Patents

Literature

293results about How to "Improve equalization performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

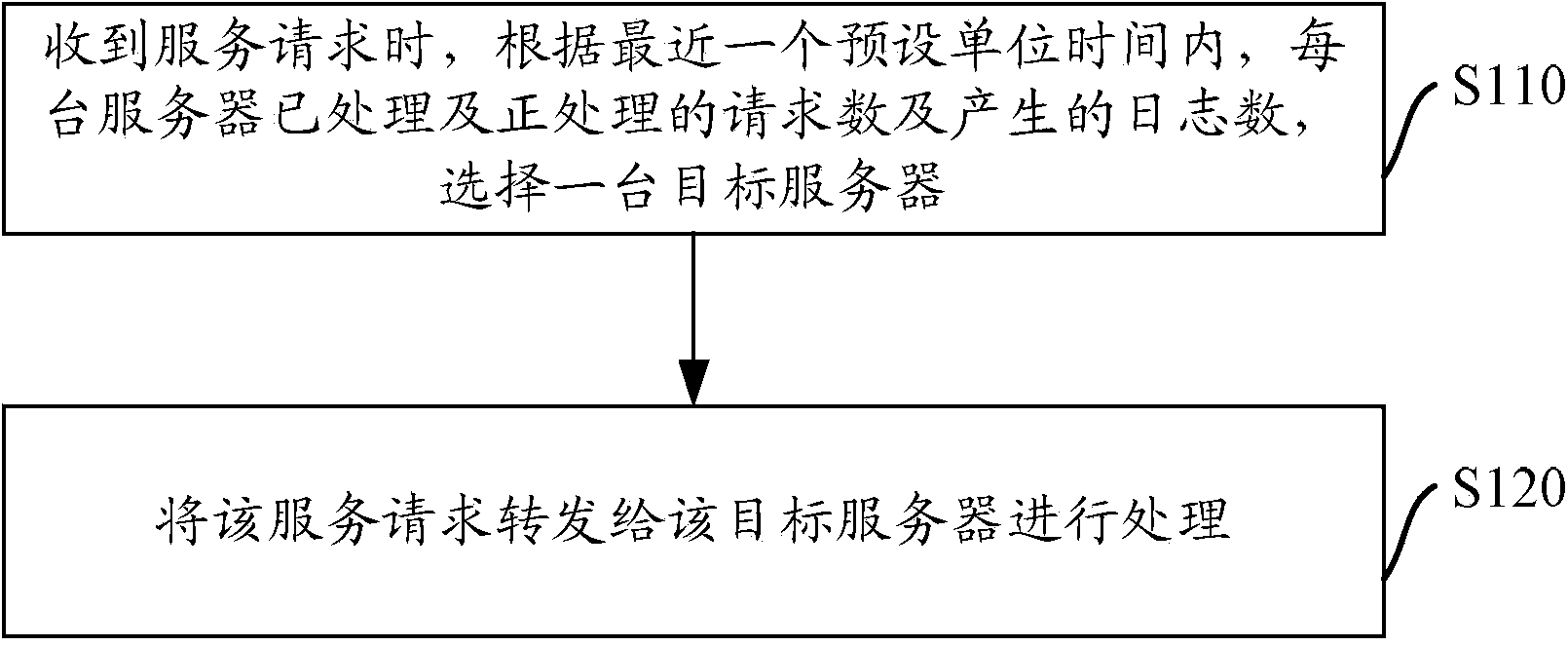

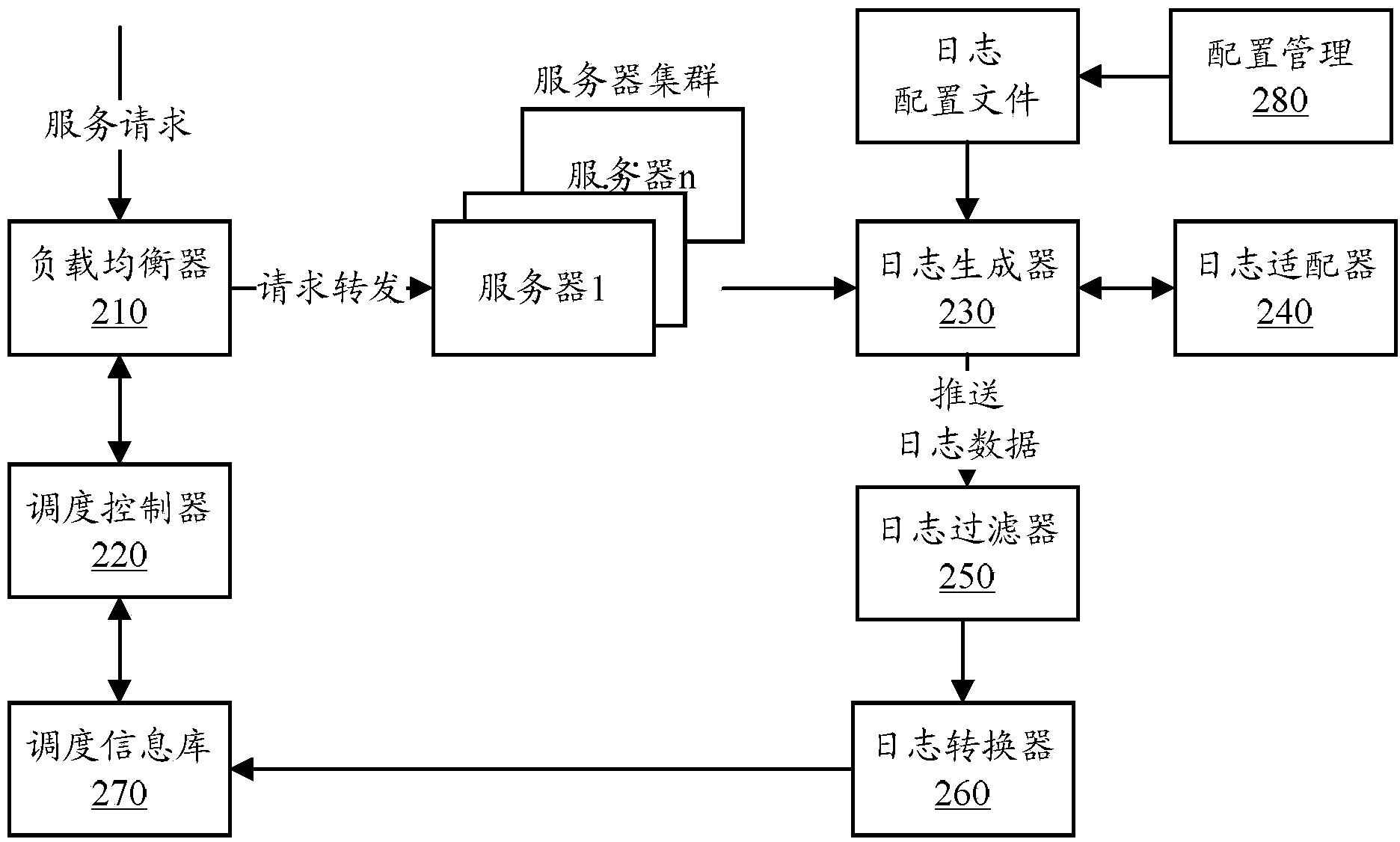

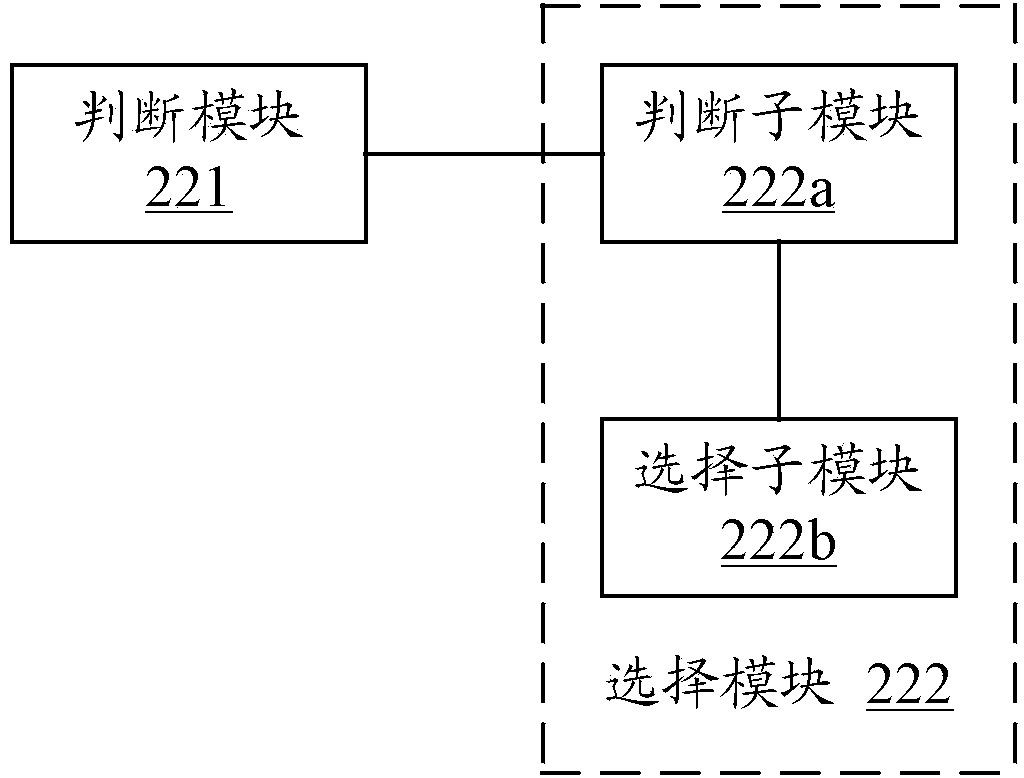

Cloud computing platform server load balancing system and method

ActiveCN103516807ANo added complexityImprove equalization performanceTransmissionTime conditionDynamic load balancing

The invention discloses a cloud computing platform server load balancing system and method, so as to overcome the defect that the current static load balancing technology cannot carry out dynamic adjustment according to the real-time condition of a load and the defect that a dynamic load balancing technology needs to additionally occupy system resources. According to the method, when a service request is received, a cloud computing platform selects a target server according to the number of requests which are processed and are being processed by each server in a cluster in recent preset unit time and the number of generated logs, and forwards the service request to the target server for processing. According to the embodiment of the invention, the load balancing can be effectively improved.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

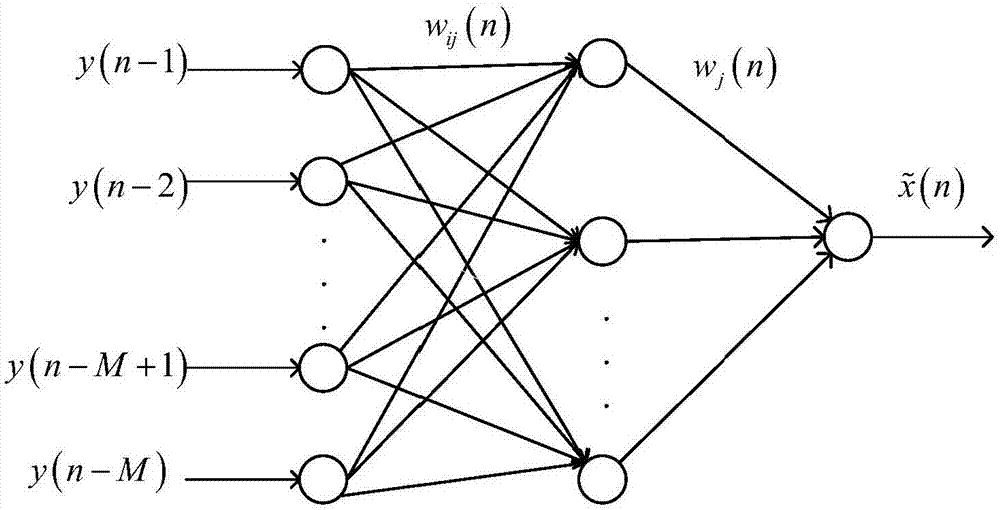

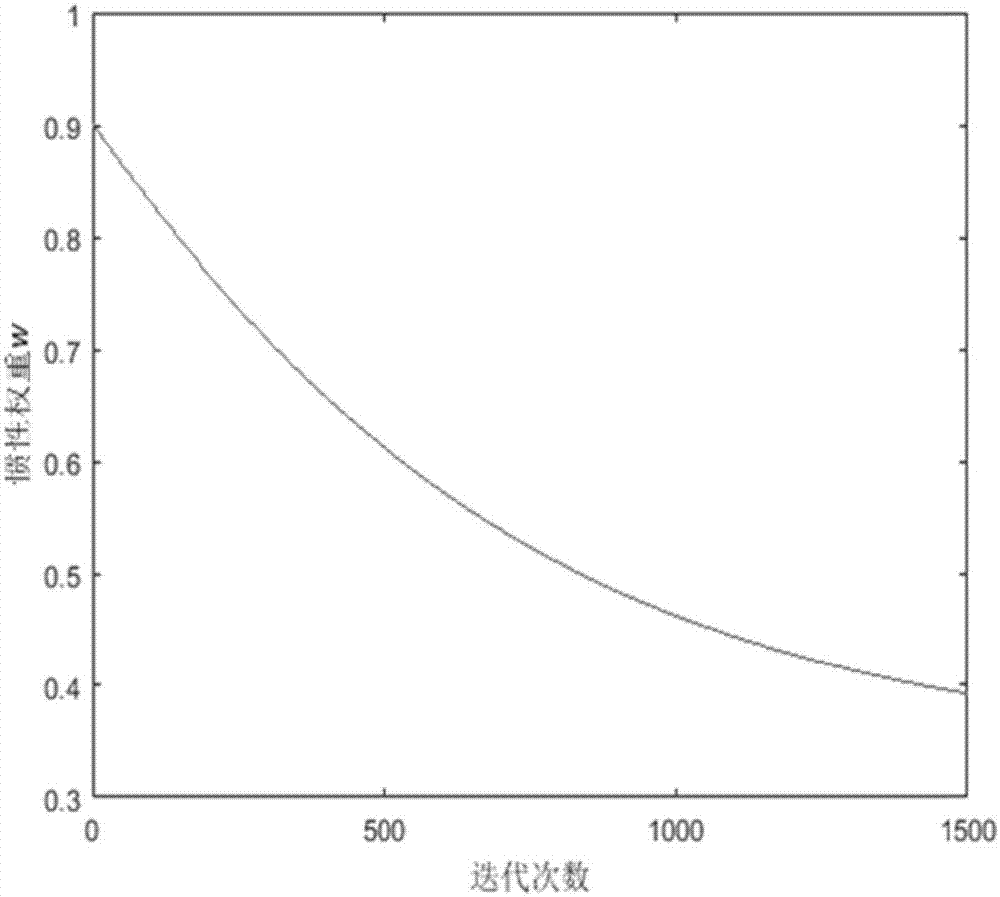

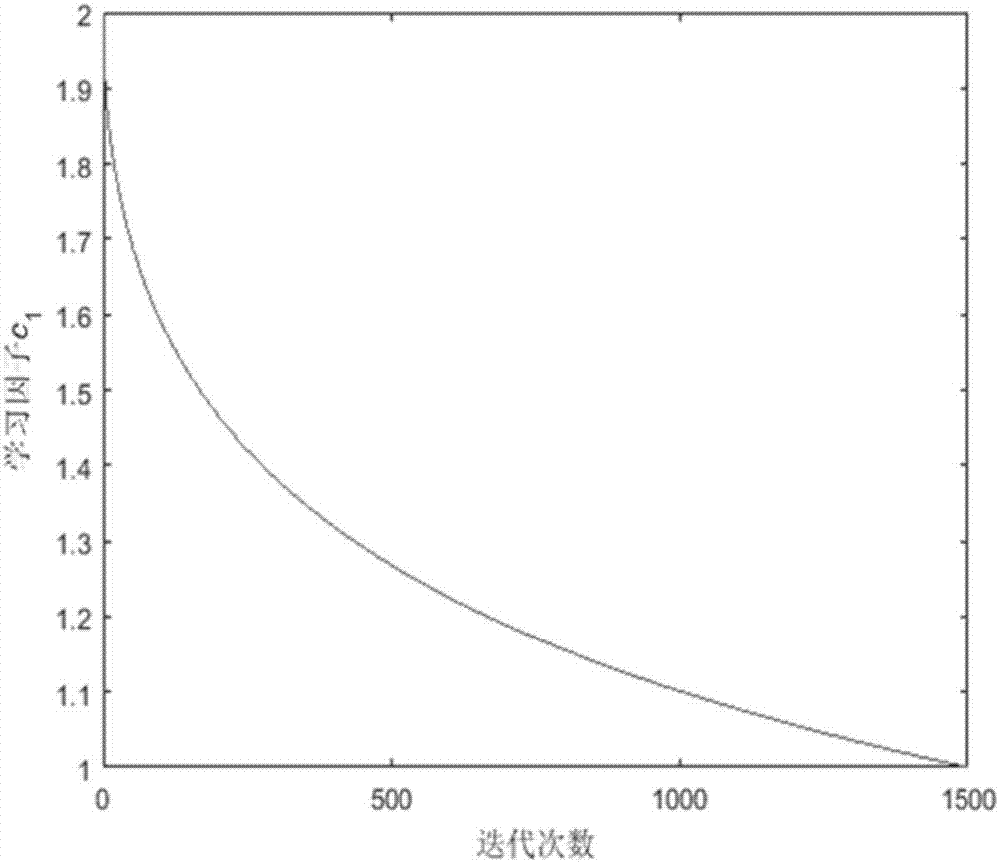

Blind channel balancing method based on improved PSO (Particle Swarm Optimization) BP (Back Propagation) neural network

InactiveCN107547457AImprove learning effectFast convergenceTransmitter/receiver shaping networksNeural learning methodsLearning factorParticle swarm algorithm

The invention designs a blind channel balancing method based on an improved PSO (Particle Swarm Optimization) BP (Back Propagation) neural network. In the process of solving the blind balancing problem on the basis of a BP neural network, determination of an initial weight and a threshold of the BP neural network is lack of the theoretical basis and has the defects of low convergence speed, easiness for falling into a local minimal value and the like so as to cause a poor channel blind balancing effect. In order to overcome the defects of the BP neural network and improving the channel blind balancing effect, the invention discloses a blink balancing method based on the improved PSO-BP neural network. According to the method, firstly, defects of a basic particle swarm algorithm are overcome, parameters of the basic particle swarm are improved, and an inertia weight and a learning factor are adaptively regulated; secondly, the initial weight and the threshold of the neural network are optimized by utilizing the advantage of high global searching capacity of the improved particle swarm, and then more accurate searching is carried out in such local space by utilizing a BP algorithm soas to obtain an optimal connection weight and threshold of the neural network; and finally, blind balancing based on the the improved PSO-BP neural network is implemented.

Owner:CHONGQING UNIV

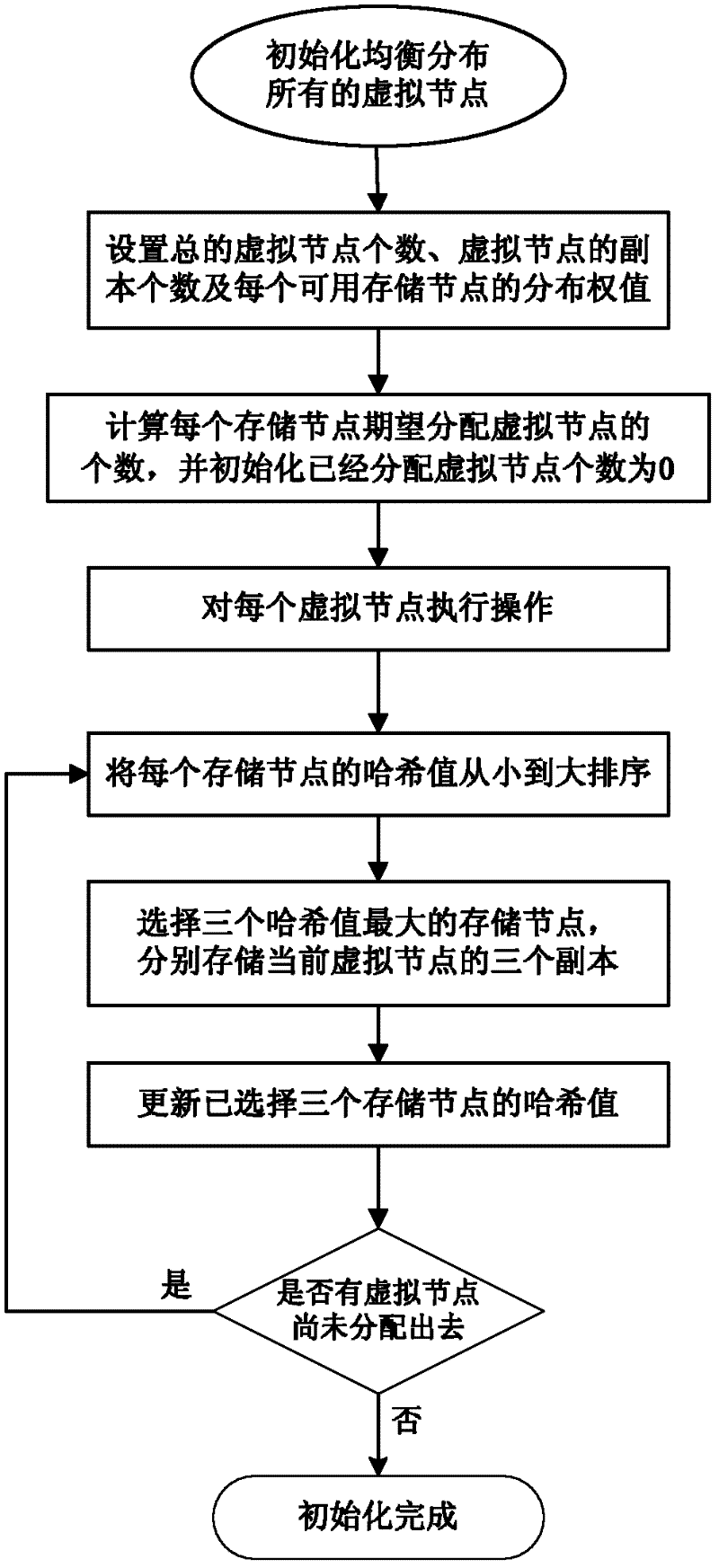

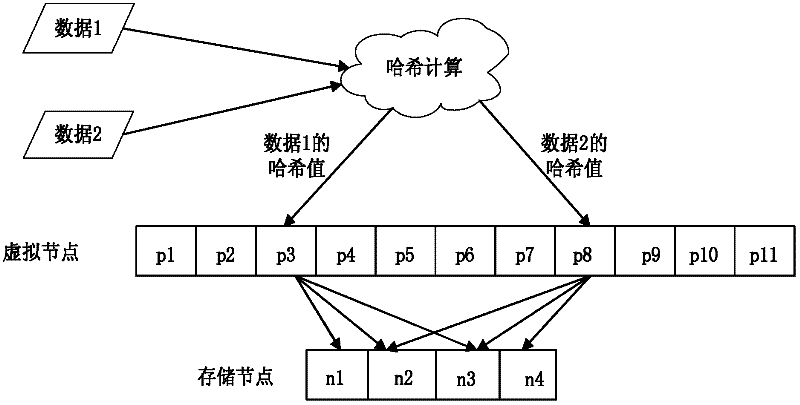

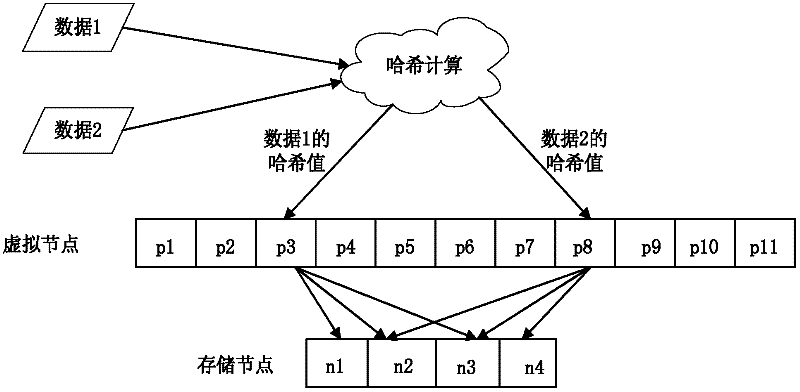

Method for uniformly distributing data in cloud storage

ActiveCN102457571AImprove equalization performanceGuaranteed availabilityTransmissionHash functionData needs

The invention relates to a method for uniformly distributing user data in a cloud storage system, which comprises the following steps of: setting a total number of virtual nodes and a number of copies in the cloud storage system; setting a distribution weight of each storage node in the cloud storage system; determining the number of virtual nodes to be distributed according to the total number of the virtual nodes, the total number of the copies and the distribution weight of each node in the cloud storage system; uniformly distributing three copies of all the virtual nodes onto different storage nodes according to the number of the virtual nodes to be distributed of each node in the cloud storage system; when the data need to be stored, mapping the data to a certain virtual node by a hash function and then respectively storing three copies of the data into the three copies of the acquired virtual nodes; and when the storage nodes are added in or removed from the cloud storage system, acquiring information of the virtual nodes to be redistributed, recalculating the number of virtual nodes to be distributed of each available storage node and then redistributing the virtual nodes.

Owner:CHINA STANDARD SOFTWARE

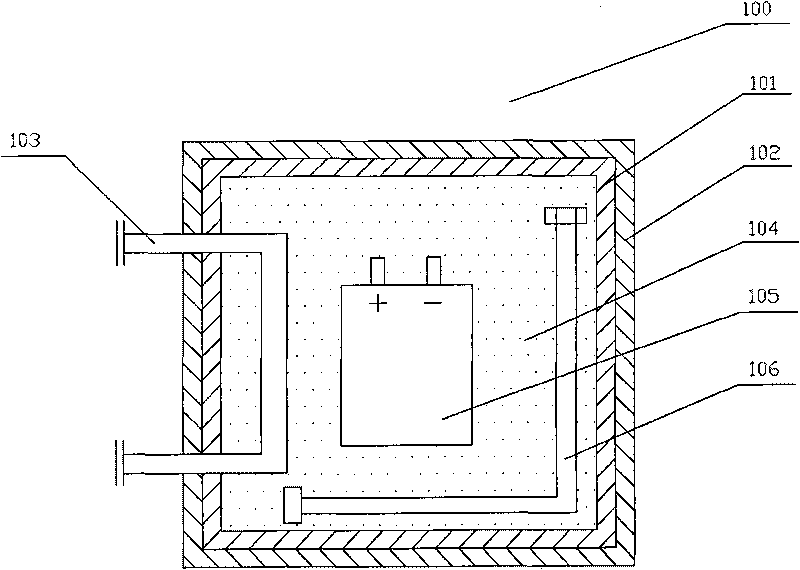

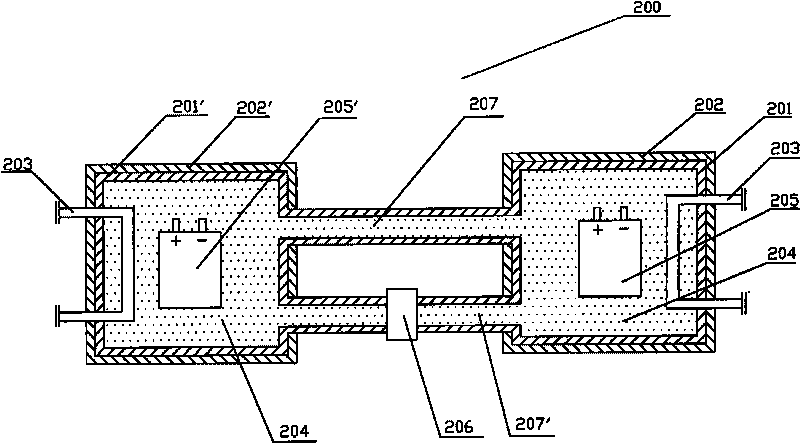

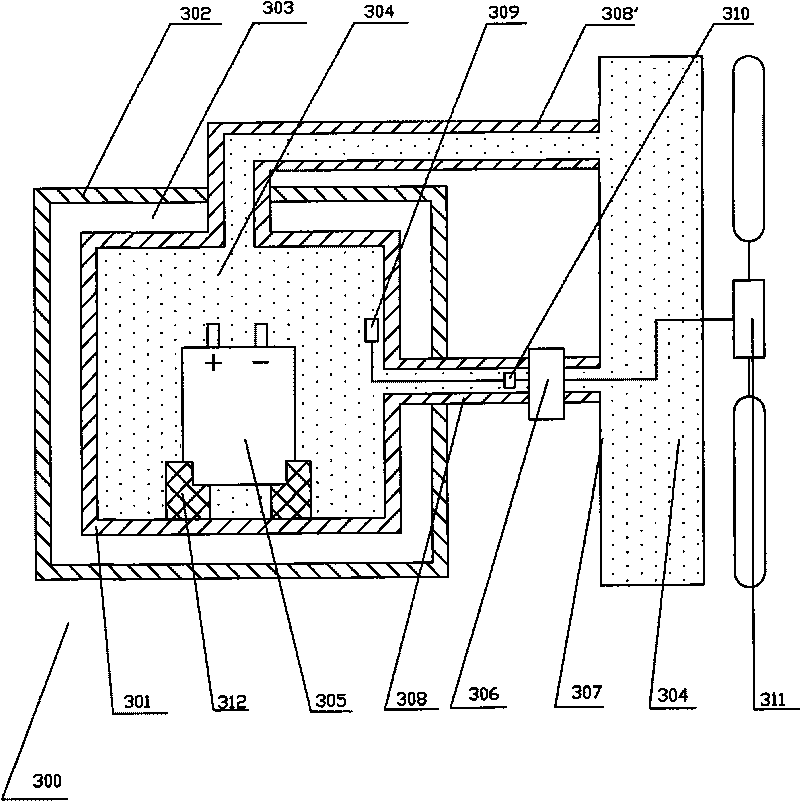

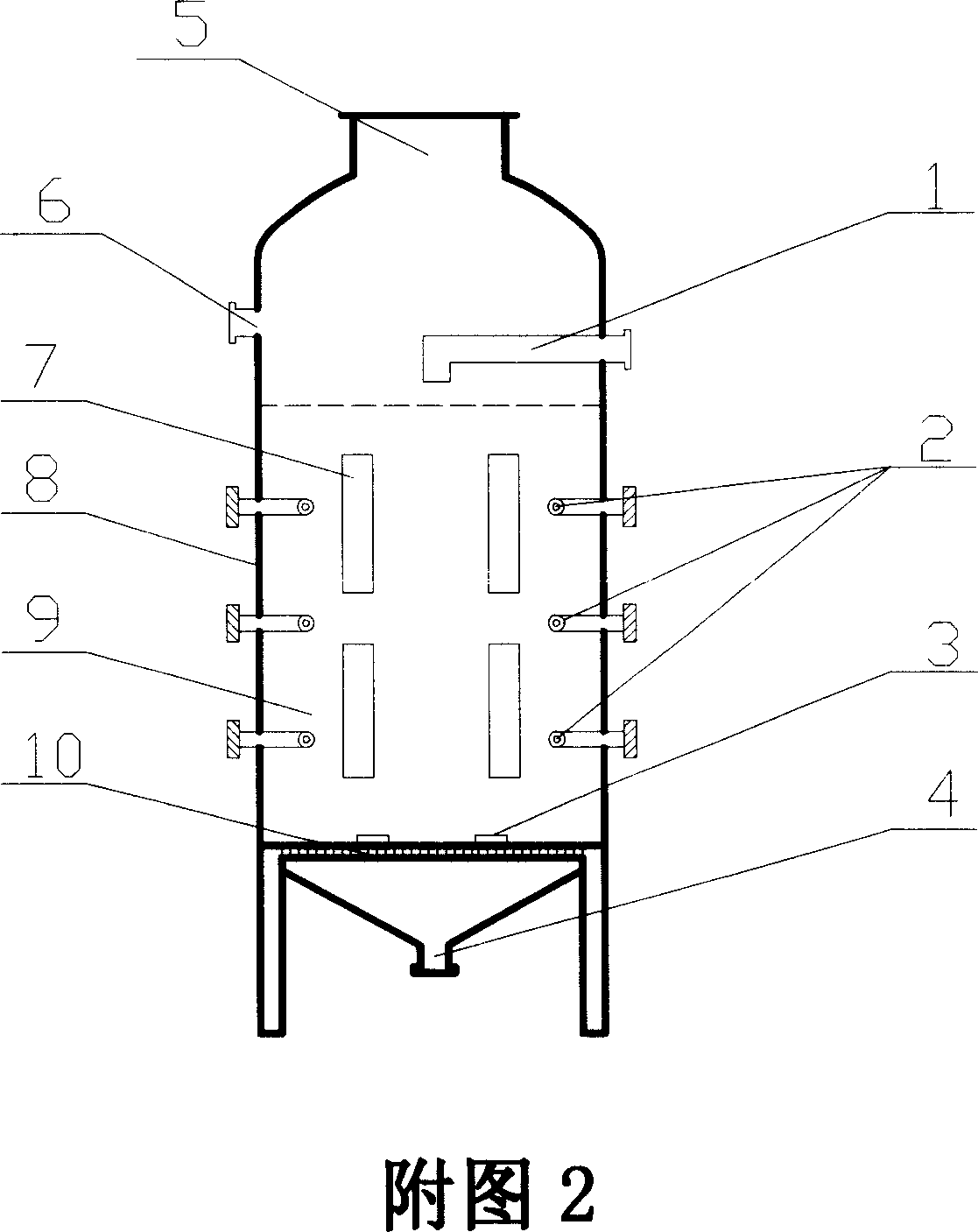

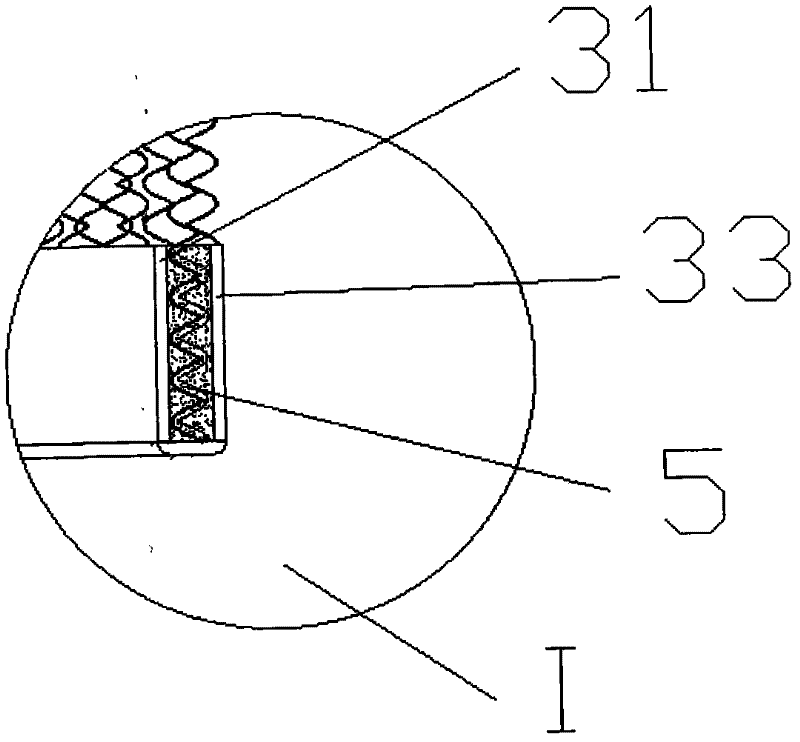

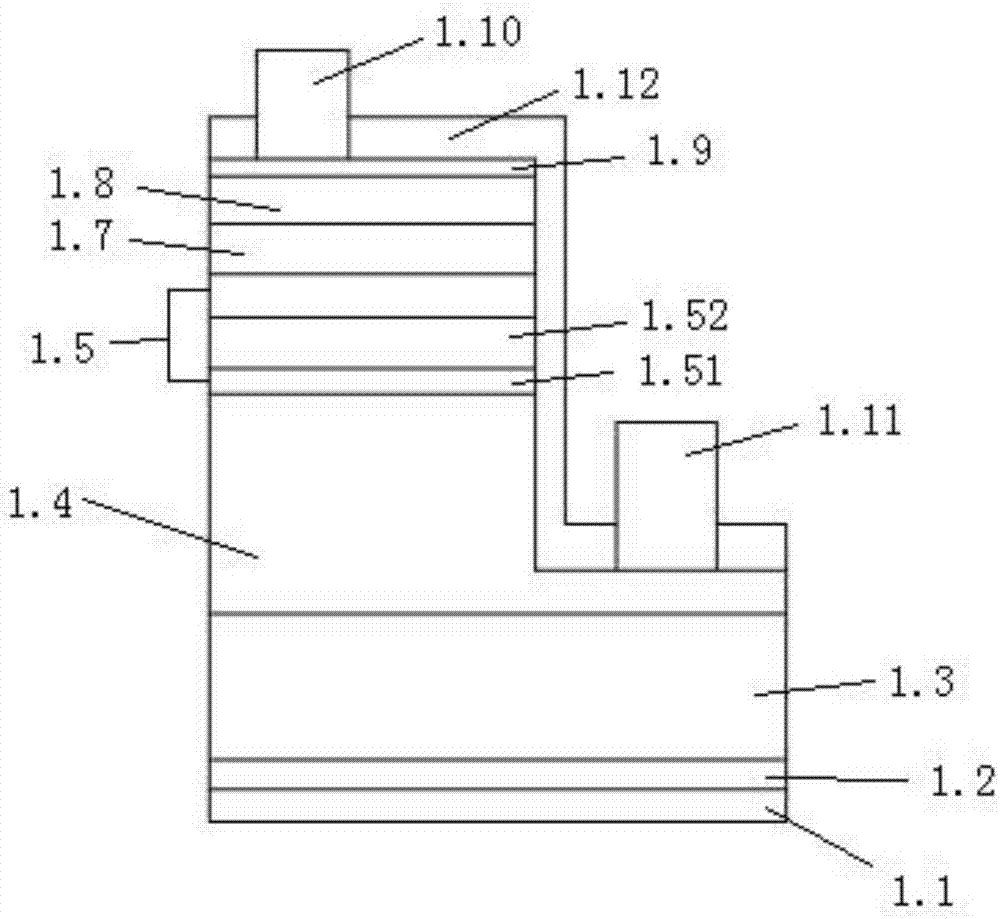

Protective device, protective device system and protective method of power battery

InactiveCN101728597AExtended service lifeImprove liquidityElectric propulsion mountingSecondary cellsElectrical batteryCharge and discharge

The invention provides a protective device of a power battery, which solves the problem that the whole battery pack forms a short-board effect because the environmental temperature difference between single batteries causes the effectiveness reduction of single batteries in the process of charging and discharging a battery pack of the power battery in the prior art. The protective device comprises a closed battery box inside which a liquid is contained, wherein the battery pack is immersed into the liquid inside the battery box. The invention also provides a protective method of the power battery, comprising the step of immersing the battery pack of the power battery into the liquid. The protective device or the protective method can equalize the environmental temperature of all single batteries in the battery pack, avoid the problem of the single batteries, prevent the short-board effect, prolong the service life of the batteries and also achieve the effect of fire prevention because of the liquid sealability of the liquid.

Owner:李光明

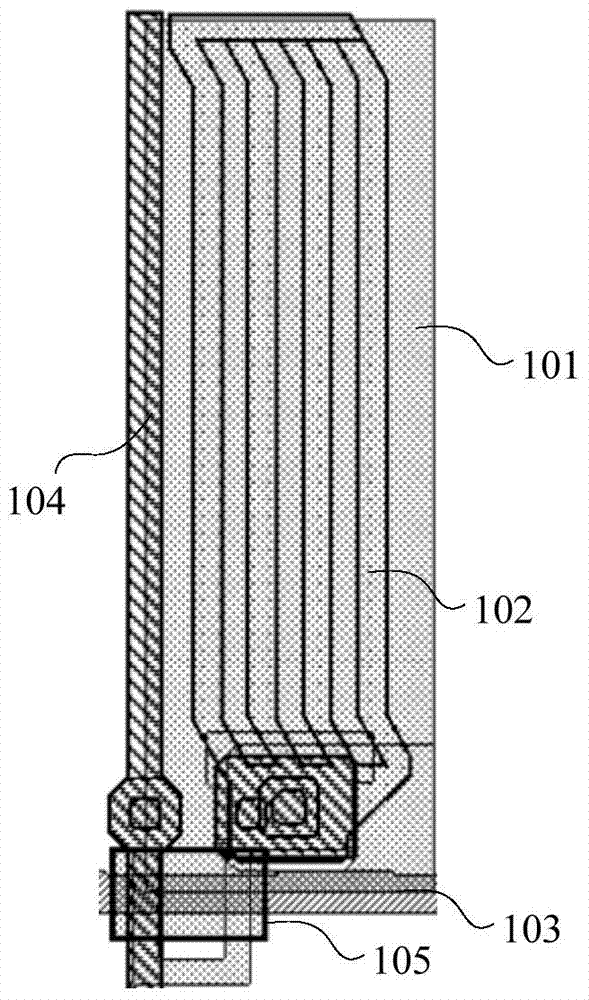

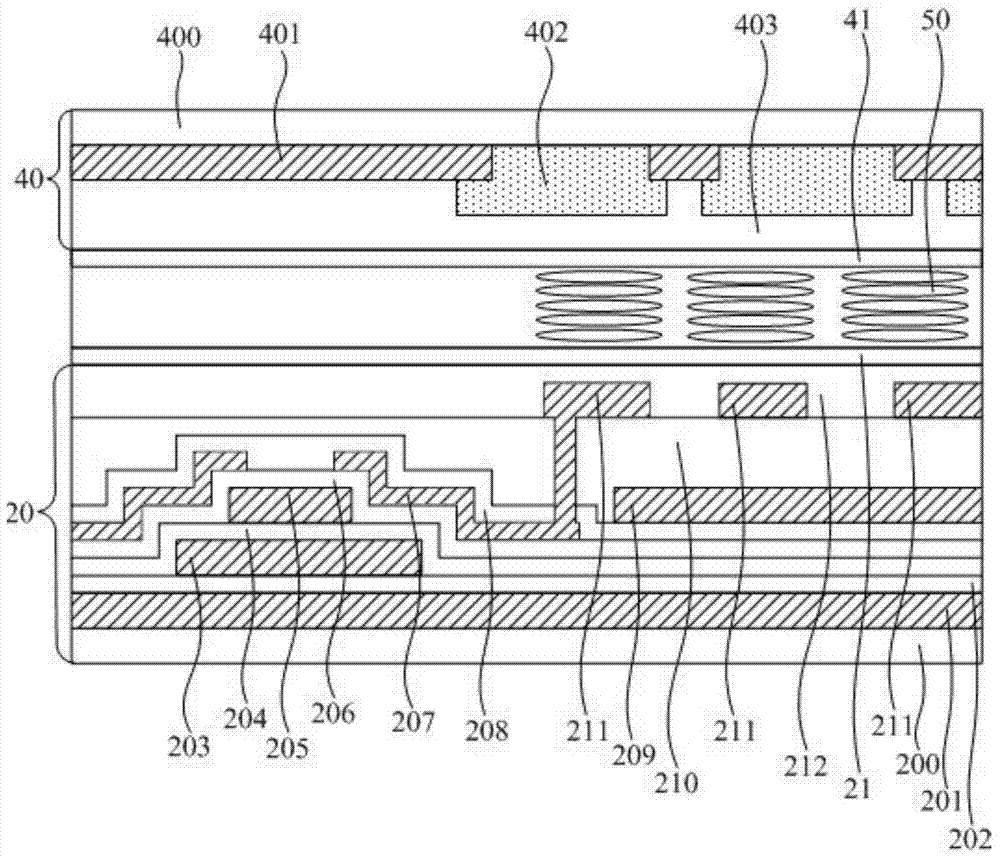

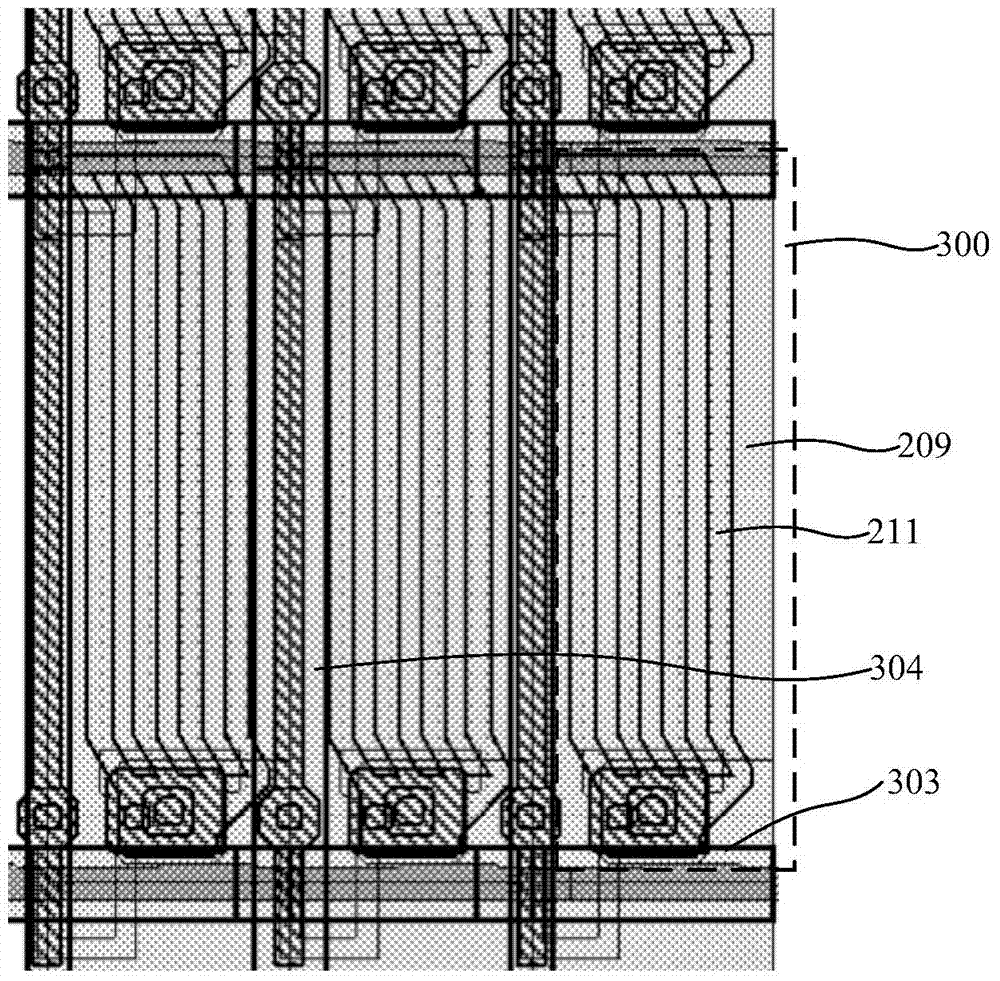

TFT array substrate, display panel and display device

ActiveCN103926757AReduce crosstalkAlleviate the problem of screen flickeringNon-linear opticsDisplay deviceEngineering

The invention provides a TFT array substrate, a display panel and a display device. The TFT array substrate comprises a base plate, a shade conducting layer, and a common electrode; the shade conducting layer is arranged on the base plate; the common electrode is arranged above the shade conducting layer. The base plate comprises a plurality of pixels. The shade conducting layer comprises shade elements, a plurality of first and second common electrode lines; the shade elements are used for shading TFT grooves in each pixel; the first common electrode lines extend in a first direction; the second common electrode lines extend in a second direction; at least one of the first and second common electrode lines is electrically connected with the common electrode; the second and first common electrode lines intersect in a mesh structure; projections of the first and second common electrode lines, perpendicular to the base plate, cover gaps among the pixels. The first and second common electrode lines forming in the mesh structure are electrically connected with the common electrode, so that voltages of the common electrode are more balanced and the problems of crosstalk and flicker are improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

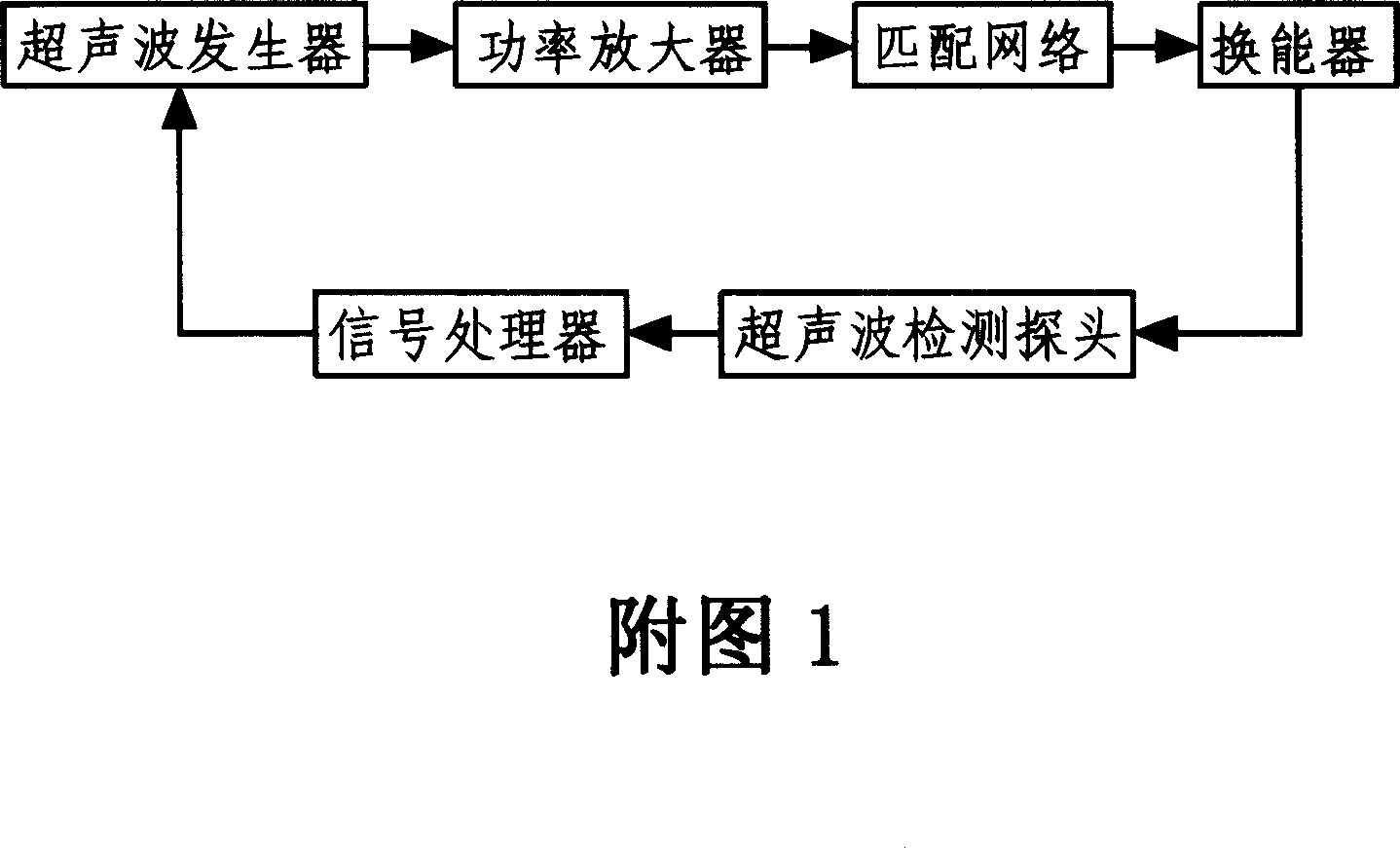

Technology for regenerating active carbon by supersonic desorptive activation

InactiveCN101073766AReduce energy consumptionNo pollution in the processOther chemical processesCombustible gas purificationShock waveSound pressure

The invention is concerned with active carbon rebirth technology to desorption and activation with large power industry ultrasonic technology after active carbon is saturation for disposing the sewage with organic matters and heavy metal ion with filtration. The ultrasonic generator sends out high frequency surging signal and the transducer changes the high frequency sound wave to spread in medium and produce exquisite machine surge. Ultrasonic travels in cleaning medium to drive the liquid to produce lots of tiny air bubbles, those air bubbles shake intensively with the action of sound field. When the press of sound reaches to a certain value, the bubbles rise quickly and close suddenly and the close produces shock wave and thousands of atmospheric pressure to force the water-fast feculence to escape from the carbon hole to disperse in the solution. It will clean the tiny space and surface of active carbon to realize the rebirth process. It has low rebirth cost without another pollution and the renewed active carbon has better adsorption efficiency, likely 95 to 130 percent of new carbon, and the wastage is less than 0.3 percent each time. This active carbon has long work time for circulation using with low cost and wide application range.

Owner:周恩民

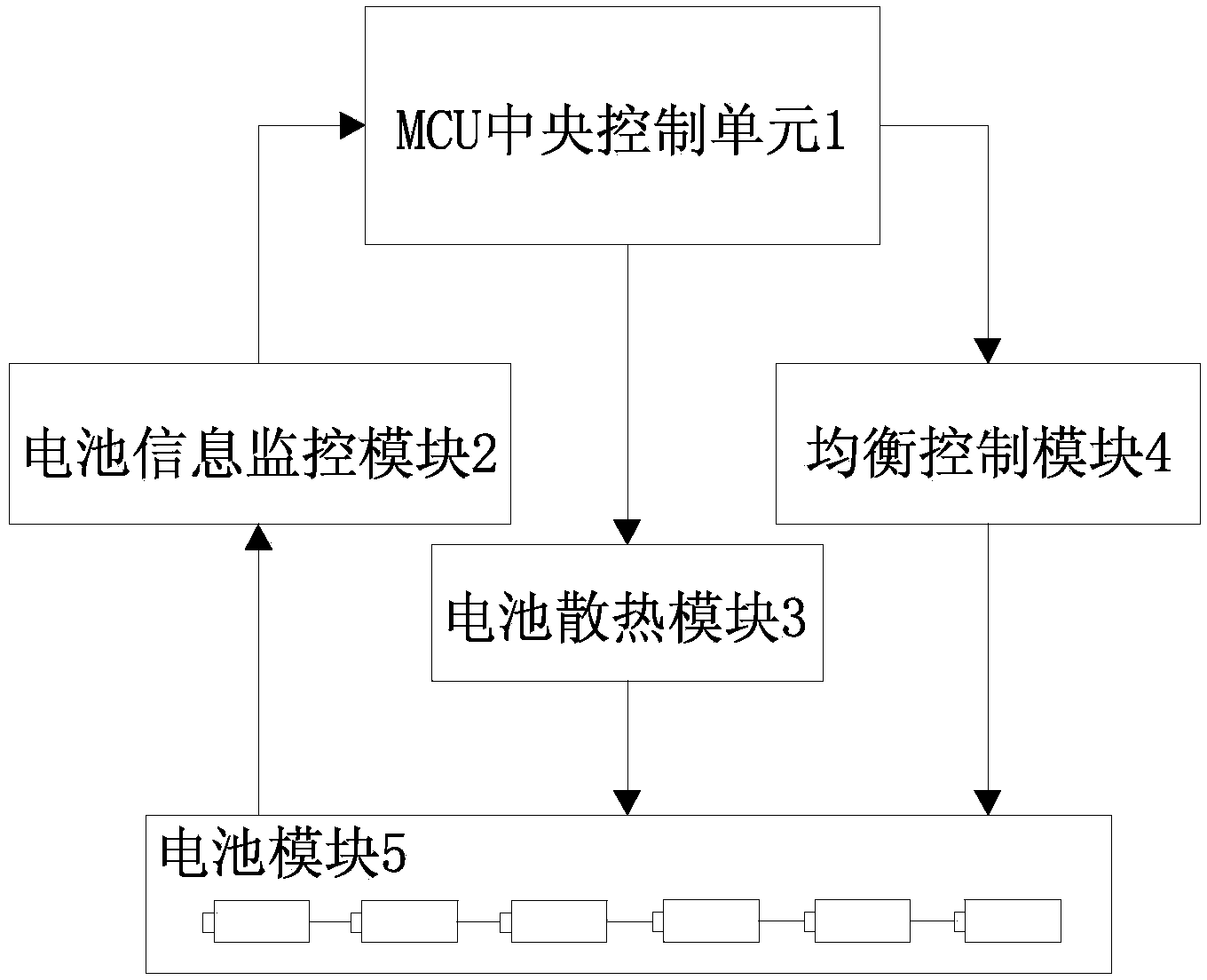

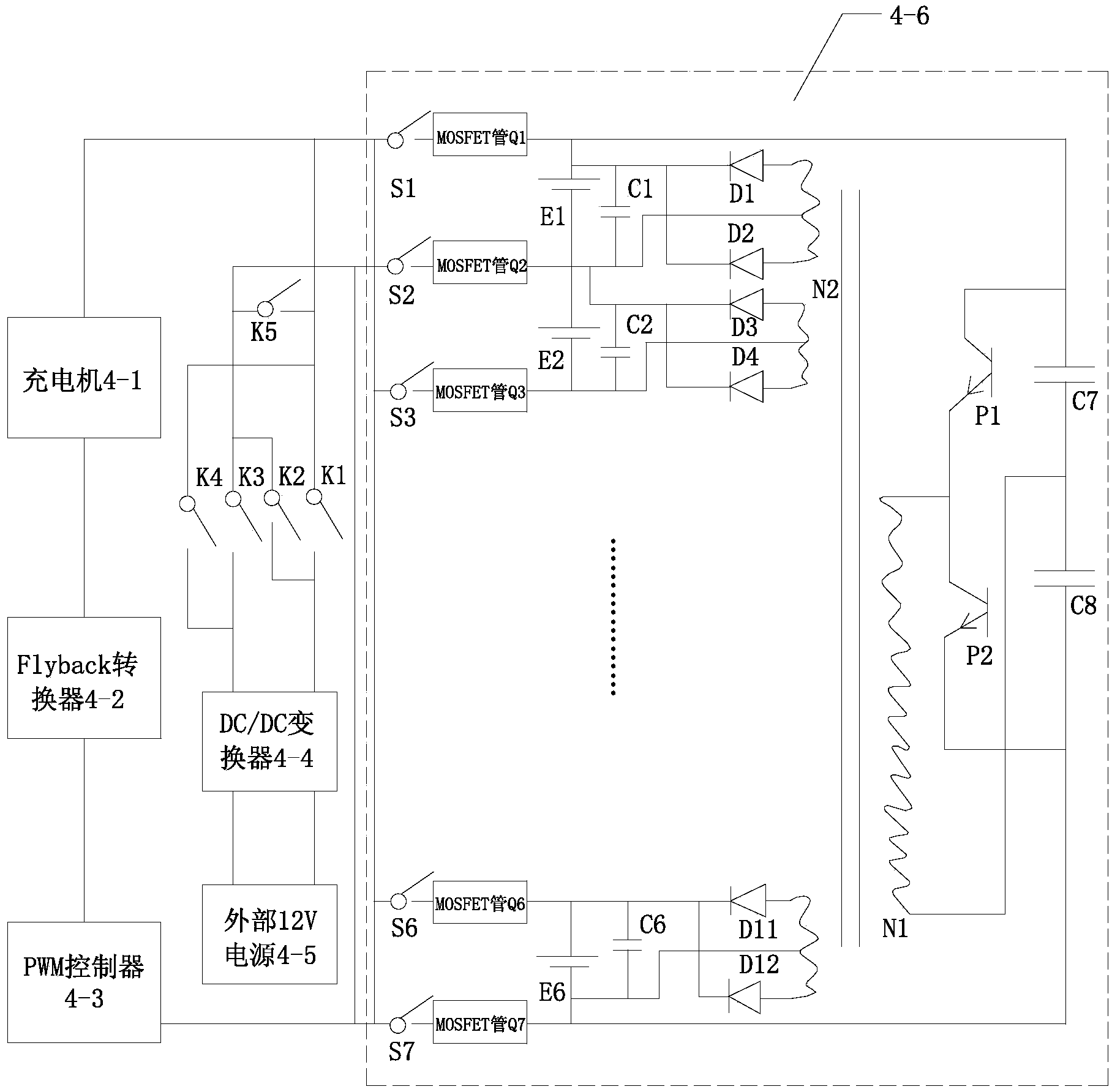

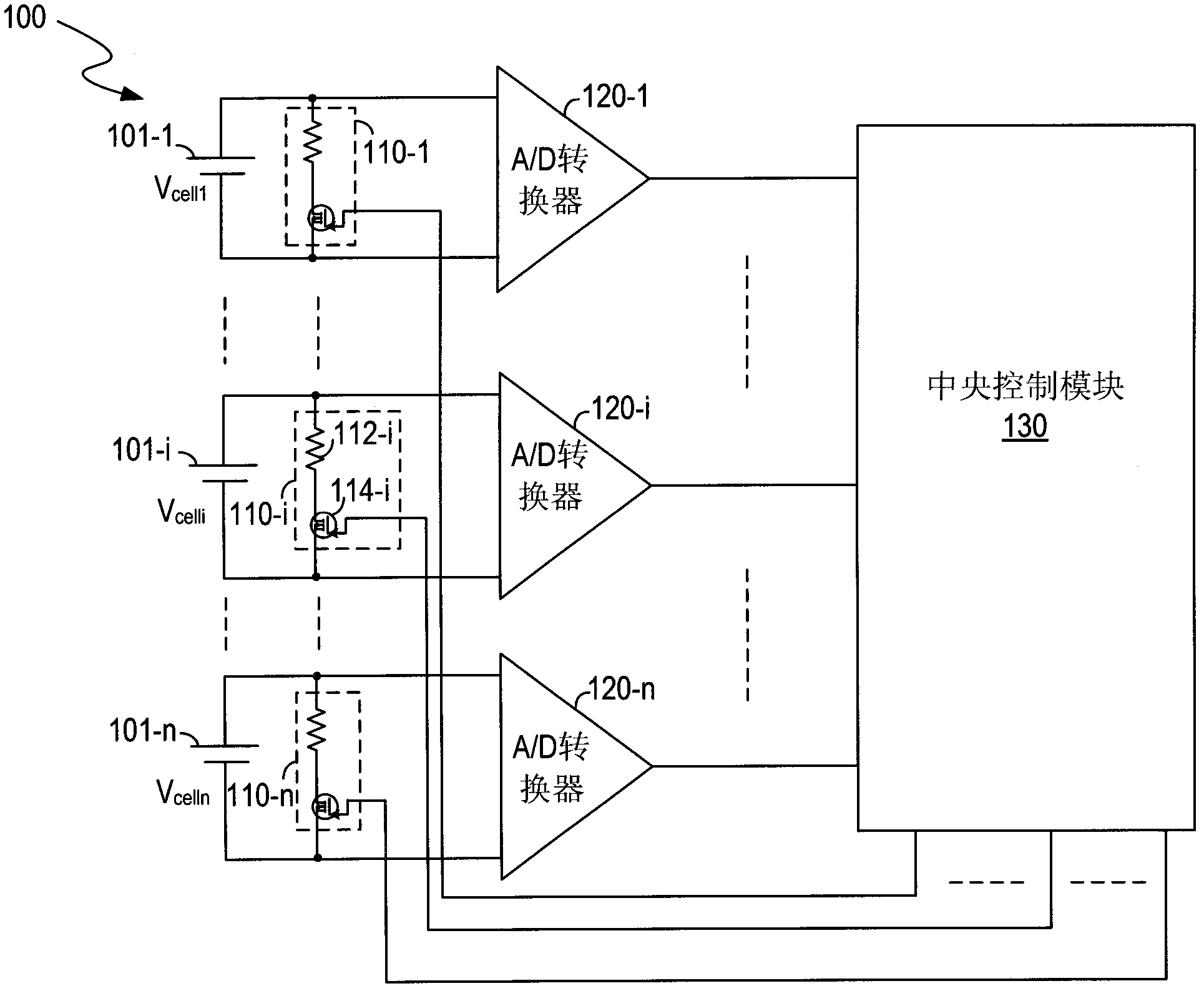

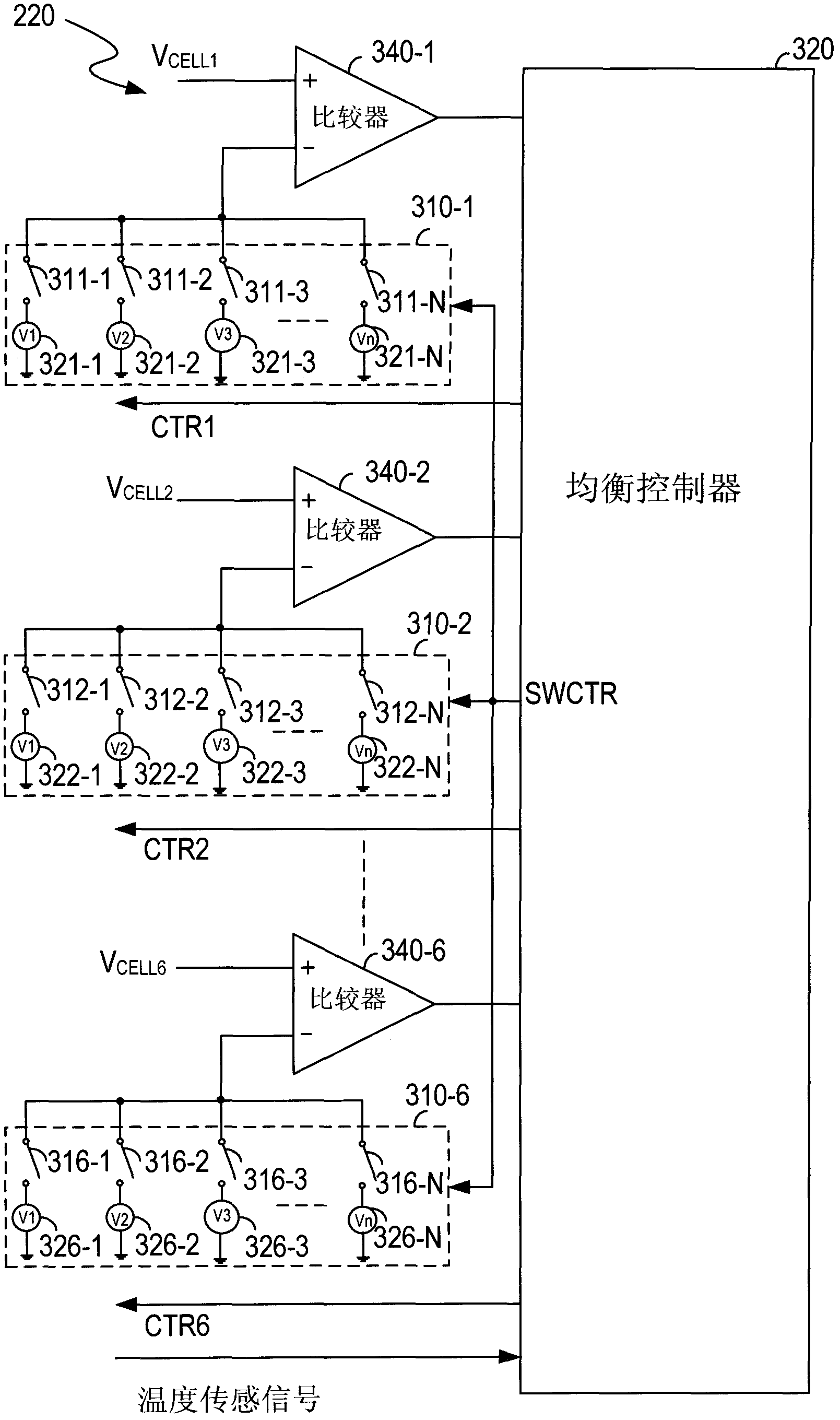

Balance control management system and balance control method of lithium-ion power battery pack

ActiveCN103915877AImprove equalization performanceGuaranteed uptimeBatteries circuit arrangementsSecondary cells charging/dischargingLithiumPower battery

The invention discloses a balance control management system and a balance control method of a lithium-ion power battery pack. The balance control management system of the lithium-ion power battery pack comprises a MCU central control unit, a battery information monitoring module, a battery heat radiation module, a balance control module and a battery module, wherein the MCU central control unit is respectively connected with the battery information monitoring module, the battery heat radiation module and the balance control module, and the battery information monitoring module, the battery heat radiation module and the balance control module are respectively connected with the battery module. According to the balance control method, in the charging process, the battery information monitoring module continuously carries out data collection and conversion on the information of a single battery, feeds the obtained data to the MCU central control unit through an infrared transmitter, and when the voltage of one battery deviates from an interval value, and the MCU central control unit charges and discharges the battery by controlling a K-series switch and an optocoupler relay. According to the balance control management system and the balance control method of the lithium-ion power battery pack, the circuit is simple, the battery balance method is effective and easy to achieve, and the same balance effect is achieved both in the processes of charging and discharging.

Owner:SOUTH CHINA NORMAL UNIVERSITY

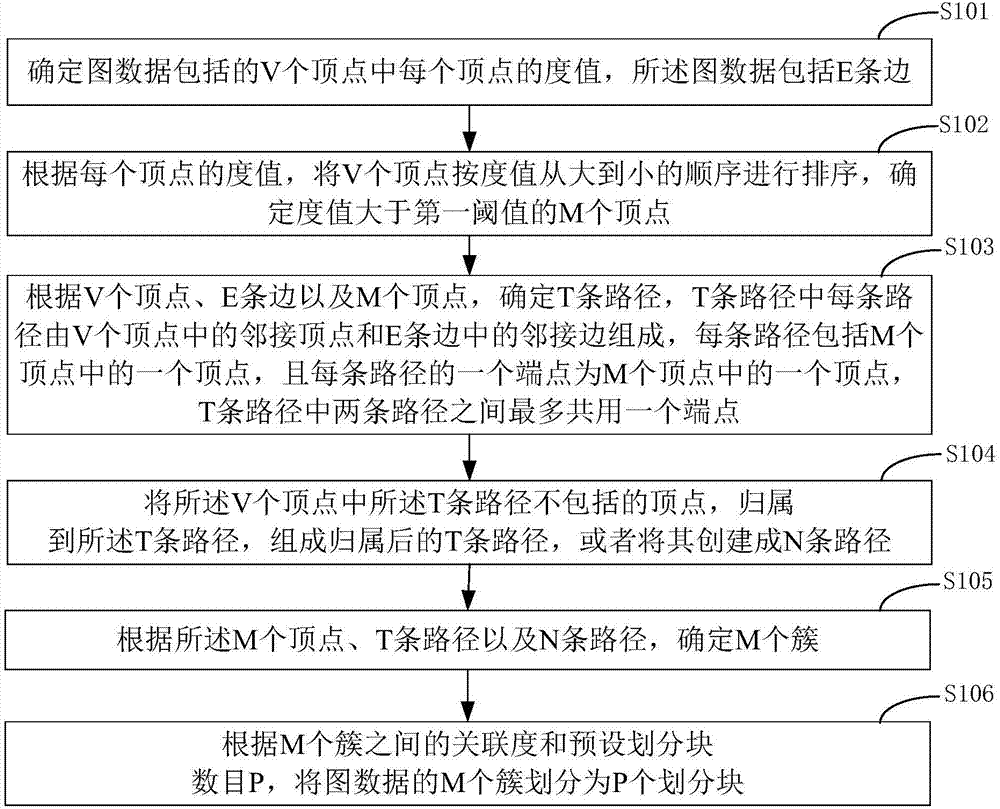

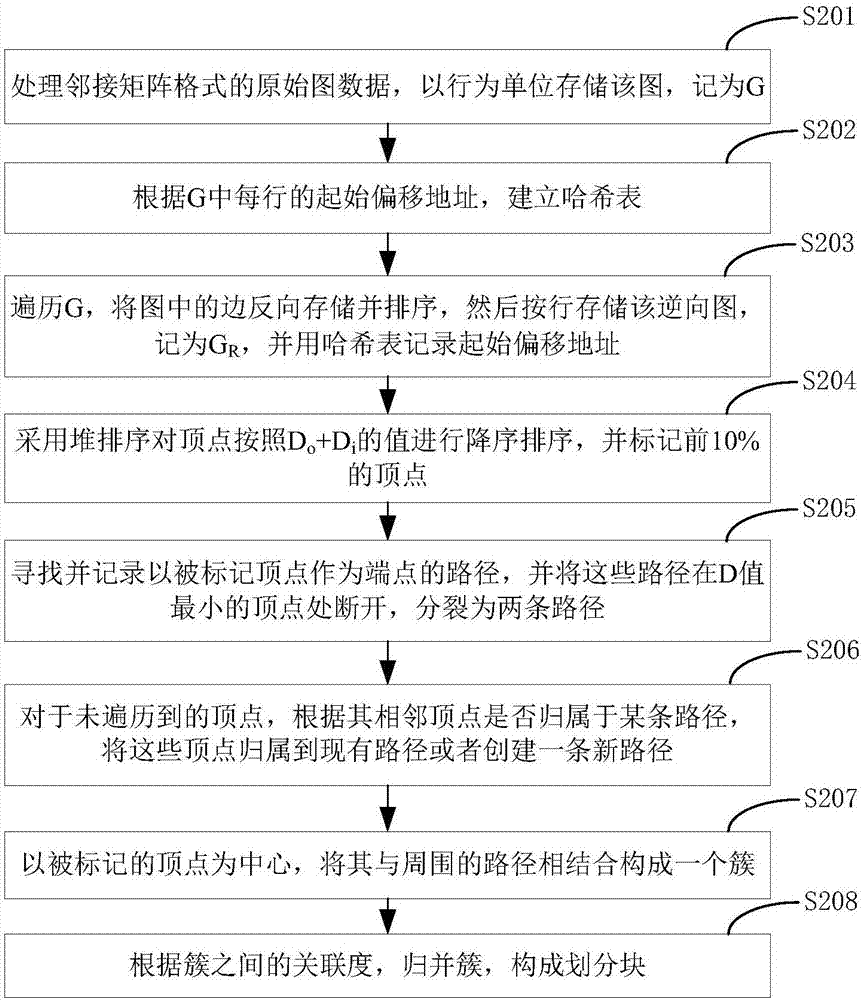

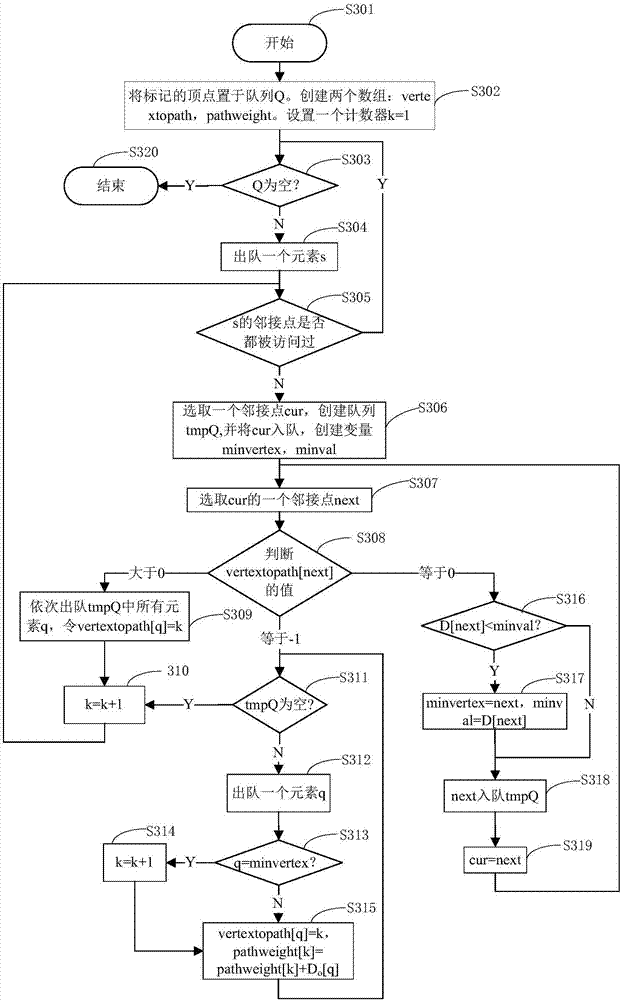

Cluster-based graph data division method

InactiveCN107193896AReduce memory overheadMaintain integritySpecial data processing applicationsCluster basedAlgorithm

The invention discloses a cluster-based graph data division method. The method comprises the steps of determining a degree value of each vertex in V vertexes comprised in graph data, wherein the graph data comprises E edges; according to the degree value of each vertex, sorting the V vertexes according to a degree value sequence from big to small, and determining M vertexes with the degree values greater than a first threshold; according to the V vertexes, the E edges and the M vertexes, determining T paths; attributing the vertexes which T paths do not comprise in the V vertexes to the T paths, forming the T paths after the attribution, or creating N paths by the T paths; according to the M vertexes, the T paths and the N paths, determining M clusters; and according to an association degree among the M clusters and a preset divided block number P, dividing the M clusters of the graph data into P divided blocks. According to the method, the vertexes with the relatively big degree values serve as end pintos of the paths, so that the repetition rate of graph data division can be reduced; the graph scale is reduced by taking the paths as units, so that the memory overhead is reduced; and large-scale graph data can be processed.

Owner:HUAZHONG UNIV OF SCI & TECH

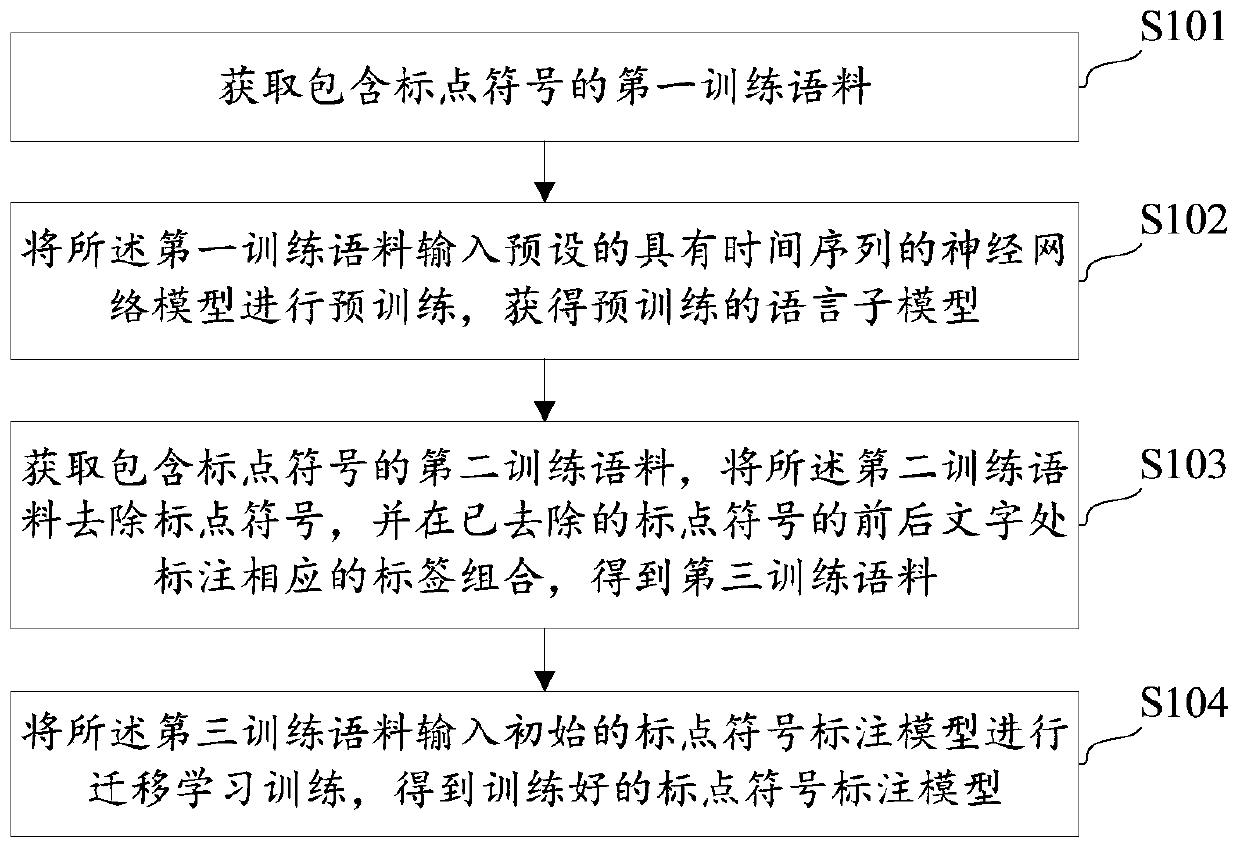

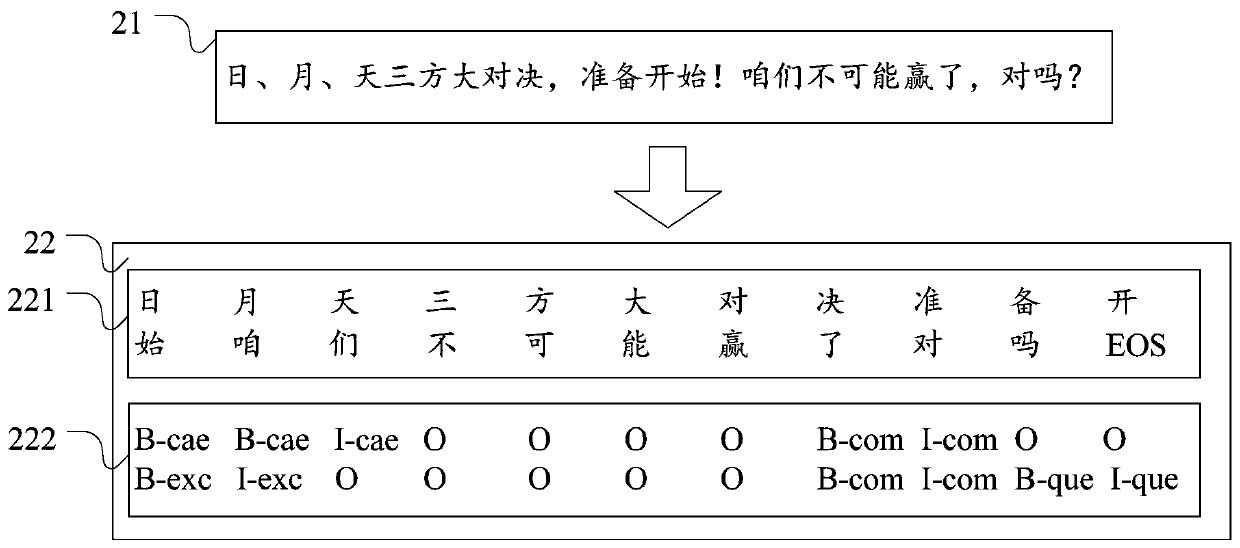

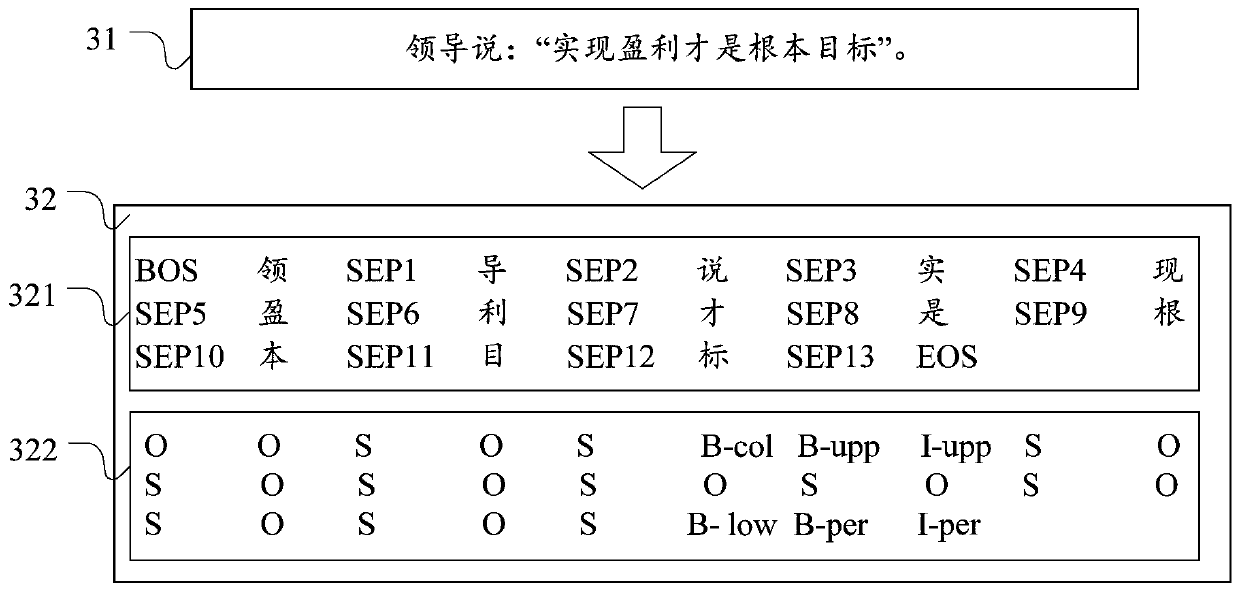

Punctuation mark labeling model and training method and device thereof, and storage medium

PendingCN110674629AImprove accuracyFast convergenceNatural language analysisNeural learning methodsNatural language processingMedicine

The invention discloses a punctuation mark labeling model and a training method and device thereof, and a storage medium. The method comprises the steps of obtaining a first training corpus containingpunctuation marks; inputting the first training corpus into a preset neural network model with a time sequence for pre-training to obtain a pre-trained language sub-model; obtaining a second trainingcorpus containing punctuation marks, removing the punctuation marks from the second training corpus, and labeling corresponding label combinations at front and rear word segmentation units of the removed punctuation marks to obtain a third training corpus; inputting the third training corpus into an initial punctuation mark labeling model for transfer learning training, obtaining a trained punctuation mark labeling model, the punctuation mark labeling model comprising a pre-trained language sub-model, and the third training corpus comprising a punctuation-free text set and a label sequence set. According to the scheme, a large amount of training data does not need to be manually labeled, the recall rate is increased, and the obtained punctuation mark labeling model has good generalizationability and universality.

Owner:SHANGHAI XIAOI ROBOT TECH CO LTD

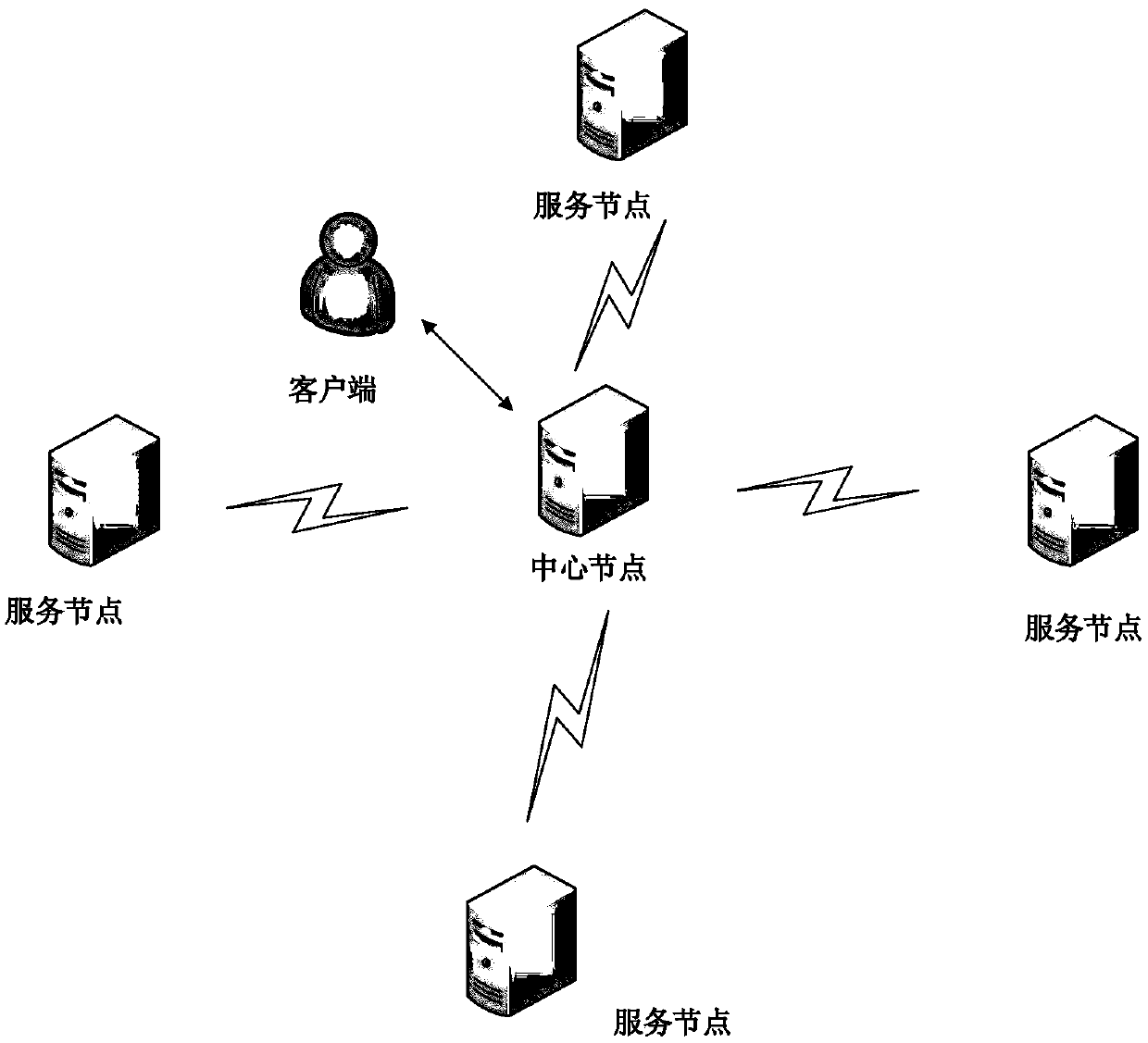

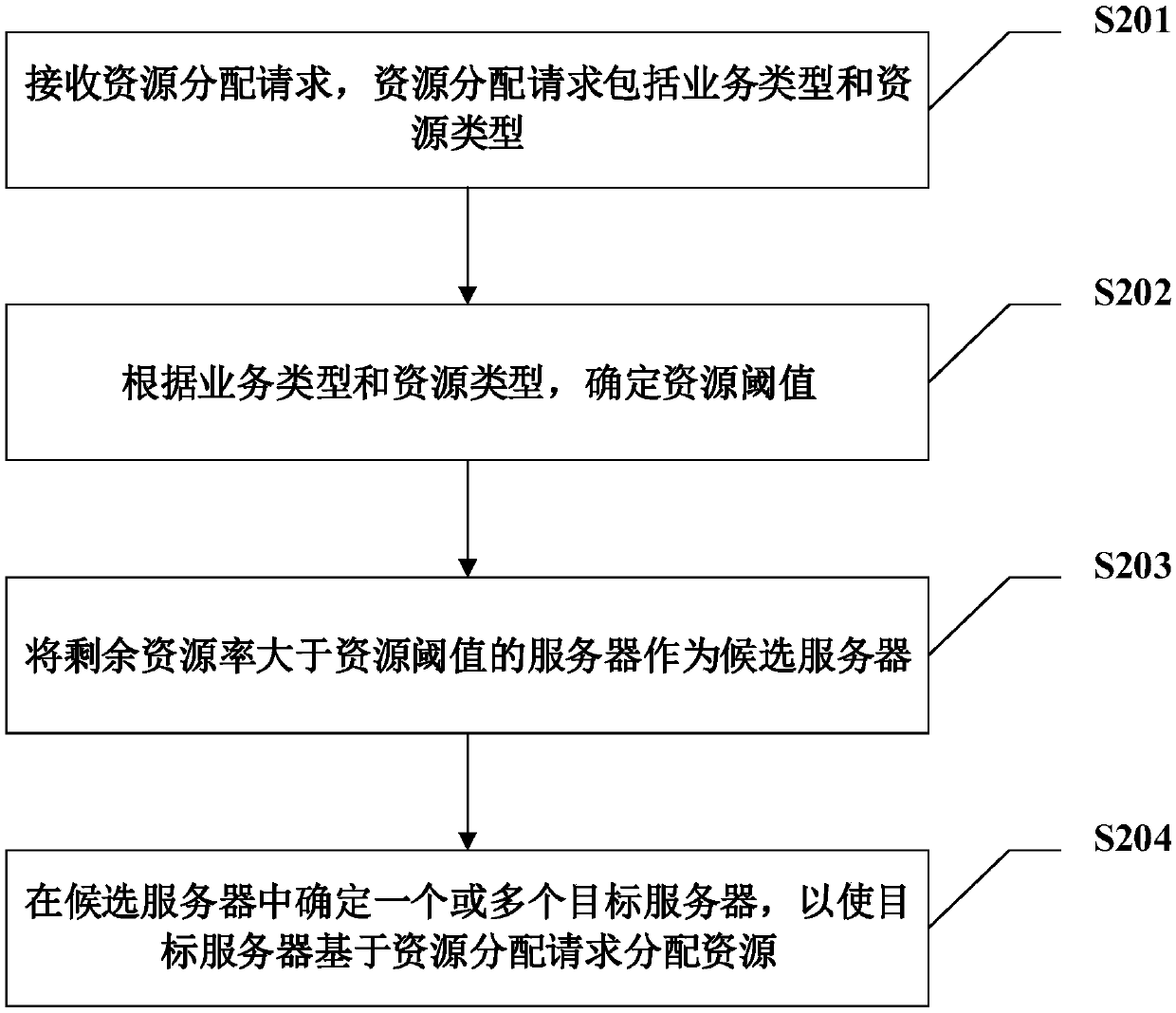

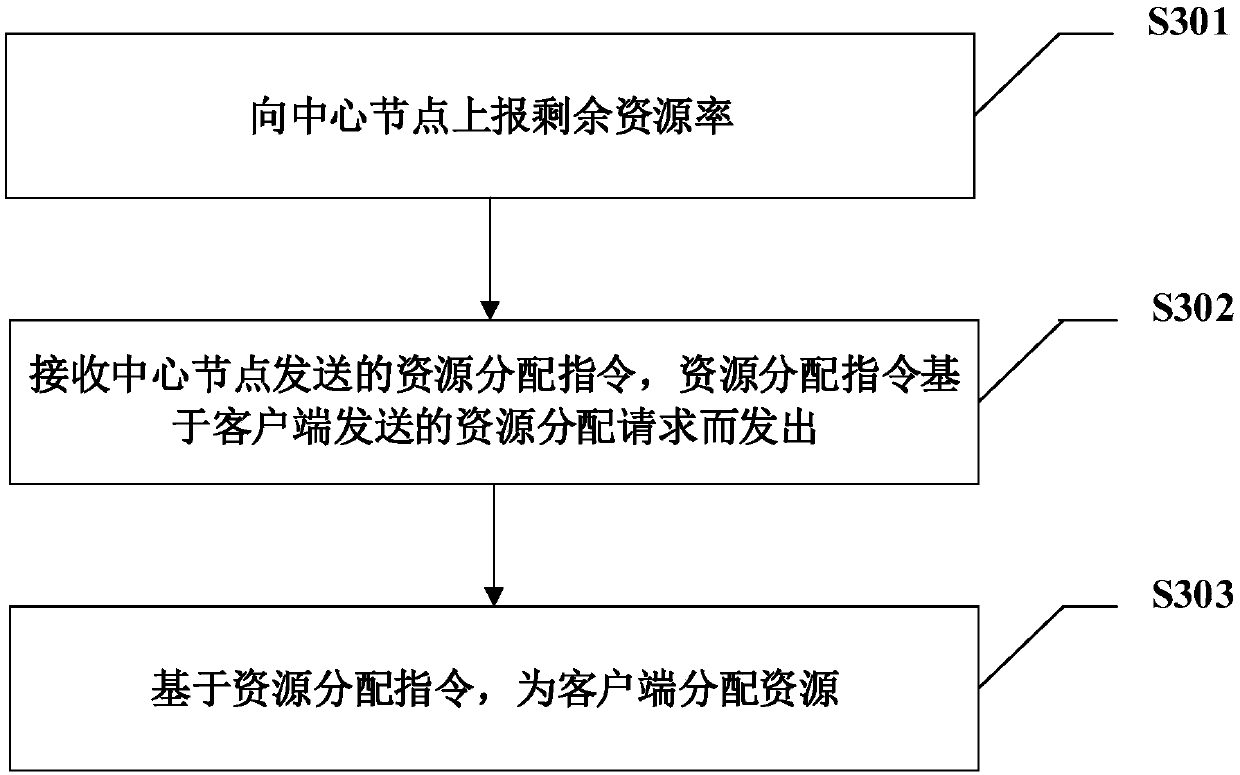

Resource allocation method, device and system, equipment and medium

ActiveCN110858161AImprove equalization performanceResource allocationResource assignmentDistributed computing

A resource allocation method, apparatus, system, device and medium, the method comprising: receiving a resource allocation request, the resource allocation request comprising a service type and a resource type; determining a resource threshold according to the service type and the resource type; taking the servers of which the residual resource rates are greater than the resource threshold as candidate servers; and determining one or more target servers in the candidate servers, thereby enabling the target servers to allocate resources based on the resource allocation request. After the embodiment of the invention is adopted, the balance of server resource allocation can be improved, and resource competition can be avoided.

Owner:ALIBABA GRP HLDG LTD

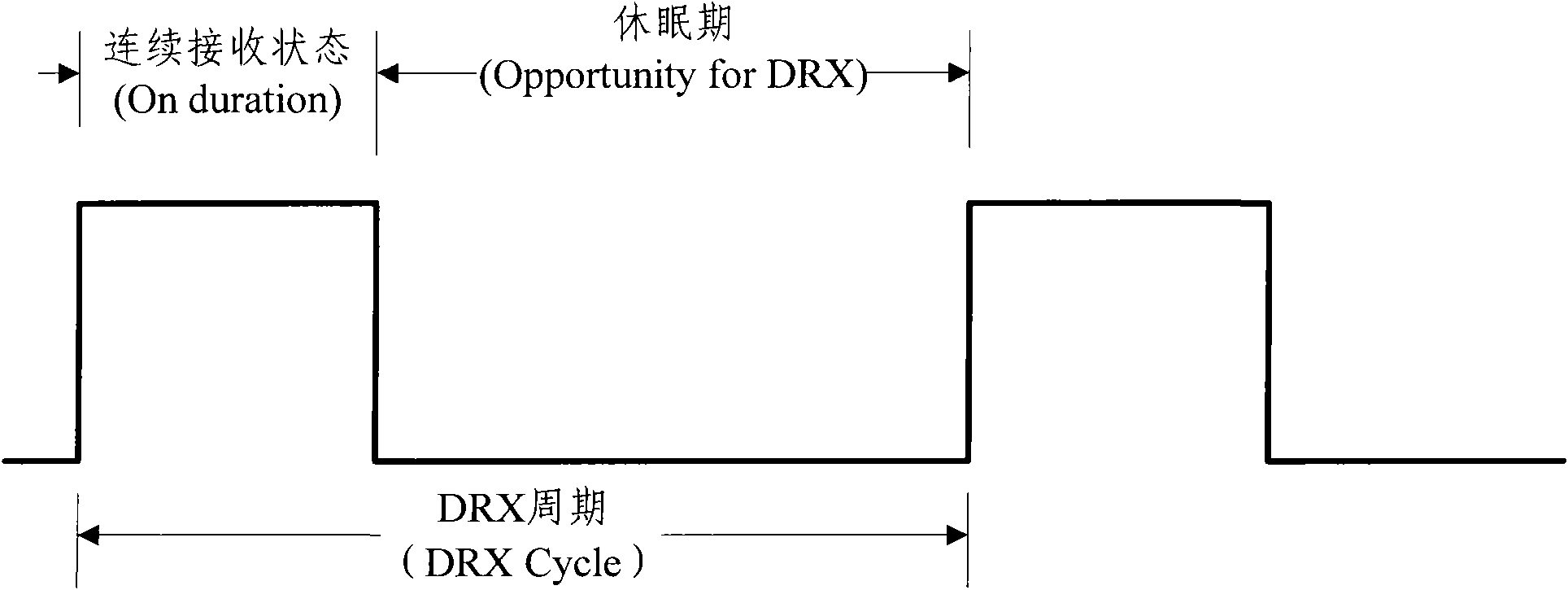

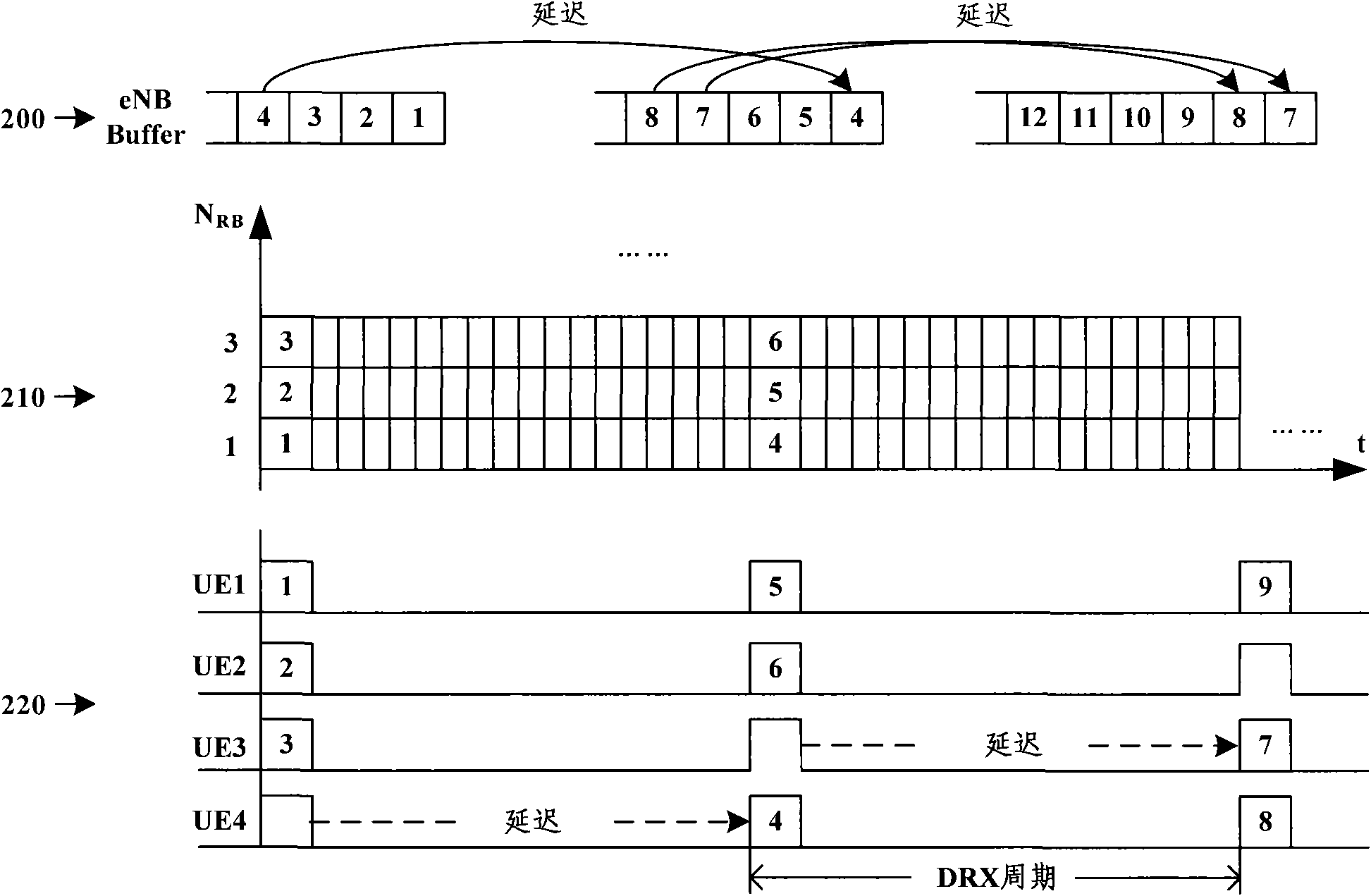

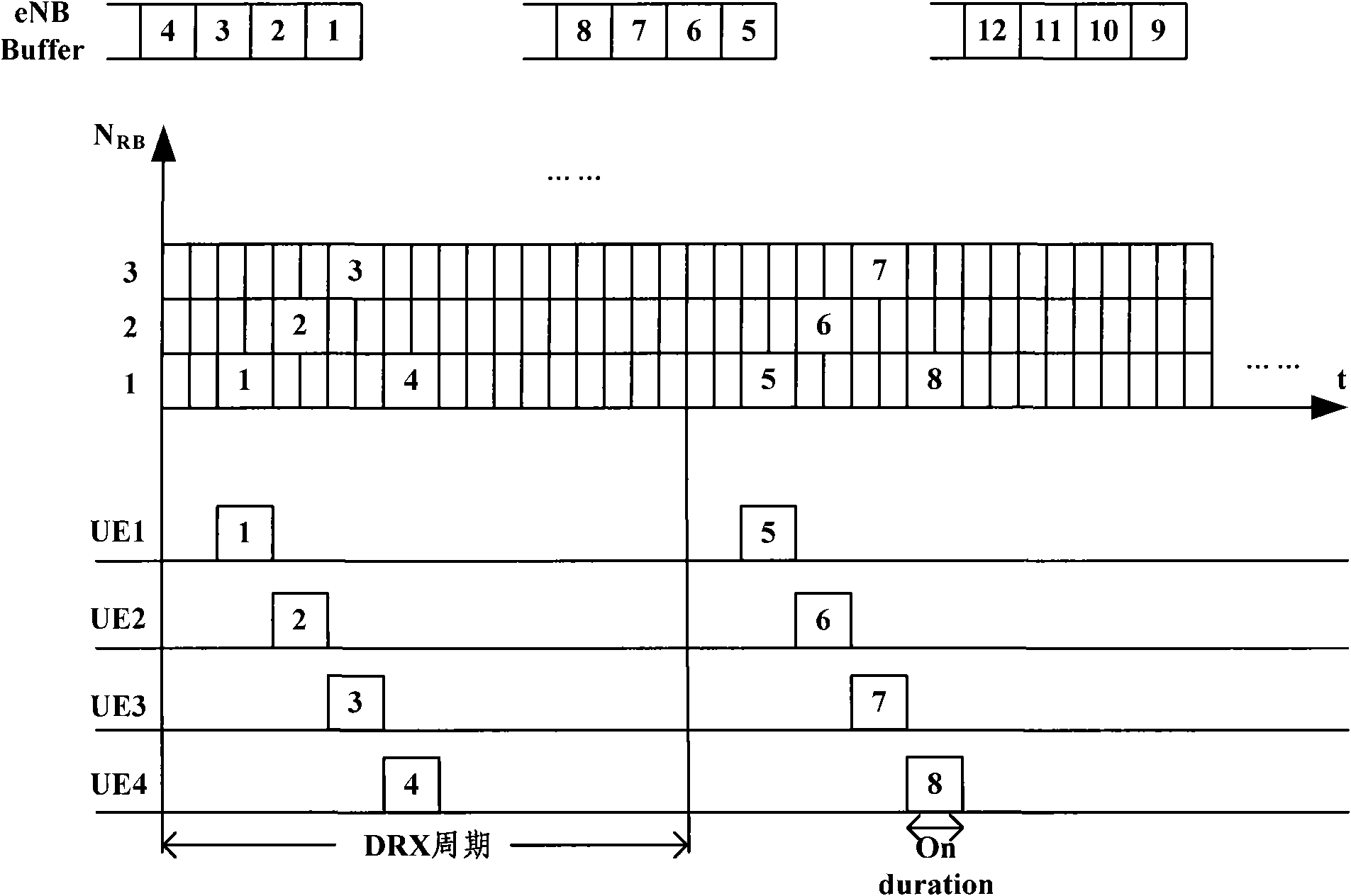

Method and base station equipment for dispatching downlink communication resources

ActiveCN101562889AImprove equalization performanceFair scheduling opportunityRadio transmission for post communicationWireless communicationResource utilizationComputer science

The invention discloses a method and base station equipment for dispatching downlink communication resources. The base station equipment comprises a DRX period configuring module, a notice module and a resource allocation module. The method which is executed by the base station equipment comprises the following concrete steps: using the DRX period configuring module to configure DRX periods of DRX users and configure starting points of the DRX periods of the DRX users on downlink subframes in balance; using the notice module to notice the DRX period and the starting point of the DRX period of each DRX user to a corresponding DRX user to carry out DRX monitoring; and using the resource allocation module to dispatch corresponding downlink communication resources in balance according to the allocated starting point of the DRX period of each DRX user. The method and the base station equipment for dispatching downlink communication resources can be used for improving the balance of the downlink dispatching of the base station and the balance of the utilization ratio of resources in the DRX working mode, and can be used for reducing the defect that part of users are dispatched in delay, but part of downlink resources are not utilized fully.

Owner:DATANG MOBILE COMM EQUIP CO LTD

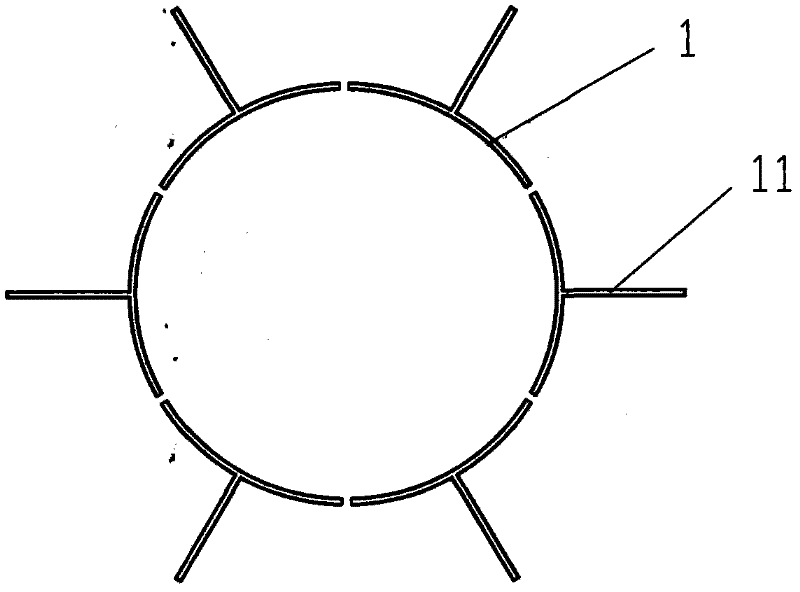

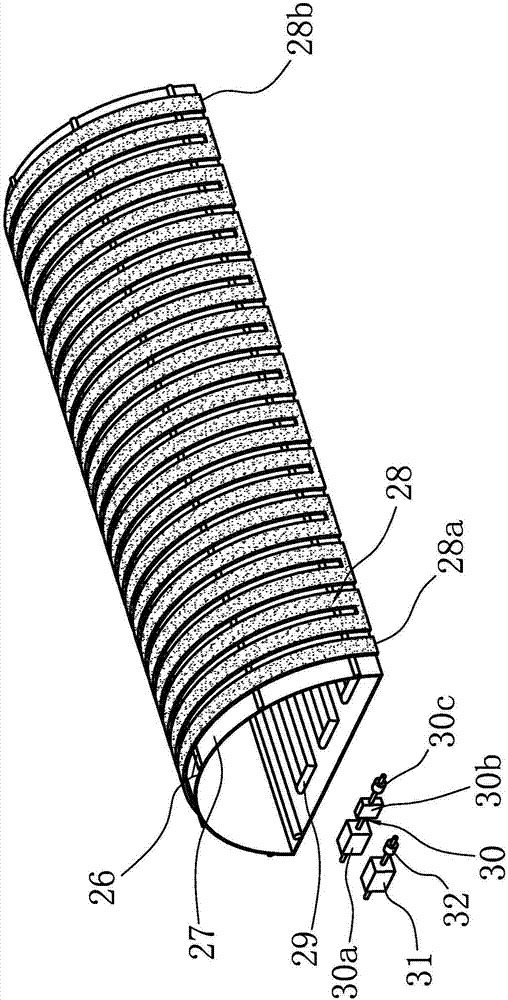

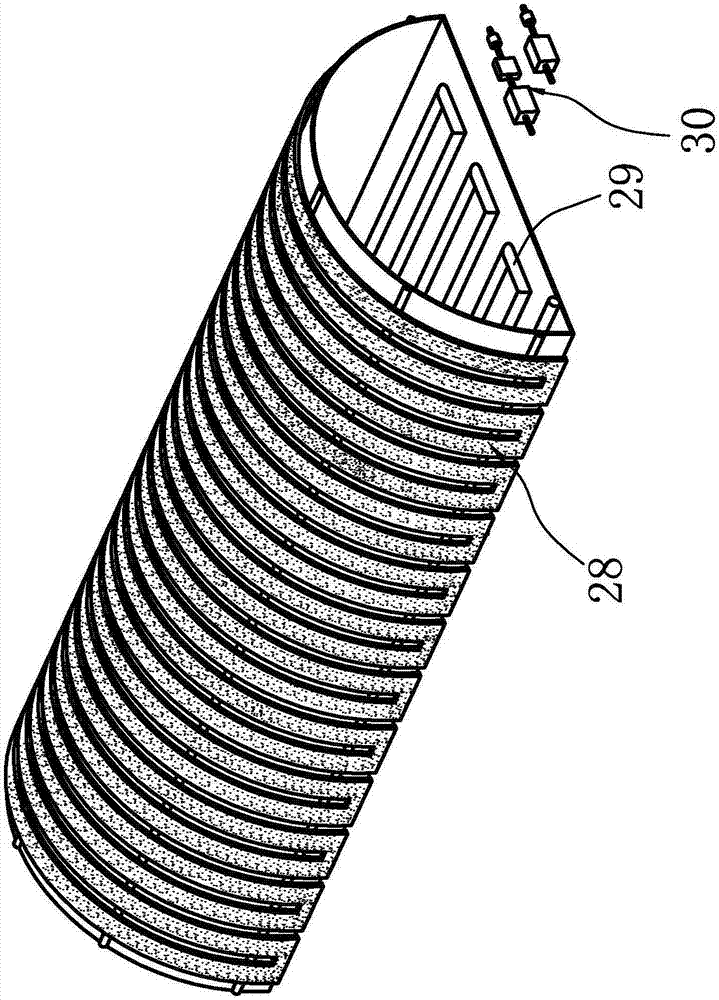

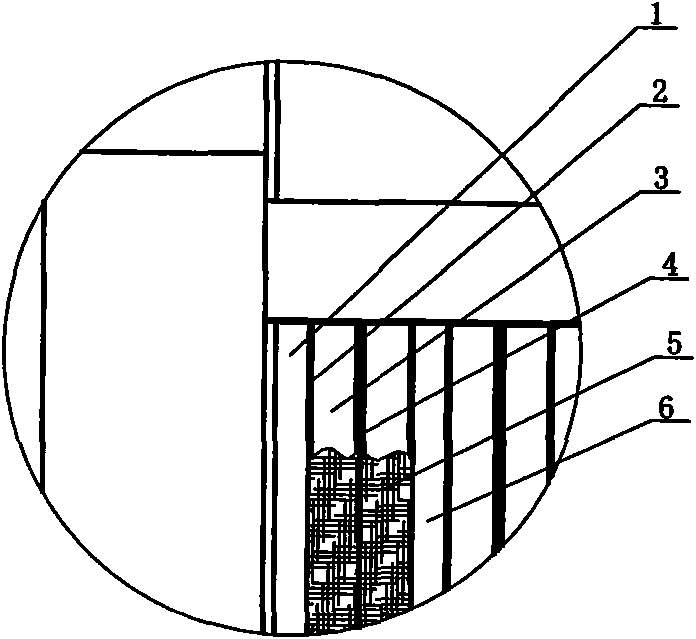

Crystal growth furnace heater and sapphire crystal growth furnace

InactiveCN102345161AImprove balanceUniform heating surfacePolycrystalline material growthBy pulling from meltTungstenSapphire

The invention discloses a crystal growth furnace heater with a cylindrical shape. The heater comprises: a plurality of electrodes distributed annularly and arranged at one end of the cylinder; a connecting ring disposed at the other end of the cylinder; a tungsten wire mesh, one end of which is connected to each of the multiple electrodes, and the other end of which is connected to the connecting ring, thus forming a barrel cylinder. On the other hand, the invention provides a sapphire crystal growth furnace with the above heater. The heater of the invention employs a double-star loaded three-phase alternating-current power supply mode, and can improve the load balance. The tungsten wire mesh heating body can endow the heater with good uniformity, reliability and stability.

Owner:江苏同人电子有限公司

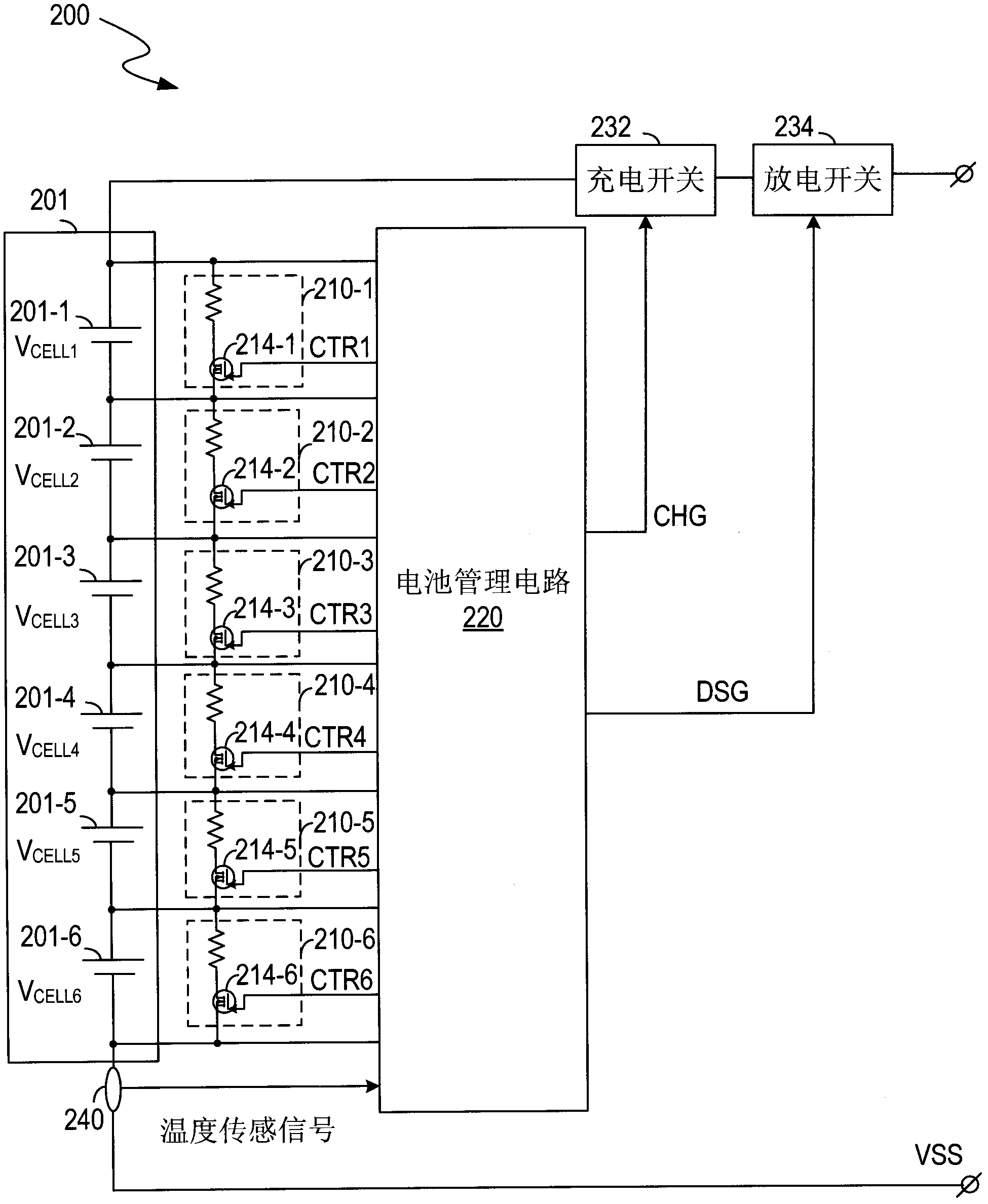

Battery equalizing system, circuit and method

InactiveCN102916458AImprove equalization performanceLow costCharge equalisation circuitElectric powerElectrical batteryEngineering

The invention provides a battery equalizing system, a battery equalizing circuit and a battery equalizing method. The battery equalizing system comprises a plurality of bypass paths and a battery management circuit, wherein the bypass paths are connected in parallel with corresponding batteries; the battery management circuit is connected with the bypass paths and is used for detecting a voltage value of each battery and comparing the voltage value of each battery in a first stage with a first reference voltage corresponding to the first stage; and the battery management circuit conducts a first bypass path connected in parallel with a first battery when the voltage value of the first battery reaches the first reference voltage value, and compares the voltage value of each battery with a second reference voltage corresponding to a second stage when a first specified value in the first stage reaches the first reference voltage value. By the battery equalizing system, the battery equalizing circuit and the battery equalizing method, the battery equalizing effect is improved and the cost of the battery equalizing system is reduced.

Owner:AOTU ELECTRONICS WUHAN

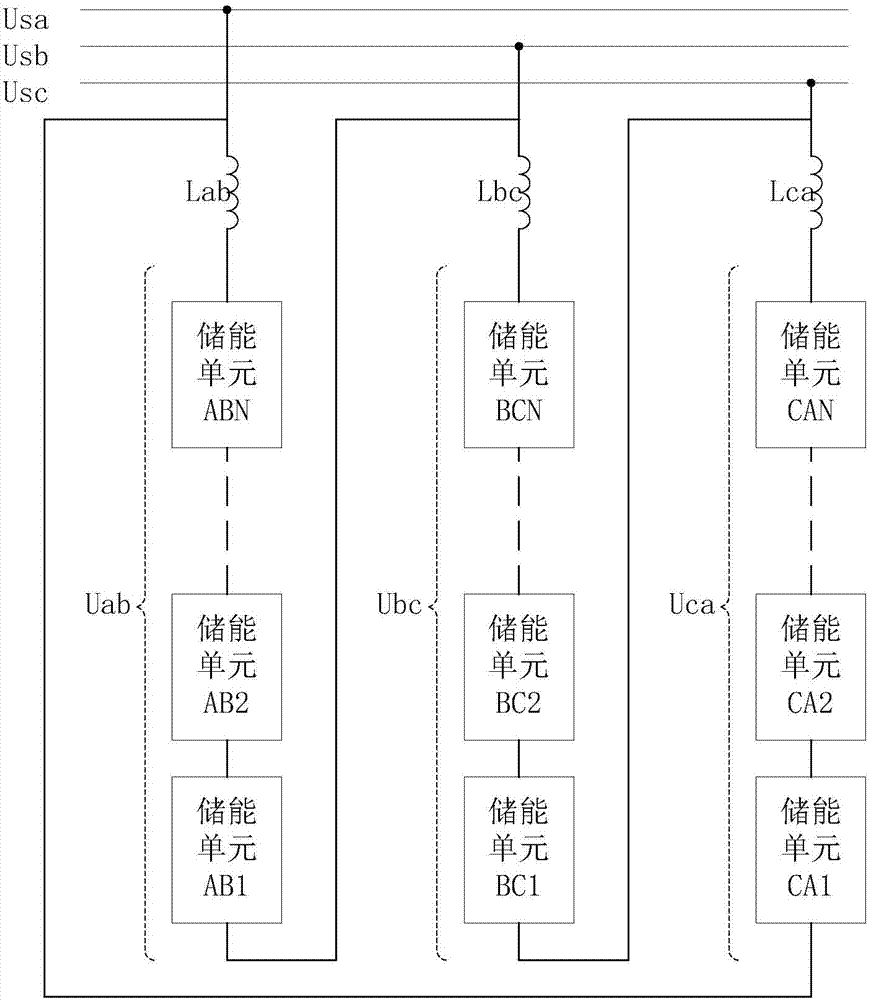

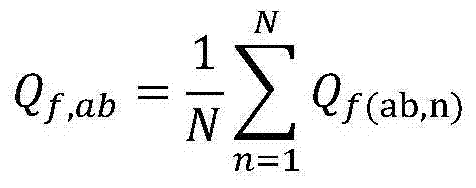

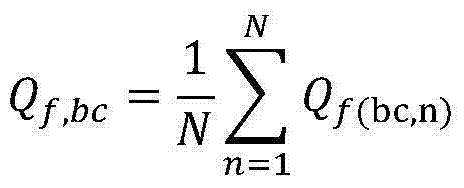

Triangle connection cascade energy storage system two stage equalization control method

ActiveCN103715733AImprove protectionImprove capacity utilizationBatteries circuit arrangementsElectric powerElectricityElectrical battery

The invention provides a triangle connection cascade energy storage system two stage equalization control method. The method comprises the steps that 1, SOC and SOH information of each link of a chained energy storage system is acquired; 2, rechargeable power and dischargeable power of each link are respectively calculated; 3, total rechargeable power and dischargeable power of each line and the whole system are calculated; 4, power distribution and control are carried out on each line; and 5, on the basis that the power of each line is determined, the voltage of each link is distributed according to the proportion of the rechargeable / dischargeable power of each link, and power distribution according to the proportion can be realized. According to the invention, the maximization of the capacity utilization rate of the energy storage system is used as a goal, namely simultaneous complete charging and discharging are carried out on batteries of all links; a safe operation boundary is considered, so that the requirement of the energy storage system for an equalization ability in different operation conditions and SOC states can be reasonably reflected; and an equalization performance is optimized in a range which can be realized.

Owner:SHANGHAI JIAO TONG UNIV +1

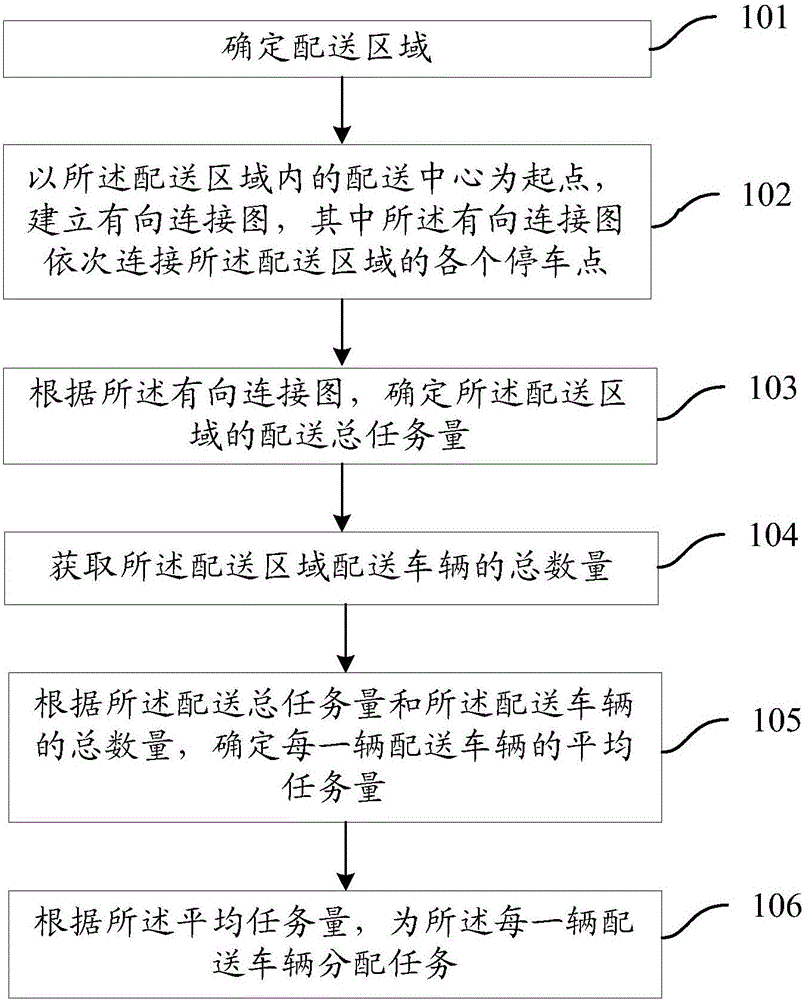

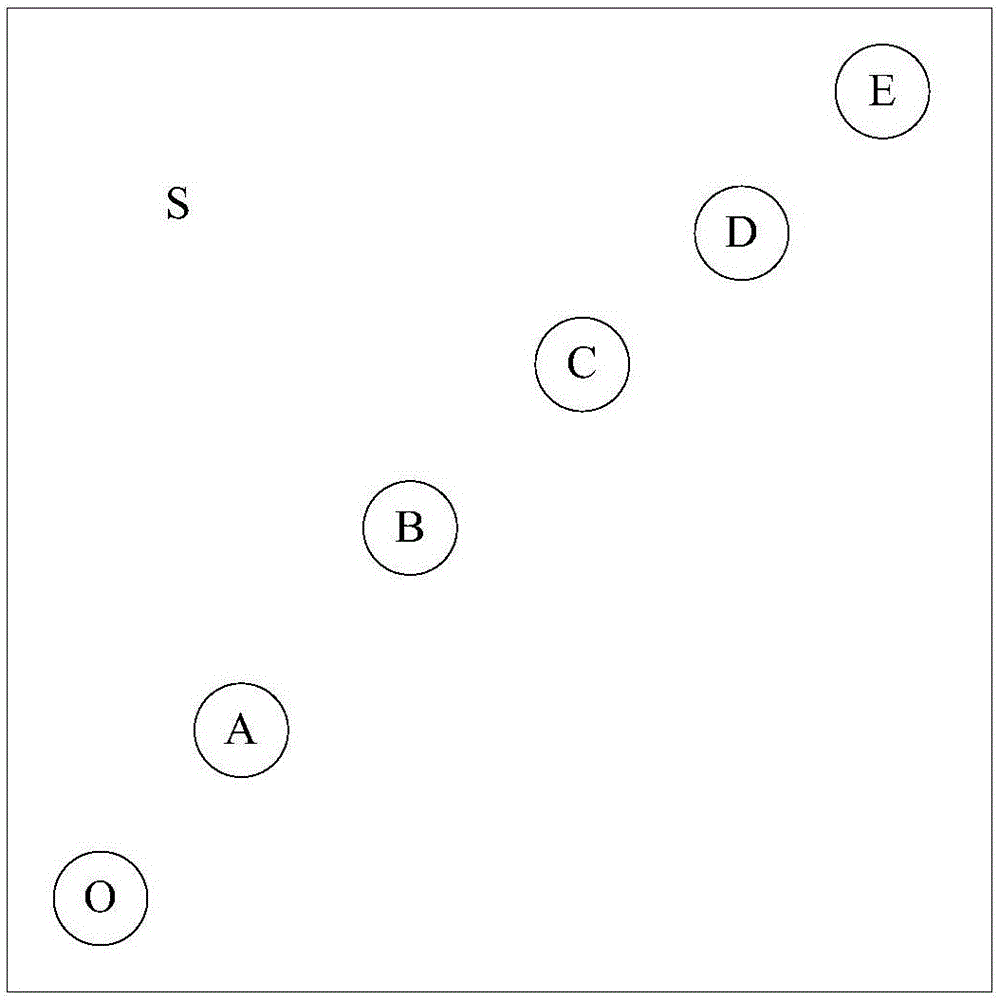

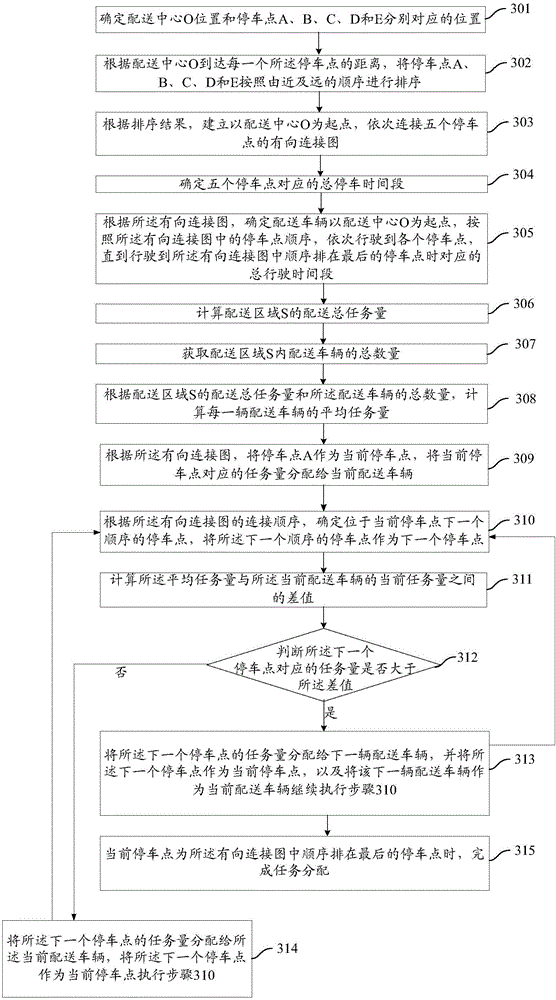

Task allocation method and apparatus

InactiveCN106372830AThe same timeImprove equalization performanceLogisticsDelivery vehicleReal-time computing

The invention provides a task allocation method and apparatus. The task allocation method comprises the steps of determining a delivery region; establishing a directed connection relationship by taking a delivery center in the delivery region as a starting point, wherein the directed connection relationship connects parking points of the delivery region in sequence; determining a total delivery task quantity of the delivery region according to the directed connection relationship; obtaining a total quantity of delivery vehicles of the delivery region; and determining an average task quantity of each delivery vehicle according to the total delivery task quantity and the total quantity of the delivery vehicles. According to the method and the apparatus, the balance of task allocation can be improved.

Owner:INSPUR SOFTWARE CO LTD

Agricultural greenhouse with marsh gas heating auxiliary system

ActiveCN106857099AImprove economySave energyBioreactor/fermenter combinationsBiological substance pretreatmentsGreenhouseWater storage tank

The invention provides an agricultural greenhouse with a marsh gas heating auxiliary system. The technical problem that in a cold environment, an existing agricultural greenhouse is low in indoor temperature, poor in heat preservation property and the like is solved. The agricultural greenhouse with the marsh gas heating auxiliary system comprises a greenhouse frame and a transparent greenhouse film; the marsh gas heating auxiliary system comprises a marsh gas fermentation pond, a transparent flow guide pipe is laid on the top face of the greenhouse film, a terrestrial heat pipe is laid on the ground in the greenhouse, and the terrestrial heat pipe is connected with a marsh gas heating device. Marsh gas generated by the marsh gas fermentation pond is connected with the marsh gas heating device through a gas conveying pipe, the liquid inlet end of the flow guide pipe is connected with a water storage tank, and the water storage tank is further connected with an output opening of a first circulating pump. An input opening of the first circulating pump is connected with the liquid outlet end of the flow guide pipe through a connecting pipe, and heat collecting sheets are arranged in the water storage tank. The agricultural greenhouse has the advantages of saving energy, being good in greenhouse heat preservation effect and the like.

Owner:李梦颖

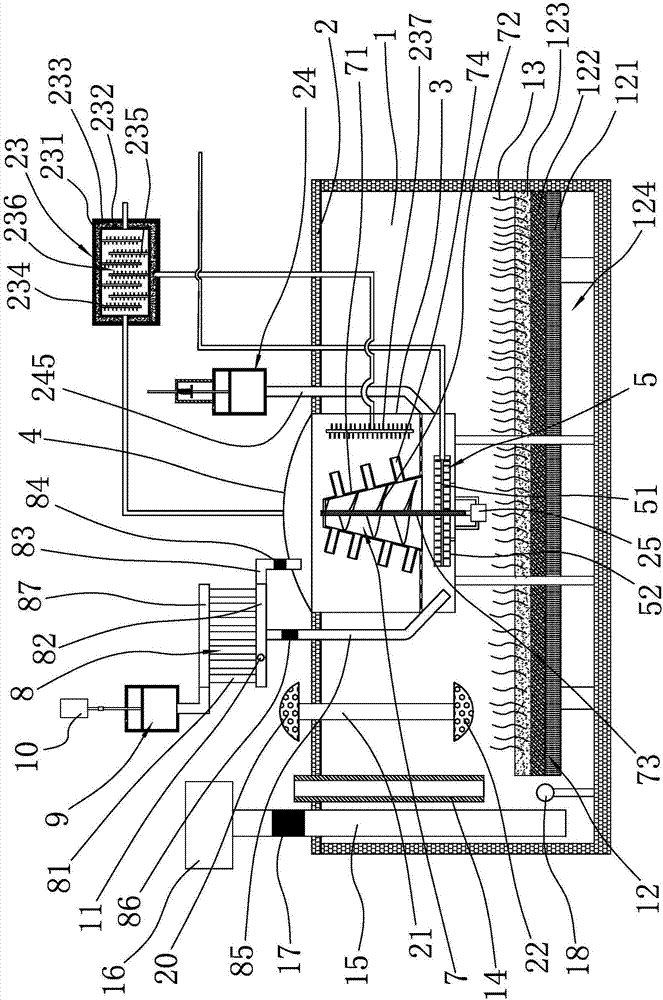

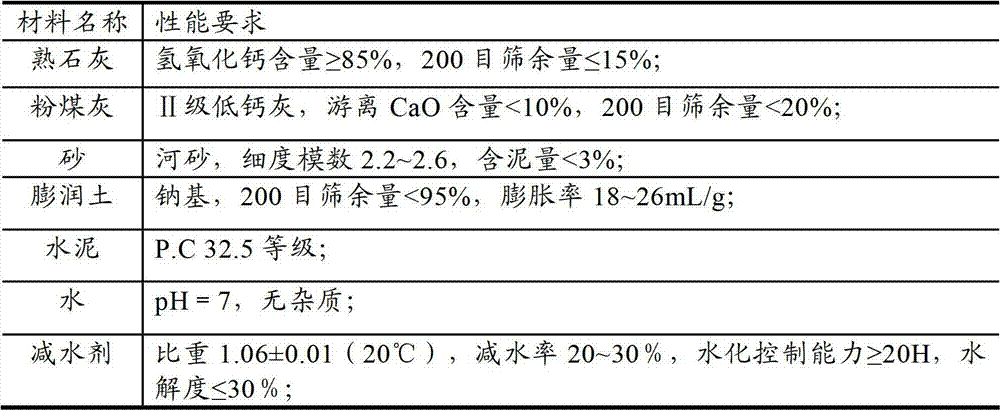

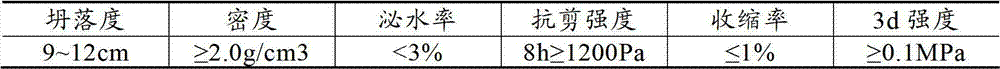

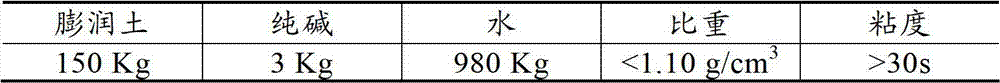

Construction method for ultralarge-diameter shield synchronous grouting

ActiveCN102758641AHigh densityReduce consistencyUnderground chambersTunnel liningQuality controlSlurry

The invention discloses a construction method for ultralarge-diameter shield synchronous grouting. The construction method comprises the following steps of: producing and preparing a slurry material, and conveying the slurry material to a shield construction working face in a tunnel; carrying out instant grouting on a building gap by using a grouting system in a shield excavation process; and treating a waste slurry material. Due to adoption of the construction method for ultralarge-diameter shield synchronous grouting, a synchronous grouting construction method which can play a favorable quality control effect can be achieved; and the construction method for ultralarge-diameter shield synchronous grouting has the characteristics of high construction efficiency, capability of protecting the surrounding environment and strong stability of a ring-forming tunnel structure.

Owner:SHANGHAI URBAN CONSTR GRP +2

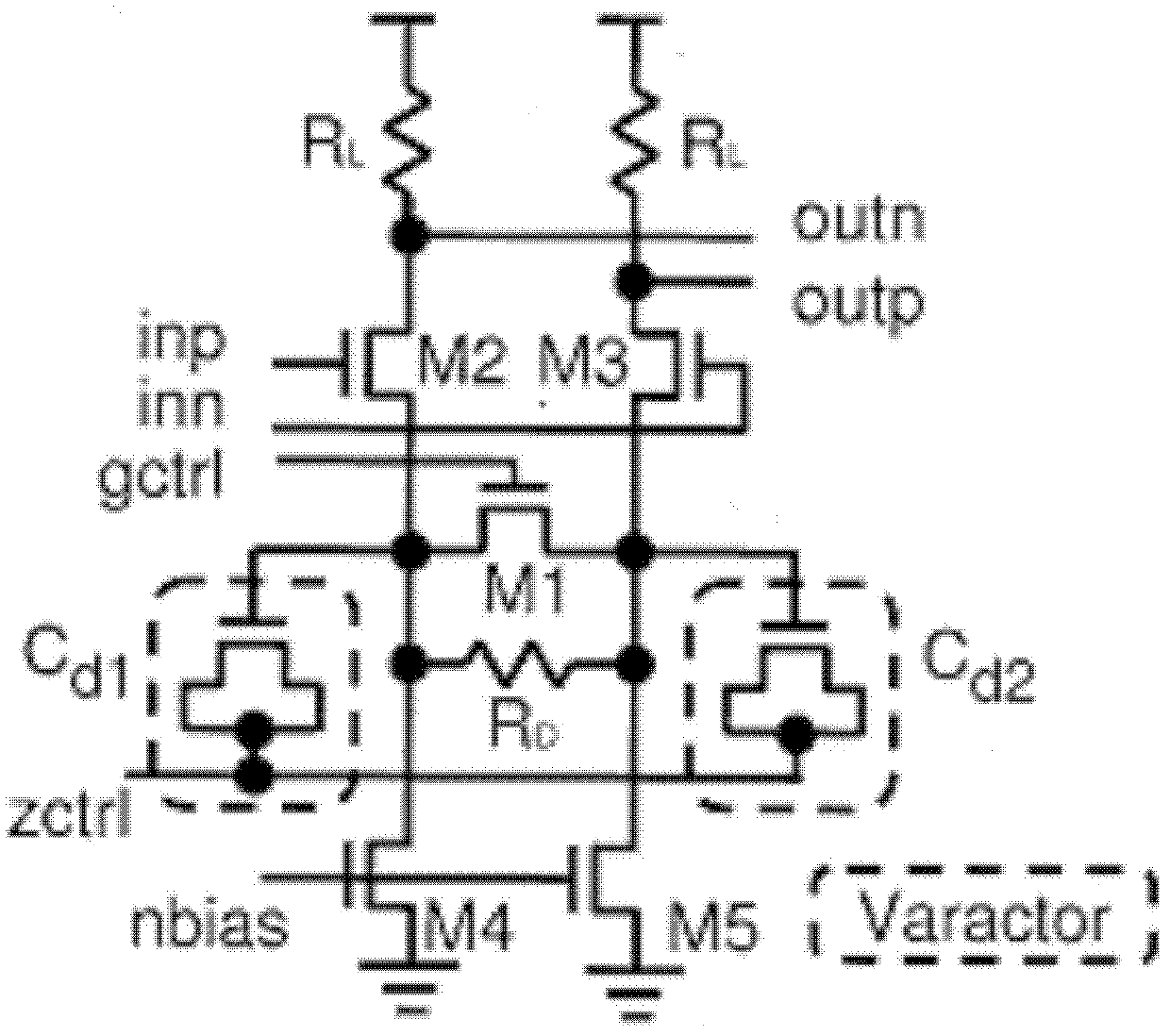

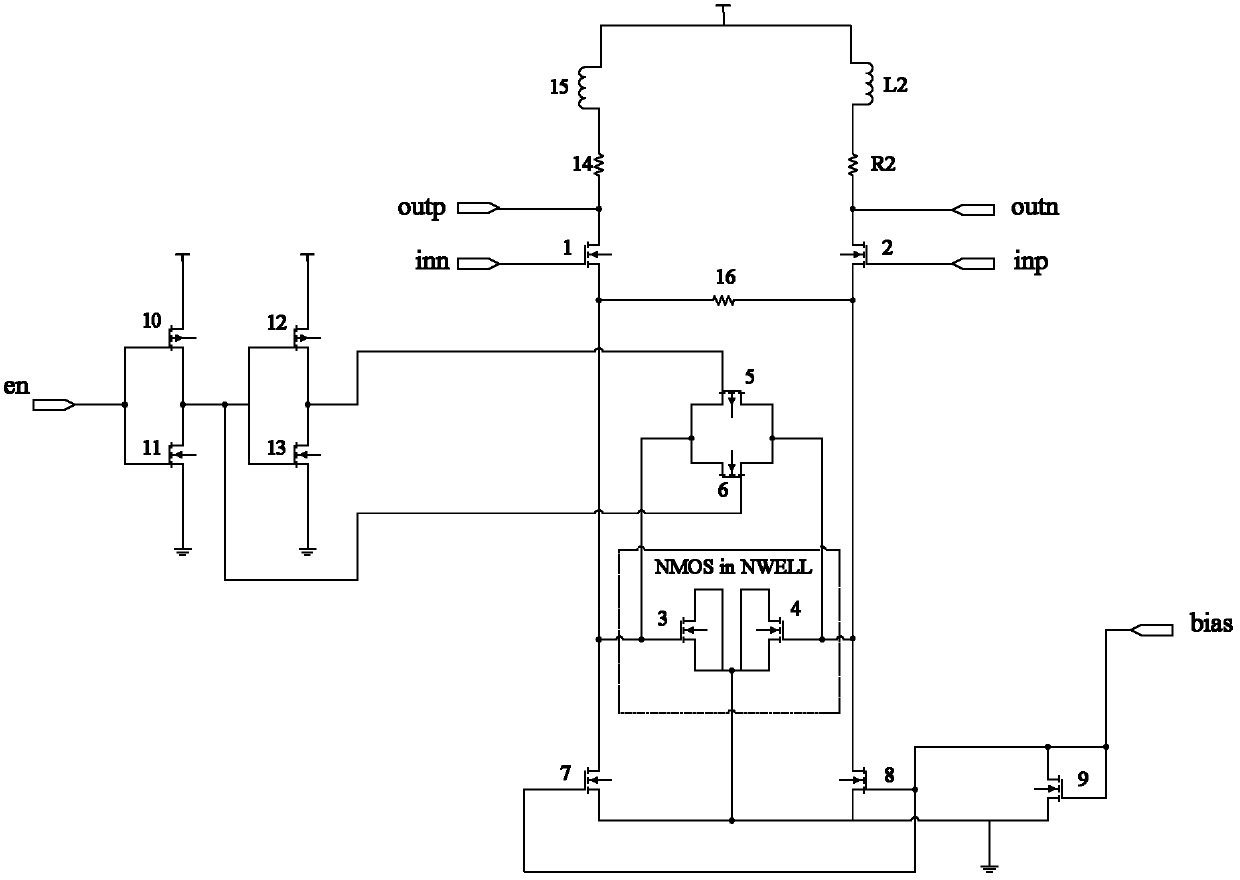

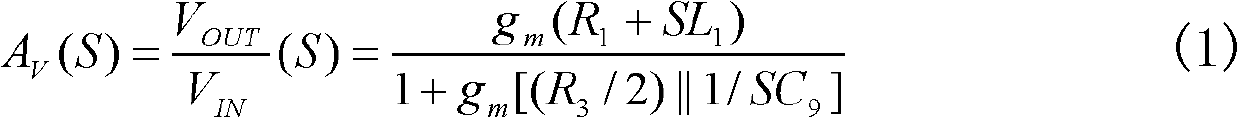

Linear equalizer

ActiveCN103379063AIncrease high frequency gainImprove equalization performanceTransmitter/receiver shaping networksInductorCapacitance

The invention discloses a linear equalizer which comprises a differential input pair pipe, a second resistor, a third MOS capacitor and a fourth MOS capacitor, wherein the differential input pair pipe is composed of a first MOS transistor and a second MOS transistor, the drain electrode of the first MOS transistor and the drain electrode of the second MOS transistor are respectively and sequentially connected with a first resistor and a first inductor in series, and the first resistors and the first inductors are required to produce a zero point higher than channel bandwidth. The two ends of the second resistor are connected with the source electrode of the first MOS transistor and the source electrode of the second MOS transistor respectively. The third MOS capacitor and the fourth MOS capacitor are composed of the MOS transistors connected through the source electrodes and the drain electrodes in a short circuit mode, a grid electrode of the third MOS capacitor and a grid electrode of the fourth MOS capacitor are connected with the source electrode of the first MOS transistor and the source electrode of the second MOS transistor respectively, and the second resistor, the third MOS capacitor and the fourth MOS capacitor are required to produce another zero point higher than the channel bandwidth. The linear equalizer can be used in high-speed serial transmission, the two zero points can be formed, low frequency small transmission gain and high frequency large transmission gain can be achieved, high frequency transmission gain can be greatly improved, and the balancing performance is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

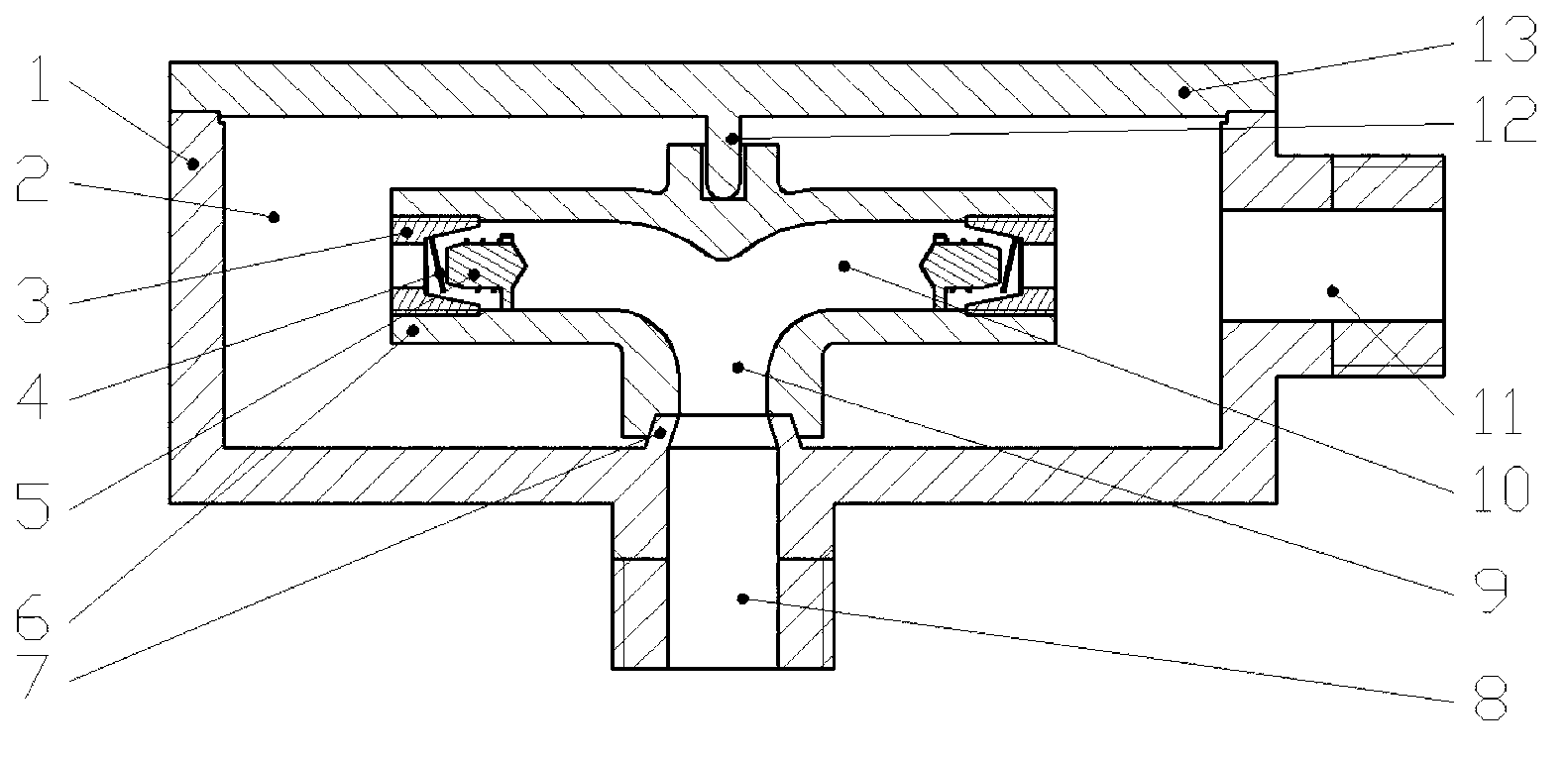

Rotary outflow control device and application method thereof

InactiveCN102853132ARealize automatic adjustmentImprove equalization performanceWatering devicesEqualizing valvesWater flowPiston

The invention relates to farmland irrigation equipment, and particularly relates to a rotary outflow control device comprising a rotating component and capable of automatically adjusting an outlet flow, and an application method thereof. The rotary outflow control device comprises a shell (1); a lateral cover (13) is arranged on the shell (1); a rotating piece (6) is mounted inside a shell inner cavity (2); a water inlet runner (9) and two water outlet runners (10) are arranged inside the rotating piece (6); the water inlet runner (9) is communicated with a water inlet (8); and two groups of piston assemblies are respectively mounted at the tail ends of the two water outlet runners (10). With the adoption of the rotary outflow control device provided by the invention, the amounts of water flowing through the water inlet and the water outlet can be automatically adjusted within an adjustable range, so that the balance of the water outlet flow can be improved. The rotary outflow control device has the advantages of simple structure and easiness of dismounting, and can be widely applied in agriculture irrigation production.

Owner:CHINA AGRI UNIV

Feed capable of increasing growth speed of rice field eels

InactiveCN104489309AFast growthImprove equalization performanceAnimal feeding stuffDiseaseAnimal science

The invention relates to the field of feeds for cultivation, and particularly relates to a feed capable of increasing the growth rate of rice field eels. Honeysuckle is added to the feed capable of increasing the growth rate of the rice field eels, so that the feed has the functions of restraining the growth of bacteria, diminishing inflammation and clearing away heat and toxins; the feed can promote the discharging of harmful substances and guarantee the healthy growth of animals due to multiple trace elements contained in honeysuckle buds. The feed for the rice field eels, prepared from sheep blood powder, pig liver powder, fish powder, wormcast and rapeseed meal cakes as the main material can provide a large amount of protein for the growth of the rice field eels, improve the balance of nutrition, and attract the rice field eels due to the addition of an attractant for the rice field eels, and therefore, the utilization rate of the feed is increased, the growth speed of the rice field eels is increased; and the feed plays the role of preventing diseases due to the addition of a small amount of garlic.

Owner:王旭

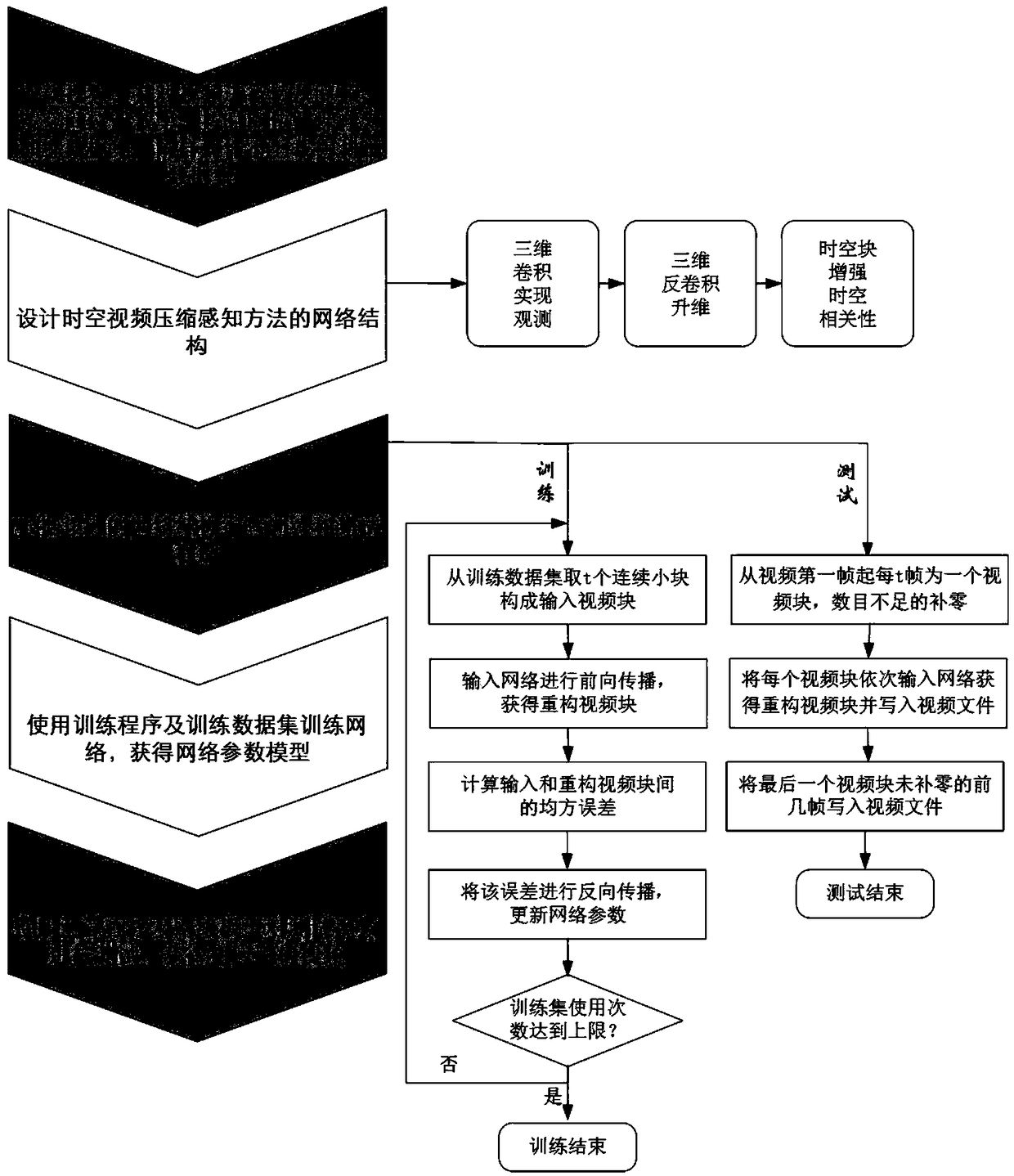

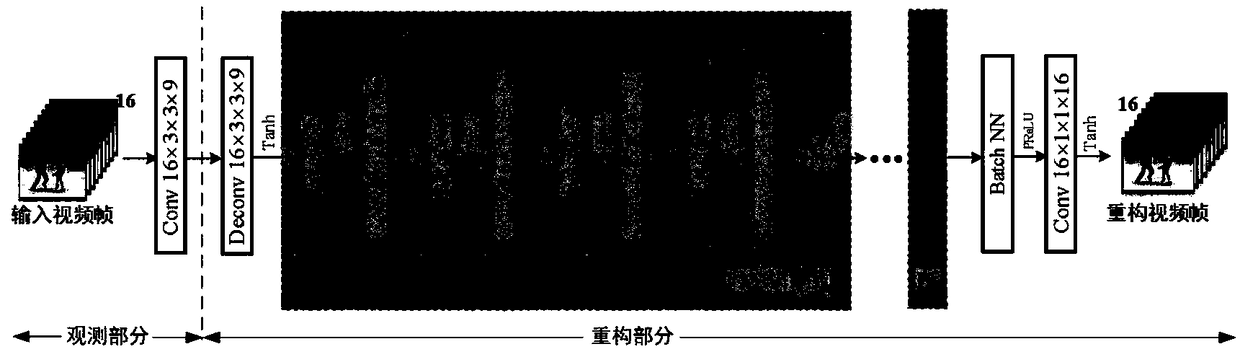

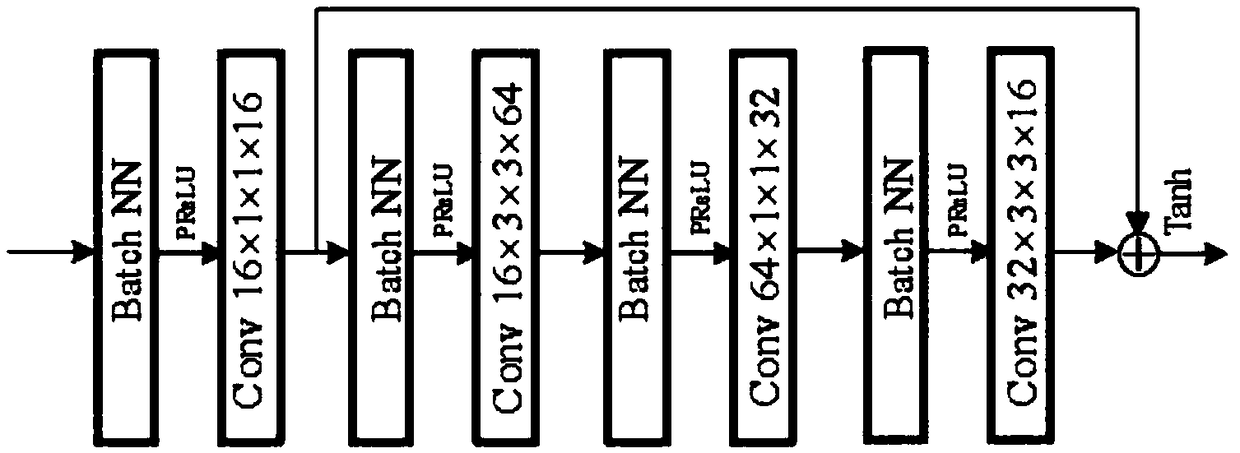

Time-space video compressed sensing method based on convolutional network

ActiveCN108923984AReduce in quantityImprove equalization performanceDigital video signal modificationData switching networksData setVideo reconstruction

The invention discloses a time-space video compressed sensing method based on a convolutional network, and mainly aims at solving the problems that in the prior art, the video compression time-space balance and the video reconstruction real-time performance are poor. The scheme of the method comprises the steps that a training data set is prepared; a network structure of a time-space video compressed sensing method is designed; training and testing files are written according to the designed network structure; a network of the time-space video compressed sensing method is trained; and the network of the time-space video compressed sensing method is tested. The network of the time-space video compressed sensing method adopts an observation technology of simultaneous time-space compression are conducted simultaneously and a reconstruction technology of using 'time-space blocks' to enhance the time-space correlation, not only can real-time video reconstruction be achieved, but also the reconstruction result has the high time-space balance, the reconstruction quality is high and stable, and the network can be used for compressed transmission of a video and follow-up video reconstruction.

Owner:XIDIAN UNIV

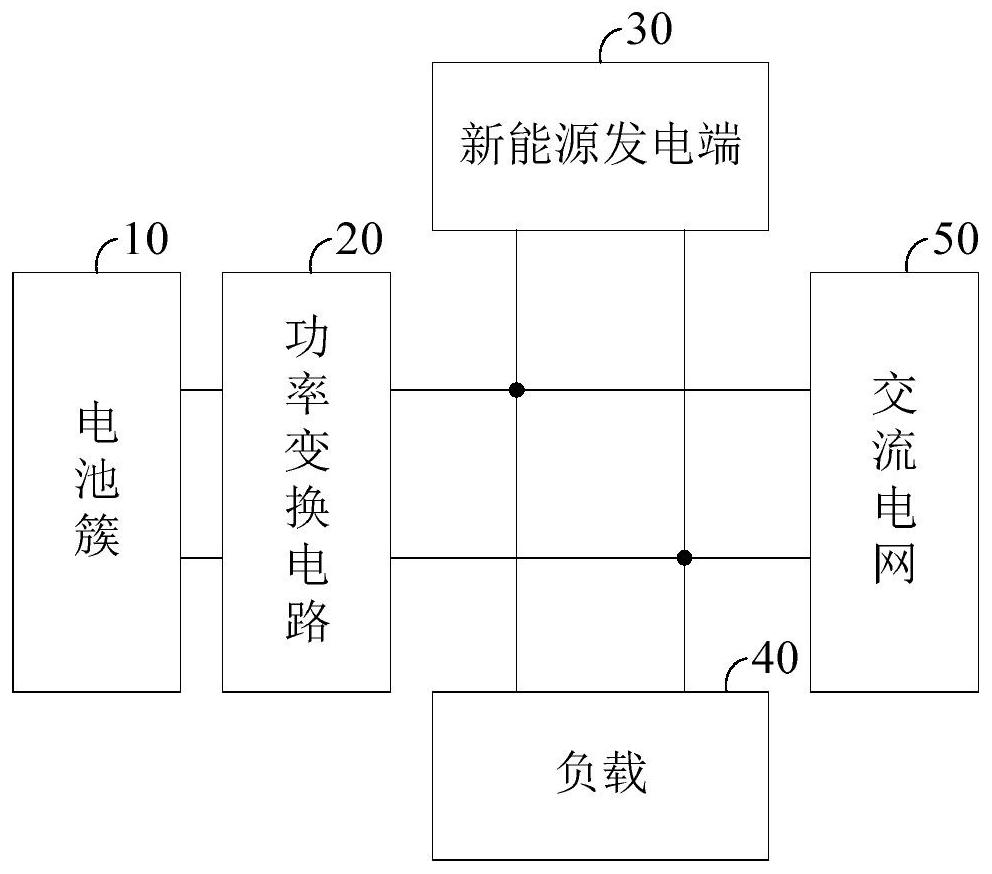

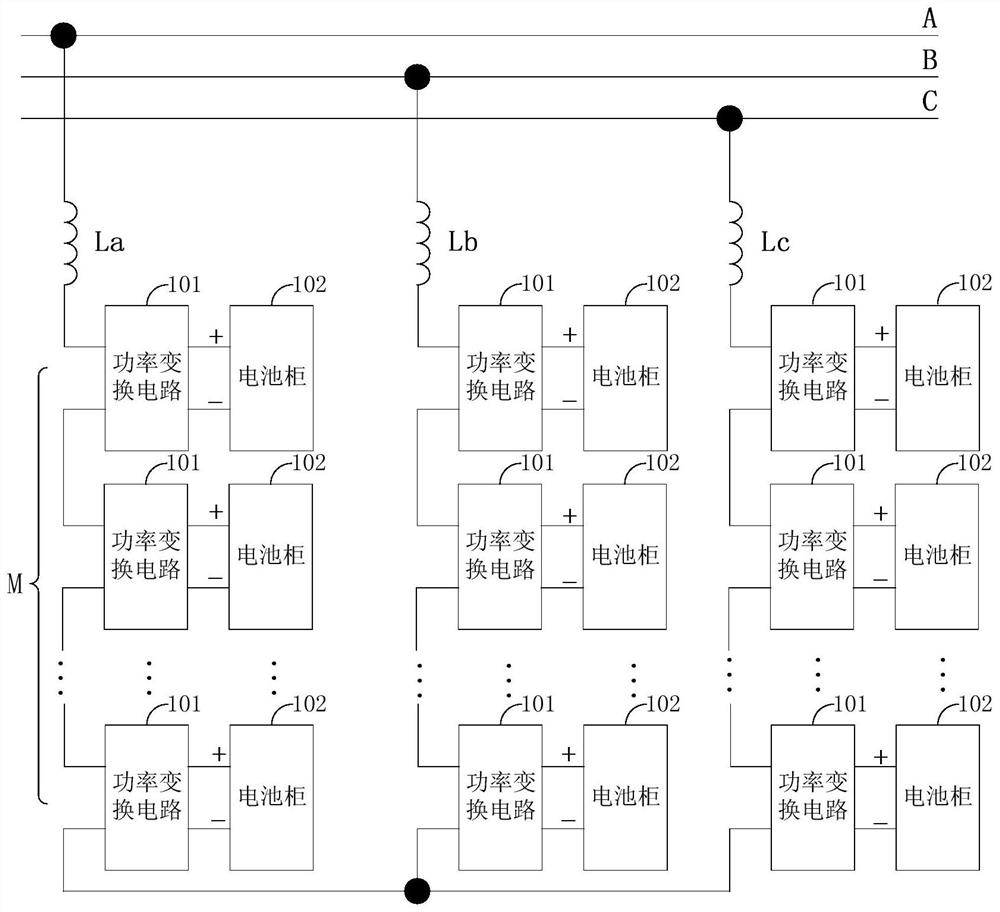

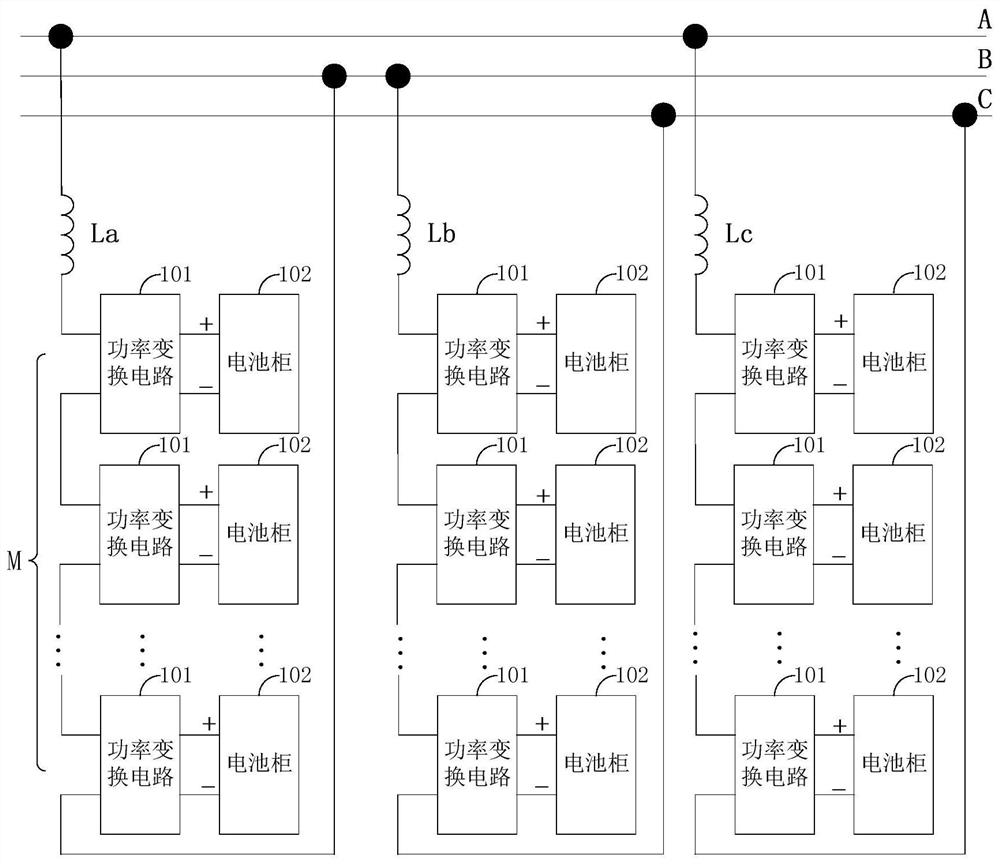

Energy storage system, balance control method of energy storage system and photovoltaic power generation system

PendingCN113270881ACell balanceLarge balance currentCircuit monitoring/indicationCharge equalisation circuitElectrical batteryEngineering

The invention provides an energy storage system, a balance control method of the energy storage system and a photovoltaic power generation system, and relates to the technical field of energy storage systems. The energy storage system comprises a controller and three power conversion branches. Each power conversion branch comprises a power conversion circuit, or each power conversion branch comprises at least two power conversion circuits which are connected in series. The second end of each power conversion circuit is connected with at least one battery cluster; each battery cluster comprises at least two energy storage modules which are connected in series, and each energy storage module comprises a direct current / direct current conversion circuit and a battery pack; the output end of each battery pack is connected with the input end of the corresponding DC / DC conversion circuit, and the output ends of the DC / DC conversion circuits are connected in parallel with the equalization bus. And the controller controls each DC / DC conversion circuit, so that the electric quantity of each battery pack in the battery cluster is balanced. By means of the scheme, the electric quantity balance capacity of the energy storage system is improved, and the influence of the battery short-plate effect is relieved.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

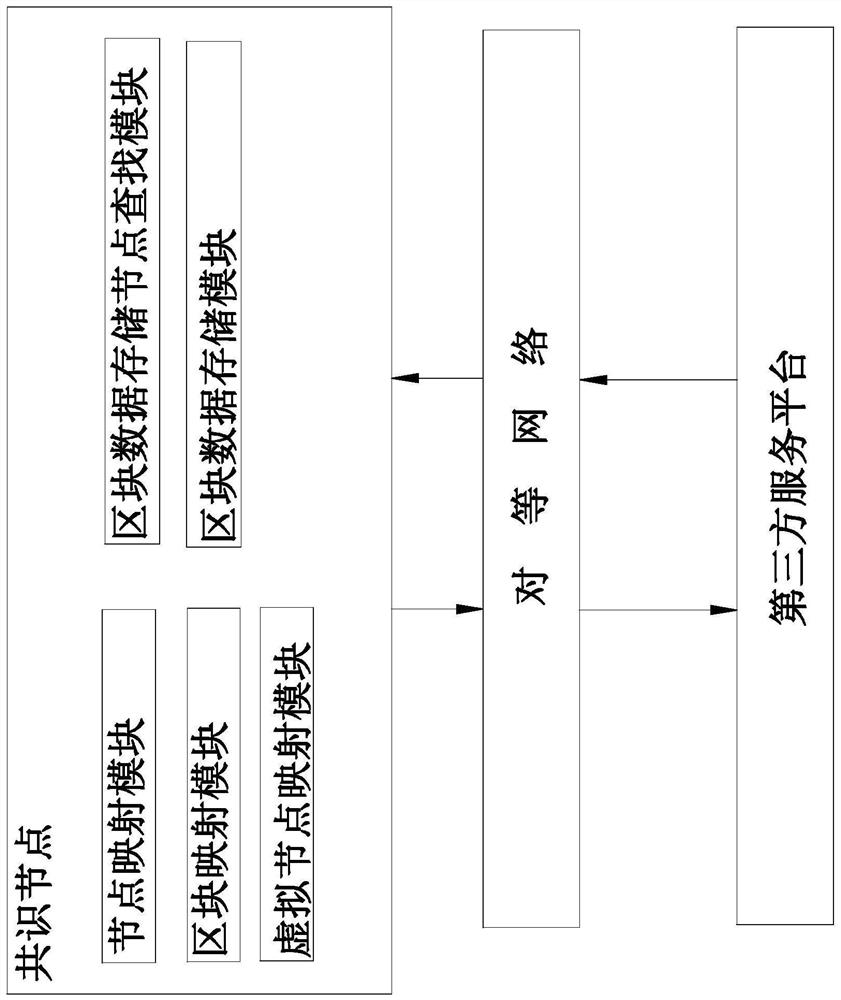

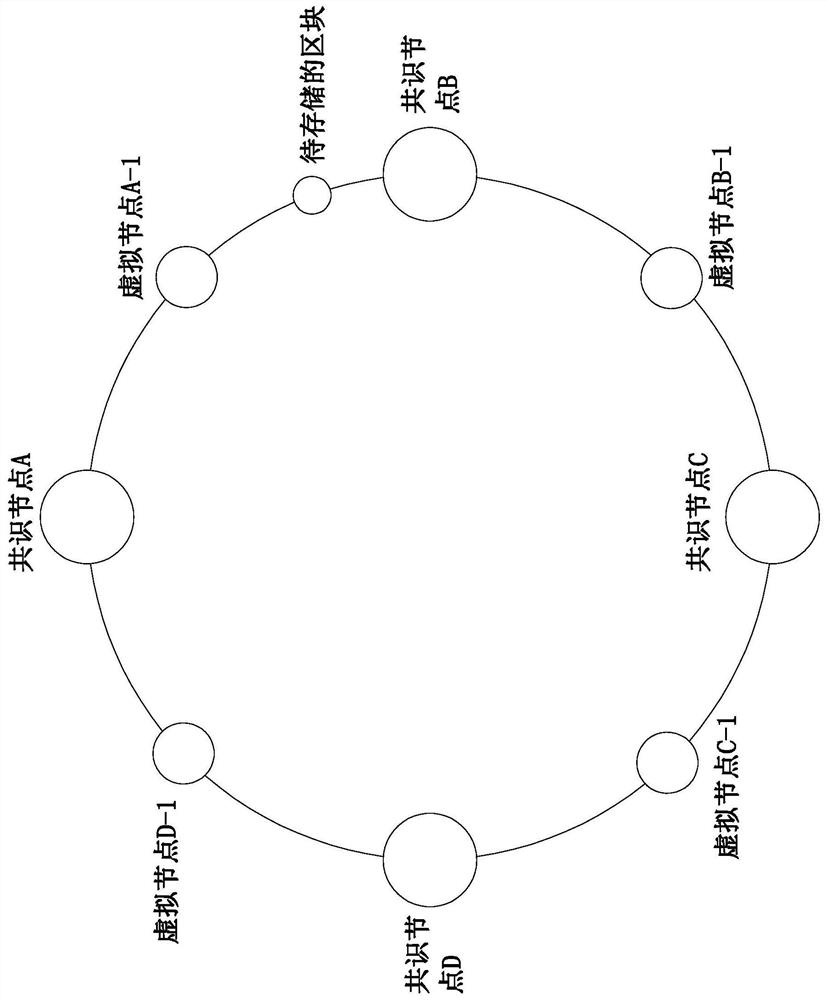

Novel alliance chain based on distributed storage

ActiveCN111770149AReduce storage space requirementsSolve the problem of uneven distributionDatabase distribution/replicationPayment protocolsComputer networkEngineering

The invention provides a novel alliance chain based on distributed storage, and belongs to the technical field of block chains. The problem that in the prior art, the hard disk space of each node mustbe expanded along with the increase of blockchain data is solved. The novel alliance chain based on distributed storage comprises consensus nodes of a block chain platform running on the bottom layer, and each consensus node is provided with the following modules: a node mapping module used for mapping each consensus node to a hash ring according to the address of each consensus node in the alliance chain; and a block mapping module which is used for mapping according to the height of the block. The novel alliance chain based on distributed storage has the advantages that the novel alliance chain based on distributed storage is provided; the hash ring is introduced to realize that the block data on the alliance chain is not stored in each consensus node, but only needs to be stored in oneconsensus node, so that the requirement of the block data on the storage space is reduced, and the network resources consumed for transmitting the block data are also reduced.

Owner:JIANGSU RONGZE INFORMATION TECH CO LTD

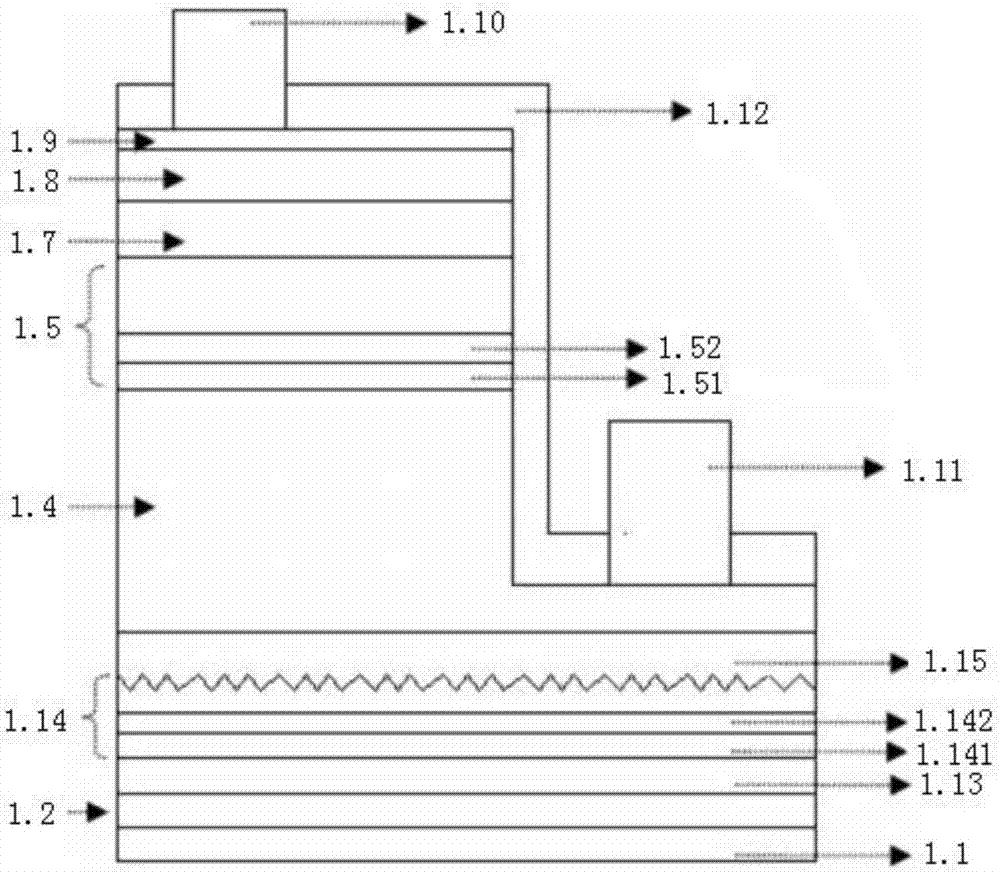

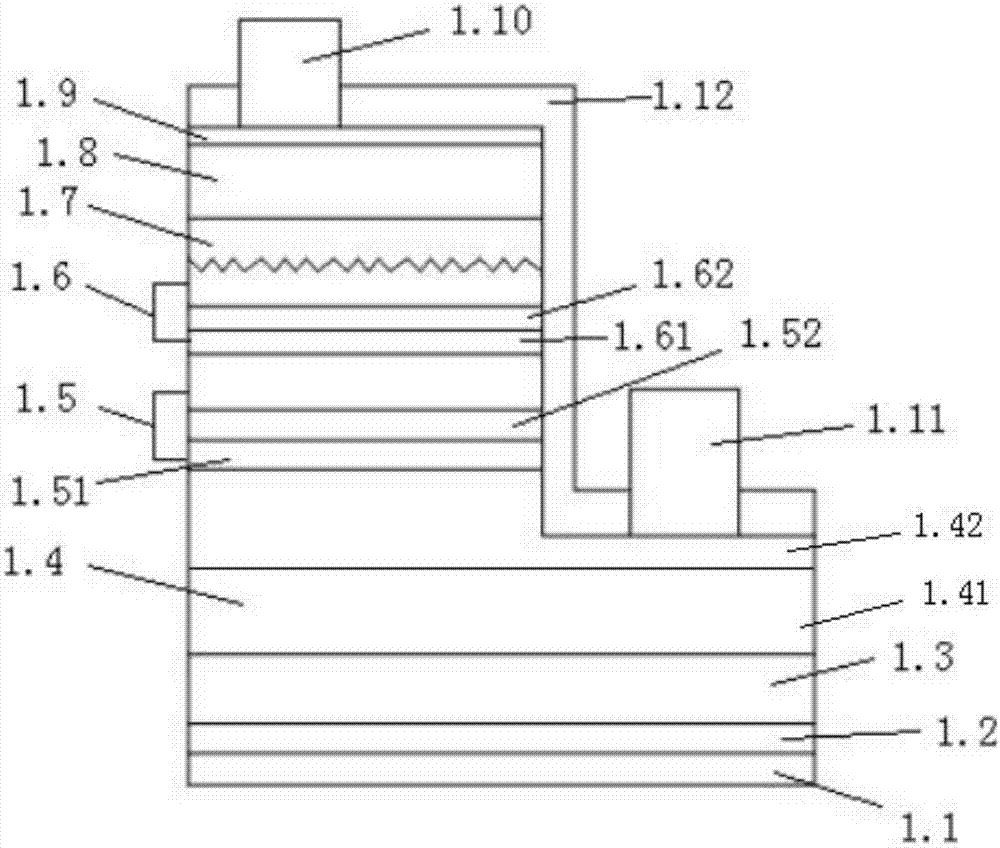

LED epitaxial structure with high light extraction efficiency and growing method thereof

InactiveCN107068822ALower activation energyImprove activation efficiencySemiconductor devicesUltrasound attenuationOptoelectronics

The invention provides an LED epitaxial structure which comprises a substrate, a low-temperature buffer layer, a non-doped GaN layer, an Si-doped n-type GaN layer, an InxGa(1-x)N / GaN light emitting layer, an InX / Mg3N2 super-lattice inner roughed layer, a p-type AlGaN layer and a magnesium-doped p-type GaN layer, wherein the substrate, the low-temperature buffer layer, the non-doped GaN layer, the Si-doped n-type GaN layer, the InxGa(1-x)N / GaN light emitting layer, the InX / Mg3N2 super-lattice inner roughed layer, the p-type AlGaN layer and the magnesium-doped p-type GaN layer are successively laminated. The InX / Mg3N2 super-lattice inner roughed layer comprises 8-10 monomers which are arranged in an overlapped manner. Each monomer comprises an InN layer and a Mg3N2 layer. The LED epitaxial structure provided by the invention is advantageous in that the InX / Mg3N2 super-lattice inner roughed layer covers the light emitting layer; the InX / Mg3N2 material has an advantage of low mismatch with the GaN crystal lattice; high quality of the epitaxial layer crystal is realized; not only is light efficiency improved, but also antistatic capability can be improved; and LED product quality is improved. As an integral technical solution, the InX / Mg3N2 super-lattice inner roughed layer has advantages of increasing number of photons extracted from the LED in light unit time, reducing number of attenuation times of the photons in the LED, and correspondingly improving light extraction strength. The invention further discloses a growing method of the LED epitaxial structure. The growing method of the LED epitaxial structure has advantages of concise steps, easy process parameter control and convenient industrial production.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

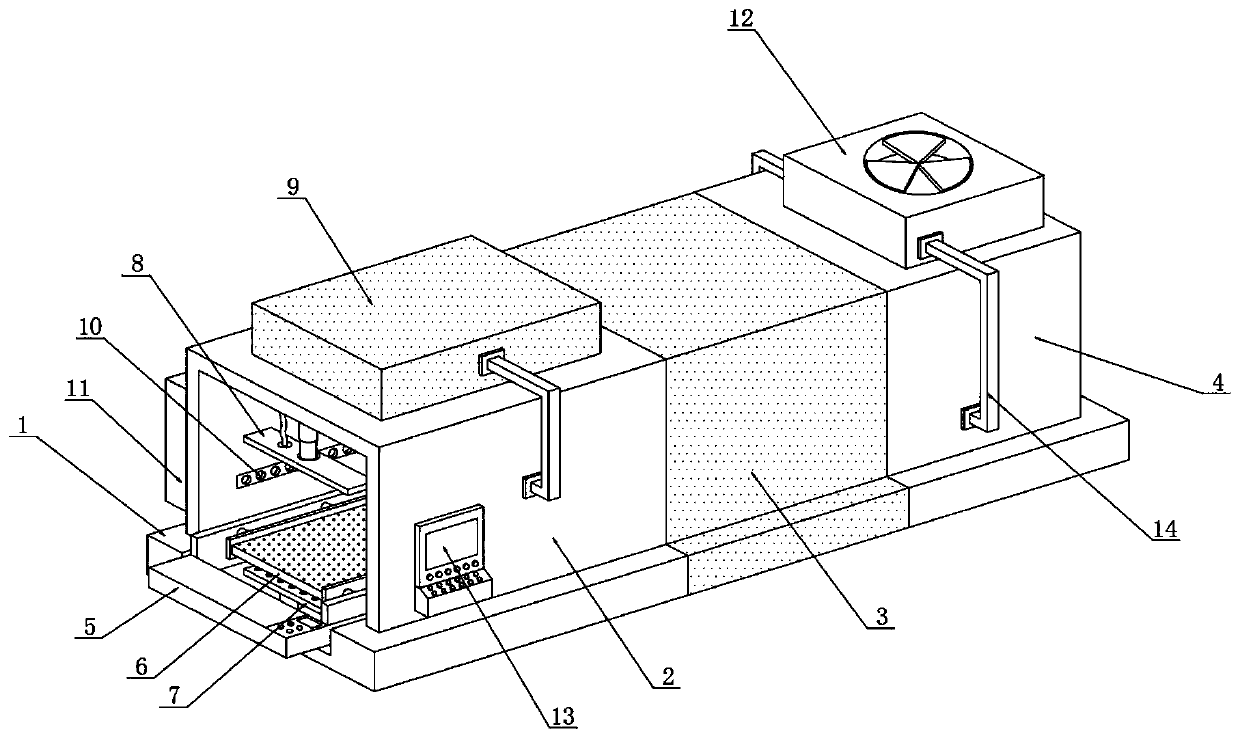

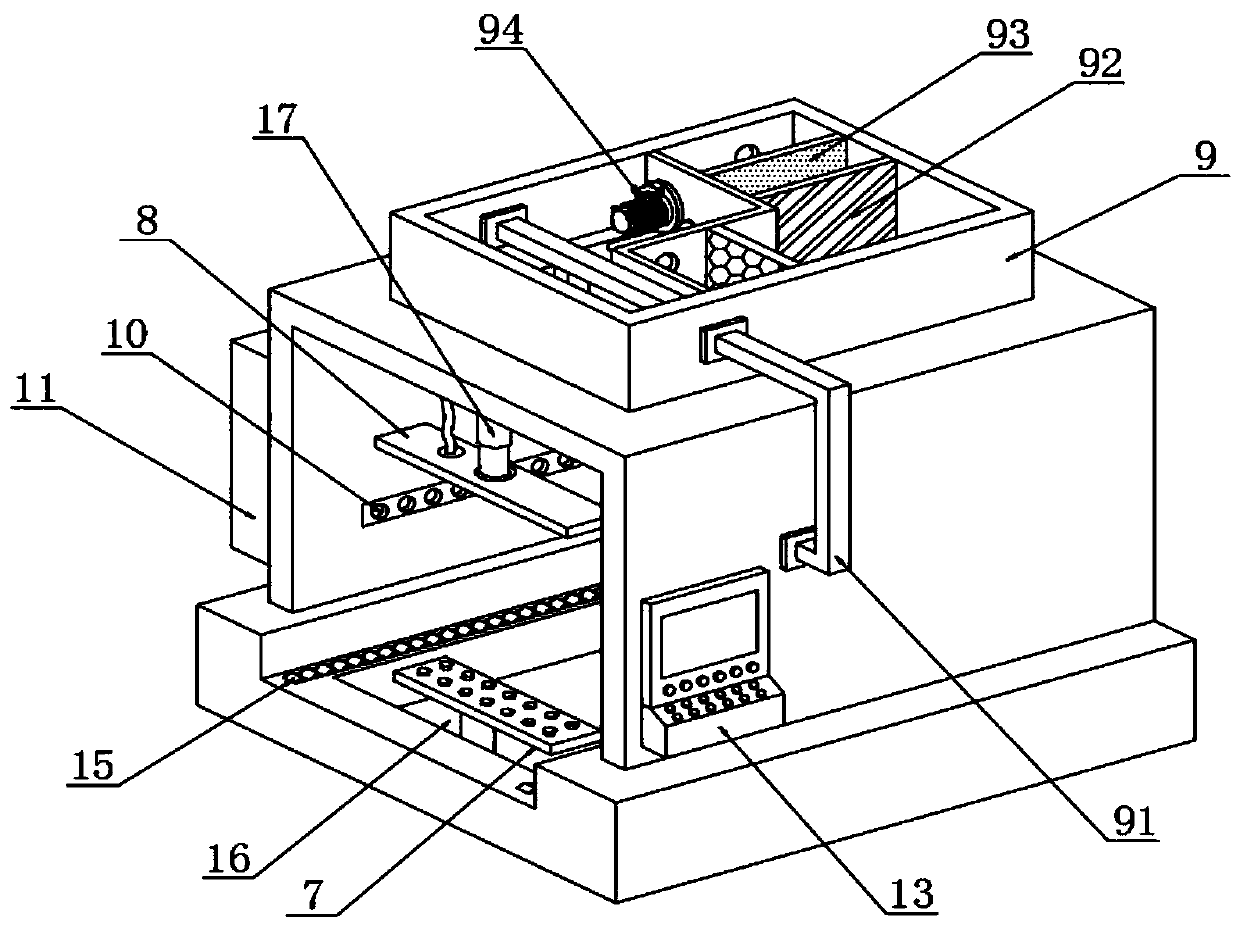

Quick product spraying device based on advanced manufacturing production line

InactiveCN111013861AImprove equalization performanceImprove processing efficiencyPretreated surfacesCoatingsProduction lineLower face

The invention relates to the technical field of advanced manufacturing, in particular to a quick product spraying device based on an advanced manufacturing production line. The quick product sprayingdevice comprises a base, a feeding mechanism, a spraying mechanism, a spraying chamber, a drying chamber and an air drying chamber, wherein the feeding mechanism comprises a feeding plate, the two sides of the upper end of the feeding plate are correspondingly provided with side plates, and the portions, located at the inner sides of the side plates, of the upper end of the feeding plate are provided with clamping plates. According to the quick product spraying device, upper-and-down opposite spraying design is adopted, materials in an upper spraying plate and a lower spraying plate are uniformly conveyed, and the balance in spraying is improved. Moreover, through the cooperation of an infrared emitter and an infrared receiver, the upper spraying plate and the lower spraying plate can be automatically controlled to conduct spraying, an upper drying plate and a lower drying plate in the drying chamber simultaneously conduct targeted drying on the upper and lower faces of panels, and besides, opposite-jetting air outlets are designed in the air drying chamber and can comprehensively blow air to the panels to air-dry the panels. Moreover, the quick product spraying device integrates functions of spraying, drying and air drying, and the processing efficiency of spraying the panels is improved.

Owner:嘉善瑞佳运动器材有限公司

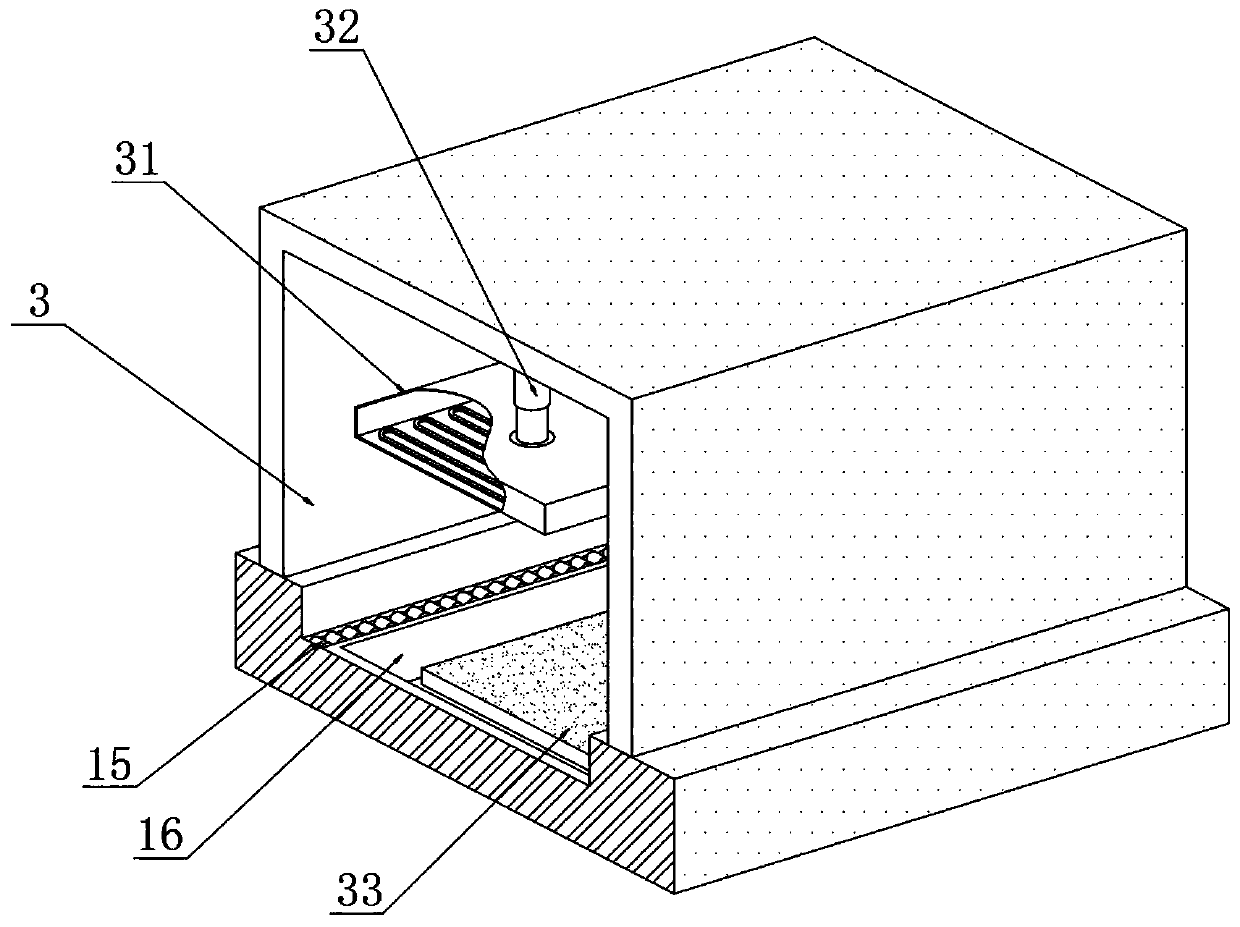

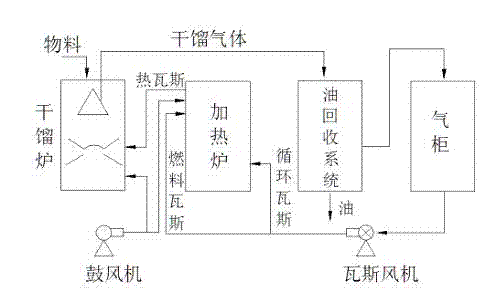

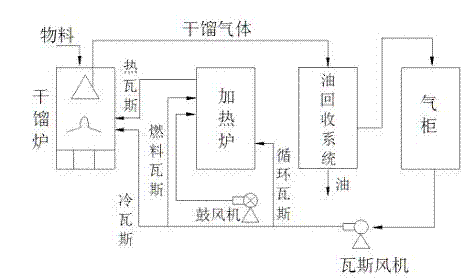

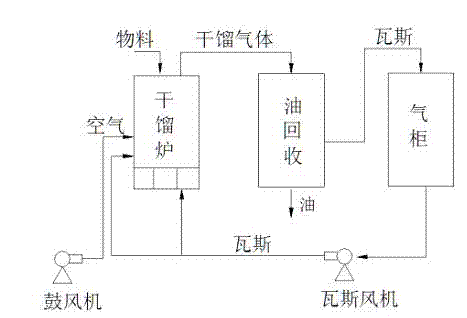

Integrated gas retort

ActiveCN102827619AReduce consumption costsLow running costEnergy inputIndirect heating destructive distillationCombustion chamberHeat carrier

The invention relates to an integrated gas retort integrating heating of a heat carrier and dry distillation of materials into the same one dry distillation unit. The integrated gas retort is characterized in that smoke gas is used as dry distillation heat carrier for indirectly heating materials; the gas retort is formed by combining a plurality of dry distillation sub units. Each dry distillation sub unit is independent, one combustion chamber corresponds to one dry distillation chamber to form one dry distillation sub unit, the upper parts of retorts comprising a plurality of dry distillation sub units are communicated, the two dry distillation sub units are separated by a smoke gas chamber, and the lower parts share one water seal tank and a tar exhaust device. The actual daily capacity of the gas retort can achieve more than 6000. The integrated gas retort is applicable to low-temperature dry distillation oil refining of materials oil sand, oil shale, coal and the like. The integrated gas retort is applicable to dry distillation and oil refining of small-particle materials, as well as various qualities of materials with low gas content, low fixed carbon content and high moisture content, and the oil recovery rate of the gas retort can achieve about 90%.

Owner:辽宁智越建设有限公司

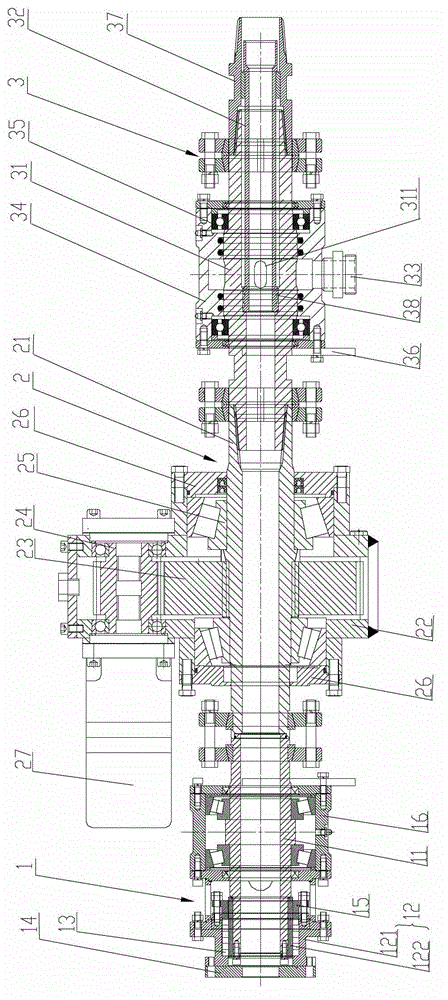

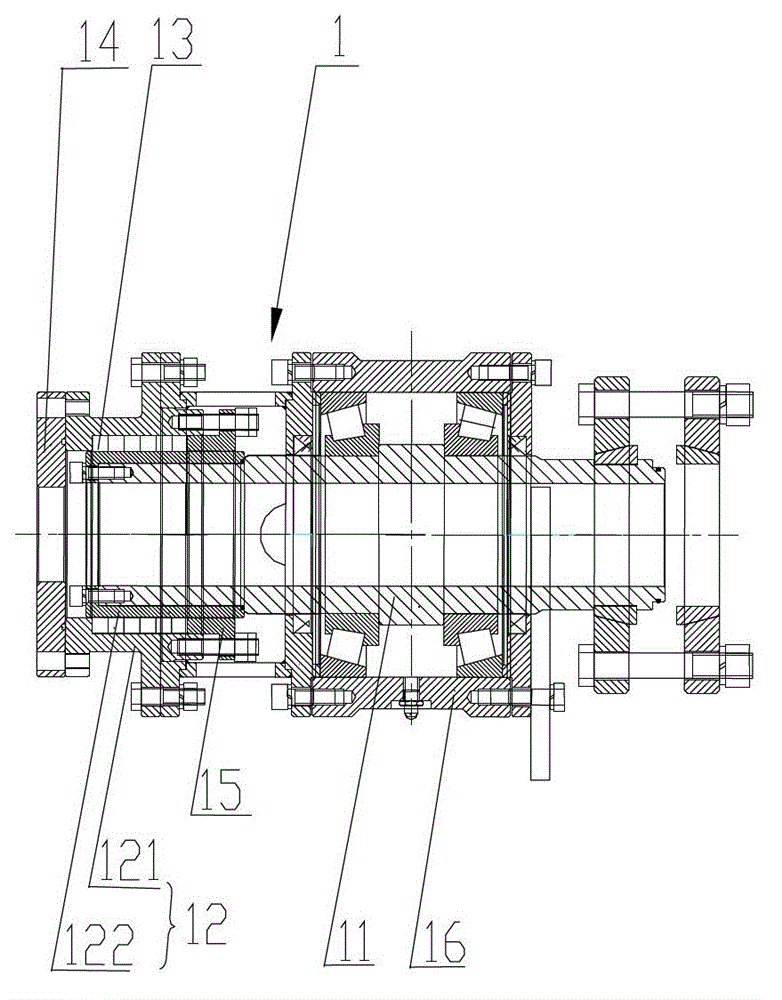

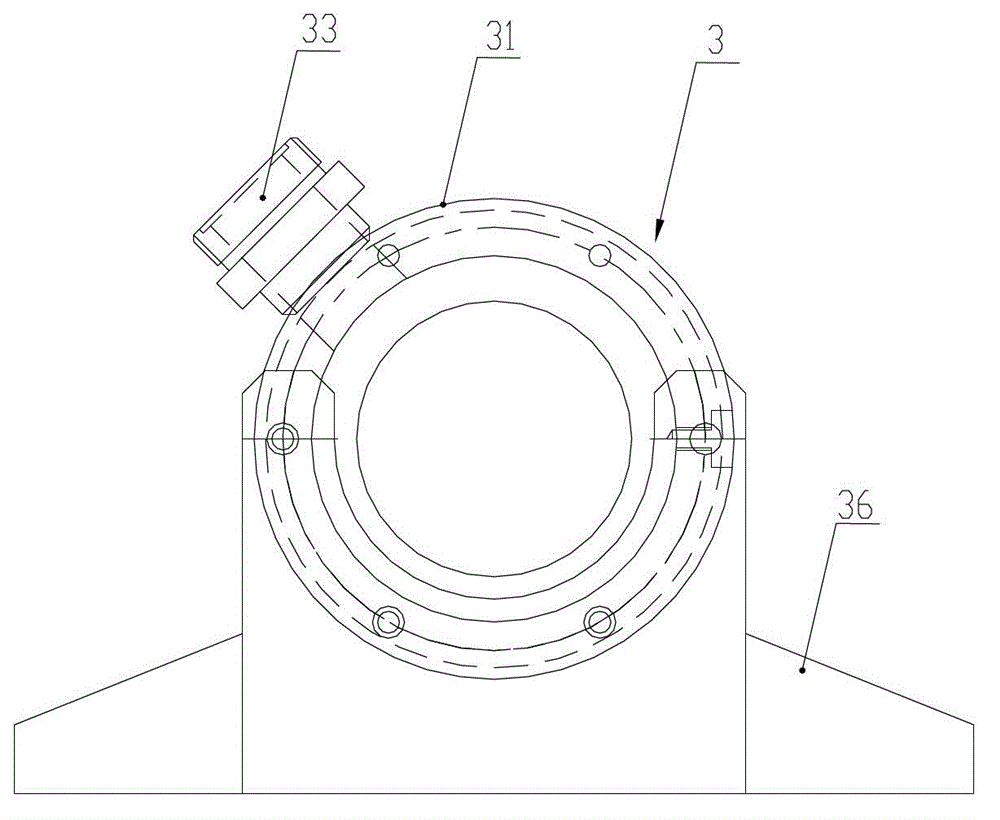

Reverse circulation drill for geological prospecting, and power head thereof

The invention provides a reverse circulation drill for geological prospecting, and a power head of the reverse circulation drill. The reverse circulation drill for geological prospecting is high in drilling efficiency. The power head comprises a rotating joint, a rotary box and a gas distributor, wherein the rotating joint, the rotary box and the gas distributor respectively comprise a rotating shaft, a main shaft and a mandrel which are hollow shafts arranged in a coaxial through way and are sequentially connected in a sealing way; the outer end of the rotating shaft is provided with a slag discharge hole; the main shaft is connected with a driving motor; the mandrel is internally provided with an inner tube in a coaxial way; the inner end of the inner tube is connected with the inner wall of the mandrel in a sealing way; the inner end of the inner tube is communicated with a hollow part of the main shaft is through; the outer diameter of the inner tube is smaller than the inner diameter of the mandrel; and at least one air inlet is arranged along the circumferential direction of the inner end of the mandrel, and compressed air enters the mandrel from through the air inlet. All the parts of the power head are independent of one another, so that the power head is convenient to assemble and disassemble; therefore, the sampling process is simplified, the quality of a sample is guaranteed, and the exploration efficiency is improved.

Owner:张家口市宣化正远钻采机械有限公司

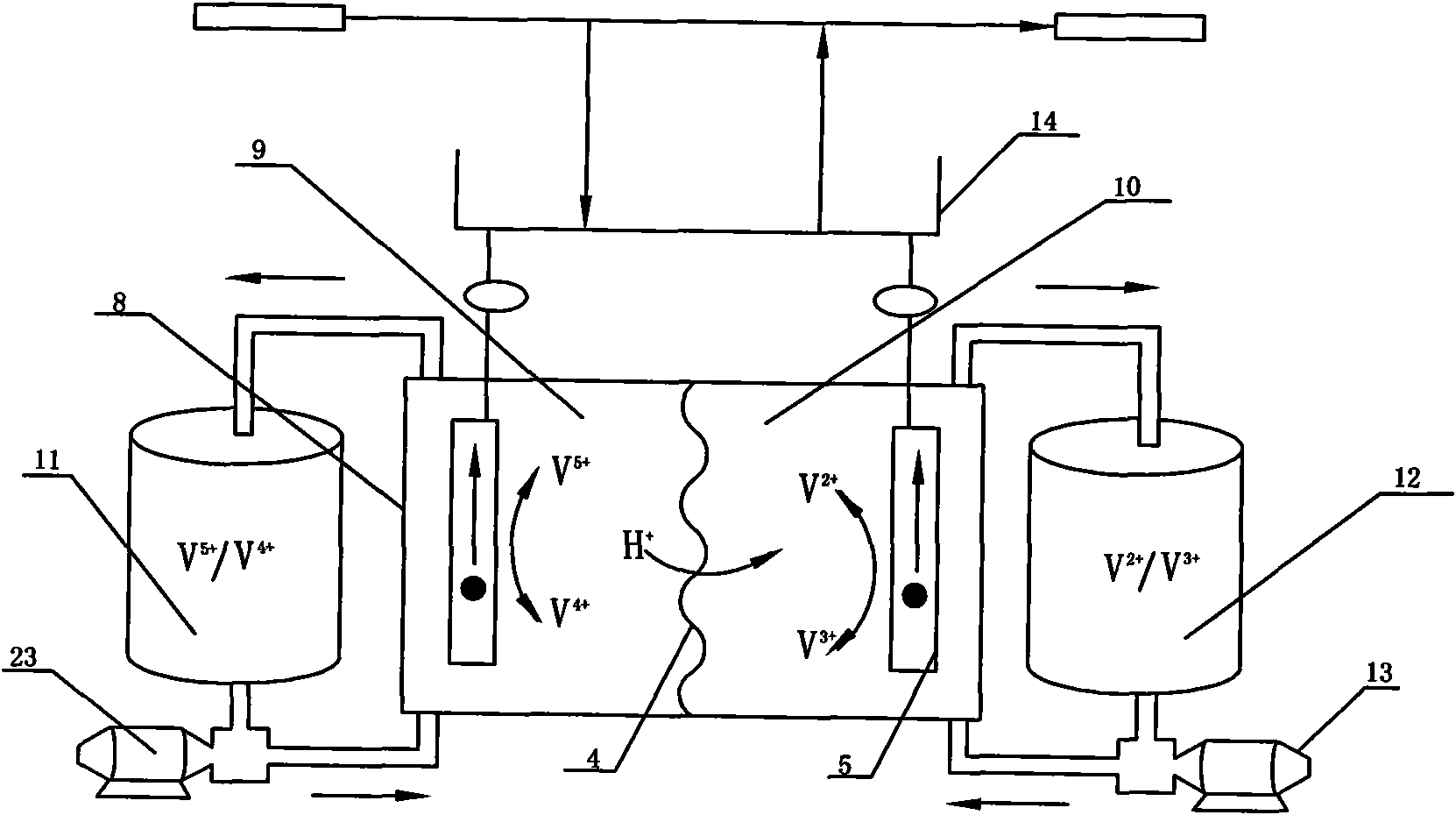

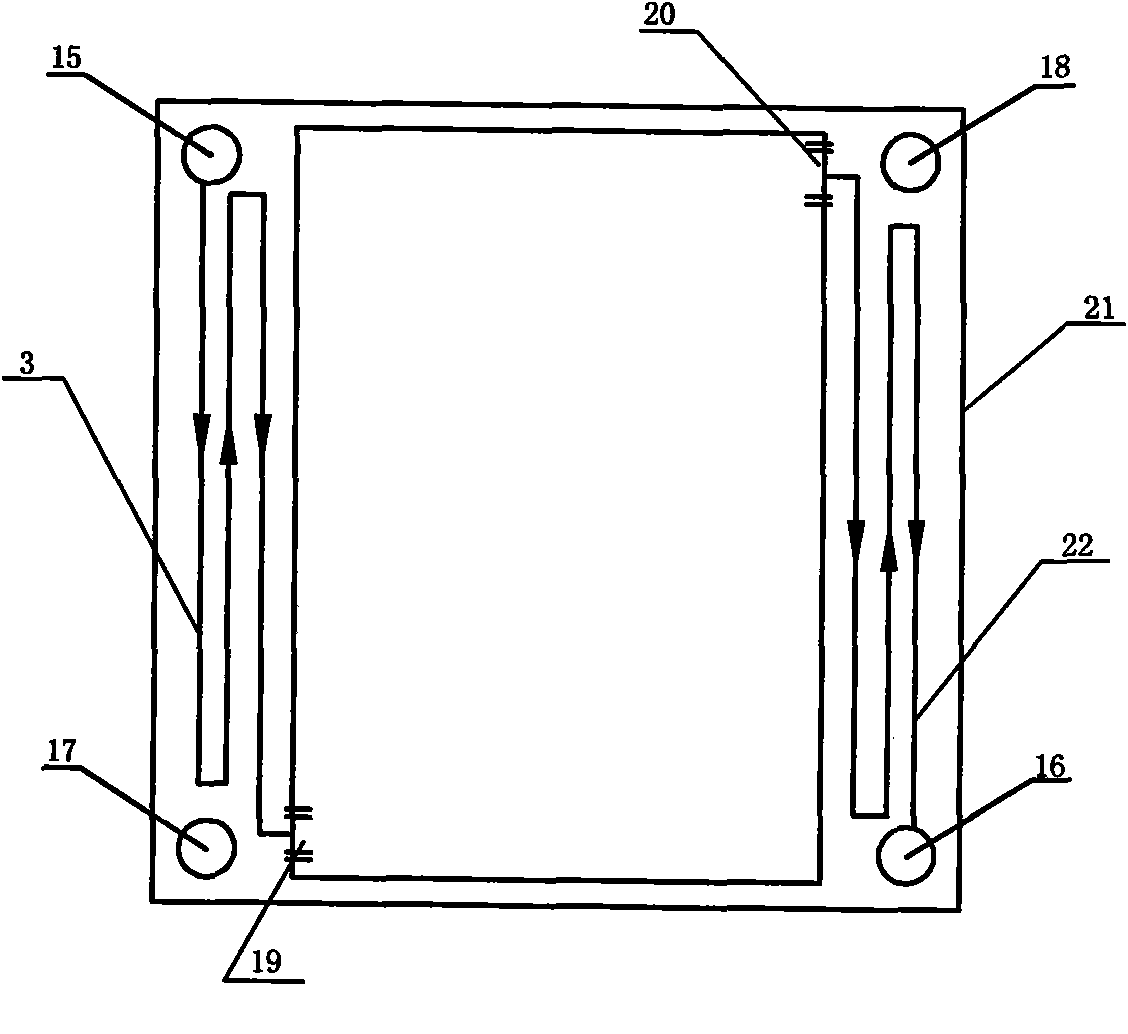

All vanadium redox flow battery structure

ActiveCN101562257AIncrease the effective resistanceAvoid corrosionFuel cells groupingRegenerative fuel cellsIon-exchange membranesElectric energy

The invention discloses an all vanadium redox flow battery structure, comprising at least two single batteries; the single battery comprises two liquid flow frames; an ion exchange membrane is arranged between the two liquid flow frames; liquid flow passages are respectively arranged on the two liquid flow frames; the liquid flow frames clamp the ion exchange membrane to respectively form a first hermetic liquid storage chamber and a second hermetic liquid storage chamber; carbon-based electrode materials are respectively arranged in the first liquid storage chamber and the second liquid storage chamber; a first liquid storage pot and a second liquid storage pot are respectively communicated with the liquid flow frames; the first liquid storage chamber is communicated with the first liquid storage pot via one liquid flow passage; the second liquid storage chamber is communicated with the second liquid storage pot via the other liquid flow passage; the single batteries are connected in series via a bipolar electrode. In the structure, derious liquid flow passages are arranged on the liquid flow frames, perfluorinated ion exchange membrane serves as the ion exchange membrane and flow passages or flow chutes are arranged on the external surfaces of the carbon-based electrode materials, thereby improving electric energy transfer efficiency and uniformity of single battery property.

Owner:QINGDAO WUXIAO GRP

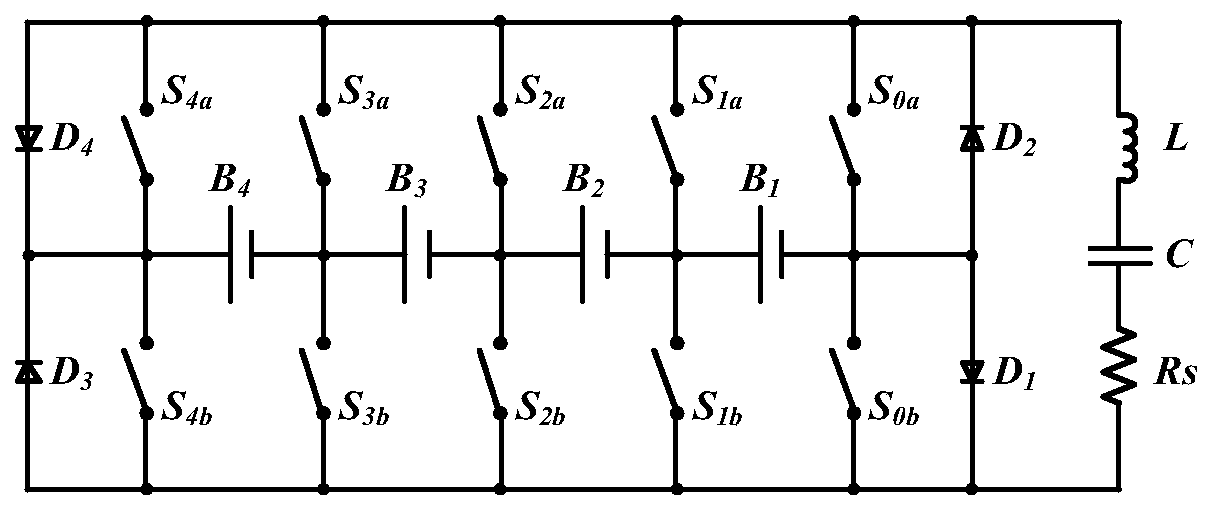

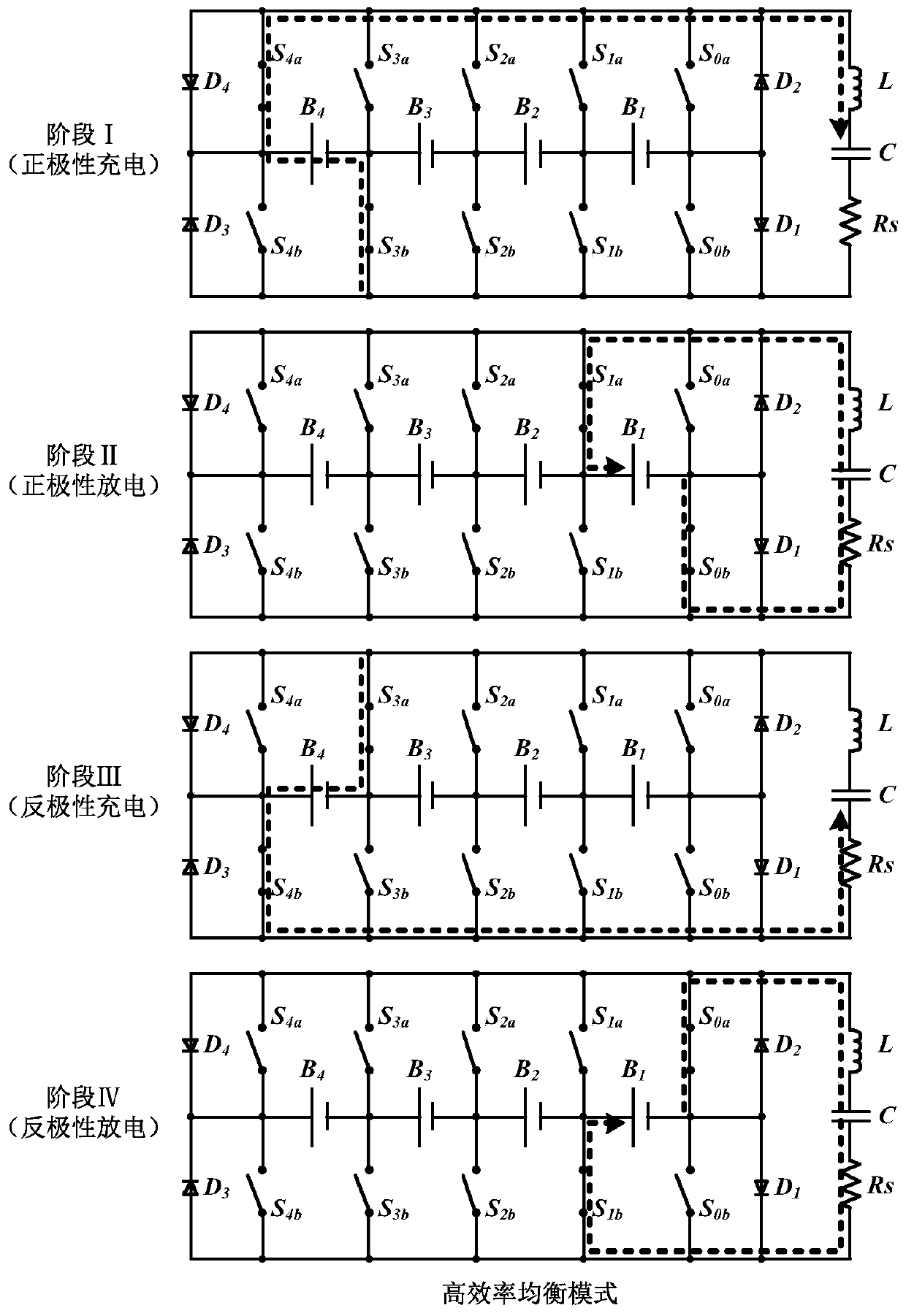

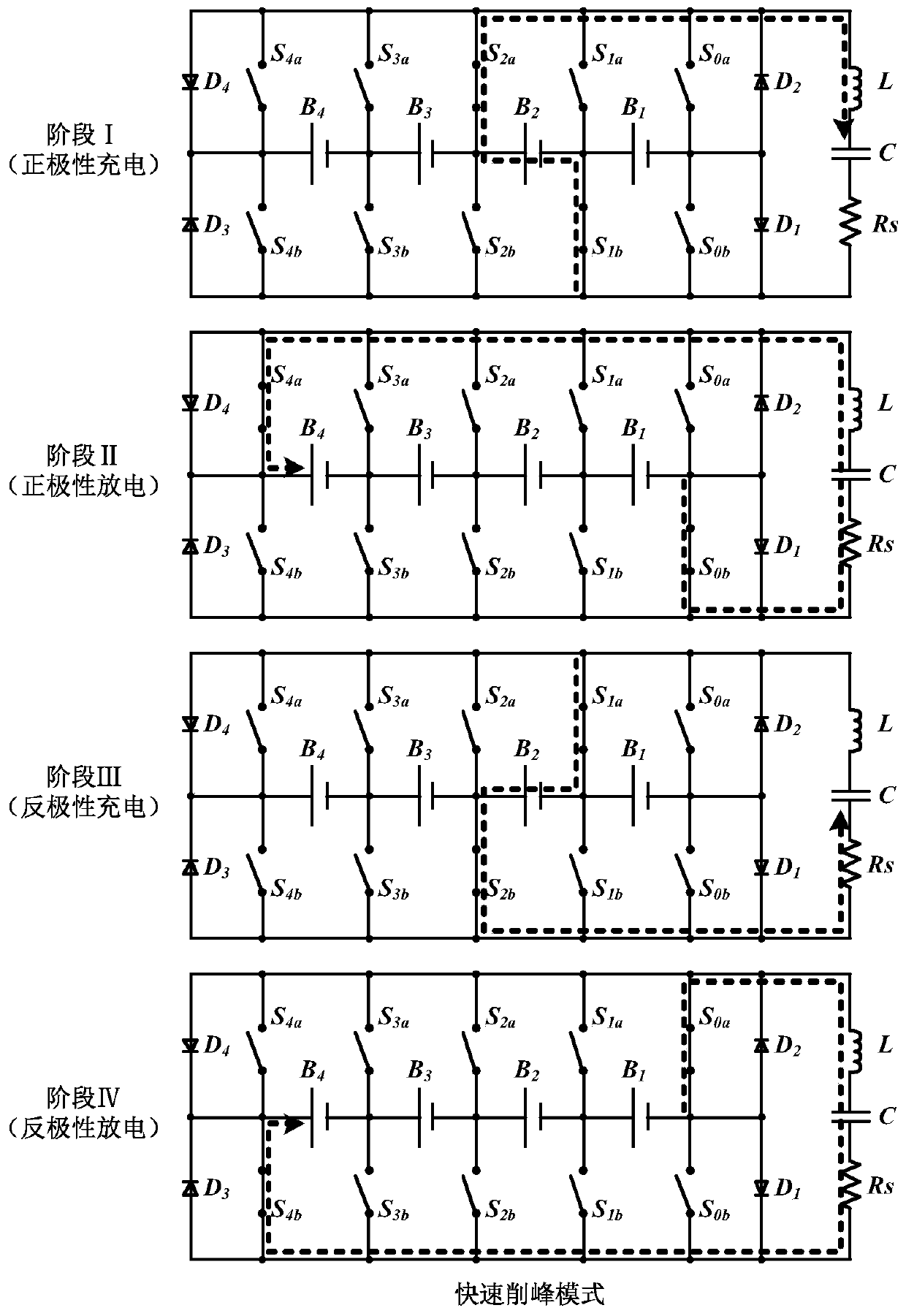

LC bipolar resonant-based Cells-to-Cells equalization circuit and control method thereof

PendingCN110034597APrevent overchargingIncrease capacityCharge equalisation circuitSecondary cells charging/dischargingMicrocontrollerCapacitance

The invention discloses an LC bipolar resonant-based Cells-to-Cells equalization circuit and a control method thereof. During the equalization process, a microcontroller outputs four paths of rectangular wave driving signal of which frequencies are half of an LC resonant frequency, the phase difference is 90 degree and the duty ratio is 25% so that an equalization source unit and an equalization target unit are bipolarly and circularly connected to an LC resonant branch by a switch network, the LC resonant branch circularly works in states of positive polarity charging, positive polarity discharging, reverse polarity charging and reverse polarity discharging, and zero-current switch equalization of which energy is transmitted from the source unit to the equalization target unit is achieved. By the equalization circuit, equivalent release of a residual voltage of a resonant capacity C during the equalization process is achieved, the equalization source unit and the equalization target unit both can be adjacent arbitrary sections of Cells, the equalization circuit has the advantages of high power density, high equalization efficiency and control flexibility, and modular manufacturingis easy.

Owner:SOUTH CHINA UNIV OF TECH

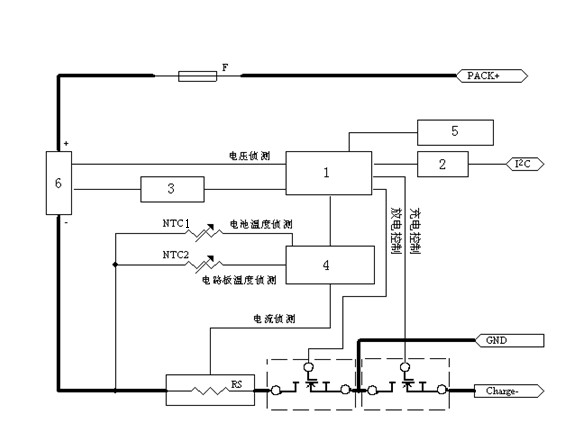

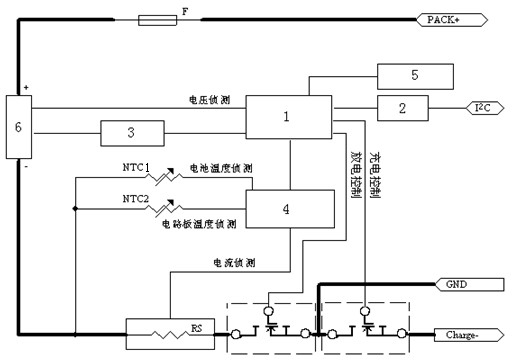

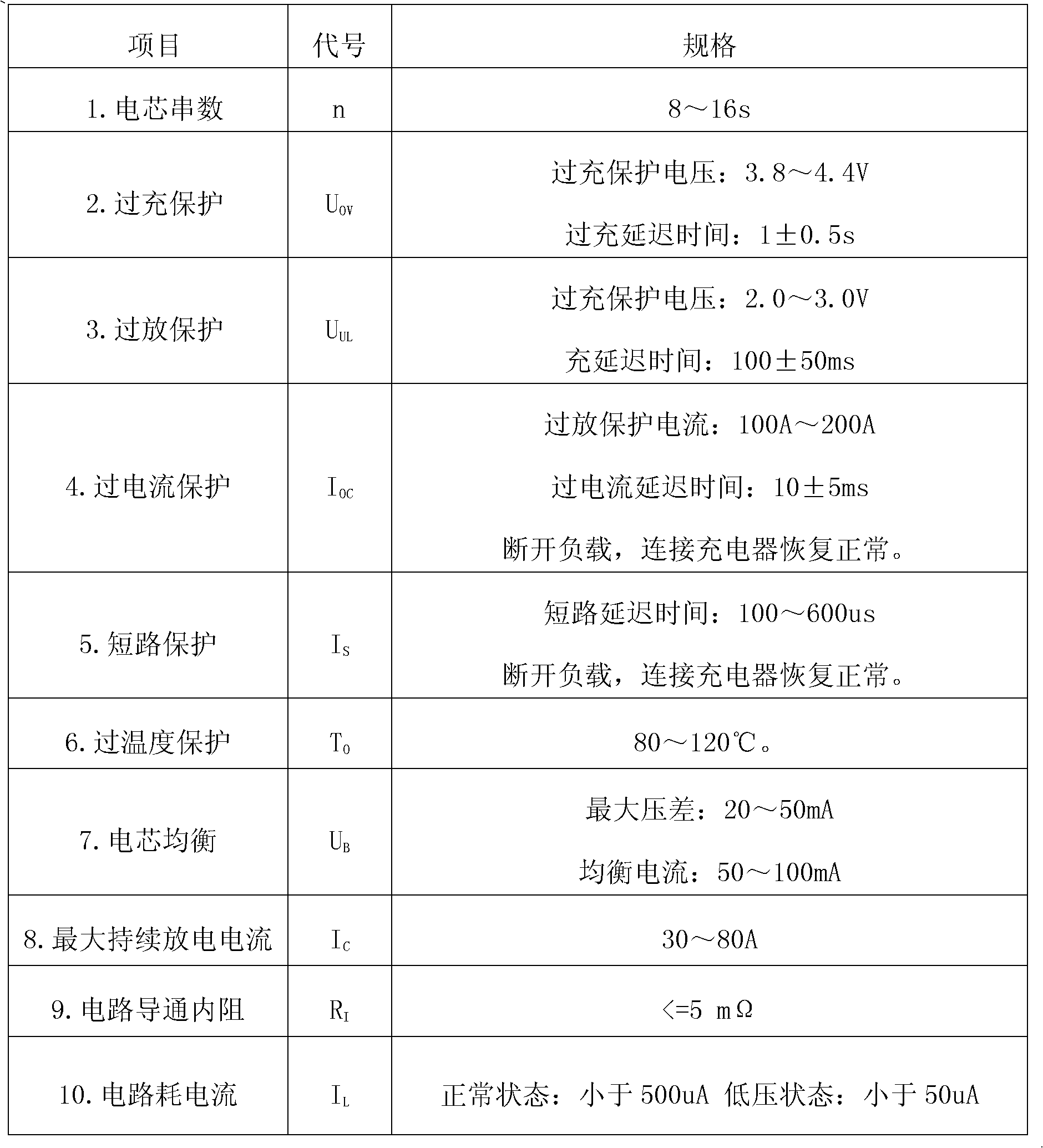

Multi-string high-power lithium battery control board

ActiveCN102593795AExtended service lifeHigh output powerBatteries circuit arrangementsEmergency protective circuit arrangementsElectrical batteryEngineering

The invention discloses a multi-string high-power lithium battery control board comprising a single chip computer control module, an equalization circuit, a battery management module and an LCD (Liquid Crystal Display) module; the single chip computer control module is used for detecting the voltage of a battery pack, and the battery management module is used for transmitting signals to the single chip computer control module; an end of the battery management module is used for detecting the temperature of the battery pack and the current flowing by a resistor via a first thermal resistor and a second thermal resistor; the positive pole of the battery pack is connected with a charge / discharge shared positive pole connection end, and the negative pole of the battery pack is connected with a discharge negative pole connection end sequentially via a resistor and a first field-effect tube and then connected with a charge negative pole connection end via a second field-effect tube; the charge and discharge of the battery pack is controlled by the single chip computer control module through the control over the connection and disconnection of the first and the second field-effect tubes; and the LCD module is also controlled by the single chip computer control module. With the adoption of the battery management module, the current, the temperature and the capacity are more accurately detected; and with the adoption of the single chip computer control module as a core, high accuracy and high efficiency are achieved, the balance of batteries is improved and the cycle lives of the batteries are prolonged.

Owner:昆山万金天宇贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com