Patents

Literature

66results about How to "Improve forming rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing process of screw pipe bending machine

The invention relates to a processing process of a screw pipe bending machine, which is used for bending hollow steel pipes. The processing process comprises the following steps of: (1) filling a real object into a hollow steel pipe, sealing both ends of the steel pipe and bending the steel pipe; (2) receding a counter shaft through a driving and reversing mechanism, mounting one end of the steel pipe in a mounting groove of the counter shaft, aligning a bending part to the end part of the counter shaft, and buckling the other end of the steel pipe into a first tooth of a thread groove; (3) forwards impelling the counter shaft through the driving and reversing mechanism until the counter shaft is engaged with a spindle; (4) starting a motor to drive the spindle to rotate and bending and molding the steel pipe along the thread groove of the spindle; (5) receding the counter shaft, taking out the counter shaft through manpower, taking out a processed and molded product and pouring out the real object in the steel pipe; and (6) mounting the counter shaft on an engine base to renewedly produce a next workpiece. The processing process does not need too much manpower so as to reduce the production cost, improve the efficiency and have stable quality.

Owner:王吉光

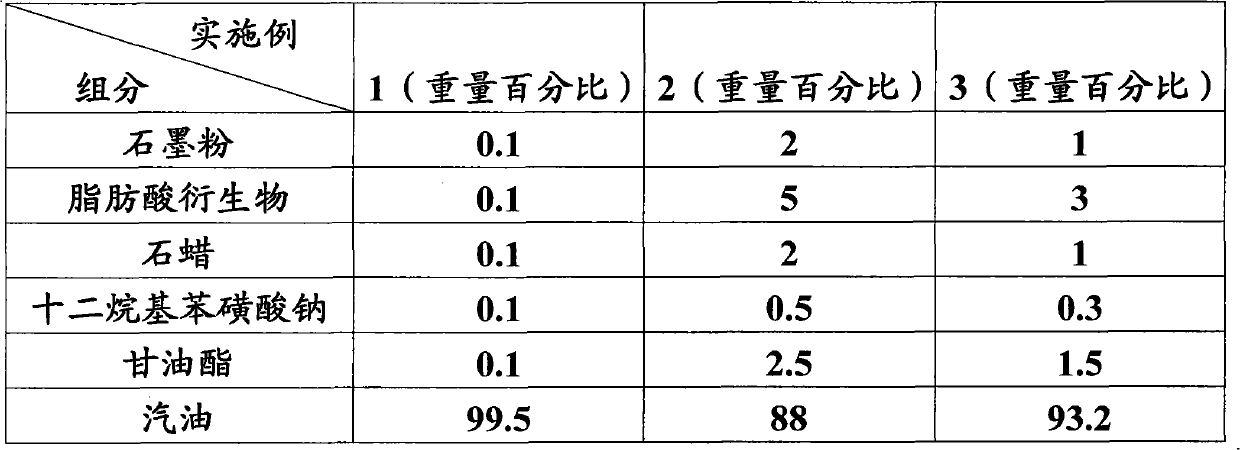

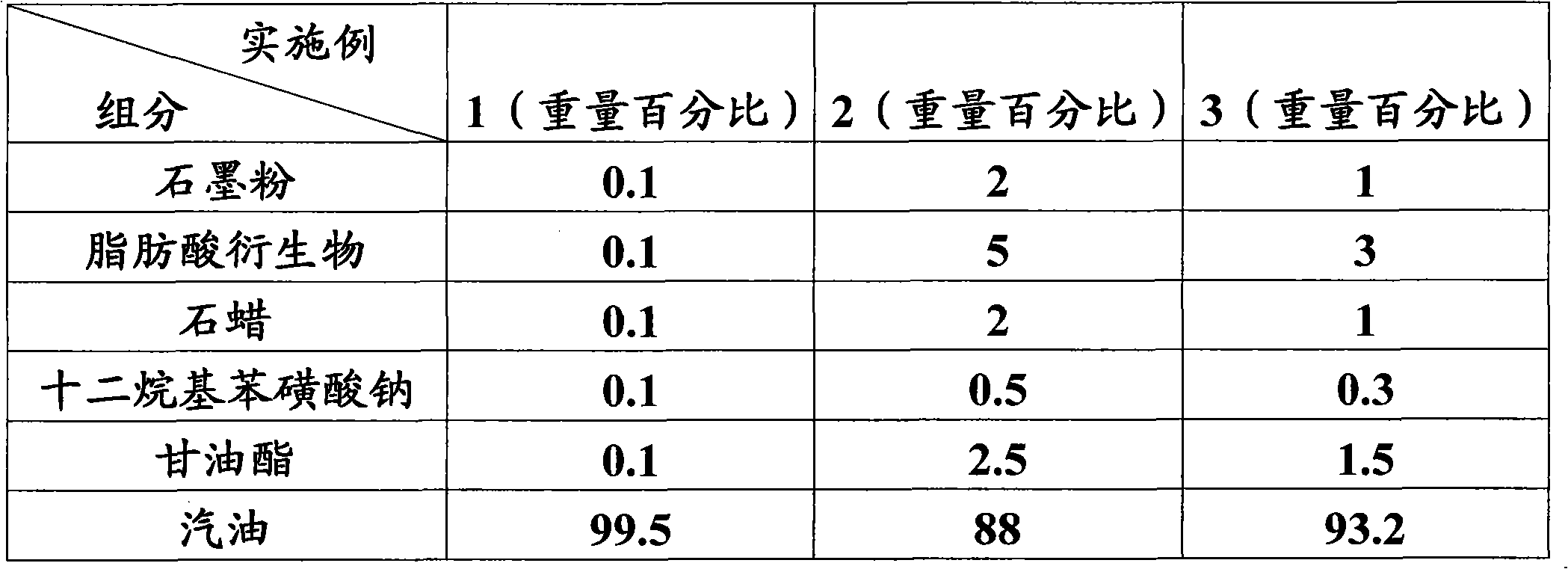

Releasing agent and preparation method thereof

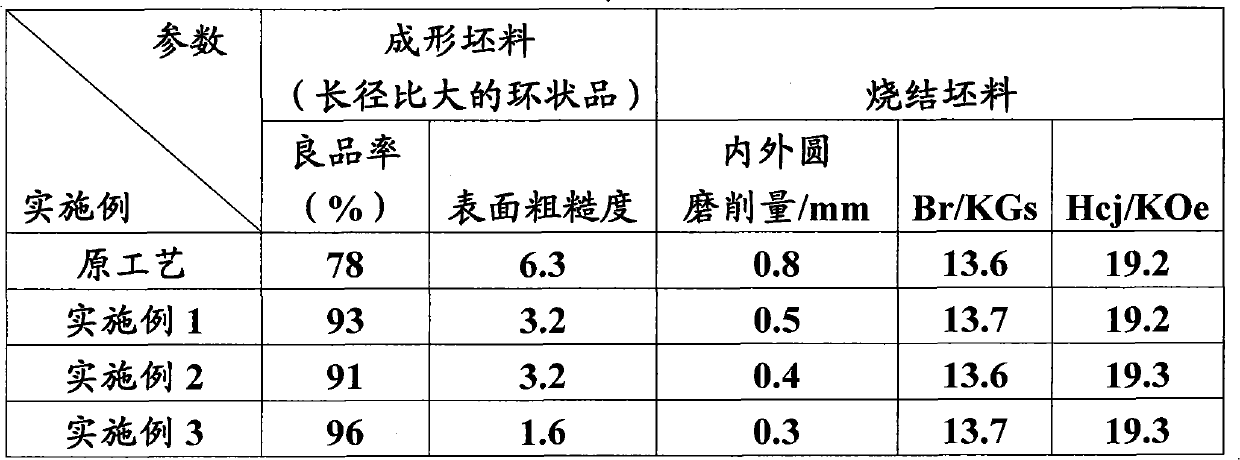

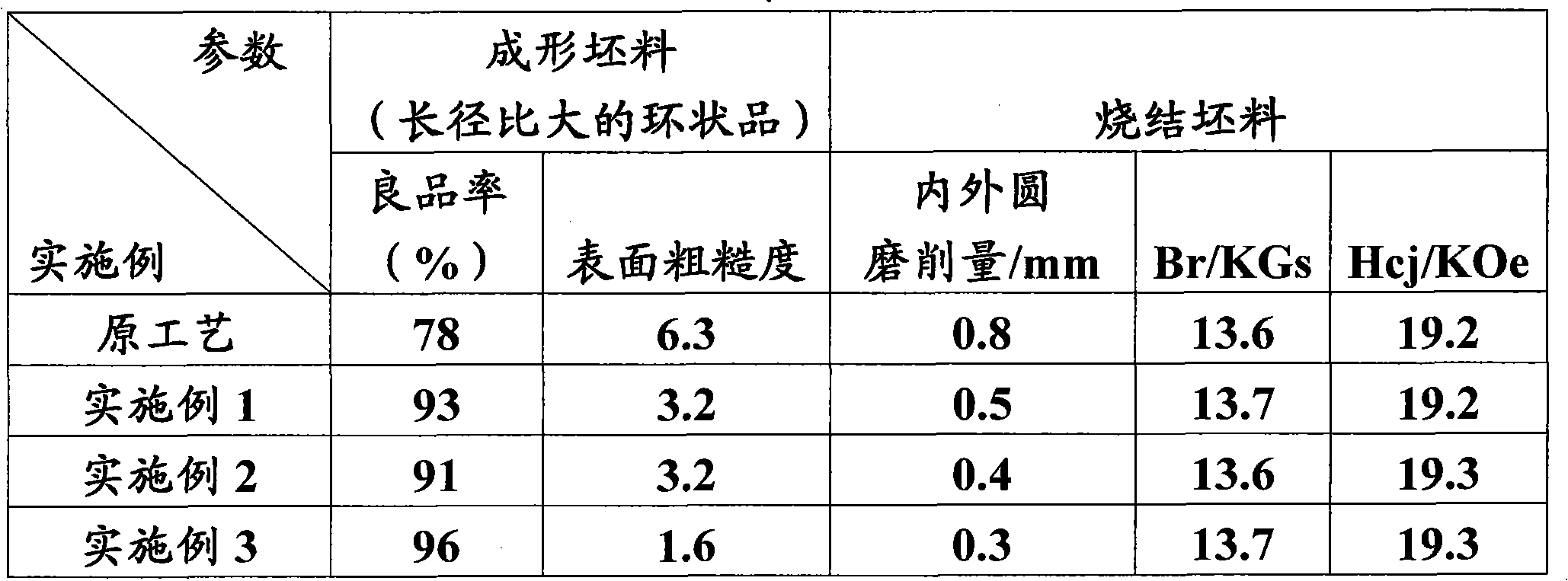

ActiveCN102085563AImprove surface qualityReduce surface roughnessFoundry mouldsFoundry coresChemistryLongest Diameter

The invention provides a releasing agent used in a process of forming a magnetic material, which comprises the following components: 0.1-2 percent by weight of graphite powder, 0.1-5 percent by weight of fatty acid derivative, 0.1-2 percent by weight of paraffin, 0.1-0.5 percent by weight of sodium dodecyl benzene sulfonate, 0.1-2.5 percent by weight of glyceride and 88-99.5 percent by weight of gasoline mixture. The invention also discloses a preparation method of the releasing agent. According to the releasing agent provided by the invention, the problem of adhesion in the process of forming the magnetic material is solved, and the surface quality of a permanent magnet material casting is improved, especially the annular permanent magnet material product with large long diameter ration; and by using the releasing agent, the surface roughness of the permanent magnet material blank product is reduced, and the forming qualified rate of products is improved.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Method for cultivating freshwater nucleated pearls

ActiveCN103636533AImprove forming rateIncrease valueClimate change adaptationPisciculture and aquariaFresh water organismSeawater

The invention relates to a method for cultivating freshwater nucleated pearls. The method includes the following steps of (1) selecting pearl nucleuses, perforating and sterilizing the pearl nucleuses, (2) selecting seawater seashells, taking mantles of the seawater seashells, sterilizing and purifying the mantles, and slicing the mantles, (3) fixing the pearl nucleuses to pieces for care, (4) inserting composites of the pearl nucleuses and the pieces into visceral mass of mussels, and (5) placing the mussels implanted with the pieces in a clean-water reservoir for rest, and transferring the mussels to a freshwater aquaculture area after a few days until the freshwater nucleated pearls are cultivated. According to the method, the seawater seashells and the mussels are combined to culture high-quality pearls, specifically, the freshwater nucleated pearls are cultivated through the mantle pieces of the seashells, the nucleus insertion method enables the mantle pieces to be attached to the pearl nucleuses, the forming rate of the high-quality pearls is improved, the obtained freshwater nucleated pearls have features of seawater seashell pearls, and value of existing freshwater pearls is remarkably improved.

Owner:BEIHAI XIUPAI JEWELRY

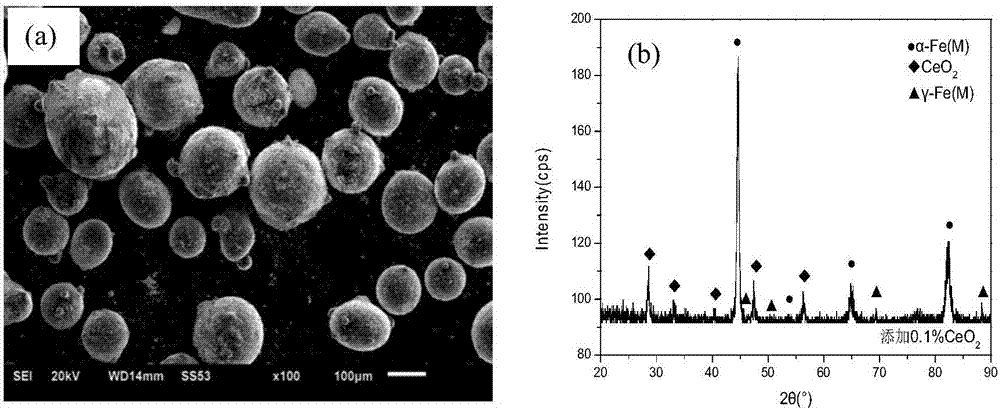

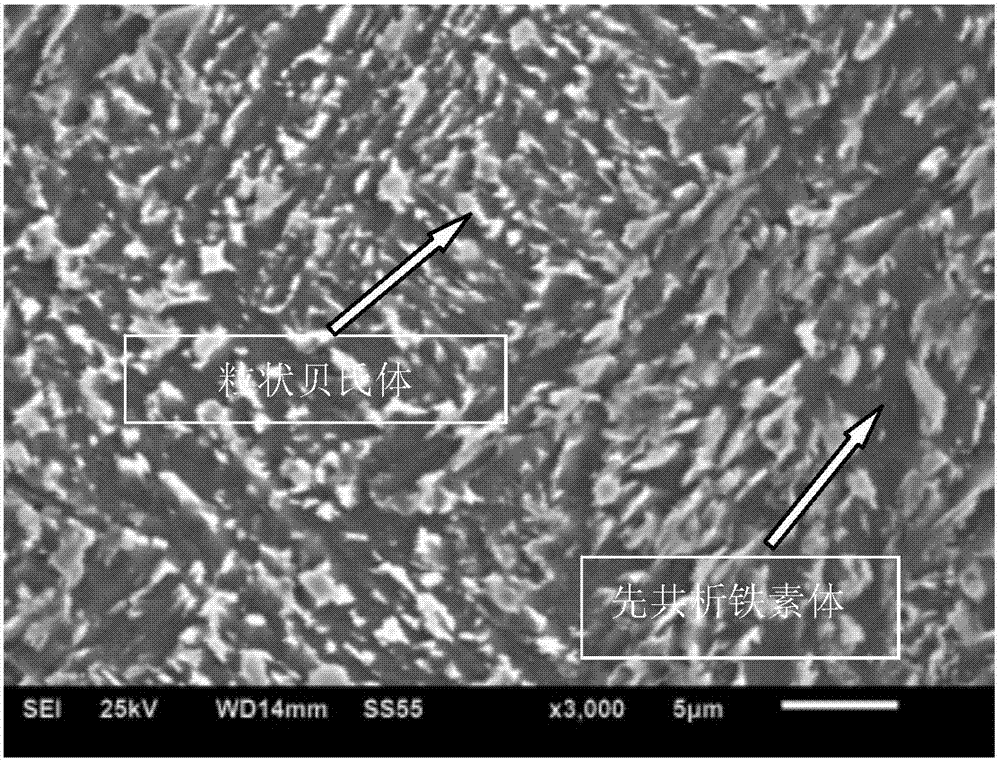

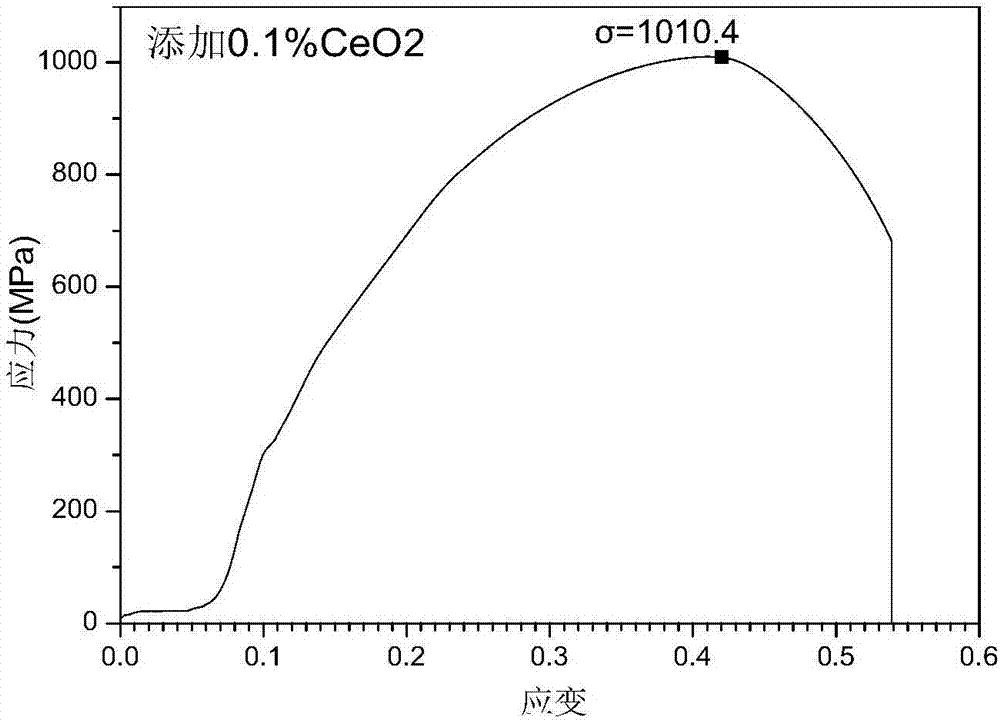

Method for preparing toughened 24 CrNiMo alloy steel through selective laser melting technology

ActiveCN107498054AImprove toughnessImprove mechanical propertiesAdditive manufacturing apparatusBraking discsMelting tankSelective laser melting

The invention relates to a method for preparing toughened 24 CrNiMo alloy steel through a selective laser melting technology. The method is characterized in that 24CrNiMo / CeO2 composite powder with a determined mass ratio and a uniform phase is prepared through mechanical ball-milling; and an alloy steel component is quickly formed layer by layer according to a predetermined selective laser melting path and process parameters. Through actions of refining crystalline grains, purifying a molten pool and the like in the laser molten pool through CeO2, samples which have small structures and are free of obvious defects such as cracks and pores are formed; and a selective laser melting process with large power, a great powder paving thickness and lower scanning speed is adopted, so that the forming rate is increased. A 24CrNiMo alloy steel component has room-temperature tensile strength of 10000 MPa level, and has ductility of 20-26%, so that strength and toughness of 24 CrNiMo alloy steel prepared by the selective laser melting technology are improved. The method is mainly applied to laser additive manufacturing of a 24 CrNiMo alloy steel high-speed railway brake disc.

Owner:NORTHEASTERN UNIV

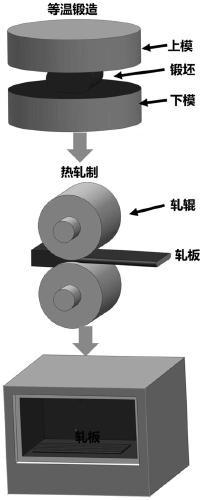

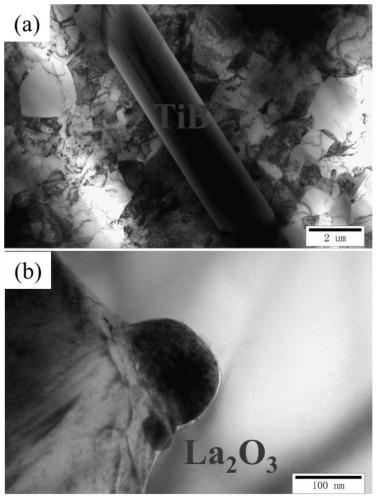

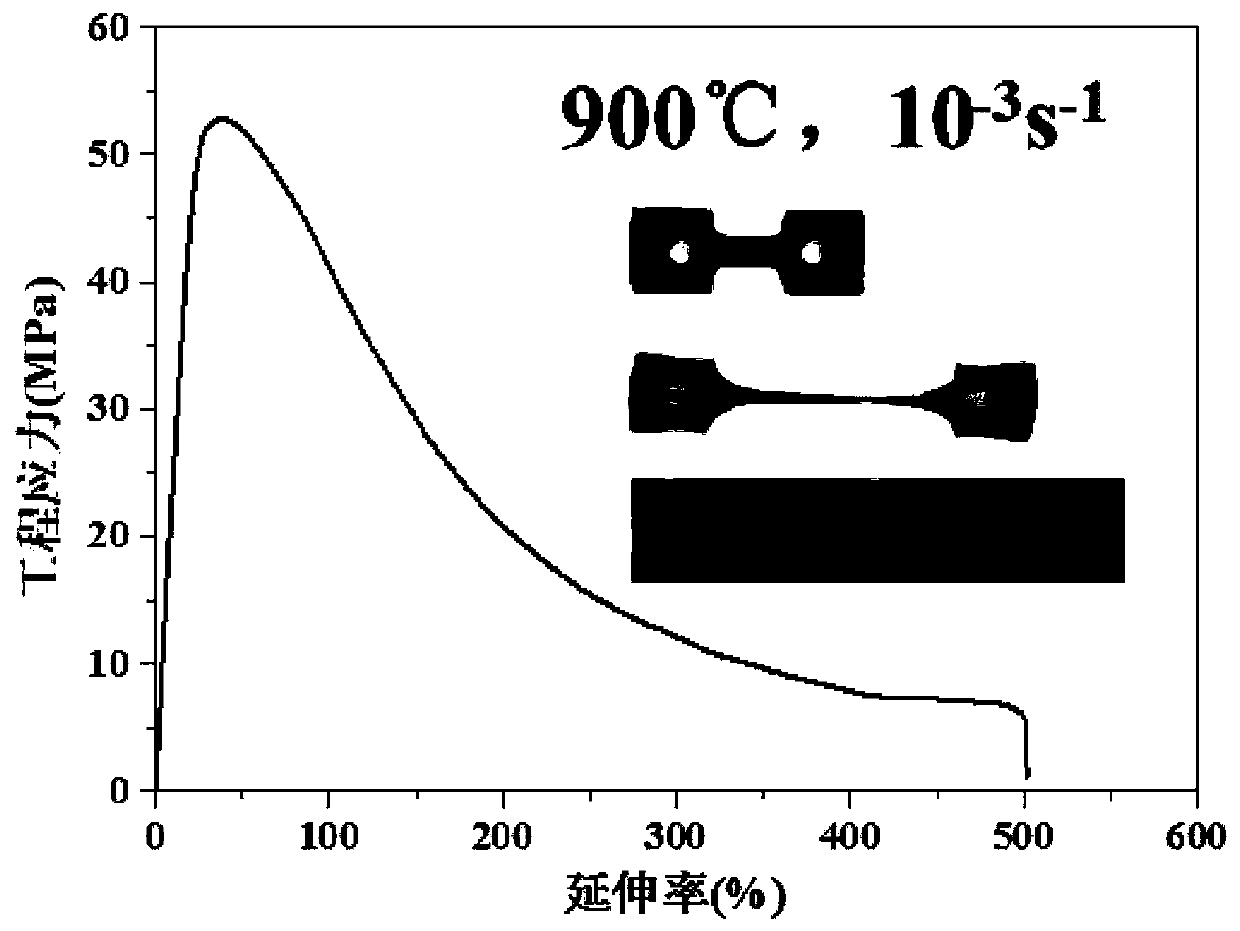

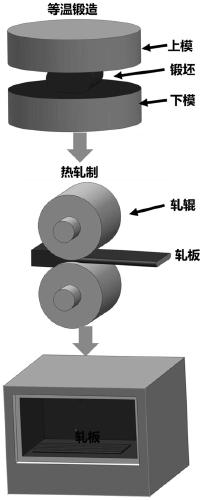

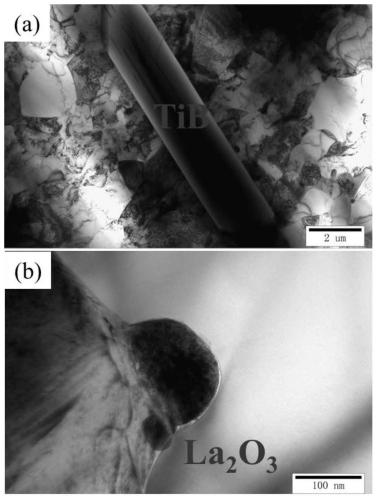

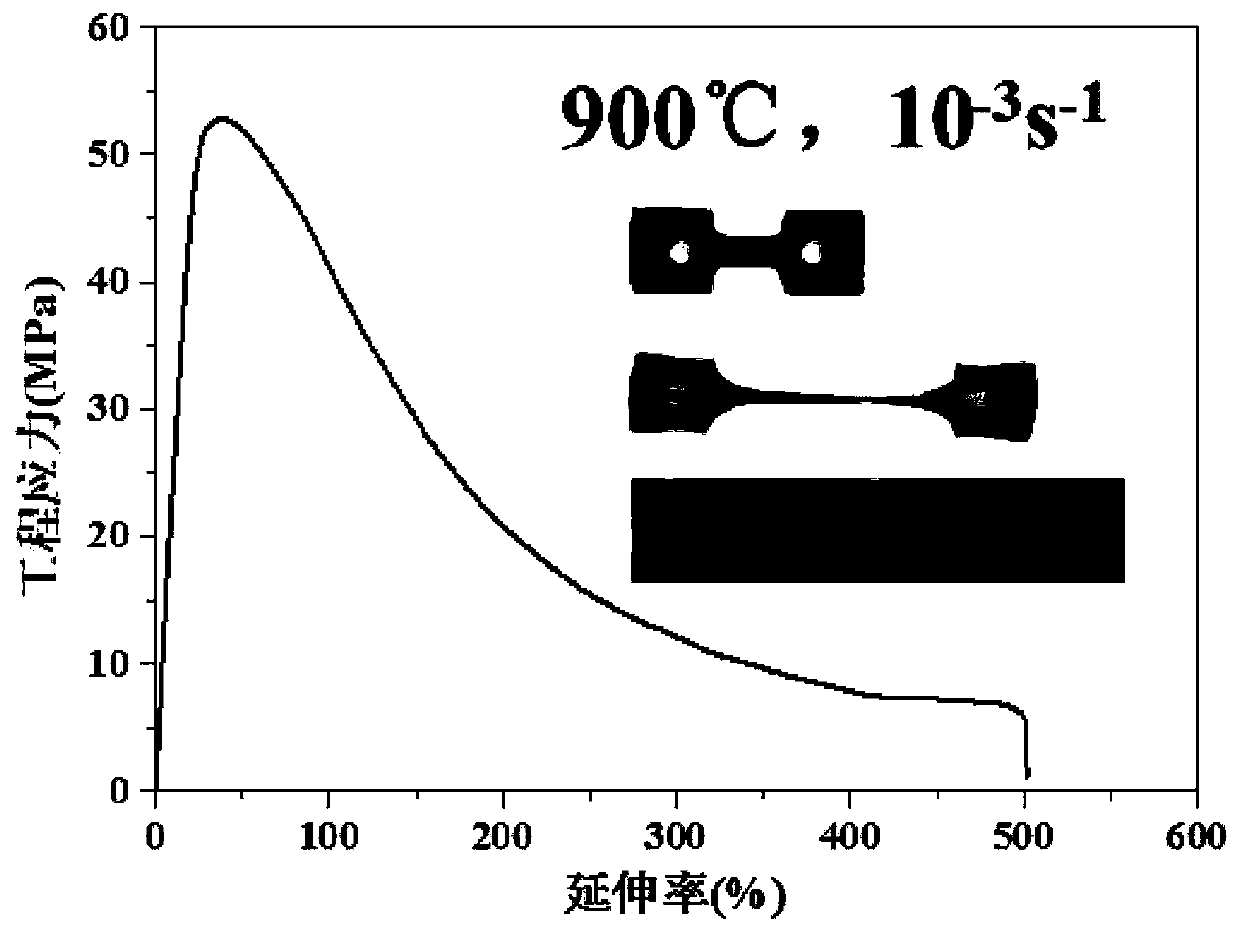

Isothermal superplastic deformation method for micro/nano particulate reinforced titanium matrix composite

The invention discloses an isothermal superplastic deformation method for a micro / nano particulate reinforced titanium matrix composite. The method comprises the following steps of A, preparing a titanium boride and rare earth oxide micro / nano particulate hybrid reinforced titanium matrix composite by utilizing an in-situ synthesis technique, and performing vacuum consumable electrode arc melting on the composite for more than two times; B, performing cogging forging on the composite in a Beta single-phase region, wherein deformation amount is greater than or equal to 50 %; performing isothermal forging on the composite in an (Alpha + Beta) two-phase region to obtain a titanium matrix composite forging blank, wherein deformation amount is greater than or equal to 60 %; and C, performing hot rolling on the titanium matrix composite forging blank in a near Beta phase region, wherein deformation amount is greater than or equal to 80 %, and performing annealing treatment to obtain the micro / nano particulate reinforced titanium matrix composite. The micro / nano particulate reinforced titanium matrix composite is formed by the isothermal forging technology and hot rolling, and thus, the matrix structure can be effectively refined, and the material forming rate is increased; and a plate has good superplasticity within the deformation process range of 800-1000 DEG C and 5 x 10<-3>-10<-4>s<-1>.

Owner:上海交通大学包头材料研究院 +1

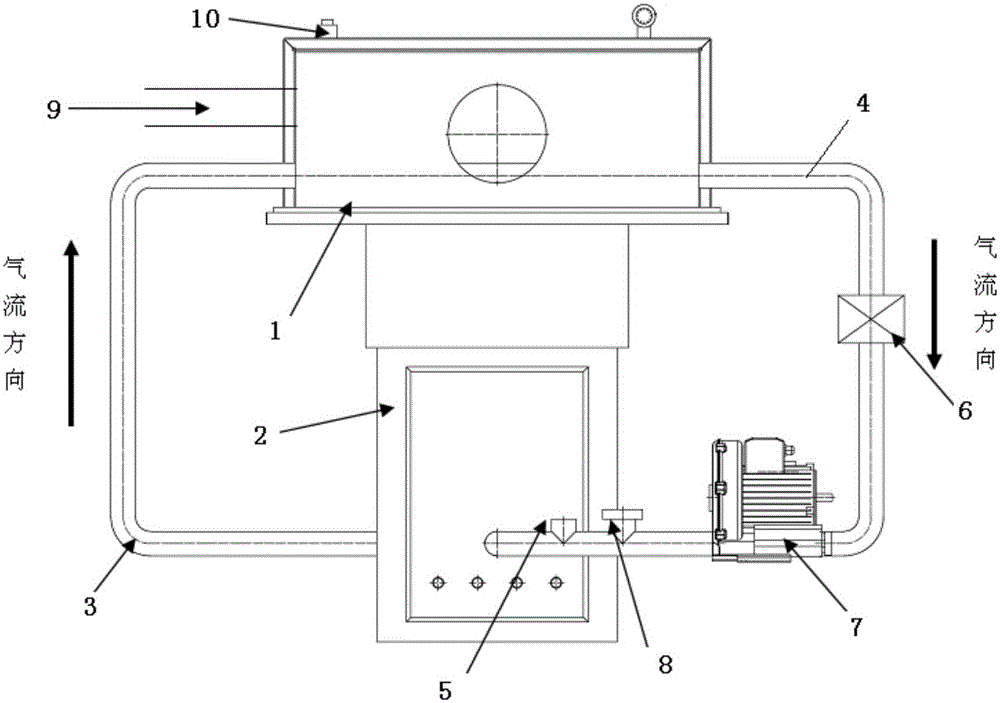

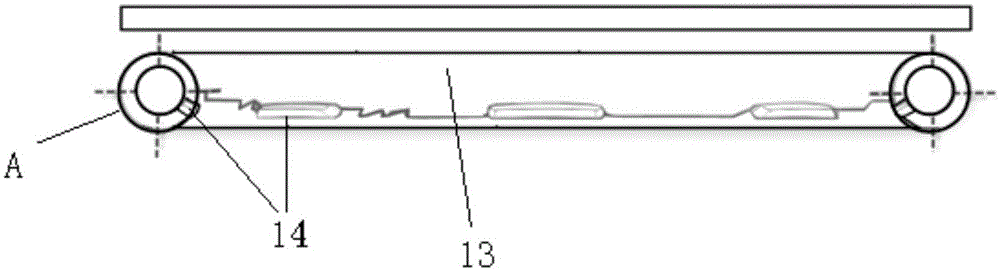

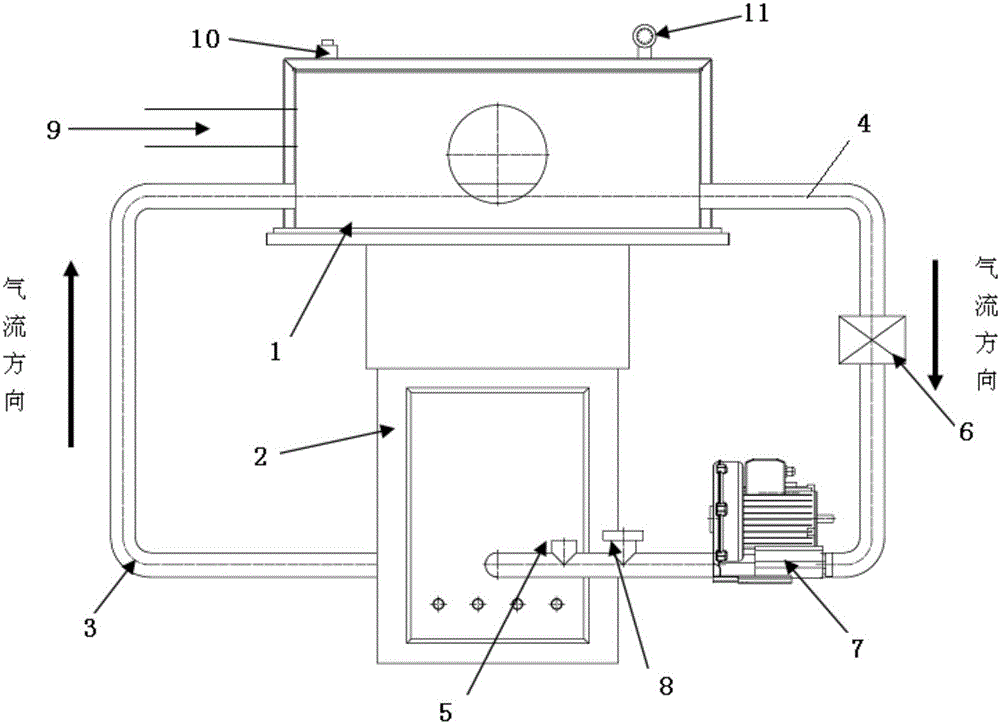

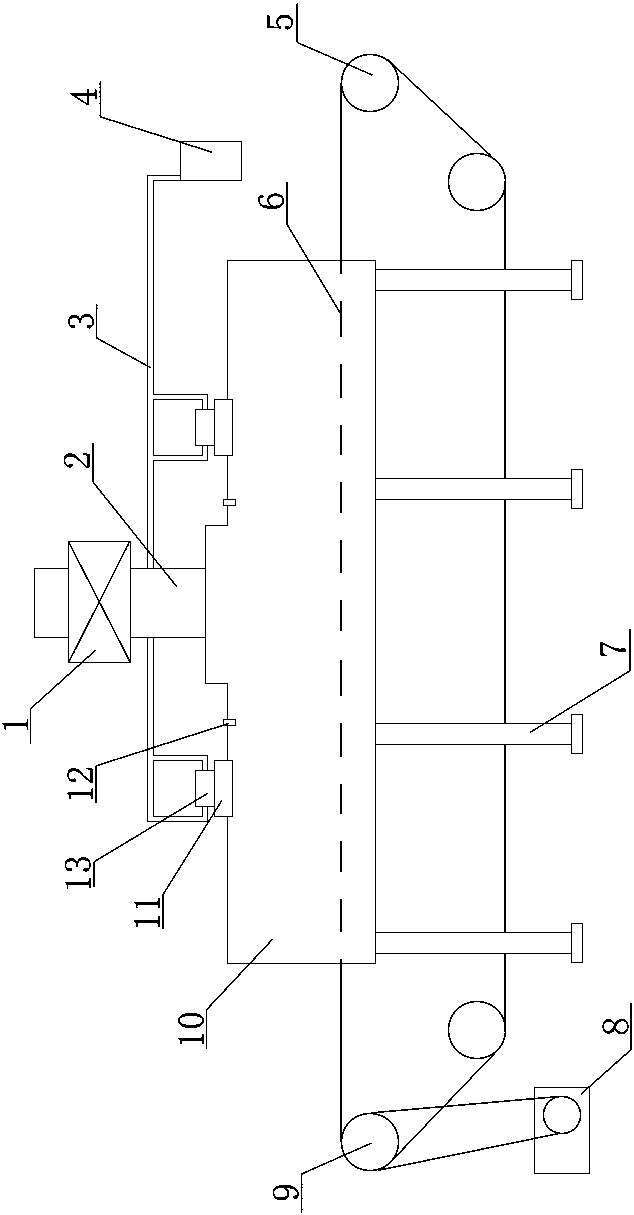

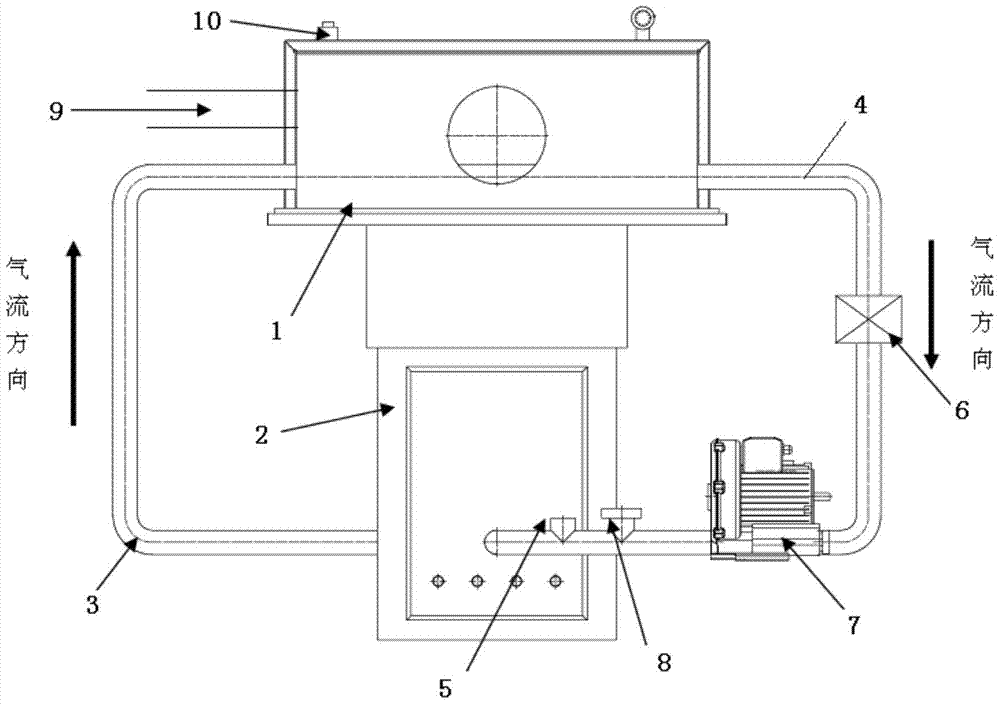

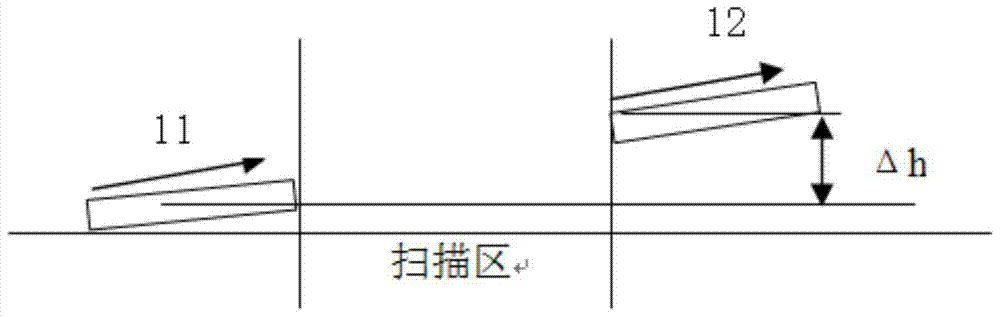

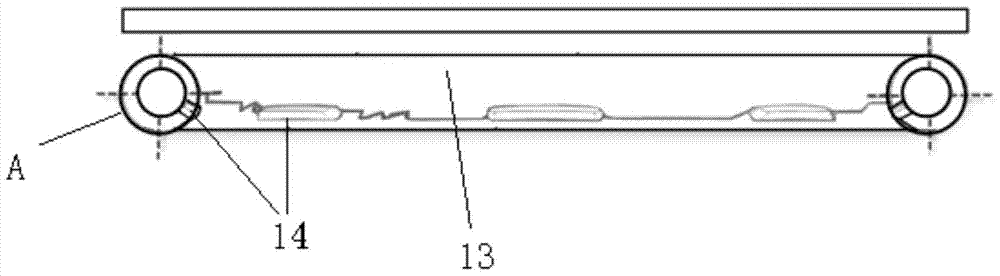

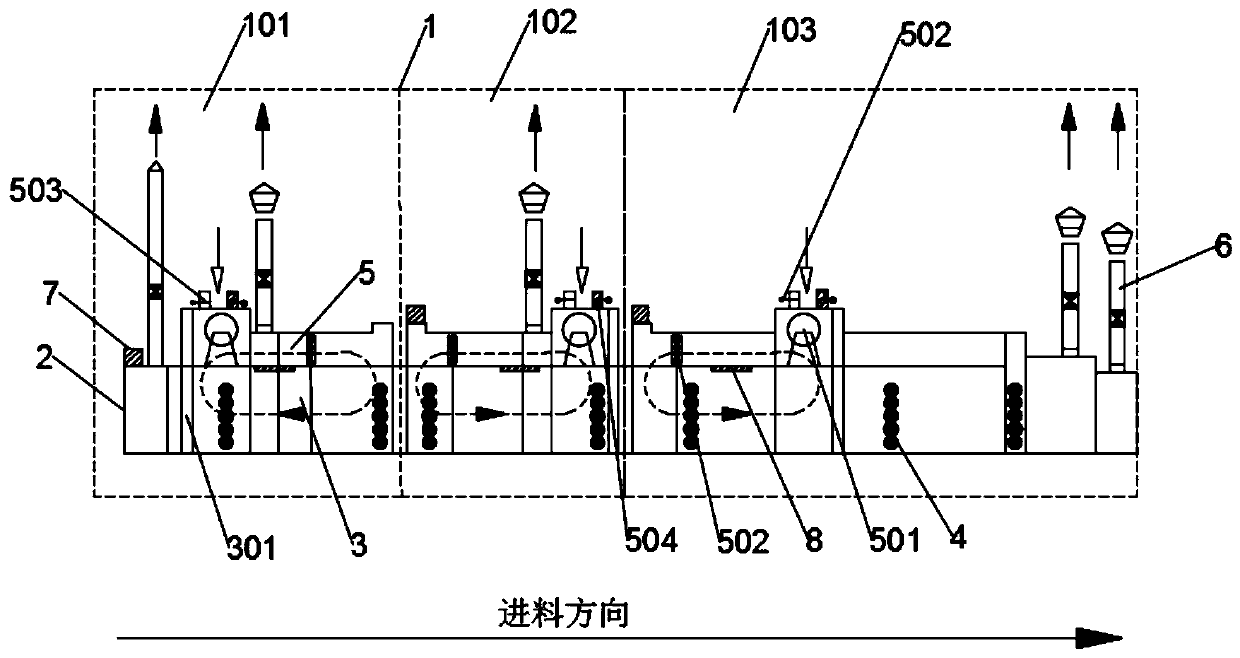

Laser melting forming dust-removing system with multifunctional circulating air flow and dust-removing method

ActiveCN105642891APrevent influence of forming qualityImprove forming rateAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringMetal powder

The invention provides a laser melting forming dust-removing system with multifunctional circulating air flow and a dust-removing method. The dust-removing system comprises an upper cavity and a lower cavity. Three induced air ways are led out of an air inlet of the upper cavity and are the first induced air way, the second induced air way and the third induced air way. The first induced air way communicates with a dust-removing subsystem in a scanning area. The second induced air way communicates with a dust-removing subsystem of a laser protection mirror. The third induced air way communicates with a dust-removing subsystem of a movement sliding table cavity. The laser melting forming dust-removing system with multifunctional circulating air flow and the dust-removing method have the beneficial effects that in the whole laser melting forming process, smoke-shaped dust generated when lasers act on metal powder can be absorbed into a dust filter in time under the effect of a draught fan, dust generated by part forming is filtered out in time through the dust filter, the influences, on the subsequent forming quality, of the smoke-shaped dust are prevented, and the forming rate is increased; and in addition, the dust is prevented from rising to the position near the laser protection mirror located over the scanning area, and the dust is prevented from entering a sliding table guide rail in the sliding table cavity.

Owner:HARBIN FORWEDO MULTI DIMENSIONAL INTELLIGENT EQUIP CO LTD

Laser melting forming protection circulating dust-removing system and method

ActiveCN105643105ATimely inhalationImprove melt forming rateLaser beam welding apparatusShielding gasCarbon Dioxide / Helium

The invention provides a laser melting forming protection circulating dust-removing system and method. The system comprises an upper cavity and a lower cavity. An exhaust opening of the lower cavity communicates with an air inlet of the upper cavity. An exhaust opening of the upper cavity communicates with an air inlet of the lower cavity. The end of a second gas conveying pipeline extends in a cavity body of the lower cavity. A second electromagnetic valve is installed at the position, located in the cavity body of the lower cavity, of the second gas conveying pipeline. The part, outside the cavity body of the lower cavity, of the second gas conveying pipeline is sequentially connected with a dust filter, a draught fan and a first electromagnetic valve in series. In addition, the upper cavity communicates with a shield gas pipeline which is provided with a third electromagnetic valve. The laser melting forming protection circulating dust-removing system and method have the beneficial effects that firstly, the content of oxygen in a forming cavity can be controlled to be low in real time, and therefore the phenomenon that melt is instantly oxidized can be avoided, and the laser melting forming rate is increased; and secondly, smoke-shaped dust generated when lasers act on metal powder can be absorbed into the dust filter in time, the influences, on the subsequent forming quality, of the smoke-shaped dust are prevented, and the forming rate is increased.

Owner:HARBIN FORWEDO MULTI DIMENSIONAL INTELLIGENT EQUIP CO LTD

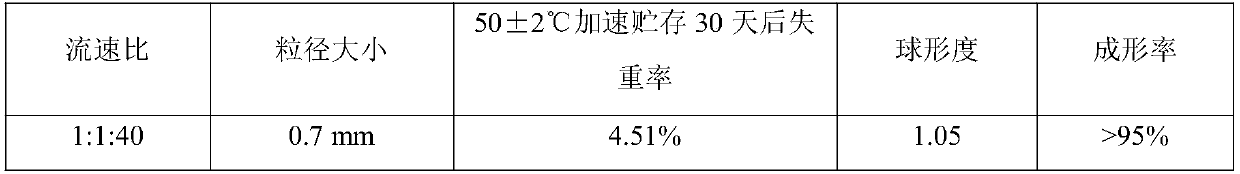

Millimetre micro-capsules and preparation method thereof

ActiveCN110302727AAchieving controllable equipmentImprove forming rateEssential-oils/perfumesPharmaceutical non-active ingredientsRoom temperatureMillimeter

The invention discloses millimetre micro-capsules and a preparation method thereof, and belongs to the technical field of micro-capsule preparation. Continuous production is realized by combining a microfluidic technology and a UV photocuring technology, the particle size and the wall thickness of micro-capsules are realized through the design of a microfluidic pipeline, and the mechanical properties of the micro-capsules are realized through the blending of a resin system or the regulation and control of the wall thickness. The micro-capsules have a scale of 1-8mm, can be rapidly and continuously prepared, can wrap any aqueous solution, can realize controllable preparation of aqueous phase micro-capsules, and the moisture volatilization amount of the micro-capsules is not more than 15% after being stored at room temperature (25 degrees) for half a year.

Owner:JIANGNAN UNIV

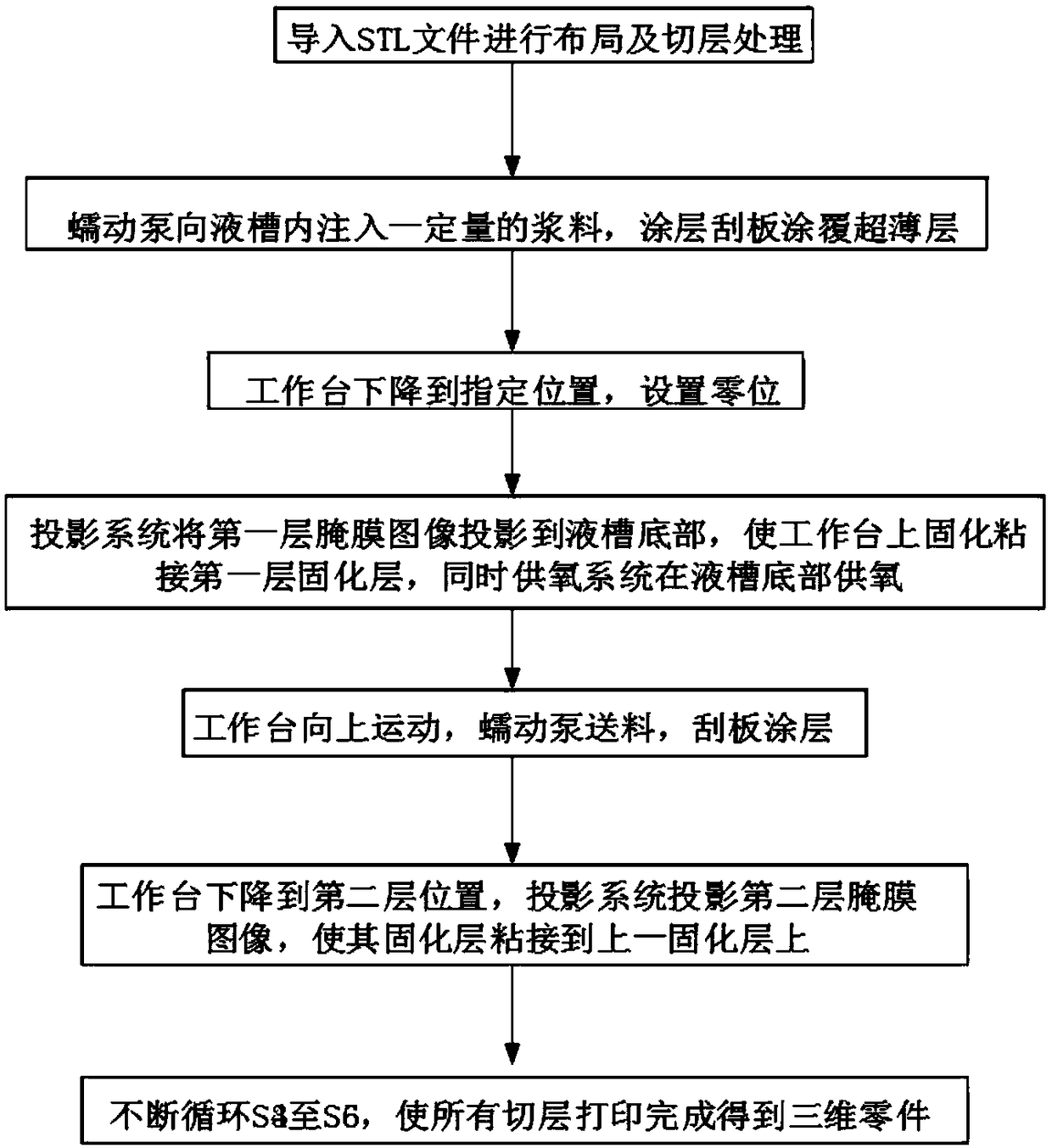

Ceramic photo-curing 3D printing system and method

InactiveCN108724430AGuaranteed reliabilityPrevent precipitationAdditive manufacturing apparatusCeramic shaping apparatusRotary stageCamera lens

The invention discloses a ceramic photo-curing 3D printing system and method. The printing system is characterized in that a liquid tank is located on a transparent bottom plate, an elastic separationmembrane is positioned between the transparent bottom plate and the liquid tank, and a working table is located right above the liquid tank; and a DLP projection system comprises a DLP projection mechanism, a fixing frame, a projection lens, a rotating table and a lens converter, wherein the projection lens is located right below the transparent bottom plate, the DLP projection mechanism is fixedon the fixing frame, light emitted by the DLP projection mechanism passes through the projection lens, the transparent bottom plate and the elastic separation membrane and then is irradiated onto light-cured slurry in the liquid tank, the lens converter is fixed on the rotating table, moreover, a fixing plate is arranged on the lens converter, a mounting hole is formed in the fixing plate, and the projection lens is located in the mounting hole. According to the ceramic photo-curing 3D printing system and method, projection equipment with different resolutions and the projection lenses with different resolutions can be relatively conveniently replaced, moreover, the precision of part forming is high, and the quality of the part surface is good.

Owner:XI AN JIAOTONG UNIV

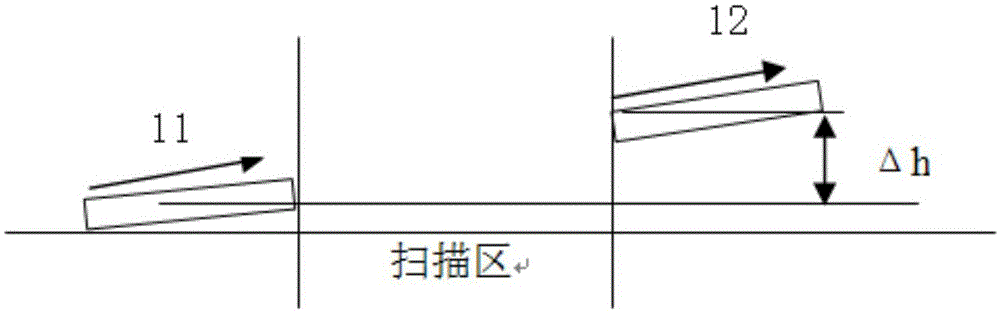

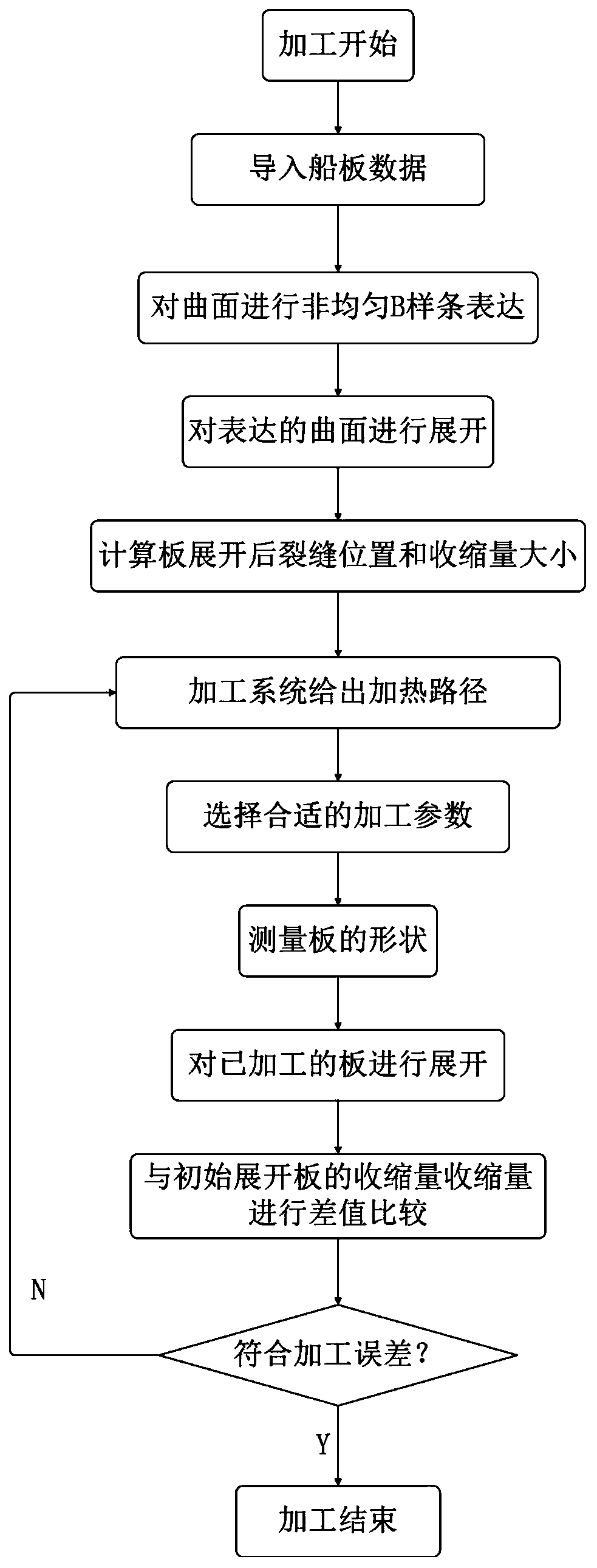

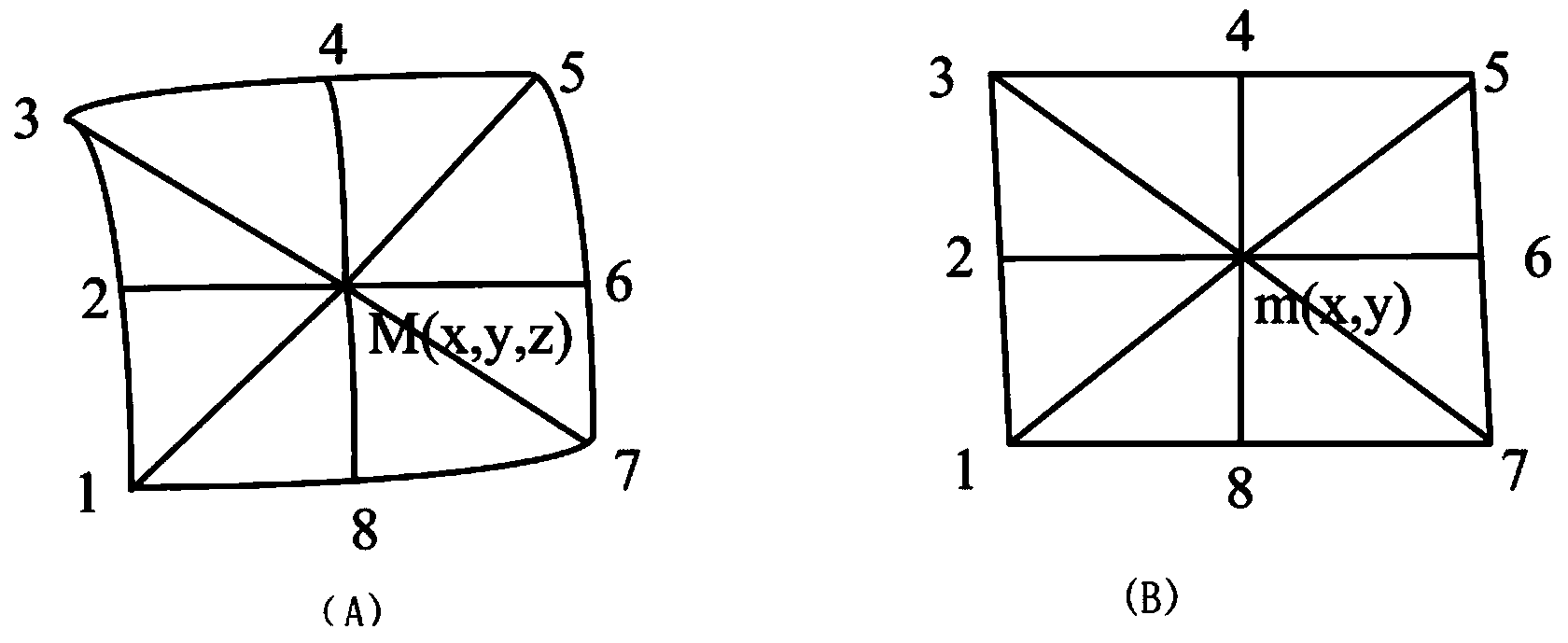

Line heating automatic forming method based on curve surface unfolding

InactiveCN104239621ARealize automatic processingImprove working conditionsSpecial data processing applicationsVisual technologyEngineering

The invention discloses a line heating automatic forming method based on curve surface unfolding. The method comprises the following steps that on the basis of the existing boat plate Tribon data, a curve surface unfolding method is adopted for calculating the path arrangement of a heating line; then, proper processing technical parameters are selected from a line heating expert system for forming processing. After the primary processing forming, the formed curve surface is subjected to measurement and fitting by using a computer visual technology and is inputted into a processing system, then, a boat plate is unfolded, the unfolding surface is compared with the unfolding surface required in the design drawing in shrinkage amount, and if the comparison result does not reach the forming quantity requirement and is beyond the error range, the processing system carries out parameter selection again; if the boat plate unfolding quantity comparison error is within the required range, the forming reaches the requirement. The method provided by the invention has the advantages that the line heating automatic forming is realized, and the forming rate and the production efficiency of the boat plate are improved.

Owner:JIANGSU UNIV OF SCI & TECH

Feed for freshwater fish fries bred in circulating water and preparation method and use method thereof

InactiveCN107874028AImprove survival rateEasy to manageClimate change adaptationAnimal feeding stuffYolkFish oil

The invention relates to feed for freshwater fish fries bred in circulating water and a preparation method and a use method thereof and belongs to the technical field of fish feed. The feed provided by the invention comprises the following raw materials in parts by weight: 2-3.5 parts of spirulina powder, 3-6 parts of schizochytrium microalga powder, 15-18 parts of sardine meal, 5-8 parts of mackerel meal, 6-9 parts of yolk powder, 8-11 parts of whole milk powder, 20-23 parts of soybean meal, 2-5 parts of chicken intestine powder, 0.5-2 parts of refined fish oil, 0.5-2 parts of soybean oil, 2.7-4.6 parts of corn flour, 14-16 parts of alpha-starch, 1.5-3 parts of calcium dihydrogen phosphate, 0.5-2 parts of a vitamin premix, 1.5-3 parts of a trace element premix, 0.2-0.4 part of a special microecological preparation and 0.4-0.7 part of a functional preparation. The special compound feed provided by the invention is capable of effectively enhancing the immunity of freshwater fish fries bred in circulating water, improves the survival rate of the freshwater fish fries, is likely to form well-shaped excrement, is favorable for breeding management in a circulating water system, ensuresthe nutritional requirements of the freshwater fish fries, in a growth period, bred in circulating water and promotes healthy growth of the freshwater fish fries.

Owner:TONGWEI

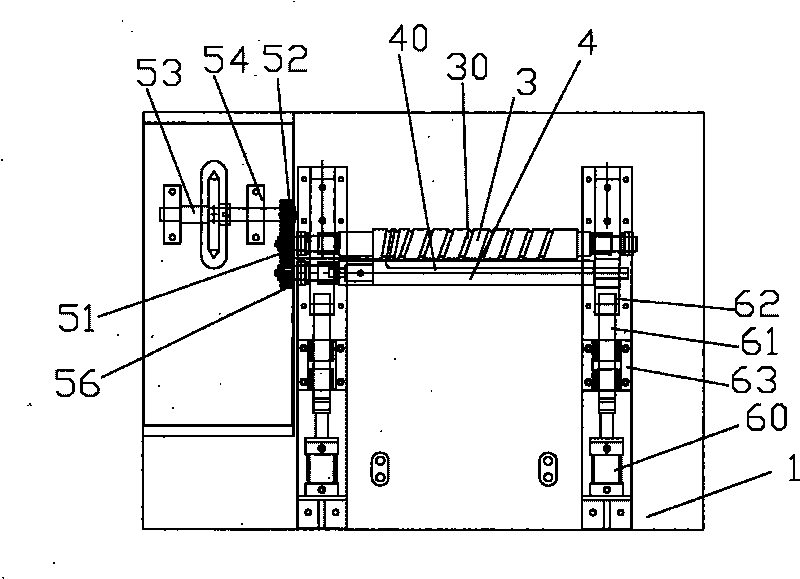

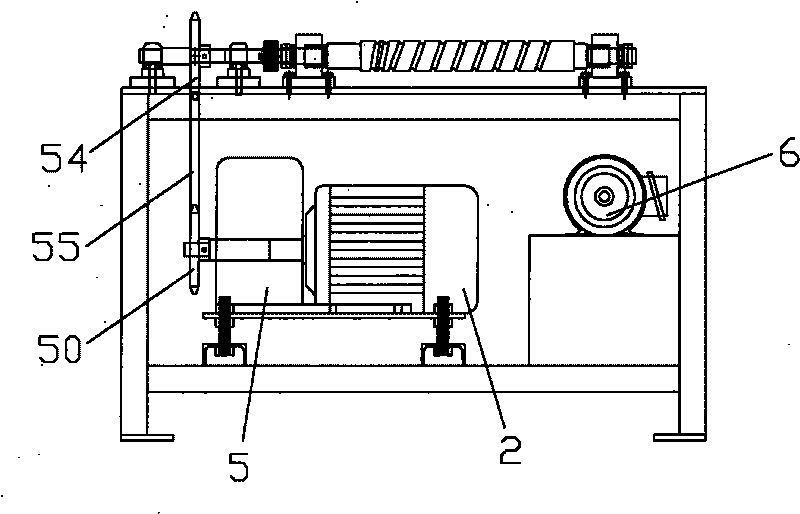

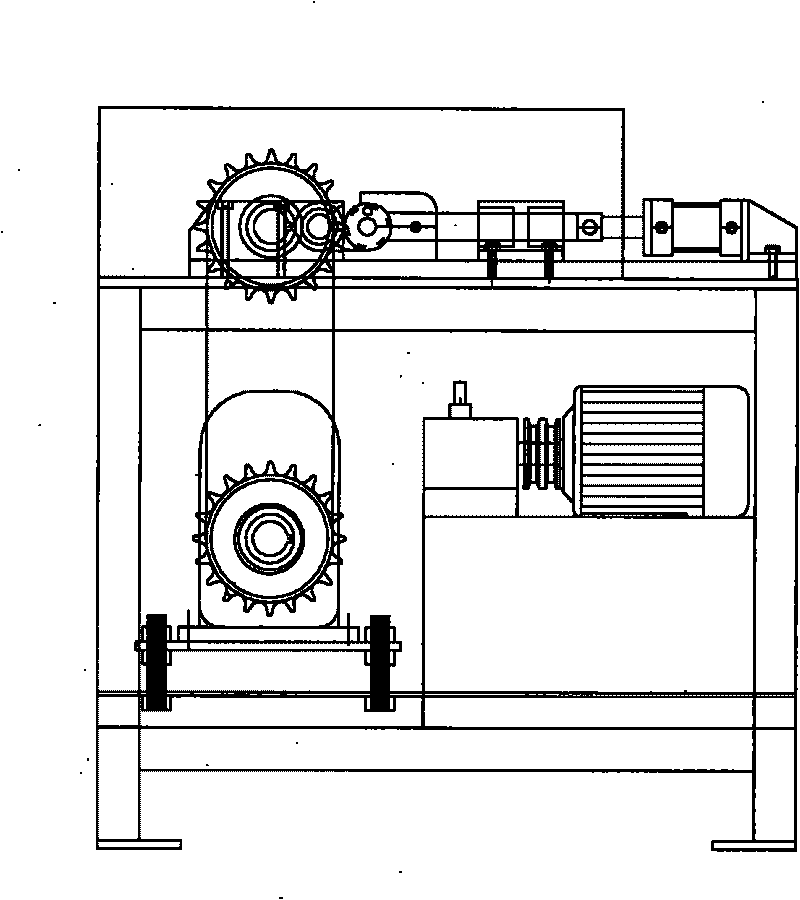

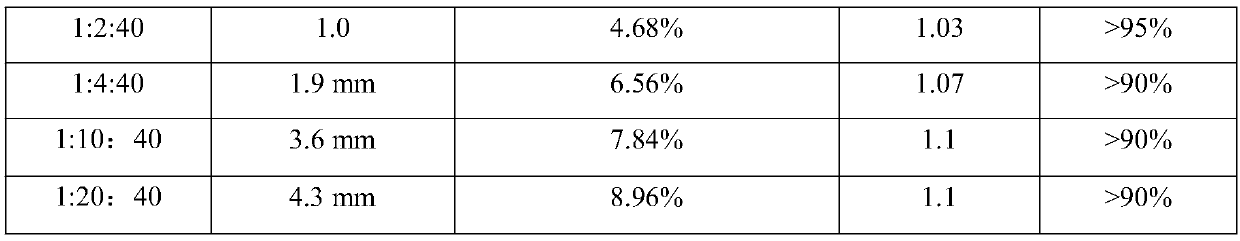

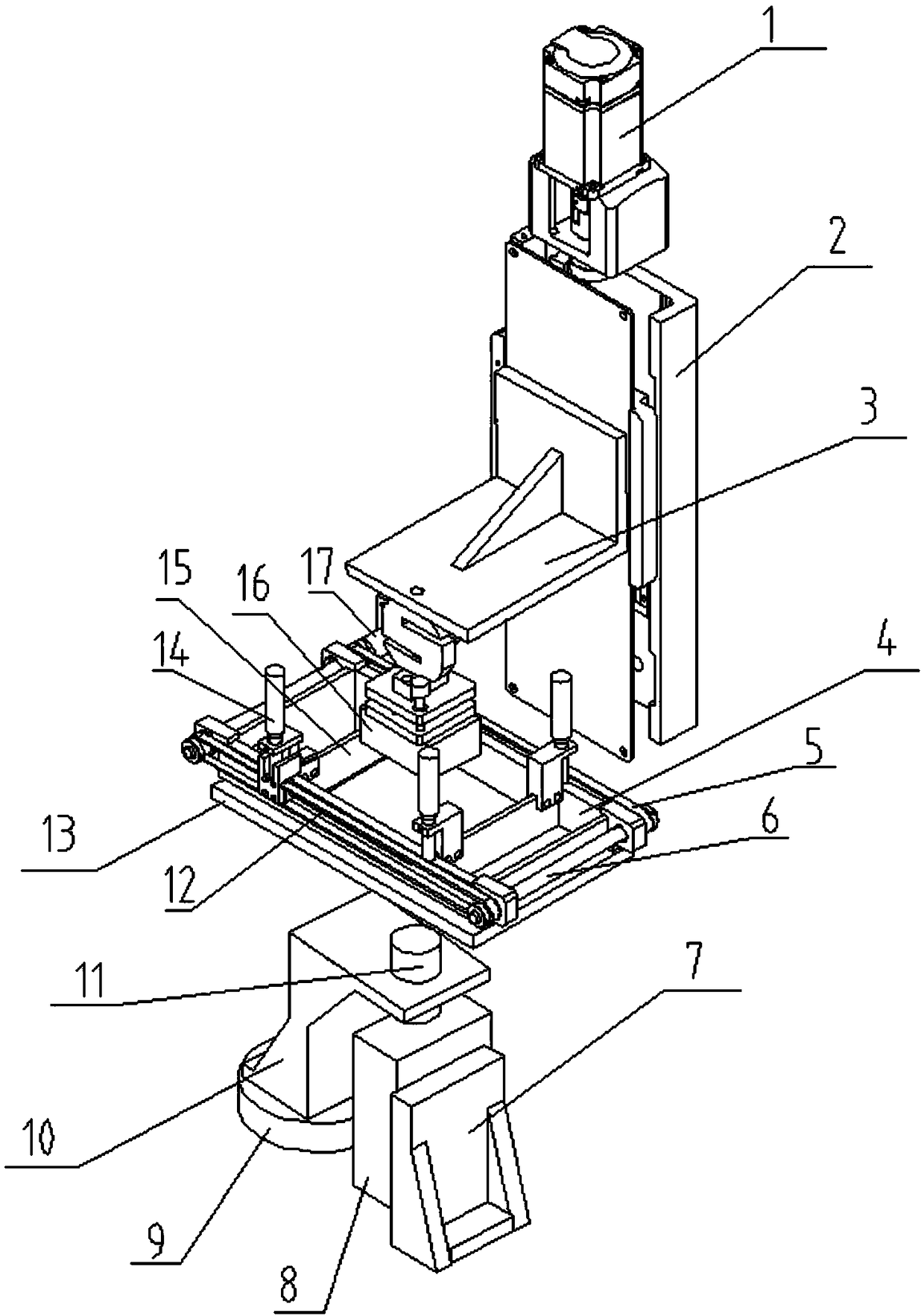

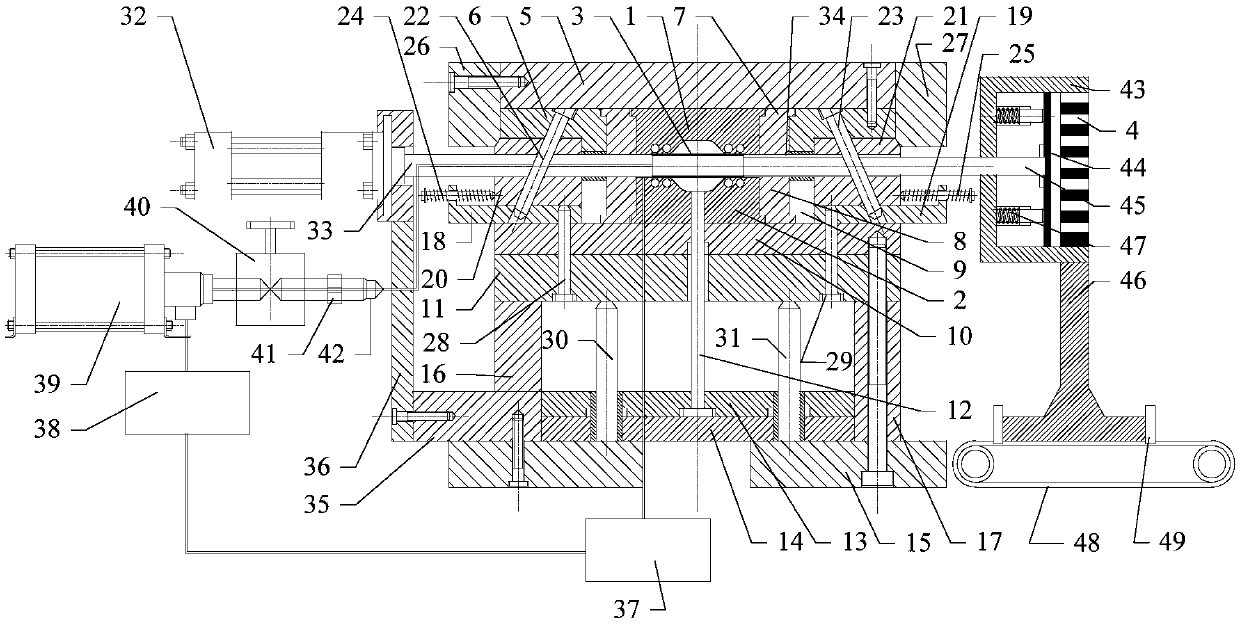

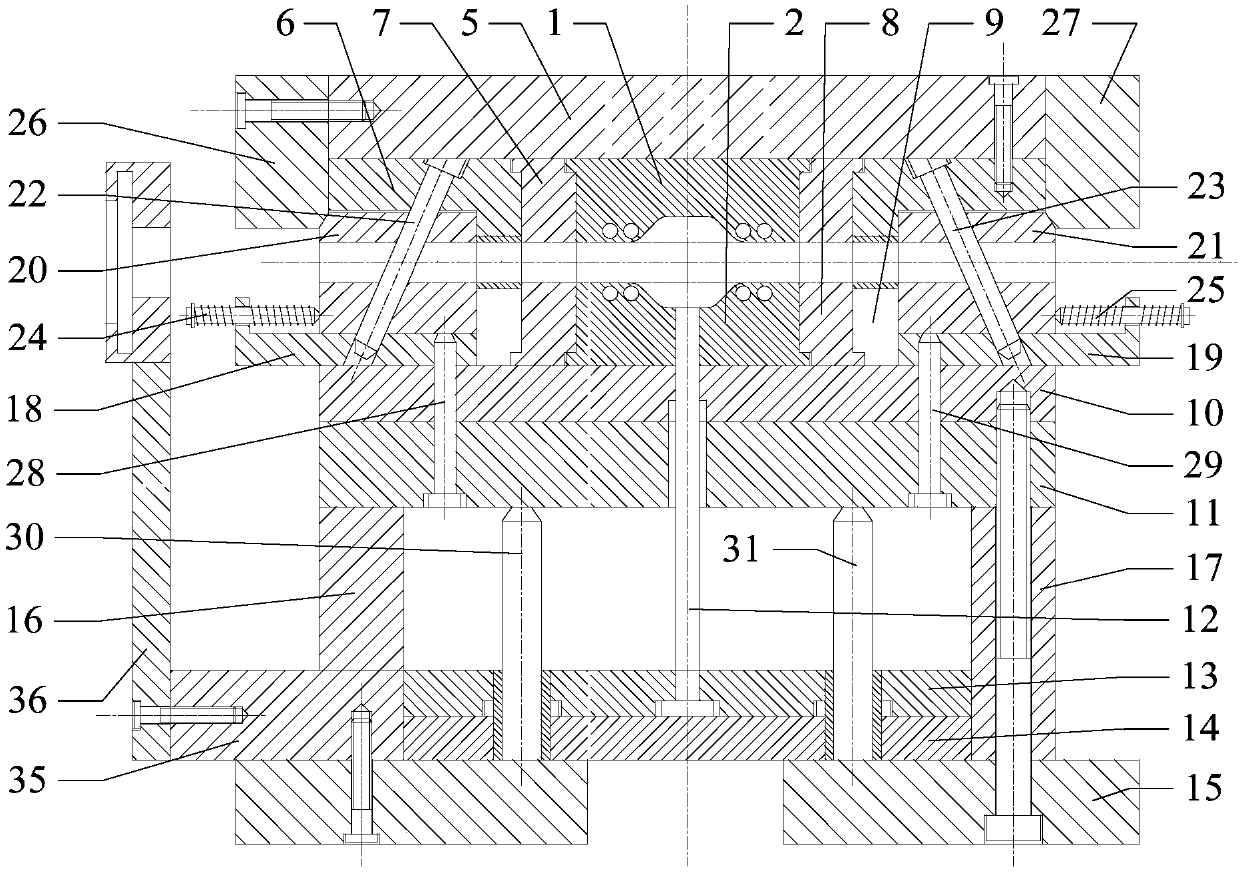

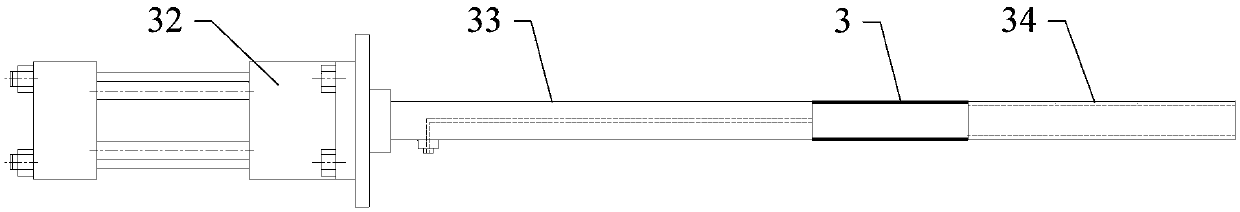

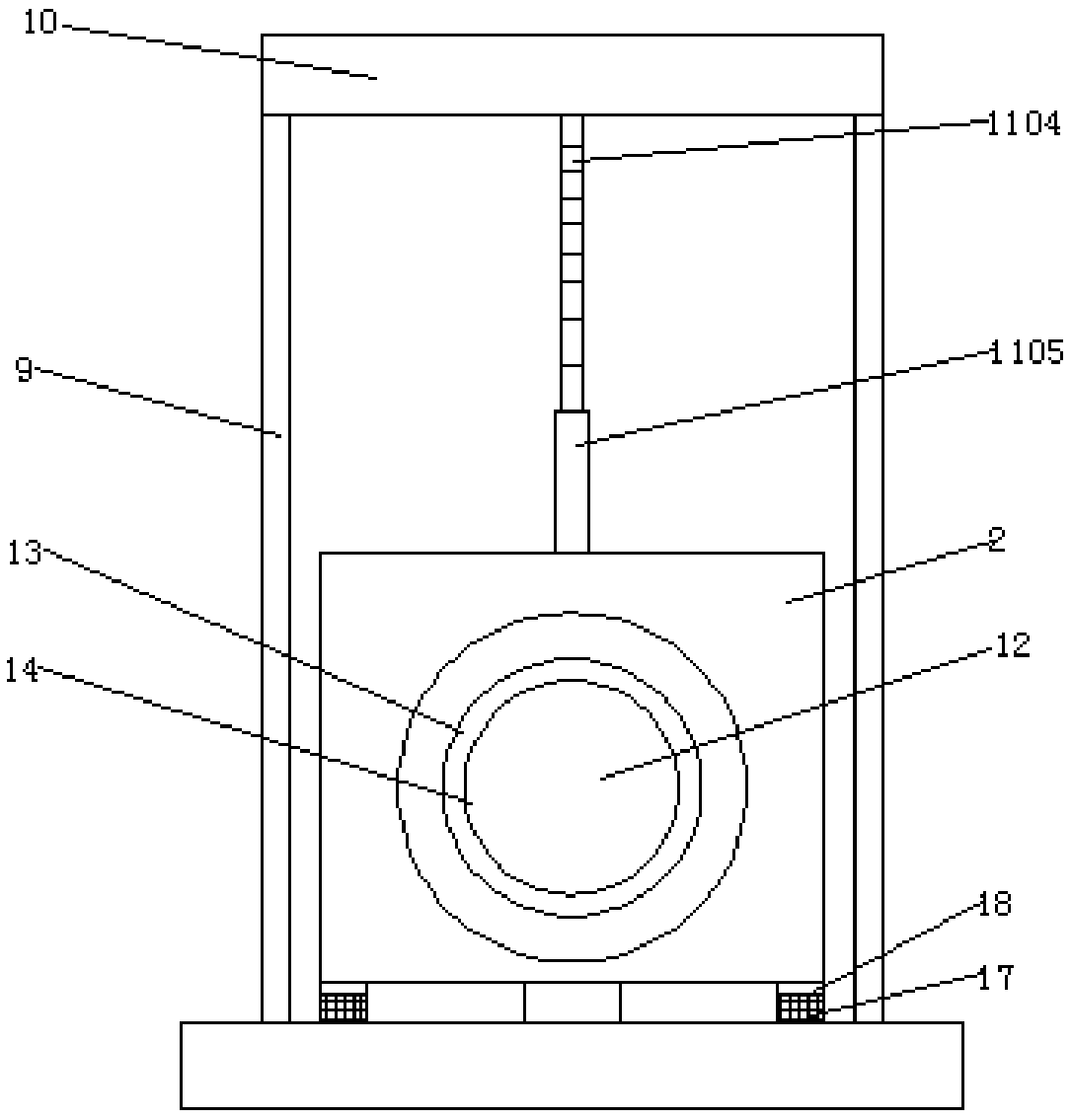

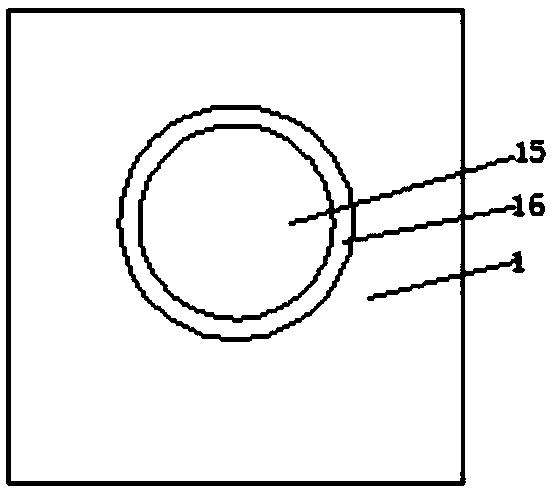

Pipe fitting composite forming device

The invention relates to a pipe fitting composite forming device, and belongs to the field of metal material processing and forming. The pipe fitting composite forming device solves the problem that efficiency losing in the manner of wrinkling, buckling, cracking and the like is prone to being caused by high pressure forming in an existing pipe fitting. The pipe fitting composite forming device ischaracterized in that an upper cavity and a lower cavity are arranged in the bottom surface of an upper die and the top surface of the lower die in a sinking manner correspondingly, a cavity of a combined die unit is formed by the upper cavity and the lower cavity, and a pipe fitting to be formed is horizontally clamped between the upper die and the lower die. A heating unit is used for heating the pipe fitting to a predetermined temperature. A hydraulic unit is used for injecting emulsion into the pipe fitting reaching the predetermined temperature to enable the pipe fitting to reach a deformation critical point, and the emulsion is recovered after the pipe fitting is formed. An axial feeding unit is used for applying axial pressure to the pipe fitting at the deformation critical point to wrinkle the outer wall of the pipe fitting. An impact unit is used for applying impact force to the pipe fitting with the wrinkling outer wall through the emulsion in the pipe fitting under the effect of an electromagnetic pulse generating unit until the pipe fitting is attached to the cavity of the combined mold unit.

Owner:XIANGTAN UNIV

Clay blank plasticizing device for ceramic processing

ActiveCN108943356AAvoid plastic damage rateIncrease success rateCeramic shaping apparatusPlastic property

The invention discloses a clay blank plasticizing device for ceramic processing. The clay blank plasticizing device for ceramic processing comprises a ceramic shaping box body, wherein a fixing box isarranged on the right side of the ceramic shaping box body, and a supporting plate is arranged at the bottom of the ceramic shaping box body and the bottom of the fixing box; and an arc-shaped fixingopening is formed in the lower portion of the front surface of the fixing box, L-shaped rail strips are fixedly connected to the portions, located on the left side and the right side of the arc-shaped fixing opening, of the front surface of the fixing box, a cover plate is arranged between the two opposite L-shaped rail strips in a sliding manner, and a lifting cover device is arranged on the front surface of the cover plate. According to the clay blank plasticizing device for ceramic processing, the lifting cover device, an adjusting fixing device and a lifting device are matched for use, to-be-plasticized ceramic clay blanks can be stably conveyed into the ceramic shaping box body before the ceramic processing process, the to-be-plasticized forming rate of the ceramic clay blanks is improved, and the reworking rate of the to-be-plasticized clay blanks is decreased. The clay blanks can be stably conveyed into a drying area before entering a drying device, so that the damage rate of plasticizing of the ceramic clay blanks is greatly avoided, and the success rate of the ceramic processing clay blanks is increased.

Owner:GUANGDONG XINHONG CERAMIC CO LTD

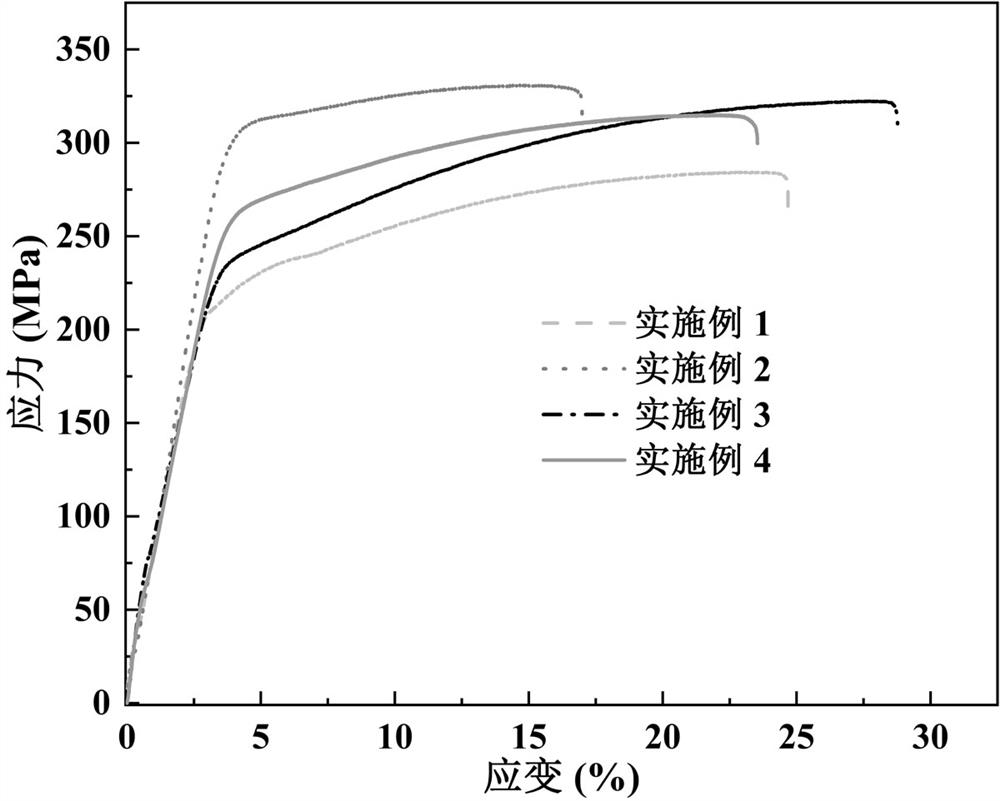

Differential thermal forming method for preparing high-strength and high-toughness magnesium alloy

The invention provides a differential thermal forming method for preparing a high-strength and high-toughness magnesium alloy. The differential thermal forming method aims at only heating a forming die at the deformation temperature without heating an alloy sample. After heat preservation is conducted for a determined time, an alloy blank at the room temperature is placed in the heated forming die, and stable deformation is achieved. The differential thermal forming method comprises the steps that (1) burdening is conducted; (2) preheating is conducted, specifically, a dried magnesium ingot, tin particles, a zinc block and an Mg-Zr intermediate alloy are preheated for 30-35min at the temperature of 200-250 DEG C; (3) smelting and casting are conducted, and a cast alloy is obtained; (4) heat treatment is conducted and comprises solution treatment and aging treatment; (5) and (6) extrusion forming is conducted; and (7) and (8) differential thermal equal-channel corner extrusion forming is conducted. The forming method serves as the core, and differential thermal equal-channel corner extrusion stable forming is successfully achieved. The tensile strength of the alloy exceeds 300MPa, the ductility is close to 30%, excellent comprehensive mechanical performance is obtained, and good strength and plasticity matching is achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Method for frying granular rounded Jinlongyuzhu tea by using two-pot Quhao machine

InactiveCN107455506AGood kneadingRound shapePre-extraction tea treatmentAssembly lineBULK ACTIVE INGREDIENT

The invention provides a method for frying granular rounded Jinlongyuzhu tea by using a two-pot Quhao machine. The method comprises the following steps: (1) spreading fresh leaves; (2) fixing; (3) cooling; (4) feeding dampened tea leaves into a refrigeration house, and freezing for 30-40 minutes; (5) rolling; (6) shaping, namely shaping the rolled tea leaves raw materials into a two-pot Quhao frying machine; and (7), cooling, and drying, thereby obtaining the product. According to the two-pot Quhao frying machine, the technology is mastered in the frying process, and by the method, feeding, stable temperature, speed and sectioned frying time can be controlled and labor intensity is low, yield is high, shaping rate is high and assembly line production can be realized. Temporary freezing treatment is performed after fixation, and the active ingredients of the tea leaves are not lost, so that the tea leaves are easily rolled, the formed tea leaves have mellow and full shape, and the finished tea is bright green in color, clean, sanitary, fresh in tea aroma and pure in taste.

Owner:ANHUI JINZHAI JINLONG YUZHU TEA IND

An electromagnetic microwave drying device for gypsum board

ActiveCN105651027BUniform heating surfaceNo expansion deformationDrying solid materials with heatDrying machines with progressive movementsMicrowaveEnergy consumption

The invention relates to an electromagnetic microwave drying device for gypsum boards. The electromagnetic microwave drying device comprises a microwave heating box, wherein an air introduction pipe is arranged at the top of the microwave heating box. Microwave generators are arranged at the top ends of the microwave heating box, and water coolers are arranged at the tops of the microwave generators. The water coolers are communicated with a water pump. Conveying rollers are arranged in the microwave heating box and are in transmission connection with driven wheels and engaged wheels through chains. The driven wheels are in transmission connection with a motor. Temperature sensing probes are arranged on the microwave heating box. The microwave heating box can effectively ensure that microwaves move in the box, the boards can fully absorb microwaves and vapor is evaporated after heat absorption, and thus the purpose of drying the boards can be achieved; the microwaves emitted by the microwave generators can penetrate through the boards and be absorbed by the boards and move uniformly in the box, and the heated faces of the boards are uniform; the dried boards are tidy and free of expansion deformation, and the forming rate is greatly increased; no gas polluting the atmosphere is generated, and thus the electromagnetic microwave drying device is environmentally friendly, safe and low in energy consumption.

Owner:孙晋玉

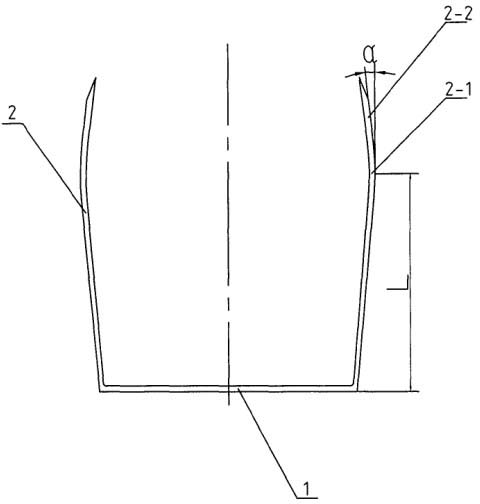

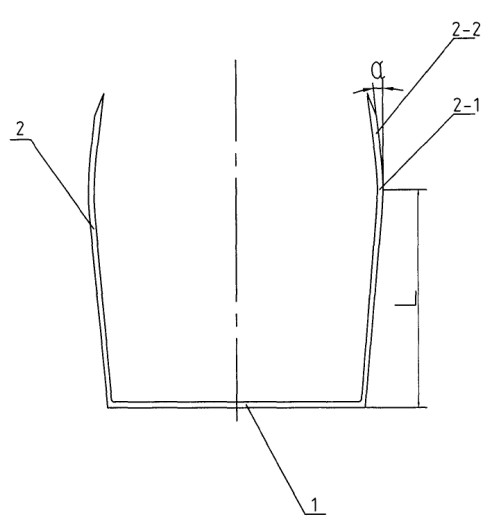

Titanium nail of anastomat

The invention discloses a titanium nail of an anastomat. The titanium nail of the anastomat comprises a nail base (1) and nail legs (2) arranged at the two ends of the nail base (1). The upper end of each nail leg (2) is provided with a nail tip (2-2); the upper part of each nail leg (2) is provided with an arc part (2-1); each nail tip (2-2) is bent inwards; and an inward bending angle alpha is 6 degrees to 8 degrees. The design of the titanium nail of the anastomat disclosed by the invention improves probability of titanium nail formation, reduces resistance of the titanium nail formation and guarantees stability of the titanium nail formation.

Owner:JIANGSU RIPE MEDICAL INSTR TECH CO LTD

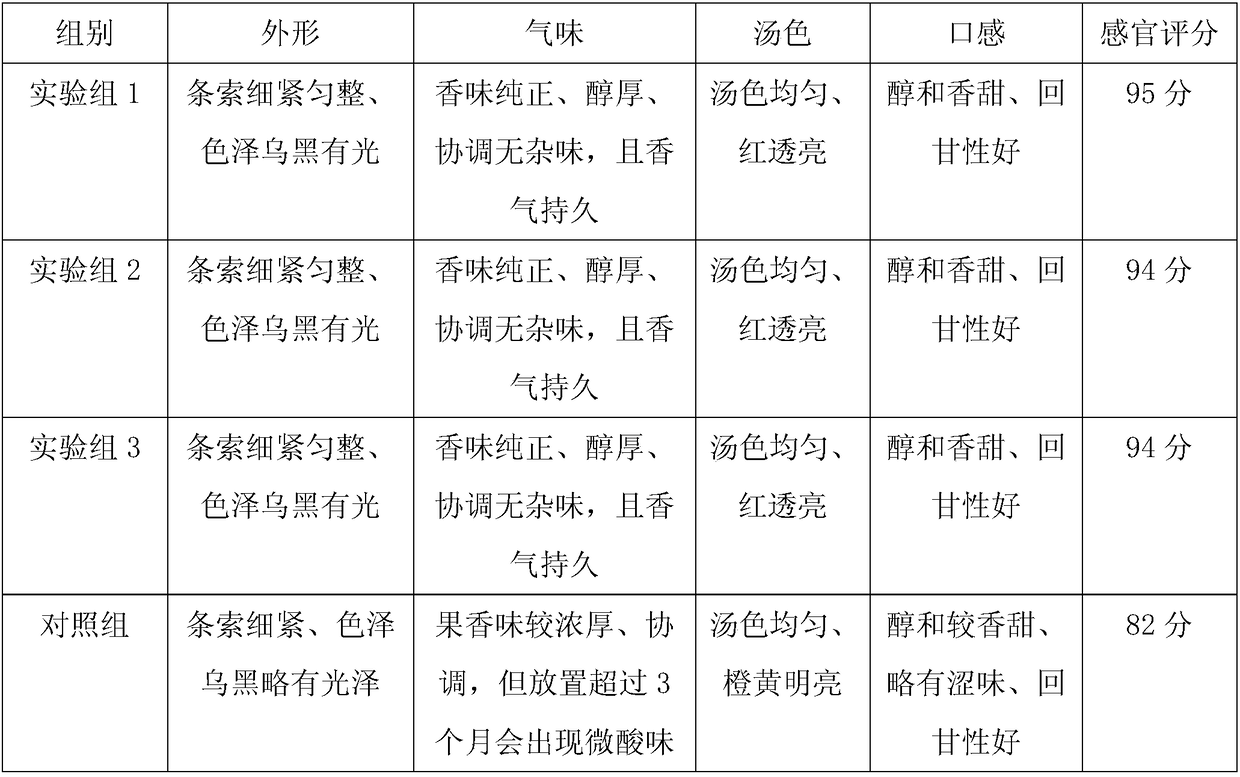

Preparation method of black tea

InactiveCN108812992AGood flexibilityReduce breakage ratePre-extraction tea treatmentBlack teaFermentation

The invention belongs to the technical field of processing of tea leaves, and particularly discloses a preparation method of black tea. The preparation method of the black tea comprises the followingsteps of (1) performing withering: withering the tea leaves, performing rolling lightly, and performing illumination for withering; (2) performing rolling: performing four-grade rolling on the tea leaves by regulating the rolling pressure and rotating speed; (3) performing rolling post-treatment; (4) performing fermentation: performing circular fermentation and red light illumination on the tea leaves, and then performing ultraviolet illumination; (5) performing fermentation post-treatment; (6) performing drying; and (7) performing sieving. According to the preparation method of the black tea,the tea leaves are treated from various technologies, so that the appearance, the color and the fragrance of the tea leaves are effectively improved. The prepared tea leaves are high in sensory quality, high in nutrient value and high in yield of finished products.

Owner:广西正道茶业有限公司

Releasing agent and preparation method thereof

ActiveCN102085563BSolve stickingImprove surface qualityFoundry mouldsFoundry coresLongest DiameterGasoline

The invention provides a releasing agent used in a process of forming a magnetic material, which comprises the following components: 0.1-2 percent by weight of graphite powder, 0.1-5 percent by weight of fatty acid derivative, 0.1-2 percent by weight of paraffin, 0.1-0.5 percent by weight of sodium dodecyl benzene sulfonate, 0.1-2.5 percent by weight of glyceride and 88-99.5 percent by weight of gasoline mixture. The invention also discloses a preparation method of the releasing agent. According to the releasing agent provided by the invention, the problem of adhesion in the process of forming the magnetic material is solved, and the surface quality of a permanent magnet material casting is improved, especially the annular permanent magnet material product with large long diameter ration; and by using the releasing agent, the surface roughness of the permanent magnet material blank product is reduced, and the forming qualified rate of products is improved.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Laser melting forming dust removal system and dust removal method with multifunctional circulating airflow

ActiveCN105642891BPrevent influence of forming qualityImprove forming rateAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringMetal powder

The invention provides a laser melting forming dust-removing system with multifunctional circulating air flow and a dust-removing method. The dust-removing system comprises an upper cavity and a lower cavity. Three induced air ways are led out of an air inlet of the upper cavity and are the first induced air way, the second induced air way and the third induced air way. The first induced air way communicates with a dust-removing subsystem in a scanning area. The second induced air way communicates with a dust-removing subsystem of a laser protection mirror. The third induced air way communicates with a dust-removing subsystem of a movement sliding table cavity. The laser melting forming dust-removing system with multifunctional circulating air flow and the dust-removing method have the beneficial effects that in the whole laser melting forming process, smoke-shaped dust generated when lasers act on metal powder can be absorbed into a dust filter in time under the effect of a draught fan, dust generated by part forming is filtered out in time through the dust filter, the influences, on the subsequent forming quality, of the smoke-shaped dust are prevented, and the forming rate is increased; and in addition, the dust is prevented from rising to the position near the laser protection mirror located over the scanning area, and the dust is prevented from entering a sliding table guide rail in the sliding table cavity.

Owner:HARBIN FORWEDO MULTI DIMENSIONAL INTELLIGENT EQUIP CO LTD

Formula and preparation method of alkali-resistant medium borosilicate medicinal glass

InactiveCN112876070AReduce difficultyImprove forming rateForehearthsElectric furnaceSodium bicarbonateBottle

The invention discloses a preparation method of alkali-resistant medium borosilicate medicinal glass, which comprises the following steps: firstly, taking corresponding parts by mass of raw materials according to the proportion for later use; secondly, fully mixing the raw materials, adding the raw materials into a smelting furnace, completely melting the raw materials, and fully conducting mixing again; then, adopting a blow-press molding process, when the temperature of the molten material reaches 1100-1120 DEG C, conveying the molten material into a corresponding mold, and completing mold pressing; then, annealing the product in the mold, and taking out the product after cooling is completed; and finally, conducting inspecting and packaging, warehousing qualified products, and recycling unqualified products. According to the invention, the difficulty of producing glass bottles for containing a sodium bicarbonate medicine can be reduced, the technical problems of difficult melting, difficult clarification and difficult forming in the glass bottle manufacturing process are solved, the forming rate of glass bottle production is greatly improved, and the glass bottle made of the medium borosilicate glass can be widely used.

Owner:SHANDONG PHARMA GLASS

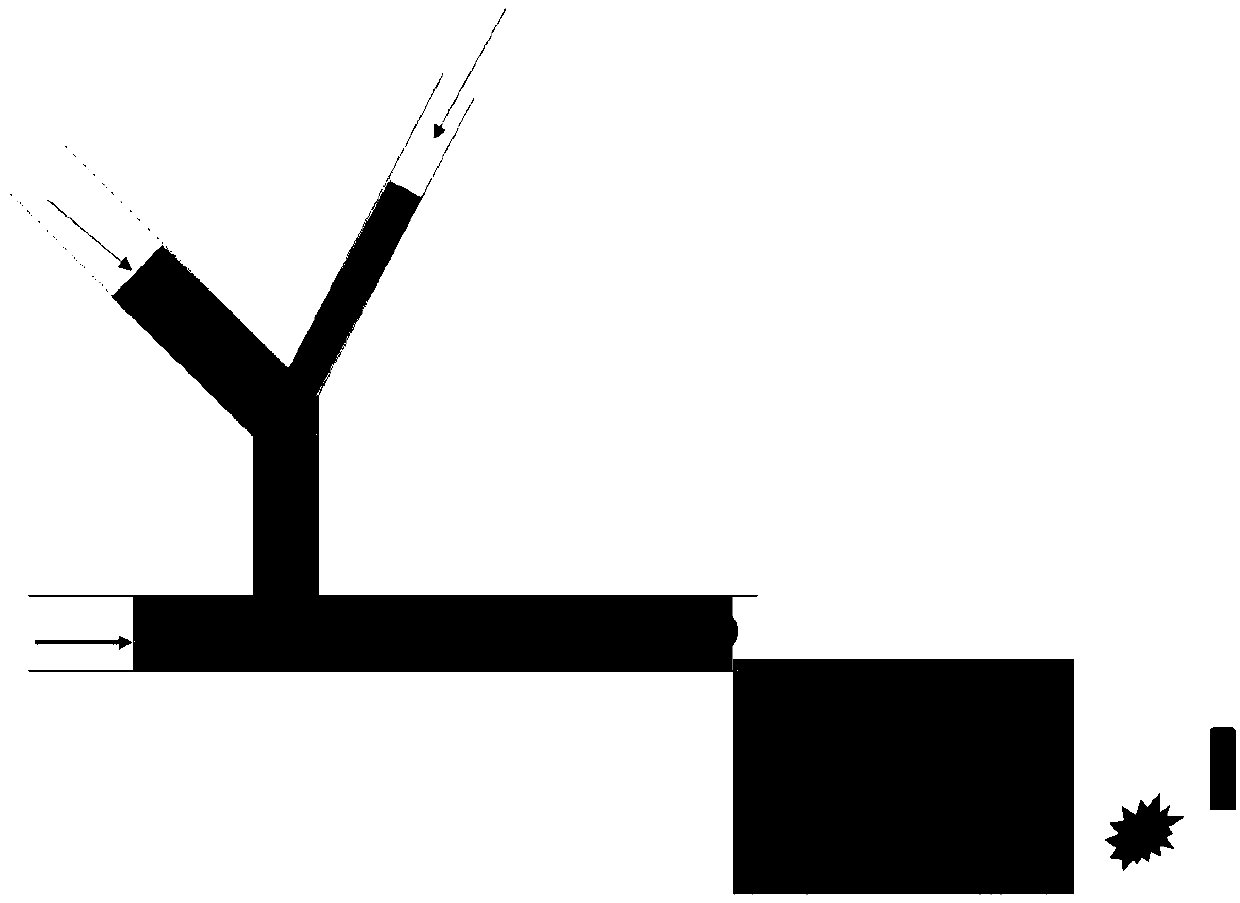

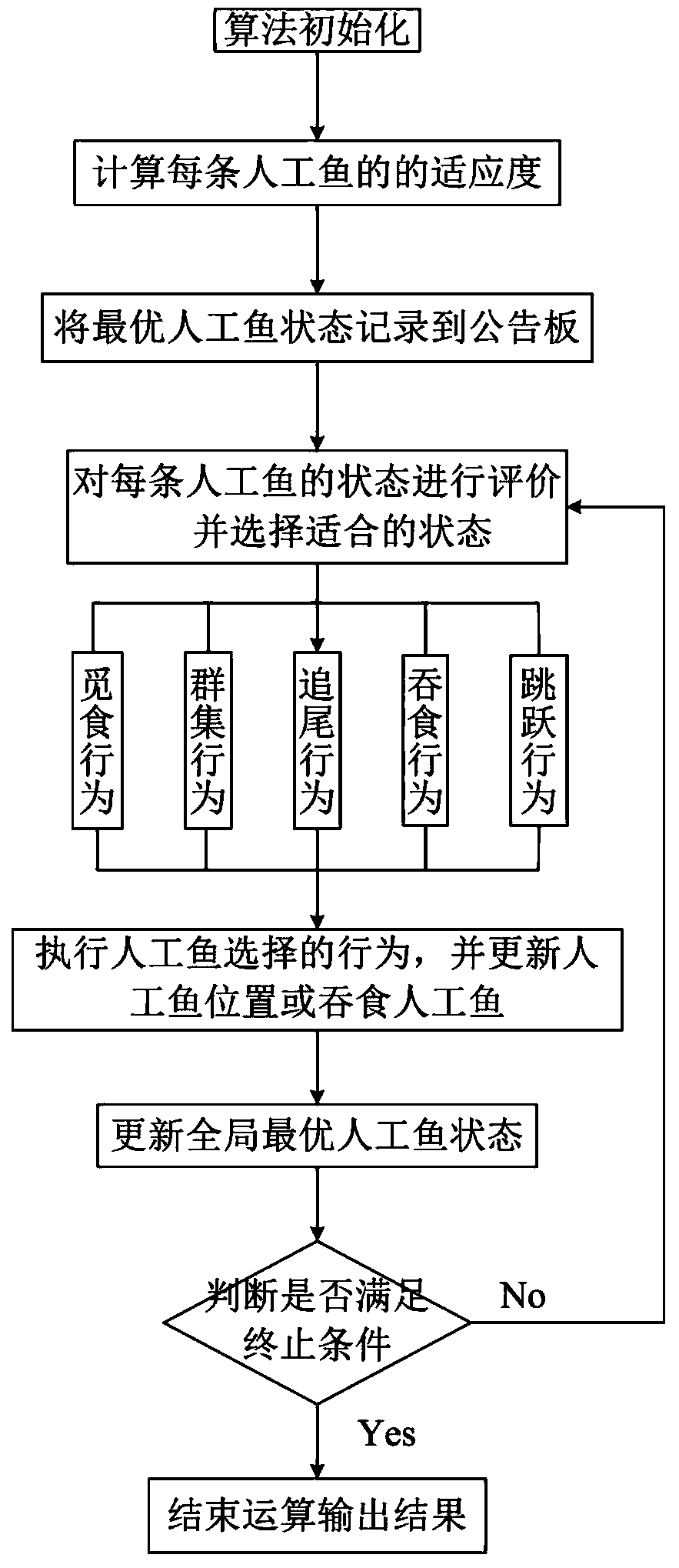

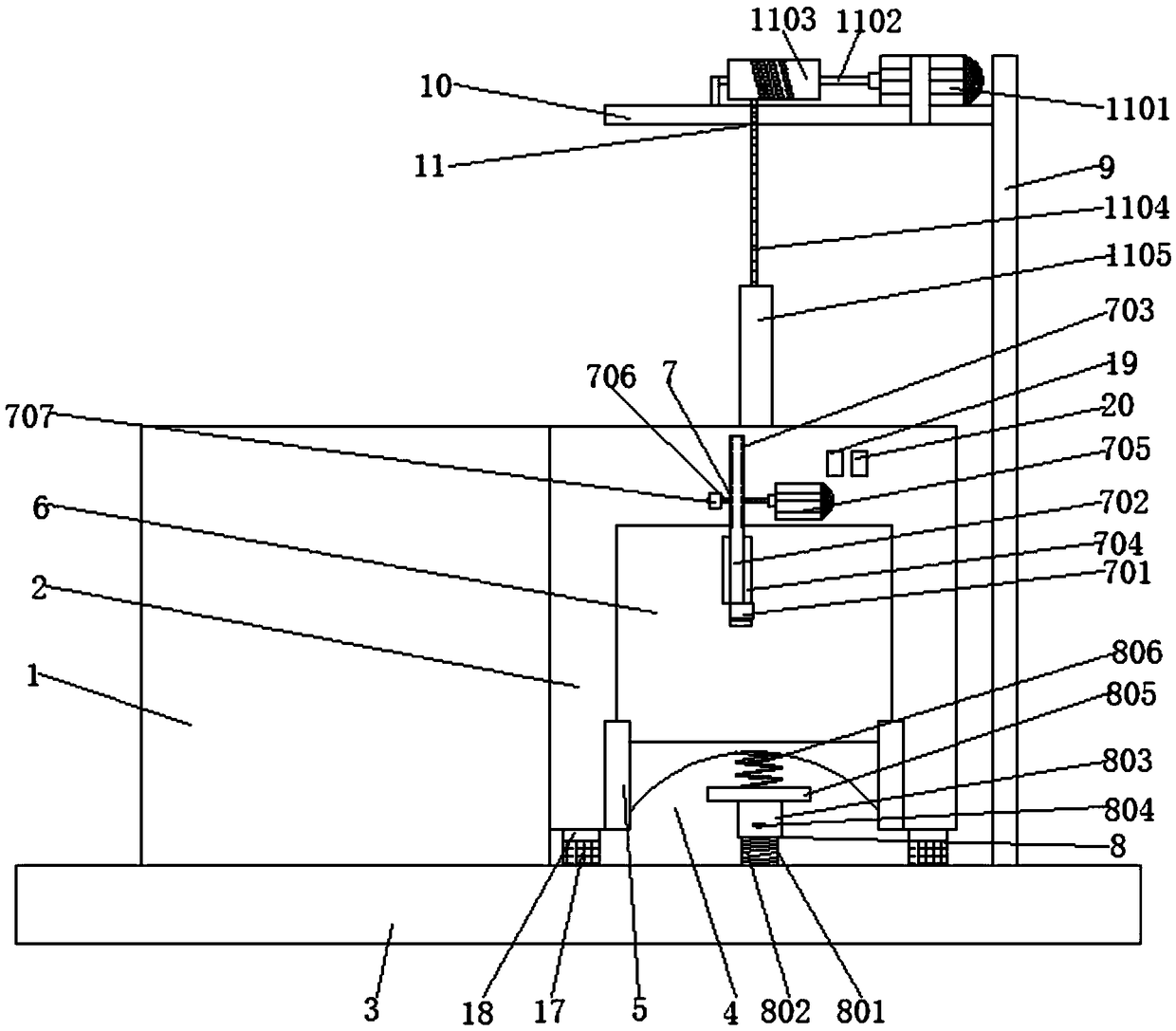

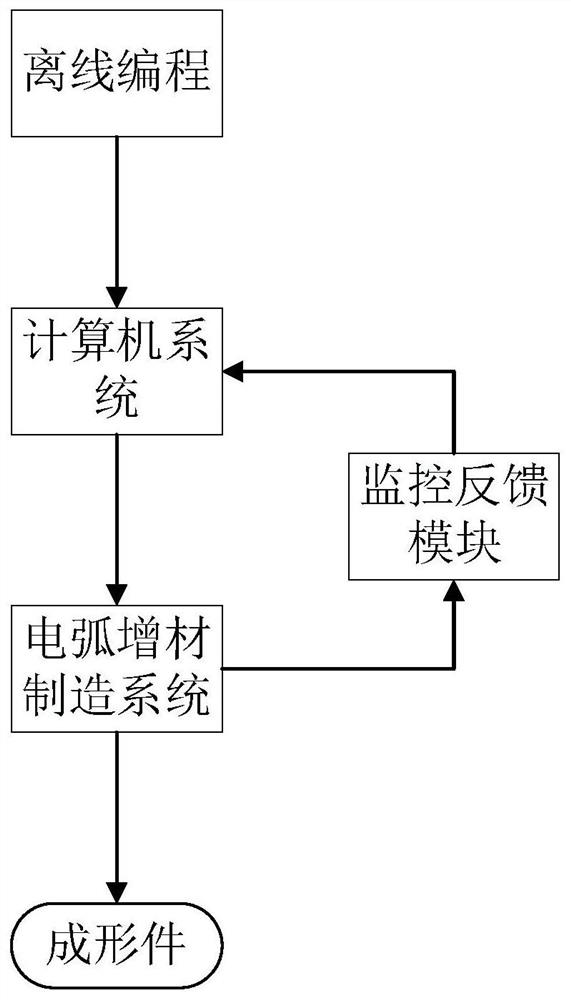

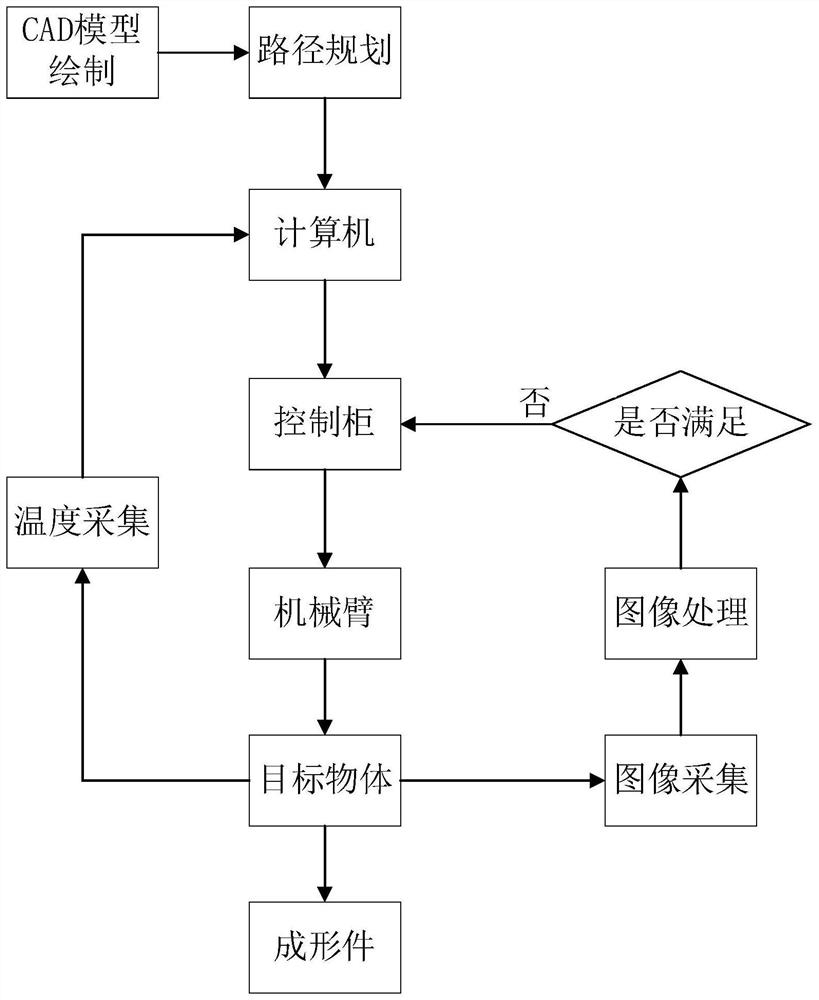

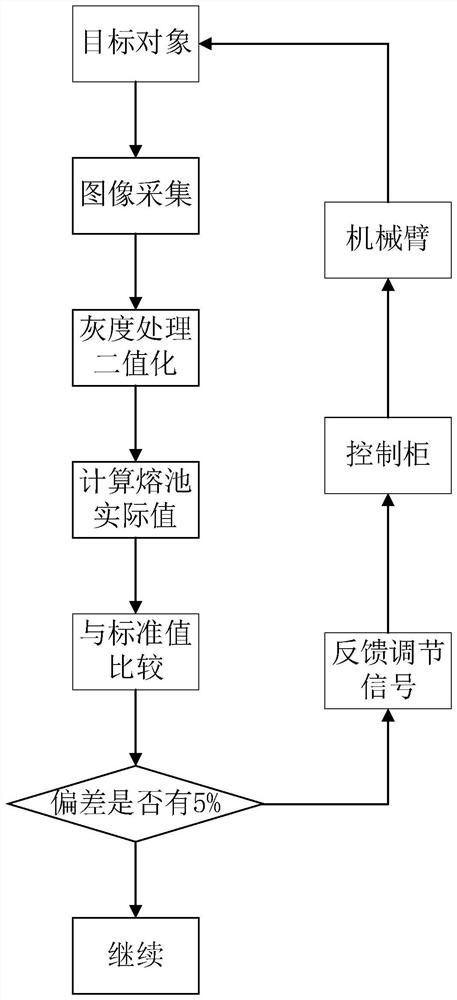

Weld bead forming control system in electric arc additive manufacturing process and parameter optimization method thereof

InactiveCN112122741AImprove forming rateIncrease profitAdditive manufacturing apparatusArc welding apparatusMachine partsContinuous feedback

The invention relates to the technical field of electric arc additive manufacturing, in particular to a weld bead forming control system in an electric arc additive manufacturing process and a parameter optimization method of the weld bead forming control system. The weld bead forming control system in the electric arc additive manufacturing process comprises a computer control module, an off-lineprogramming module, an electric arc additive manufacturing system and a monitoring and feedback adjusting system; the off-line programming module designs a deposition path and sends the deposition path to the computer control module; the electric arc additive manufacturing system welds machined parts according to the deposition path; the monitoring and feedback adjusting system monitors the temperature of a molten pool; and the computer control module controls the electric arc additive manufacturing system to conduct welding according to data fed back by the off-line programming module and the monitoring and feedback system. According to the weld bead forming control system in an electric arc additive manufacturing process, change of the molten pool can be effectively reduced, stability in a deposition process can be improved, and technological parameters in a welding process can be effectively optimized through continuous feedback adjustment.

Owner:JIANGSU UNIV OF TECH

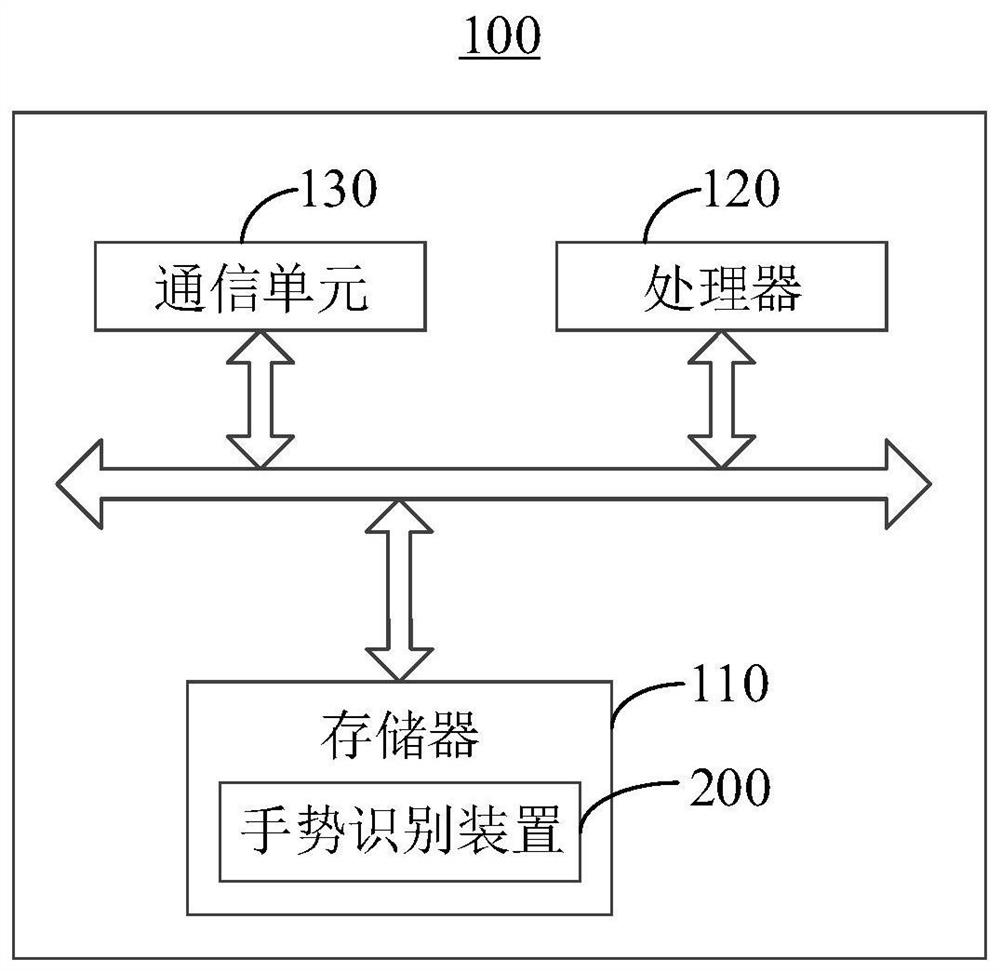

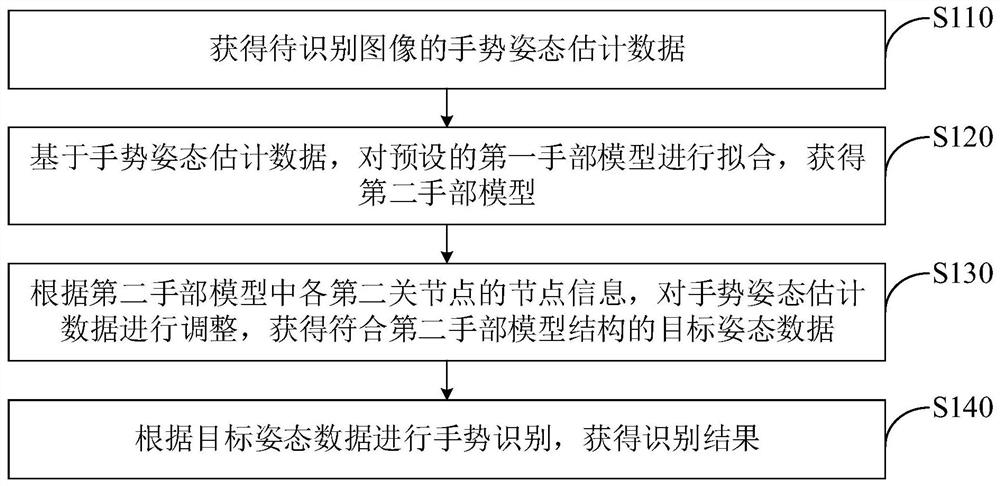

Gesture recognition method and device, electronic equipment and readable storage medium

PendingCN113221738AImprove accuracyMitigating the MisalignmentCharacter and pattern recognitionImaging processingMedicine

The embodiment of the invention provides a gesture recognition method and device, electronic equipment and a readable storage medium, and relates to the field of image processing. The method comprises the steps of obtaining gesture posture estimation data of an image to be recognized, wherein the gesture posture estimation data comprise position information of a first joint point of a hand; fitting a preset first hand model based on the gesture estimation data to obtain a second hand model; according to node information of each second joint point in a second hand model, adjusting the gesture attitude estimation data to obtain target attitude data conforming to the structure of the second hand model; and performing gesture recognition according to the target posture data to obtain a recognition result. Therefore, the position information of each joint point conforming to the actual hand model structure can be obtained, the position information of the joint points used during gesture recognition is more accurate, drifting of points can be reduced, the forming rate of the hand shape is increased, and therefore the accuracy of the recognition result is improved.

Owner:GUANGZHOU HUYA TECH CO LTD

A Method for Isothermal Superplastic Deformation of Micro/Nano Particle Reinforced Titanium Matrix Composites

ActiveCN110284089BEvenly distributedEnhanced interface bindingTitanium matrix compositesIsothermal forging

The invention discloses an isothermal superplastic deformation method for a micro / nano particulate reinforced titanium matrix composite. The method comprises the following steps of A, preparing a titanium boride and rare earth oxide micro / nano particulate hybrid reinforced titanium matrix composite by utilizing an in-situ synthesis technique, and performing vacuum consumable electrode arc melting on the composite for more than two times; B, performing cogging forging on the composite in a Beta single-phase region, wherein deformation amount is greater than or equal to 50 %; performing isothermal forging on the composite in an (Alpha + Beta) two-phase region to obtain a titanium matrix composite forging blank, wherein deformation amount is greater than or equal to 60 %; and C, performing hot rolling on the titanium matrix composite forging blank in a near Beta phase region, wherein deformation amount is greater than or equal to 80 %, and performing annealing treatment to obtain the micro / nano particulate reinforced titanium matrix composite. The micro / nano particulate reinforced titanium matrix composite is formed by the isothermal forging technology and hot rolling, and thus, the matrix structure can be effectively refined, and the material forming rate is increased; and a plate has good superplasticity within the deformation process range of 800-1000 DEG C and 5 x 10<-3>-10<-4>s<-1>.

Owner:上海交通大学包头材料研究院 +1

Three-dimensional printing preparation method for iron-based magnetic core

InactiveCN109378206AImprove performanceFast curingAdditive manufacturing apparatusInductances/transformers/magnets manufactureAlloyMaterials science

The invention discloses a 3D printing preparation method for an iron-based magnetic core. By adopting a plurality of elements including Ni, Cr, Cu, Al, P and C which facilitate the overall performanceof iron-based amorphous magnetically soft alloy, the iron-based magnetically soft composite magnetic core is prepared. In the method, chemical curing is combined with light curing, the curing time isshortened, the curing speed of the magnetic material is increased, and therefore, the forming rate of a product is improved.

Owner:瞿凌飞

Method for preparing composite magnetic material by using gel method by using ferromagnetic particles

InactiveCN109599243AUniphasic goodEvenly dispersedInorganic material magnetismState of artMagnetite Nanoparticles

The invention discloses a method for preparing a composite magnetic material by using a gel method by using ferromagnetic particles. An improved sol-gel method is adopted to prepare NiFe2O4 magnetic nano-particles, the single-phase performance is good, the dispersion is relatively uniform, the preparation method is simple, and the cost is relatively low in comparison with the prior art. Accordingto the method in the invention, chemical curing and photo-curing are combined so that the curing time is shortened, the curing speed of the magnetic material is increased, and consequently, the forming rate of the product is improved.

Owner:瞿凌飞

Method for preparing samarium cobalt permanent magnet material by using printing method

InactiveCN109599237ASubcooling degree of large alloy compositionSmall grain sizeMagnetic materialsAlloySamarium cobalt

The invention discloses a method for preparing a samarium cobalt permanent magnet material by using a printing method. The ingredients of an SmCo5 alloy is adjusted by doping to obtain a large alloy ingredient supercooling degree, and anisotropic SmCo5 with a fine grain size is obtained in cooperation with a high-speed rapid quenching process; and in the method disclosed by the invention, chemicalcuring and photocuring are combined to shorten the curing time and improve the curing speed of the magnetic material, thereby improving the forming rate of a workpiece and improving the preparation efficiency of the magnetic material.

Owner:王群华

Paperbacked plasterboard drying device with natural gas as heat source and drying process

InactiveCN110103332ASimple equipmentUniform heating surfaceSurface layering apparatusExhaust gasProcess engineering

An embodiment of the invention discloses a paperbacked plasterboard drying device with natural gas as a heat source. The device comprises a plurality of drying areas which are sequentially connected,wherein drying machines are arranged in the drying areas, an air distribution chamber and conveying roller beds are arranged in each drying machine, the conveying roller beds sequentially pass throughthe air distribution chambers of different drying areas, and an air distribution damper used for distributing heat to roller bed space is arranged in each air distribution chamber; each air distribution chamber is connected with a combustion chamber, and a circulating fan is arranged in each combustion chamber; a burner is further arranged in each combustion chamber, a gas feeding pipeline and anair feeding pipeline are arranged on each combustion chamber, each air feeding pipeline is connected with the corresponding circulating fan, and a gas feeding damper and an air feeding damper are arranged on each gas feeding pipeline and the corresponding air feeding pipeline respectively; chimneys are further arranged on the drying machines. A drying process comprises steps as follows: S100, feeding the paperbacked plasterboard to the roller beds; S200, sequential drying; S300, tail gas treatment; S400, discharging from the roller beds. According to the paperbacked plasterboard drying device, paperbacked plasterboard is dried with heat produced by natural gas in combustion, and equipment is simplified and pollution is reduced by contrast with a production process of a coal-fired plant.

Owner:BEIJING NEW BUILDING MATERIAL

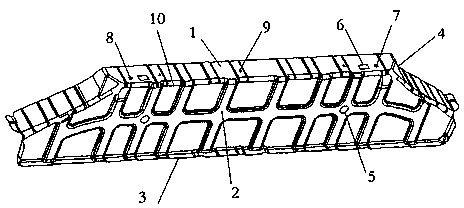

Vehicle rear floor front beam

PendingCN108216384AReduce stressImprove forming rateSuperstructure subunitsStress concentrationEngineering

The invention discloses a vehicle rear floor front beam which comprises a bottom plate, a vertical plate, a first turned edge, inclined faces, liquid leakage holes, trim seat clamping holes, main positioning holes, auxiliary positioning holes and carpet installation holes. A protruding arched structure is arranged in the middle of the bottom plate. The bottom of one side of the bottom plate is fixedly connected with the top of the vertical plate through welding. The two ends of the arched structure are fixedly connected with the vertical plate through the inclined faces respectively. The liquid leakage holes are formed in the middles of the two sides of the vertical plate respectively. The first turned edge is fixed to the bottom of the vertical plate. The trim seat clamping holes are formed in the two sides of the arched structure respectively. The main positioning holes are formed in the positions, on one sides of the trim seat clamping holes, of one end of the arched structure. Through the inclined faces, the stress borne by the position, at the arched structure, of the joint of the vertical plate and the bottom plate is remarkably reduced in the stamping process, it is avoidedthat the joint of the vertical plate and the bottom plate is prone to breakage and corrugation under the concentrated stress during stamping, and therefore the forming rate and structural strength ofan outer plate of the vehicle rear flow front beam are improved.

Owner:合肥亿恒智能科技有限公司

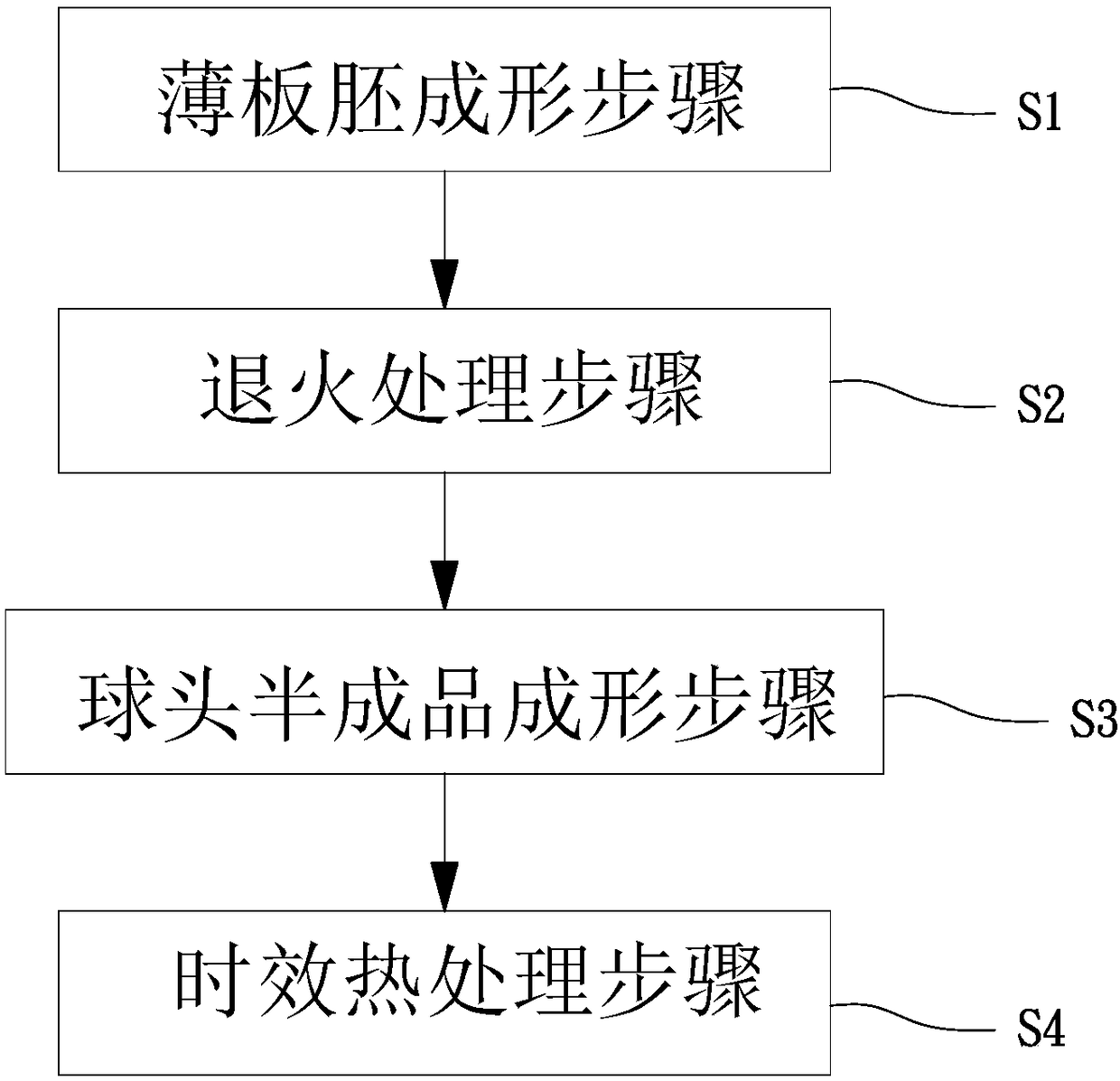

Golf club head alloy and method for preparing golf club head from alloy

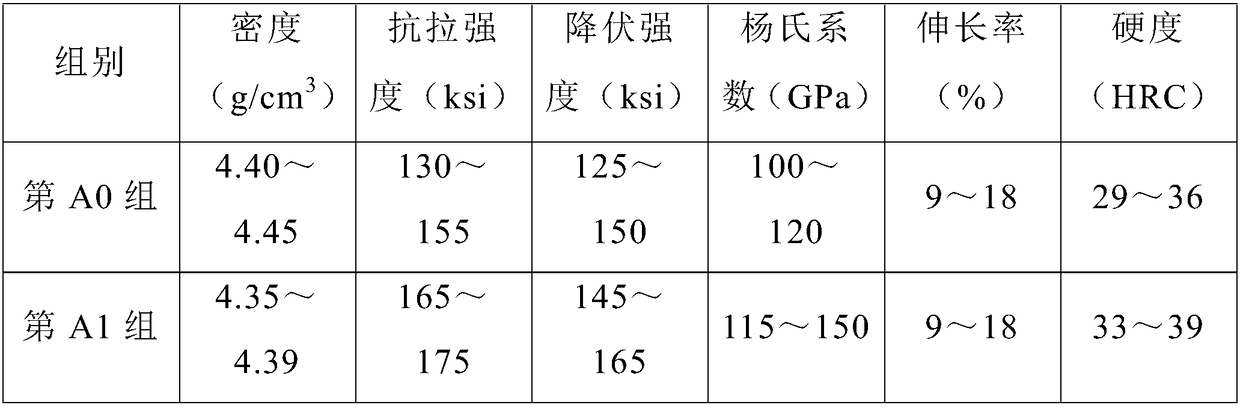

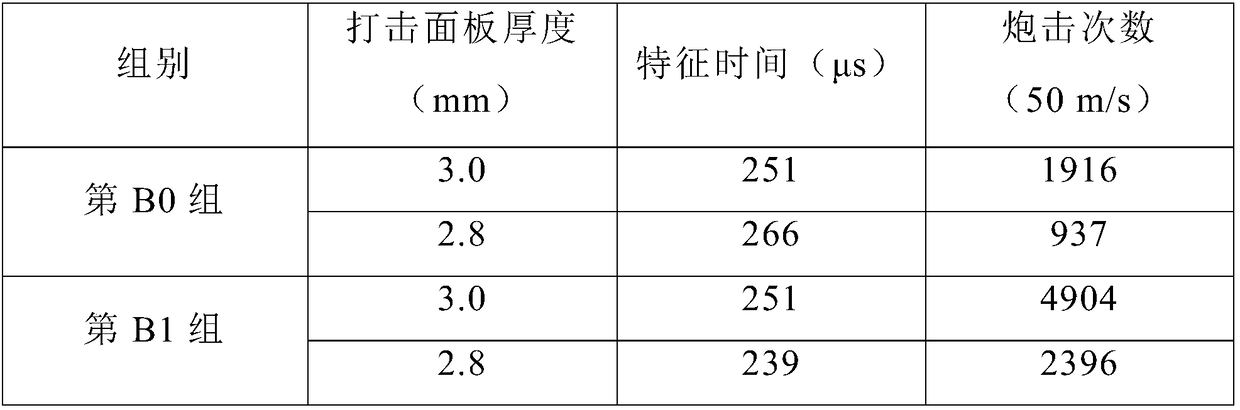

The invention provides a golf club head alloy and aims to solve the problem that the golf club head prepared from the conventional golf club head alloy is too heavy. The golf club head alloy is prepared from 6.5%-7.5% by weight of aluminum, 1.0%-2.5% by weight of iron, 0.05%-0.2% by weight of silicon, smaller than 0.15% by weight of oxygen, smaller than 0.1% by weight of carbon, smaller than 0.05%by weight of nitrogen and the balance of titanium and inevitable impurities, and density of the golf club head alloy is 4.35-4.39 g / cm<3>.

Owner:FUSHENG IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com