Patents

Literature

141 results about "Laves phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laves phases are intermetallic phases that have composition AB₂ and are named for Fritz Laves who first described them. The phases are classified on the basis of geometry alone. There are three different classification classes: cubic MgCu₂ (C15), hexagonal MgZn₂ (C14), and hexagonal MgNi₂ (C36). The latter two classes are unique forms of the hexagonal arrangement, but share the same basic structure.

Preparation method of material increase manufactured nickel-based high-temperature alloy reserved with Laves phase

ActiveCN105543747AShorten the manufacturing cycleFast preparationMetallic material coating processesFree coolingSuperalloy

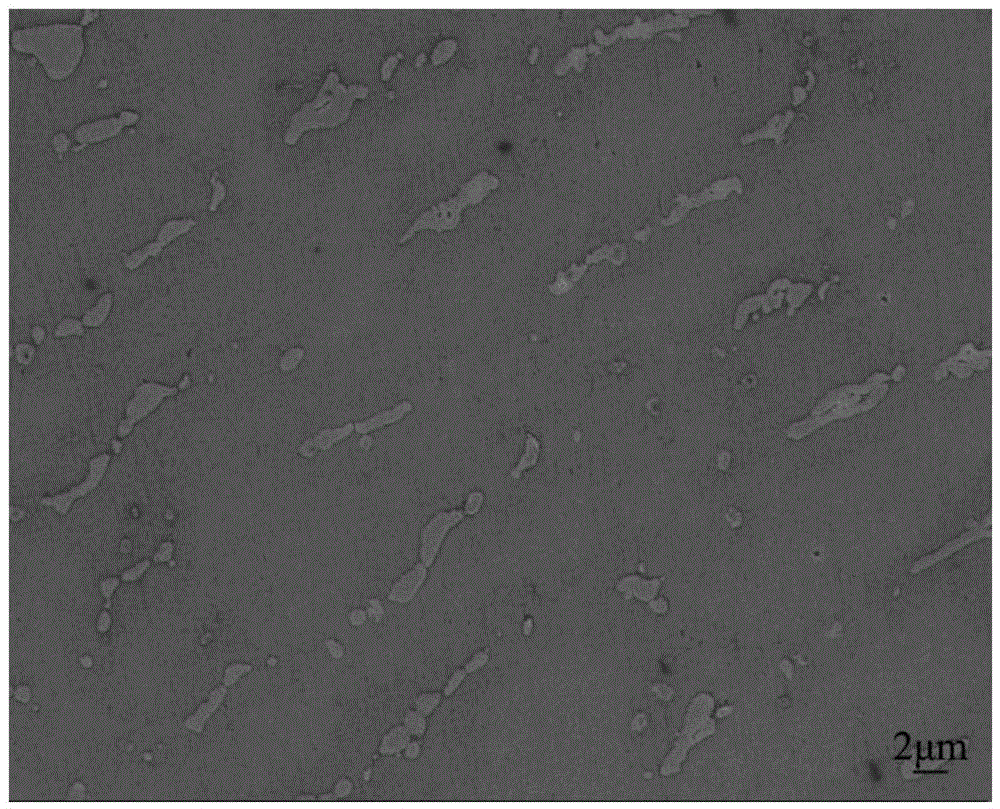

The invention provides a preparation method of a material increase manufactured nickel-based high-temperature alloy reserved with the Laves phase. GH4169 high-temperature alloy with the Laves phase distributed in a dispersed particle shape is prepared through the preparation method, and compared with industrial forged and cast isometric crystal high-temperature alloy, the high-temperature mechanical properties, especially the high-temperature creep property, the high-temperature endurance life and the like are greatly improved. The preparation method comprises the following steps that firstly, in a processing rood, GH4160 high-temperature alloy powder or wire materials are processed through a high-energy beam heat source to be continuously melted and deposited on a base plate, so that the GH4169 high-temperature alloy reserved with the Laves phase is prepared; secondly, the prepared GH4169 high-temperature alloy reserved with the Laves phase is naturally cooled in the processing room and taken out after the temperature of the GH4169 high-temperature alloy is below 100 DEG C; and thirdly, two stages of heat treatment is conducted on the GH4169 high-temperature alloy which is taken out of the processing and reserved with the Laves phase in sequence, the first stage is completed by conducting heat preservation for 8-24 hours under the condition that the GH4169 high-temperature alloy is heated to the temperature of 700-740 DEG C, then the second stage is completed by cooling the GH4169 high-temperature alloy to the temperature below 600-640 DEG C along with a heat preservation furnace and then conducting heat preservation for eight hours, and finally air cooling is conducted till the indoor temperature is reached, so that the material increase manufactured nickel-based high-temperature alloy reserved with the Laves phase is obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

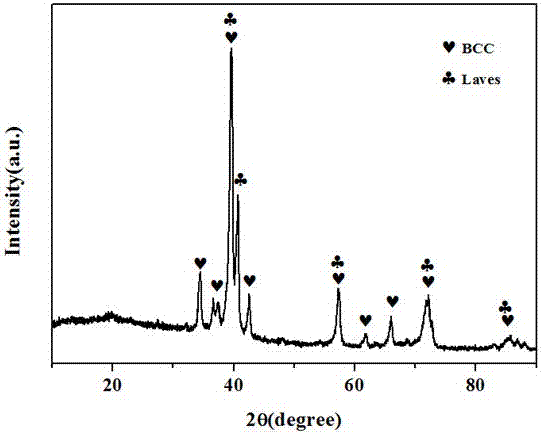

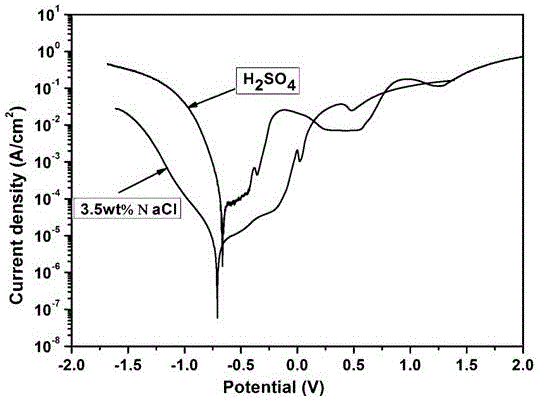

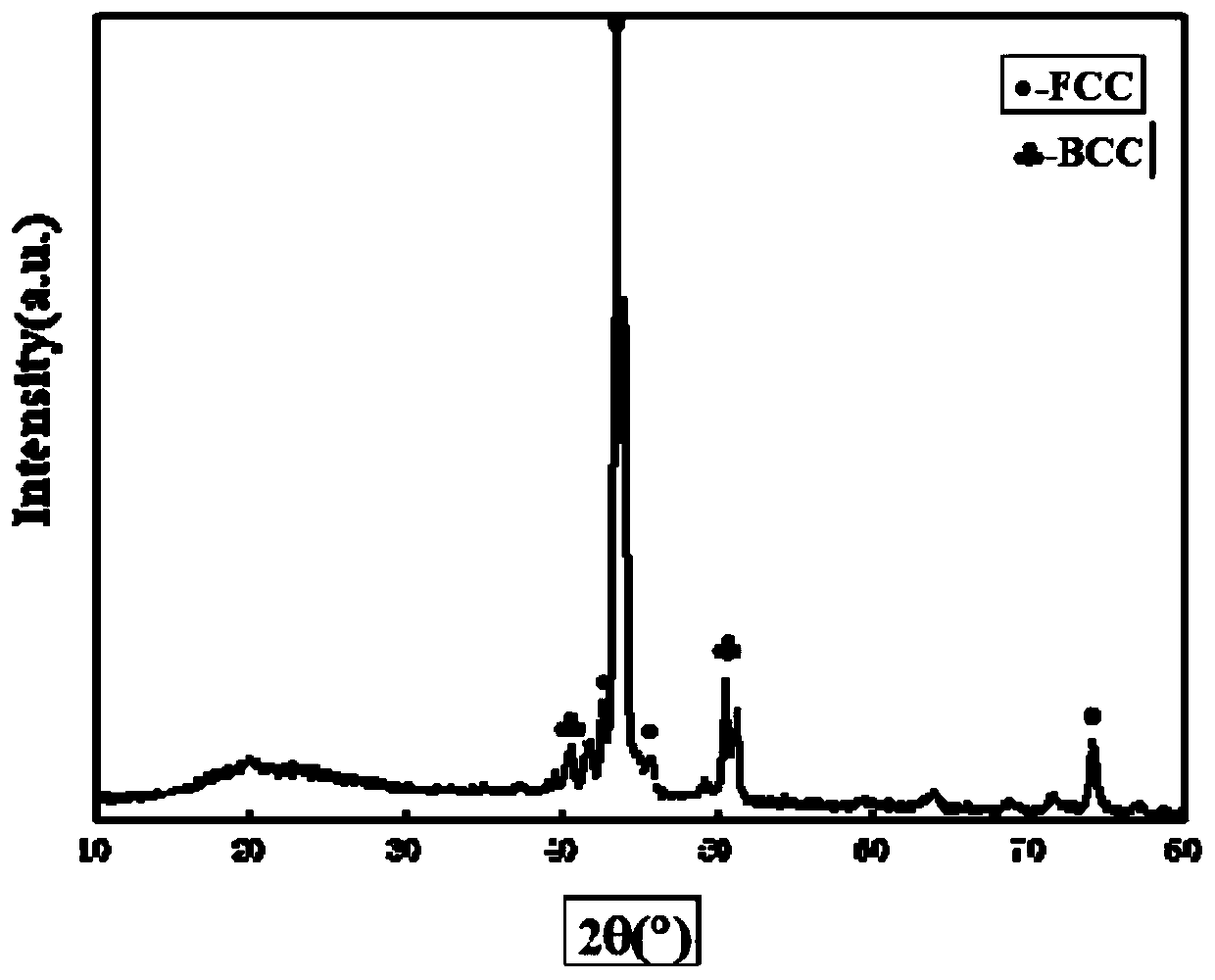

CrMoNbTiZr high-entropy alloy material and preparation method thereof

The invention relates to a CrMoNbTiZr high-entropy alloy material and a preparation method of the CrMoNbTiZr high-entropy alloy material. The high-entropy alloy material comprises Cr, Mo, Nb, Ti and Zr, wherein the molar ratio of Cr to Mo to Nb to Ti to Zr is 1:1:1:1:1. The preparation method comprises the steps that 1, powder is prepared, and particularly metal powder is prepared according to the equal molar ratio; 2, powder mixing is carried out, and particularly the prepared powder is mixed to be uniform in a V-shaped powder mixing machine; 3, pressing and block forming are carried out, and particularly the mixed powder is subjected to cold pressing under a pressing machine to form blocks; and alloy is molten, and particularly a vacuum non-consumable arc melting furnace is used for melting the samples which are obtained after the powder is pressed to be blocks. The CrMoNbTiZr high-entropy alloy material mainly comprises a BCC solid solution phase and a small amount of Laves phase, meanwhile has the advantages of being high in hardness, high in corrosion resistance and the like, and has the good application prospect in the field of wear resistance and corrosion resistance.

Owner:XIANGTAN UNIV

Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy

The invention relates to an Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy, and belongs to the technical field of metal materials. According to the Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy, through adjusting of proportioning of basic components of Al, Ni, Co, Cr and Fe and adding of microelement Nb, forming of an L12 phase is promoted, and occurrence of detrimental phases such as a B2phase, an Laves phase and a sigma phase is avoided; the high-entropy alloy is mainly composed of an FCC phase, the grain size is within 100 [mu]m-400 [mu]m, the yield strength is not lower than 300 MPa, the tensile strength is not lower than 740 MPa, the elongation rate is not lower than 18%, the good toughness and the high yield strength are both achieved, and the Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy meets the requirements of a modern industry for mechanical properties of materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

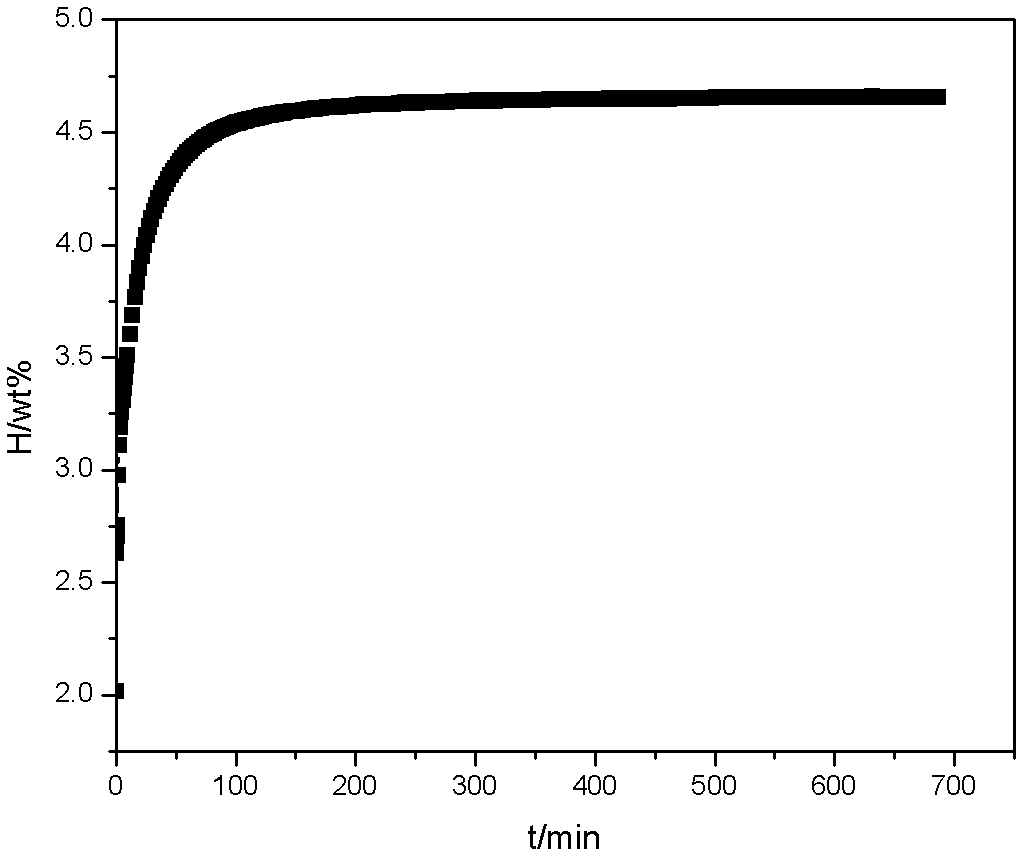

Under-measurement Laves phase hydrogen storage alloy and preparation method thereof

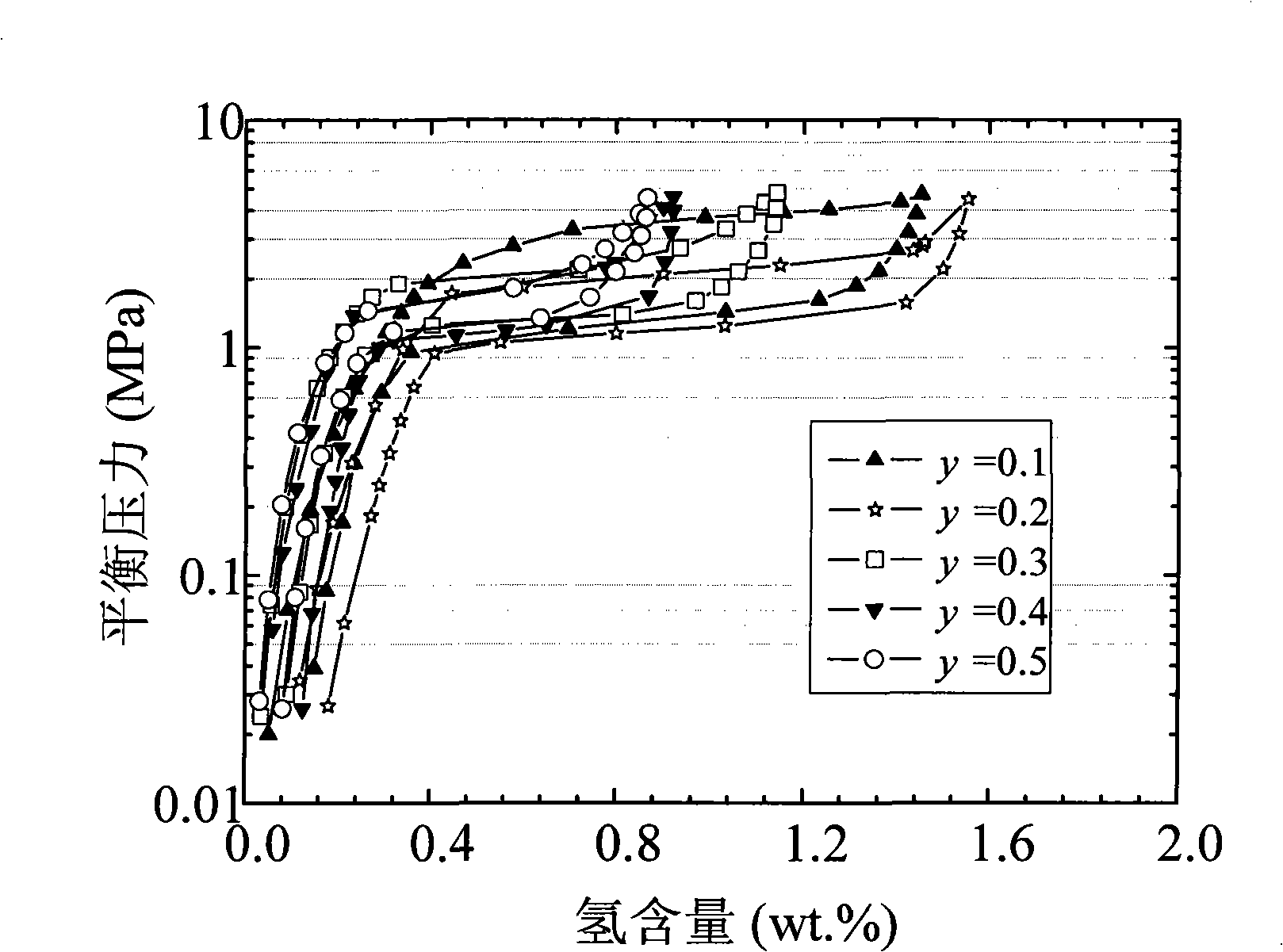

The invention discloses an under-measurement Laves phase hydrogen storage alloy and a preparation method thereof. The general chemical formula of the alloy is TiuZrxMnvMyVz, wherein x is more than or equal to 0 and is less than or equal to 0.2; y is more than or equal to 0.1 and is less than or equal to 0.4; z is more than or equal to 0.1 and is less than or equal to 0.5, u plus x is equal to 1, and v plus y is equal to 1.5; the optimal range of y is more than or equal to 0.1 and is less than or equal to 0.2, and the optimal range of z is more than or equal to 0.1 and is less than or equal to 0.3; M element can be Cr, Ni or Cu; and the preparation method comprises the following steps: weighing the alloy according to the blending ratio; repeatedly melting block-shaped pure metal in a magnetic suspension high frequency induction furnace under the protection of argon gas for two times to three times; and annealing the obtained cast alloy for six to eight days at the temperature of 950 DEG C to 1050 DEG C under the protection of inert gas. The invention has the advantages of large hydrogen storage amount, small lag, long platform area and other good comprehensive performances.

Owner:FUDAN UNIV

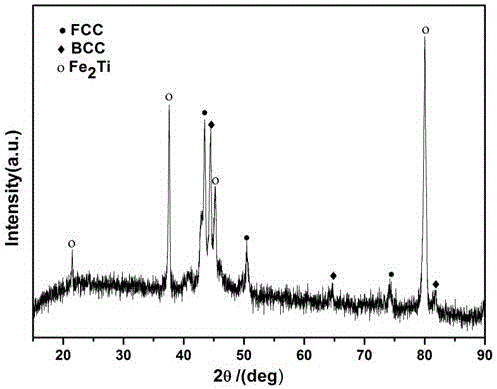

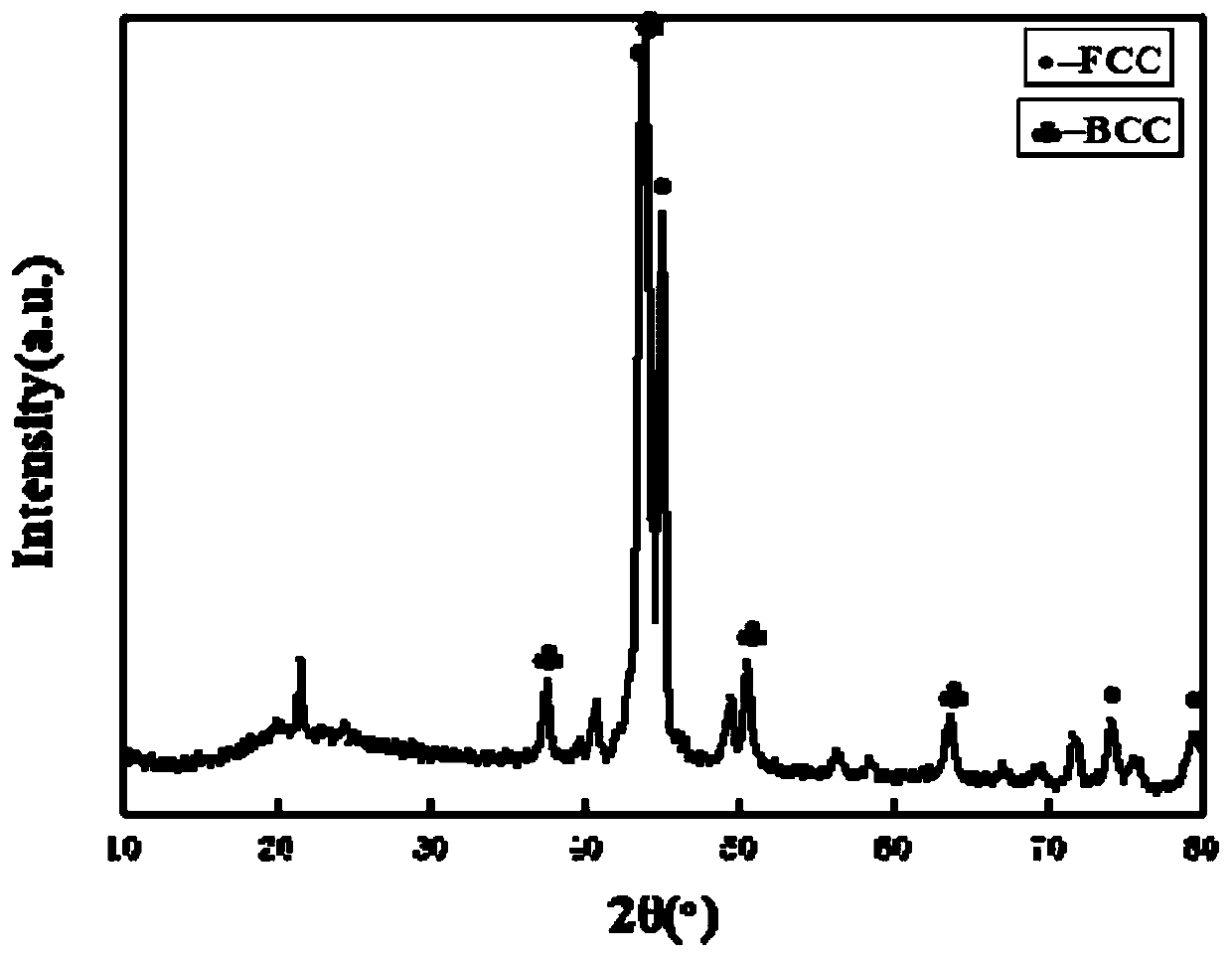

CuCrFeNiTi high-entropy alloy material and preparation method thereof

The invention relates to a high-entropy alloy material and a preparation technology of the high-entropy alloy material. The composition of the high-entropy alloy material is CuCrFeNiTi, wherein the mole ratio of Cu to Cr to Fe to Ni to Ti is 1:1:1:1:1 in sequence. A preparation method of the high-entropy alloy material comprises the steps that firstly, ultrasonic treatment is conducted, wherein the Cu material, the Cr material, the Fe material, the Ni material and the Ti material are processed through ultrasonic cleaning with an acetone solution and an absolute ethyl alcohol successively; secondly, material weighing is conducted, wherein the materials are weighed according to the mole ratio; and thirdly, smelting is conducted, wherein the weighed materials are repeatedly smelted for 4-5 times through a vacuum nonconsumable electrode electric arc smelting furnace so as to achieve alloy preparation. Compared with a conventional alloy material, the prepared CuCrFeNiTi high-entropy alloy material comprises a simple face-centered cubic structure, a simple body-centered cubic structure and the Laves phase, has the high hardness and high corrosion resistance, and can be applied to wear-proof and corrosion-resistant chemical containers and high-strength and corrosion-resistant parts for engineering.

Owner:XIANGTAN UNIV

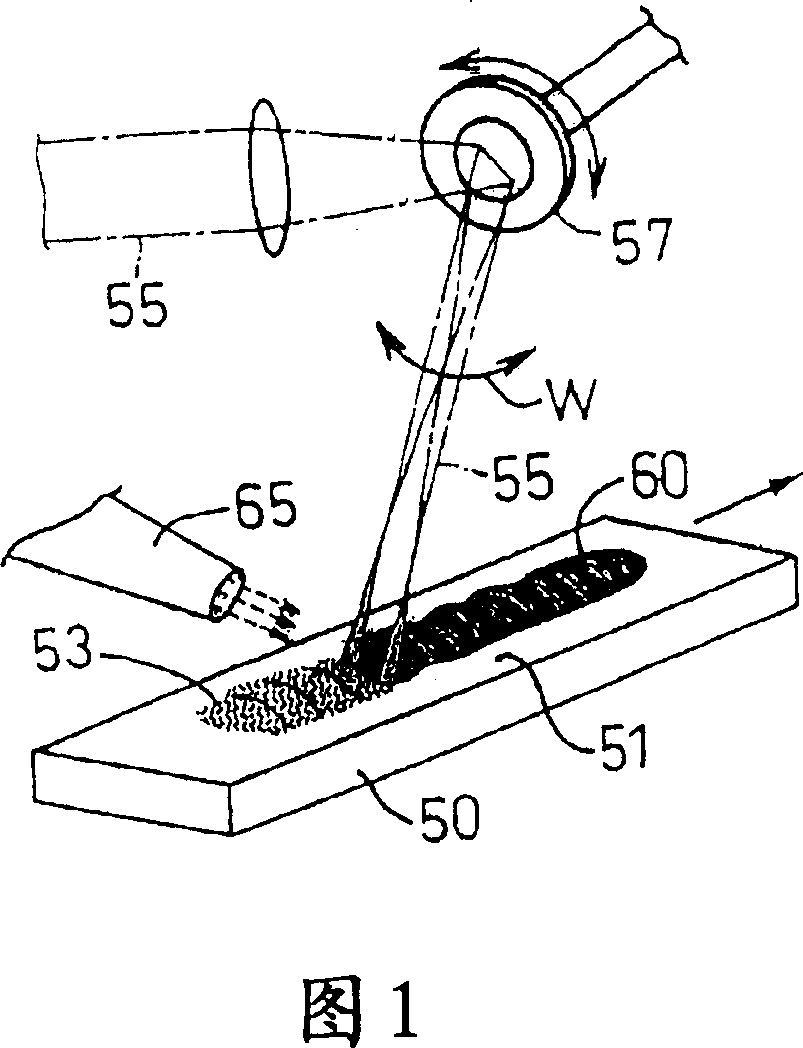

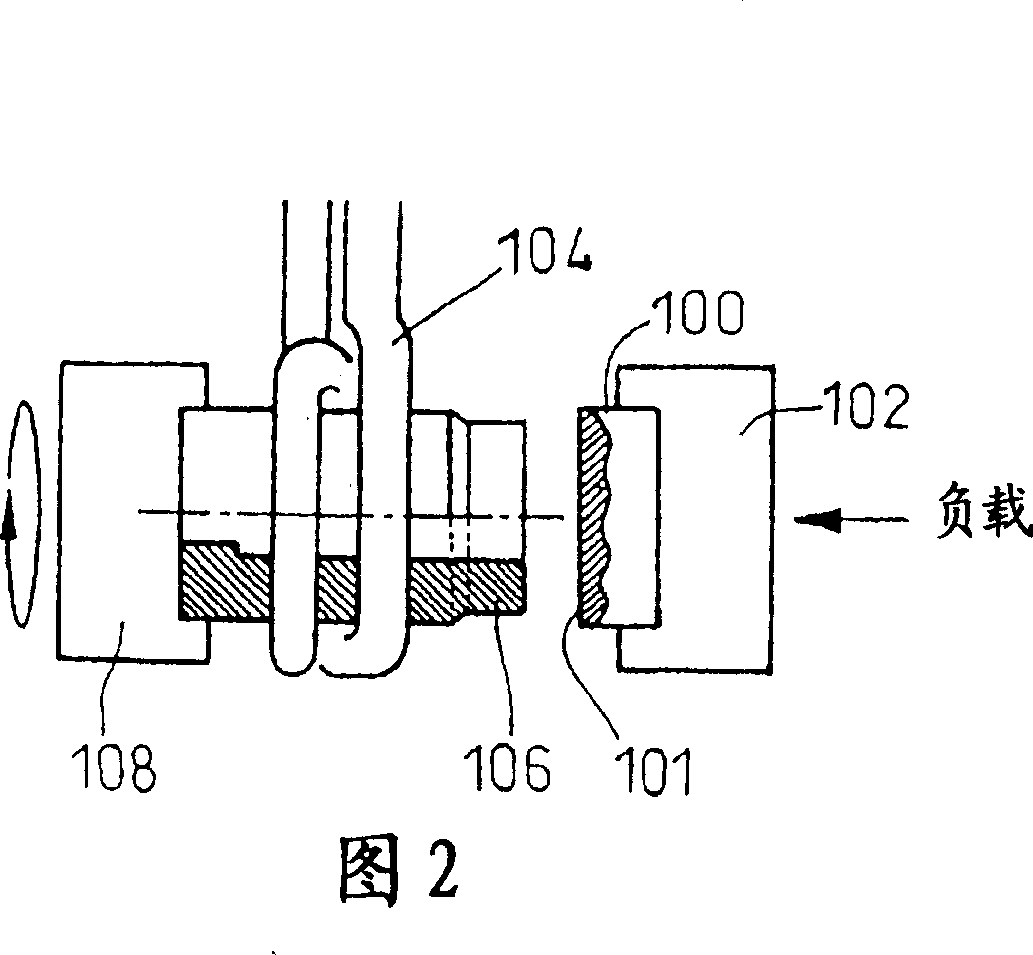

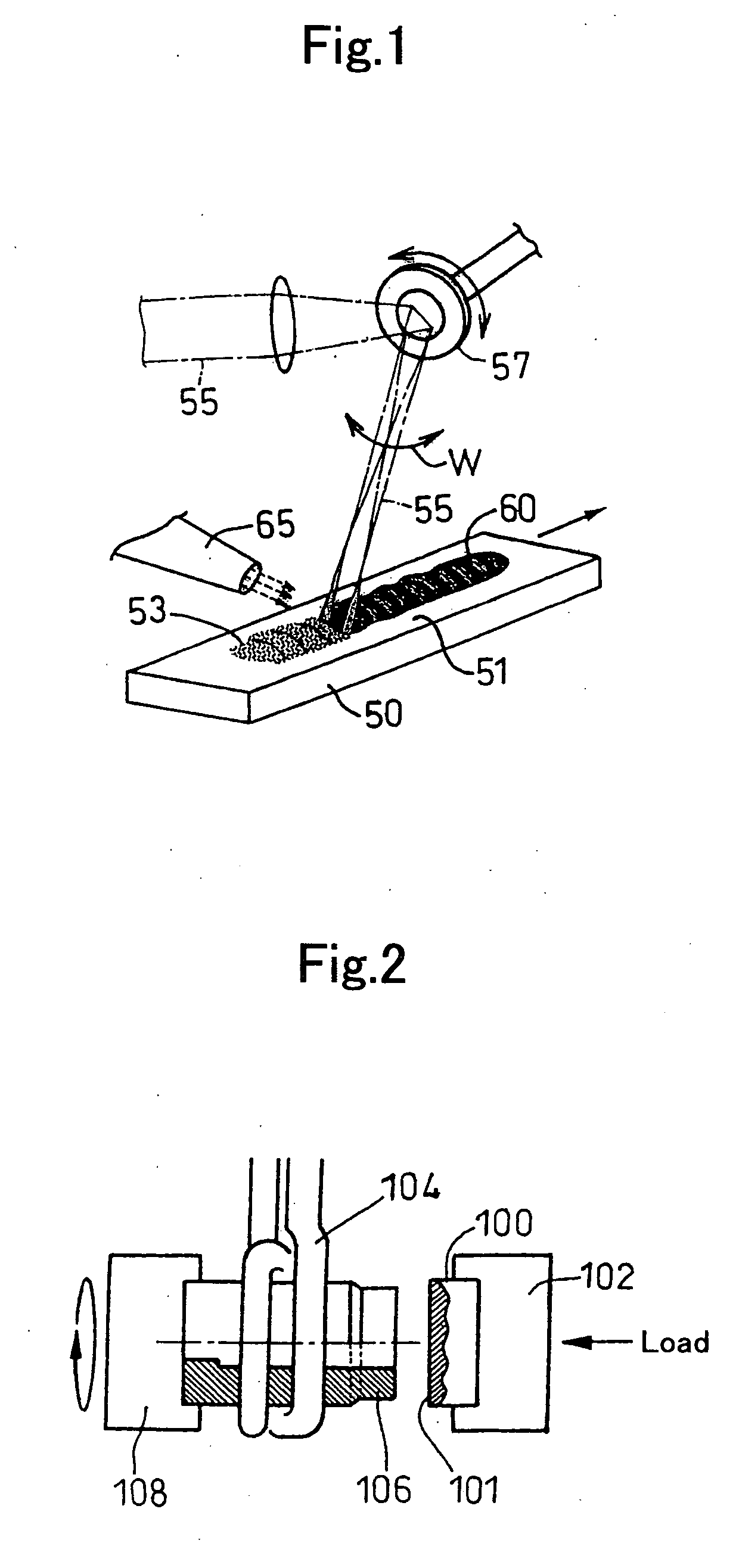

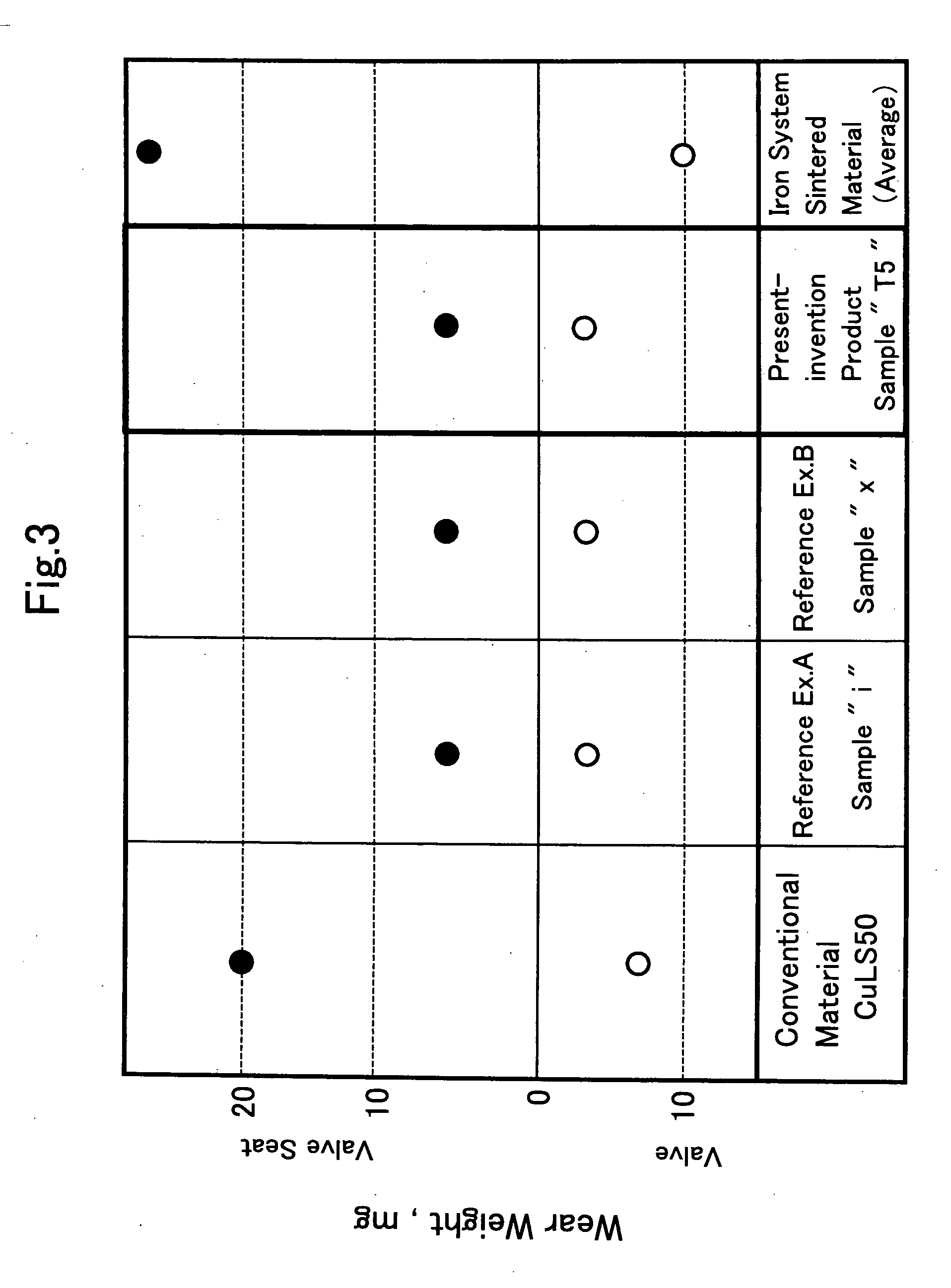

Build-up wear-resistant copper-based alloy

InactiveCN1930315AExcellent machinabilityMeet the crack resistanceMolten spray coatingMachines/enginesCrack resistanceNiobium

This is to provide a build-up wear-resistant copper-based alloy, which is advantageous for enhancing the cracking resistance and machinability, which is appropriate for cases of building up to form built-up layers especially, and which is equipped with the wear resistance, cracking resistance and machinability combinedly in a well balanced manner. A build-up wear-resistant copper-based alloy is characterized in that it has a composition, which includes nickel: 5.0-20.0%; silicon: 0.5-5.0%; manganese: 3.0-30.0%; and an element, which combines with manganese to form a Laves phase and additionally to form silicide: 3.0-30.0%; by weight %, and inevitable impurities; and additionally the balance being copper. The element can be one member or two or more members of titanium, hafnium, zirconium, vanadium, niobium and tantalum.

Owner:TOYOTA JIDOSHA KK

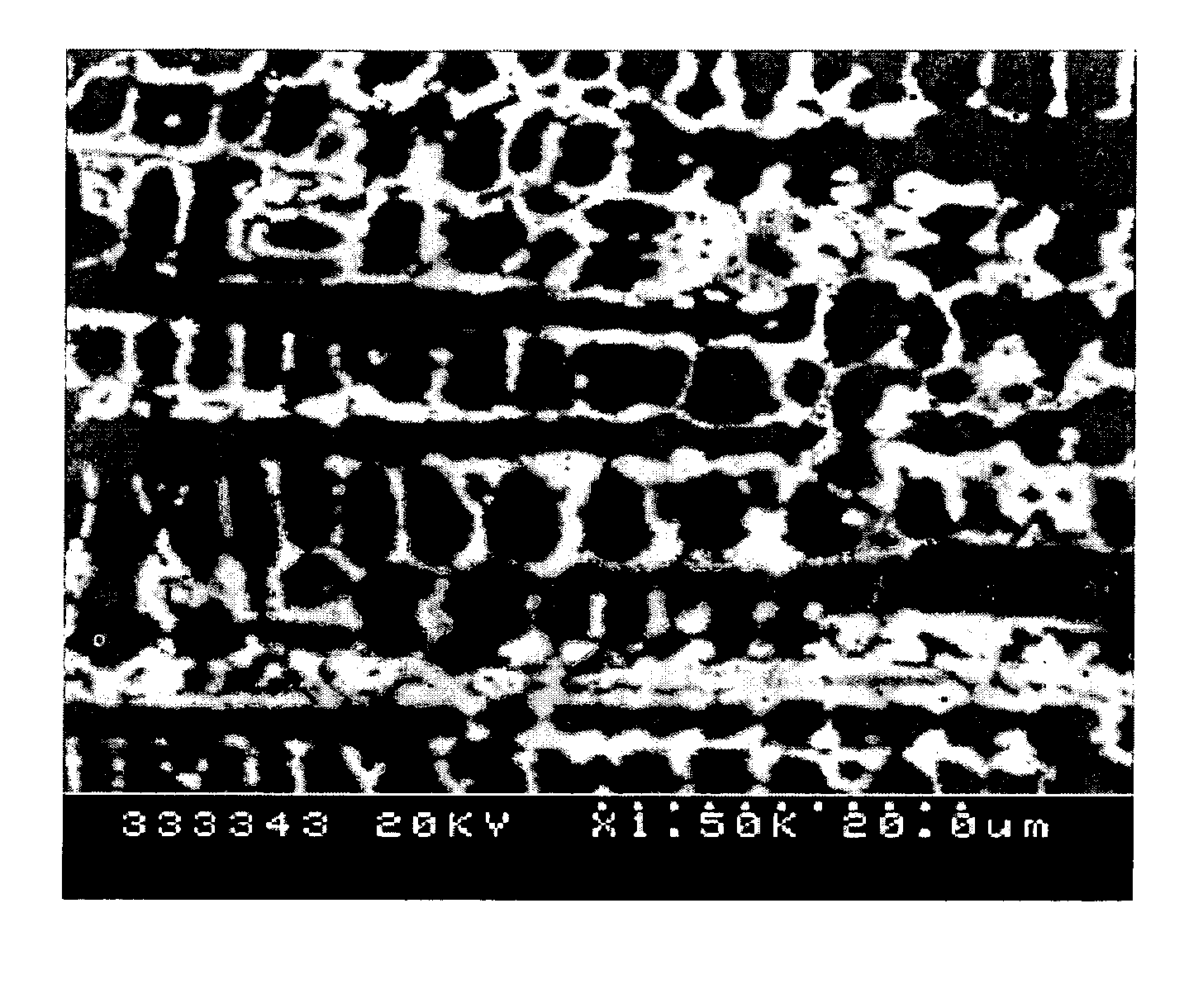

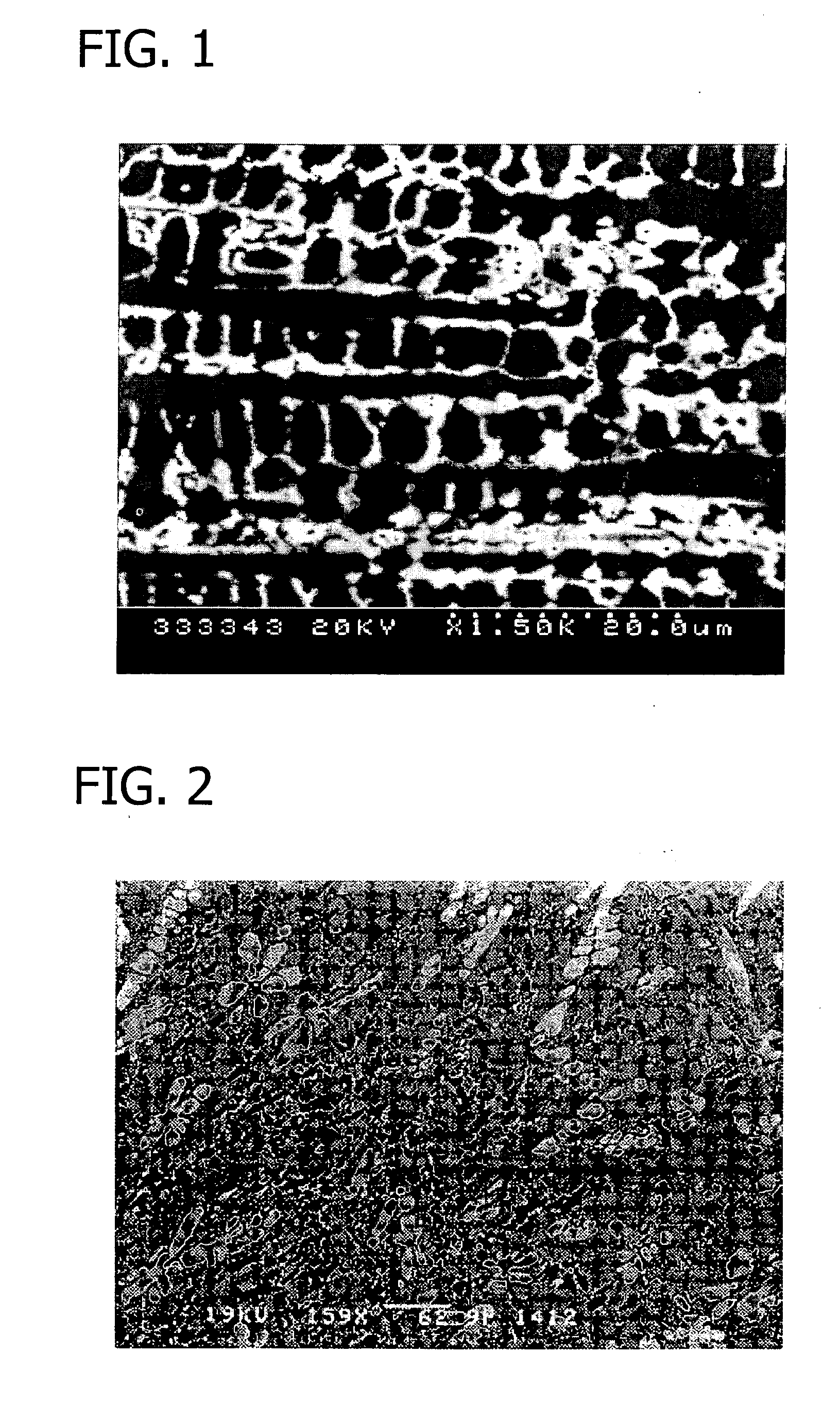

Ductile cobalt-based Laves phase alloys

A Co—Mo—Cr Co-based alloy and overlay for wear and corrosion applications. The Mo:Si ratio is between about 15:1 and about 22:1 for enhanced ductility with a Laves phase.

Owner:KENNAMETAL INC

High-strength martensitic stainless steel with excellent resistances to carbon dioxide gas corrosion and sulfide stress corrosion cracking

Owner:NIPPON STEEL CORP

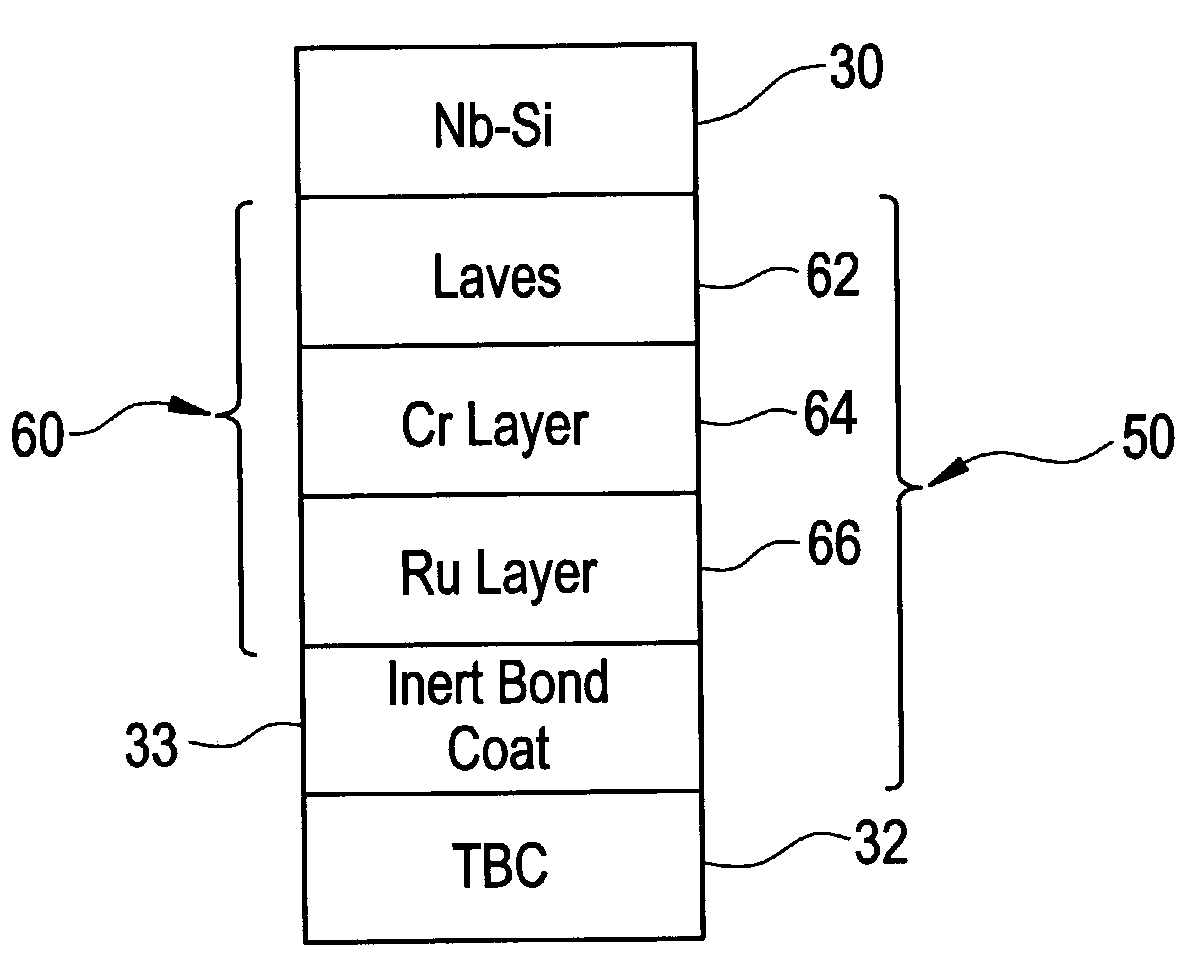

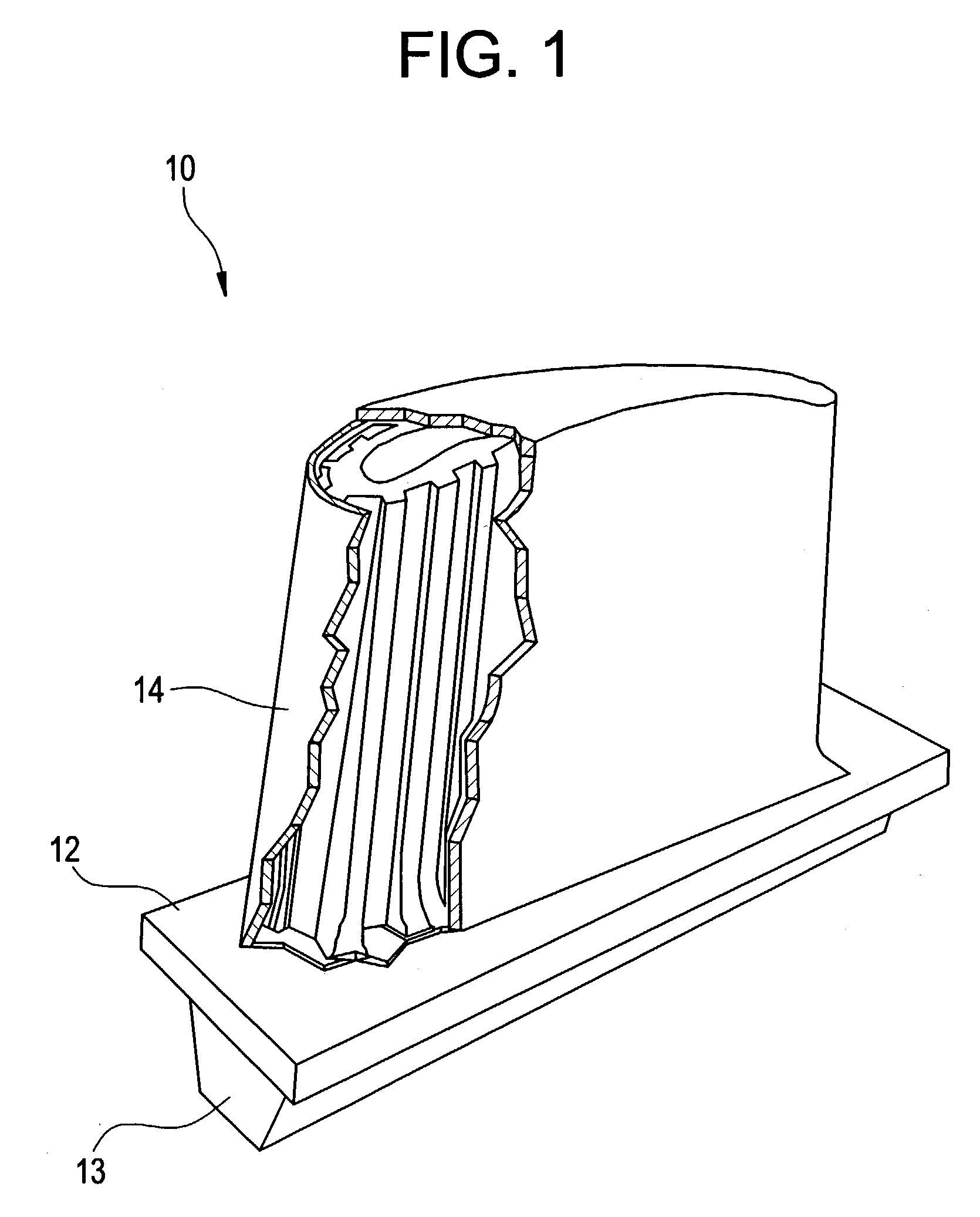

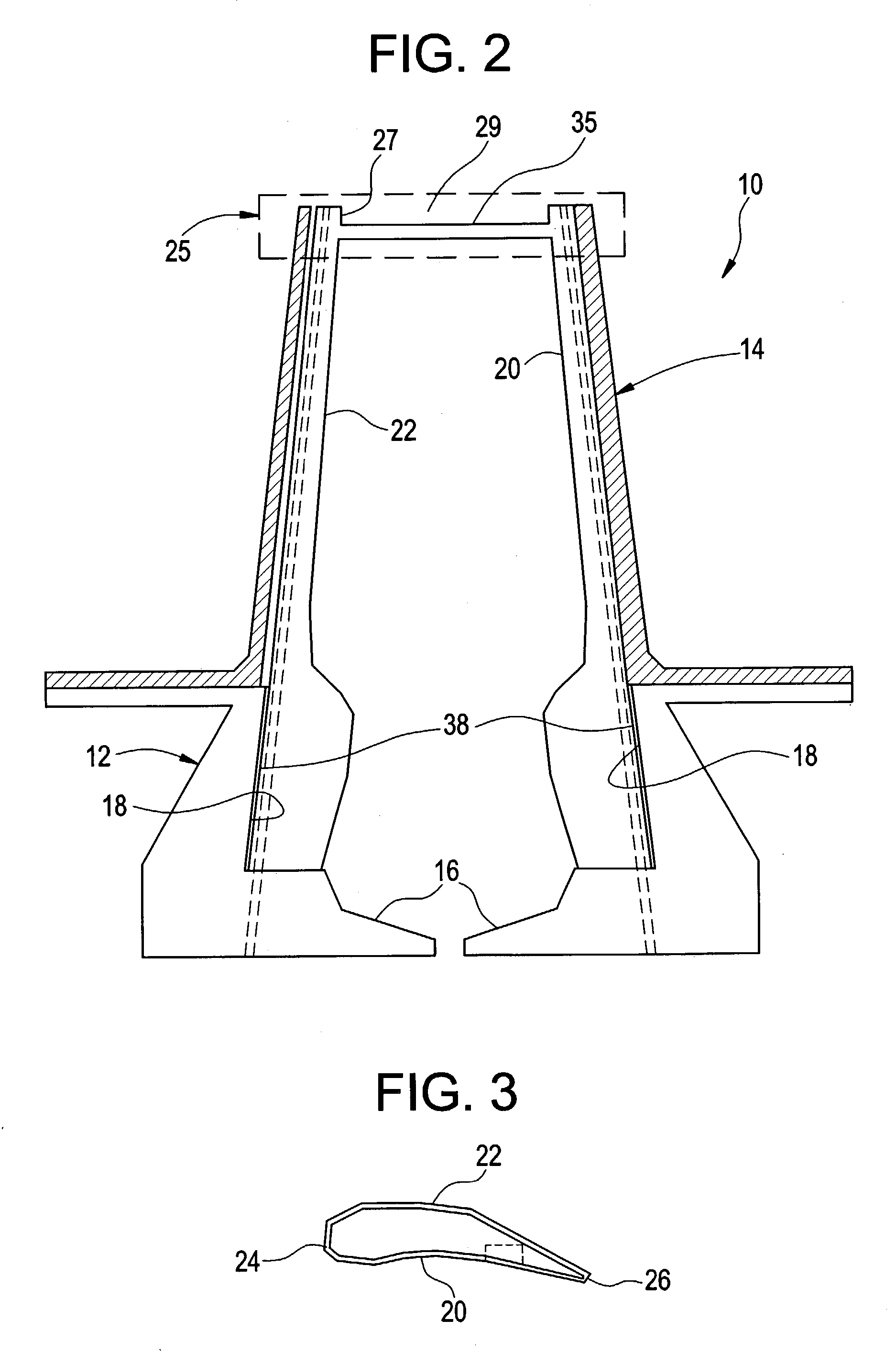

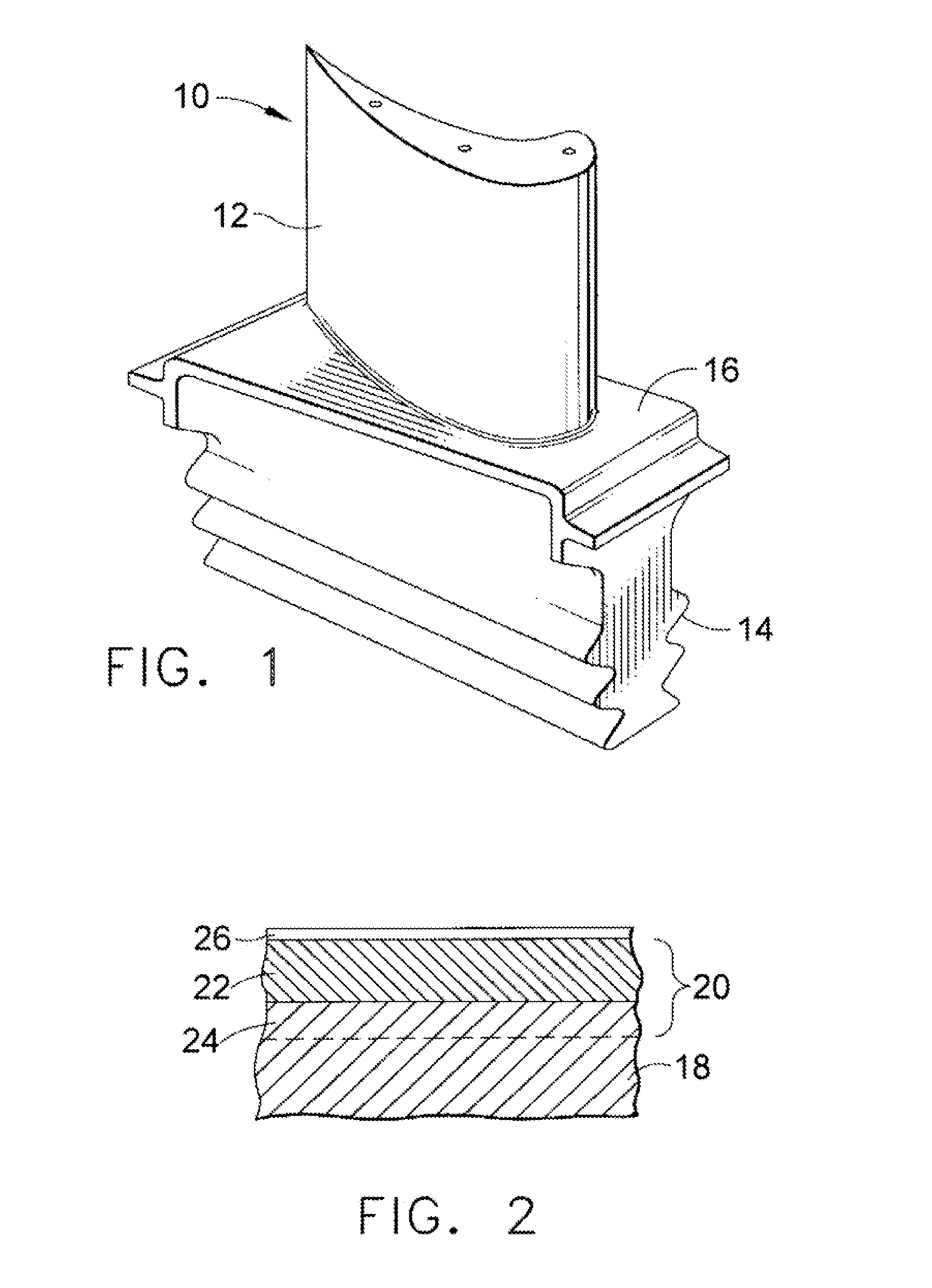

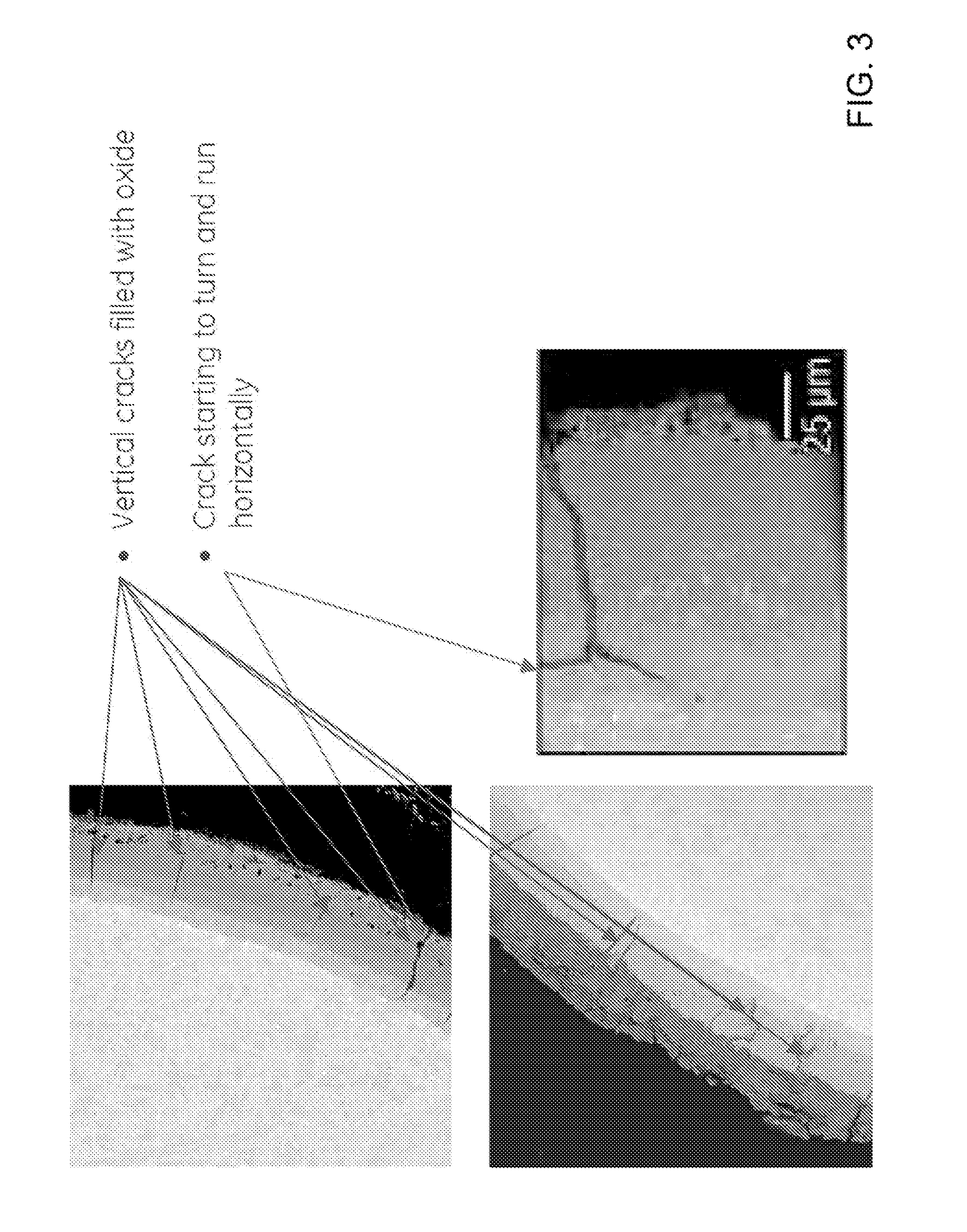

Turbine blade for extreme temperature conditions

One exemplary embodiment of a turbine component (which may be a blade) comprises a substrate comprising a silicide-based material, a plurality of through holes disposed in the substrate, the holes being configured to receive an airflow, a silicide coating disposed at the surfaces of the substrate and the through holes, and a thermal barrier coating disposed at the silicide coating. In another exemplary embodiment the silicide coating may be replaced by a Laves phase-containing layer. In still another exemplary embodiment the silicide coating may be replaced by a diffusion barrier layer disposed at a surface of the substrate and a platinum group metal layer disposed at the diffusion barrier layer. One exemplary embodiment of a blade may comprise an airfoil comprising a silicide-based material and through holes disposed therein, a cooling plenum disposed in the airfoil, and a base configured to receive the airfoil in a dovetail fit, the base comprising a superalloy.

Owner:GENERAL ELECTRIC CO

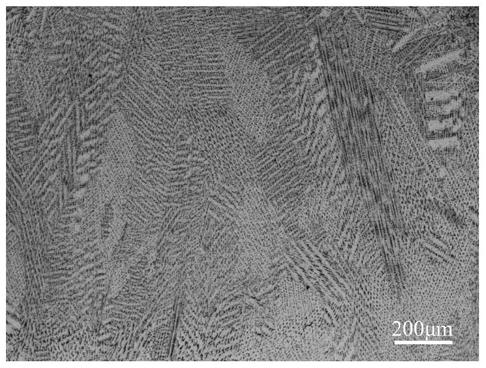

Eliminating method for brittle phase in laser-repaired nickel-base high temperature alloy

ActiveCN109182935AImprove mechanical propertiesInhibit deteriorationMetallic material coating processesSolution treatmentMechanical property

The invention provides an eliminating method for a brittle phase in a laser-repaired nickel-base high temperature alloy, and belongs to the technical field of metal material heat treatment. The eliminating method comprises the steps that the laser-repaired nickel-base high temperature alloy is sequentially subjected to delta aging treatment and delta solution treatment, wherein the temperature ofdelta aging treatment is 850-970 DEG C, and the temperature of delta solution treatment is 1015-1035 DEG C. In the method, delta aging treatment is carried out on the laser-repaired nickel-base high temperature alloy at first, and the Laves brittle phase is eliminated; and then delta solution treatment is carried out at the temperature of 1015-1035 DEG C for eliminating the delta phase separated out in the previous step. Since the temperature of delta solution treatment is lower than the solution temperature for eliminating the Laves phase in conventional heat treatment, damage caused by hightemperature solution on the alloy structure and the mechanical property can be avoided, and the mechanical property of the nickel-base high temperature alloy is obviously improved along with eliminating of the Laves phase.

Owner:NANCHANG HANGKONG UNIVERSITY

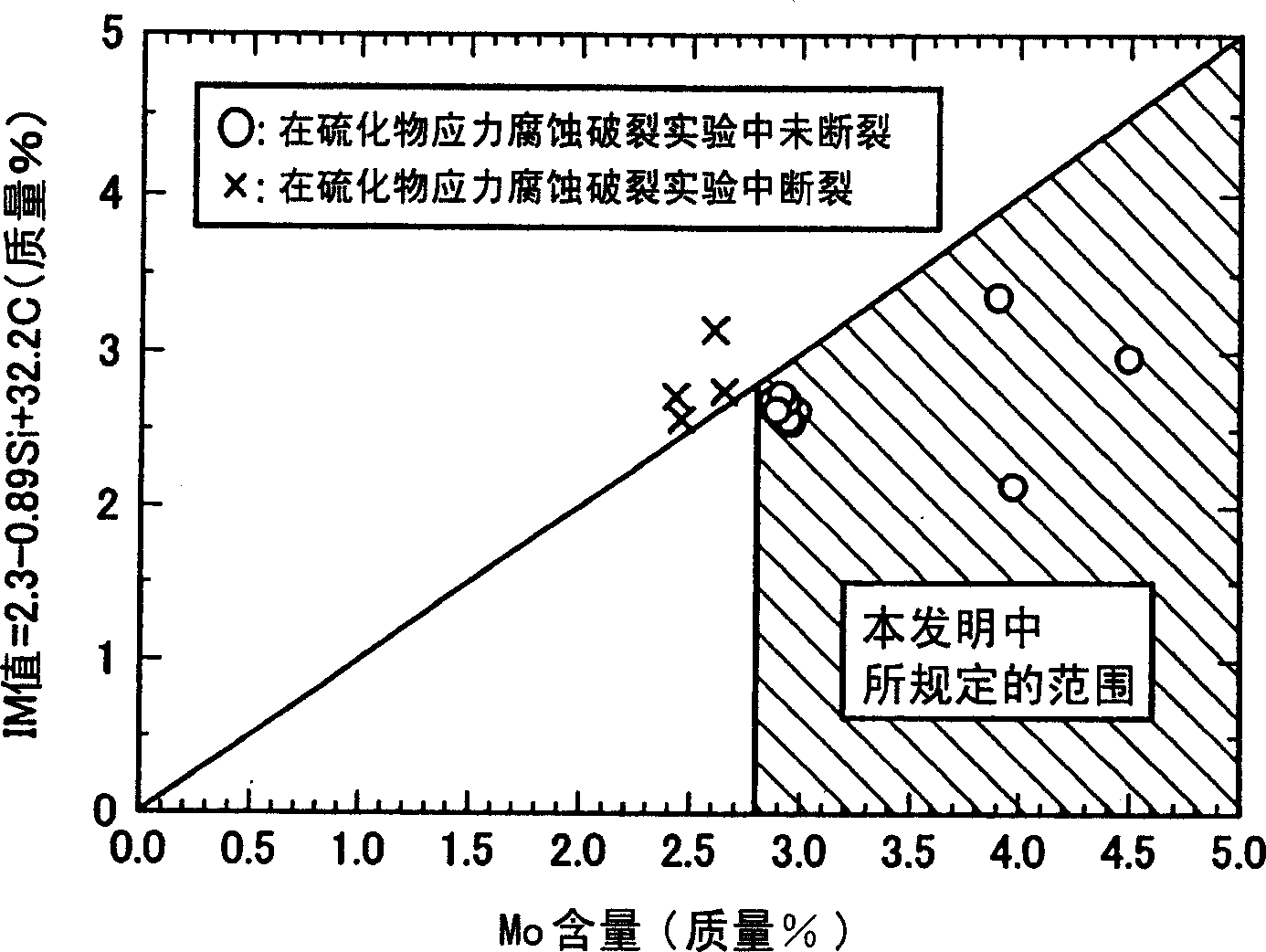

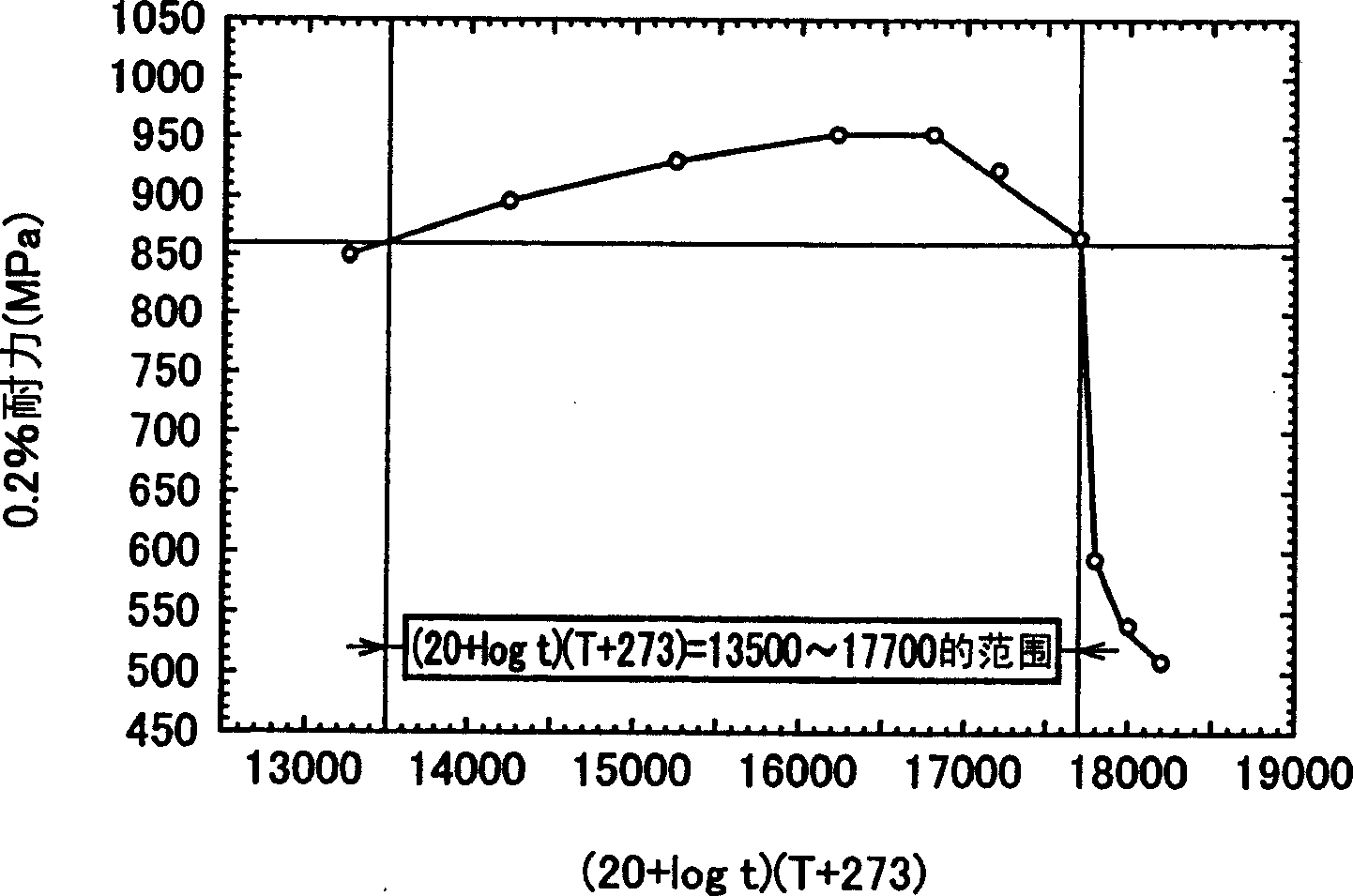

High strength martensitic stainless steel excellent in carbon dioxide gas corrosion resistance and sulfide stress-corrosion cracking resistance

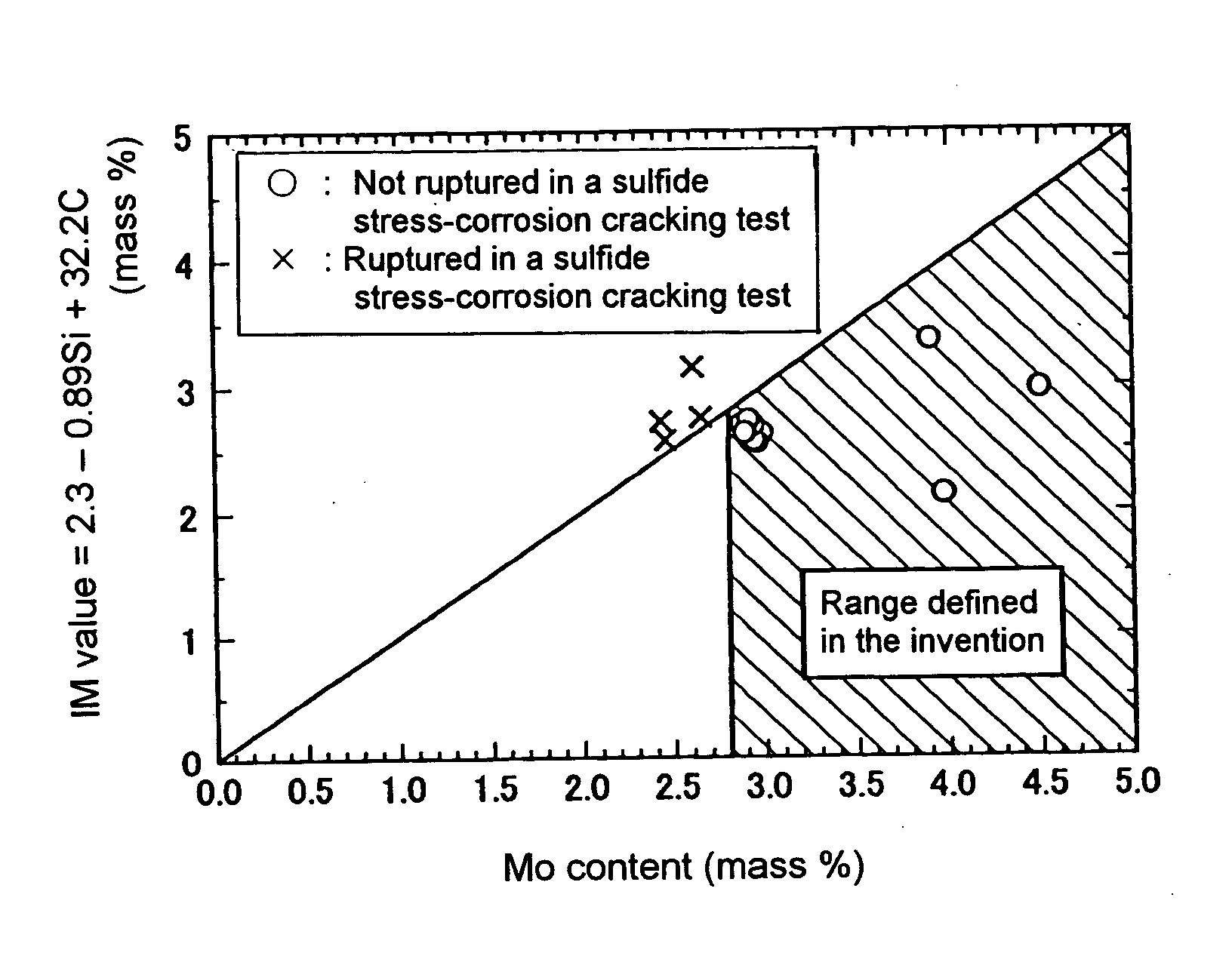

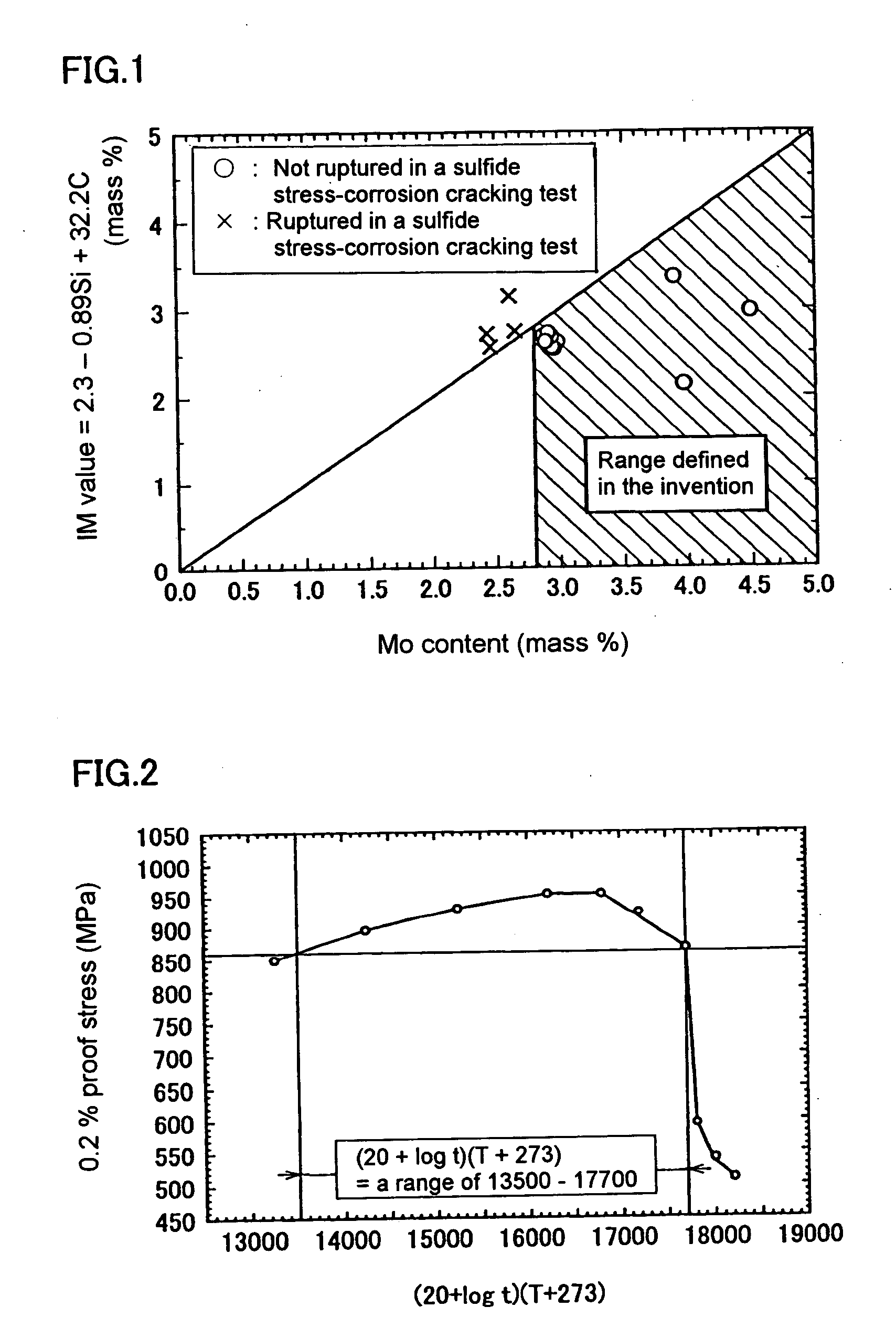

InactiveUS20050224143A1High strengthExcellent in carbon dioxide gas corrosion resistanceWide fieldMartensitic stainless steel

The present invention provides a martensitic stainless steel in which specified elements in a steel composition are limited. The martensitic stainless steel can have high strength of 0.2% proof stress of 860 MPa or more and excellent carbon dioxide gas corrosion resistance and sulfide stress-corrosion cracking resistance by limiting the steel composition of specified elements and defining Mo content in the steel by relationships with IM values as well as by forming microstructure of the steel with main tempered martensite, carbide precipitated during tempering, and intermetallic compounds such as a Laves phase, a σ phase and the like. As a result the martensitic stainless steels of the present invention can be applied to practical steels, which can be widely used in oil well tubes and the like under environment including carbon dioxide gas, hydrogen sulfide, chlorine ions or two or more of them, in wide fields.

Owner:SUMITOMO METAL IND LTD

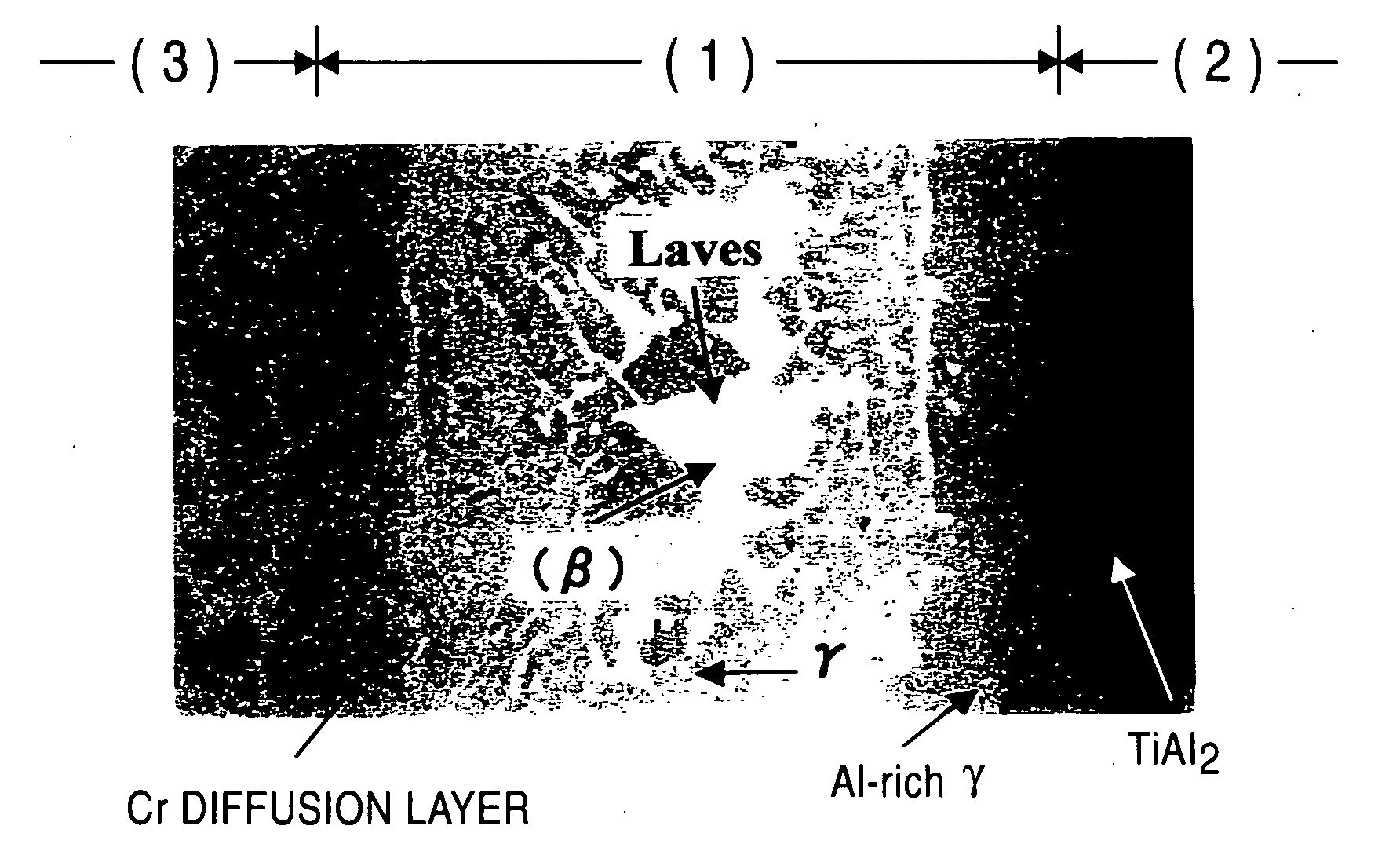

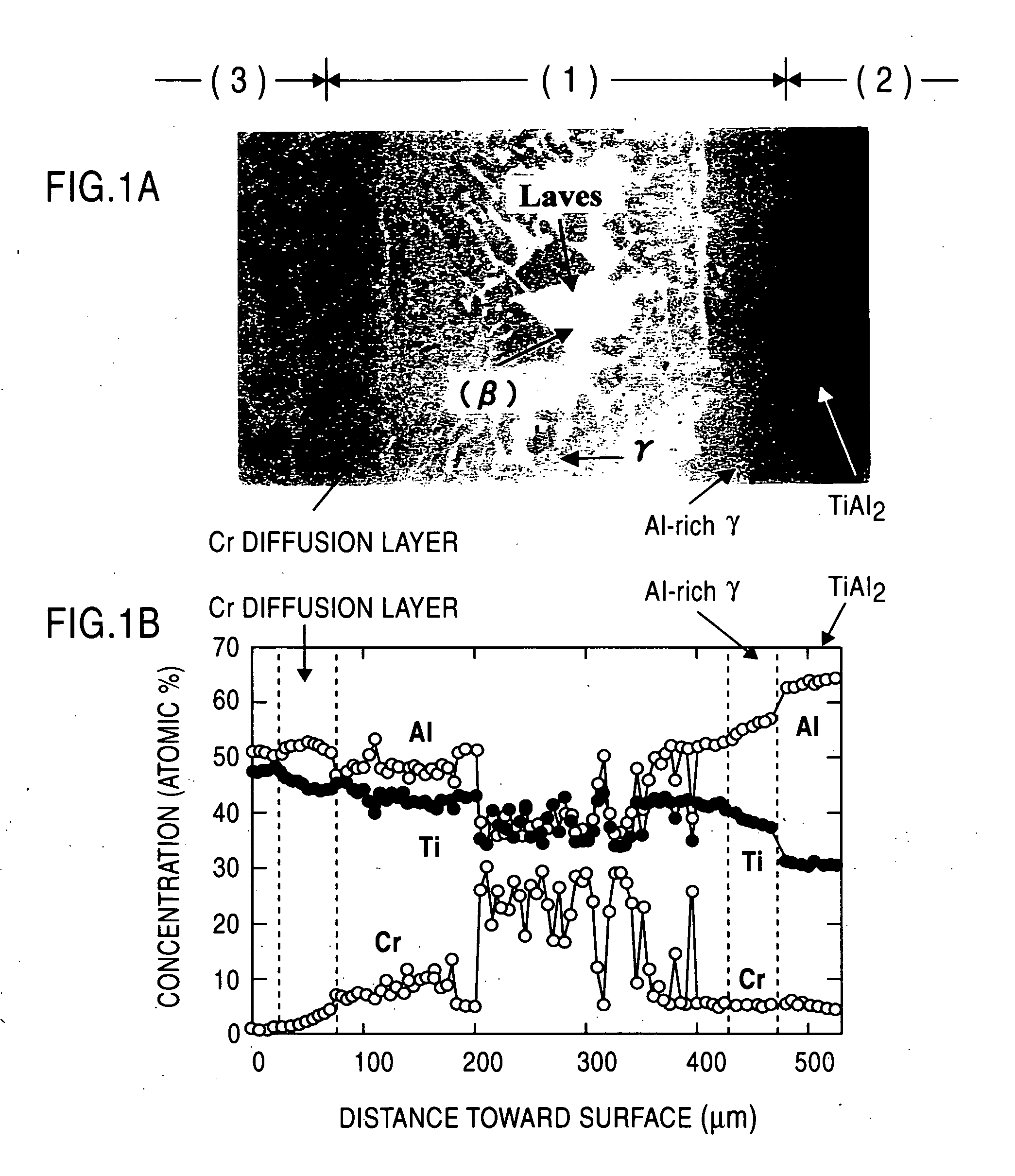

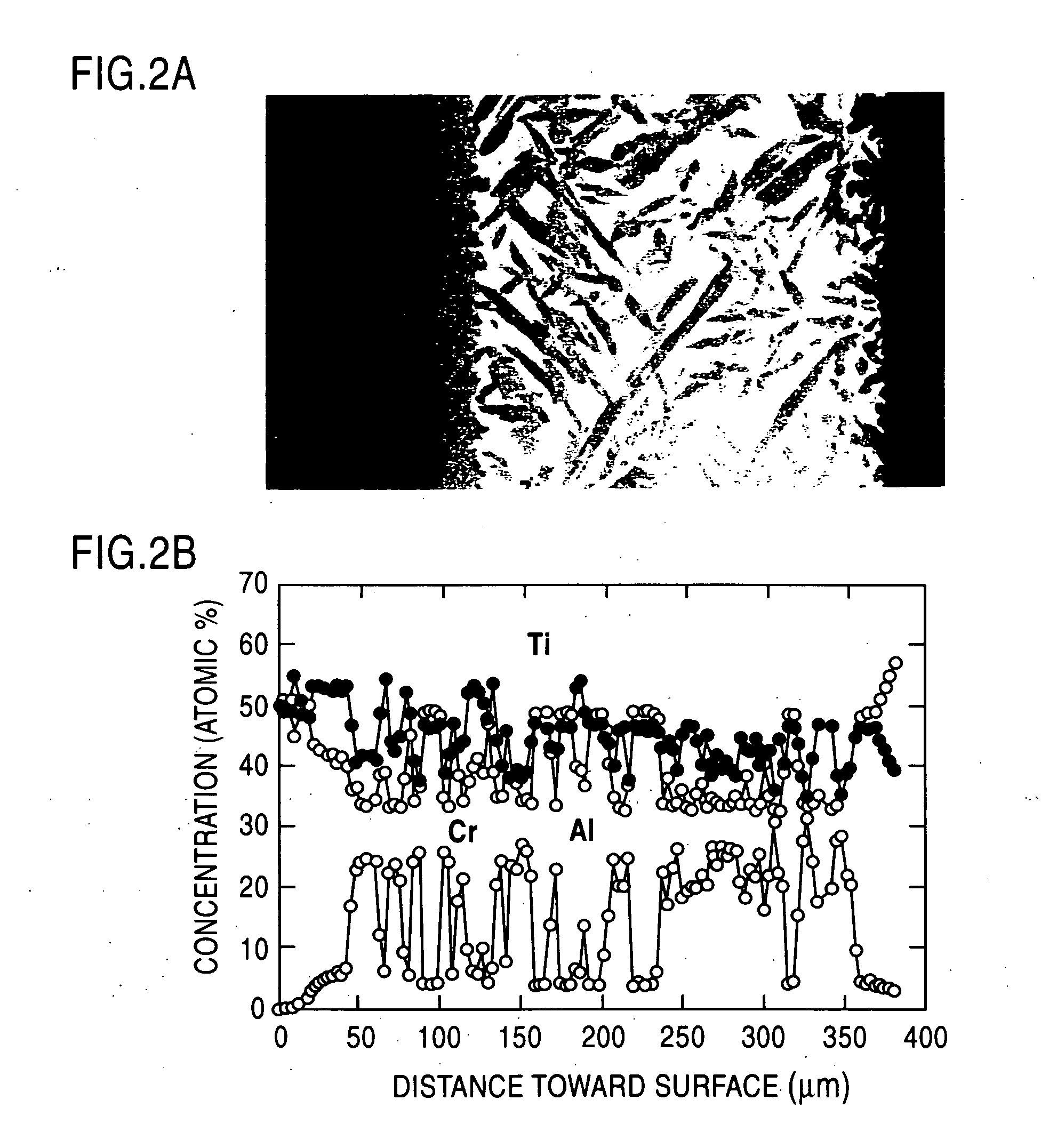

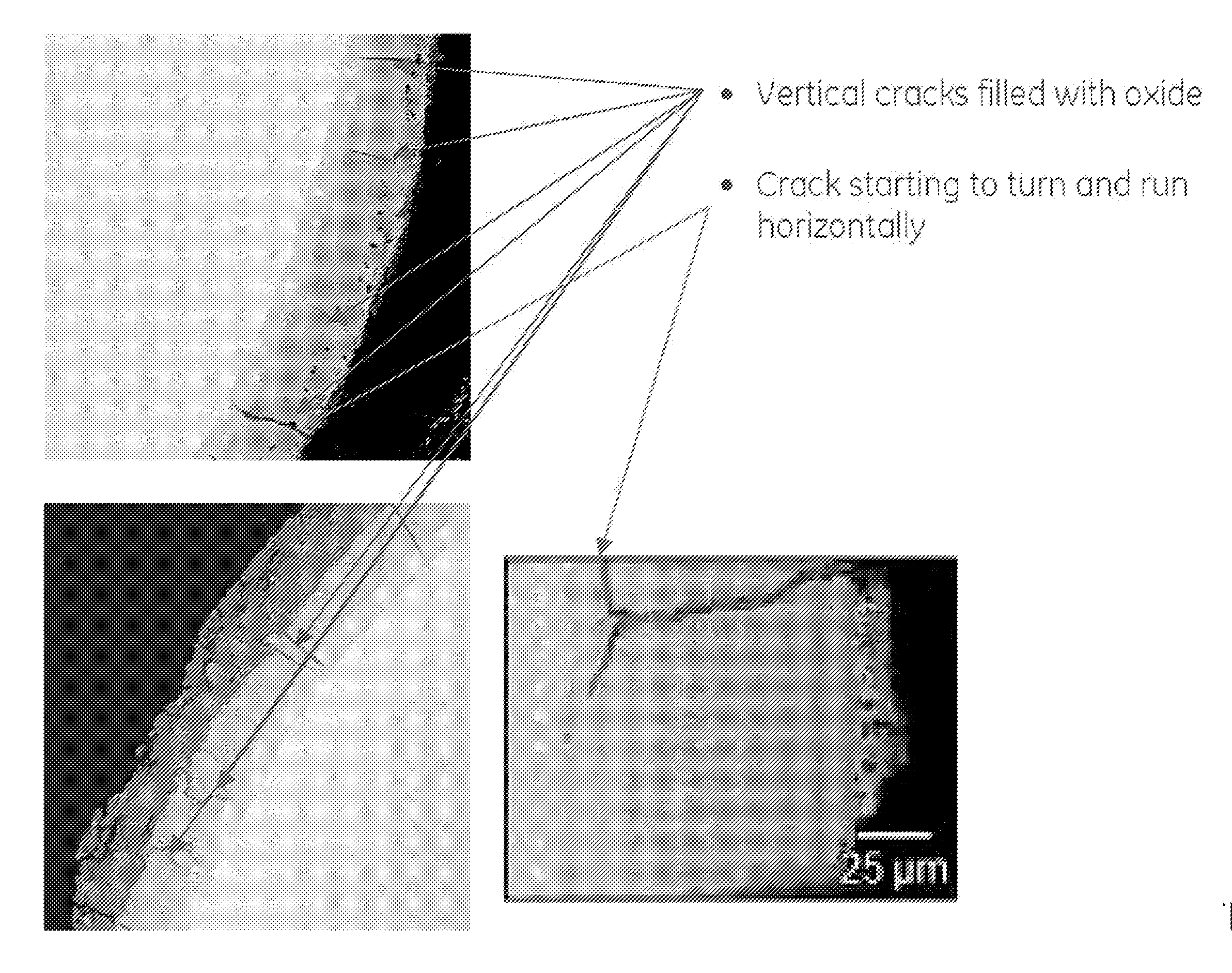

Heat-resistant ti alloy material excellent in resistance to corrosion at high temperature and to oxidation

InactiveUS20050244668A1Inhibited DiffusionInhibitionLiquid surface applicatorsSolid state diffusion coatingSurface layerHeat resistance

Disclosed is a heat-resistant Ti alloy material excellent in high-temperature corrosion resistance and oxidation resistance, which comprises a base made of a heat-resistant Ti alloy and a surface layer formed on the surface of the base. The surface layer has a multilayer structure including an inner layer and an outer layer. The inner layer has three coexistent phases consisting of a β phase, a γ phase and a Laves phase in the phase diagram of a Ti—Al—Cr based alloy, and the outer layer is made of an Al—Ti—Cr based alloy having an Al concentration of 50 atomic % or more. The heat-resistant Ti alloy material is produced by subjecting a substrate made of a heat-resistant Ti alloy to a Cr diffusion treatment at a temperature within a β single-phase region in the phase diagram of a Ti—Al—Cr based alloy, precipitating a γ phase and a Laves phase from the β phase during a cooling process to form the inner layer with three coexistent phases consisting of the β, γ and Laves phases, and then subjecting the obtained product to an Al diffusion treatment to form the outer layer. The heat-resistant Ti alloy material can prevent the diffusion of Al from the outer layer to the base and the diffusion of elements of the base to the outer layer while forming a protective Al2O3 film in a self-repairing manner, to provide excellent high-temperature corrosion resistance and oxidation resistance to the heat-resistant Ti alloy base.

Owner:NARITA TOSHIO

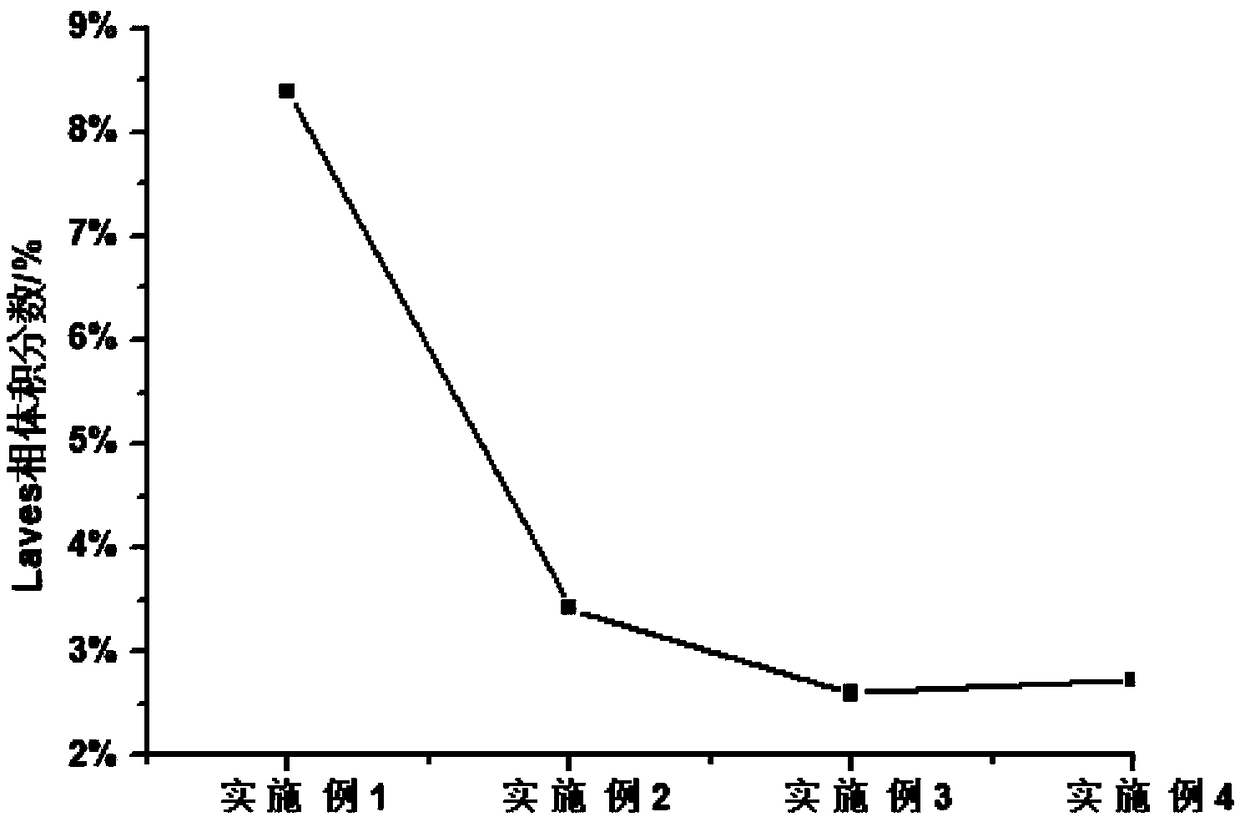

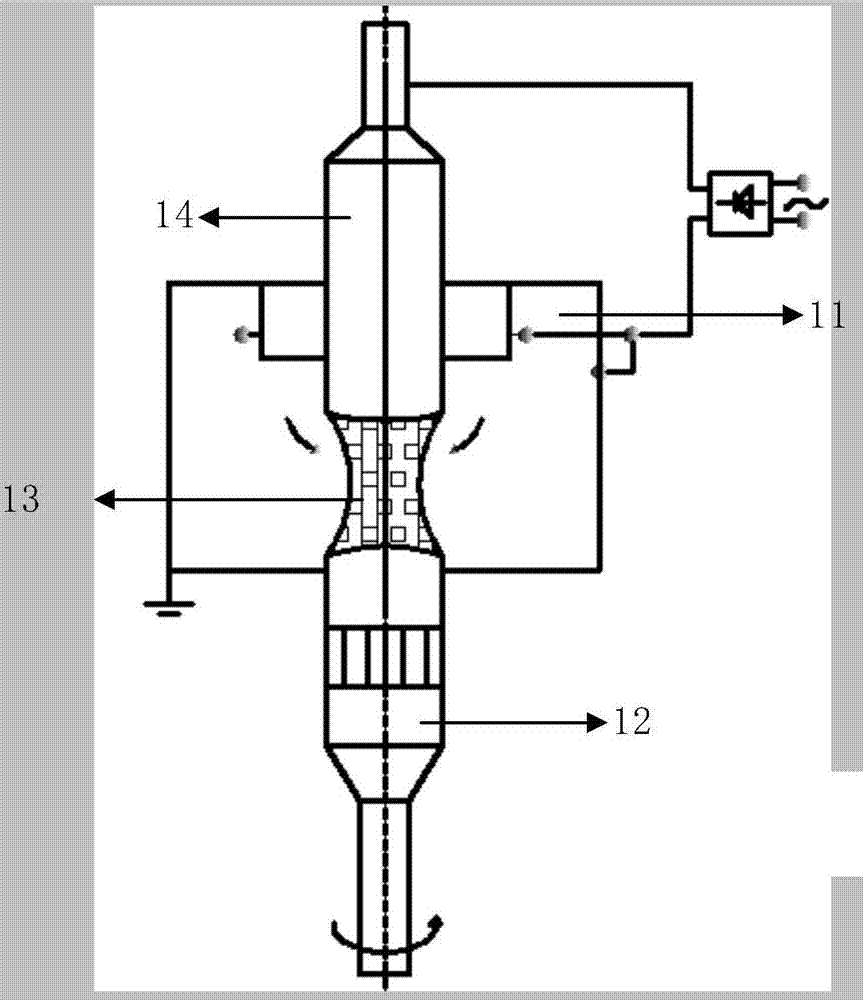

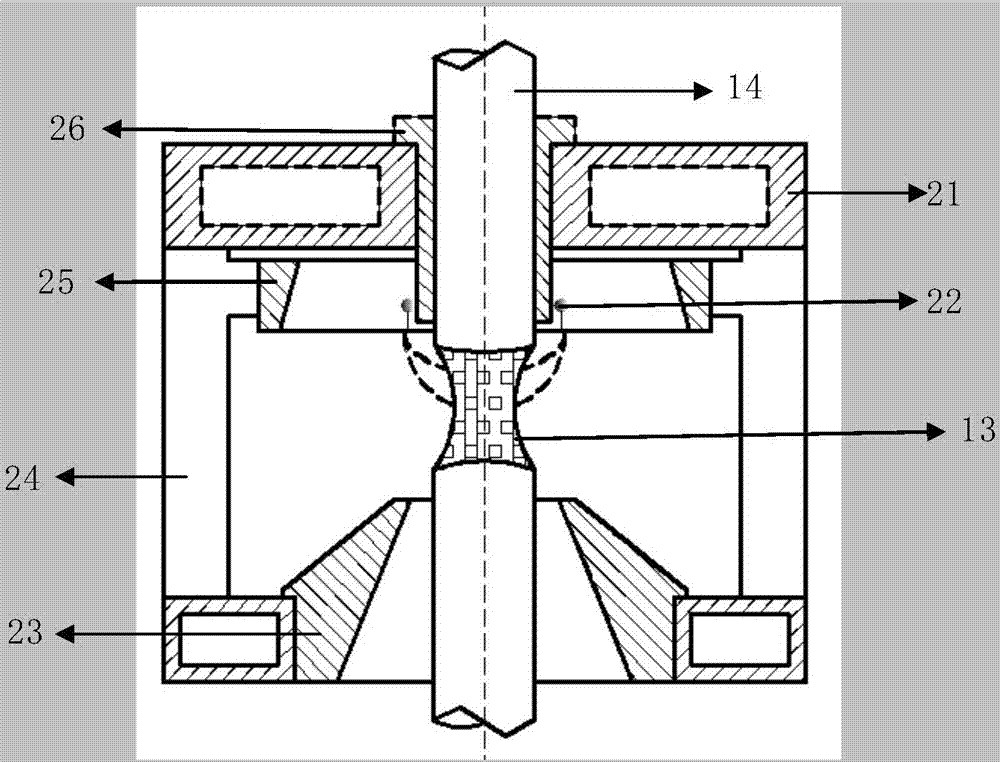

Method for reducing Laves phase in nickel-based high-temperature alloy steel ingot

The invention relates to a method for reducing a Laves phase in a nickel-based high-temperature alloy steel ingot. The method comprises the following steps that firstly, the nickel-based high-temperature alloy serves as a mother alloy; secondly, the mother alloy is taken out, and vacuum induction smelting is carried out, after total melting, refining is carried out, at the refining tail period, the vacuum degree is larger than or equal to 3 Pa, a valve is closed, Ar is inflated to 7 to 9 kPa, a ferrovanadium intermediate alloy is added, sufficient stirring and vibrating are carried out, afterfive minutes, the temperature is adjusted to 1470 to 1500 DEG C, slow continuous casting is carried out, discharging is carried out, and the steel ingot is obtained; thirdly, electroslag smelting is carried out, wherein electroslag with the mass percent of CaF2:CaO:Al2O3:MgO being 60:15:20:5 is used; fourthly, homogenizing annealing is 1140 DEG C*24h. The precipitation proportion of the Laves phase in the solidification process of the steel ingot obtained in the method can be obviously reduced, the steel ingot microstructure uniformity can be improved, the steel ingot subsequent homogenizationtreatment difficulty is reduced, and the mechanical property of the nickel-based high-temperature alloy is ensured.

Owner:CHONGQING MATERIALS RES INST

FeCrCuTiV high-entropy alloy powder for laser melting deposition manufacturing and preparation method of FeCrCuTiV high-entropy alloy powder

ActiveCN109957700AModerated coefficient of thermal expansionModerate differences in modulus of elasticity, etc.Additive manufacturing apparatusTransportation and packagingHigh entropy alloysThermal expansion

The invention discloses FeCrCuTiV high-entropy alloy powder for laser melting deposition manufacturing and a preparation method of the FeCrCuTiV high-entropy alloy powder. The high-entropy alloy powder is prepared from the following components in percentage by weight: 17-20% of Cr, 22-25% of Cu, 16-19% of Ti, 17-20% of V and 19-22% of Fe. The differences of the thermal expansion coefficient, the melting point, the elastic modulus and the like of a tungsten / steel interface can be effectively relieved through the solid solution effect of alloy elements such as Ti, V and Cu of a high-entropy alloy, the level of residual stress at a heterogeneous interface in the laser melting deposition preparation process can be reduced, precipitation of a Laves phase is avoided, and the manufacturing requirements of tungsten steel heterogeneous parts for a fusion reactor can be met.

Owner:SUZHOU UNIV

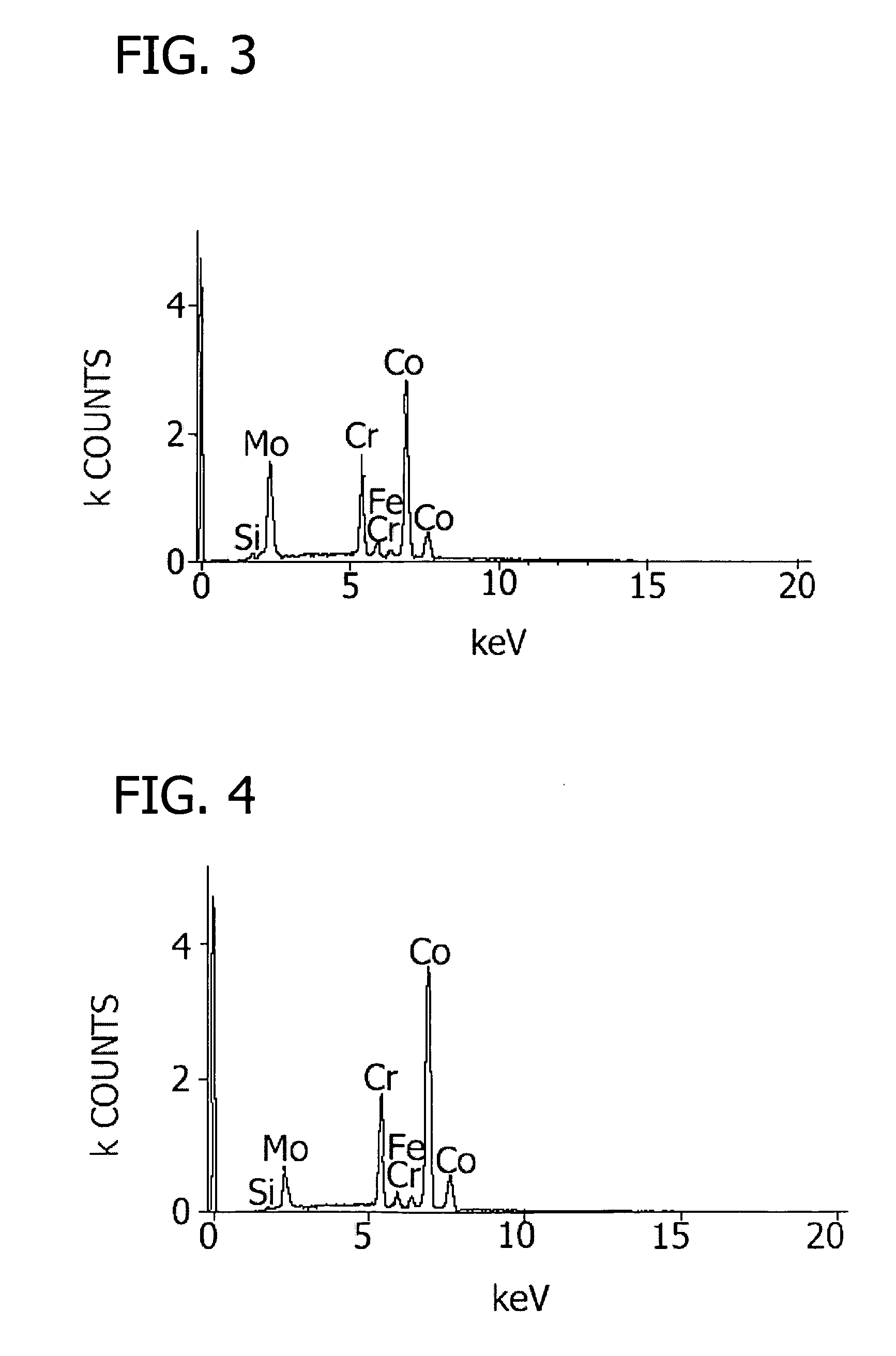

Oxide-forming protective coatigns for niobium-based materials

ActiveUS20110146848A1Improve antioxidant capacityImprove the immunityEngine fuctionsVacuum evaporation coatingRheniumNiobium

Coatings suitable for use as protective oxide-forming coatings on Nb-based substrates exposed to high temperatures and oxidative environments. The coatings contain chromium and / or molybdenum, preferably contains silicon, and optionally contains niobium, titanium, hafnium, iron, rhenium, tantalum, and / or tungsten, which in combination form multiple intermetallic phases, which in combination form one or more intermetallic phases that promote the formation of a slow-growing oxide scale. Depending on the particular coating composition, the intermetallic phases may be: a silicon-modified Cr2Nb Laves phase and optionally a chromium solid solution phase, a CrNbSi intermetallic phase, and / or an M3Si intermetallic phase where M is niobium, titanium, and / or chromium; or M5Si3, MSi2 and / or M3Si2 where M is molybdenum, niobium, titanium, chromium, hafnium, iron, rhenium, tantalum, and / or tungsten.

Owner:GENERAL ELECTRIC CO

GH4700 alloy ingot homogenizing treatment method

InactiveCN103484649AEliminate segregationImprove hot working plasticityFurnace typesHeat treatment furnacesRoom temperatureIngot

A GH4700 alloy ingot homogenizing treatment method is characterized in that cast-condition alloy is placed into a resistance heated furnace with the temperature lower than 400 DEG C, the temperature is raised to 1130-1150 DEG C at the speed of 100 DEG C / hour, the temperature of 1130-1150 DEG C is kept for 8-10 hours, then the temperature is raised to 1180-1210 DEG C in half an hour, the temperature of 1180-1210 DEG C is kept for 24-32 hours, then the temperature is lowered to 1000 DEG C in a furnace, and the cast-condition alloy is moved out of the furnace to be cooled to room temperature in air. According to the method, Nb and Ti elements of the alloy are made to undergo segregation, the alloy is made to undergo Laves phase elimination, and hot-working plasticity of the alloy is improved.

Owner:TAIYUAN IRON & STEEL GROUP

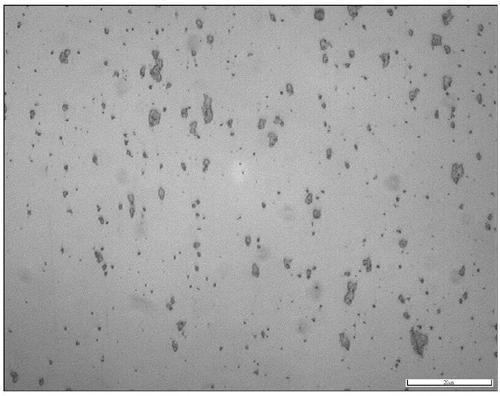

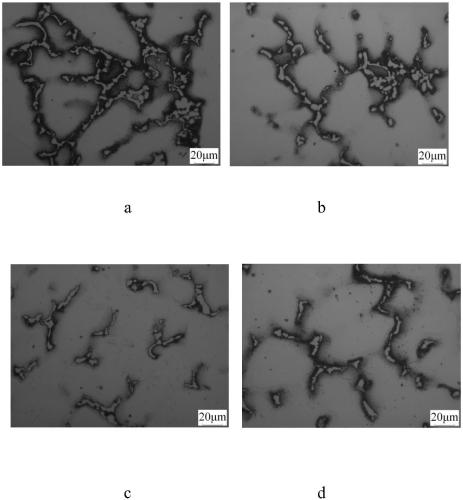

Synchronous laser heat treatment method for laser additive manufacturing nickel-based high-temperature alloy

ActiveCN110315075AImprove coordination and deformation abilityFine and uniform grainAdditive manufacturing apparatusIncreasing energy efficiencyMechanical propertyHeat treated

The invention discloses a synchronous laser heat treatment method for laser additive manufacturing a nickel-based high-temperature alloy. According to the method, morphology size and distribution of Laves phase can be effectively regulated and controlled, the Laves phase is converted into a discrete granular shape from a deposited continuous long strip, and the volume fraction of the Laves phase is obviously reduced along with extension of the laser heat treatment time. According to the laser heat treatment method, synchronous heat treatment in a deposition forming process can be realized, local area Laves phase morphology and distribution can be regulated and controlled under the condition that the tissue performance of a laser repair base material area is not influenced, the granular Laves phase which are fined and dispersion distributed is obtained, so that the overall mechanical property of parts is improved, and effective utilization can be obtained in the repair and remanufacturing of the high-temperature alloy structural member; and in addition, the method can also be applied to the fields of high-temperature alloy material preparation, high-temperature alloy structural member rapid manufacturing and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Electron beam floating zone melting directional solidification preparation method for Fe-Al-Ta composite material

InactiveCN107254716AHigh orientation accuracyAdjustable volume fractionPolycrystalline material growthEutectic material solidificationZone meltingFragility

The invention discloses an electron beam floating zone melting directional solidification preparation method for a Fe-Al-Ta composite material. The method includes: adding trace of high-ductility refractory metal Ta into a Fe-Al intermetallic compound, preparing eutectic alloy or non-eutectic alloy, and performing eutectic reaction to obtain a Fe(Al, Ta) / Fe2Ta(Al) eutectic composite material or Fe-Al-Ta non-eutectic composite material, wherein the Laves phase Fe2Ta(Al) has a hexagonal C14 structure (with a melting point higher than 700 DEG C) and is high in strength when the temperature is higher than 1000 DEG C, and fragility improvement and strength improvement of the material are realized due to intergrowth compounding of the matrix phase Fe(Al, Ta) and the Laves phase Fe2Ta(Al) in melt. A theoretical basis is provided for Laves phase alloy composition design and novel high-temperature structural material research and development, and a significant academic value in development of application of the electron beam floating zone melting directional solidification technique is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Ultra high strength alloy for severe oil and gas environments and method of preparation

ActiveUS20110011500A1Improve corrosion resistanceHigh strengthJoints with sealing surfacesIncreasing energy efficiencyAlloyQuenching

A Ni—Fe—Cr—Mo alloy containing a small amount of Cu and correlated percentages of Nb, Ti and Al to develop a unique microstructure to produce 145 ksi minimum yield strength. The unique microstructure is obtained by special annealing and age hardening conditions, by virtue of which the alloy has an attractive combination of yield strength, impact strength, ductility, corrosion resistance, thermal stability and formability, and is especially suited for corrosive oil well applications that contain gaseous mixtures of carbon dioxide and hydrogen sulfide. The alloy comprises in weight percent the following: 0-15% Fe, 18-24% Cr, 3-9% Mo, 0.05 3.0% Cu, 3.6-6.5% Nb, 0.5-2.2% Ti, 0.05-1.0% Al, 0.005-0.040% C, balance Ni plus incidental impurities and a ratio of Nb / (Al+Ti) in the range of 2.5-7.5. To facilitate formability, the composition range of the alloy is balanced to be Laves phase free. According to the disclosed method of manufacture, the above alloy is provided and hot worked to a desired shape such as a bar or tube for corrosive oil and gas deep wells. The shaped alloy is heat treated by solution annealing, quenching or air cooling, followed by one or two aging steps to precipitate.y′ and y″ phases.

Owner:HUNTINGTON ALLOYS CORP (US)

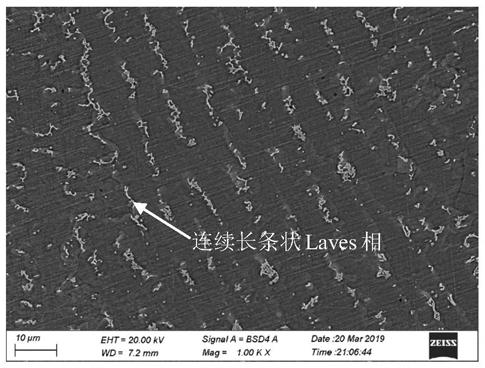

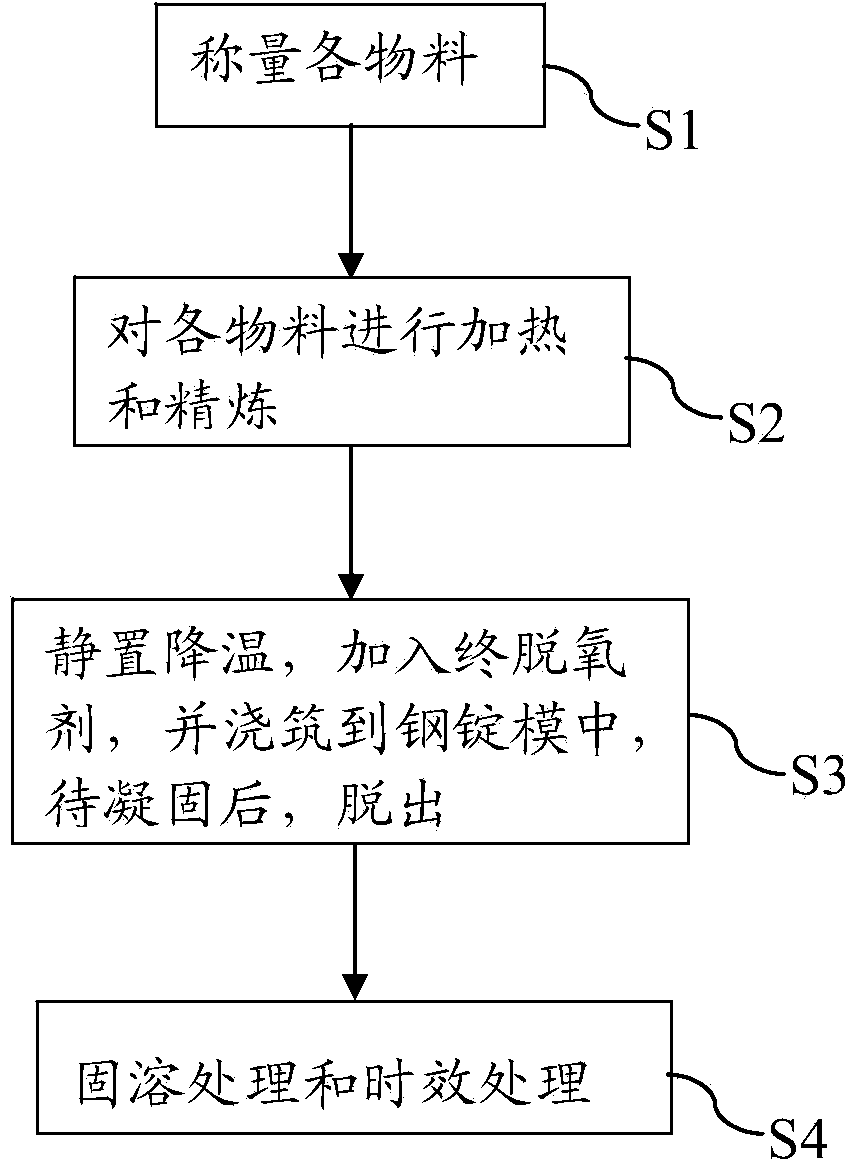

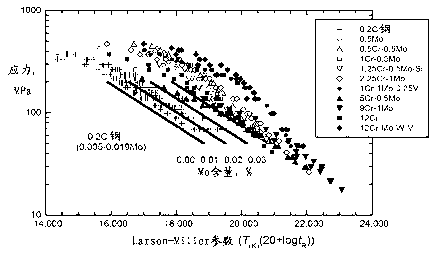

Austenitic heat-resistant steel and preparation method thereof

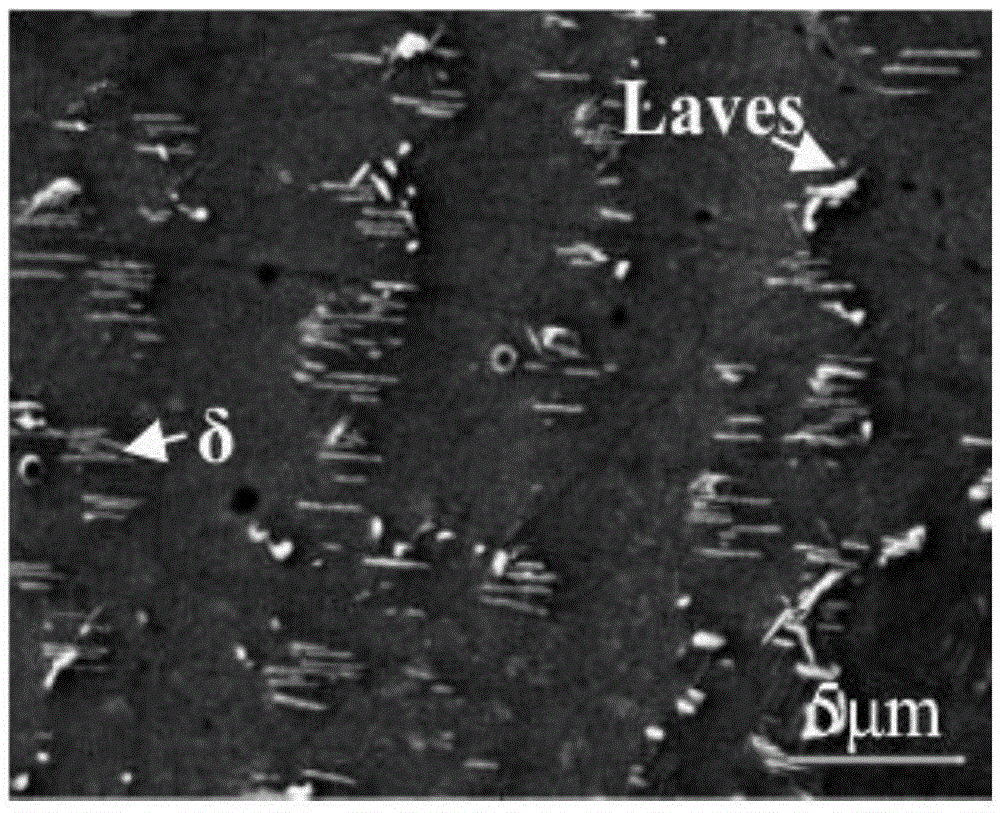

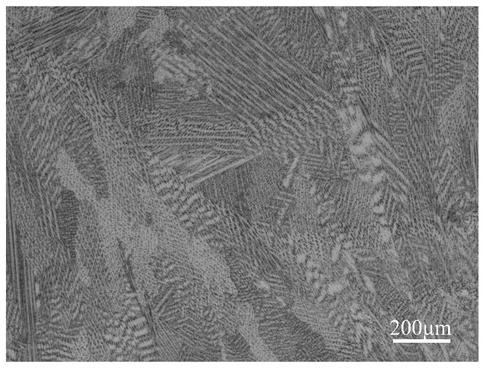

The invention discloses an austenitic heat-resistant steel and a preparation method thereof. The preparation method comprises the following steps: S1, weighing materials; S2, heating and refining the materials; S3, standing still for temperature reduction, adding an end deoxidizing agent, casting the materials into ingot molds, and demoulding after solidification; S4, carrying out solution treatment and aging treatment. The austenitic heat-resistant steel has favorable high-temperature resistant croop property and permanent strength. The austenitic heat-resistant steel cannot change in phase, nor coarsen and enlarges remarkably, and is favorable in stability. After solution treatment and aging treatment, continuous Laves phase precipitates from austenitic grain boundary and strip-shaped Laves-phase Fe2Nb precipitates from austenitic crystal. The Laves-phase Fe2Nb continuous precipitates as a precipitation strengthening phase, so as to efficiently improve the high-temperature long-time strength of the austenitic heat-resistant steel. The austenitic heat-resistant steel is less in element, simple in ingredient, and easy for industrial production.

Owner:马鞍山市星新机械材料有限公司

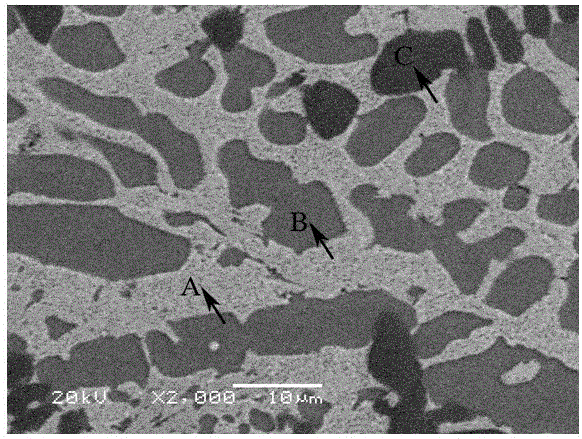

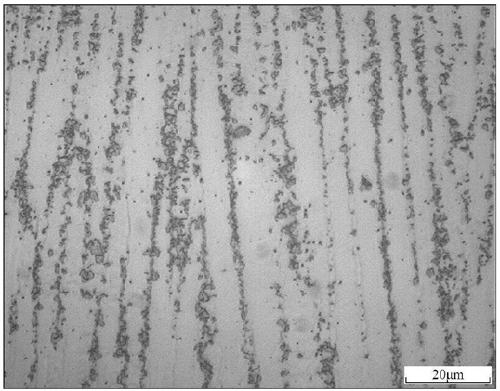

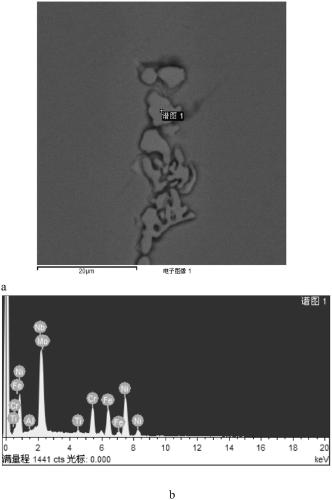

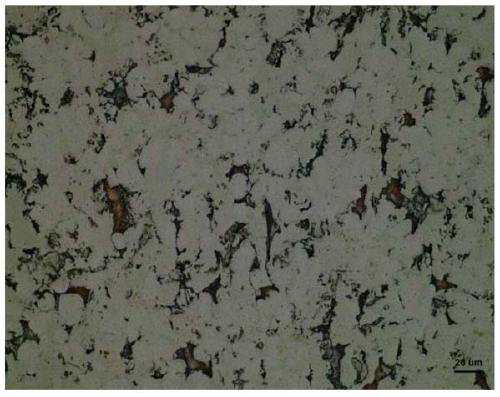

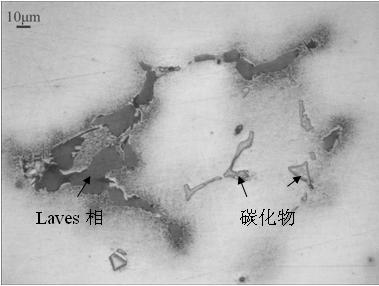

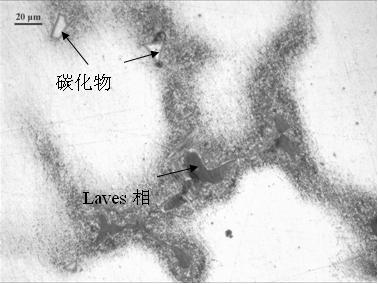

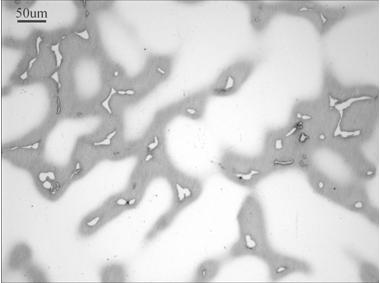

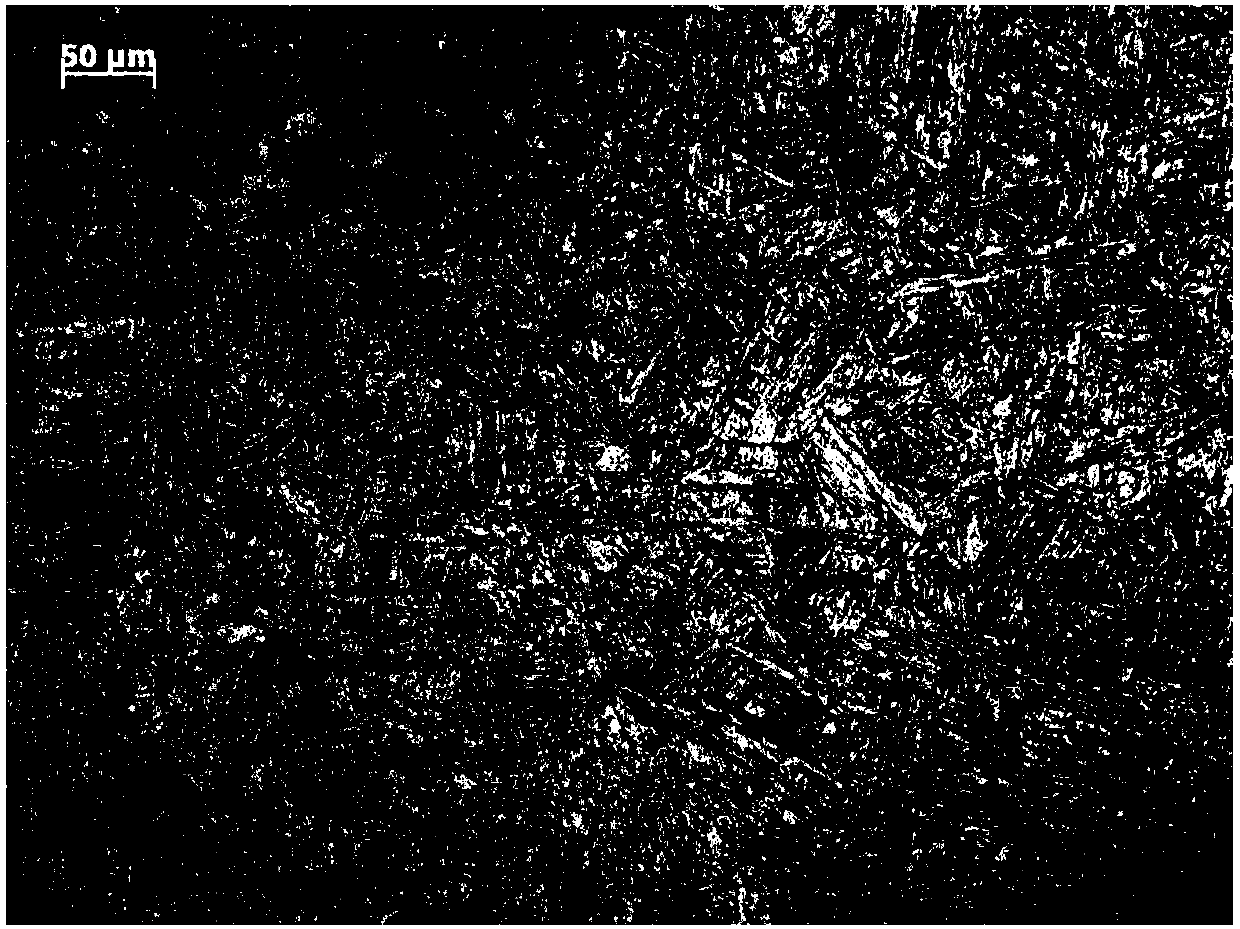

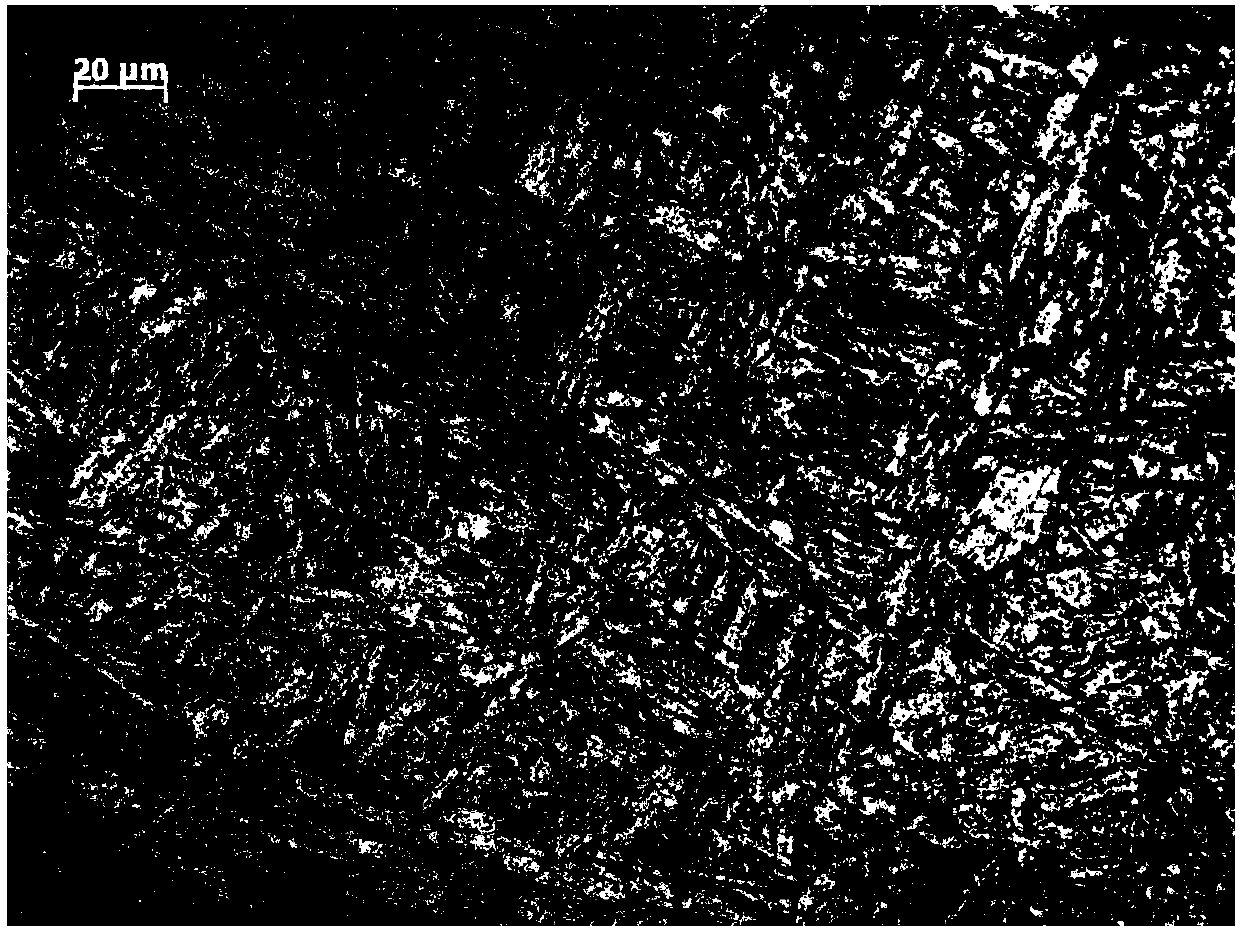

Method for discriminating Laves phase and carbide phase in high Nb iron nickel base high temperature alloy

ActiveCN102486460AModerate thicknessAvoid affecting the reflective effectPreparing sample for investigationMaterial analysis by optical meansFurnace temperatureMicroscopic observation

The invention relates to a method for discriminating Laves phase and carbide phase in a high Nb iron nickel base high temperature alloy, which is characterized in that the method comprises the following steps: A) grinding and polishing the high Nb iron nickel base high temperature alloy sample, exposing a polished surface, then placing in a heat treatment furnace, keeping the furnace temperature at 350-600 DEG C, standing for 10-200 minutes, air cooling; B) using a metallographic microscope for observing the high Nb iron nickel base high temperature alloy sample treated in step A). According to the invention, the common metallographic microscope can be used for discriminating a precipitated phase, and the method of the invention is convenient for practical operation of factory, and has the advantages of simple and practical operation, and low cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Composite hydrogen storage material with foamed structure and preparation method thereof

InactiveCN103183314AGood reversible hydrogen storage and discharge performanceHydrogen productionNitrogenHydrogen desorption

The invention relates to composite hydrogen storage material with a foamed structure, which is formed by uniformly mixing and pressing Mwt% of NaAlH4 and Nwt% of Laves phase titanium system metal hydride. The general formula of the composite material is (100 percent-x)M+xN, wherein x is equal to 10wt% to 40wt%, and M is the weight percent of NaAlH4 powder. N is the weight percent of Laves titanium system hydrogen storage alloy powder prepared through at least two of titanium, zirconium, vanadium, ferrum and chromium elements. 200 to 700 MPa mechanical compression molding is performed under the protection of argon and nitrogen with purities not lower than 99.95 percent, the compression time is 10 to 22 minutes, and then a porous foamed space structure is formed. The composite hydrogen storage material with the foamed structure has good hydrogen storage and desorption performances, and can effectively discharge more than 3.7wt% of hydrogen within 50 minutes at 150 DEG C under 0.1 MPa hydrogen desorption pressure.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

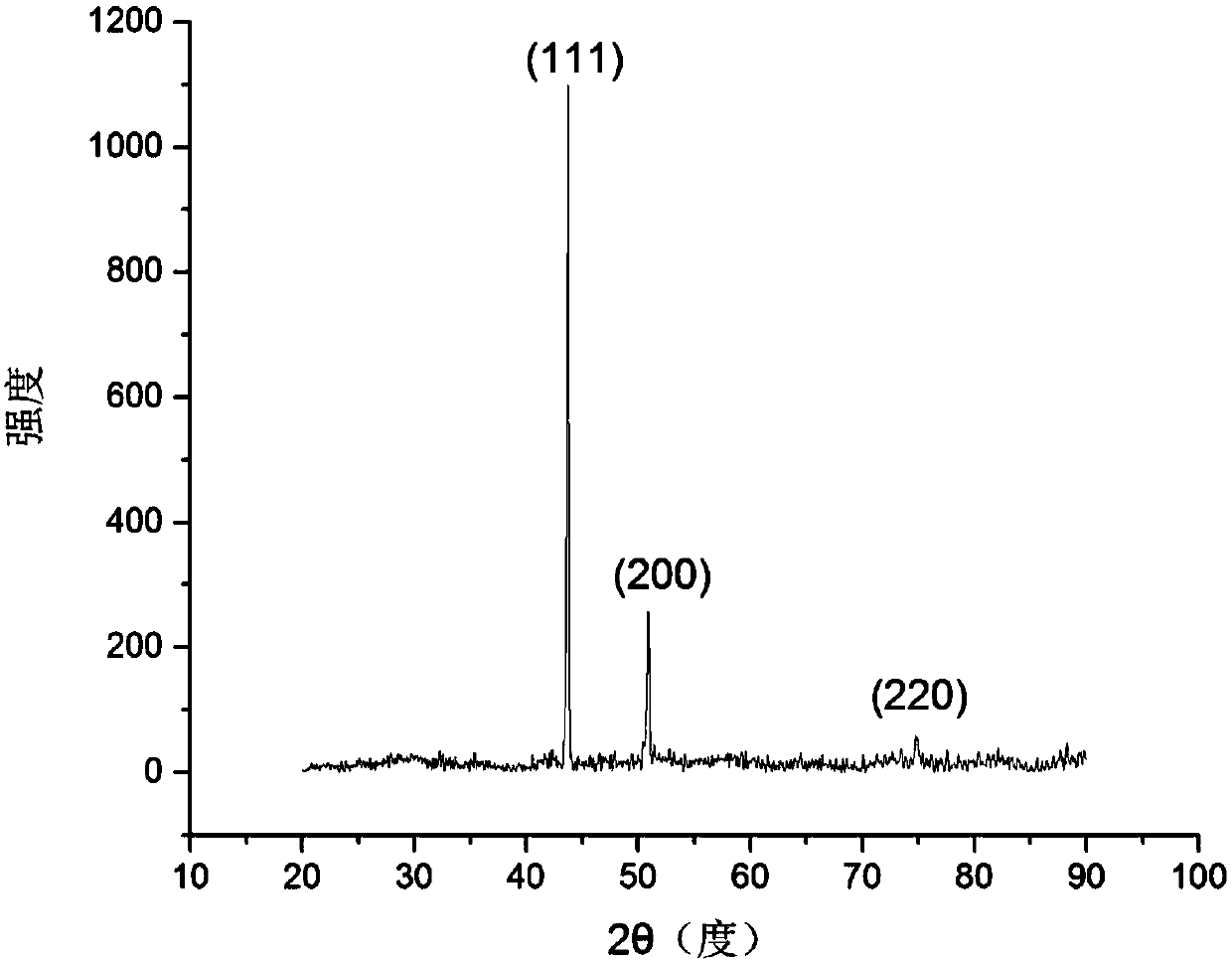

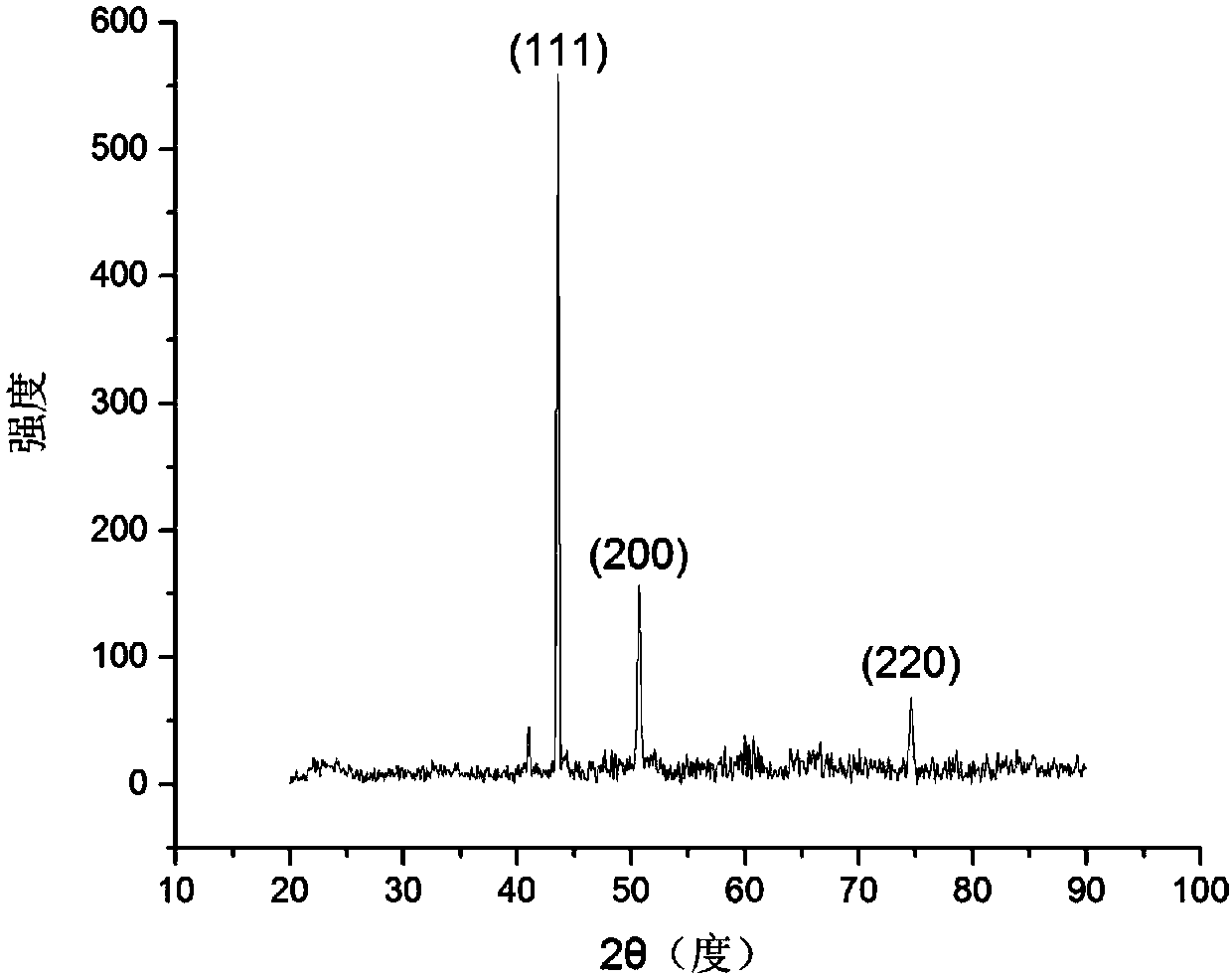

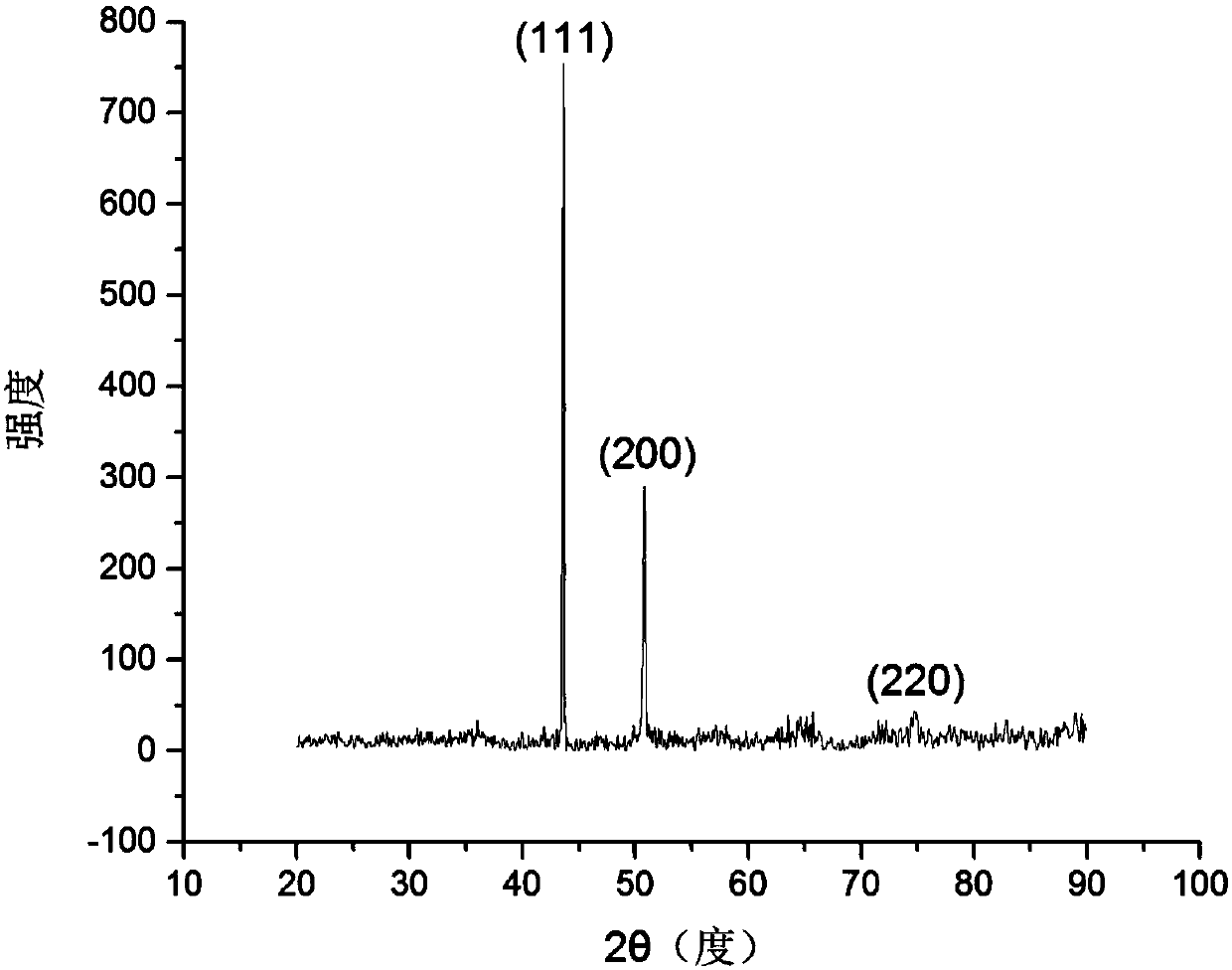

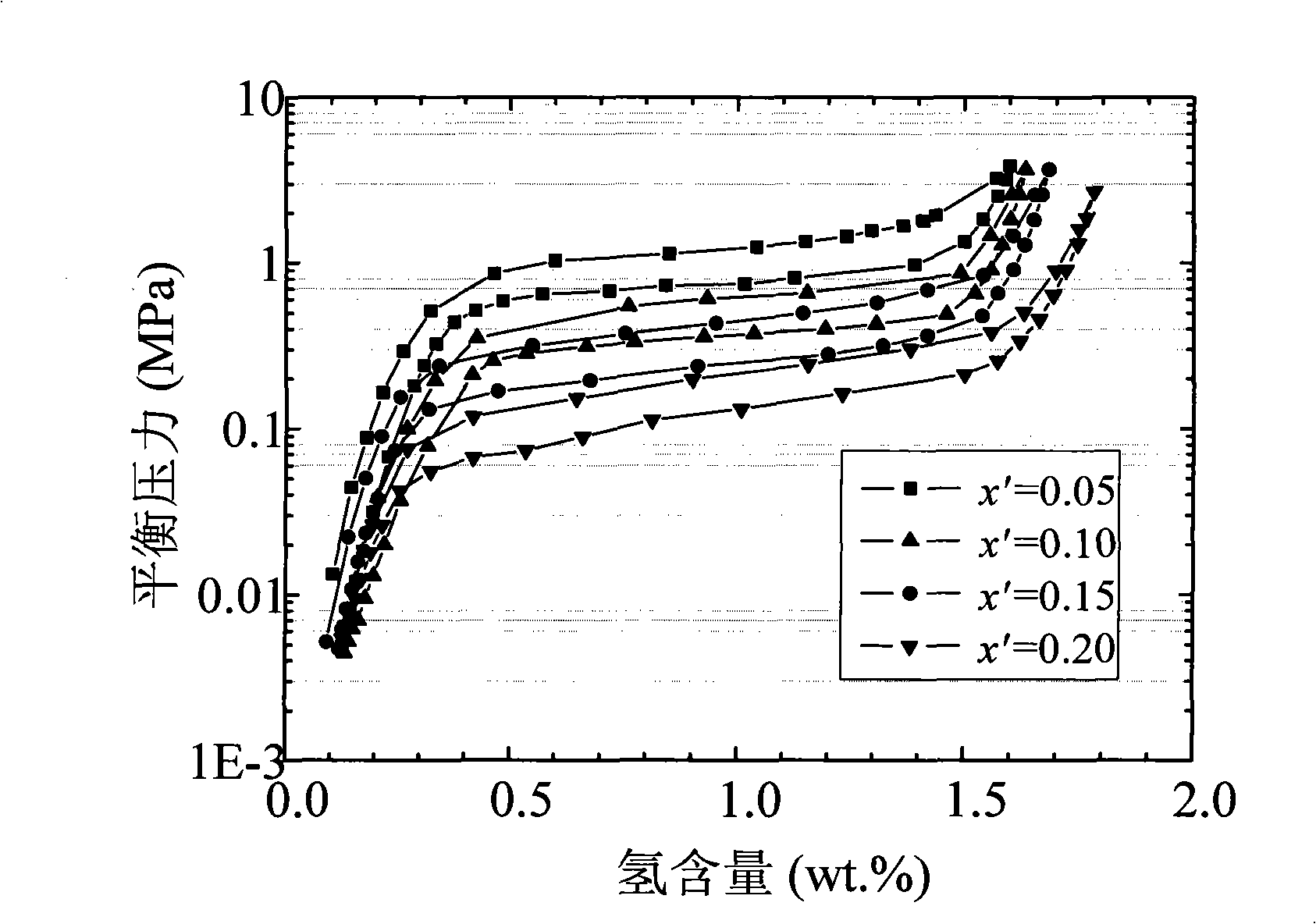

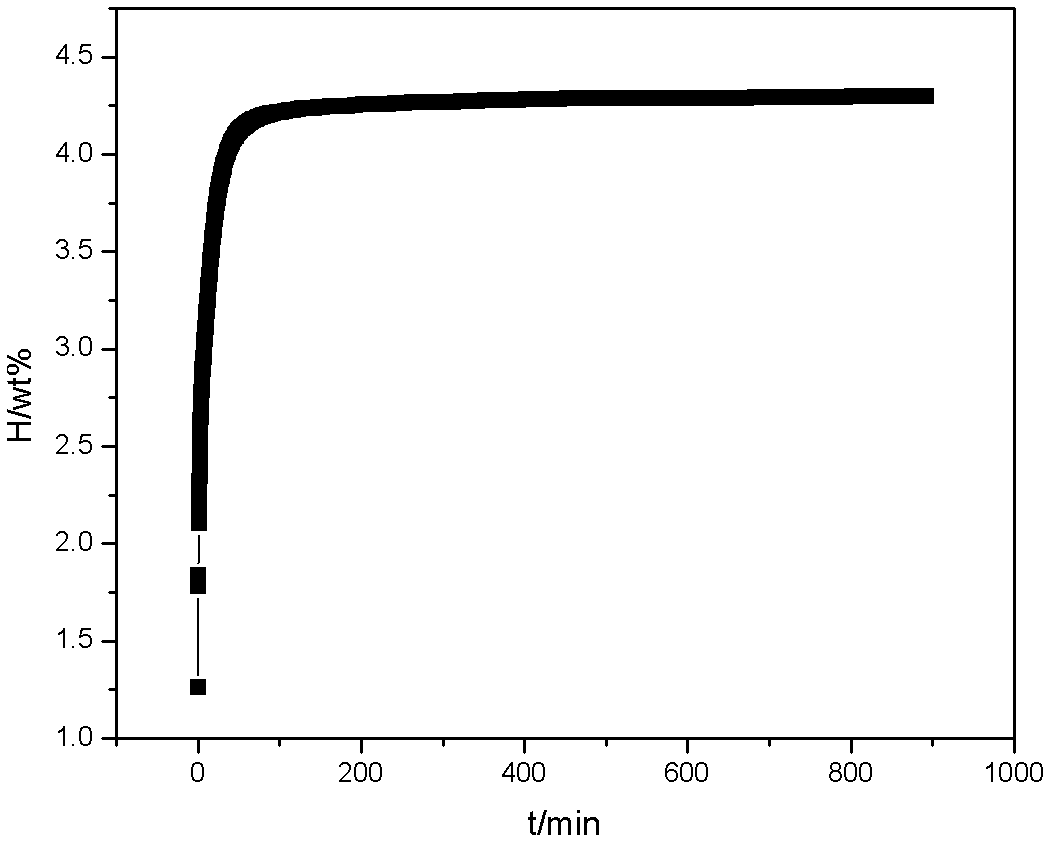

Zr-Ti-Cr-V complex phase hydrogen storage alloy and preparing method thereof

The invention discloses a Zr-Ti-Cr-V complex phase hydrogen storage alloy and a preparing method thereof. The hydrogen storage alloy is composed of Zr, Ti, Cr and V; the atomic ratio is 1:0.2-0.6:0.1-0.6:1.8-2.1. Through component design of the non-stoichiometric ratio, through vacuum heat treatment, a C15 type Laves phase, V-rich solid solution and Zr-rich solid solution coexistence complex phasestructure with the specific proportion can be formed in the alloy. The alloy room temperature hydrogen absorbing amount can reach 2.80wt%, and the excellent hydrogen absorbing dynamics property can be achieved.

Owner:江西新节氢能源科技有限公司

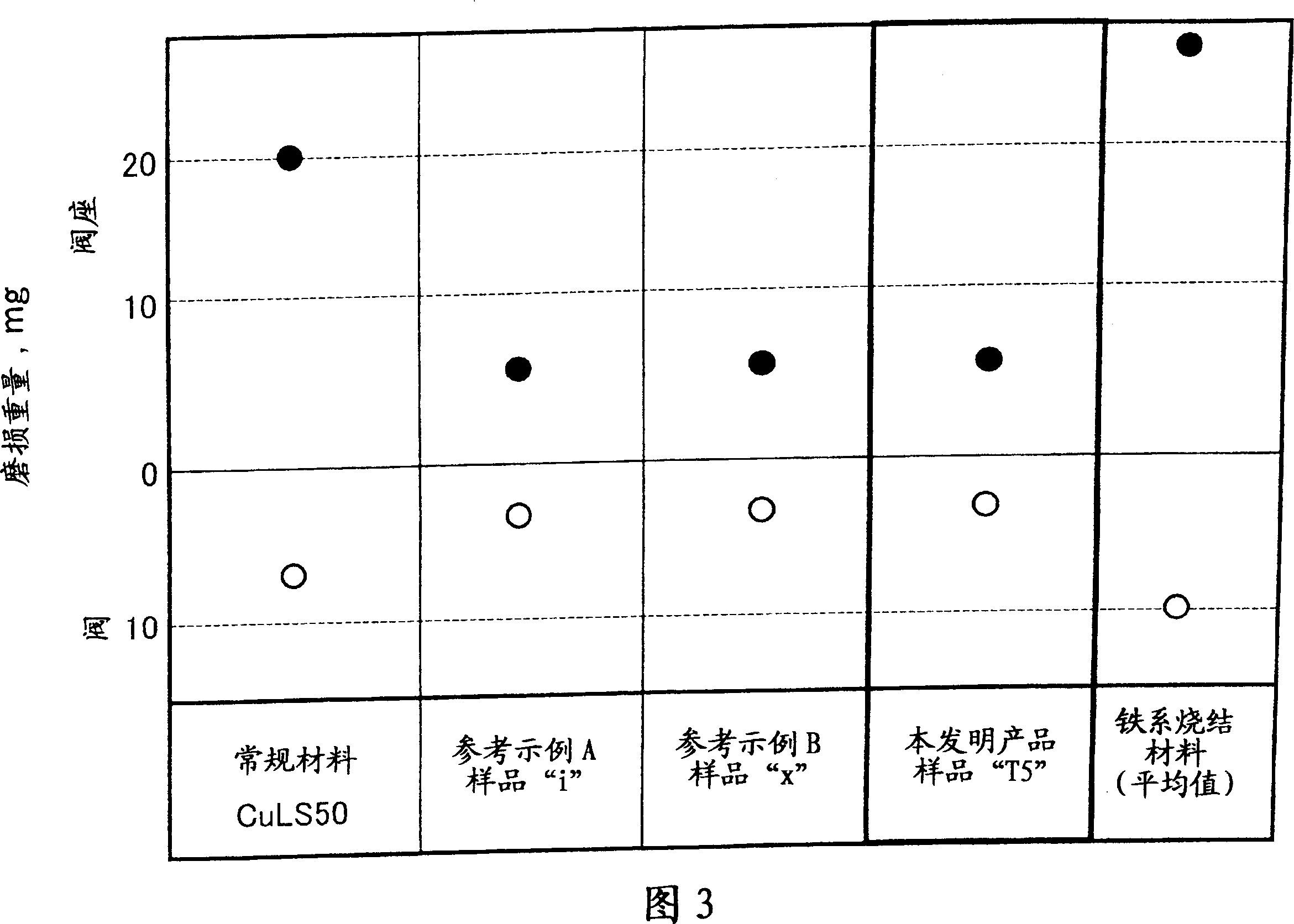

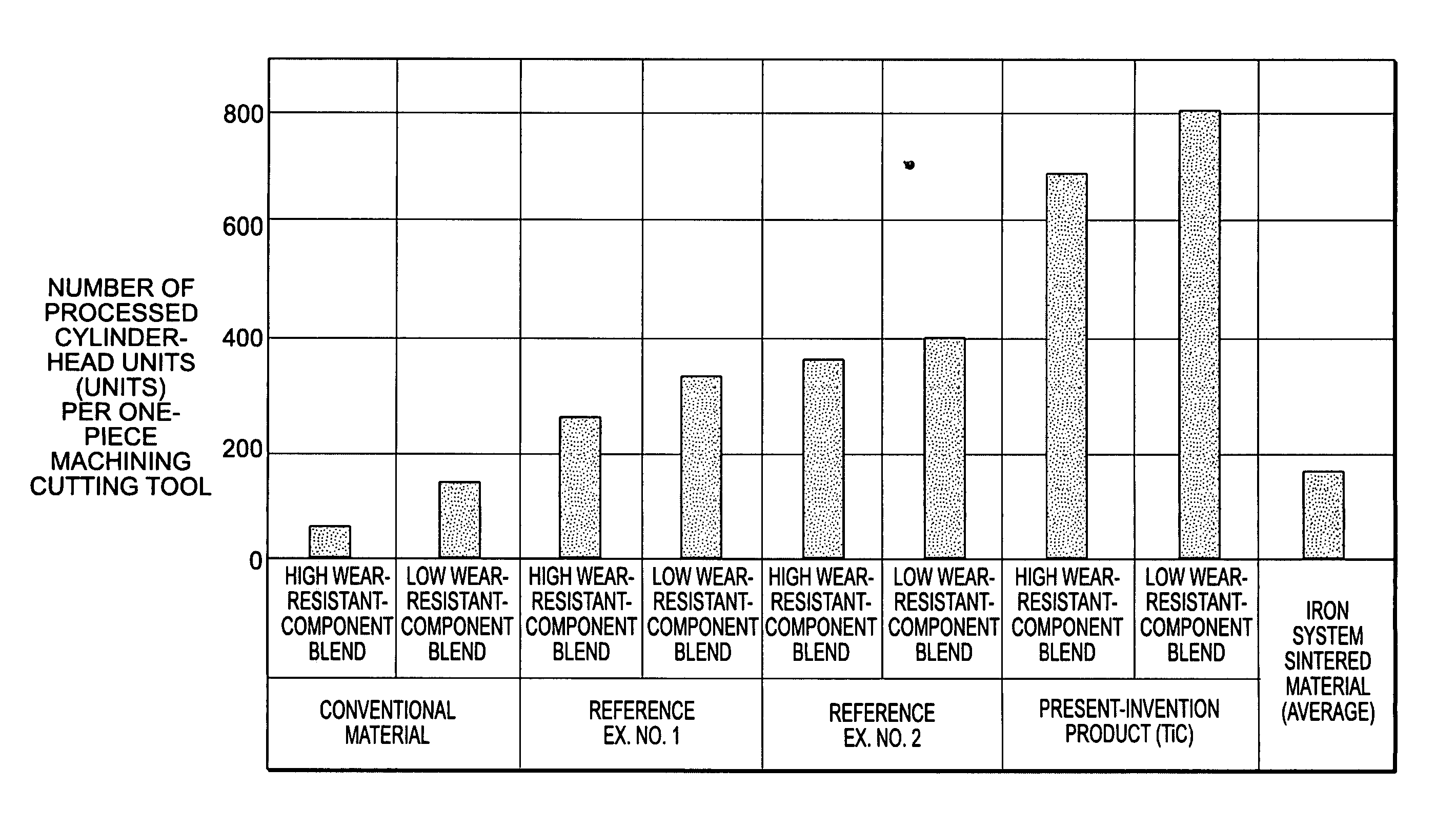

Build-up wear-resistant copper-based alloy

InactiveUS20070065331A1Enhancing cracking resistance (cladding property)Improve machinabilityMolten spray coatingMachines/enginesCrack resistanceWear resistant

This is to provide a build-up wear-resistant copper-based alloy, which is advantageous for enhancing the cracking resistance and machinability, which is appropriate for cases of building up to form built-up layers especially, and which is equipped with the wear resistance, cracking resistance and machinability combinedly in a well balanced manner. A build-up wear-resistant copper-based alloy is characterized in that it has a composition, which includes nickel: 5.0-20.0%; silicon: 0.5-5.0%; manganese: 3.0-30.0%; and an element, which combines with manganese to form a Laves phase and additionally to form silicide: 3.0-30.0%; by weight %, and inevitable impurities; and additionally the balance being copper. The element can be one member or two or more members of titanium, hafnium, zirconium, vanadium, niobium and tantalum.

Owner:TOYOTA JIDOSHA KK

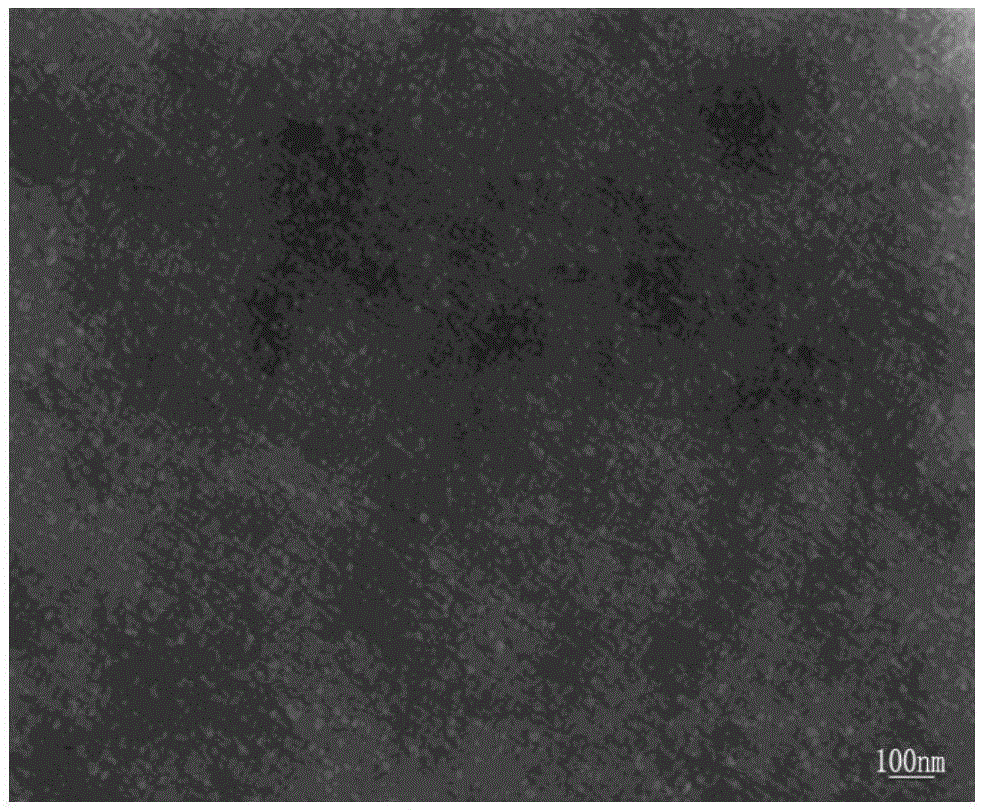

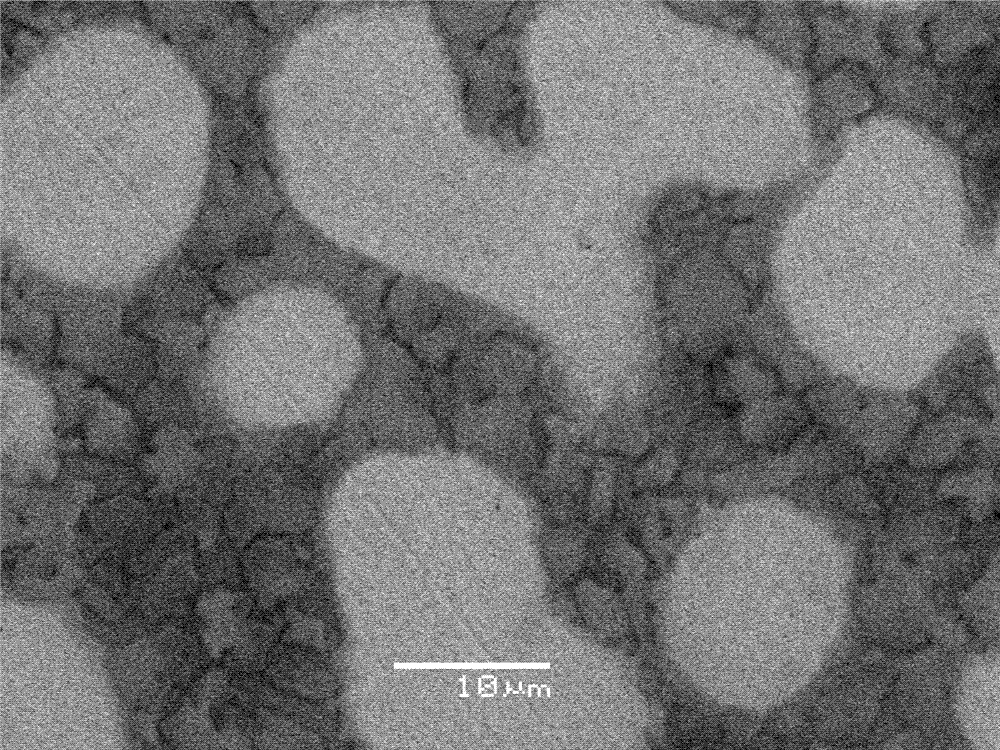

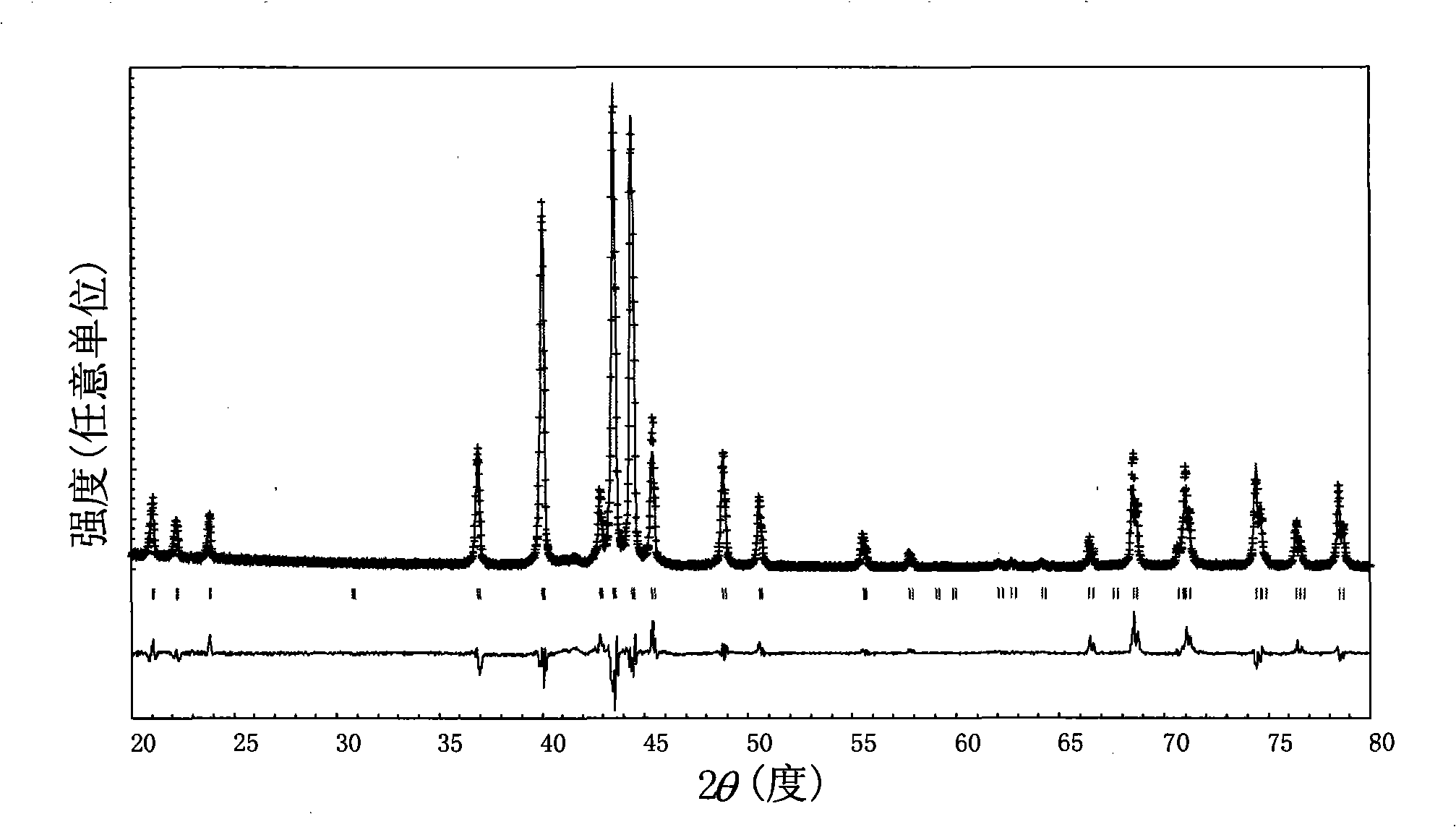

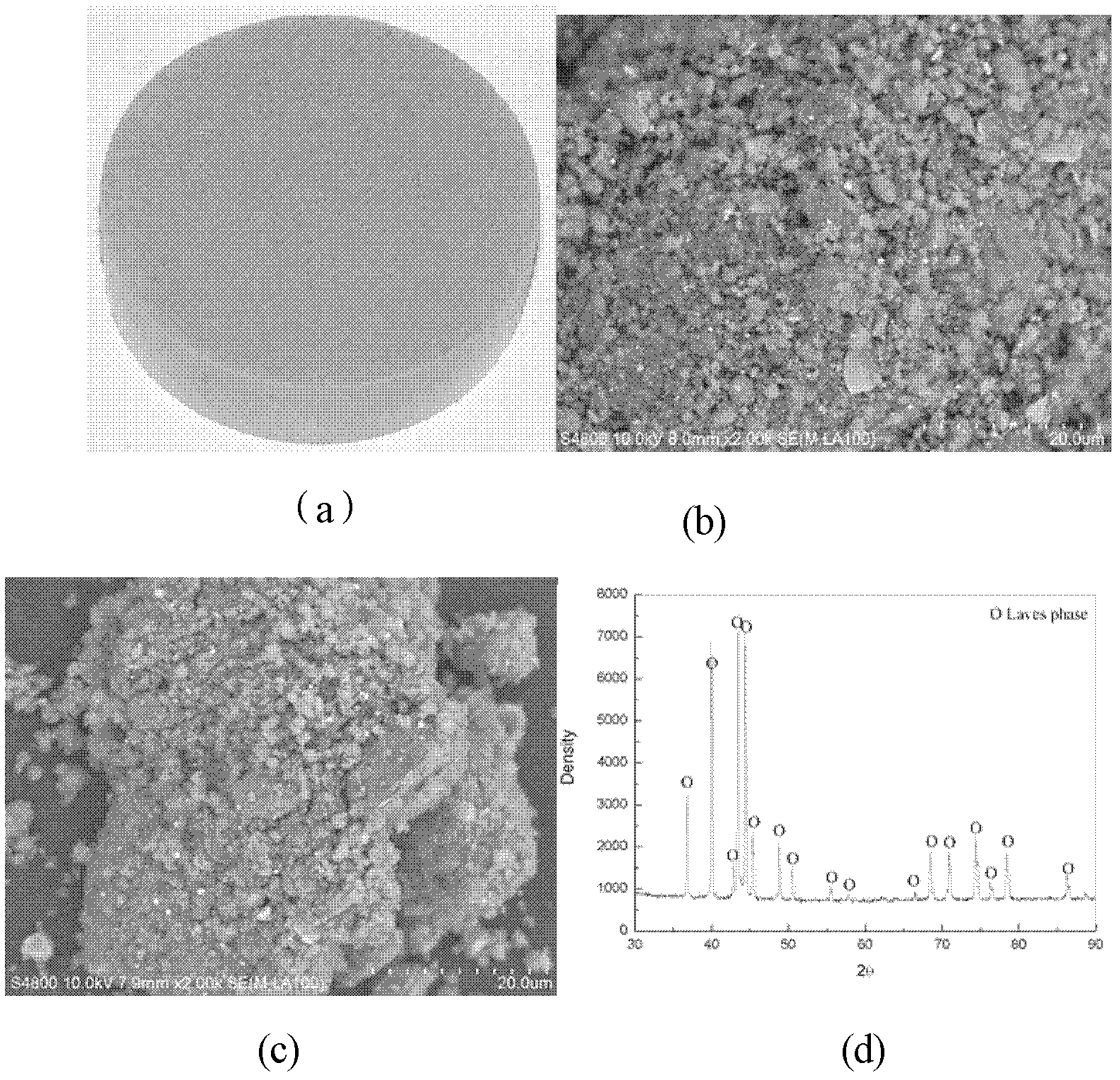

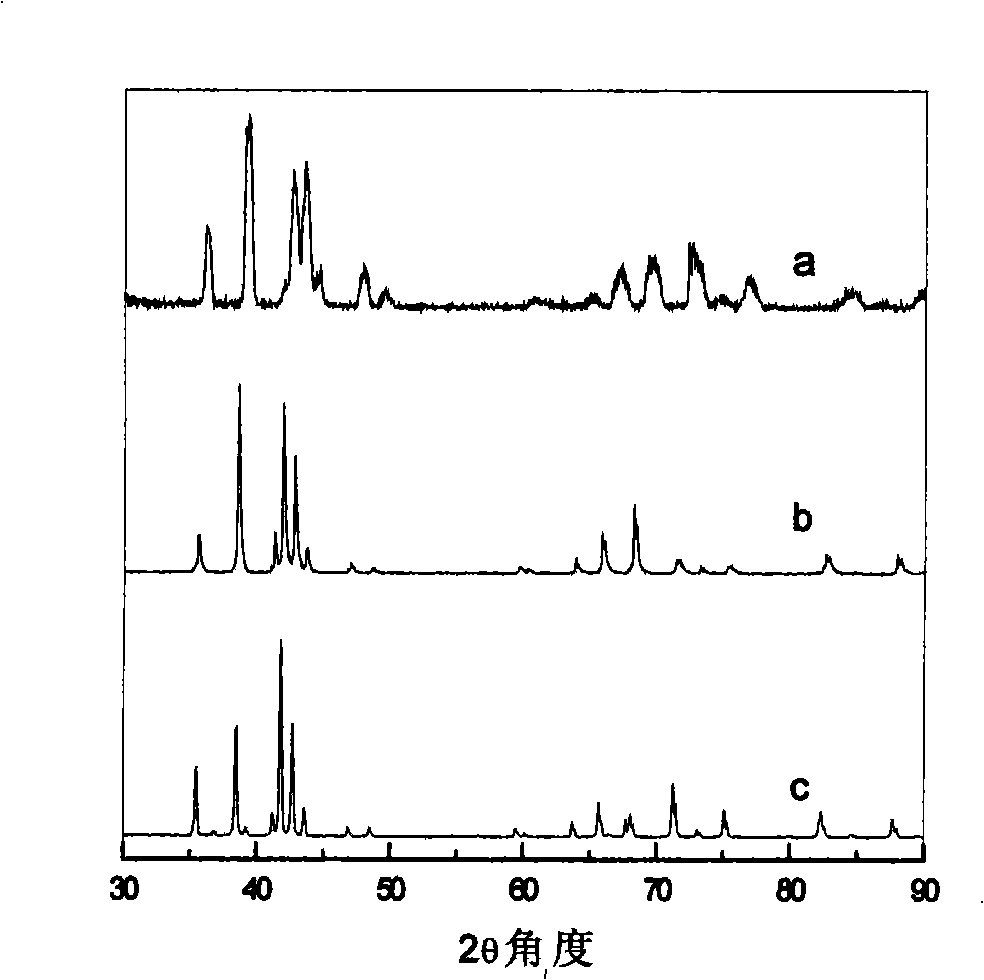

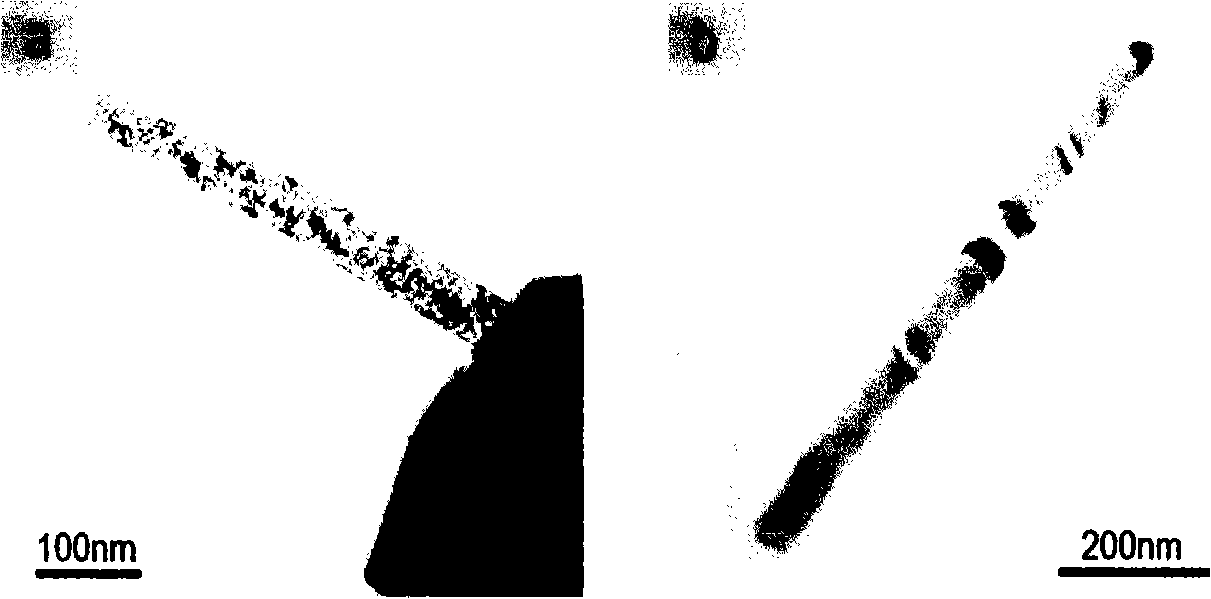

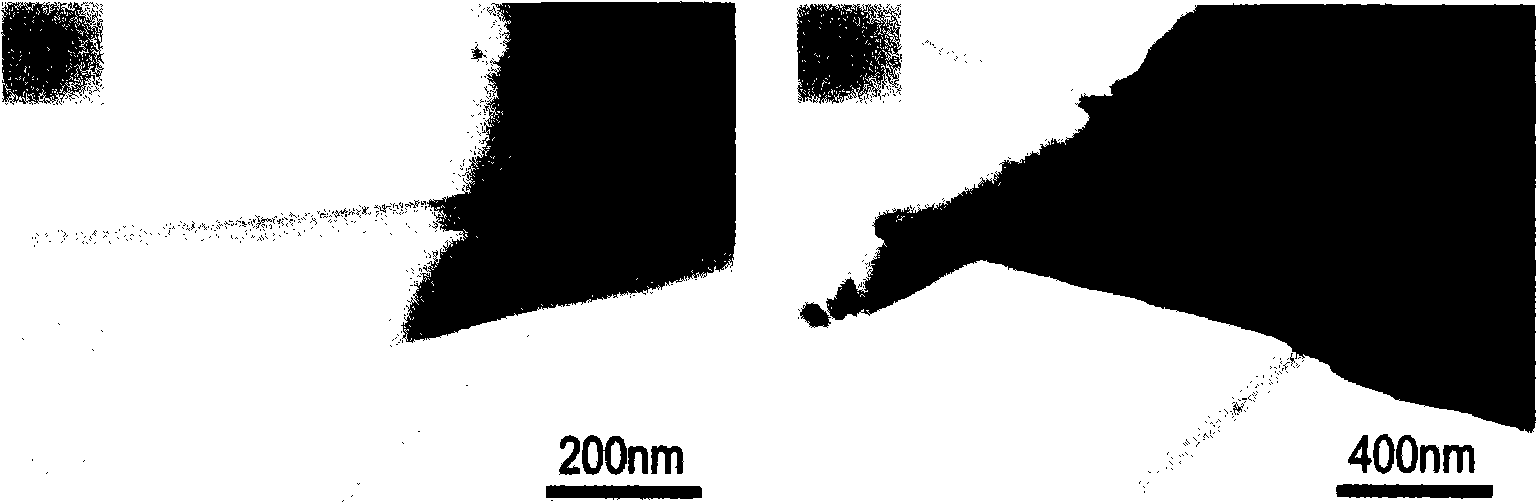

Metal alloy nano-stick or nano-wire manufactured with Laves phase hydrogenation method and process thereof

The invention discloses the metal alloy nano rods and nano wires which are prepared by a Laves phase hydrogenation method and a technique. The metal alloy nano rods and nano wires are characterized by being a Laves phase alloy of nanometer whisker which can produce simple-substance manganese and the alloy of the manganese. The expression formula of the alloy component is Ti1-xZrx (Mn1-yCry)2; wherein, x is equal to 0 to 1.0; y is equal to 0 to 0.9. The technique is characterized by carrying out hydrogen-charging / dehydrogenation treatment to the alloy for once to ten times, then carrying out ultrasonic vibration treatment to the sample containing little amount of hydrogen after dehydrogenation treatment in ethanol solvent and placing the sample in the air for 12 to 72 hours. The invention has the advantages of being a process technology which leads metals to grow out nanometer whisker automatically at a normal temperature under specific hydrogenation condition. The alloy whisker belongs to nanometer whisker materials and the diameter is less than 100nm; the crystal structure is novel hexagonal structure and the shape is a regular round bar or wire. The alloy whisker has high melting point, high hardness and unique magnetic performance, and is magnetic nano-material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

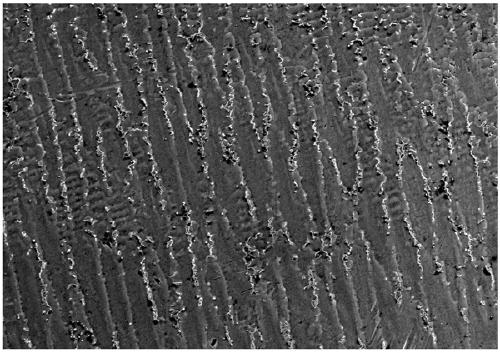

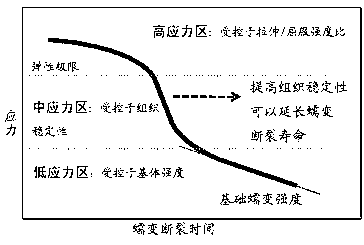

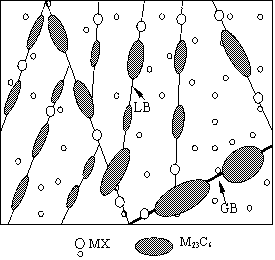

Thermal power plant T/P92 heat-resistant steel aging grade evaluation method based on combination of Brinell hardness, structure and precipitation phase characteristic

InactiveCN107843706AEasy to masterThe rating method is simplePreparing sample for investigationMaterial analysis by optical meansPower stationHardness

The invention relates to the field of inspection of iron and steel materials, particularly to a thermal power plant T / P92 ultra supercritical unit heat-resistant steel aging grade evaluation method based on the combination of the Brinell hardness, the structure and the precipitation phase characteristic. According to the present invention, by selecting the strict sample preparation method and using the etchant with the suitable ratio, the metallurgical structure morphologies with different aging grades can be evaluated under the low-magnification microscope, and especially the conversion fromthe martensite lath to the ferrite structure can be evaluated; and the evaluation standard considers the average grain size of the precipitation phase, and comprehensively considers the growth of theaverage grain size of the Laves phase and the hardness of the service steel at different aging degrees, wherein the hardness of the steel can intuitively and accurately characterize the aging condition.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

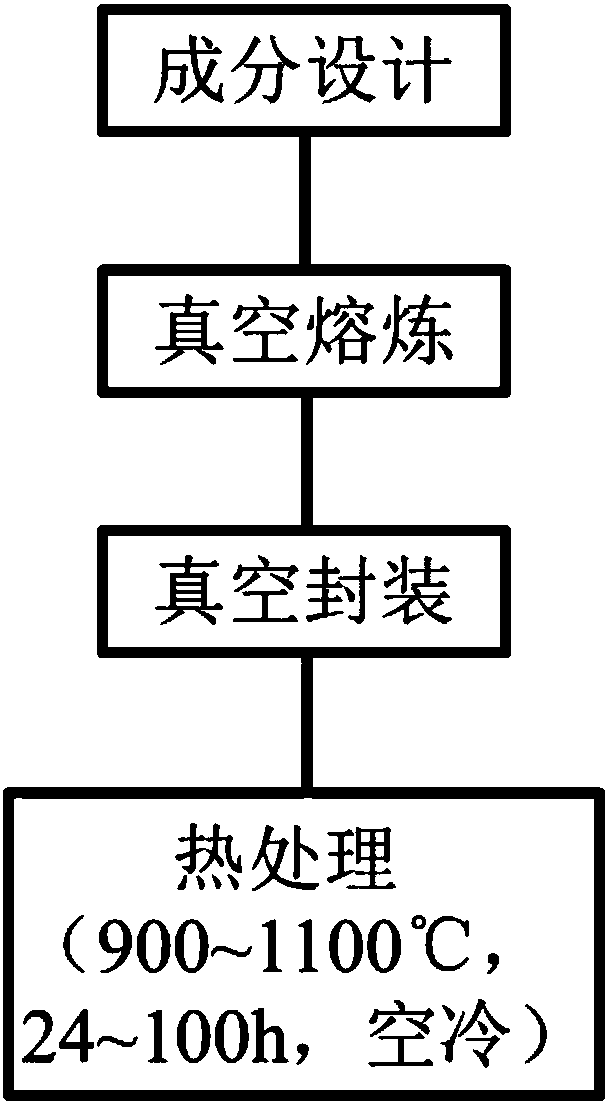

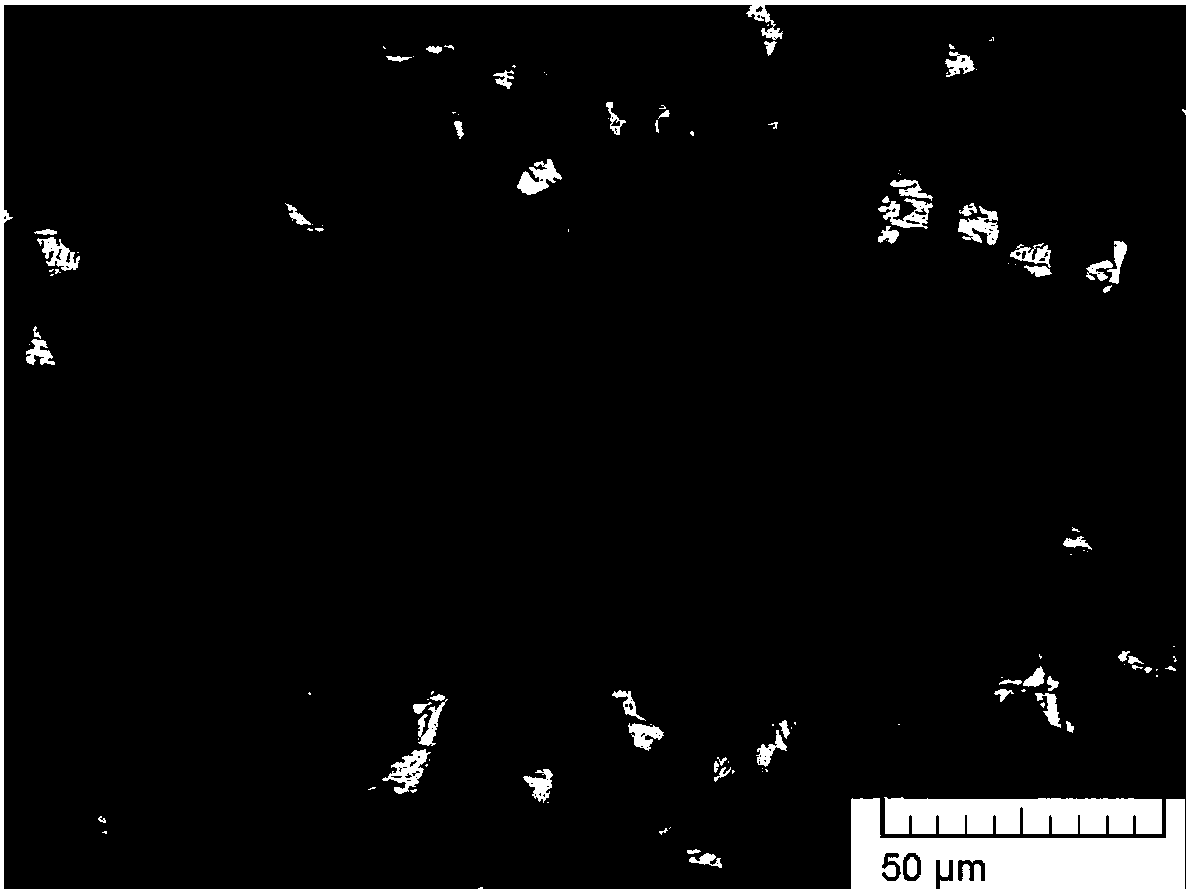

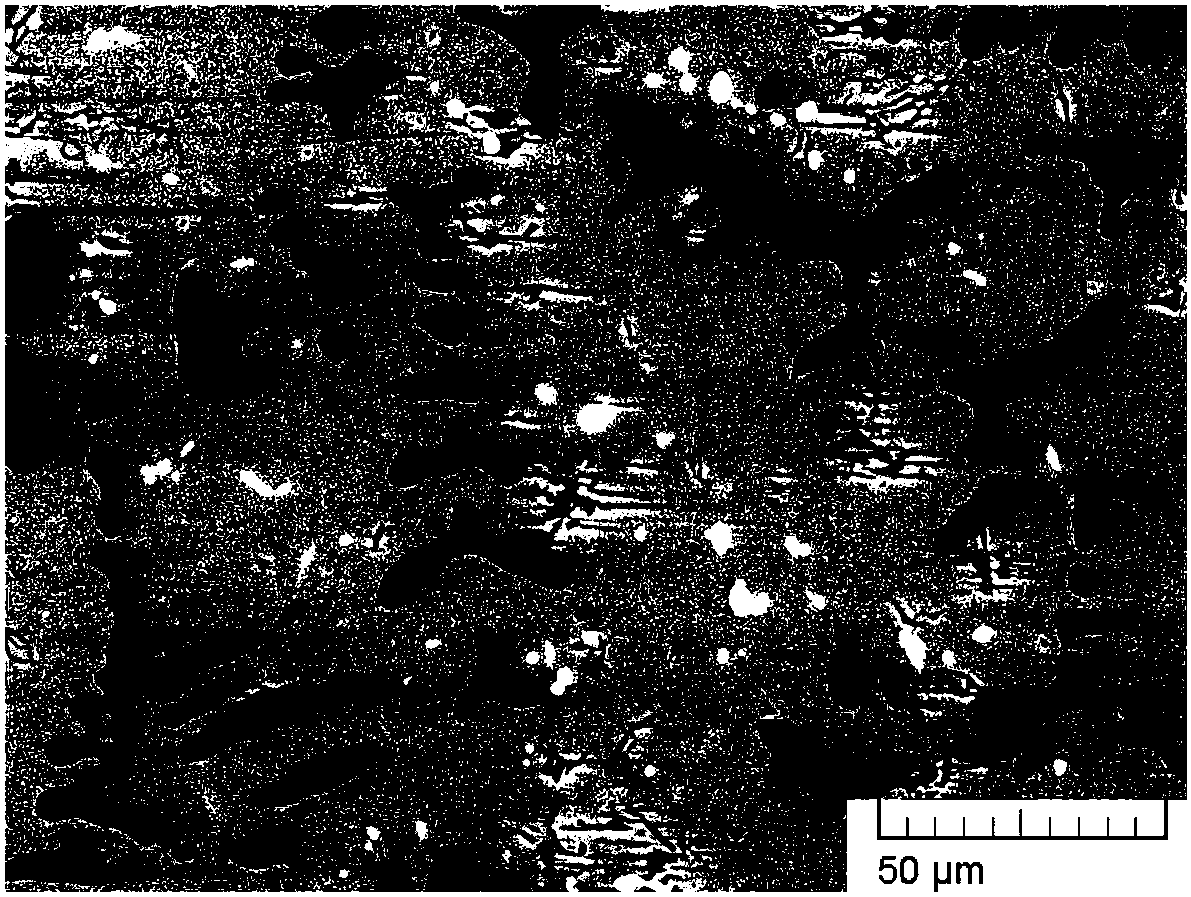

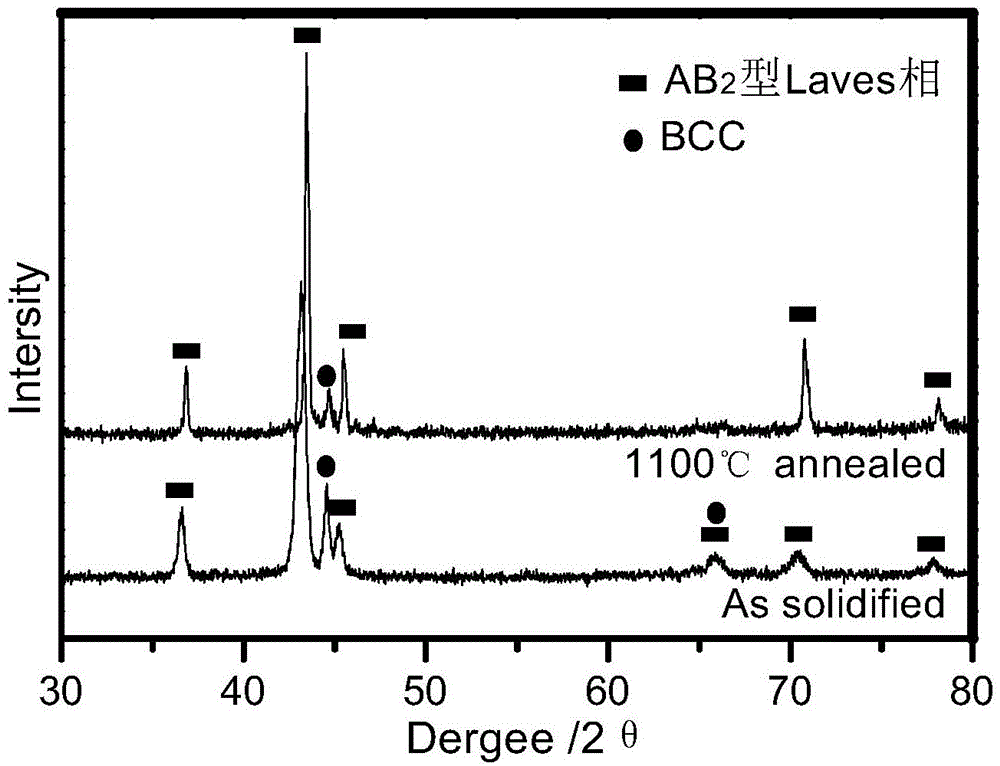

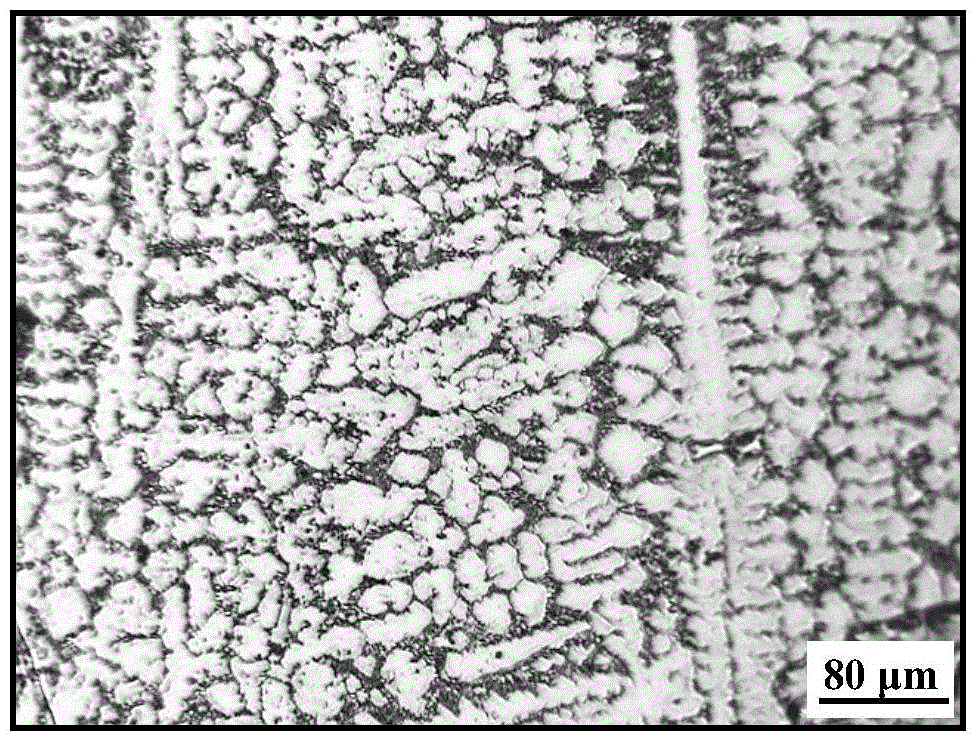

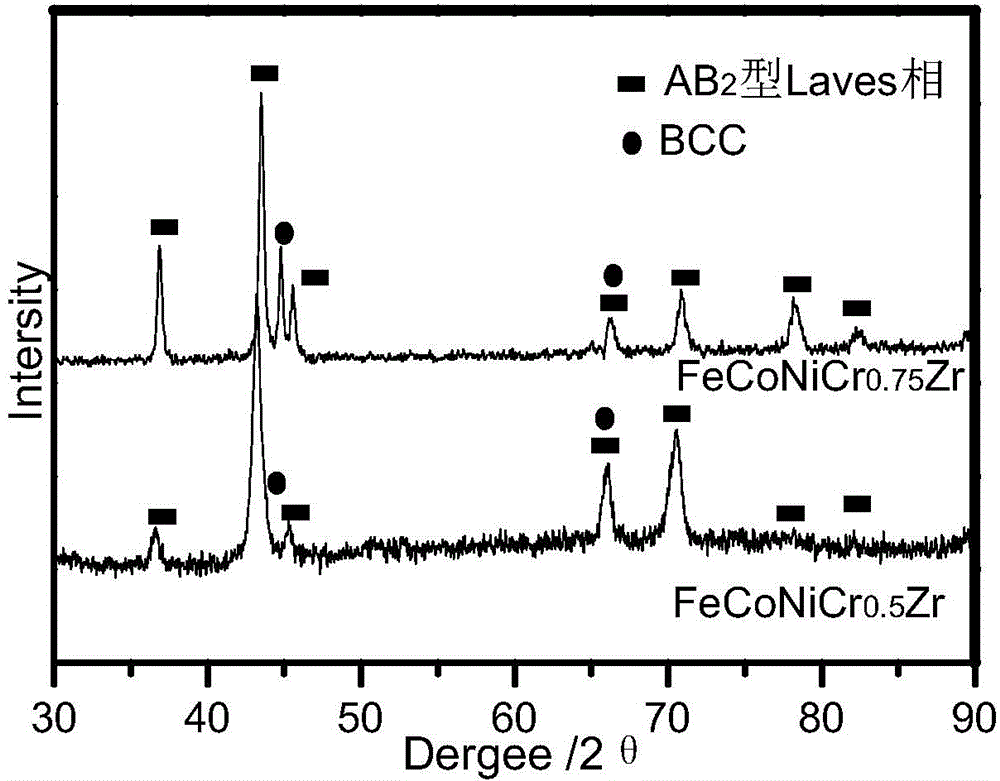

Multiple-principal-component Laves-base intermetallic compound and preparation method thereof

ActiveCN104818418AGood high temperature aging strengthening effectHigh hardnessMaterial DesignElectric arc furnace

The invention discloses a multiple-principal-component Laves-base intermetallic compound and a preparation method thereof, belonging to the field of alloy material design. The component element is FeCoNiCrxZr, wherein x is 0.5-1. The principal phase of the multiple-principal-component Laves-base intermetallic compound obtained by arc smelting and heat treatment is a Laves intermetallic compound, or the Laves phase base contains a small amount of bcc-structure solid solution. Due to the high entropic effect and topology structure features of the multiple-principal-component Laves phase, the multiple-principal-component Laves-base intermetallic compound has the advantages of superhigh hardness, superhigh structural stability, superhigh tempering softening resistance and favorable high-temperature aging reinforcement effect, and is applicable to the field of 1100-DEG C-below high-temperature structure materials in industry.

Owner:菏泽市金沃泰化工有限公司

Novel nitride-reinforced martensite heat-resisting steel

InactiveCN102758141AImprove thermal stabilityGood high temperature mechanical propertiesAlloyThermal stability

The invention provides a novel nitride-reinforced martensite heat-resisting steel. The steel is characterized in that main alloy components of the martensite heat-resisting steel comprises, by weight, 0.8-1.5% of Mn; 8.0-10.0% of Cr; no more than 1.5% of W; no more than 1.5% of Mo (wherein wherein the sum of the weight percentages of W and Mo is 1.5-2.0%); no more than 0.06% of Nb; no more than 0.15% of Ta (wherein Nb+Ta accounts for 0.05-0.15%); 0.1-0.3% of V; 0.03-0.05% of N; and balance of Fe. According to the invention, the content of the element Mn is increased. On a basis that a phase change point of a material AC1 is almost not reduced, heat-resisting steel original martensite tissues reinforced by high-thermal-stability nitride precipitate is obtained. With the controlling over the contents of elements Co, W, Mo, N, and the like, Laves phase and Z phase precipitation of steel during long-term high-temperature service can be retarded. Therefore, the obtained steel has relatively high tissue stability and good high-temperature mechanical properties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

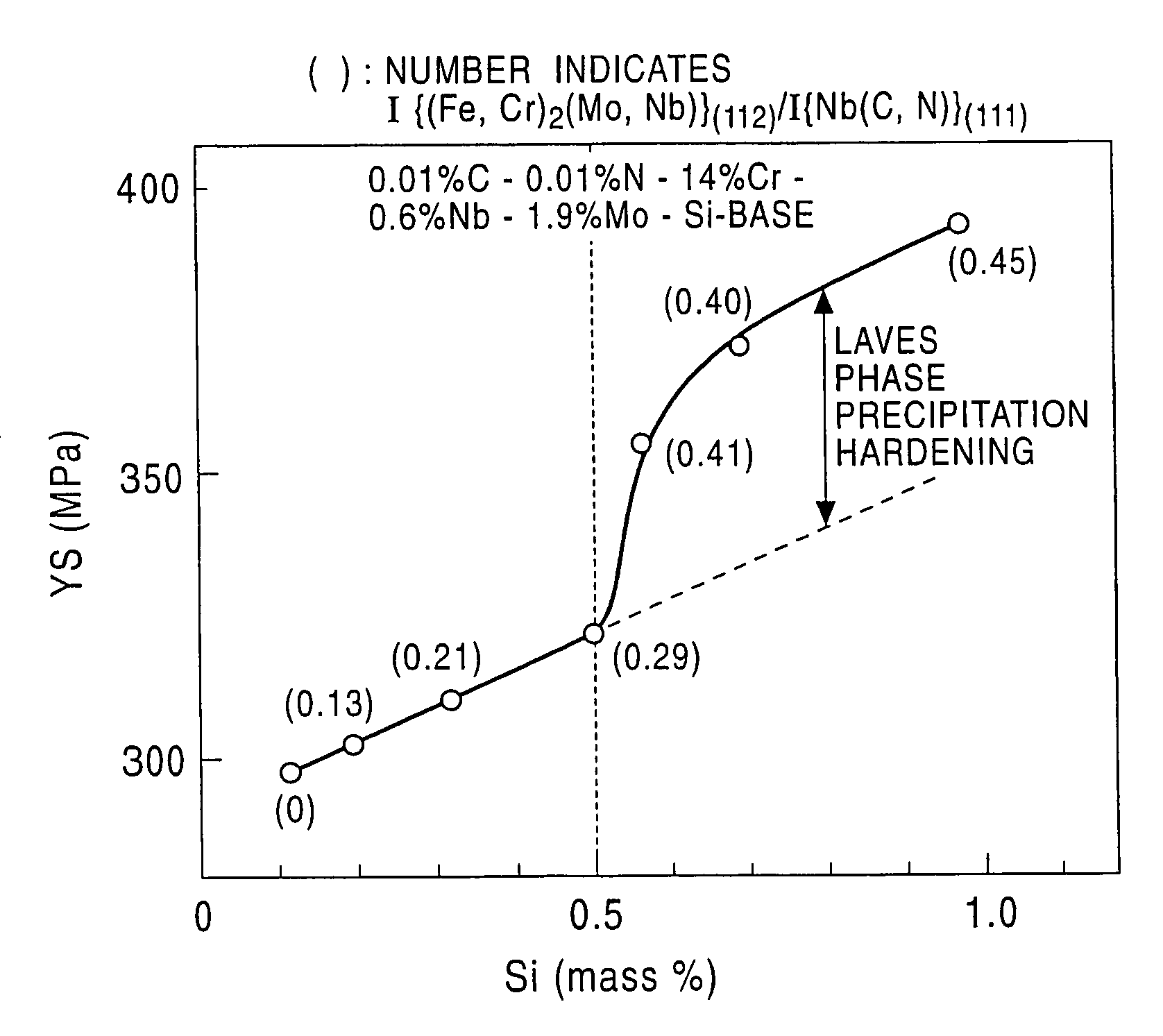

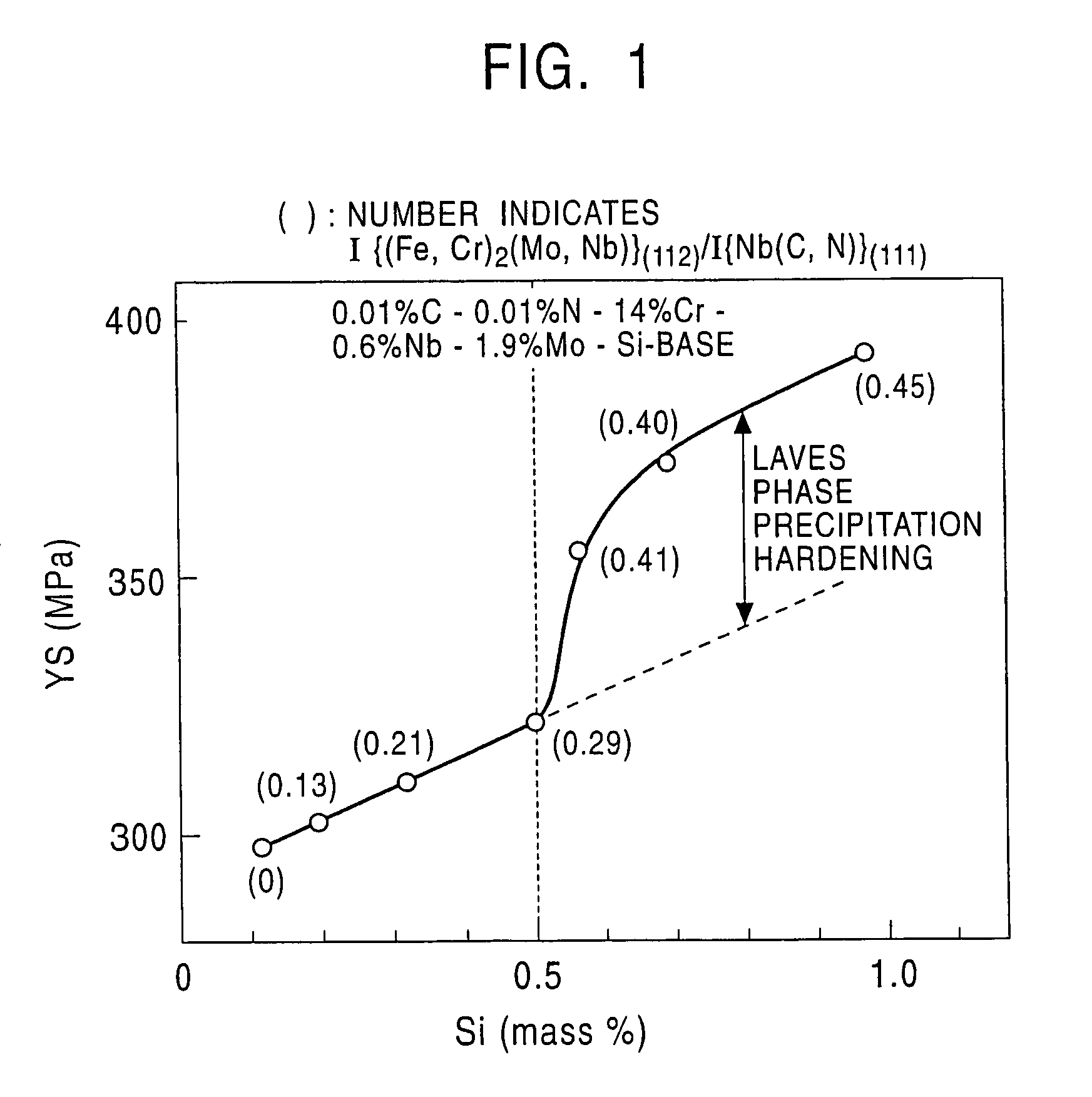

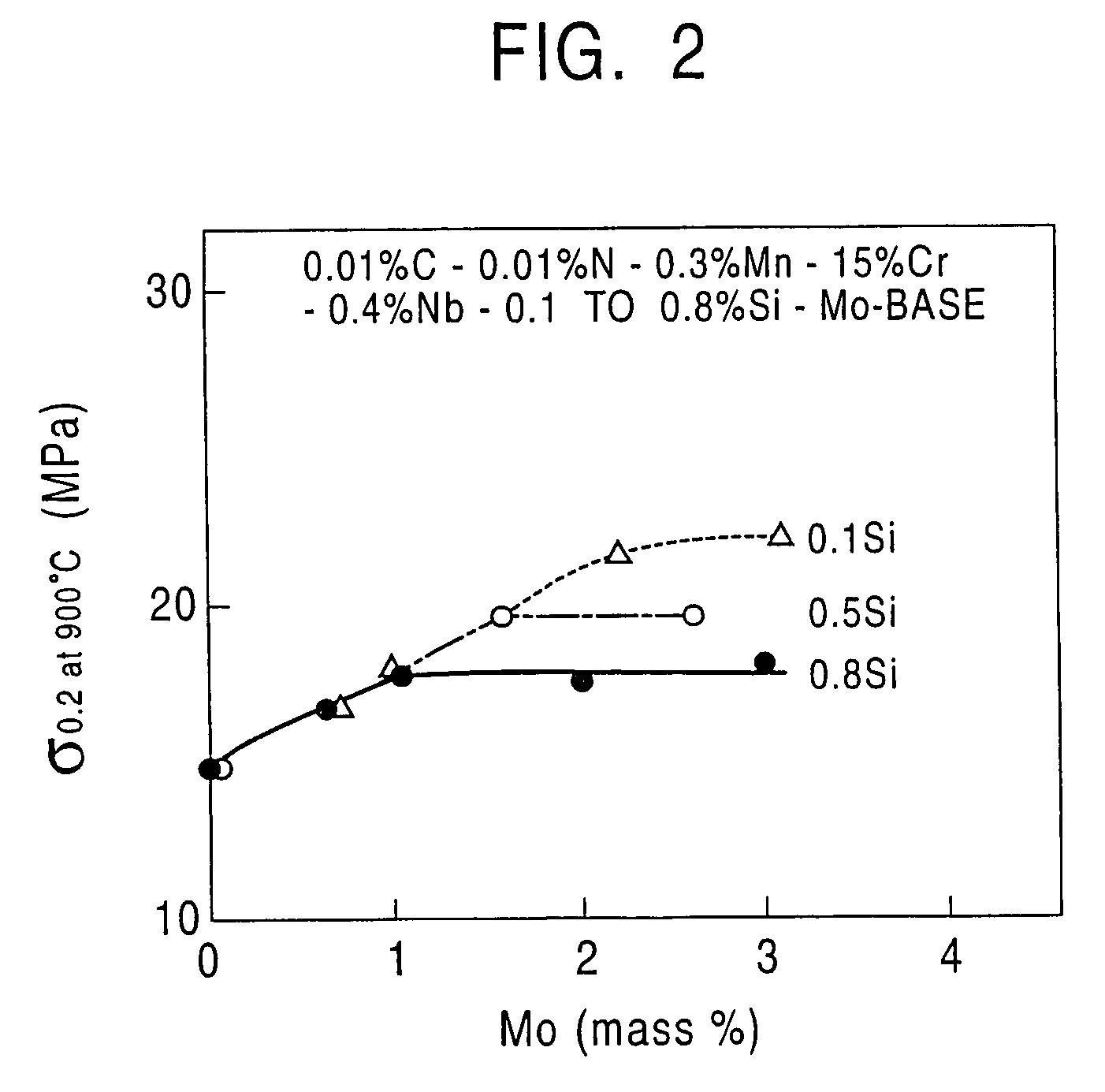

Soft Cr-containing steel

The soft Cr-containing steel includes, on a % by mass basis, C: from about 0.001% to about 0.020%, Si: more than about 0.10% and less than about 0.50%, Mn: less than about 2.00%, P: less than about 0.060%, S: less than about 0.008%, Cr: from about 12.0% to about 16.0%, Ni: from about 0.05% to about 1.00%, N: less than about 0.020%, Nb: from about 10×(C+N) to about 1.00%, Mo: more than about 0.80% and less than about 3.00%, wherein the contents of alloying elements, represented by Si and Mo, respectively, on a % by mass, satisfy the formula Si≦1.2−0.4Mo, so as to prevent precipitation of the Laves phase and to stably secure an effect of increasing high-temperature strength due to solid solution Mo.

Owner:JFE STEEL CORP

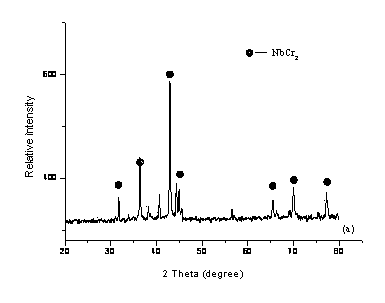

Method for preparing and synthesizing NbCr2 intermetallic compound porous material through reaction of Cr powder and Nb powder

The invention discloses a method for preparing and synthesizing an NbCr2 intermetallic compound porous material through a reaction of Cr powder and Nb powder. The method comprises the steps as follows: 1), the Cr powder and the Nb powder which have the atomic percent of 2:1 and a grinding ball are placed into a ball grinding tank, the tank is sealed, and ball grinding is performed; 2), a proper quantity of a binding agent is added into the fully-mixed powder, and the mixture is pressed into sheet briquettes after uniform mixing; and 3), briquette-pressing is performed, a sectional type sintering process is adopted, and sintering is performed in a vacuum sintering furnace, so that the Cr powder and the Nb powder have a reaction fully, so that the intermetallic compound NbCr2 is formed. According to the method, the Laves-phase NbCr2 intermetallic compound porous material is synthesized, and the porosity of the synthesized porous material reaches 35%-55%.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com