High-temperature-resistant heat-insulation vibration-reduction composite material

A composite material and high-temperature-resistant technology, which is applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problem that heat insulation materials do not have the function of damping and vibration reduction, and achieve convenient construction and high vibration reduction Function, the effect of excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

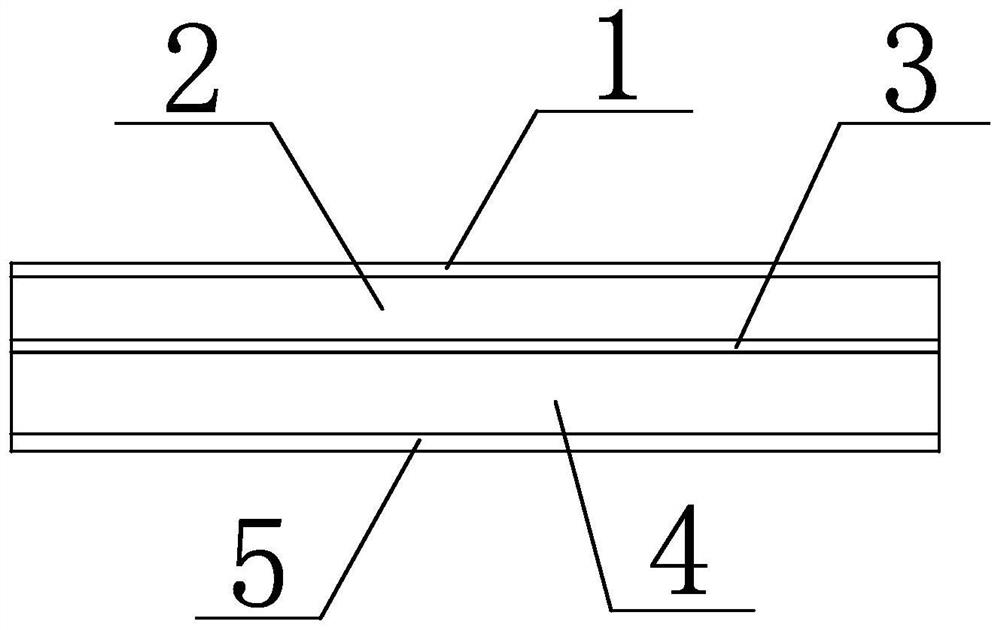

[0025] like figure 1 As shown, a high-temperature-resistant heat-insulating and vibration-damping composite material includes a protective layer 1, an upper heat-insulating layer 2, a middle-low damping layer 3, a lower heat-insulating layer 4, and a damping alloy layer 5 arranged sequentially from top to bottom. The layer is 0.1mm thick glass fiber cloth, the upper and lower insulation layers are 5mm thick silica airgel nanoporous composite insulation felt, the middle and low damping layer is 0.5mm polyurethane viscoelastic damping material, and the damping alloy layer is The 0.3mm magnesium-lithium alloy is laminated with an adhesive to obtain a composite thermal insulation material, and the performance test is carried out.

Embodiment 2

[0027] A high-temperature-resistant heat-insulating and vibration-damping composite material, comprising a protective layer 1, an upper heat-insulating layer 2, a middle-low damping layer 3, a lower heat-insulating layer 4, and a damping alloy layer 5 arranged sequentially from top to bottom, and the protective layer is 0.3 mm thick polyimide foam, the upper insulation layer is 5mm thick silica airgel nanoporous composite insulation felt, the lower insulation layer is 10mm thick silica airgel nanoporous composite insulation felt, the middle The low damping layer is 0.5mm butyl rubber viscoelastic damping material, the damping alloy layer is 0.3mm magnesium-lithium alloy foil, and each layer is laminated with an adhesive to obtain a composite thermal insulation material, and the performance test is carried out.

Embodiment 3

[0029] A high-temperature-resistant heat-insulating and vibration-damping composite material, comprising a protective layer 1, an upper heat-insulating layer 2, a middle-low damping layer 3, a lower heat-insulating layer 4, and a damping alloy layer 5 arranged sequentially from top to bottom, and the protective layer is 0.3 mm thick polyimide foam, the upper insulation layer is 5mm thick silica airgel nanoporous composite insulation felt, the lower insulation layer is 10mm thick silica airgel nanoporous composite insulation felt, The middle and low damping layer is 0.5mm nitrile rubber viscoelastic damping material, and the damping alloy layer is 0.2mm manganese-copper alloy. The composite thermal insulation material is laminated by adhesive between each layer, and the performance test is carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com