Paperbacked plasterboard drying device with natural gas as heat source and drying process

A technology of plasterboard and drying equipment, which is applied in the direction of surface layering equipment, manufacturing tools, ceramic molding machines, etc., can solve the problems of large environmental pollution and complex production process, and achieve uniform heating surface, low energy consumption, and board materials. neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

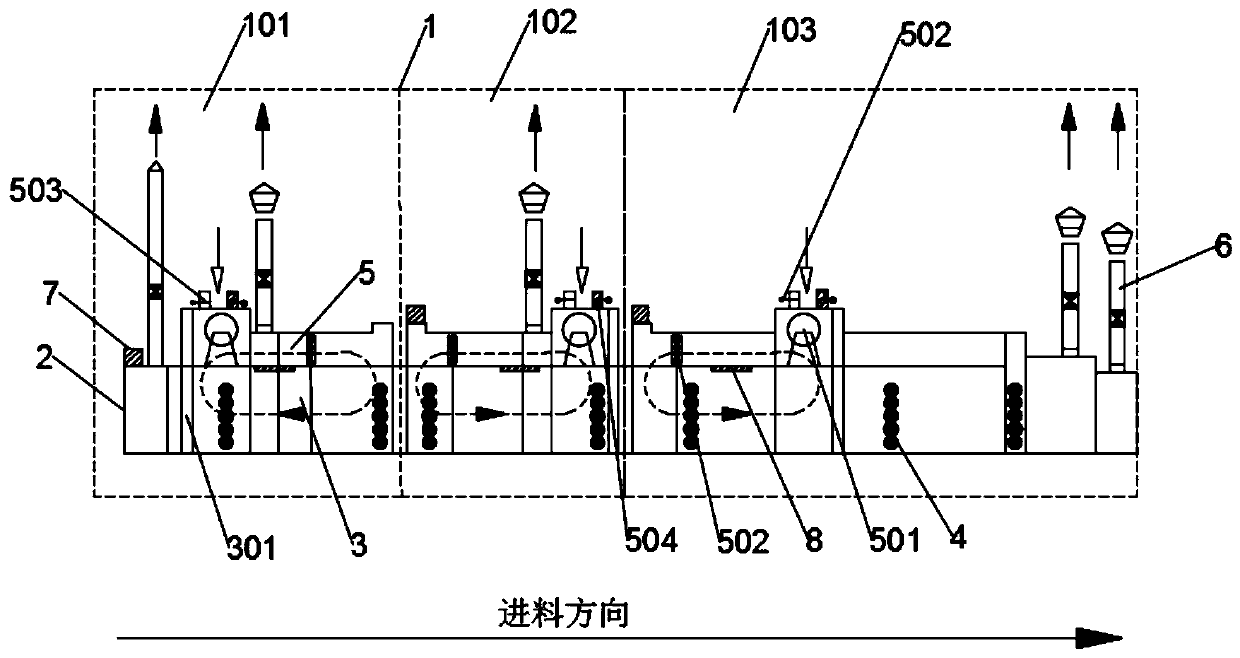

[0030] Such as figure 1 As shown, the present invention provides a gypsum board drying device whose heat source is natural gas, including several drying areas 1 connected in sequence, three drying areas 1 in the embodiment of the present invention. Drying area 1 is equipped with dryer 2, inside of which is equipped with air distribution chamber 3 for air circulation and conveying roller table 4 for conveying plasterboard, and conveying roller table 4 passes through different drying areas 1 in sequence The air distribution chamber 3, and the paper-faced gypsum board is dried by the hot air in the air distribution chamber 3. The air distribution chamber 3 is provided with an air distribution gate 301 for distributing heat to the roller table space. The air distribution chamber 3 is connected with a combustion chamber 5 , and a circulation fan 501 is arranged in the combustion chamber 5 , and the circulation fan 501 is used to realize the circulating flow of hot gas in the air d...

Embodiment 2

[0036] A kind of heat source is the drying process of the gypsum board of natural gas, it is characterized in that: comprise the steps:

[0037] S100, upper roller: place the gypsum board to be dried in layers on the conveying roller table 4 in the dryer 2;

[0038] S200, sequential drying: use the heat generated by natural gas combustion to heat the gypsum board on the conveying roller table 4 during operation, and the gypsum board passes through the first drying zone 101, the second drying zone 102 and the third drying zone 103 in sequence Carry out drying in different directions and at different temperatures; in this embodiment, the running speed of the conveying roller table 4 is controlled at 70-90 m / min. The temperature of the first drying zone 101 is controlled to be 170-220°C, the temperature of the second drying zone 102 is controlled to be 180-225°C, the temperature of the third drying zone 103 is controlled to be 90-125°C, and the chimneys in each zone of the dryer 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com