Laser melting forming protection circulating dust-removing system and method

A laser melting and dust removal system technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low forming rate, limited forming quality precision, and influence on forming quality, so as to improve laser melting forming rate and simplify The effect of system structure complexity and system cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

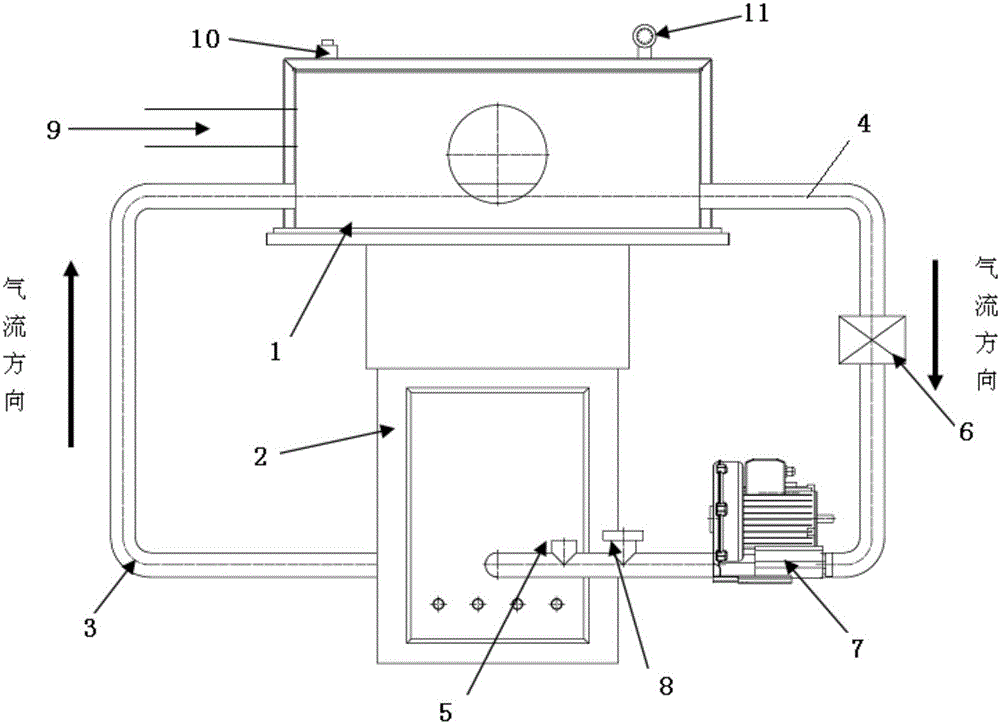

[0032] combine figure 1 , the present invention provides a laser melting forming protection cycle dust removal system, including an upper cavity 1 and a lower cavity 2; the upper cavity 1 and the lower cavity 2 are connected to each other; for a 3D printer, the upper cavity 1 is The cavity is formed by laser melting, and the lower cavity 2 is connected to the upper cavity 1 to provide related auxiliary equipment for 3D printing.

[0033] In addition, the exhaust port of the lower cavity 2 is communicated with the air inlet of the upper cavity 1 through the first gas delivery pipeline 3; air inlet, and the end of the second gas delivery pipeline 4 extends into the cavity of the lower cavity 2, and the second electromagnetic valve 5 is installed on the second gas delivery pipeline 4 in the lower cavity 2, through Controlling the opening or closing state of the second solenoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com