Patents

Literature

281 results about "Samarium cobalt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A samarium–cobalt (SmCo) magnet, a type of rare earth magnet, is a strong permanent magnet made of an alloy of samarium and cobalt. They were developed in the early 1960s based on work done by Karl Strnat and Alden Ray at Wright-Patterson Air Force Base and the University of Dayton, respectively.

Insulation for cryogenic tanks

InactiveUS20060196876A1Domestic cooling apparatusLighting and heating apparatusMetal foilMagnetic poles

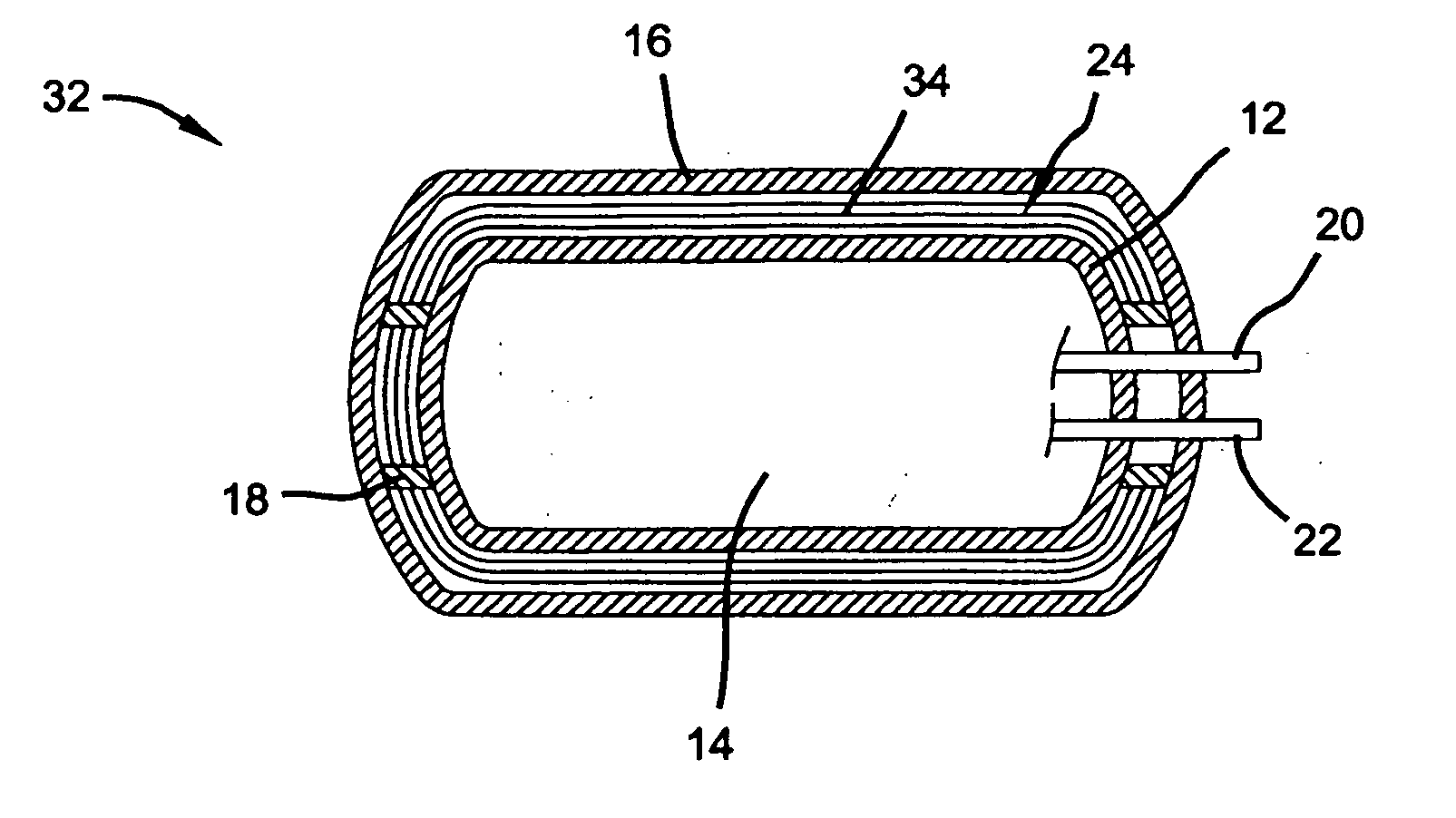

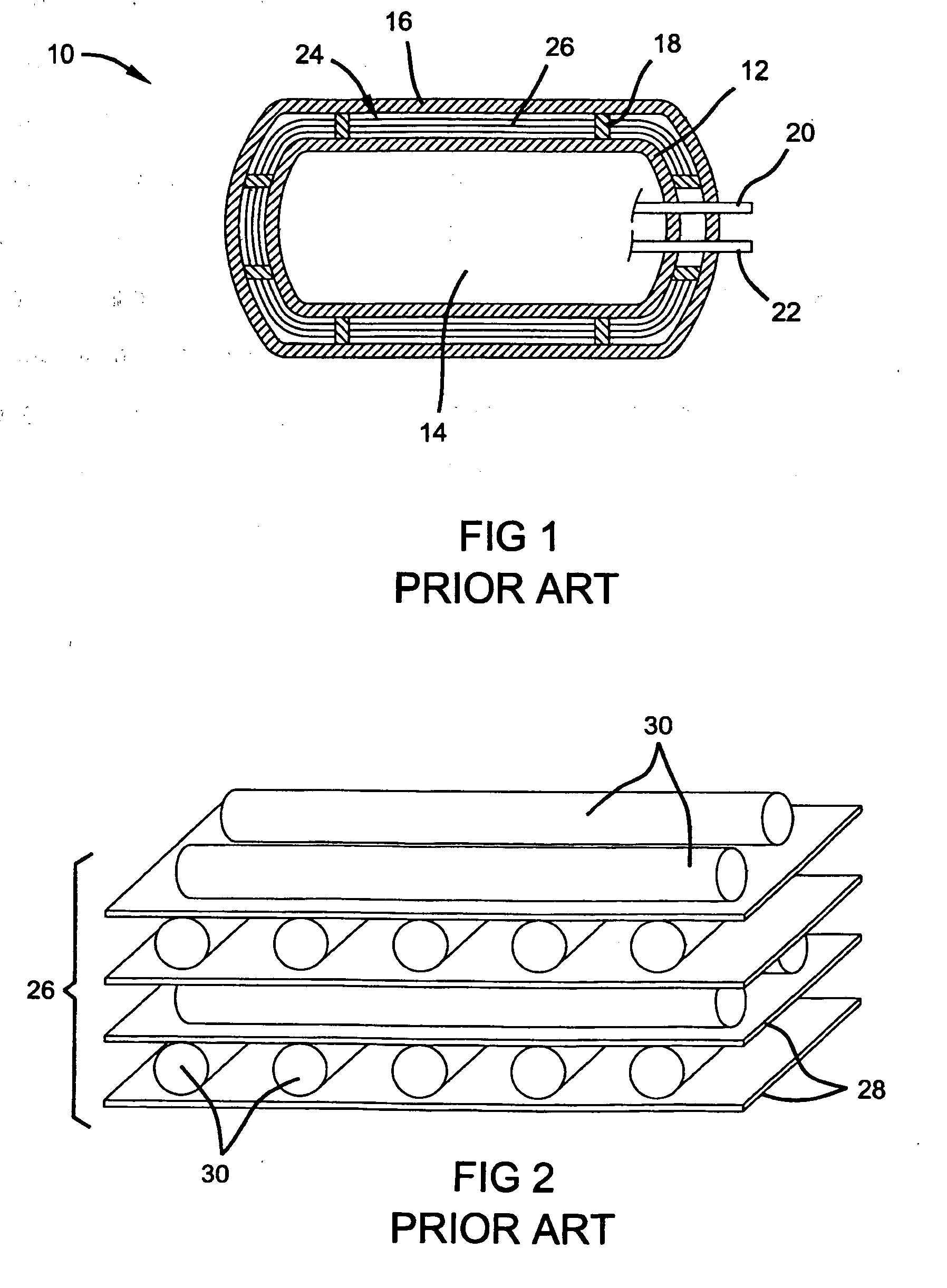

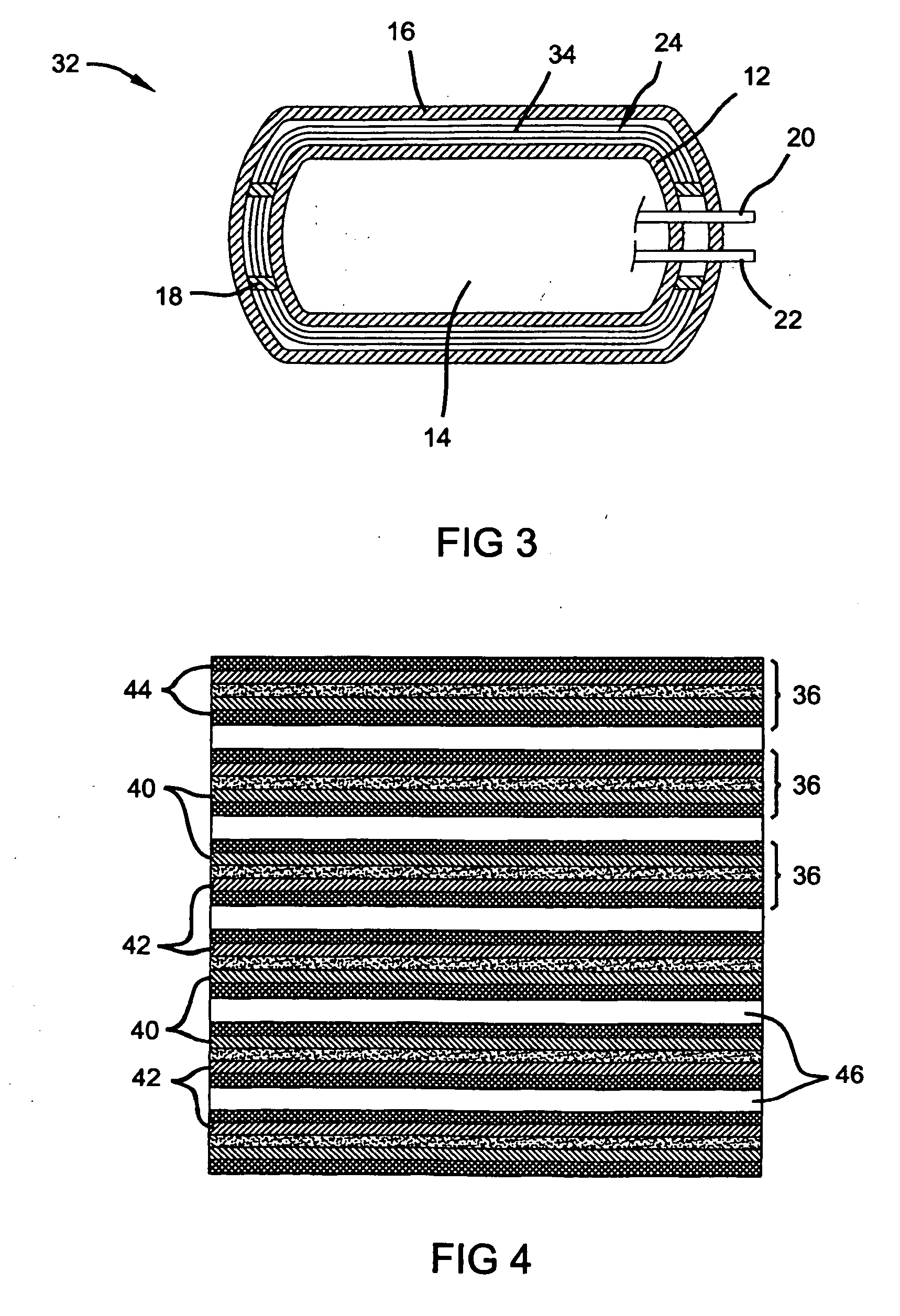

A magnetic multi-layer insulation system for a cryogenic storage tank. The system includes multiple layers of insulation comprising a carrier support structure disposed between a first major surface of a magnetic material defining a north pole facing away from the carrier support structure, and a second and opposite major surface of a magnetic material defining a south pole facing away from the carrier support structure. A reflective surface, or metal foil, is disposed adjacent the magnetic poles to deflect radiation. The layers are repelled from one another without the use of spacers. In various embodiments, the magnetic material is a permanent magnet selected from the group consisting of Samarium-Cobalt, Alnico, Neodymium-Iron-Boron, an alloy of the Lanthanide group of elements, and mixtures and alloys thereof.

Owner:GM GLOBAL TECH OPERATIONS LLC

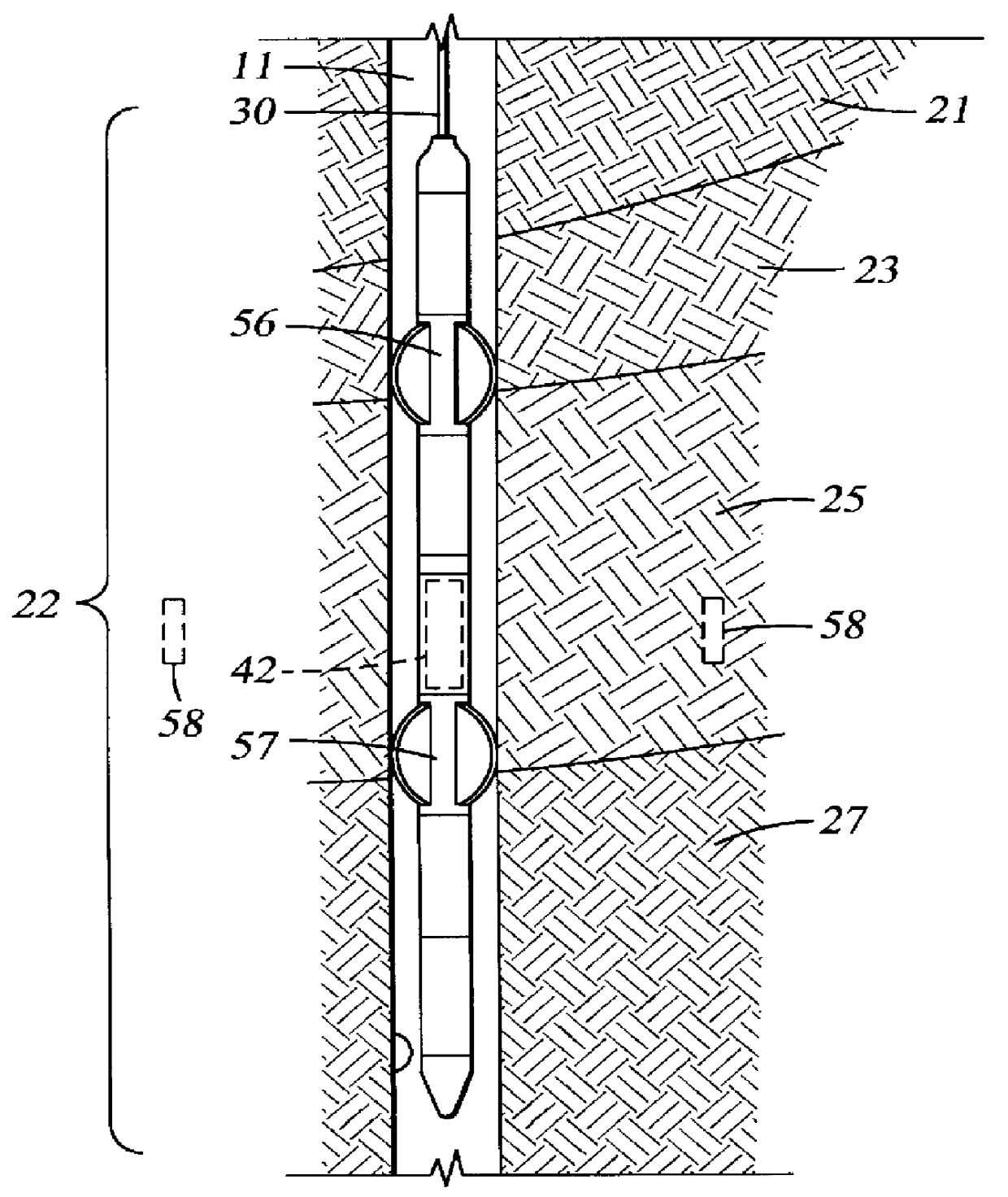

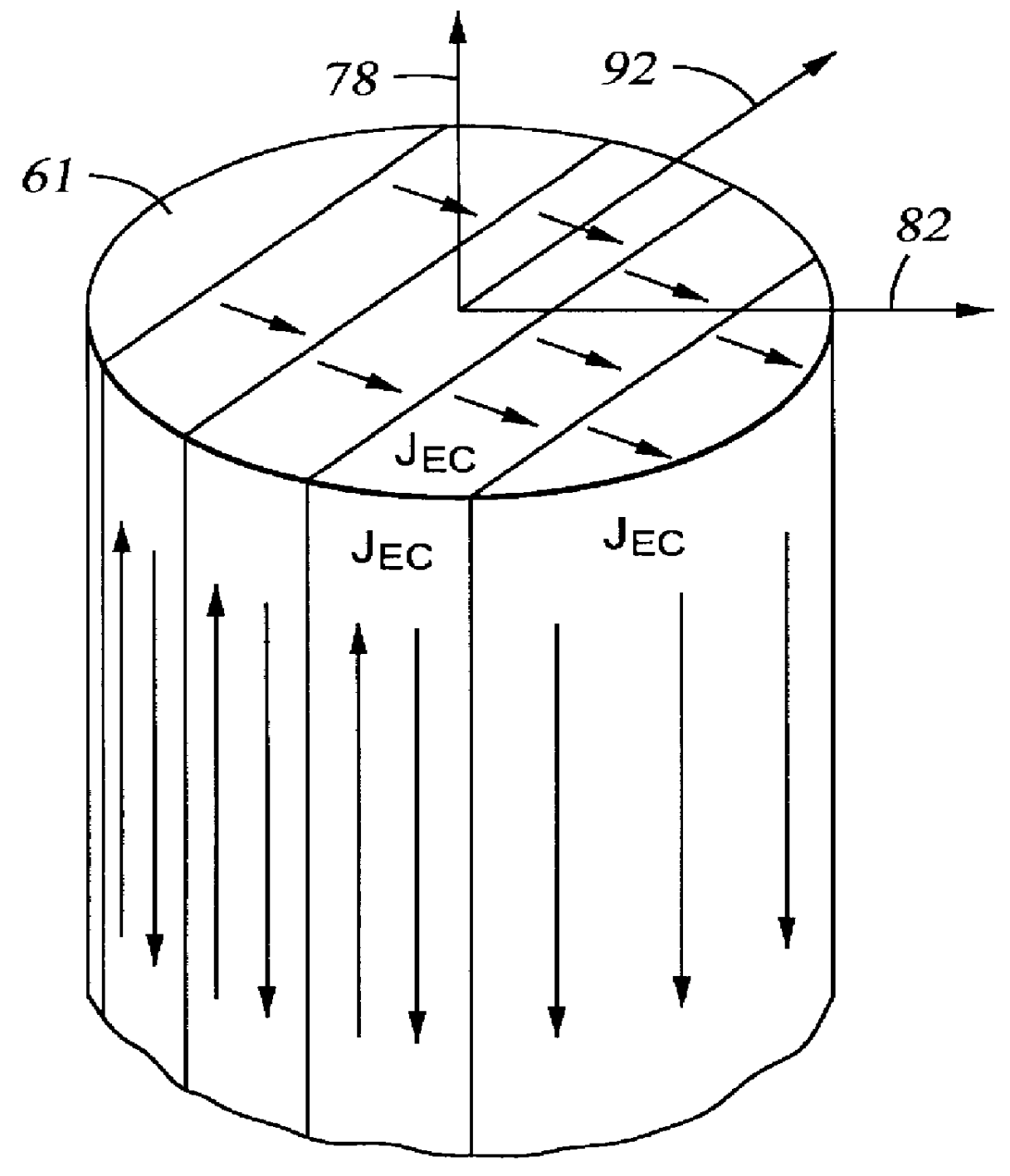

Permanent magnet material composition and structure for eddy current suppression in a nuclear magnetic resonance sensing apparatus

InactiveUS6069479AElectric/magnetic detection for well-loggingWork measurementElectricityNMR - Nuclear magnetic resonance

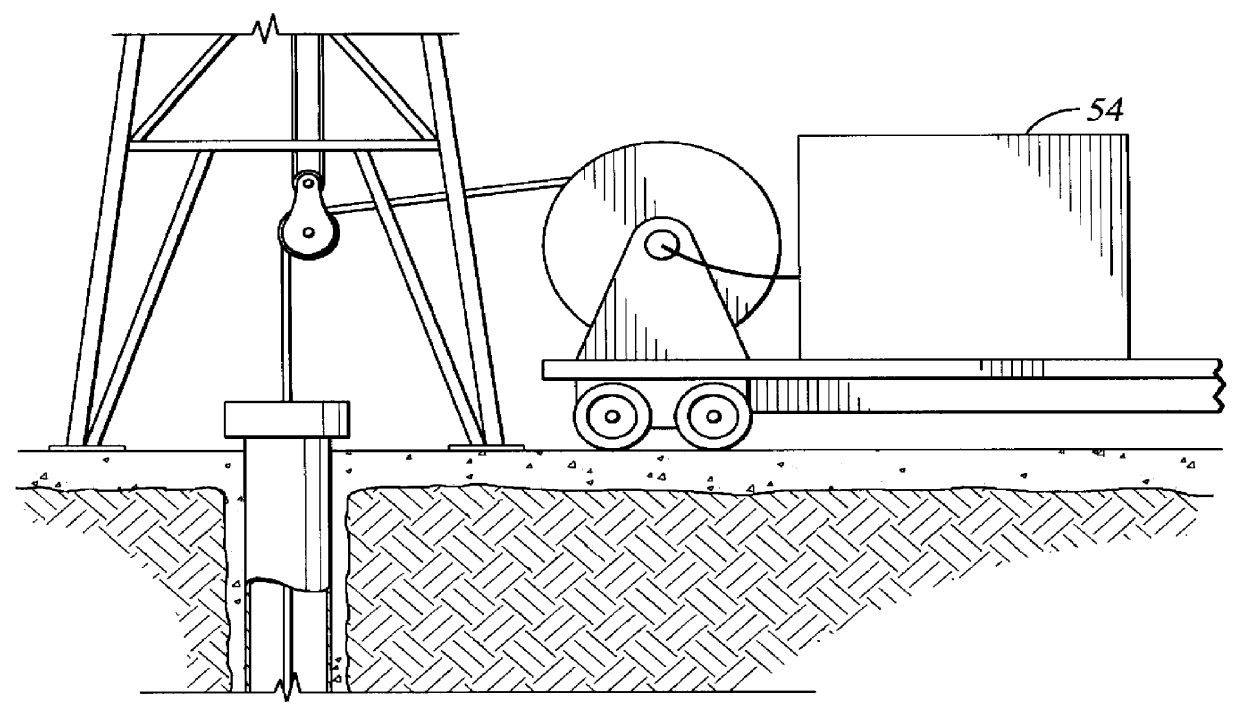

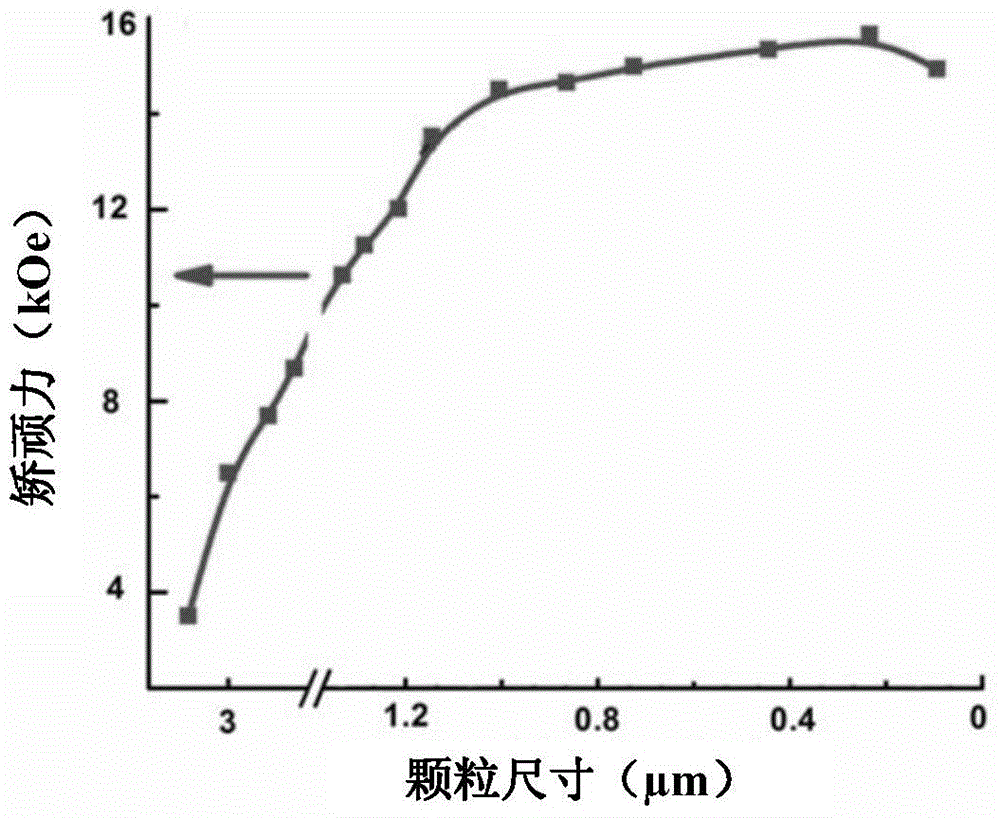

A nuclear magnetic resonance well logging apparatus, comprising an antenna for inducing a radio frequency magnetic field in earth formations surrounding the apparatus and for detecting nuclear magnetic resonance signals from the earth formations; and a magnet for inducing a static magnetic field within the earth formations. The magnet is formed from a powdered, electrically conductive permanent magnet material. The grain size of the magnet material small enough with respect to the frequency of the radio frequency magnetic field to substantially prevent intragranular power loss of the radio frequency magnetic field. The magnet is formed from electrically isolated blocks of the magnet material each having a thickness less than a skin depth of the radio frequency magnetic field within the magnet material. The boundaries between the blocks are oriented to interrupt flow of eddy currents in the magnet resulting from the radio frequency magnetic field. In a preferred embodiment, the magnet material comprises powdered, epoxy resin-bonded Samarium-Cobalt.

Owner:WESTERN ATLAS INTERNAIONAL INC

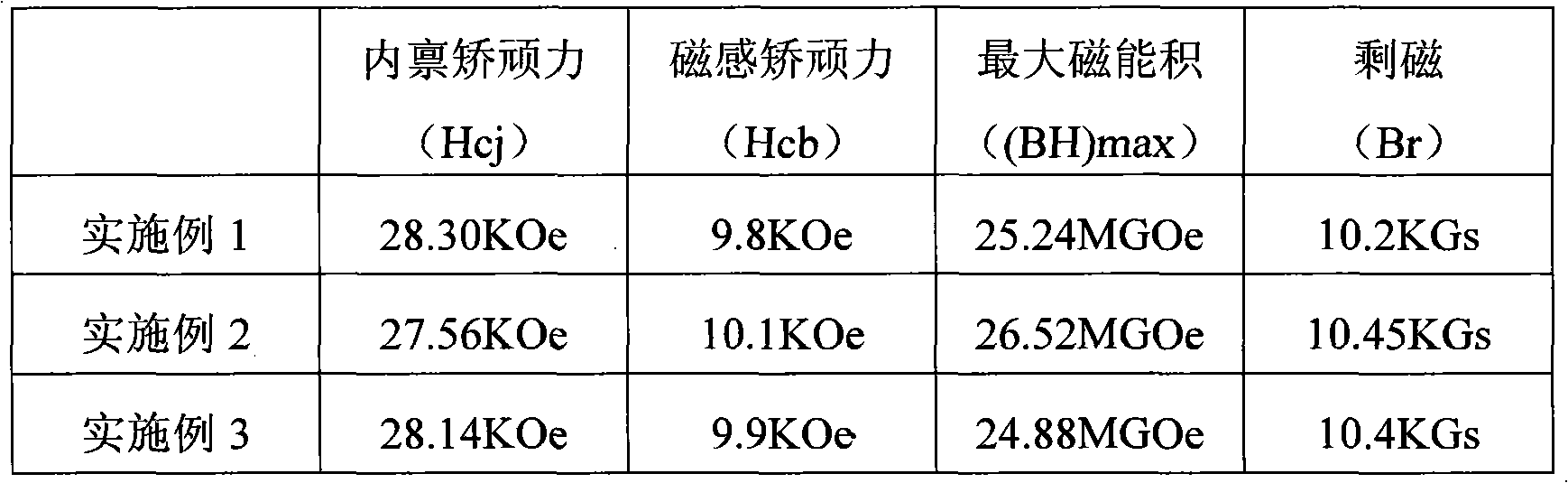

Samarium-cobalt permanent magnet material and preparation method thereof

The invention provides a samarium-cobalt permanent magnet material, which consists of the following components in percentage by mass: 23 to 25.5 percent of samarium, 44 to 50 percent of cobalt, 14 to 20 percent of iron, 3 to 8 percent of copper, 2 to 4 percent of zirconium and 0.5 to 2 percent of heavy rare earth element. The invention also provides a method for preparing the samarium-cobalt permanent magnet material, which comprises the following steps of: mixing; smelting alloys; preparing magnetic power; orienting and forming; sintering and performing solid solution; and ageing. The samarium-cobalt permanent magnet material has the characteristic of high coercive force and can effectively meet the requirement of the field of high and new technology on the high coercive force of a rare earth permanent magnet material.

Owner:NINGBO STAR MATERIALS HI TECH

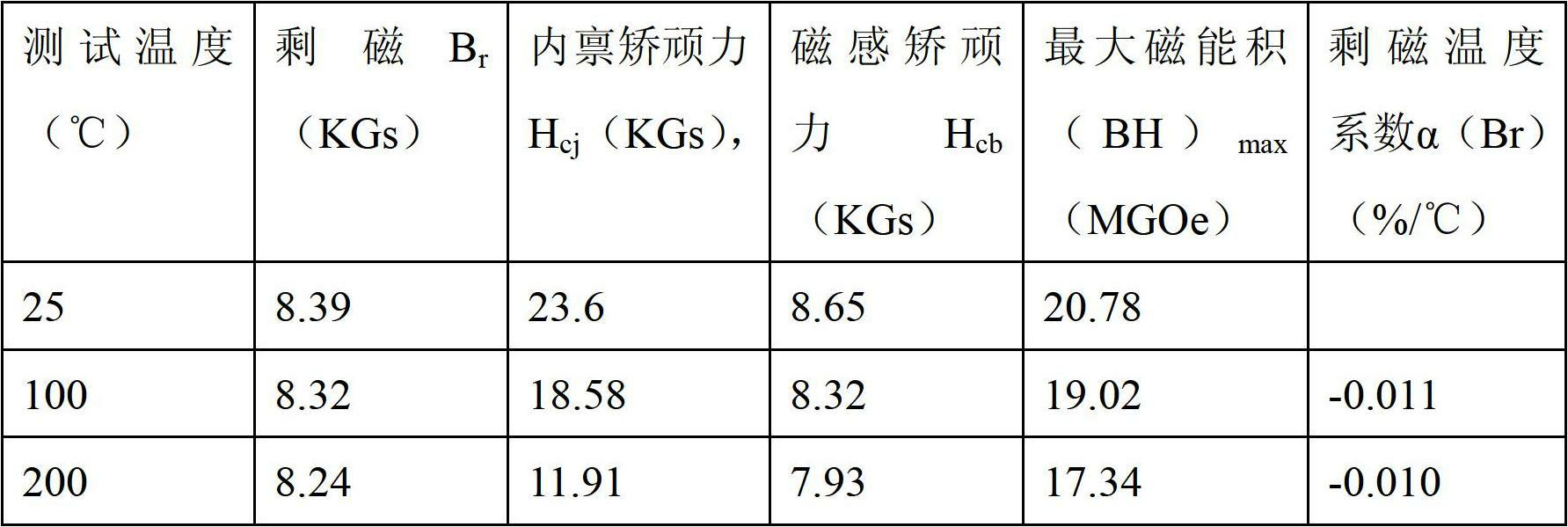

Samarium-cobalt sintered magnet material and preparation method thereof

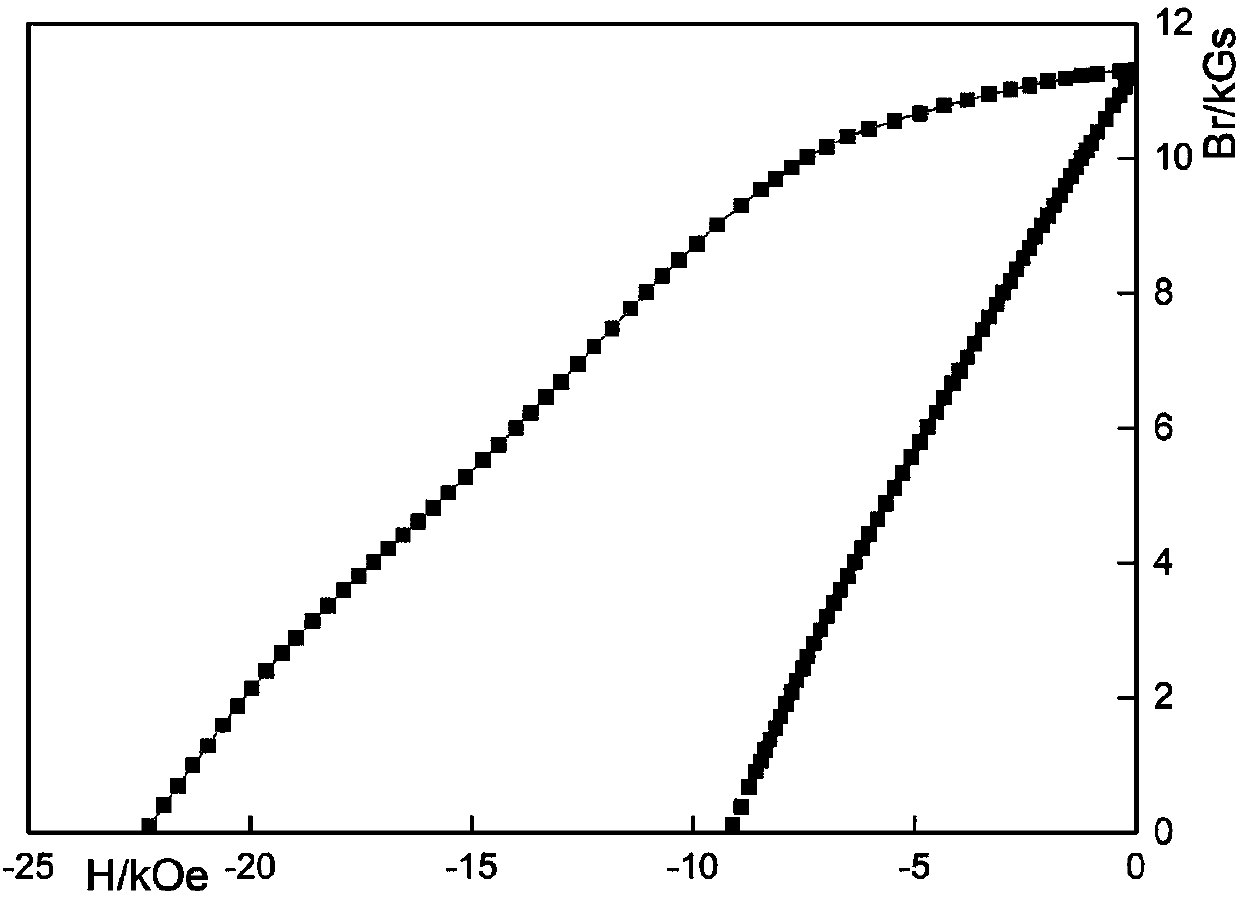

InactiveCN101882494ALower temperature coefficient of remanenceLower flux temperature coefficientMagnetic materialsRare earthCobalt

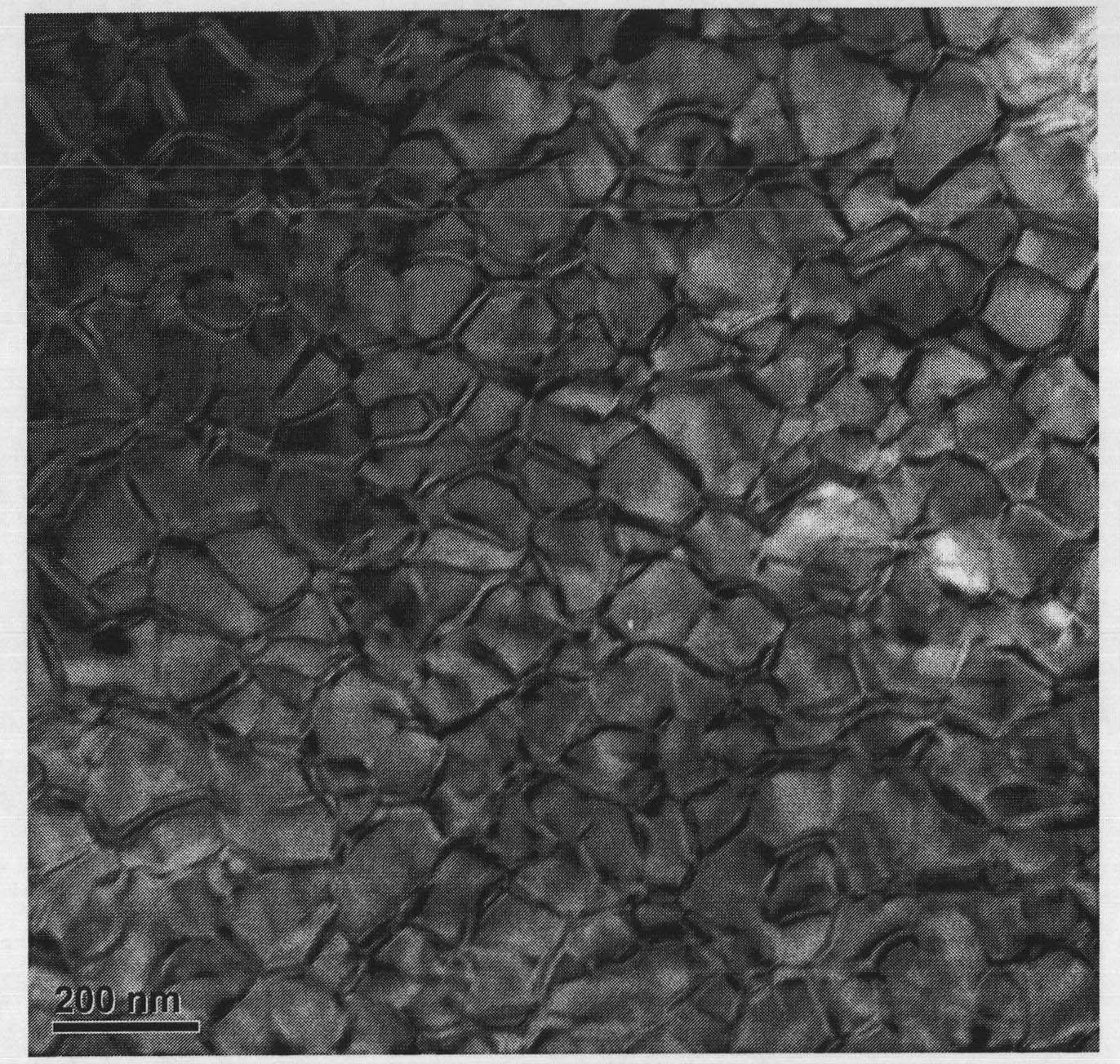

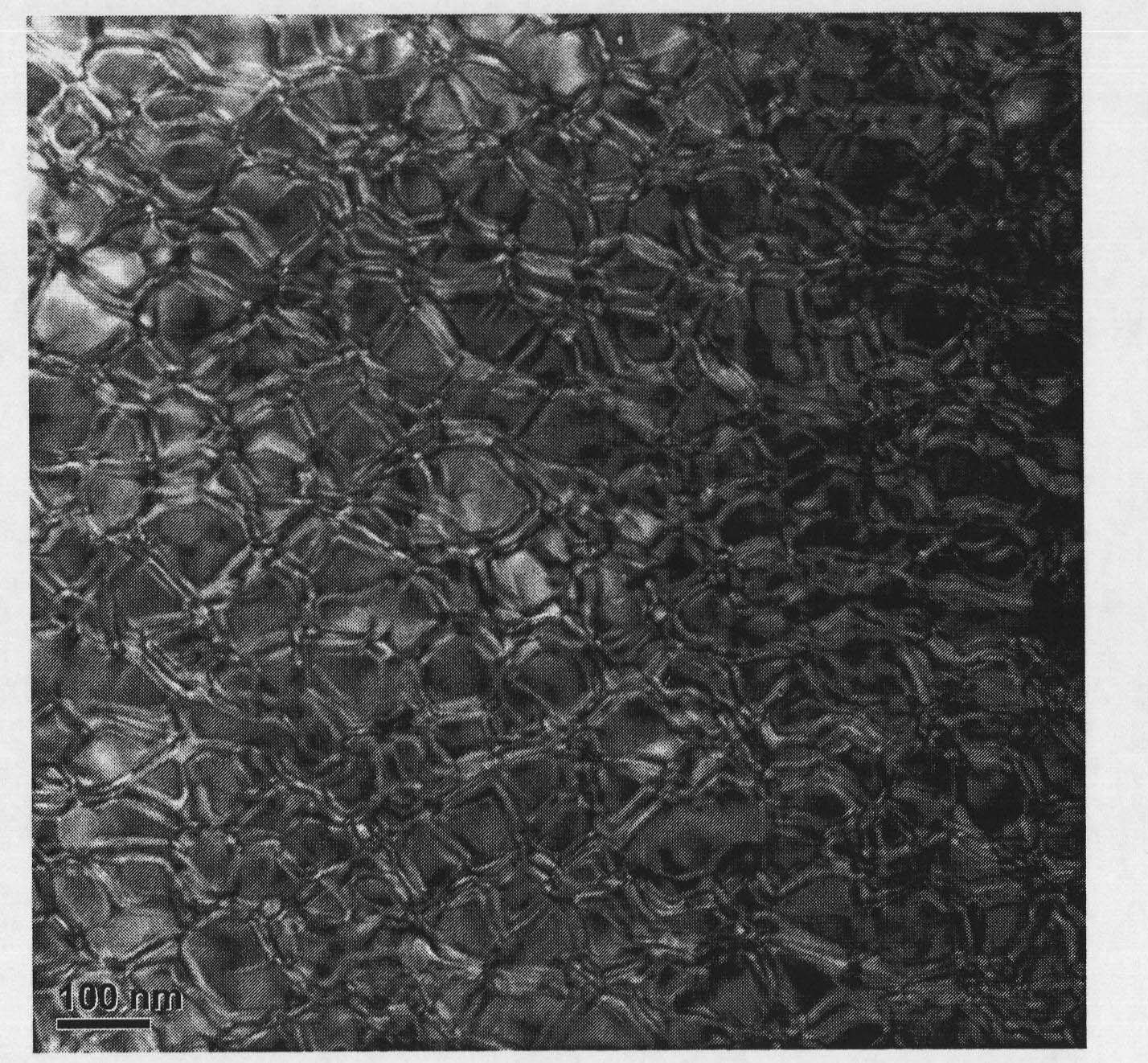

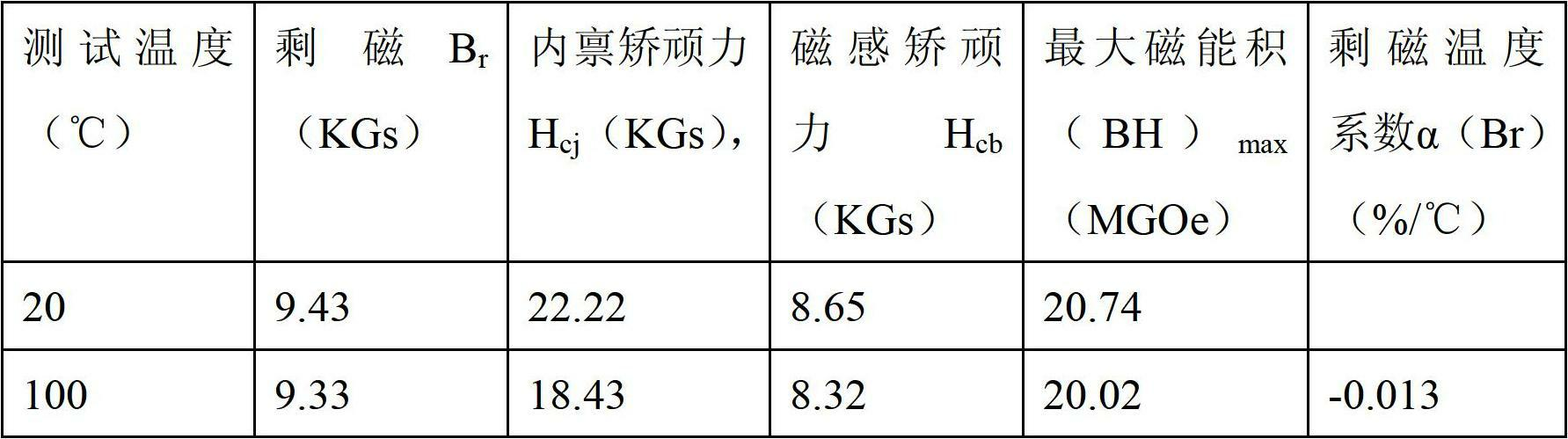

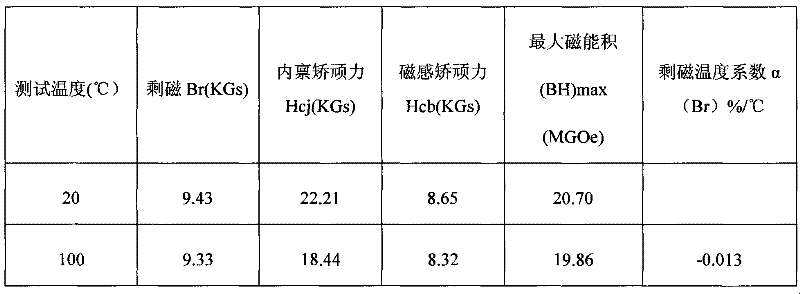

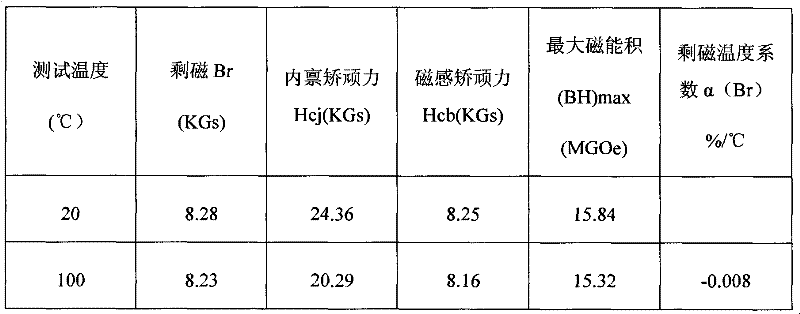

The invention discloses a 2:17 type samarium-cobalt sintered magnet material and a preparation method thereof. The 2:17 type samarium-cobalt sintered magnet material comprises the following raw materials in percentage by mass: 10 to 25 percent of samarium, 45 to 55 percent of cobalt, 10 to 20 percent of iron, 3 to 9 percent of copper, 1 to 3 percent of zirconium and 5 to 15 percent of at least one heavy rear earth element. Due to the selection and the proportion of the raw materials and the innovation of the sintering process, a microstructure of the magnet material is optimized, and the aims of reducing the temperature coefficient of a magnet and simultaneously maintaining higher magnetic energy product of the magnet are fulfilled, wherein the magnetic energy product of the prepared magnet is 14 to 25 MGsOe, the residual magnetism temperature coefficient is about -0.005 to -0.03 percent per DEG C, and a lower magnetic flux temperature coefficient is maintained in an environment at the temperature of between -35 and 300 DEG C.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of sintered samarium-cobalt magnet

ActiveCN107316726AControl magnet oxygen contentGood mechanical propertiesInductances/transformers/magnets manufactureMagnetic materialsSamarium–cobalt magnetAlloy

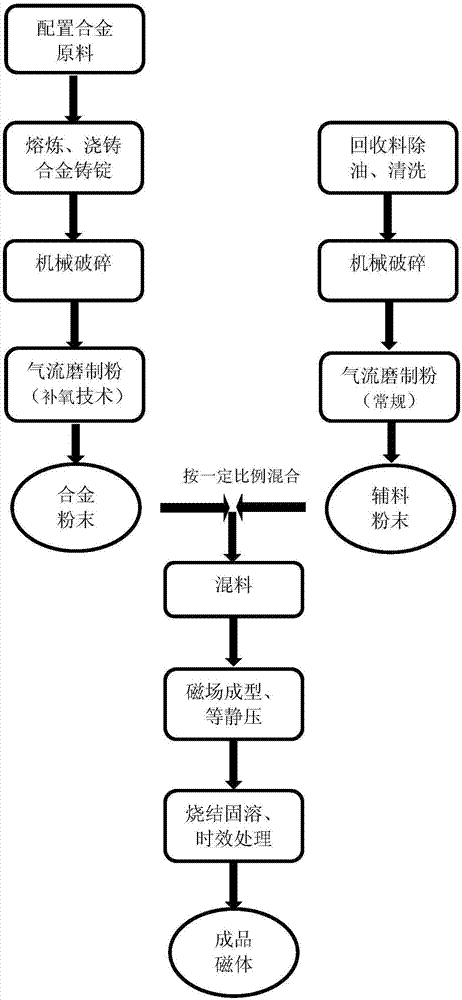

The invention relates to a preparation method of a sintered samarium-cobalt magnet. The preparation method comprises the steps that alloy powder is prepared, wherein samarium-cobalt alloy raw materials are prepared, by weight, 25%-27% of (Sml-xRx), 6%-25% of Fe, 2%-3.5% of Zr, 3%-8% of Cu and the balance Co, 0<=x<=0.9, R is one or more of Ce, Pr, Nd, Gd, Tb, Dy, Ho and Er, and the samarium-cobalt alloy raw materials are subjected to smelting, casting and mechanical crushing and then subjected to an oxygen supplementary flow powder grinding technique to prepare the alloy powder; 2, leftover materials and waste materials which have the components similar to those of the alloy powder are subjected to cleaning, crushing and conventional air flow powder grinding and then fully mixed with a lubricant to prepare auxiliary material powder; 3, the materials are mixed, wherein the alloy powder and the auxiliary material powder are mixed in proportion to prepare samarium-cobalt alloy powder; 4, magnetic field molding and isostatic pressing are conducted to prepare a green body; and 5, sintering, solid solution and aging processing is conducted, and the samarium-cobalt magnet is prepared. The sintered samarium-cobalt magnet prepared through the method has the good mechanical performance and has the bending strength higher than 100 MPa.

Owner:CENT IRON & STEEL RES INST

High-temperature high-coercivity samarium-cobalt permanent magnet material and preparation method thereof

ActiveCN108039258ALarge-scale industrial productionPromote growthInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementIngot

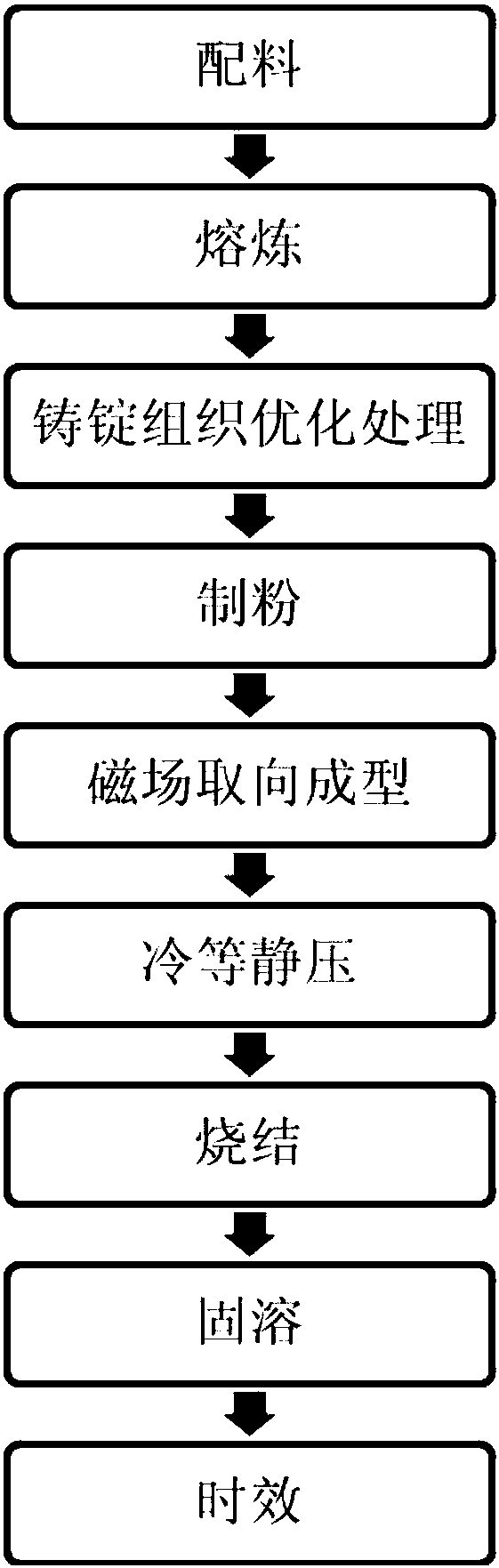

The invention provides a high-temperature high-coercivity samarium-cobalt permanent magnet material and a preparation method thereof. The permanent magnet material is Sm(Co1-u-v-wFeuCuvZrw)z, whereinu ranges from 0.09-0.18, v ranges from 0.05-0.10, w ranges from 0.02-0.04 and z ranges from 6.9-7.8. The preparation method includes the steps that the rare earth element Sm with the purity of 99.95%,Co with the purity of 99.98%, Cu with the purity of 99.99%, Fe with the purity of 99.9% and Zr with the purity of 99.9% are evenly mixed and smelted into an alloy ingot, and the ingot is subjected tostructure optimization treatment; micron-sized alloy powder is prepared by using the powder metallurgy technology, then orientation forming, high-temperature sintering, solid solution and aging treatment are conducted, and the samarium-cobalt permanent magnetic alloy is prepared. According to the method, the proportion of a TbCu7 structure is effectively improved, and a samarium-cobalt permanentmagnet free of a Zr6(FeCo)23 phase and uniform in structure is prepared, has high coercivity, high magnetic energy and other excellent properties at ultra-high temperature and can be suitable for ultra-high-temperature environments with the temperature of 550 DEG C or above.

Owner:BEIHANG UNIV

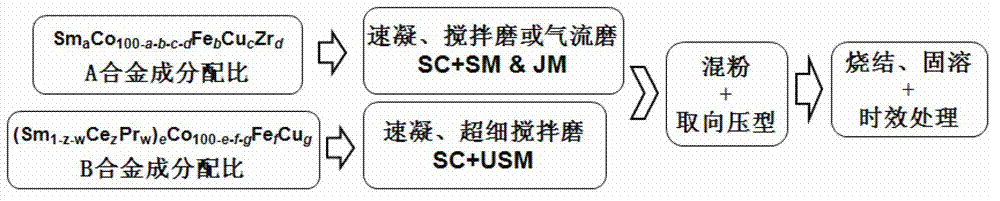

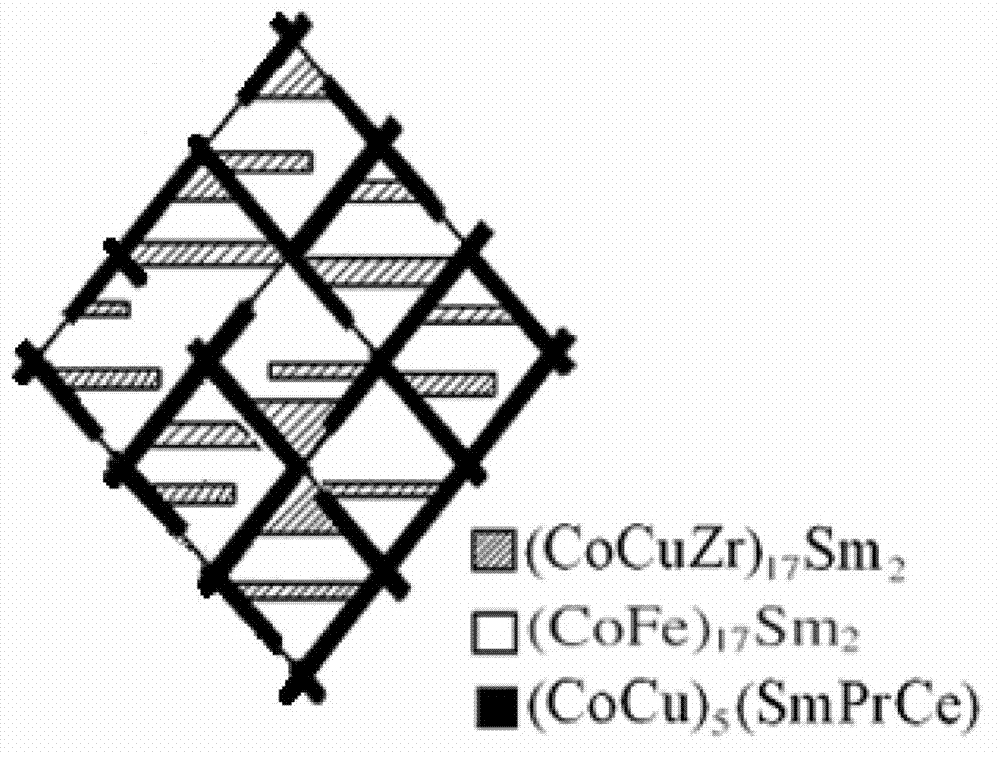

High-remanence low-coercivity samarium cobalt permanent magnetic material and preparation method

ActiveCN102760545AHigh surface magnetic fieldReduce sinteringMagnetic materialsRemanenceChemical composition

The invention belongs to the field of rare earth permanent magnetic material manufacturing, and relates to a high-remanence low-coercivity samarium cobalt permanent magnetic material and a preparation method. The chemical components of the permanent magnetic material by mass percent are shown as follows: 23-26.5% of [Sm1-x-y(Prx, Cey)], 17-20% of Fe, 3-6% of Cu, 1-3% of Zr, and the balance of Co, wherein x is not less than 0 and not more than 0.1, and y is not less than 0 and not more than 0.1. In the preparation method, a double main phase alloying method and a rapid hardening technology are used, a rapid hardening belt with two components is needed only, and a high-remanence low-coercivity magnet can be prepared; an anti-oxidation lubricant is added in a jet milling process so as to prevent agglomeration and oxidation of magnetic powder, and the oxygen content of the magnet is less than 1500ppm. By addition of Ce and Pr, the thermal treatment temperature of the samarium cobalt permanent magnetic material is reduced. The magnet performance is shown as follows: Br=11.0-11.5kGs, Hcj=10-20kOe, and (BH)max=28-33MGOe.

Owner:CENT IRON & STEEL RES INST

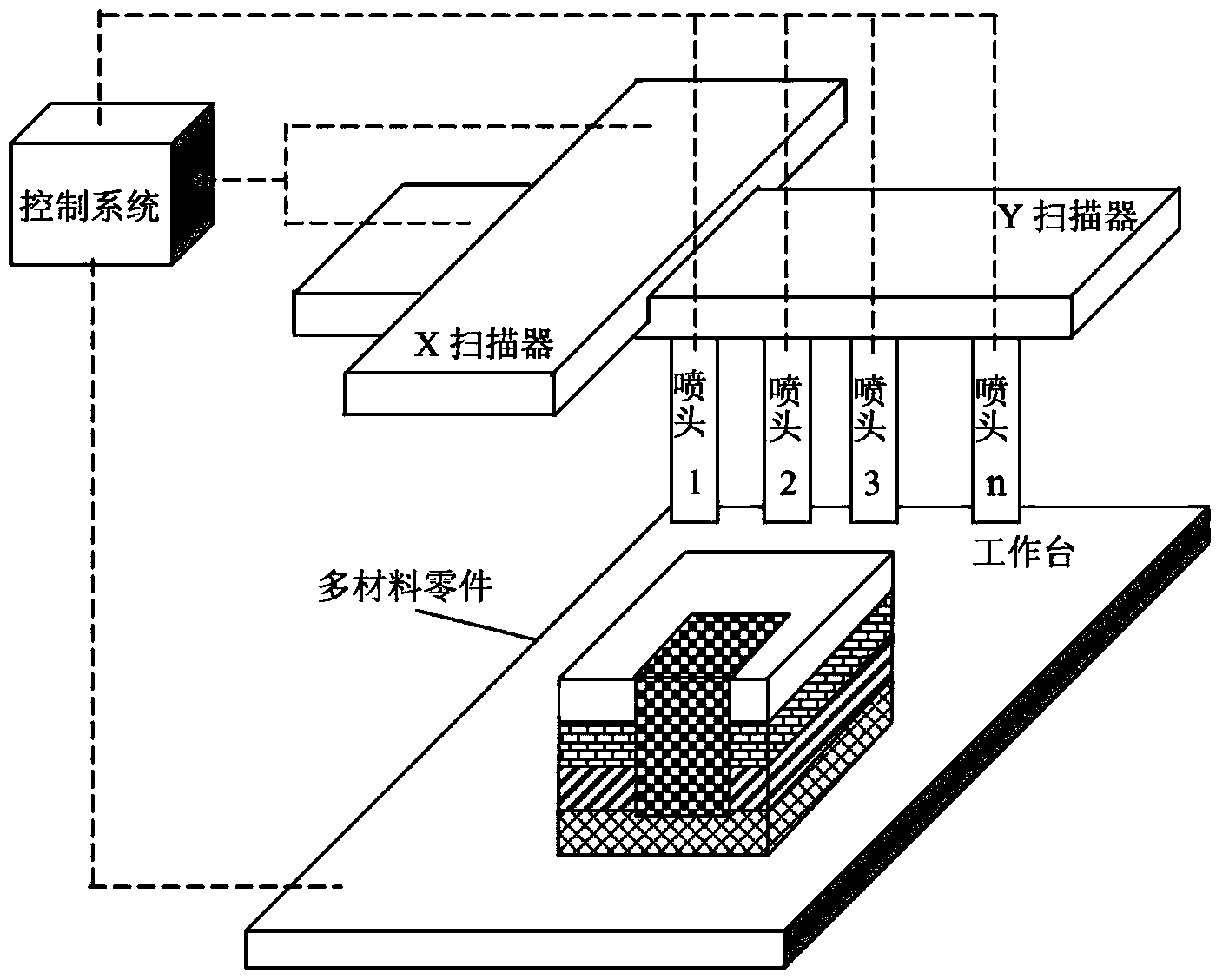

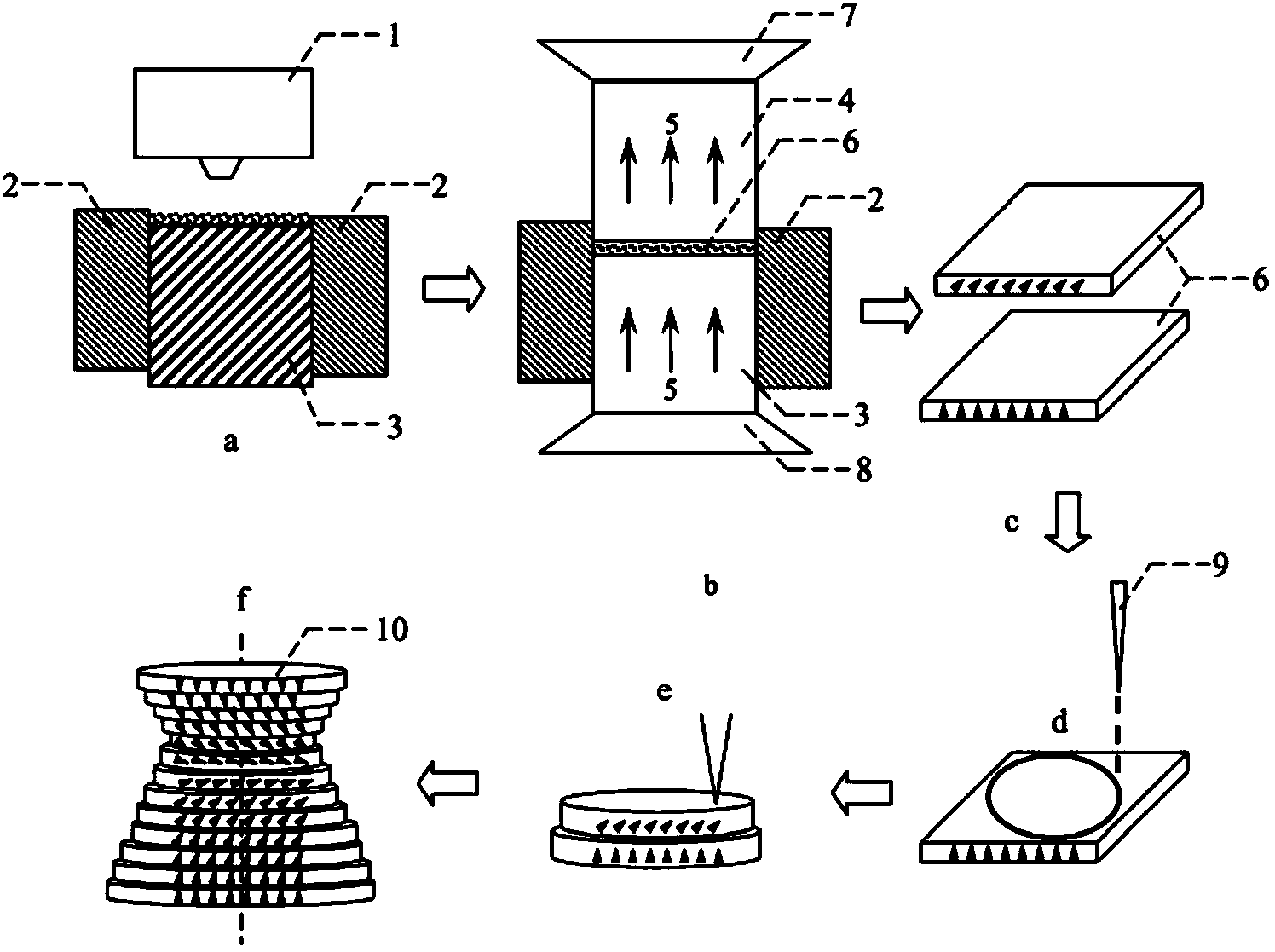

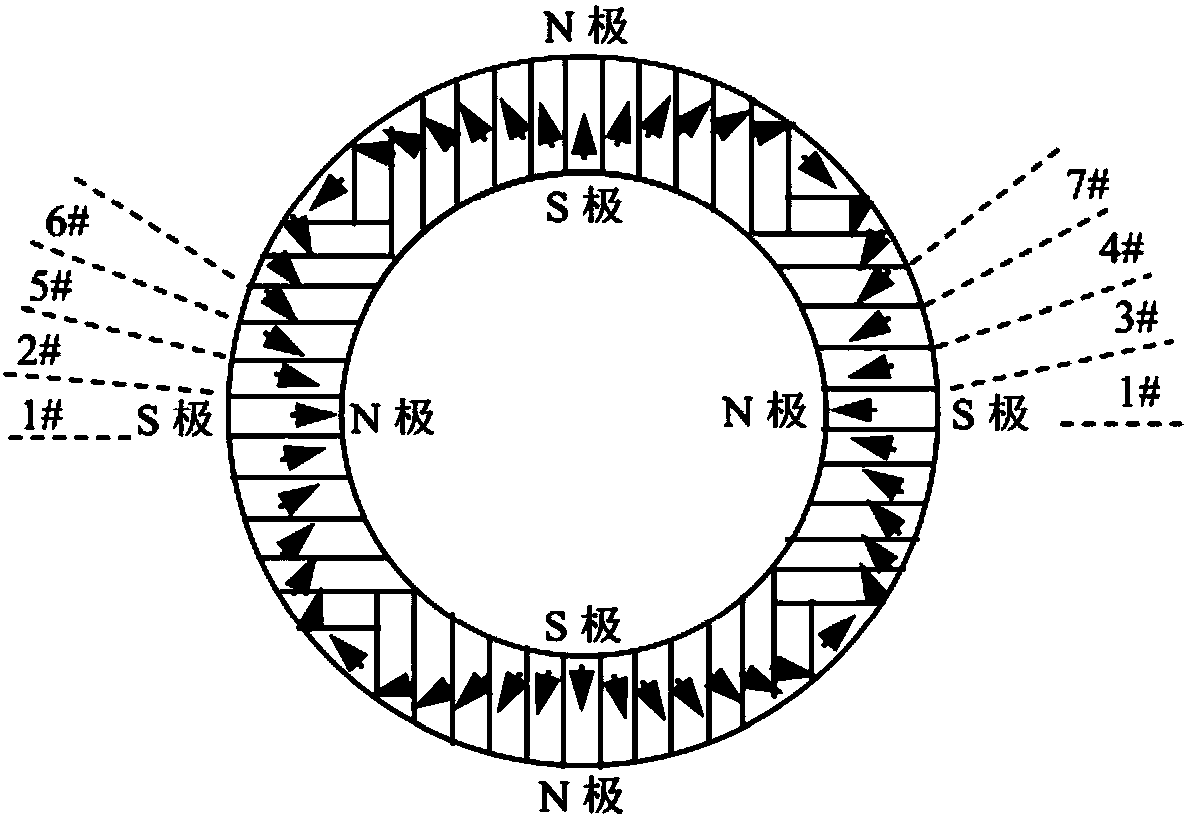

Magnetic field orientation three-dimensional printing anisotropic bonded permanent magnet and preparation method thereof

ActiveCN104269265AAchieve regulationElimination of magnetic interaction forcesInductances/transformers/magnets manufactureRare earthNitrogen

The invention relates to the technical field of rare earth permanent magnetic materials, in particular to a magnetic field orientation three-dimensional printing anisotropic bonded permanent magnet and a preparation method thereof. The magnetic field orientation three-dimensional printing anisotropic bonded permanent magnet, adopts magnet powder having magnetocrystalline anisotropy, comprises one or a plurality of anisotropic neodymium iron boron magnetic powder, samarium cobalt magnetic powder and samarium iron nitrogen powder and is a semi-continuous or continuous orientation changed anisotropic bonded permanent magnet. The magnetic field orientation three-dimensional printing anisotropic bonded permanent magnet is prepared by the following steps of powder filling, orienting and forming into sheet layers, thermal demagnetizing, cutting the sheet layers into required-shaped unit sheet layers, stacking and solidifying the unit sheet layers layer by layer and magnetizing. According to the magnetic field orientation three-dimensional printing anisotropic bonded permanent magnet and the preparation method thereof, preparation of the three-dimensional printing anisotropic bonded permanent magnet is achieved, adjustment of the orientation and the order degree of powder in the sheet layers are achieved by adjusting the magnetic field direction and or the magnetic field strength, the defect that orientation of the traditional bonded permanent magnet cannot be changed is overcame, and continuous or semi-continuous change of magnetic orientation in the same three-dimensional entity is achieved.

Owner:CENT IRON & STEEL RES INST

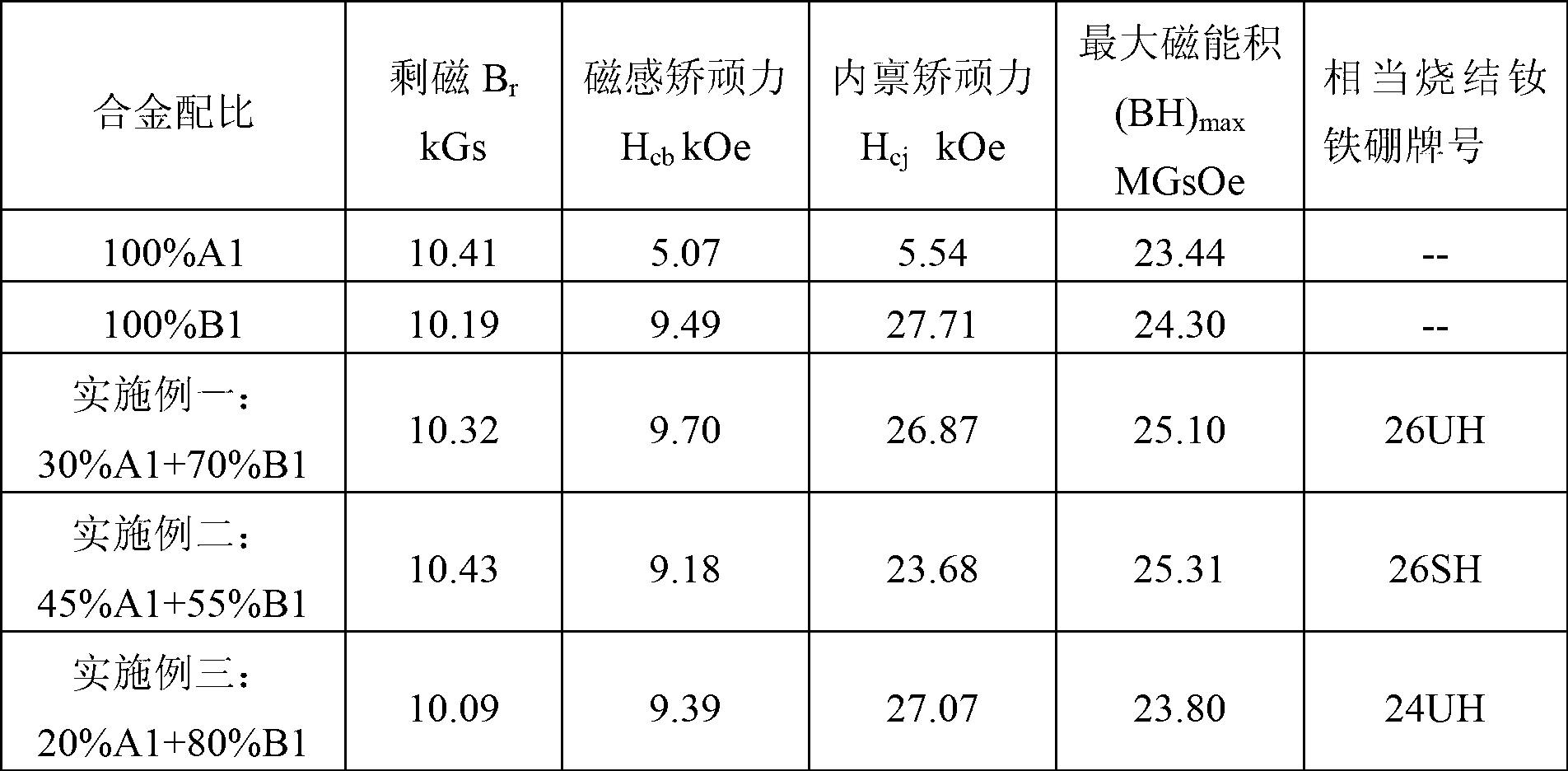

Method for preparing sintered samarium-cobalt magnet

ActiveCN103065788AGet over the actual ingredientsTo overcome the large deviation of design componentsInorganic material magnetismInductances/transformers/magnets manufactureRemanenceSamarium–cobalt magnet

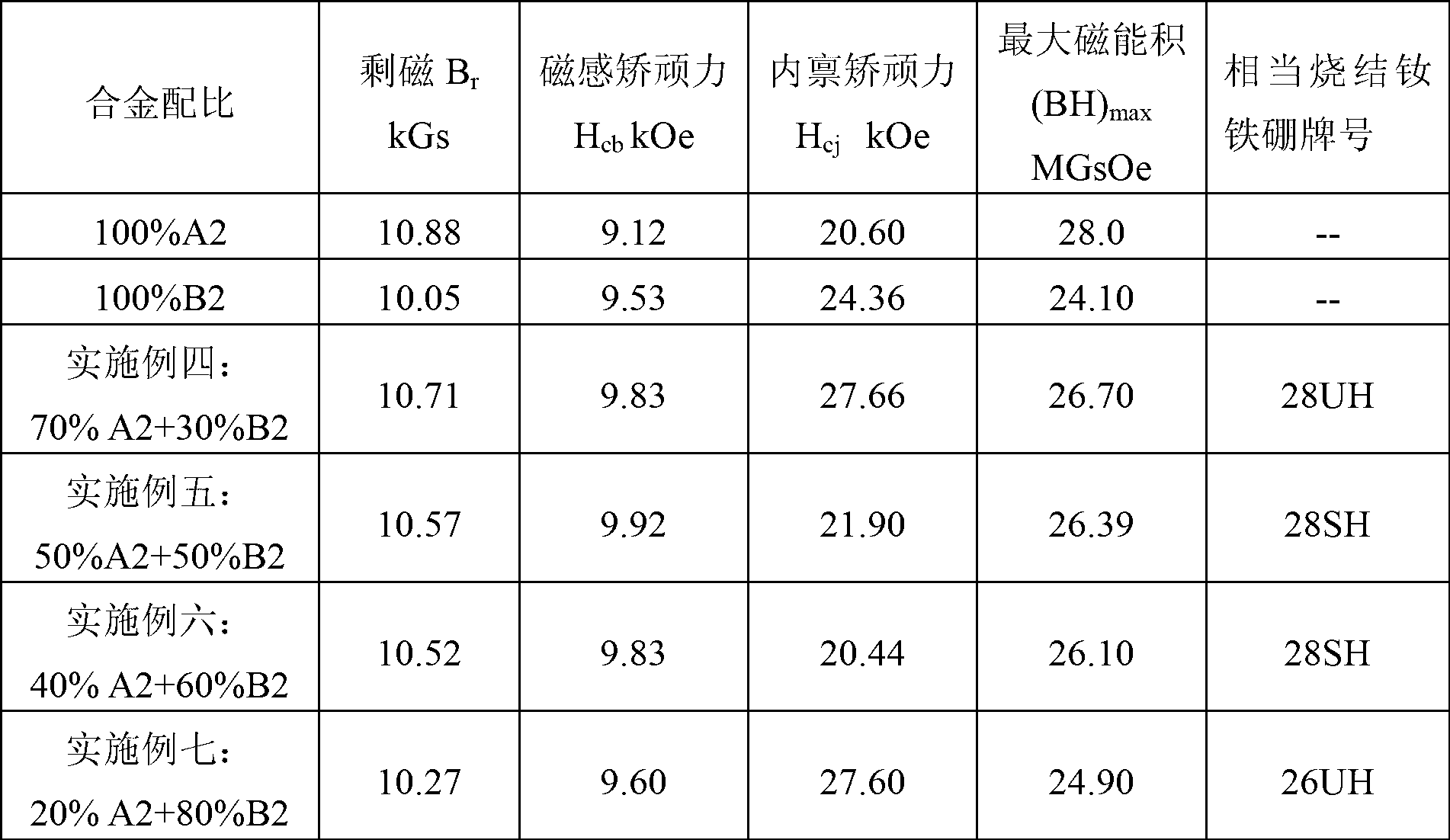

The invention discloses a method for preparing a sintered samarium-cobalt magnet. The method comprises the following steps of: preparing a first samarium-cobalt alloy and a second samarium-cobalt alloy; performing primary crushing on the first samarium-cobalt alloy and the second samarium-cobalt alloy; mixing first samarium-cobalt alloy primarily crushed magnetic powder and second samarium-cobalt alloy primarily crushed magnetic powder, and performing fine crushing, so that primarily crushed mixed magnetic powder is refined, and components are homogenized; and performing magnetic field orientation forming, cold isostatic pressing, sintering, solid solution treatment and ageing treatment on samarium-cobalt magnetic powder obtained by fine crushing in sequence. The method has the advantages that the first samarium-cobalt alloy has high remanence component characteristic, the second samarium-cobalt alloy has high coercivity component characteristic, the sintered samarium-cobalt magnets with various magnetic properties can be obtained by adjusting the mixing ratio of the first samarium-cobalt alloy primarily crushed magnetic powder to the second samarium-cobalt alloy primarily crushed magnetic powder, and the process is stable and low in cost.

Owner:NINGBO YUNSHENG +3

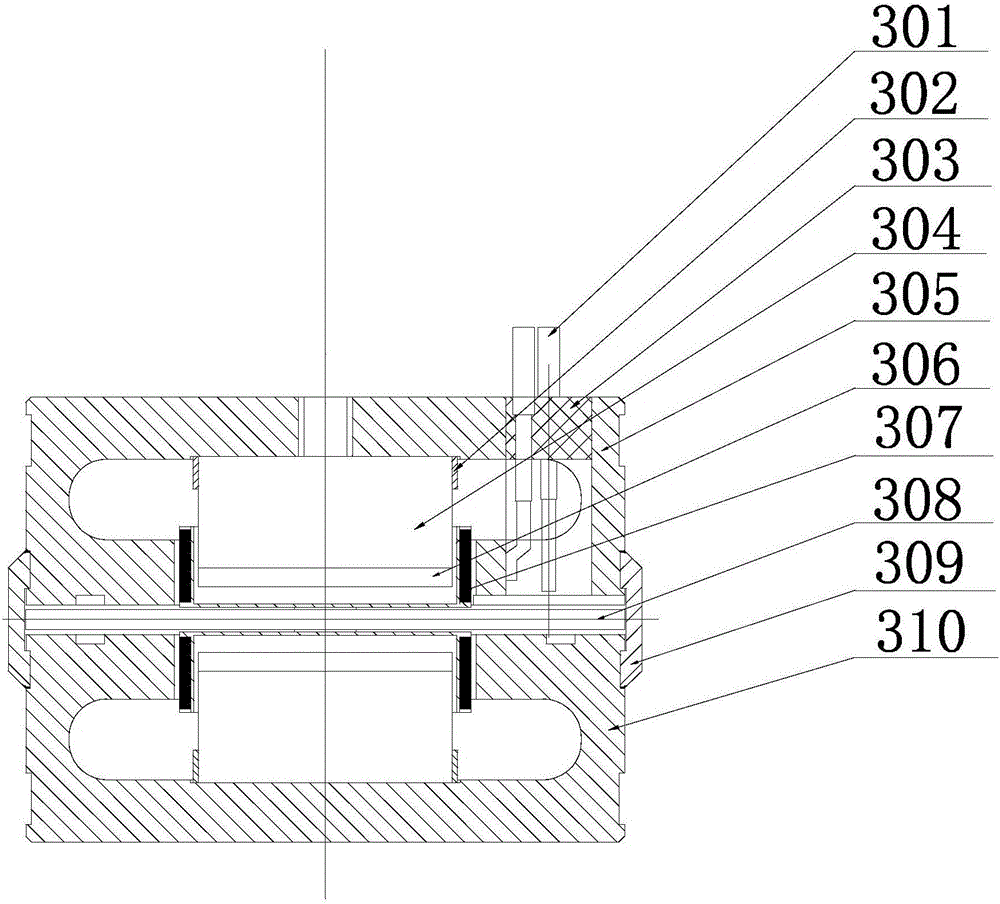

High-temperature resistant quartz flexure accelerometer

ActiveCN106226555AIncrease the dosage ratioImprove stabilityAcceleration measurementAccelerometerMass ratio

The invention discloses a high-temperature resistant quartz flexure accelerometer, and the flexure accelerometer comprises a meter head and a servo circuit, wherein the meter head and the servo circuit are welded through a wire to form electrical connection. The housing of the servo circuit and the meter head are welded through a laser welding machine to form an integrated machine. The meter head comprises a meter core, a housing, and an isolating ring. The meter core comprises a quartz swinging piece assembly, an upper torquer, and a lower torquer. The upper and lower torquers respectively comprise a magnetic steel, which is a samarium cobalt magnetic steel, wherein the mass ratio of all elements in the samarium cobalt magnetic steels (samarium: cobalt: ferrum: copper: zirconium: praseodymium) is 2: 25: 1.5: 0.1: 0.05: 0.08. According to the invention, the flexure accelerometer can enable the resisted temperature of the flexure accelerometer to be increased to 180 DEG C, and the temperature coefficient of a scale factor (K1) of the flexure accelerometer is controlled to be less than 200ppm / DEG C. Moreover, the flexure accelerometer can work under 200 DEG C for at least four hours.

Owner:保定开拓精密仪器制造有限责任公司

A method for preparing samarium cobalt permanent magnet

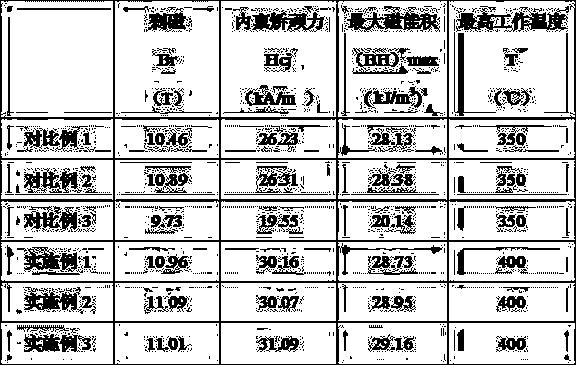

InactiveCN109273240AOvercoming high comprehensive magnetic propertiesOvercome temperatureInductances/transformers/magnets manufactureMagnetic materialsWorking temperatureCobalt

A method for preparing samarium cobalt permanent magnet comprises the following steps: (1) smelting the prepared raw materials containing samarium, cobalt, iron, copper and zirconium, refining at reduced frequency and heat preservation, and quenching to obtain samarium-cobalt alloy ingots; (2) coarsely crushing the samarium-cobalt alloy ingot into coarse particles with the particle size of 20 to 100 microns; 3) that coarse particle of the samarium-cobalt alloy are further crushed by a jet mill; 4) orient that jet mill powder unde a magnetic field, pressing and shaping, and cold isostatic pressing to obtain a samarium cobalt compact; 5) sequentially vacuum pre-sinter that samarium-cobalt blank, sintering by filling inert gas, cooling and solid solution, and air cooling to room temperature to obtain the sintered blank; 6) perform aging treatment to obtain a samarium cobalt permanent magnet. As that formula and the sinter process are adjust, the samarium-cobalt permanent magnet can overcome the shortcoming that the high comprehensive magnetic property and the high working temperature of the samarium-cobalt permanent magnet cannot be taken into account, and the samarium-cobalt permanent magnet with excellent comprehensive property and the high working temperature can be obtained.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

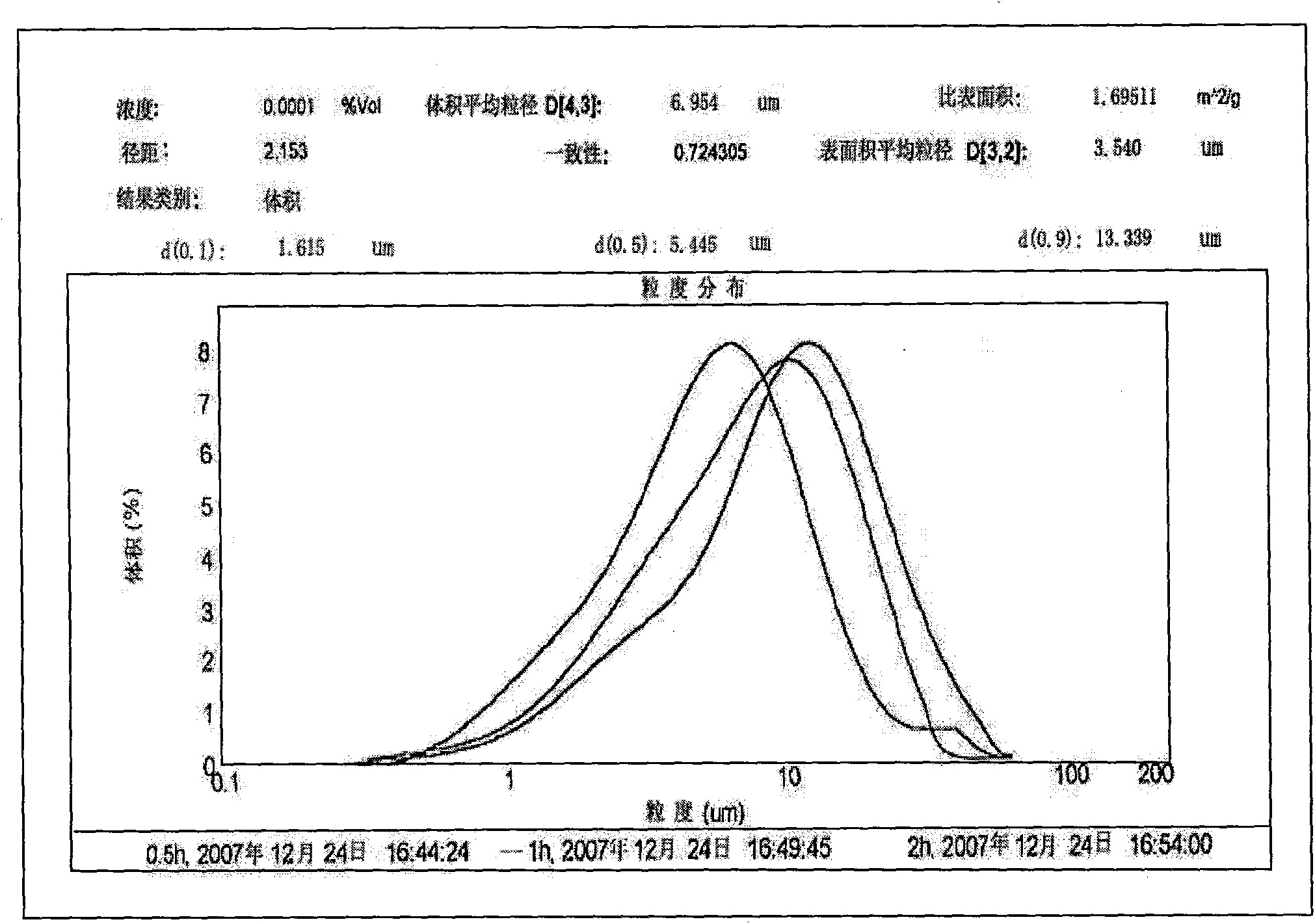

Preparation method of samarium-cobalt (SmCo) system sintered materials

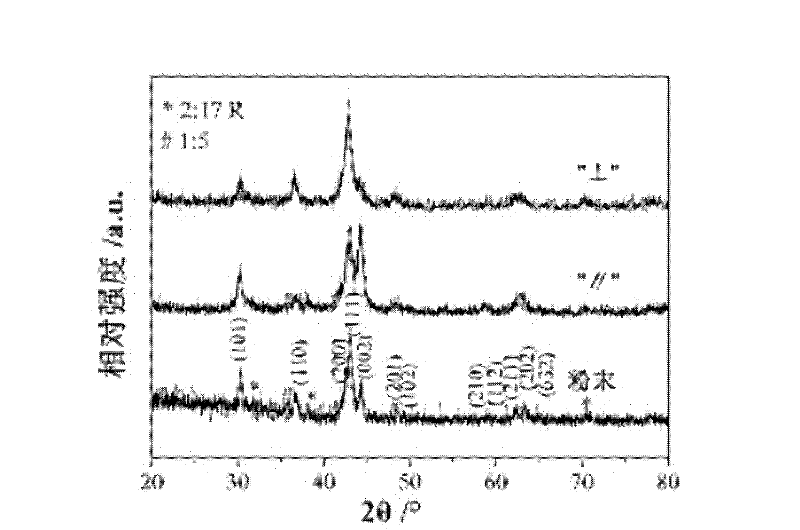

ActiveCN102651263AImprove microstructureGood orientationInductances/transformers/magnets manufactureMagnetic materialsPositive pressureAlloy

The invention relates to a preparation method of samarium-cobalt (SmCo) system sintered materials. The preparation method comprises the steps of alloy smelting, alloy cast strip preparation through rapid quenching, magnetic powder preparation through combination of a hydrogenated disproportionation method and an airflow grinding method, orientation and forming, positive pressure sintering and solid dissolving and aging treatment. The preparation method has the advantages that through the innovation of the ingot casting and powder making process, the microstructure of a magnetic body is optimized to the greatest degree, the magnetic body mainly consists of columnar crystals, the orientation is easy, and in addition, the performance of the magnetic body is stable; and in the hydrogenated disproportionation process of alloy cast sheets, hydrogen enters gap positions in SmCo crystal lattices, and the crystal lattice expansion is caused, so the pulverization is realized under the condition of ensuring the crystal particle integrity, the oxidation in the powder making process is reduced, the magnetic body with low oxygen content is obtained, and the magnetic performance of the magnetic body is ensured.

Owner:NINGBO STAR MATERIALS HI TECH

Samarium-cobalt-base nanocrystalline permanent magnet material and preparation method thereof

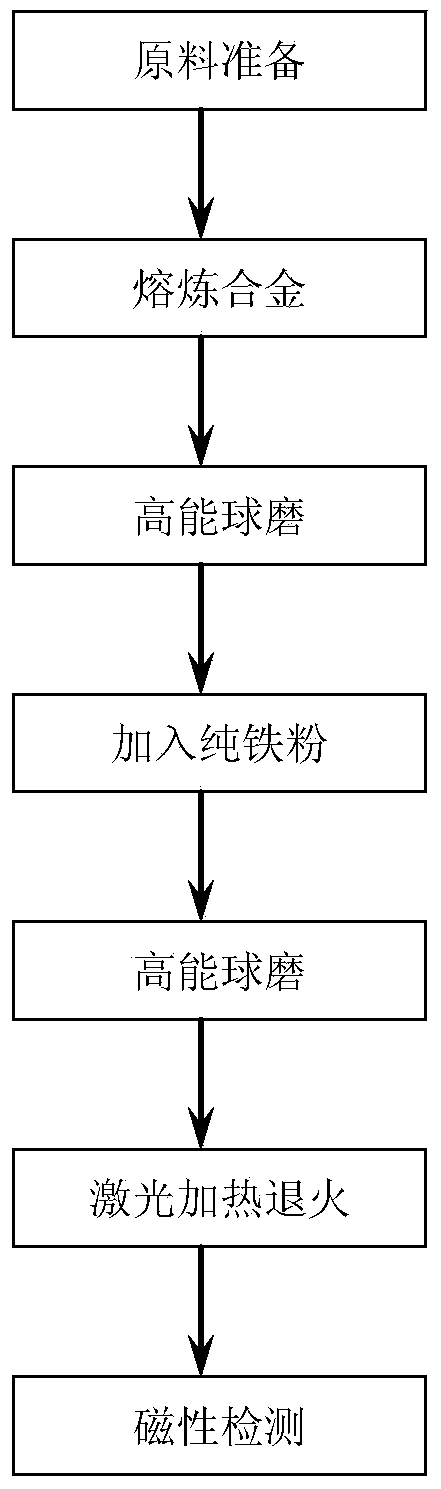

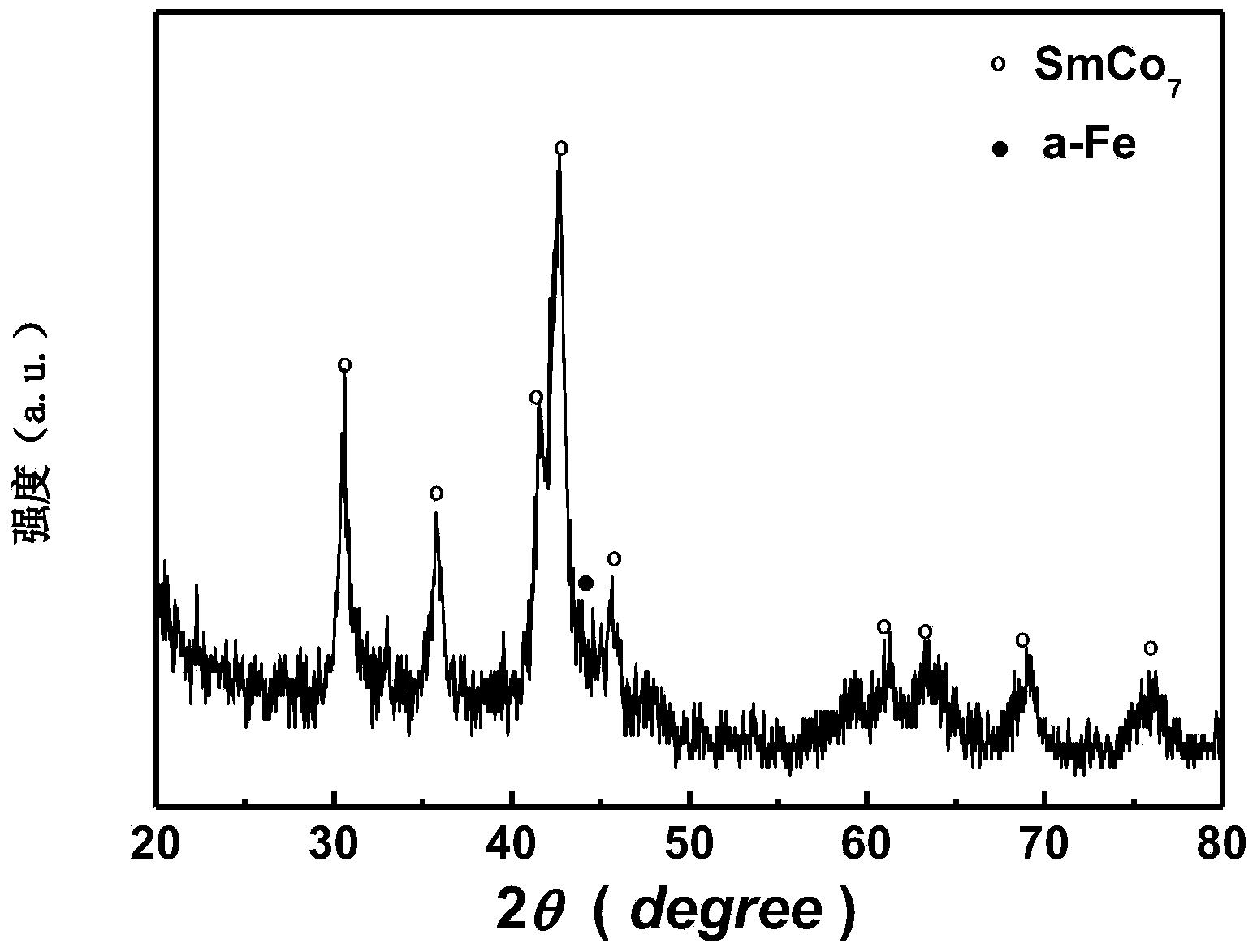

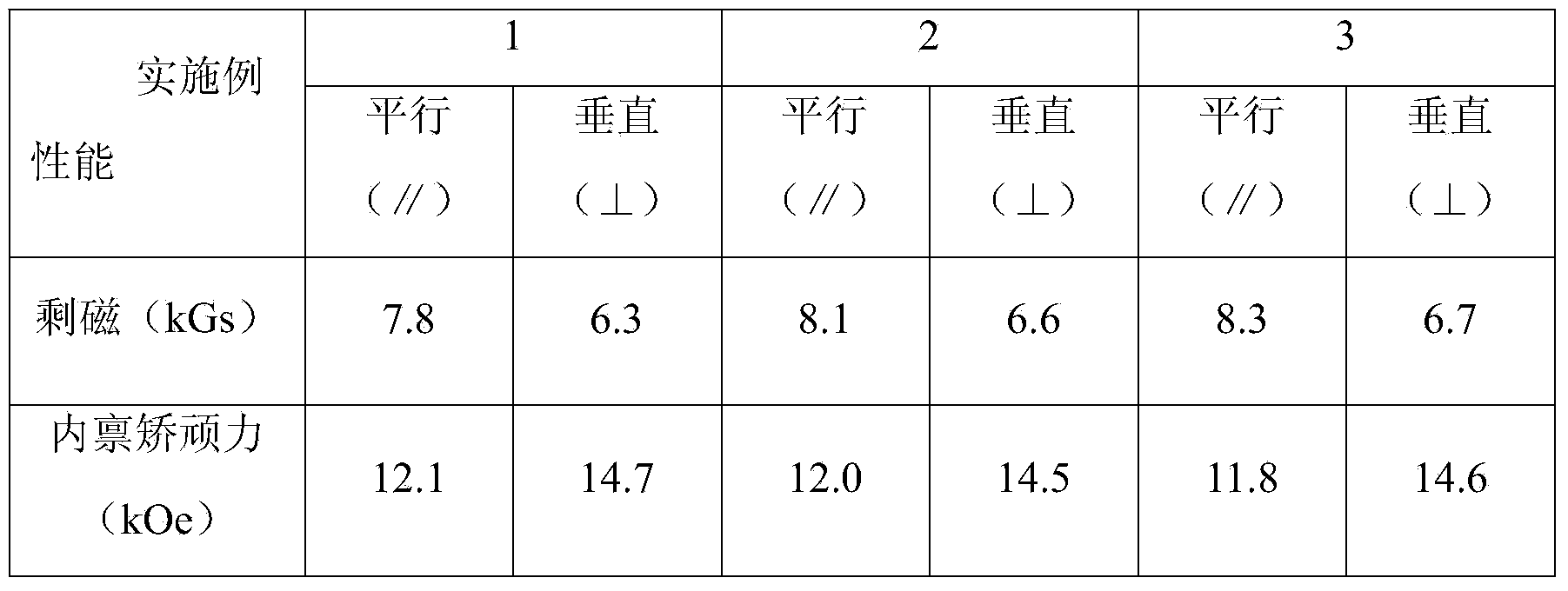

The invention relates to the metallurgy field and discloses novel samarium-cobalt-base nano-composite permanent magnetic material. The samarium cobalt base is (Sm, R)1(Co, Fe, Cu, Zr)7 in type and comprises a TbCu7 type structure, and Co is partially replaced by Fe, Cu and Zr; Re is any one of heavy rare earth Lu, Dy and Tb and partially replaces Sm. The preparation method includes steps that 1) mixing raw materials of the samarium cobalt base according to proportion, and smelting to obtain a 1: 7 type samarium cobalt base alloy ingot; 2) ball milling the alloy ingot through a high-energy ball milling technique, mixing with Fe powder according to proportion, and performing high-energy ball milling to obtain nanocrystalline composite magnetic powder; 3) carrying out annealing heat treatment on the nanocrystalline composite magnetic powder. According to the samarium-cobalt-base nanocrystalline permanent magnet material and the preparation method thereof, the soft / hard-magnetic phase composite magnetic powder is prepared through the high-energy ball milling, laser heat treatment and other techniques, a high magnetic energy product is obtained through exchange coupling between the nanocrystalline hard magnetic phase and nanocrystalline soft magnetic phase, and meanwhile, because rare-earth Fe phase is not used, the cost is lowered, and the operation technique is simplified.

Owner:嘉兴市鹏程磁钢有限公司 +1

Preparation method of anisotropic samarium cobalt-based nanocrystalline rare earth permanent magnet

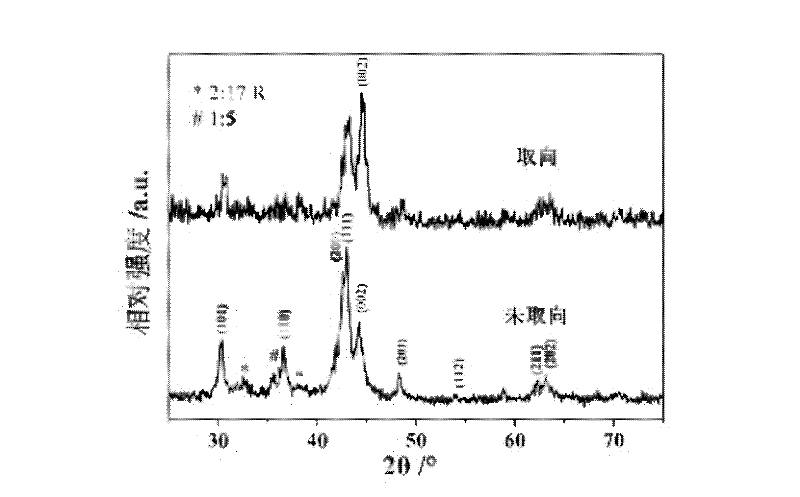

ActiveCN102403118APermanent magnetsInductances/transformers/magnets manufactureMagnetic anisotropyHigh energy

The invention belongs to the new powder metallurgy process, and specifically to a special method for preparing an anisotropic SmCo based nanocrystalline rare earth permanent magnet. The invention breaks through the nano-crystal particle tropism problem of the SmCo based nanocrystalline rare earth permanent magnet nanocrystalline grain and obtains the nanocrystalline permanent magnet with obvious crystallographic anisotropism and magnetic anisotropism. The invention obtains the anisotropic nanocrystalline rare earth permanent magnet by the operations of adopting surfactant to auxiliary high-energy ball mill, orientating the pulse magnetic field, cold isostatic pressing and low-temperature pressurizing and sintering. The SmCo based nanocrystalline rare earth permanent magnet with obvious anisotropism can be obtained after sintering without any treatment.

Owner:BEIHANG UNIV

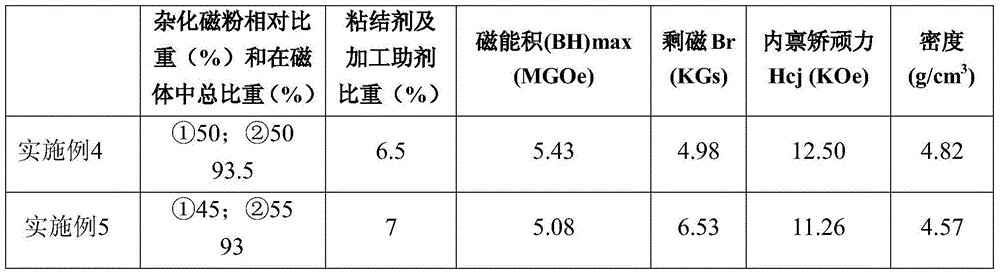

A submicron anisotropic samarium iron nitrogen magnet powder and a method for preparing a hybrid bonded magnet therefrom

ActiveCN106312077AHigh energy productImprove remanenceInductances/transformers/magnets manufactureMagnetic materialsAdditive ingredientSingle crystal

The invention provides a submicron anisotropic samarium iron nitrogen magnet powder and a method for preparing a hybrid bonded magnet therefrom. Samarium-iron alloy is prepared by using a quick setting sheet technology; the samarium-iron alloy is made to perform gas-solid phase reaction in nitrogen or mixed gas of nitrogen and hydrogen to form samarium-iron-nitrogen alloy; then airflow milling and / or ball milling is performed to obtain anisotropic samarium iron nitrogen single-crystal particle magnet powder with a particle size of 0.01-3 [mu]m. Further, the samarium iron nitrogen single-crystal particle magnet powder, as a first ingredient, is mixed with a second ingredient consisting of permanent magnetic ferrite, rapid quenching isotropic neodymium iron boron, anisotropic neodymium iron boron, samarium cobalt and / or neodymium iron nitrogen to form hybrid magnetic powder; processing agents are added; a hybrid bonded magnet is prepared by using a rolling, mould pressing, extrusion or injection method. The prepared samarium iron nitrogen magnet powder are high in magnetic energy product, residual magnetism and intrinsic coercive force, is low in cost and small in particle size; the corresponding hybrid bonded magnet exploits the advantages of different magnetic powder ingredients, is high in shaping degree and mechanical strength and is good in temperature performance.

Owner:NINGXIA MAGVALLEY NOVEL MATERIALS TECH CO LTD

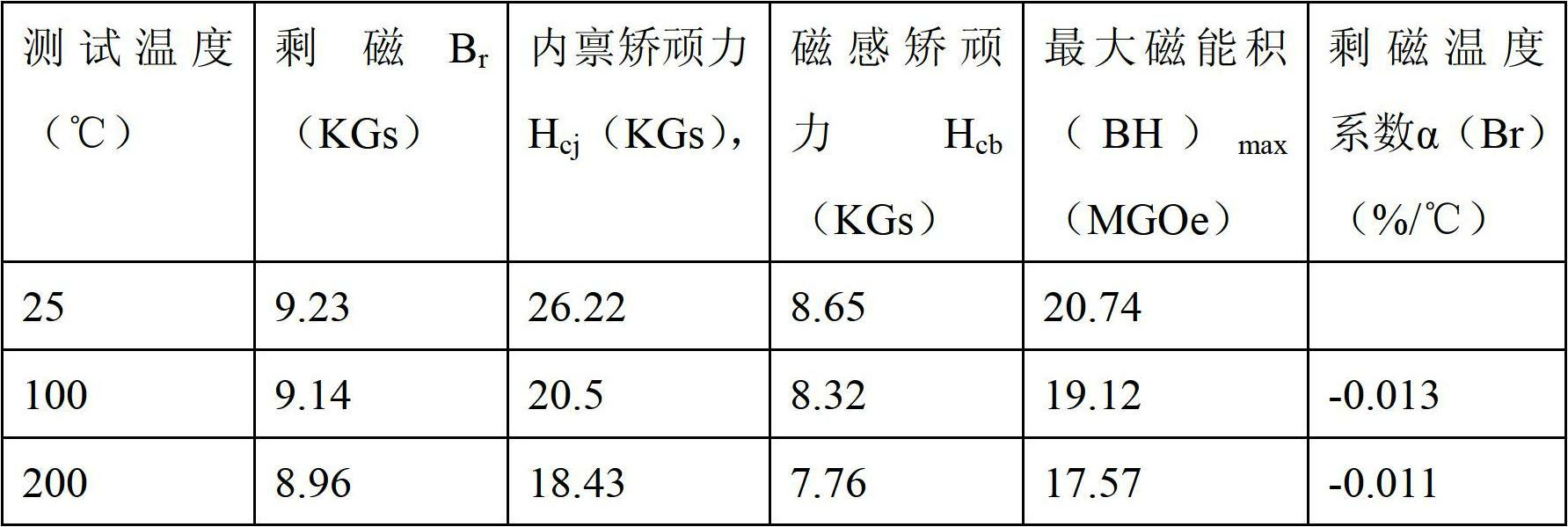

Rare earth permanent magnet material and preparation method thereof

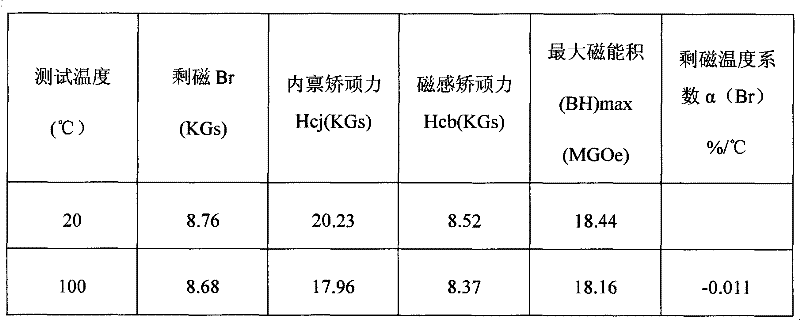

InactiveCN102290180ALow costAccelerate the process of industrializationMagnetic materialsRare-earth elementCobalt

The invention discloses a rare earth permanent magnet material, which is prepared from the following components in weight percentage: 14-20% of samarium, 45-50% of cobalt, 12-16% of iron, 3-7% of copper, and 1-3% of zirconium %, heavy rare earth elements 5 to 15%. The invention also discloses a preparation method of the above-mentioned rare earth permanent magnet material: (1) weighing the raw material; (2) preparing an alloy casting sheet with fine grain and uniform composition through the quick-setting sheet technology; (3) making the quick-setting casting sheet Carry out hydrogen crushing and rod milling to obtain magnetic powder with an average particle size of 3.0-5 microns; (4) Compress the magnetic powder under a magnetic field of 2-2.5T; (5) Sintering: Sinter the compacted blank under the protection of argon ; (6) aging: the sintered blank is kept warm, cooled, and quickly air-cooled to room temperature to obtain a samarium-cobalt permanent magnet. The rare earth permanent magnet of the invention not only has a lower remanence temperature coefficient but also has a high magnetic energy product, and has low manufacturing cost and simple process.

Owner:NINGBO STAR MATERIALS HI TECH

Multistage cusped magnetic field plasma thruster with channel magnetic field guide structure

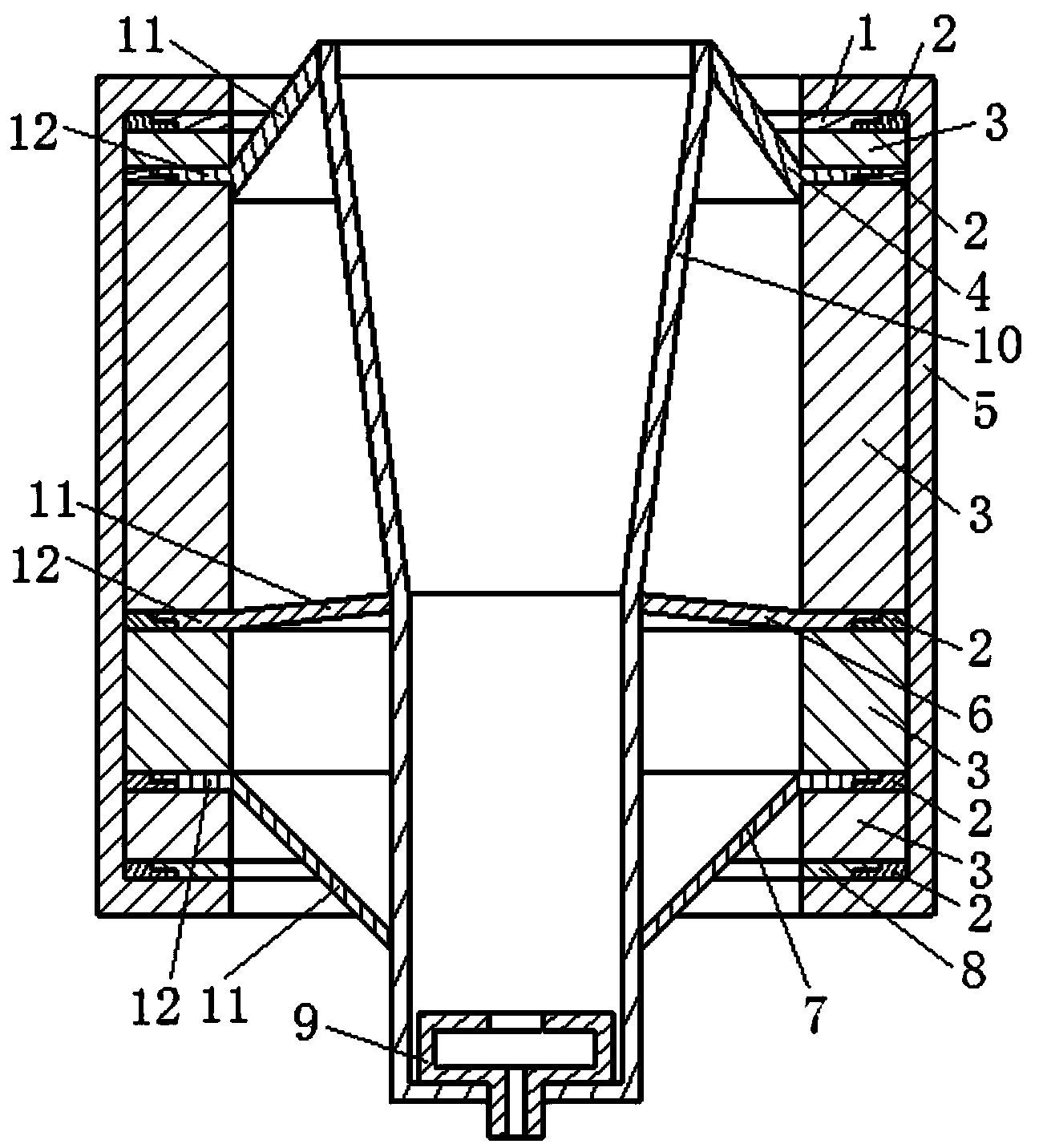

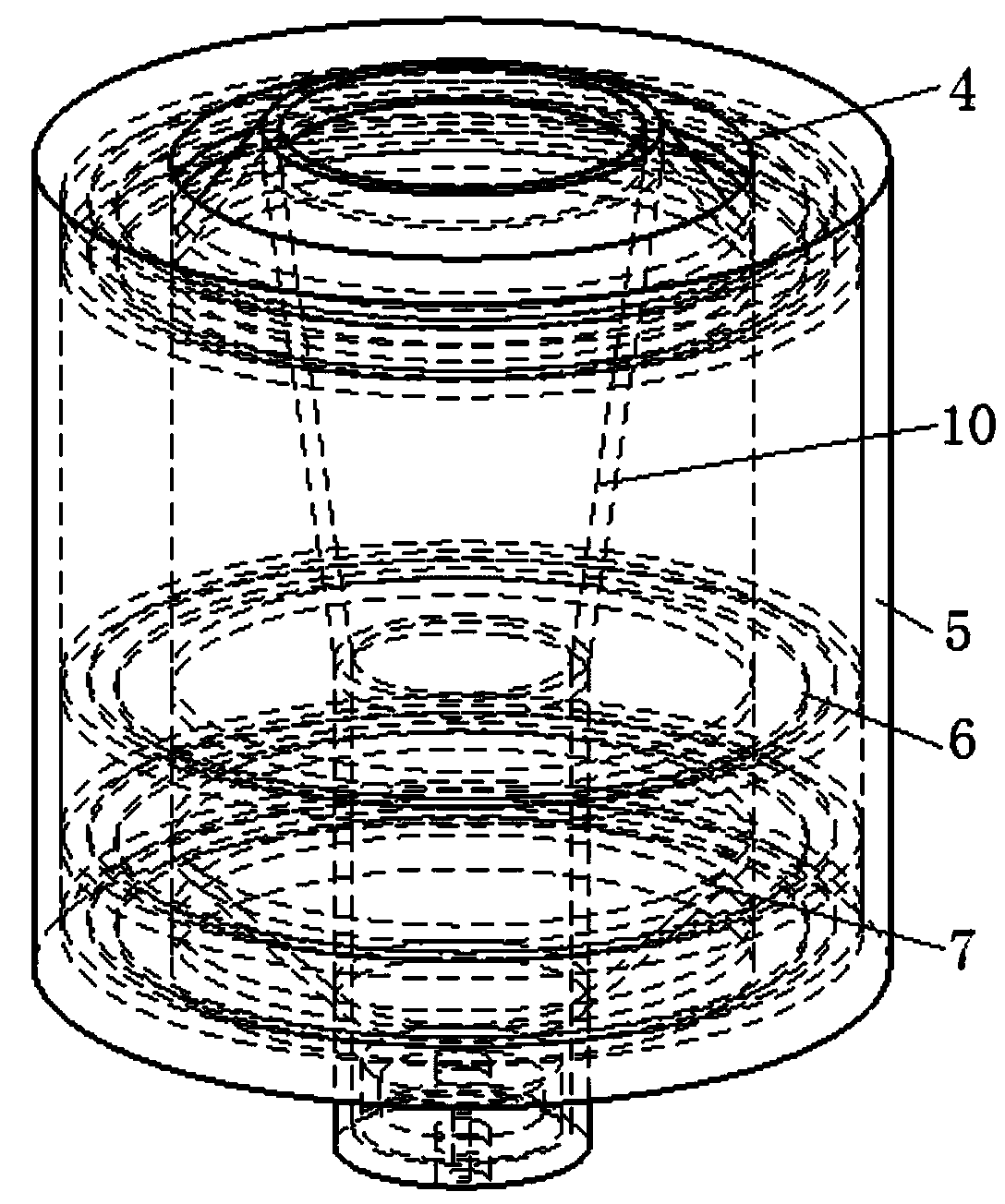

ActiveCN104033346AEasy accessStable working conditionMachines/enginesUsing plasmaNon magneticSpaceflight

The invention relates to an electric thruster, in particular to a multistage cusped magnetic field plasma thruster with a channel magnetic field guide structure, so as to solve the problems that magnetic field configuration of an existing thruster and the position of a magnetic mirror tip cannot be adjusted conveniently according to section changes of a discharge channel, the angle of a magnetic interface at the magnetic mirror tip is not easy to adjust, and a samarium cobalt permanent magnet material for variable cross-section experiments is long in processing cycle and high in cost. The plasma thruster comprises a ceramic bushing, an engine casing, four permanent magnets, five magnetic-conducting rings and five non-magnetic-conducting matching rings, the permanent magnets are round permanent magnets and arranged sequentially from top to bottom, the ceramic bushing is arranged among the four permanent magnets, the large-diameter port of the ceramic bushing faces upwards, the four permanent magnets are clamped together through the engine casing; the five magnetic-conducting rings are a first magnetic-conducting ring, a second magnetic-conducting ring, a third magnetic-conducting ring, a fourth magnetic-conducting ring and a fifth magnetic-conducting ring respectively. The plasma thruster is applied to the field of spaceflight.

Owner:HARBIN INST OF TECH

Method for producing a magnetic alloy powder

InactiveUS6352597B1Improve propertiesImprove magnetic propertiesTransportation and packagingMetal-working apparatusHydrogen pressureHydrogen desorption

A method is disclosed enabling a technologically controllable and economical production of a hard-magnetic powder composed of a samarium-cobalt base alloy for highly coercive permanent magnets. The method is based on a HDDR treatment in which a starting powder is subjected to hydrogenation with disproportionation of the alloy in a first method step under hydrogen and, in a subsequent, second method step under vacuum conditions, a hydrogen desorption with recombination of the alloy. A starting powder containing samarium and cobalt is treated in the first method step either at a high temperature in the range of 500° C. to 900° C. and with a high hydrogen pressure of >0.5 MPa or by applying an intensive fine grinding at a low temperature in the range of 50° C. to 500° C. and with a hydrogen pressure of >0.15 MPa. By means of the method of the invention, magnetic alloy powders can be produced from samarium-cobalt base alloys; highly coercive permanent magnets can be produced from these magnetic alloy powders, particularly by hot compacting or plastic bonding.

Owner:INST FUER FESTKOERPER & WERKSTOFFORSCHUNG DRESDEN EV

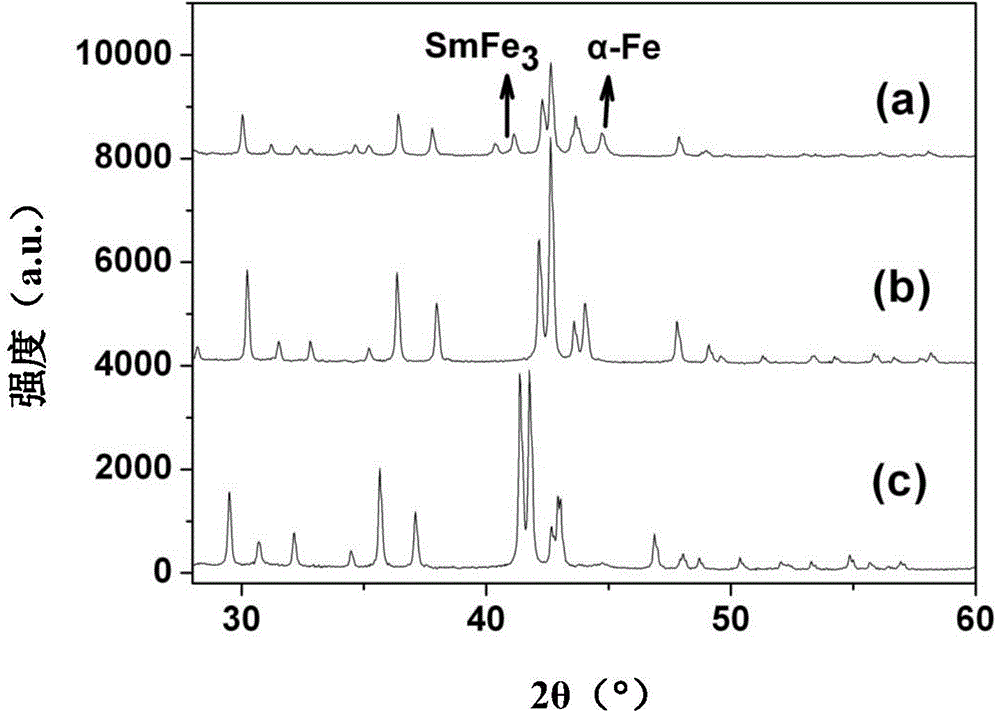

Apreparation method of SmCu alloy doped samarium-cobalt based nano composite permanent magnet

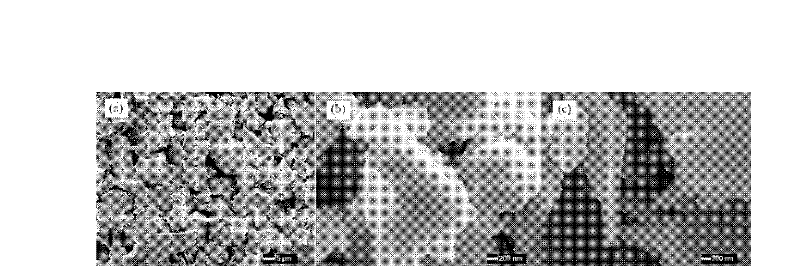

ActiveCN108962523AImprove textureImprove coercive forceTransportation and packagingMetal-working apparatusMagnetic phaseAlloy

The invention discloses a preparation method of a SmCu alloy doped samarium-cobalt-based nano composite permanent magnet, belonging to the technical field of magnetic materials. The material takes 1:5-type SmCo nanometer magnet and nanocrystalline alpha-Fe composite magnet as the base body, employs the magnetron sputtering and spark plasma sintering technology to take the low melting point Sm_6Cu_4 alloy as interface phase to improve the grain boundary and diffuse into the hard magnetic phase, , thus improving the magnet coercivity, and the Sm-Co based nanocrystalline composite permanent magnet with good magnetic properties was obtained. At that same time, the invention has the advantage of simple process and low cost, and is favorable for the application of samarium-cobalt-based nano composite permanent magnet in more permanent magnet device.

Owner:ZHEJIANG ZHONGKE MAGNETIC IND

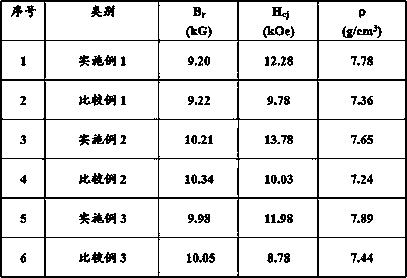

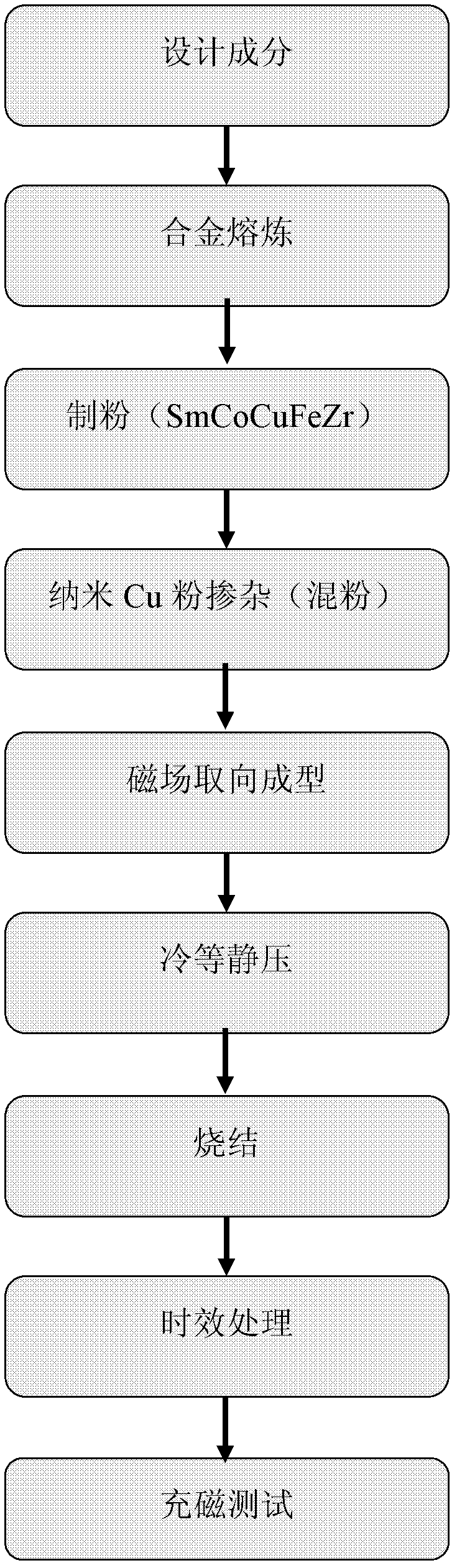

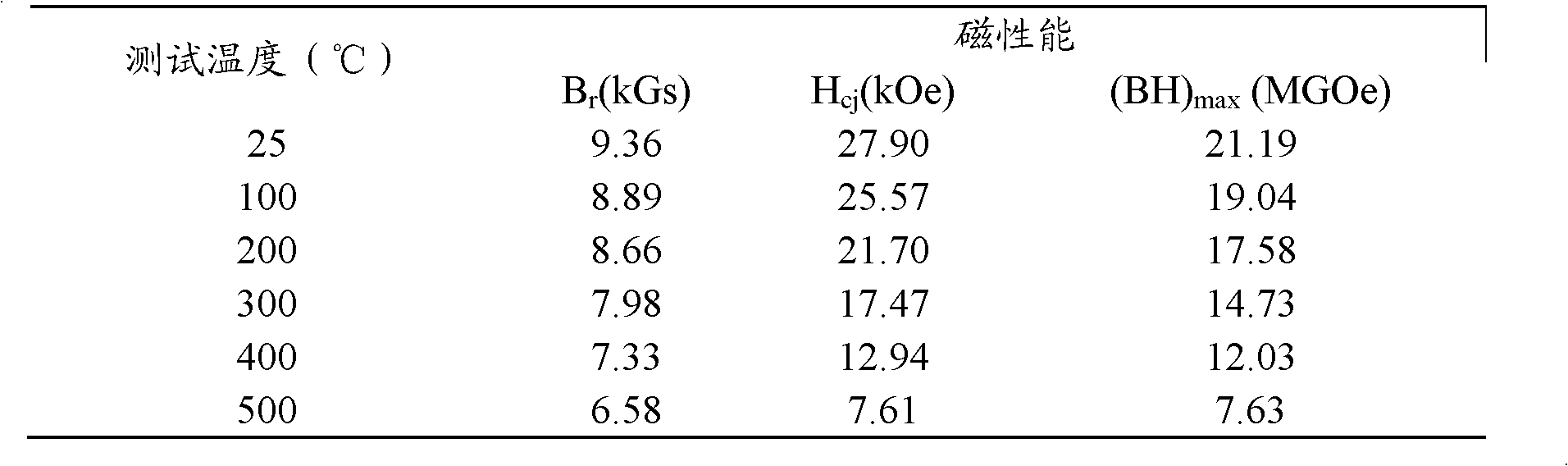

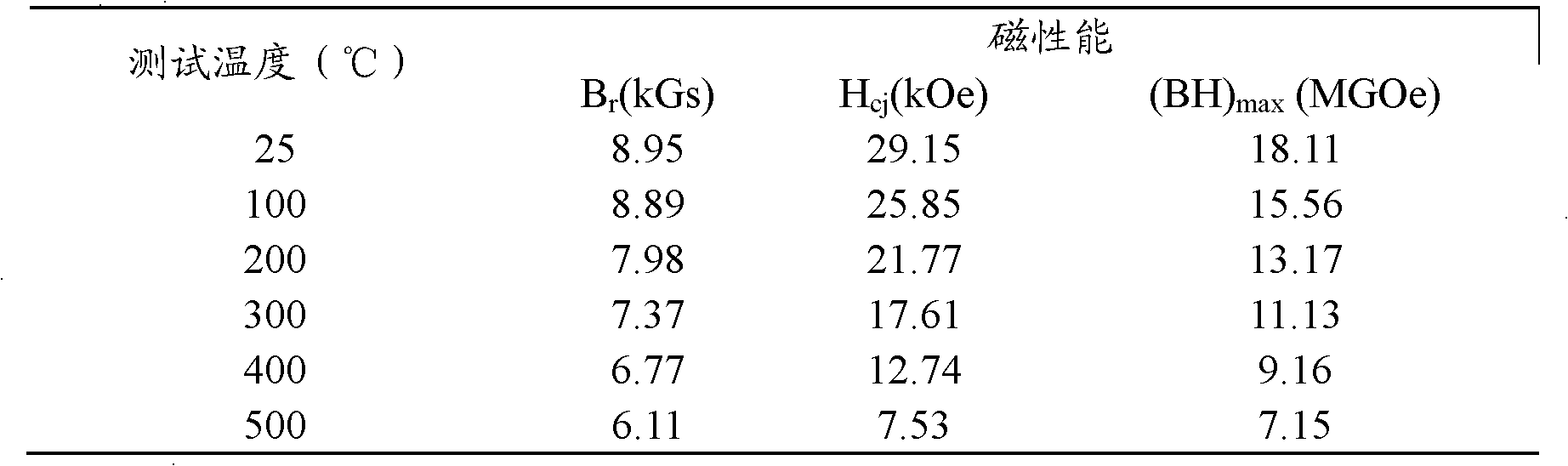

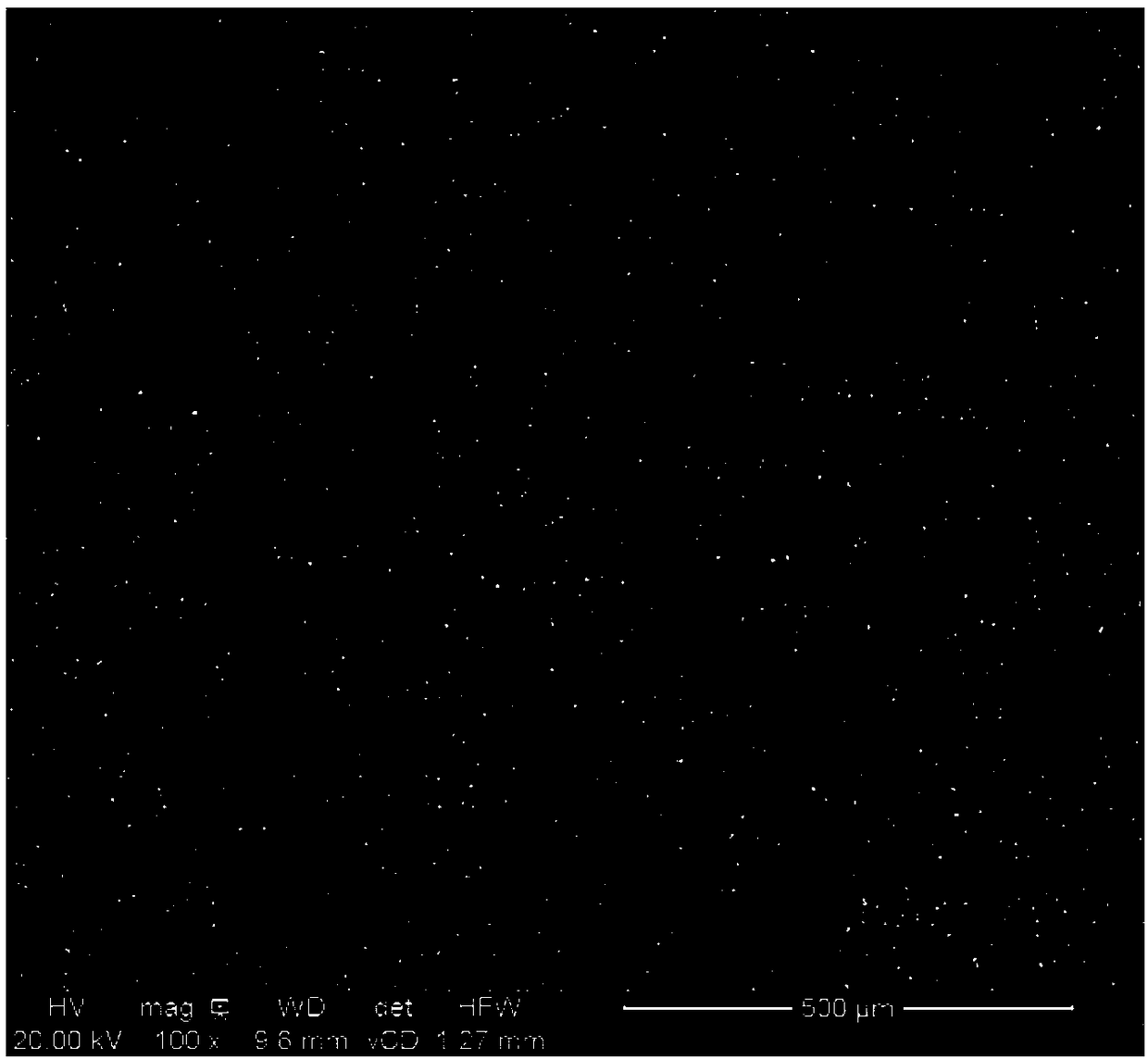

Method for preparing high-coercivity SmCoFeCuZr (samarium-cobalt-ferrum-copper-zirconium) high-temperature permanent magnet by doping nano-Cu powder

InactiveCN102568807AImprove coercive forceIncreased coercive force at room temperatureInductances/transformers/magnets manufactureMagnetic materialsMaterials preparationMicrometer

The invention relates to a method for preparing a high-coercivity SmCoFeCuZr (samarium-cobalt-ferrum-copper-zirconium) high-temperature permanent magnet by doping nano-Cu powder, which belongs to the technical field of rare-earth permanent magnetic material preparation. The method comprises the steps of: smelting a SmCoFeCuZr alloy ingot by the conventional powder metallurgy method; processing the SmCoFeCuZr alloy ingot to micrometer-level alloy powder; uniformly blending commercial nano-Cu powder and the SmCoFeCuZr alloy powder according to a ratio; sintering; and aging to obtain a 2:17 SmCosintered magnet. The doped nano-Cu powder has uniform distribution in the sintered magnet, so that the room-temperature and high-tempreature coercivity of the magnet can be improved greatly. The room-temperature coercivity can be improved by 2 to 2.5 times, and the 500 DEG C coercivity and magnetic energy of the magnet doped with the nano-Cu powder are significantly higher than those of undoped magnets. Accordingly, the magnet doped with the nano-Cu powder is very suitable for application in high-temperature environment.

Owner:BEIJING UNIV OF TECH

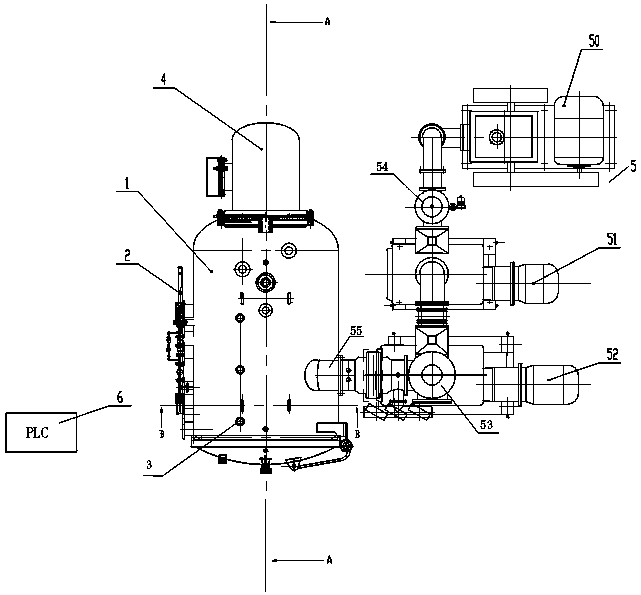

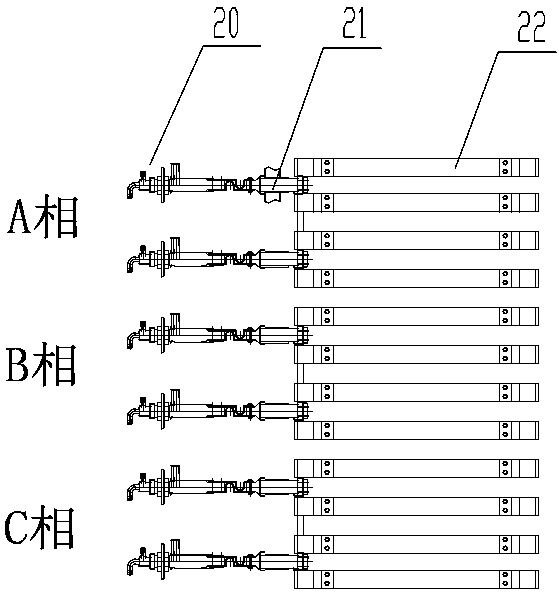

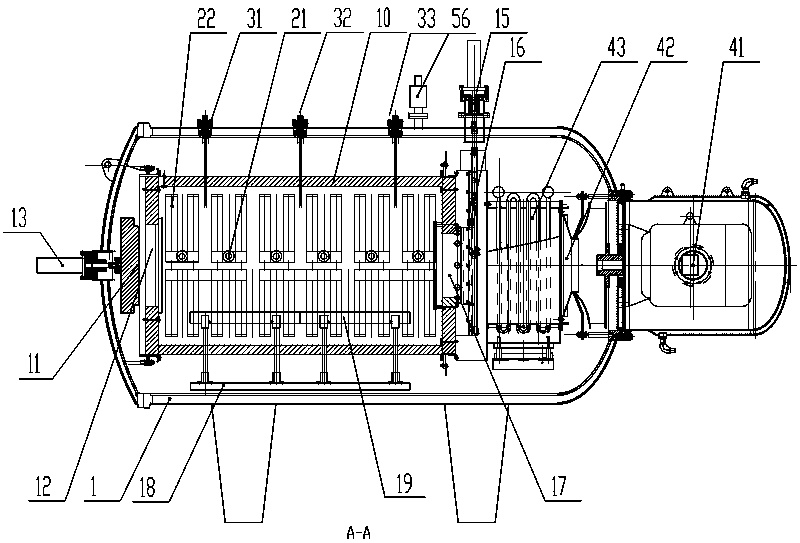

Samarium cobalt permanent magnet vacuum sintering furnace

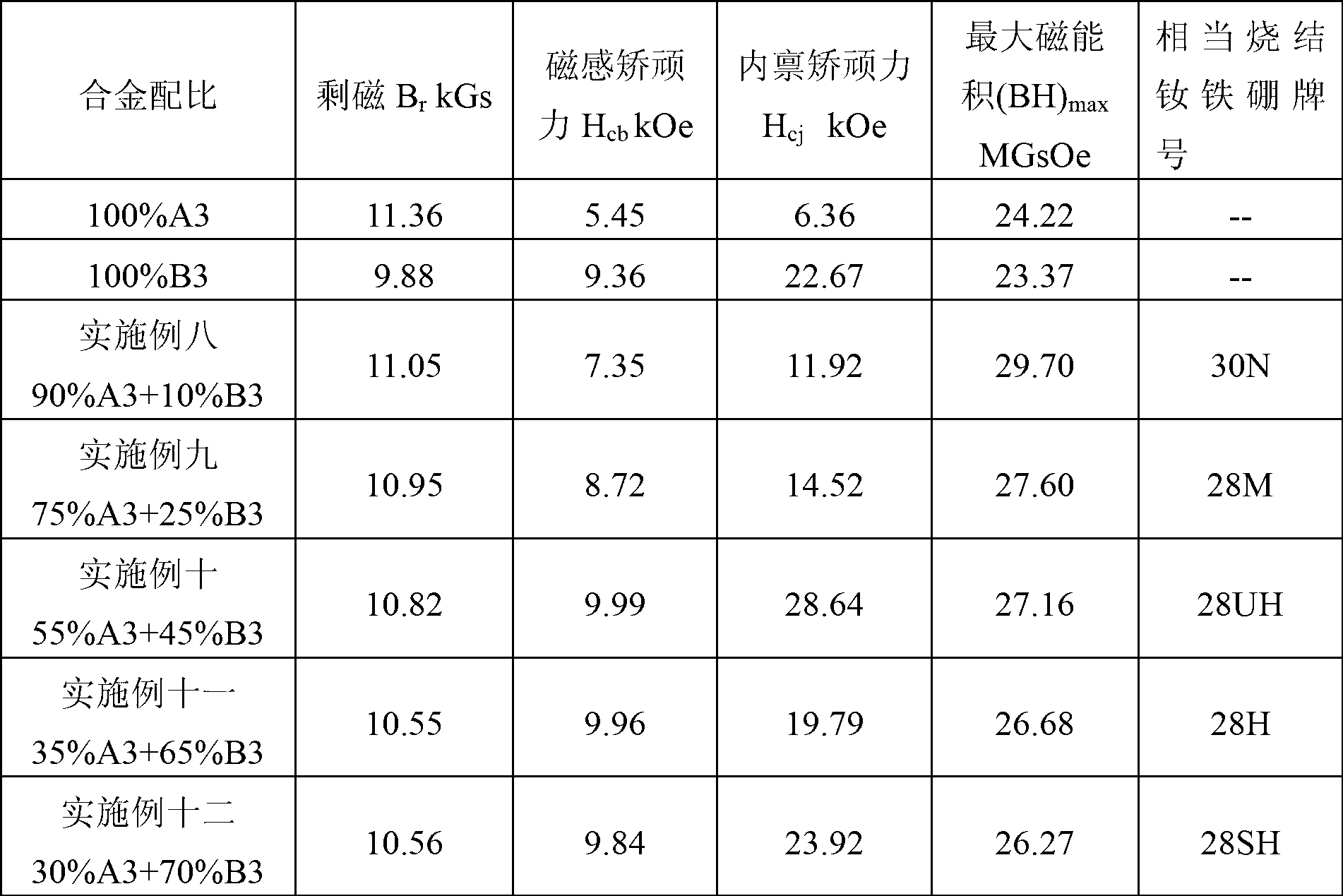

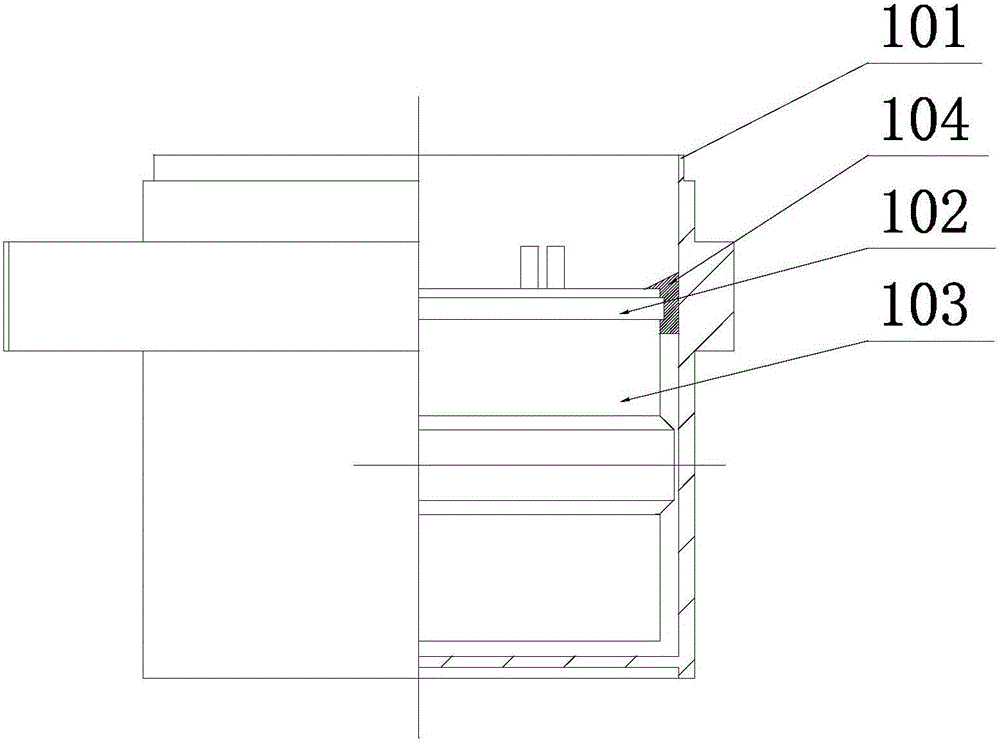

ActiveCN103398577AShorten cooling timeImprove turnover rateMuffle furnacesRetort furnacesTemperature controlVacuum pumping

A samarium cobalt permanent magnet vacuum sintering furnace comprises a vacuum-pumping system, a furnace body, a graphite electric heater, a temperature control device, a fan cooling coil pipe and a PLC system. The vacuum-pumping system comprises a first roots pump, a second roots pump, a slide valve pump and a vacuum-pumping pipeline and can be adjusted and controlled. The furnace body comprises a sealing hearth composed of a heat insulation layer, a front door sealing pad and a back door sealing pad. A plurality of evenly-distributed graphite heating frame plates are arranged in the sealing hearth. A plurality of thermocouples which detect temperature of the sealing hearth are evenly arranged between the graphite heating frame plates. The fan cooling coil pipe is arranged at the back end of the sealing hearth. The vacuum-pumping pipeline is arranged between one side of the sealing hearth and the fan cooling coil pipe. The vacuum-pumping system can select different vacuum degrees, the graphite heating frame plates and the temperature-detecting thermocouples which are evenly arranged in the heating hearth monitor temperature in the furnace, and a high-temperature sintering zone, stable temperature and vacuum degree are formed. Permanent magnet product quality is improved, sintering furnace productivity effect is improved, product pass percent is improved by 30%, production efficiency is multiplied, and total energy is saved by more than 60%.

Owner:NINGBO NINGGANG PERMANENT MAGNETIC MATERIALS +1

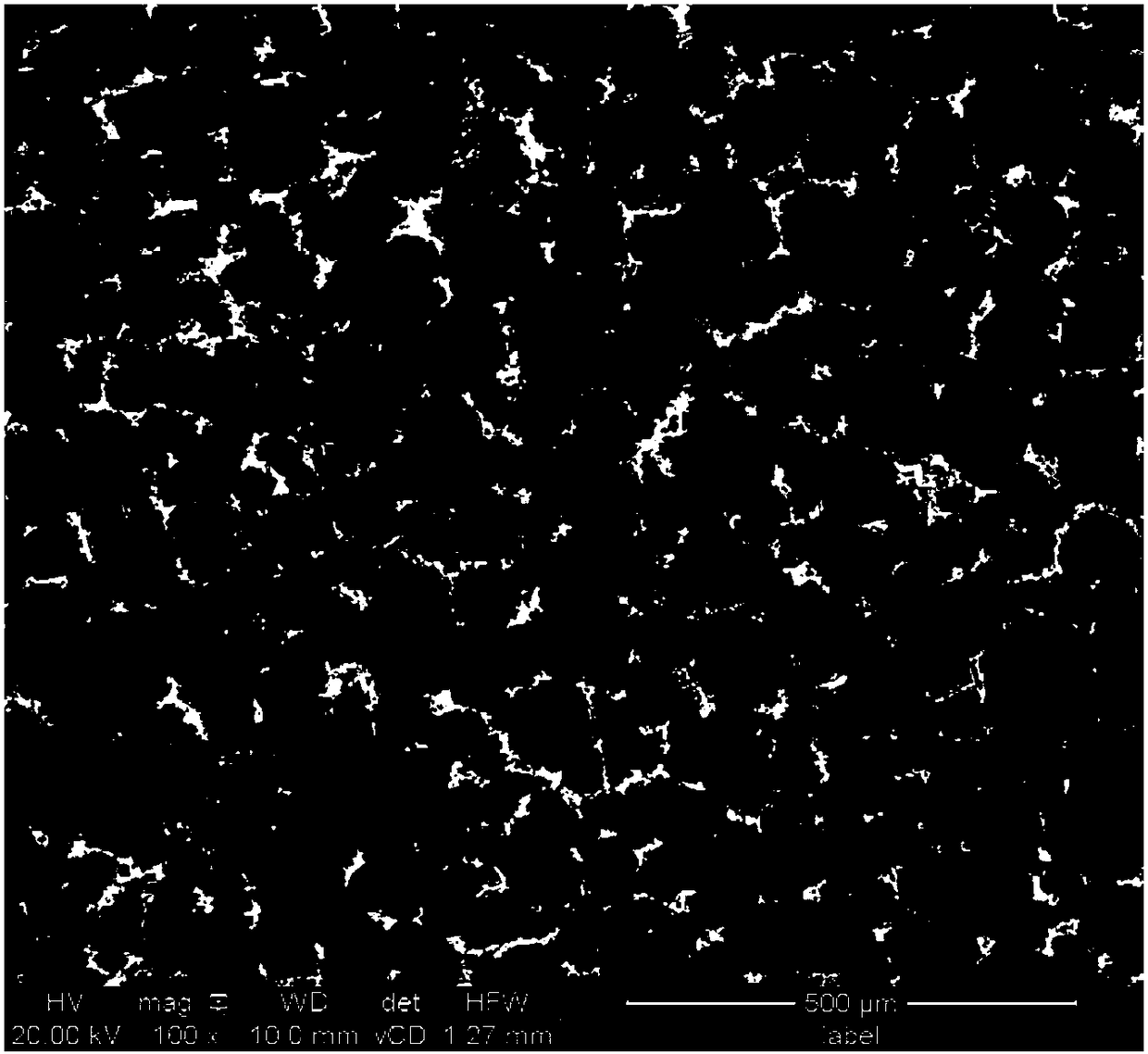

High-performance and high-resistivity sintered samarium-cobalt permanent-magnet material and preparation method and application thereof

ActiveCN108305735AHigh resistivitySmall sizeInorganic material magnetismInductances/transformers/magnets manufactureSamarium–cobalt magnetHigh resistivity

The invention provides a high-performance and high-resistivity sintered samarium-cobalt permanent-magnet material and preparation method and application thereof. The chemical formula of the high-performance and high-resistivity sintered samarium-cobalt permanent-magnet material is Sm<Co<1-a-b-c>FeCuZr<c>M<y>)<z>, wherein a is more than 0 but less than 0.5, b is more than 0 but less than 0.15, c is more than 0 but less than or equal to 0.025, y is more than 0 but less than 0.04, z is more than 6.5 but less than 8.5, and M is a high-resistivity element. The preparation method comprises thestep of sequentially performing processes of directional formation, sintering, thermal processing and equal-temperature aging on alloy with the chemical formula being Sm<Co<1-a-b-c>FeCuZr<c>M<y>)<z> to obtain the high-performance and high-resistivity sintered samarium-cobalt permanent-magnet material. Compared with the prior art, the samarium-cobalt permanent-magnet material has the advantages that a high-resistivity compound is combined without a complicated process, the process flow of the sintered samarium-cobalt magnet is not needed to be changed, the production cost is low, and theresistivity of the magnet can be obviously improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Nano-crystalline anisotropic magnet prepared by 3D (three-dimensional) printing technique

InactiveCN106683867AImprove magnetismShorten the production cycleAdditive manufacturingInorganic material magnetismManganeseProduct model

The invention discloses a method for preparing a nano-crystalline anisotropic magnet by a 3D (three-dimensional) printing technique. The method includes that: hard magnetic alloys including neodymium iron boron alloy, samarium cobalt alloy, aluminum nickel cobalt alloy, manganese bismuth alloy, samarium iron alloy and the like are melted; the alloys are prepared into irregularly-shaped magnetic powder through melt-spinning and airflow grinding; the irregularly-shaped magnetic powder is subjected to spray drying and the like so as to obtain spherical nanometer agglomerated powder; the spherical nanometer agglomerated powder is mixed with a binding agent and a processing agent uniformly; the mixture is conveyed into a hot extruding machine and extruded to form silks; a three-dimensional model is established by computer software according to the size and the shape of a product, and the product model is subjected to layered slicing; the three-dimensional model is lead into a 3D printer; the silks are conveyed into 3D printer and heated to soften, through an extruder and a movable spraying nozzle with a heating function, the material is extruded and deposited on a workbench which can be heated, and the extruded material is solidified on the workbench, accumulated and adhered layer by layer and magnetized during printing until the product is printed completely. The method for preparing the nano-crystalline anisotropic magnet by the 3D printing technique has the advantages that the prepared product is high in cost performance and processing performance, production period of the magnet can be shorted, and production cost of the magnet can be reduced.

Owner:解伟

Melting method of sintered samarium cobalt base rare earth permanent magnet material master alloy

The invention discloses a melting method of sintered samarium cobalt base rare earth permanent magnet material master alloy, in which a vacuum induction melting technology is adopted to melt alloy ingot, and the alloy ingot is cast on a rotary water-cooled copper roll, a water-cooled molybdenum roll, a copper plate or a molybdenum plate so as to obtain high cooling speed to prepare samarium cobalt base master alloy ingot. The method comprises the steps that (1) cobalt with a high melting point and one or a plurality of the elements of iron, zirconium, copper, gadolinium, dysprosium, holmium, praseodymium and the like are put into a crucible in a vacuum quick coagulating melting furnace to be melted firstly, and then samarium is added for refining, so the volatilization of the samarium can be significantly reduced; and (2) melted alloy liquid is cooled quickly on the rotary water-cooled copper roll, the water-cooled molybdenum roll, the copper plate or the molybdenum plate, and the rotary speed on the water-cooled copper roll, the water-cooled molybdenum, the copper plate or the molybdenum plate is 1-4m / s. The invention provides a melting method which can control the melting alloy composition precisely and refines sintered samarium cobalt base rare earth permanent magnet material master alloy with columnar crystal tissues and a single phase structure.

Owner:CENT SOUTH UNIV

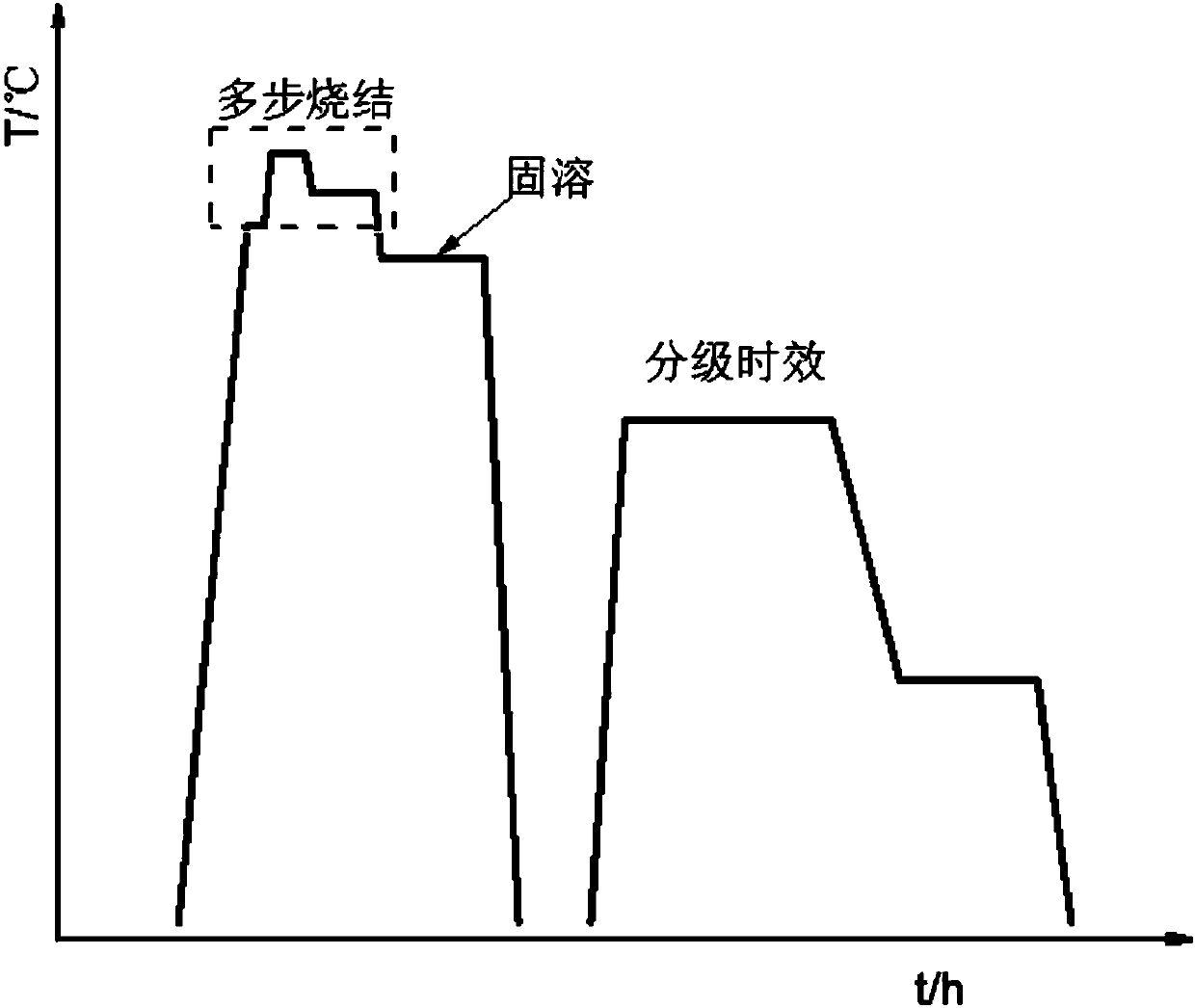

High-iron-content samarium-cobalt permanent magnet material and preparation method

ActiveCN107895620AImprove coercive forceImprove squarenessInorganic material magnetismSquare degreeRemanence

The invention provides a high iron content samarium cobalt permanent magnet material and preparation method. The expression of the high-iron-content samarium-cobalt permanent magnetic material is Sm1-pMp(Co1-x-y-wFexCuyZrw)z, where M is at least one of the selected elements Pr, La, Ce, Nd, Y, Dy, and Er, p=0.02 to 0.15, x=0.28 to 0.36, y=0.04 to 0.08, w=0.015 to 0.025, z=7.5 to 8.2, and z is an atomic ratio of a transition metal to a rare earth metal. The invention adopts a multi-step sintering process to improve the squareness of the high-iron-content Sm1-pMp (Co1-x-y-wFexCuyZrw) z permanentmagnet material, and solves the problem that the decrease of the squareness of the iron content leads to the decrease of the magnetic performance. The goal of increasing the maximum energy product byincreasing the Fe content has been achieved. The magnetic properties were as follows: remanence Br = 11.18-12.07 kGs, the maximum energy product (BH) max = 28 - 34 MGOe, the square degree Hk / Hcj = 0.311 - 0.504, and the coercive force Hcj = 21.32 - 26.94 kOe.

Owner:BEIHANG UNIV

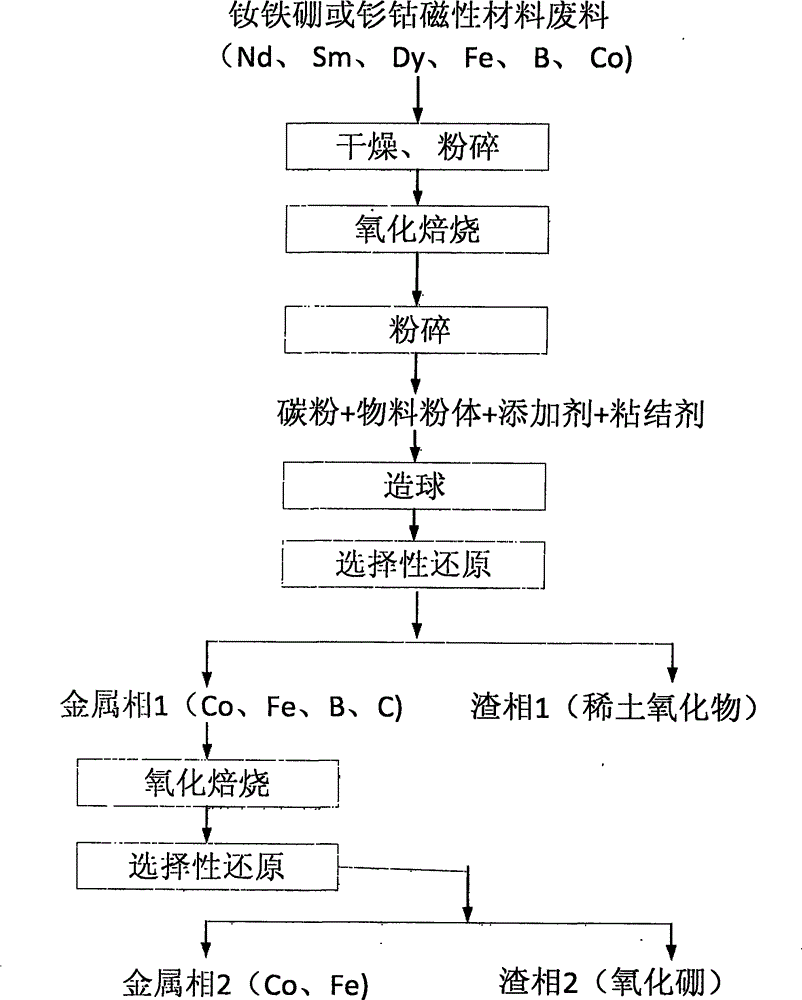

Method for recovering rare earth and other metals from neodymium iron boron and samarium cobalt magnetic material waste

InactiveCN102978401AAchieve recyclingRealize continuous productionProcess efficiency improvementAdhesiveSamarium–cobalt magnet

The invention relates to a method for recovering rare earth and other metals from neodymium iron boron and samarium cobalt magnetic material waste. The method comprises the following steps of: drying and grinding the fine-particle muddy neodymium iron boron or samarium cobalt waste, and performing oxidizing roasting; grinding the obtained solid; adding carbon powder, additive powder and an adhesive and pelletizing; performing selective reduction and melting on the pellets with carbon at a high temperature to obtain a rare earth oxide slag phase 1 and a carbon-containing metal phase 1; grinding the carbon-containing metal phase 1, and performing oxidizing roasting, selective reduction and melting; and for the neodymium iron boron waste, separating to obtain a boron oxide slag phase product 2 and a Fe-Co metal phase product 2, and for samarium cobalt waste, separating to only obtain a Fe-Co metal phase product 2, wherein the rare earth oxide slag phase 1 and the Fe-Co metal phase product 2 can be used as the primary raw materials for manufacturing samarium cobalt magnet; and the rare earth oxide slag phase 1, the Fe-Co metal phase product 2 and the boron oxide slag phase product 2 can be used as the primary raw materials for manufacturing neodymium iron boron magnet.

Owner:沈少波

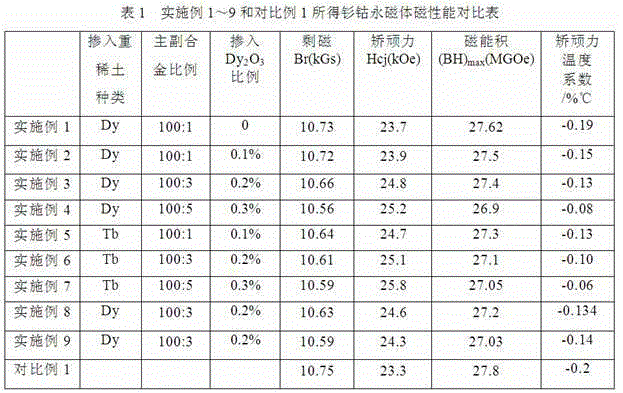

High-coercivity samarium-cobalt permanent magnet material and preparation method thereof

The invention discloses a high-coercivity samarium-cobalt permanent magnet material and a preparation method thereof. The high-coercivity samarium-cobalt permanent magnet material comprises a main alloy and an auxiliary alloy, wherein a chemical formula of the main alloy is Sm<x>Co<y>Fe<z>Cu<w>Zr<bal>; x is smaller than or equal to 27% and greater than or equal to 24%; y is smaller than or equal to 55% and greater than or equal to 45%; z is smaller than or equal to 20% and greater than or equal to 15%; w is smaller than or equal to 10% and greater than or equal to 4%; the chemical formula of the auxiliary alloy is NMFe<c>; N represents one or a mixture of light rare earth elements Sm, Pr and Nd; M is one or the mixture of heavy rare earth elements Dy and Tb; a is smaller than or equal to 25% and greater than or equal to 20%; b is smaller than or equal to 65% and greater than or equal to 60%; c is smaller than or equal to 20% and greater than or equal to 15%; and meanwhile, Dy<2>O<3> powder which is equivalent to 0.1%-0.5% of the weight of the main alloy is added. According to the high-coercivity samarium-cobalt permanent magnet material, growth of crystal particles in a sintering process can be prevented; the crystal particles of a samarium-cobalt alloy are refined; and improvement of the coercivity is facilitated; and continuously adjustable coercivity can be achieved by proportioning the main alloy and the auxiliary alloy with different ratios.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

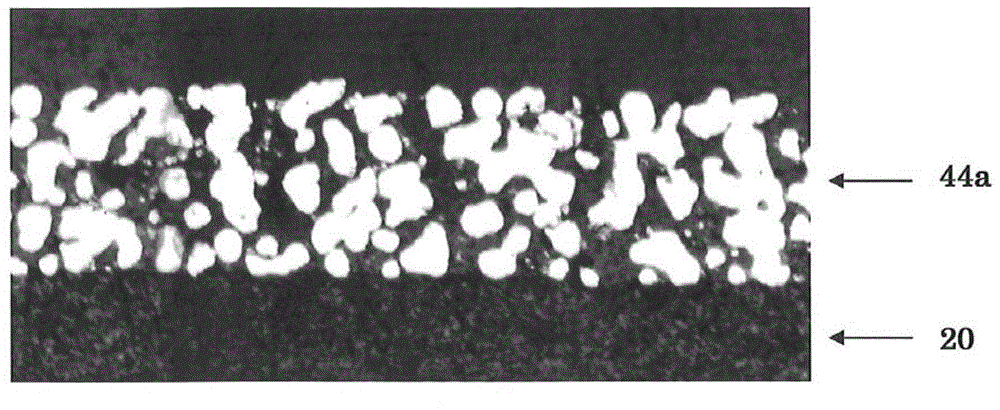

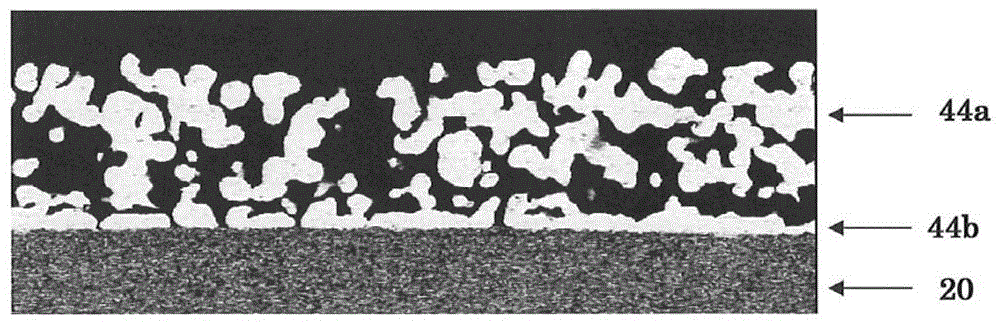

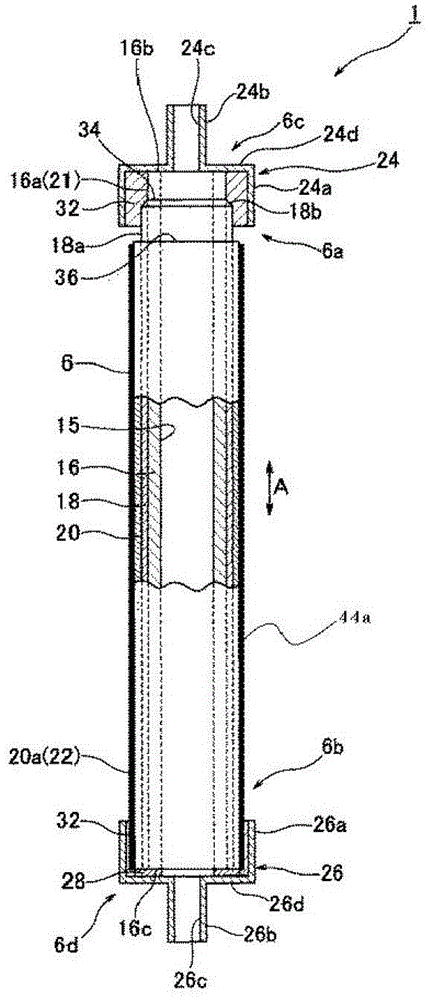

Solid oxide fuel battery cell

InactiveCN103187581AEnsure tightnessHigh initial power generation performanceFuel and primary cellsCell electrodesLanthanumCobalt

There is provided a solid oxide fuel battery cell that has a high initial power generation performance and a good power generation durability while ensuring adhesion between an air electrode layer and a current collector layer. The solid oxide fuel battery cell includes at least a solid electrolyte, a fuel electrode layer provided on one surface side of the solid electrolyte, an air electrode layer provided on the other surface side of the solid electrolyte, and a current collector layer provided on the surface of the air electrode layer, wherein the air electrode layer is formed of an oxide selected from the group consisting of lanthanum ferrite perovskite oxides, lanthanum cobalt perovskite oxides, and samarium cobalt perovskite oxides, and the current collector layer is a porous layer including silver, palladium, and an oxide and has an average porosity of 20% to 70% in a portion other than a portion near a boundary between the current collector layer and the air electrode layer and, in the near-boundary portion, an average porosity of not less than 50% of the average porosity of the portion other than the near-boundary portion.

Owner:TOTO LTD

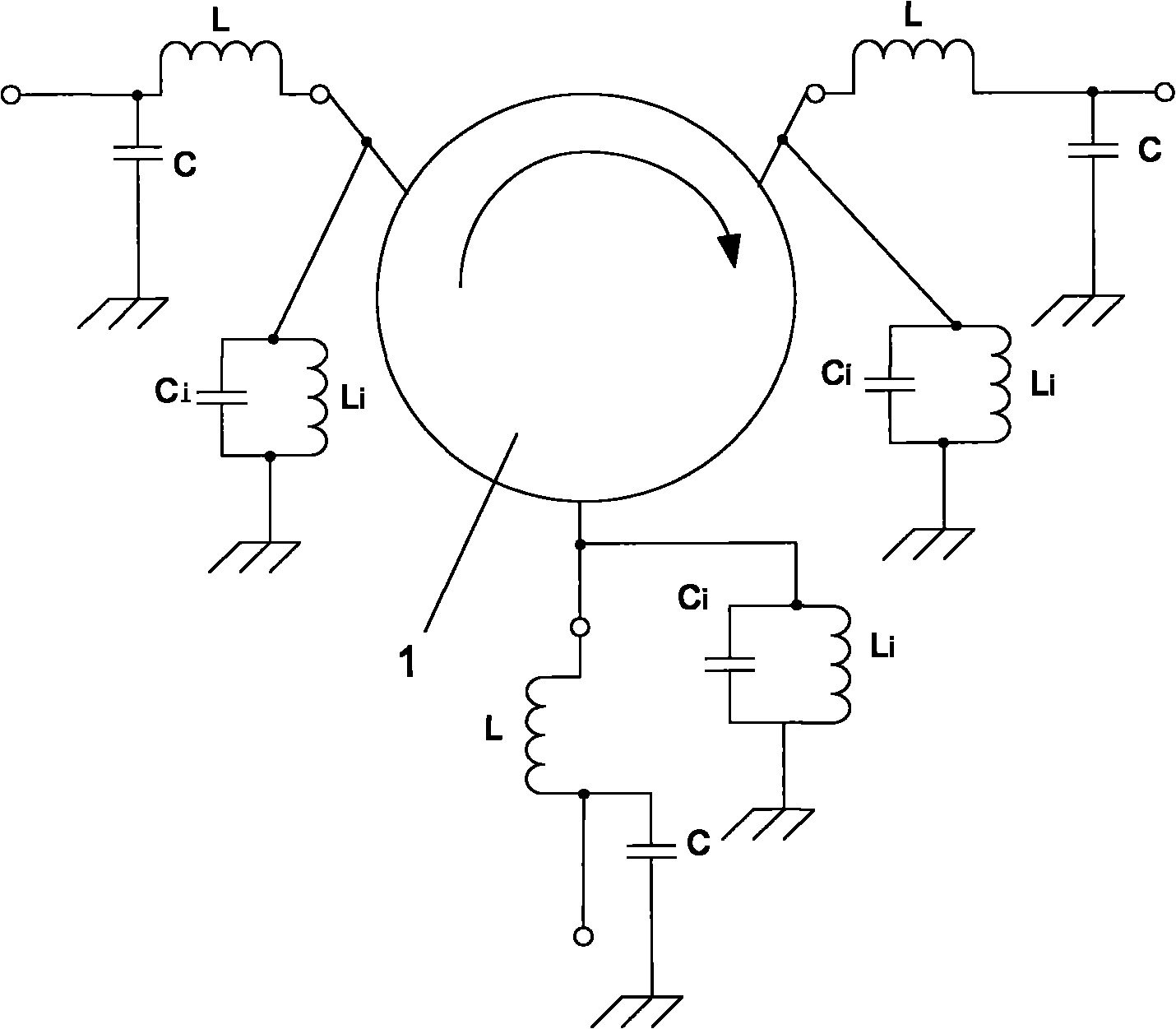

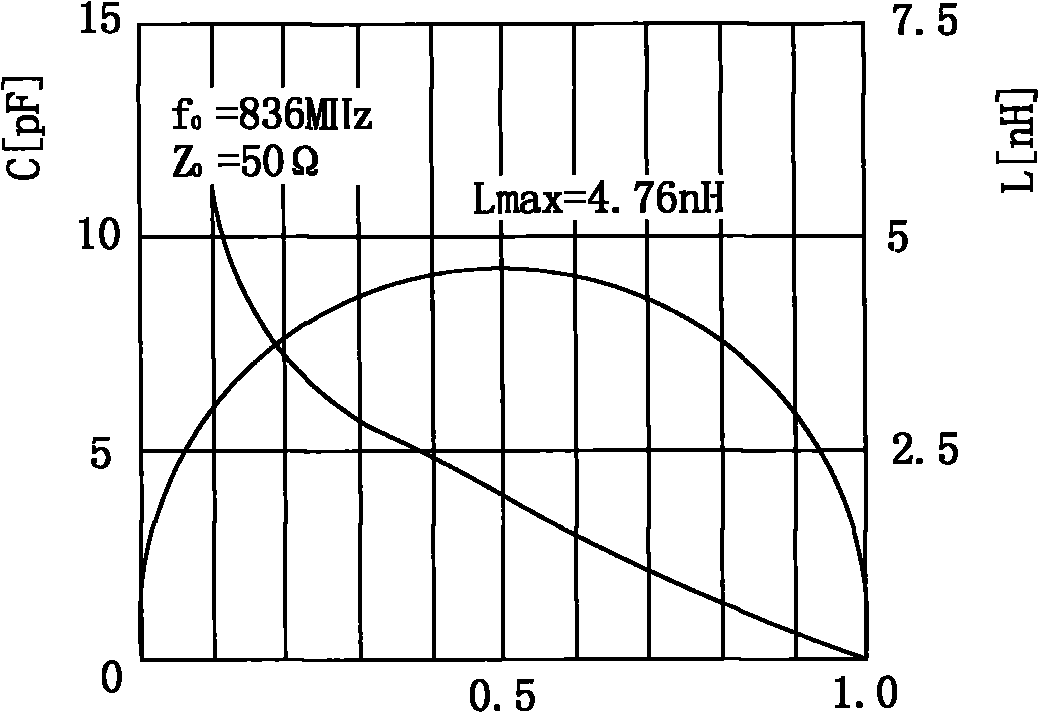

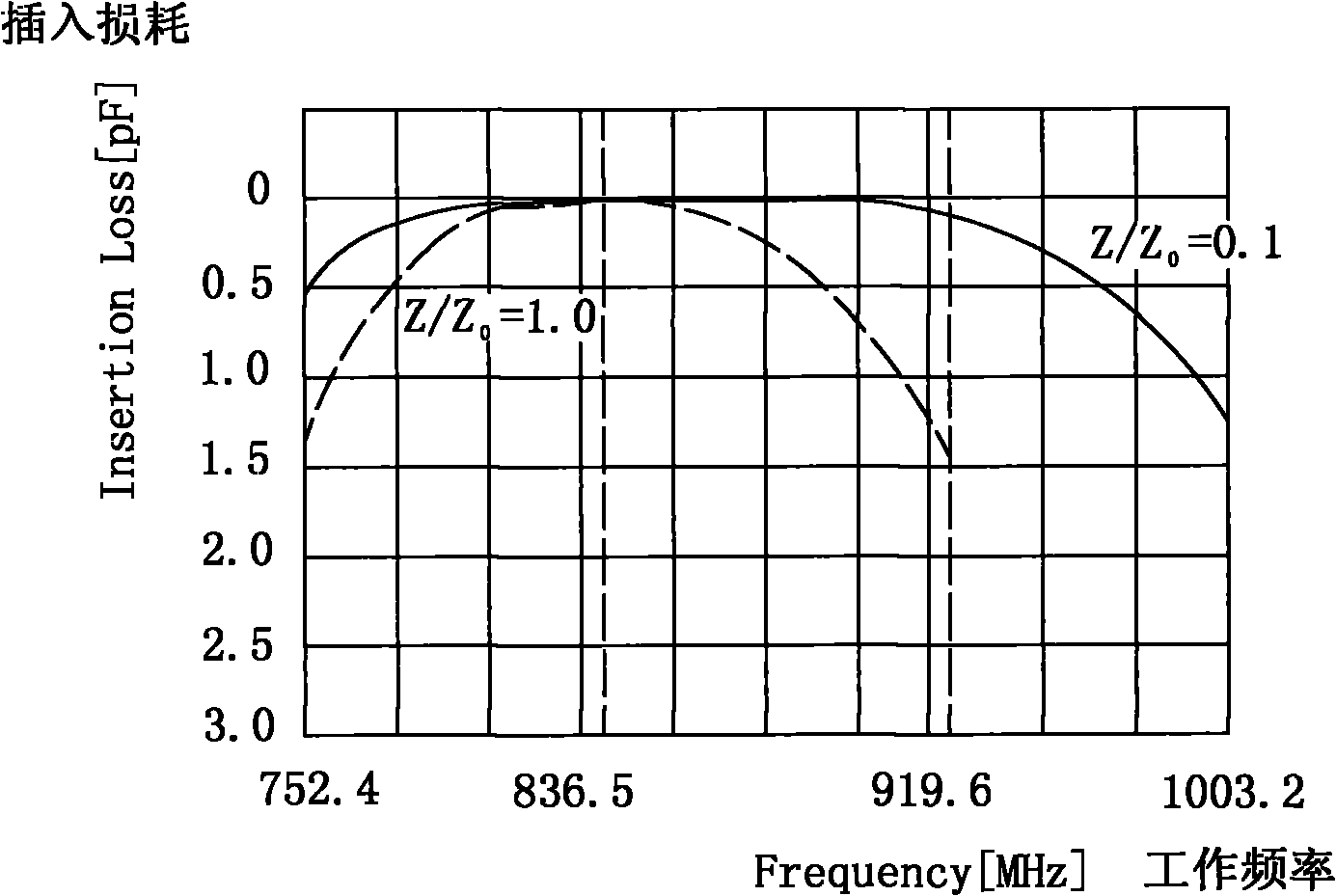

Miniature isolator

The invention discloses a miniature isolator which comprises a three-port circulator connected with loads at ports. The three-port circulator comprises an external cavity, a garnet disc, samarium-cobalt alloy permanent-magnetic material and Y-shaped center conductors, wherein the samarium-cobalt alloy permanent-magnetic material is arranged on the garnet disc and contains a bias magnetic field and the Y-shaped center conductors are distributed between the samarium-cobalt alloy permanent-magnetic material and the garnet disc. The equivalent circuits of the three-port circulator are three LC impedance matching circuits, and the LC impedance matching circuits are respectively connected with the three ports of the three-port circulator and respectively consist of an inductor L and a capacitorC. The three ports of the three-port circulator are respectively connected with an LC parallel resonance circuit which is formed by connecting an inductor Li and a capacitor Ci in parallel. The impedance of the three LC parallel resonance circuits respectively counteracts the impedance of the three LC impedance matching circuits. The invention has the advantages of simple structure, small volume,convenient processing and manufacture, batch production, novel and reasonable design and good use effect and can ensure enough bandwidth while reducing the size of the isolator greatly.

Owner:西安雷讯电子科技有限责任公司

Preparation method of high-coercivity anisotropic flake samarium-cobalt nano-crystal magnet

InactiveCN109448983ALow coercivityImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsMelting pointCopper mold

The invention discloses a preparation method of a high-coercivity anisotropic flake samarium-cobalt nano-crystal magnet. The preparation method comprises the following steps: smelting to acquire Sm-Co-Fe-Cu-Zr master alloy ingot; removing surface oxide skin of the Sm-Co-Fe-Cu-Zr master alloy ingot, crushing into pieces, and performing ultrasonic cleaning; spraying the molten alloy liquid to injectinto copper molds with different thicknesses, and applying low-pulse axial magnetic field; soaking the flake samarium-cobalt nano-crystal magnet into a mixed solution of the Sm6Cu4 alloy nano-powderand absolute ethyl alcohol, and placing in a strong magnetic field annealing furnace in parallel to perform vacuum magnetic field thermal treatment so as to acquire the high-coercivity anisotropic flake samarium-cobalt nano-crystal magnet. The samarium-cobalt nano-crystal magnet prepared through the preparation method disclosed by the invention has high anisotropy and high coercivity. The preparation method disclosed by the invention is simple in process, easy to operate, and capable of reducing the cost, and in favor of the application of the high-coercivity anisotropic flake samarium-cobaltnano-crystal magnet on more permanent magnet devices.

Owner:CHINA JILIANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com