Foaming concrete made by waste and old concrete and production method thereof and use

A technology of waste concrete and foamed concrete, which is applied in the field of foamed concrete, can solve the problems of high cost of foamed concrete, achieve the effects of accelerating the solidification speed, ensuring continuity, and improving the safety of mining areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

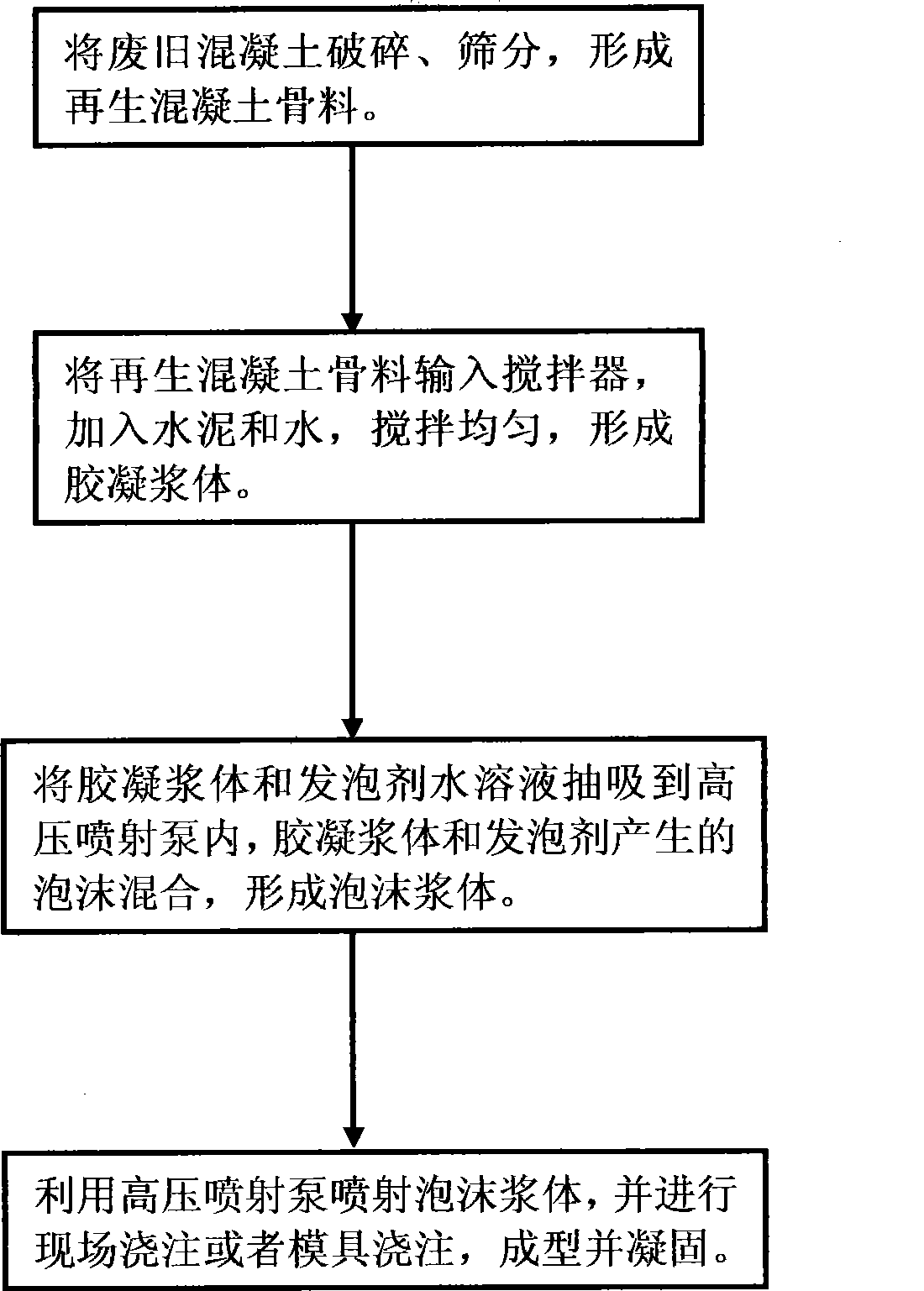

Method used

Image

Examples

Embodiment 1

[0030] After the waste concrete produced during the excavation of the concrete pavement is crushed and screened, coarse aggregate, fine aggregate and powder of different particle sizes are mixed to form recycled concrete aggregate; the recycled concrete aggregate is input into the mixer, and an appropriate amount is added The cement and water are stirred and mixed to form a gelled paste. At the same time, inject the foaming agent and an appropriate amount of water into the foaming agent barrel to form a foaming agent aqueous solution. The gelled slurry and the foaming agent aqueous solution are pumped into the high-pressure jet pump, and the gelled slurry and the foam generated by the blowing agent are mixed to form a foam slurry. Use a high-pressure jet pump to spray and pour the foam slurry into narrow slits and grooves, without mechanical tamping, to form a firm and dense filling body in narrow slits and narrow grooves.

Embodiment 2

[0032] After the waste concrete produced during the excavation of the concrete pavement is crushed and screened, coarse aggregate, fine aggregate and powder of different particle sizes are mixed to form recycled concrete aggregate; the recycled concrete aggregate is input into the mixer, and an appropriate amount is added The cement, crushed stone and water are stirred and mixed to form a cementitious slurry. At the same time, inject the foaming agent and an appropriate amount of water into the foaming agent barrel to form a foaming agent aqueous solution. The gelled slurry and the foaming agent aqueous solution are pumped into the high-pressure jet pump, and the gelled slurry and the foam generated by the blowing agent are mixed to form a foam slurry. Use a high-pressure jet pump to spray and pour the above-mentioned foam slurry on both sides of the expressway that needs to be widened, and make the outer surface of the pouring body form a vertical surface, that is, no slope i...

Embodiment 3

[0034] After crushing and screening the waste concrete produced during the construction process, mix coarse aggregate, fine aggregate and powder of different particle sizes to form recycled concrete aggregate; input the recycled concrete aggregate into the mixer, and add an appropriate amount of cement , quicklime powder, fly ash and water are stirred and mixed to form a gelled slurry. At the same time, inject the foaming agent and an appropriate amount of water into the foaming agent barrel to form a foaming agent aqueous solution. The gelled slurry and the foaming agent aqueous solution are pumped into the high-pressure jet pump, and the gelled slurry and the foam generated by the blowing agent are mixed to form a foam slurry. The above-mentioned foam slurry is sprayed and poured into the waste mine tunnel by using a high-pressure jet pump, and a compact filling body can be formed in the waste mine tunnel after the foamed concrete is solidified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com