Method for inhibiting Laves phase precipitation in nickel-based alloy laser additive manufacturing process

A nickel-based alloy and laser additive technology, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency, can solve problems such as high maintenance costs, low cost performance, and cumbersome on-site repairs, and achieve reduction in size and volume fraction , increase the front temperature gradient, and promote the effect of solid solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

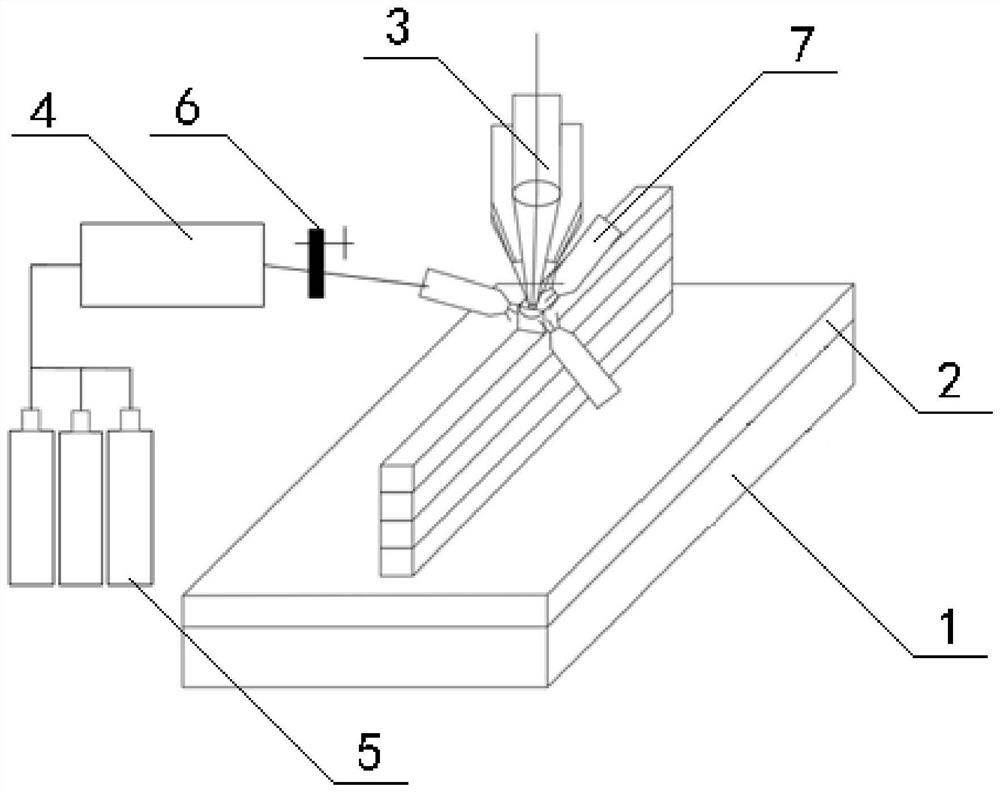

[0032] 1) Inconel 718 superalloy is selected as the substrate 2, the surface is polished with sandpaper, and the oil stain is removed with alcohol solution. Put the prepared special powder into the oven for half an hour to remove moisture, and place it in the boiling powder feeder after drying, using the coaxial powder feeding method.

[0033] 2) A 2000W semiconductor laser was used for cladding experiments. The spot diameter of the laser beam emitted by the laser processing head 3 of the semiconductor laser was 4mm; the selected process was: laser power 900W, scanning speed 360mm / s, and powder feeding volume 10g / min. The flow rate of protective gas and carrier gas is 15L / min.

[0034] 3) The substrate 2 cooling device 1 whose cooling medium is liquid nitrogen cools the bottom of the substrate to reduce heat accumulation during the forming process.

[0035] 4) Determine the forming position, adjust the position and direction of the three chilled copper tubes in the synchronou...

Embodiment 2

[0038] 1) Select Inconel 625 as the substrate 2, polish the surface with sandpaper, and then use alcohol solution to remove its oil stains.

[0039] 2) Put the prepared special powder in an oven for half an hour to remove moisture, and place it in a scraper-type powder feeder after drying, using coaxial powder feeding.

[0040] 3) A 2000W semiconductor laser is used for cladding, and the spot diameter of the laser beam emitted by the laser processing head 3 of the semiconductor laser is 4mm; the selected process is: laser power 1600W, scanning speed 420mm / s, powder feeding amount 10g / min.

[0041] 4) Determine the forming position, adjust the position and direction of the three chilled copper tubes in the synchronous suppression device, open the air cooling valve; adjust the flow rate to 3L / min until the end of the additive process.

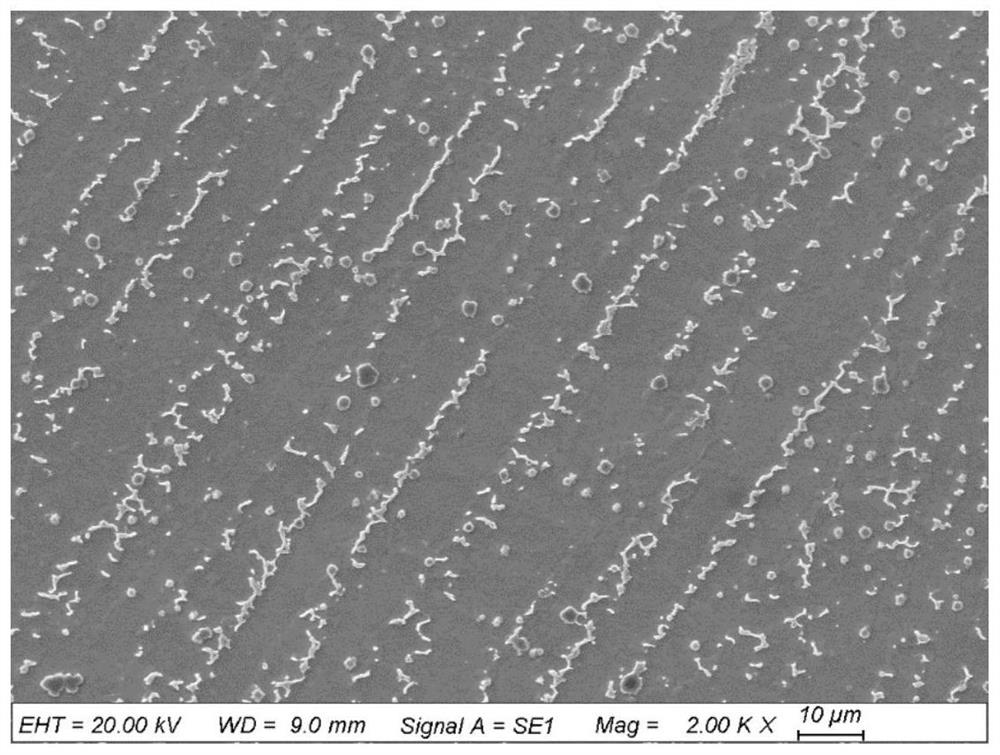

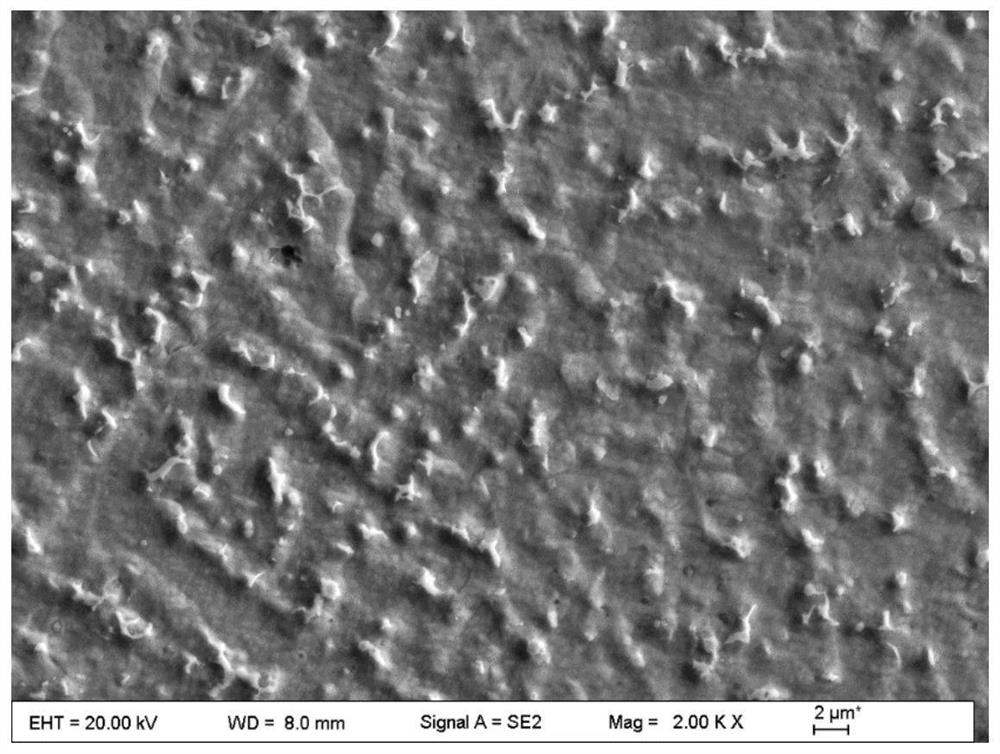

[0042] 5) After forming, observe the structure after a series of processes such as wire cutting, inlaying, rough grinding, fine grinding, polish...

Embodiment 3

[0044] 1) Select Inconel 939 as the substrate 2, polish the surface with sandpaper, and then use alcohol solution to remove its oil stains.

[0045] 2) Put the prepared special powder into the dryer for half an hour to remove moisture, and place it in the scraper type powder feeder after drying, adopting the method of coaxial powder feeding.

[0046] 3) A 2000W semiconductor laser is used for cladding, and the spot diameter of the laser beam emitted by the laser processing head 3 of the semiconductor laser is 4mm; the selected process is: laser power 1800W, scanning speed 420mm / s, powder feeding amount 15g / min.

[0047] 4) Determine the forming position, adjust the position and direction of the three chilled copper tubes in the synchronous suppression device, open the air cooling valve; adjust the flow rate to 20L / min until the end of the additive process.

[0048] 5) After forming, conduct a series of processes such as wire cutting, inlaying, rough grinding, fine grinding, po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com