Patents

Literature

48results about How to "Uniform heating surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

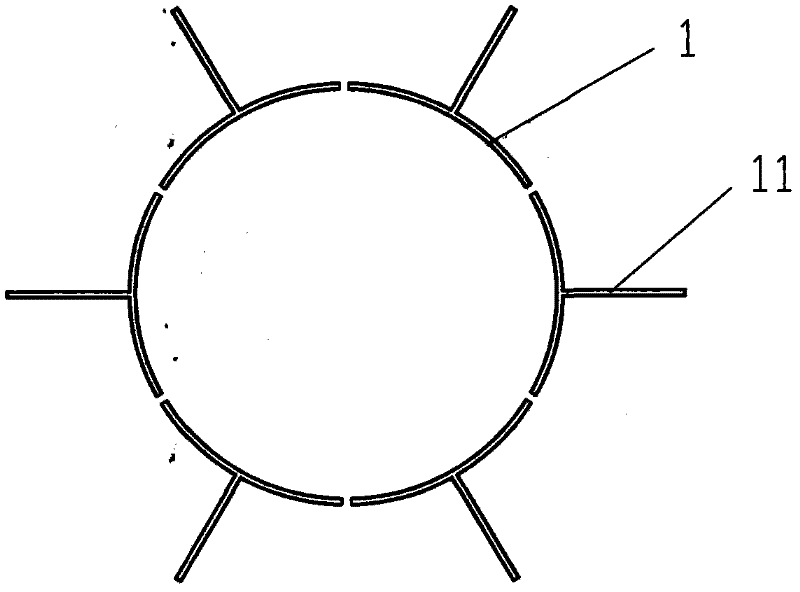

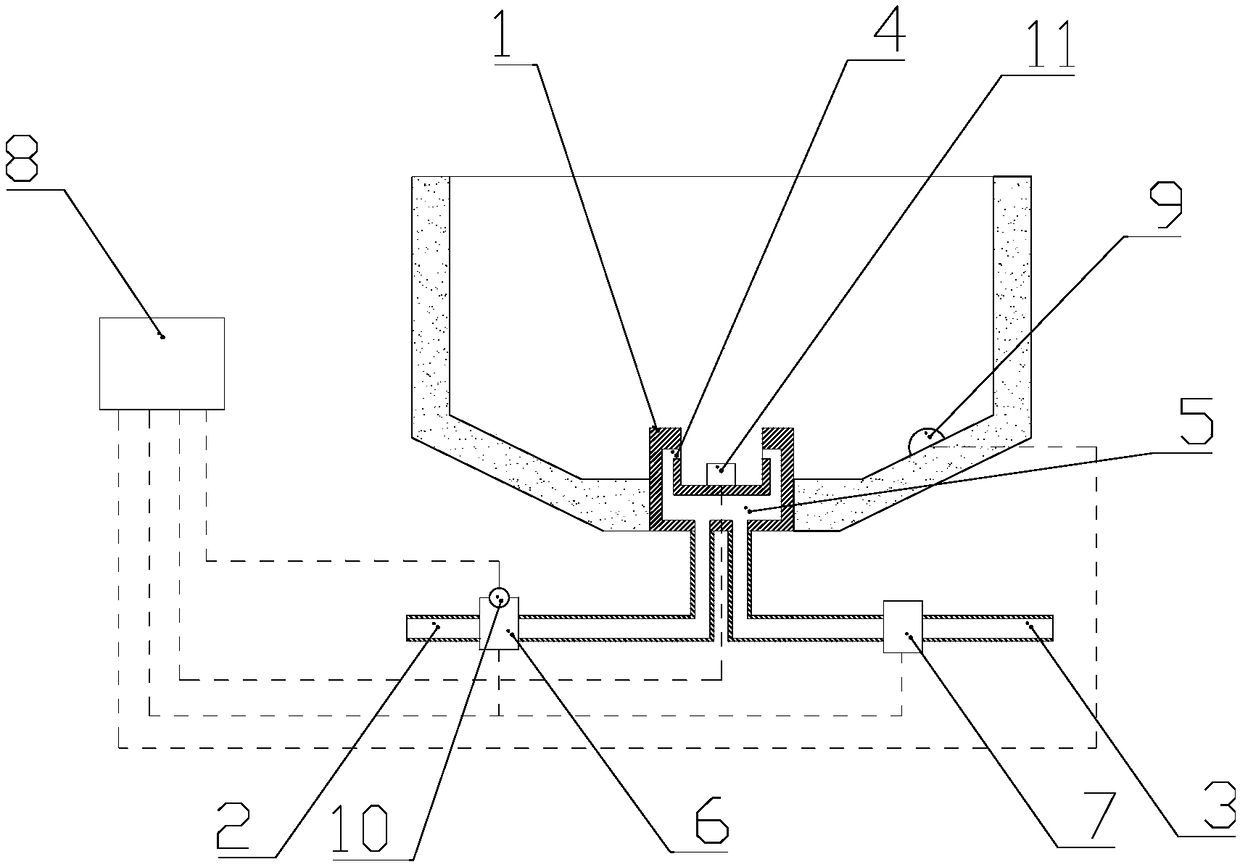

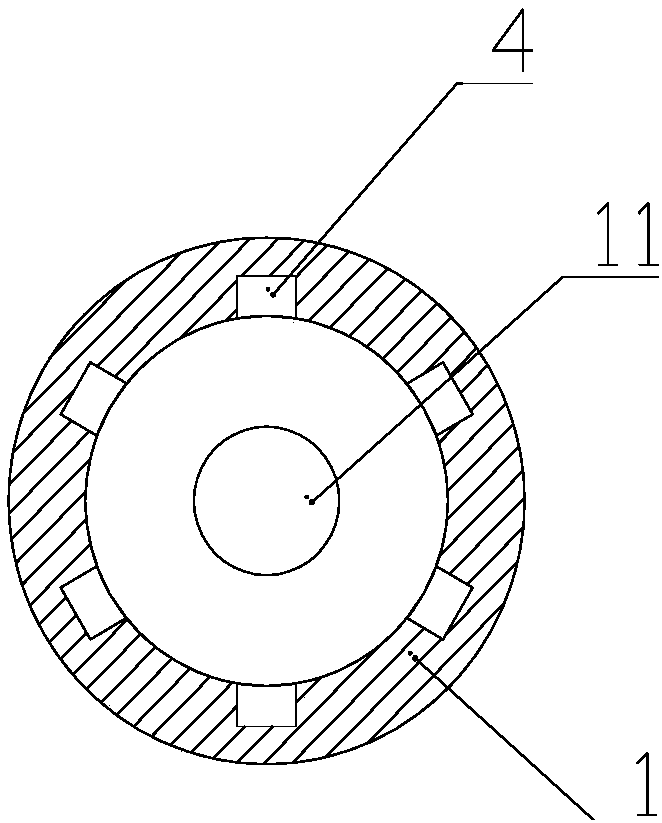

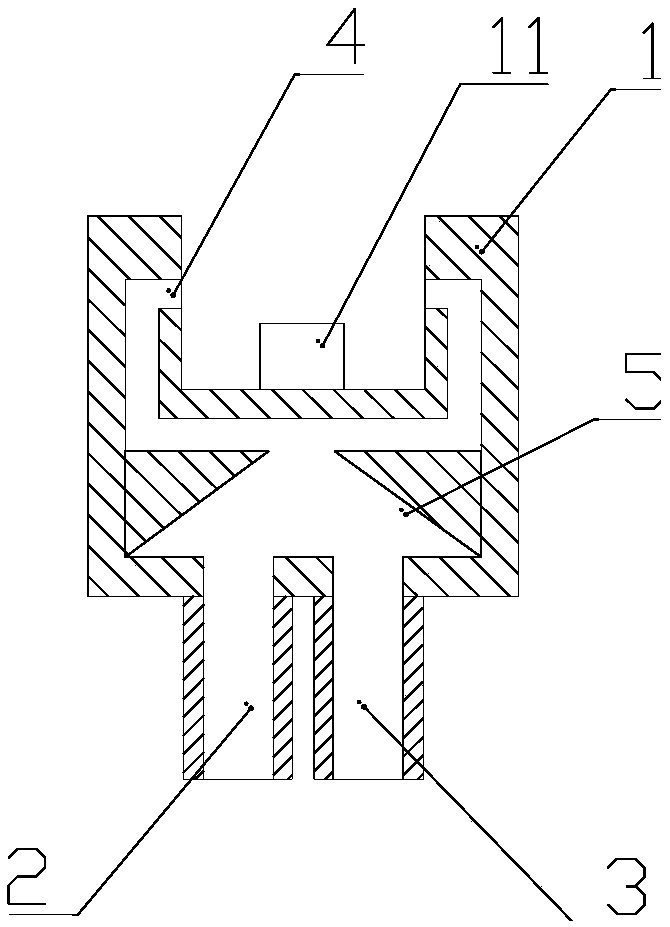

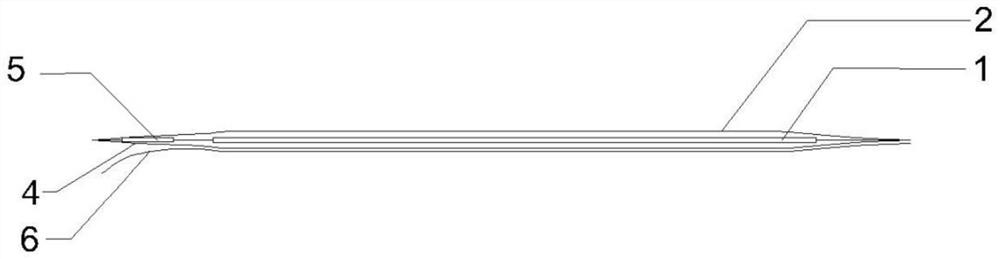

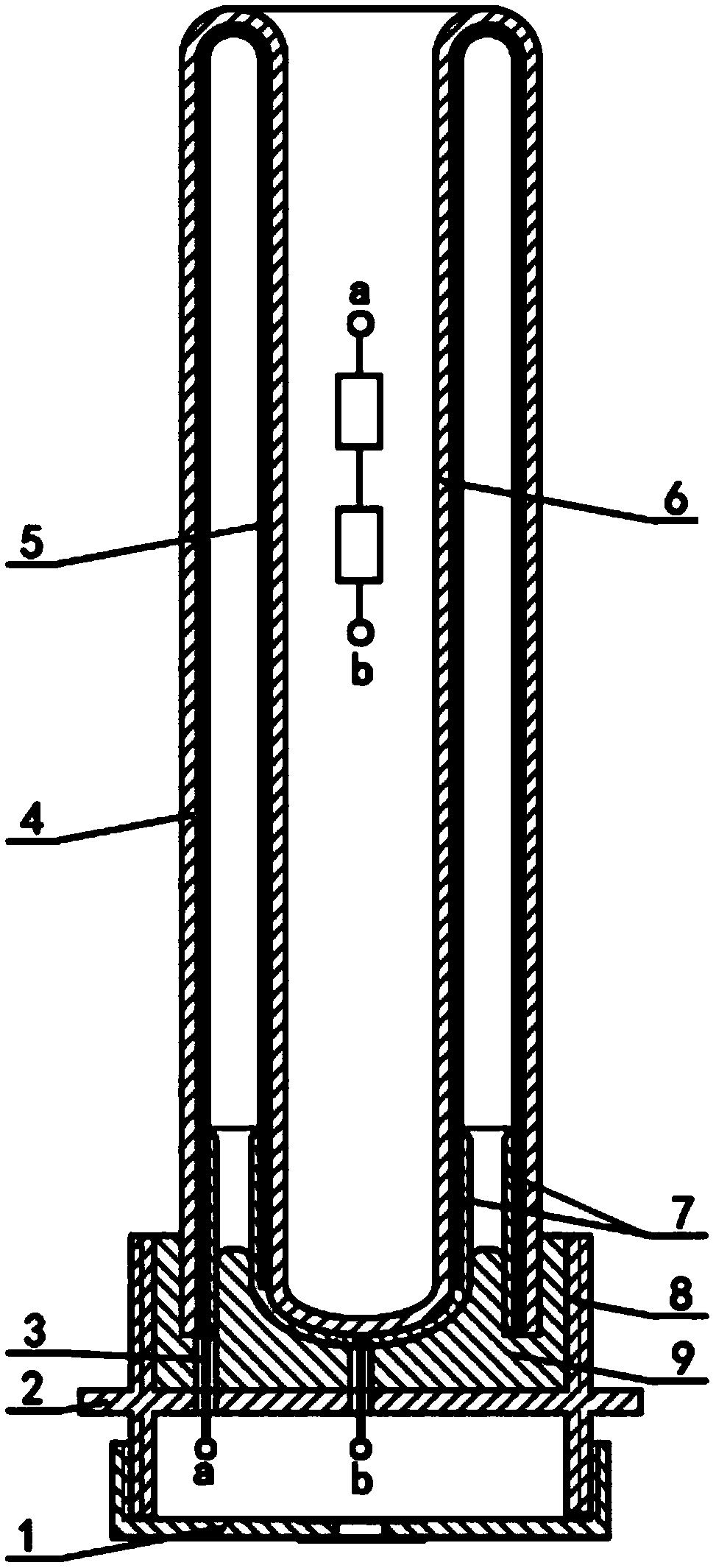

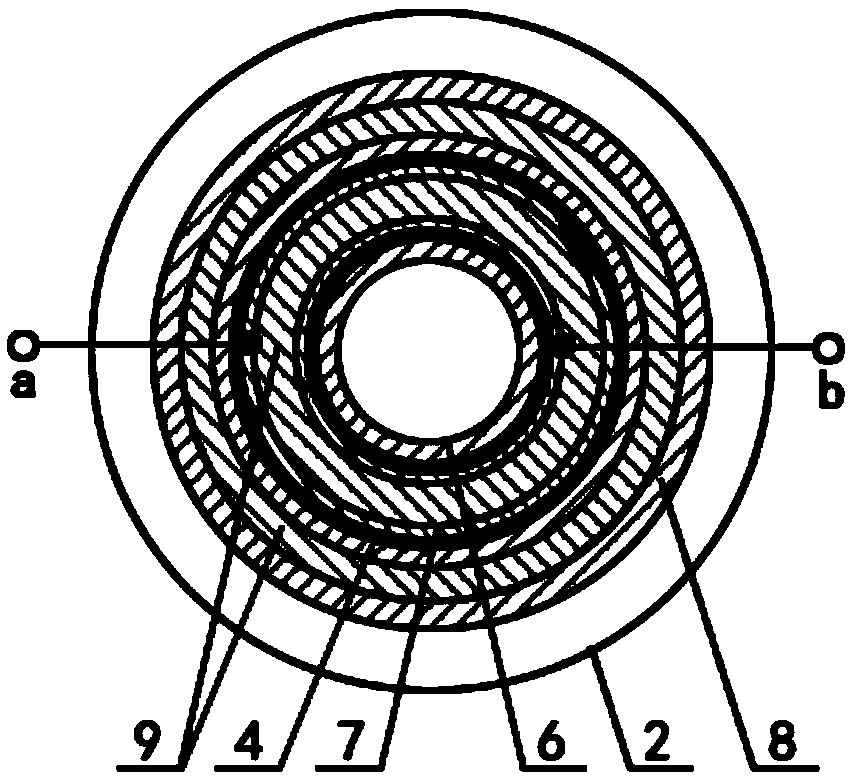

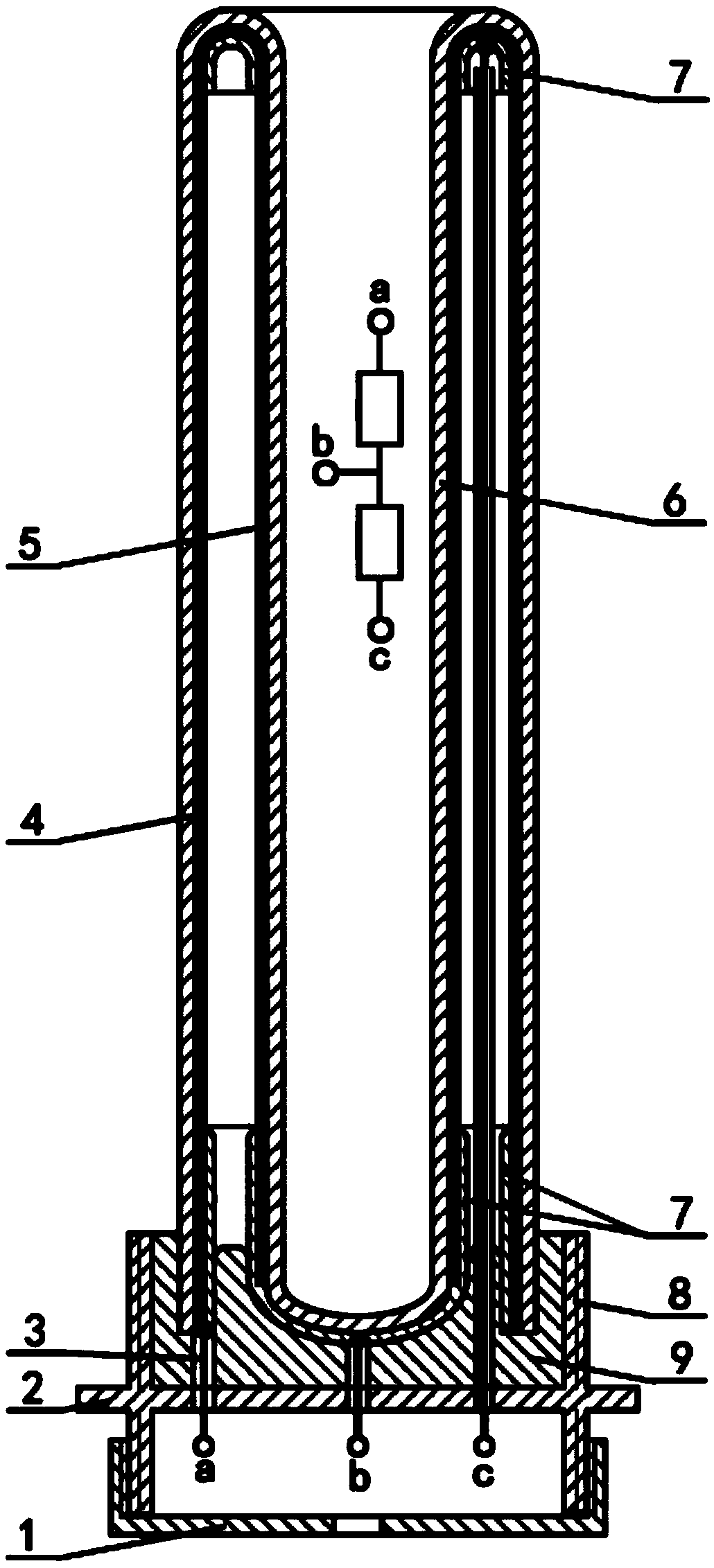

Crystal growth furnace heater and sapphire crystal growth furnace

InactiveCN102345161AImprove balanceUniform heating surfacePolycrystalline material growthBy pulling from meltTungstenSapphire

The invention discloses a crystal growth furnace heater with a cylindrical shape. The heater comprises: a plurality of electrodes distributed annularly and arranged at one end of the cylinder; a connecting ring disposed at the other end of the cylinder; a tungsten wire mesh, one end of which is connected to each of the multiple electrodes, and the other end of which is connected to the connecting ring, thus forming a barrel cylinder. On the other hand, the invention provides a sapphire crystal growth furnace with the above heater. The heater of the invention employs a double-star loaded three-phase alternating-current power supply mode, and can improve the load balance. The tungsten wire mesh heating body can endow the heater with good uniformity, reliability and stability.

Owner:江苏同人电子有限公司

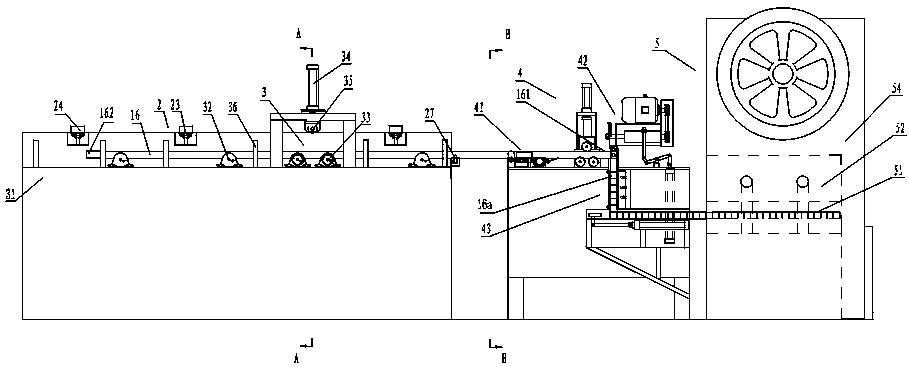

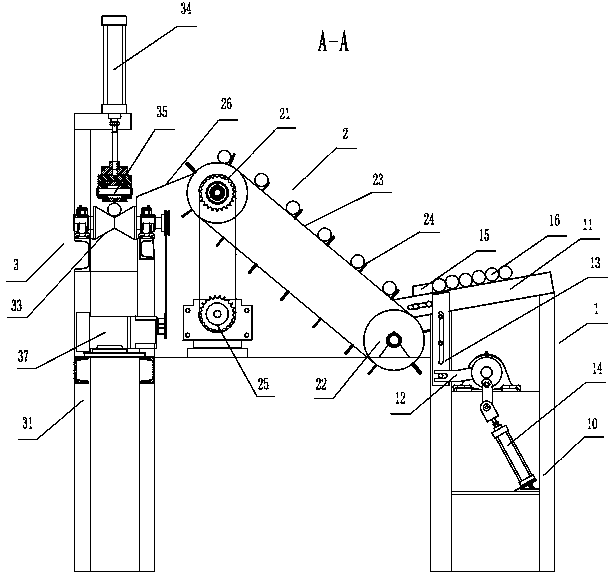

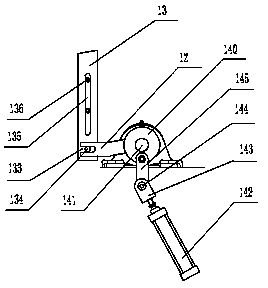

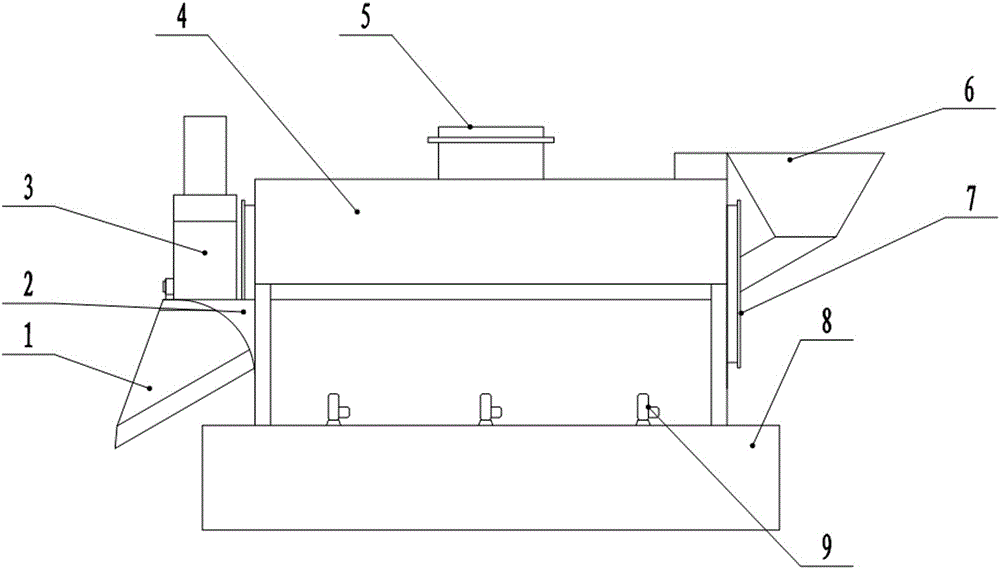

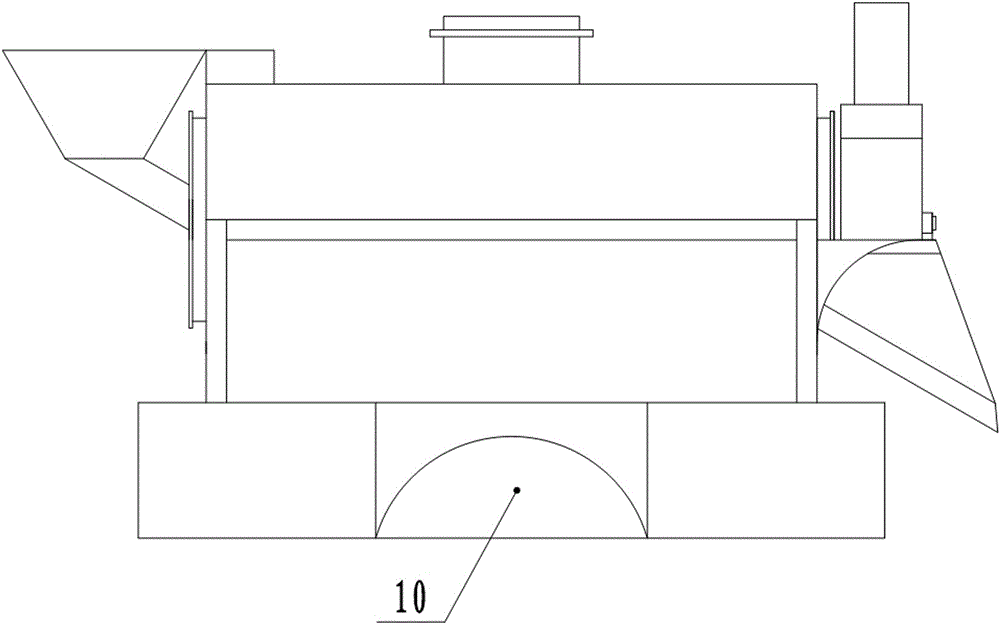

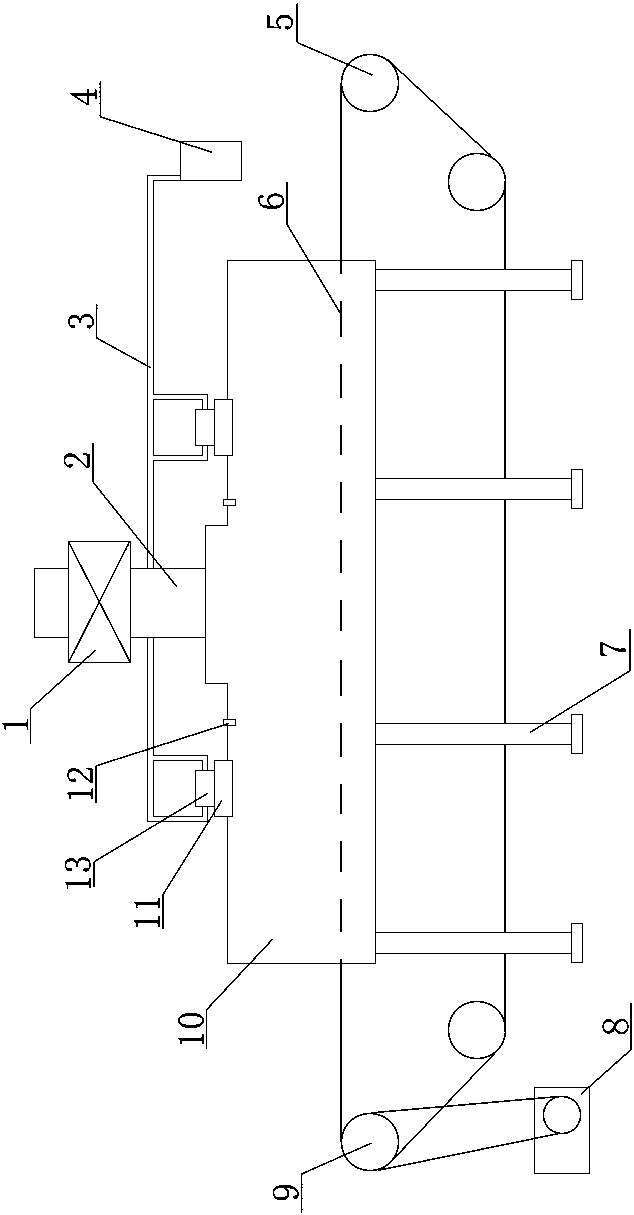

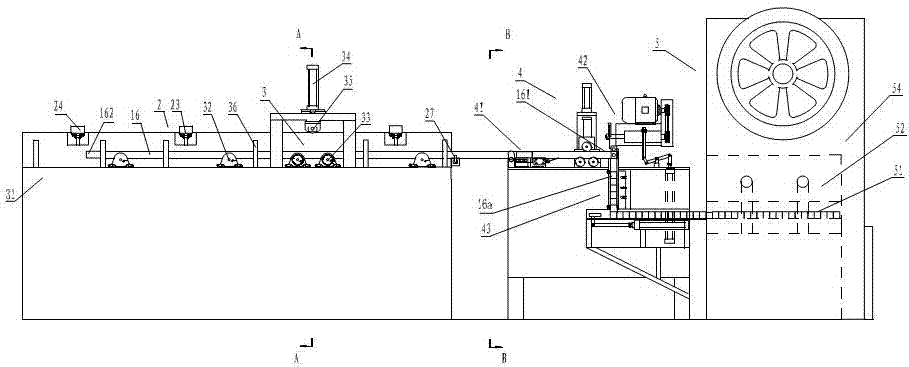

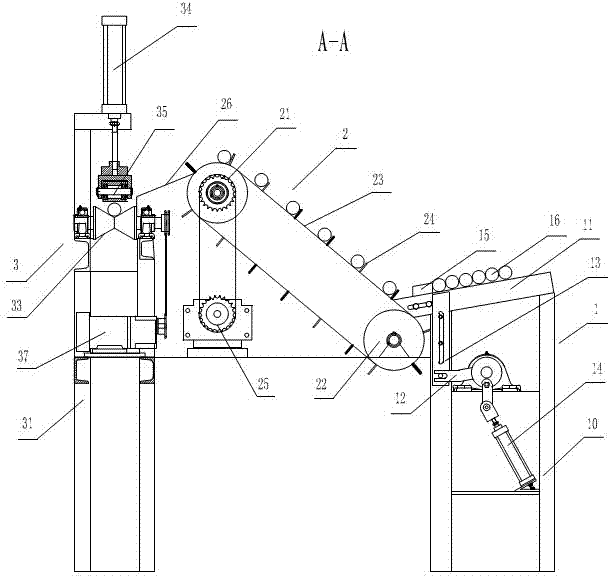

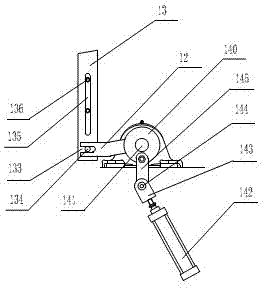

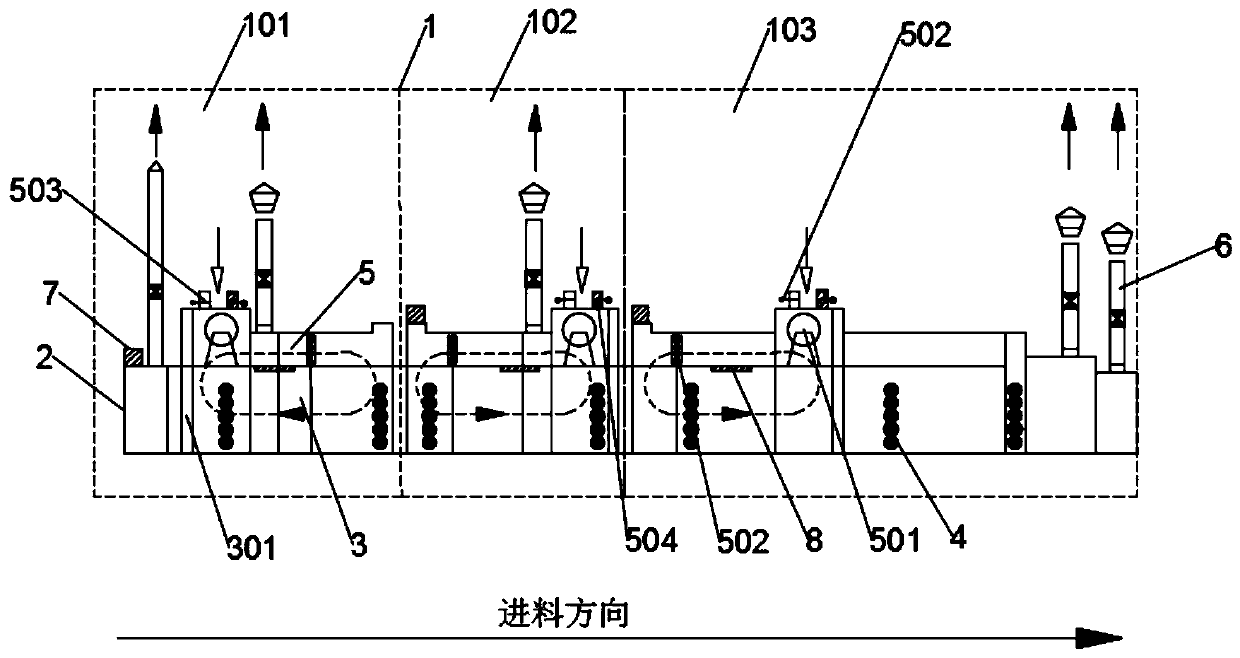

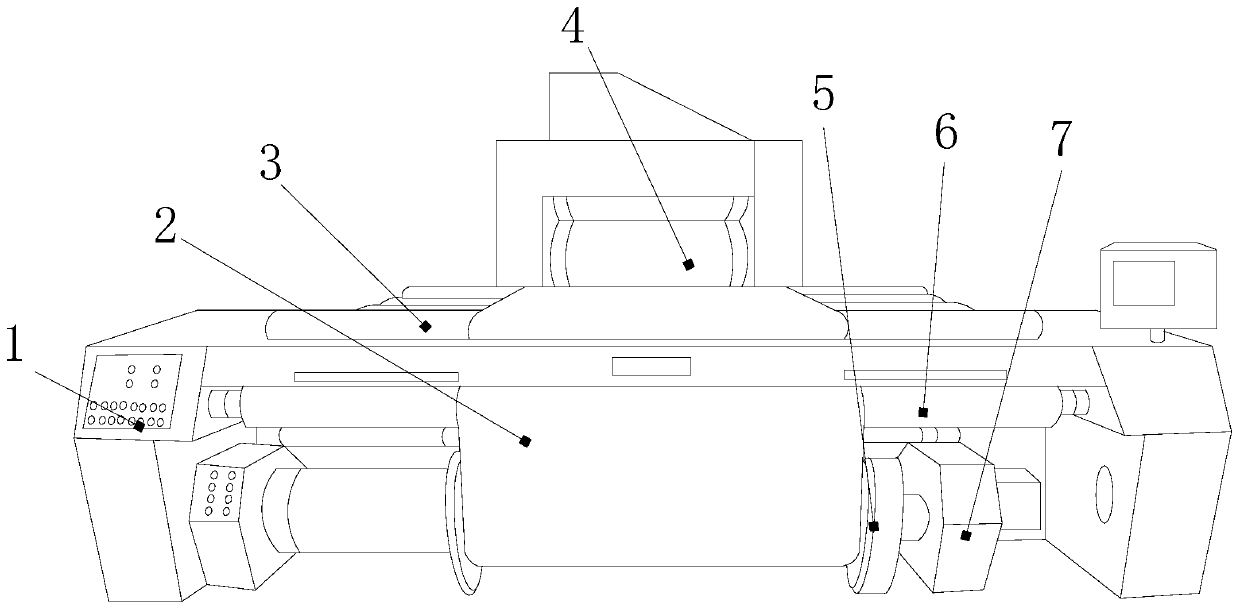

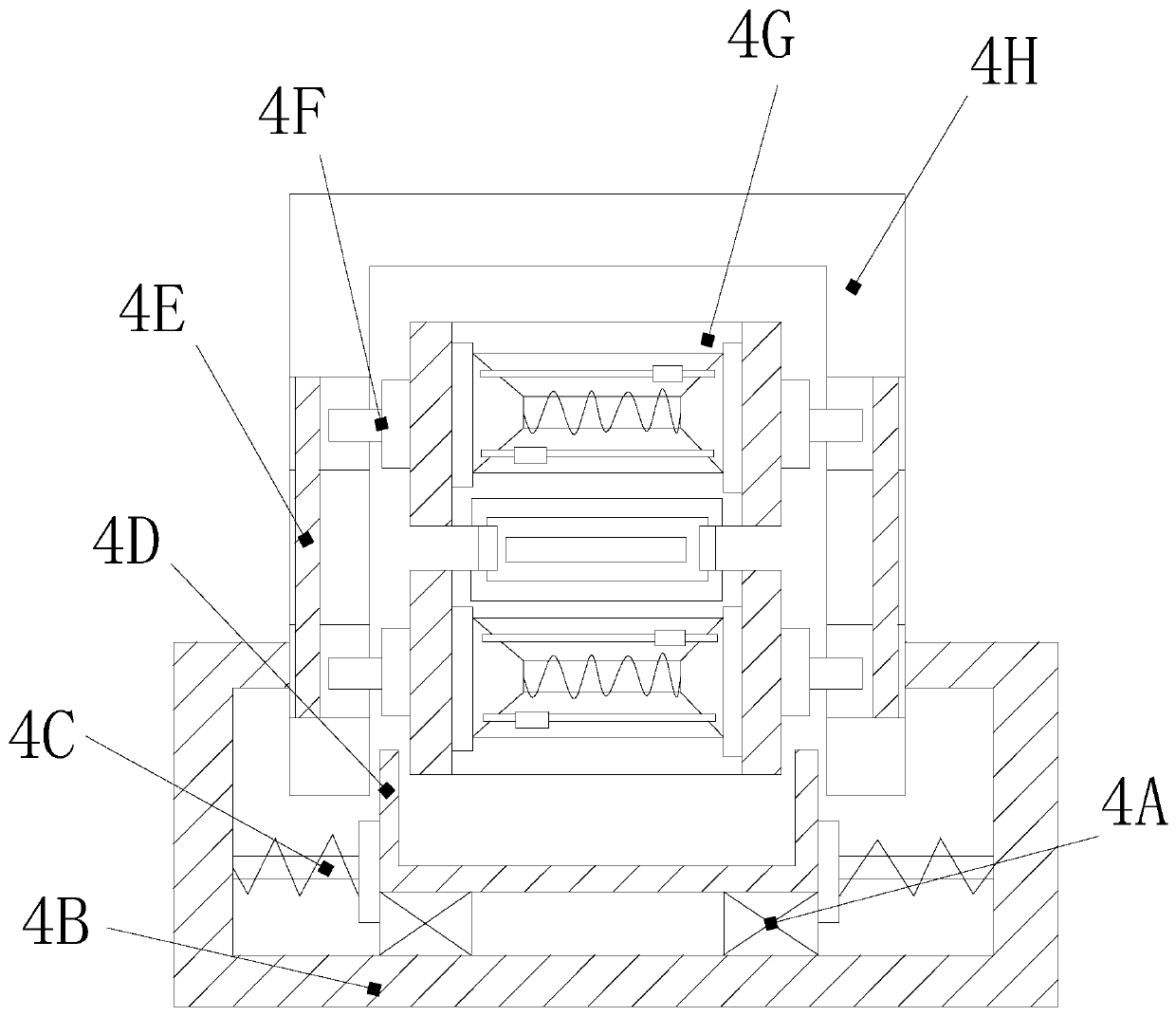

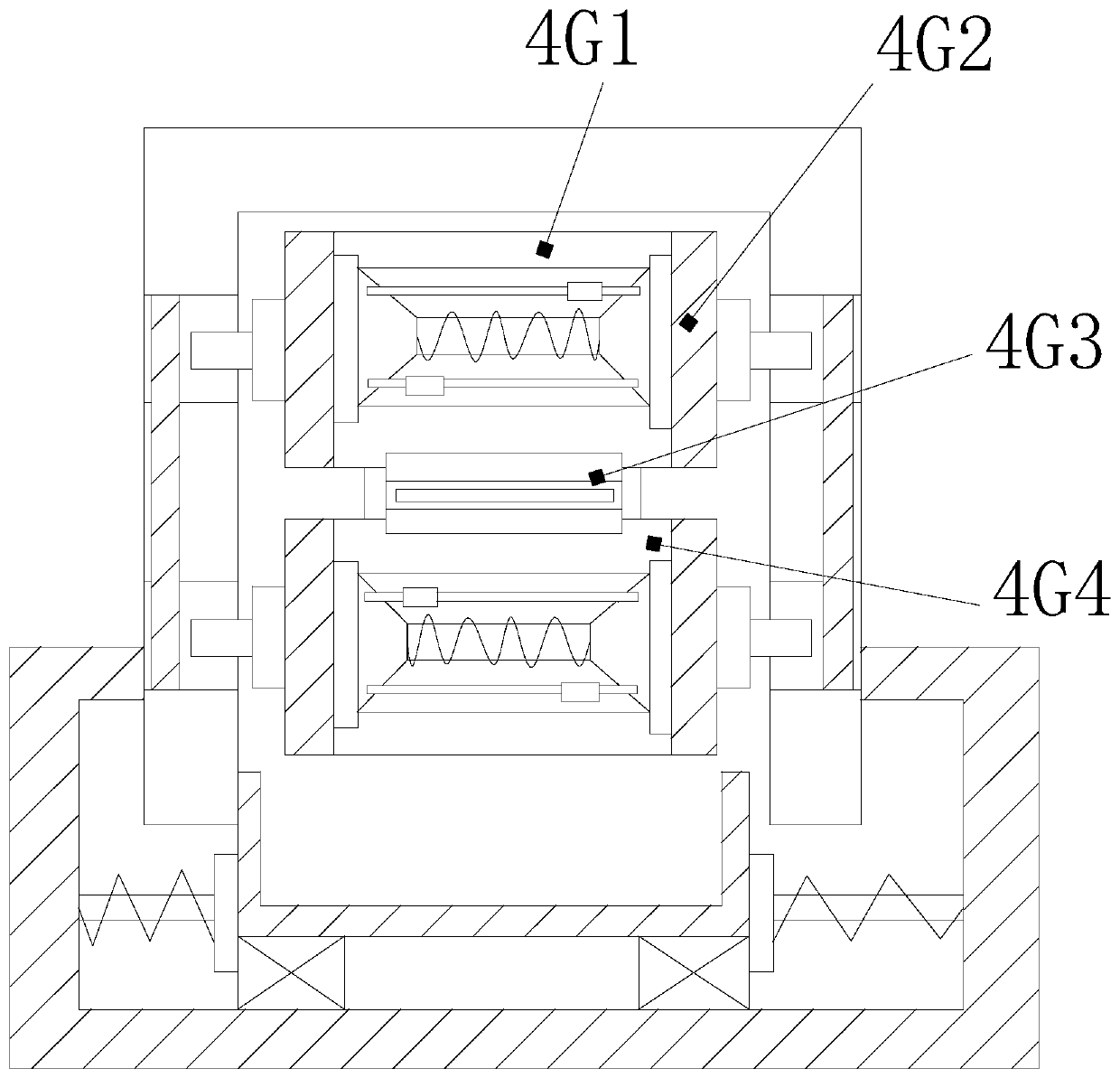

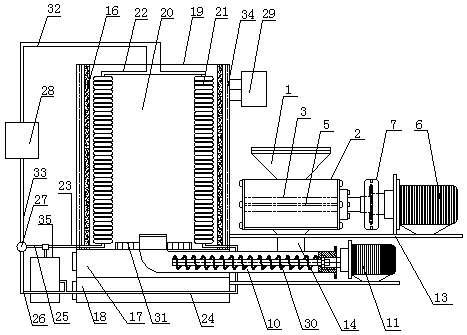

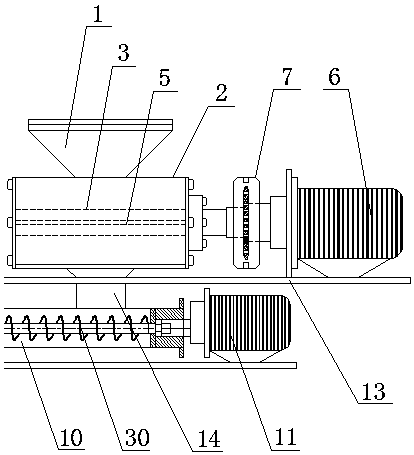

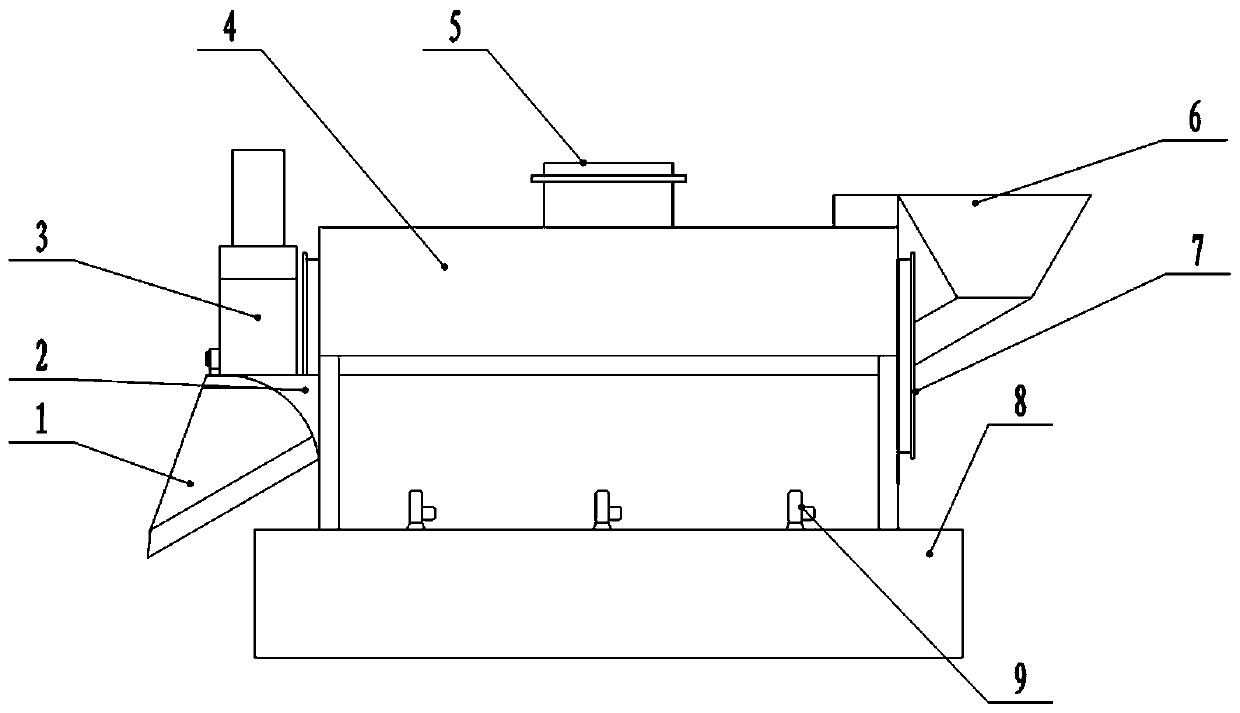

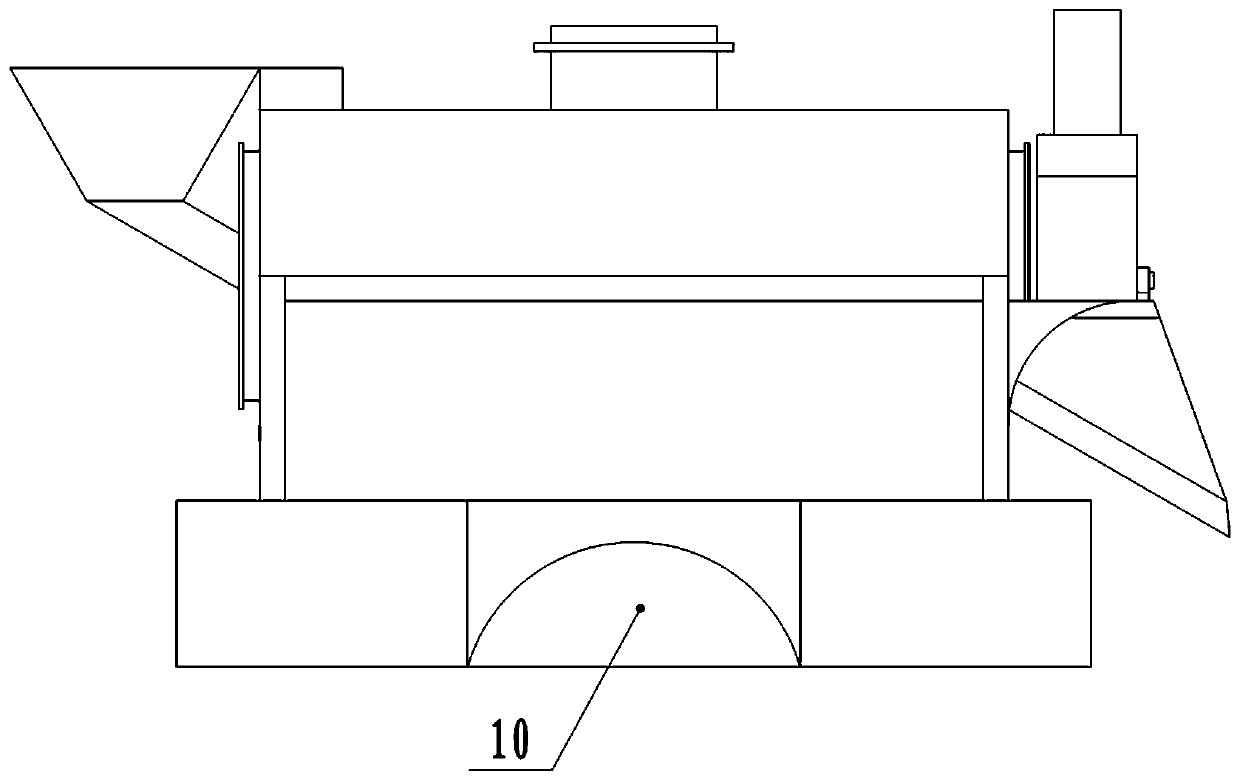

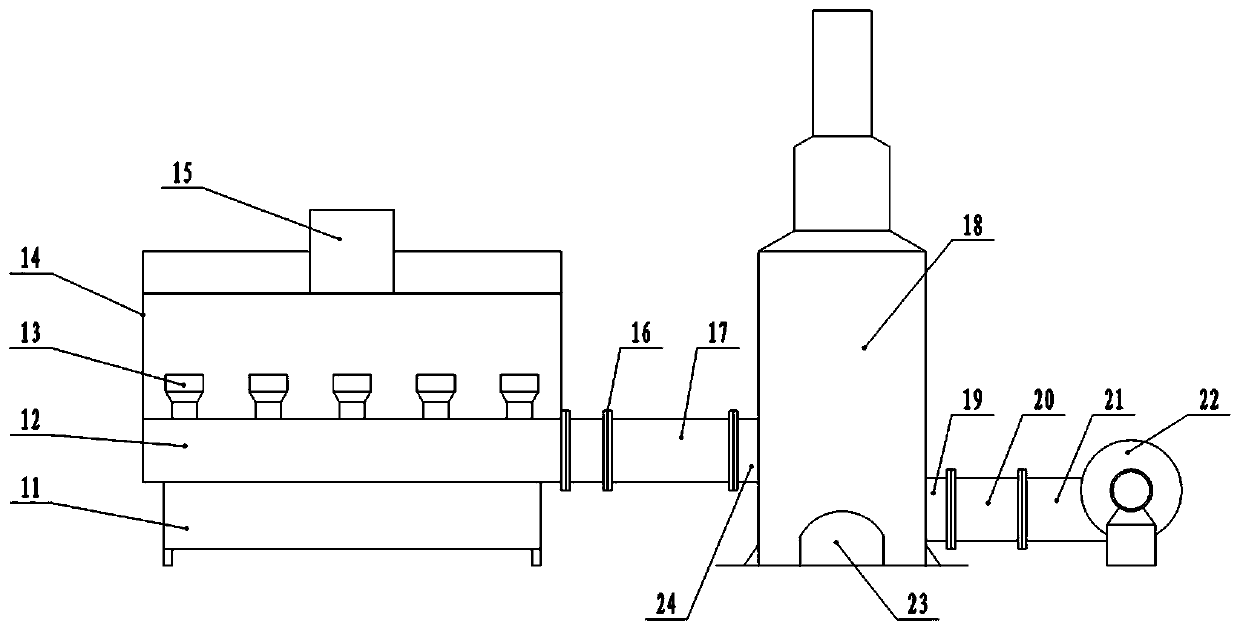

Equipment for automatically lifting, continuously feeding, sawing and heating bars

ActiveCN103447825AReduce labor intensitySame lengthOther manufacturing equipments/toolsMetal working apparatusProduction linePunch press

The invention relates to equipment for automatically lifting, continuously feeding, sawing and heating bars. The equipment comprises a loading device, a lifting device, a feeding device, a blanking device and a heating hot punching device, wherein the loading device comprises a loading frame, a loading platform, an ejector rod, a linkage rod, a driving wheel and an ejector cylinder; the lifting device comprises a lifting chain, a chain wheel, a driving chain wheel and a lifting motor; the feeding device comprises a feeding frame, a V-shaped wheel, a compression cylinder, a compression guide wheel and a feeding limit switch; the blanking device comprises a guide mechanism, a saw-cutting mechanism and a material rotating mechanism; and the heating hot punching device comprises a heating groove, a heating furnace, a blanking guide groove and a punch press. A fully-automatic production line of lifting, feeding, blanking and heating hot punching is manufactured and formed on a valve shell, so full-automatic control is realized, production efficiency is improved, energy consumption is saved, workers are protected from directly operating beside the heating furnace, scalding and sunstroke accidents are avoided, labor intensity is reduced, and the automatic level is increased and product quality is improved.

Owner:NINGBO JIEKELONG PRECISION MFG +1

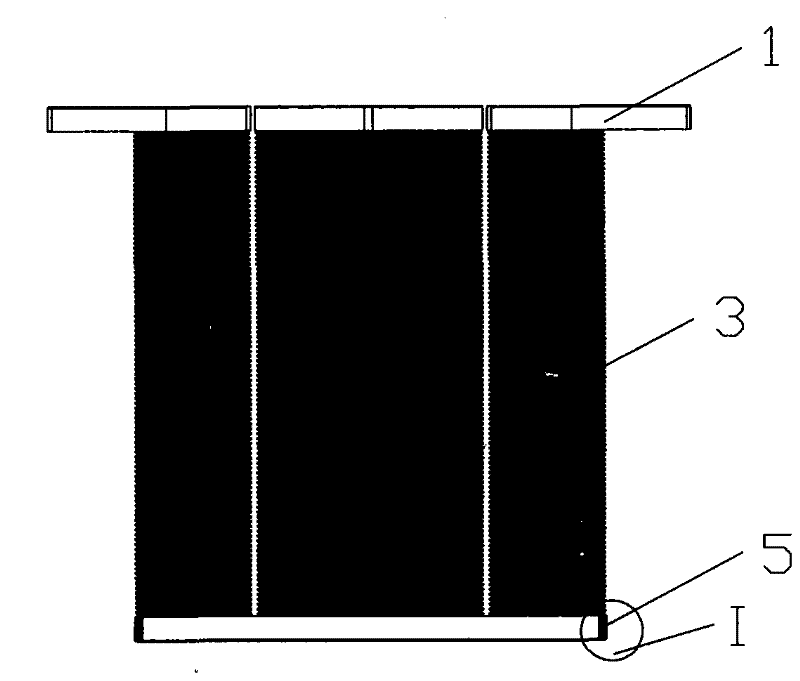

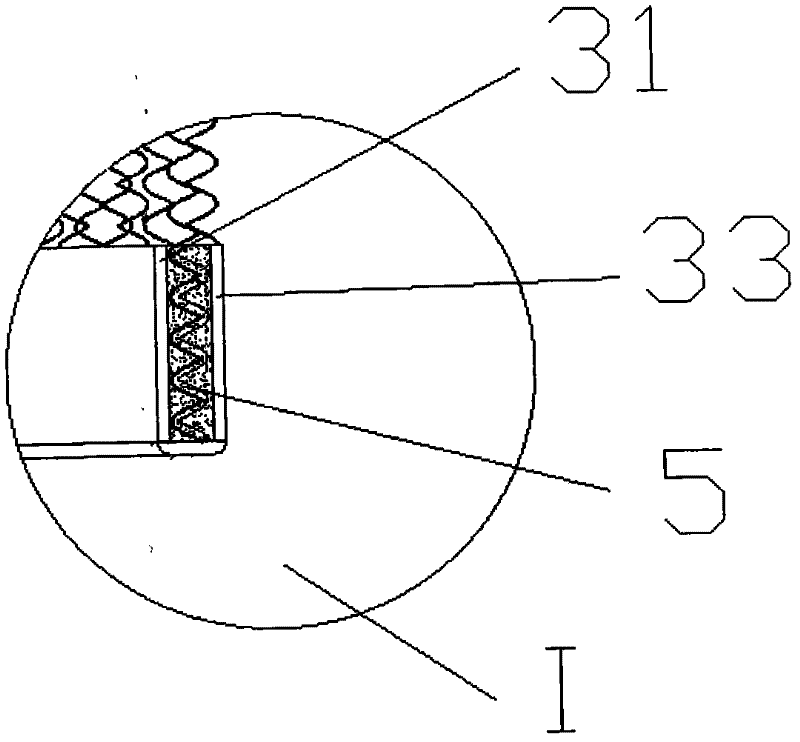

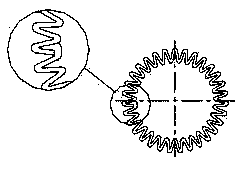

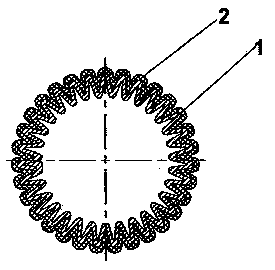

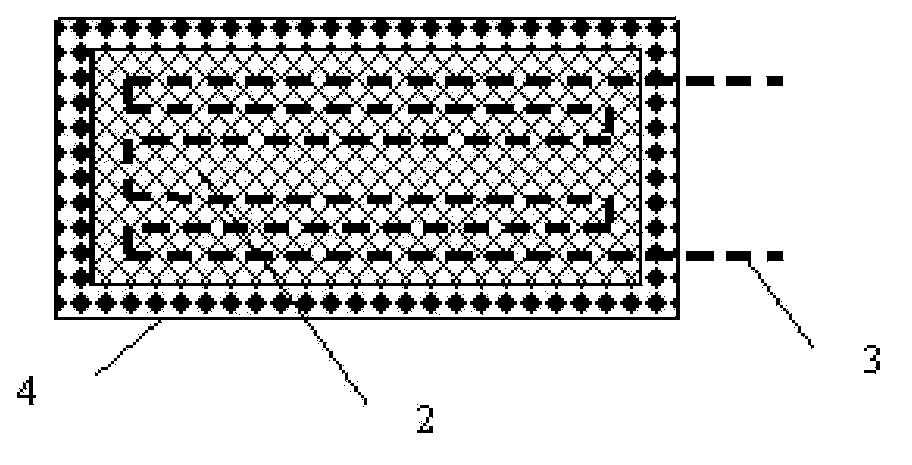

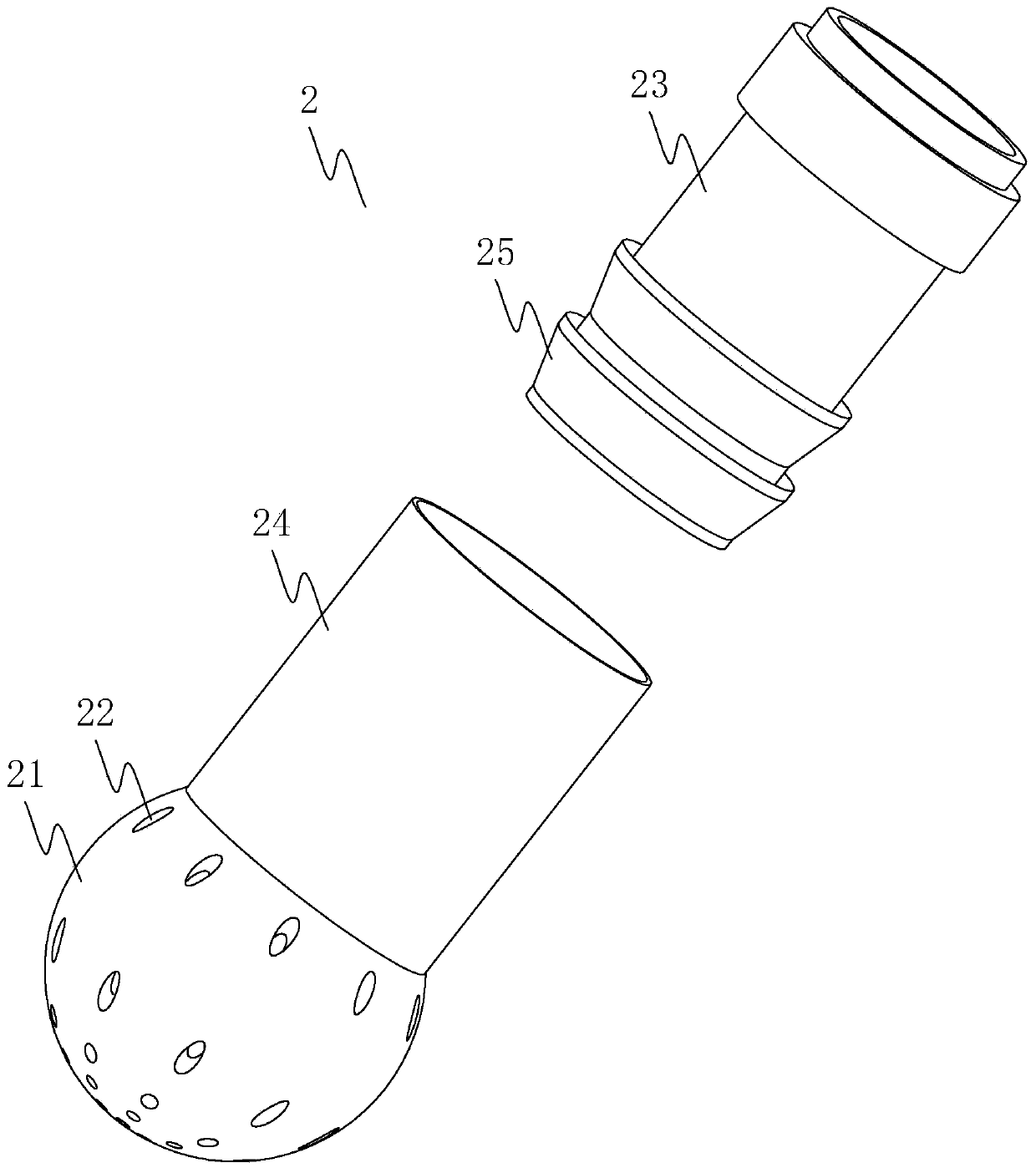

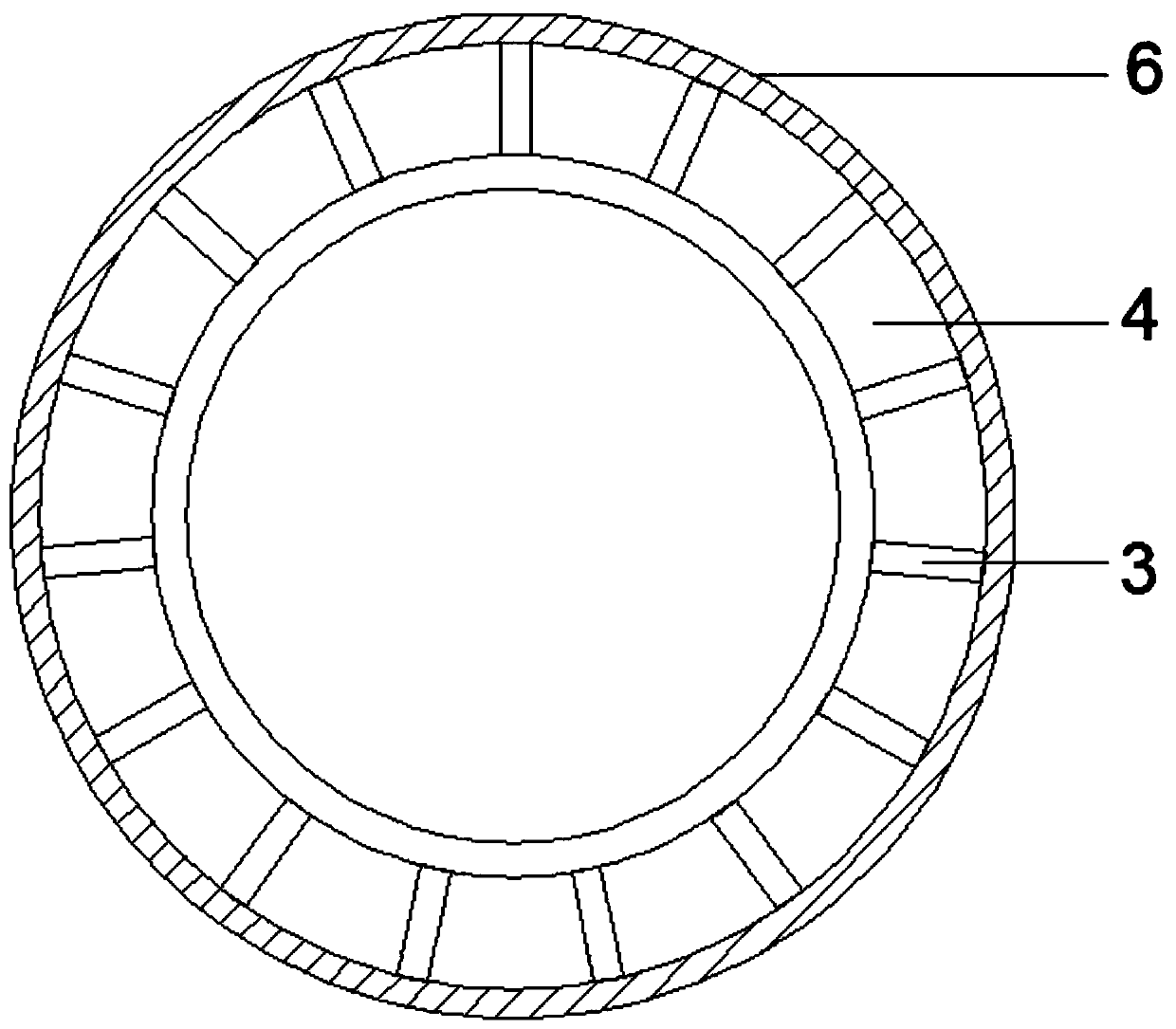

Corrugated circular pipe filter formed by plastic sinter board pipe coiling process and manufacturing method of corrugated circular pipe filter

ActiveCN104226041ALarge filter areaImprove dust removal efficiencyDispersed particle filtrationAdhesiveEngineering

The invention relates to a corrugated circular pipe filter formed by a plastic sinter board pipe coiling process and a manufacturing method of the corrugated circular pipe filter. The corrugated circular pipe filter is characterized in that corrugated toothed structures are arranged on the inner surface and the outer surface of a corrugated circular pipe filter element; the two ends of the corrugated circular pipe filter element are connected with each other in an embedded manner to form a coil pipe; the outside of the corrugated circular pipe filter element is sleeved with an socket joint sleeve and is connected with the socket joint sleeve by gluing; the inner cavity of the socket joint sleeve and the corrugated circular pipe filter element are same in outer diameter and shape, so that the corrugated circular pipe filter element can be inserted into the inner cavity of the socket joint sleeve in a butted manner. The manufacturing method comprises the following steps: adding a high-molecular-weight polyethylene material with the particle size of 20-100 meshes into a metal forming mould, putting the mould into a sintering box, gradually heating to enable plastic particles to form a formed product with micropores, cooling, coating the two ends of the plate-type product with a layer of adhesive, coiling to be in a circular pipe shape, and mutually embedding and shaping the glued edges of the two ends of the product to form the corrugated circular pipe filter. The corrugated circular pipe filter can be subjected to reverse jet-pulse cleaning and has numerous advantages of large filtering area, high filtering precision, energy conservation, emission reduction and the like, and the service life of the corrugated circular pipe filter is prolonged.

Owner:SHANGHAI SUPERHIGH ENVIRONMENTAL PROTECTION TECH CO LTD

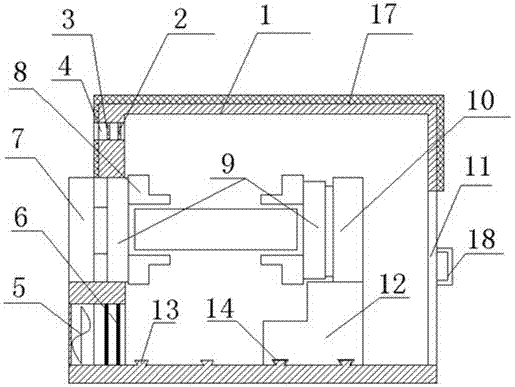

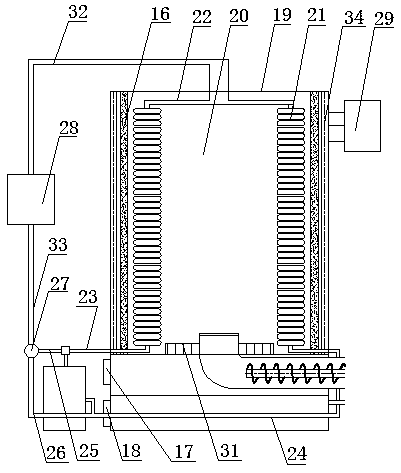

Wood drying device

InactiveCN107314640AUniform heating surfaceNo localized heatingDrying gas arrangementsDrying solid materialsEngineeringResistor

The invention discloses a wood drying device, which relates to the technical field of drying equipment. Fan and electric heating resistance wire mesh, trapezoidal protrusions are arranged horizontally on the inner lower surface of the casing, and square protrusions are arranged vertically, a machine base is arranged on the inner lower surface of the casing, and trapezoidal protrusions are arranged horizontally on the ground of the machine base. Groove, a square groove is arranged longitudinally, and a fixed plate is arranged on the upper part of the base. The left side of the fixed plate and the right side of the motor are both rotatably connected with a four-jaw chuck. The four-jaw chuck is composed of claws and a disk It consists of a body, wood is sandwiched between the four-jaw chucks, and a door is provided on the right side of the casing. The invention can be adjusted according to the length of the wood, and by rotating the wood, the wood is heated more evenly without local heating and the working efficiency is improved.

Owner:涟水县佳兴木材加工厂

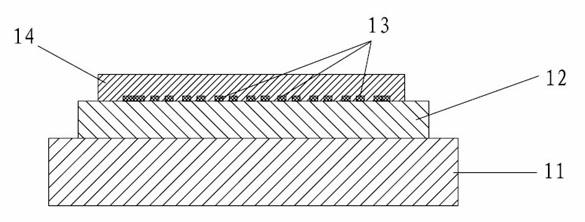

High thermal efficiency steam generating device for caring products

InactiveCN102252305AFirmly connectedUniform heating surfaceSteam generation heating methodsLayered productsVaporizationEngineering

The invention provides a high thermal efficiency steam generating device for caring products. The steam generating device at least comprises a heating element and a vaporization duct; the vaporization duct is provided with a water inlet and a steam outlet; the heating element is a thick film heating element; and the vaporization duct is regularly and fixedly arranged on the thick film heating element to form a whole. A heating plate made of the thick film heating element and the vaporization duct connected with the heating plate are adopted in the steam generating device, the vaporization duct is provided with the water inlet and the steam outlet, and the vaporization duct is fixedly connected with the heating plate, so that reliable connection between the vaporization duct and the heating plate is ensured and the heating surface is uniform. Therefore, the advantages of long service life of the thick film heating element, extremely high heating efficiency, high reliability of the product, convenience for cleaning and maintenance and the like are fully exerted; and the defects of short service life, low heating efficiency, heavy weight, inconvenience for cleaning and maintenance and the like of the conventional steam hot pot products are radically overcome.

Owner:MIDEA GRP CO LTD

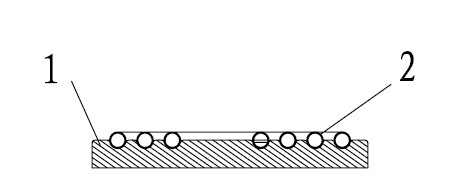

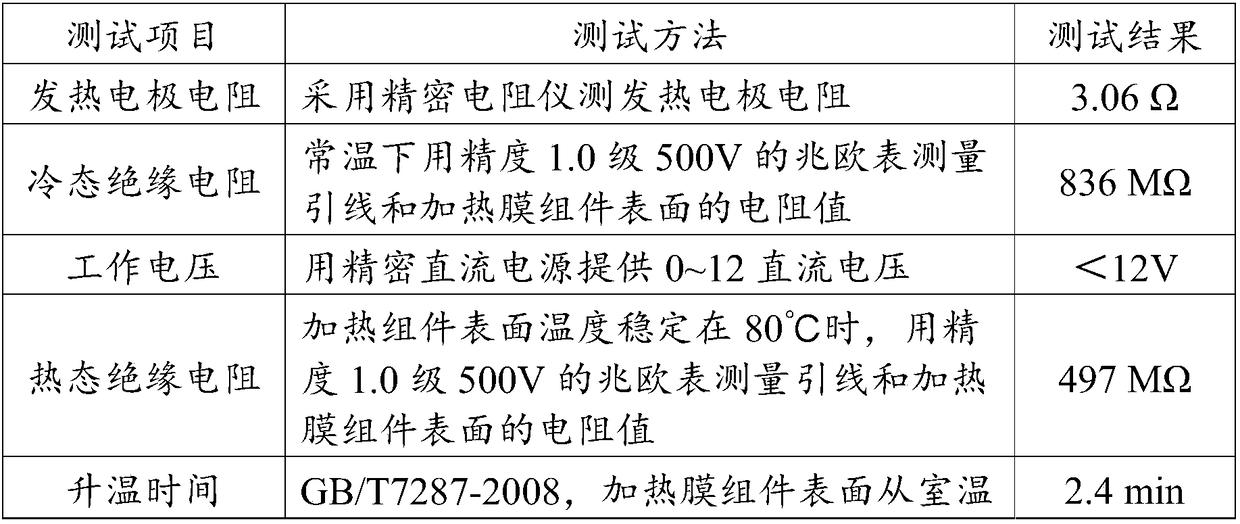

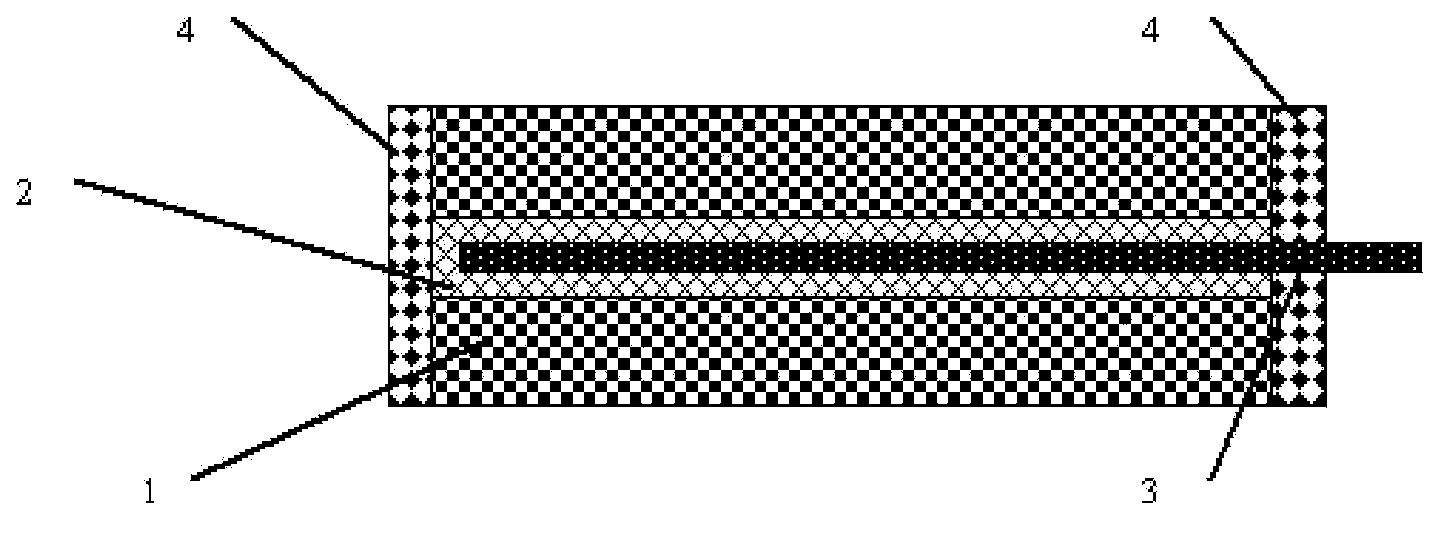

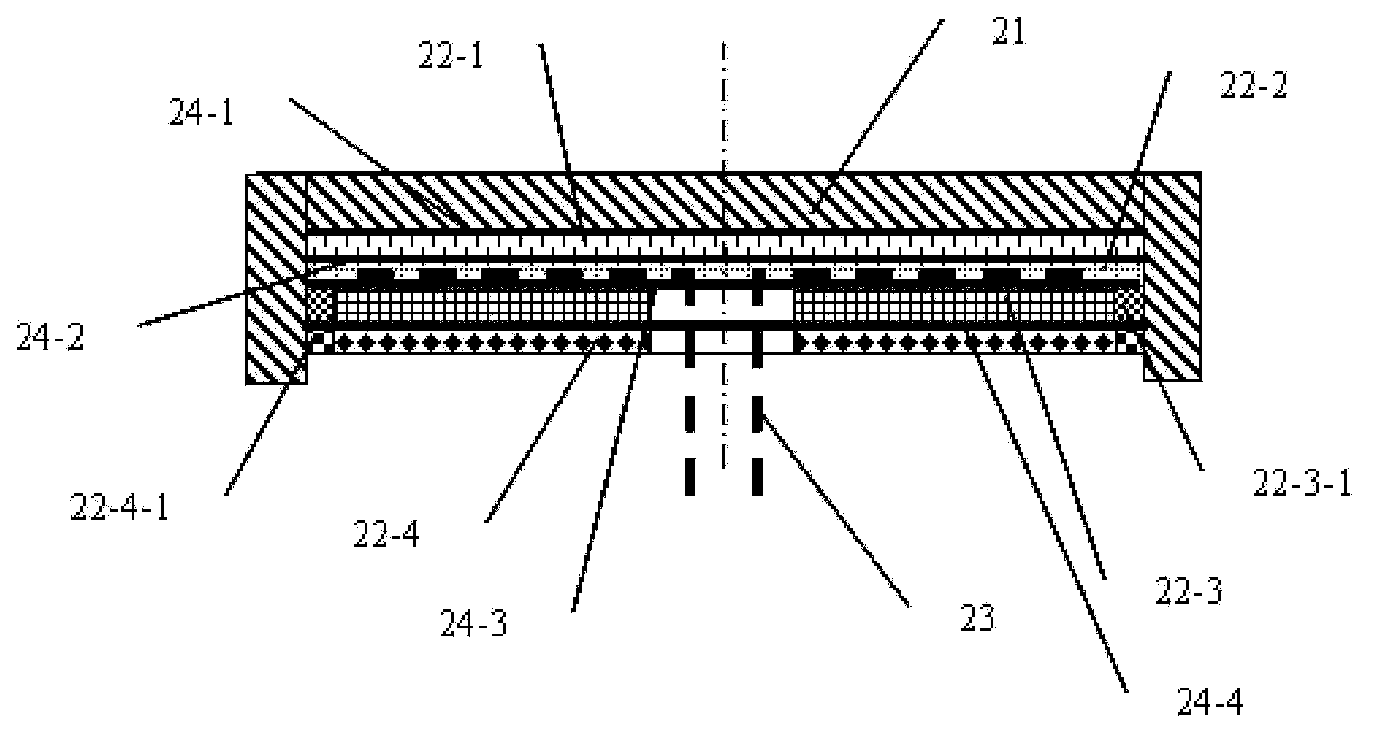

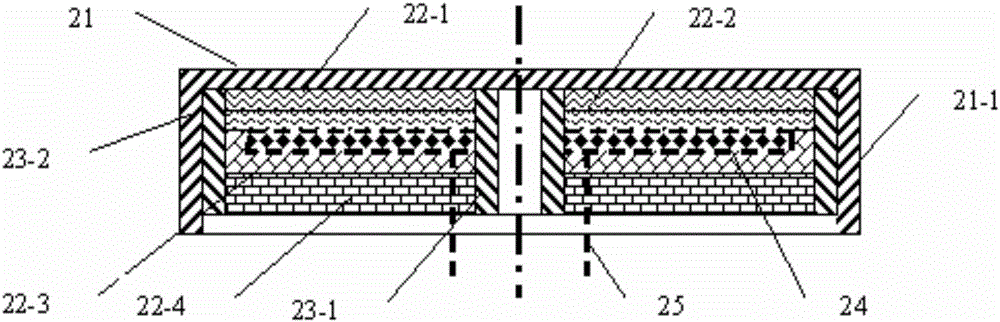

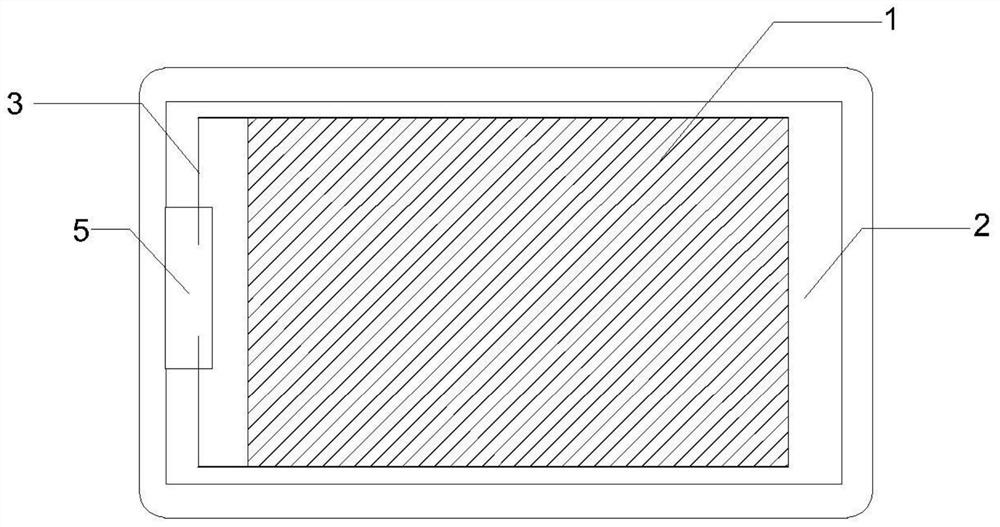

Graphene heating film suitable for power cell bag and graphite alkene heating film assembly

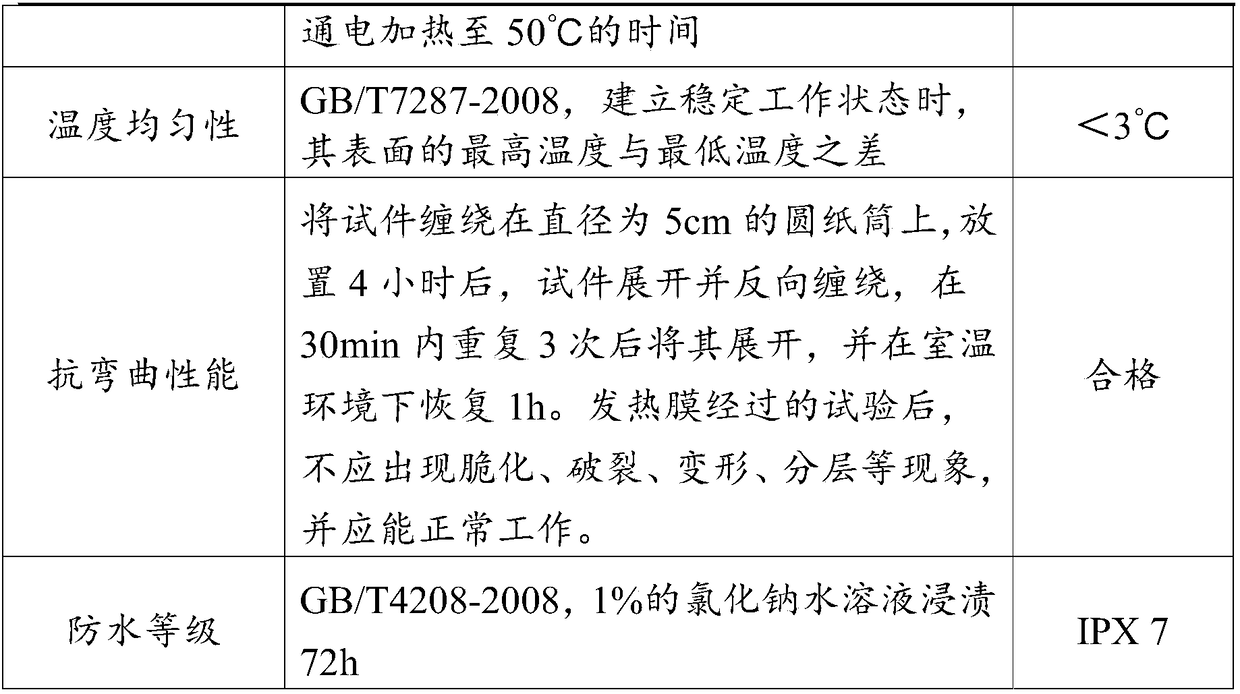

PendingCN108093501AHigh electrothermal efficiencyUniform heating surfaceChemical industrySecondary cellsCvd grapheneOn cells

The invention discloses a graphene heating film and a grapheme heating film assembly. The graphene heating film comprises an organic polymer base film and a heating line disposed on at least one surface of the organic polymer base film. The heating line is formed by applying grapheme conductive slurry to at least one surface and conducting solidification. The graphene heating film assembly is composed of the graphene heating film, a thermal conductive silicone, a graphene heat conductive piece, the organic polymer insulation film and a temperature sensor. The graphene heating film assembly isadvantageous in that the high conductivity, high thermal conductivity, high mechanical strength and high flexibility of the grapheme can be utilized; heating voltage is low, heating speed is fast, electro-thermal efficiency is high, heating surface is even, no redness or hotness exists, winding performance is good, quality is soft, light and thin, and conformity is good; teat source can be provided for the power cell bag, and the influence of low-temperature charging and discharging on cell performance can be resolved.

Owner:SHENZHEN HOVERBIRD ELECTRONICS TECH CO LTD

Arc-shaped heater

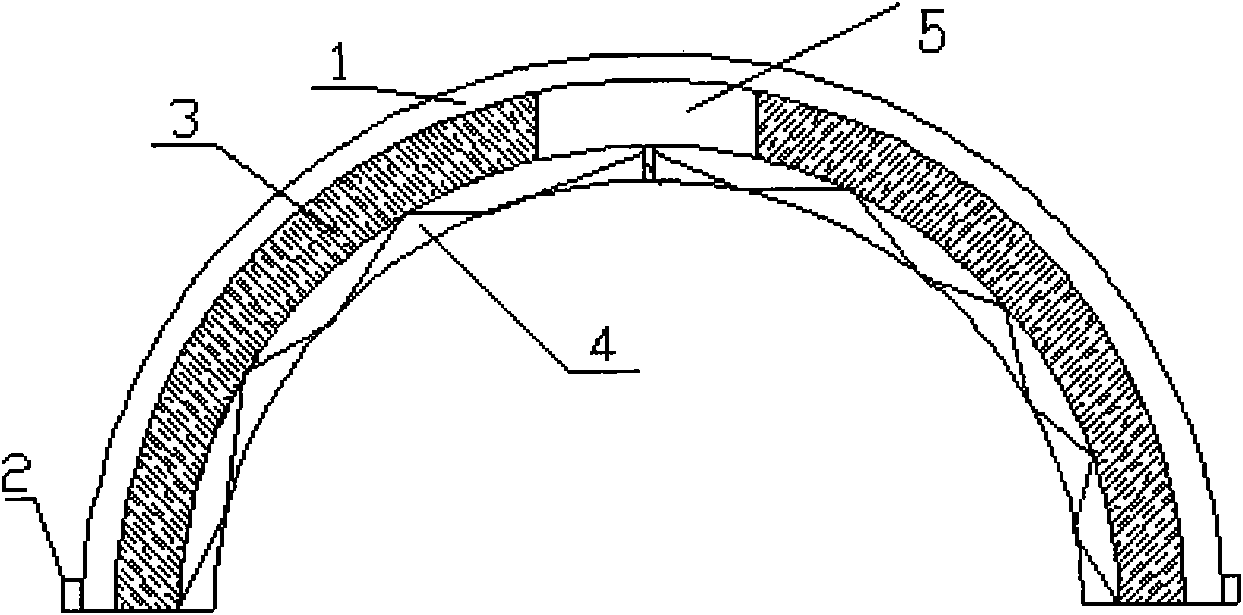

InactiveCN101642859ASimple structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingFlange

The invention relates to an arc-shaped heater, comprising a shell, a heat preservation layer and a heating layer; a flange is arranged at the outer end of the bottom of the shell, the shape of inner wall of the shell is in match with that of the exterior of the pipe fitting, the heat preservation layer and the heating layer are attached on the inner wall of the shell in sequence, wherein the heatpreservation layer is arranged between the shell and the heating layer, and through holes are opened from the top of the shell to the interior of the shell. The invention is simple in structure and easy for operation, the heating surface thereof is comparatively uniform, and the heating speed is rapid, thus greatly improving the productivity and the quality of the products.

Owner:合肥实华管件有限责任公司

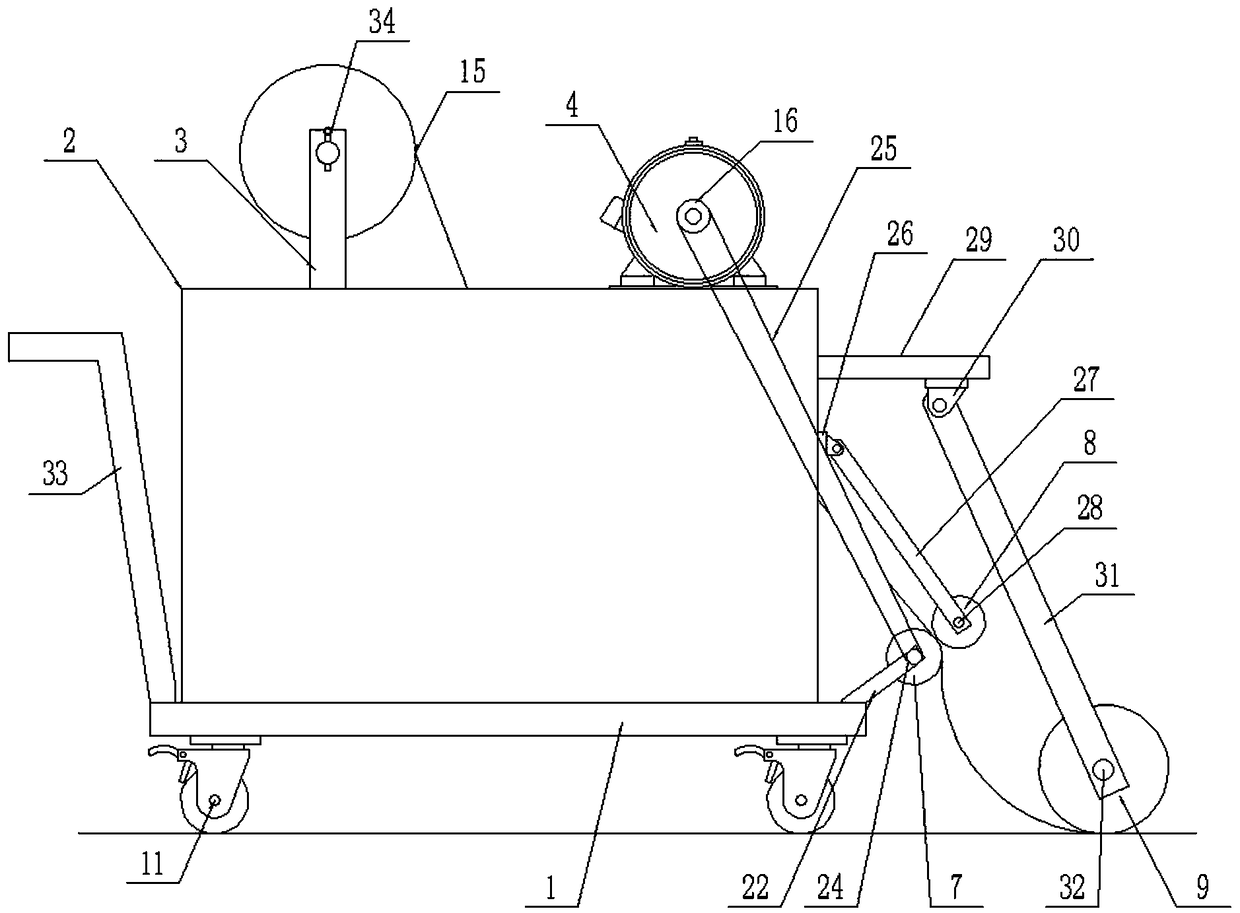

Efficient and convenient waterproof roll spreading device

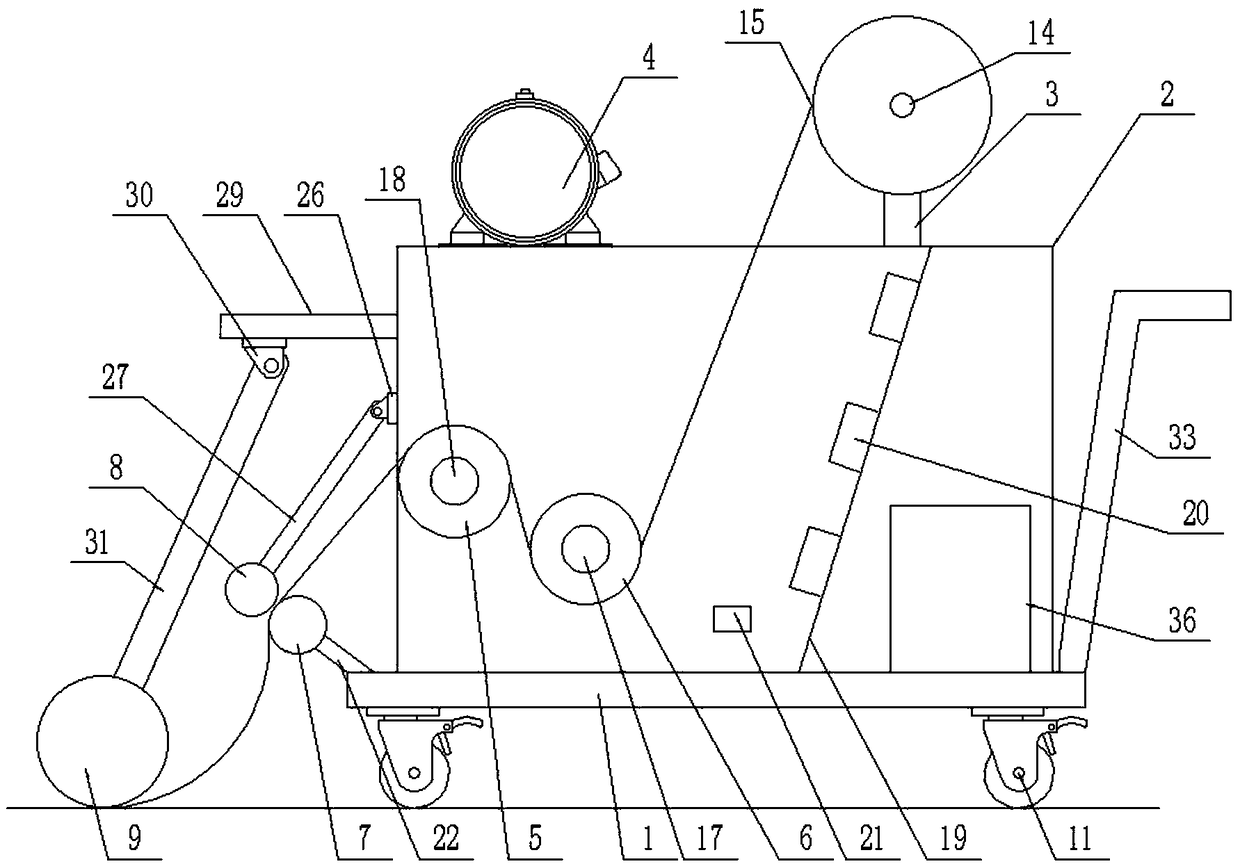

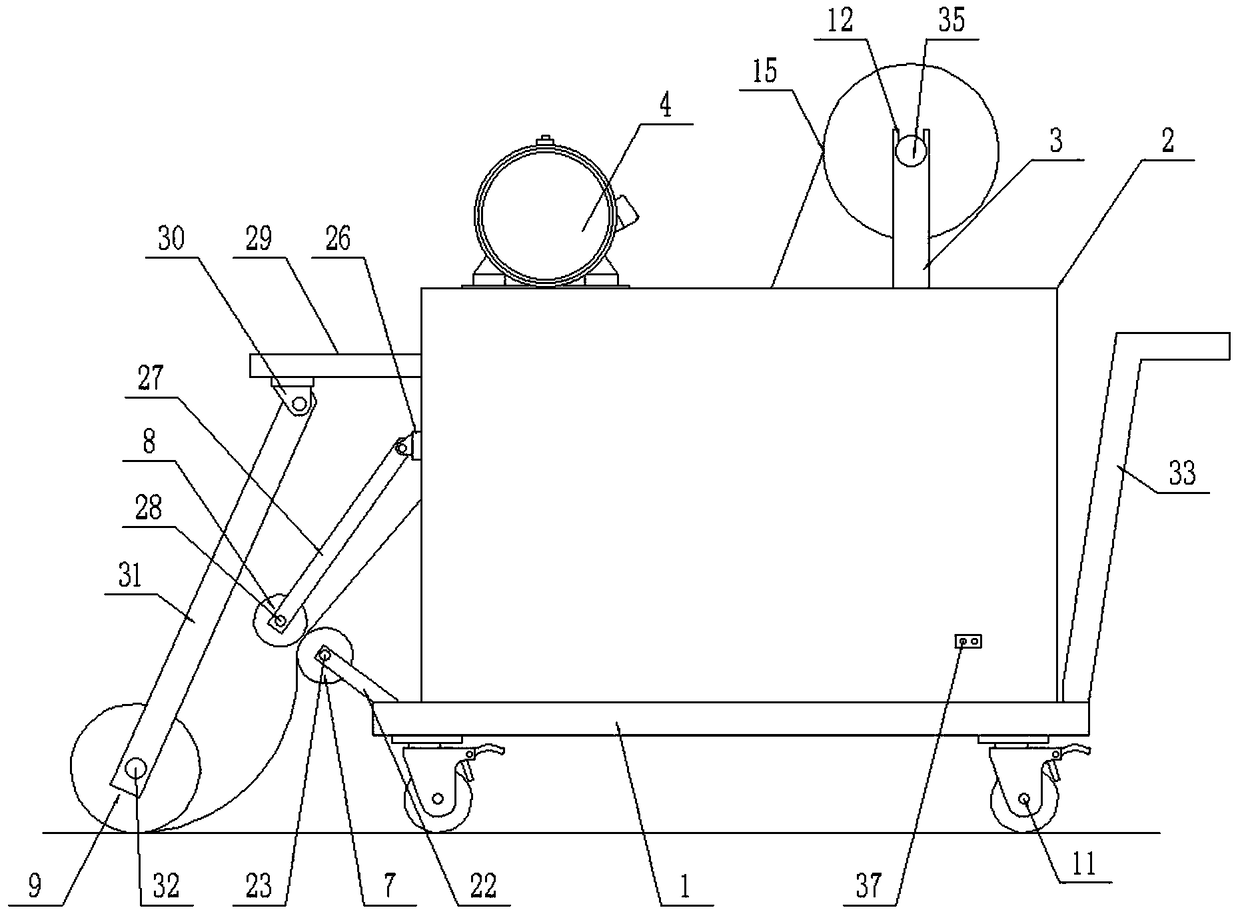

ActiveCN109025098AUniform heating surfaceImprove leveling effectRoof toolsBuilding material handlingElectrical and Electronics engineeringElectromagnetic heating

The invention discloses an efficient and convenient waterproof roll spreading device including a bottom board, a main case, a roll rack, a reduction motor, a preheating mechanism, an electromagnetic heating roller, a first driven roller, a second driven roller, a first press roll, a second press roll and a controller. The main case is fixed on the bottom board. Universal wheels are arranged on thelower end of the bottom board. The main case is provided with the roll rack and the reduction motor. The first driven roll, the electromagnetic heating roll and a storage battery are arranged in themain case. The preheating mechanism is composed of a partition board, a PTC heater and a temperature sensor. A first rack is fixed on the left end of the bottom board in an inclined manner. The seconddriven roller is arranged on the first rack. A second rack is hinged to the left end face of the main case. The first roller is arranged on the second rack. A third rack is fixed on the main case. Afourth rack is hinged on the third rack. The second press roller is arranged on the lower end of the fourth rack. The invention has beneficial effects of simple structure and high practicability.

Owner:湖北中骋金禹防水技术股份有限公司

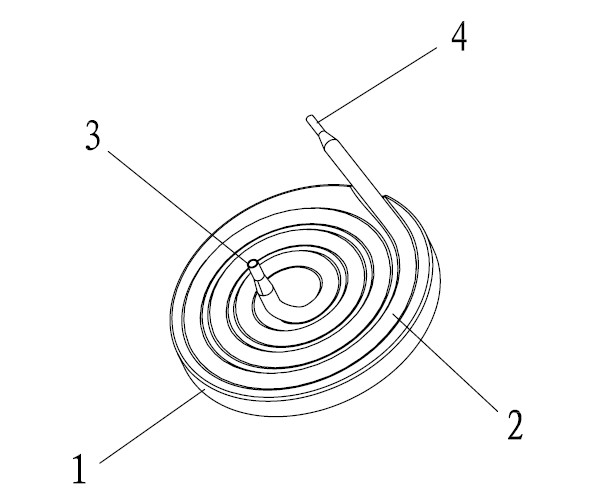

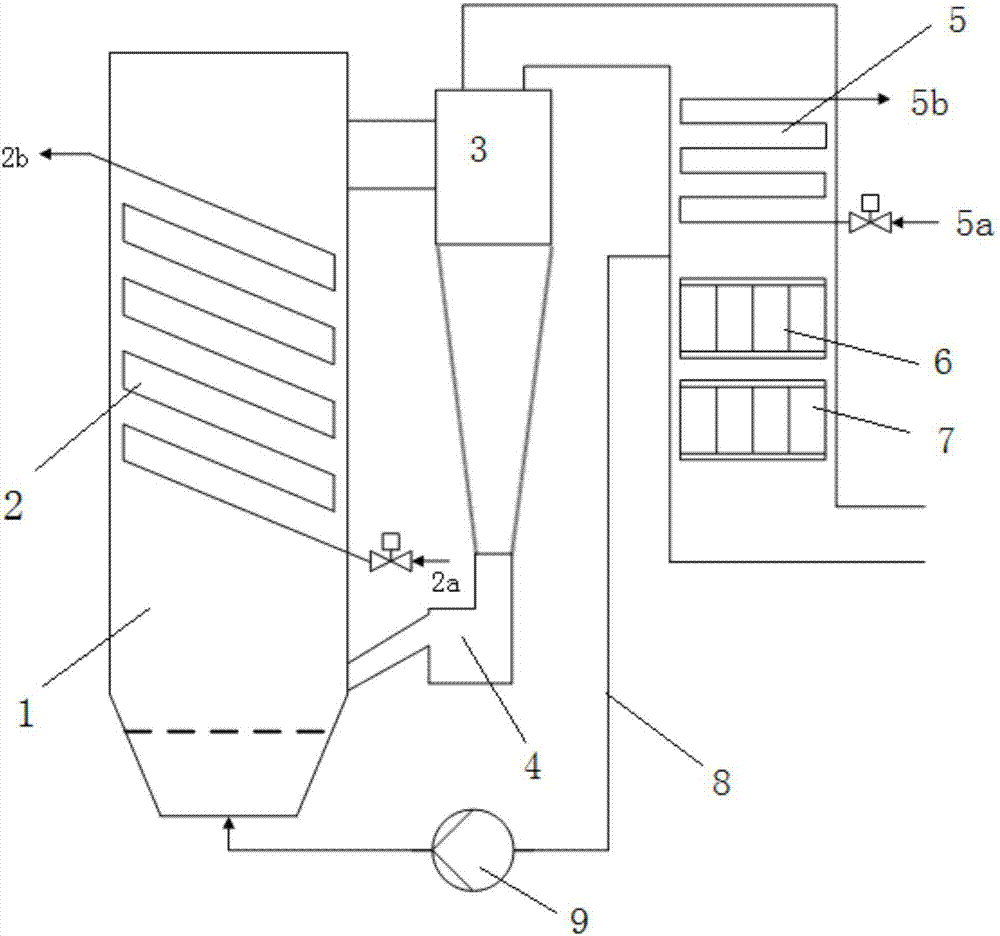

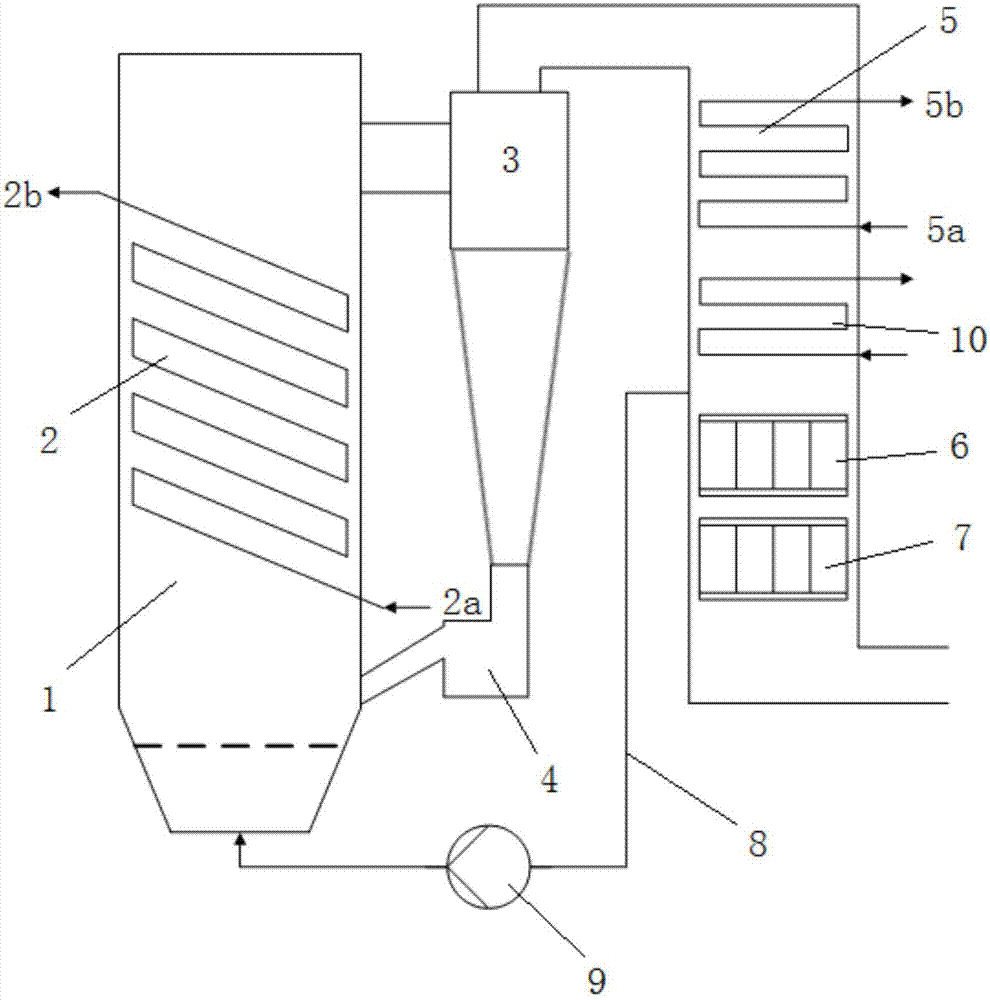

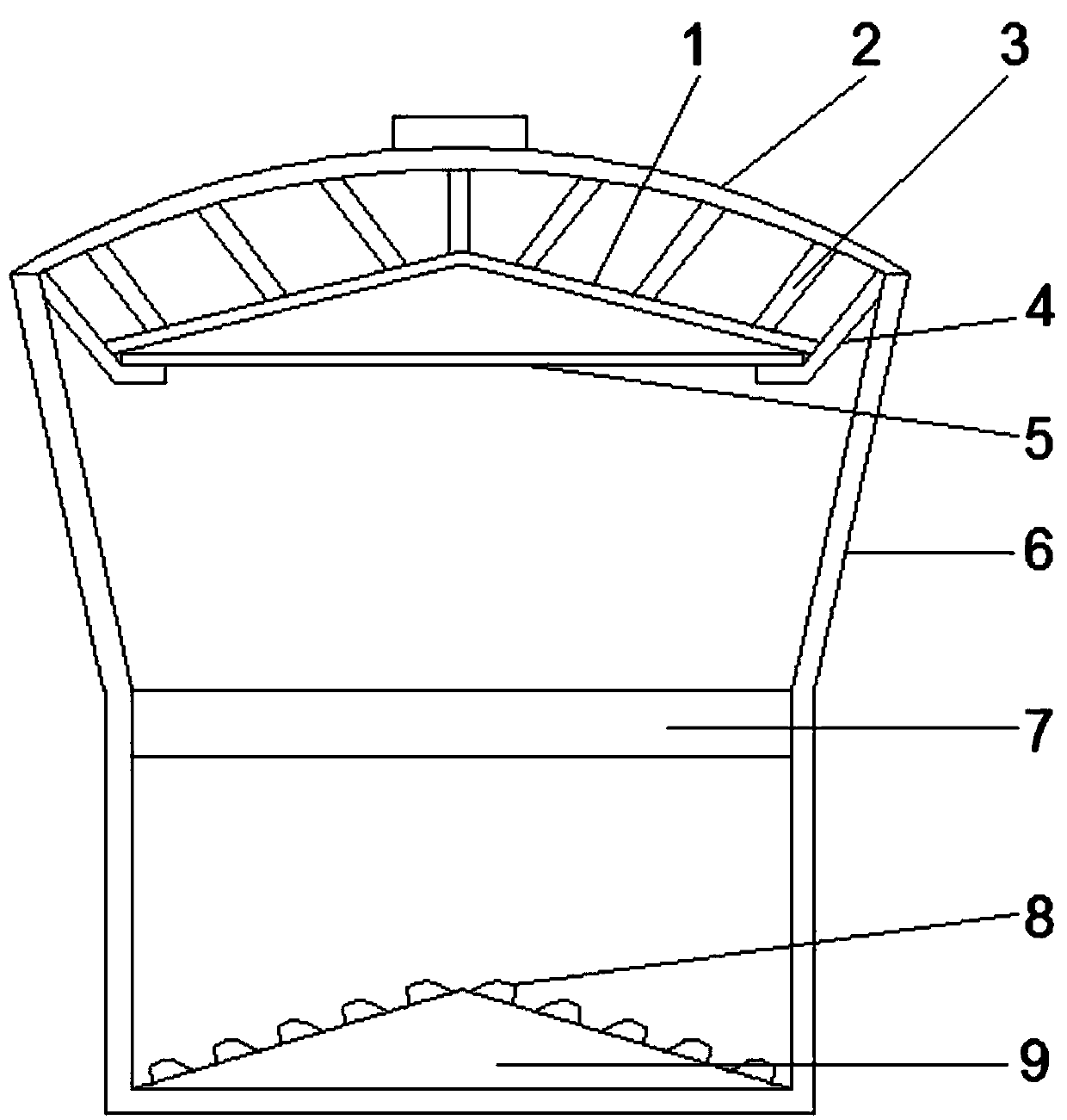

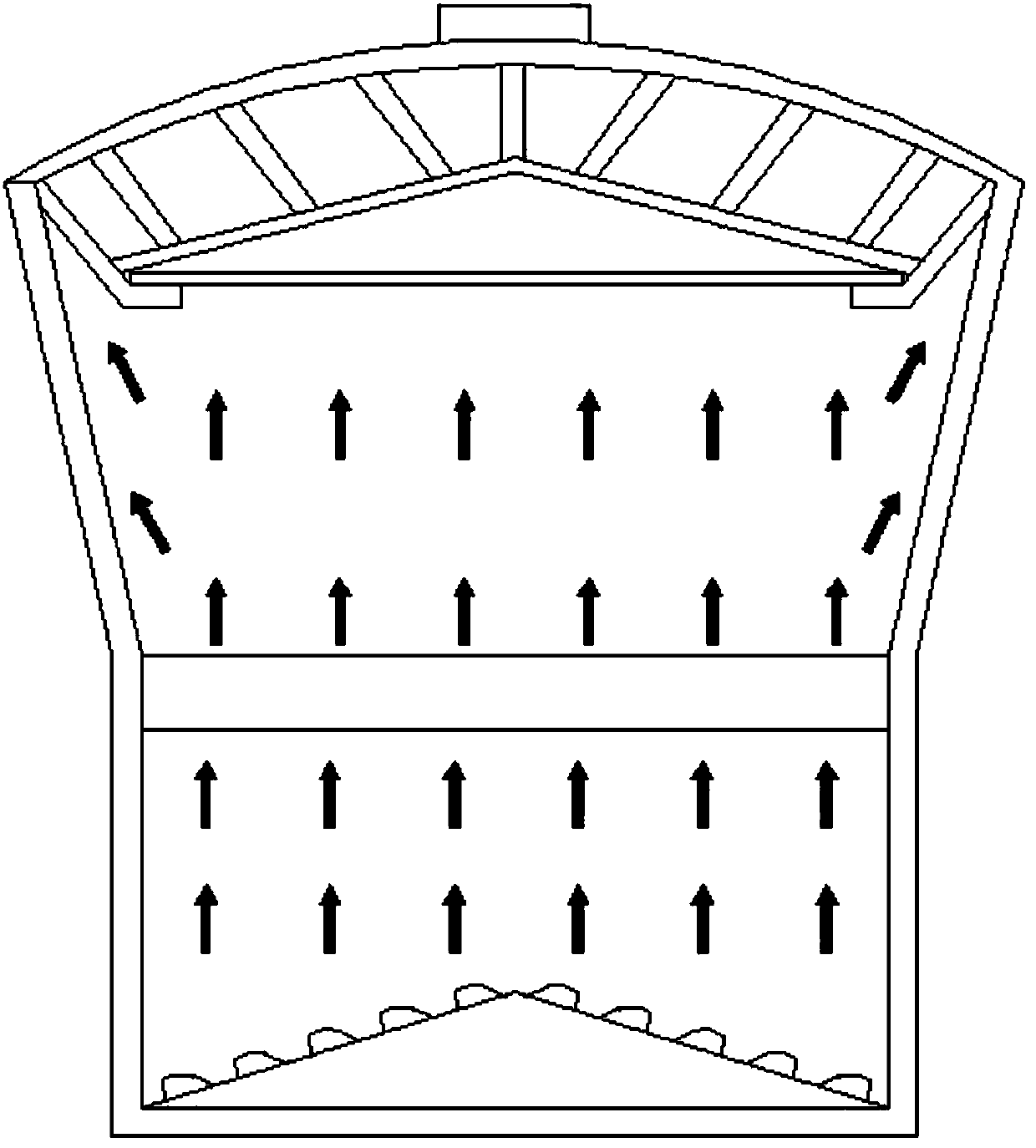

Supercritical-carbon-dioxide circulating fluidized bed boiler heating system and heating method

ActiveCN107120642AEasy to adjustAvoid Overheating ProblemsFluidized bed combustionIndirect carbon-dioxide mitigationSolid particleEngineering

The invention discloses a supercritical-carbon-dioxide circulating fluidized bed boiler heating system and a heating method. The supercritical-carbon-dioxide circulating fluidized bed boiler heating system comprises a boiler, a spiral tube coil super-heater, a classifier, a gas pass and a convection super-heater, wherein the spiral tube coil super-heater is mounted in a boiler chamber of the boiler, and of a spiral tube coil structure, and a spiral tube coil provides a supercritical-carbon-dioxide circulating channel; the convection super-heater is mounted in the gas pass, and provides a supercritical-carbon-dioxide circulating channel; the upper end of the boiler chamber communicates with an inlet of the classifier, an smoke outlet of the classifier communicates with one end of the gas pass, and an solid-particle outlet of the classifier communicates with the boiler chamber of the boiler through a refeed valve; and the spiral tube coil super-heater and the convection super-heater are arranged in parallel or in series.

Owner:SHANDONG UNIV

Cookware for processing rice and rice processing method

ActiveCN105455625AIncrease the burdenUniform heating surfaceSteam cooking vesselsWarming devicesSpecial designEngineering

Owner:王忠

Preparation method of green tea

ActiveCN106551016AMaximize incentive valueImprove use valuePre-extraction tea treatmentCooking & bakingGreen tea

The invention discloses a preparation method of green tea. The preparation method comprises the following steps of selecting planting lands; performing picking; performing baking of tea leaves; performing rolling; performing pyrolysis; performing drying twice; performing careful choosing; obtaining primary finished products; and obtaining finished products and the like. According to the preparation method disclosed by the invention, the efficacies of the green tea can be furthest arouse out, the utilization value of the green tea can be increased, the prepared green tea is bright in color, brewed tea leaves are still green and rich in fragrance, and tea soup has the characteristics of being rich, mellow, fresh and brisk, sweet in aftertaste and the like.

Owner:湖南长健农业发展有限责任公司

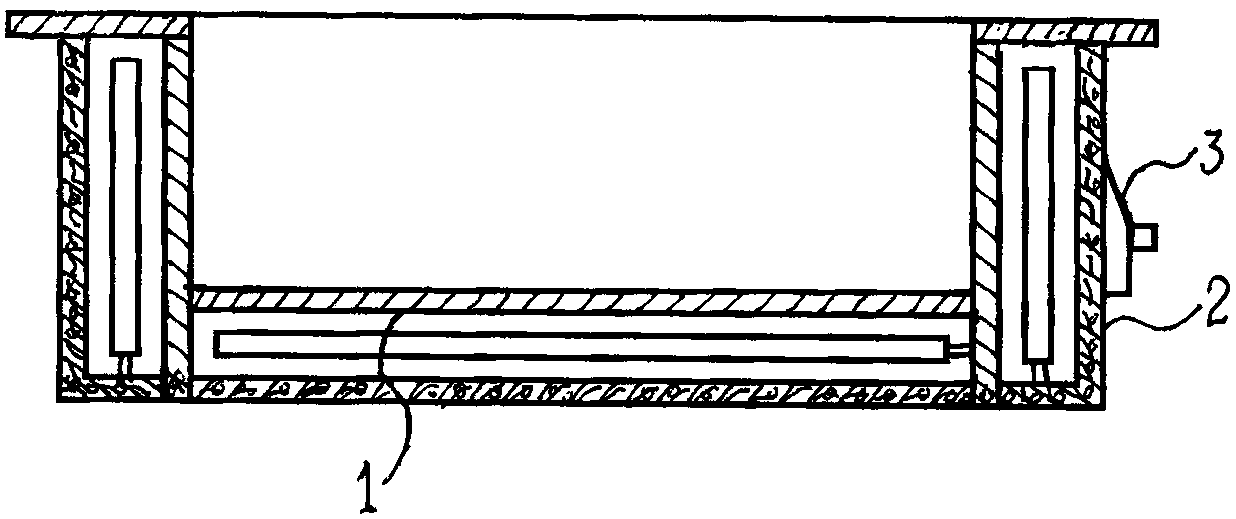

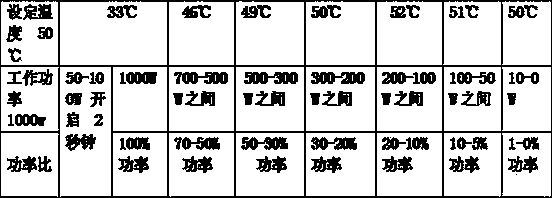

Safe energy saving method for electric heating fire box

InactiveCN104279602AUniform heating surfaceNo fireLighting and heating apparatusElectric heating systemHeating timeElectric heating

The invention discloses a safe energy saving method for an electric heating fire box. In order to overcome the defects that an existing electric heating fire box covered with an object easily causes fire disasters, safety performance is poor and control is not suitable, a face heat conduction insulating layer, a heating face plate layer and an insulating heat preservation layer are arranged on a foot containing mechanism and box walls, the comfortable temperature values, the safe temperature value and the safe heating time value are set on a control device, the comfortable temperature values are divided into at least two gradient values corresponding to gradients of heating power of electric heating elements, and the control device comprises an installation control inclined panel and an installation control straight panel. The safe energy saving method is used for manufacturing the electric heating fire box, office tables, study desks and the like which conduct heating and heat preservation during work and study, the 719 person-time tests show that no fire disasters can be caused, the electric heating fire box is safe and comfortable in use, energy is saved by 15% or above, the blood circulation of the lower parts of the human body can be promoted, the pain from rheumatism is relieved, life cultivation and health preservation are facilitated, and practicability is high.

Owner:黄子晋

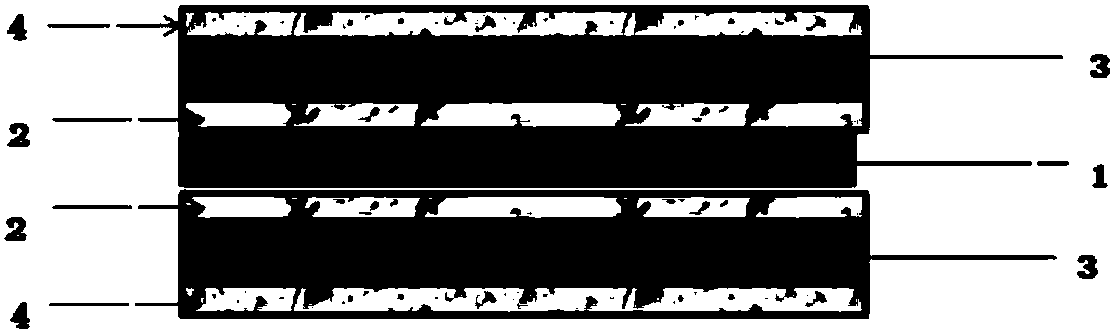

Microcrystal heating element and metal microcrystal heating element

InactiveCN103731940AHigh bonding strengthSmall thermal inertiaHeating element materialsOxide ceramicNon oxide ceramics

The invention provides a microcrystal heating element which comprises multi-phase composite ceramic and an electric heating component. The multi-phase composite ceramic comprises microcrystal glass and oxide ceramic and / or non-oxide ceramic, and the microcrystal glass and the oxide ceramic and / or the non-oxide ceramic are tightly combined through sintering in the environment of 900-1450 DEG C. The invention further provides a metal microcrystal heating element which comprises a metal shell, the multi-phase composite ceramic and the electric heating component, wherein the multi-phase composite ceramic comprises the microcrystal glass and the oxide ceramic and / or the non-oxide ceramic, and the oxide ceramic and / or the non-oxide ceramic, the electric heating component, basic glass particles of the microcrystal glass and the metal shell are tightly combined through sintering in the environment of 900-1450 DEG C to form a laminated structure. The combination strength between the metal shell serving as a cooling element and the multi-phase composite ceramic and the combination strength between the multi-phase composite ceramic and the electric heating component are high, heat shock resistance is high, safety is improved, the heating surface is uniform, thermal inertia is little, and thermal efficiency is high.

Owner:张鸿鸣 +1

Laminated ceramic electrical-heating element

InactiveCN106851871AImprove thermal conductivityImprove conductivityHeating element materialsGlass-ceramicMultiple layer

The invention provides a laminated ceramic electrical-heating element. Laminated ceramic combines with a metal member and a heat generating element through sintering and contains in-situ crystallized glass ceramic. The laminated ceramic is manufactured by co-sintering multiple layers in a pressure state. Compared with a green body of the laminated ceramic, the lamination thickness direction shrinks, and the area of the plane perpendicular to the lamination thickness direction does not shrink. The laminated ceramic electrical-heating element has the advantages that the laminated ceramic electrical-heating element is strong in heat impact resisting capability, safe, hygienic, uniform and small in thermal inertia and is light, thin and quick, and a temperature sensing element is quick to react and high in efficiency.

Owner:HANGZHOU GELASIKANG TECH CO LTD

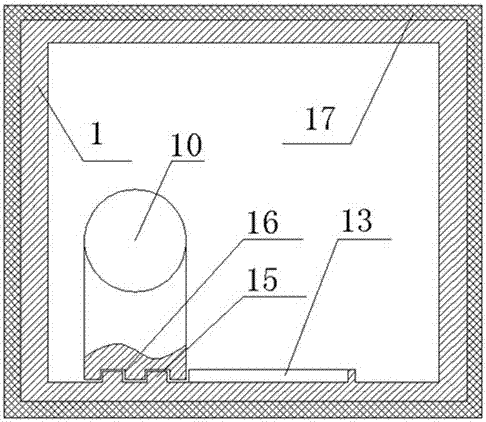

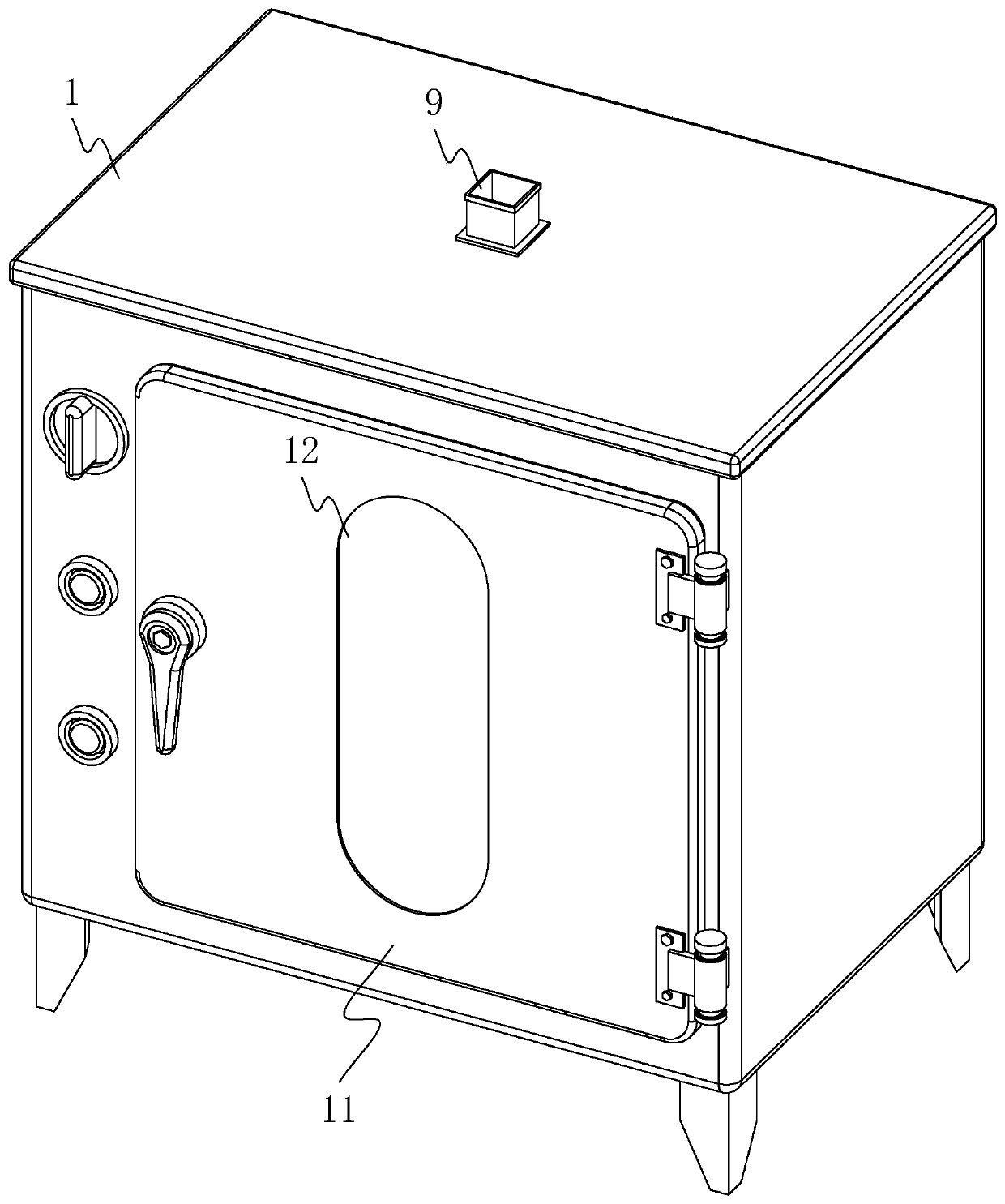

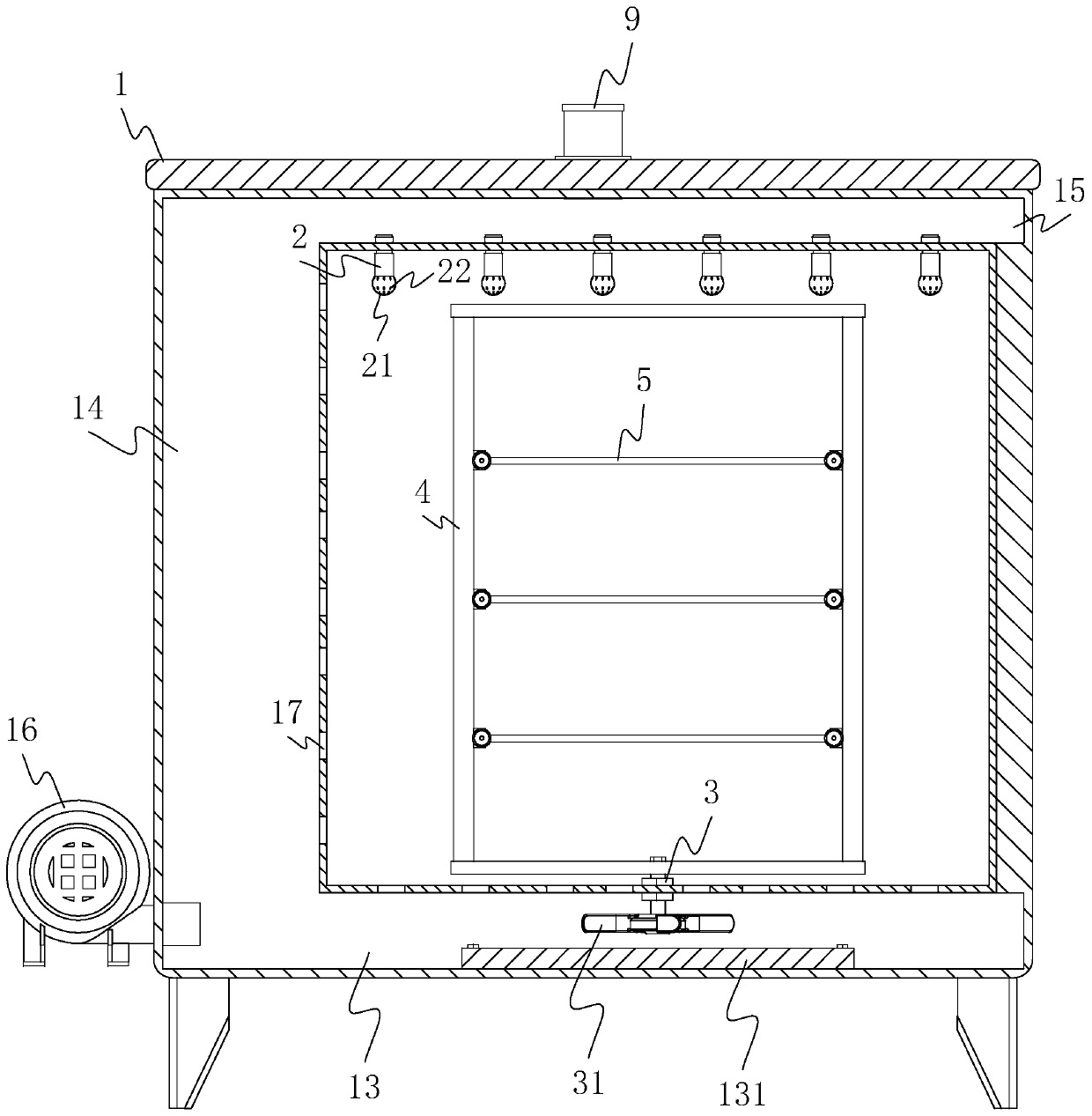

a drying oven

ActiveCN108800780BUniform heating surfaceAvoid overheating damageDrying gas arrangementsDrying chambers/containersEngineeringAir blower

The invention discloses a drying box, and relates to the field of drying instruments. The drying box comprises a box body, a box door and an exhaust pipe communicating with the interior of the box body, and a first hollow cavity and a second hollow cavity communicating with the first hollow cavity are formed in the box body; and a heating sheet is arranged in the first hollow cavity, the side wallof the box body is provided with a blower fan which communicates with the second hollow cavity and is aligned with the first hollow cavity, exhaust holes are formed in the bottom wall and the side wall of the box body, the bottom wall of the box body is rotationally connected with a rotating shaft, a fan blade is arranged at the end, located in the first hollow cavity, of the rotating shaft, moreover, a supporting frame is arranged at the other end, located in the box body, of the rotating shaft, and trays are arranged on the supporting frame. The drying box has the following advantages and effects that the trays and materials are indirectly driven to rotate through the blower fan, meanwhile, the materials undergo air blowing drying in multiple directions, so that the heating surfaces ofthe materials in the drying box are more uniform, overheating damage caused by uneven heating of the materials is avoided, then drying quality and efficiency are improved, the waste of energy and resources is reduced, and the drying rate of the materials is improved.

Owner:台州市台环环境检测科技有限公司

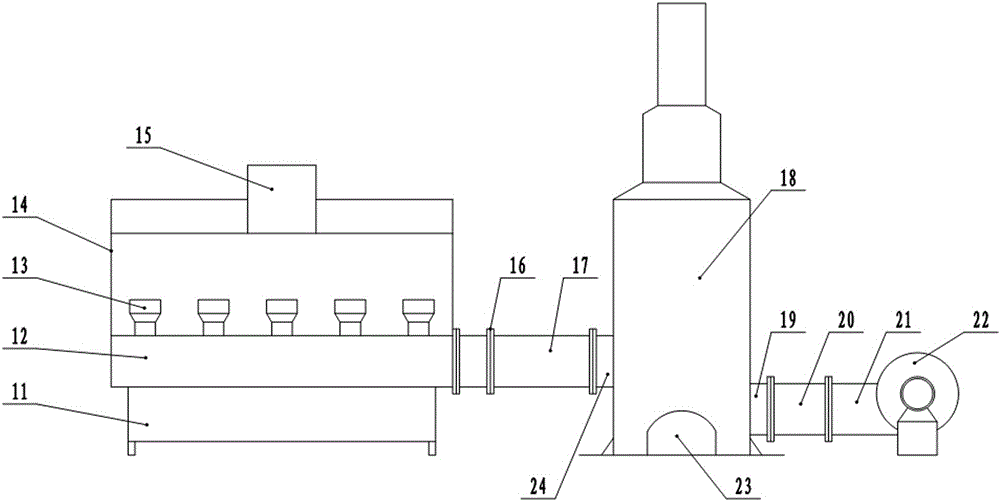

An electromagnetic microwave drying device for gypsum board

ActiveCN105651027BUniform heating surfaceNo expansion deformationDrying solid materials with heatDrying machines with progressive movementsMicrowaveEnergy consumption

The invention relates to an electromagnetic microwave drying device for gypsum boards. The electromagnetic microwave drying device comprises a microwave heating box, wherein an air introduction pipe is arranged at the top of the microwave heating box. Microwave generators are arranged at the top ends of the microwave heating box, and water coolers are arranged at the tops of the microwave generators. The water coolers are communicated with a water pump. Conveying rollers are arranged in the microwave heating box and are in transmission connection with driven wheels and engaged wheels through chains. The driven wheels are in transmission connection with a motor. Temperature sensing probes are arranged on the microwave heating box. The microwave heating box can effectively ensure that microwaves move in the box, the boards can fully absorb microwaves and vapor is evaporated after heat absorption, and thus the purpose of drying the boards can be achieved; the microwaves emitted by the microwave generators can penetrate through the boards and be absorbed by the boards and move uniformly in the box, and the heated faces of the boards are uniform; the dried boards are tidy and free of expansion deformation, and the forming rate is greatly increased; no gas polluting the atmosphere is generated, and thus the electromagnetic microwave drying device is environmentally friendly, safe and low in energy consumption.

Owner:孙晋玉

Bar material automatic lifting continuous feeding saw material heating equipment

ActiveCN103447825BReduce labor intensitySame lengthOther manufacturing equipments/toolsMetal working apparatusProduction linePunch press

The invention relates to equipment for automatically lifting, continuously feeding, sawing and heating bars. The equipment comprises a loading device, a lifting device, a feeding device, a blanking device and a heating hot punching device, wherein the loading device comprises a loading frame, a loading platform, an ejector rod, a linkage rod, a driving wheel and an ejector cylinder; the lifting device comprises a lifting chain, a chain wheel, a driving chain wheel and a lifting motor; the feeding device comprises a feeding frame, a V-shaped wheel, a compression cylinder, a compression guide wheel and a feeding limit switch; the blanking device comprises a guide mechanism, a saw-cutting mechanism and a material rotating mechanism; and the heating hot punching device comprises a heating groove, a heating furnace, a blanking guide groove and a punch press. A fully-automatic production line of lifting, feeding, blanking and heating hot punching is manufactured and formed on a valve shell, so full-automatic control is realized, production efficiency is improved, energy consumption is saved, workers are protected from directly operating beside the heating furnace, scalding and sunstroke accidents are avoided, labor intensity is reduced, and the automatic level is increased and product quality is improved.

Owner:NINGBO JIEKELONG PRECISION MFG +1

Multi-nozzle energy-saving mixed fuel gas stove

PendingCN108224492AUniform heating surfaceWell mixedDomestic stoves or rangesGaseous fuel burnerEngineeringGas cooking stove

The invention discloses a multi-nozzle energy-saving mixed fuel gas stove comprising a combustion disc, a fuel gas pipe and an air pipe; the combustion disc is a cylinder structure, a plurality of nozzles are formed on the inner side wall of the combustion disc, a mixing chamber is arranged on the bottom of the combustion disc, the mixing chamber is in communication with the nozzles, the fuel gaspipe and the air pipe; a fuel gas flow valve is arranged on the pipeline of the fuel gas pipe, and an air flow valve is arranged on the pipeline of the air pipe. The mixing chamber is arranged on thebottom of the combustion disc, so that fuel gas and air are thoroughly mixed in the mixing chamber, the mixed fuel gas is ejected from the nozzles to burn, compared with a conventional fuel gas stove,a pot body heating surface is even, and at the same time, the fuel gas and the air are metered in ratio and fully mixed in the mixing chamber, and the multi-nozzle energy-saving mixed fuel gas stovehas the advantages of being energy-saving, controllable, sufficient in combustion and the like.

Owner:何志明

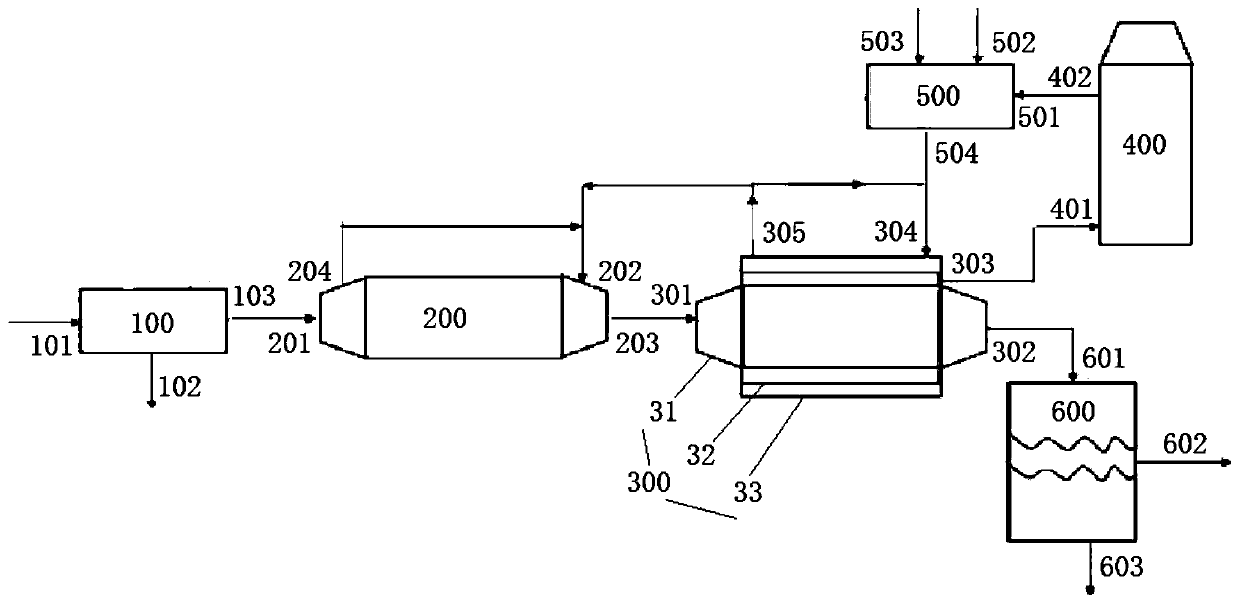

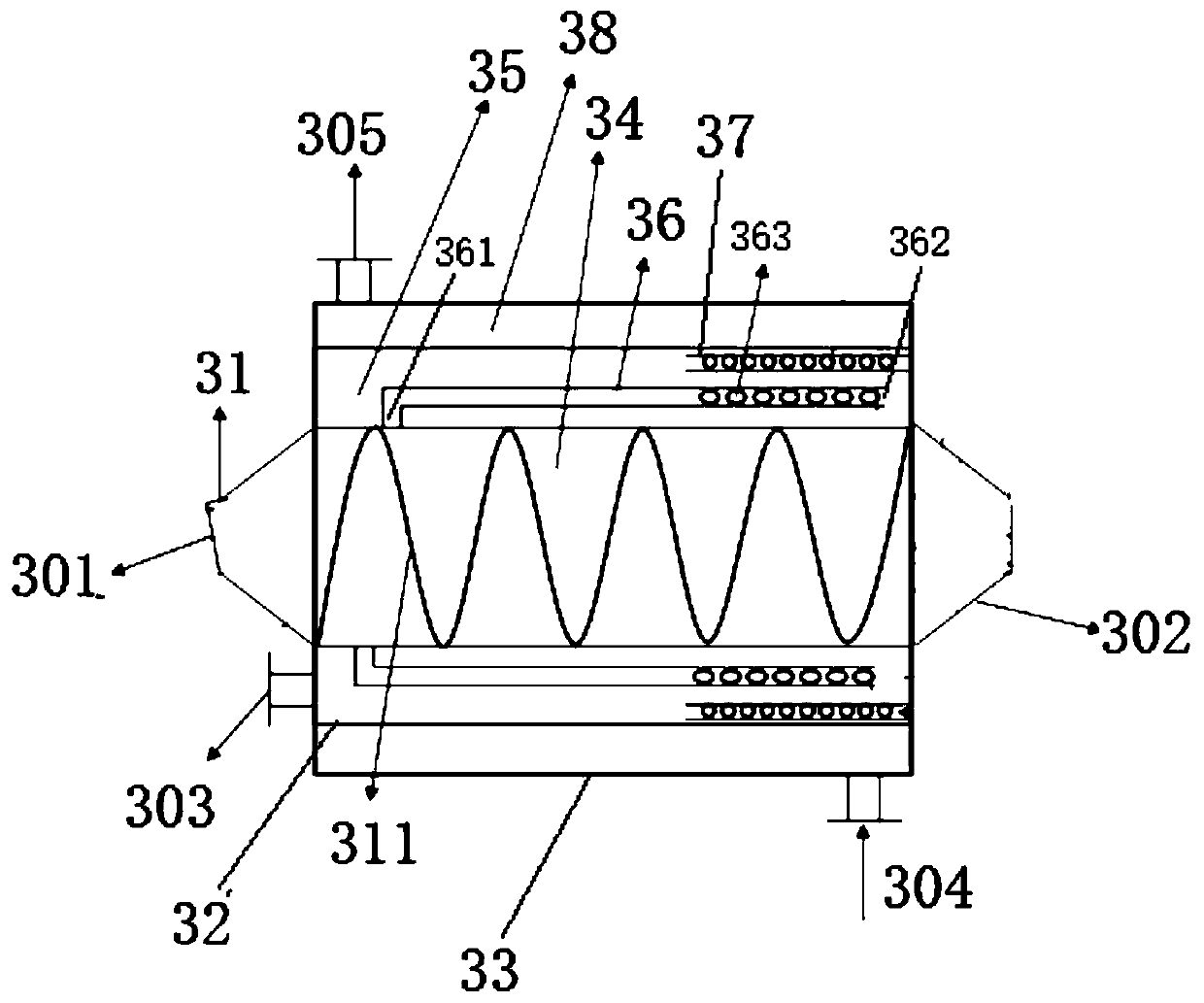

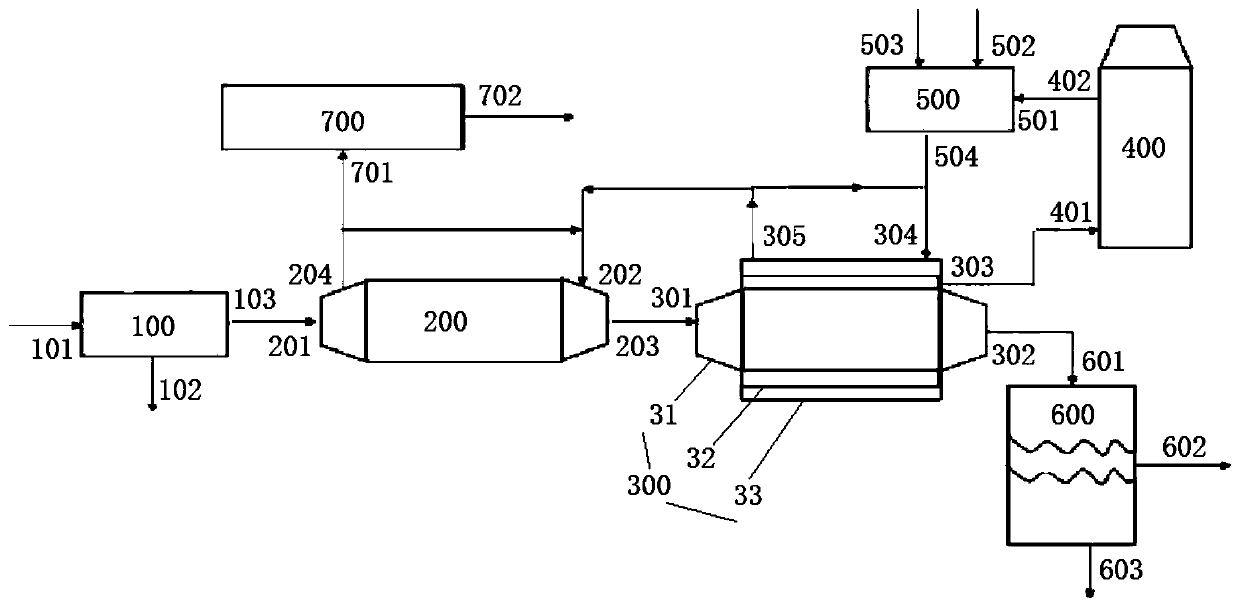

System and method for treating solid wastes

The invention discloses a system and method for treating solid wastes. The system comprises a pre-treatment unit, a drying unit, a pyrolyzation unit, a purifier, a burner and a screening unit, whereinthe pyrolyzation unit comprises an internal cylinder, a secondary external cylinder and an external cylinder. The internal cylinder is rotationally arranged, a pyrolyzation space is formed in the internal cylinder, a helical blade is arranged on the inner wall of the internal cylinder, a drying material inlet is formed in the front end of the internal cylinder, and a solid material outlet is formed in the rear end of the internal cylinder. The internal cylinder is sleeved with the secondary external cylinder to form a gasification space, a pyrolytic oil gas pipeline and an atomized water pipeline are arranged in the gasification space, one end of the pyrolytic oil gas pipeline is communicated with the pyrolyzation space, the other end of the pyrolytic oil gas pipeline extends into the gasification space, and a gasified gas outlet is formed in the portion, at the other end away from the pyrolytic oil gas pipeline, of the secondary external cylinder; the secondary external cylinder is sleeved with the external cylinder to form a heat exchange space, a high-temperature flue gas inlet and a heat-exchange flue gas outlet are formed in the heat exchange space, and the heat-exchange fluegas outlet and a drying cold air outlet are connected with a drying hot air inlet.

Owner:北京云水浩瑞环境科技有限公司

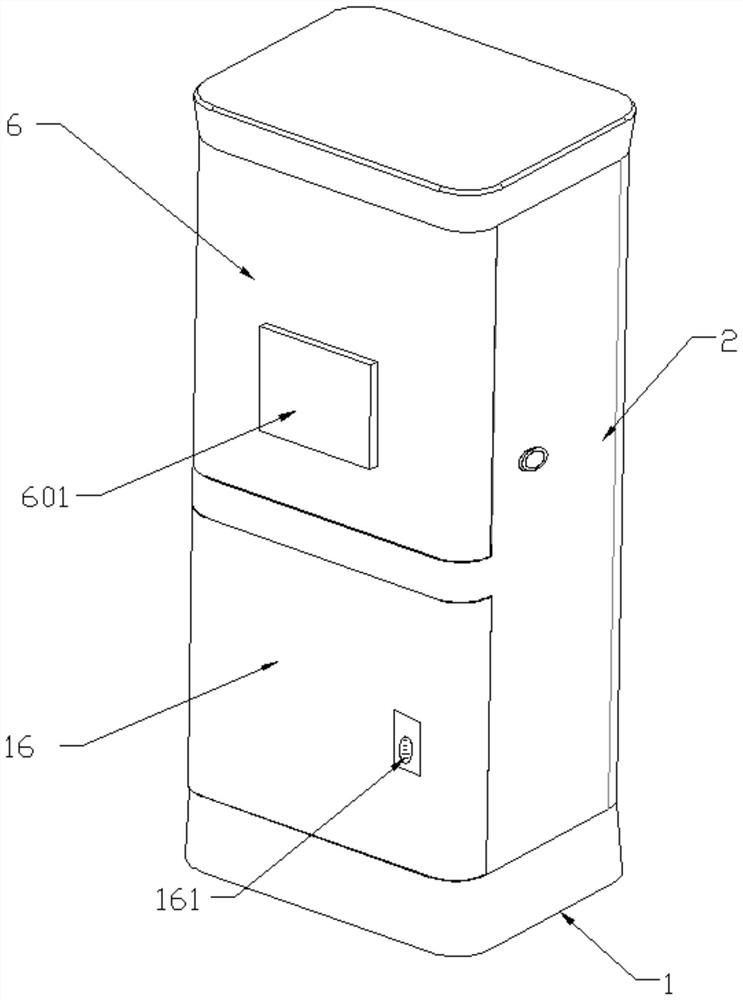

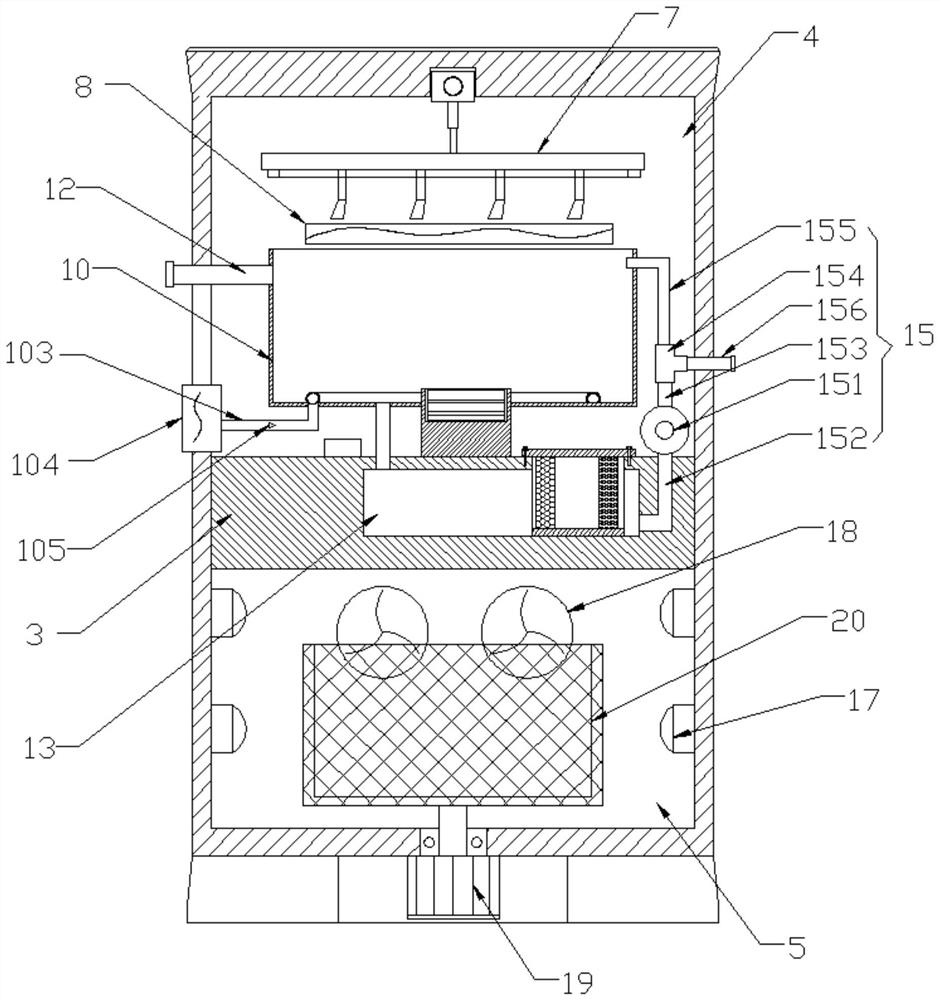

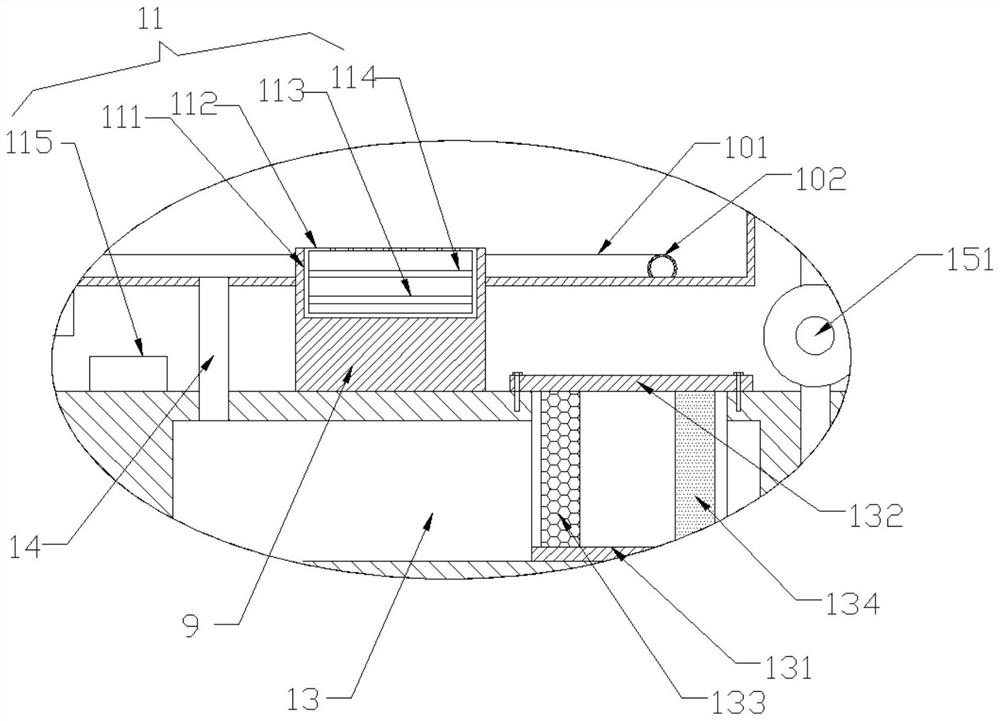

Filtering type electrolyzed water ozone cleaning and disinfecting device

PendingCN112411111AEasy to cleanReasonable structural designElectrolysis componentsOther washing machinesElectrolysed waterEnvironmental engineering

The invention discloses a filtering type electrolyzed water ozone cleaning and disinfecting device. The filtering type electrolyzed water ozone cleaning and disinfecting device comprises a base; a shell is connected to the top of the base; a partition plate is connected to the middle of an inner cavity of the shell; the shell is divided into a washing and drying cavity and a storage cavity throughthe partition plate; an upper cabinet door is installed at the front end of the washing and drying cavity; a hanging rod mechanism is connected to the top of an inner cavity of the washing and dryingcavity; an infrared drying lamp tube is installed on the upper portion of the rear side wall of the inner cavity of the washing and drying cavity; a supporting base is connected to the bottom of theinner cavity of the washing and drying cavity; a stainless steel inner barrel is connected to the top of the outer wall of the supporting base; an electrolyzed water generating mechanism is installedat the upper end of the supporting base; a water inlet pipe communicates between the top of the stainless steel inner barrel and the shell; a filtering cavity is formed in the partition plate; a flowguide pipe communicates between the left end of the filtering cavity and the bottom of the stainless steel inner barrel; and the right end of the filtering cavity is connected with a reflux mechanism.The filtering type electrolyzed water ozone cleaning and disinfecting device is reasonable in structural design, underwear can be effectively washed without adding any chemical detergent, the effectthat the underwear is washed in a hung mode can be achieved, and the underwear is prevented from being mixed and twisted together in the washing process.

Owner:苏州康安贝智能科技有限公司

Paperbacked plasterboard drying device with natural gas as heat source and drying process

InactiveCN110103332ASimple equipmentUniform heating surfaceSurface layering apparatusExhaust gasProcess engineering

An embodiment of the invention discloses a paperbacked plasterboard drying device with natural gas as a heat source. The device comprises a plurality of drying areas which are sequentially connected,wherein drying machines are arranged in the drying areas, an air distribution chamber and conveying roller beds are arranged in each drying machine, the conveying roller beds sequentially pass throughthe air distribution chambers of different drying areas, and an air distribution damper used for distributing heat to roller bed space is arranged in each air distribution chamber; each air distribution chamber is connected with a combustion chamber, and a circulating fan is arranged in each combustion chamber; a burner is further arranged in each combustion chamber, a gas feeding pipeline and anair feeding pipeline are arranged on each combustion chamber, each air feeding pipeline is connected with the corresponding circulating fan, and a gas feeding damper and an air feeding damper are arranged on each gas feeding pipeline and the corresponding air feeding pipeline respectively; chimneys are further arranged on the drying machines. A drying process comprises steps as follows: S100, feeding the paperbacked plasterboard to the roller beds; S200, sequential drying; S300, tail gas treatment; S400, discharging from the roller beds. According to the paperbacked plasterboard drying device, paperbacked plasterboard is dried with heat produced by natural gas in combustion, and equipment is simplified and pollution is reduced by contrast with a production process of a coal-fired plant.

Owner:BEIJING NEW BUILDING MATERIAL

Slasher, with high drying performance, for performing double-dipping and quartic-pressing on wet slashed yarns through roller warp beams

InactiveCN110172793AOptimization of shaft movement trip rotation phenomenonHigh calorific valueLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFlangingTar

The invention discloses a slasher, with high drying performance, for performing double-dipping and quartic-pressing on wet slashed yarns through roller warp beams. The slasher structurally comprises an industrial control base, a supporting cushion transporting platform, a roller rod group groove, a double-dipping and quartic-pressing oven, an I-shaped roller winding frame, an inner pressing revolving column and gearboxes. The slasher achieves the purpose that by the matching between the roller rod group groove and the double-dipping and quartic-pressing oven, the effect of upper-section, middle-section and lower-section four-layer desizing decrement is formed, sized hairiness is subjected to slurry infiltration to enable the fiber to be adhered and ensure the film toughness, the middle-section upper-surface lower-surface squeezing operation is performed, then filtering slurry falls and smoothly flows back to a large soaking groove tar, the recycling of materials is ensured, the interference on the yarn quality due to too much slurry is avoided, after a two-roller yarn pressing frame performs rolling, slashing and desizing, an oven housing is matched with a top electric heating roller to heat a baffle, the uniform heated surface under the drying matched revolving air pressure is reinforced, the roller rod group groove is connected after yarn discharging, and the flanging and hairiness of yarns are compacted and adhered, and the slasher has no impurity residuals, and the maintenance of warps is excellent.

Owner:褚晓婷

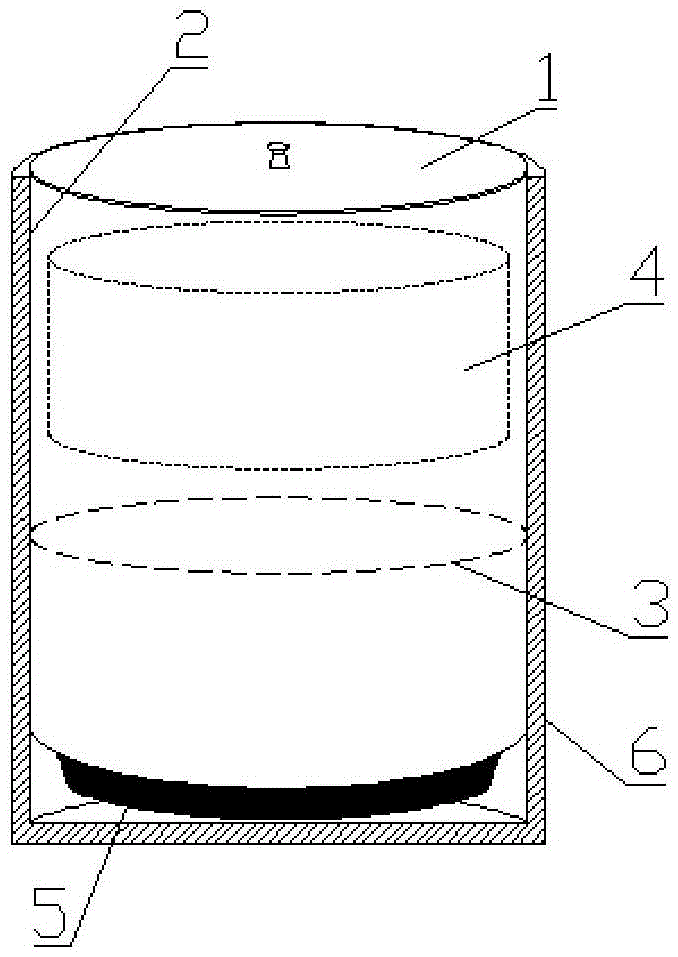

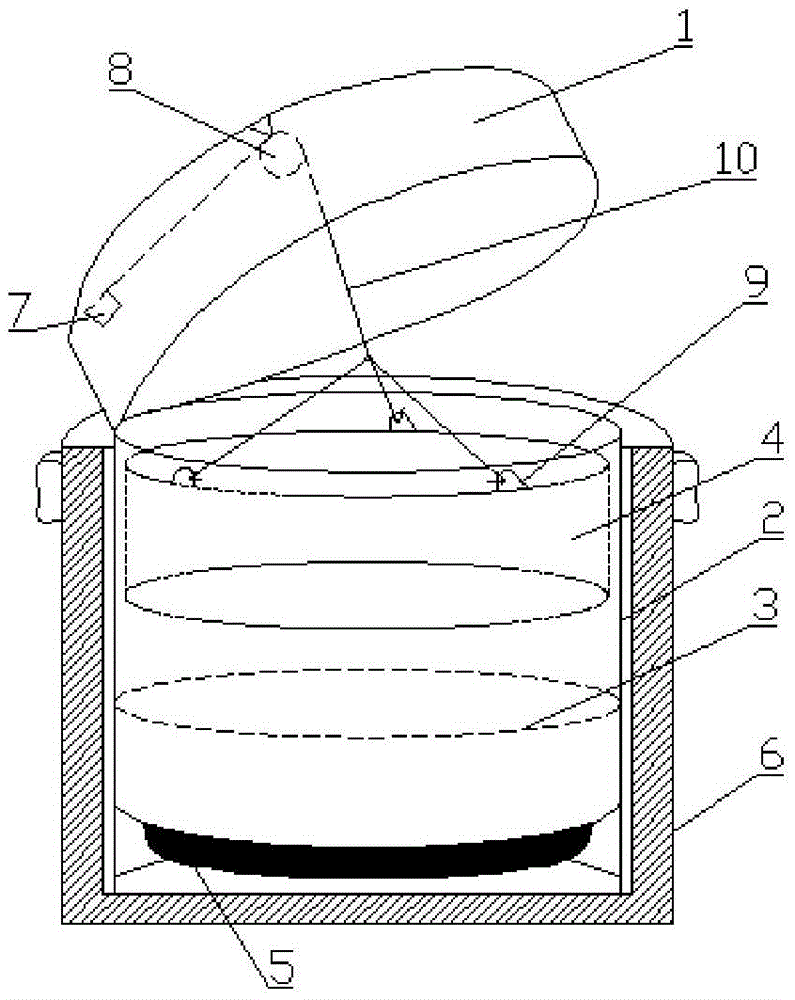

Organic heat carrier heating equipment

ActiveCN105135678BTake advantage ofClean up thoroughlyStorage heatersHeat carrierParticle combustion

The invention discloses an organic heat carrier heating device, which comprises a furnace body and a heat-conducting oil tank. The furnace body is provided with a furnace, the outer wall of the furnace is provided with a ring of heat-insulating jackets, and the bottom of the furnace body is respectively provided with air inlet cylinders. And ash chamber, including heating system, secondary circulation system, rotary quantitative feeding system and ash cleaning system; the advantage of the present invention is that it can feed quantitatively and orderly, strictly control the feeding speed and feeding amount, and prevent tempering The phenomenon occurs, the combustion reaction is sufficient, and the utilization rate of the combustion of biological particles in the furnace body is improved, the heat can be fully recycled for the second time, and the heating surface of the spirally coiled tube group can be made uniform, which greatly saves resources and saves biological energy. The usage of pellets saves cost.

Owner:ANHUI SANDING BOILER MFG CO LTD

Novel gas type wide-mouth oven and working method thereof

The invention relates to the technical field of gas ovens, in particular to a novel gas type wide-mouth oven and a working method thereof. The novel gas type wide-mouth oven comprises a grill, an ovencover, a gas outlet, a supporting frame, a baking tray, an oven body, a ceramic net, a flame dispersion plate and a burner placement opening. The ceramic net is arranged in the middle in the oven body and connected with the oven body in an embedded mode. The supporting frame is arranged on the edge in the oven body and connected with the oven body in a welded mode. The gas outlet is formed in thesupporting frame. The baking tray is arranged on the top side of the supporting frame and connected with the supporting frame in an embedded mode. The grill is arranged on the top side of the bakingtray and connected with the supporting frame in an embedded mode. The oven cover is arranged on the top side of the oven body. Through the improvement of the structure, the oven has the advantages ofbeing uniform in heating, consistent in baking maturity and capable of avoiding waste, and therefore the problems and defects of an existing device are effectively solved and overcome.

Owner:惠州市创美科技有限公司

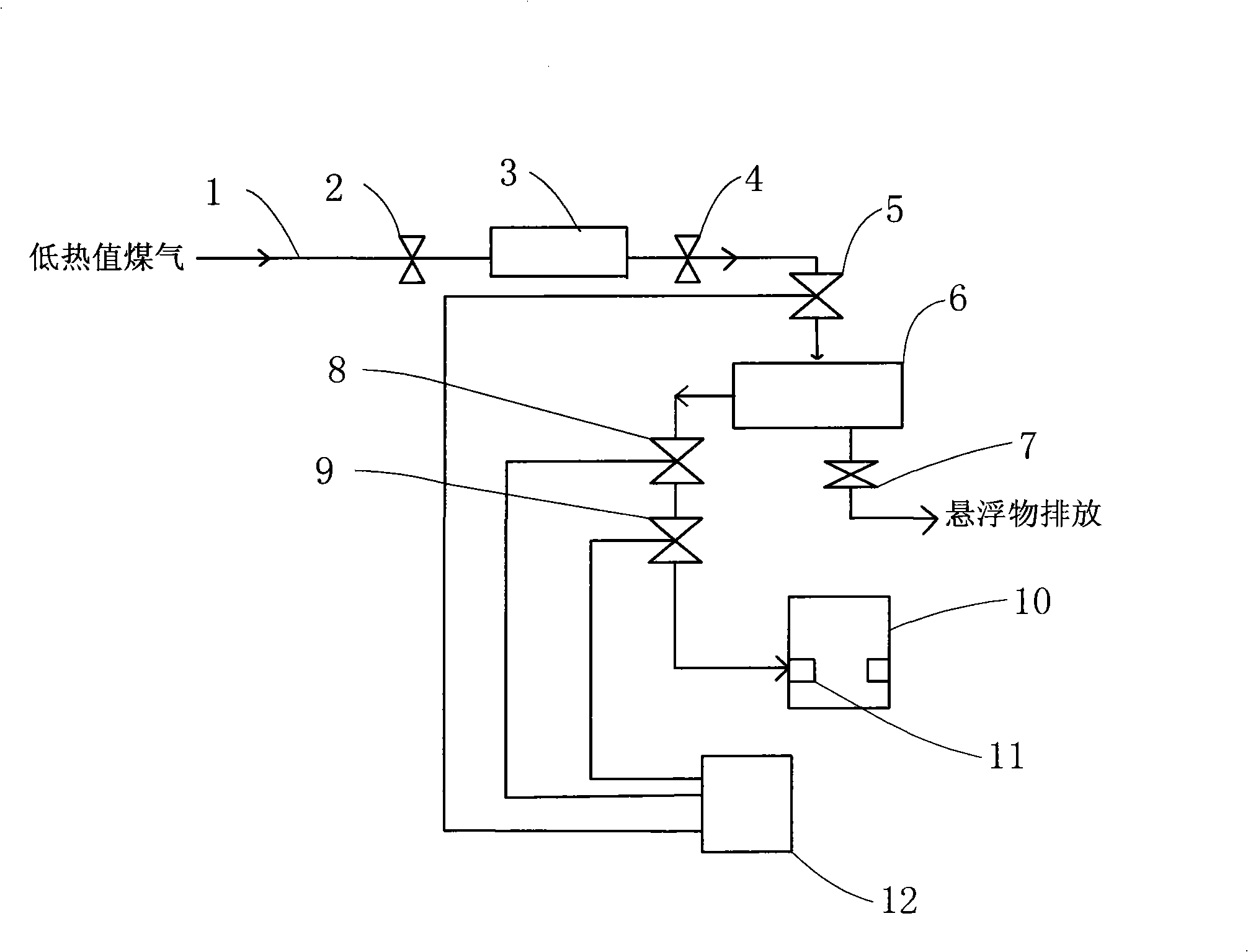

Low-heat value gas combustion device

InactiveCN101526212BAvoid overheatingGuaranteed uptimeFluidized bed combustionGas dust removalCombustorAutomatic control

The invention relates to a low-heat value gas combustion utilizing method. Low-heat value gas is supplied to a dust separator by a gas input pipeline, a gas valve, an emptying device, a gas stop control valve and a gas-distributing valve; dust and gas are separated, and separated suspended substances are discharged by a floating dust sinking discharge valve; the obtained pure low-heat value gas is supplied to a combustor arranged in a circulating fluidized bed boiler by a control gas source connecting valve and a gas supply valve for combustion and heat supply; and gas ducts which are respectively led from the gas-distributing valve, the control gas source connecting valve and the gas supply valve are communicated with an automatic gas flow control device for adjusting and controlling thegas flow amounts of different routes. The method can prevent a combustion nozzle from being blocked, uniformizes heated surfaces, can avoid a partial overhigh temperature phenomenon, achieves the effect of together burning the low-heat value gas with general fuel and is suitable for being used in the field utilizing the combustion and the heat of the low-heat value gas.

Owner:中冶葫芦岛有色金属集团有限公司

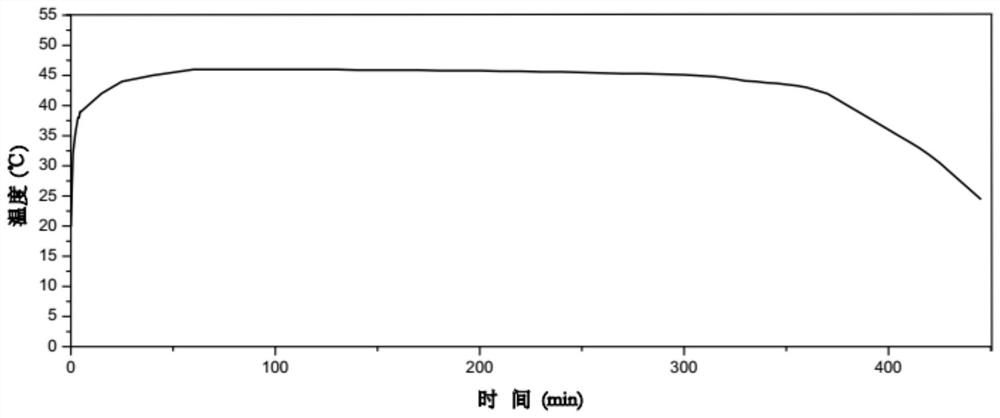

A kind of rapid heating and constant temperature hot compress spirit and preparation method thereof

ActiveCN109907878BStable heating temperatureUniform heating surfaceTherapeutic coolingTherapeutic heatingTemperature controlEngineering

The invention discloses a rapid-heating constant-temperature hot compress patch and a preparation method thereof. The rapid-heating constant-temperature hot compress patch comprises a nonwoven fabriccoating layer, an adhesive layer, an automatic-temperature-control heating layer, a power-on circuit and a power source. The automatic-temperature-control heating layer is peripherally coated with thenonwoven fabric coating layer, one surface of the nonwoven fabric coating layer is provided with the adhesive layer, and the outer face of the adhesive layer is provided with a release layer. The automatic-temperature-control heating layer is connected with the power source through the power-on circuit to form electrical connection. The automatic-temperature-control heating layer is prepared from, by mass, 10-30 parts of a base material, 30-60 parts of organic crystals, 30-40 parts of conductive particles and 2-10 parts of a synthesis auxiliary agent. Compared with existing hot compress patches on the market, the rapid-heating constant-temperature hot compress patch has advantages of light weight, softness, portability, high accuracy in temperature control, elimination of scalding causedby overheating and suitableness for the demand of human body hot compress.

Owner:SOUTH CHINA UNIV OF TECH +1

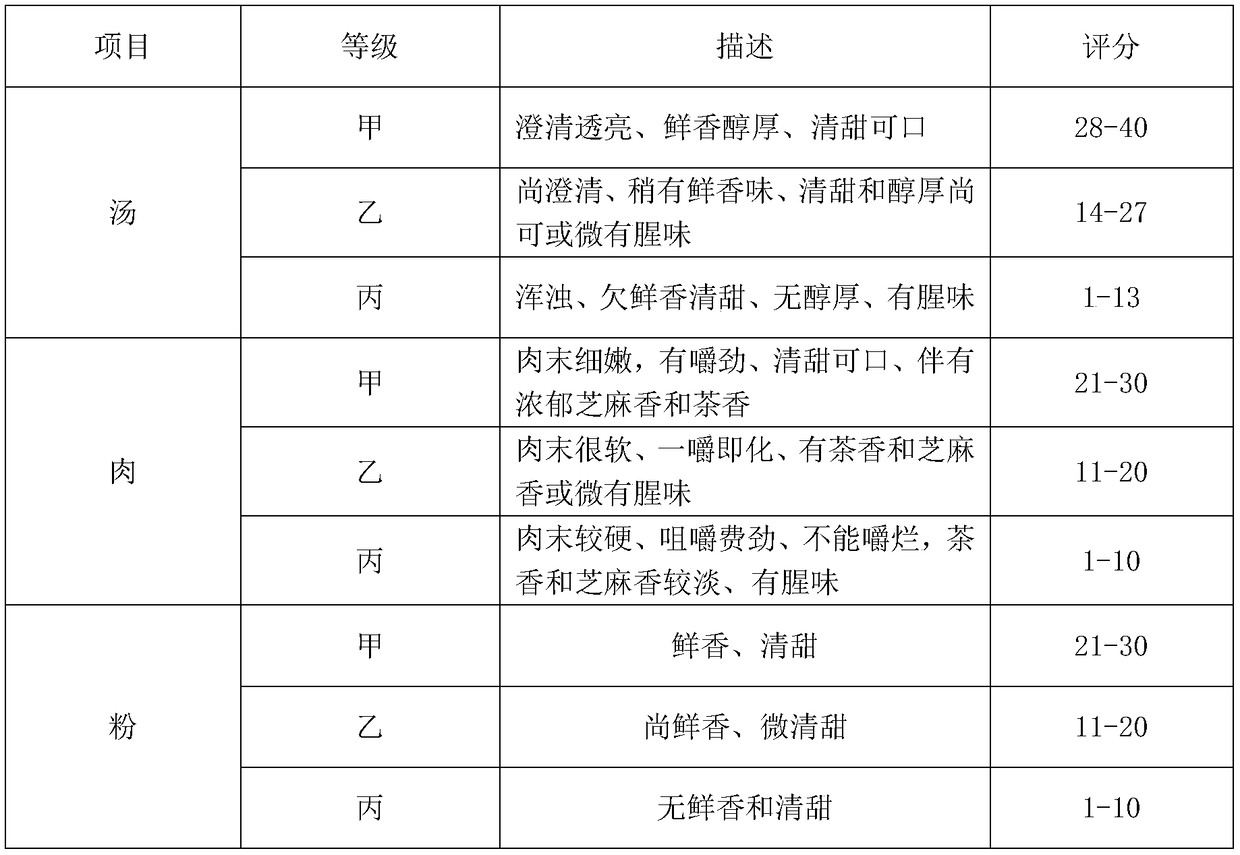

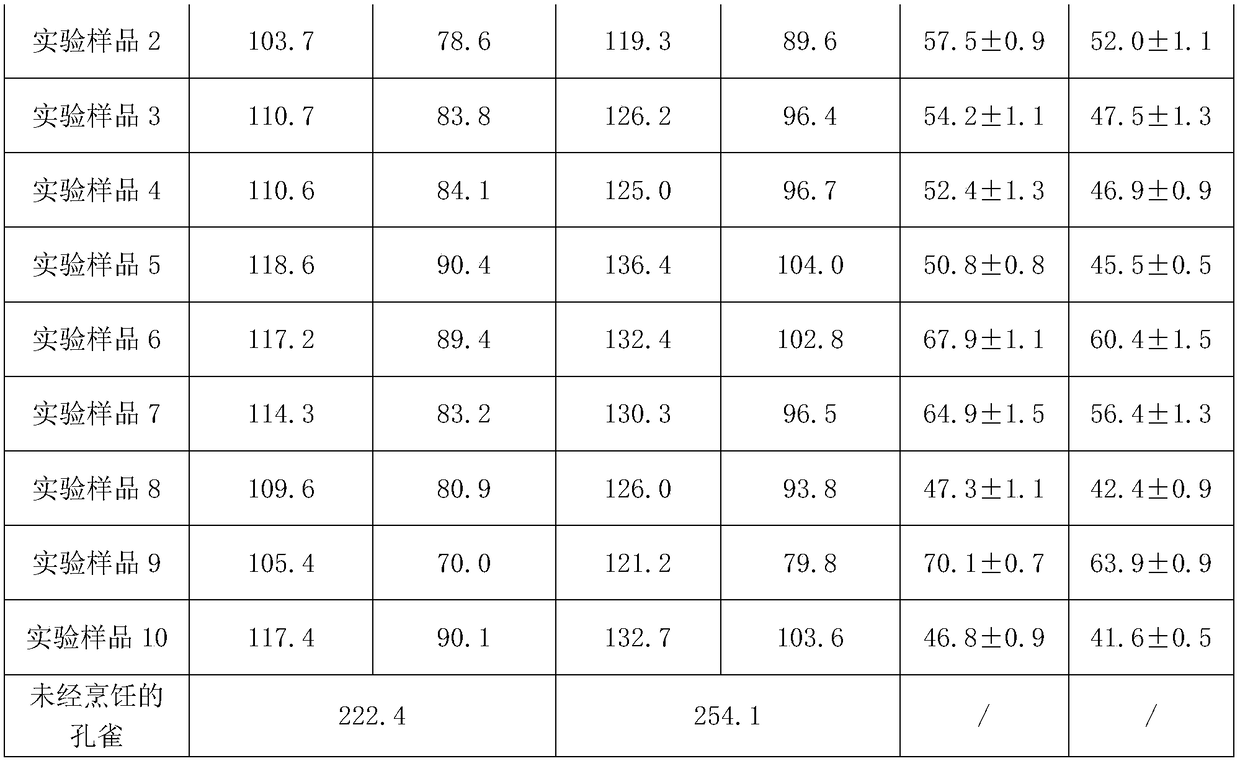

Peacock soup powder and preparation method thereof

InactiveCN109275864AIncrease profitThe soup is delicious and sweetFood ingredient as mouthfeel improving agentFlavorFood processing

The invention provides peacock soup powder and a preparation method thereof, and particularly relates to the technical field of food processing. The preparation method of the peacock soup powder comprises the following steps: a, killing and washing peacocks; b, carrying out primary deodorization treatment; and c, carrying out further deodorization treatment, and preparing peacock soup, cooked peacock meat and cooked internal organs; and d, pouring the soup, and adding the materials to obtain the peacock soup powder. The peacock soup powder disclosed by the invention contains the meat and the internal organs of blue peacocks, and the utilization rate of the raw materials in the processing of blue peacock food is greatly improved. The peacock soup powder prepared by the method is fresh, fragrant and sweet in soup and tender in meat quality, and is chewy and not hard, blue peacock blood is fine and smooth, and the peacock soup powder has strong flavor and tea fragrance. The method disclosed by the invention is simple to operate, stable and controllable in product and easy for large-scale promotion.

Owner:广西三江县蓝天养殖开发有限公司

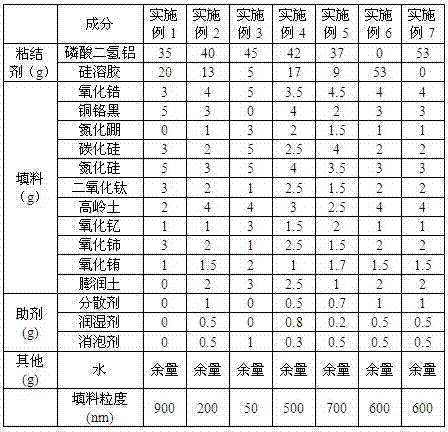

A high-temperature-resistant, stain-resistant and slagging-resistant ceramic coating and its preparation method and application

ActiveCN104446325BImprove heat transfer efficiencyImprove heat transfer effectGranularityCeramic coating

A high temperature-, stain- and slagging-resistant ceramic coating and a preparation method and use thereof. The ceramic coating comprises the following components by mass percentage: 15-30 percent of a filler, 40-65 percent of an adhesive agent and the balance being water, wherein the filler comprises 3-5 percent of zirconia, 3-5 percent of silicon carbide, 3-5 percent of silicon nitride, 1-3 percent of titanium dioxide, 2-4 percent of kaolin and 3-8 percent of a rare earth oxide. The preparation method thereof comprises the steps of mixing the adhesive agent with water to prepare an adhesive agent liquid, then adding the filler refined to a particle size up to 50-900 nm to the adhesive agent liquid, and then adding an auxiliary, uniformly mixing, filtering and packaging. The coating can be applied on the external surfaces of a boiler tube and a heater tube to form a ceramic coating so as to prepare a boiler tube and a heater tube having high performance.

Owner:QINGDA SAISIDI NEW MATERIAL TECH BEIJING

A kind of preparation method of green tea

ActiveCN106551016BMaximize incentive valueImprove use valuePre-extraction tea treatmentGreen teaEpigallo-catechin gallate

The invention discloses a preparation method of green tea. The preparation method comprises the following steps of selecting planting lands; performing picking; performing baking of tea leaves; performing rolling; performing pyrolysis; performing drying twice; performing careful choosing; obtaining primary finished products; and obtaining finished products and the like. According to the preparation method disclosed by the invention, the efficacies of the green tea can be furthest arouse out, the utilization value of the green tea can be increased, the prepared green tea is bright in color, brewed tea leaves are still green and rich in fragrance, and tea soup has the characteristics of being rich, mellow, fresh and brisk, sweet in aftertaste and the like.

Owner:湖南长健农业发展有限责任公司

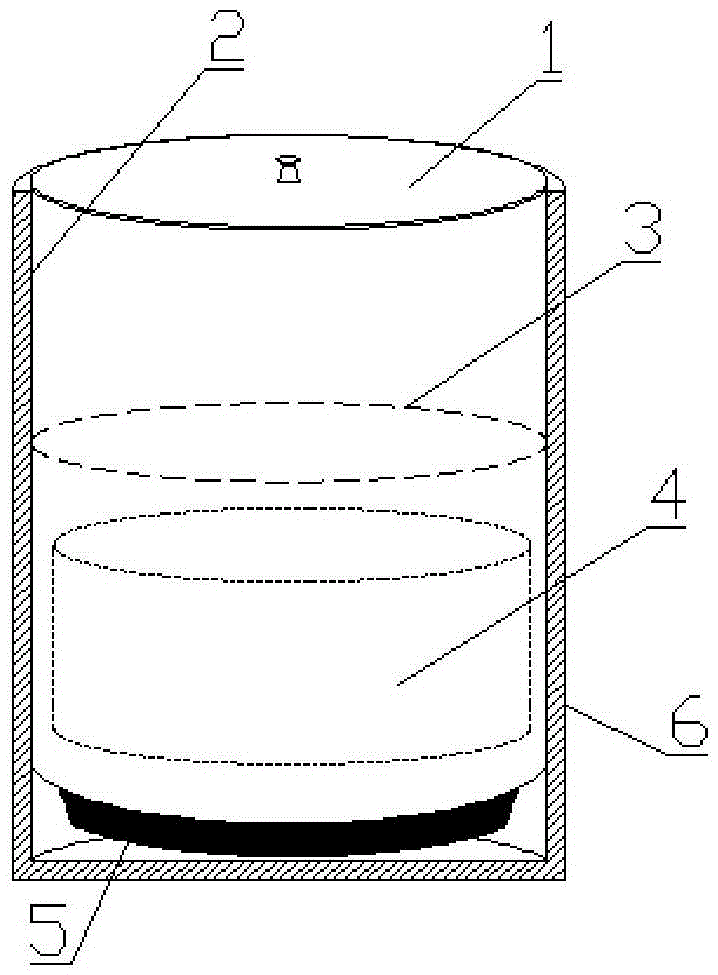

Scale inhibition double-flow-channel loop tube electric heater with electric insulating surface as heating surface

PendingCN109392204AIncrease the heating areaHeating up fastImmersion heating arrangementsSilver pasteElectricity

The invention provides a scale inhibition double-flow-channel loop tube electric heater with an electric insulating surface as a heating surface. The inner surface of a loop tube electric heater framework is coated with a coating for forming an electric heating film, after the electric heating film is formed by sintering, an appropriate position of the electric heating film is coated with a conductive silver paste, a silver electrode is made through an oven, and the electric heater which has at least two tubular heat dissipating surfaces and comprises an electric heating circuit is made. The silver electrode is connected to an electrical conductive wire to make an electric heating core. According to an electrically insulating glass surface and an electrically insulating ceramic surface, the combined force of calcium and magnesium ions to the surfaces is weak, and it is difficult to form hard scale. The silver electrode and the electrical conductive wire passes through a set sealing rubber sleeve which seals an opening end of the loop tube electric heater framework, an electrode closing electrical conductive wire is led out, and a wiring terminal which facilitates electrical connection is welded to the led electrical conductive wire. Since the scale inhibition double-flow-channel loop tube electric heater has the advantages of simple and reliable structure, high safety, low costand easy processing, a water heater is quickly started, the energy is saved, and the water heater is ready to use and has good performance and represents the future development direction of water heater application.

Owner:ZIBO ENVIRONMENTAL PROTECTION TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com