Patents

Literature

181 results about "Compression time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Time compression is the concept of condensing all of time and space into a single moment, or "singularity". It can be initiated by the casting of a spell, which requires incredible power on behalf of the caster(s) and places them at the center of said singularity.

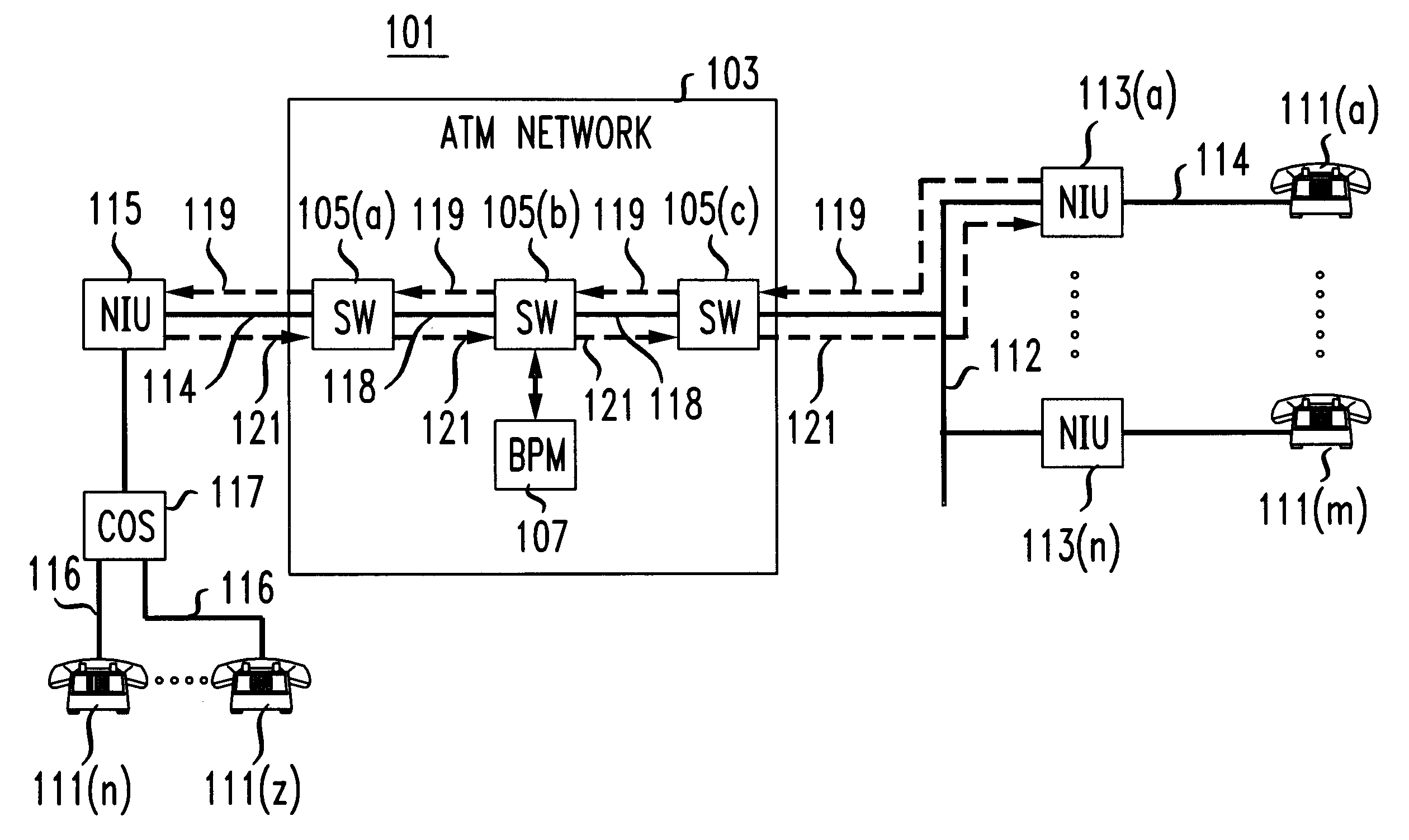

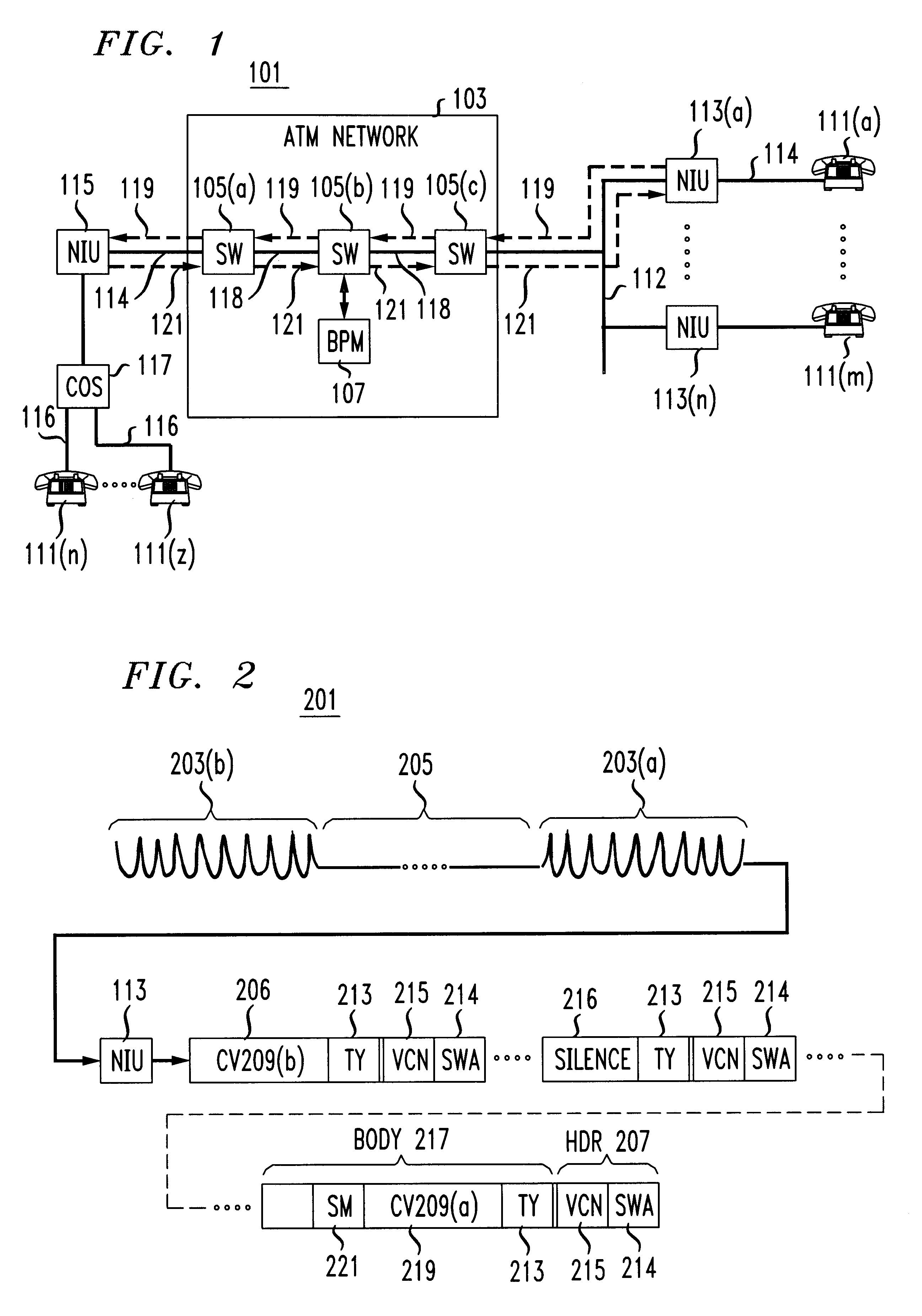

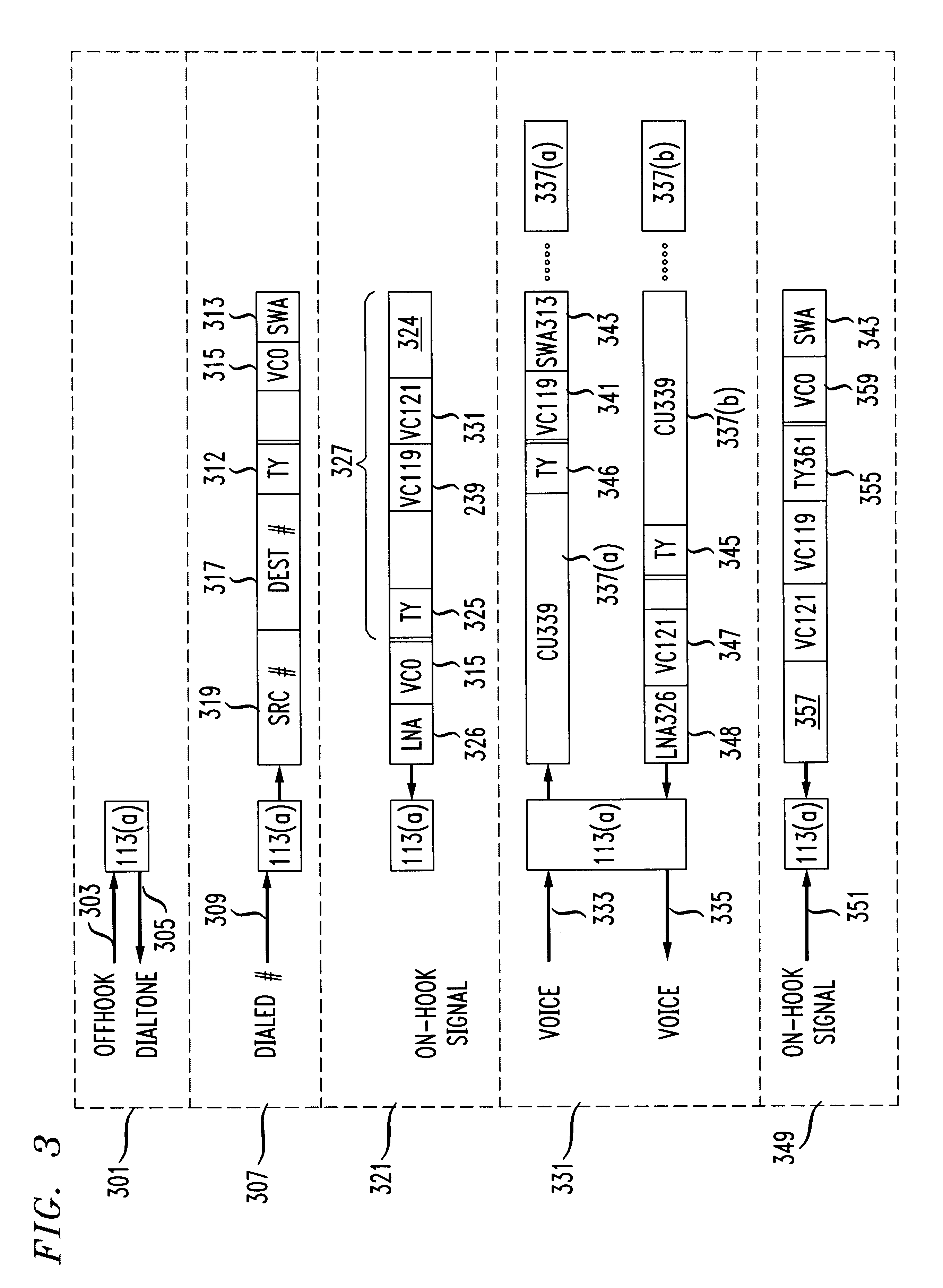

Packet telephone system

InactiveUS6487200B1Simple designReduce the amount requiredInterconnection arrangementsSupervisory/monitoring/testing arrangementsData connectionBounded delay

A packet telephone system which employs a packet network that provides virtual circuits. The packet telephone system employs short packets containing compressed speech. The use of the short packets makes possible compression and decompression times and bounded delays in the virtual circuits which are together short enough to permit toll-quality telephone service. The packet telephone system employs an intelligent network interface unit to interface between the packet network and standard telephone devices. The network interface unit does the speech compression and decompression and also responds to control packets from the packet network. Consequently, many telephone system features can be implemented in the network interface unit instead of in the switches. The network interface unit may also be used to provide data connections to devices attached to it. The combination of virtual circuits, with bounded delays, short packets, rapid compression and decompression, and intelligent network interface units makes it possible to build a telephone system with fewer and cheaper switches and fewer links for a given volume of traffic than heretofore possible and also permits substantial savings in provisioning and maintaining the system.

Owner:AT&T INTPROP I L P

Manufacture process of disposable bowl cover and bowl cover made by same

InactiveCN101637982AReduce energy consumptionImprove waterproof performanceWater-repelling agents additionPaper/cardboard articlesMolded pulpHigh pressure

The invention provides a manufacture process of disposable bowl cover with high strength, strong stability and good water proof performance. The process includes the concrete steps of raw material beating-batching-compression molding-side shearing and punching-making back-off slot by pressing; wherein the material beating includes that: the used raw material is mainly bagasse paddle board accounting for 80-90% of total mass and supported by a small amount of wood pulp and bamboo pulp accounting for 10-20%, water dissociation beating is carried out by a beating engine, and the beating concentration is 4-6%; the compression molding includes: wet blank with water content of 65-75% is directly transferred into an aluminium or steel compression molding mold for high temperature high pressure dehydration, so that the water content of product can reach 5-7%, and the pressure thereof is 15-20x10<3>kgf, the temperature is 150+ / -10 DEG C, and the compression time is 45+ / -5 seconds. Compared withthe existing molded pulp process, the invention saves energy consumption; and the water proof performance, the strength and the stability of the product are greatly improved.

Owner:佛山浩博环保制品有限公司

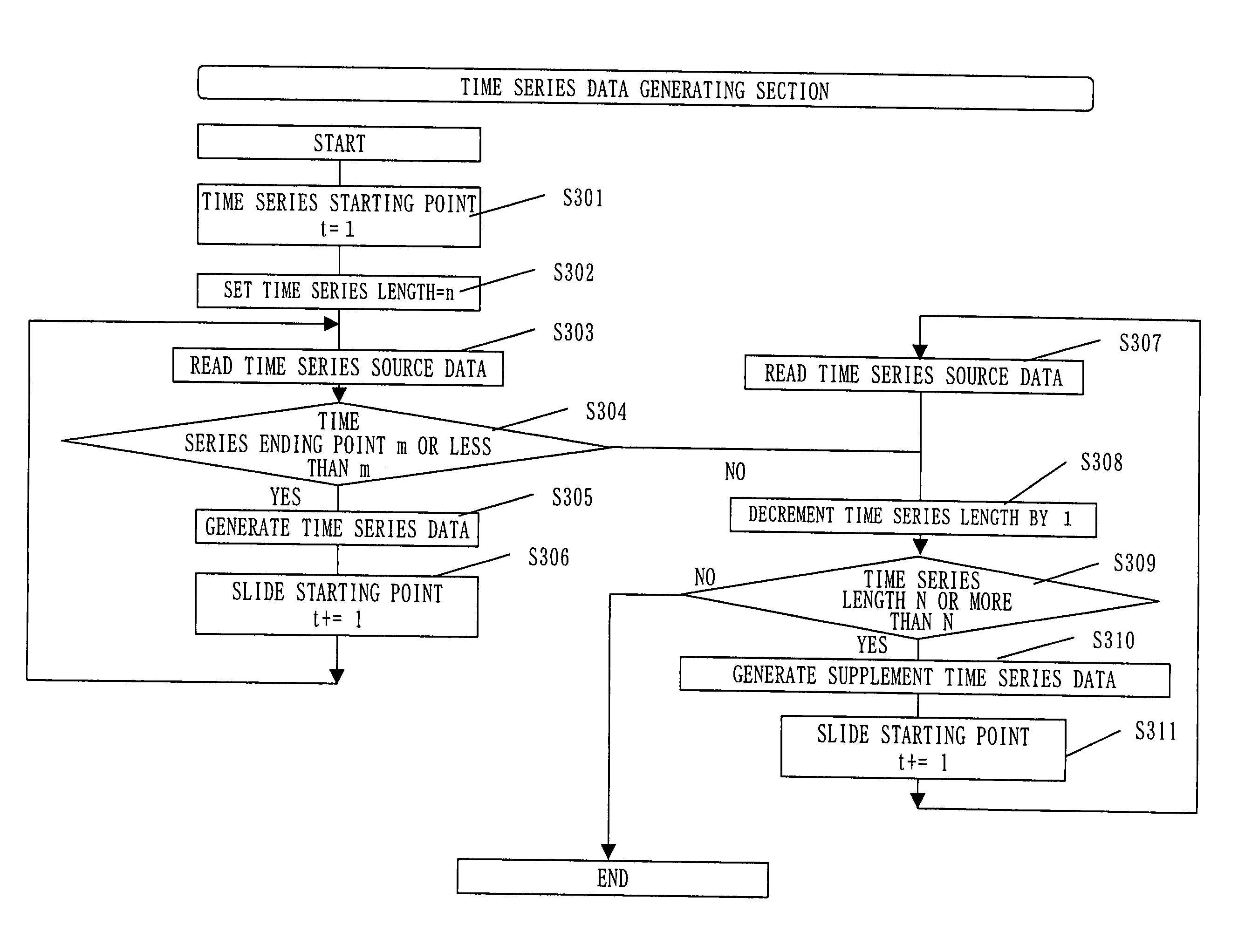

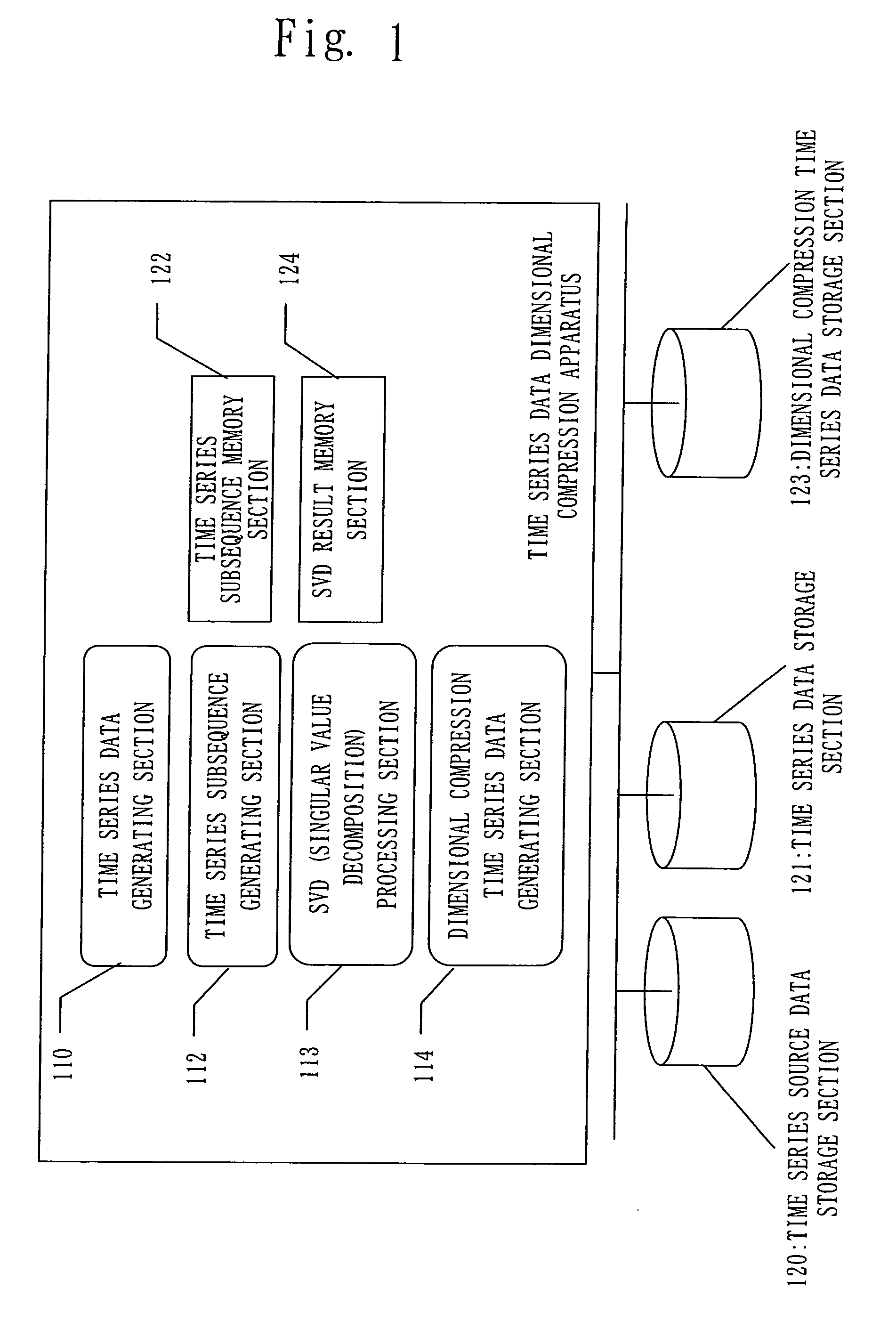

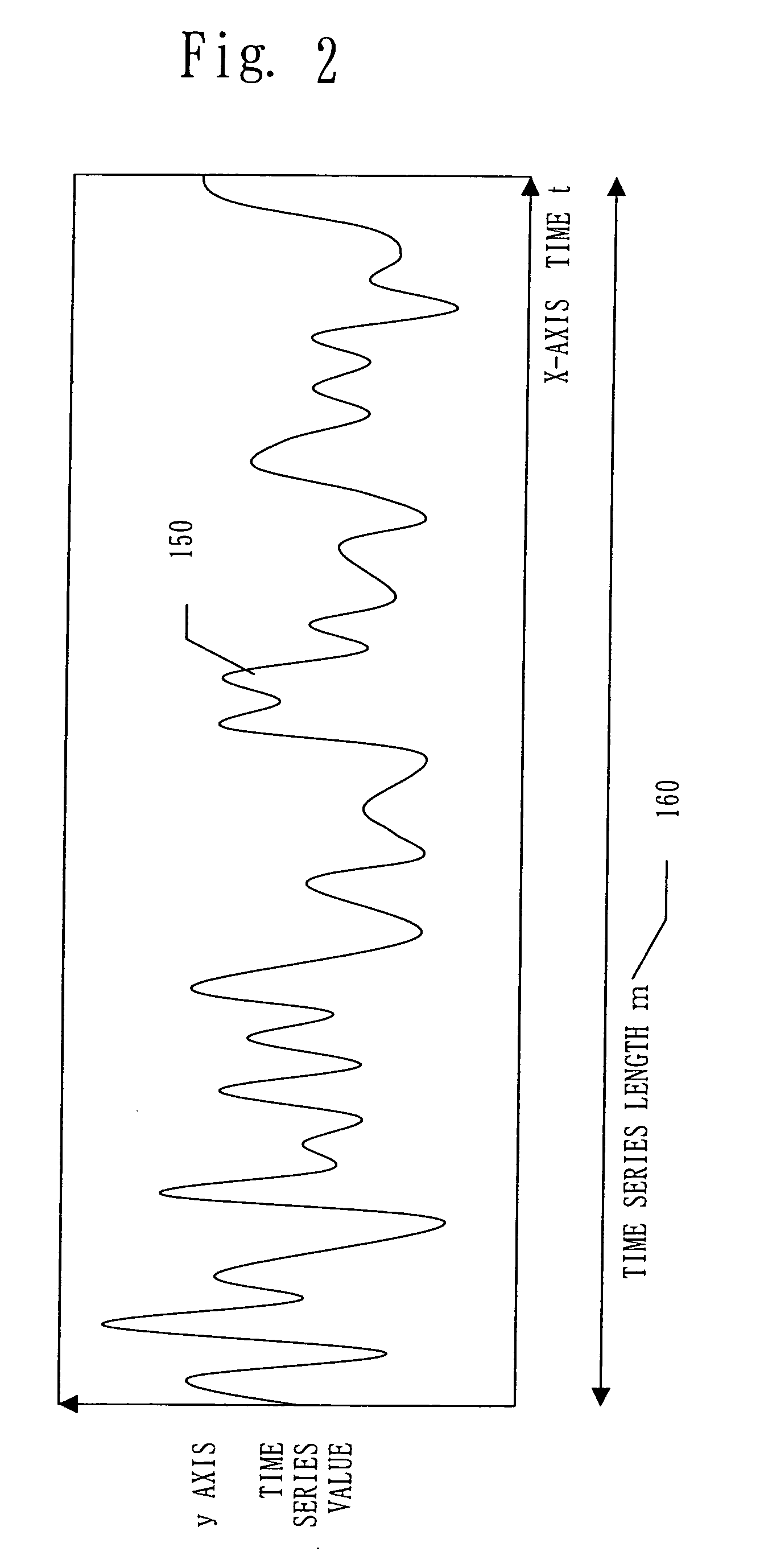

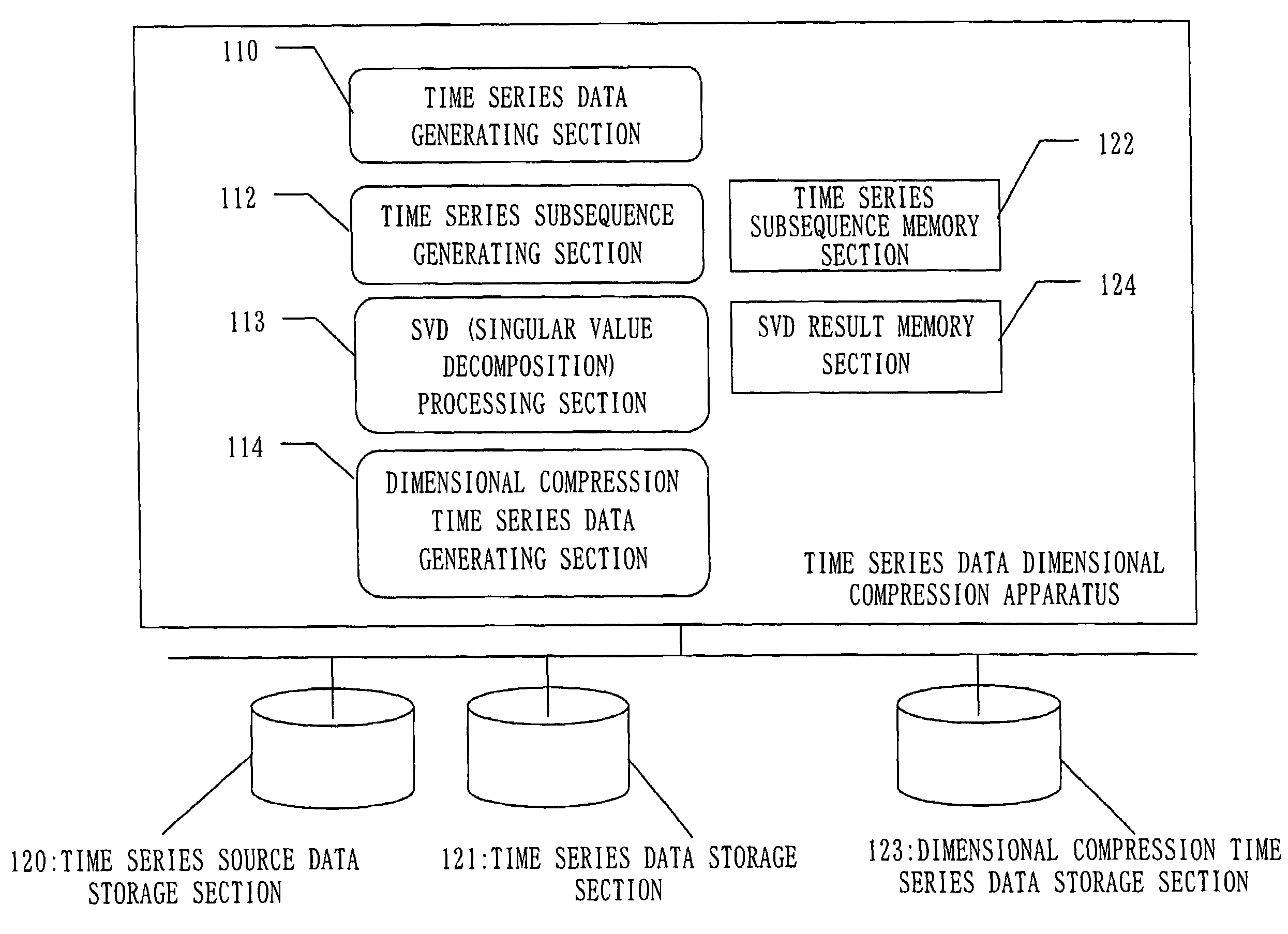

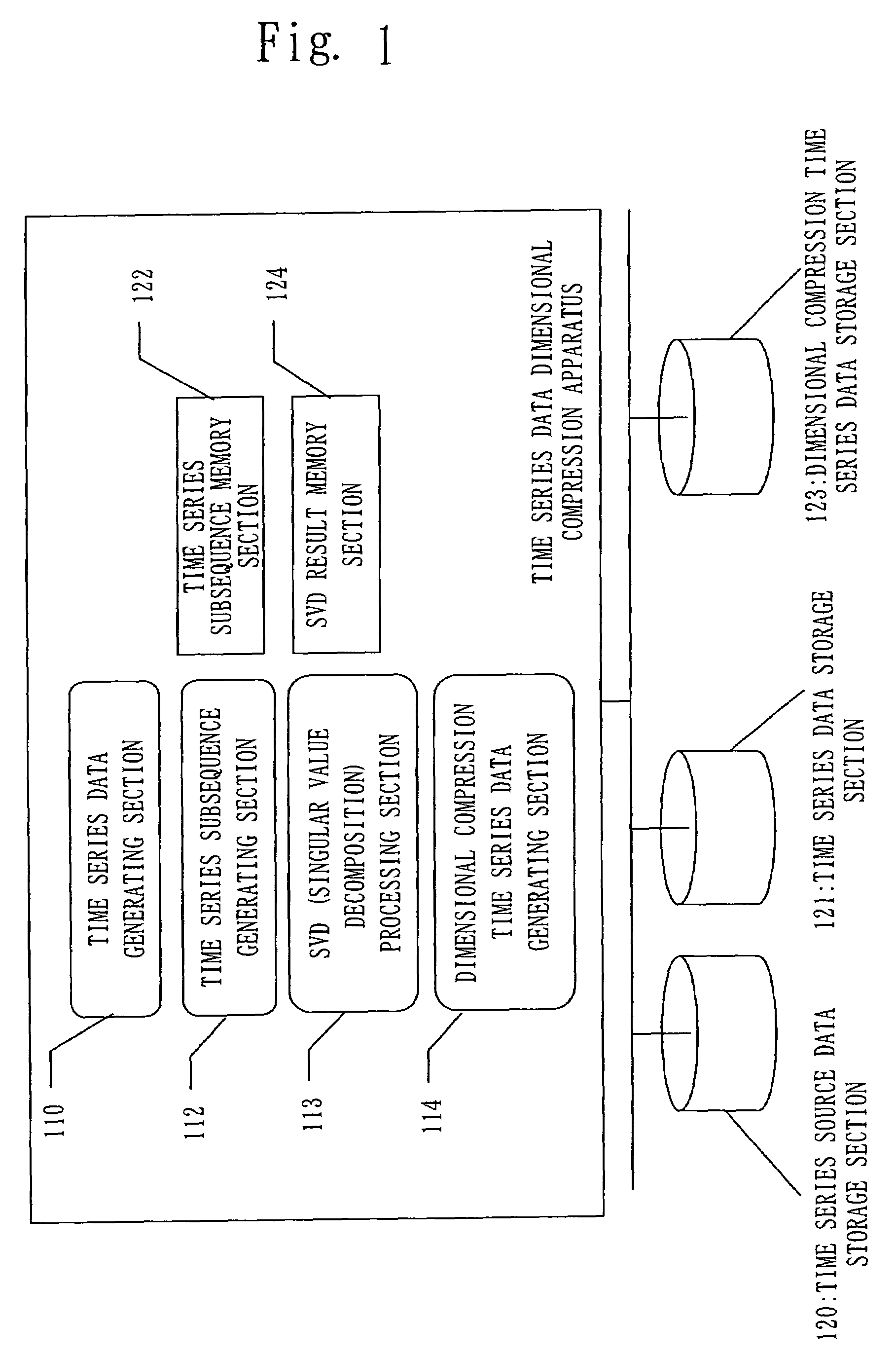

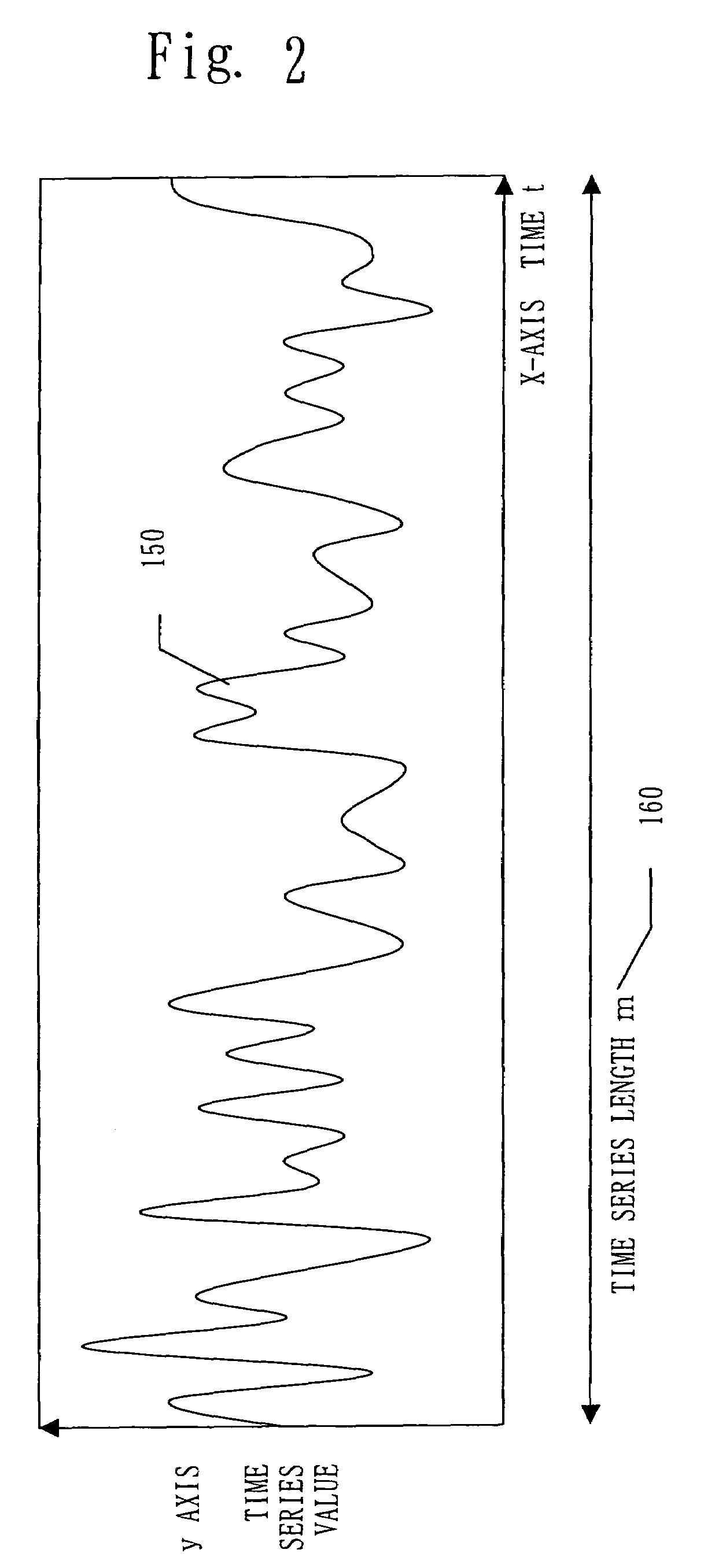

Time series data dimesional compression apparatus

InactiveUS20070147519A1Vehicle testingNoise figure or signal-to-noise ratio measurementSingular value decompositionAlgorithm

A time series data dimensional compression apparatus performing dimensional compression for improving the efficiency of searching for time series data without losing the features of data. The compression is made to a determined dimension so that a larger volume of information may be extracted therein. A time series subsequence generating section (112) generates time series subsequences of a specified segment width into which a plurality of pieces of time series data generated at a time series data generating section (110) are divided. A singular value decomposition processing section (113) performs singular value decomposition on all of the time series subsequences. A dimensional compression time series data generating section (114) generates dimensional compression time series data by using high-order elements of the singular value decomposition as a representative value of the time series subsequence.

Owner:MITSUBISHI ELECTRIC CORP

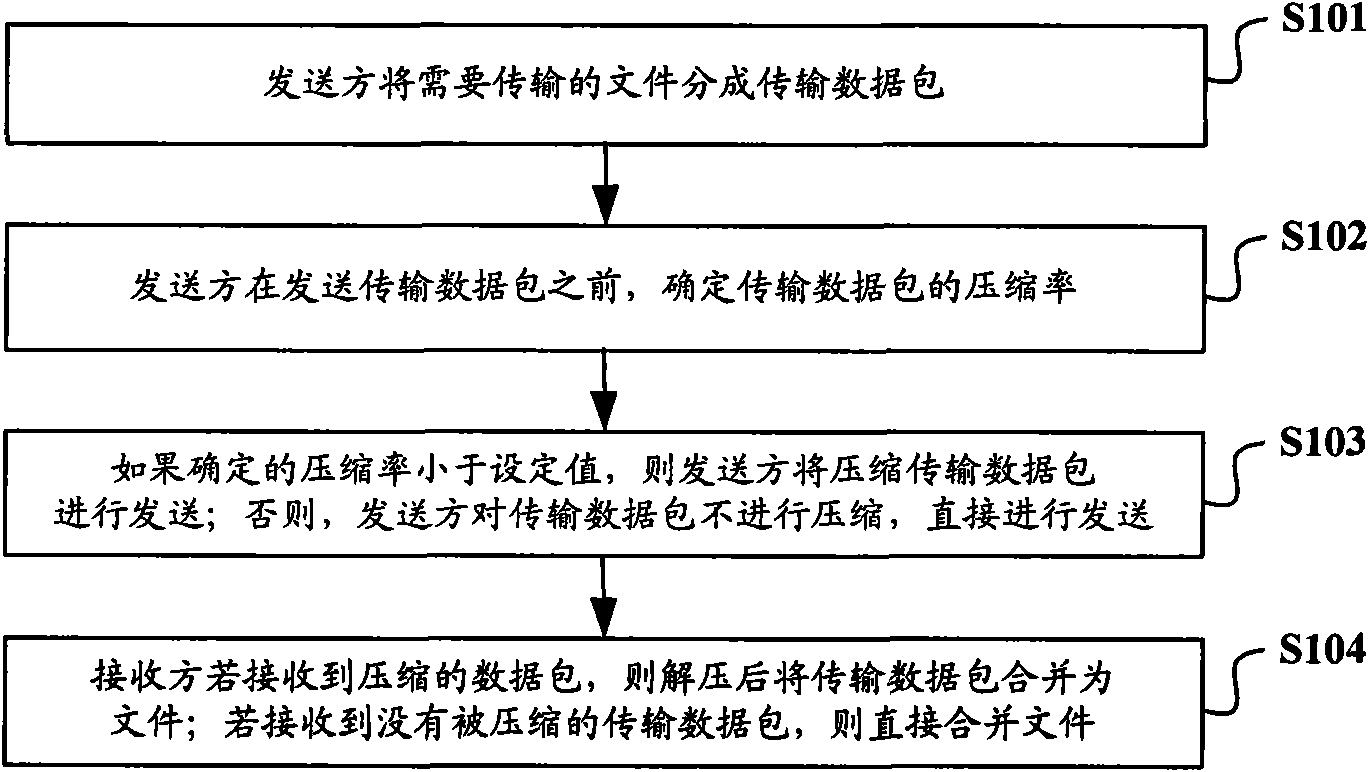

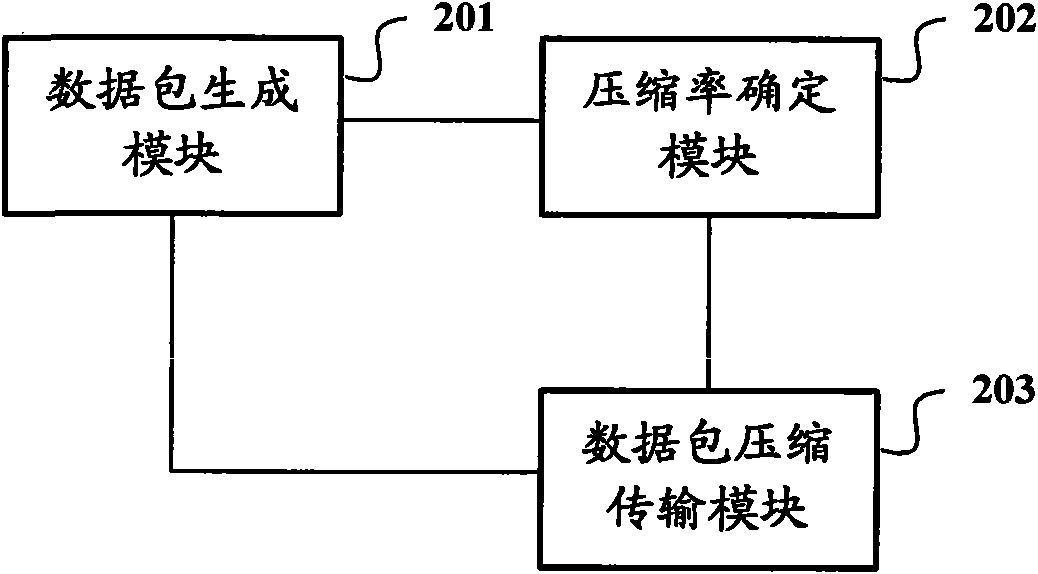

A document transmission method and transmission device

InactiveCN101552652AReduce transfer timeSave decompression timeError preventionCompressibilityComputer science

The present invention relates to data communications field, especially relates to a technology for improving transmission efficiency in document transmission process. The invention provides a document transmission device and a method thereof, including: dividing the document to be transmitted into set size packets, determining compressibility of the packets; if the compressibility is less than a set value, then compressing the packet and transmitting; otherwise, transmitting the packet directly. Judging compressibility of the packet before transmission. If the compressibility is determined as low then compressing the packet and transmitting the packet, this moment, the data to be transmitter is compressed greatly and the transmission time is reduced; if the compressibility is determined as high, then transmitting the packet without compression so as to reduce a compression time of senders and a decompression time of receivers which improving transmission efficiency on the whole.

Owner:BEIJING JIAODA SIYUAN SCI & TECH

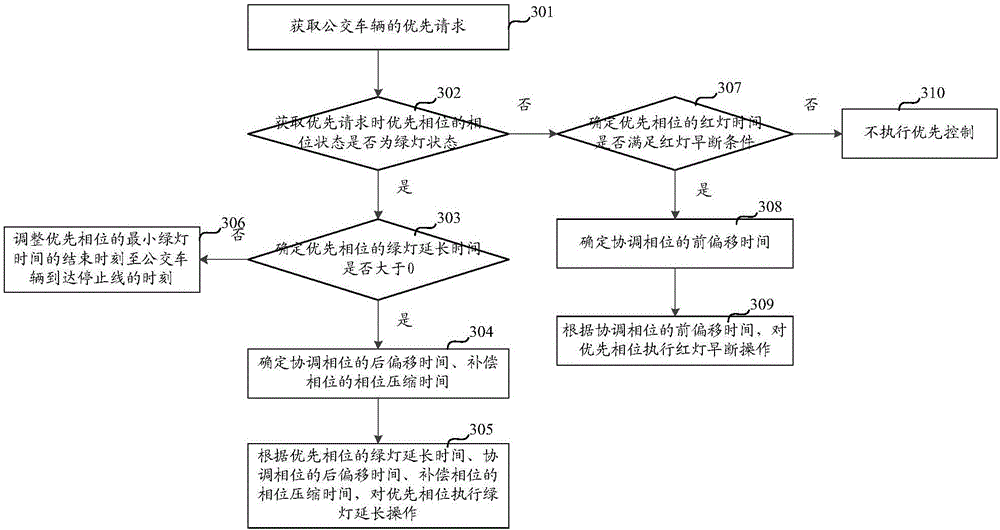

Public transport priority control method and device

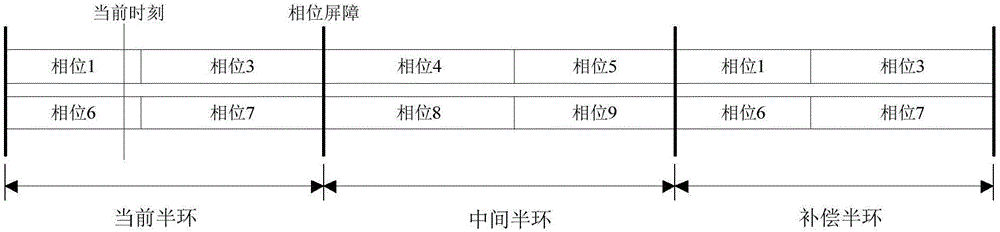

The invention discloses a public transport priority control method and device, and the method comprises the steps: obtaining a priority request of a bus; carrying out the green-light prolonging operation for a priority phase according to the green-light prolonging time of the priority phase, the rear offset time of a coordination phase and phase compression time of a compensation phase when the green-light prolonging time of the priority phase is greater than zero if the phase state of the priority phase is a green-light state; and carrying out the red-light early breaking operation for the priority phase according to the front offset time of the coordination phase when the red-light time of the priority phase is determined to meet an early breaking condition if the phase state of the priority phase is a red-light state. Because the front and rear offset time of the coordination phase is considered during the execution of the green-light prolonging operation or the red-light early breaking operation, the method can improve the public transport priority level on the basis that a green wave effect is not affected. Meanwhile, the method reduces the loss of non-priority phase time through the time compensation of the priority phase, and can effectively reduce the impact on the passing of social vehicles from the public transport priority control.

Owner:QINGDAO HISENSE TRANS TECH

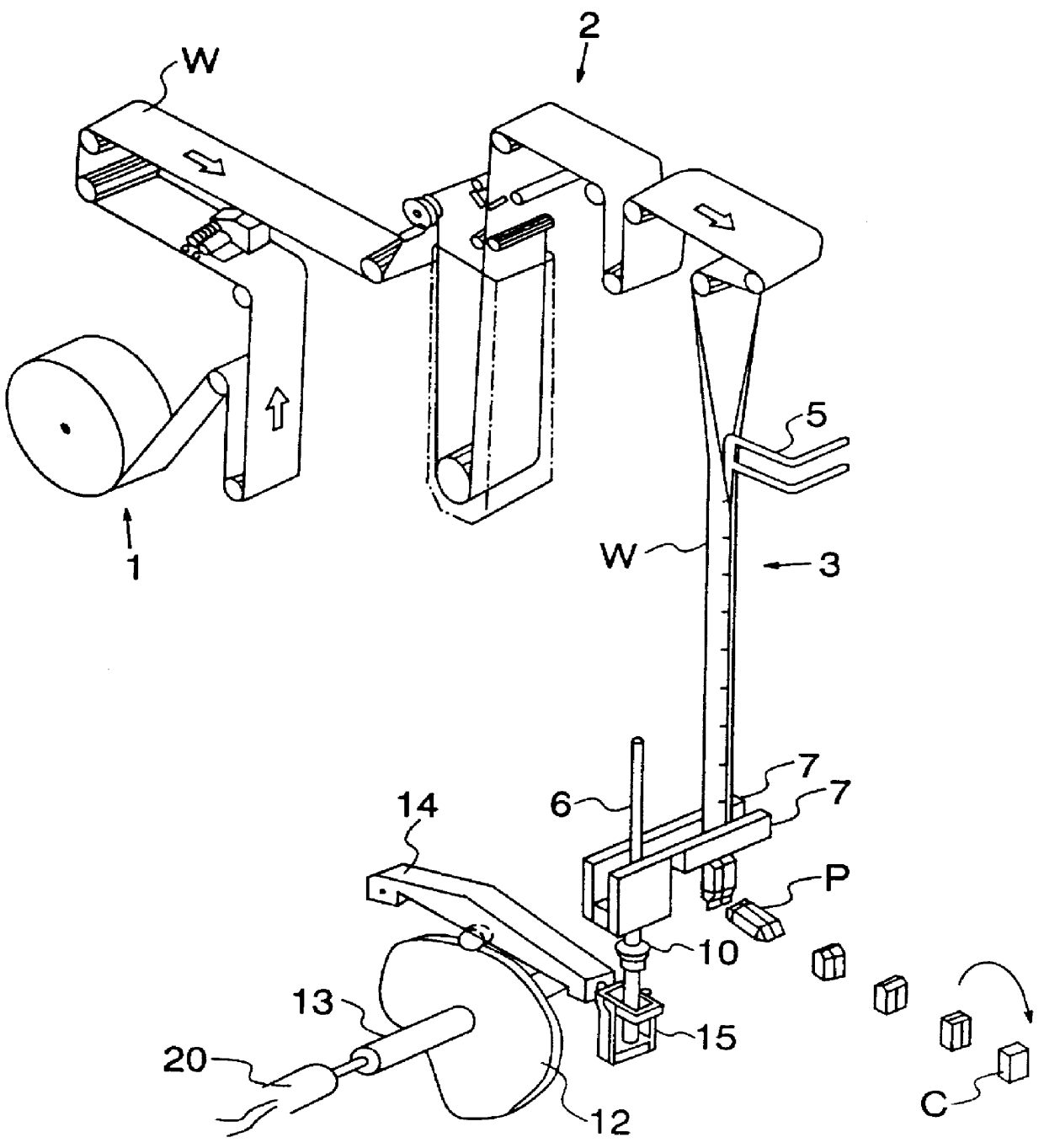

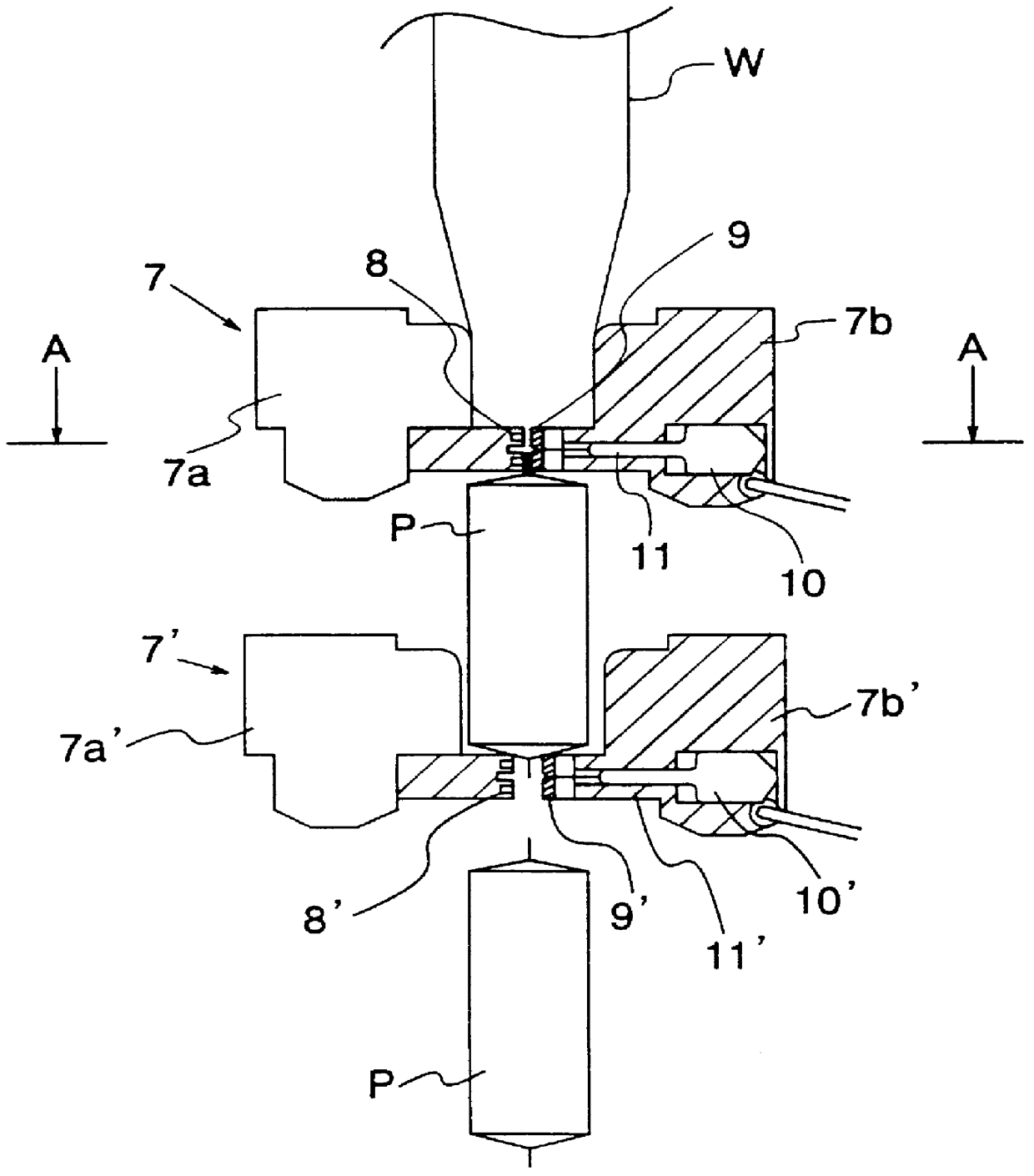

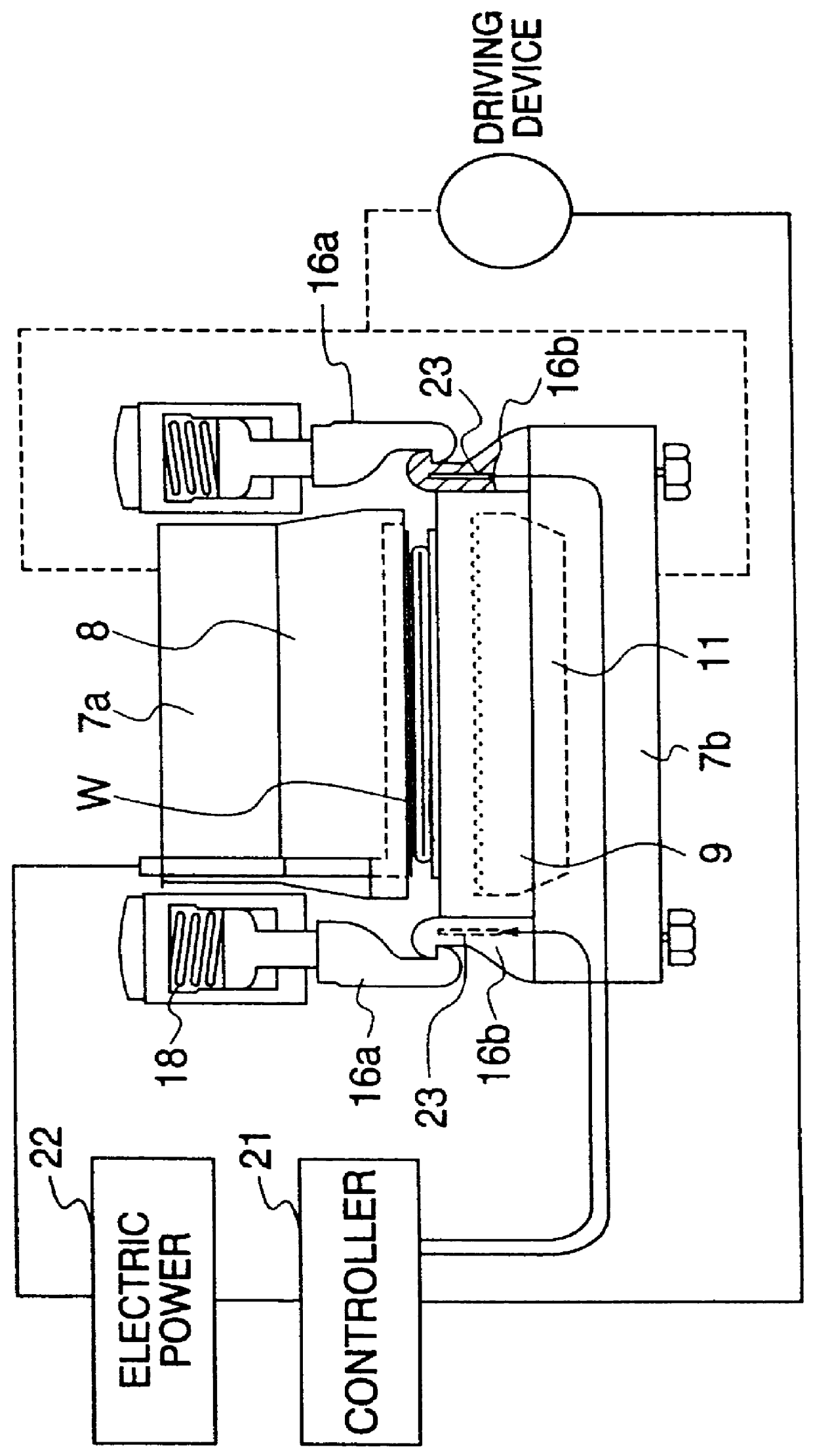

Web sealing method and device, and packaging container producing method and packaging container producing equipment

Featured is a web sealing device for controlling the sealing pressure so as to carry out a sufficient sealing while monitoring the sealing pressure directly acting on the web. Also featured is a packaging container producing equipment using the aforementioned sealing device and a packaging container producing method using the same. When sealing a part of web W by engaging hooks 16a, 16b, which directly give a sealing pressure to the web W in order to seal a part of both web N by heating and melting both side surfaces of a double web while pressing the same, the strain amount of the hooks 16a, 16b is measured by a strain gauge 23. and the aforementioned sealing pressure is controlled by the controller 21 so that the waveform of the data, in which the values obtained by converting the aforementioned measured strain amount to pressure are continuously recorded in line with the elapse of time, becomes nearly identical to that of the master data, reflecting on the compressing time by the hooks 16a, 16b, compression timing, and the pressing force of the cylinder 18 for actuation of the hooks, and the adjustment of the drive amount of the drive device for the cross sealing of a pair of sealing jaws 7a, 7b.

Owner:SHIKOKU KAKOOKI CO LTD

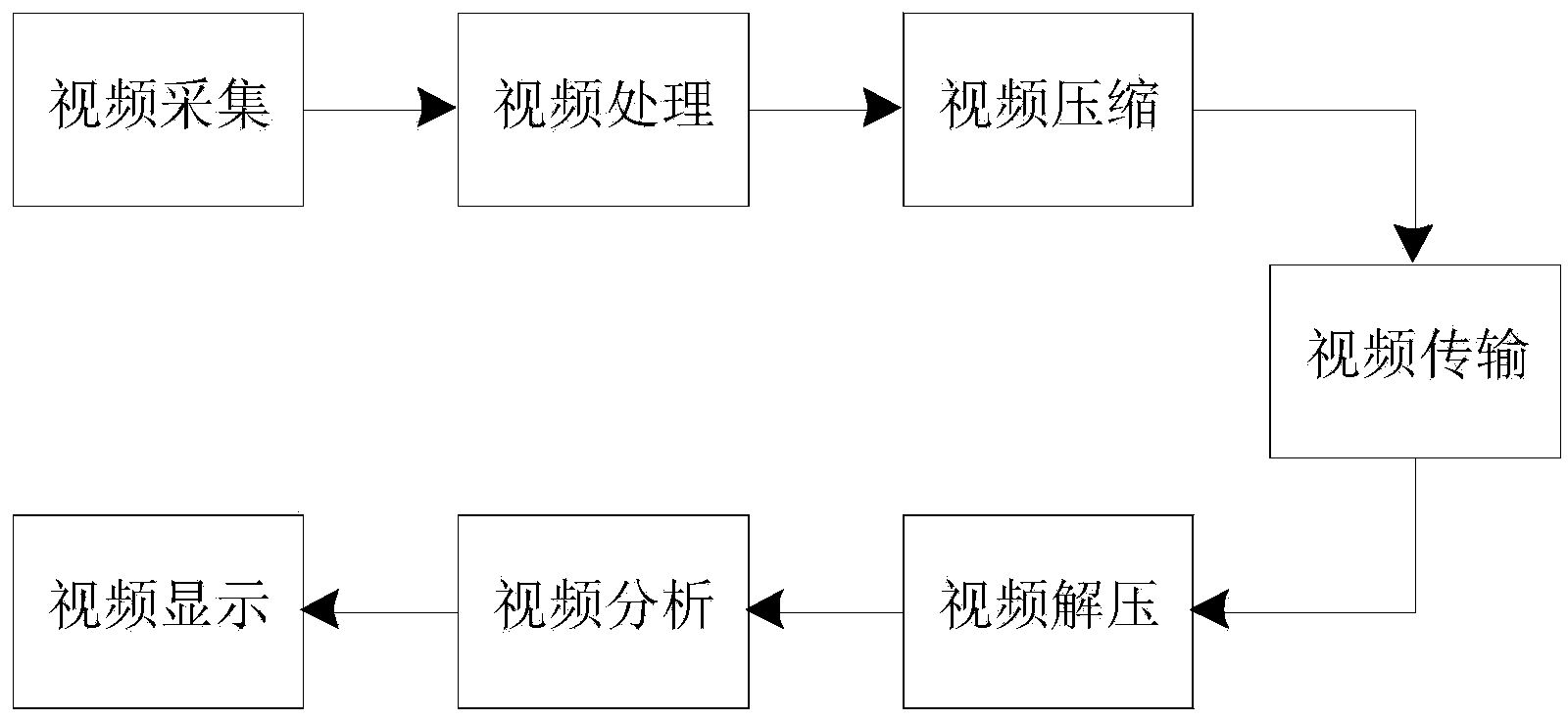

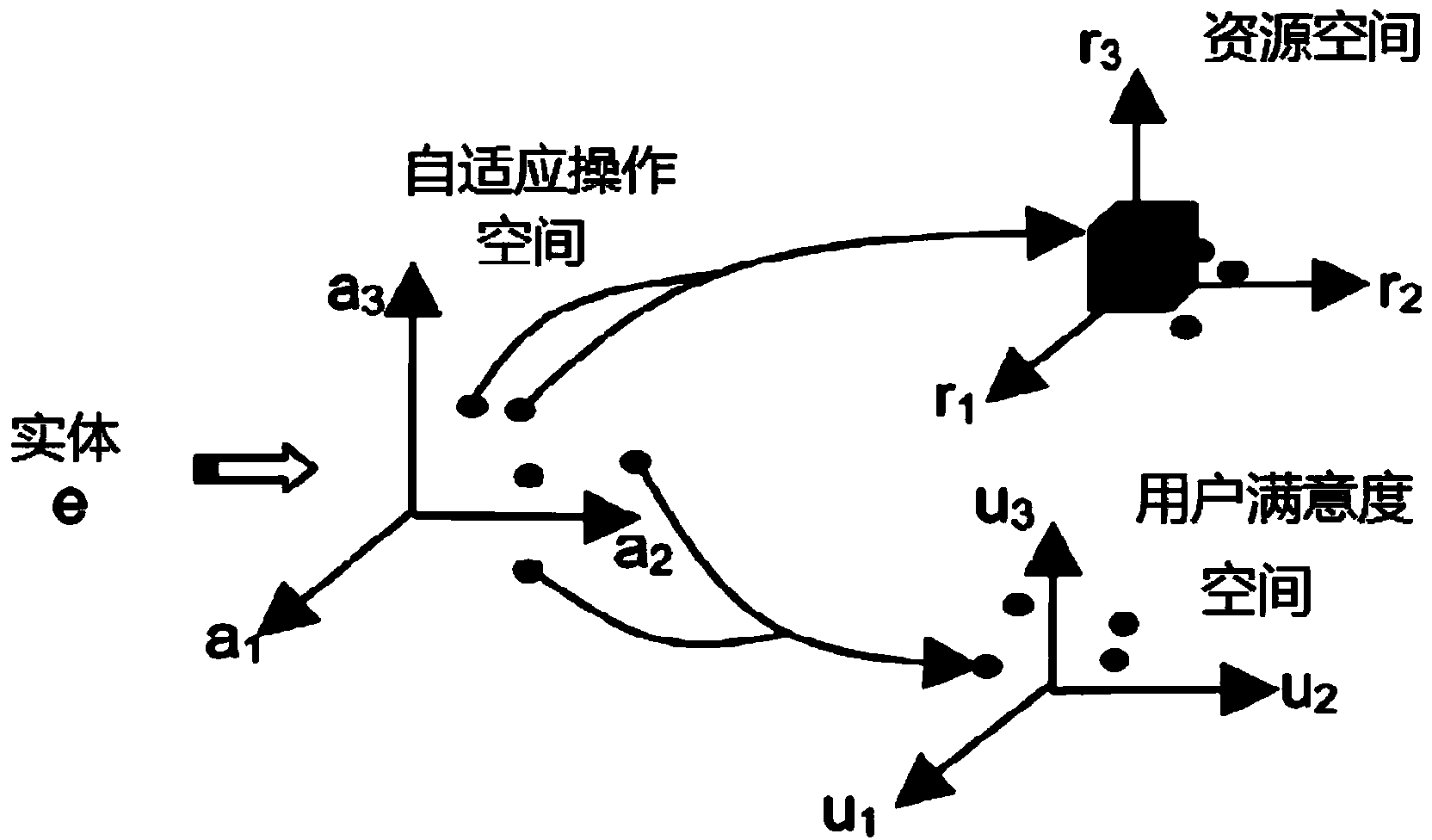

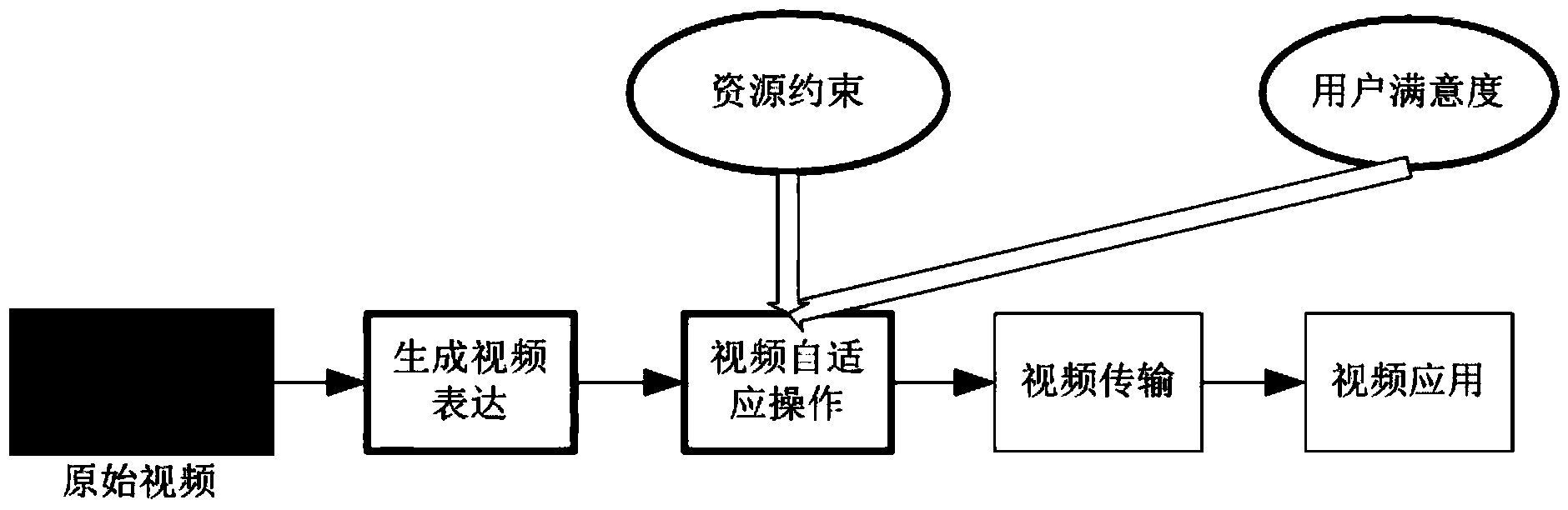

Layered representation-based unmanned plane video adaptive transmission method

ActiveCN104349142AImprove compression efficiencyFlexible organizationClosed circuit television systemsDigital video signal modificationComputer graphics (images)Video sequence

The invention discloses a layered representation-based unmanned plane video adaptive transmission method. A device for realizing the method comprises a layered structure for video representation, wherein the layered structure sequentially comprises a background layer, an object layer and an enhancement layer from bottom to top. According to different requirements, a corresponding layered structure is selected to transmit a video, and the problem that the movement of an independent moving object in the video is vague and cannot be recognized after the independent moving object is compressed is solved by dividing the moving object. A clear panoramic picture can be provided, or a video sequence with relatively high quality can be provided. The output precision is improved, the compression time is greatly shortened, and the working efficiency is improved to a great extent.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

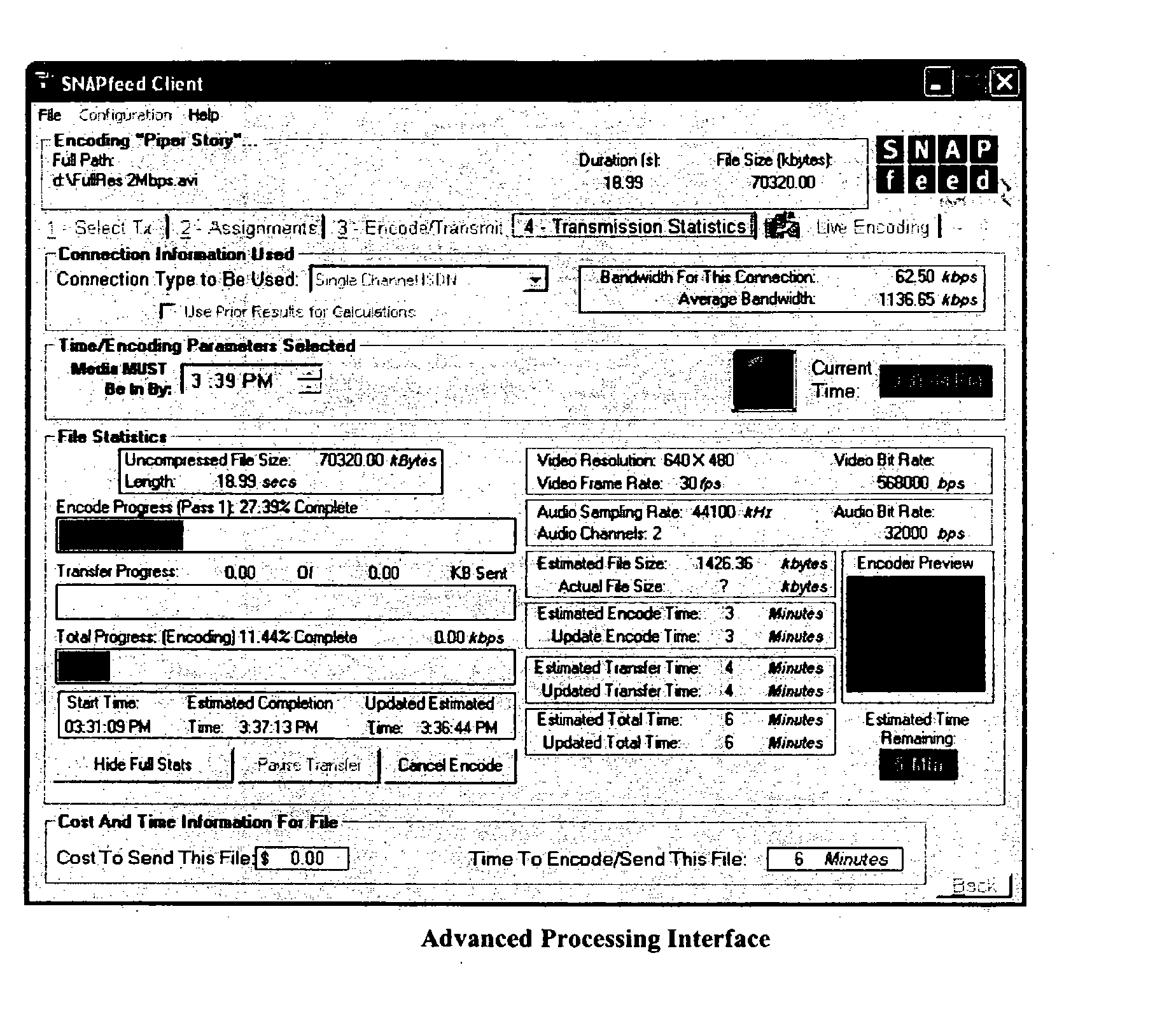

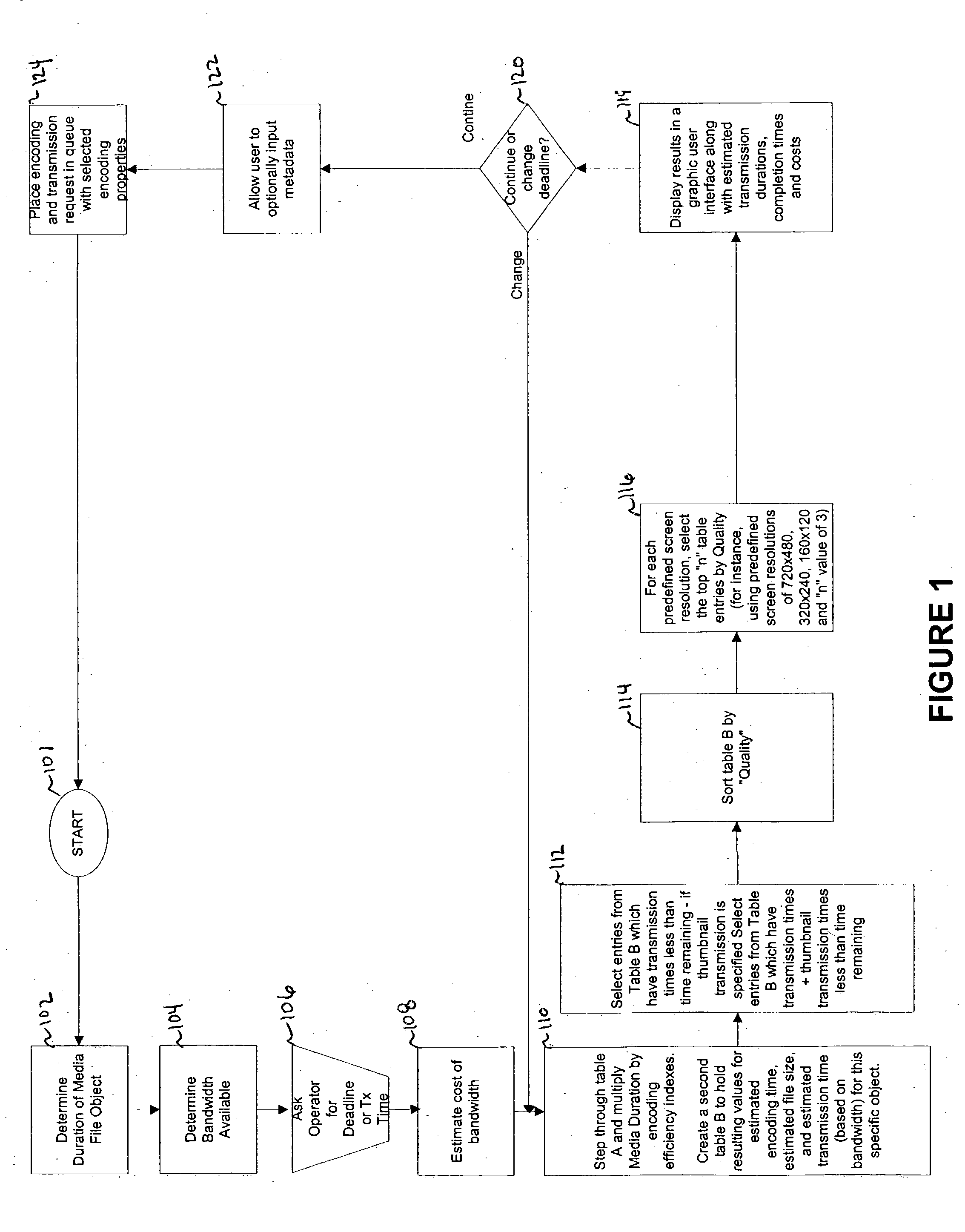

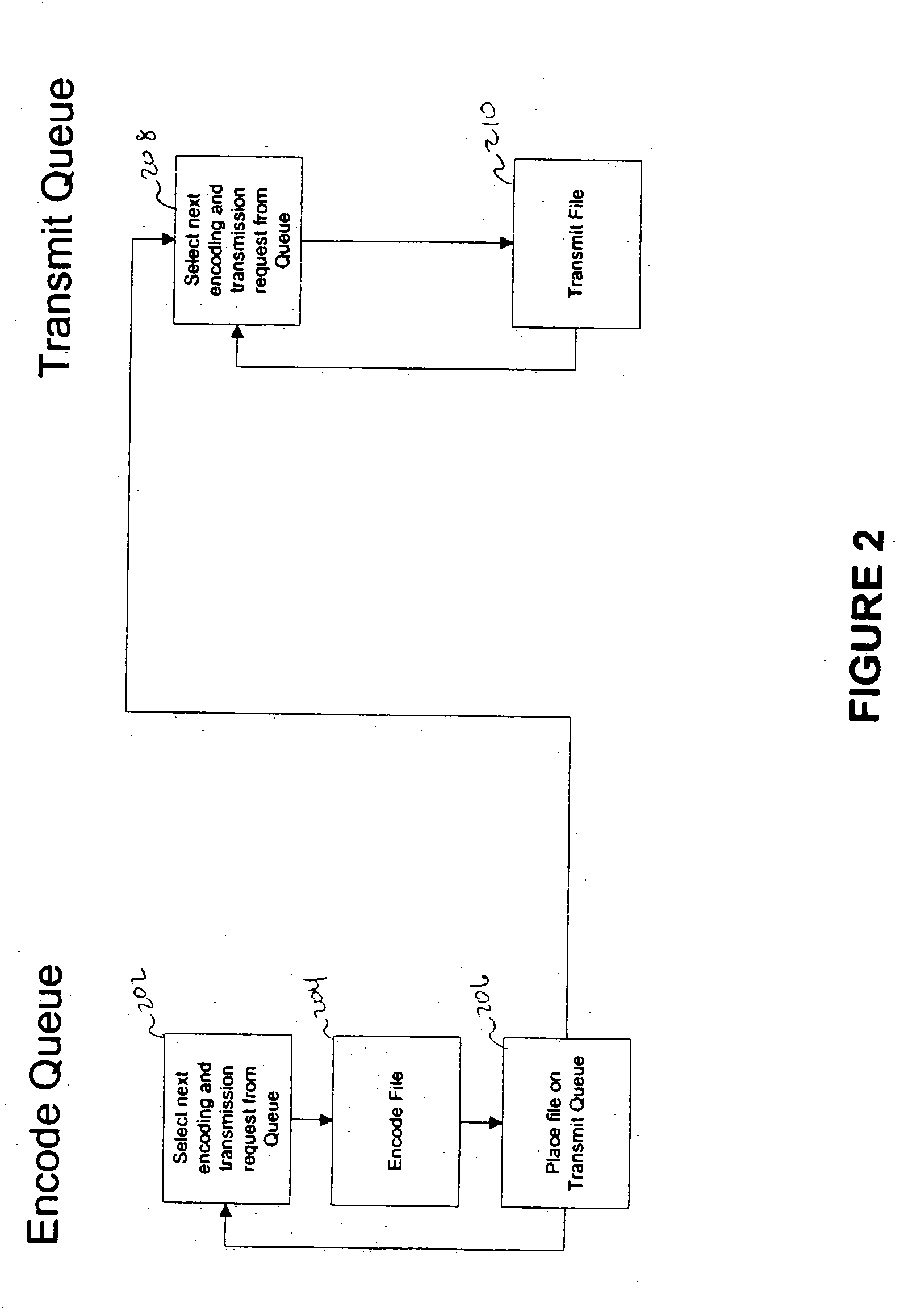

Automatic selection of encoding parameters for transmission of media objects

ActiveUS20040210930A1Better presentInappropriate qualityTelevision system detailsColor television detailsComputer scienceCompression time

A system, method and computer program product for automatic selection of encoding parameters for transmission of media objects is provided. The method and computer program product involve the automatic selection of media encoding parameters based on editorial and technical contexts. Such contexts include time constraints, duration, size, quality, processing time and compression time. The media objects are then automatically encoded using these automatically selected parameters, and then transmitted from a remote site to one or more additional sites via a communications network.

Owner:THE ASSOCD PRESS

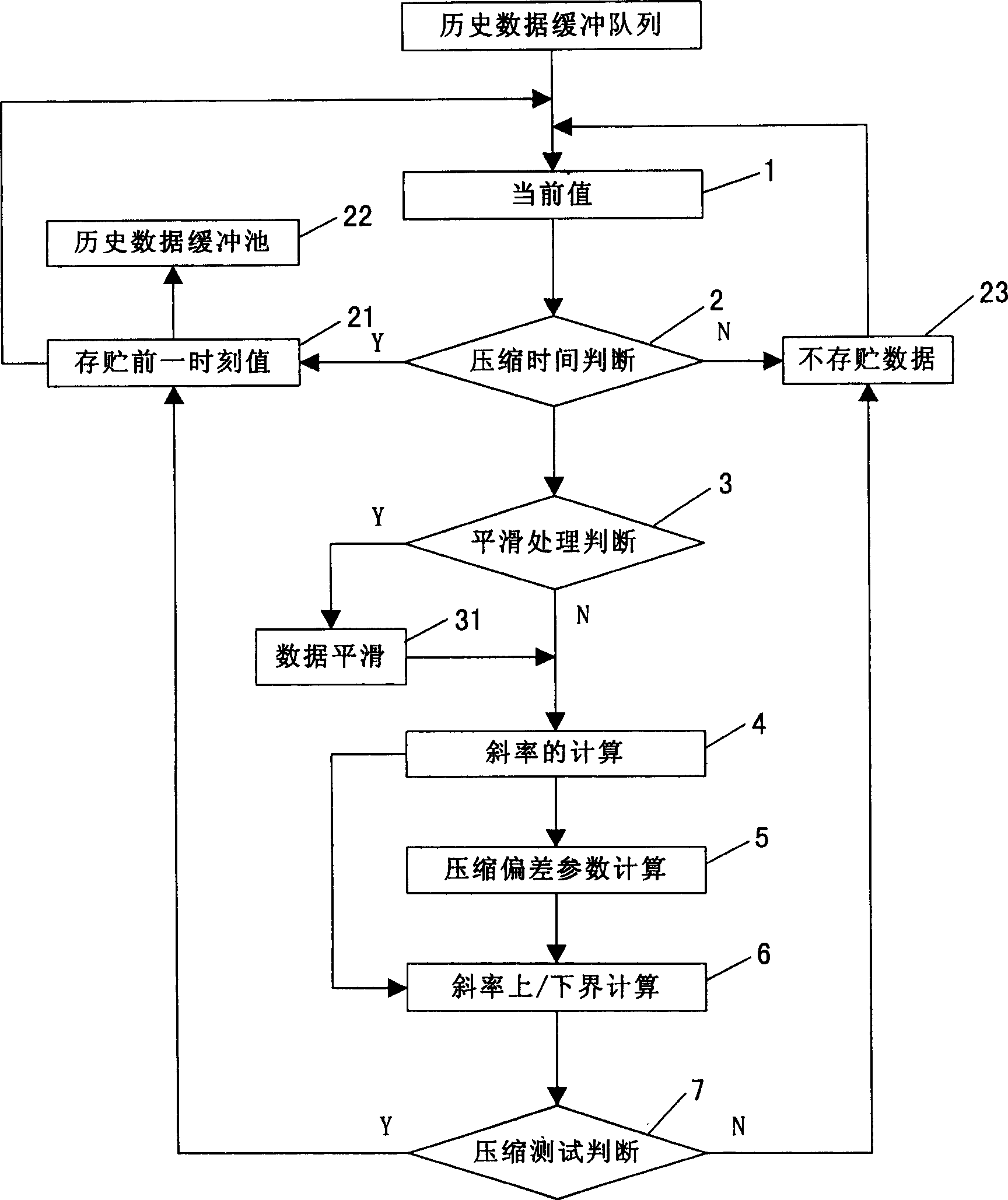

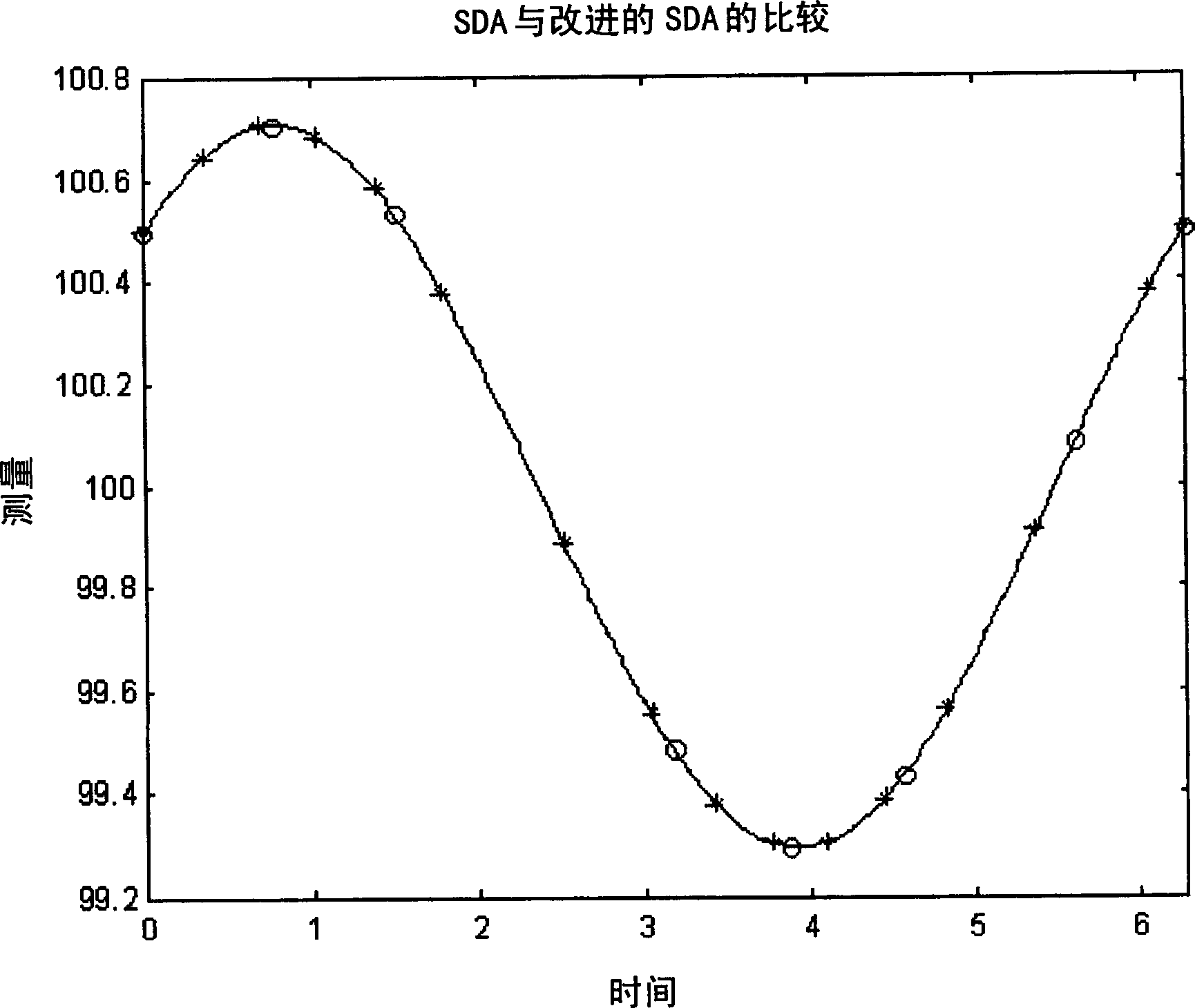

Self adapting history data compression method

InactiveCN1459743ASuppression of measurement noiseSpecial data processing applicationsData compressionLower limit

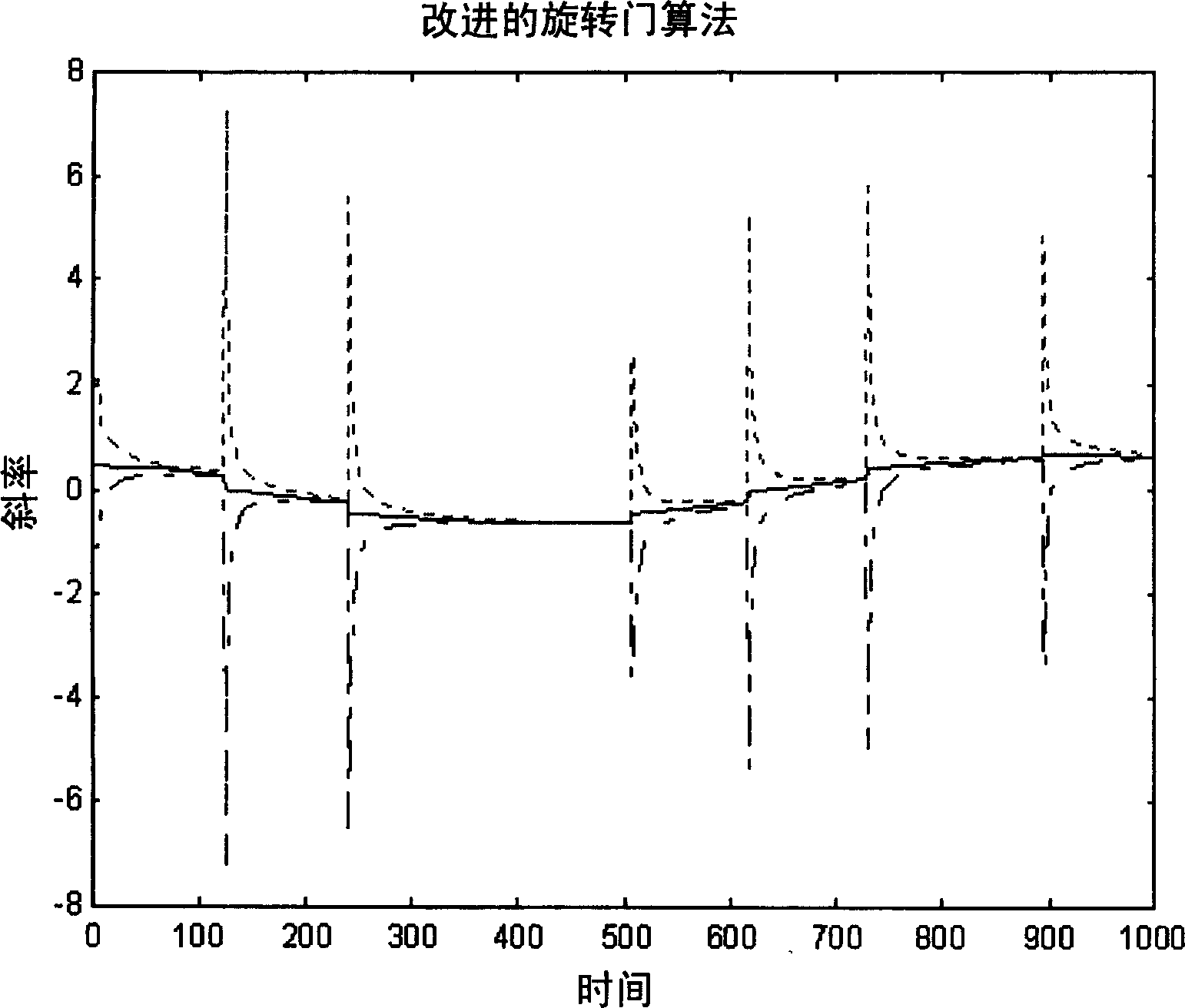

An adaptive history data compression method includes such steps as judging if the time when current measured value is measured is in the compression time range, storing the preceding value of current value as the beginning point of next data compression test and new preceding stored point if the time difference of current time is to longer, calculating the slope of current value and current maximal and minimal slopes, adaptively dynamic calculation of compression deviation parameter, calculating the upper and lower limits of current value's slope, compression test of current value, and storing the preceding value of current value.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

Methods for Soft Bit Companding for Time De-interleaving of Digital Signals

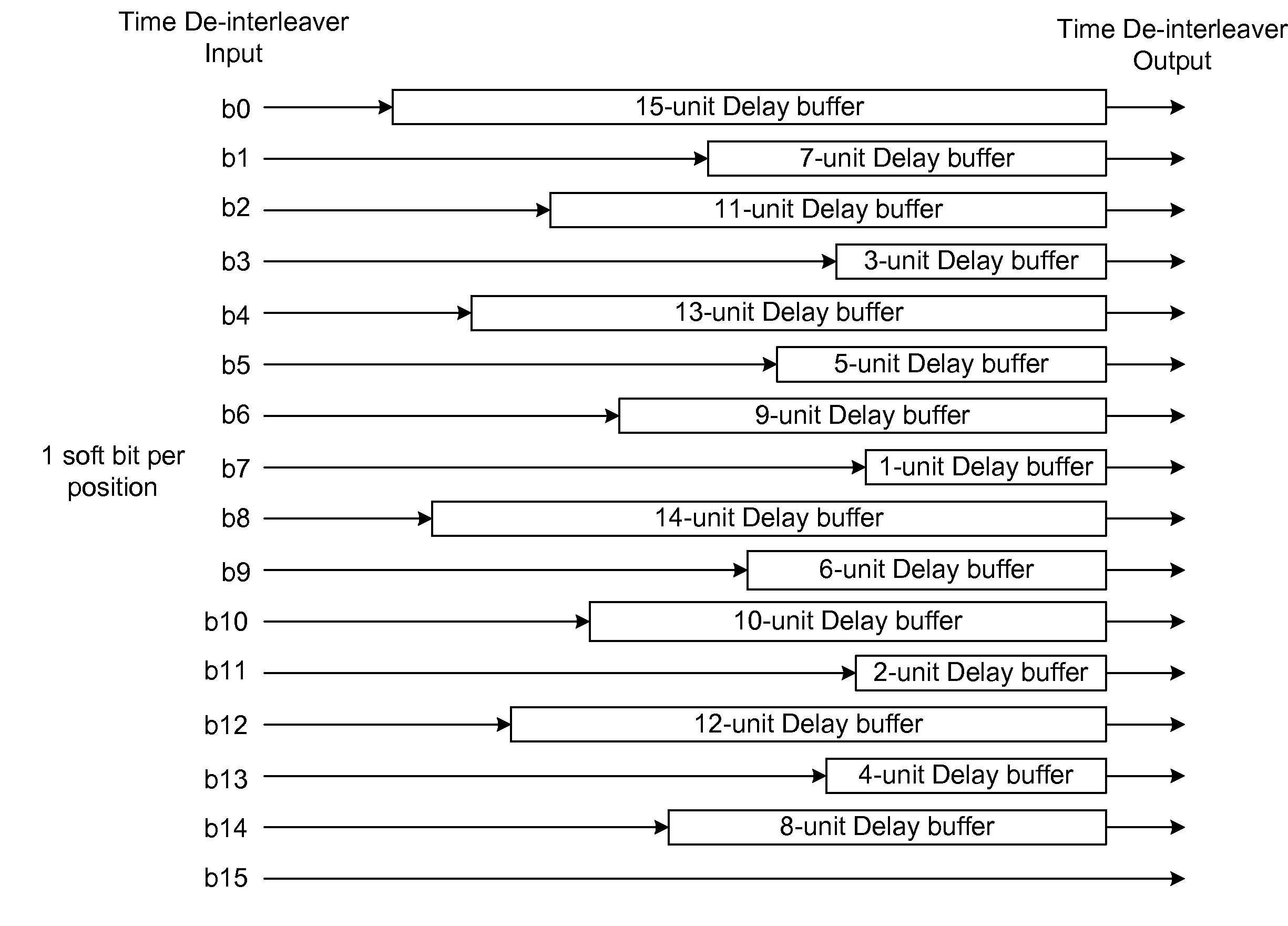

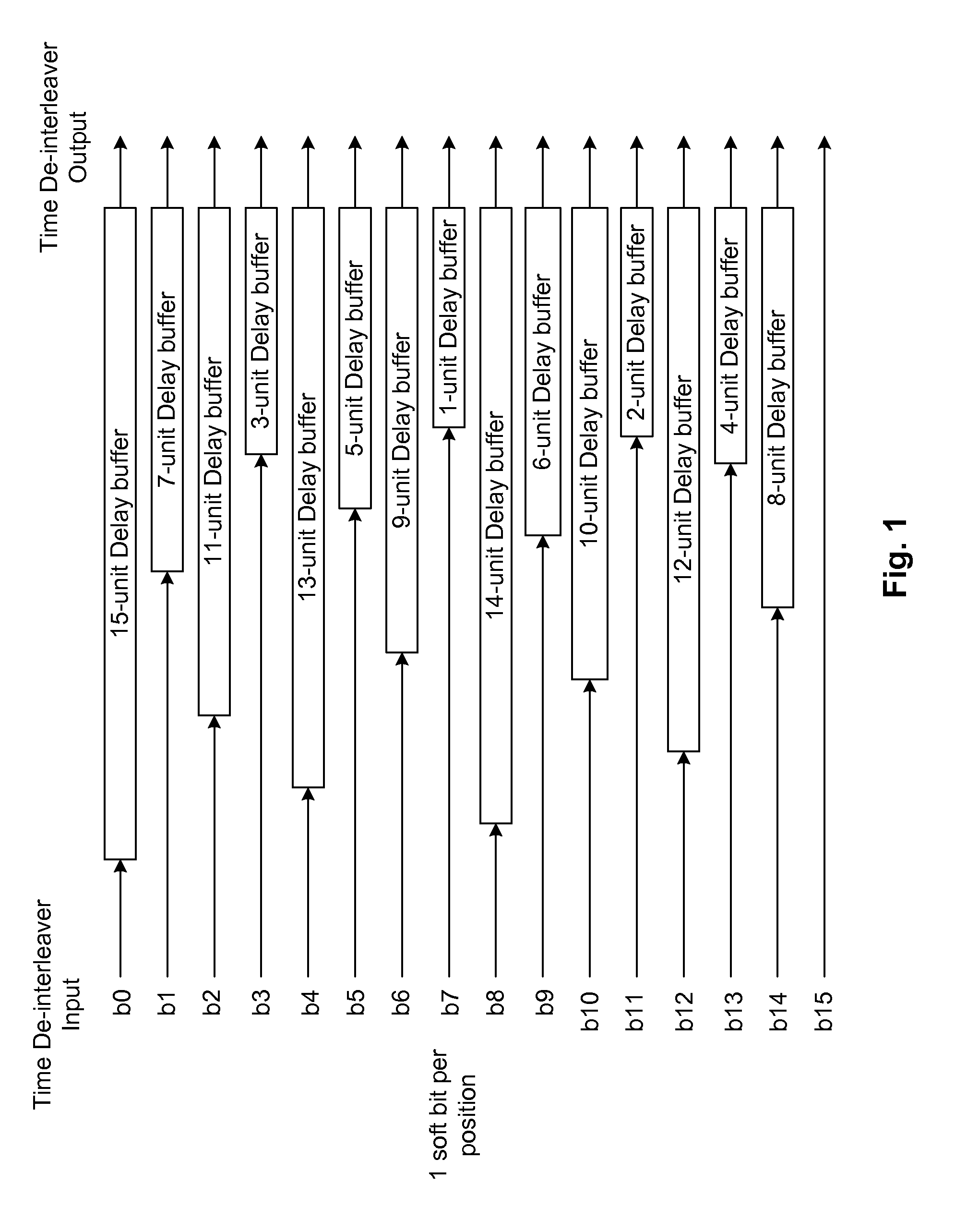

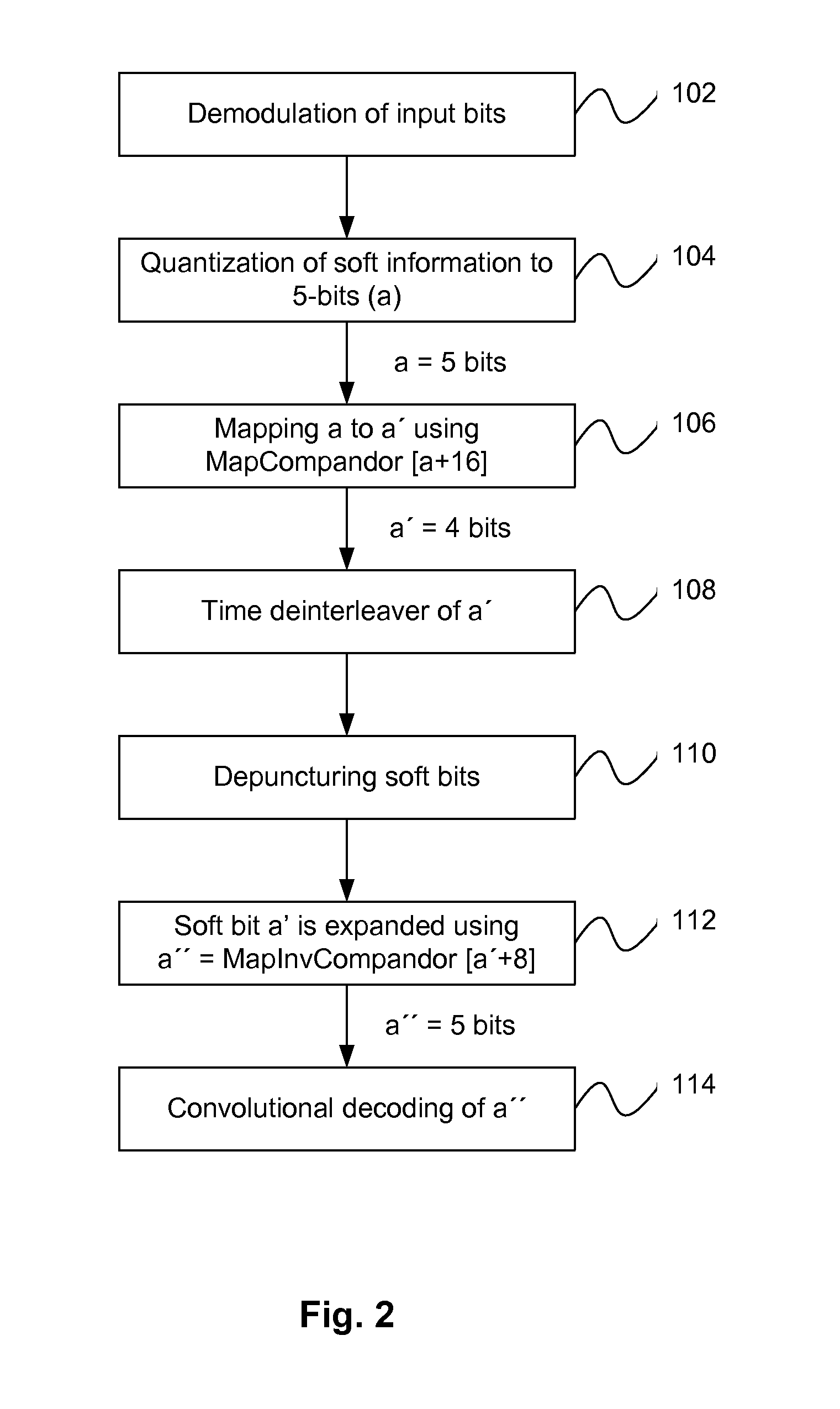

InactiveUS20090103601A1Small bit widthImprove dynamic rangeTransmission path divisionCode conversionSoft informationCompression time

This invention provides methods for reducing the bit width of soft information, while maintaining a large dynamic range by applying compression and expansion. In particular, this invention provides methods for time de-interleaving of soft information, comprising the steps of: quantizing the soft information into a first soft information having a first pre-defined number of bits; compressing the first soft information into a second soft information having a second pre-defined number of bits; time de-interleaving the second soft information; and decompressing the time de-interleaved second soft information.

Owner:AUGUSTA TECHNOLOGIE

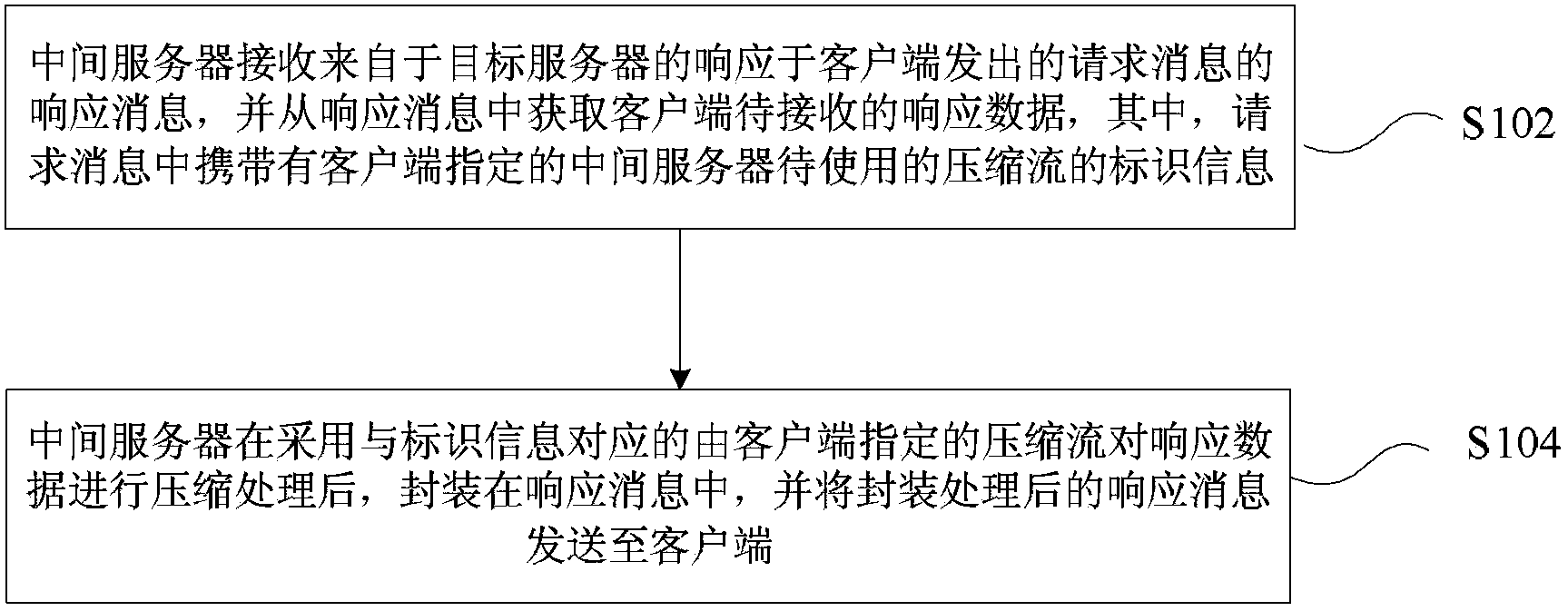

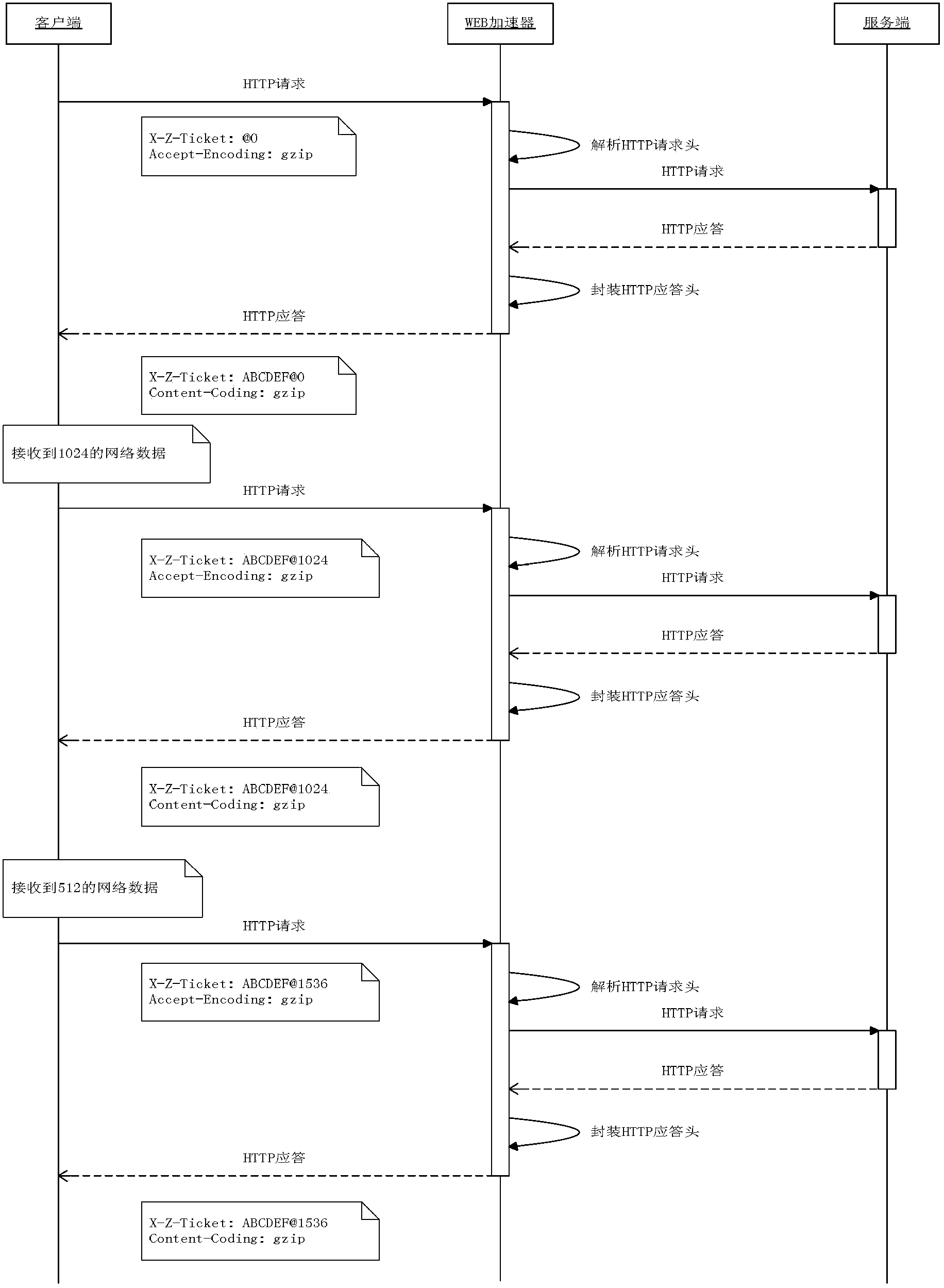

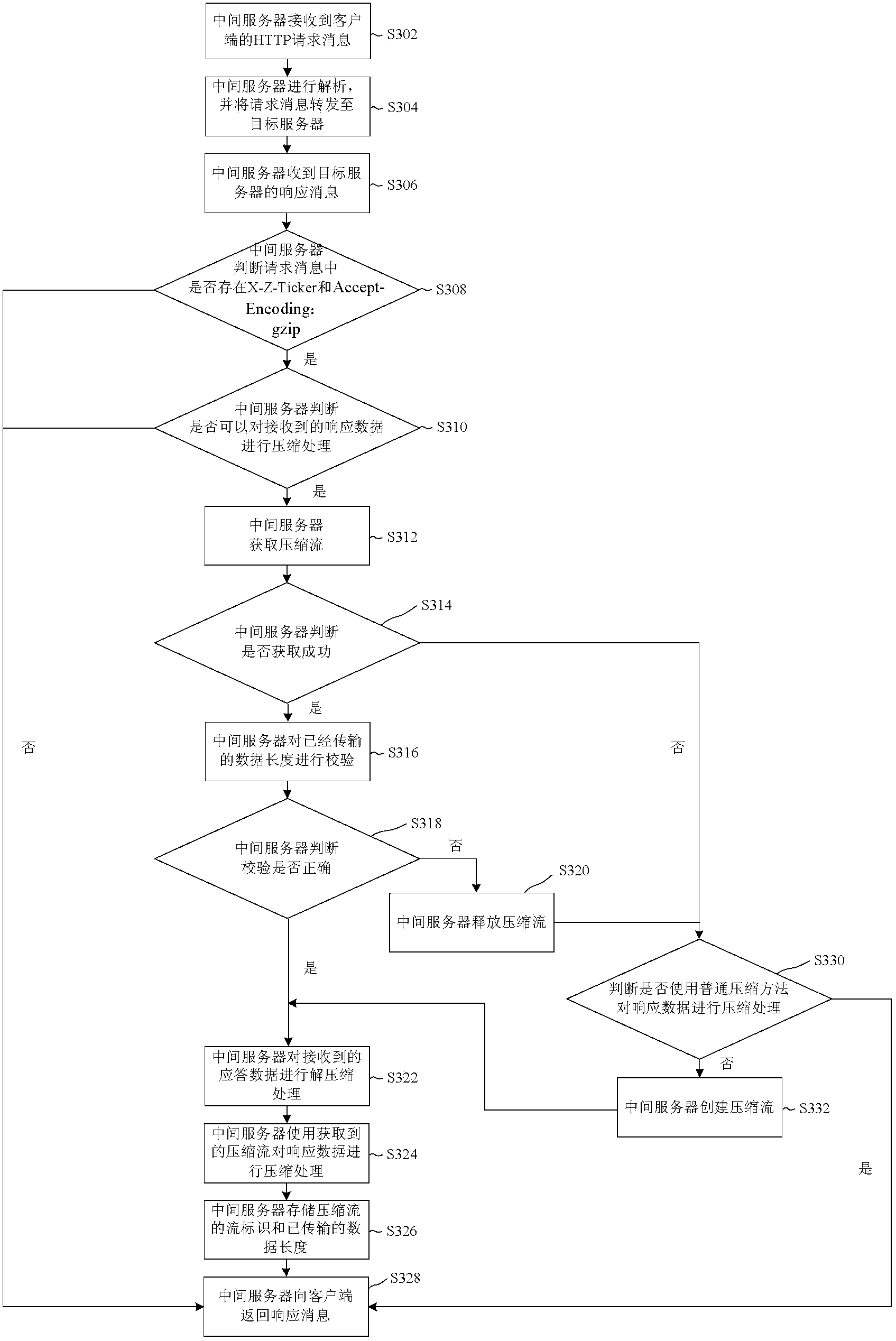

Data compression processing method, system and device

ActiveCN103581130AImprove access speedSolve the problem of low compression efficiencyError preventionTraffic capacityData compression

The invention discloses a data compression processing method, system and device. In the method, a middle server receives a response message, responding to a request message sent from a client terminal, sent from a target server and obtains response data to be received by the client terminal from the response message, wherein the request message carries identification message, appointed by the client terminal, of compressive flow to be used by the middle server; the middle server carries out compression processing on the response data through the compression flow, corresponding to identification message, appointed by the client terminal and seals the response data in the response message, and transmits the response message after the sealing processing to the client terminal. According to the technical scheme, compression rate of network data is improved, compression time of the network data is reduced, access speed of the client terminal is accelerated, and network flow is saved.

Owner:ALIBABA (CHINA) CO LTD

Production method of modified wood, bamboo glued mould

InactiveCN101450493ASimplify and save the secondary veneer lamination processSave resourcesOther plywood/veneer working apparatusWood treatment detailsMoistureMaterials science

The invention discloses a method for manufacturing modified plywood formwork of wood or bamboo wood. The method is implemented by the following steps: small-diameter cotton-wood, China fir or small-diameter mixed bamboo instead of large-diameter high-quality wood and large-diameter moso bamboo are taken as raw materials to process into wood wool and bamboo filaments; soluble phenolic resin with a solid content of 20 to 30 percent is used as a modifier of the material; the phenolic resin is impregnated in the fiber cell lumens of the material by a pressure impregnation method to change the moisture expansion property of the material; the wood wool or the bamboo filaments containing less than or equal to 15 percent of water is used as assembly materials; modified and dried wood wool or bamboo filaments and paper impregnated with phenolic resin are used as assembly materials for plywood, and an assembly structure is a three-layer composite structure; main parameters of thermo-compression and bonding include: a unit pressure of 40 to 50 kg / cm<2>, a bonding temperature of 150 + / -10 DEG C, thermo-compression time of one minute for each millimeter of the thickness of board; the board is unloaded when cooled to less than or equal to 50 DEG C after thermo-compression and bonding and is subjected to edge cutting to be processed to the plywood; and after the worn surface finish of the plywood is restored through recoating by a secondary veneering method, the plywood is reused.

Owner:李茂林

Manufacturing method of cold plasma modified cellulolytic enzyme lignin/plant fiber composite material

ActiveCN101712179AHigh strengthImprove controllabilityWood working apparatusDomestic articlesFiberDry weight

The invention discloses a manufacturing method of a cold plasma modified cellulolytic enzyme lignin / plant fiber composite material. The manufacturing method comprises the following steps of: firstly dehydrating and drying the cellulolytic enzyme lignin to be with a moisture content of 6-10 percent; after processing the cellulolytic enzyme lignin into pulverulent bodies with grain diameters of 200-300 mesh by high-energy ball-milling, placing the pulverulent bodies into a sample chamber of cold plasma modified equipment; vacuumizing the sample chamber to 2-4 Pa; introducing oxygen or nitrogen; controlling a vacuum degree to be 10-30 Pa; starting a radio frequency power supply and adjusting treating power to 100-300 W; modifying the cellulolytic enzyme lignin for 30-150 s; uniformly mixing the modified cellulolytic enzyme lignin with the plant fiber, wherein the oven dry weight of the modified cellulolytic enzyme lignin accounts for 5-25 percent of the oven dry weight of the plant fiber; and spreading the mixed modified cellulolytic enzyme lignin and the plant fiber in a plate blank form for thermo-compression, wherein thermo-compression temperature is 160-210 DEG C, and thermo-compression pressure is 3.0-4.0 MPa, and thermo-compression time is 20-40 s / mm. The material contains no free formaldehyde, and can be widely applied to industries, such as architectural decoration, furniture manufacturing, packaging, children toy manufacturing, and the like.

Owner:NANJING FORESTRY UNIV

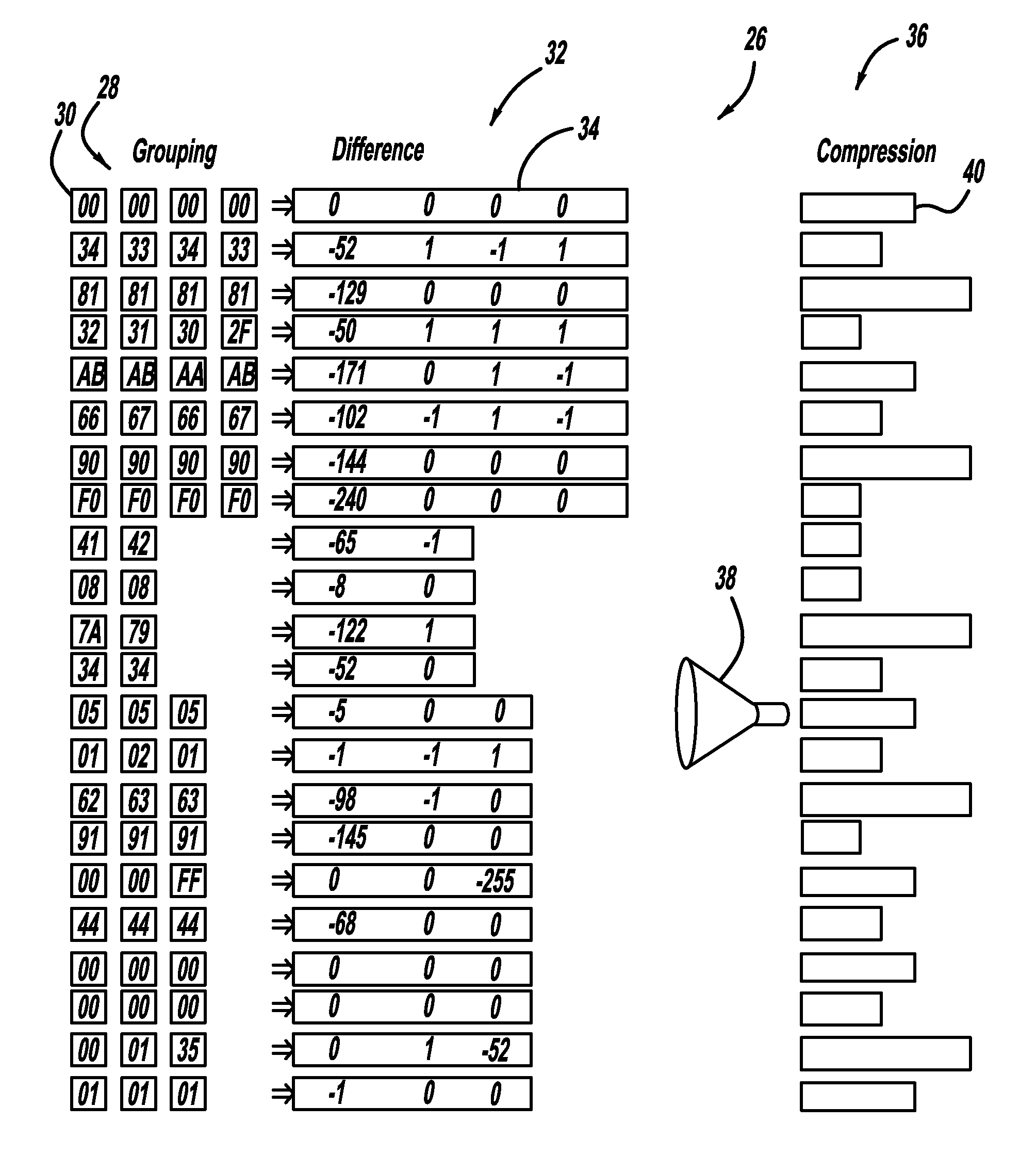

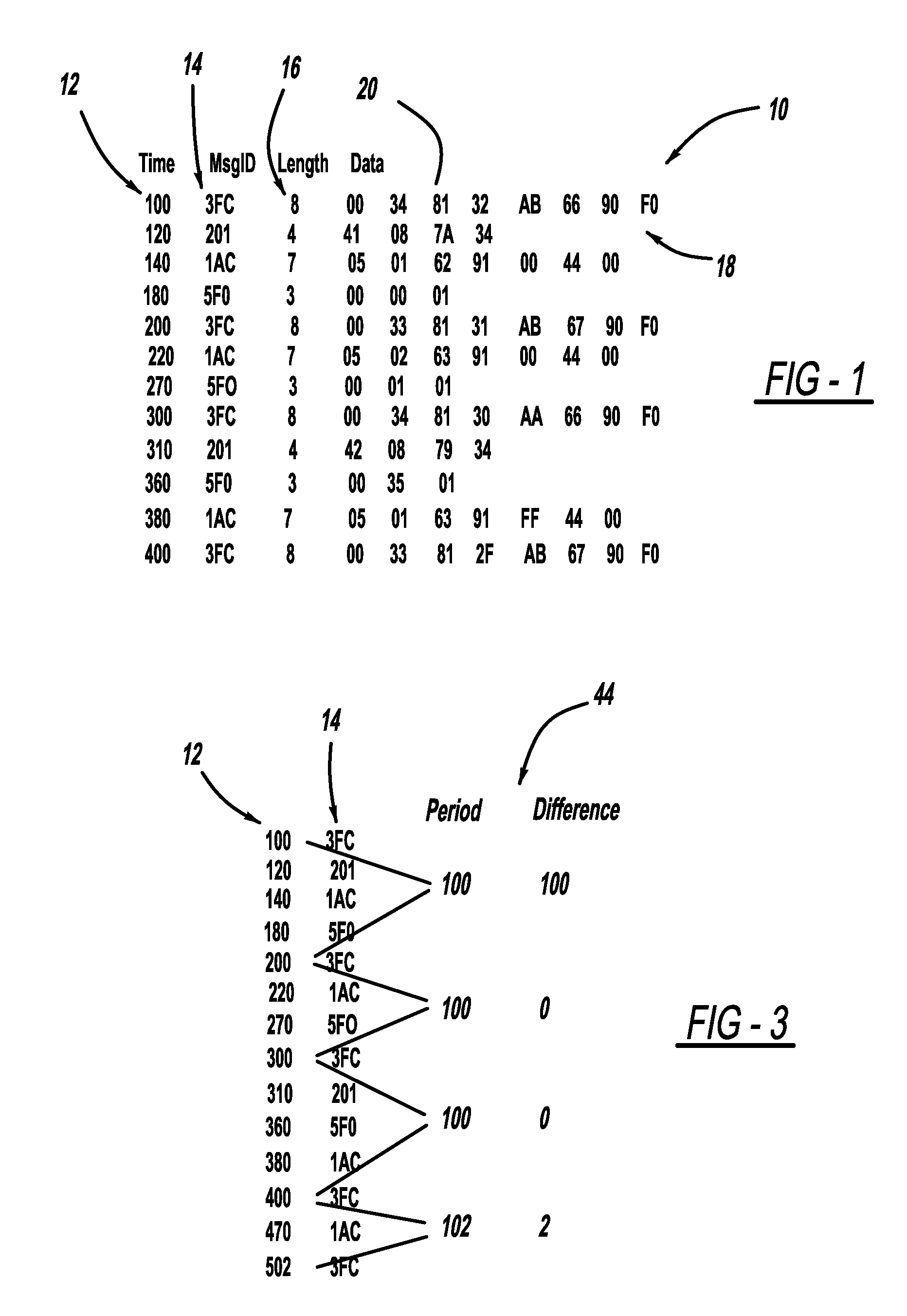

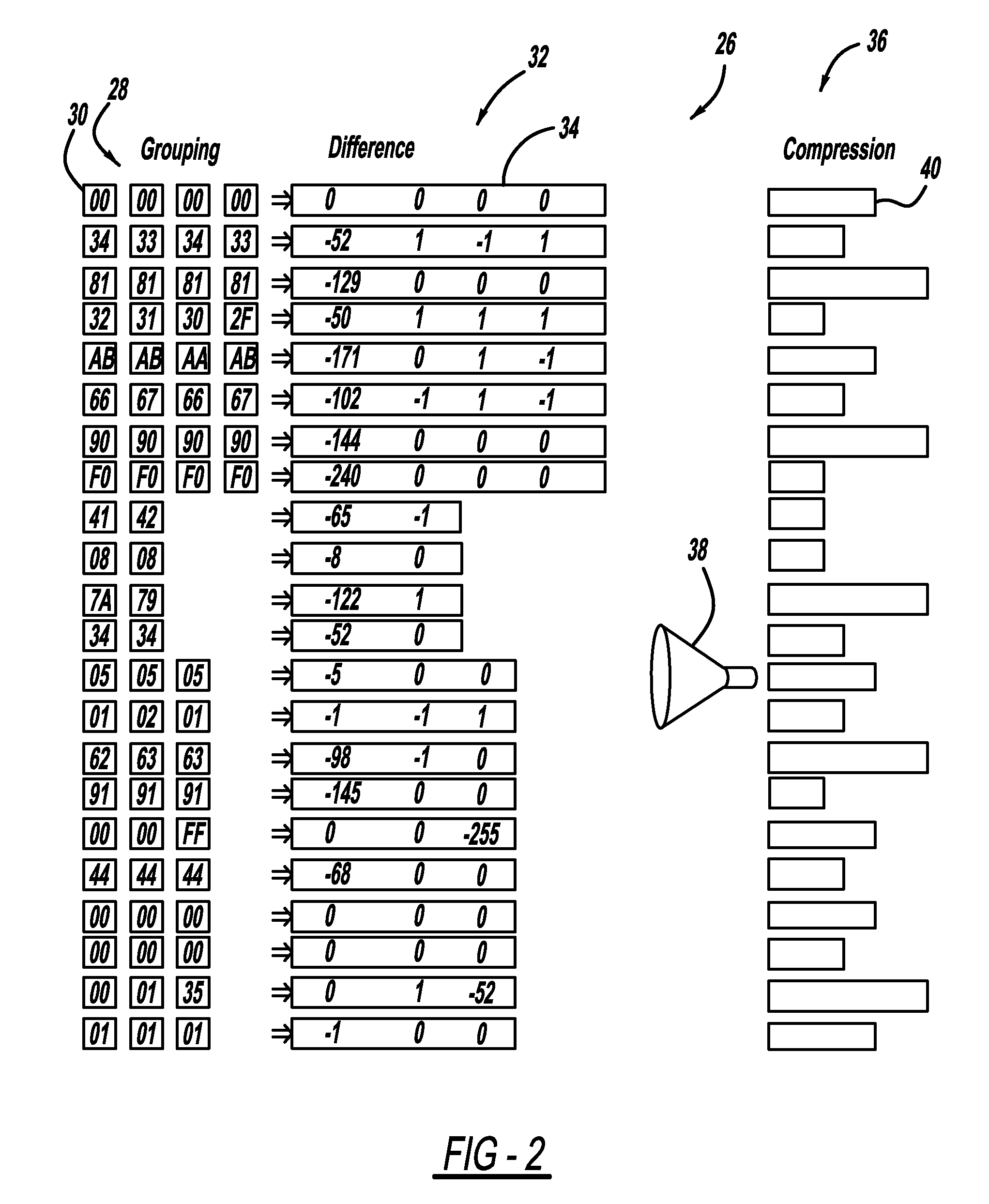

Method of efficient compression for measurement data

ActiveUS20090300039A1Code conversionMultiple digital computer combinationsSequential dataCompression method

A method for compressing measurement data that includes grouping common data elements in common data messages. Sequential data elements in the groups are subtracted from each other to provide difference values. The difference values are compressed using a suitable compression algorithm to provide compressed blocks of data. Time stamp periods associated with each common data message are also subtracted from each other to provide time stamp difference values. The time stamp difference values are also compressed to provide compressed time stamp blocks. The compressed blocks of data and time stamp blocks are then stored.

Owner:GM GLOBAL TECH OPERATIONS LLC

Time series data dimensional compression apparatus

InactiveUS7433527B2Vehicle testingNoise figure or signal-to-noise ratio measurementSingular value decompositionAlgorithm

A time series data dimensional compression apparatus performing dimensional compression for improving the efficiency of searching for time series data without losing the features of data. The compression is made to a determined dimension so that a larger volume of information may be extracted therein. A time series subsequence generating section (112) generates time series subsequences of a specified segment width into which a plurality of pieces of time series data generated at a time series data generating section (110) are divided. A singular value decomposition processing section (113) performs singular value decomposition on all of the time series subsequences. A dimensional compression time series data generating section (114) generates dimensional compression time series data by using high-order elements of the singular value decomposition as a representative value of the time series subsequence.

Owner:MITSUBISHI ELECTRIC CORP

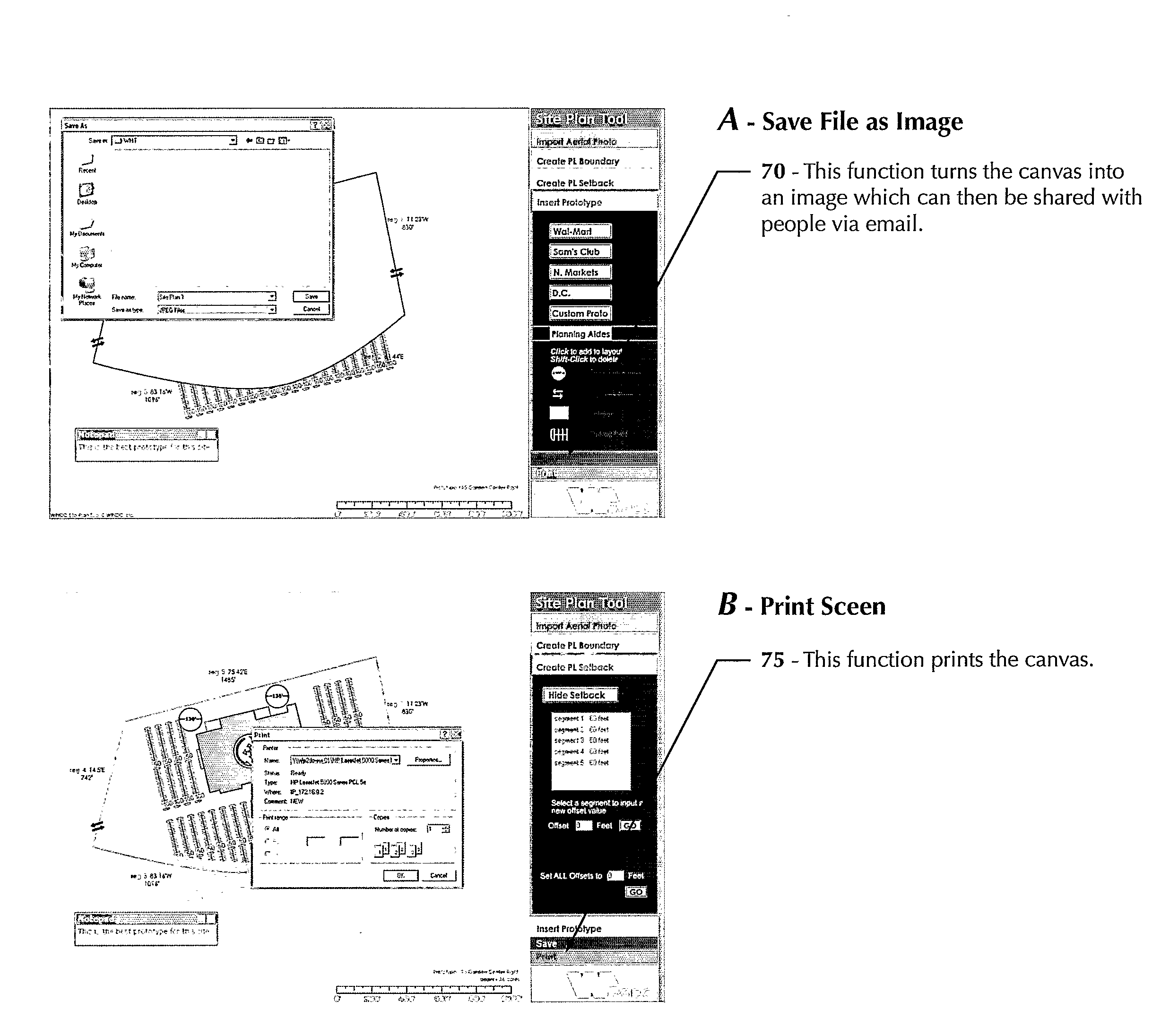

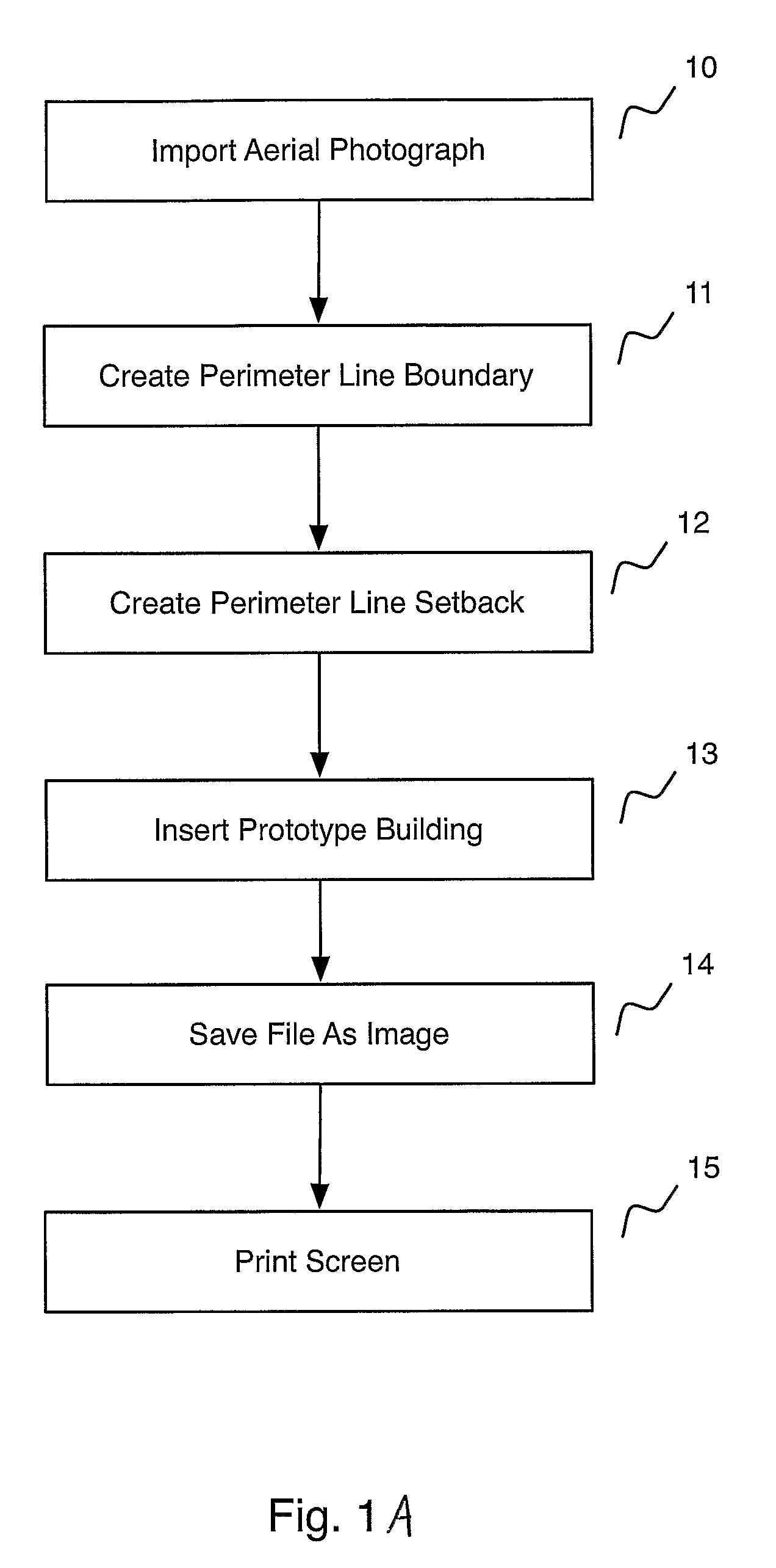

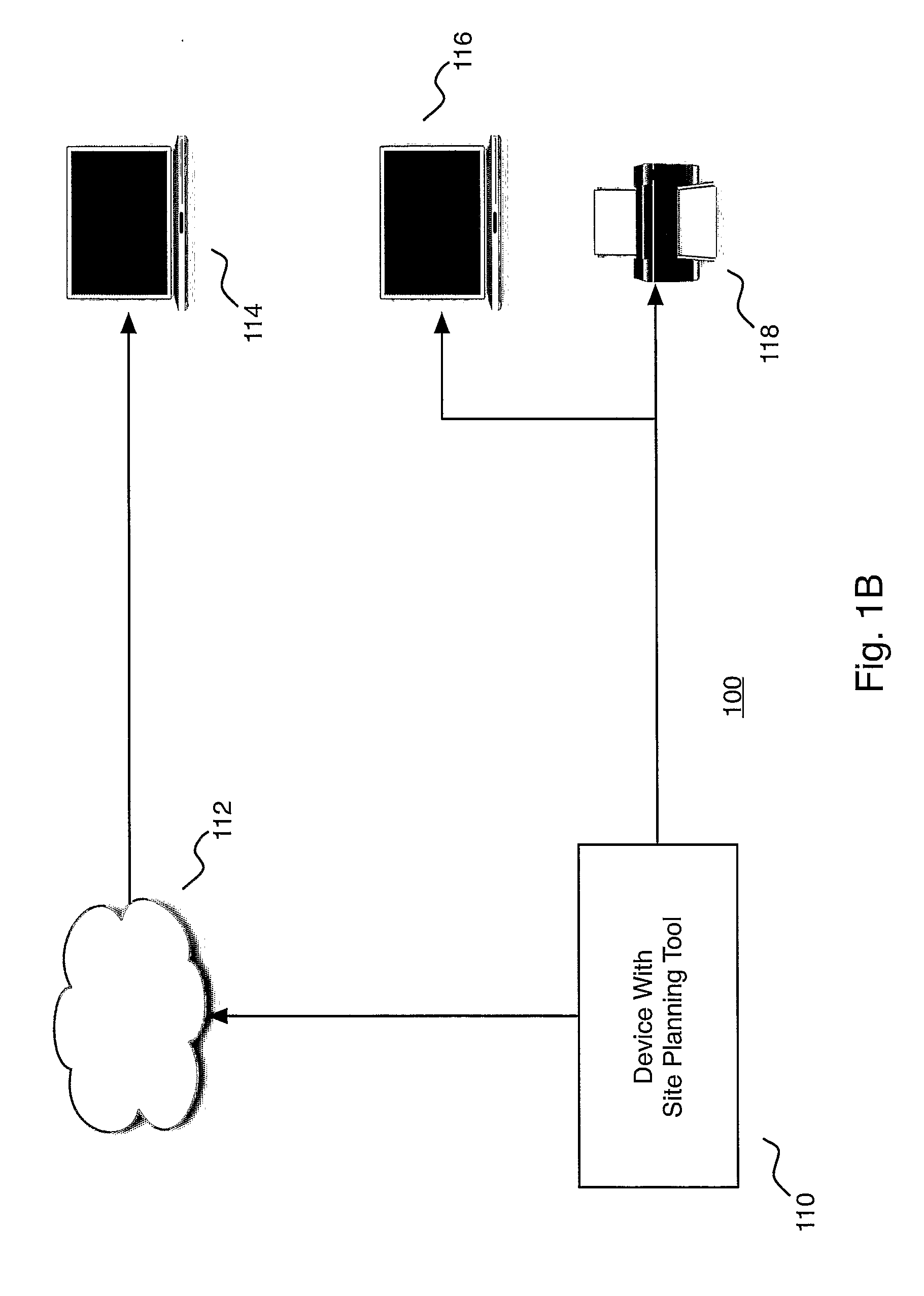

Site plan tool

InactiveUS20090037834A1Need for costlySpecial trainingInput/output processes for data processingEditing/combining figures or textThe InternetEngineering

The invention provides a simple to use site planning tool suitable useful in the field and capable of supporting site feasibility decision-making. Several advantages include cost savings owing to a) the expense of the tool itself (as compared with current CAD drawn site plans) and b) the compressed time-line to a decision-point regarding any site under consideration. More specifically, the invention provides a lightweight and intuitive design tool which requires no training to use, and permits a user to draw, to scale, property boundary lines within a browser interface and with or without an Internet connection. The invention further provides that a user may perform other rapid and scaled visualization concerning possible site plans, and to save site plans into a graphic file suitable for transmission and / or printing.

Owner:PARRISH WILLIAM

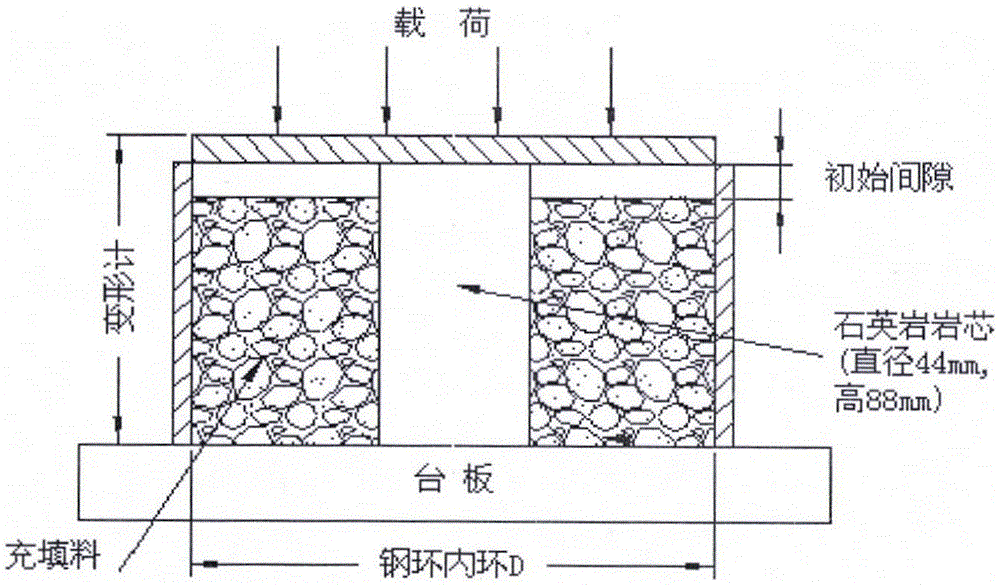

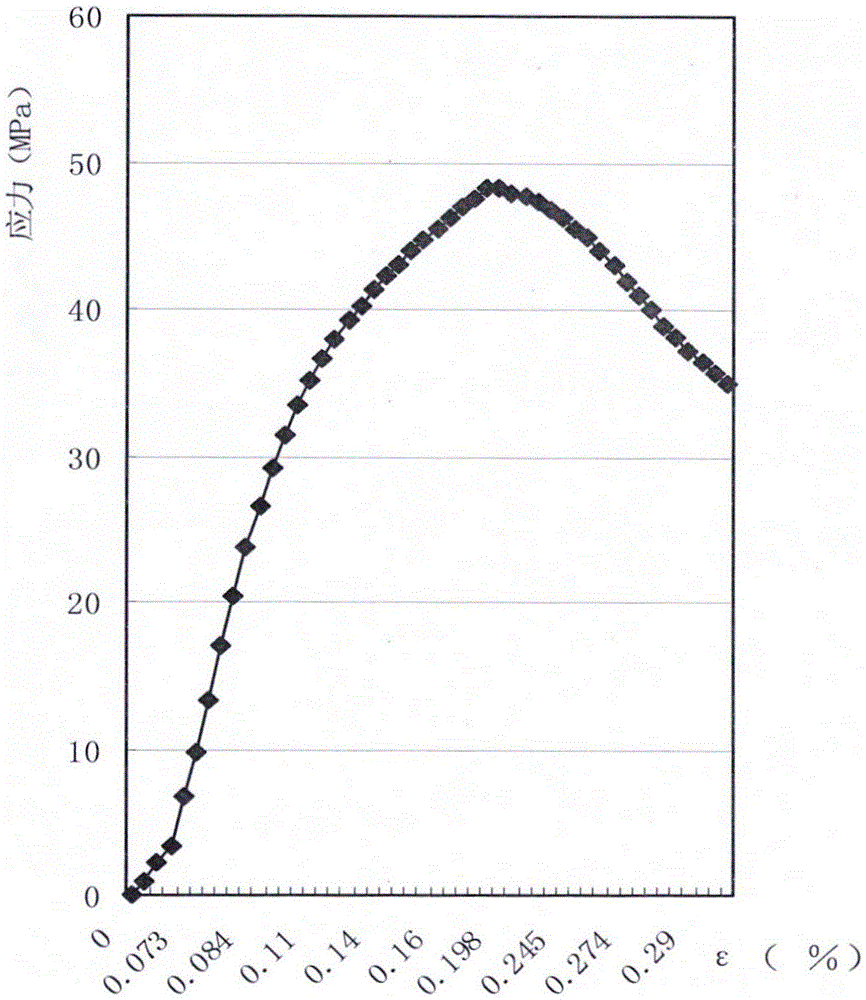

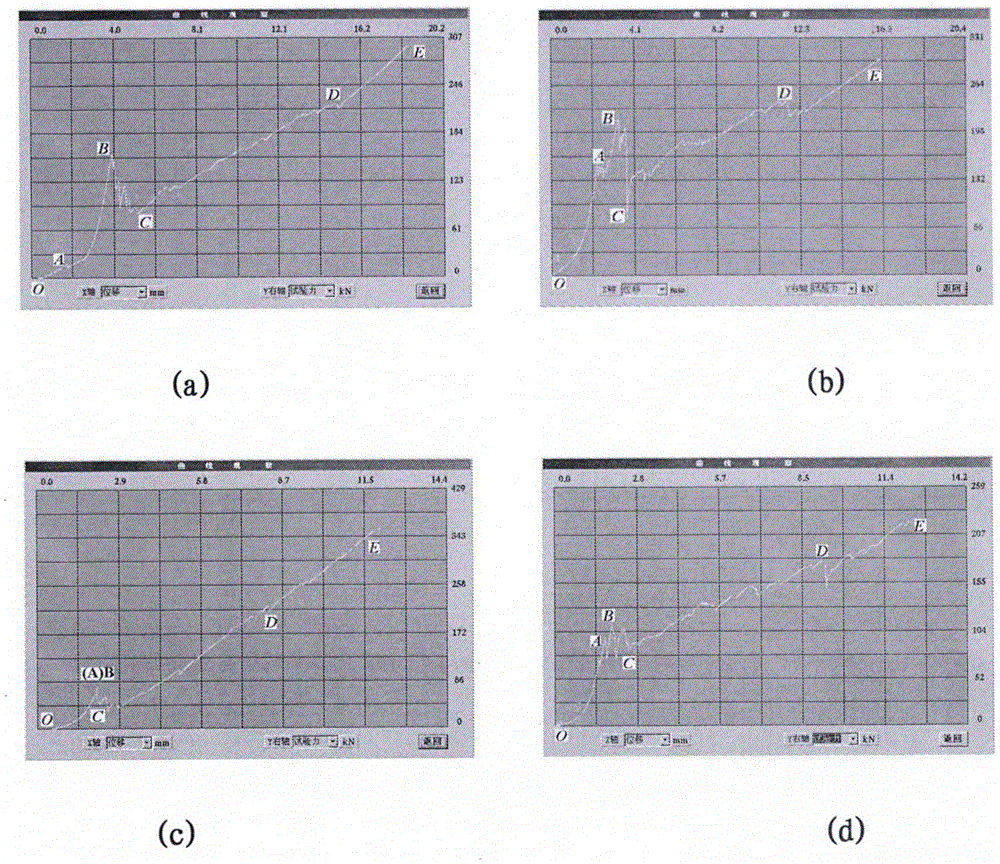

Filling body-pillar system mechanical effect mechanism test method

InactiveCN105547844AMaterial strength using tensile/compressive forcesElectrical resistance and conductanceMaintenance stage

The invention discloses a filling body-pillar system mechanical effect mechanism test method. The method comprises the steps of: processing and preparing a pillar test piece and a homemade elasticity module, and subjecting a resistance strain gauge to paste, waterproof and moistureproof treatment; pasting the pillar test piece with the strain gauge, conducting waterproof treatment, placing the pillar test piece in a middle position of a square lateral confinement steel mold; filling the steel mold with a prepared filling slurry; embedding an resistance strain gauge module treated in advance and matching with the ratio of the filling slurry; after full filling of the filling slurry in the steel mold, flattening the surface; leading and marking a wire connected to the strain gauge; taking out the filling body after certain maintenance stage; according to the testing requirements, connecting the connected wire of the embedded strain gauge with a strain gauge outside the device and carrying out a load test as required. The invention analyzes and researches on the relationship characteristic of deformation rules, rock pillar destroy characteristic and compression time of the filling body in the loading process.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

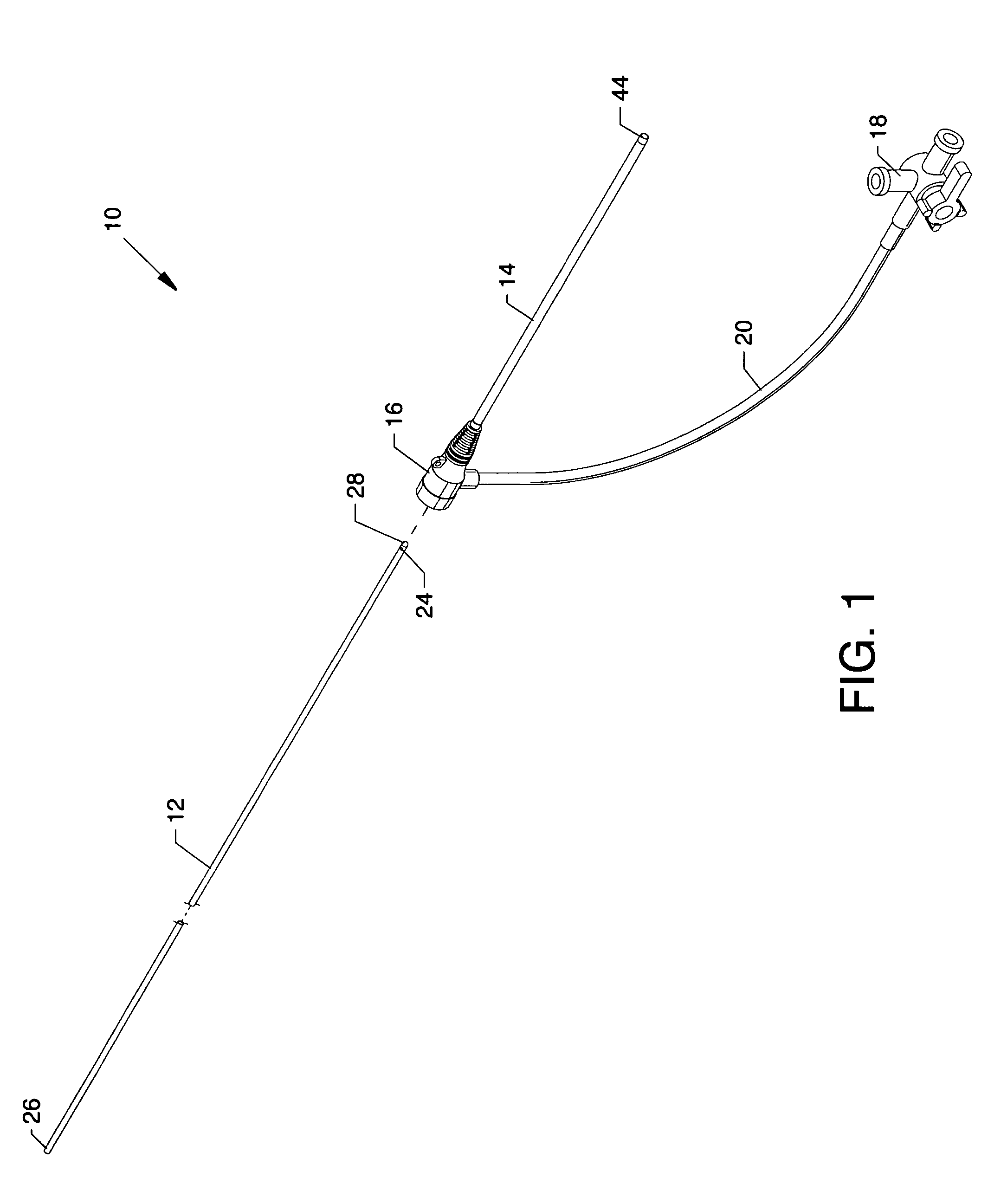

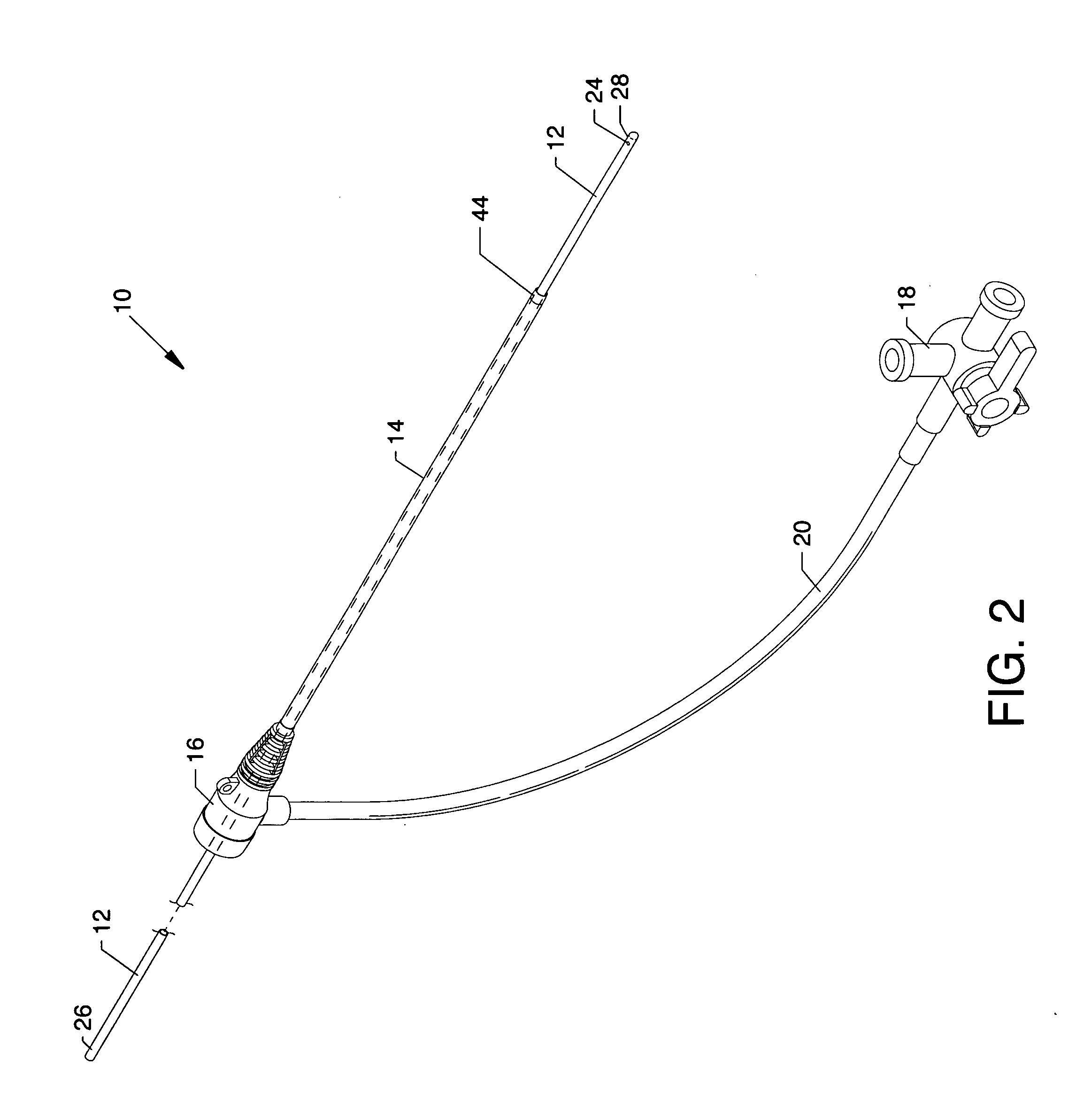

Closure device

InactiveUS20080287986A1Reduce compression timeSurgical veterinaryWound clampsShortest distanceWound site

The present invention is for an arterial closure device which can be used to implement and augment the closure of a femoral artery or other related, adjacent or similar members of the vasculature and to reduce compression times associated therewith. A resorbable tubular plug is introduced through a delivery sheath subsequent to a procedure in which the delivery sheath is first utilized. The resorbable tubular plug is inserted through the delivery sheath and the distal tip of the resorbable tubular plug is positioned a short distance into the artery, whereby a suitable entry can be indicated by blood flow through and from the resorbable tubular plug. The delivery sheath is withdrawn to expose the resorbable tubular plug to the tissue track and to the arteriotomy and manual compression is applied to the wound site to foster and promote hemostasis.

Owner:MEDRAD INC.

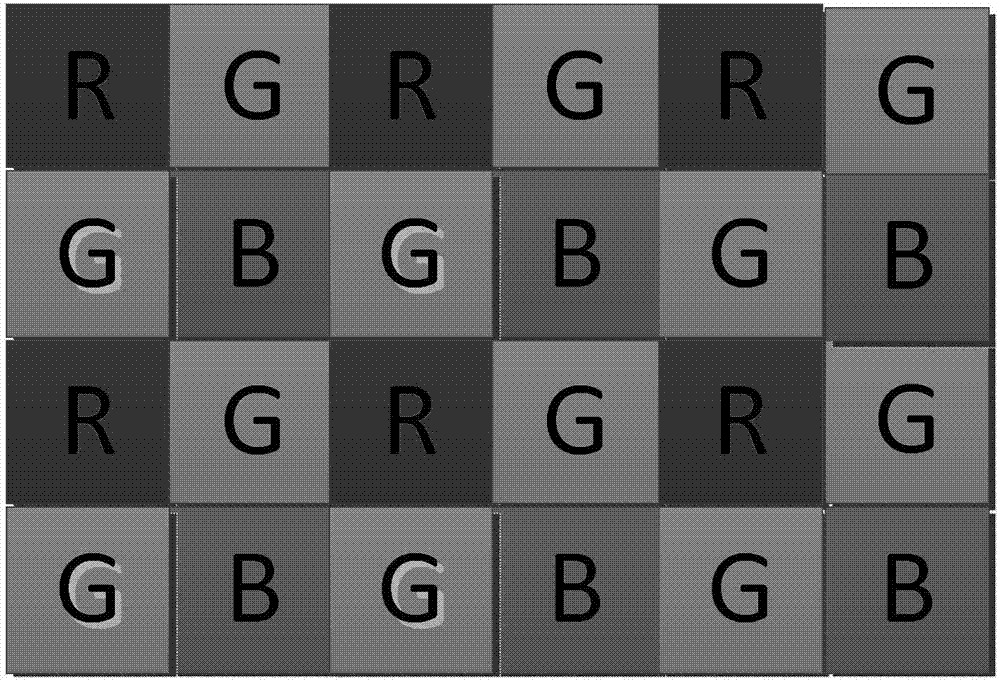

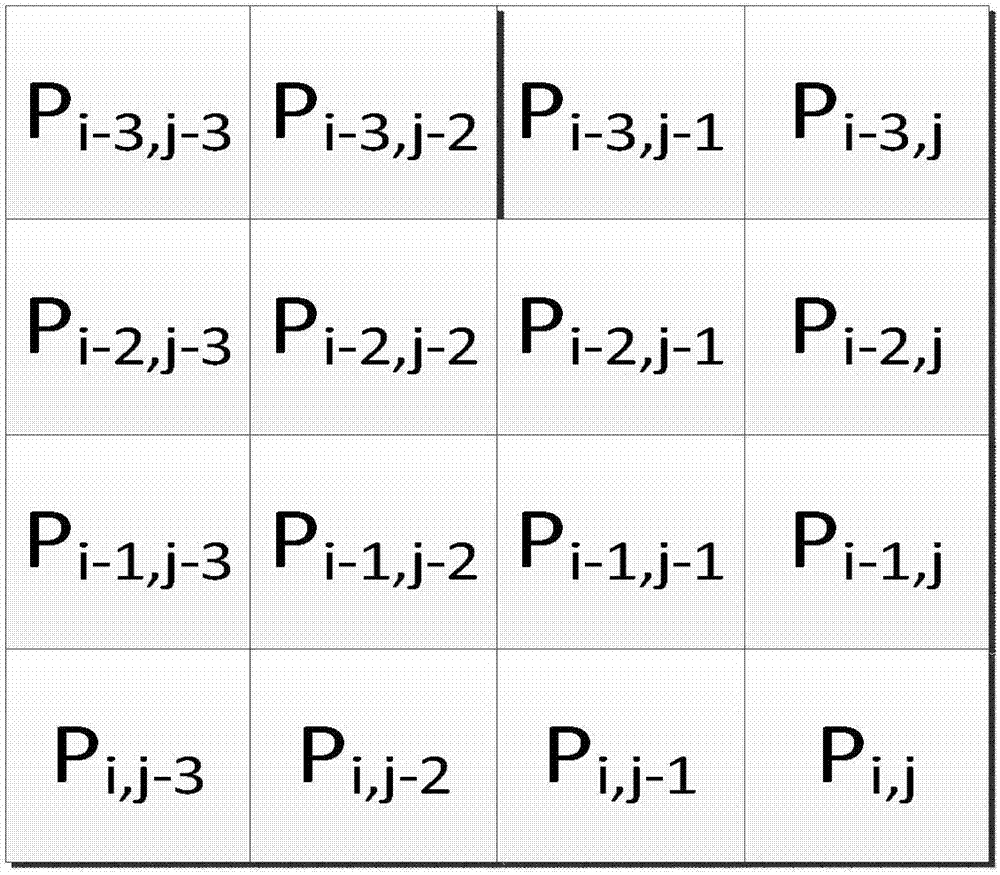

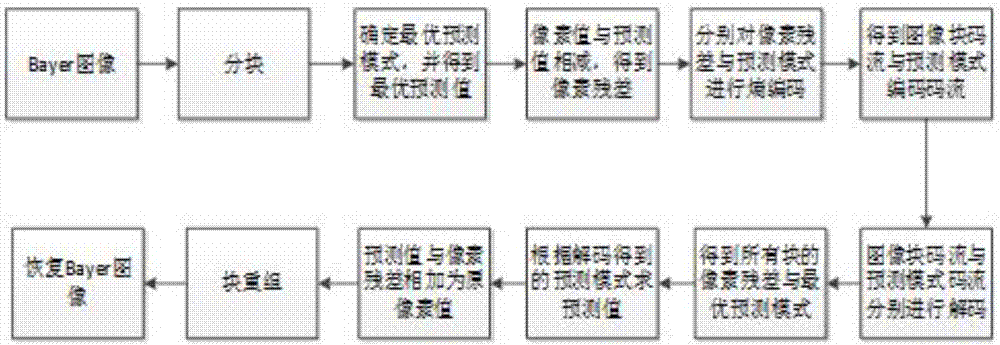

Lossless encoding and decoding method of Bayer image

InactiveCN107105208AReduce memory overheadReduce design costPicture signal generatorsDigital video signal modificationLossless codingSingle image

The invention provides a lossless encoding and decoding method of a Bayer image. The method comprises a lossless encoding process and a lossless decoding process of the Bayer image; the encoding process comprises: selecting the Bayer image, performing block division on a single image, predicting each block, performing entropy encoding on a prediction residual and a prediction mode obtained on the basis of the block, and finally obtaining a code stream of each block; and the decoding process comprises: performing entropy decoding on the code stream of each block to obtain the prediction residual of each pixel, performing reverse prediction according to the prediction mode used in the encoding process, and reconstructing the pixel value of each block to obtain the original Bayer image. By adoption of the method, the memory cost of a front end processing chip in a camera is saved, the design and manufacturing costs of the chip are also reduced, and the compression time is shortened while a high compression ratio is guaranteed. The experimental results show that the compression ratio of the method can reach 1:1.9 on average, and the complexity is low.

Owner:SHANDONG UNIV

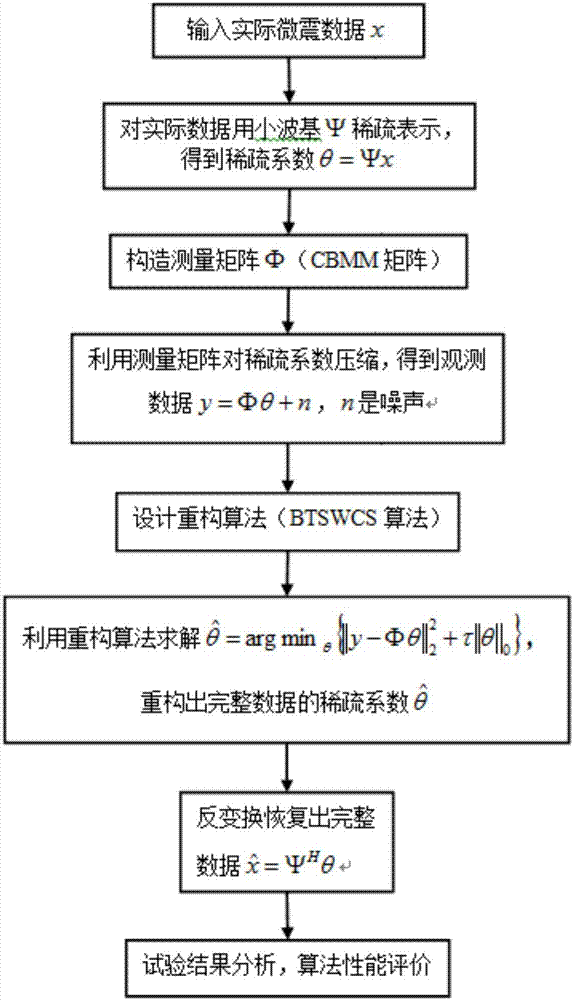

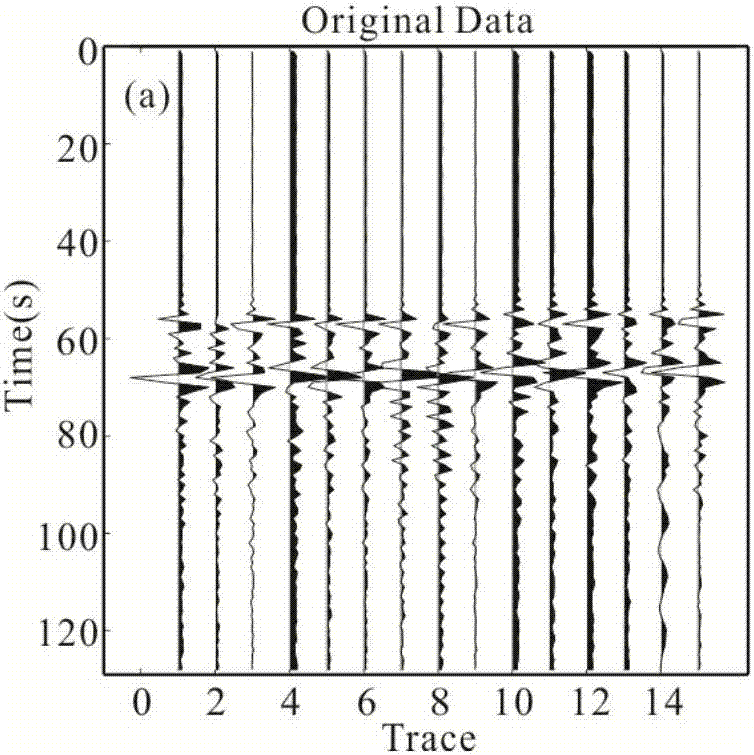

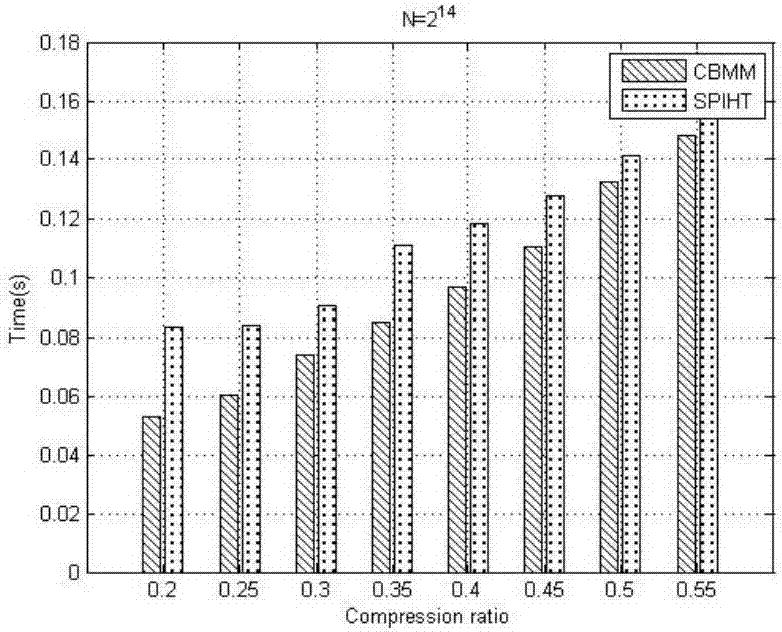

Wavelet domain seismic data real-time compression and high-precision reconstruction method based on compressed sensing

ActiveCN107045142AImprove wireless communication data transmission performanceSave data storage spaceCode conversionSeismic signal processingOriginal dataReconstruction method

The invention relates to a wavelet domain seismic data real-time compression and high-precision reconstruction method based on compressed sensing. The wavelet domain seismic data real-time compression and high-precision reconstruction method comprises the steps of: firstly, carrying out sparse representation on a microseismic signal in a wavelet domain; secondly, constructing a chaos Bernoulli measurement matrix (CBMM) by utilizing a Logistic chaotic sequence, and performing compressed observation on the sparsely-represented microseismic signal by using the chaos Bernoulli measurement matrix; and finally, adopting a Bayesian wavelet tree structure tree structure reconstruction method (BTSWCS), and recovering complete original data. Actual contrast experimental results show that the compression time can be shortened to 10<-5> s by using the wavelet domain seismic data real-time compression and high-precision reconstruction method for compressing data with total sampling points being 2<8>, that is, if a sampling rate of a seismometer is 1 KSPS, the CBMM measurement matrix can realize real-time compression on the acquired 0.25 s data basically. The wavelet domain seismic data real-time compression and high-precision reconstruction method increases a PSNR value by at least 5 dB, significantly improves the peak signal to noise ratio when compared with the greedy algorithm, and reduces reconstruction errors.

Owner:JILIN UNIV

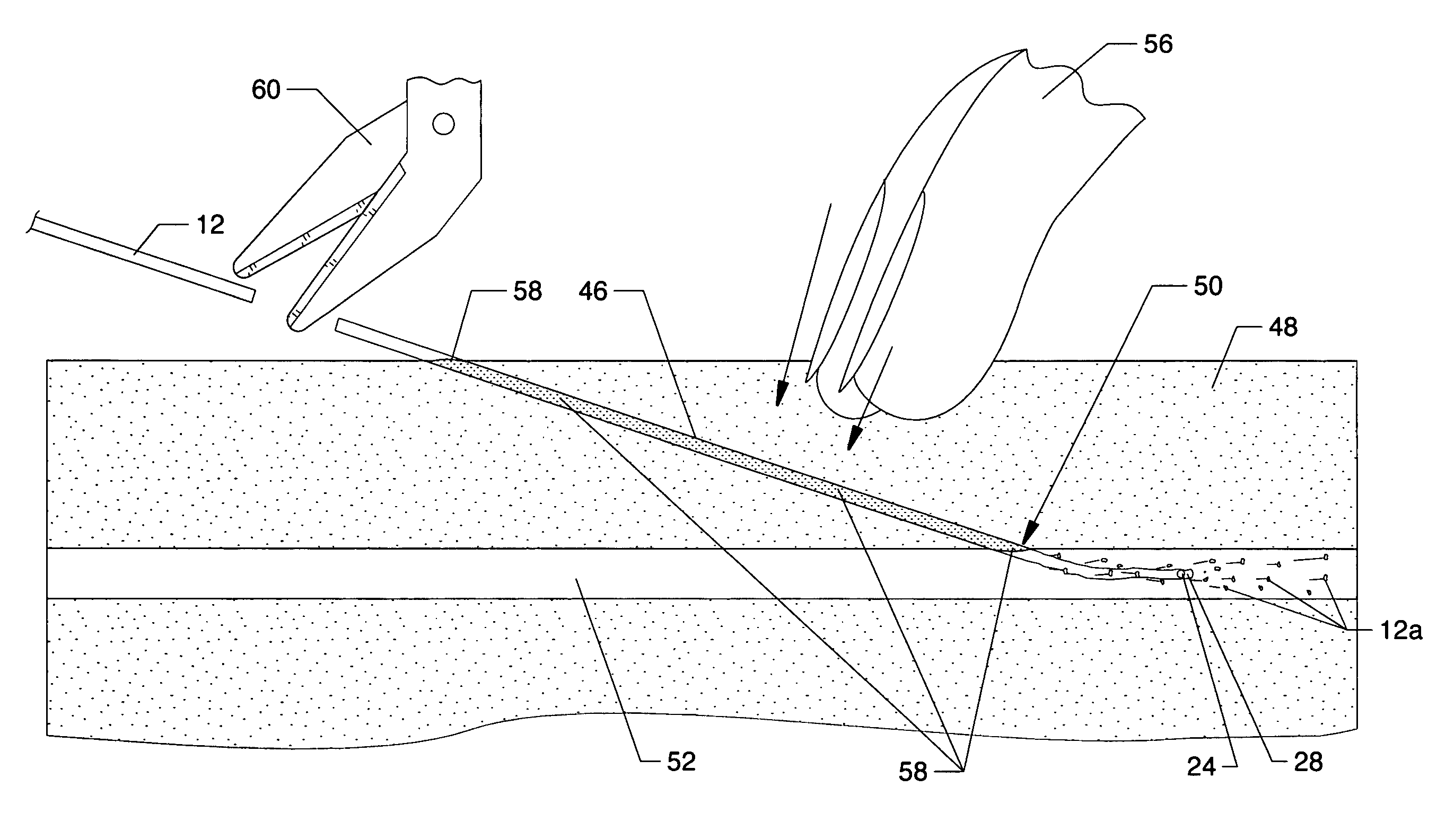

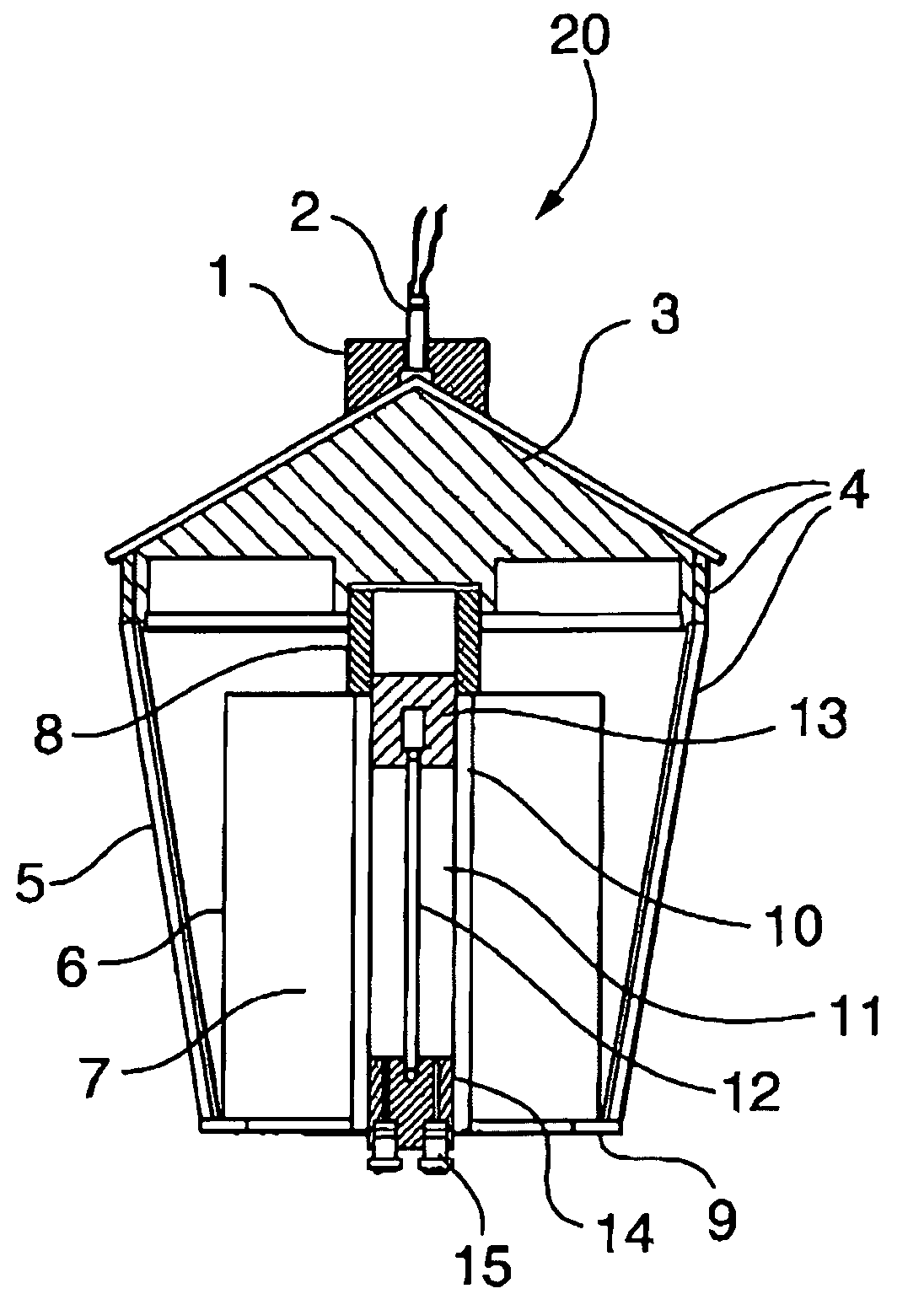

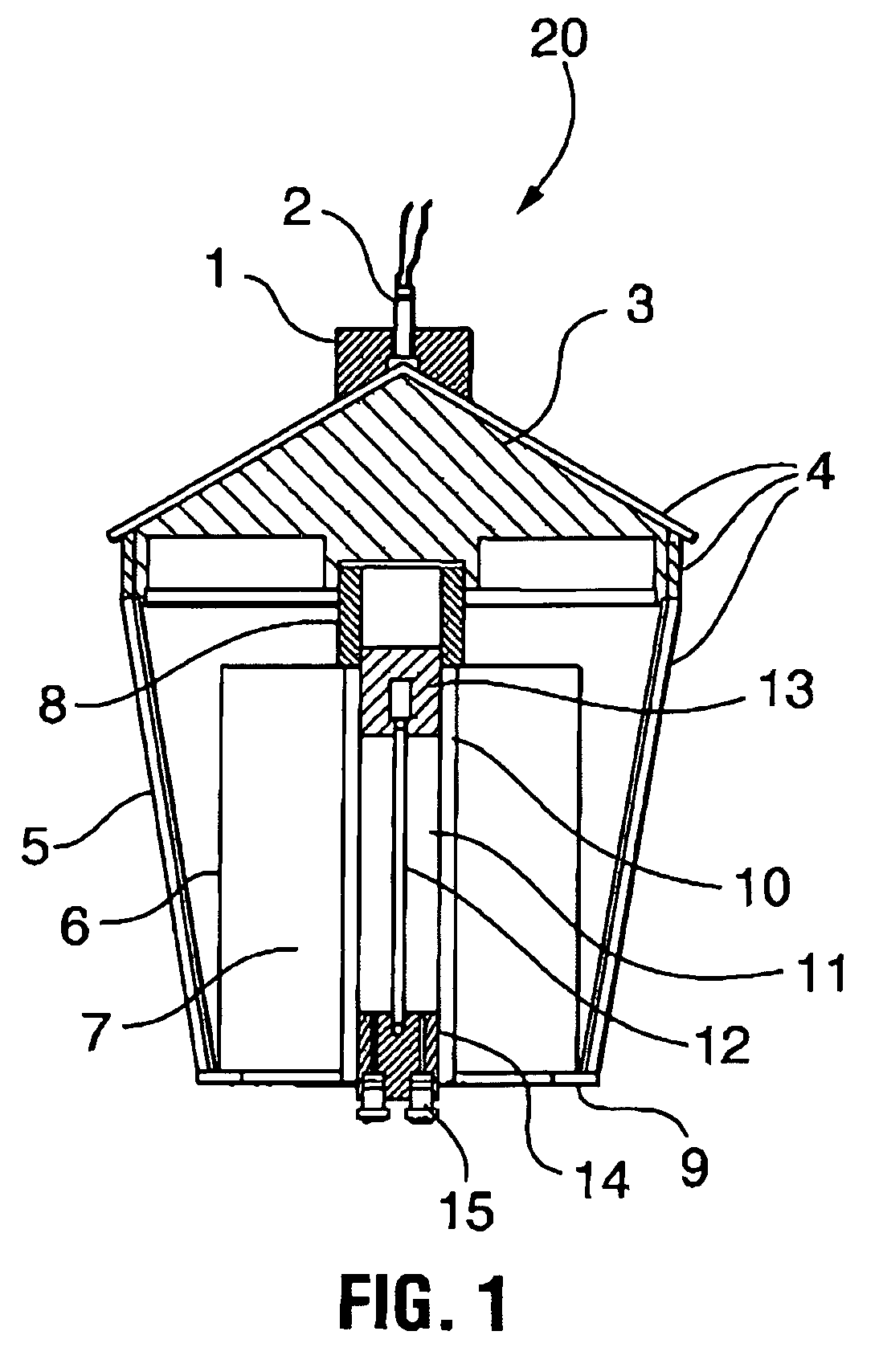

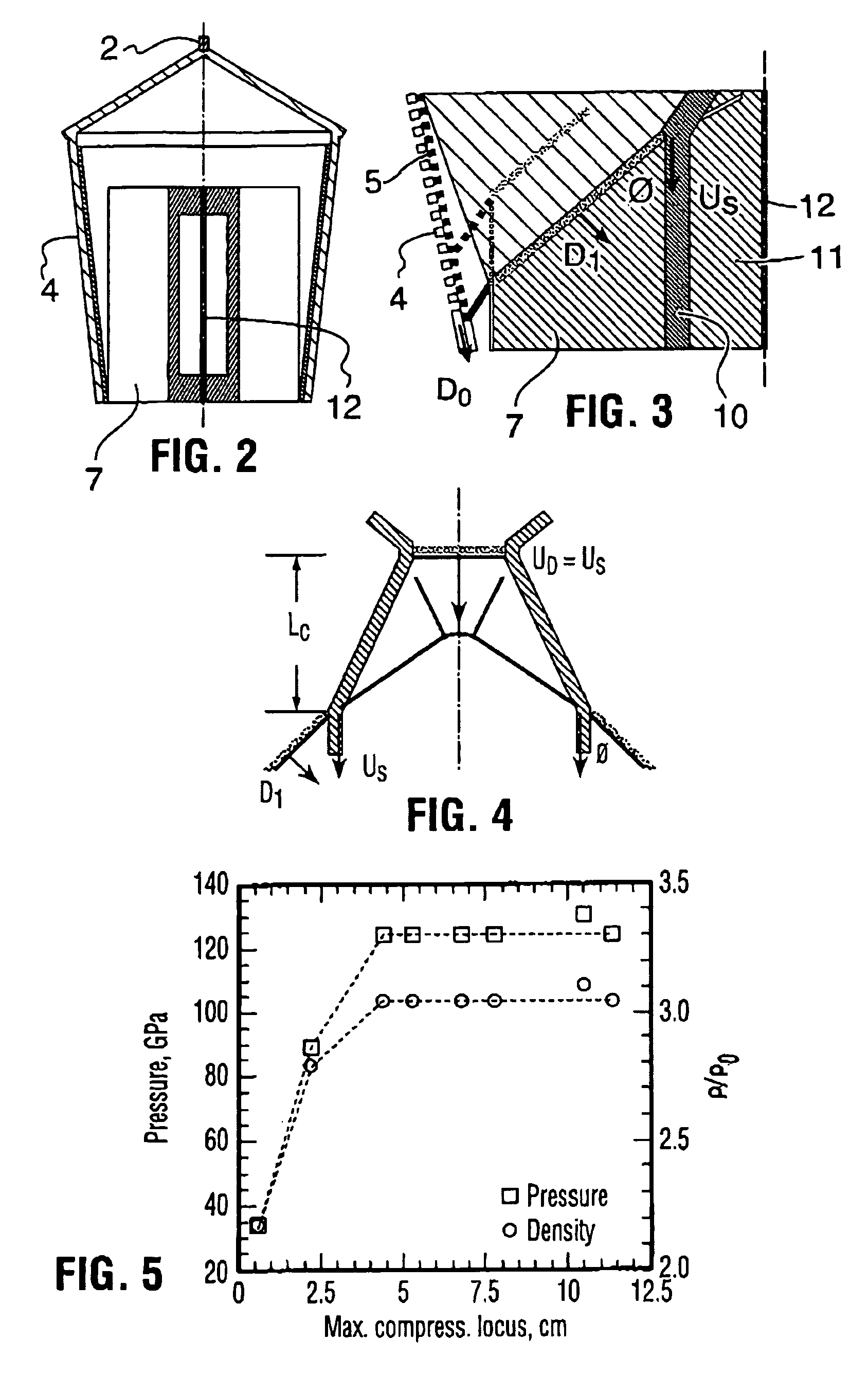

Super compressed detonation method and device to effect such detonation

ActiveUS7513198B2Improve propertiesHigh energyExplosive chargesAmmunition projectilesShock waveDelayed time

A method and apparatus are provided for detonation of a super-compressed insensitive energetic material by cylindrical implosion followed by an axial detonation to a detonation velocity several times that of TNT and a detonation pressure in excess of ten times that of TNT. The device provides a conical metal flyer shell within which is disposed a cylindrical anvil surrounded by explosive. The anvil retains an insensitive energetic material to be compressed and detonated. A first detonation of explosive by impact of the flyer shell generates a reverberating oblique shock wave system for sample compression. Axial detonation of the compressed sample through any length of a sample is achieved following the principal of matching the axial velocity and compression time of the oblique shock wave system to the detonation velocity and induction delay time of the compressed sample. The method and apparatus are also applicable to enhancing the effect of anti-armour and anti-hard-target munitions. The apparatus is also applicable to inert sample compression to the megabar range without using the axial detonation.

Owner:HER MAJESTY THE QUEEN AS REPRESENTED BY THE MINIST OF NAT DEFENCE OF HER MAJESTYS CANADIAN GOVERNMENT

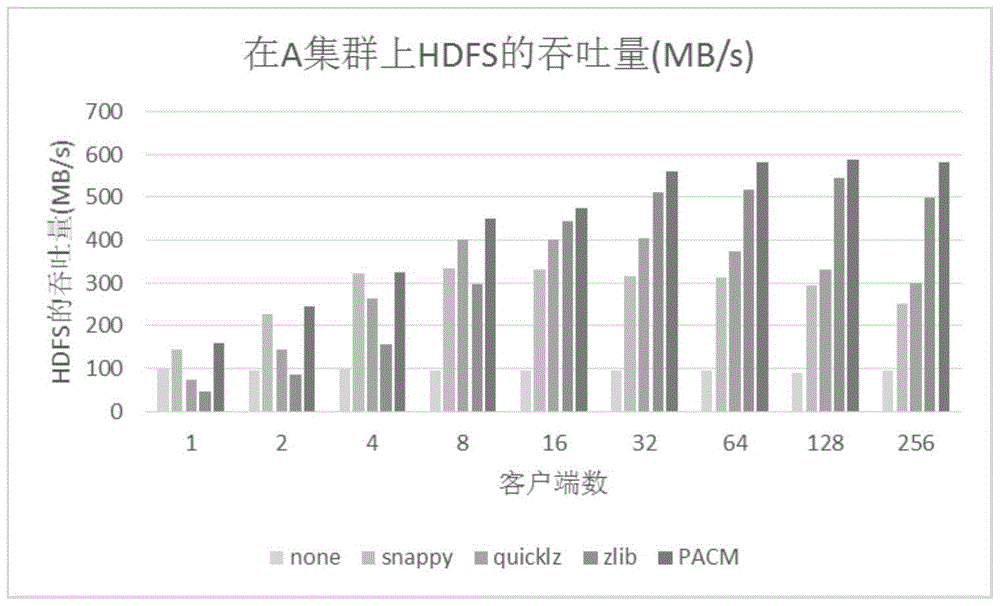

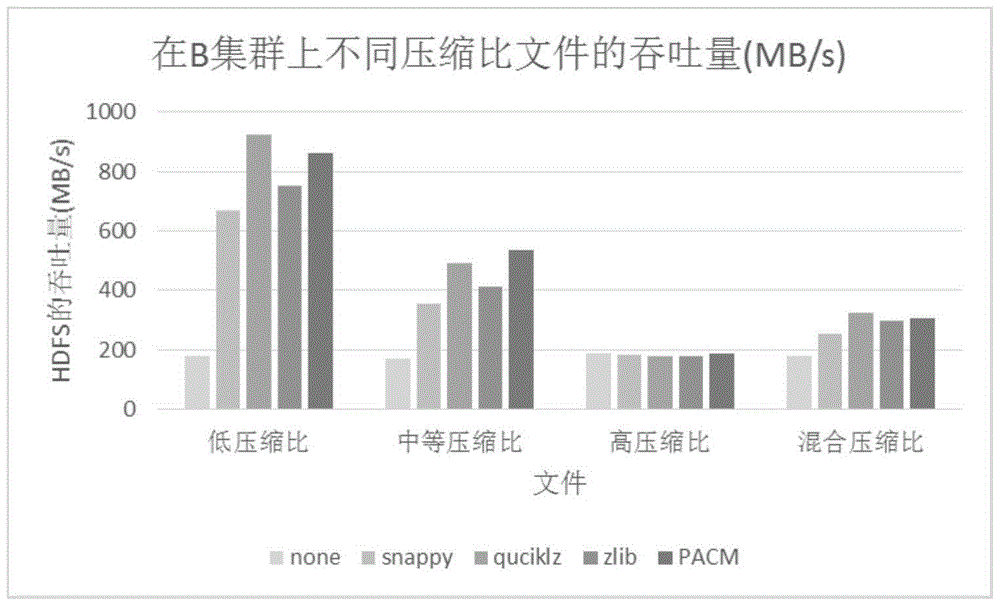

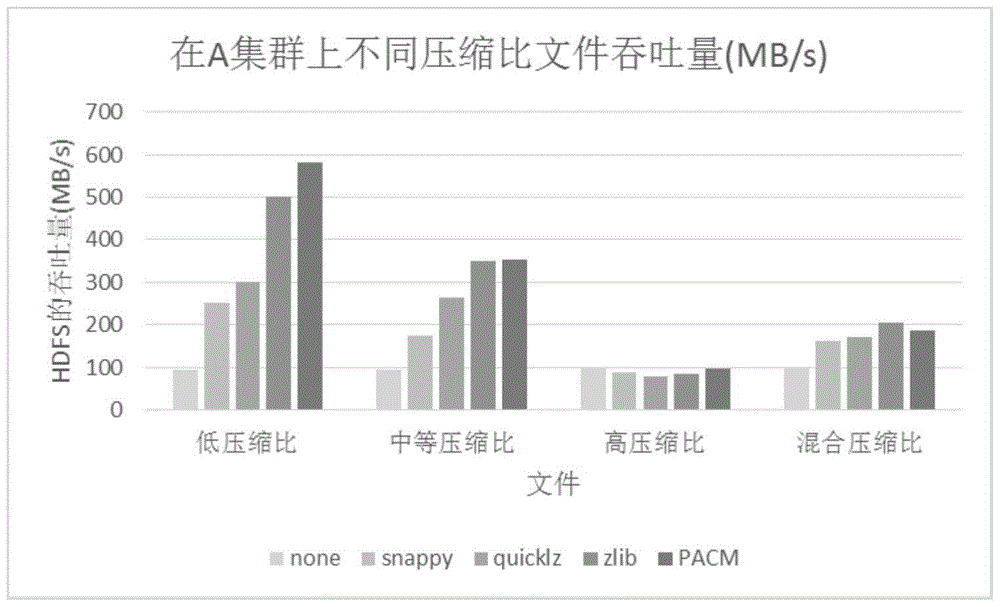

Adaptive compression method and system for distributed file system

ActiveCN105718538AExcellent throughputImprove adaptabilitySpecial data processing applicationsAdaptive compressionData stream

The present invention provides an adaptive compression method and system for a distributed file system, and relates to the field of distributed system file compression. The method comprises the steps of: setting a compressed file format, and forming a compressed data stream, wherein the compressed data stream consists of head information and a plurality of data blocks, and the head information is used for determining whether the compressed data stream is compressed; receiving a to-be-compressed file, and compressing the to-be-compressed file according to the compressed file format so as to generate the compressed data stream; and setting an index file, wherein the index file consists of a plurality of records, and each record maintains data information of data in the compressed data stream, and the index file is used for rapidly positioning the compressed data stream. The method and system provided by the present invention are capable of improving compression efficiency and saving compression time.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

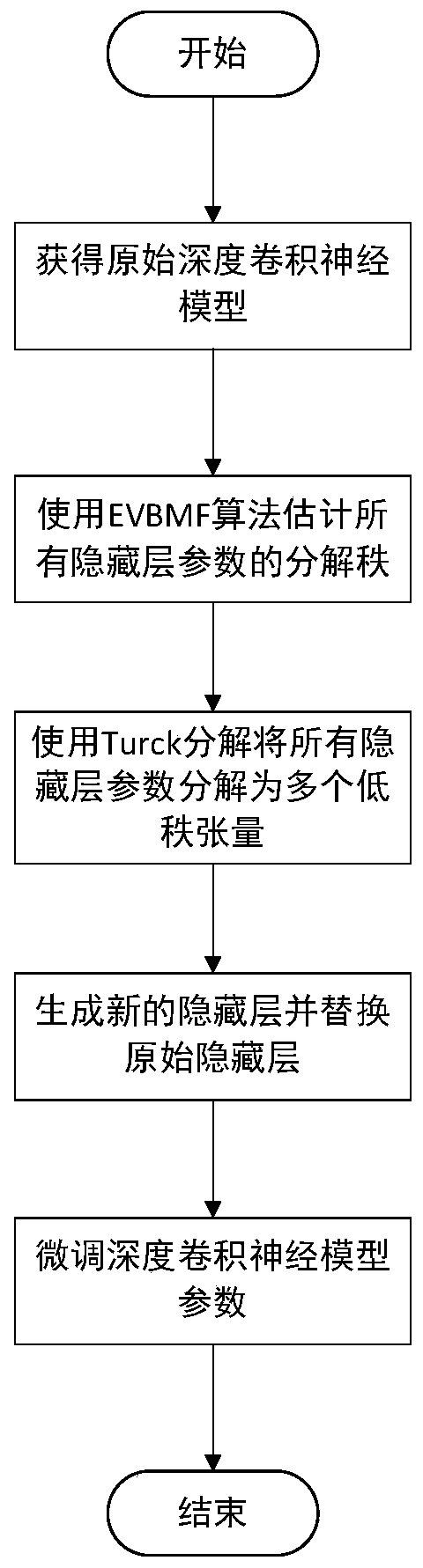

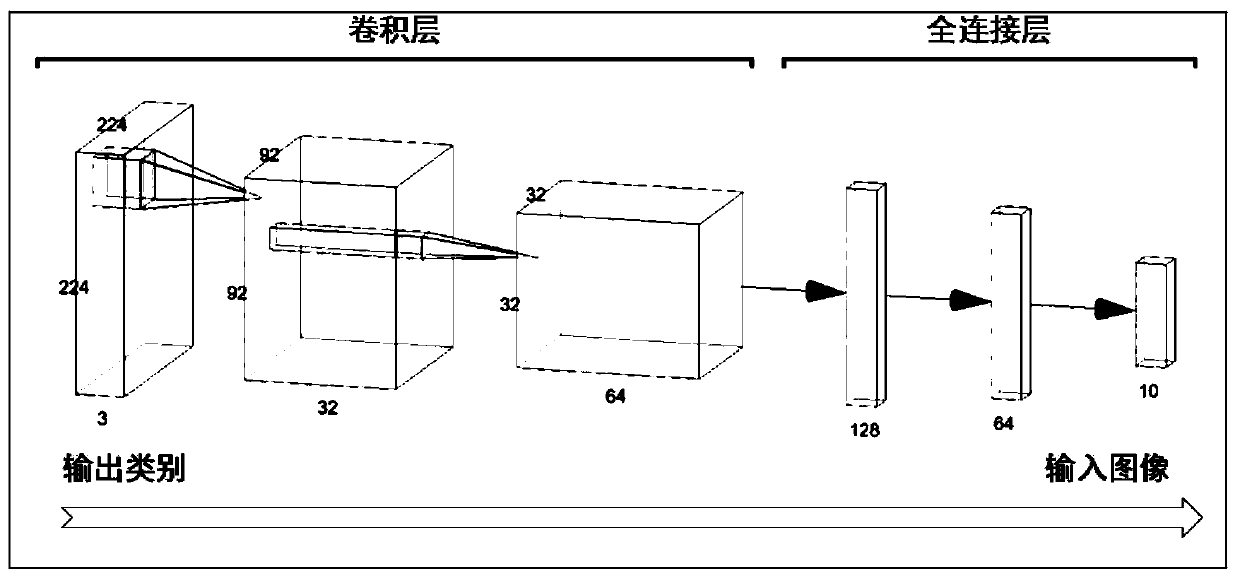

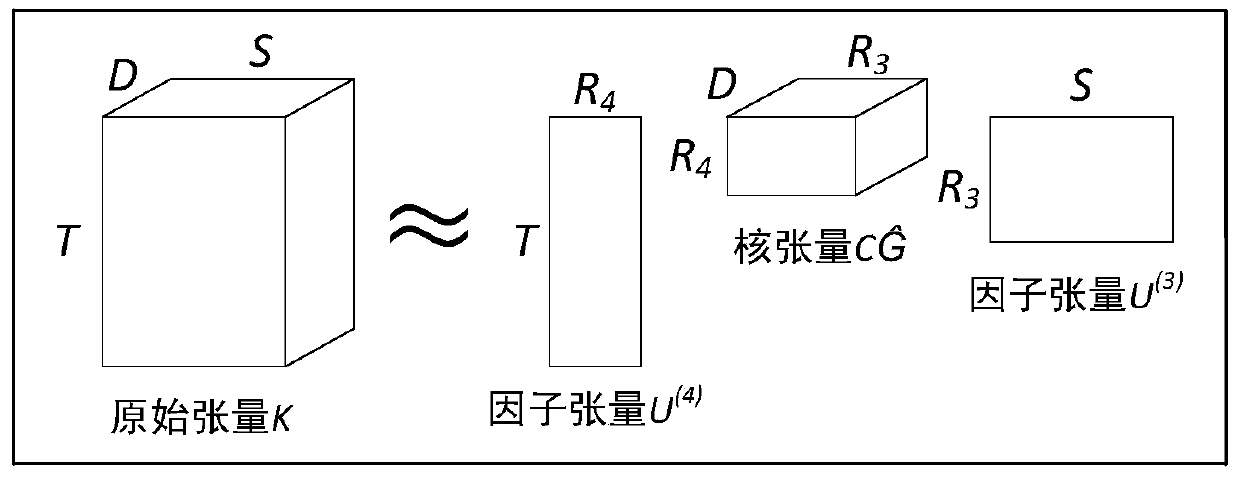

Deep convolutional neural network compression method based on Tucker algorithm

InactiveCN110428045AGuaranteed performanceAvoiding Convolution Kernel ProblemsNeural architecturesHidden layerAlgorithm

The invention relates to a deep convolutional neural network compression method based on a Tucker algorithm. The method comprises the steps of A, obtaining a deep convolutional neural network model; B, sequentially estimating a decomposition rank of each hidden layer parameter in the deep convolutional neural network model by using an EVBMF algorithm; C, according to the parameter tensor of the hidden layer in the deep convolutional neural network model and the corresponding decomposition rank, sequentially decomposing each parameter tensor through a Tucker algorithm to generate a plurality oflow-rank sub-tensors; and D, generating a new hidden layer through the low-rank sub-tensor, and replacing the original hidden layer in the deep convolutional neural network model with the new hiddenlayer to generate a new deep convolutional neural network model. According to the deep convolutional neural network compression method based on the Tucker algorithm, the compression multiple can be greatly improved, and the compression time and the system overhead are effectively reduced.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

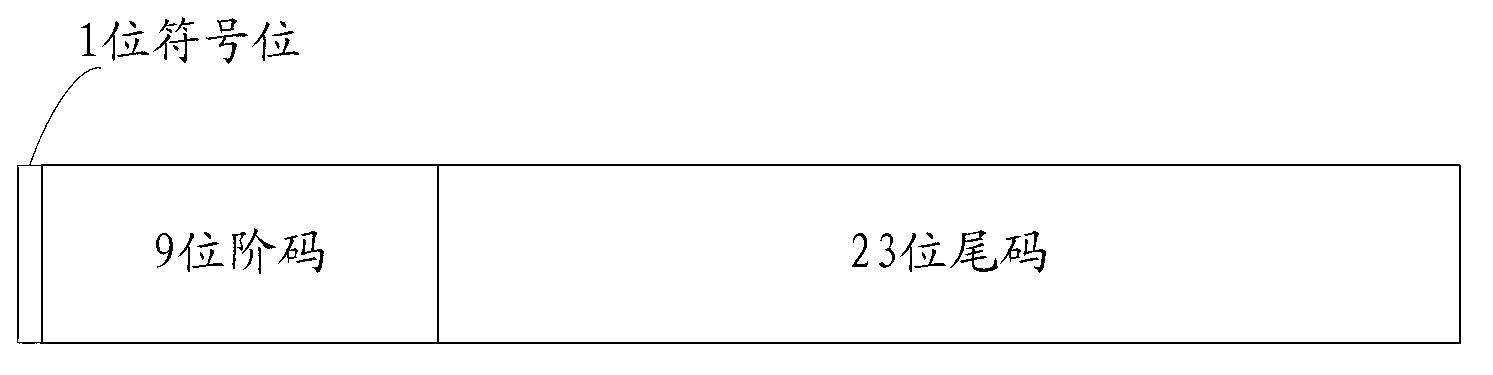

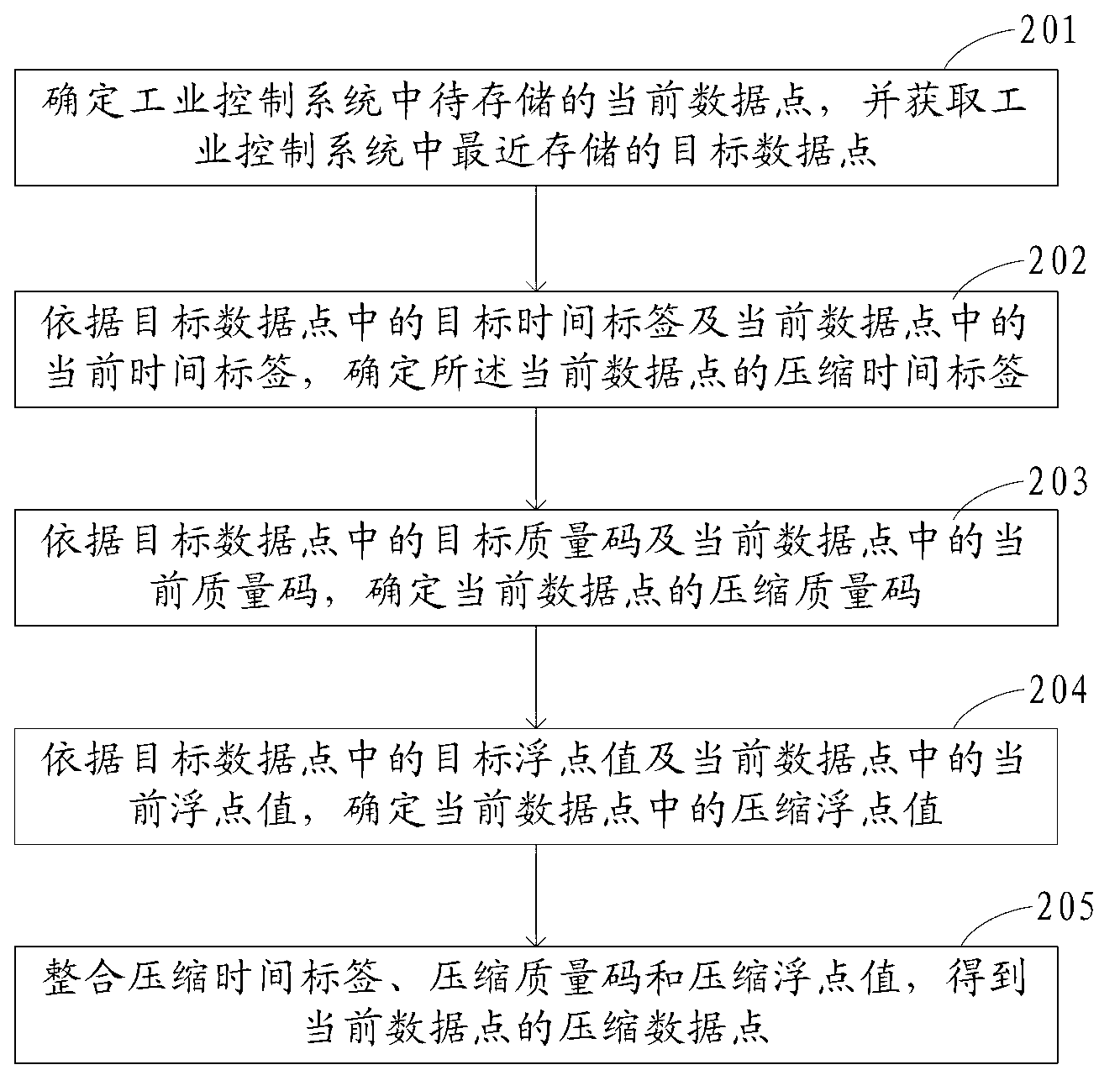

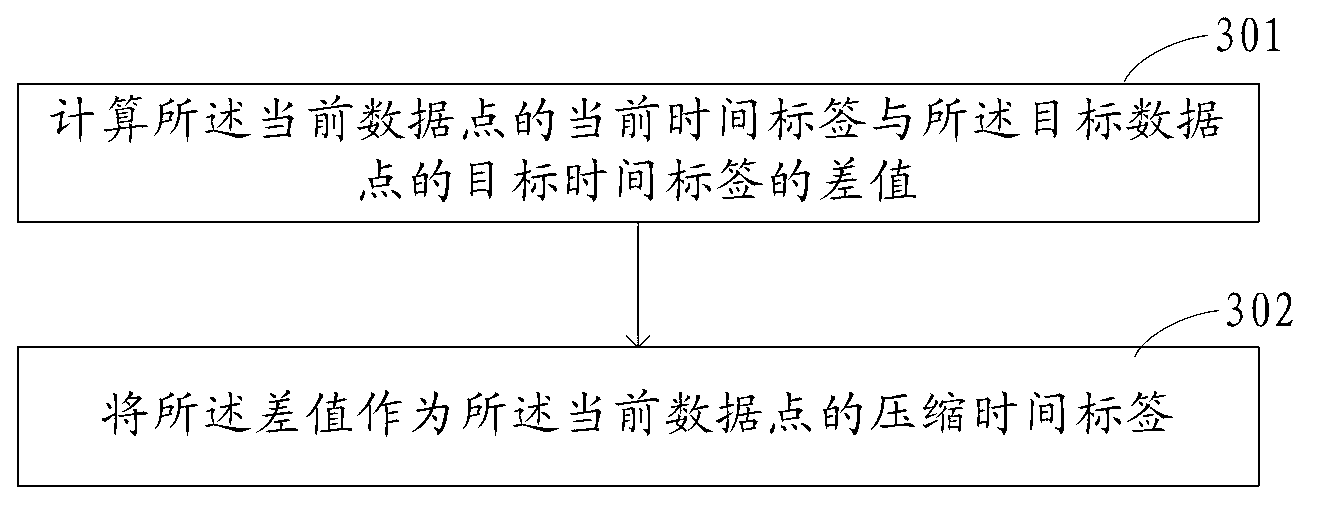

Method and device for compressing industrial real-time data

ActiveCN103236846ALittle correlationIncrease the compression ratioCode conversionReal-time dataSimulation

The invention discloses a method and a device for compressing industrial real-time data, which are applied to an industrial control system. The method comprises the following steps of determining a current data point to be stored in the industrial control system, and acquiring a latest stored data point in stored data points in the industrial control system for serving as a target data point; determining a compression time tag of the current data point according to a target time tag in the target data point and a current time tag in the current data point; determining the compression quality code of the current data point according to a target quality code in the target data point and a current quality code in the current data point; determining a compression floating point value in the current data point according to a target floating point value in the target data point and a current floating point value in the current data point; and integrating the compression time tag, the compression quality code and the compression floating point value to obtain a compression data point of the current data point.

Owner:浙江蓝卓工业互联网信息技术有限公司

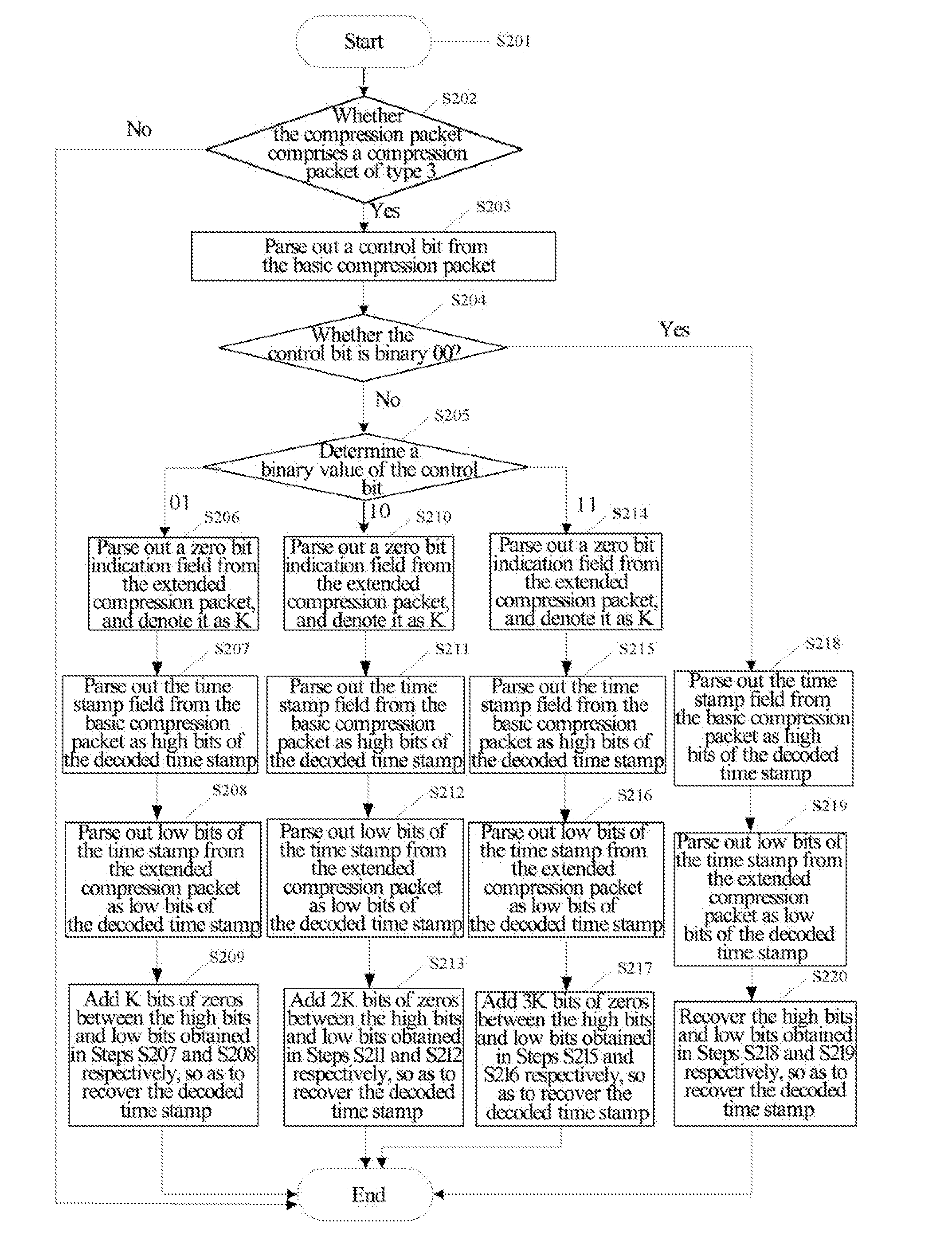

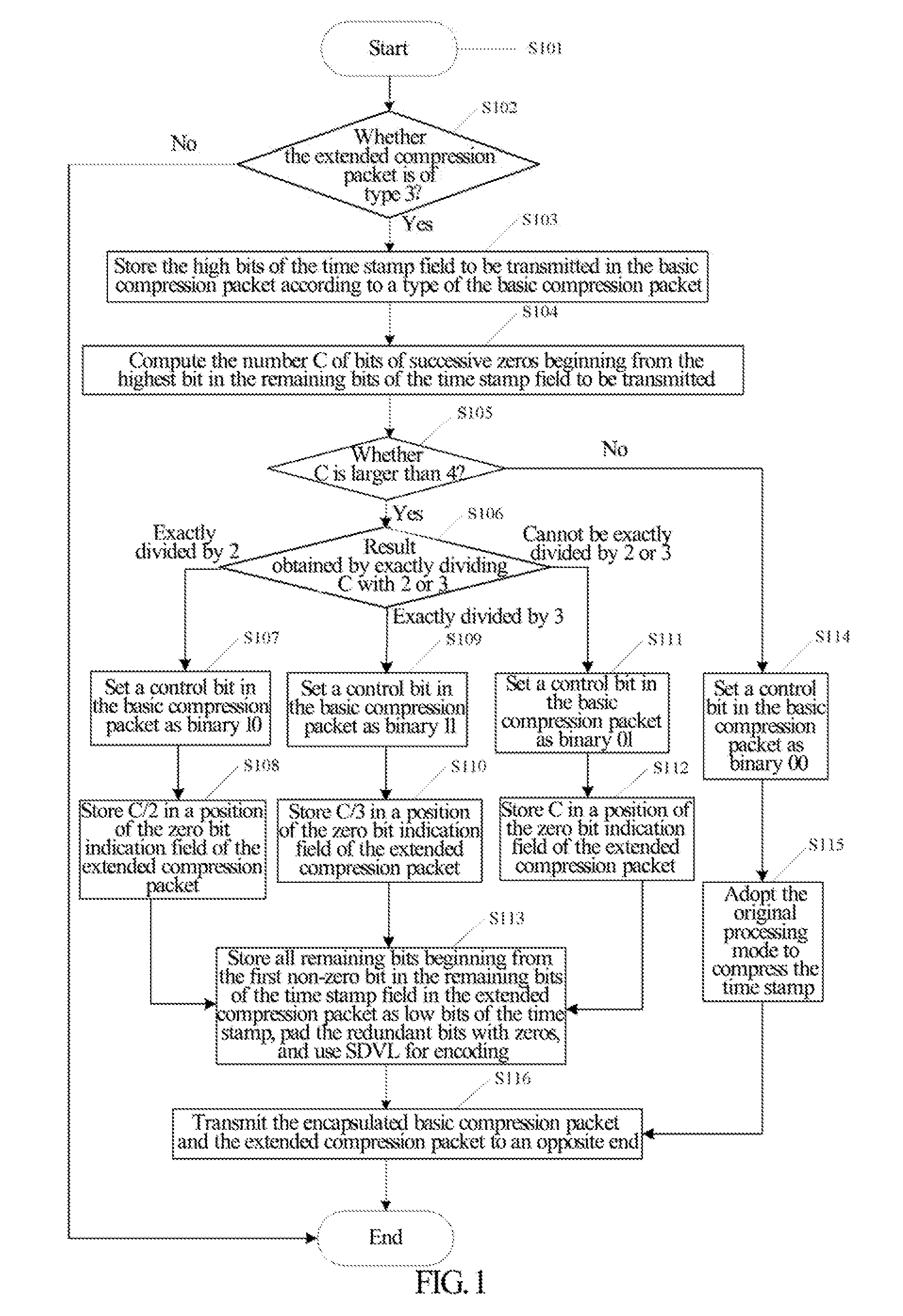

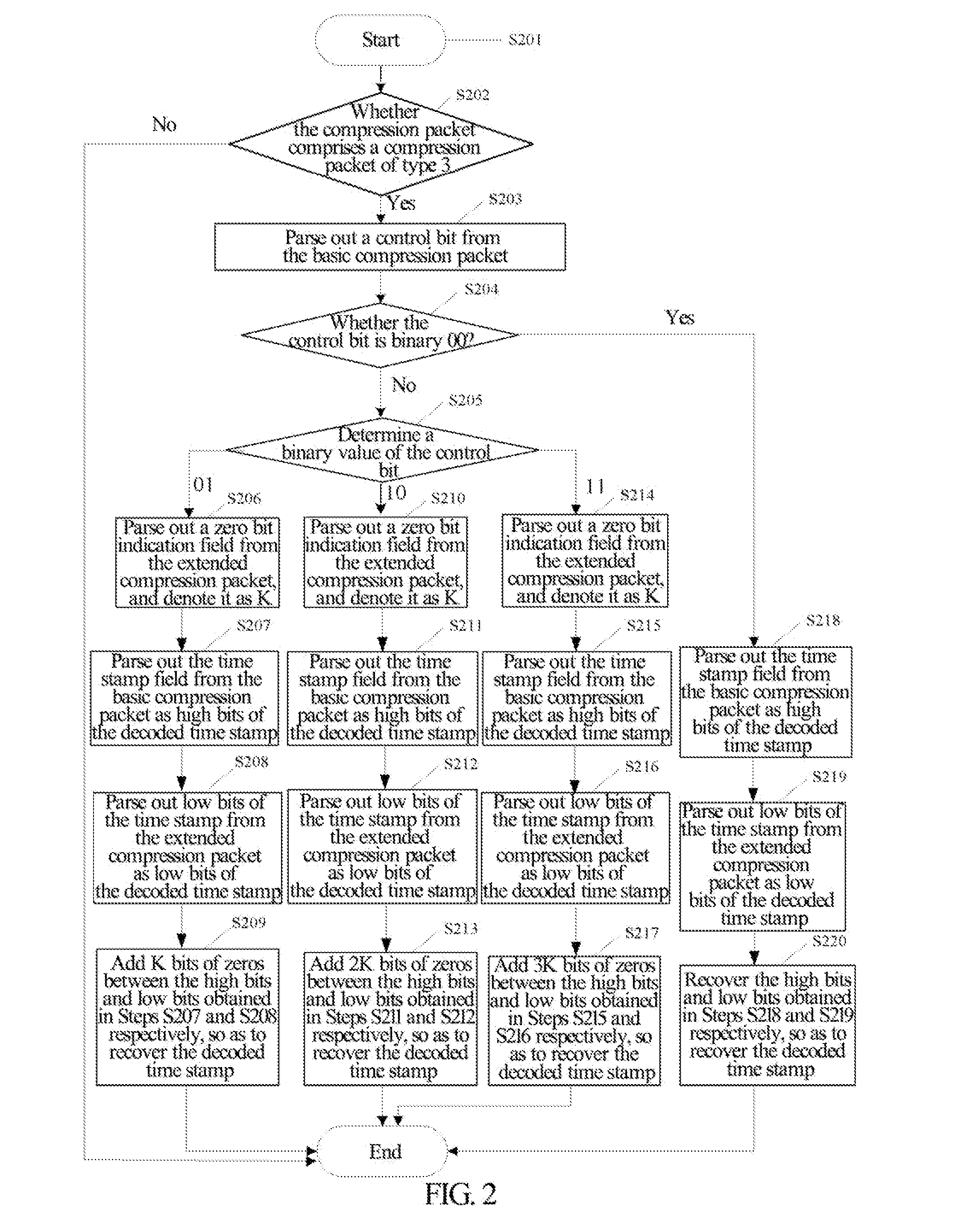

Method for Compressing and Decompressing Time Stamp and Equipment Thereof

InactiveUS20120213234A1Use the overall spaceImprove compression efficiencyNetwork traffic/resource managementTime-division multiplexComputer hardwareTime mark

A method and apparatus for compressing and decompressing a time stamp is provided, applied in a scenario of compressing a basic compression packet carrying an extended compression packet of type 3 in Robust Header Compression (ROHC). The compression method comprises: storing high bits of a time stamp to be transmitted in a time stamp field of the basic compression packet; storing bits of successive zeros beginning from the highest bit of the remaining bits of the time stamp to be transmitted after removing said high bits in the extended compression packet in a form of number information; and storing the remaining bits of the time stamp to be transmitted after removing said high bits and said bits of successive zeros in the time stamp field of the extended compression packet as low bits. Therefore the compression space can be effectively used and compression efficiency can be improved.

Owner:ZTE CORP

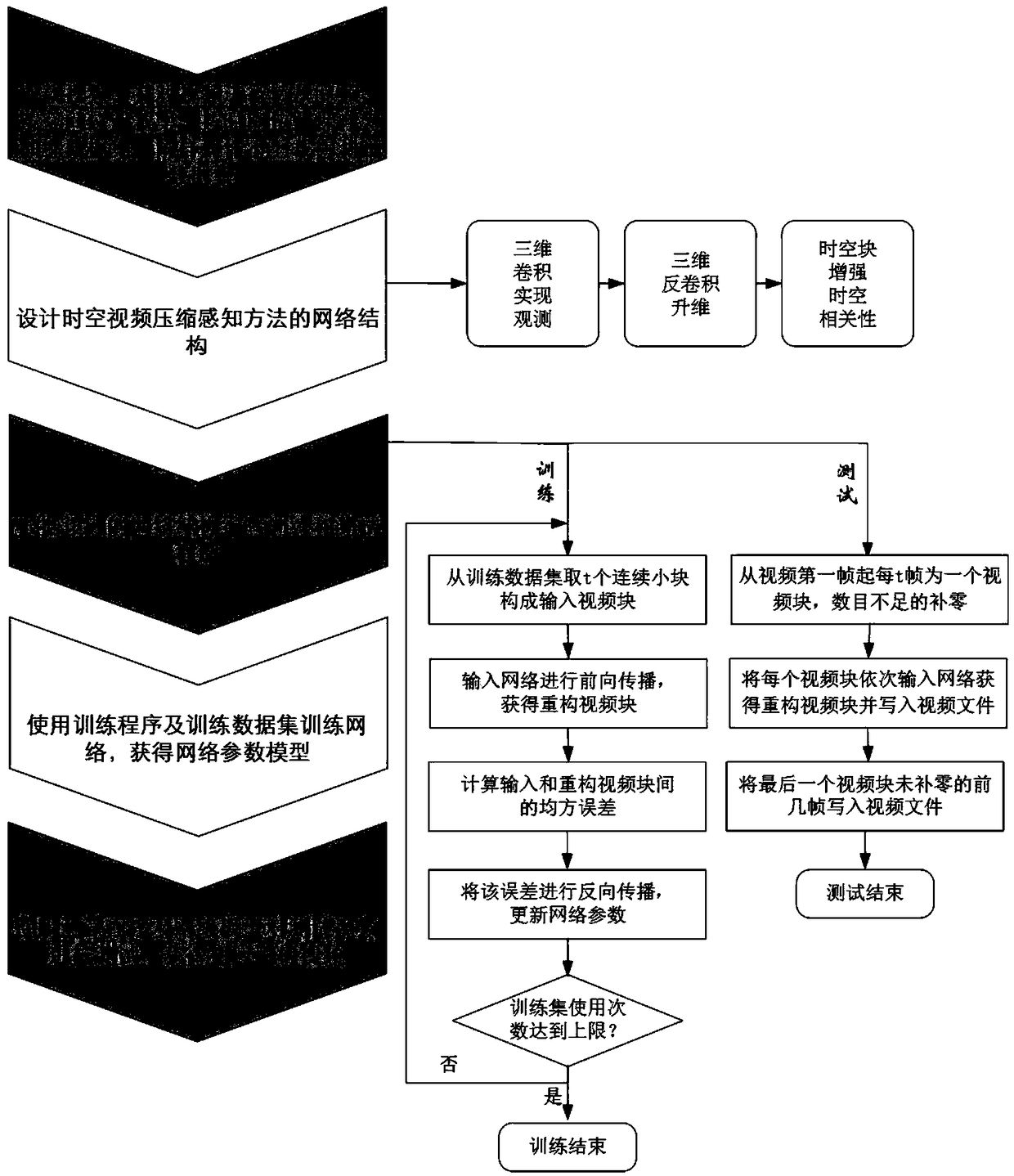

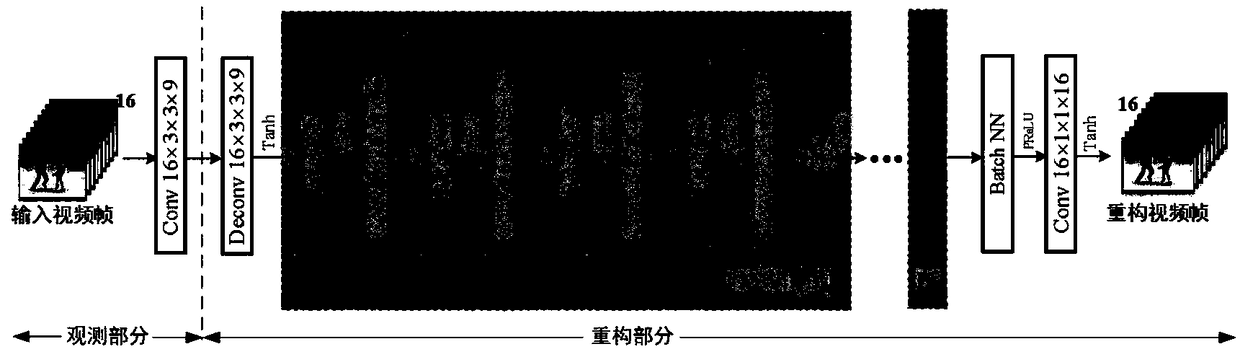

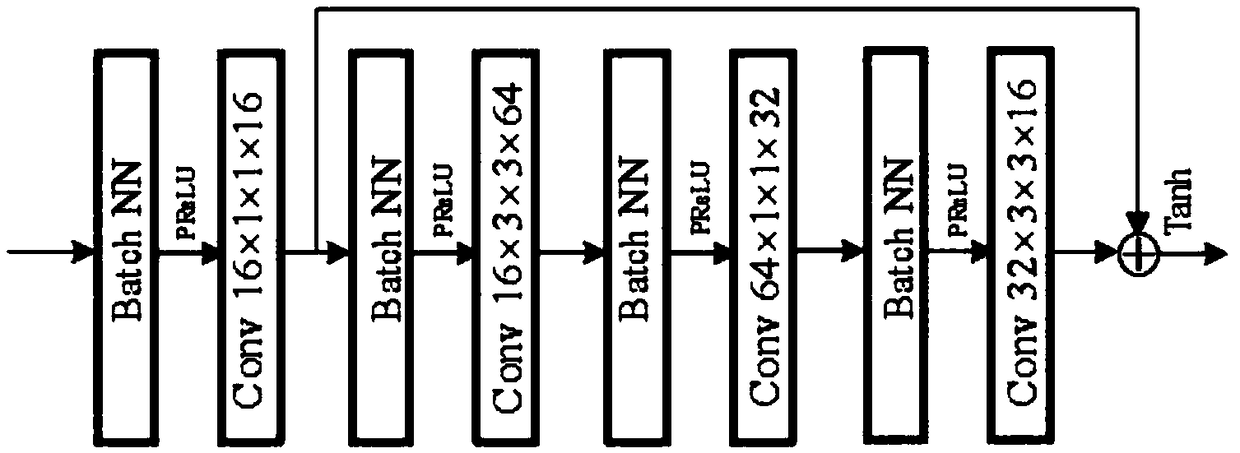

Time-space video compressed sensing method based on convolutional network

ActiveCN108923984AReduce in quantityImprove equalization performanceDigital video signal modificationData switching networksData setVideo reconstruction

The invention discloses a time-space video compressed sensing method based on a convolutional network, and mainly aims at solving the problems that in the prior art, the video compression time-space balance and the video reconstruction real-time performance are poor. The scheme of the method comprises the steps that a training data set is prepared; a network structure of a time-space video compressed sensing method is designed; training and testing files are written according to the designed network structure; a network of the time-space video compressed sensing method is trained; and the network of the time-space video compressed sensing method is tested. The network of the time-space video compressed sensing method adopts an observation technology of simultaneous time-space compression are conducted simultaneously and a reconstruction technology of using 'time-space blocks' to enhance the time-space correlation, not only can real-time video reconstruction be achieved, but also the reconstruction result has the high time-space balance, the reconstruction quality is high and stable, and the network can be used for compressed transmission of a video and follow-up video reconstruction.

Owner:XIDIAN UNIV

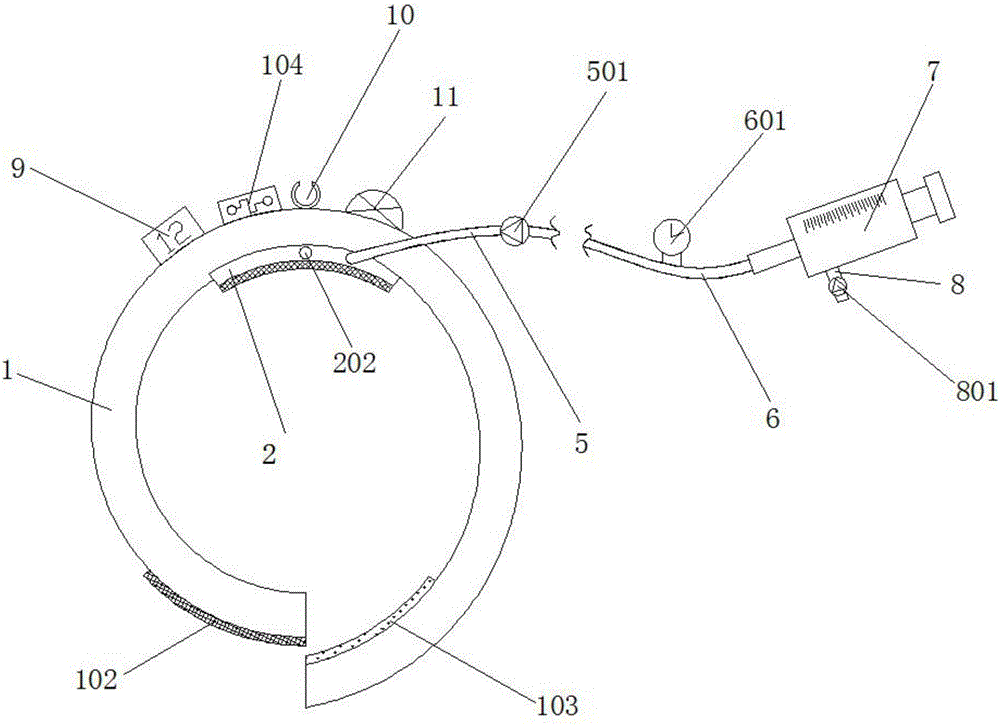

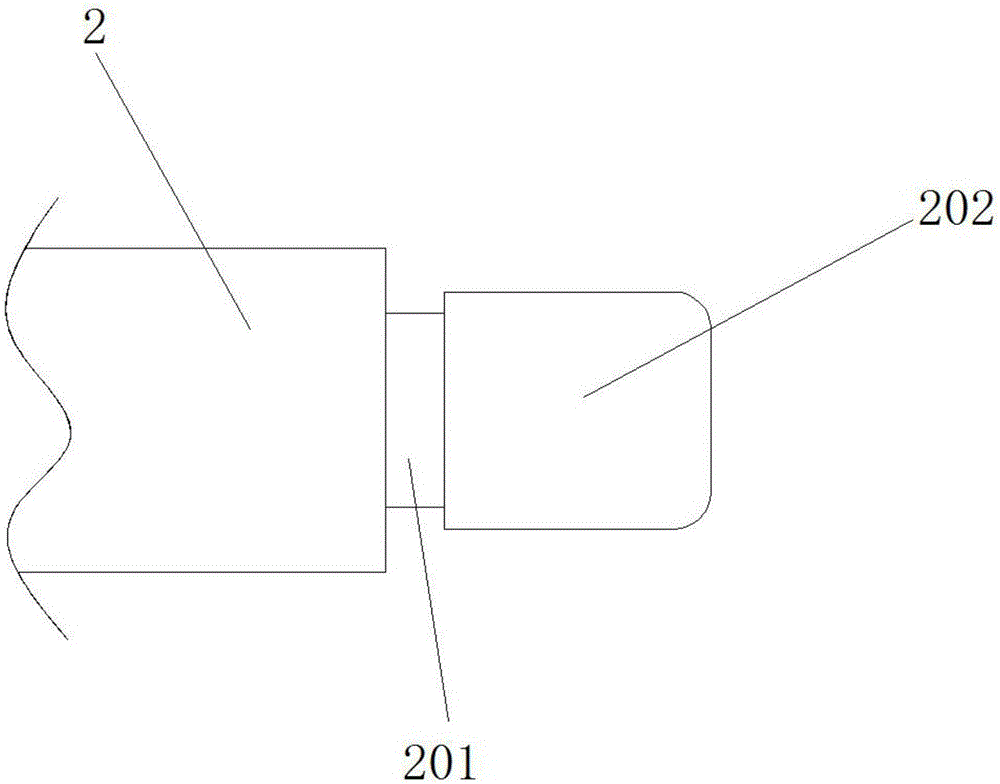

Multifunctional blood vessel compression hemostasis device

The invention discloses a multifunctional blood vessel compression hemostasis device which comprises a bandage, an air cushion, a liquid sensor, sponge, a connecting pipe, an injection pipe, an injector, an air inlet pipe, a timer, snap ring and a warner. The multifunctional blood vessel compression hemostasis device is ingenious in structure, powerful in function and simple to operate; by using the device, effective dot oppression can be performed on a patient's blood vessel puncture part, local compression force is added under the same pressure, and a compression hemostasis effect is improved; pressure applied to a puncture point can further be measured and controlled accurately, pressure values are adjusted according to different patients, a sound alarm is given against local bleeding, complications such as bleeding of the puncture position, far-end limb ischemia and internal fistula blockage are avoided, and the patients' prognosis is improved. By using the device, local compression time can be preset, the complications caused by improper compression time are avoided, and medical workers' working efficiency is improved.

Owner:皖南医学院第一附属医院

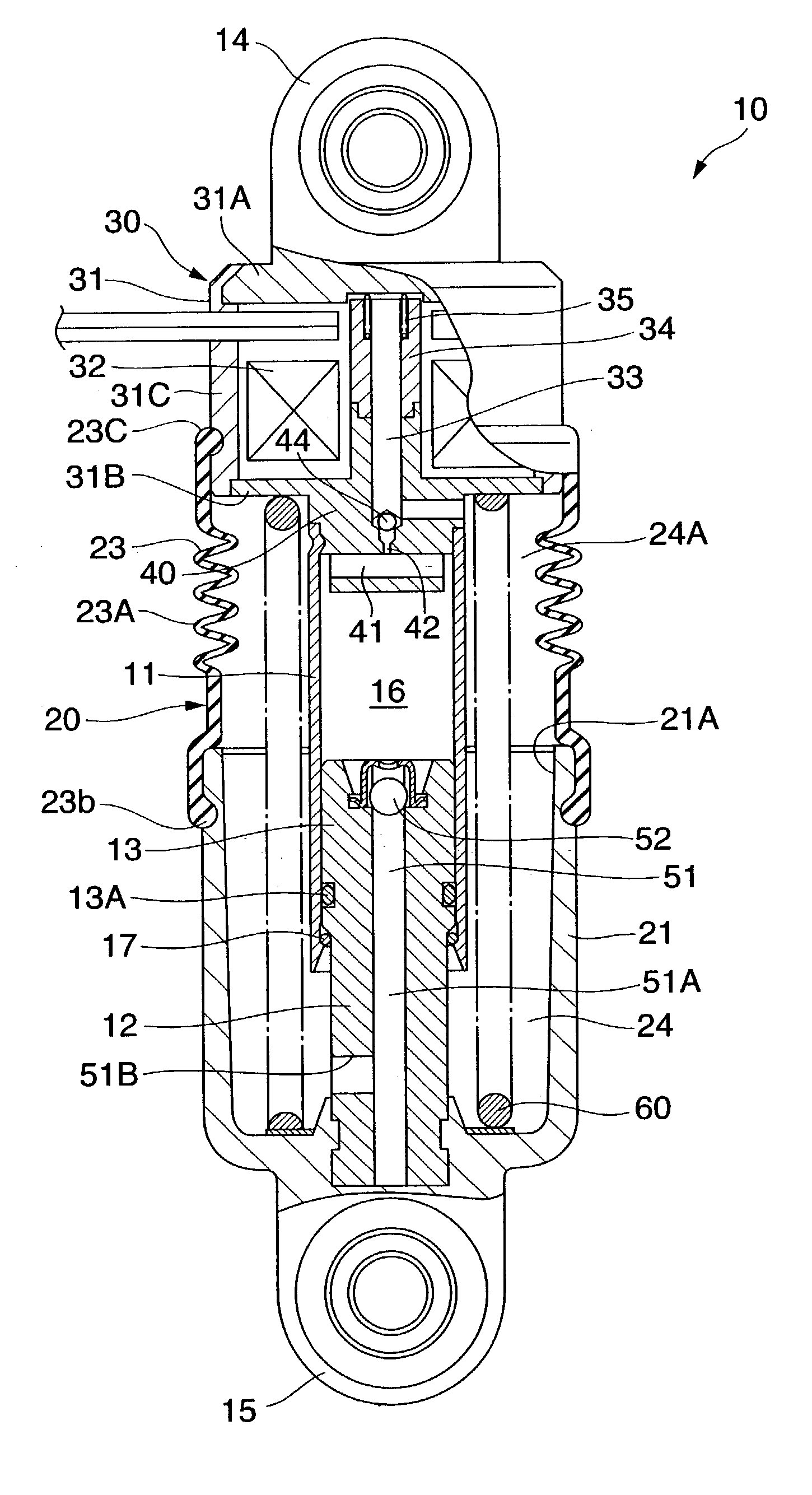

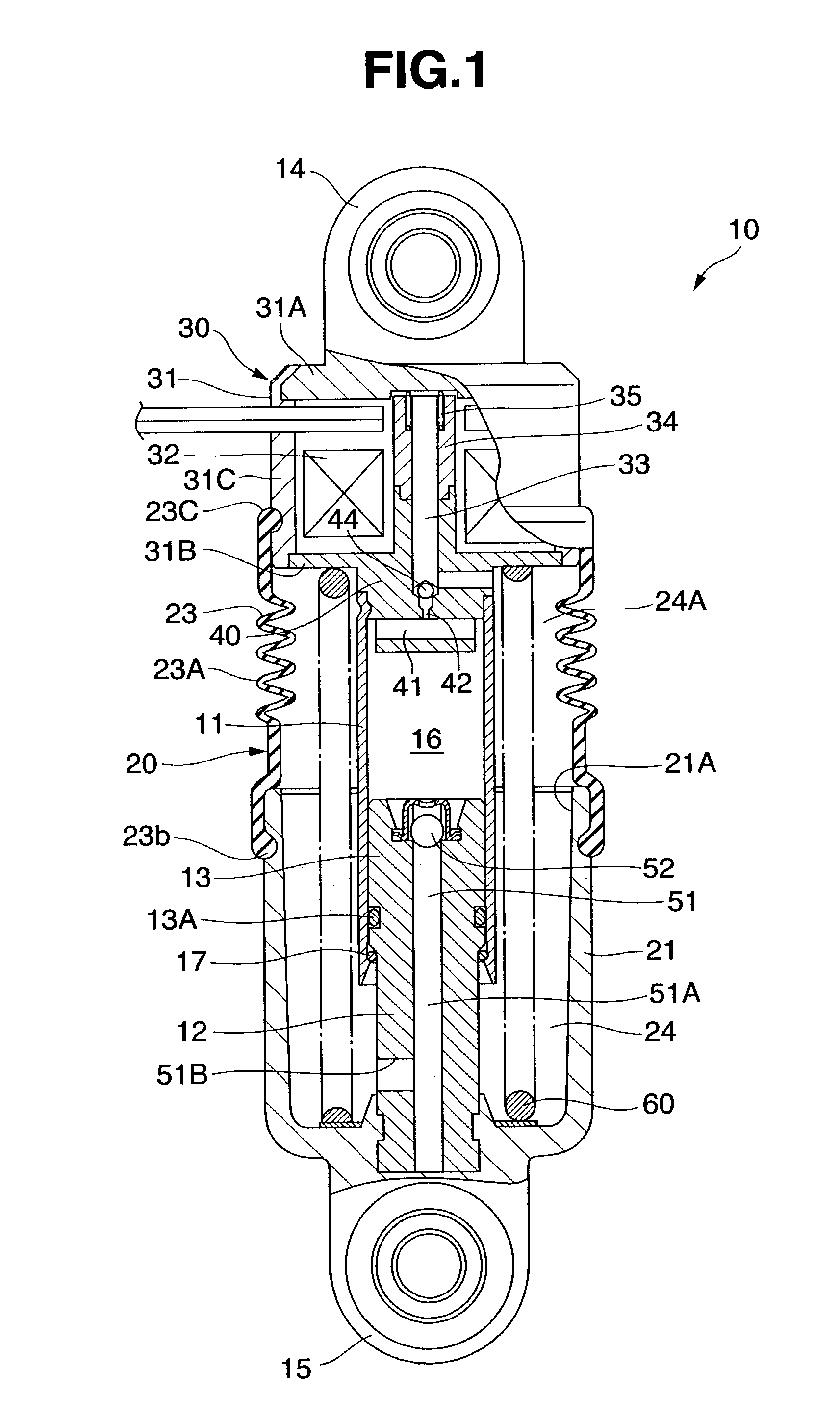

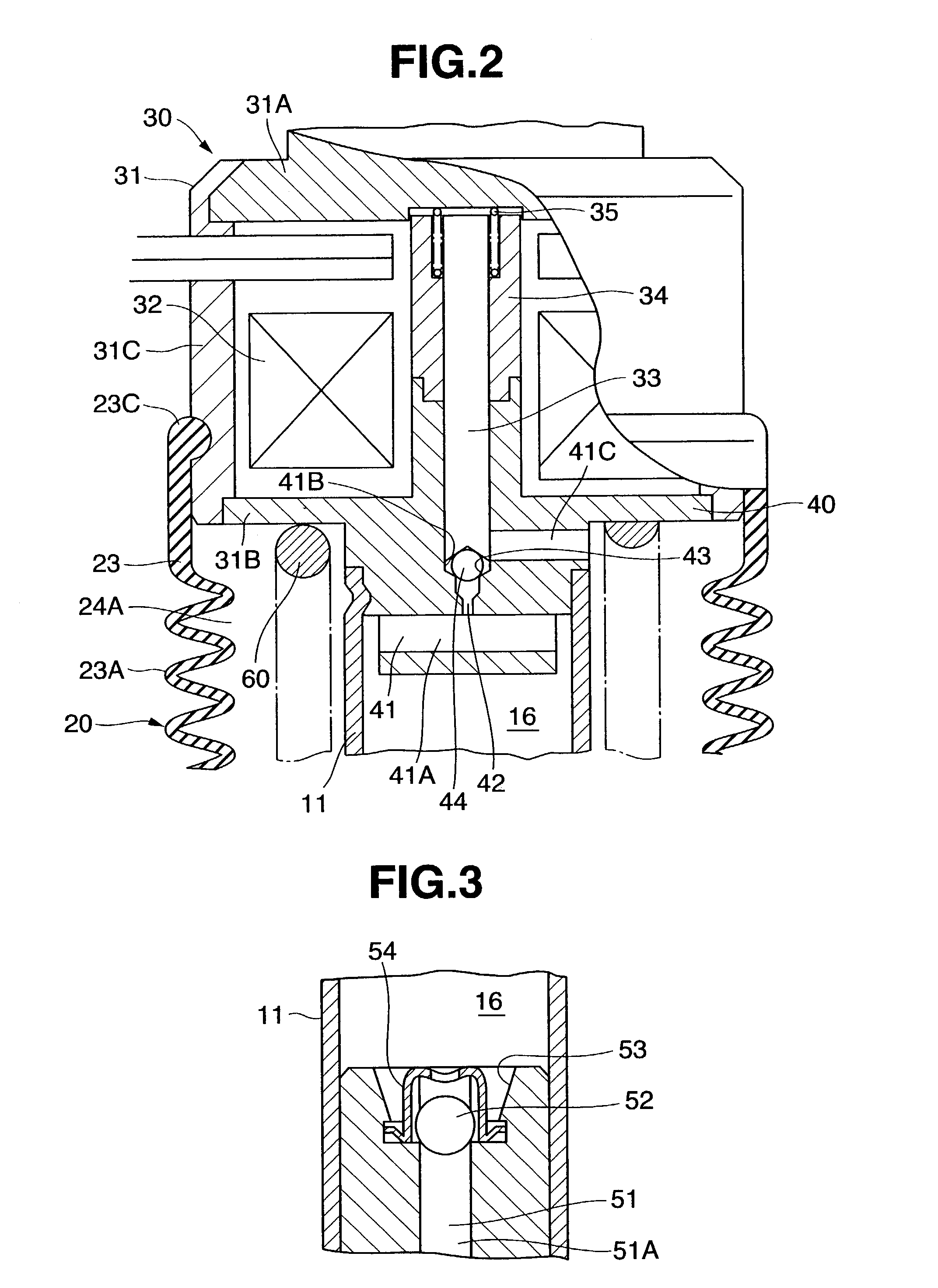

Belt tensioner

In a belt tensioner, a cylinder is mounted to a side of a stationary member positioned in an upper side. A plunger is mounted to a side of a pulley positioned in a lower side. An outer tube sectioning an oil reservoir forming a gas chamber in an upper portion is provided in an outer periphery of the plunger and the cylinder. A first oil passage communicating the gas chamber with a high pressure oil chamber is provided in an upper portion of the cylinder. A second oil passage communicating the high pressure oil chamber with the oil reservoir is provided in the plunger. An orifice hole is provided in the first oil passage. A first check valve closing at an expansion time is provided in the first oil passage, and a second check valve closing at a compression time is provided in the second oil passage.

Owner:SHOWA CORP

Control system for vehicle

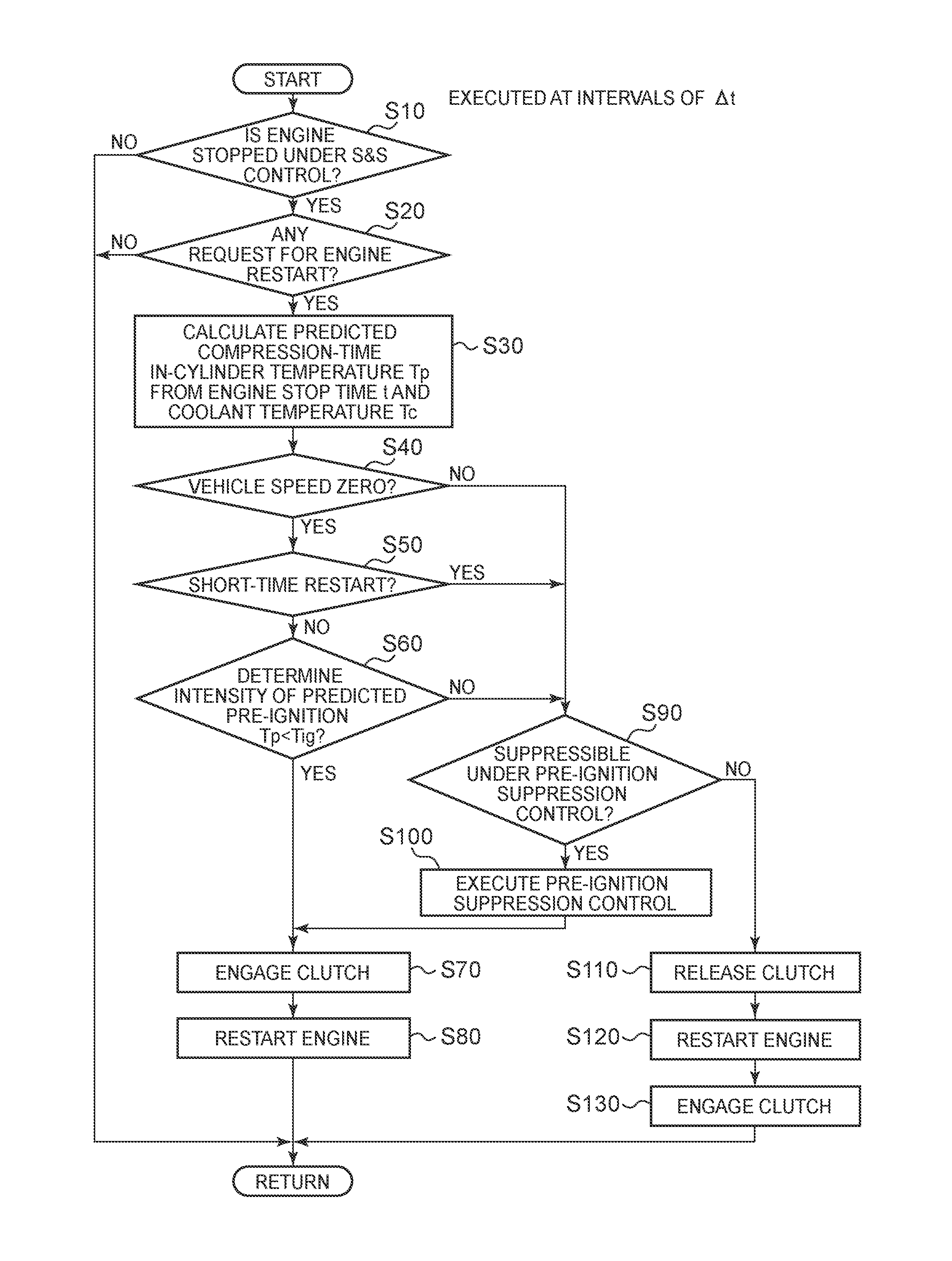

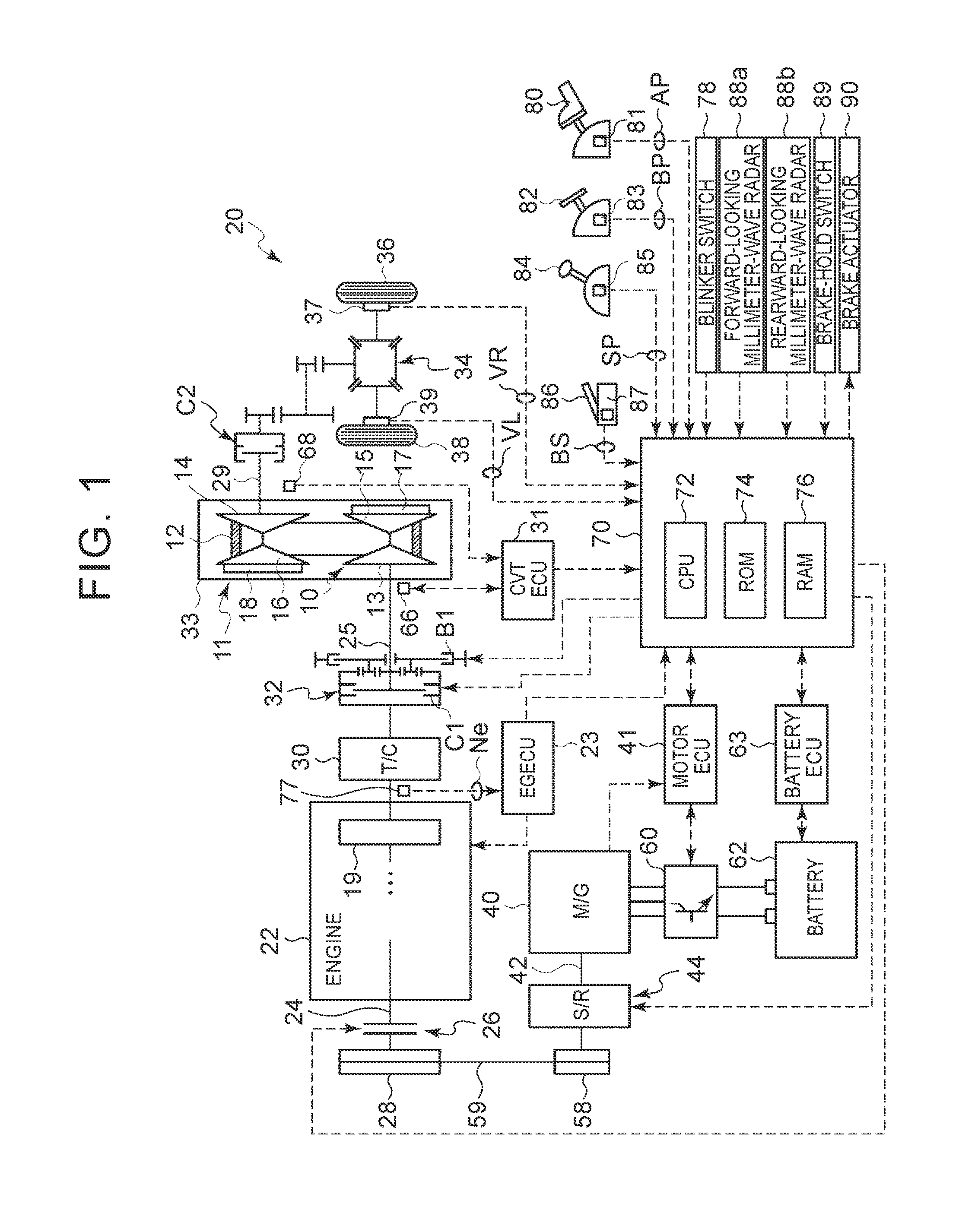

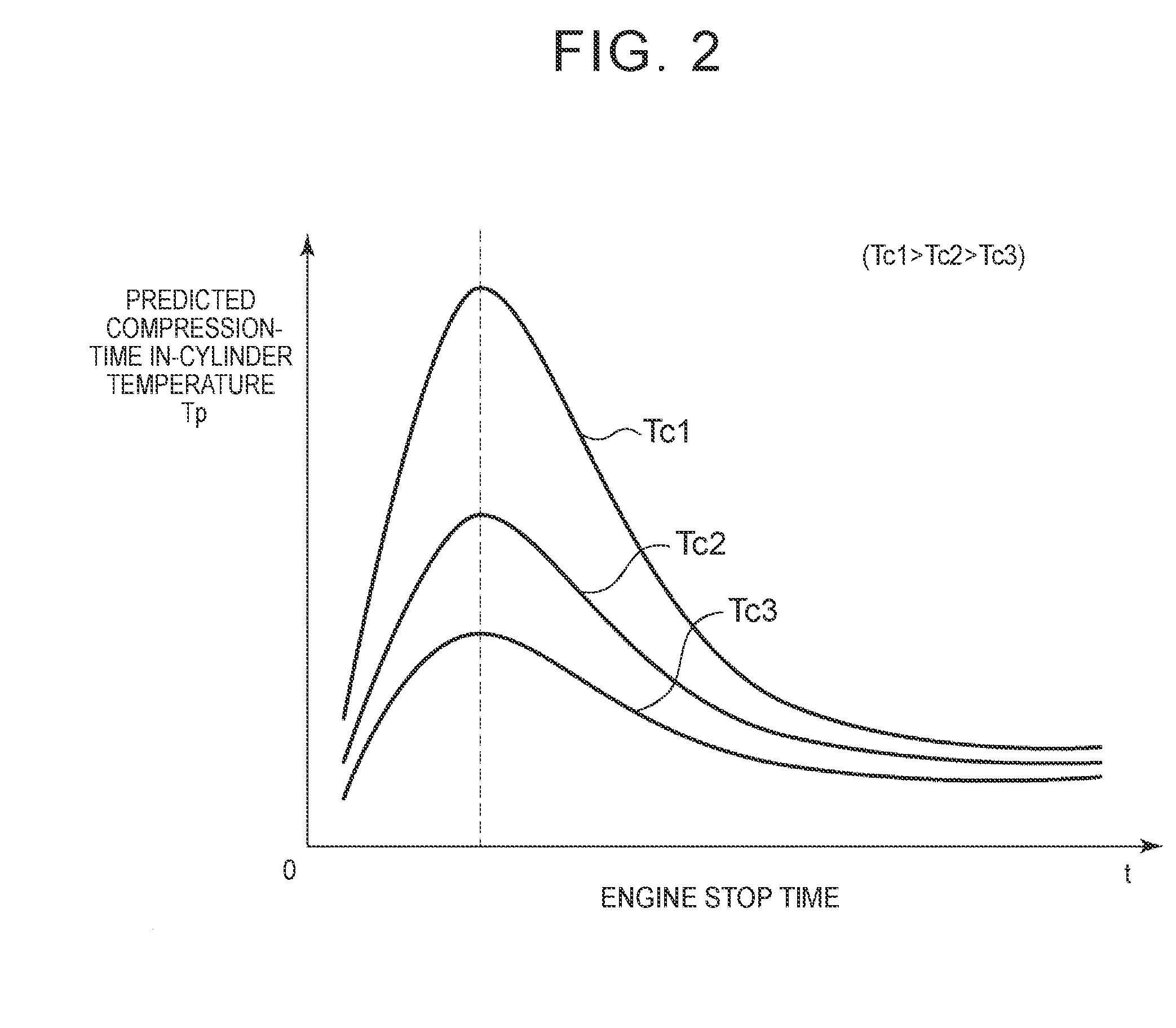

ActiveUS20160194007A1Shorter required timeRapid responseHybrid vehiclesElectrical controlControl systemEngineering

If a predicted compression-time in-cylinder temperature Tp having a positive correlation with the intensity of predicted pre-ignition is equal to or higher than a pre-ignition threshold value Tig when a request for automatic start is made, a forward / reverse switching mechanism is placed in a released state, and an engine is automatically started. If the predicted compression-time in-cylinder temperature Tp is lower than the pre-ignition threshold value Tig, the forward / reverse switching mechanism is placed in an engaged state, and the engine is automatically started.

Owner:TOYOTA JIDOSHA KK

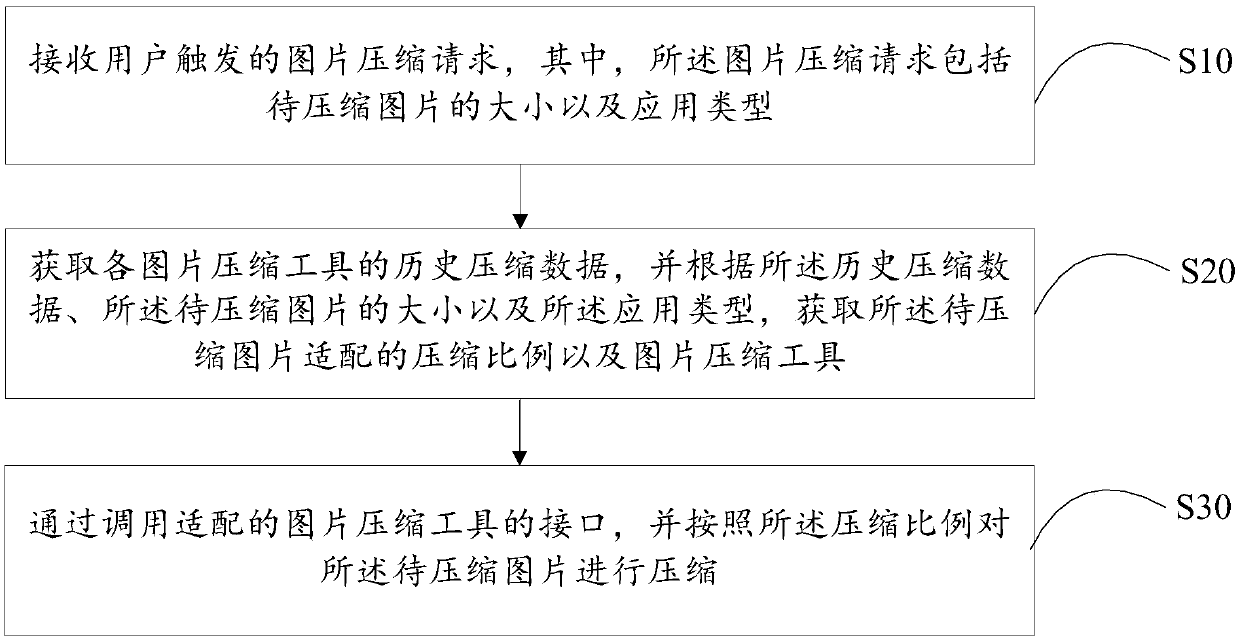

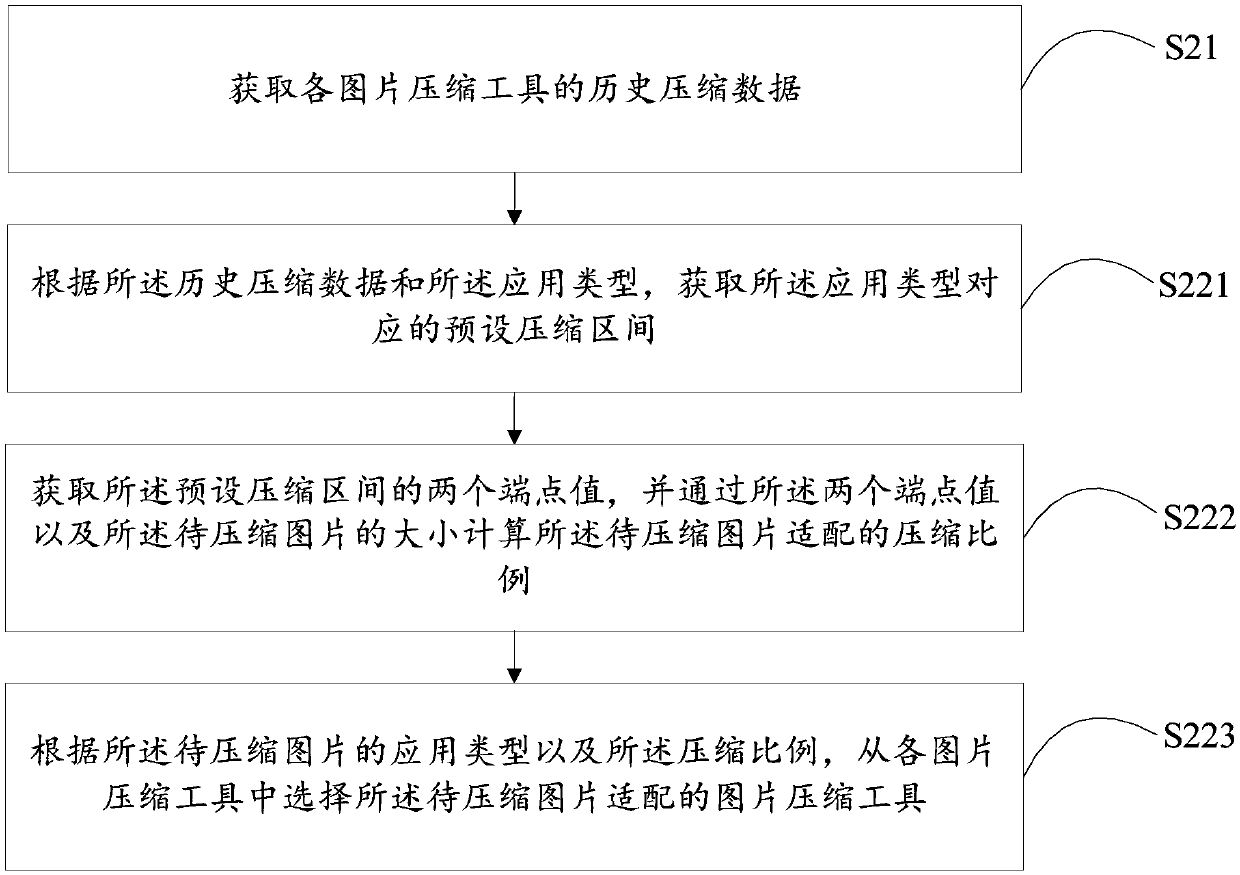

Image compression methods and equipment and computer readable memory medium

ActiveCN109672888AReduce the number of repeated compressionReduce workloadCharacter and pattern recognitionDigital video signal modificationImage compressionWorkload

The invention discloses image compression methods and equipment and a computer readable memory medium. A method comprises the steps of receiving an image compression request triggered by a user, wherein the image compression request comprises a size and an application type of a to-be-compressed image; obtaining historical compression data of each image compression tool, and obtaining a compressionproportion and the image compression tool fitting with the to-be-compressed image according to the historical compression data, and the size and the application type of the to-be-compressed image; and calling an interface of the fitting image compression tool and compressing the to-be-compressed image according to the compression proportion. A big data analysis method is employed, and the compression proportion and the image compression tool are fitted through reference to the historical compression data, so an image which is compressed once is close to a size required by a platform system ora client, repeated compression times of the image is reduced, and workload of an engineer is also reduced.

Owner:PING AN TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com