Functional nonwoven sea water desalination material and preparation method and application thereof

A non-woven fabric, functionalized technology, applied in non-woven fabrics, chemical instruments and methods, seawater treatment, etc. Transport, produce high efficiency, avoid the effect of solar energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

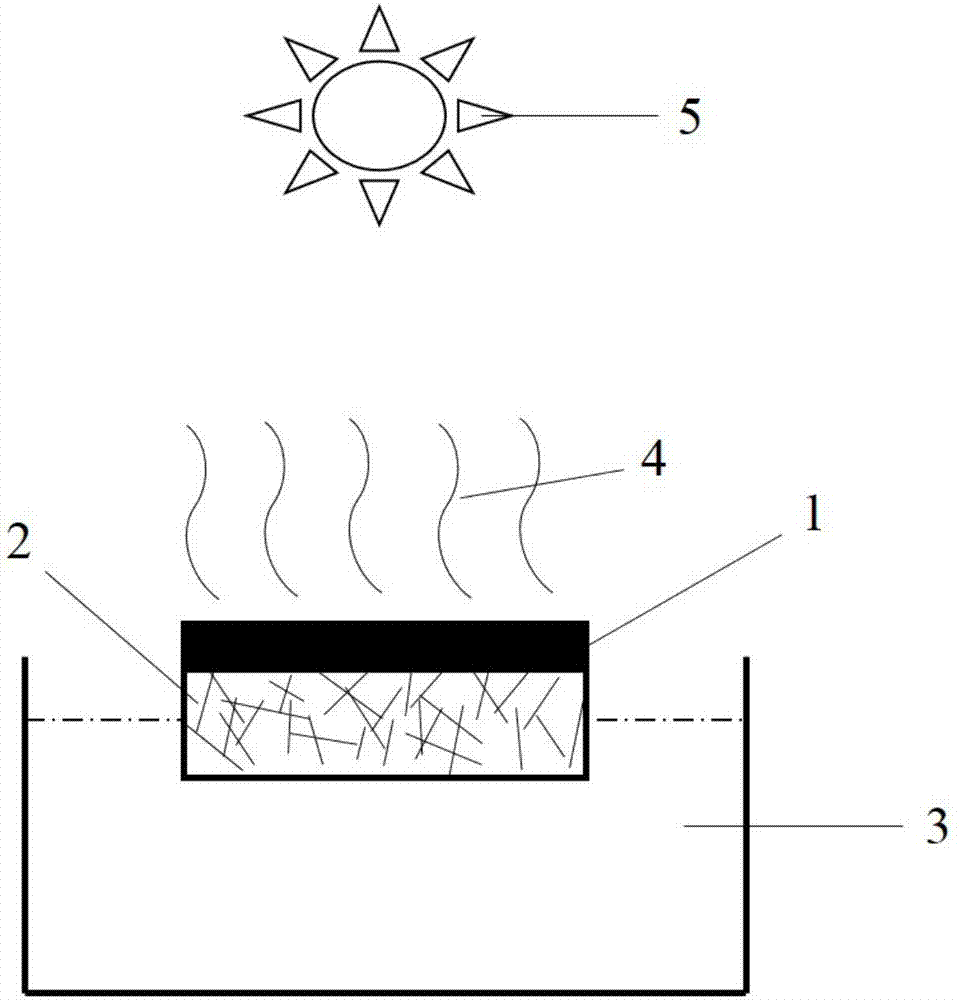

[0018] A functionalized non-woven seawater desalination material, the material uses non-woven fabric as a base material, and a carbon material is loaded on the surface as a light absorber.

[0019] The non-woven fabric is polyester with a diameter of 100 mm and a hole diameter of 0.08 mm.

[0020] The carbon material is graphene oxide.

[0021] The preparation method of any described functionalized nonwoven seawater desalination material comprises the following steps:

[0022] (1) Preparation of a carbon material dispersion: disperse 0.6 g of graphene oxide in 200 mL of deionized water, and perform ultrasonic treatment for 1 hour to obtain a carbon material dispersion;

[0023] (2) Preparation of functionalized nonwoven seawater desalination material: take 60 mL of the carbon material dispersion prepared in step (1) and fix it on the surface of the base material by means of suction filtration, and make it after drying. The suction filtration pressure is 0.1 MPa, and the suct...

Embodiment 2

[0025] A functionalized non-woven seawater desalination material, the material uses non-woven fabric as a base material, and a carbon material is loaded on the surface as a light absorber.

[0026] The non-woven fabric is polypropylene with a diameter of 120 mm and a hole diameter of 0.06 mm.

[0027] The carbon materials are graphene oxide and carbon nanotubes.

[0028] The preparation method of any described functionalized nonwoven seawater desalination material comprises the following steps:

[0029] (1) Preparation of carbon material dispersion: disperse 0.4 g of graphene oxide and 0.2 g of carbon nanotubes in 200 mL of deionized water, and ultrasonically treat for 1.5 h to obtain a carbon material dispersion;

[0030] (2) Preparation of functionalized nonwoven seawater desalination material: take 80 mL of the carbon material dispersion prepared in step (1) and fix it on the surface of the base material by means of suction filtration, and make it after drying. The suctio...

Embodiment 3

[0032] A functionalized non-woven seawater desalination material, the material uses non-woven fabric as a base material, and a carbon material is loaded on the surface as a light absorber.

[0033] The non-woven fabric is viscose, and its specification is 200 mm in width, 800 mm in length, and 0.09 mm in aperture.

[0034] The carbon material is carbon nanotube.

[0035] The preparation method of any described functionalized nonwoven seawater desalination material comprises the following steps:

[0036] (1) Preparation of carbon material dispersion: disperse 3 g of carbon nanotubes in 1000 mL of deionized water, and ultrasonically treat for 5 hours to obtain a carbon material dispersion;

[0037] (2) Preparation of functionalized nonwoven seawater desalination material: take 500 mL of the carbon material dispersion prepared in step (1) and fix it on the surface of the base material by coating, and make it after drying. The coating speed is 8cm / s, and the coating is dried at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com