Liquid containing groove and pparatus and method for three-dimensional printing

A three-dimensional printing, liquid-containing technology, applied in the processing of main material accessories, additive manufacturing, processing and manufacturing, etc., can solve the problems of release film pulling, workpiece damage, low-pressure area, etc., to improve speed and stability, The effect of avoiding damage to the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

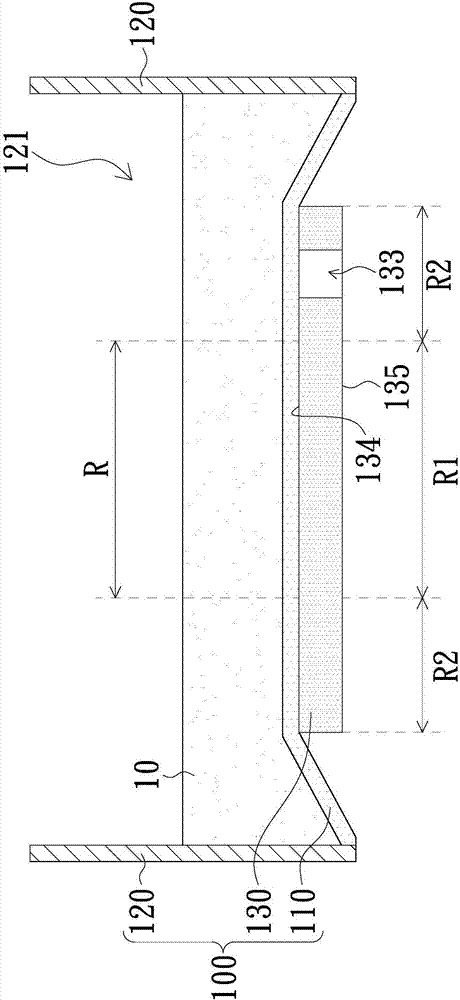

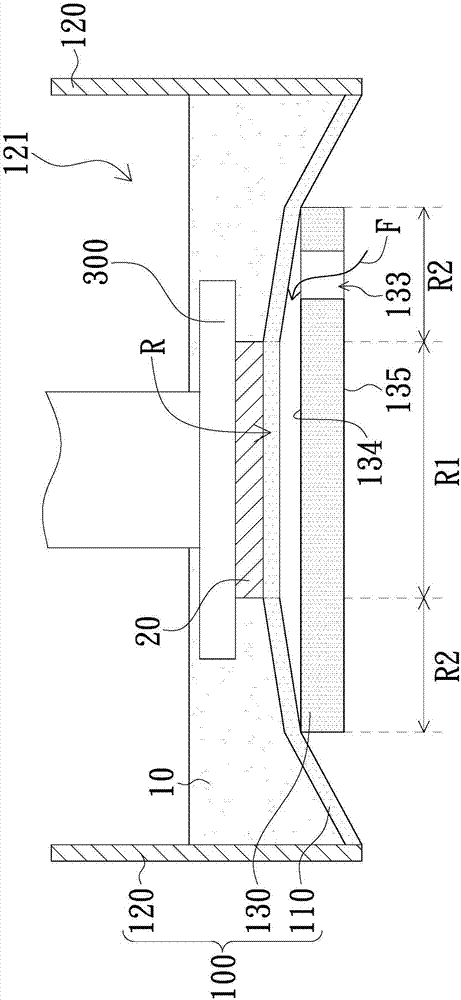

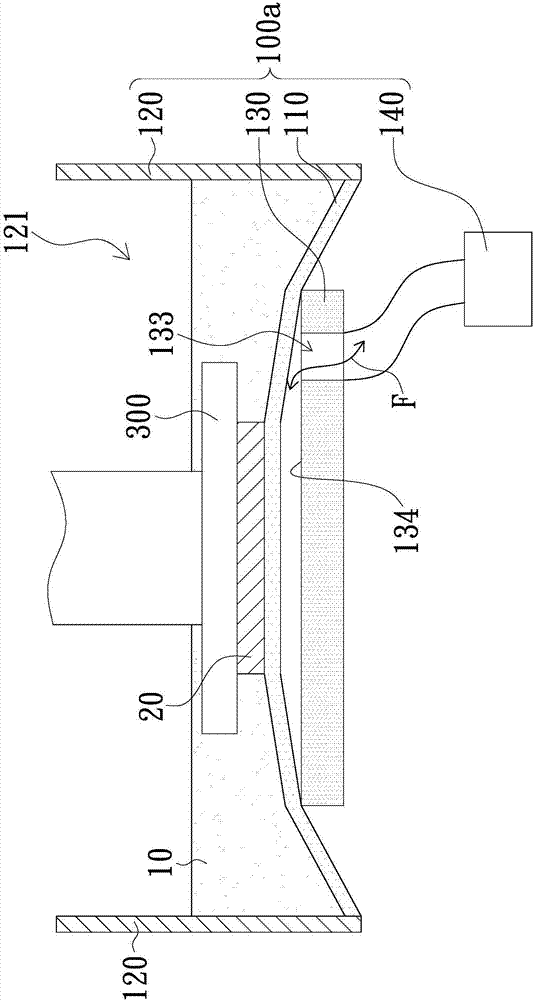

[0025] see figure 1 , the liquid storage tank 100 of this embodiment is suitable for a three-dimensional printing device to accommodate the liquid photosensitive material 10 , and the liquid storage tank 100 includes a release layer 110 and a flat plate 130 . The release layer 110 has a workpiece forming region R. The workpiece forming area R is an area where the shaping beam provided by the three-dimensional printing device can be irradiated. The flat plate 130 supports the release layer 110, and has a first area R1 corresponding to the workpiece forming area R and a second area R2 next to the first area R1. There is at least one fluid channel 133 connected to the flat plate 130 in the second area R2. The surface 134 of the release layer 110 extends to another surface of the plate 130 , such as the surface 135 opposite to the surface 134 .

[0026] The above-mentioned liquid holding tank 100 also includes a plurality of side walls 120, for example, these side walls 120 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com