Multistage cusped magnetic field plasma thruster with channel magnetic field guide structure

A technology of magnetic field guidance and cusp magnetic field, which is applied in the field of plasma thrusters, can solve the problems of long processing cycle of samarium cobalt permanent magnet materials, difficult adjustment of magnetic interface angle, and inconvenient adjustment, so as to shorten the processing cycle and avoid Effect of weakened magnetism and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

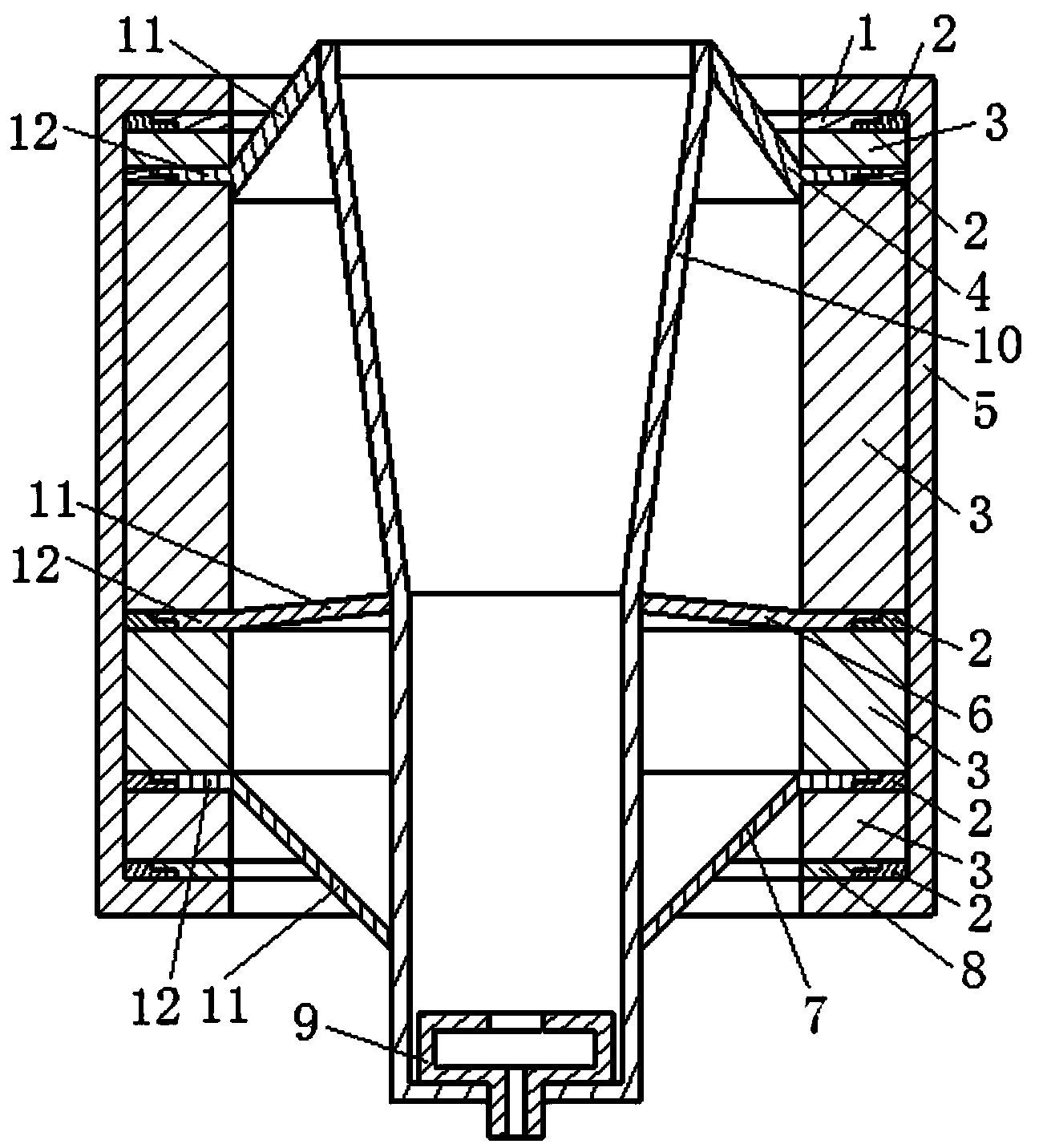

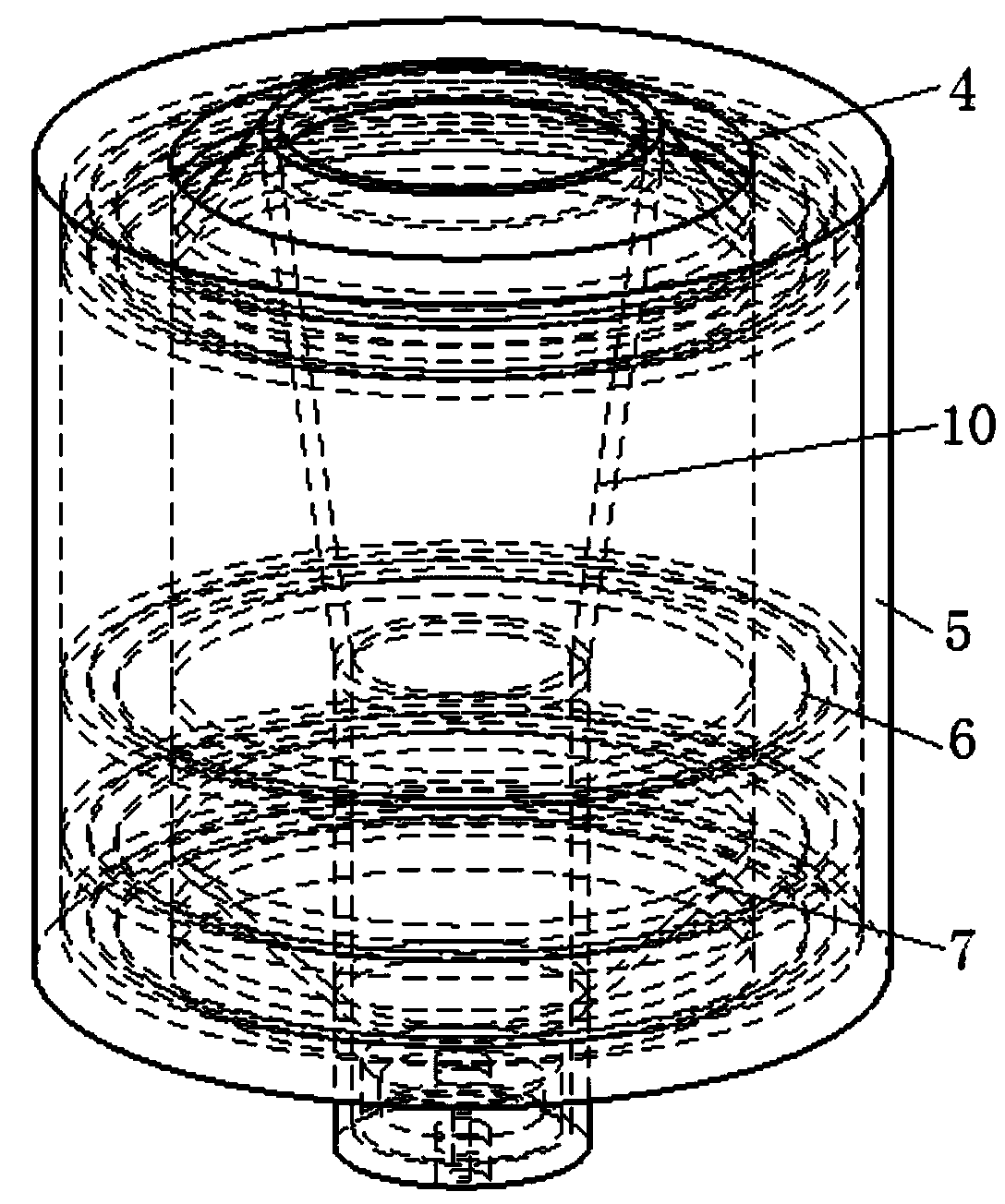

[0013] Specific implementation mode one: combine Figure 1-Figure 8 Illustrate, a kind of multi-stage tangent magnetic field plasma thruster with channel magnetic field guiding structure of the present embodiment comprises ceramic sleeve 10, motor case 5 and four permanent magnets 3, permanent magnet 3 is the annular permanent magnet, four The permanent magnets 3 are arranged sequentially from top to bottom, and the middle part of the four permanent magnets 3 is arranged with a ceramic sleeve 10, the large-diameter port of the ceramic sleeve 10 faces upward, and the four permanent magnets 3 are snapped together through the engine casing 5 ;

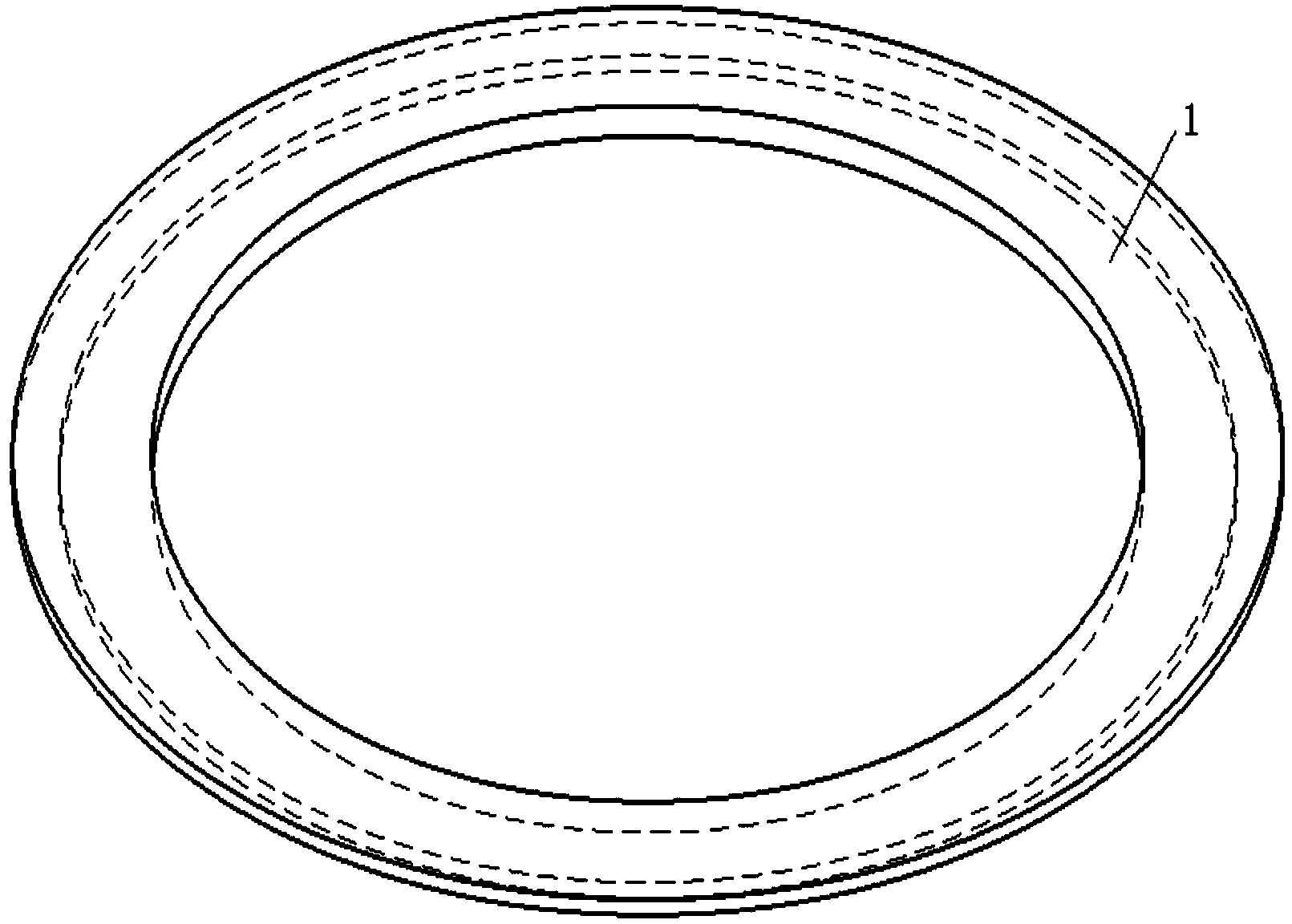

[0014] It also includes five magnetically conductive rings and five nonmagnetically conductive matching rings 2; the five magnetically conductive rings are the first magnetically conductive ring 1, the second magnetically conductive ring 4, the third magnetically conductive ring 6, and the fourth magnetically conductive ring. The magneti...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 1-Figure 7 Note that the five magnetic permeable rings in this embodiment are all made of pure iron. Such an arrangement is cheap and easy to obtain, and is conducive to heat conduction. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination Figure 1-Figure 7 Note that the five non-magnetic mating rings 2 in this embodiment are all made of aluminum alloy. With such arrangement, the heat deposited on the magnetic conduction ring can be conducted to the engine casing, which is beneficial to heat dissipation. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com