Patents

Literature

83results about How to "Avoid problems such as deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

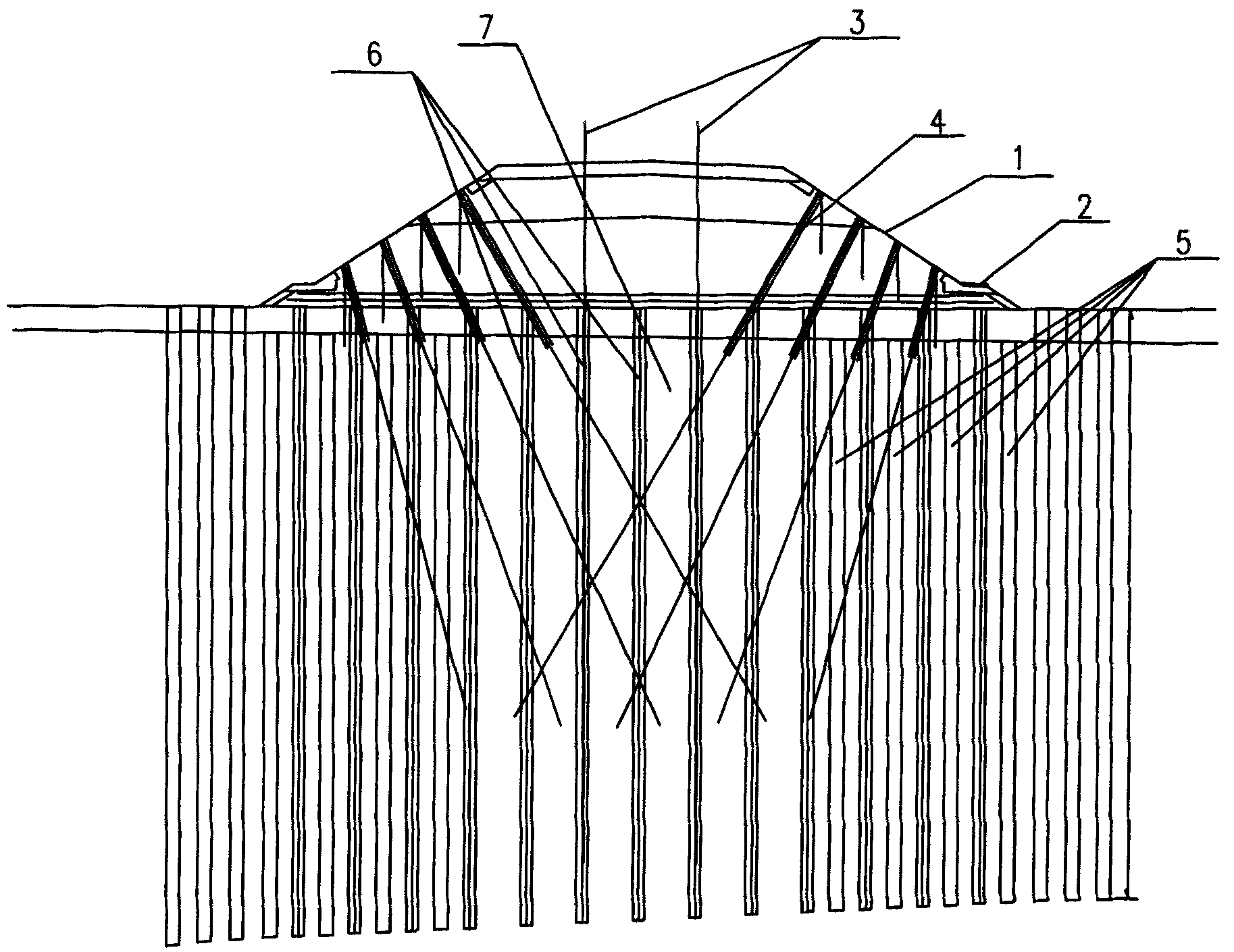

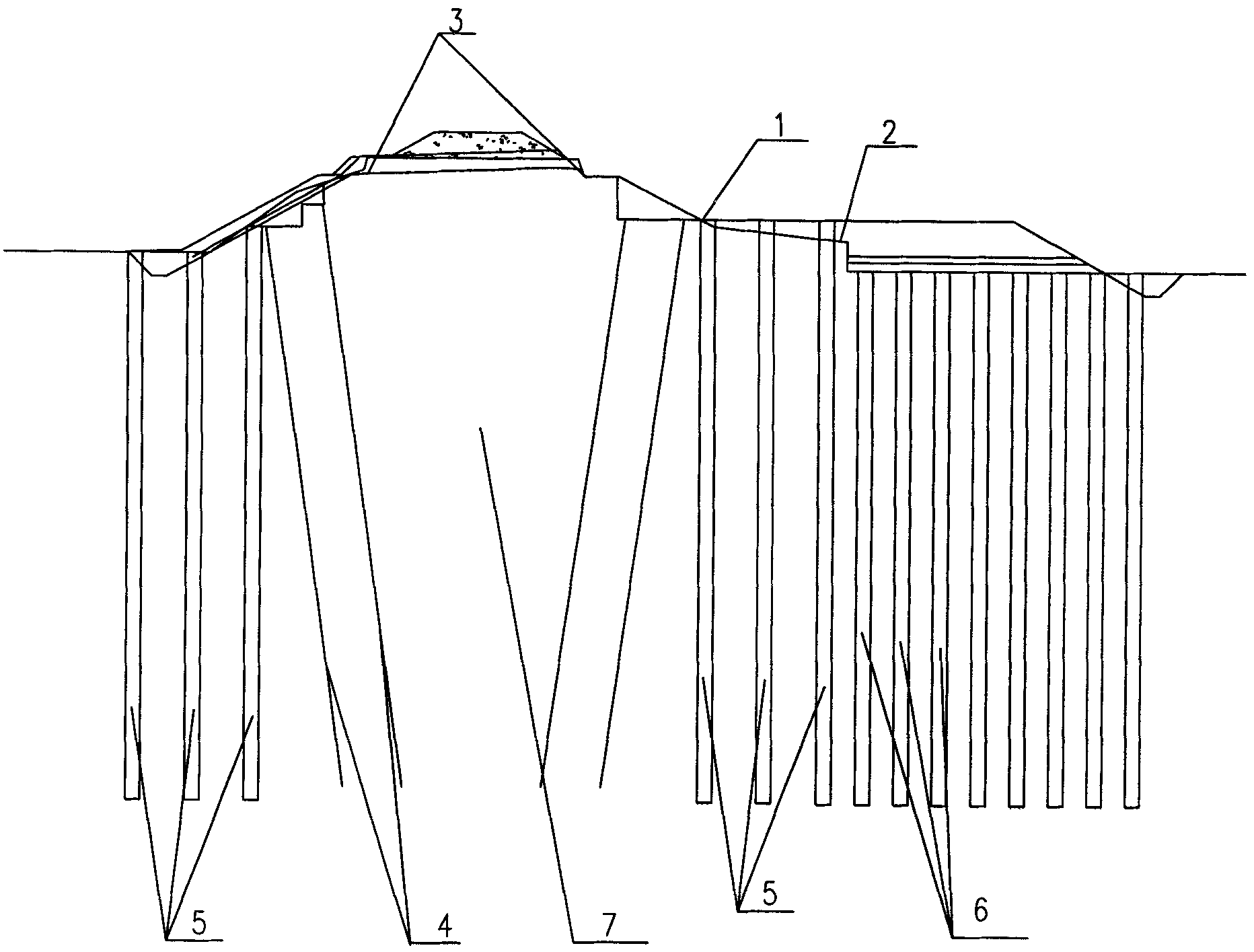

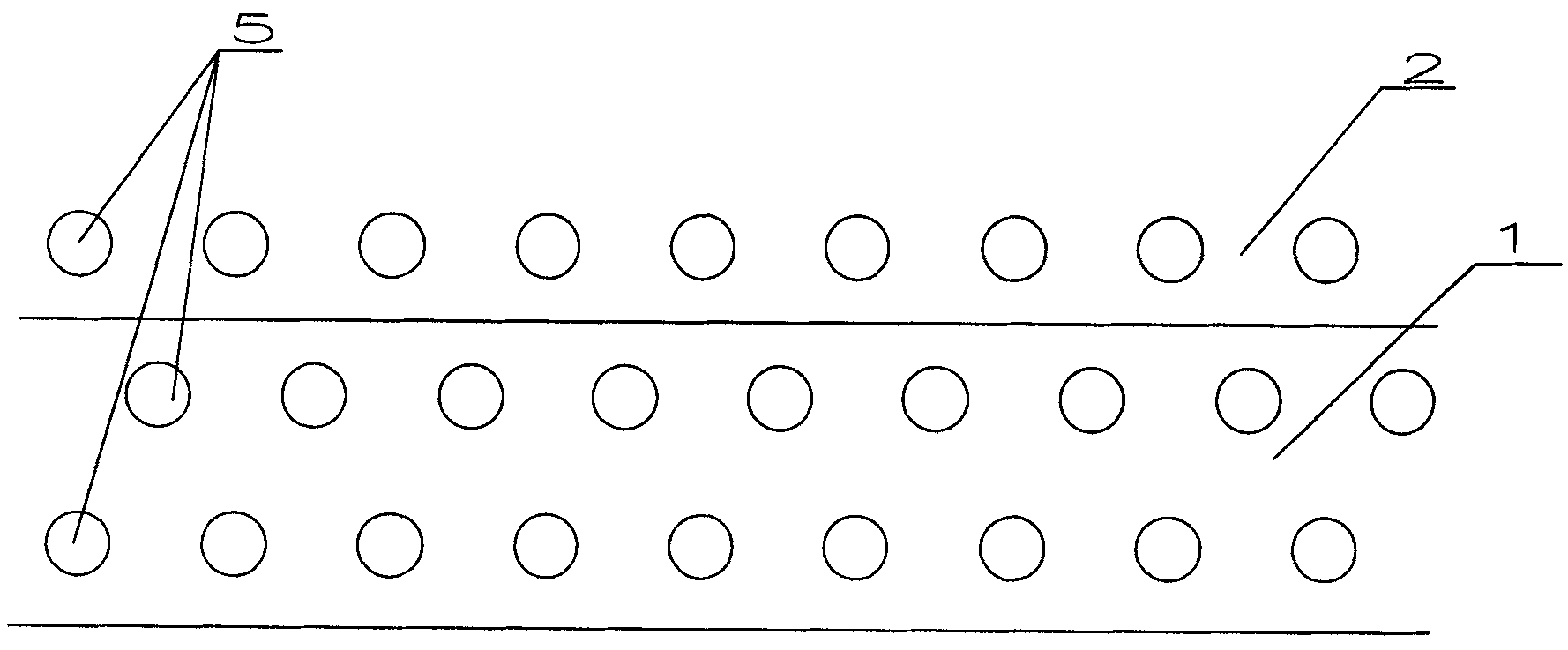

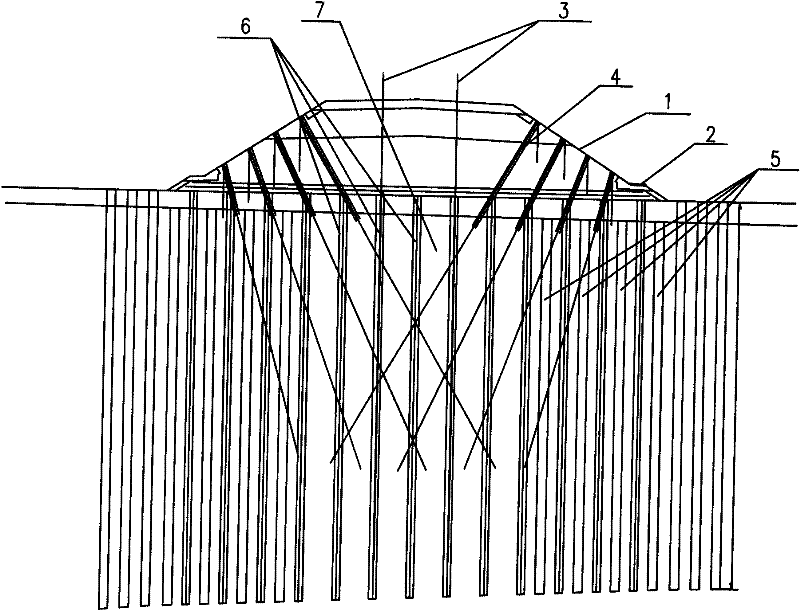

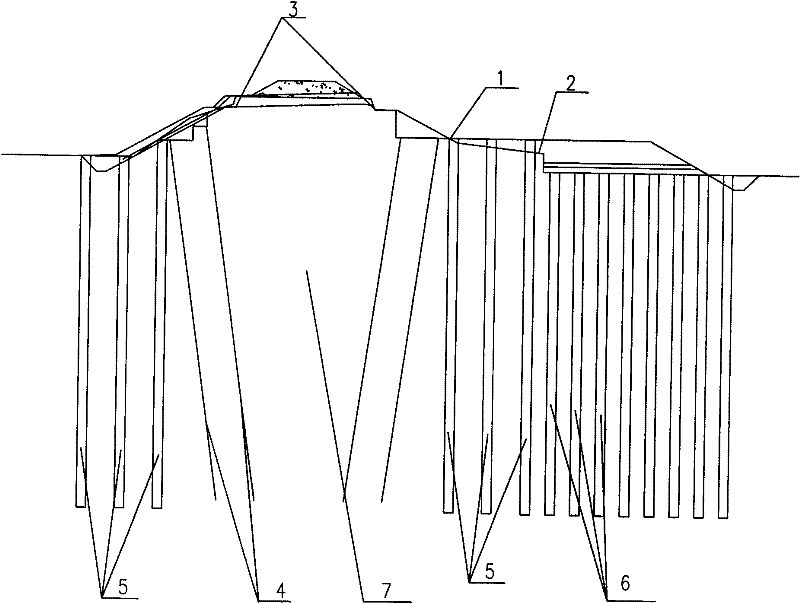

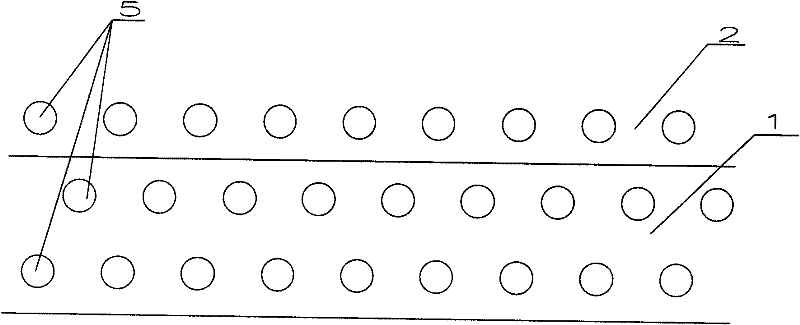

Soft foundation reinforcing method of existing railway or highway subgrade construction

ActiveCN101886382AAvoid traffic disturbanceLess equipmentBulkheads/pilesSoil preservationEngineeringSizing

The invention relates to a soft foundation reinforcing method of the existing railway or highway subgrade construction, which comprises the following steps of: constructing vertical chemical churning piles on the side slope and the slope toe of a subgrade to be reinforced; after the vertical chemical churning piles are cured, drilling a plug hole tilting toward the center line of a track and extending into the soft foundation in the side slope by using a drilling machine; and performing shock tube grouting in the plug hole. A sizing agent in the plug hole permeates towards the periphery of the foundation, the cured sizing agent, the vertical chemical churning piles and the foundation form an integrated reinforcing block, and thus, the reinforcement of the railway or highway subgrade construction is completed. Compared with the traditional single technique, the method has the advantages of no construction transition, no traveling interruption and no reinforcing dead zone by adopting the vertical chemical churning piles together with a shock tube grouting technique. The advantages of both the vertical chemical churning piles and the shock tube grouting technique are fully exerted, and the safety and the quality are controllable.

Owner:广东省铁路规划设计研究院有限公司

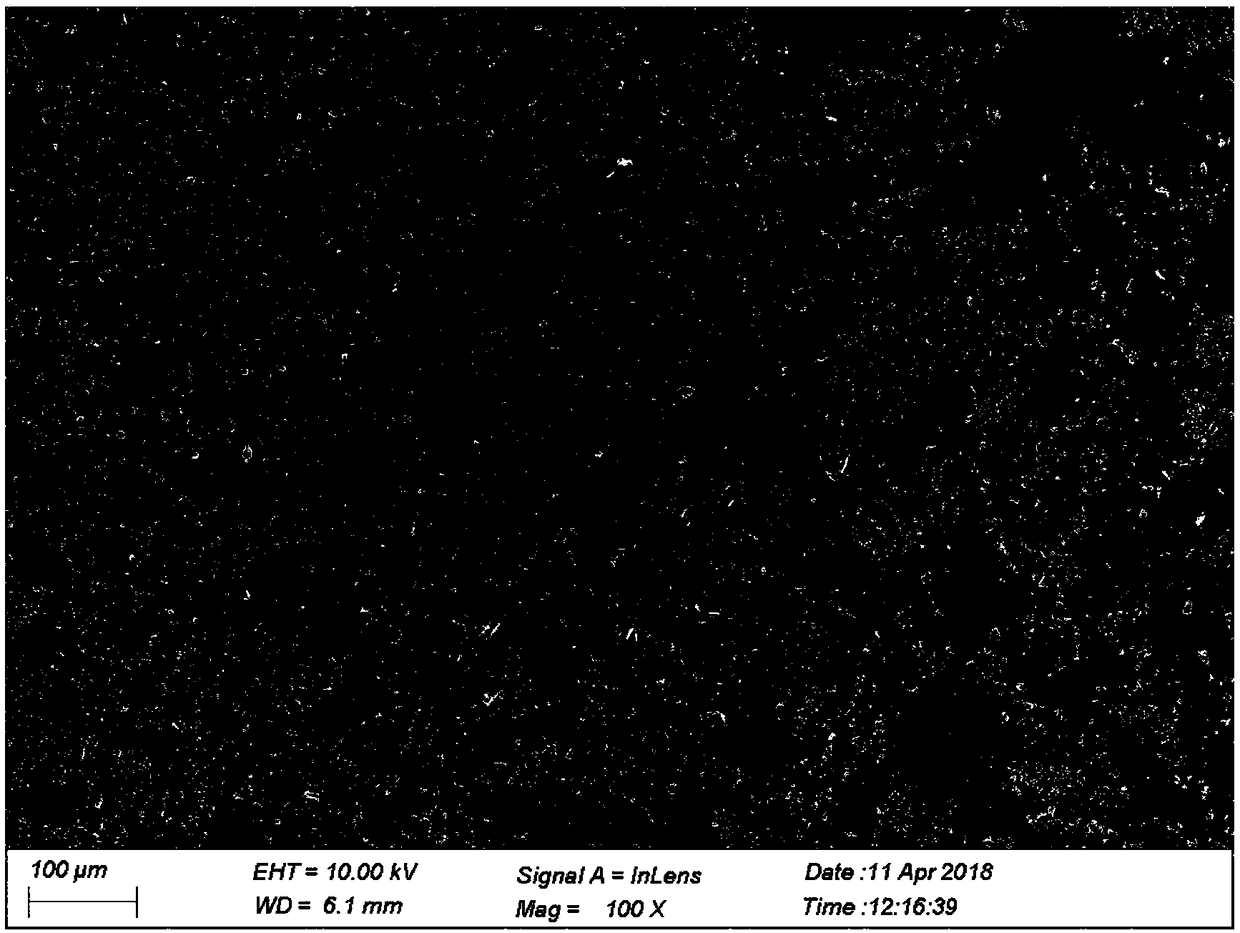

Middle and low temperature curing conductive silver slurry

InactiveCN101373646AAvoid problems such as deformationShorten drying timeConductive materialNon-conductive material with dispersed conductive materialState of artSilver paste

The invention relates to a middle and low temperature curing conductive silver paste. The conductive silver past (by mass percentage )contains 60 to 80 percent of silver powder, 1 to 10 percent of glass powder, 10 to 30 percent of organic solvent, 0.1 to 5 percent of macromolecule resin, and the remaining amount of additive. Compared with the prior art, the curing temperature is 300 to 400 DEG C, the conductive silver paste can be used as a plasma TV dielectric paste and a DBD plane light source paste. Since the curing temperature of the paste is lower, the quality of the product and the production efficiency can be improved.

Owner:IRICO

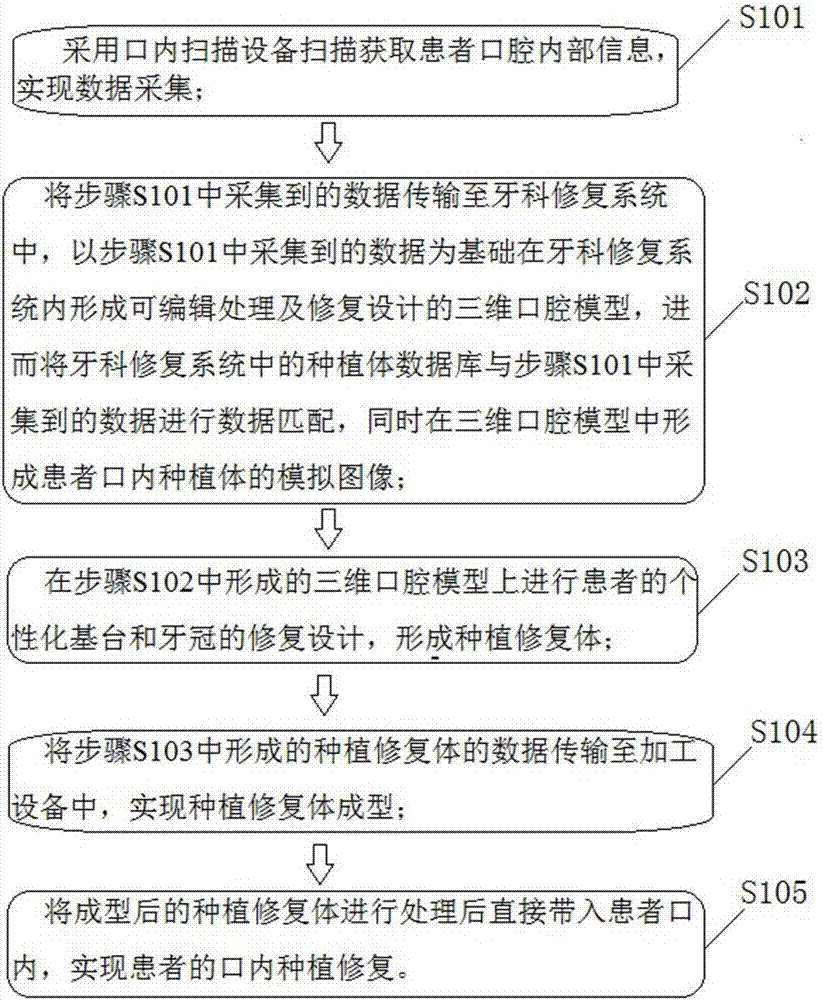

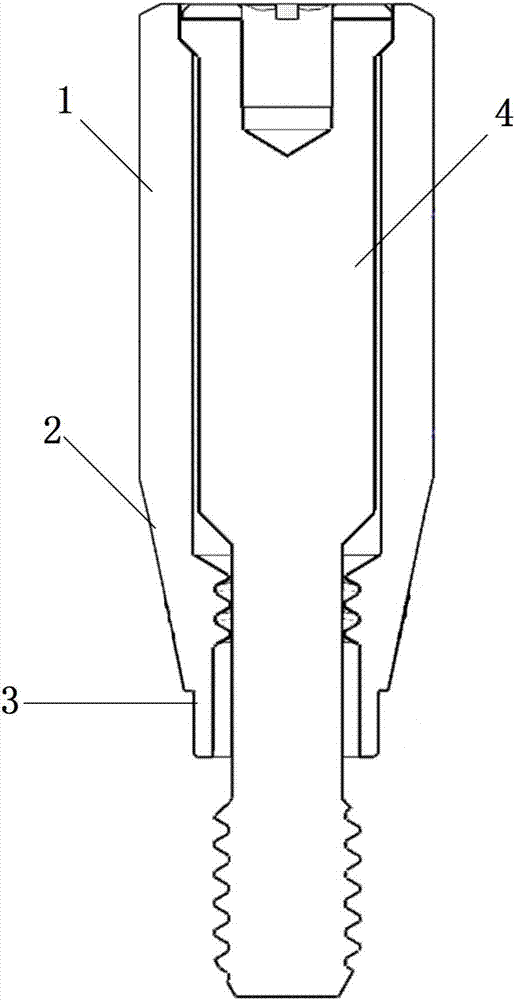

Dental chair-side implant restoration digitization implementation method

InactiveCN107019570AGet quicklyEasy accessDental implantsImpression capsData matchingData acquisition

The invention belongs to the technical field of dental restoration, and discloses a dental chair-side implant restoration digitization implementation method. The method comprises the following steps: scanning and acquiring internal formation of the mouth cavity of a patient by adopting in-mouth scanning equipment to realize data acquisition; transmitting the acquired data into a dental restoration system; forming a three-dimensional mouth cavity model capable of being subjected to edition processing and restoration design in the dental restoration system based on the acquired data to further carry out data matching between an implant database and the acquired data in the dental restoration system; forming an analog image of the implant in the mouth of the patient in the three-dimensional mouth cavity model at the same time; carrying out restoration design of a personalized base and a dental crown of the patient on the formed three-dimensional mouth cavity model to form an implant-supported prosthesis; transmitting the data of the formed implant-supported prosthesis into processing equipment to realize formation of the implant-supported prosthesis; processing the formed implant-supported prosthesis and directly bringing into the mouth of the patient to realize implant restoration in the mouth of the patient. The dental chair-side implant restoration digitization implementation method is suitable for being applied to the field of dental restoration.

Owner:江苏福隆数齿科技有限公司

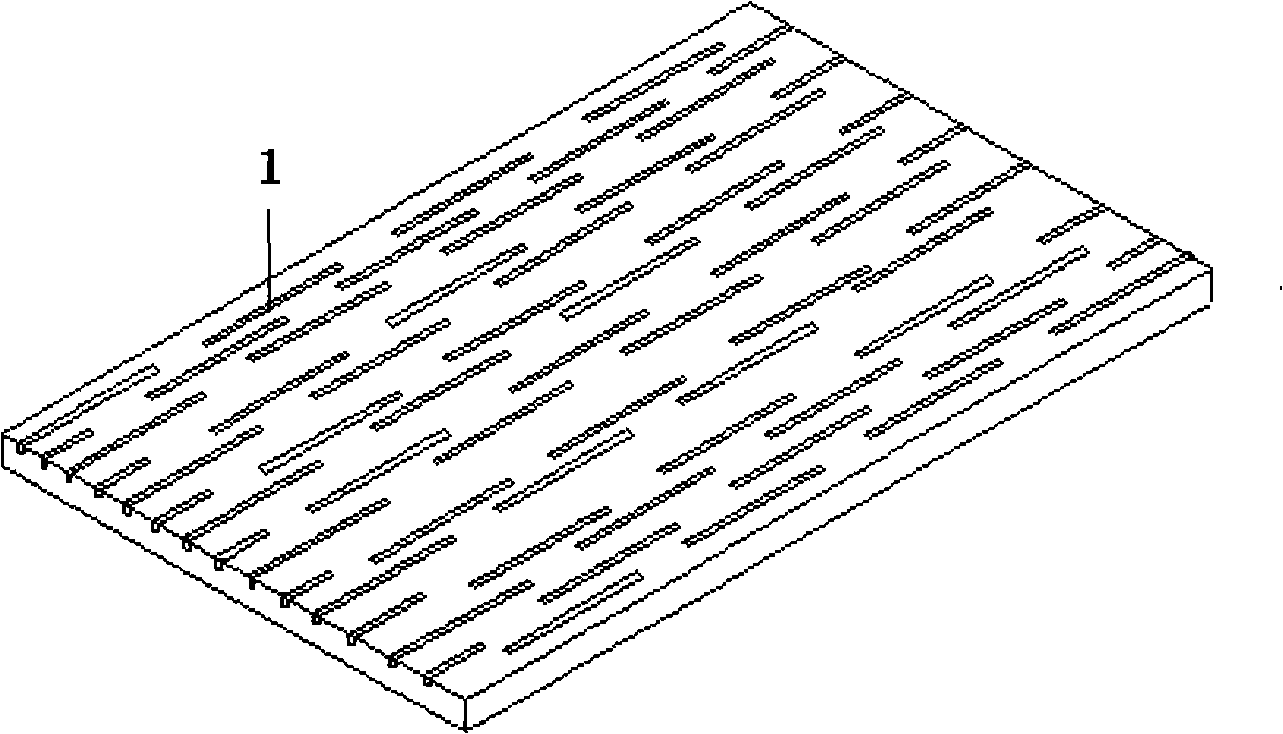

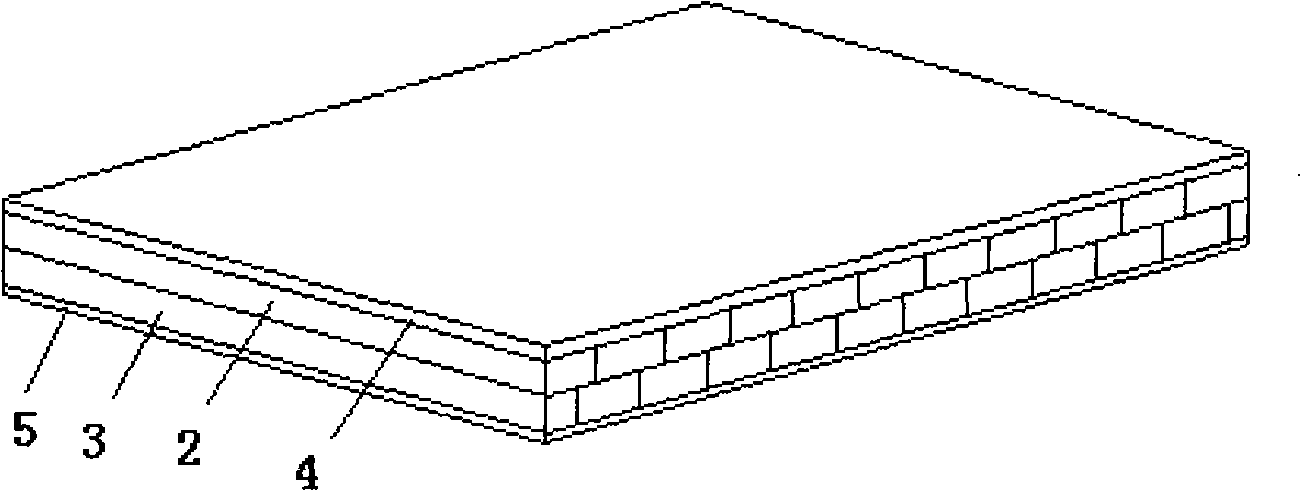

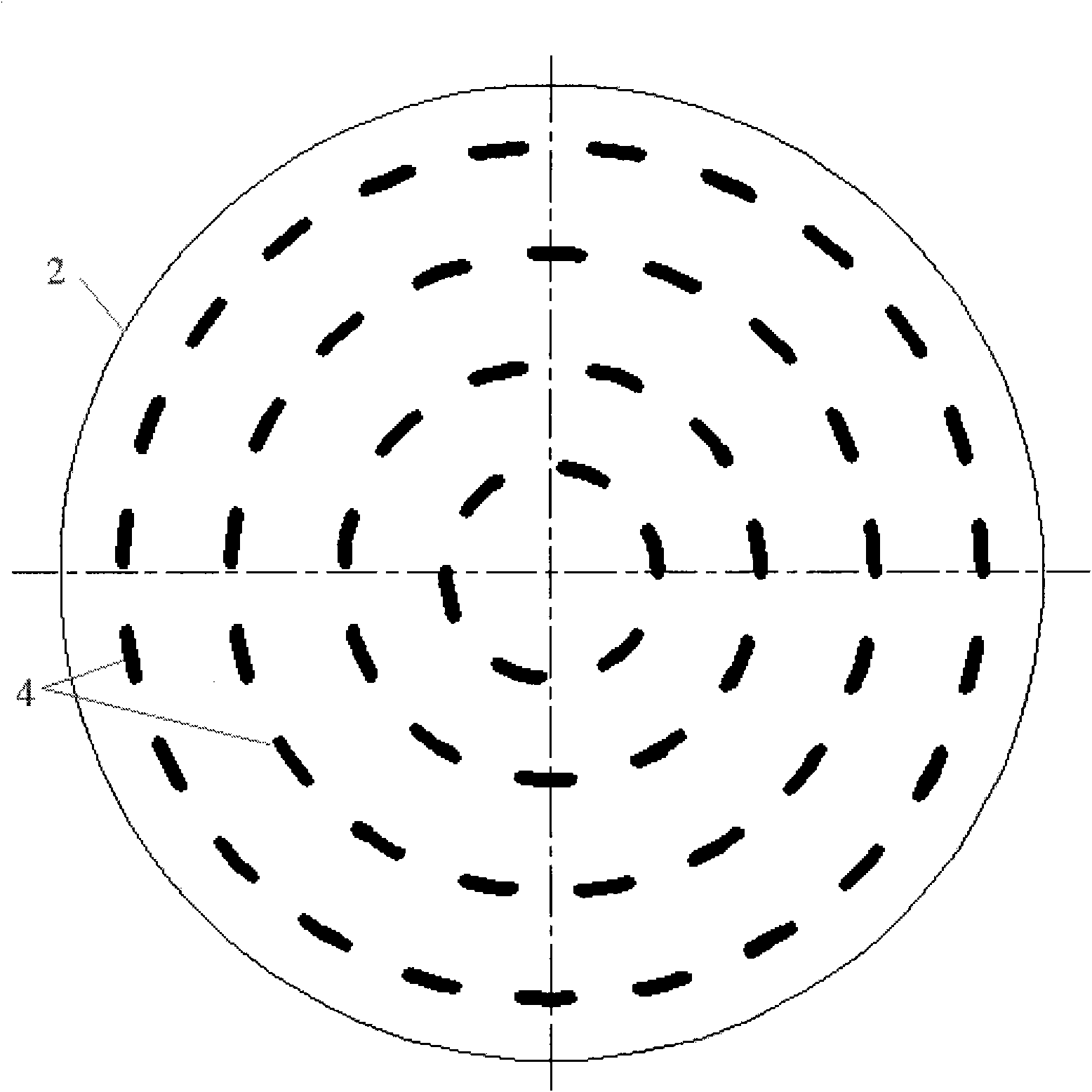

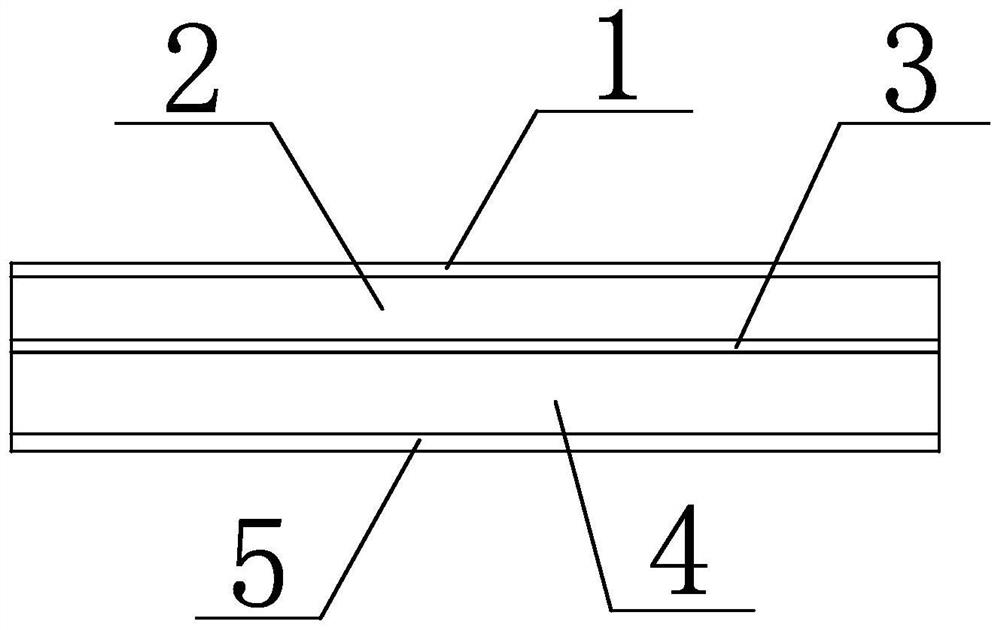

Solid-wood composite board made of super-thick single boards and producing method thereof

ActiveCN101524859ALarge specific surface areaImprove drying rateWood veneer joiningWood layered productsSolid woodSurface layer

The invention provides a solid-wood composite board made of super-thick single boards, which comprises two surface layers on external surfaces and a core layer between the two surface layers, adhesive is arranged among single boards, the core layer comprises a super-thick single board with the thickness of 6 mm to 12 mm, and the surface layers comprise single boards with the thickness of 0.2mm to1.5 mm. The super-thick single boards of the core layer are single boards made by rotatably cutting logs, and spot-shape or segment-shape crack grains are arranged on the loosened surface of the single boards in the direction along the grain. The solid-wood composite board made of super-thick single boards enables the composite board combined by the super-thick core boards to have no distortion or deformation by adopting the central-symmetric single-board assembly structure and forming spot-shape or segment-shape crack grains by discongesting on the surfaces of the single boards of the core layer, and has equal performance as that of the solid wood. The super-thick core board enables the glue layers of the veneer to be reduced, the applied glue amount is reduced, the cost is saved, and the release amount of the formol can be reduced to enable the solid-wood composite board to be more environmental friendly.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Regenerative ceramic tile and producing method thereof

The invention discloses a regenerative ceramic tile and a producing method thereof, which belongs to the field of building materials. The regenerative ceramic tile is prepared by mainly comprising the steps that discarded electrolytic manganese waste-residues of electrolytic manganese factories, discarded porcelain tile polishing waste residues of ceramics factories and waste glass fragments are taken as raw materials, after electrolytic manganese waste-residues, porcelain tile polishing waste residues and waste glass dust subjected to natural air-drying are uniformly mixed according to certain proportion, the obtained mixture is subjected to compression molding, and then a regenerative ceramic tile is produced by using a high-temperature fast burning process. By using the technical scheme of the invention, because all the product raw materials come from industrial waste residues, the regenerative ceramic tile is an effective way for carrying out recycling reutilization on industrial solid wastes and solving the environment pollution problem of the regenerative ceramic tile. The regenerative ceramic tile disclosed by the invention is simple in production technique and high in product quality, can be widely applied to the laying of building walls, roads and squares, and has good social, economic and environmental benefits.

Owner:HUNAN UNIV OF SCI & TECH

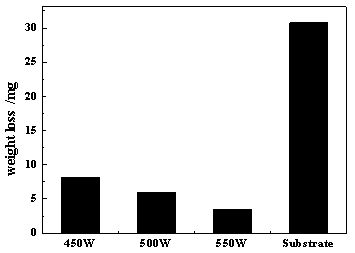

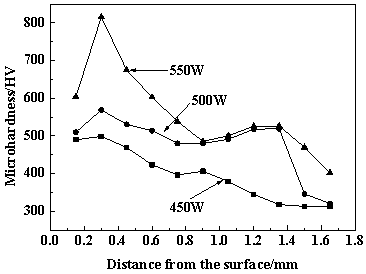

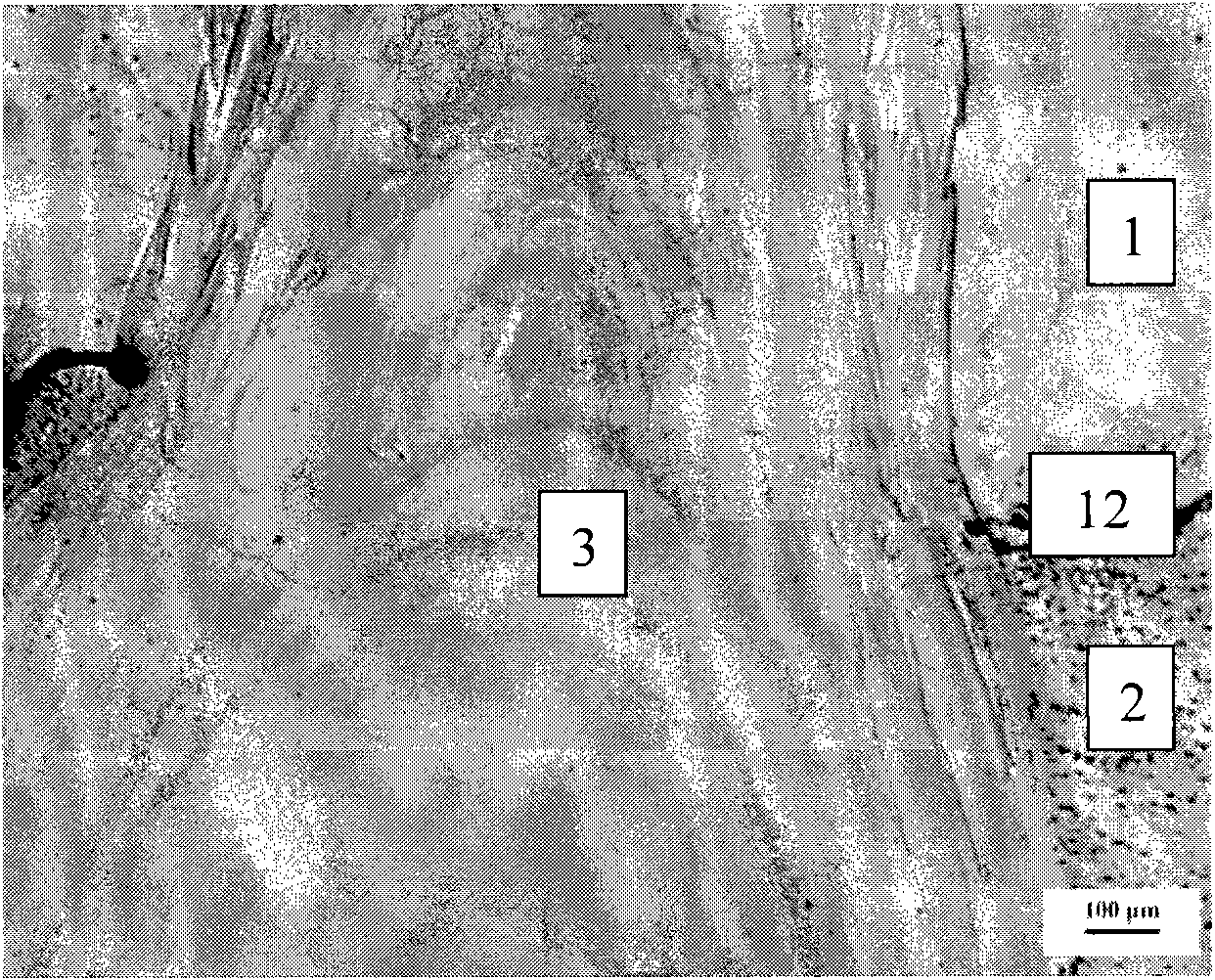

Preparation method for wear-resistant and corrosion-resistant composite coating layer

InactiveCN108611636AHigh hardnessAccelerated corrosionAdditive manufacturing apparatusMetallic material coating processesStellite alloySurface layer

The invention discloses a preparation method for a wear-resistant and corrosion-resistant composite coating layer. The preparation method specifically comprises the following steps: S1. carrying out pretreatment on a cladding matrix; S2. carrying out drying treatment on a cladding material; S3. melting the cladding material and the surface layer of the cladding matrix simultaneously through a laser device and in combination with a coaxial powder feeding method to form an alloy coating layer, that is, the high-hardness corrosion-resistant layer, wherein the cladding matrix in the step S1 is made from Q960 steel; and the cladding material in the step S2 is made from the mixture of tungsten carbide powder and Stellite 6 alloy powder. According to the preparation method disclosed by the invention, the composite coating layer is creatively prepared on the surface of the Q960 steel through a laser cladding technology; the tungsten carbide powder and the Stellite 6 alloy powder are mixed as the cladding material in a specific ratio; and the process parameters of the laser cladding technology are scientifically and reasonably designed, so that the problems of low hardness and short servicelife under the working condition of abrasive wear, of a laser cladding coating layer made from Stellite 6 cobalt alloy, are effectively solved.

Owner:HUNAN UNIV OF TECH +2

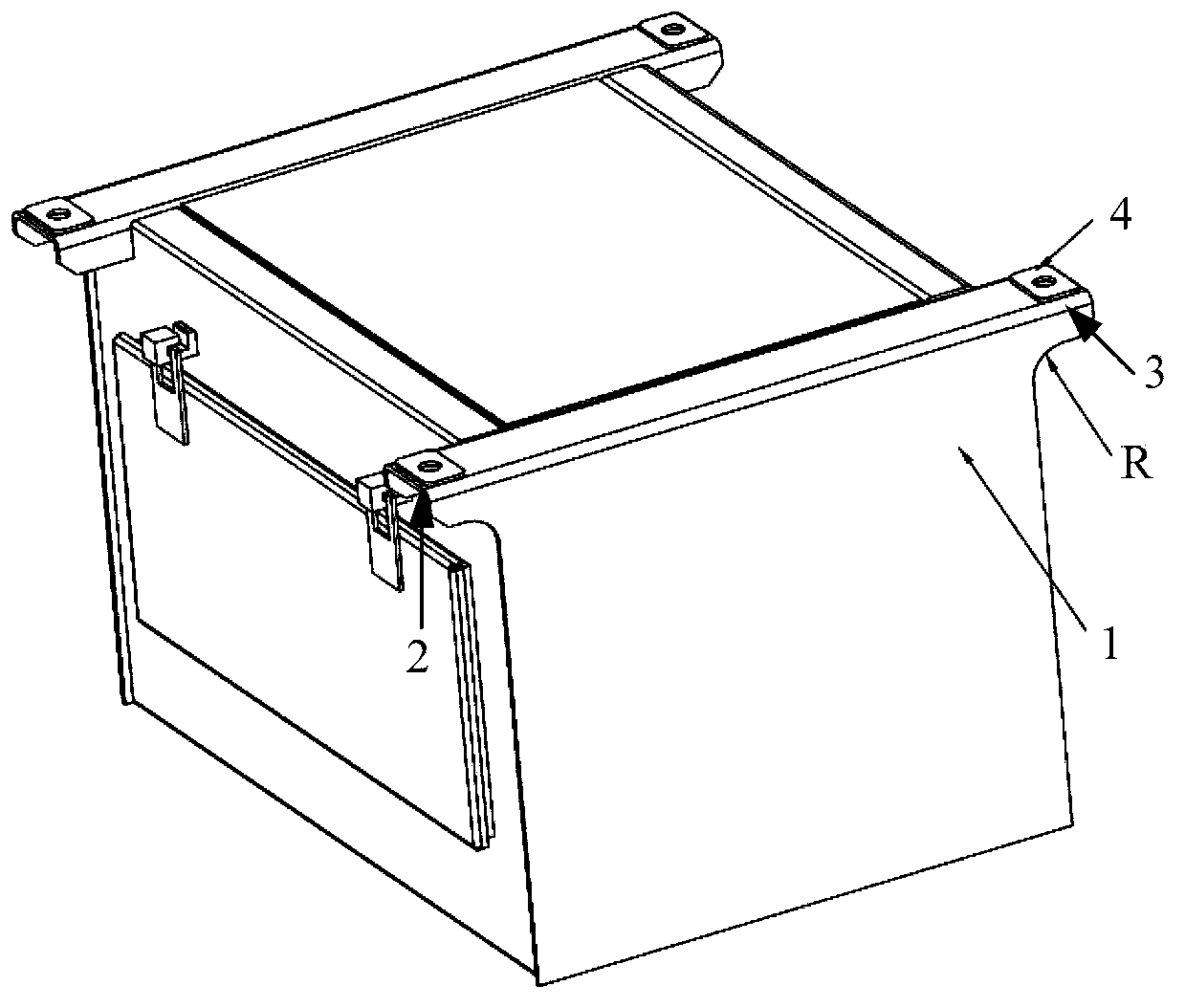

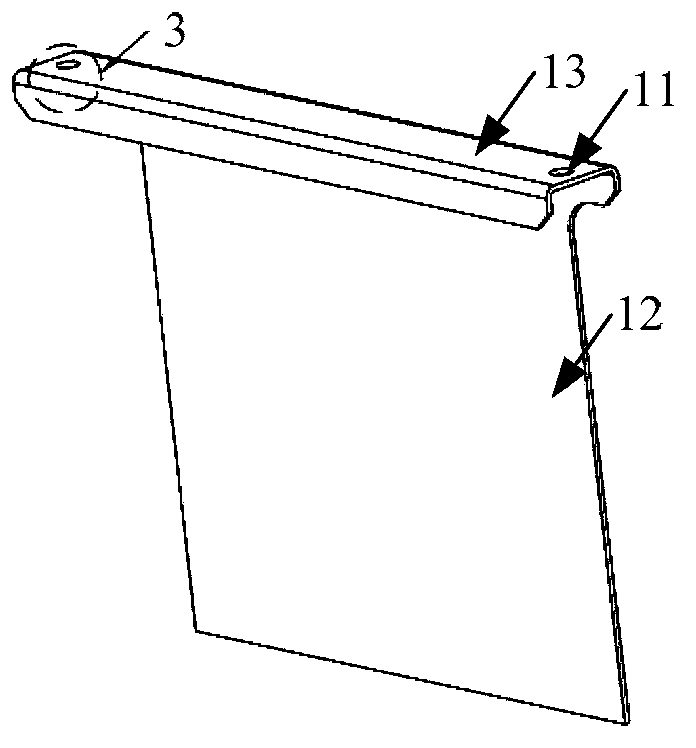

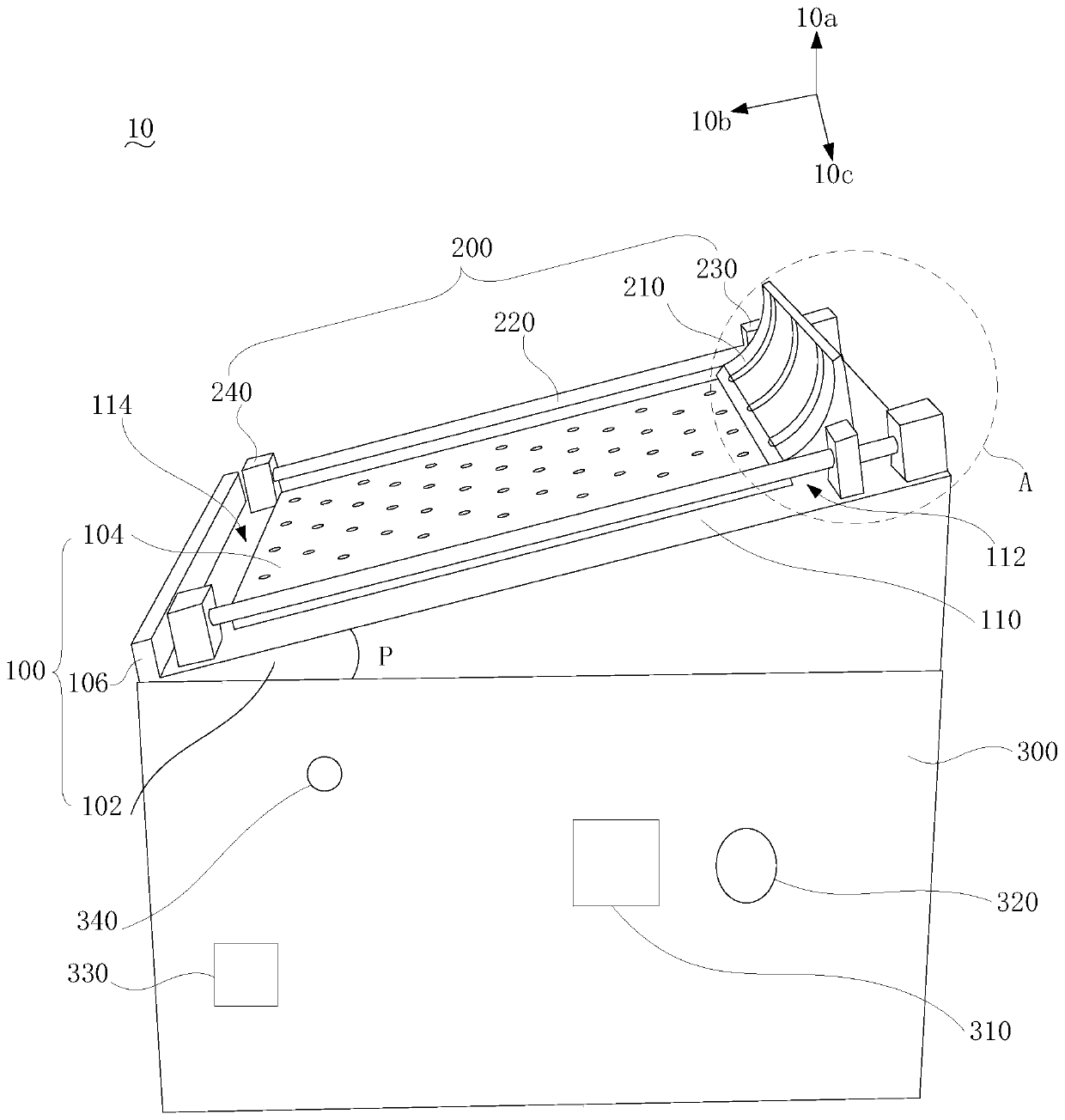

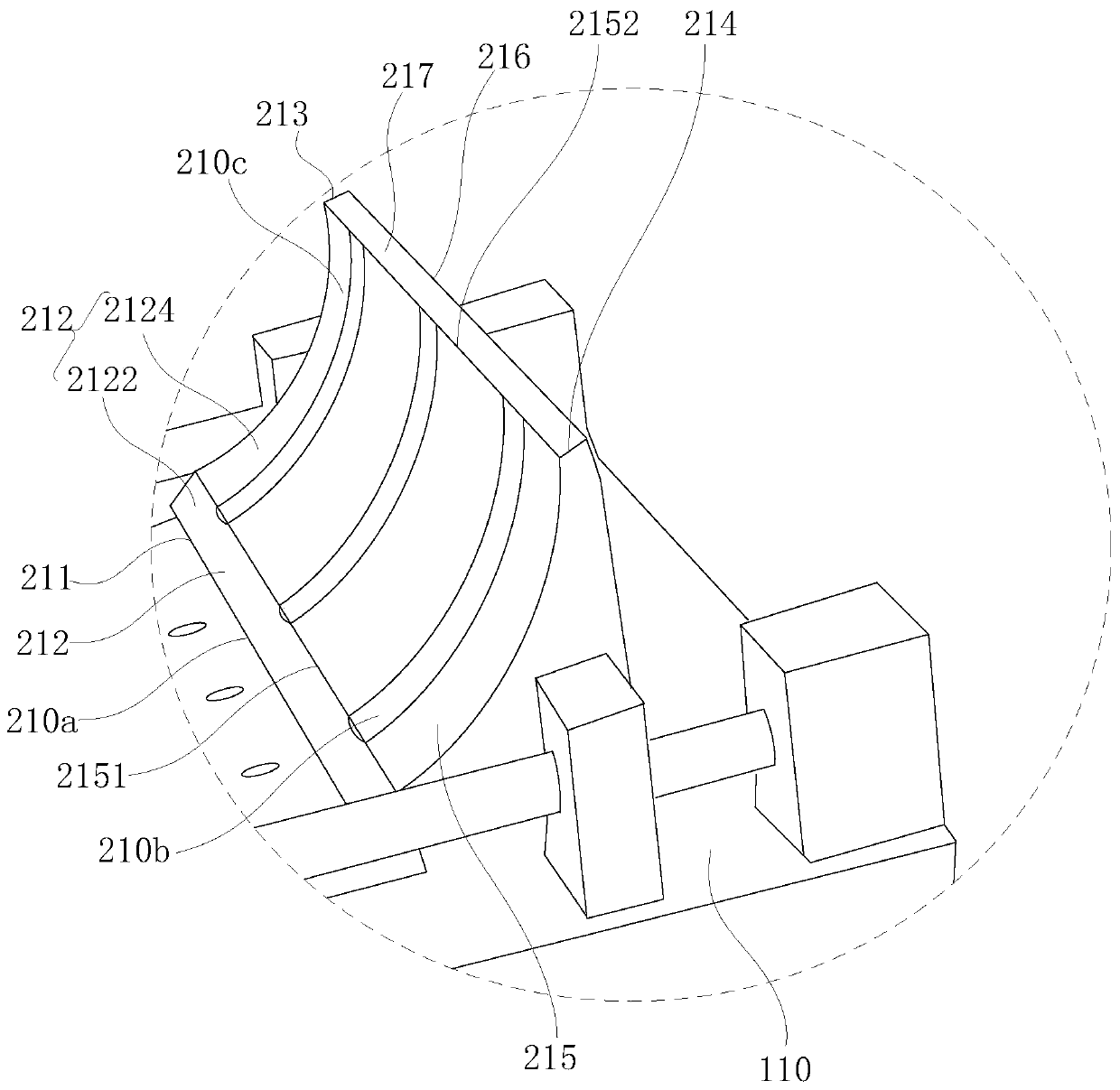

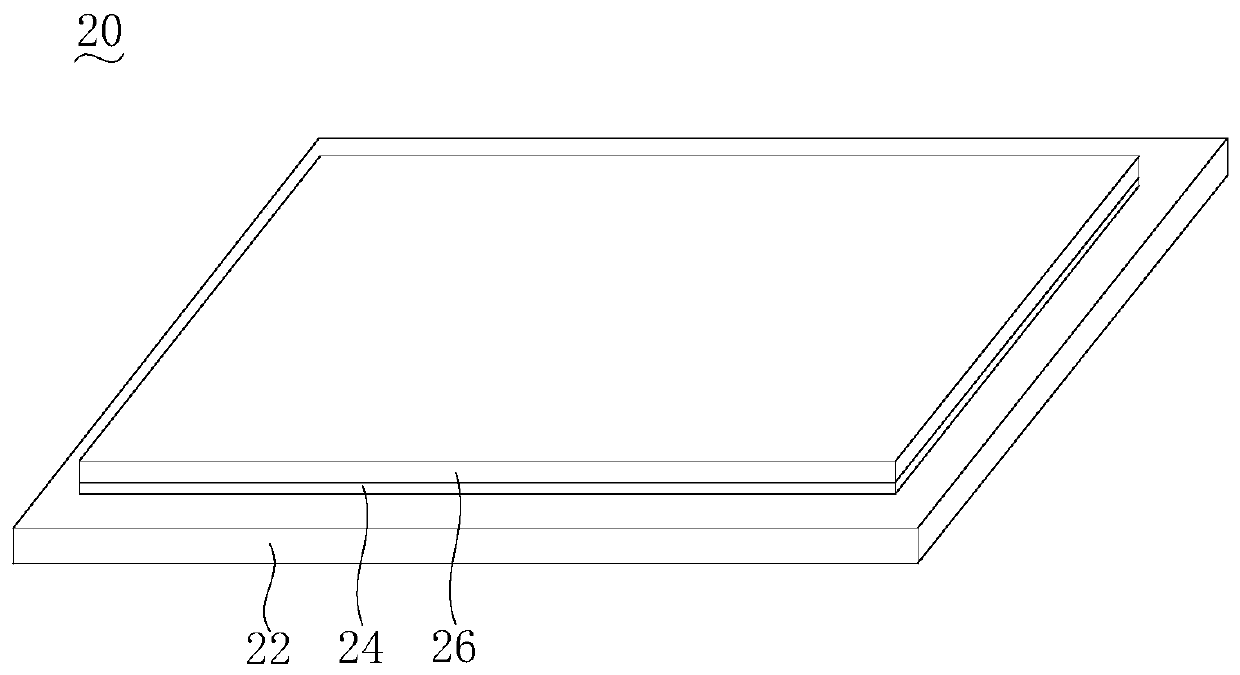

Liquid containing groove and pparatus and method for three-dimensional printing

ActiveCN106926449AAvoid problems such as deformationAvoid damageManufacturing enclosures3D object support structuresLiquid stateLiquid tank

A liquid containing groove is suitable for a three-dimensional printing device for containing liquid photosensitive material. The liquid tank includes a film and a plate. The film has a working area, and the plate supports the film and has at least one fluid tunnel extending from a first surface of the plate contacting the film to a second surface of the plate. The motor is disposed on the liquid tank, providing dragging-down traction to incline the liquid tank. The embodiments of the present invention facilitate the separation of workpieces from the film. Another three-dimensional printing apparatus and a three-dimensional printing method are also provided.

Owner:YOUNG OPTICS

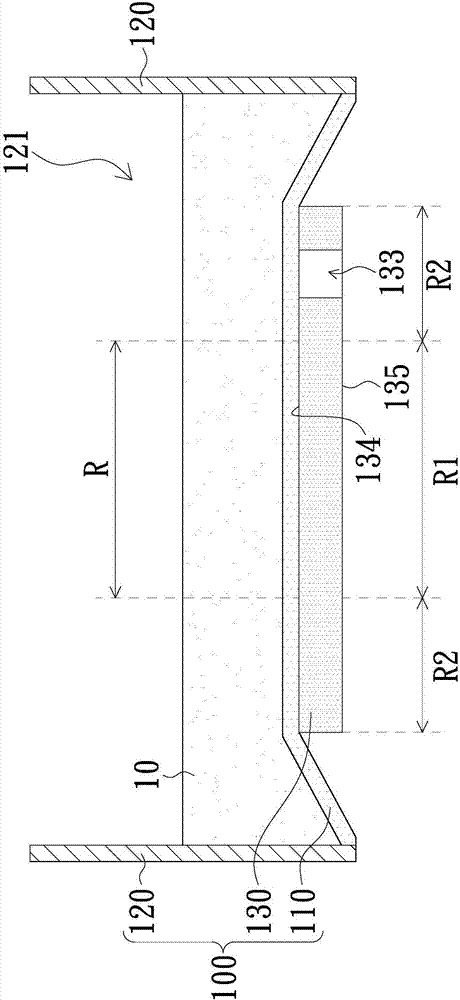

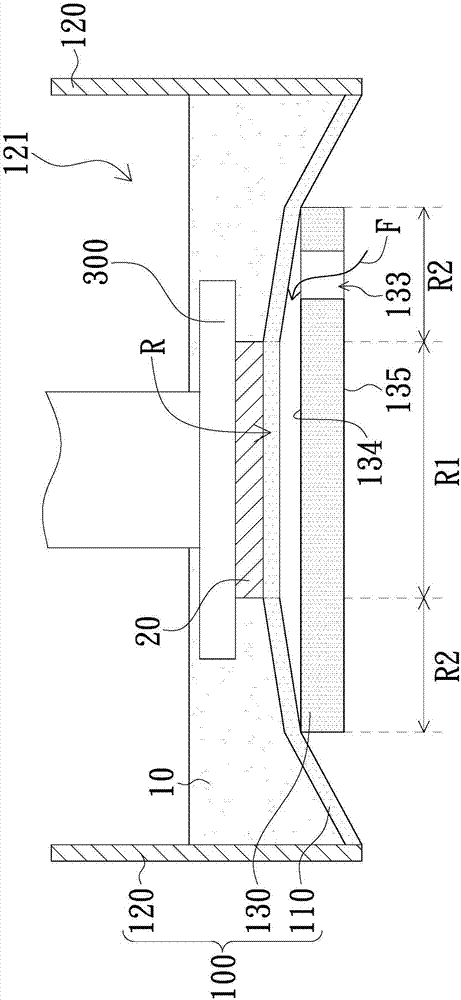

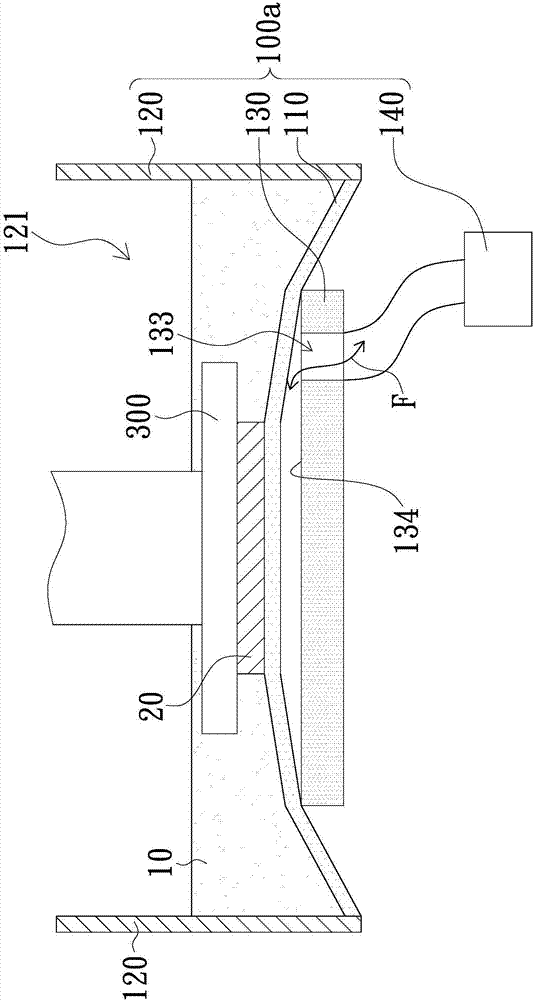

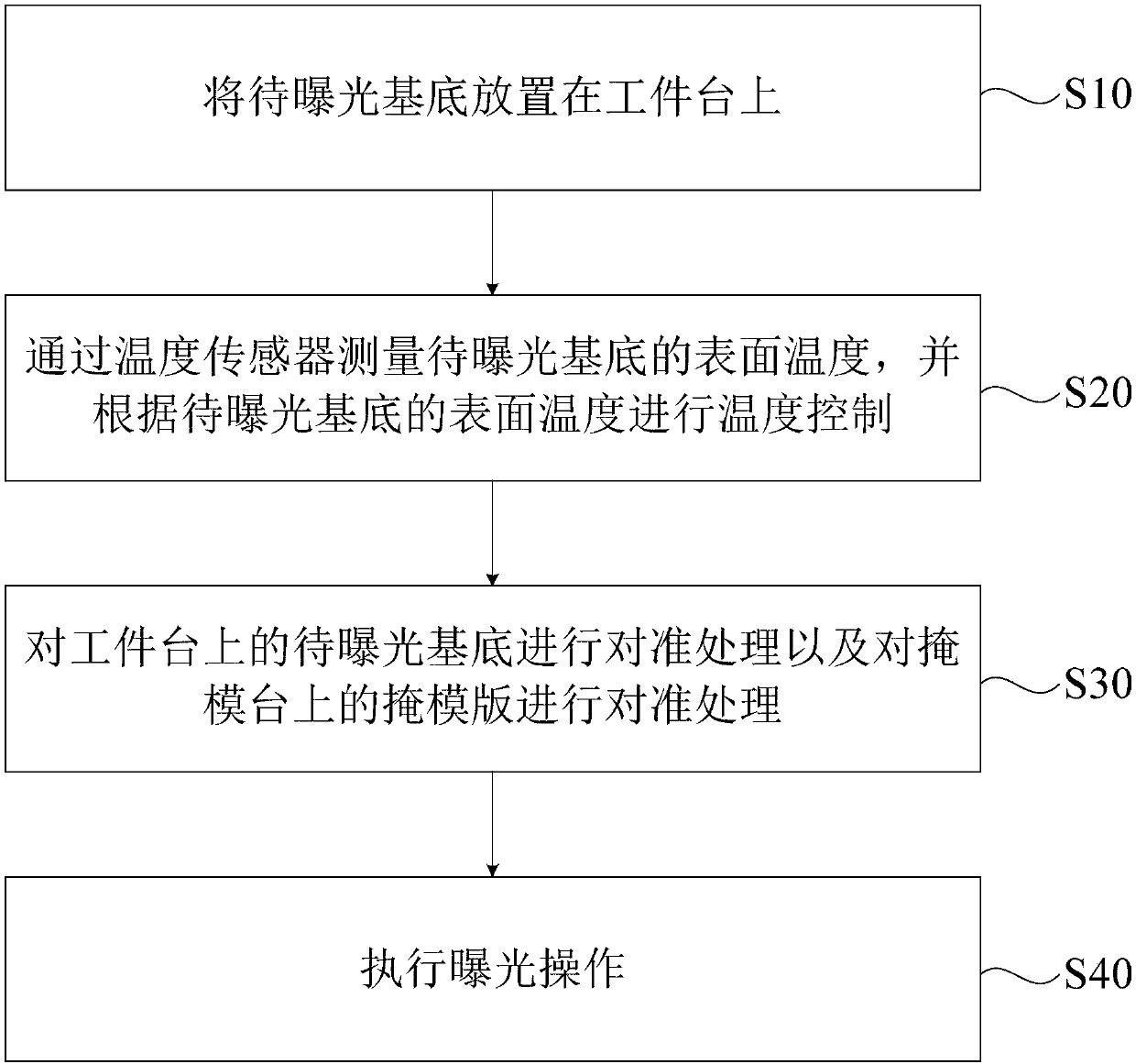

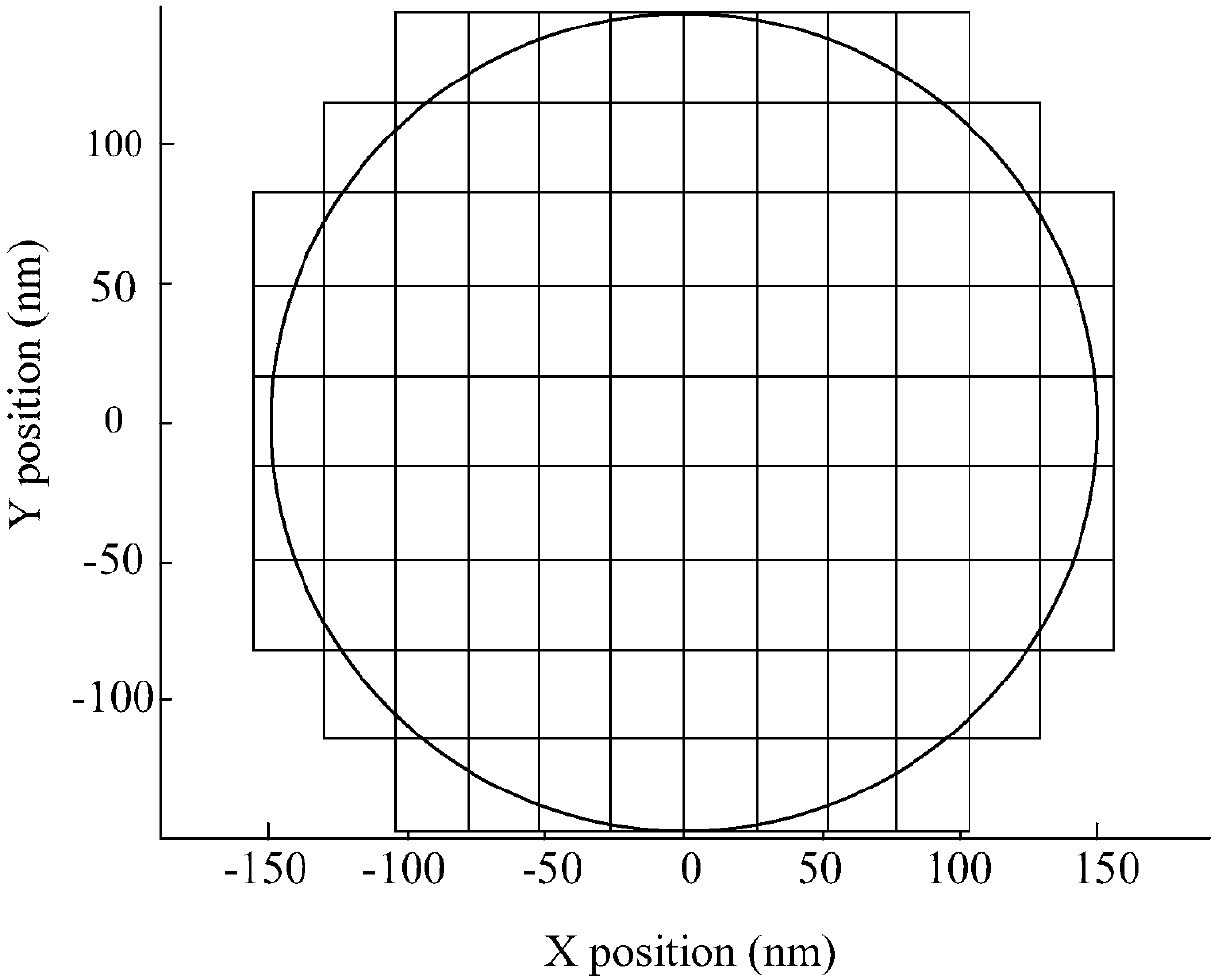

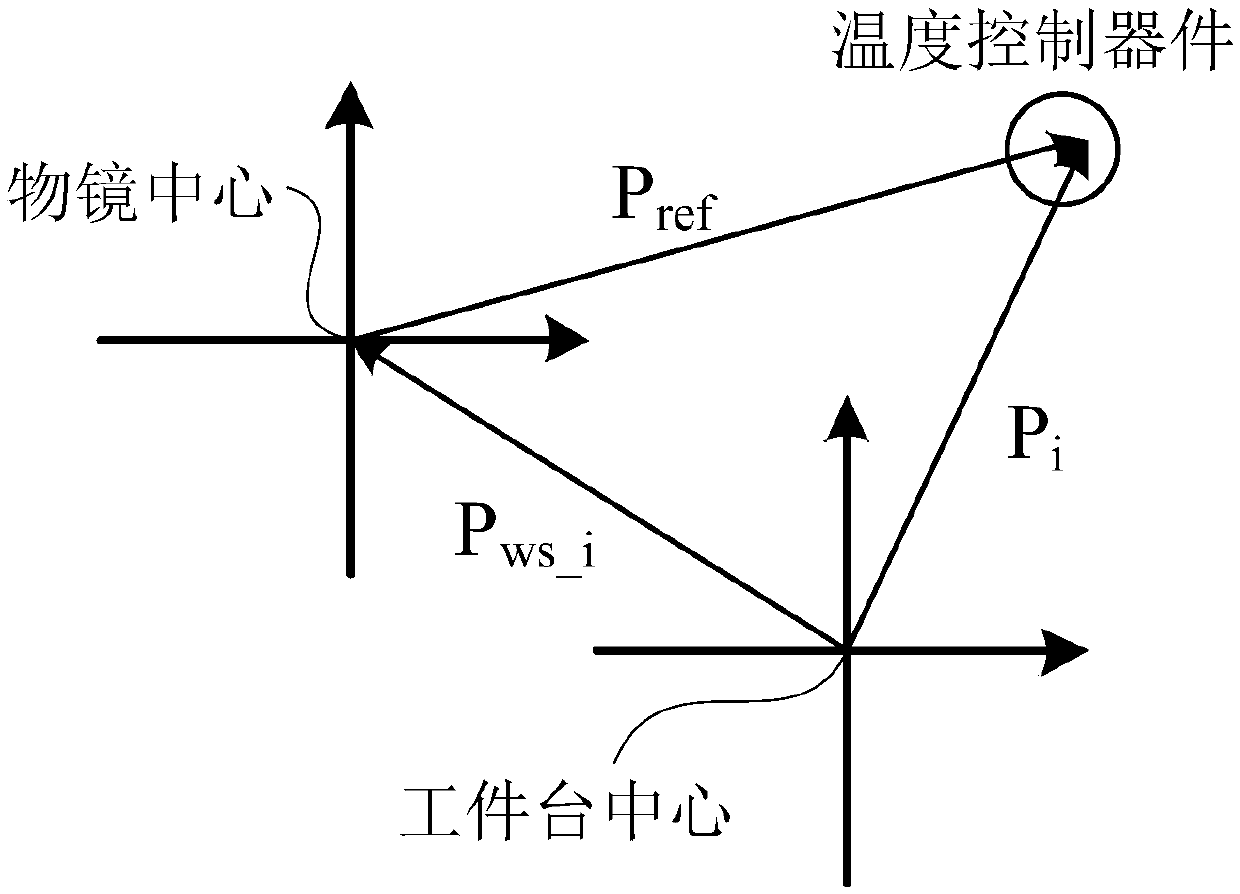

Exposure method and manufacturing method of semiconductor device

ActiveCN110361938AReduce temperature differenceAvoid problems such as deformationPhotomechanical exposure apparatusMicrolithography exposure apparatusTemperature controlTemperature difference

The invention provides an exposure method and a manufacturing method of a semiconductor device. The exposure method comprises the steps of: putting a substrate to be exposed on a workpiece table; measuring the surface temperature of the substrate to be exposed by a temperature sensor, and performing temperature control according to the surface temperature of the substrate to be exposed; performingaligning processing for the substrate to be exposed on the workpiece table, and performing aligning processing for a mask on a mask platform; and executing exposure operation. According to the technical scheme provided by the invention, the substrate to be exposed is subjected to temperature control to reduce the temperature difference of the substrate to be exposed between the aligning operationand the exposure operation so as to avoid the problems of the deformation of the substrate to be exposed caused by too large temperature difference and improve the accuracy when the substrate to be exposed is exposed.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Cabinet used for converter, converter and rail vehicle

ActiveCN104143899AImprove structural rigidityPlay a sealing roleSupports/enclosures/casingsPower conversion systemsBiomedical engineering

The invention provides a cabinet used for a converter, the converter and a rail vehicle. The cabinet used for the converter comprises a wallboard assembly and skin, wherein the wallboard assembly comprises a plurality of first wallboards and a plurality of second wallboards, and the first wallboards and the second wallboards define a cavity in an enclosed mode; the first wallboards and the second wallboards are wrapped with the skin. Lugs extending outwards are integrally formed at the two ends of each first wallboard and are wrapped with the skin, each lug is provided with a first installation hole, and the skin is provided with second installation holes corresponding to the first installation holes. According to the cabinet, the lugs and a cabinet body are integrated, the structural strength of the cabinet is improved, the service life of the skin is prolonged and hoisting installation performance of the cabinet is improved.

Owner:CHINA CNR CORPORATION

Ultra-thin renewable ceramic brick and making method thereof

InactiveCN104326734AEasy curingAvoid problems such as deformationCeramic materials productionClaywaresSlagIon

Owner:谭国华

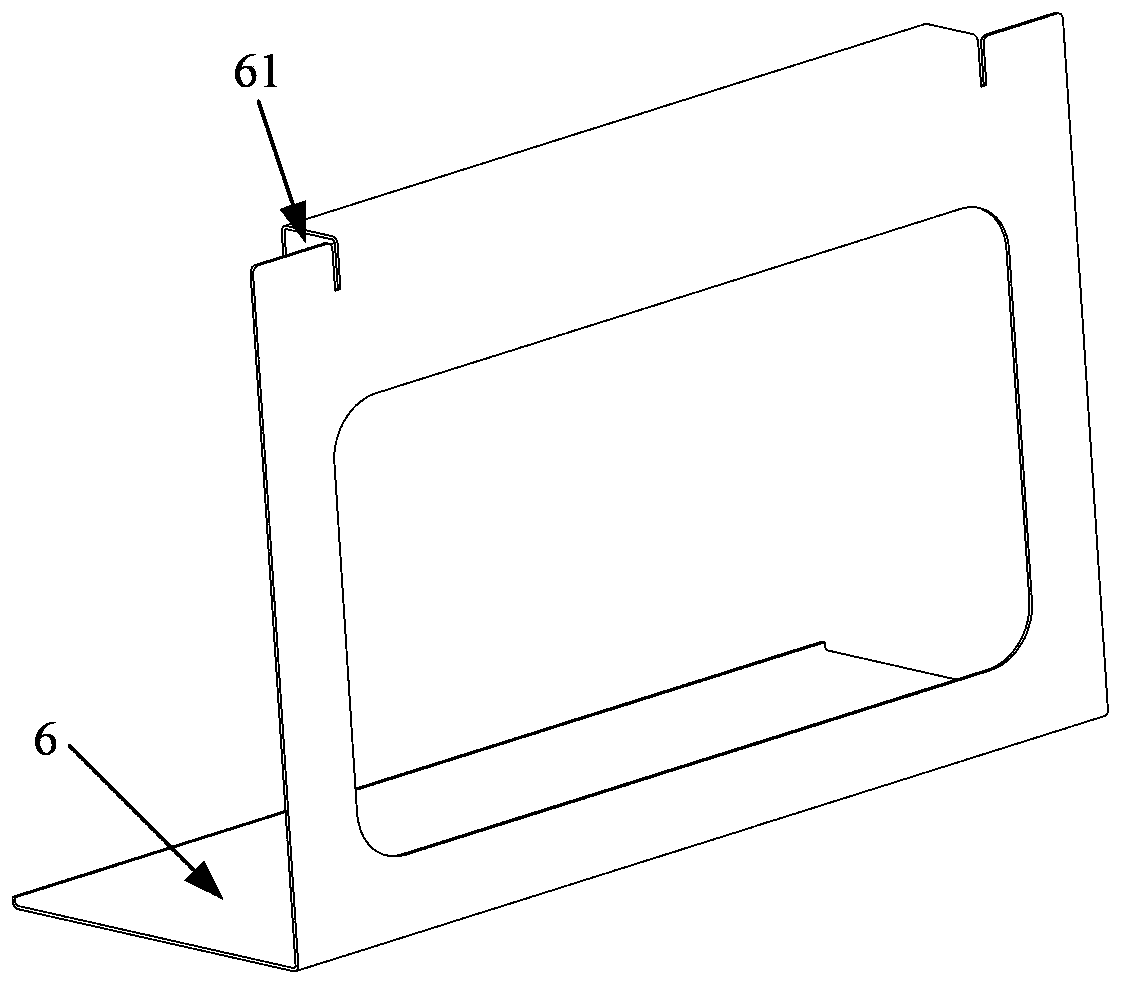

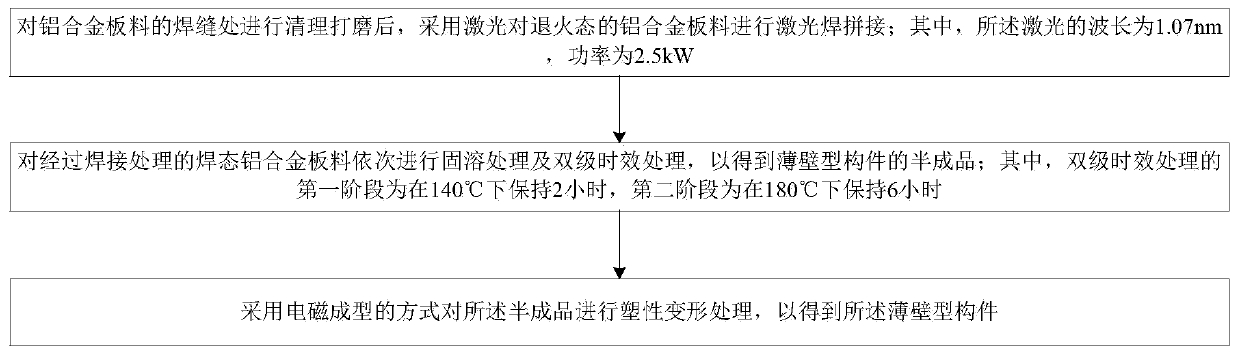

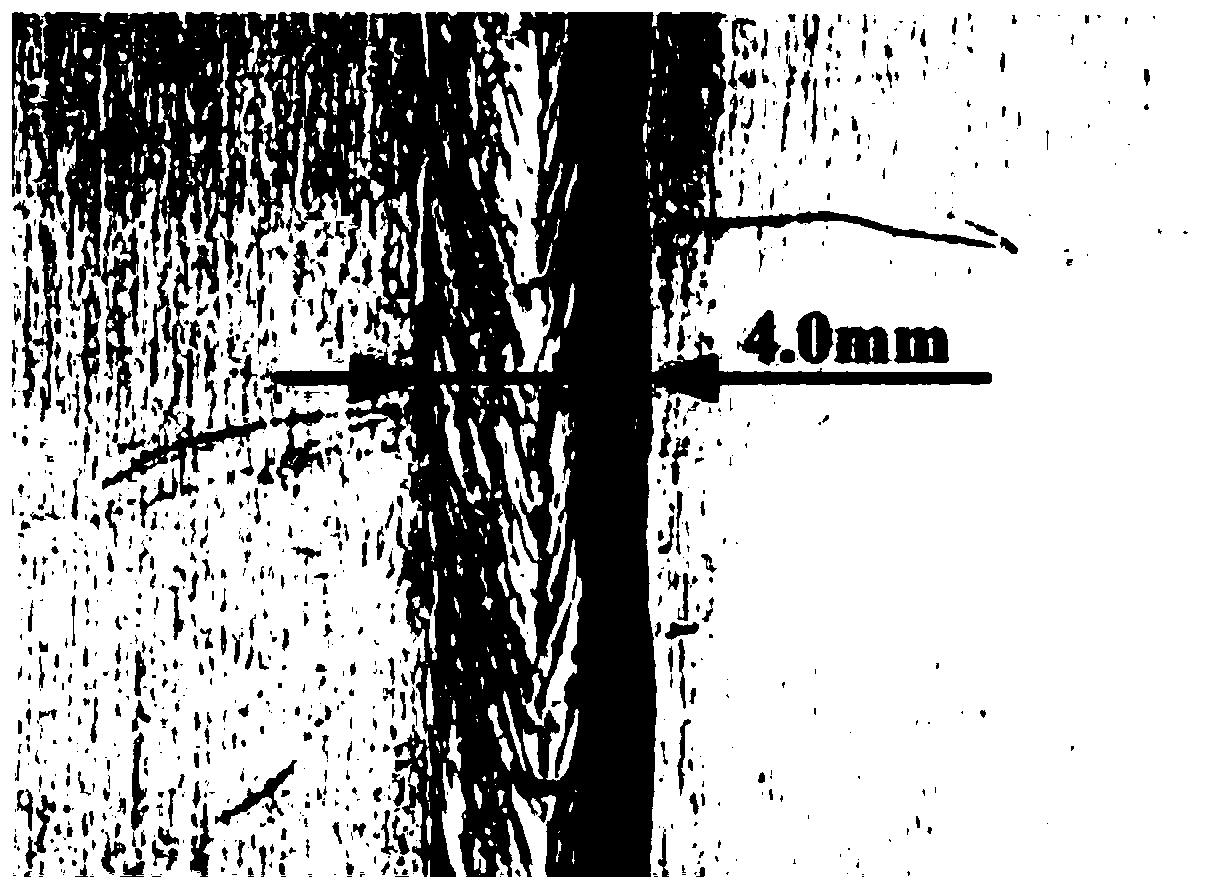

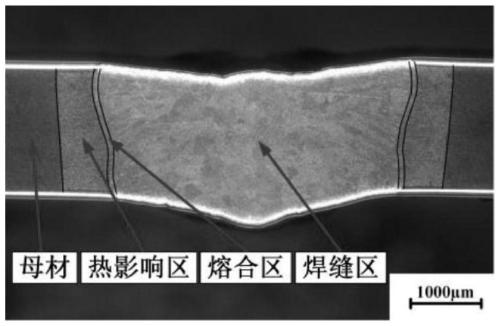

Full-process processing method applicable to heat-treatment-enhanced aluminum alloy

PendingCN109732206AAvoid clamping difficultiesAvoid welding residual stress is difficult to releaseLaser beam welding apparatusThin walledWork in process

The invention belongs to the technical field related to the preparation of aviation and spaceflight large thin-wall components, and discloses a full-process processing method applicable to a heat-treatment-enhanced aluminum alloy. The method comprises the following steps that (1) after a weld joint of an aluminum alloy plate material is cleaned and polished, laser welding and splicing are carriedout on the aluminum alloy plate material in an annealed state by using laser, wherein the wavelength of the laser is 1.07 nm, and the power of the laser is 3.5 kW; (2) solution treatment and dual-stage aging treatment are sequentially carried out on the welded aluminum alloy plate material subjected to welding treatment so as to obtain a semi-finished product of a thin-wall component, wherein thefirst stage of the dual-stage aging treatment is kept at 140 DEG C for 2 hours, and the secondary stage of the dual-stage aging treatment is kept at 180 DEG C for 6 hours; and (3) plastic deformationprocessing is carried out on the semi-finished product by means of electromagnetic forming so as to obtain the thin-wall component. The full-process processing method simplifies the technology, improves the precision, has good flexibility, and is easy to implement.

Owner:HUAZHONG UNIV OF SCI & TECH

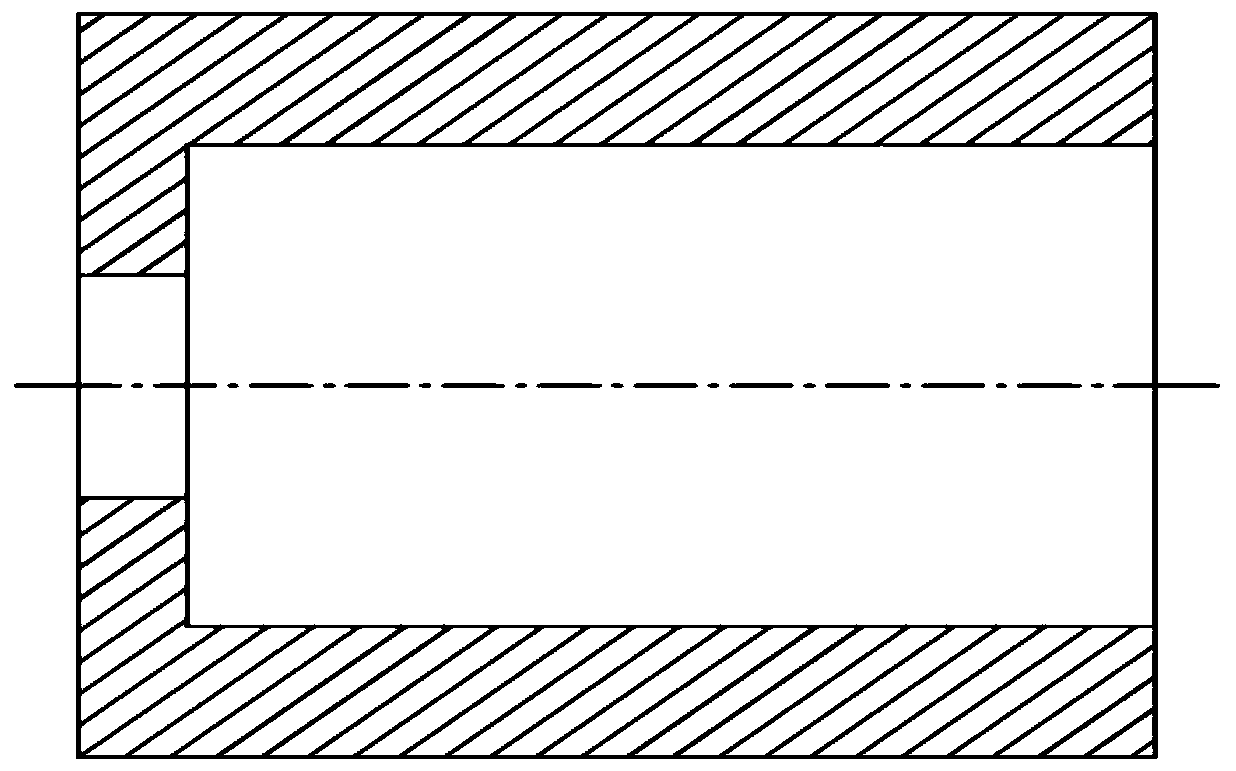

Machining method of flexible stress isolation thin ring for precise optical-mechanical system

The invention provides a machining method of a flexible stress isolation thin ring for a precise optical-mechanical system. The method comprises the following specific steps that S1, rough machining is carried out, specifically a blank is roughly turned to be a cylindrical workpiece, the inner diameter and the outer diameter of the workpiece both reserve allowance, and primary heat treatment is carried out on the roughly turned workpiece to remove internal stress; S2, semi-finish machining is conducted, specifically, one end of the workpiece is clamped on a machine tool and turned into all thin rings, allowance is reserved for the thickness of each thin ring, every two adjacent thin rings are connected with each other through the roots of the inner diameters, and then the workpiece is subjected to second-time heat treatment to remove internal stress; S3, finish machining is carried out, specifically the thickness and the inner diameter of each thin ring on the cylindrical workpiece aremachined to target values in sequence, the workpiece is cut off to obtain the single thin rings, and S4, the end faces of the single thin rings are subjected to linear cutting to machine flexible patterns. The method has the advantages of simple process, material saving, cost reduction, high processing efficiency and high yield.

Owner:CHANGCHUN UP OPTOTECH

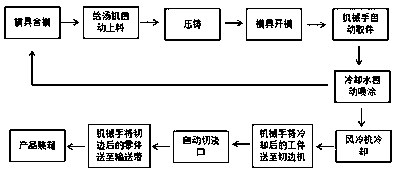

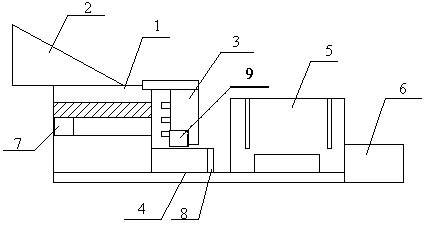

Robot pressure casting island automatic circulating device and process

InactiveCN108188750AAvoid problems such as deformationAvoid it happening againOther manufacturing equipments/toolsPressure castingHigh pressure

The invention discloses a robot pressure casting island automatic circulating device and process. The robot pressure casting island automatic circulating device comprises a pressure casting machine, asoup feeding machine, a spraying robot, a piece taking robot, an edge trimmer and a casting conveyor. The soup feeding machine is installed on the upper portion of the pressure casting machine, the spraying robot is connected with the pressure casting machine, and the piece taking robot is installed below the spraying robot and connected with the pressure casting machine. The edge trimmer is installed on the right side of the spraying robot and the right side of the piece taking robot, and the casting conveyor is installed on the right side of the edge trimmer. According to the robot pressurecasting island automatic circulating device, by means of a soup feeding mechanical arm, a spraying mechanical arm, a piece taking mechanical arm, a pressure casting cutting pouring gate device, a product conveying device and other automatic equipment, all motions are integrated according to procedure requirements, the automatic production requirement is met, the high pressure casting production efficiency is improved, the product quality is stabilized, the production cost is reduced, the problem that a workpiece is deformed due to improper actions in the manual piece taking process and otherproblems are eradicated, spraying is more uniform, the situation that air holes appear due to the too high local die temperature of a die is prevented, and the casting deformation situation caused byknocking a material cake can be effectively prevented.

Owner:江苏宏马科技股份有限公司

Method for repairing core rods for rolling seamless steel pipes

PendingCN113478168ALower performance requirementsImprove performanceMetallic material coating processesWelding accessoriesAlloyPipe

The invention discloses a method for repairing core rods for rolling seamless steel pipes. The method comprises the following specific steps: (1), cleaning and detecting before repairing; (2), machining before repairing; (3), detecting before surfacing; (4), surfacing and preheating; (5), surfacing to recover the size; (6), carrying out heat treatment after surfacing; (7), machining after surfacing; (8), detecting before laser cladding; (9), carrying out high-speed laser cladding by carrying out strengthening treatment on the surfaces of core rods by adopting high-speed laser cladding, wherein the used powder material is alloy powder with excellent wear resistance, corrosion resistance and plasticity and toughness; (10), machining after cladding; and (11), detecting finished products. According to the method, the wear resistance, the corrosion resistance and the cold and hot fatigue resistance of the core rods can be greatly improved; the service life of the core rods reaches more than 1.5 times of that of a new product; meanwhile, the whole repairing and manufacturing process is green and pollution-free.

Owner:泰尔(安徽)工业科技服务有限公司

Production technology of extremely flat nuts

A production technology of extremely flat nuts includes the following steps of raw material selection, cold heating, punching, tapping and post-treatment. In the punching process, pits are punched in the two ends of a steel segment, and then middle holes are punched in the pits. Heat treatment processes exist in both the raw material selection process and the post-treatment process, and quenching liquid adopted in the post-treatment process is borax solution. The production technology of the extremely flat nuts has the advantages of being high in production efficiency, stable in product quality, low in production cost, convenient to operate and the like, thereby having good application prospects in the industry.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Water-soluble degradable quenching agent

The invention discloses a water-soluble degradable quenching agent which consists of the following raw materials, by weight: 2-6 parts of alcohol, 4-8 parts of rhamnolipid, 6-10 parts of citric acid, 2-4 parts of butyl hydroxy anisole, 8-12 parts of rapeseed oil, 11-17 parts of cyclodextrin, 6-10 parts of pine oil, 15-25 parts of acrylic acid, 7-8 parts of saccharose, 0.5-0.8 part of 2-thioketone-trihydroxymethyl benzothiazoline and 10-20 parts of shell powder. A preparation method for the water-soluble degradable quenching agent comprises the following steps of: firstly, dissolving citric acid, butyl hydroxy anisole and pine oil into alcohol to obtain a mixed solution; then, adding water into the mixed solution and transferring the mixed solution into a reaction kettle, cooling the mixed solution and adding rhamnolipid, rapeseed oil, cyclodextrin and saccharose into the mixed solution after reaction is ended, stirring for 10 minutes and standing to obtain a mixture; centrifuging the mixture, taking liquid supernatant after the mixture is centrifuged, adding acrylic acid, 2-thioketone-trihydroxymethyl benzothiazoline and shell powder into the mixture, uniformly stirring, heating, preserving the temperature, cooling, and sealing by use of paraffin oil, and thereby obtaining the water-soluble degradable quenching agent. The prepared quenching agent has relatively good water solubility, is ecologically degradable, and is small in environmental pollution.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

Glue bonding piece separating device and glue bonding piece separating method

InactiveCN110065291AImprove securityAvoid damageLamination ancillary operationsLaminationEngineeringAdhesive bonding

The invention relates to a glue bonding piece separating device and a glue bonding piece separating method. The adhesive bonding piece separating device comprises a glue bonding piece, wherein the glue bonding piece comprises a first bonding piece, an adhesive layer and a second bonding piece which are sequentially laminated, and the adhesive bonding piece also comprises a vacuum adsorption heating table, wherein the vacuum adsorption heating table comprises a bearing table surface, the bearing table surface is obliquely arranged relative to a horizontal plane, the bearing table surface comprises a high end and a low end, and the direction from the high end to the low end is a first direction; a cutter head assembly, wherein the cutter head assembly comprises a separation cutter head, wherein the separation cutter head can move in the first direction so as to be inserted between the first bonding piece and the second bonding piece of the glue bonding piece which is vacuum-adsorbed on the bearing table surface, and the first bonding piece and the second bonding piece are completely separated in the moving process. The separating device omits the step of manually tearing off the first and second bonding pieces, can improve the separation efficiency, and can avoid the problems of product fragmentation, deformation and the like caused by manual tearing off.

Owner:INTERFACE TECH CHENGDU CO LTD +2

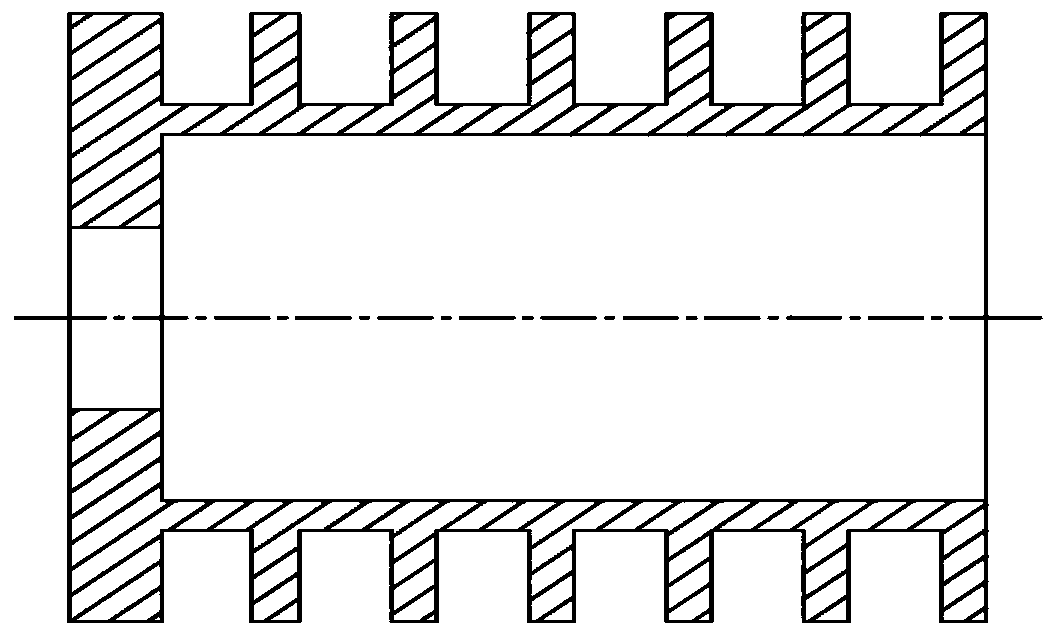

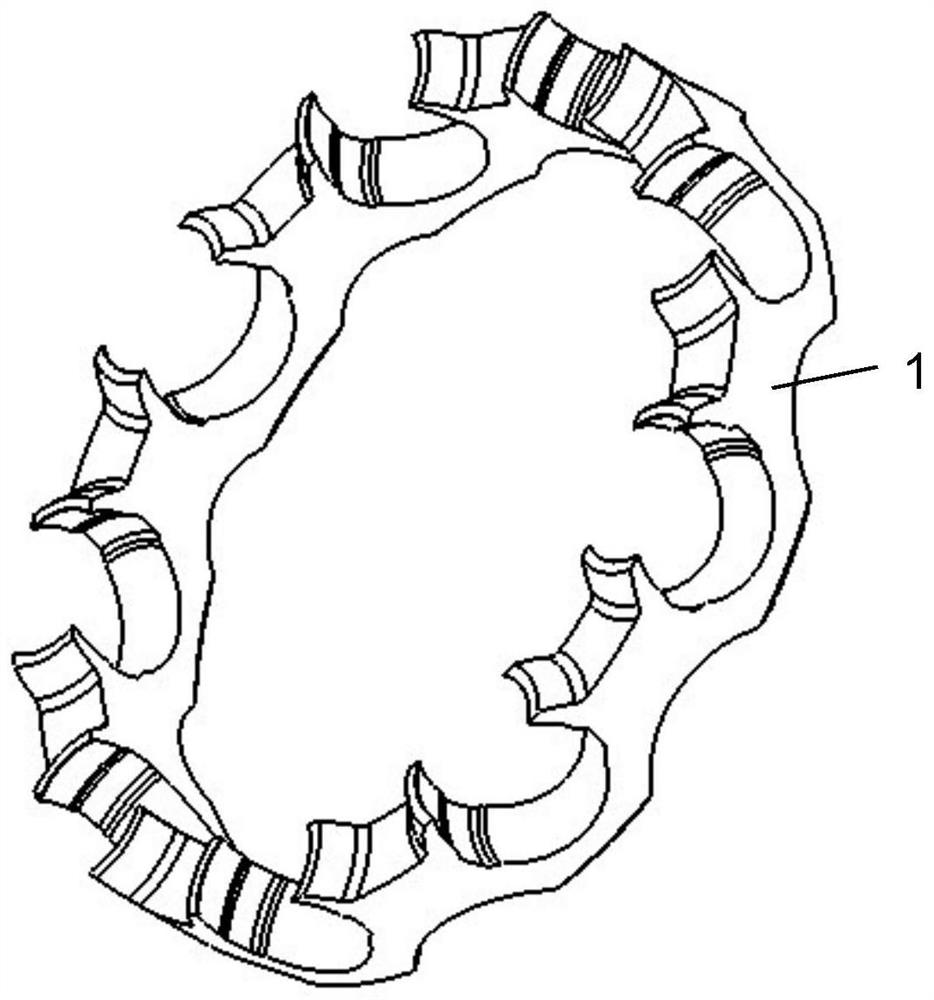

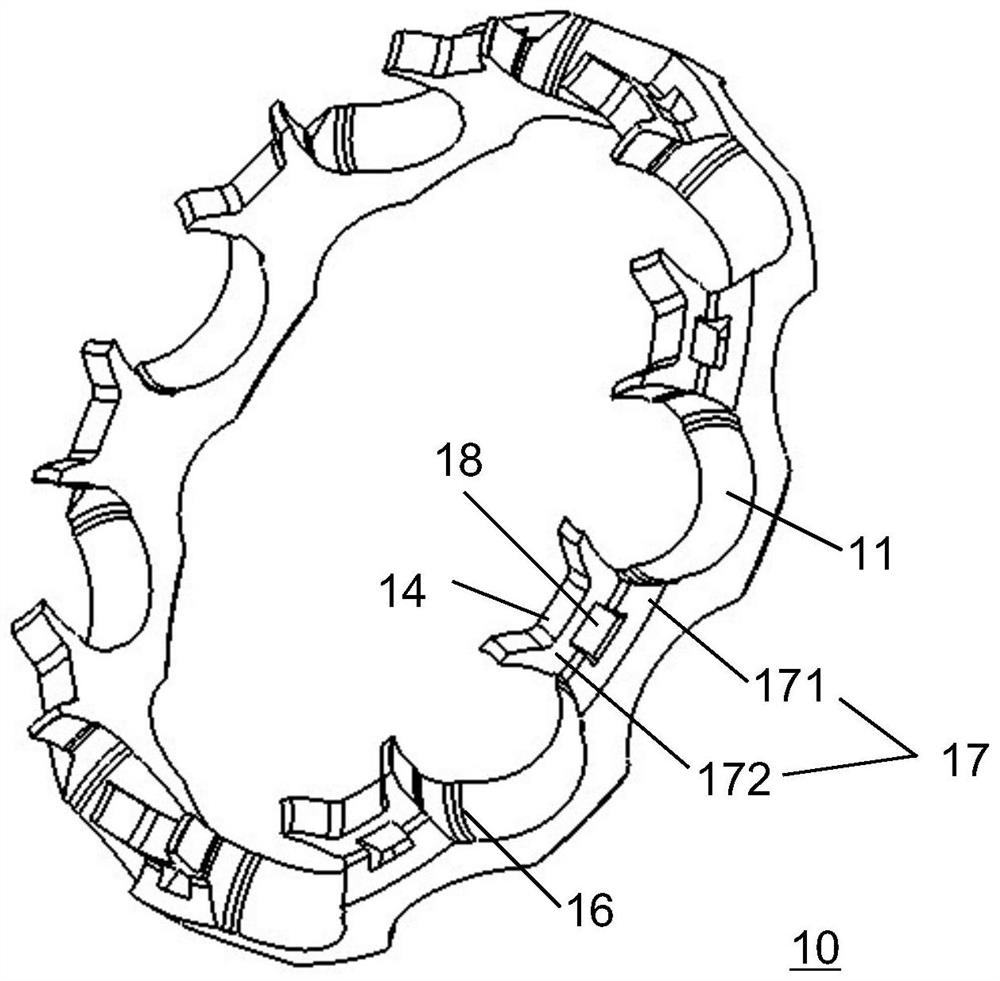

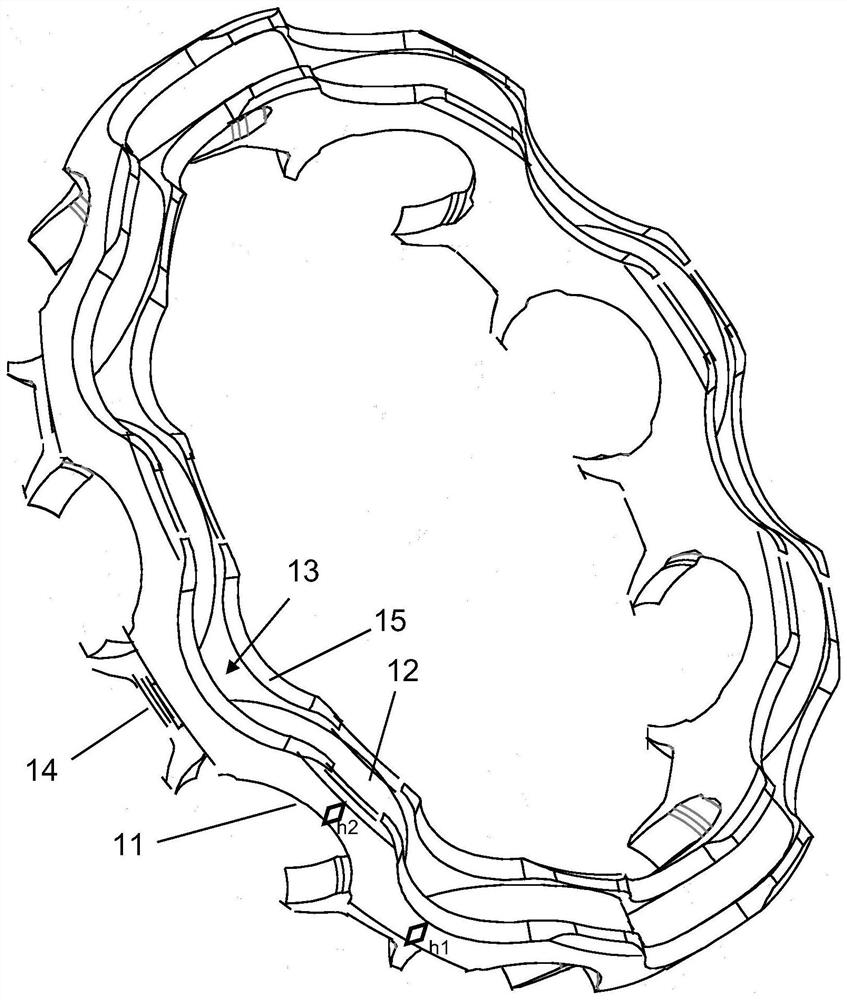

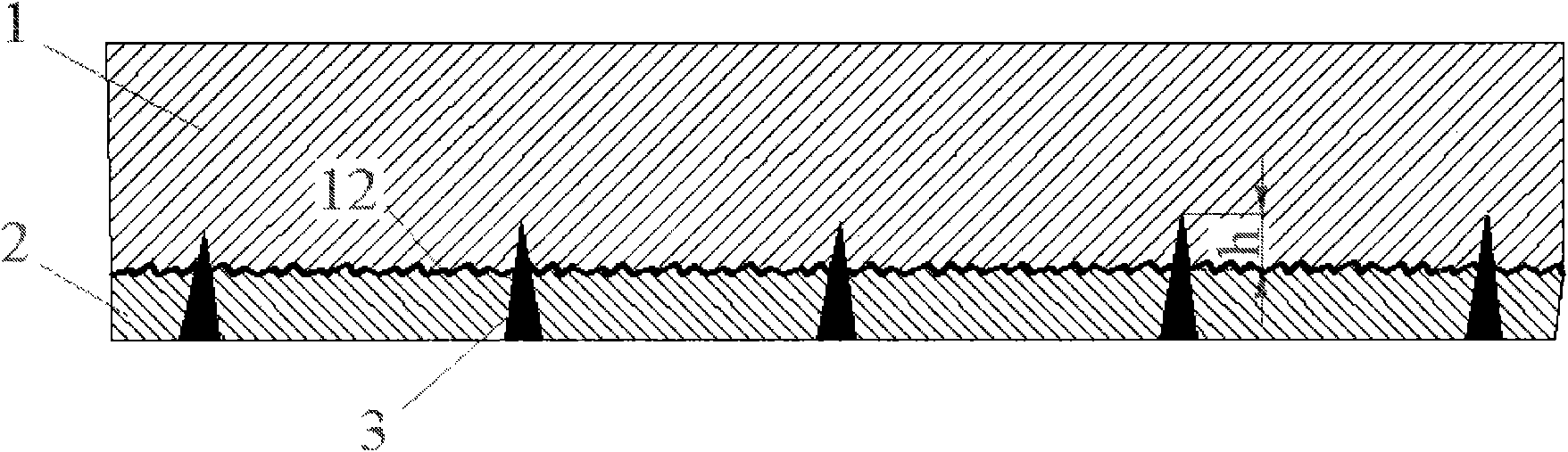

High-speed bearing retainer

PendingCN111649068AEvenly distributedImprove the lubrication effectBearing componentsStructural engineeringMechanical engineering

The invention discloses a high-speed bearing retainer. The high-speed bearing retainer comprises a frame body, a plurality of pockets arranged at the upper end of the frame body and a ring groove formed in the bottom of the frame body, concave-up arc surfaces are arranged at the bottoms of connecting parts between every two adjacent pockets, lubricating grease accommodating cavities are formed inthe connecting parts, bottom openings of the lubricating grease accommodating cavities are located in the ring groove, and oil grooves are formed in the inner surfaces of the pockets. The connecting parts are divided into upper parts and lower parts, the lower parts have the same thickness as the frame body, the upper parts are thinner than the lower parts, and the upper parts and the lower partsforms a step outside the connecting parts, and oil guide holes communicating with the corresponding lubricating grease accommodating cavities on the lower part are formed in the step. According to thehigh-speed bearing retainer, through the design of the arc surfaces, the step and the oil guide holes, the high-speed bearing retainer has the advantages of reducing own weight, shifting up the center of mass and enhancing the lubricating effect while the strength of pocket claw mouths is ensured to the greatest extent, the weight is reduced, the lubricating effect is improved, the strength and stability of the pockets are ensured, and problems such as relatively large deformation are solved.

Owner:马纯

Method for connecting target and rear panel through fusion welding

ActiveCN101671810AAvoid problems such as deformationImprove bindingVacuum evaporation coatingSputtering coatingHeat-affected zoneHigh energy

The invention belongs to a method for connecting a target and a rear panel through fusion welding, which comprises the following steps of: firstly, coarsening at least one surface to be connected of the target and the rear panel; secondly, pressing the target and the rear panel together; and finally, performing distributive penetration fusion welding from the surface of the rear panel with high energy beams, such as electronic beams and laser beams so as to weld the rear panel and target component together. The method utilizes the characteristics of the high energy beams of intensive energy density, good controllability, high depth-to-width ratio of welding lines and the like, and can directly and thoroughly weld the rear panel; and the welding lines which are formed by welding the rear panel and the target material have high bonding strength and small heat affected zone. In a distributed discontinuous welding mode, the method solves the problems such as growth of crystalline grains caused by suddenly raised target material temperature because of too large input amount of the welding heat and deformation caused by high welding heat stress. The method is a simple and reliable methodfor connecting the target and the rear panel because of low requirements on processing of the target and the rear panel, short welding time and high bonding strength, and is suitable for the preparation of sputtering targets.

Owner:GRIKIN ADVANCED MATERIALS

Embryo forming and slicing equipment for food processing and use method

InactiveCN111660339AAvoid problems such as deformationEasy to useMetal working apparatusPress ramStructural engineeringMechanical engineering

The invention relates to the technical field of food processing, and discloses an Embryo forming and slicing equipment for food processing and a use method. The equipment comprises two workbenches; aslicing groove is formed between the workbenches; a forming box is arranged above the slicing groove; a placing plate is arranged below; sealing plates are glidingly connected in the slicing groove and are connected with moving assemblies; top plates are arranged above the workbenches; and lifting assemblies are arranged on the top plates and are connected with moving rods and forming blocks. According to the equipment and the use method, the bottom of the forming box is sealed through cutting plates of the sealing plates, the cutting plates are supported by supporting plates, third threaded shafts are rotated to be separated from the supporting plates, and thus the cutting plates are driven by the moving assemblies to reciprocate to slice formed cakes; and the moving rods and the formingblocks move downwards by the aid of the lifting assemblies, the cakes in forming barrels are extruded by the forming blocks, meanwhile, cooling water is input into a cooling cavity through a water inlet pipe, water cooling is performed on the cakes in the forming box, and cooling forming is performed on the cakes.

Owner:安徽曼夫企业管理有限公司

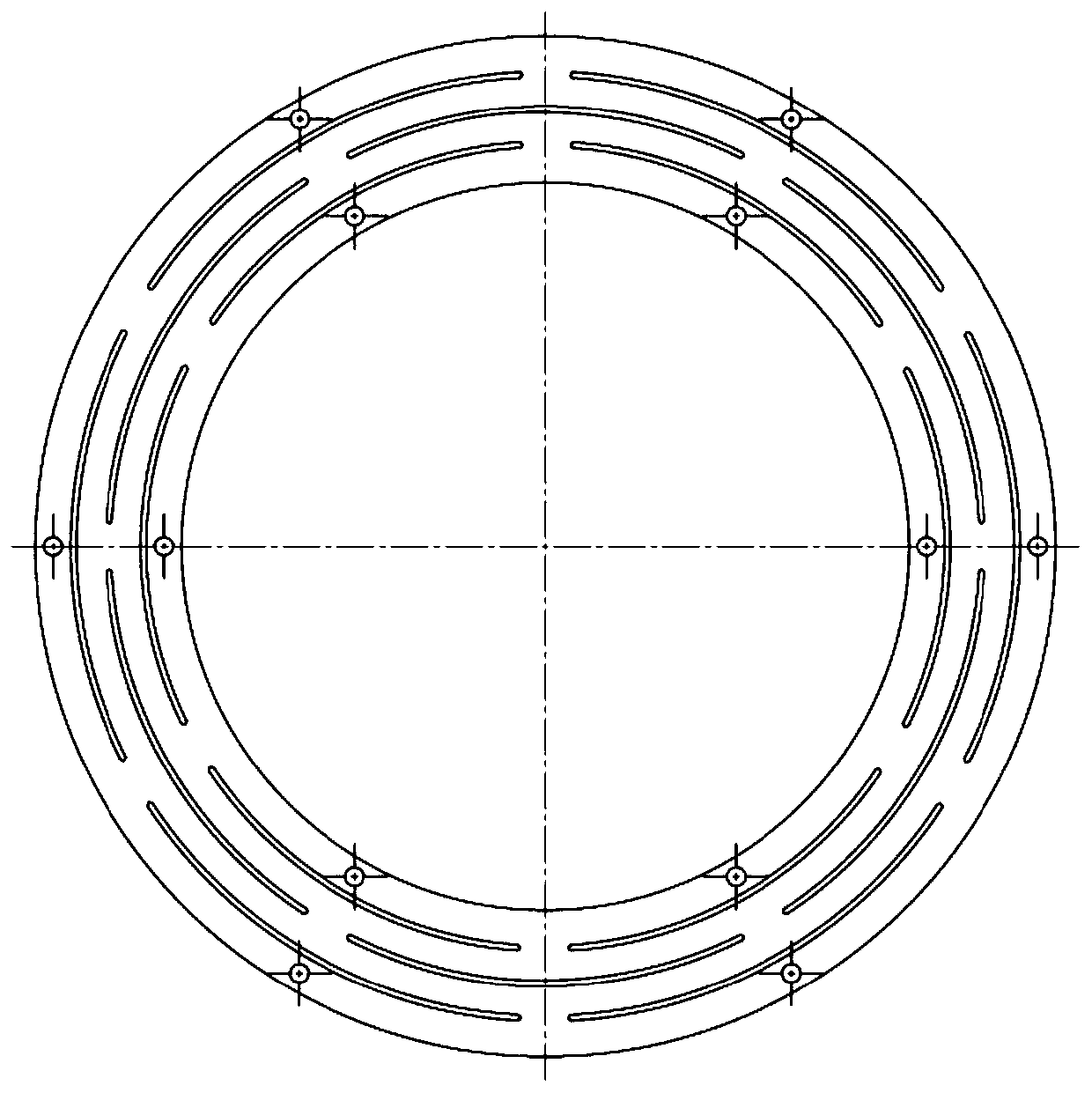

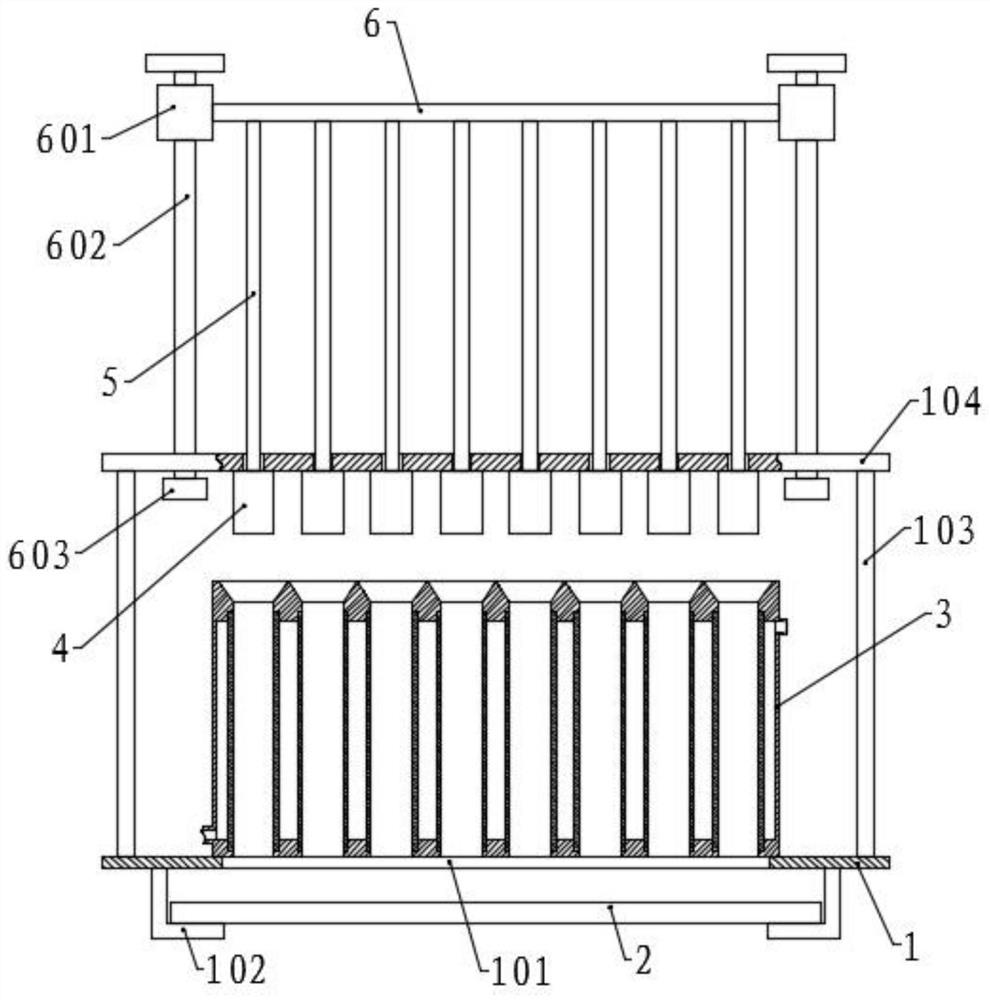

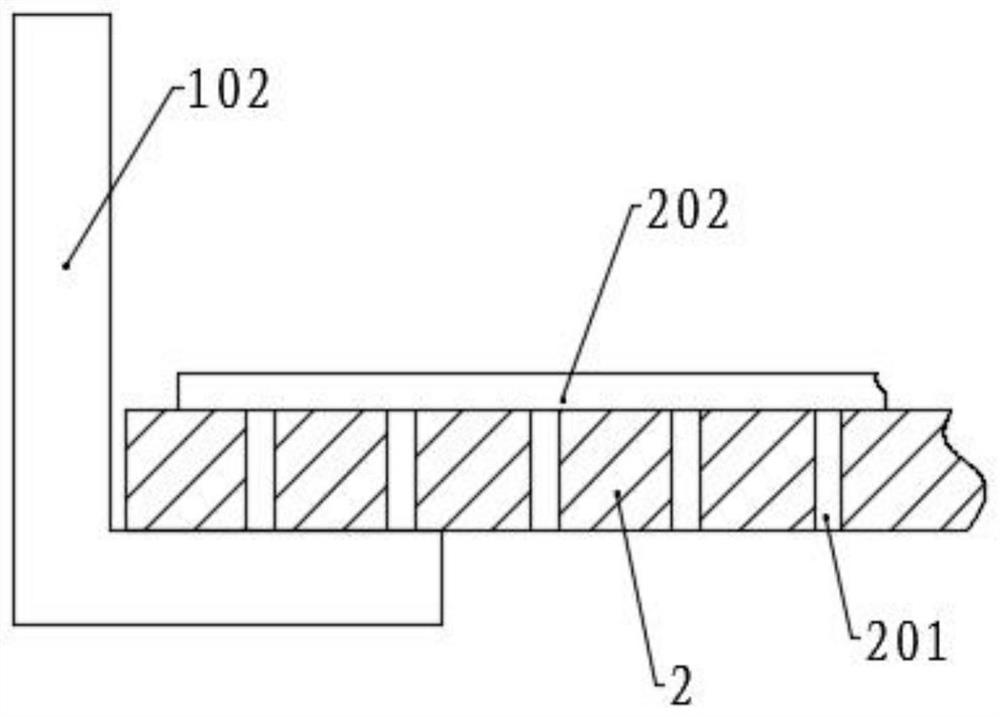

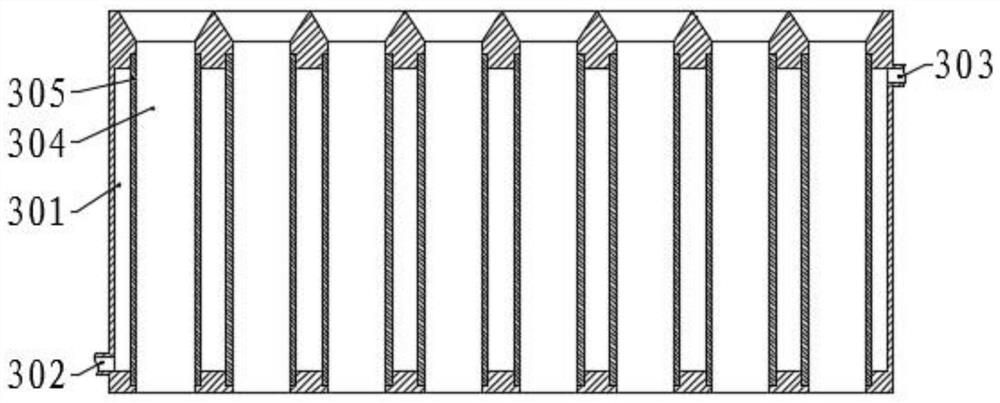

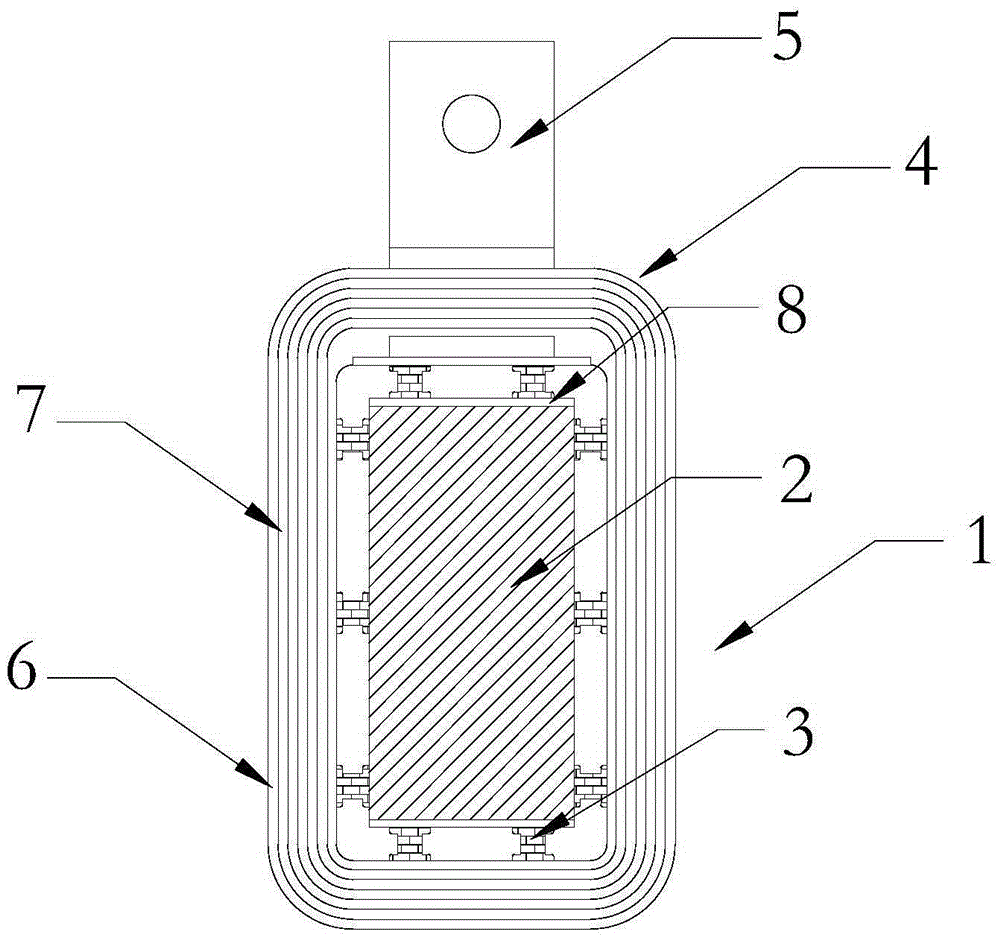

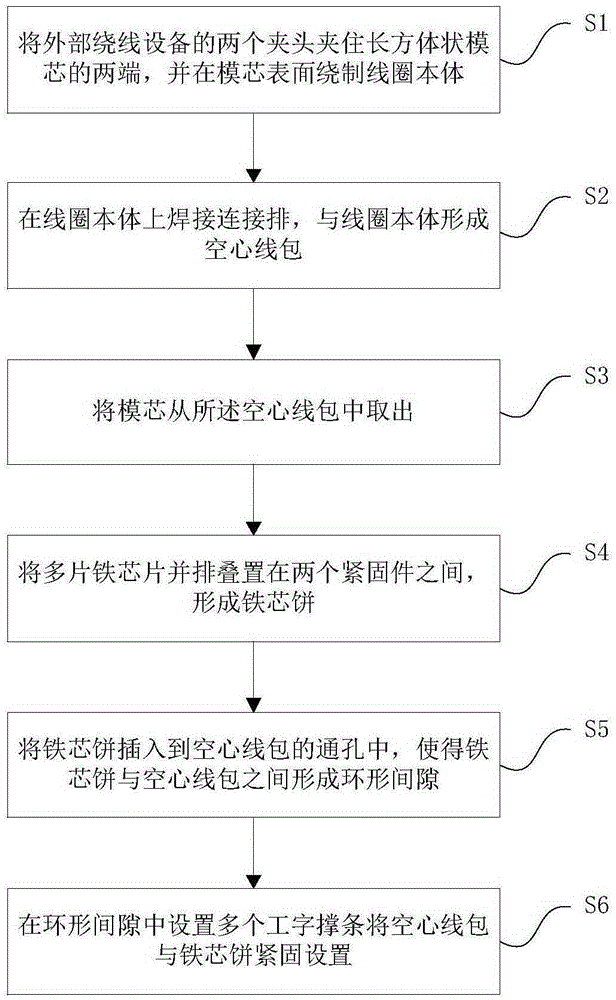

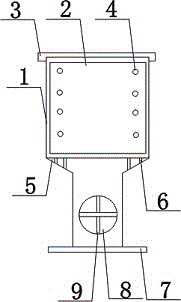

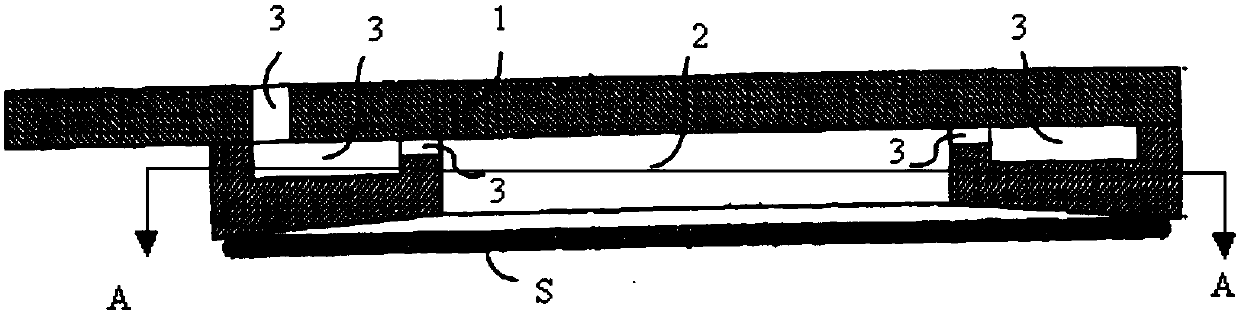

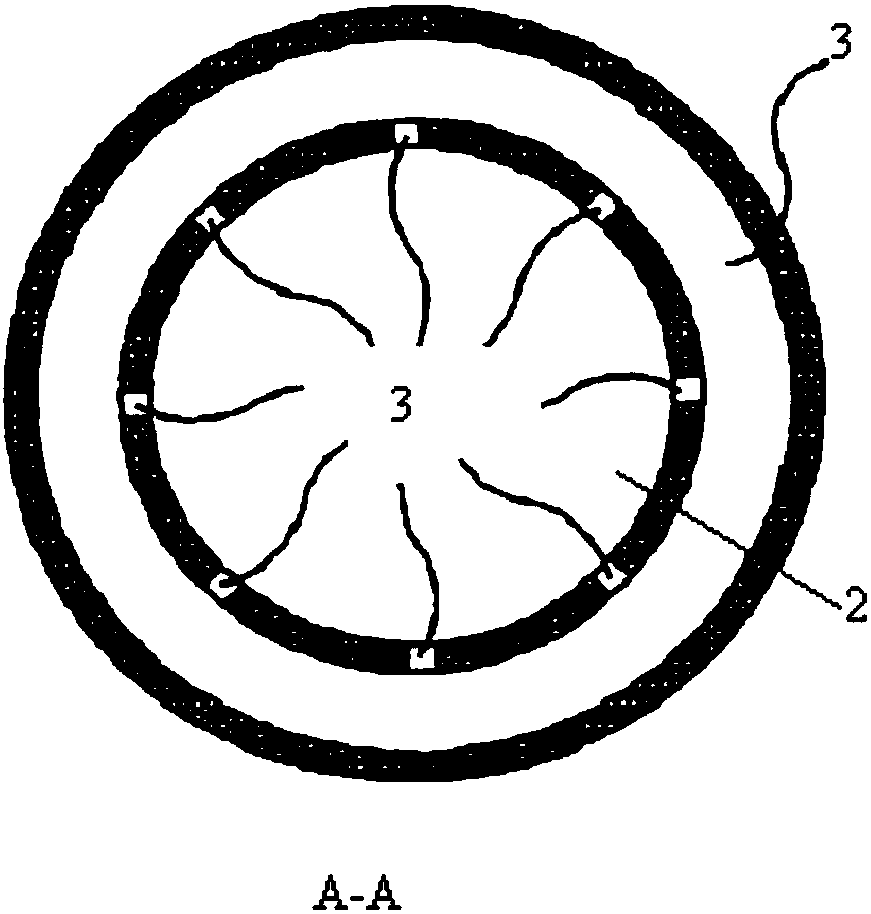

Electric reactor based on hollow wire wrap and manufacturing method of electric reactor

ActiveCN105428005ASimple structureEasy to processTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringUltimate tensile strength

The invention relates to an electric reactor based on a hollow wire wrap and a manufacturing method of the electric reactor. The electric reactor comprises the hollow wire wrap and an iron core cake, wherein the hollow wire wrap is connected onto the iron core cake in a sleeving manner, and an annular gap is reserved between the hollow wire wrap and the iron core cake; a plurality of I-shaped bar stays are arranged in the annular gap by surrounding the periphery of the outer surface of the iron core cake; the hollow wire wrap and the iron core cake are arranged in a fastening manner through the plurality of I-shaped bar stays. According to the electric reactor based on the hollow wire wrap, provided by the invention, the structure is simple, the machining is convenient, deformation problems of iron core cakes during enwinding with iron core cakes are avoided, the labor intensity of workers is reduced, dangers in the transportation process, particularly of heavier iron core cakes, are avoided; besides, the I-shaped bar stays are arranged, so that the insulation distance between the hollow wire wrap and the iron core cake can be ensured, and air passages between adjacent I-shaped bar stays facilitate heat dissipation, so that heating problems of the hollow wire wrap and the iron core cake are solved.

Owner:WUHAN HICONICS ELECTRICAL CONNECTION SYST CO LTD

Soft foundation reinforcing method of existing railway or highway subgrade construction

ActiveCN101886382BLess equipmentDoes not affect operationsBulkheads/pilesSoil preservationSizingDrilling machines

The invention relates to a soft foundation reinforcing method of the existing railway or highway subgrade construction, which comprises the following steps of: constructing vertical chemical churning piles on the side slope and the slope toe of a subgrade to be reinforced; after the vertical chemical churning piles are cured, drilling a plug hole tilting toward the center line of a track and extending into the soft foundation in the side slope by using a drilling machine; and performing shock tube grouting in the plug hole. A sizing agent in the plug hole permeates towards the periphery of the foundation, the cured sizing agent, the vertical chemical churning piles and the foundation form an integrated reinforcing block, and thus, the reinforcement of the railway or highway subgrade construction is completed. Compared with the traditional single technique, the method has the advantages of no construction transition, no traveling interruption and no reinforcing dead zone by adopting the vertical chemical churning piles together with a shock tube grouting technique. The advantages of both the vertical chemical churning piles and the shock tube grouting technique are fully exerted, and the safety and the quality are controllable.

Owner:广东省铁路规划设计研究院有限公司

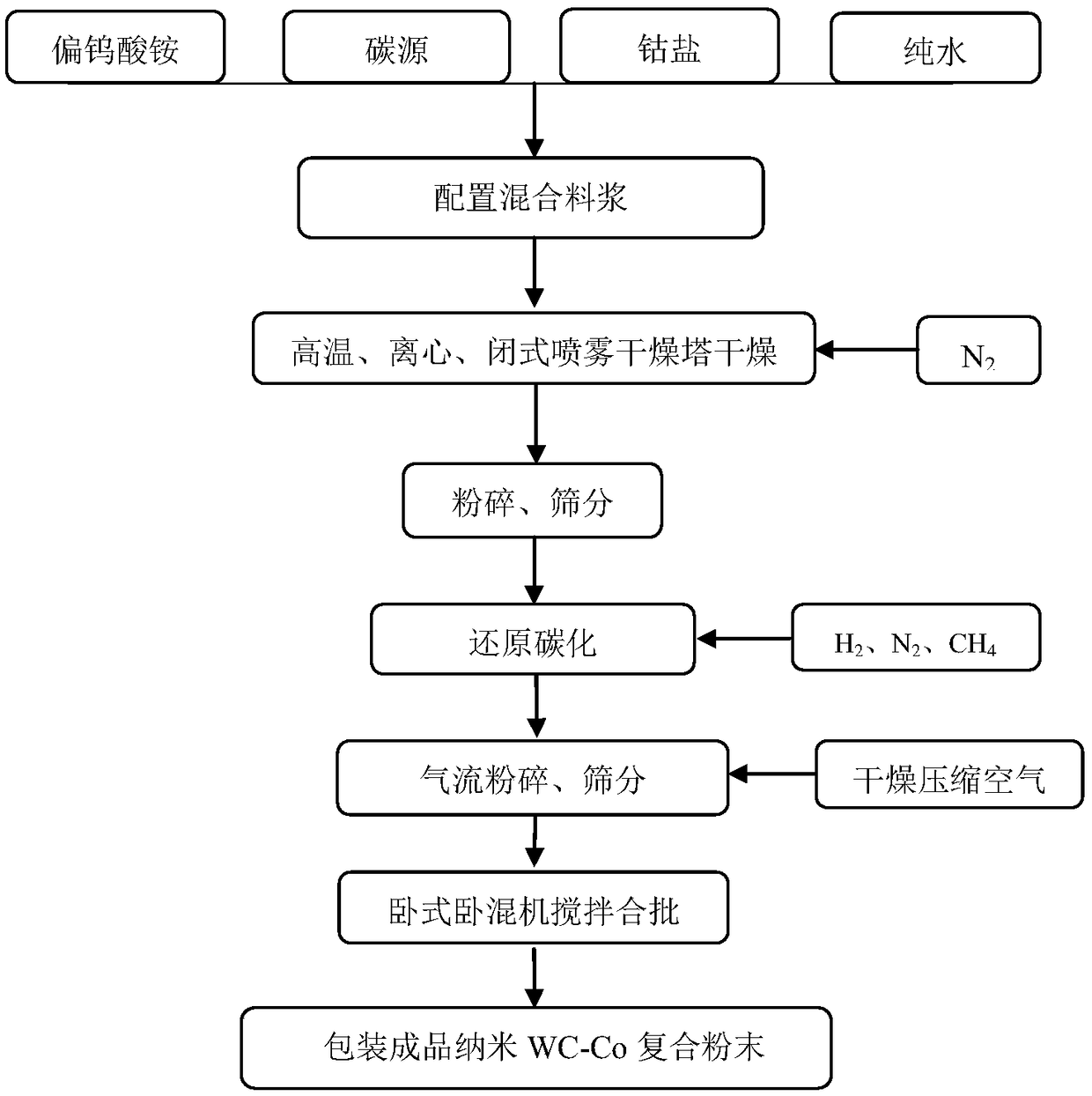

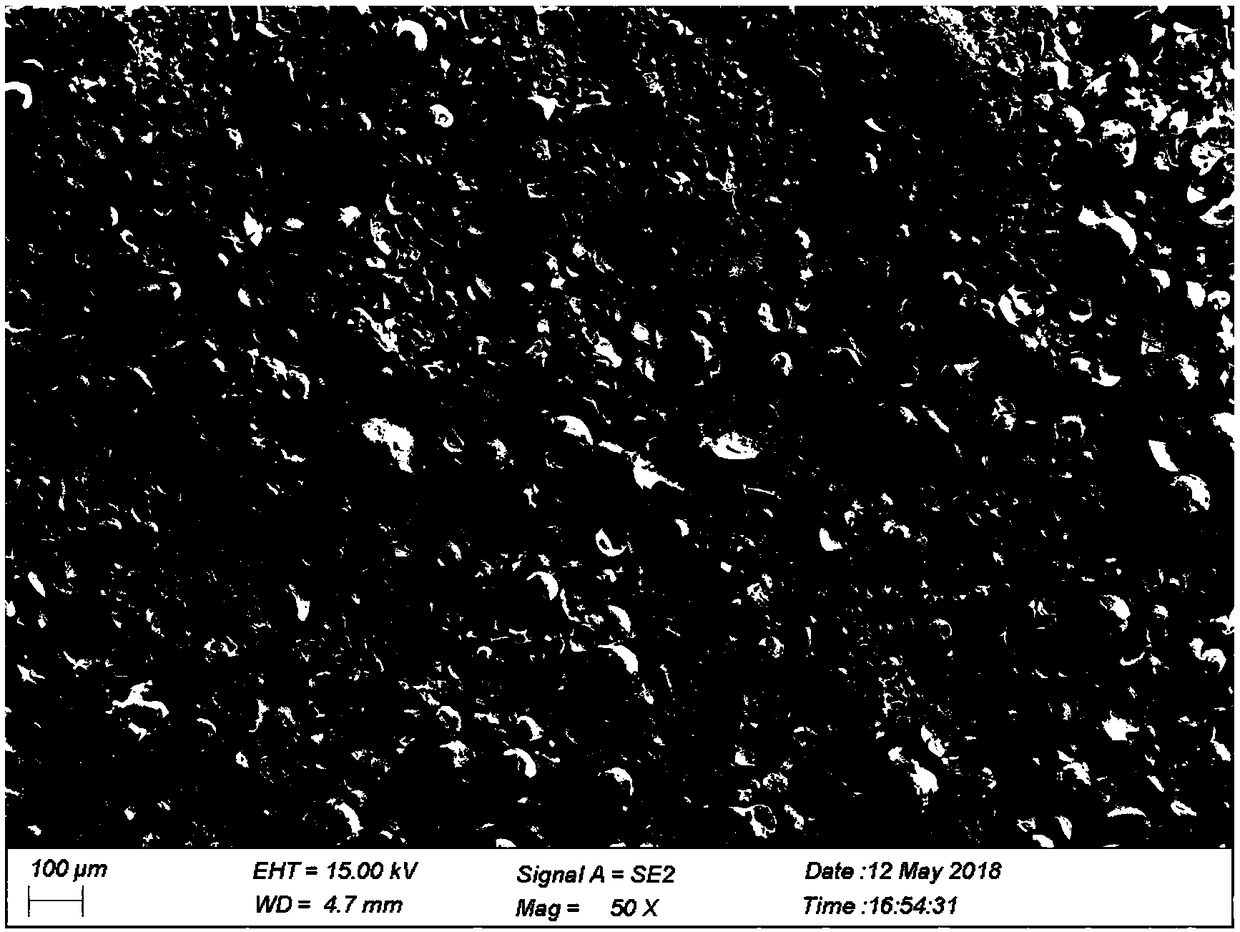

Method for preparing nanometer WC-Co composite powder through high-temperature spray drying short process

ActiveCN109365829AAvoid burnsEliminate the calcination processMaterial nanotechnologyTransportation and packagingCarbon sourceWater soluble

The invention discloses a method for preparing nanometer WC-Co composite powder through high-temperature spray drying short process. The method comprises the steps that water-soluble ammonium metatungstate, water-soluble cobalt salt and a water-soluble carbon source serve as a raw material; the raw material is added to a heated and stirred container containing pure water to be prepared into slurry; the slurry is delivered to a closed type centrifugal high-temperature spray drying tower of which nitrogen is introduced through a feed pump to be dried; the spray dried precursor material is crushed and screened and then is subjected to reduction and carbonization; the reduced and carbonized material is crushed and screened through air flow and finally is blended to obtain the WC-Co composite powder. The nanometer WC-Co composite powder prepared through the method is stable in property, single in phase, uniform in ingredient, narrow grain size distribution and fine in grain, powder ingredients are controlled easily, and the method belongs to the process through which industrialized and mass production can be achieved.

Owner:HEFEI UNIV OF TECH

Multifunctional sound structure

InactiveCN105979410ANice appearanceClosely connectedMicrophonesLoudspeakersEngineeringOutdoor activity

The invention discloses a multifunctional sound structure. The structure comprises a sound body. The sound body is located in a mounting frame. The mounting frame is formed by splicing four rectangular panels. A top cover is connected with the top of the mounting frame. Two ends of the top cover extend to two outer side faces of the mounting frame. The top cover and the mounting frame are connected in a clamping mode. Twinkle lamps are arranged on the front side face of the sound body. A switch and a battery box for controlling the twinkle lamps to work are arranged at one side of the twinkle lamps. A battery is arranged in the battery box. The battery supplies power to the twinkle lamps. A support device is arranged at the bottom of the sound body. A plurality of connecting bars are connected between the support device and the sound body. The sound body is detachably arranged on the support device. The multifunctional sound structure provided by the invention is beautiful in appearance and tight in connection and has good protection effect. According to the structure, the problem that the sound shell deforms is avoided, the mounting is convenient, the movement is very convenient, the certain dustproof effect is realized, and moreover, the structure has illumination and twinkle functions and is especially suitable for an outdoor activity in the night.

Owner:CHENGDU XUNDE SCI & TECH

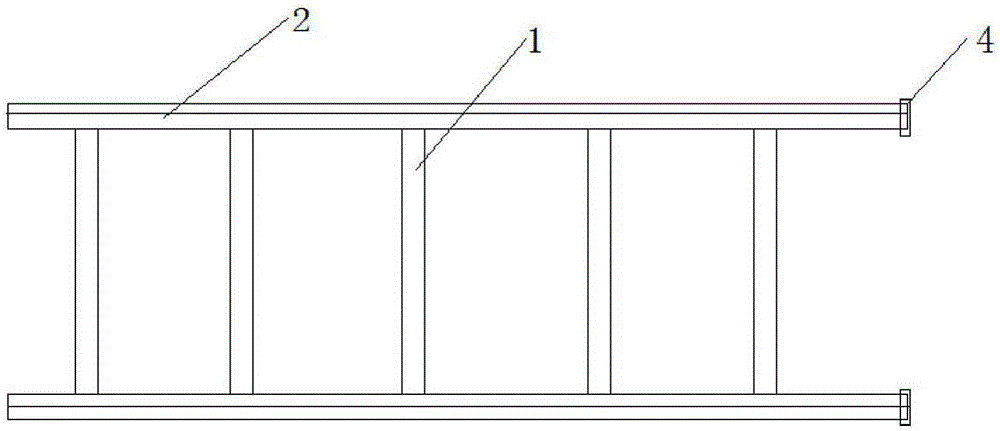

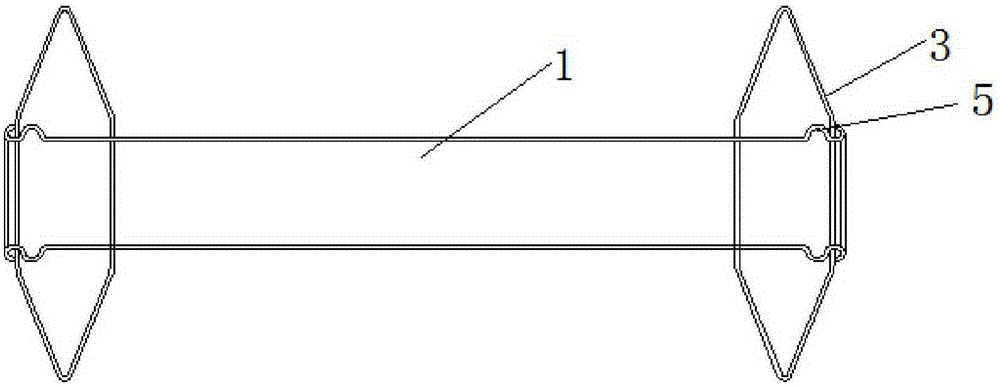

Rhombic cable ladder applied to wind power generation system

InactiveCN105244825APlay a protective effectAvoid wear and tearElectrical apparatusWind power systemWind power generation

The invention discloses a rhombic cable ladder applied to a wind power generation system. The rhombic cable ladder applied to the wind power generation system comprises a round tube and rhombic tubes, wherein the round tube penetrate through the two rhombic tubes, mounting holes are formed in opposite positions of the two rhombic tubes, and the rhombic tubes are not provided with indents. The rhombic cable ladder applied to the wind power generation system is simple in structure, simple in procedure and high in manufacturing efficiency; the rhombic tubes can effectively prevent a protective layer on the surface of a cable from being worn, protect the cable well and effectively prevent cable leakage and short circuit caused by breakage of the protective layer, thus improving the operating safety of the whole wind power generation system; the invention further relates to a processing technique for the rhombic cable ladder applied to the wind power generation system, which realizes indent-free connection and installation by adopting the technologies of stamping, expansion and the like during processing, thus effectively ensuring the appearance and flatness of the product.

Owner:SUZHOU BAOHAN SHUNTIAN IND CO LTD

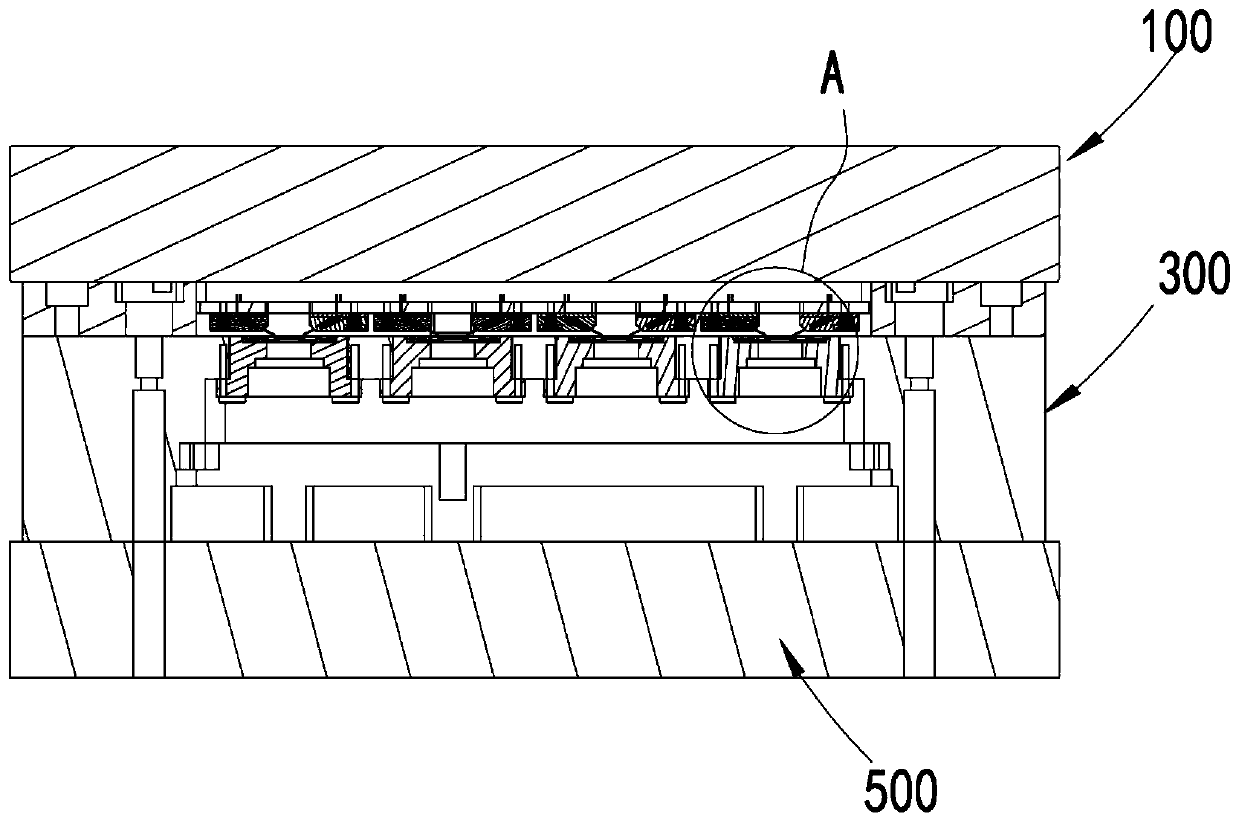

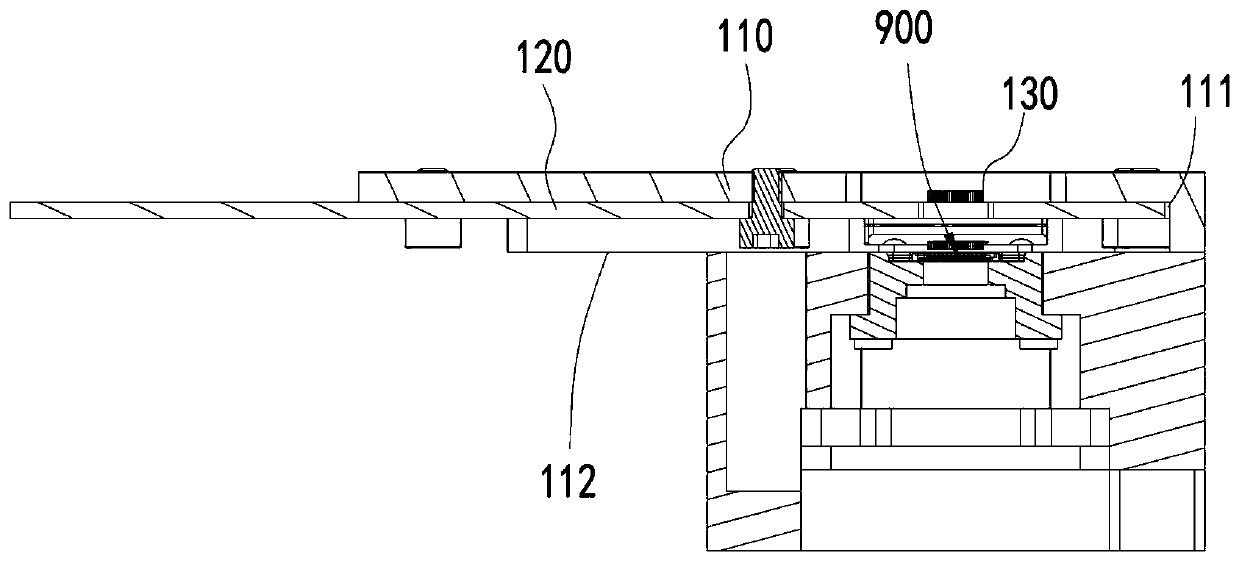

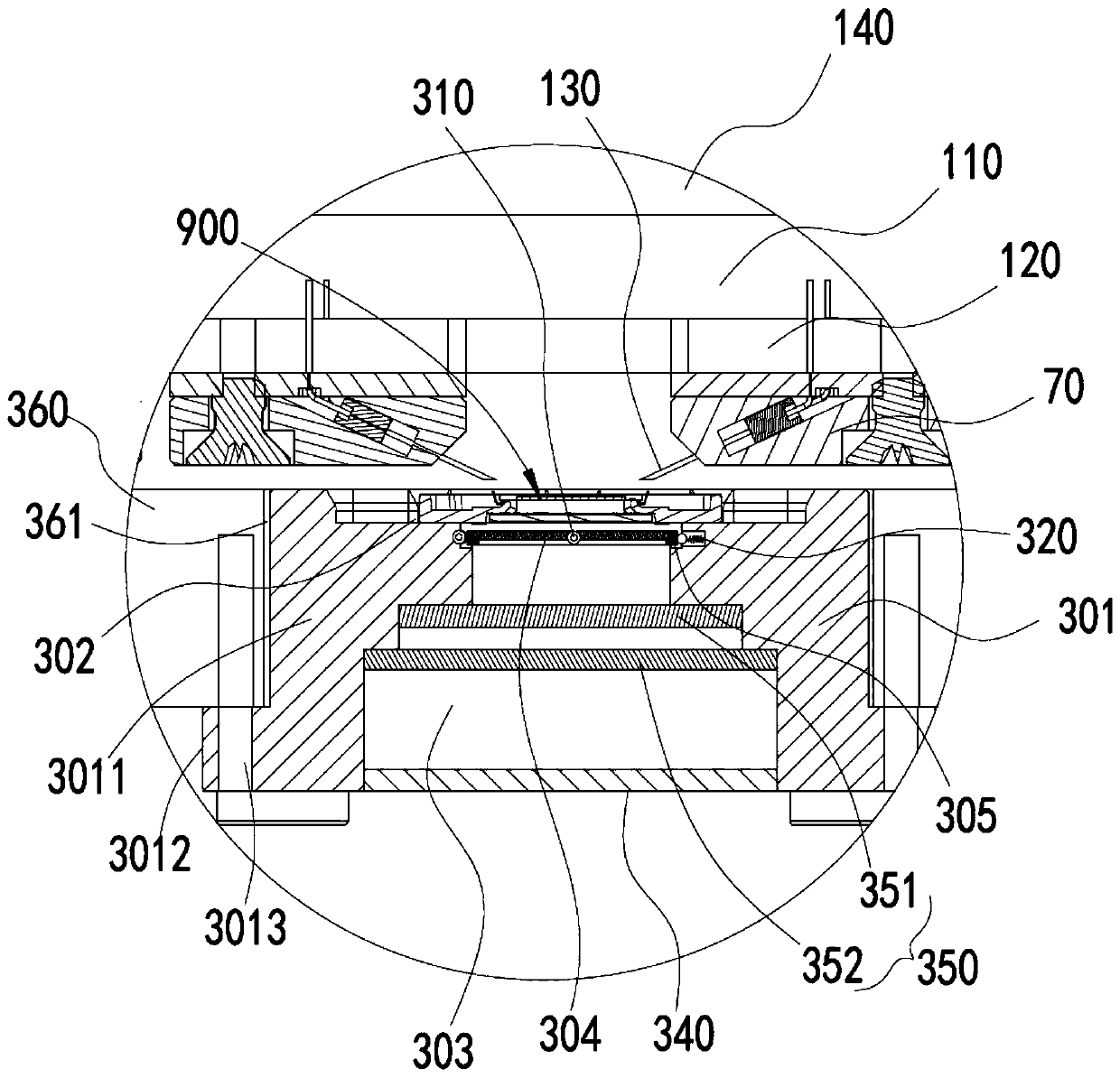

Optical chip module testing device

PendingCN111398790ASmall sizeIncrease contact areaElectronic circuit testingManufacture of electrical instrumentsEngineeringMechanical engineering

The invention discloses an optical chip module testing device which comprises an upper module and a lower module which are matched. The upper module comprises a test probe, the lower module comprisesa chip placing base, a chip placing groove is formed in the chip placing base, an installation space which is opposite to the chip placing groove and is communicated with the groove bottom of the chipplacing groove is formed in the chip placing base, and an LENS is arranged in the installation space in a translational mode. According to the scheme, the installation space corresponding to the chipplacing groove is formed in the chip placing base, and the LENS with the adjustable position is arranged in the installation space so that the horizontal position of the LENS can be flexibly adjustedaccording to test requirements, the centering precision of the center of the lens and the optical center of the chip is ensured to be within 0.01 mm, the error interference can be reduced and the precision of the test result can be improved.

Owner:SUZHOU CHUANGRUI MACHINERY & ELECTRICAL TECH

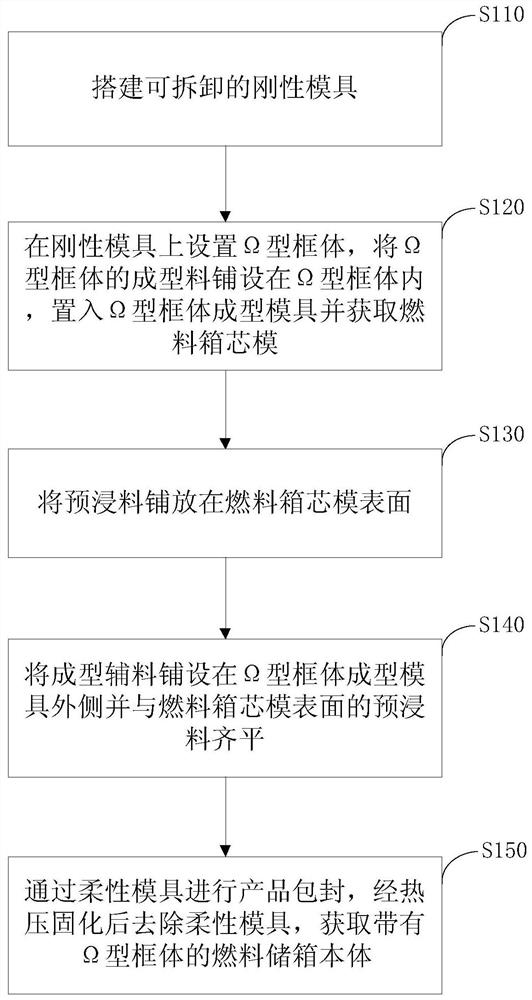

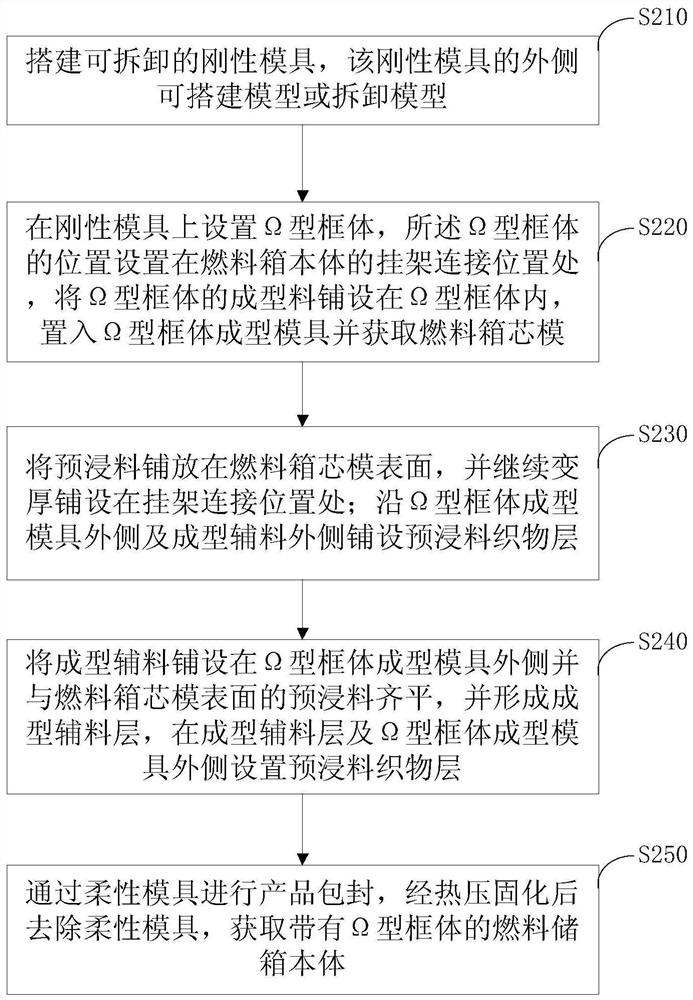

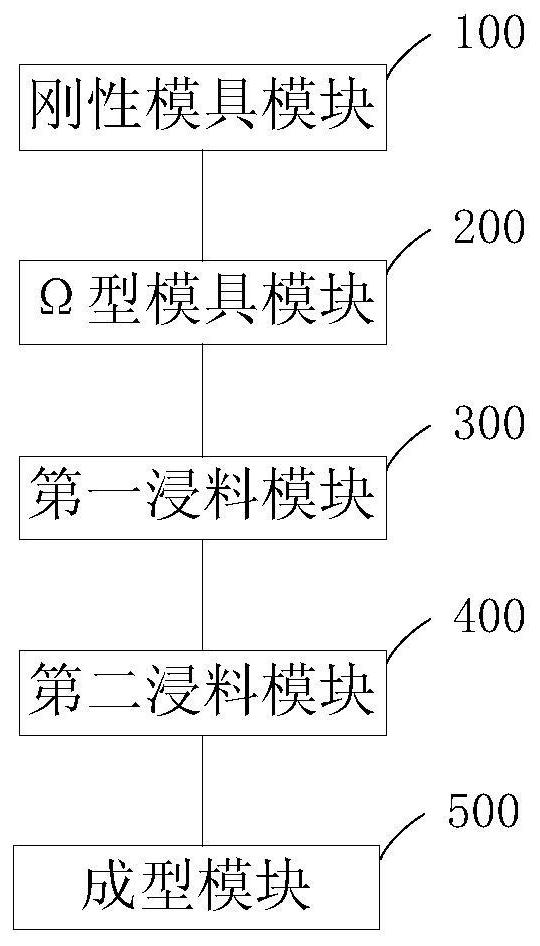

Co-curing composite material thin-wall fuel tank with omega-shaped frame body and forming method

The invention provides a co-curing composite material thin-wall fuel tank with an omega-shaped frame body and a forming method, and relates to the technical field of aviation aircraft lightweight. The forming method comprises the following steps that 1, a detachable rigid mold is built; 2, an omega-shaped frame is arranged on the rigid mold, and prepreg is laid on the surface of a fuel tank core mold; 3, auxiliary materials are laid at the outer side of an omega-shaped frame forming mold and are flush with the prepreg on the surface of the fuel tank core mold; and 4, product packaging is conducted through a flexible mold, the flexible mold is removed after hot pressing curing, and a fuel tank body with the omega-shaped frame body is obtained. According to the forming method, under the condition that the fuel volume is guaranteed, the overall structural strength of the connecting position of a hanging frame is improved, the omega-shaped frame body and the overall fuel tank body are formed by adopting similar or same materials, and the stability, reliability and overall bearing strength of the local structure of the fuel tank are improved through co-curing forming; The forming method is simple in process and low in forming cost, and greatly reduces the overall assembly cost and the production cycle of the thin-wall fuel tank.

Owner:TIANJIN ISTAR ADVANCED MATERIAL TECH CO LTD

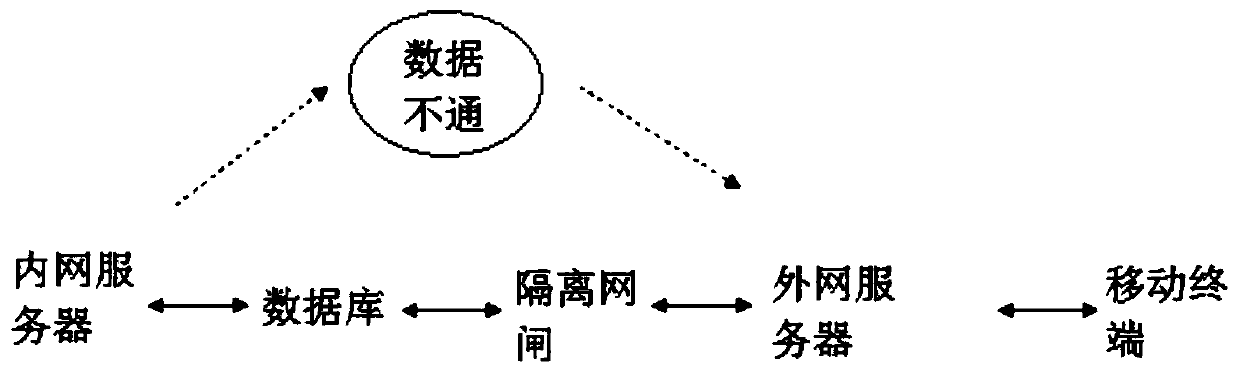

Intranet and extranet data transmission method and system based on mobile training terminal

The invention discloses an intranet and extranet data transmission method and system based on a mobile training terminal, and the method comprises the steps: enabling an intranet server to carry out mapping on obtained unstructured data, converting the unstructured data into binary stream data, and storing the binary stream data into an intranet database; injecting an unstructured transmission utility class equipped with data transmission technology into a service layer by a third-party management module according to service demand, calling a corresponding interface according to the service demand and realizing the service demand; through an extranet server, receiving the data request and acquiring binary stream data in the intranet database through an isolation gatekeeper, performing reflection processing on the binary stream data, restoring the binary stream data into initial unstructured data and responding to the data request. The defect that the data of the intranet is not communicated with the data of the extranet is overcome, so that the safety of the data of the intranet is ensured, physical isolation is realized, and the data connectivity of the intranet and the extranet environment is also ensured.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

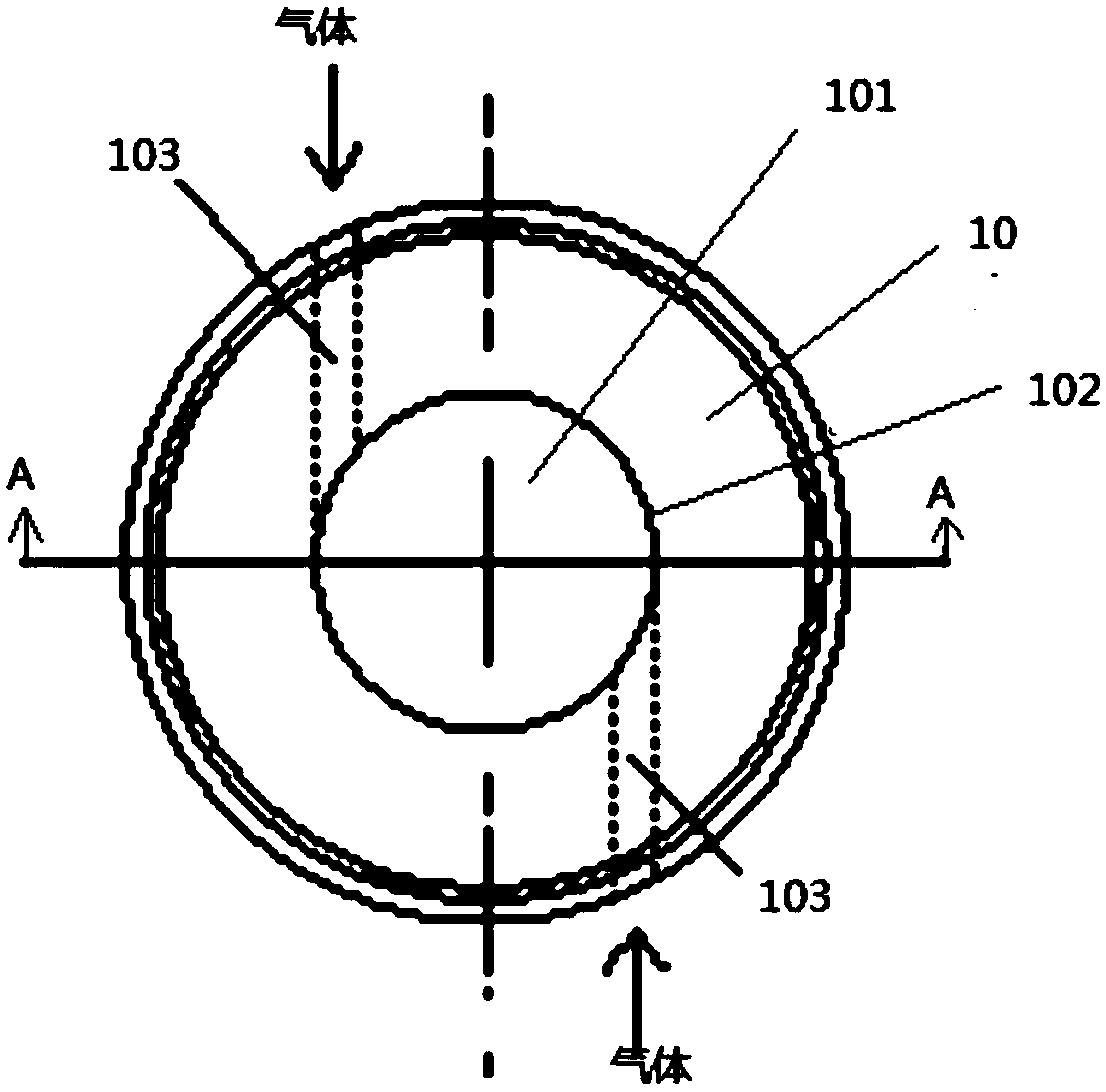

Substrate suction device and semiconductor processing equipment

InactiveCN110323171AAvoid damageAvoid problems such as deformationSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention provides a substrate suction device. The substrate suction device comprises a body. A cavity with an opening at the lower end is formed in the body; an air inlet hole communicated with the cavity is formed in the upper end of the body; the air inlet hole is connected with a compressed air source, and the compressed air provided by the compressed air source enters the cavity from theair inlet hole to form vortex air flow and is discharged from the opening; and the vortex air flow enables the central area of the cavity to be a negative pressure area, so that the substrate locatedbelow the opening and having a preset gap with the opening is adsorbed and fixed. The invention also provides semiconductor processing equipment. The substrate suction device is a non-contact substrate fixing device, and can avoid the problems of damage, deformation and the like on the surface of a substrate when the substrate is conveyed.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

High-temperature-resistant heat-insulation vibration-reduction composite material

ActiveCN111923542AGood insulation performanceEasy constructionSynthetic resin layered productsGlass/slag layered productsNuclear reactorInsulation layer

The invention discloses a high-temperature-resistant heat-insulation vibration-reduction composite material, which comprises a protective layer, an upper heat-insulation layer, a middle-low damping layer, a lower heat-insulation layer and a damping alloy layer sequentially arranged from top to bottom. The protective layer is glass fiber cloth, polyimide foam or silica gel fireproof cloth, the upper heat-insulation layer and the lower heat-insulation layer are both made of a silicon dioxide aerogel heat-insulation material, the middle-low damping layer is made of a viscoelastic damping material, and the damping alloy layer is made of a vibration-reduction alloy. The vibration-reduction composite material is light in weight, efficient, resistant to high temperature and irradiation, excellentin heat-insulation performance and high in vibration-reduction function; due to the structure, the problems of dust separation, material deformation caused by heating and vibration and the like are solved; during mounting, skin discomfort of workers cannot be caused, construction is convenient, and the composite material is more suitable for heat insulation of thermal equipment and pipelines of anuclear reactor system.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com