Construction method for ultralarge-diameter shield synchronous grouting

A synchronous grouting and ultra-large diameter technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of high grouting cost, short grout setting time, easy blockage, etc., and achieve better balance and higher construction efficiency effect on construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific examples.

[0037] A construction method for synchronous grouting of a super-large diameter shield tunnel of the present invention comprises the following steps:

[0038] First, produce and prepare slurry materials;

[0039] A stirring system receives a command from a control room and starts;

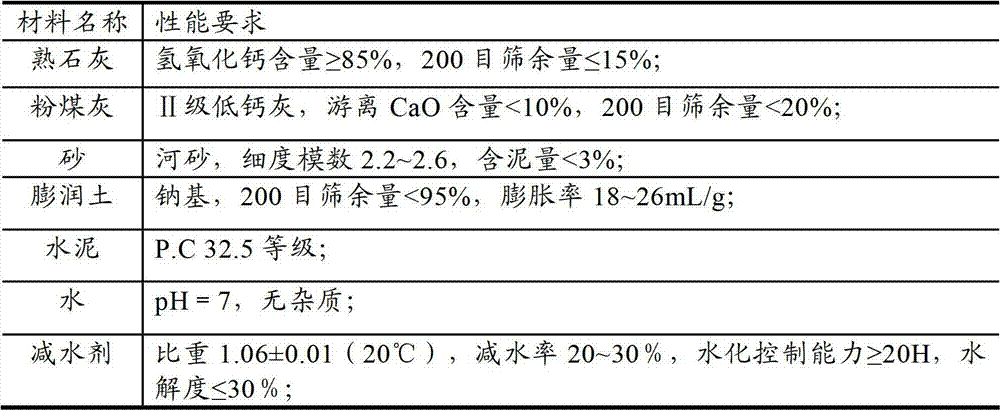

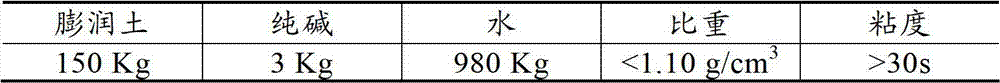

[0040] The mixing system weighs each raw material according to the ratio of the fixed volume slurry material; the raw materials include bentonite, fly ash, slaked lime, cement and sand according to the feeding order; in the mixing step, when the raw materials are mixed evenly, add water and Aqua.

[0041] According to the preset feeding sequence, each weighed raw material is sequentially added to a mixer and stirred to form a slurry material;

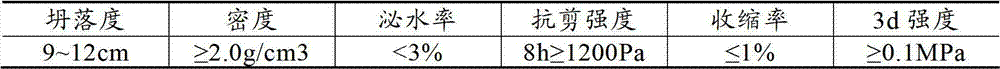

[0042] The slurry material is loaded into a ground container and the next mixing of a fixed volume of slurry material is performed. Performance testing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com