Composite hydrogen storage material with foamed structure and preparation method thereof

A technology of hydrogen storage materials and composite materials, which is applied in the field of composite hydrogen storage materials with a foam structure and its preparation, can solve the problems of unsatisfactory hydrogen discharge capacity rate and capacity, poor hydrogen discharge kinetic performance, and high price, and achieve The effect of good reversible hydrogen storage and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The specific composition of the N component of the composite material is: according to the ratio of titanium to manganese atomic ratio of 1:2, TiMn is prepared by induction melting 2alloy ingot.

[0030] A certain amount of the alloy is subjected to powder refinement through mechanical crushing, multiple hydrogen absorption and desorption cycles, and planetary ball milling. The ball milling time was 50 hours, the ball-to-material ratio was 30:1, and the rotation speed was 300 rpm. The average grain size of the finally obtained alloy is 60nm.

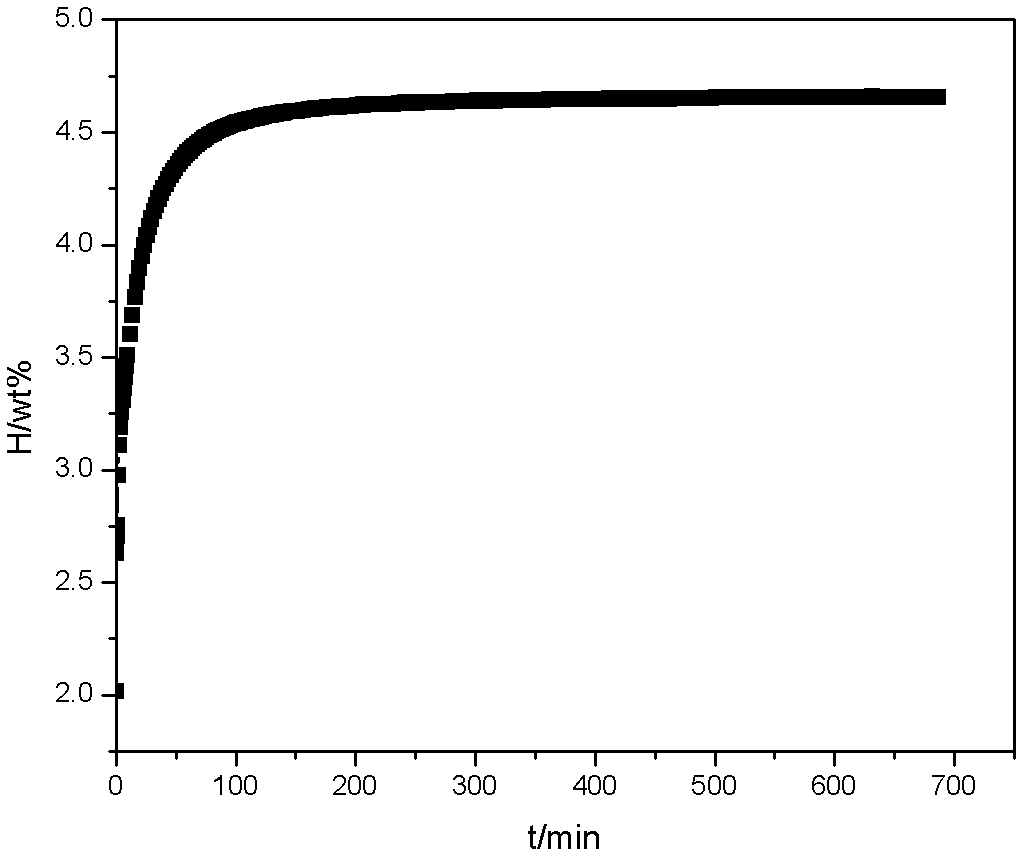

[0031] Finally, to NaAlH 4 Add 10wt.% of the alloy powder to the hydrogen storage material relative to the total amount of the composite hydrogen storage material, and mix it through a planetary ball mill. The process parameters are: ball milling time 3 hours, ball-material ratio 10:1, rotation speed 500rpm, and The tank is filled with hydrogen with a certain pressure (2 MPa) and a purity >99.99%. 90wt.%NaAlH 4 +10wt.%TiMn 2...

Embodiment 2

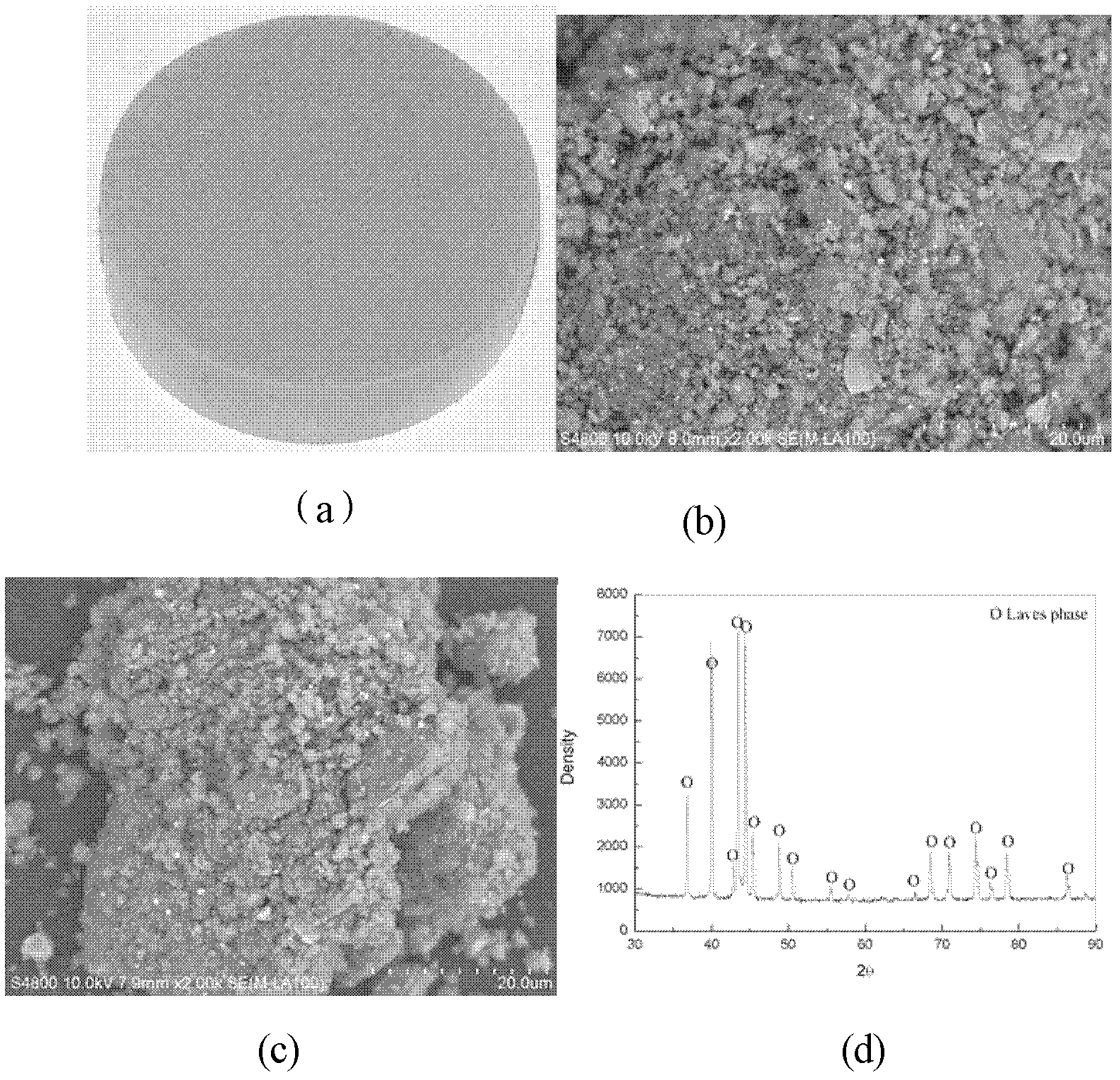

[0033] The specific composition of the composite material component N is: according to Ti 0.98 Zr 0.02 V 0.43 Fe 0.09 Cr 0.05 mn 1.43 Alloy general formula for proportioning. Preparation of Ti by induction melting 0.98 Zr 0.02 V 0.43 Fe 0.09 Cr 0.05 mn 1.43 (AB 2 alloy) alloy ingot. Ti 0.98 Zr 0.02 V 0.43 Fe 0.09 Cr 0.05 mn 1.43 The XRD diffraction pattern of the alloy is shown in 1-(d).

[0034] A certain amount of the alloy is subjected to powder refinement through mechanical crushing, multiple hydrogen absorption and desorption cycles, and high-energy ball milling. The ball milling time is 100 hours, the ball-to-material ratio is 15:1, the amplitude is 30 mm, and the rotation speed is 3000 rpm. An alloy powder with an average particle size of 80 nm was finally obtained.

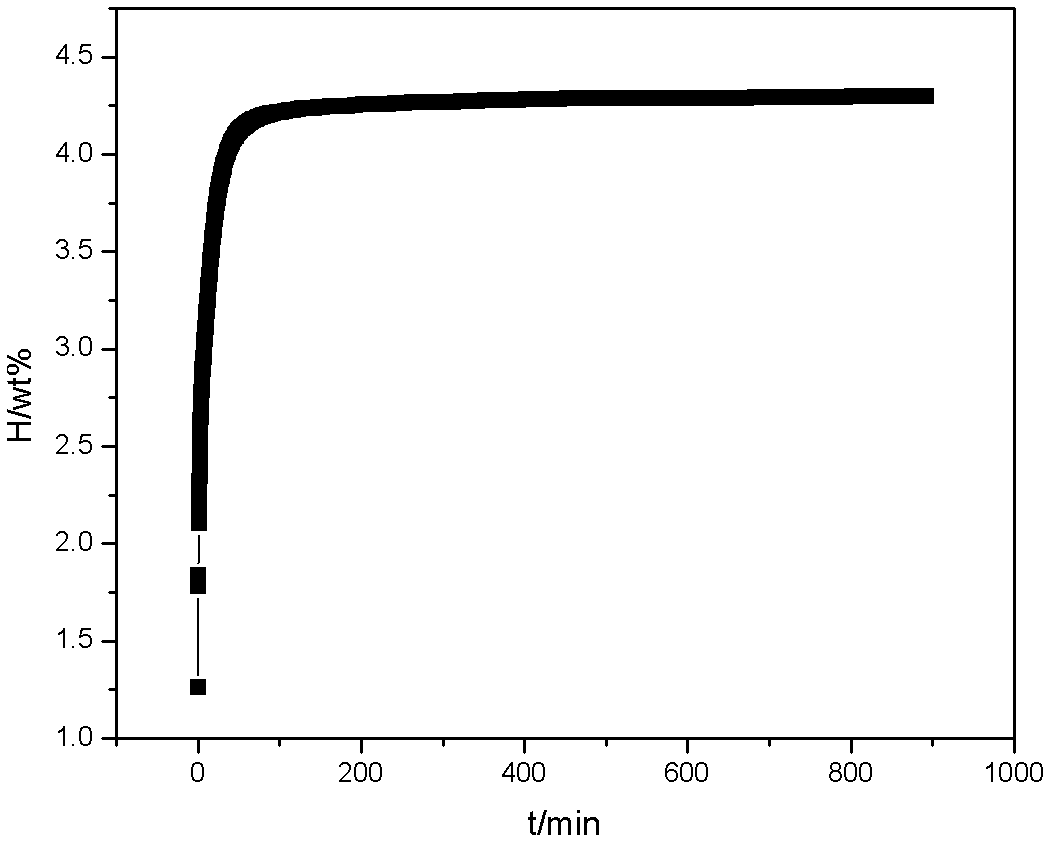

[0035] NaAlH 4 40% by mass of the alloy powder relative to the total amount of the composite hydrogen storage material is added to the hydrogen storage material, and the mixture is mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com