Golf club head alloy and method for preparing golf club head from alloy

Technology of a golf club head, manufacturing method, applied in the field of alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

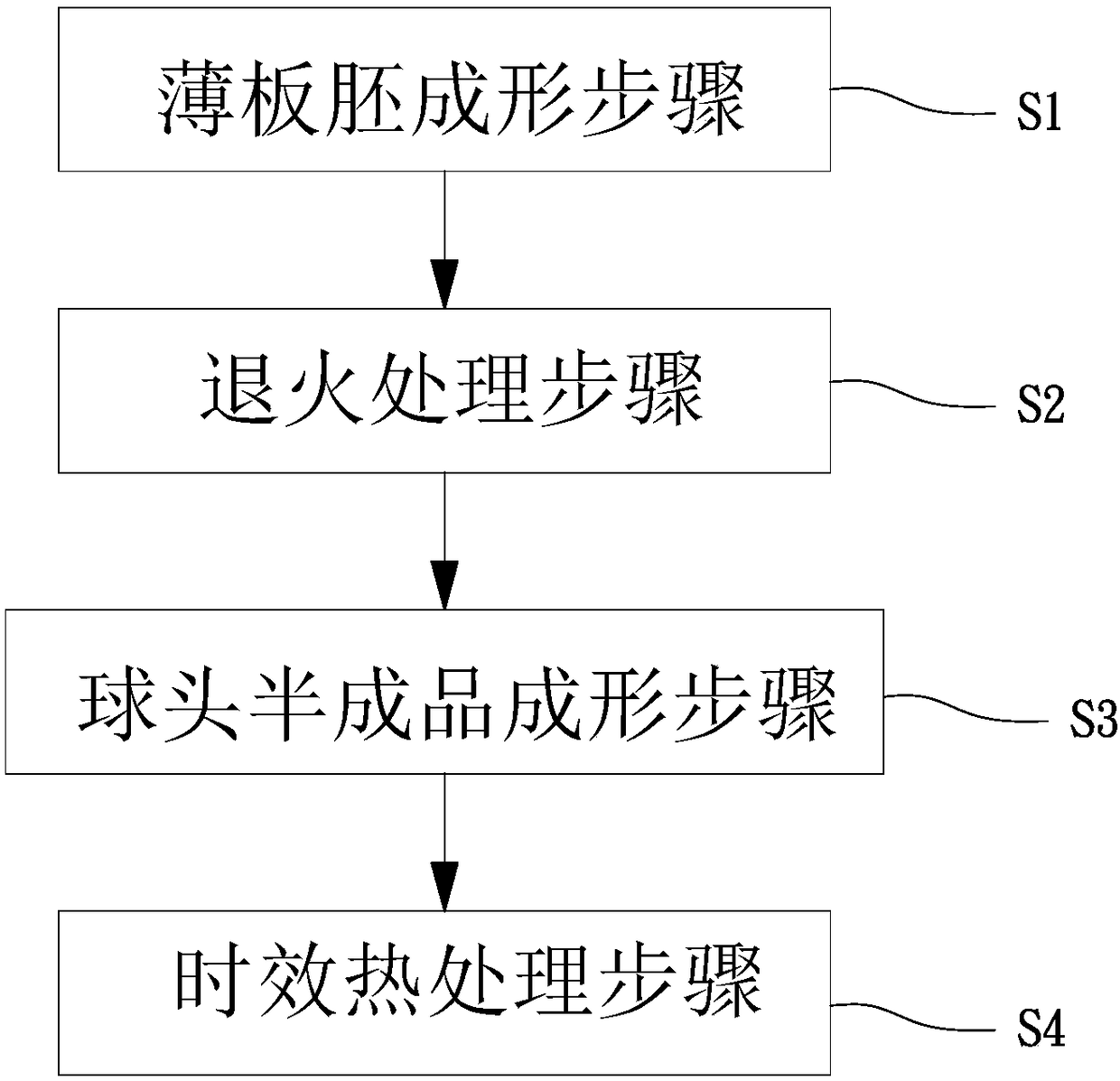

Method used

Image

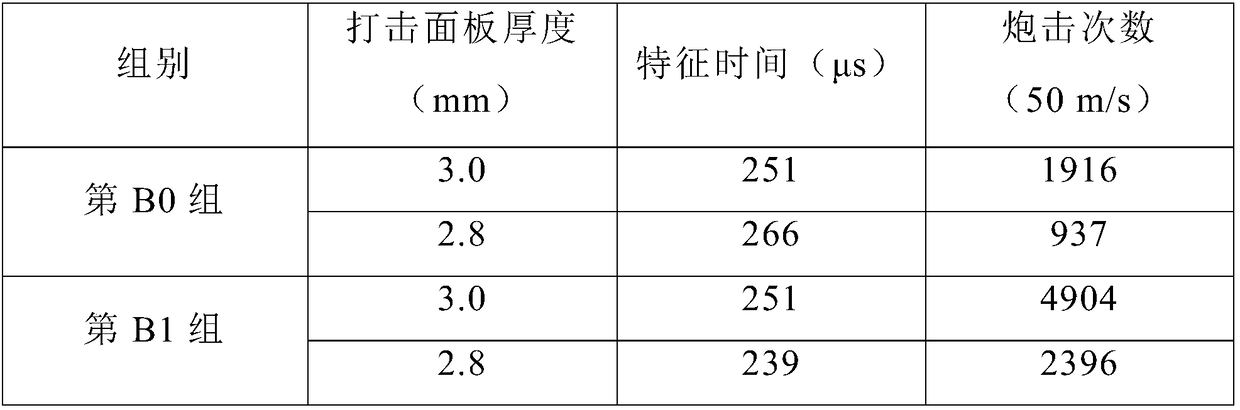

Examples

Embodiment Construction

[0020] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the following is based on the preferred embodiments of the present invention and is described in detail as follows in conjunction with the accompanying drawings:

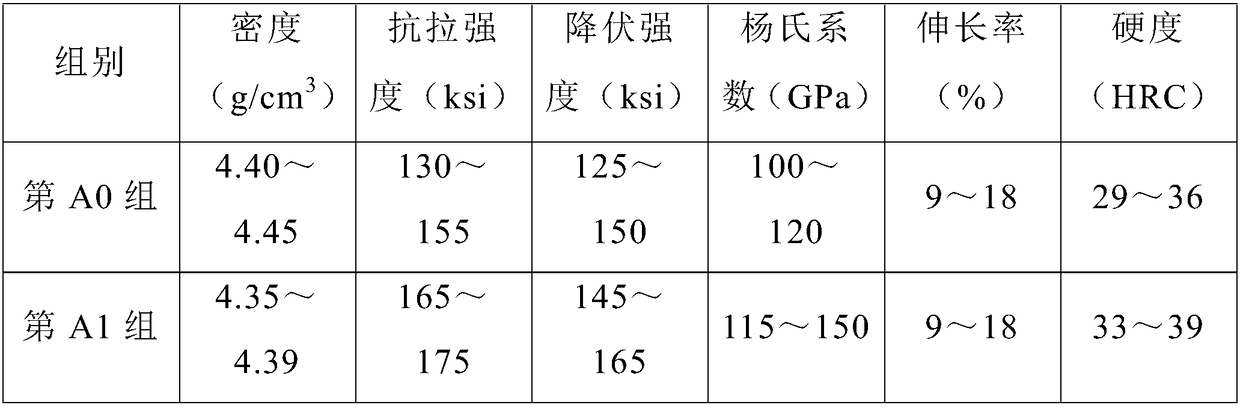

[0021] The golf club head alloy of the present invention may contain: 6.5 to 7.5% of aluminum, 1.0 to 2.5% of iron, 0.05 to 0.2% of silicon, 0.15% or less of oxygen, 0.1% or less of carbon, 0.05 % of nitrogen, the remaining proportion is titanium and unavoidable impurities, preferably can include: 6.8 to 7.5% of aluminum, 1.55 to 1.95% of iron, 0.11 to 0.15% of silicon; as the above-mentioned golf The density of the club head alloy is about 4.35~4.39g / cm 3 , by adjusting the composition ratio of the golf club head alloy, the golf club head alloy can have a lower density.

[0022] Additionally, the aluminum equivalent ([Al] eq ) can conform to the following formula: [Al] eq =[Al]+10[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com