Solid-wood composite board made of super-thick single boards and producing method thereof

A technology of solid wood composite and manufacturing method, which is applied in the joining of wooden veneers, manufacturing tools, wood processing appliances, etc. problems such as the surface process, to achieve the effect of reducing resistance, reducing energy consumption, and improving drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Solid wood composite panels made of even-numbered extra-thick veneers

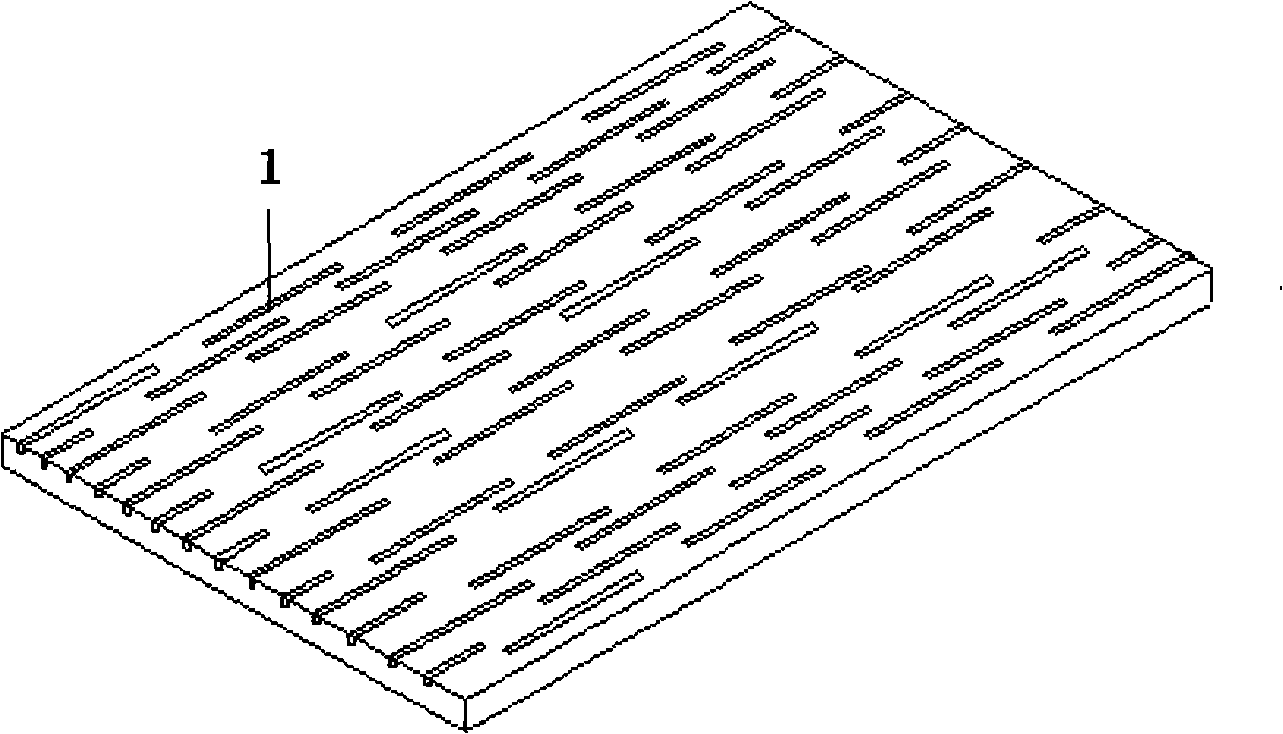

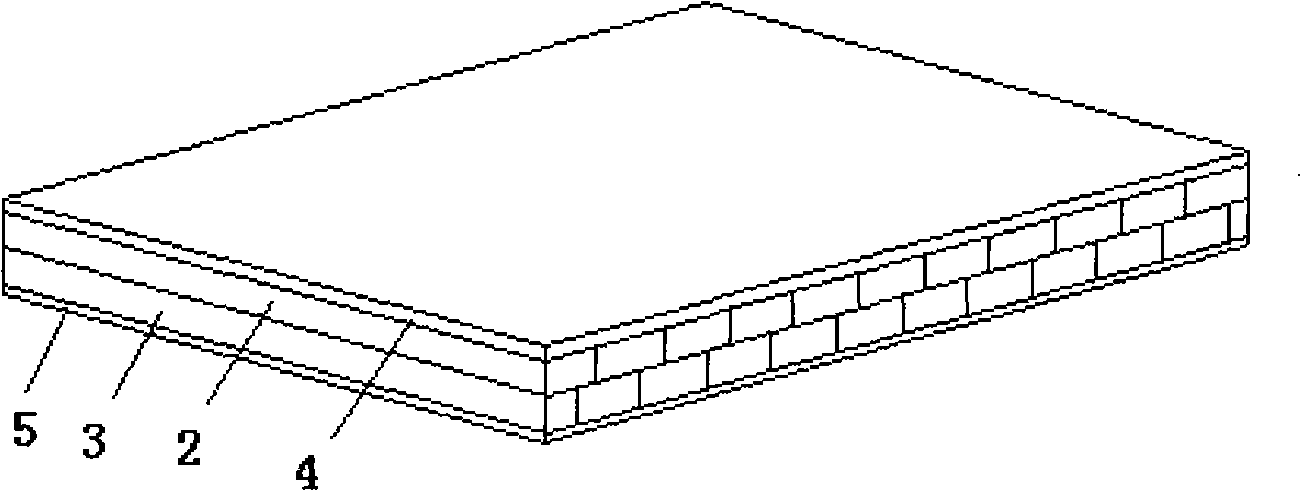

[0047] The solid wood composite board made of extra-thick veneer provided by the present invention is composed of even-numbered veneers, including two outer surface layers and a core layer therebetween, and an adhesive is provided between each layer of veneers;

[0048] The core layer can be composed of 2-layer, 4-layer, 6-layer, 8-layer, . It is an intermediate core board, and its loose sides are relatively joined, and the loose surfaces of the outer layers of veneers are all facing the intermediate core board, and the blanks are symmetrically assembled. The middle core board is vertical, and between the core layer and the surface layer, a sub-surface layer, also called a balance layer, can be included. It is perpendicular to the grain direction of the surface veneer, and its function is to prevent the lateral warpage of the core layer.

[0049] In this embodiment, as image 3 As shown in the fi...

Embodiment 2

[0077] Solid wood composite panels made of odd-numbered layers of extra-thick veneers

[0078] A. Veneer production:

[0079] The low-quality woods such as masson pine, eucalyptus or hemlock are peeled into super-thick veneers of 6mm to 12mm (such as Figure 4 shown) 6, 7, 8, the veneers 6, 7, 8 are decomposed by a decompression device, and point-shaped and / or line-shaped cracks are formed in the direction of the loose surface along the grain, as the veneer for the core layer.

[0080] The hardwoods such as paulownia, birch, teak, rosewood or cloned wood are peeled into veneers 8 and 9 of 0.6mm to 1.5mm as surface decorative veneers;

[0081] If there is a sub-surface layer between the core layer and the surface layer, the sub-surface layer (balance layer) is composed of 2 layers of veneer of 1mm to 3mm, and one layer is arranged on each side of the core layer, which is poplar, birch or eucalyptus. It is made of fast-growing wood from plantation forests (not shown in the fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com