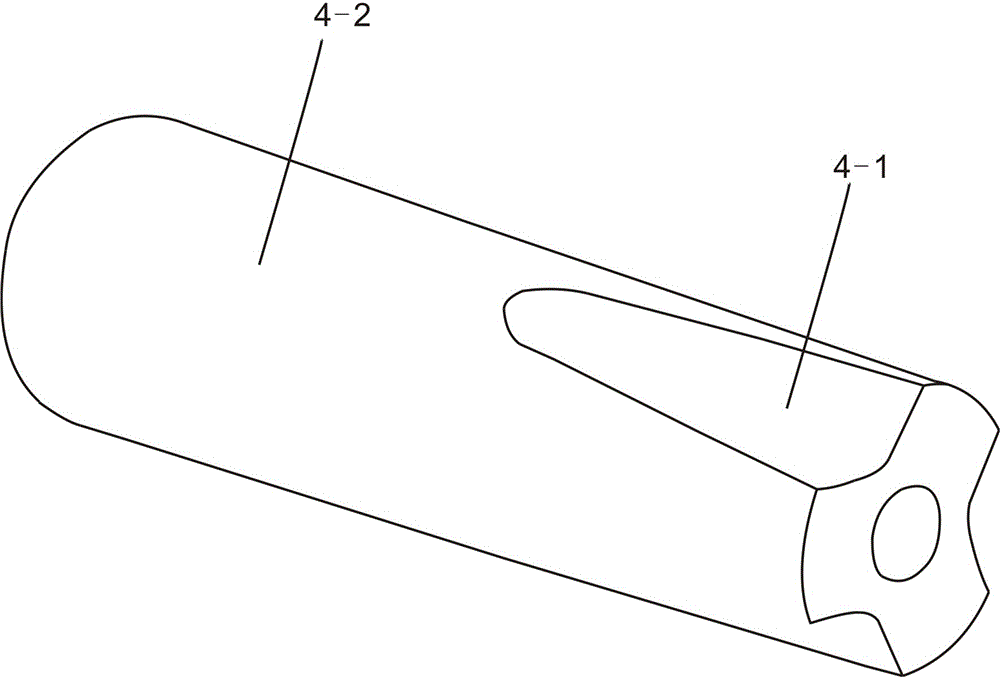

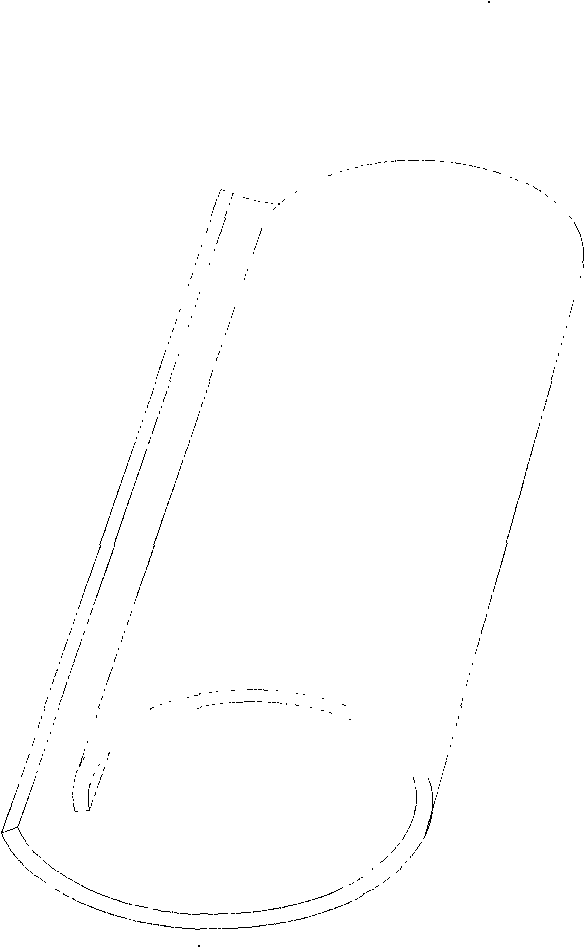

Solid rocket engine with high thrust ratio and manufacturing method thereof

ActiveCN105003355AImprove bonding qualityRelieve stress concentrationRocket engine plantsPhysicsCombustion chamber

A solid rocket engine with a high thrust ratio comprises a combustion chamber shell. A heat insulated layer is pasted to the inner surface of the combustion chamber shell. A heat insulated sleeve is bonded to the outer surface of a grain and forms a whole with the grain. The grain with the heat insulated sleeve is arranged in the combustion chamber shell with the heat insulated layer in a free-filling mode. A spray pipe is arranged at the outlet end of the combustion chamber shell. The grain comprises a booster-stage three-arm type grain body and a cruising-stage end-burning grain body which are connected in series to form the integrated grain. The booster-stage three-arm type grain body and the cruising-stage end-burning grain body are grain bodies for four-component hydroxy-terminated polyb propellants of the same formula. By means of the solid rocket engine with the high thrust ratio and a manufacturing method thereof, the problem of a small thrust ratio can be solved, the high thrust ratio can be provided, working is table, and the structure and performance are reliable.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

Solid-wood composite board made of super-thick single boards and producing method thereof

ActiveCN101524859ALarge specific surface areaImprove drying rateWood veneer joiningWood layered productsSolid woodSurface layer

The invention provides a solid-wood composite board made of super-thick single boards, which comprises two surface layers on external surfaces and a core layer between the two surface layers, adhesive is arranged among single boards, the core layer comprises a super-thick single board with the thickness of 6 mm to 12 mm, and the surface layers comprise single boards with the thickness of 0.2mm to1.5 mm. The super-thick single boards of the core layer are single boards made by rotatably cutting logs, and spot-shape or segment-shape crack grains are arranged on the loosened surface of the single boards in the direction along the grain. The solid-wood composite board made of super-thick single boards enables the composite board combined by the super-thick core boards to have no distortion or deformation by adopting the central-symmetric single-board assembly structure and forming spot-shape or segment-shape crack grains by discongesting on the surfaces of the single boards of the core layer, and has equal performance as that of the solid wood. The super-thick core board enables the glue layers of the veneer to be reduced, the applied glue amount is reduced, the cost is saved, and the release amount of the formol can be reduced to enable the solid-wood composite board to be more environmental friendly.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Bi-component bisphenol A type epoxy resin structured fluid sealant and preparation thereof

InactiveCN101343524AImprove wear resistanceImprove thixotropyOther chemical processesEpoxy resin adhesivesPliabilityUltimate tensile strength

The invention discloses sealant of a dual-component and bisphenol A type epoxy resin structure and the preparation method, which comprises a first component and a second component, wherein, the first component comprises 75 parts to 95 parts of bisphenol A type epoxy resin, 8 parts to 22 parts of toughening agent, 75 parts to 95 parts of filling agent and 15 parts to 25 parts of plasticizing agent, the second component comprises 40 parts to 60 parts of curing agent, 45 parts to 55 parts of filling agent and 5 parts to 15 parts of ferric oxide powder. The preparation method comprises the followings: the preparation of the first component: the materials in the first component are poured into an agitating barrel according to the weight parts proportion, evenly stirring the materials, until grayish white fluid is obtained, namely the first component; the preparation of the second component: the materials in the second component are poured into the agitating barrel according to the weight part proportion, evenly stirring the materials, until grayish red fluid is obtained, namely the second component; the first component and the second component are mixed and evenly stirred according to the weight part of 2.8 to 3.2:1, and the sealant of the dual-component and bisphenol A type epoxy resin structure is obtained. The sealant has the advantages that the pliability is good, the stripping strength is strong, and the physical mechanical performance and the process performance are well improved.

Owner:SYST EQUIP CO LTD OF THE 28TH RES INST LI YANG

Piston ring for internal combustion engines

InactiveUS20080136116A1Promote absorptionIncrease the difficultyPiston ringsBraking action transmissionHigh resistanceGas phase

A piston ring for internal combustion engines with a coating of Chromium nitride (CrN) deposited by a physical vapor deposition process on a sliding surface with a typical crystal structure of CrN phase, has a high wear resistance and superior resistance to the generation of micro-cracks and consequent localized loss of pieces of the coating. The coating is a columnar crystalline coating of CrN having a dispersed pore content lower than 10% in volume and ratio of intensities, measured through x-ray diffraction, between the crystal planes (111) and planes (200), parallel to the surface, in the range of 0.40 to 0.70. This crystalline distribution is obtained through an oxygen content impregnated in the CrN coating between 1.0% in weight to 7.0% in weight. The Vickers hardness of the film ranges from 1,500 to 2,200 HV.

Owner:MAHLE METAL LEVE +1

High-hardness and wear-resistant ball and preparation method thereof

ActiveCN104099531AEliminate internal stressIncrease internal stressFurnace typesMetallic material coating processesWear resistantHeat resistance

The invention discloses a high-hardness and wear-resistant ball. The high-hardness and wear-resistant ball comprises components of C, Mn, W, Si, Ni, Cr, Mo, V, Nb, Ca, Zr, Cu, Zn, S and P. The invention further discloses a preparation method for the high-hardness and wear-resistant ball, wherein a heat treatment process of the preparation method comprises the following steps: heating the temperature to 980-1030 DEG C, keeping the temperature for 50-80 min, and cooling to the room temperature; heating the temperature to 800-820 DEG C, keeping the temperature for 30-75 min, and cooling to the room temperature; heating the temperature to 500-530 DEG C, keeping the temperature for 130-150 min, and cooling to the room temperature. According to the preparation method, the surface of the wear-resistant ball is modified by using the reactive nitrogen arc cladding, and cladding powder is a composition of titanium powder and graphite powder, wherein the titanium powder comprises components of C, Mo, Si, Fe, Cl, N, O, H, and the balance Ti; the cladding current is 150-180 A; a nitrogen flow rate is 12-18 L / min. The wear-resistant ball provided by the invention has high hardness, and meanwhile, has excellent impact strength, heat resistance, wearing resistance and corrosion resistance.

Owner:宁国市宁武新材料科技有限公司

Composite thick film based on diamond-like carbon thin film and coating method of composite thick film

PendingCN107022761AReduce internal stressIncrease internal stressVacuum evaporation coatingSputtering coatingCarbon layerFilm base

The invention discloses a composite thick film based on a diamond-like carbon thin film and a coating method of the composite thick film. The composite thick film comprises a metal base layer, a transition layer and a diamond-like carbon layer which are successively formed from the surface of a substrate to the outside, wherein the transition layer is a mixture layer which is formed by stacking two film layers in a staggered manner by simultaneously using a magnetron sputtering technology and an enhanced type cathode arc technology; and the thickness of the diamond-like carbon layer is between 1 mu m and 10 mu m. The composite thick film is exquisite in design and simple in structure; the transition layer has the structure which is formed by stacking the two film layers in the staggered manner, the advantages of small internal stress of a magnetron sputtering film layer and large hardness of an enhanced type cathode arc film layer are played fully, large hardness and small internal stress of the transition layer are combined effectively, large hardness and small stress facilitate increasing of the thickness of the diamond-like carbon layer, and the thickness of the finally formed composite thick film reaches 20 mu m or above; and moreover, huge stress caused by a thick film function layer can be buffered effectively, therefore, the binding force of the composite thick film and the substrate is guaranteed, and meanwhile, surface defects of the composite thick film can be reduced effectively.

Owner:STARARC COATING TECH SUZHOU

Plasma chemical vapor deposition and magnetron sputtering or ion plating compounded plating method

InactiveCN107142463AImprove performanceImprove use valueVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

The invention relates to the technical field of new materials and modern surfaces, in particular to a plasma chemical vapor deposition and magnetron sputtering or ion plating compounded plating method. Voltage is applied to the position between a negative pole and a positive pole to enable reaction gases or inert gases to conduct glow discharging, and then plasma composed of electrons and ions is generated. Movement of the electrons is constrained by orthogonal electric field and magnetic field and limited in a certain area to conduct rotation drift movement, the collision probability of the electrons and gas atoms is enhanced, and therefore the ionization rate of the gas is enhanced; and under the combined action of the potential difference between the negative pole and the positive pole and Hall current formed by a crossed electric and magnetic field, the ions are subjected to beam extraction, and deposited on the surface of a base material directly to form a needed thin film. One important use of the compounded surface technology is to be used for preparing a high-quality diamond-like carbon film. The film has excellent performances, so the film is of great use value.

Owner:湖州中科金象科技股份有限公司

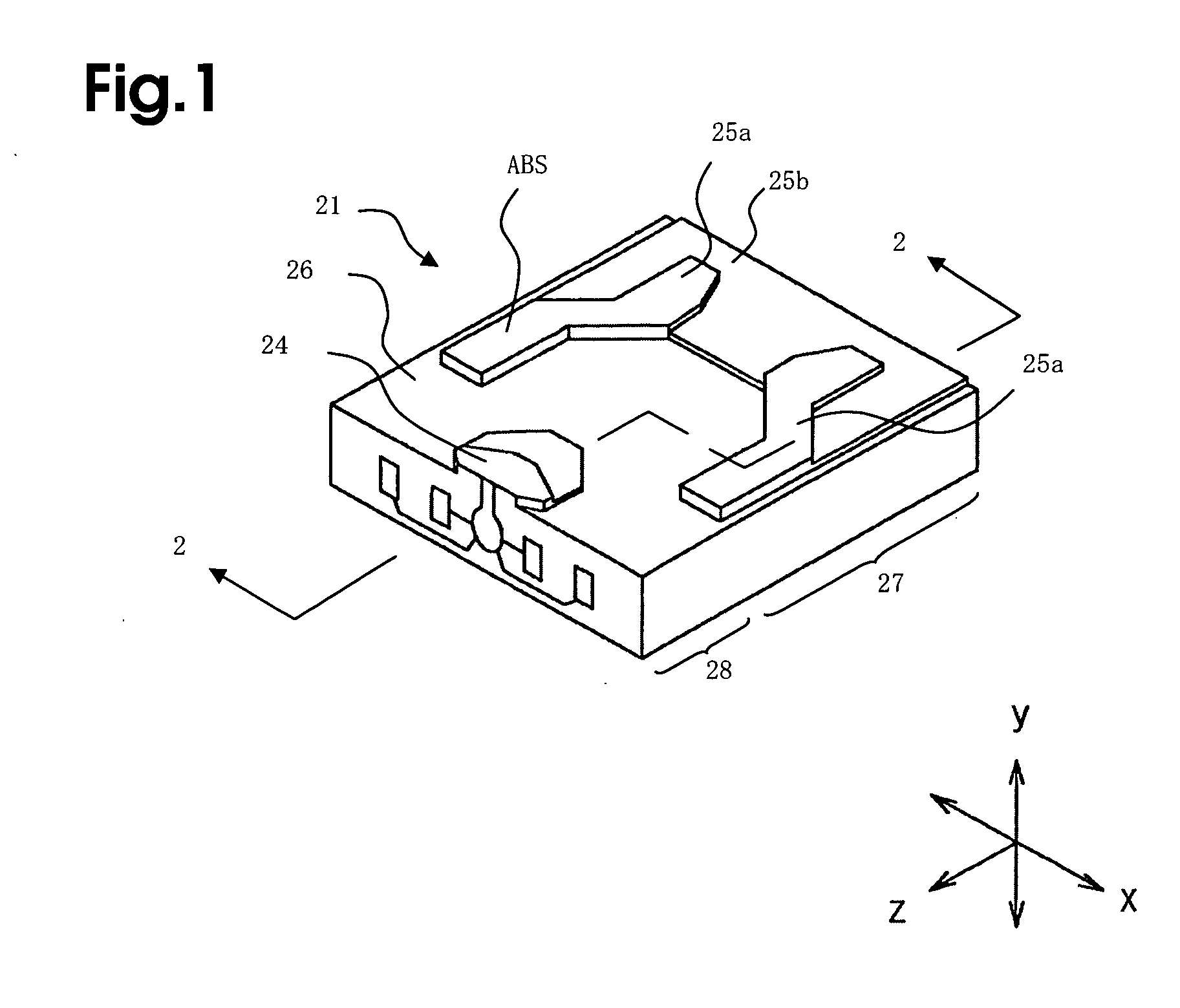

Slider and method of producing the same

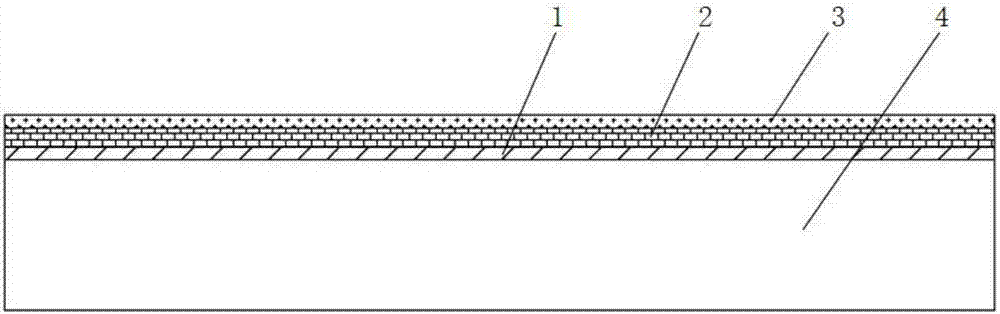

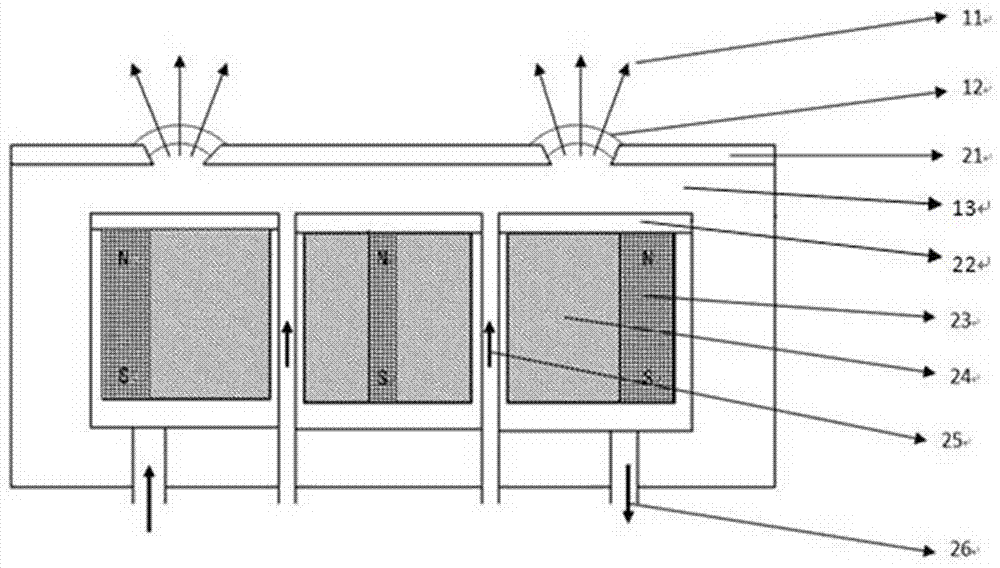

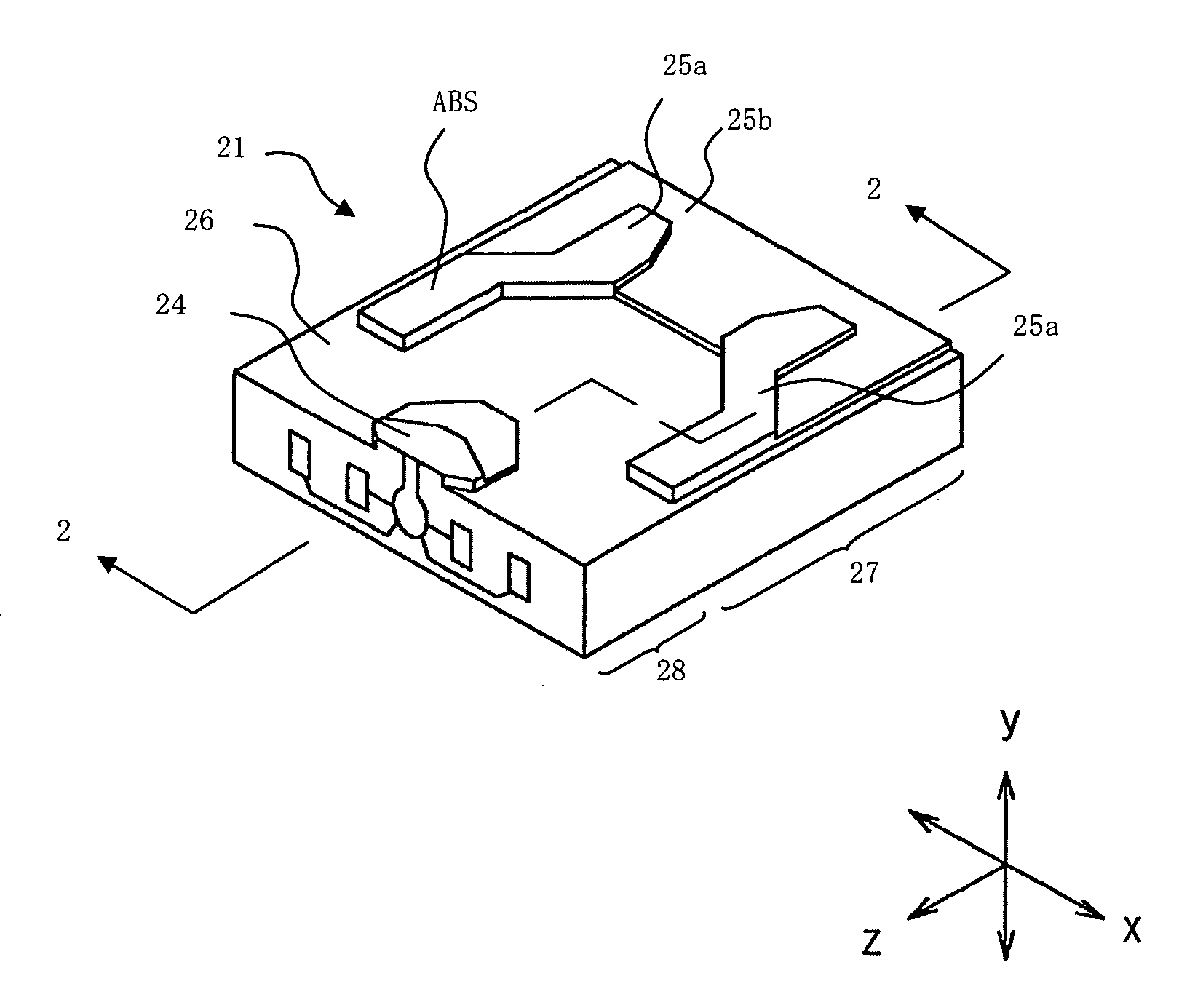

ActiveUS20070115589A1Improve adhesionSecurement of abrasive resistanceManufacture head surfaceFluid-dynamic spacing of headsTectorial membraneHydrogen

A slider comprises an air bearing surface which is arranged to face a recording medium and a protective film which covers at least a part of the air bearing surface. The protective film includes a first protective film formed on the air bearing surface and made of an amorphous material based on carbon and hydrogen and a second protective film formed to cover the first protective film and made of an amorphous material based on carbon and hydrogen. Further, the atomic fraction of hydrogen in the second protective film is lower than that in the first protective film.

Owner:SAE MAGNETICS (HK) LTD

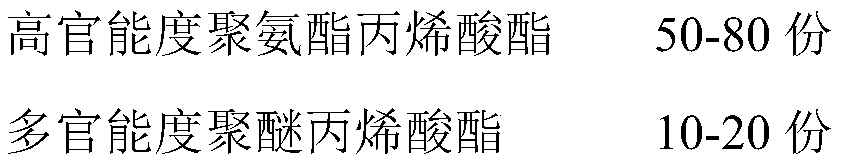

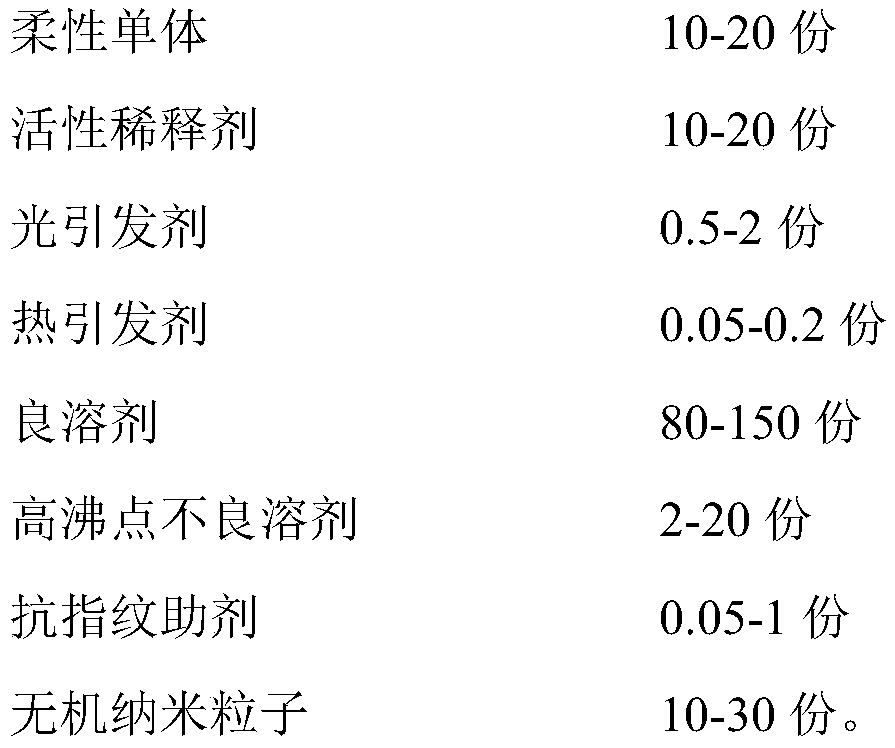

Transparent polyimide hardened film with low shrinkage, high hardness and high wear resistance

ActiveCN110358439AHigh hardnessImprove toughnessAntifouling/underwater paintsPaints with biocidesSolventLow shrinkage

The invention specifically relates to a transparent polyimide hardened film with low shrinkage, high hardness and high wear resistance, belonging to the technical field of transparent polyimide hardened films. A hardening solution used for preparing the transparent polyimide hardened film comprises, by weight, 50-80 parts of high-functionality urethane acrylate, 10-20 parts of polyfunctional polyether acrylate, 10-20 parts of a flexible monomer, 10-20 parts of a reactive diluent, 0.5-2 parts of a photoinitiator, 0.05-0.2 part of a thermal initiator, 80-150 parts of a good solvent, 2-20 parts of a high-boiling-point poor solvent, 0.05-1 part of an anti-fingerprint agent and 10-30 parts of inorganic nanoparticles. According to the invention, the high-functionality urethane acrylate and the polyfunctional polyether acrylate are adopted to improve the hardness of the hardened film, and the toughness of the hardened film is enhanced by the flexible monomer; and the thermal initiator and thephotoinitiator are added at the same time, and through cooperation between thermal curing and photocuring, shrinkage stress caused by polymerization during curing process is properly released, so warpage is avoided.

Owner:新纶光电材料(常州)有限公司

Phosphorus-free scale and corrosion inhibitor, and preparation technology thereof

InactiveCN107215968AReduce usageGood chelation dispersionSpecific water treatment objectivesScale removal and water softeningToxic materialChemistry

The invention belongs to the technical field of sewage treatment, and especially relates to a phosphorus-free scale and corrosion inhibitor, and a preparation technology thereof. The preparation technology of the phosphorus-free scale and corrosion inhibitor has the advantages of simplicity, no generation of toxic substances, environmental protection and low cost; and the molecular chain of the prepared scale and corrosion inhibitor contains rich ether groups, carboxylate radicals and other active groups, the phosphorus-free scale and corrosion inhibitor and scale forming cations form a stable structure in order to reach the high-efficiency scale and corrosion inhibition purpose, the corrosion inhibitor has the advantages of phosphorus-free, nontoxic, green and environmentally-friendly components, good biodegradability and small use amount, can form an adsorption film on the surface of metal in order to realize the corrosion inhibition effect, has good chelating and dispersing effects on calcium salts in water, and has a distortion effect on crystals to increase the internal stress of the crystals in order to make the crystals easily ruptured.

Owner:太仓市格雷得五金有限公司

Preparation method for carbon film with vacuum long-lasting lubricating performance

ActiveCN107653438AIncrease internal stressHigh mechanical strengthVacuum evaporation coatingSputtering coatingCarbon filmAviation

The invention provides a preparation method for a carbon film with vacuum long-lasting lubricating performance. Metal Cu with special nano morphology and the high catalytic characteristic is adopted as a target material, argon serves as sputtering gas, methane serves as a reaction gas source, a graphene precursor is formed on the surface of the target material through a hydrocarbon gas source, then sputtering is conducted, and thus the carbon film material inlaid with a graphene nano structure is prepared. Graphene has excellent mechanical strength and elastic deformation capacity, the graphene in the carbon film is of an ordered nanostructure and accordingly can take an effect of a reinforcing agent, thus, the mechanical performance of the carbon film is improved by a large margin, especially the high internal stress of the amorphous carbon film is relieved, and thus the carbon film has excellent roughness, the ultra-low friction coefficient under the vacuum environment and long service life. In consideration of the comprehensive performance advantages such as super-low friction under vacuum, the long service life, high hardness and high chemical stability of the carbon film, thecarbon film can be widely applied to surface lubricating treatment of moving parts used under the vacuum environment in various fields of aviation, spaceflight and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com