Microcrystal heating element and metal microcrystal heating element

A heating element and microcrystalline technology, applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of poor thermal shock resistance, short life of heat concentration, easy scale formation, etc., and achieve improved corrosion resistance, resistance The effect of excellent corrosion performance and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

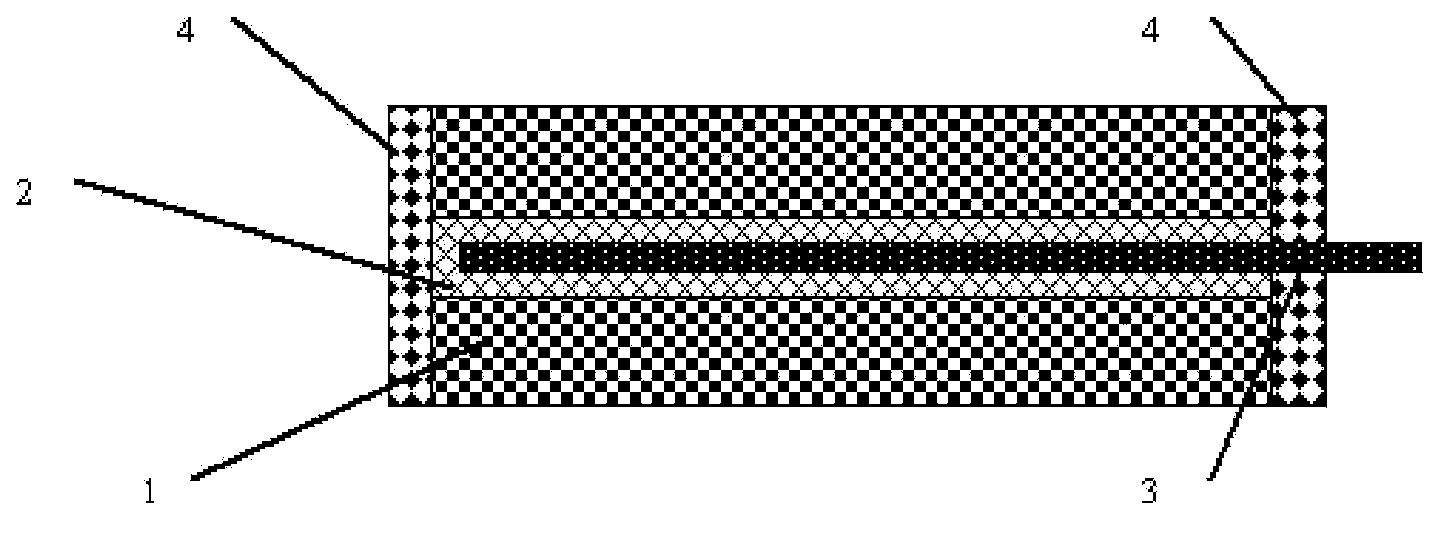

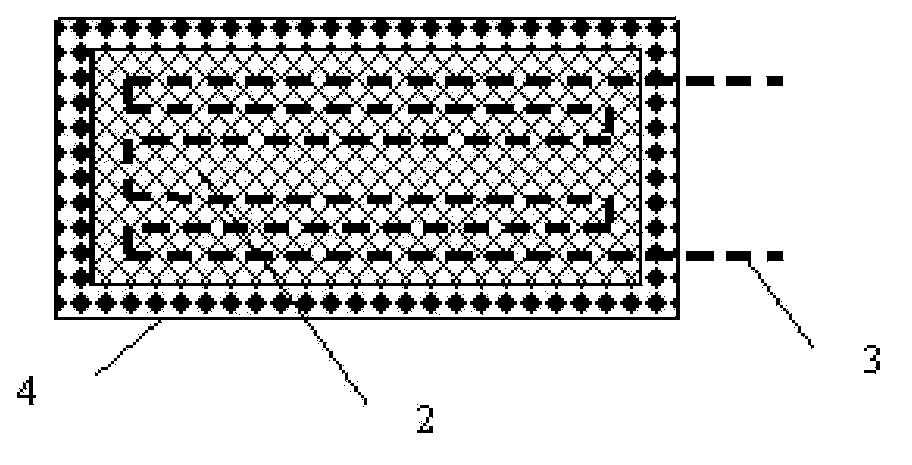

[0061] Embodiment 1, with reference to attached figure 1 , figure 2 .

[0062] This embodiment provides a sheet-shaped microcrystalline heating element, which includes a base layer multi-phase composite ceramic 1 as an insulating and heat-conducting layer, an interface layer multi-phase composite ceramic 2, an electrothermal alloy foil 3 and a frame 4 as an electric heating element.

[0063] The simple production process is as follows: (reference figure 1 , figure 2 )

[0064]Coat the interface layer multiphase composite ceramic slurry 2 on the surface of the electrothermal alloy foil 3 as the electric heating element, and then coat the matrix layer multiphase composite ceramic slurry 1 as the insulating and heat conducting layer or put the matrix layer as the insulating and heat conducting layer The multi-phase composite ceramic green sheet 1, and then paste the multi-phase composite ceramic green sheet 4 as a frame on the outer edge of the stack, and after stacking tog...

Embodiment 2

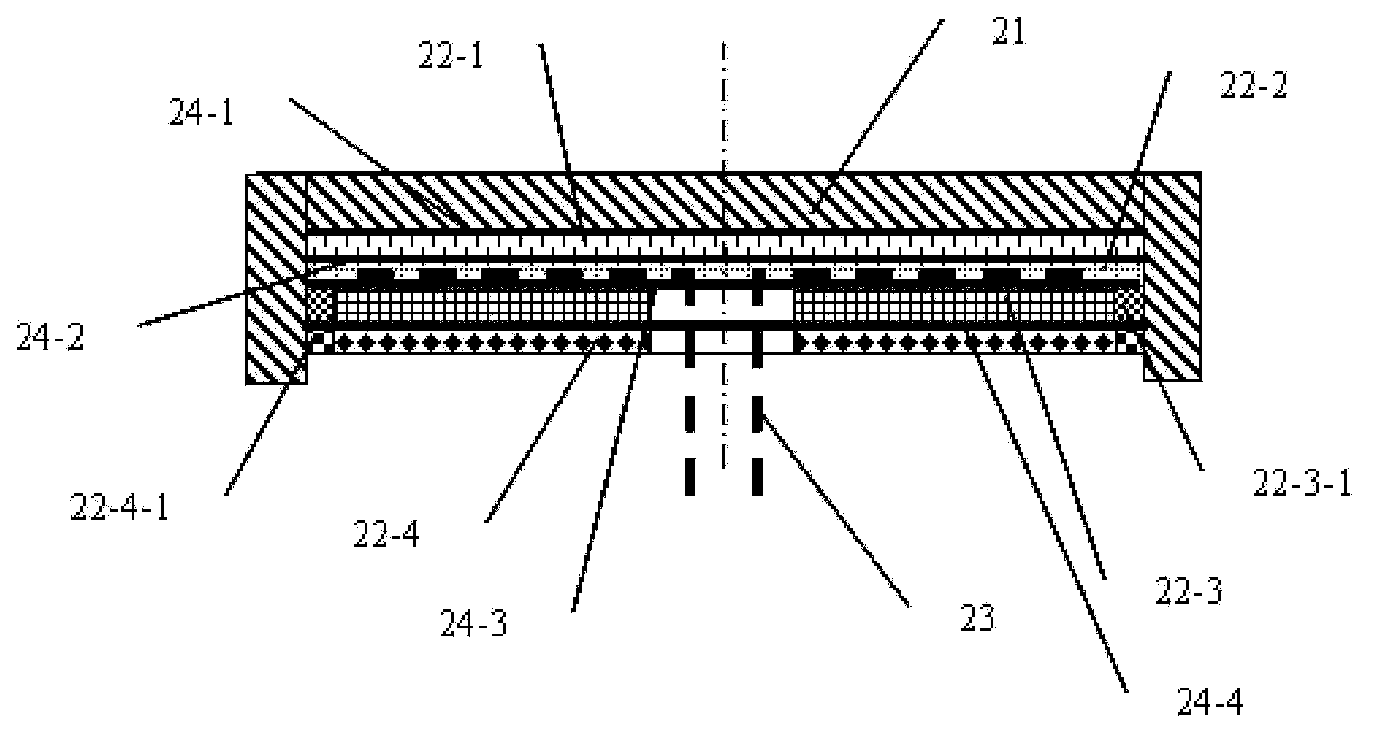

[0071] Embodiment 2, with reference to attached image 3 .

[0072] What this embodiment provides is a disc-shaped metal microcrystalline heating element, which includes a metal shell 21, and sintered on the metal shell 21 are multi-phase composite ceramic insulating and heat-conducting layers 22-1, 22-2, 22-3, 22-4 and 4-layer interfacial layer multi-phase composite ceramic insulation heat conduction layer 24-1, 24-2, 24-3, 24-4 are composed of multi-phase composite ceramics, which are combined into axial layers, so The layered multiphase composite ceramics have frames 22-3-1 and 22-4-1, the frame 22-3-1 is located at the periphery of 22-3, and the frame 22-4-1 is located at the periphery of 22-4. The metal shell 21 has a flanging 21-1, and the flanging 21-1 constitutes the outermost frame, so that it is combined with the frame 22-3-1, 22-4-1 to form a radial direction of the multi-phase composite ceramic insulating and heat-conducting layer. Layered frames, the frames 22-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com