Laser melting forming dust-removing system with multifunctional circulating air flow and dust-removing method

A technology of laser melting and circulating airflow, applied in the direction of improving energy efficiency, process efficiency, additive processing, etc., can solve problems such as damage to the optical path, adverse effects, rising smoke and dust, to ensure forming quality, improve service life, improve The effect of forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

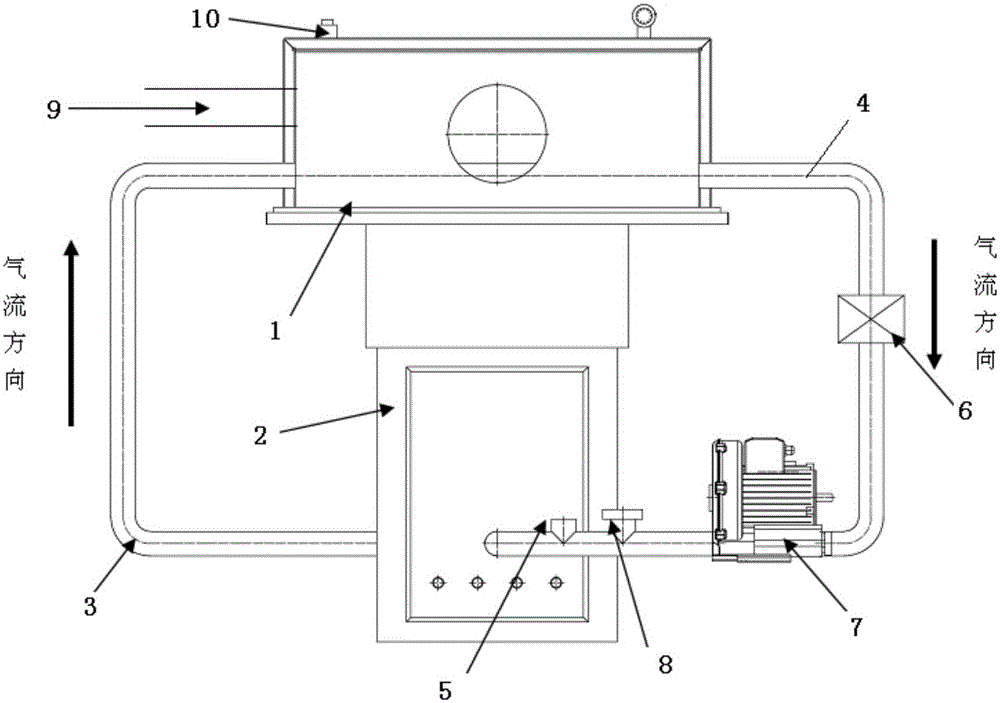

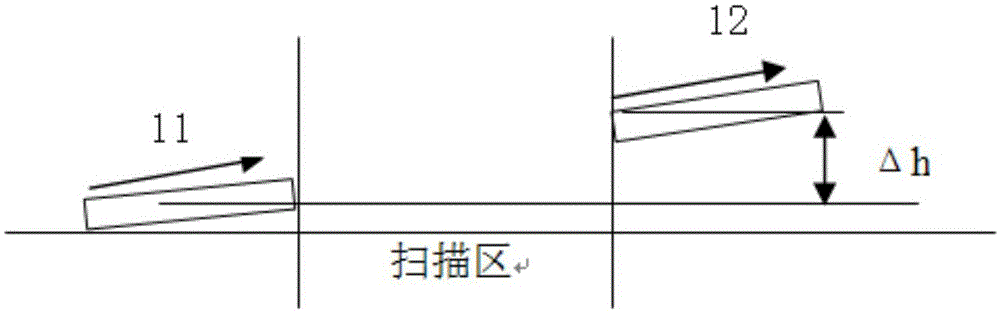

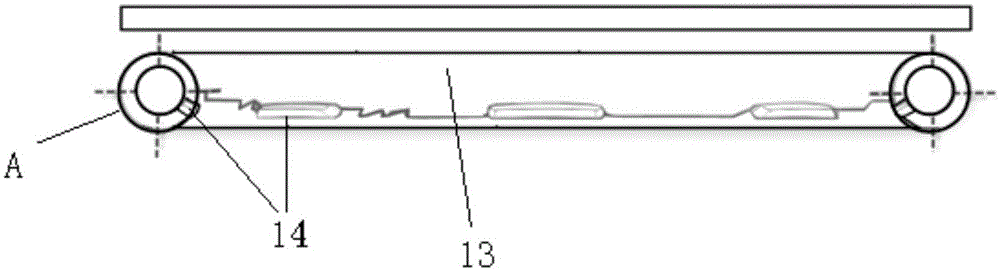

[0038] The present invention provides a laser melting and forming dust removal system with multifunctional circulating air flow, through the internal air circulation design, the air flow flowing into the laser forming working chamber is promoted, refer to Image 6 , to complete at least three main functions, the first is the directional dust removal function of blowing and sucking for the smoke generated by the laser action powder; It is to introduce the airflow into the cavity of the moving slide to produce the effect of discharging dust.

[0039] Specifically, combine figure 1 , the laser melting forming dust removal system with multifunctional circulating air flow includes an upper cavity 1 and a lower cavity 2; the upper cavity 1 is a laser melting forming cavity, and the upper cavity 1 and the lower cavity 2 are connected to each other;

[0040] In addition, the exhaust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com