Method for preparing sintered samarium-cobalt magnet

A samarium-cobalt magnet and samarium-cobalt technology are applied in the direction of magnetic objects, magnetic materials, and inorganic materials, which can solve the problems of poor consistency of sintered samarium-cobalt magnets, incompatibility of preparation methods, and increased production costs of enterprises. High consistency, stable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: a method for preparing a sintered samarium cobalt magnet, comprising the following steps:

[0026] ① Preparation of the first samarium-cobalt alloy A1 and the second samarium-cobalt alloy B1; the specific process is:

[0027] ①-1 Ingredients: The material ratio of the first samarium-cobalt alloy A1 is: Sm: 26.69% (weight percent), Zr: 2.26% (weight percent), Fe: 19.43% (weight percent), Cu: 4.74% (weight percent percentage) and Co: 46.88% (weight percentage); the material ratio of the second samarium-cobalt alloy B1 is: Sm: 23.88% (weight percentage), Zr: 3.48% (weight percentage), Fe: 10.65% (weight percentage) , Cu: 8.07% (weight percent) and Co: 53.92% (weight percent);

[0028] ①-2 Put the raw material of the first samarium-cobalt alloy A1 and the raw material of the second samarium-cobalt alloy B1 configured in step ①-1 into the vacuum induction melting furnace respectively, and start vacuuming;

[0029] ①-3 When the vacuum degree in the vacuum indu...

Embodiment 2

[0037] Embodiment 2: This embodiment is basically the same as Embodiment 1, the only difference is that in this embodiment, the first samarium-cobalt alloy primary crushing magnetic powder and the second samarium-cobalt alloy primary crushing magnetic powder are put into the ball mill tank according to the weight ratio of 9:11 ball milled.

Embodiment 3

[0038] Embodiment 3: This embodiment is basically the same as Embodiment 1, the only difference is that in this embodiment, the first samarium-cobalt alloy primary crushing magnetic powder and the second samarium-cobalt alloy primary crushing magnetic powder are put into the ball mill tank according to the weight ratio of 1:4 ball milled.

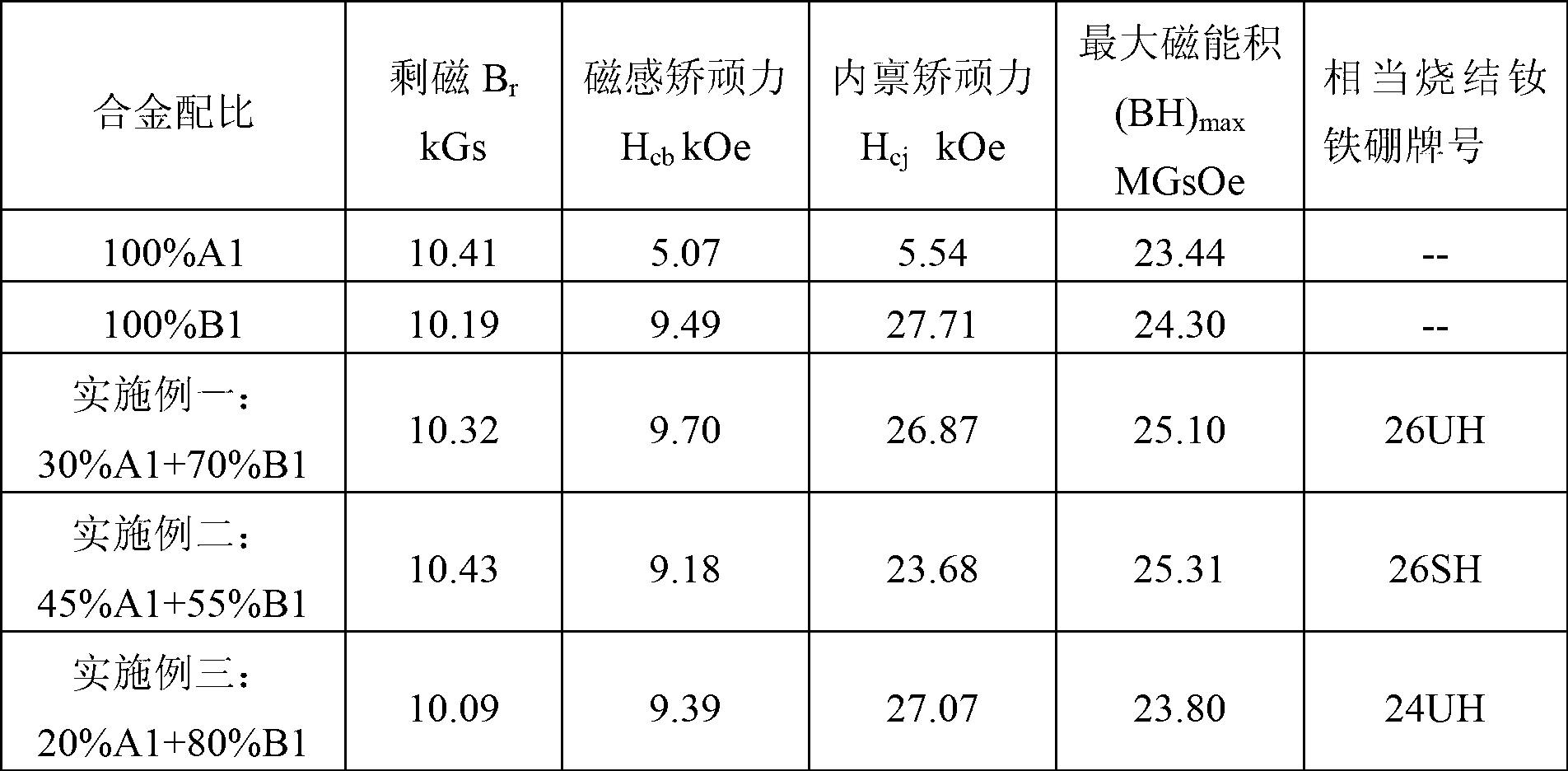

[0039] The sintered samarium cobalt magnets prepared by single alloy technology in the prior art and the sintered samarium cobalt magnets obtained in Examples 1 to 3 of the present invention were tested for relevant magnetic property parameters, and their magnetic properties are shown in Table 1.

[0040] Table 1

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com