Preparation method of sintered samarium-cobalt magnet

A samarium cobalt magnet, samarium cobalt technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc. The effect of oxidizing capacity, improving storage cycle and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

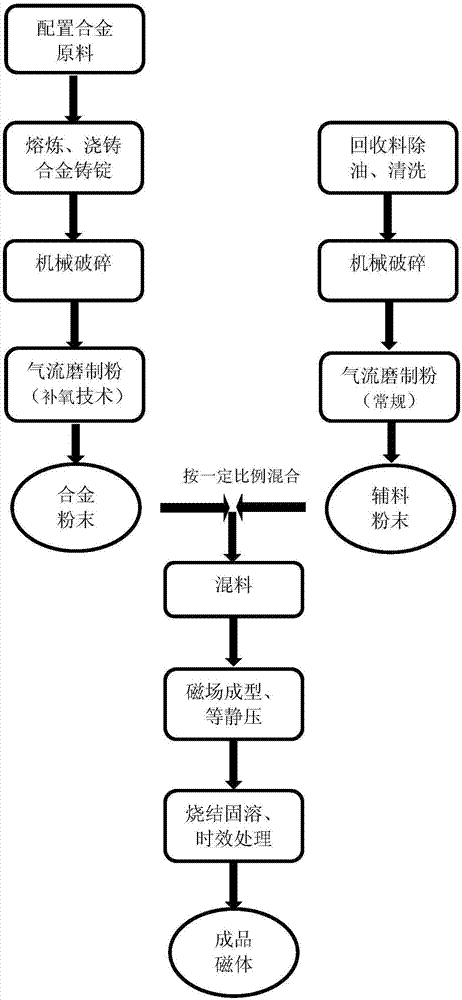

[0037] Such as figure 1 Shown, a kind of preparation method of sintered samarium cobalt magnet comprises the following steps:

[0038] (1) Preparation of alloy powder a

[0039] Prepare the samarium-cobalt alloy raw material according to the following percentage by weight: (Sm 1-x R x ): 25-27%, Fe: 6-25%, Zr: 2-3.5%, Cu: 3-8%, the balance is Co, 0≤x≤0.9.

[0040] Wherein, R is one or more of Ce, Pr, Nd, Gd, Tb, Dy, Ho and Er,

[0041] The prepared samarium-cobalt alloy raw material is melted in an intermediate frequency melting furnace, and then cast in a double-sided water-cooled copper mold to prepare alloy ingots. The melting and casting are carried out under the protection of argon, which effectively prevents the volatilization of Sm; The alloy ingot is mechanically crushed to prepare alloy particles with a size of 0.5-1 mm.

[0042] The jet milling technology is used to make the alloy particles fully mixed with the lubricant into 2.5-5μm alloy powder; during the jet...

Embodiment 1

[0062] (1) Preparation of alloy powder: Using improved jet mill powder technology, add 50ppm of oxygen in the jet mill gas path (oxygen supplement technology), and make the alloy particles fully mixed with lubricant to have an average particle size of 2.8 μm alloy powder.

[0063] The alloy powder is composed of the following components: 25.1% by weight of Sm, 20.5% by weight of Fe, 2.3% by weight of Zr, 5.9% by weight of Cu and 46.2% by weight of Co;

[0064] The preparation method of the alloy particles is as follows: configure the samarium-cobalt alloy raw material; melt the configured raw material in an intermediate frequency melting furnace, and then cast it in a double-sided water-cooled copper mold to prepare an alloy ingot with an average thickness of 30 mm; The alloy ingot is mechanically crushed to prepare alloy particles with a size of 0.5-1mm.

[0065] (2) Preparation of auxiliary material powder: using conventional jet milling technology, the auxiliary material a...

Embodiment 2

[0072] (1) Preparation of alloy powder; using improved jet mill powder technology, add 2000ppm of oxygen in the jet mill gas path (oxygen supplement technology), and make the alloy particles fully mixed with lubricant to have an average particle size of 3.5 μm alloy powder.

[0073] The alloy powder is composed of the following components: 25.6% by weight of Sm, 17% by weight of Fe, 2.9% by weight of Zr, 5.9% by weight of Cu and 48.6% by weight of Co;

[0074] The preparation method of the alloy particles is as follows: configure the samarium-cobalt alloy raw material; melt the configured raw material in an intermediate frequency melting furnace, and then cast it in a double-sided water-cooled copper mold to prepare an alloy ingot with an average thickness of 30 mm; The alloy ingot is mechanically crushed to prepare alloy particles with a size of 0.5-1mm.

[0075] (2) Preparation of auxiliary material powder: using conventional jet milling technology, the auxiliary material a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com