Patents

Literature

382results about How to "High energy product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of neodymium iron boron magnet

ActiveCN102103916AReduce usageUniformity controllableInductances/transformers/magnets manufactureMagnetic materialsRare earthImpurity

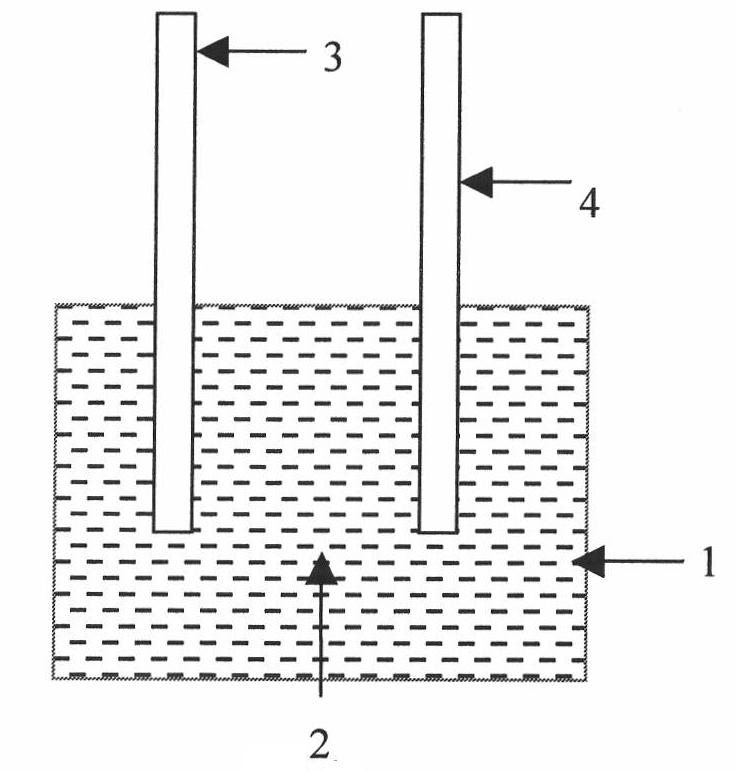

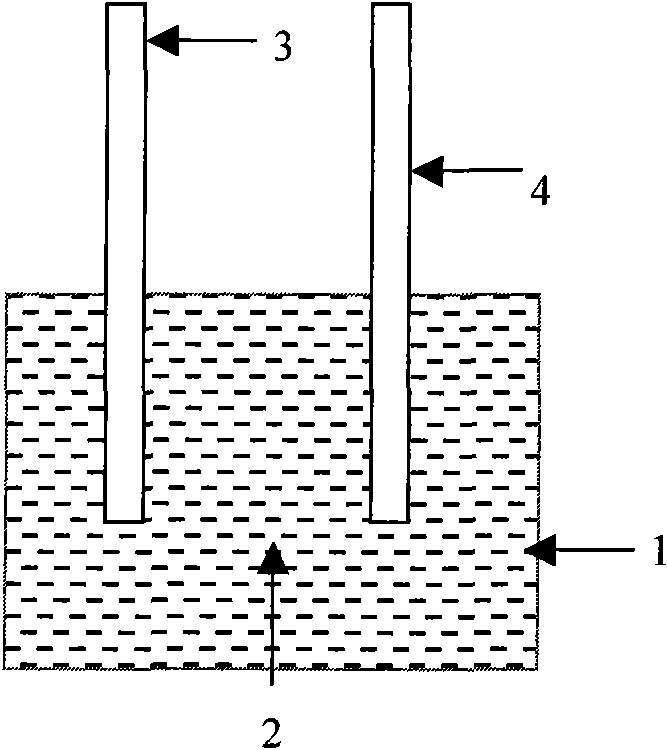

A preparation method of neodymium iron boron magnet is disclosed. The composition general formula of the magnet provided by the invention is R1R2FeMB, wherein R1 is at least one element selected from the group consisting of Nd, Pr, La, Ce, Sm, Sc, Y and Eu, having a content of 23 to 35 wt%; R2 is at least one element selected from the group consisting of Tb, Dy, Gd, and Ho, having a content of 0.1 to 5 wt%; M represents transition group metal with the exception of Fe, having the content of 0.01 to 5 wt%; B represents simple substance boron, having the content of 0.8 to 1.2 wt%; the balance isFe and the other inevitable impurities. The preparation method of neodymium iron boron magnet provided by the invention works in such a manner that: one or more elements in the R2 are plated to the surface of the magnet, the metal R2 is diffused into the interior of the magnet by primary high temperature heat treatment, and imbalance organization and internal stress brought by the high temperature treatment are eliminated through secondary low temperature tempering. Low temperature molten salt electrodeposition method is employed to plate films. The present invention is advantageous in greatly improving the production efficiency, reducing the dosage of the heavy rare earth during preparation process of magnet, saving rare earth resource, and obtaining high coercivity without reducing remanent magnetism and magnetic energy product of a magnet.

Owner:GRIREM ADVANCED MATERIALS CO LTD

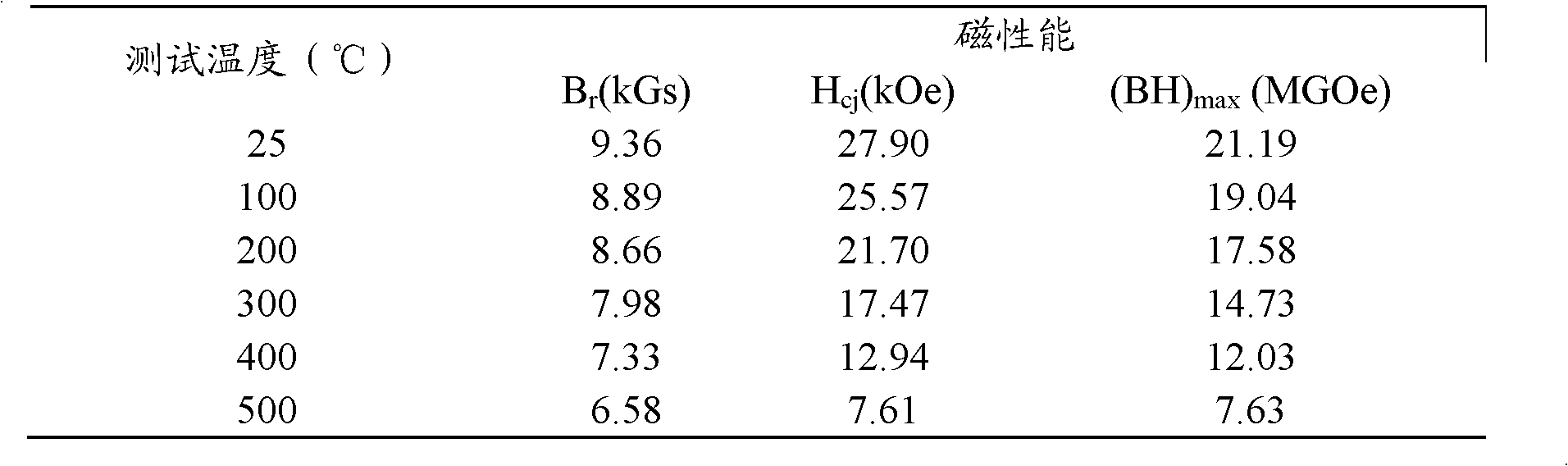

Samarium-cobalt sintered magnet material and preparation method thereof

InactiveCN101882494ALower temperature coefficient of remanenceLower flux temperature coefficientMagnetic materialsRare earthCobalt

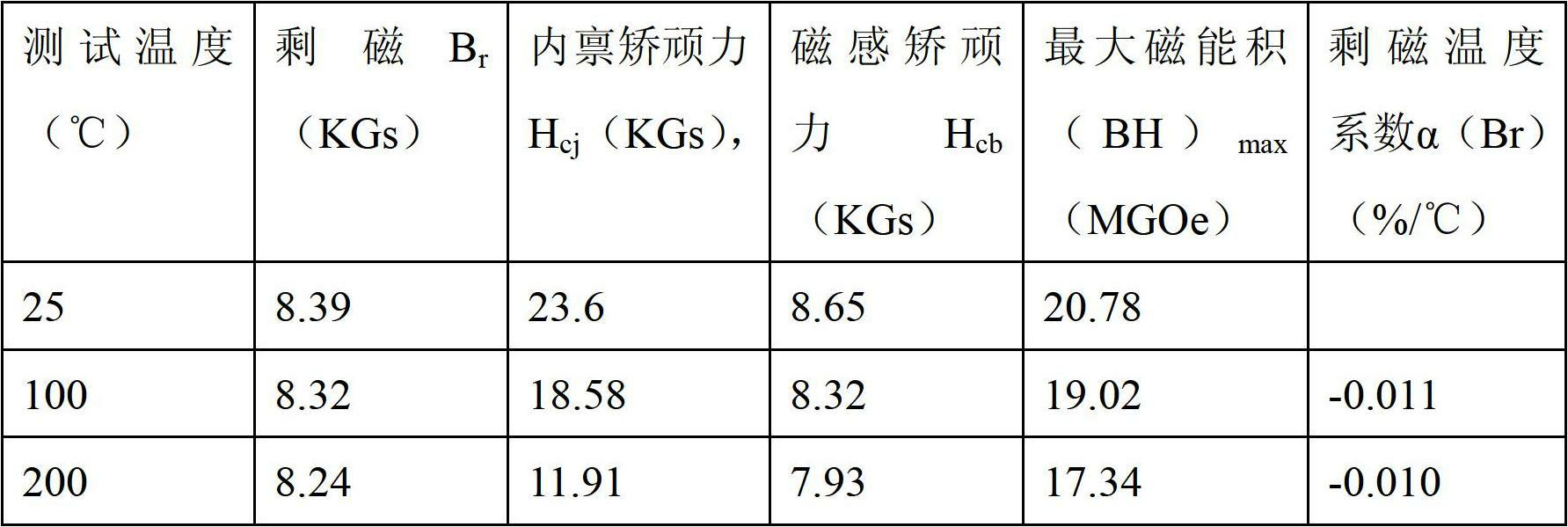

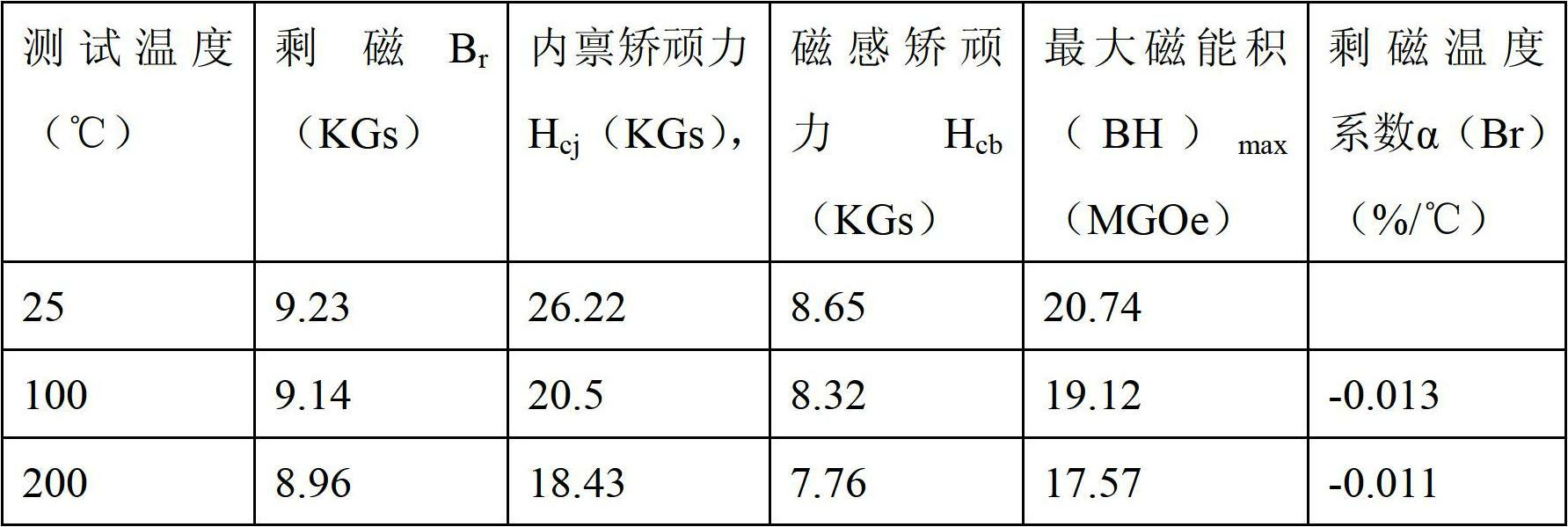

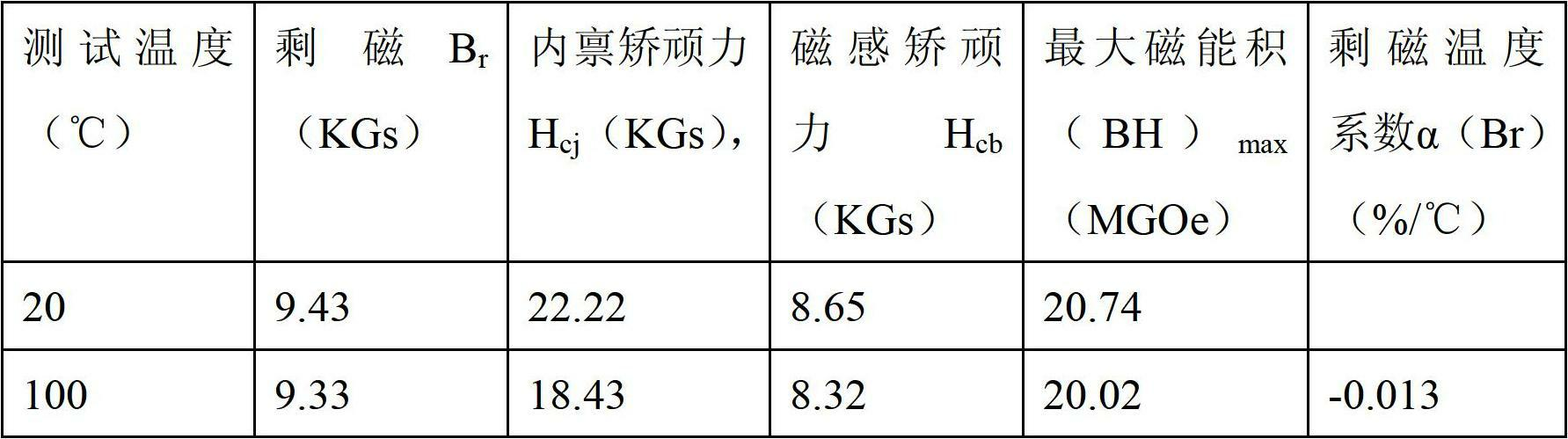

The invention discloses a 2:17 type samarium-cobalt sintered magnet material and a preparation method thereof. The 2:17 type samarium-cobalt sintered magnet material comprises the following raw materials in percentage by mass: 10 to 25 percent of samarium, 45 to 55 percent of cobalt, 10 to 20 percent of iron, 3 to 9 percent of copper, 1 to 3 percent of zirconium and 5 to 15 percent of at least one heavy rear earth element. Due to the selection and the proportion of the raw materials and the innovation of the sintering process, a microstructure of the magnet material is optimized, and the aims of reducing the temperature coefficient of a magnet and simultaneously maintaining higher magnetic energy product of the magnet are fulfilled, wherein the magnetic energy product of the prepared magnet is 14 to 25 MGsOe, the residual magnetism temperature coefficient is about -0.005 to -0.03 percent per DEG C, and a lower magnetic flux temperature coefficient is maintained in an environment at the temperature of between -35 and 300 DEG C.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing high coercive force sintering rare-earth-iron-p permanent magnetic material

ActiveCN1905088AImprove remanenceHigh energy productInorganic material magnetismTerbiumWorking environment

The invention relates to the method used to make rare earth-iron-boron permanent magnetic material with high coercive force which belongs to magnetic material field. The excellent magnetism of the NdFeB permanent magnetism will be obviously reduced while the working environment temperature rises. The invention includes the following steps: using rapid hardening slice technology to make NdFeB rapid hardening slice; smashing to powder with 3-5 micron; making terbium and dysprosium powder with 10-50nm; mixing them with 1-3% weight ratio; orientating at 2.5T magnetic field; processing secondary heat treatment after 2-4 hours sintering at 1050-1120 centigrade degree; the first order heat treatment is at 900-1000 degree centigrade for 1-3h; the secondary is at 550-700 degree centigrade for 1-3h. The invention has better coercive force and lower terbium and dysprosium content compared with the traditional NdFeB permanent magnetic material.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Ultrahigh-coercivity sintered neodymium-iron-boron magnet and preparation method thereof

ActiveCN103794322AImprove coercive forceAchieve magnetic hardeningPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementHigh volume manufacturing

The invention discloses an ultrahigh-coercivity sintered neodymium-iron-boron magnet and a preparation method thereof. The ultrahigh-coercivity sintered neodymium-iron-boron magnet comprises a main phase and a crystal boundary adding phase. The main phase comprises low-HA main alloy and high-HA main alloy. The high magnetocrystalline anisotropy field HA main alloy and the low-HA main alloy are used as the main phase, so that the heavy rare earth element diffuses from the high-HA phase to the low-HA phase in the sintering and heat treatment process to initially improve the coercivity; in addition, alloy components and the preparation technology can be controlled at the same time, the content of Nd2Fe14B in the magnet is improved, and it is ensured that the magnet has the high magnetic energy product. The crystal boundary adding phase can further achieve crystalline grain surface magnetic hardening and improve the coercivity, the microscopic structure is optimized, and the coercivity is further improved. The preparation method of the ultrahigh-coercivity sintered neodymium-iron-boron magnet has the advantages of both a traditional dual alloy method and a single alloy crystal boundary adding method, and is easy to operate and suitable for mass production of ultrahigh-coercivity high-residual-magnetism sintered neodymium-iron-boron magnets.

Owner:ZHEJIANG UNIV +1

High-temperature high-coercivity samarium-cobalt permanent magnet material and preparation method thereof

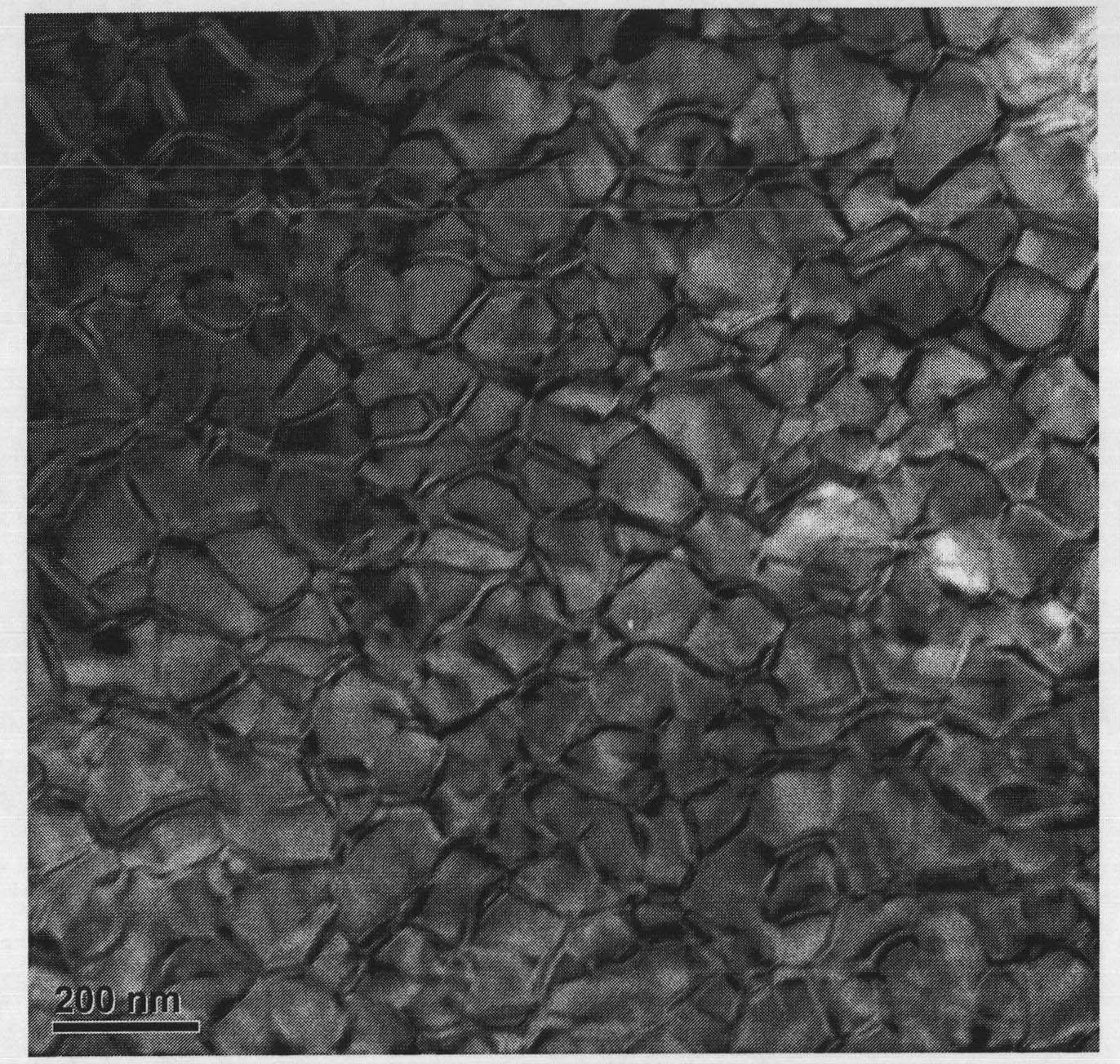

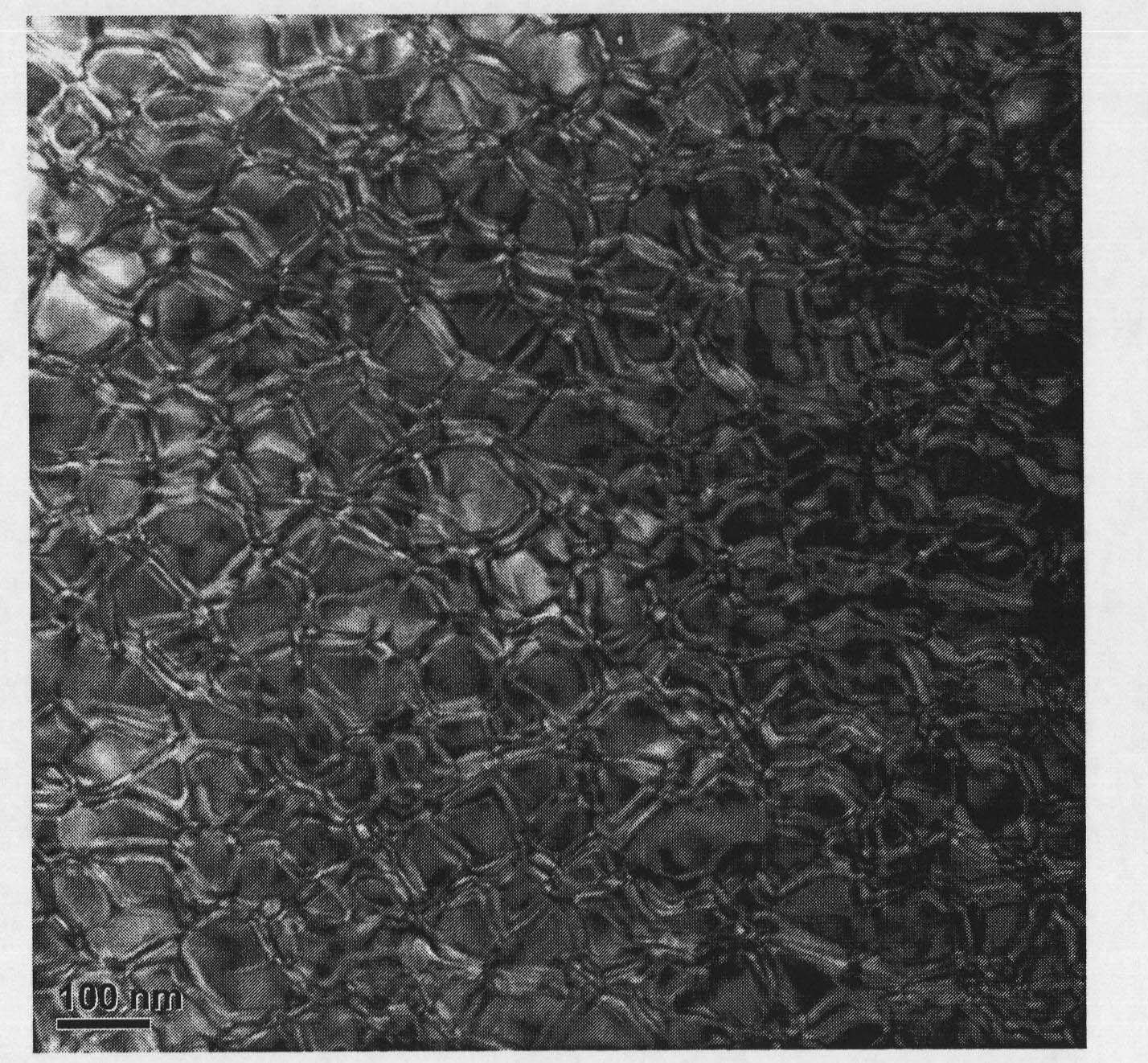

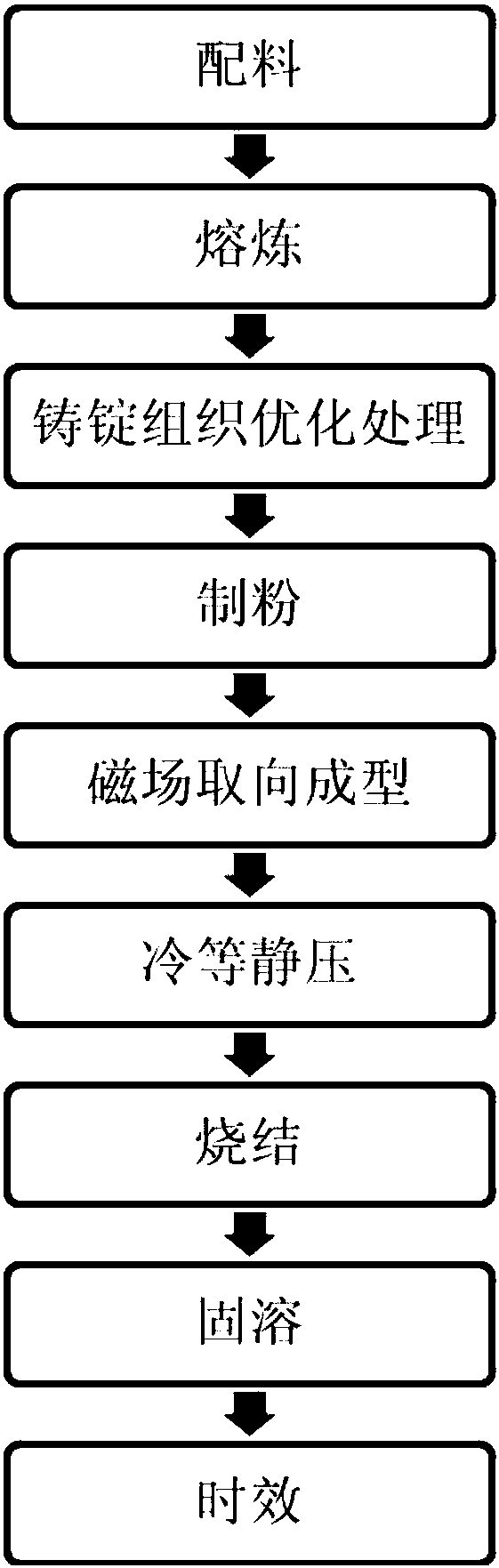

ActiveCN108039258ALarge-scale industrial productionPromote growthInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementIngot

The invention provides a high-temperature high-coercivity samarium-cobalt permanent magnet material and a preparation method thereof. The permanent magnet material is Sm(Co1-u-v-wFeuCuvZrw)z, whereinu ranges from 0.09-0.18, v ranges from 0.05-0.10, w ranges from 0.02-0.04 and z ranges from 6.9-7.8. The preparation method includes the steps that the rare earth element Sm with the purity of 99.95%,Co with the purity of 99.98%, Cu with the purity of 99.99%, Fe with the purity of 99.9% and Zr with the purity of 99.9% are evenly mixed and smelted into an alloy ingot, and the ingot is subjected tostructure optimization treatment; micron-sized alloy powder is prepared by using the powder metallurgy technology, then orientation forming, high-temperature sintering, solid solution and aging treatment are conducted, and the samarium-cobalt permanent magnetic alloy is prepared. According to the method, the proportion of a TbCu7 structure is effectively improved, and a samarium-cobalt permanentmagnet free of a Zr6(FeCo)23 phase and uniform in structure is prepared, has high coercivity, high magnetic energy and other excellent properties at ultra-high temperature and can be suitable for ultra-high-temperature environments with the temperature of 550 DEG C or above.

Owner:BEIHANG UNIV

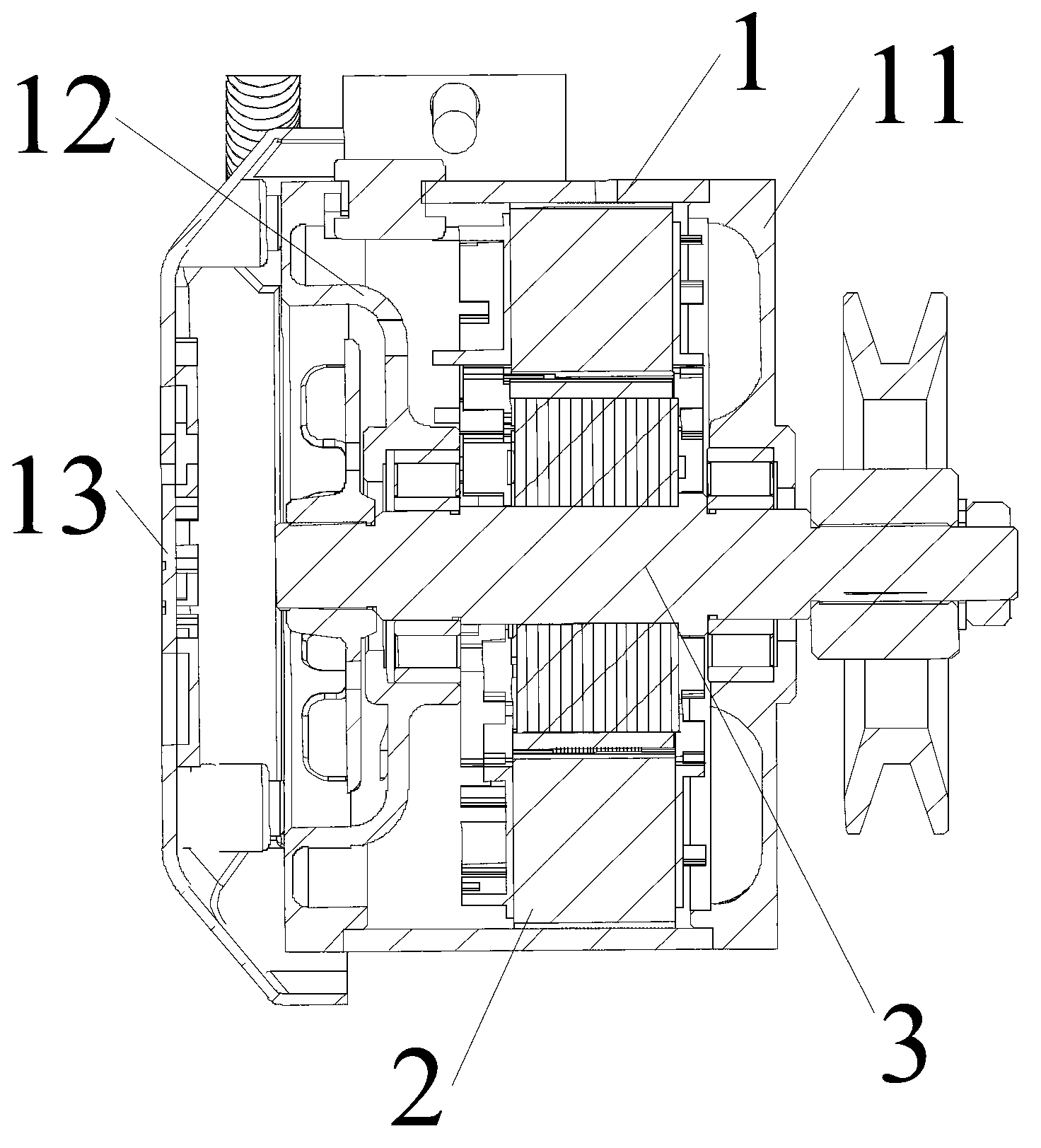

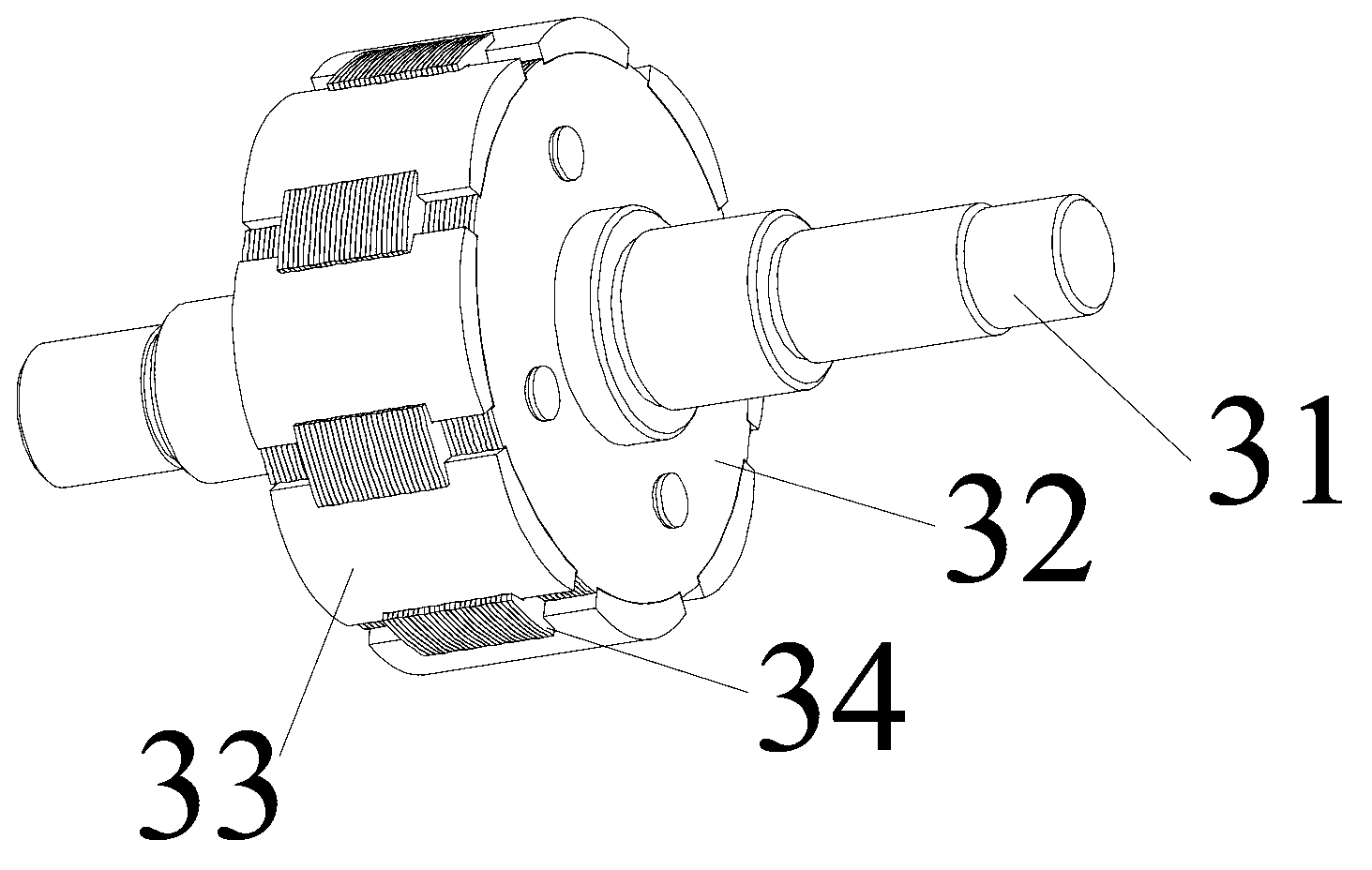

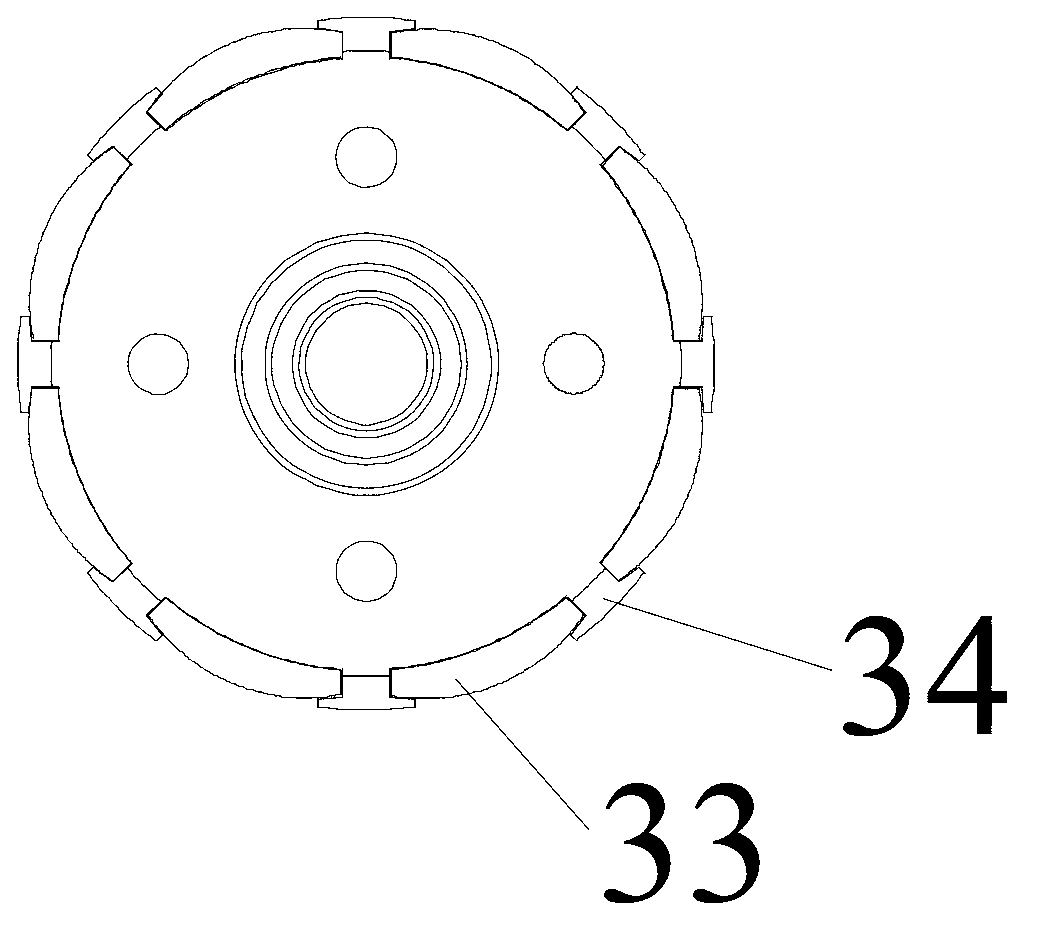

Energy-saving servo motor

InactiveCN103312068AGood energy saving effectEnergy saving effectMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringMagnetic energy

The invention discloses an energy-saving servo motor which comprises a case, a stator assembly and a rotor assembly. The rotor assembly comprises a motor shaft and a rotor iron core, the rotor iron core is fixedly sleeved on the motor shaft, a plurality of silicon steel sheets are laminated to form the rotor iron core, a plurality of steel magnets made of neodymium, iron and boron materials are mounted on the rotor iron core, T-shaped lugs which are distributed circumferentially are arranged on the circumferential surfaces of the silicon steel sheets in the middle of the rotor iron core, the quantity of the T-shaped lugs is identical to that of the steel magnets, the lugs on the silicon steel sheets are laminated to form clamp grooves, and the steel magnets can be embedded into the clamp grooves. Compared with the prior art, the energy-saving servo motor has the advantages that the steel magnets made of the neodymium, iron and boron materials are mounted on the rotor iron core of a rotor of the servo motor, excitation windings are omitted, the neodymium, iron and boron steel magnets are superior in magnetic properties such as high magnetic energy products and high coercivity, the lengths of air gaps can be maximized owing to the high coercivity of the materials, and accordingly an energy-saving effect of the servo motor is improved by 20% as compared with the traditional ferrite motor and other types of motors, and is excellent.

Owner:WUHU WEITE MOTOR

Flexible bonding rare-earth permanent magnet and manufacturing method thereof

ActiveCN101783219AImprove flexibilityNice appearanceInorganic material magnetismInductances/transformers/magnets manufacturePolyesterPlasticizer

The invention provides a flexible bonding rare-earth permanent magnet and a manufacturing method thereof. The flexible bonding rare-earth permanent magnet comprises the following components in percentage by weight: 84.6 to 96.5 percent of NdFeB magnetic powder, 2.5 to 12 percent of bonder of a thermoplastic elastomer with properties of engineering plastics and 1 to 3.4 percent of processing aid, wherein the bonder is a blend of two or three composites of the single thermoplastic elastomers which take polyurethane, polystyrene, polyamide, polyester and polyimide as base materials; and the processing aid comprises a coupling agent, a lubricant and a plasticizer. In the permanent magnet of the invention, the packing ratio of the magnetic powder reaches 96.5 weight percent; the tensile strength, namely the flexibitity, for calendering to form the magnet is more than 3MPa; and while the deficiency of quick magnetic ageing of the flexible magnet at a high temperature is overcome, the shortcomings of easy crack and deformation at a high temperature are also overcome.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

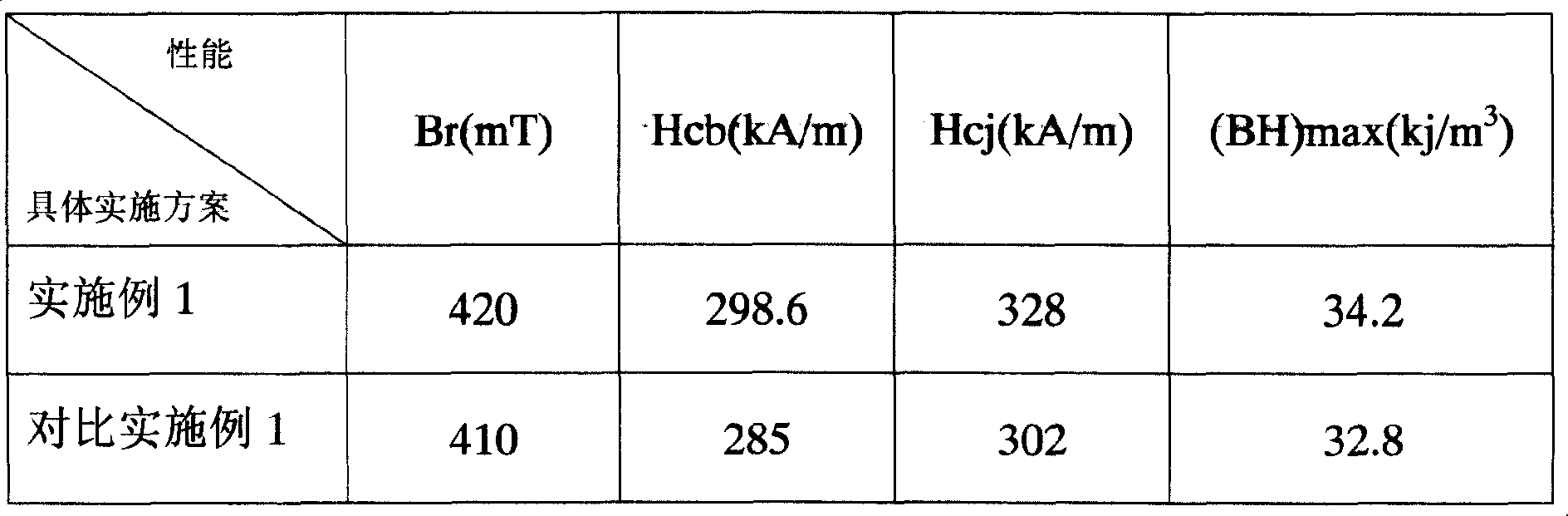

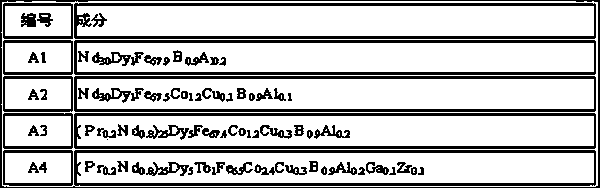

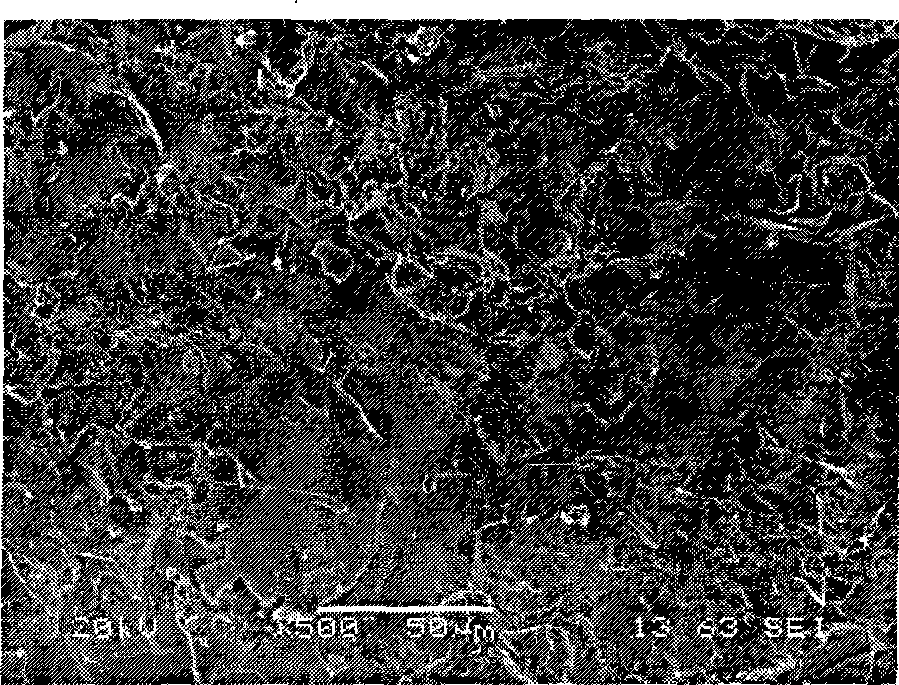

Method for preparing high-magnetic energy product high-coercive force low-cost sintered neodymium iron boron

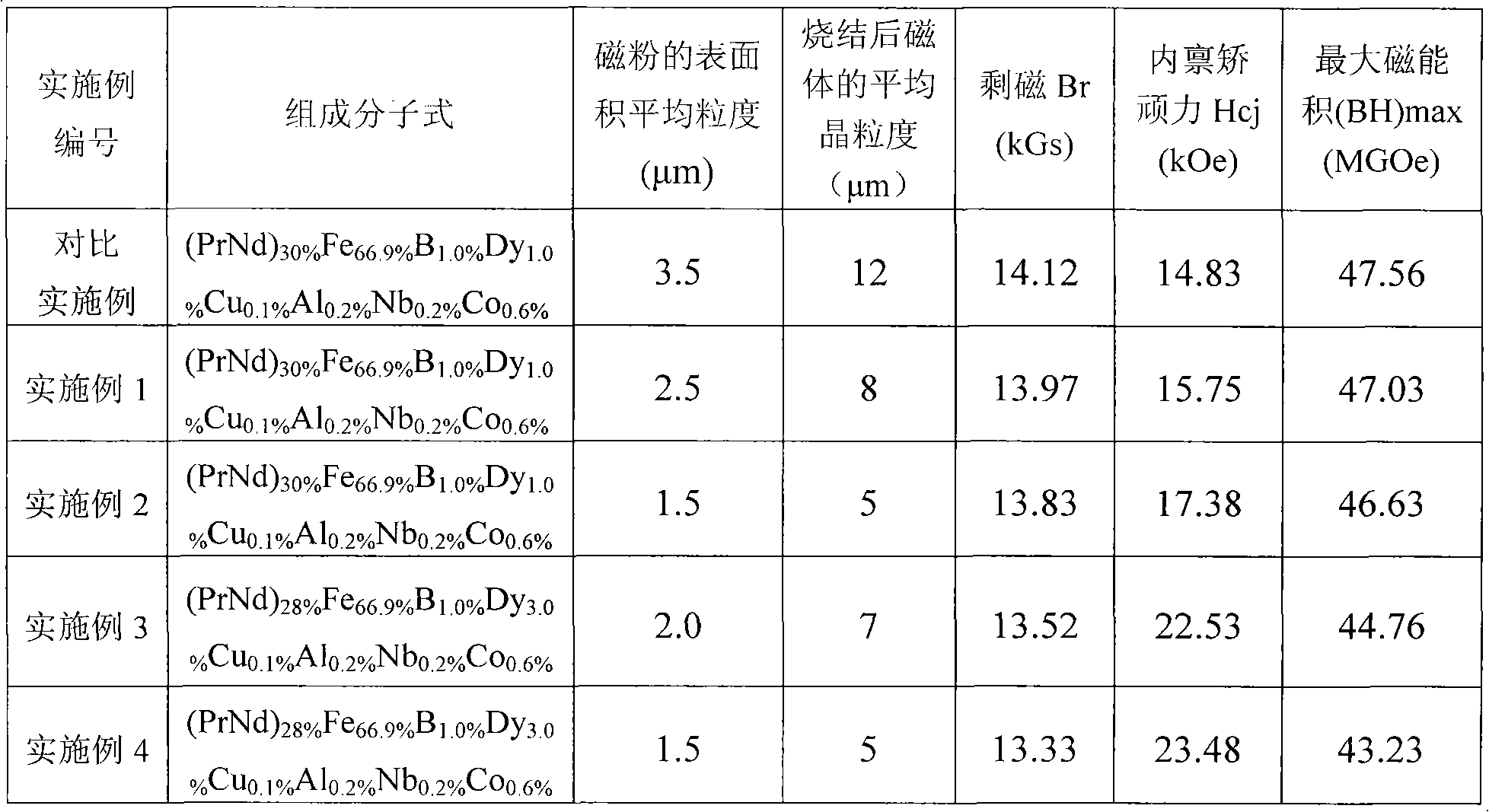

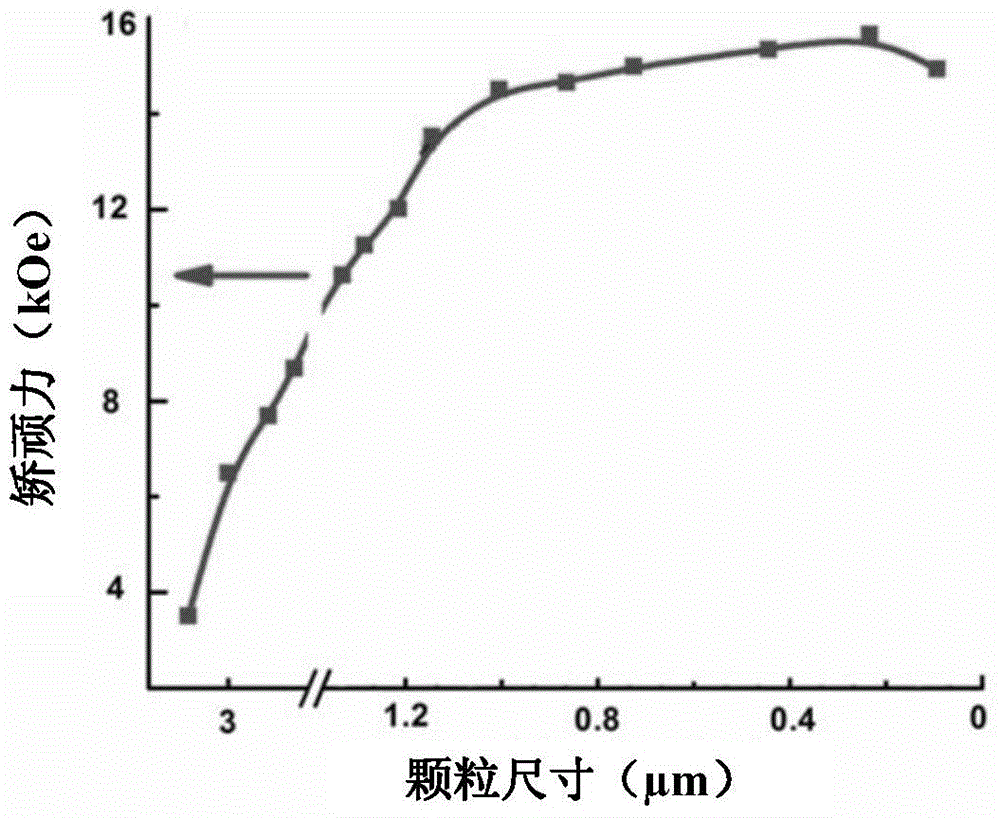

InactiveCN102031445AReduced Surface Area Average Particle SizeImprove coercive forceMagnetic materialsNeodymium iron boronRaw material

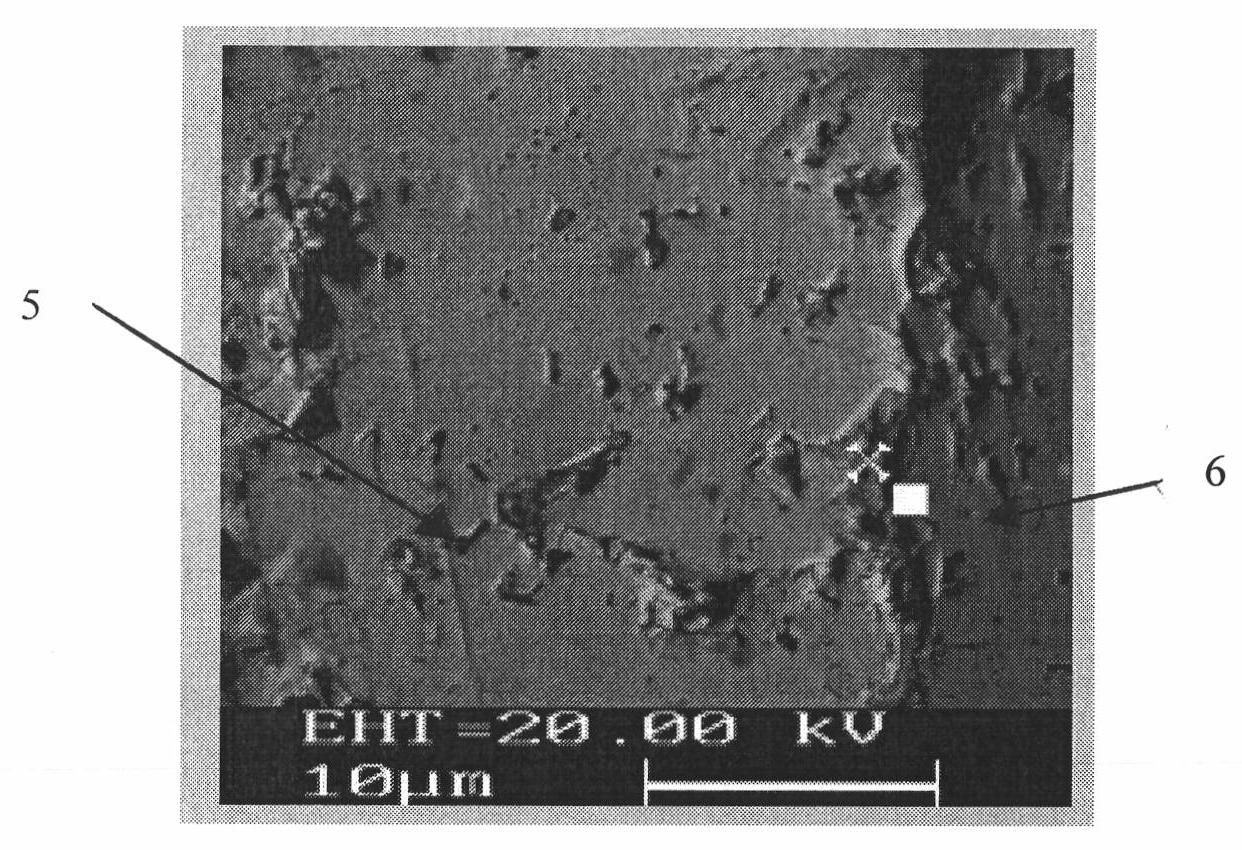

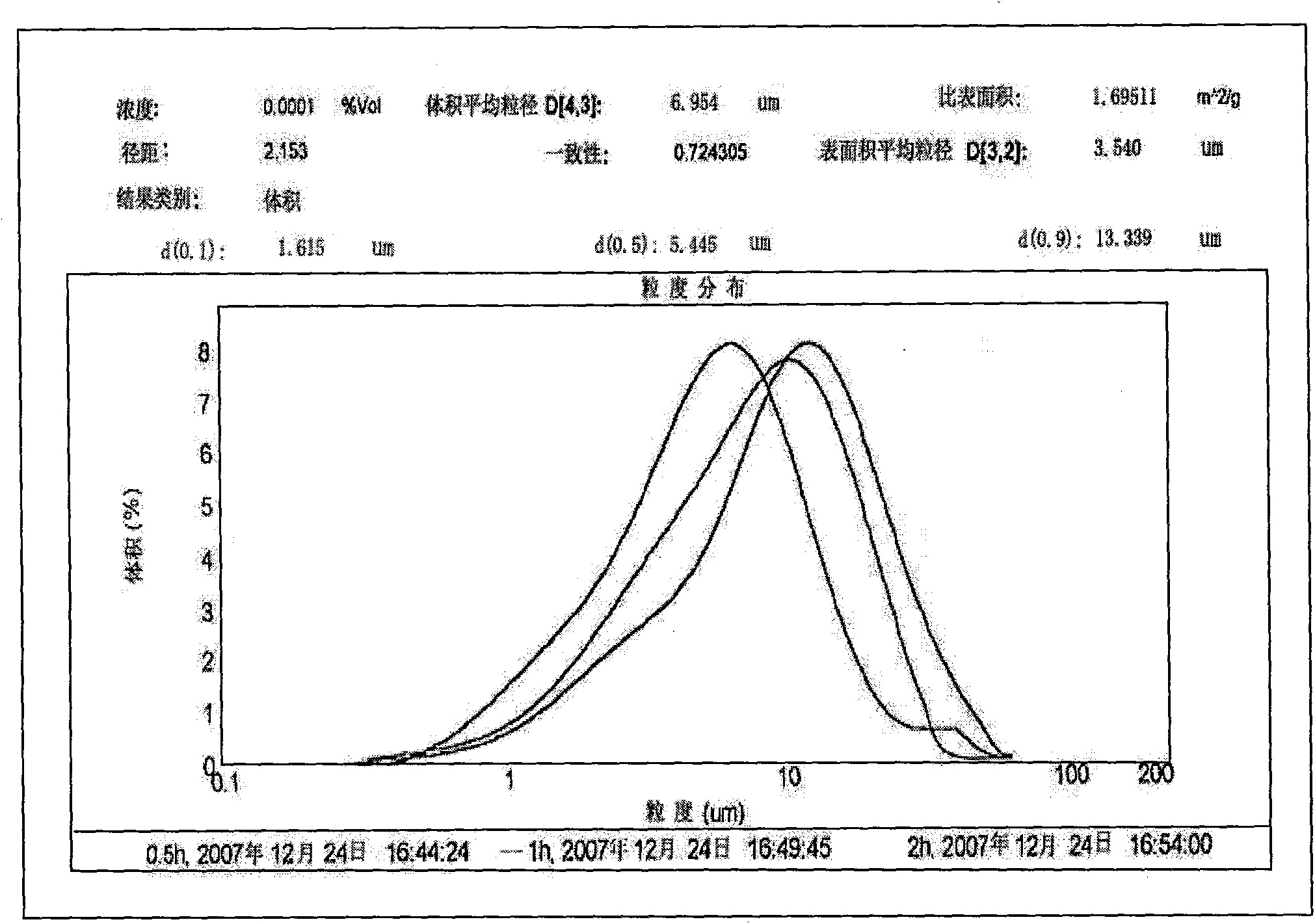

The invention discloses a method for preparing high-magnetic energy product high-coercive force low-cost sintered neodymium iron boron (NdFeB). The method comprises the following steps of: throwing raw materials into a rapid coagulating furnace and smelting in the protective atmosphere of inert gases or nitrogen, and pouring smelting liquid onto a copper roller at a roller speed of 2 to 4m / s to form a rapid coagulating thin strip with the mean thickness of 0.1 to 0.3mm; performing hydrogen breaking and jet milling to obtain magnetic powder with the superficial area mean particle size of 1.5 to 3 mu m, and orientating and molding the magnetic powder in a magnetic field to obtain a blank; and finally, sintering, cooling and ageing to obtain a sintered NdFeB magnet with the mean grain size of 5 to 6 mu m. Compared with the conventional preparation method, by optimizing the rapid coagulating process and combining the adjustment of raw materials, the preparation method makes NdFeB columnar crystals reduced during smelting; therefore, the superficial area mean particle size of the magnetic powder is reduced in the process of performing jet milling, the mean grain size of the sintered NdFeB magnet is reduced finally, and the coercive force of the sintered NdFeB magnet is improved. Therefore, the preparation method is suitable for preparing a high-magnetic energy product and low-cost high-coercive force magnet.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

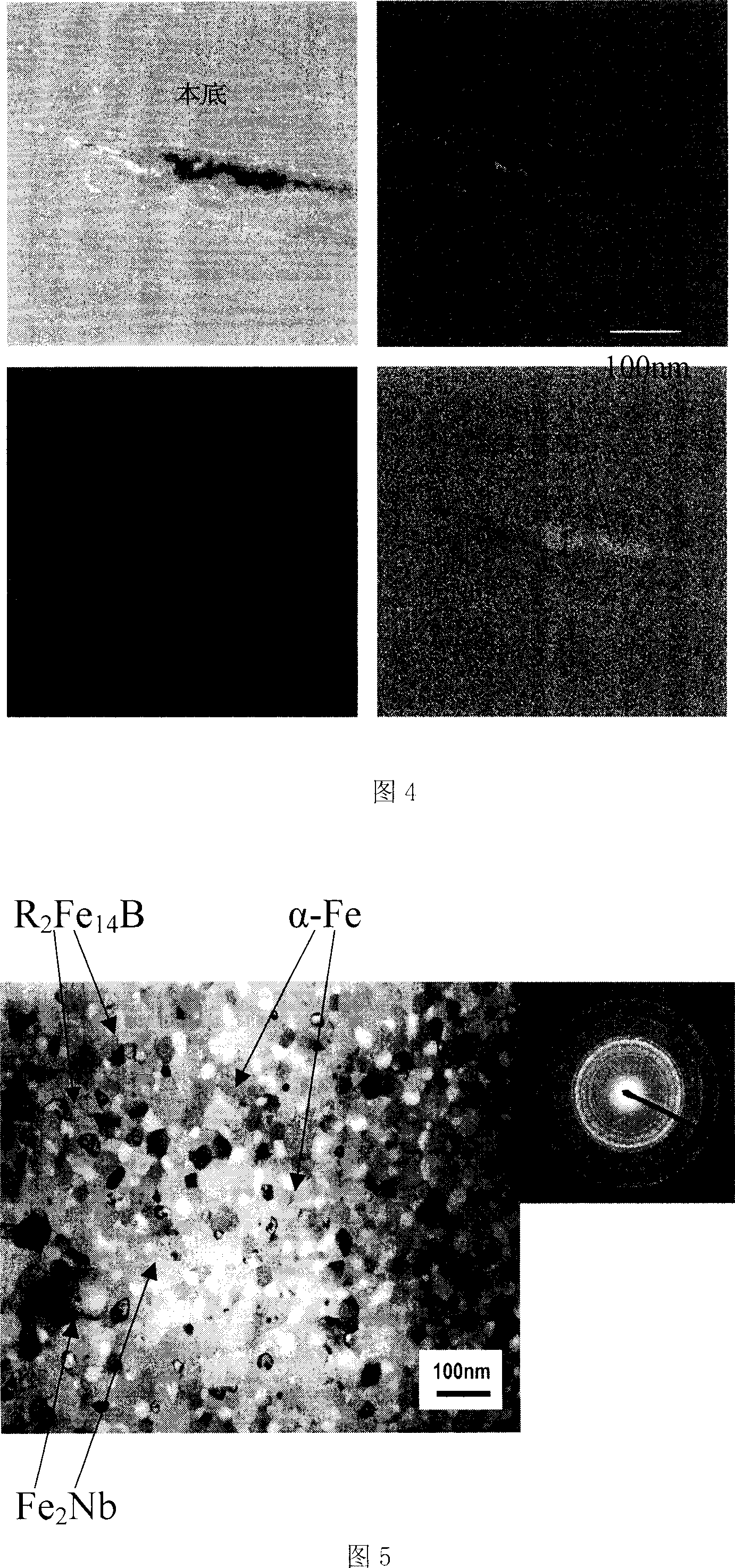

High stability and high magnetism quenched R-Fe-B base permanent magnetic alloy powder

The high stability and high magnetism quenched R-Fe-B base permanent magnetic alloy powder has the basic expression of RxFe100-x-y-z-vMzCovBy, where R is light RE element(s) Nd, Pr and La, and M is element(s) of Nb, Zr, Ti, etc; and consists of main R2Fe14B phase and small amount of superfine auxiliary Fe-alpha-M-beta phase. Adding Nb and other transition elements to form small amount of superfine auxiliary Fe-alpha-M-beta phase during fast solidification can inhibit over nucleation and growth of Nd2Fe14B crystal grain, improve the performance of the quenched material, fine the Nd2Fe14B crystal grain and raise the temperature stability and antioxidant process of the material. In addition, the permanent magnetic alloy powder has obviously raised intrinsic coercive force, high saturated magnetization, high residual magnetism and other advantages.

Owner:DONGFANG MICRON & NANOMETER SCI TECH

Process for preparing magnetic powder and sintered magnet and product produced thereby

ActiveCN1655295AIncrease the anisotropy constantImprove intrinsic coercive forceInorganic material magnetismInductances/transformers/magnets manufactureMetallurgyFerrite powder

This invention relates to magnetic material field and especially to a process method improvement and its formula to hexagonal magnetic lead ferrite powder and sinter magnetism, wherein the said magnetism or magnetic powder has one-Curie temperature with A,R, B and Fe hexagonal ferrite main phase and the following molecular formula: A1-XRx[(Fe3+aFe2+b)12-yBy]zO19, through adding positive three Co and optimizing the formula and improving the magnetism crystal aeolotropism constant K1.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

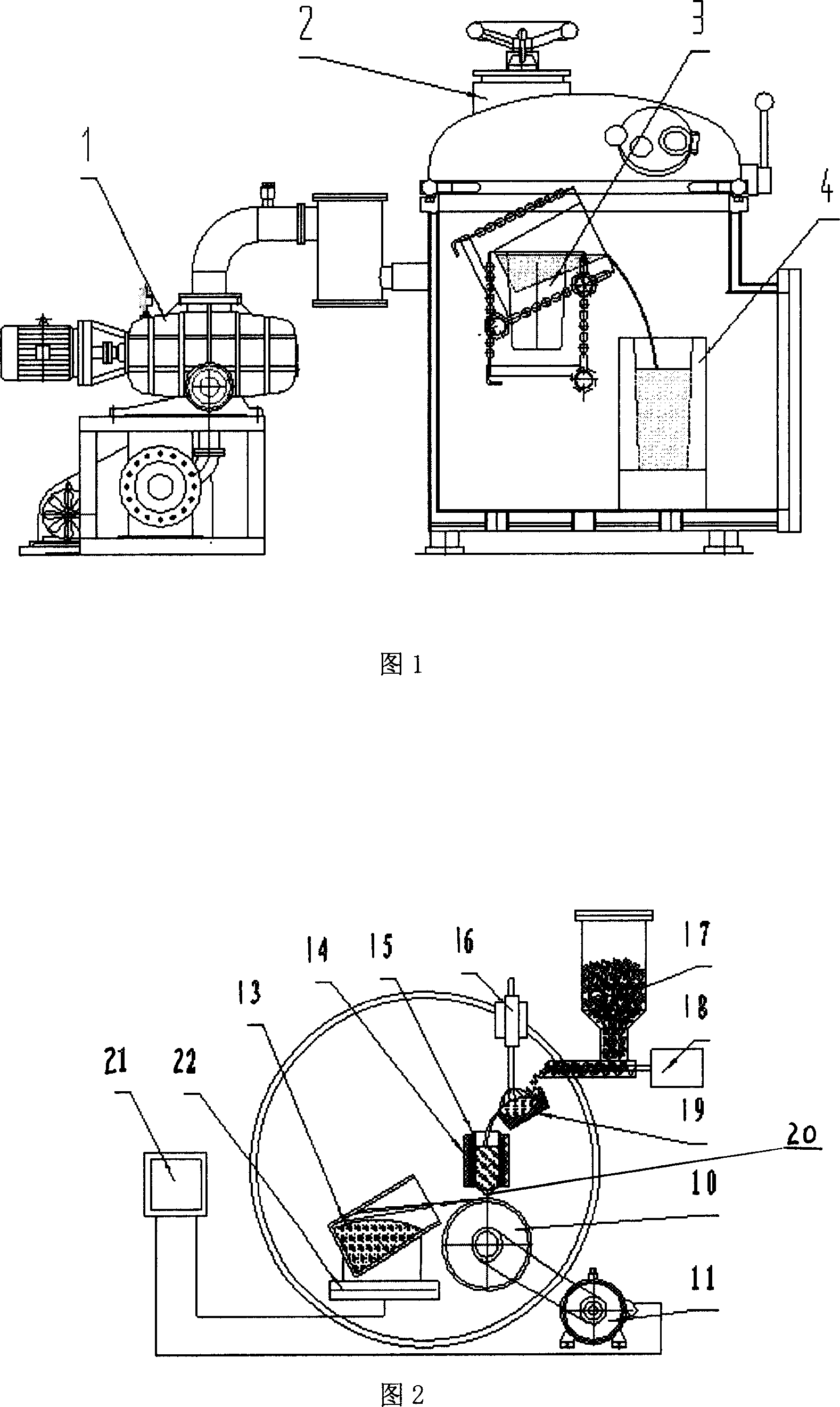

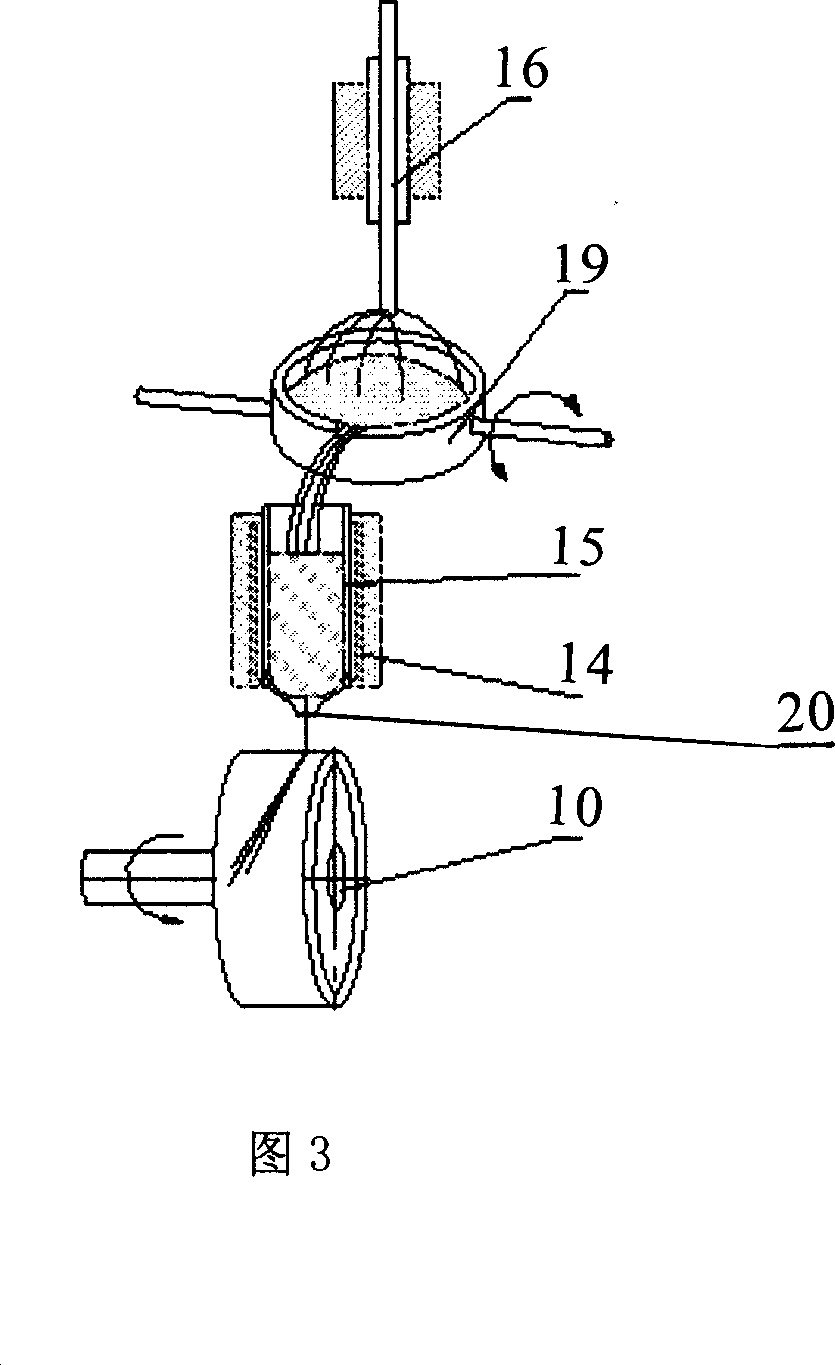

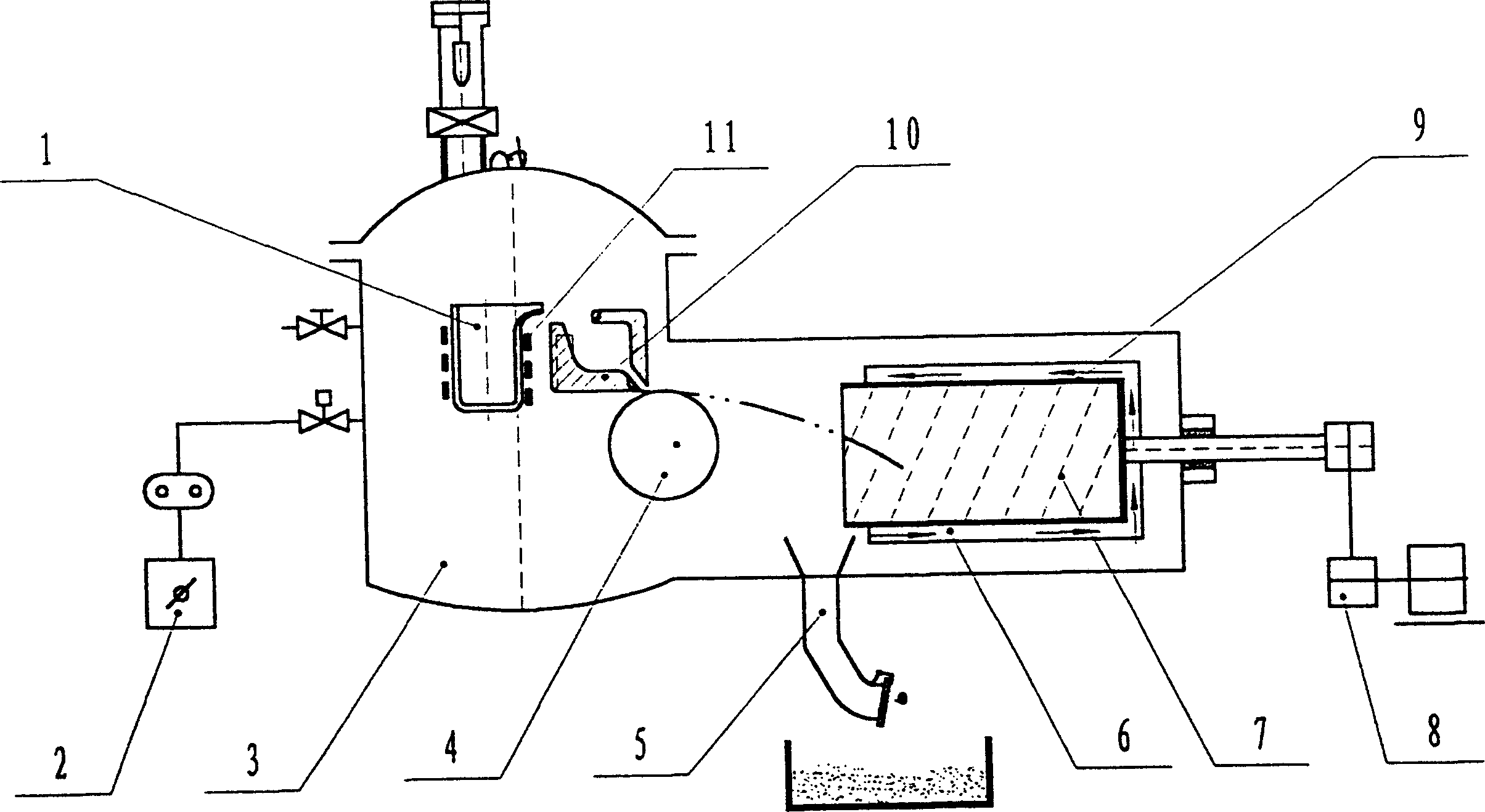

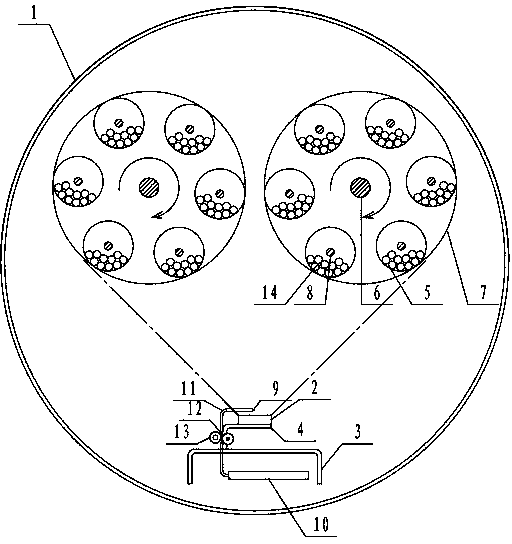

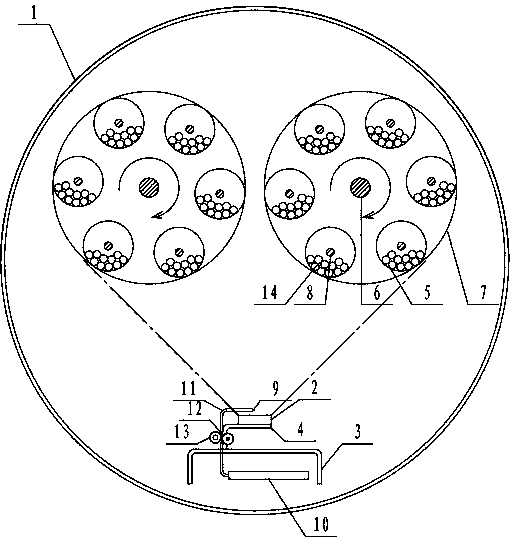

Vacuum smelting quick condensation furnace

A vacuum smelting furnace with quick setting-up function is composed of vacuumizing system, vacuum case of furnace, induction heating coil, crucible, tundish, rotary wheel, and the drum with internal spiral plate and external cooler wrapping it. It can be used to prepare permanent-magnet RE Nd-Fe-B alloy material and hydrogen-bearing RE alloy material. Its advantages are quick and uniform cooling, good microstructure, and high performance.

Owner:沈阳中北真空技术有限公司

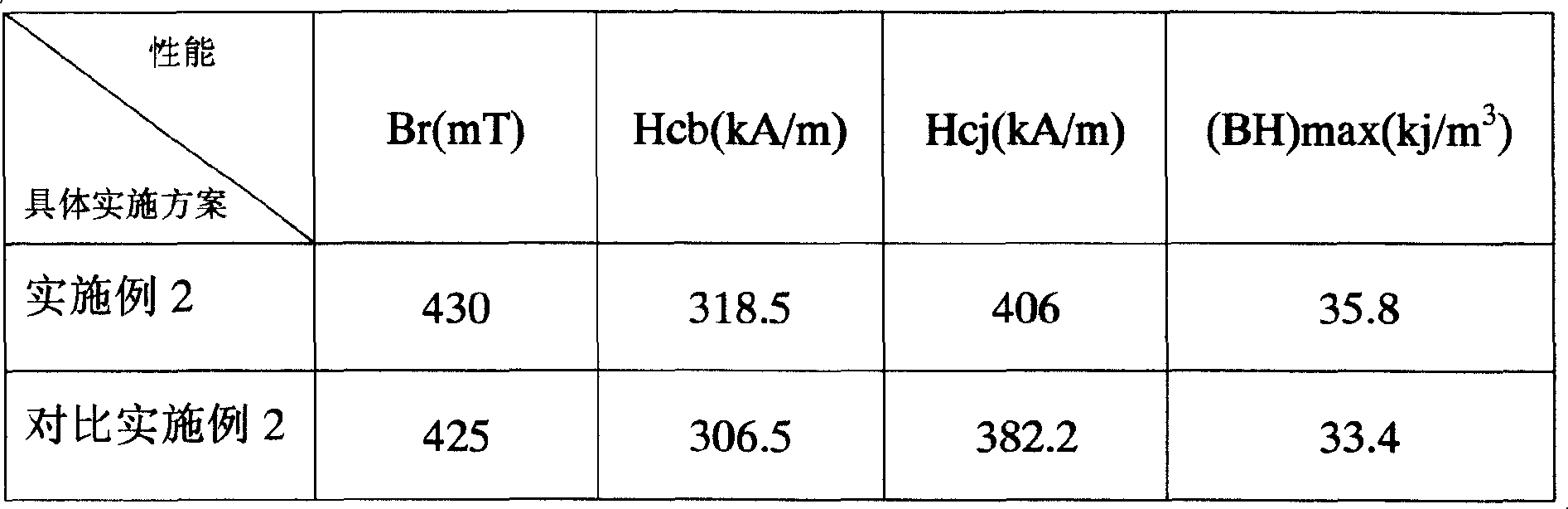

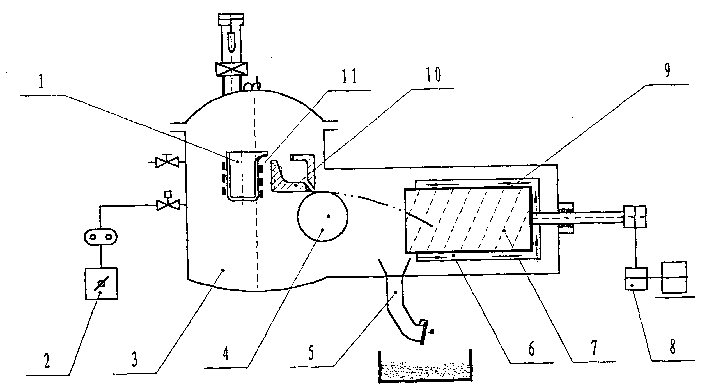

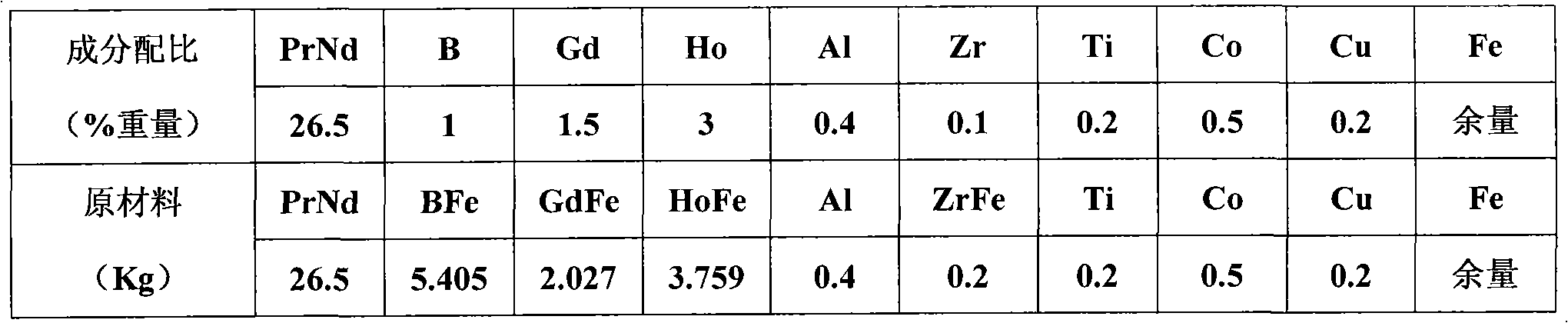

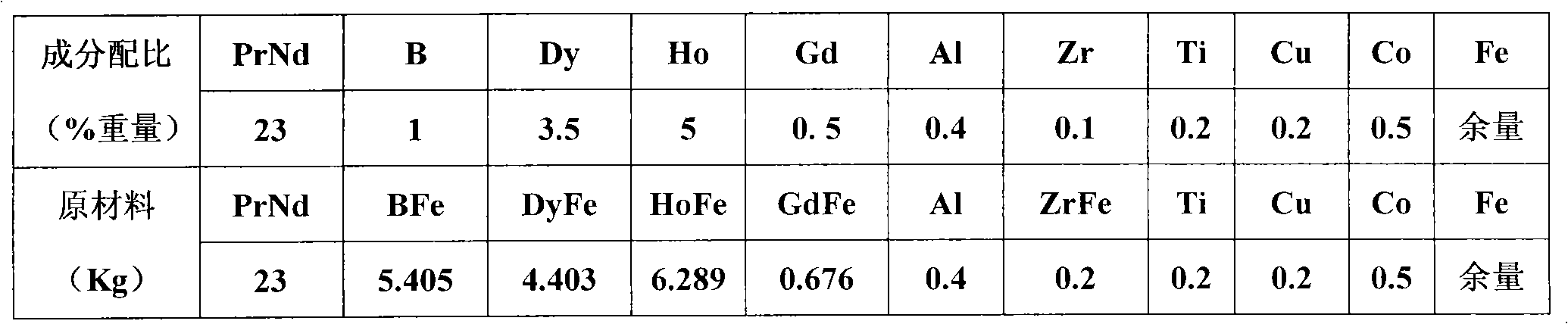

Medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium

InactiveCN101552062AAlleviate shortagesPowder speed increasedInductances/transformers/magnets manufactureMagnetic materialsCobaltImpurity

The invention discloses a medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium, which is composed of the following components by weight percentage: 20 percent-33 percent of praseodymium-neodymium alloy, 0.5 percent-10 percent of gadolinium, 0.5 percent-10 percent of holmium, 0.9 percent-1.2 percent of boron, 0.1 percent-0.8 percent of aluminum, 0.1 percent-0.5 percent of copper, 0.1 percent-0.5 percent of zirconium, 0.1 percent-0.5 percent of titanium, 0 percent-10 percent of dysprosium, 0 percent-3.0 percent of cobalt and the balance of iron and a small amount of inevitable impurities in materials. The medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium has high corrosion resistance, square degree and magnetic energy product; furthermore, the powder discharging speed of the powder production procedure in the preparation process is fast, thereby shortening the production cycle, improving the magnetic performances of the magnet and enhancing the enterprise competitiveness.

Owner:宁波同创强磁材料有限公司

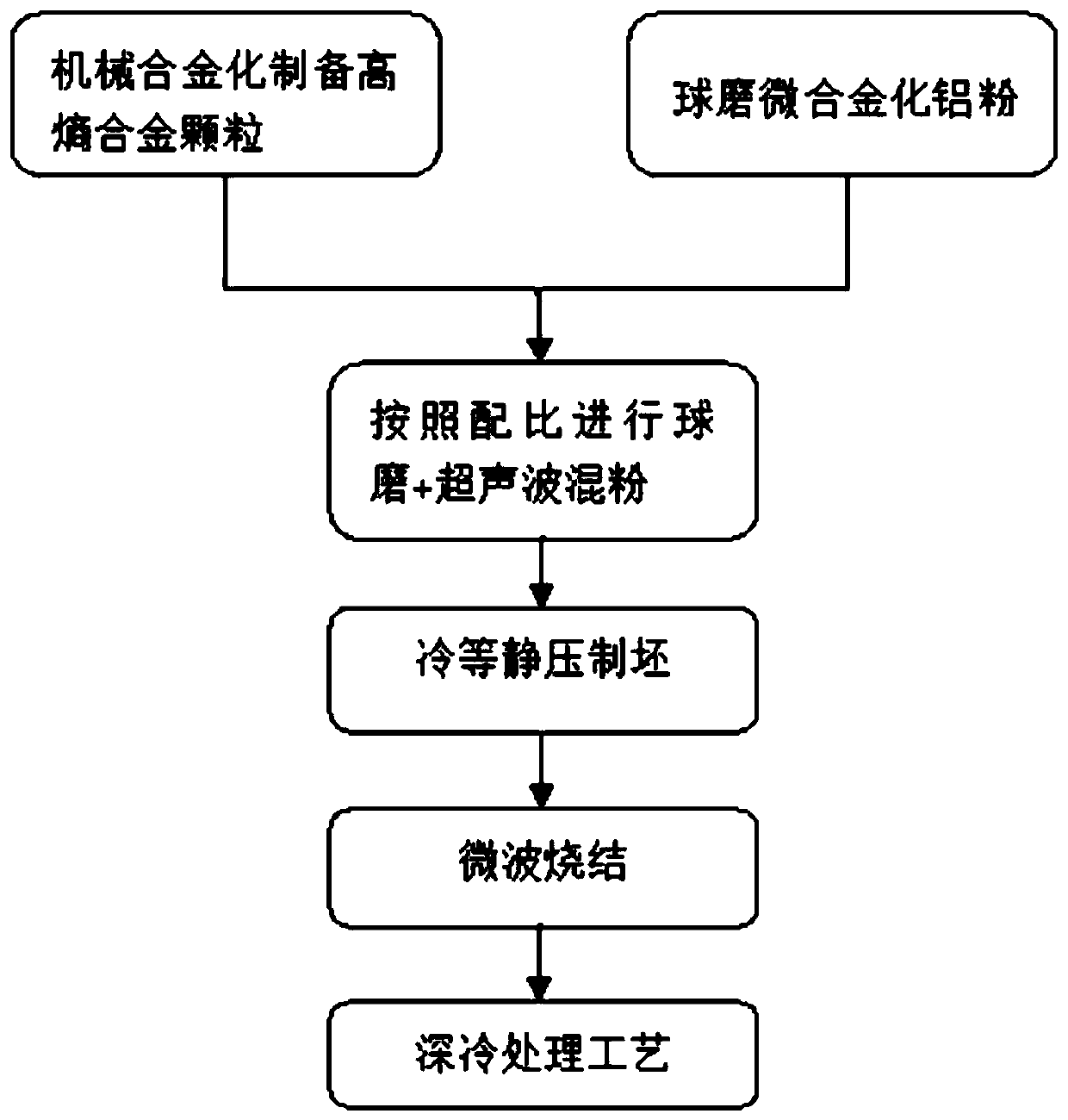

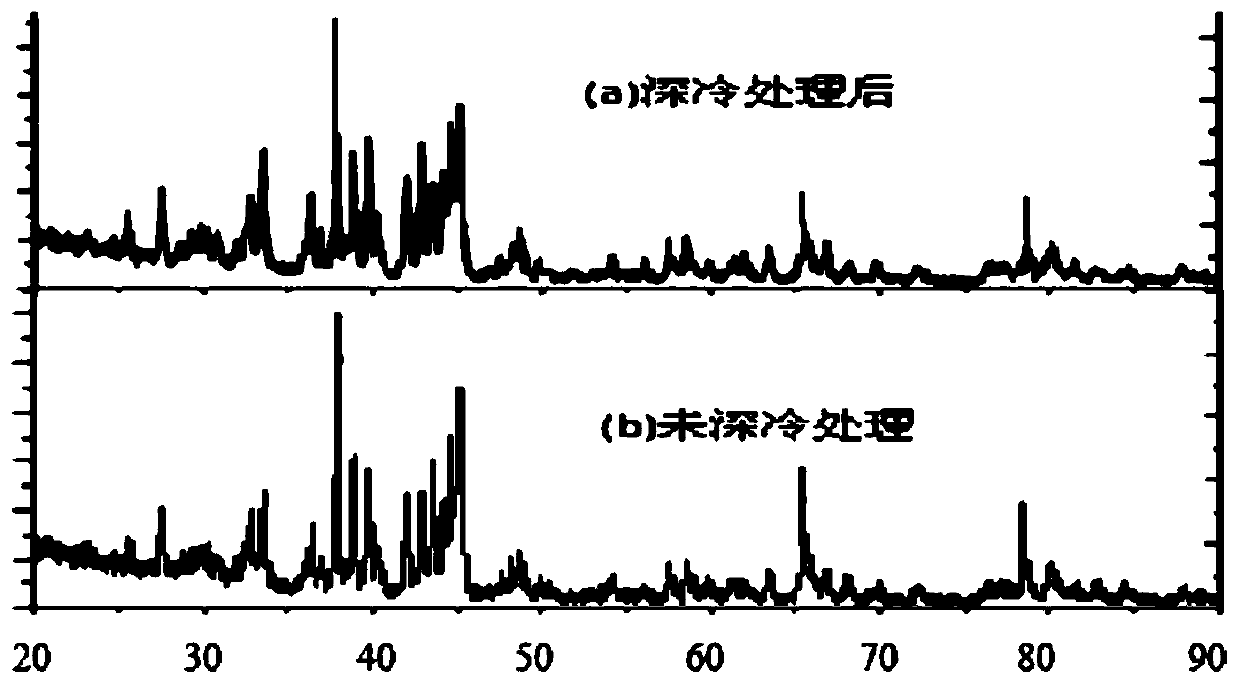

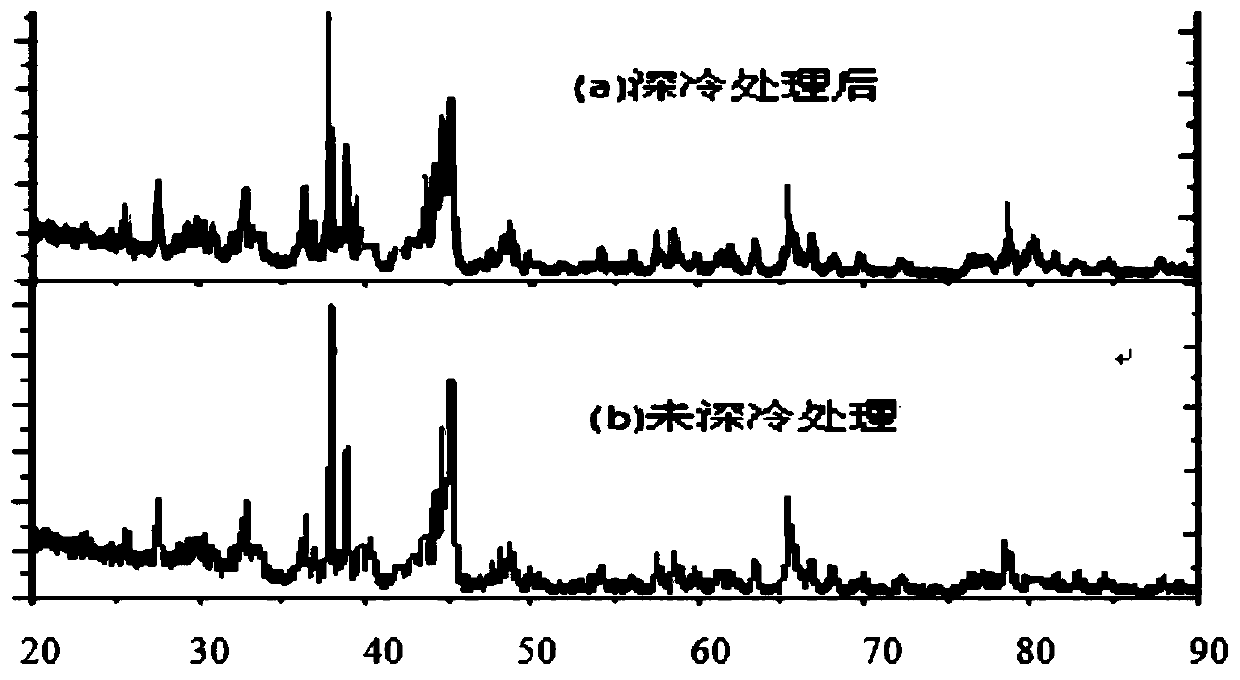

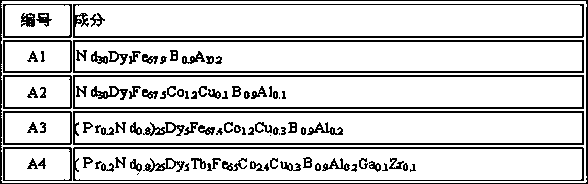

High-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and preparation method thereof

ActiveCN110523997AHigh strengthEvenly distributedTransportation and packagingMetal-working apparatusCompression moldingMaterials preparation

The invention belongs to the technical field of composite material preparation, and particularly relates to a high-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and a preparation method thereof. High-entropy alloy components are optimally designed, then vacuum ball milling is conducted to prepare high-entropy alloy, and high-entropy alloy powder and microalloyed aluminum matrix powder are evenly mixed in proportion and dried to obtain mixed powder; compression molding is performed by utilizing isostatic cool pressing to obtain a composite billet; a microwave sintering process is adopted to obtain a high-entropy alloy particle reinforced aluminum-based composite material; and finally, cryogenic treatment is performed on the aluminum-based compositematerial. According to the high-entropy alloy particle reinforced aluminum-based composite material, the strength and plasticity of the aluminum-based composite material are improved, and meanwhile the aluminum-based composite material can have good magnetic performance.

Owner:JIANGSU UNIV

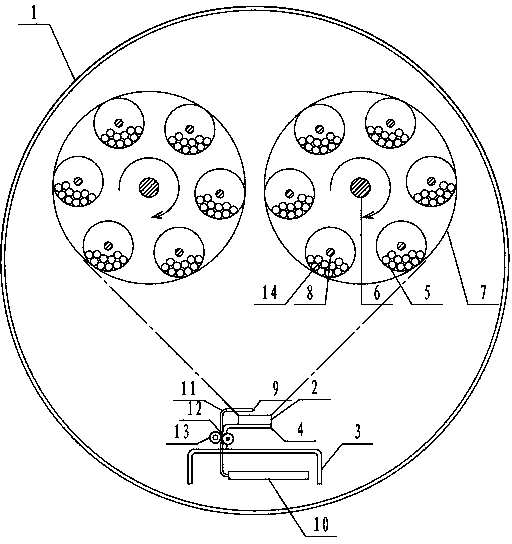

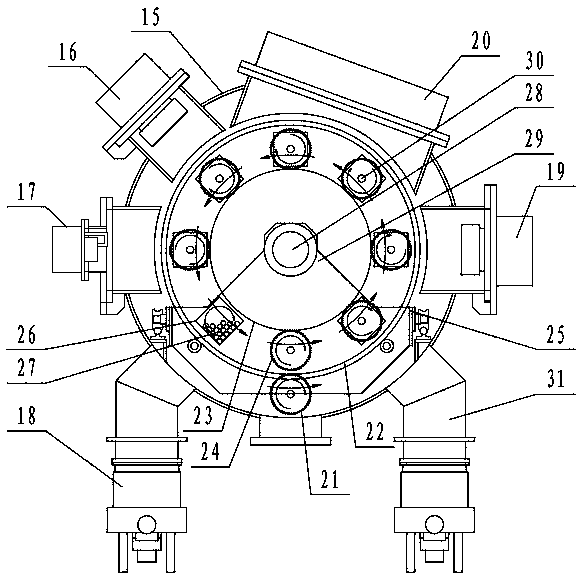

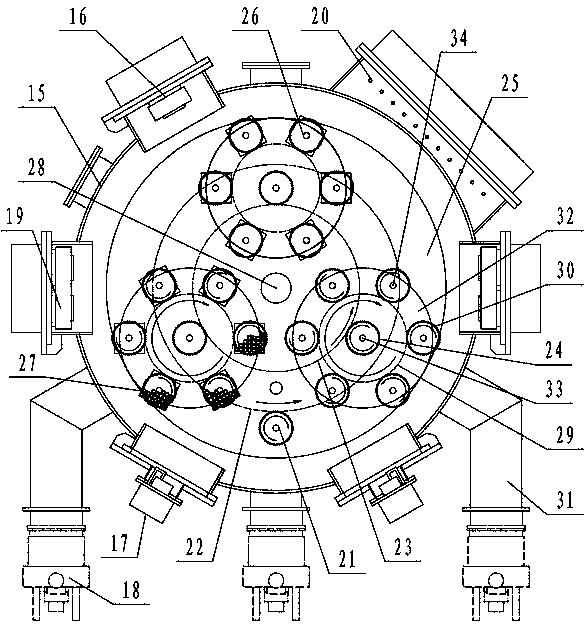

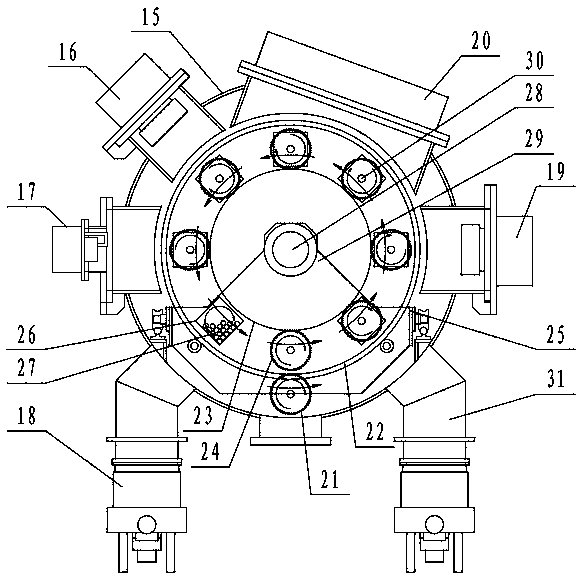

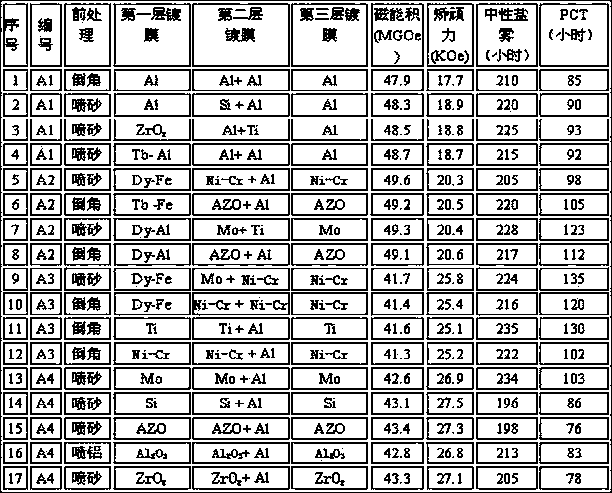

Composite coating equipment and manufacturing method for neodymium iron boron rare-earth permanent magnetic device

InactiveCN103820765AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingRare earthPlanar magnetron

The invention discloses composite coating equipment and a manufacturing method for a neodymium iron boron rare-earth permanent magnetic device. The coating equipment comprises a vacuum chamber, a cylindrical rotary cathode magnetron target, a planar cathode magnetron target, a cylindrical or rectangular cathode multi-arc ion target, an anode layer linear ion source, a rotating stand and a charging basket. When the coating equipment works, the rotating stand revolves in the vacuum chamber, and rotating shafts at two ends of the netlike charging basket are arranged on the rotating stand, namely that the rotating stand rotates automatically along with revolution. The cylindrical rotary cathode magnetron target is arranged in the rotating stand in the vacuum chamber; the planar magnetron target, the multi-arc ion target, the anode layer linear ion source and a heating device are arranged around the rotating stand in the vacuum chamber; a composite coating is divided into three layers, wherein the first layer is a magnetron sputtering coating of which the thickness is 0.1-5mu m, the second layer is a magnetron sputtering and multi-arc mixed coating of which the thickness is 1-15mu m, and the third layer is a magnetron sputtering coating of which the thickness is 0.1-5mu m. The composite coating is used for a surface treatment procedure of the rare-earth permanent magnetic device, so that the corrosion resistance of the rare-earth permanent magnetic device is improved, and the magnetic performance of the rare-earth permanent magnetic device is also improved.

Owner:SHENYANG CHINANORTH VACUUM TECH CO LTD

Method of raising permanent magnetic ferrite residual magnetization by adding additive

InactiveCN1414575AImprove remanenceHigh energy productInorganic material magnetismStrontiumSilicon dioxide

An additive to be used for raising the residual magnetism of ferrite in permanent magnetism adds an additive of raising the residual magnetism with the molecular formula of MxSiyO2, where X=1=4, y=0-2, Z=2-6 in addition to add calcium carbonate and 1-4 additives of kaolin silica, aluminium oxide and boracic acid to increase its coercive force in the secondary process during production course of strontium ferrite or barium ferrite, where X, Y and Z can be decimal and M is one or more kinds of mixtures of Fe, Pr, Nd, Mn, Sr and C. With the same raw material, by use of the additive of MxSiyO2 ofthe present invention, the residual magnetism can be raised by 50-150 Gs based on 3600-4100 Gs.

Owner:BGRIMM TECH CO LTD +2

Preparation method of samarium-cobalt (SmCo) system sintered materials

ActiveCN102651263AImprove microstructureGood orientationInductances/transformers/magnets manufactureMagnetic materialsPositive pressureAlloy

The invention relates to a preparation method of samarium-cobalt (SmCo) system sintered materials. The preparation method comprises the steps of alloy smelting, alloy cast strip preparation through rapid quenching, magnetic powder preparation through combination of a hydrogenated disproportionation method and an airflow grinding method, orientation and forming, positive pressure sintering and solid dissolving and aging treatment. The preparation method has the advantages that through the innovation of the ingot casting and powder making process, the microstructure of a magnetic body is optimized to the greatest degree, the magnetic body mainly consists of columnar crystals, the orientation is easy, and in addition, the performance of the magnetic body is stable; and in the hydrogenated disproportionation process of alloy cast sheets, hydrogen enters gap positions in SmCo crystal lattices, and the crystal lattice expansion is caused, so the pulverization is realized under the condition of ensuring the crystal particle integrity, the oxidation in the powder making process is reduced, the magnetic body with low oxygen content is obtained, and the magnetic performance of the magnetic body is ensured.

Owner:NINGBO STAR MATERIALS HI TECH

Rare earth permanent magnetic powder and preparation method thereof

ActiveCN101552060AEasy to oxidizeImprove performanceInorganic material magnetismDehydrogenationRare earth

The invention discloses a rare earth permanent magnetic powder and a preparation method thereof. The magnetic powder is a multi-crystal powder containing columnar crystal and comprises the following component of R-T-B, wherein the R represents at least one kind of 17 kinds of elements including Sc and Y and accounts for 26.1-37.0 wt percent, the B represents at least boron or hydrogen and accounts for 0.8-1.5 wt percent, and the balance is T, and the T represents Fe and at least one kind of other transitional elements including Al, Ga, Si, Ge, Sn, Pb, Mg and Ca. The magnetic powder has high proportion of the column crystal, uniform particle size distribution and low oxygen content, and the prepared sintered permanent neodymium-iron-boron magnet has large coercive force and high magnetic energy product. The preparation method of the rare earth permanent magnetic powder comprises the following steps of precursor alloy preparation, hydrogen absorption or precursor alloy preparation, hydrogen absorption and dehydrogenation.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Commercial rare earth permanent magnet produced from high-abundance rare earth and preparing method thereof

ActiveCN103794323AImprove remanenceHigh energy productPermanent magnetsInductances/transformers/magnets manufactureElectrode potentialRemanence

The invention discloses a commercial rare earth permanent magnet produced from high-abundance rare earth and a preparing method of the commercial rare earth permanent magnet. The commercial rare earth permanent magnet comprises a main phase and a grain boundary modification phase, wherein the main phase comprises low H (RE100-aMMa)-Fe-B alloy and high H Nd-Fe-B alloy. According to the commercial rare earth permanent magnet, two kinds of main alloy is adopted, the ingredients of the magnet are controlled, a stable 2:14:1 phase is formed by the high-abundance rare earth, and decomposing will not happen in the sintering process; the Cu element high in electrode potential is added into the grain boundary modification phase, the corrosion resistance of the magnet is improved, and meanwhile the microstructure of the magnet can be optimized by the grain boundary modification phase. According to the method, the two main alloy method is combined with the grain boundary modification technology, the advantages of both the two main alloy method and the grain boundary modification technology are achieved simultaneously, the problems that because of addition of the high-abundance rare earth, the corrosion resistance, the residual magnetism and the magnetic energy product of the magnet are reduced are solved, and the prepared rare earth permanent magnet meets the application requirements of commercial magnets.

Owner:ZHEJIANG UNIV +1

Samarium-cobalt-base nanocrystalline permanent magnet material and preparation method thereof

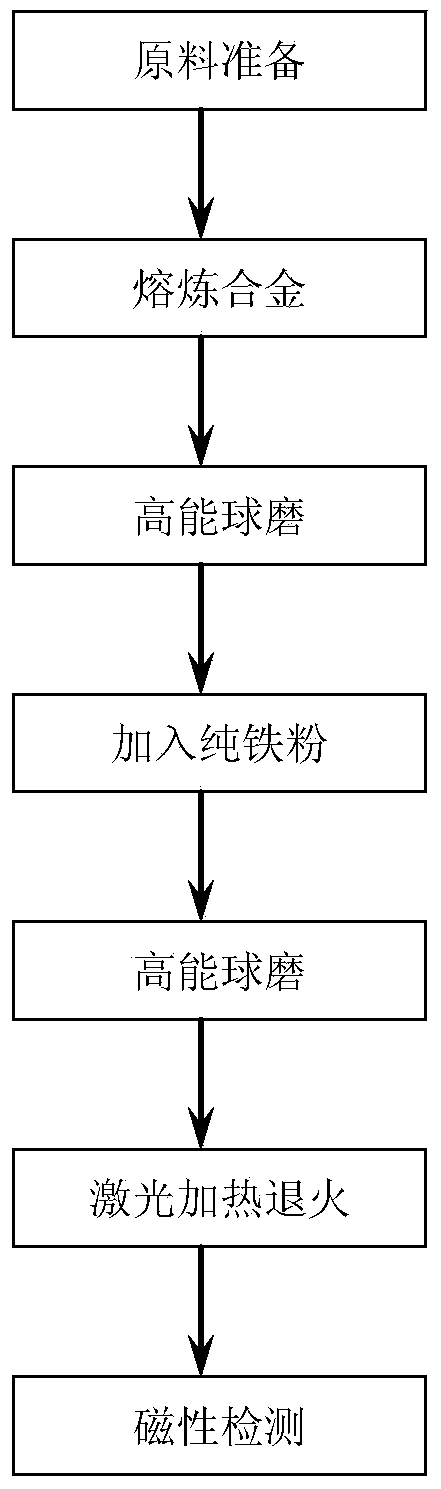

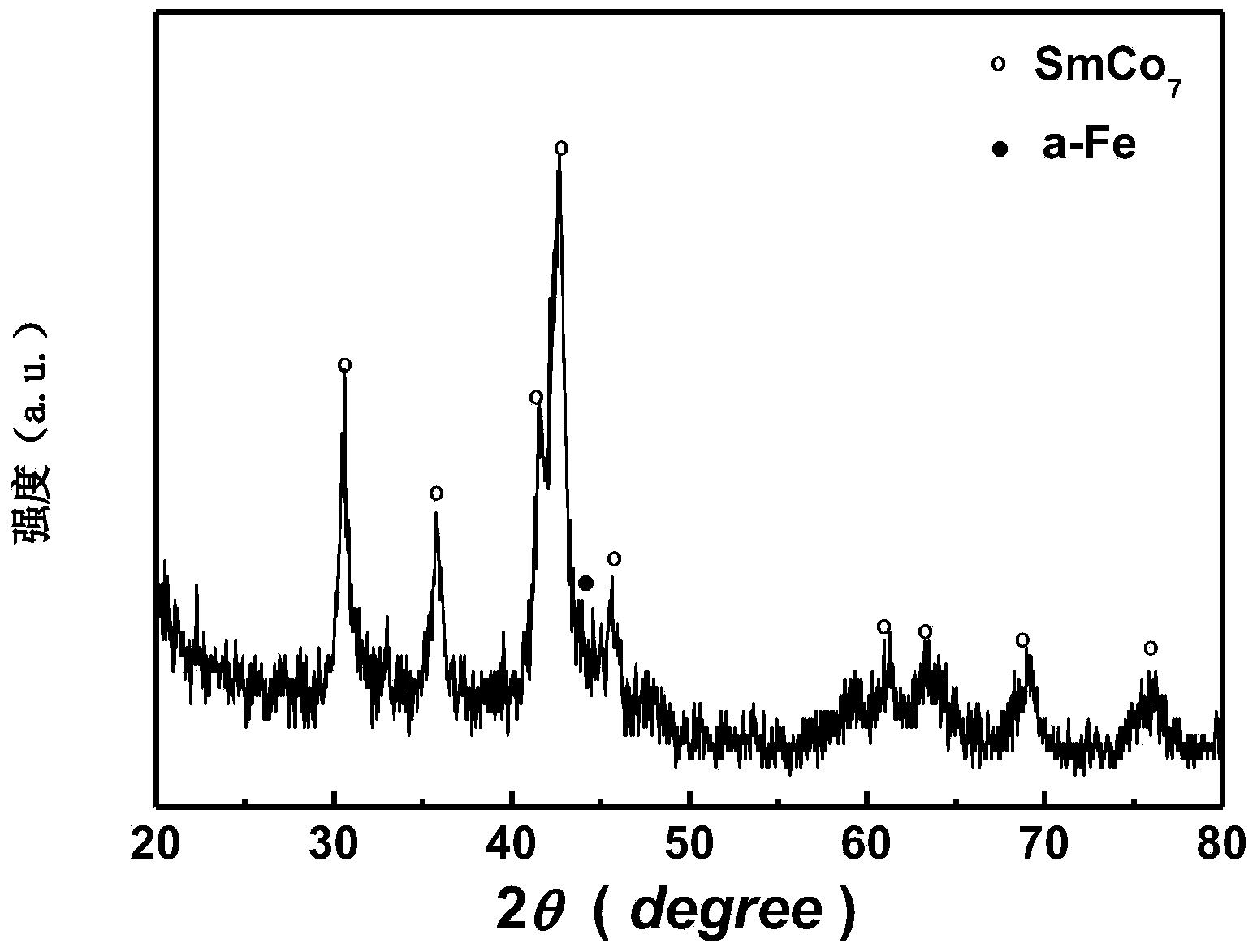

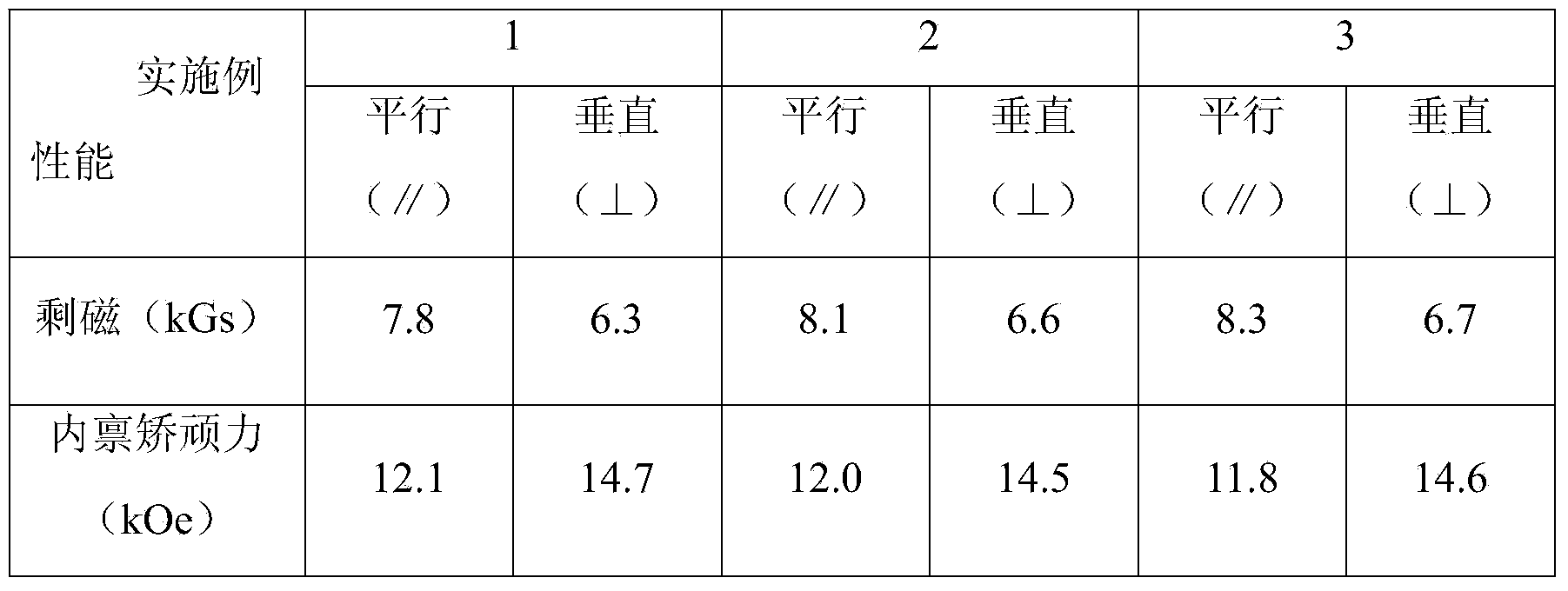

The invention relates to the metallurgy field and discloses novel samarium-cobalt-base nano-composite permanent magnetic material. The samarium cobalt base is (Sm, R)1(Co, Fe, Cu, Zr)7 in type and comprises a TbCu7 type structure, and Co is partially replaced by Fe, Cu and Zr; Re is any one of heavy rare earth Lu, Dy and Tb and partially replaces Sm. The preparation method includes steps that 1) mixing raw materials of the samarium cobalt base according to proportion, and smelting to obtain a 1: 7 type samarium cobalt base alloy ingot; 2) ball milling the alloy ingot through a high-energy ball milling technique, mixing with Fe powder according to proportion, and performing high-energy ball milling to obtain nanocrystalline composite magnetic powder; 3) carrying out annealing heat treatment on the nanocrystalline composite magnetic powder. According to the samarium-cobalt-base nanocrystalline permanent magnet material and the preparation method thereof, the soft / hard-magnetic phase composite magnetic powder is prepared through the high-energy ball milling, laser heat treatment and other techniques, a high magnetic energy product is obtained through exchange coupling between the nanocrystalline hard magnetic phase and nanocrystalline soft magnetic phase, and meanwhile, because rare-earth Fe phase is not used, the cost is lowered, and the operation technique is simplified.

Owner:嘉兴市鹏程磁钢有限公司 +1

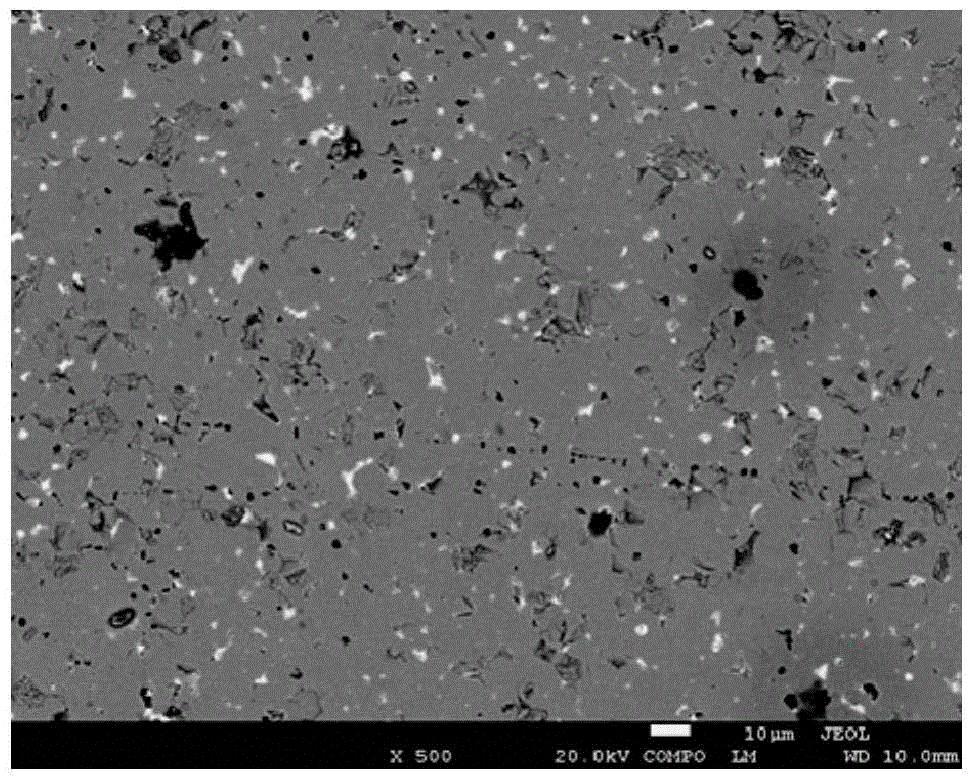

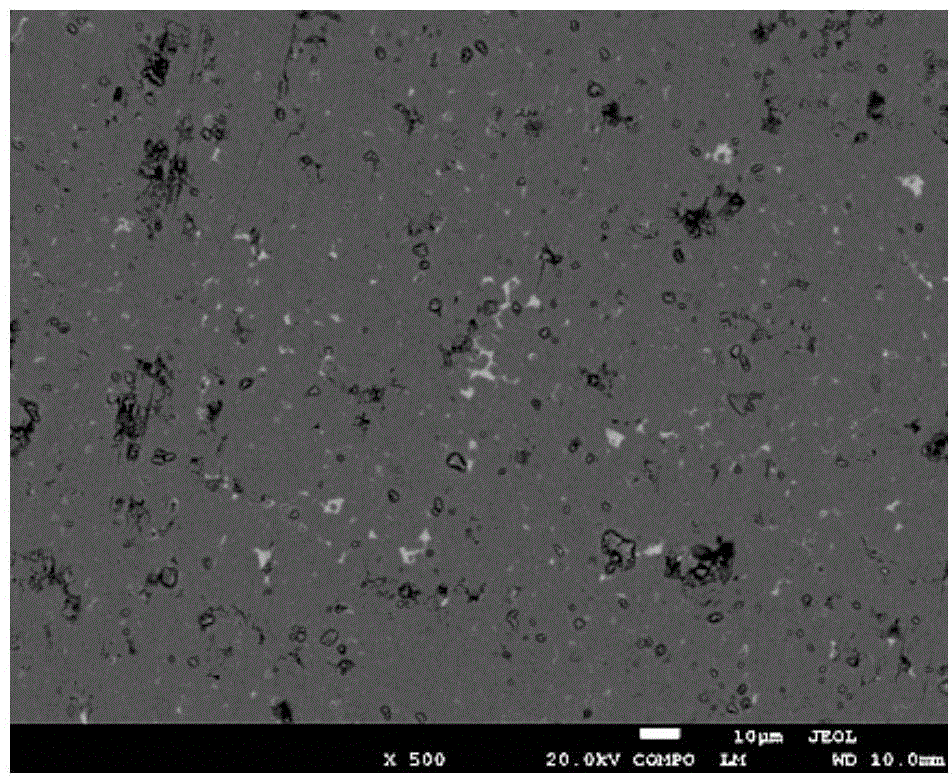

Hybrid film coating method of neodymium iron boron rare earth permanent magnet device

ActiveCN103854819AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingMolten stateRare earth

The invention discloses a hybrid film coating method of a neodymium iron boron rare earth permanent magnet device. According to the method, firstly, alloy smelting is carried out, alloy in a molten state is cast onto a rotary copper roller with a water cooling effect for being cooled to be manufactured into an alloy sheet, then, the alloy sheet is subjected to hydrogen decrepitation, material mixing and airflow powder grinding, next, materials are mixed by a material mixing machine and are then sent to a nitrogen gas protection magnetic field orientation pressing machine to be formed, the mixed materials are subjected to isostatic pressing after being encapsulated in a protection box, then, the sintering and the aging are carried out, a neodymium iron boron rare earth permanent magnet blank is prepared, the blank is subjected to machining, a neodymium iron boron rare earth permanent magnet is prepared, next, the neodymium iron boron rare earth permanent magnet is subjected to film coating, the neodymium iron boron rare earth permanent magnet device is formed, the film coating comprises three layers, the first layer and the second layer are magnetron sputtering coatings, and the second layer is a magnetron sputtering and multi-arc ion plating hybrid coating. The hybrid film coating is adopted as a surface treatment work procedure of the rare earth permanent magnet device, the anti-corrosion capability of the rare earth permanent magnet device is improved, and meanwhile, the magnetic performance of the rare earth permanent magnet device is also improved.

Owner:SHENYANG GENERAL MAGNETIC

Pr/Nd based biphase composite permanent magnetic material and block body preparing method thereof

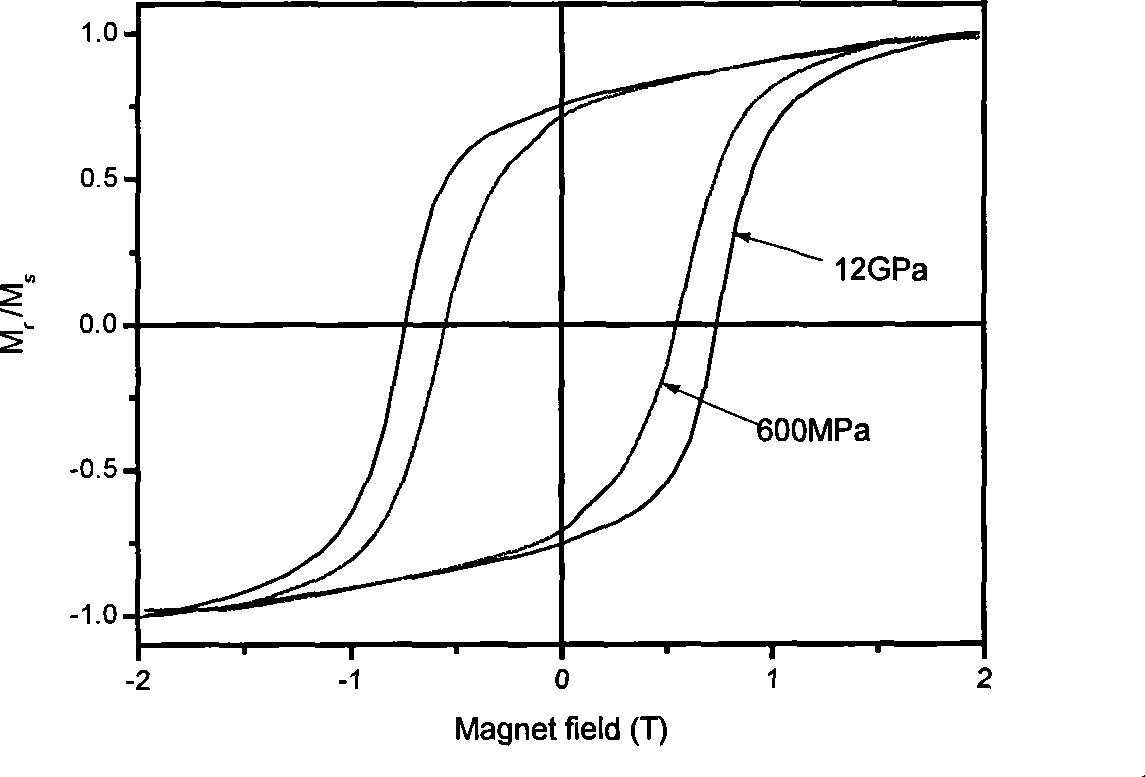

ActiveCN101425355AEnhanced exchange couplingHigh energy productMagnetic materialsMagnetic phaseUltra high pressure

The invention relates to a Pr / Nd-based two-phase nano-composite permanent magnet material and a method for the preparation of the block body thereof. The invention comprises the composing general formula of the two-phase nano-composite permanent magnet material: a (Pr, Nd)-Fe-R-Ti-QB system, wherein Pr and Nd are main rare earth components in hard magnetic phase (Pr, Nd)2Fe14B base material; R is one or more than two of Nb, Dy, Tb and Ga; Q is one or more than two of V, Mo, Zr, W and Au; the molar fraction is as follows: x is more than or equal to 4 and less than or equal to 11, y is more than or equal to 0.1 and less than or equal to 3, z is more than or equal to 0.1 and less than or equal to 4, m is more than or equal to 0 and less than or equal to 2, n is more than or equal to 6 and less than or equal to 10, w is more than or equal to 20 and less than or equal to 80, and the balance being Fe. The preparation of the block body (Pr, Nd) 2Fe14B / Alpha-Fe comprises the following steps of (1) smelting master alloy; (2) fast quenching of thin strips; (3) preparing the block body by ultra-high heat pressing, in which the thin strip alloy is put in a graphite mold and then is placed in an ultra-high pressure device, and is sintered for 1 to 30min when the temperature is heated to between 500 and 1000 DEG C at 10-50 DEG C / min, under the pressure intensity of between 1 and 12 GPa and Ar gas protective environment. The Pr / Nd-based two-phase nano-composite permanent magnet material has the advantages of low-content rare earth, low cost, good anti-saturation effect, and the like; the magnetic energy is more than 180 kJ / m3, and the density is more than 74.5 g / cm3.

Owner:浙江凯文磁钢有限公司

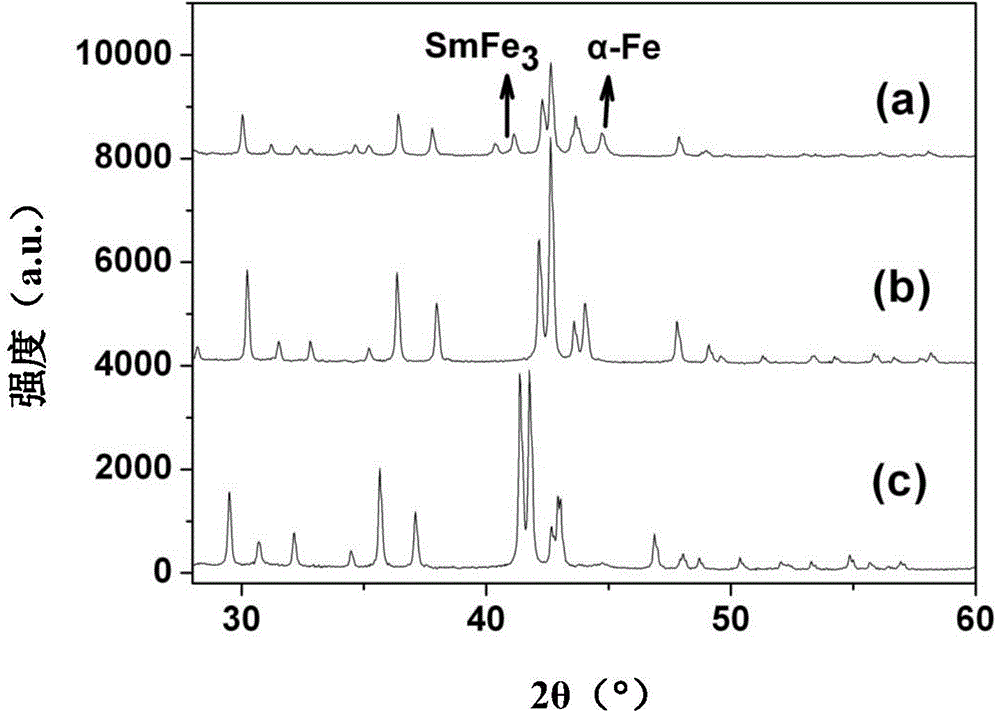

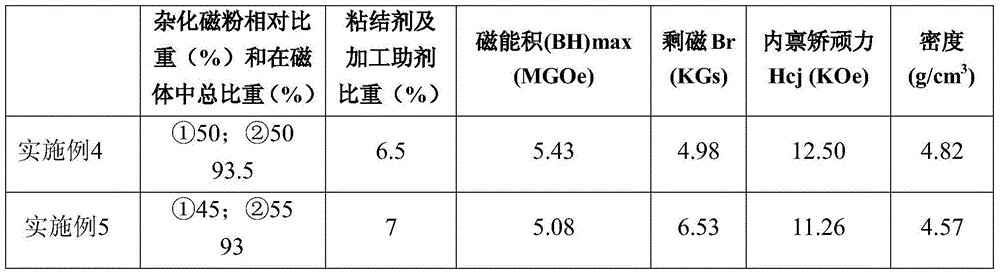

A submicron anisotropic samarium iron nitrogen magnet powder and a method for preparing a hybrid bonded magnet therefrom

ActiveCN106312077AHigh energy productImprove remanenceInductances/transformers/magnets manufactureMagnetic materialsAdditive ingredientSingle crystal

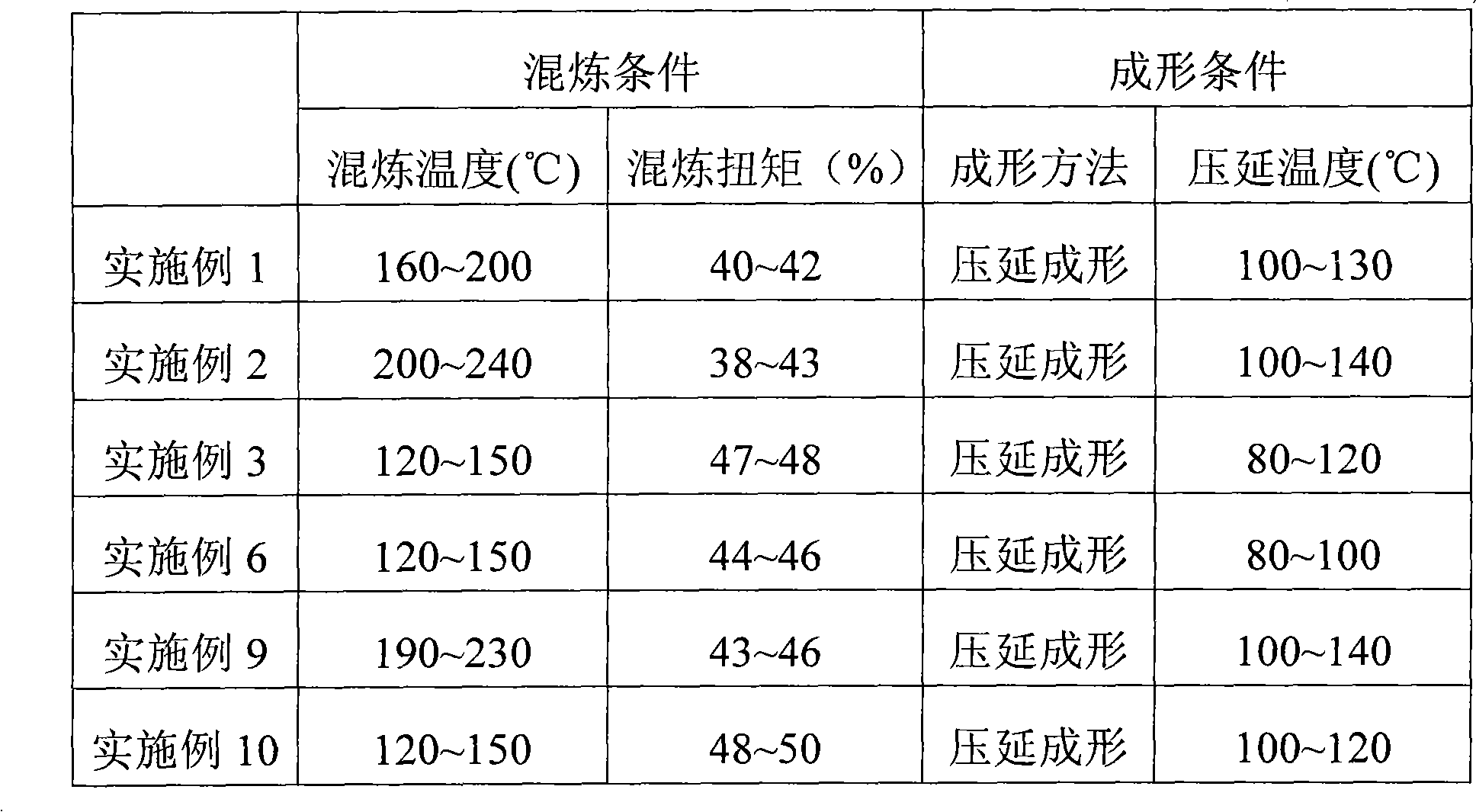

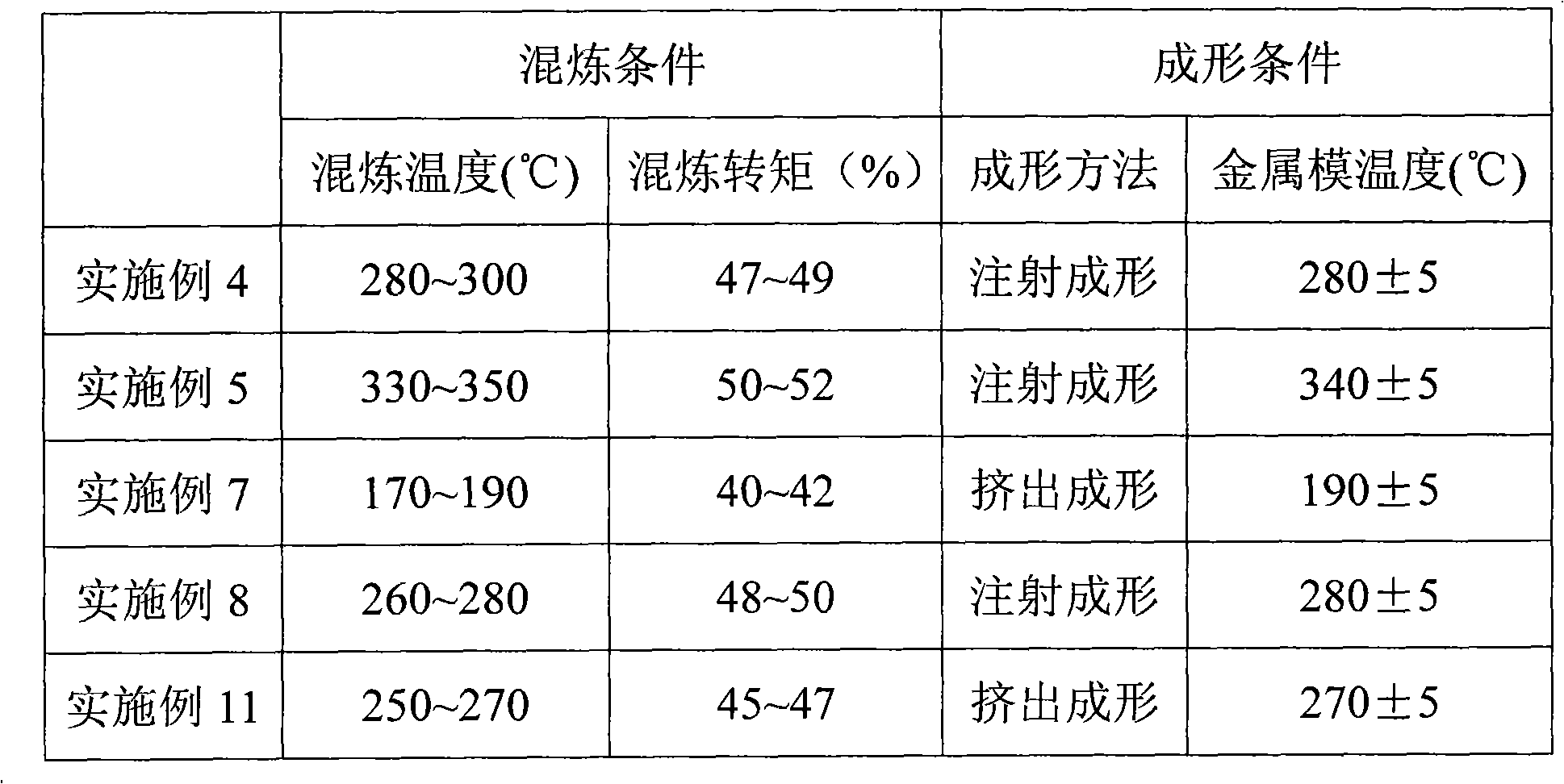

The invention provides a submicron anisotropic samarium iron nitrogen magnet powder and a method for preparing a hybrid bonded magnet therefrom. Samarium-iron alloy is prepared by using a quick setting sheet technology; the samarium-iron alloy is made to perform gas-solid phase reaction in nitrogen or mixed gas of nitrogen and hydrogen to form samarium-iron-nitrogen alloy; then airflow milling and / or ball milling is performed to obtain anisotropic samarium iron nitrogen single-crystal particle magnet powder with a particle size of 0.01-3 [mu]m. Further, the samarium iron nitrogen single-crystal particle magnet powder, as a first ingredient, is mixed with a second ingredient consisting of permanent magnetic ferrite, rapid quenching isotropic neodymium iron boron, anisotropic neodymium iron boron, samarium cobalt and / or neodymium iron nitrogen to form hybrid magnetic powder; processing agents are added; a hybrid bonded magnet is prepared by using a rolling, mould pressing, extrusion or injection method. The prepared samarium iron nitrogen magnet powder are high in magnetic energy product, residual magnetism and intrinsic coercive force, is low in cost and small in particle size; the corresponding hybrid bonded magnet exploits the advantages of different magnetic powder ingredients, is high in shaping degree and mechanical strength and is good in temperature performance.

Owner:NINGXIA MAGVALLEY NOVEL MATERIALS TECH CO LTD

Method for preparing rolling anisotropic magnetic powder and magnet

ActiveCN1937111AHigh residual magnetic inductionImprove coercive forceInorganic material magnetismInductances/transformers/magnets manufactureExtensibilitySingle crystal

Using specific technique of rapid hardening slice produces alloy based on neodymium (or praseodymium) iron. Then, through reaction of gas-solid phase, crumbling procedure produces RxFe100-x-y-zMyIz magnetic powder. The magnetic powder is single crystal grain in sheet form with average grain size as 1-3 micro. The magnetic powder produced by the disclosed technique possesses anisotropy of magnetocrystalline under action of external magnetic field as well as rolling anisotropy and stress anisotropy. Based on three kinds of anisotropy, the invention discloses method for preparing high performance flexible rubber magnet with rolling anisotropy. The prepared flexible magnet possesses excellent magnetism, flat surface, good cohesiveness, and feasible mechanical properties including tensile strength, extensibility, and rigidity as well as characteristics of temperature resisting, moisture resistance, oil proof and anticorrosion.

Owner:NINGXIA MAGVALLEY NOVEL MATERIALS TECH CO LTD

Isotropic bonded NdFeB magnet and magnetic roller consisting of same

ActiveCN101673606AHigh energy productImprove remanencePermanent magnetsInorganic material magnetismMetallurgyRare earth

The invention relates to a magnetic roller used in a laser printer and a copier. An isotropic bonded NdFeB magnet used by the magnetic roller contains rare earth permanent magnetic powder and adhesive resin, wherein the rare earth permanent magnetic powder is a mixture of NdFeB magnetic powder and ferrit magnetic powder, and the formed magnet has the length of between 210 and 910mm. When the isotropic bonded NdFeB magnet is used to replace one or more ferrit permanent magnet poles in the magnetic roller, because the bonded NdFeB magnet has stronger magnetic performance than ferrit magnets, a strong magnetic filed can be formed on an outer surface taking the bonded NdFeB magnet as a pole so as to provide stronger magnetic filed adsorptive power, contribute to the size distribution of multiple kinds of color matching powder, and reduce the grey back of copying and printing to contribute to clear imaging.

Owner:上海三环磁性材料有限公司 +1

Sintered NdFeB magnet and manufacturing method thereof

ActiveCN102592770AImprove coercive forceHigh energy productPermanent magnetsInorganic material magnetismMagnetic energyStrip casting

The invention discloses a sintered NdFeB magnet and a manufacturing method of the sintered NdFeB magnet; the sintered NdFeB magnet comprises the following components: 27.3-27.8wt% of Nd and Pr, 1.0-1.8wt% of Tb, 0.1-0.4wt% of A1, 0.08-0.14wt% of Cu, 0-2wt% of Co, 0-0.14wt% of Ga, 0.93-1.0wt% of B and the balance of Fe, wherein the (BH) max of the magnet is greater than 47 MGOe, and the Hcj of the magnet is greater than 16kOe. The manufacturing method of the sintered NdFeB magnet comprises the following steps of: burdening; smelting in a vacuum sensing rapid hardening furnace to obtain a strip-casting alloy sheet; hydrogenating to crush the strip-casting alloy sheet and preparing into micro powder in an air-stream mill; mixing the obtained micro powder; compressing the mixed micro powder into a blank; placing the blank into a vacuum sintering furnace for sintering after carrying out isostatic pressing; and carrying out secondary aging after the sintering to obtain the magnet. In the invention, through accurately designing the burdening and technological parameters of the sintered NdFeB magnet, magnets with high coercive force and high magnetic energy product can be produced in batch, and the (BH) max is greater than 47 MGEo, and the Hcj is greater than 16 KOe.

Owner:SANVAC BEIJING MAGNETICS +1

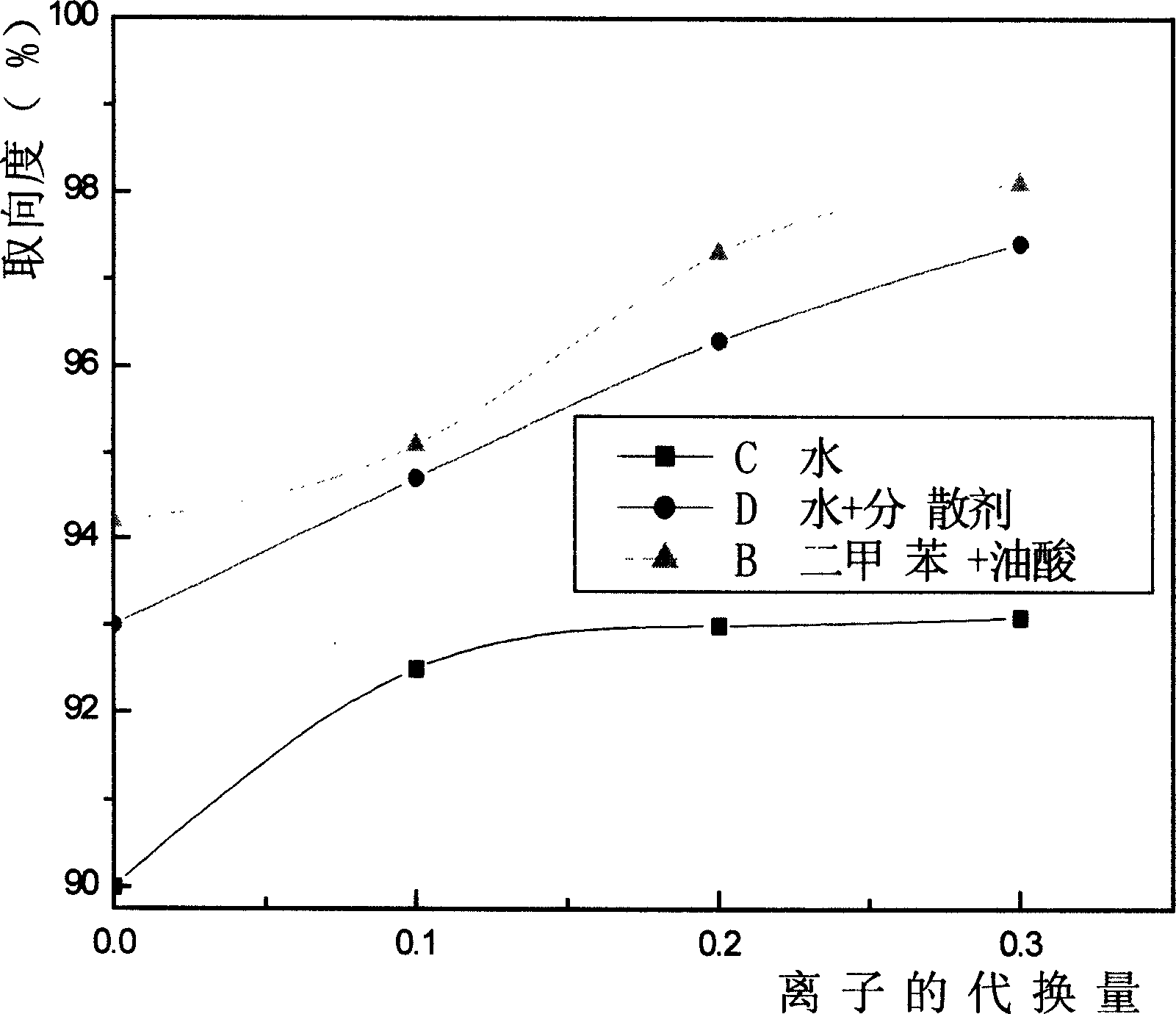

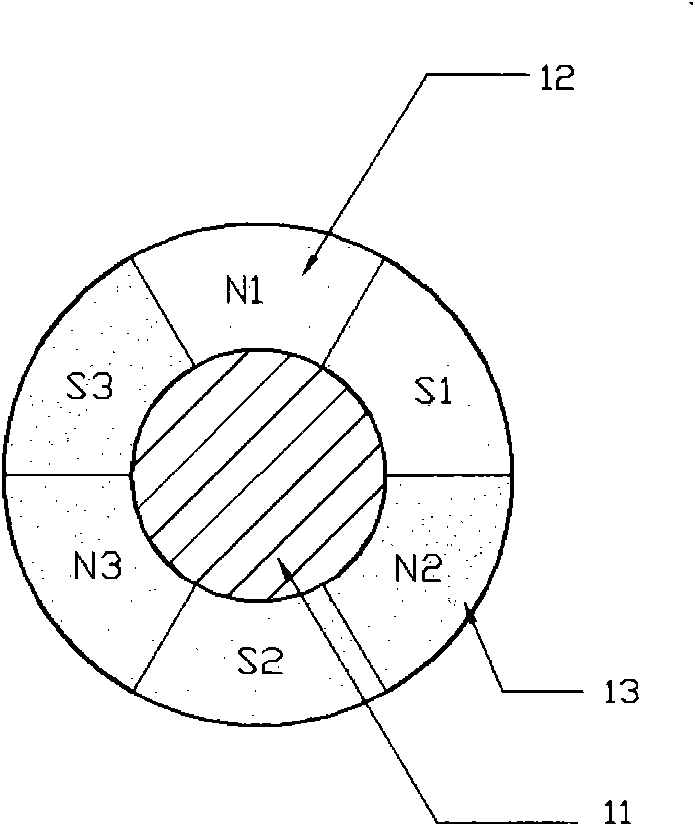

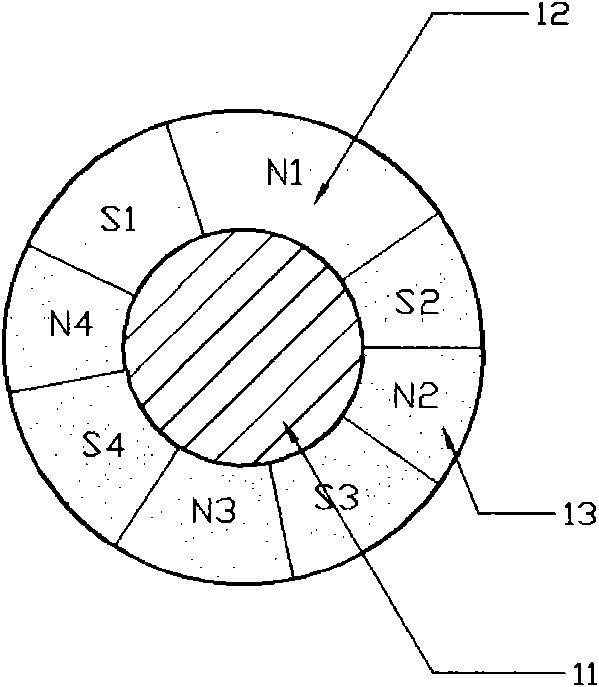

Method for preparing radiation oriental magnetic ring and radiation multipolar magnetic ring

ActiveCN101770862AGood orientationImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureAlicyclic HydrocarbonsNitrogen gas

The invention provides a method for preparing a radiation oriental magnetic ring and a radiation multipolar magnetic ring. The method comprises the following steps of: melting and casting raw material of alloy in a vacuum furnace; carrying out coarse / hydrogen decrepitation on the ingots in the inert atmosphere; adding matters into the powder subject to coarse / hydrogen decrepitation to mix; carrying out micro crushing on the alloy coarse powder by an airflow mill in the nitrogen atmosphere; annealing the alloy powder in the inert gas, vacuum or reduction atmospheres; adding carbonyl iron powder and at least one type of alicyclic hydrocarbon into the annealed alloy powder to mix; carrying out preorientation operation on the mixing powder; enabling the mixing powder to form a circular former in the magnetic field; carrying out integral grinding treatment on the inner wall of the circular former; and sintering the circular former in the vacuum or inert gas atmosphere. The invention has the advantages of effectively decreasing the oriental field required in forming, enhancing the oriental degree of the magnetic rings and improving the property of the magnetic rings.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

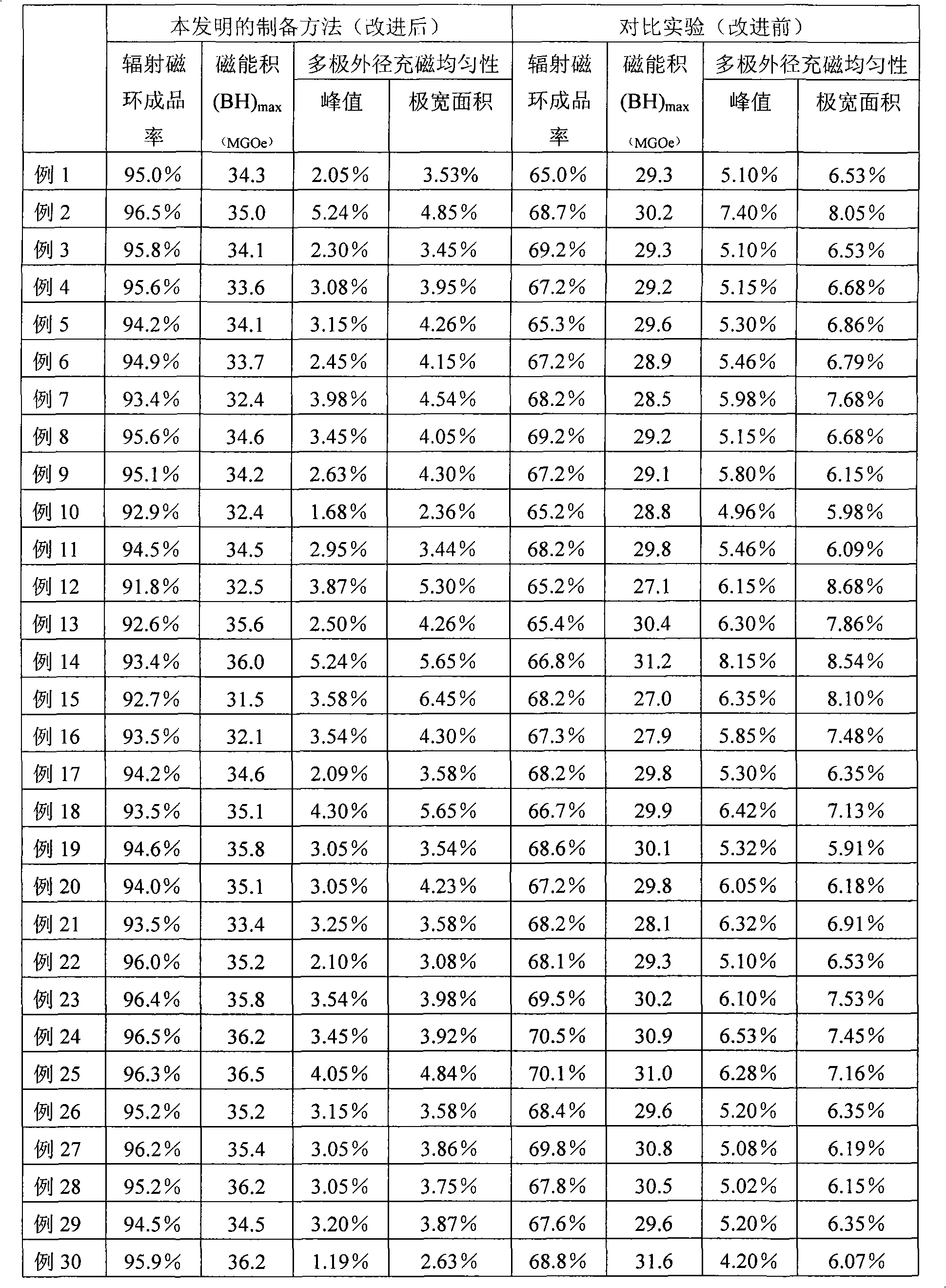

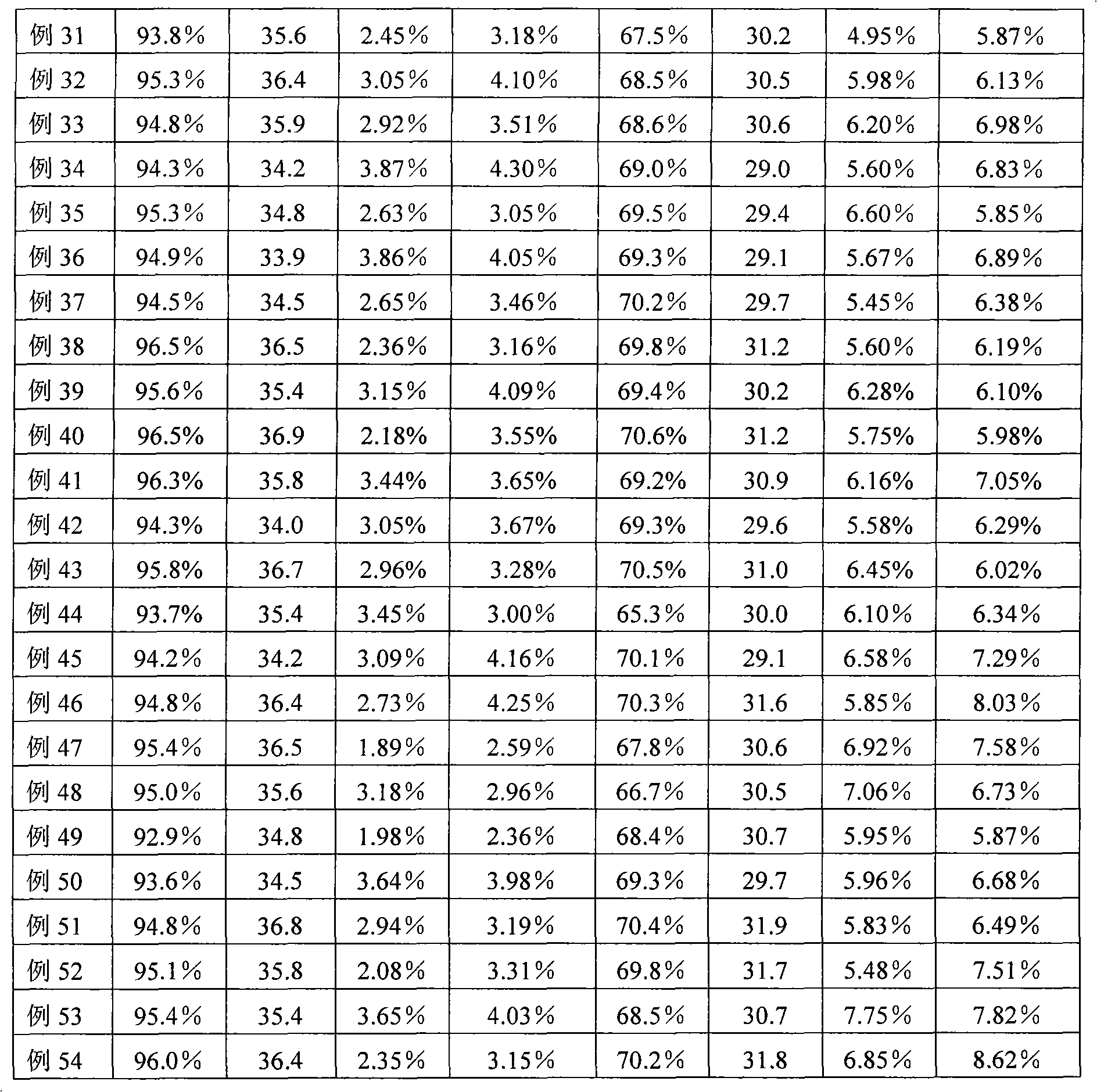

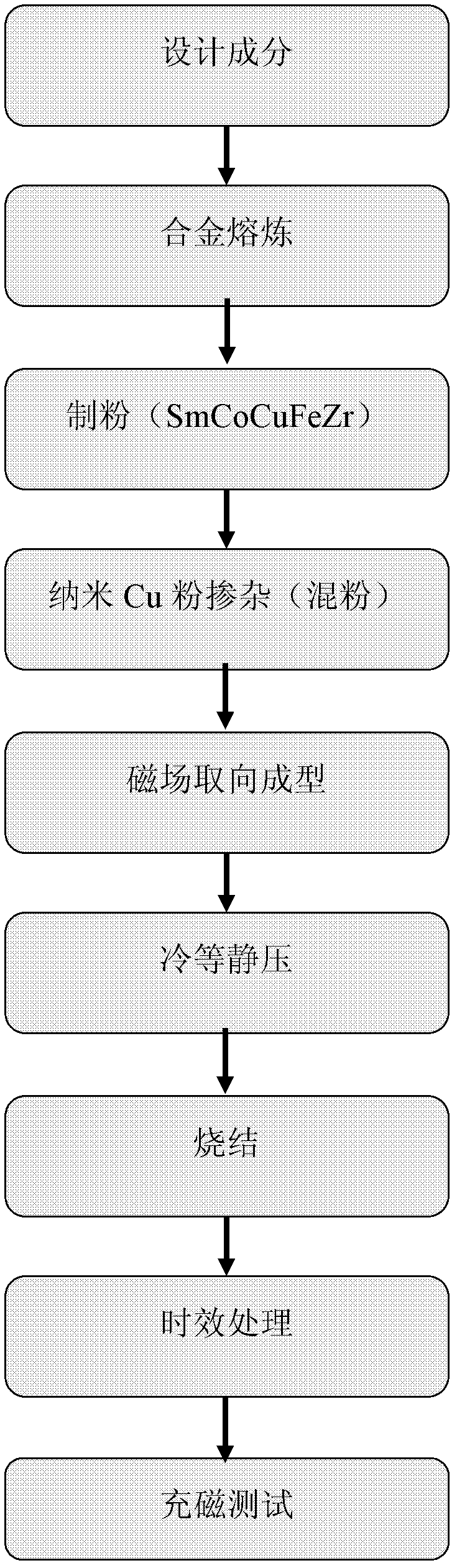

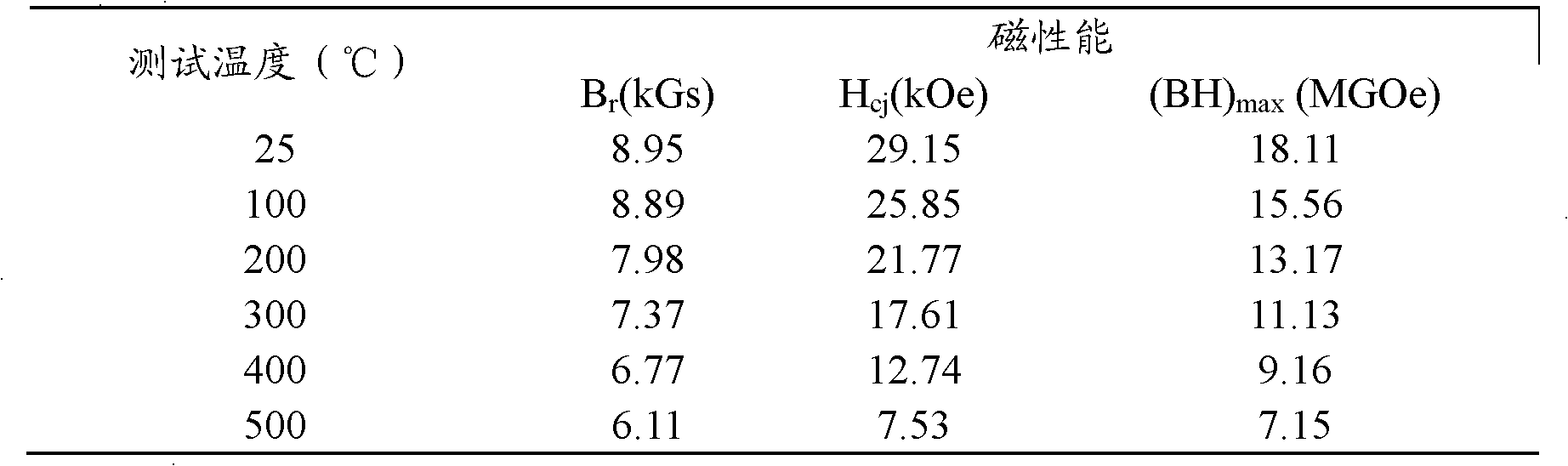

Method for preparing high-coercivity SmCoFeCuZr (samarium-cobalt-ferrum-copper-zirconium) high-temperature permanent magnet by doping nano-Cu powder

InactiveCN102568807AImprove coercive forceIncreased coercive force at room temperatureInductances/transformers/magnets manufactureMagnetic materialsMaterials preparationMicrometer

The invention relates to a method for preparing a high-coercivity SmCoFeCuZr (samarium-cobalt-ferrum-copper-zirconium) high-temperature permanent magnet by doping nano-Cu powder, which belongs to the technical field of rare-earth permanent magnetic material preparation. The method comprises the steps of: smelting a SmCoFeCuZr alloy ingot by the conventional powder metallurgy method; processing the SmCoFeCuZr alloy ingot to micrometer-level alloy powder; uniformly blending commercial nano-Cu powder and the SmCoFeCuZr alloy powder according to a ratio; sintering; and aging to obtain a 2:17 SmCosintered magnet. The doped nano-Cu powder has uniform distribution in the sintered magnet, so that the room-temperature and high-tempreature coercivity of the magnet can be improved greatly. The room-temperature coercivity can be improved by 2 to 2.5 times, and the 500 DEG C coercivity and magnetic energy of the magnet doped with the nano-Cu powder are significantly higher than those of undoped magnets. Accordingly, the magnet doped with the nano-Cu powder is very suitable for application in high-temperature environment.

Owner:BEIJING UNIV OF TECH

Manufacturing method for neodymium iron boron lanthanon permanent magnet device with composite plated film

ActiveCN103824693AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingMolten stateRare earth

Owner:SHENYANG GENERAL MAGNETIC

Heat treatment process for sintered nd-fe-b

The invention discloses a heat treatment process for sintered nd-fe-b, which comprises the following steps: 1) primary tempering: carrying out first-time heat treatment on sintered nd-fe-b magnets subjected to sintering under the conditions of 4-8*10<-3>Pa and 900-1000 DEG C; 2) secondary tempering: carrying out second-time heat treatment on the sintered nd-fe-b magnets under the conditions of 4-8*10<-3>Pa and 650-750 DEG C; and (3) tertiary tempering: carrying out third-time heat treatment on the sintered nd-fe-b magnets under the conditions of 4-8*10<-3>Pa and 500-600 DEG C. According to the technical scheme of the invention, nd-fe-b magnets are subjected to heat treatment by using a heat treatment method implemented through tertiary tempering treatment, the coercivity or remanence of nd-fe-b magnets are further improved through controlling the pressure and the time in the process of heating, and then the magnetic energy product of the sintered nd-fe-b magnets is increased, thereby achieving the purpose of improving the magnetic property of the magnets.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing low-cost sintered neodymium (Nd) iron (Fe) boron (B) by doping lanthanum (La) cerium (Ce)

ActiveCN102842400AEasy to sinterLow melting pointInorganic material magnetismCeriumVolumetric Mass Density

The invention discloses a method for preparing low-cost sintered neodymium (Nd) iron (Fe) boron (B) by doping lanthanum (La) cerium (Ce), and the method comprises following steps of (1) utilizing a quick-hardening sheet vacuum sensing smelting furnace to smelt a NdFeB material and to prepare a NdFeB alloy sheet with thickness of 0.3 to 0.5mm; (2) utilizing a hydrogen broken furnace to pulverize the NdFeB alloy sheet to NdFeB alloy powder of 110 to 150 micrometers; (3) grinding the obtained powder into NdFeB alloy powder of 3.5 to 4.5 micrometers through the airflow; (4) adding the LaGe alloy powder into the powder to be uniformly mixed; (5) utilizing a magnetic field press machine to orient and form the powder under the magnetic field, and acquiring pressed blank with density of 4.6 to 4.8 g / cm<3> through isostatic cool pressing; (6) placing the pressed blank into a vacuum sintering furnace to be sintered, and ensuring the sintered magnet of (PrNdGd)2936 to 29.65(LaCe)0.99 to 1.96(FeCoAlCu)67.63 to 68.3B1.05 to 10.6. The LaGe powder which is processed by special process is added to substitute rich neodymium phase in the NdFeB, so that the LaCe can be prevented from being excessively mixed with the NdFeB mani phase to influence the magnetic performance, and an effect for improving the product performance and reducing the product cost can be realized.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com