Isotropic bonded NdFeB magnet and magnetic roller consisting of same

An isotropic, NdFeB technology, applied in magnetic objects, magnetic materials, permanent magnets, etc., can solve the problems of difficulty in obtaining a homogeneous magnetic field, affecting imaging quality, and high production costs, achieving difficult demagnetization and high remanence. , the effect of strong magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

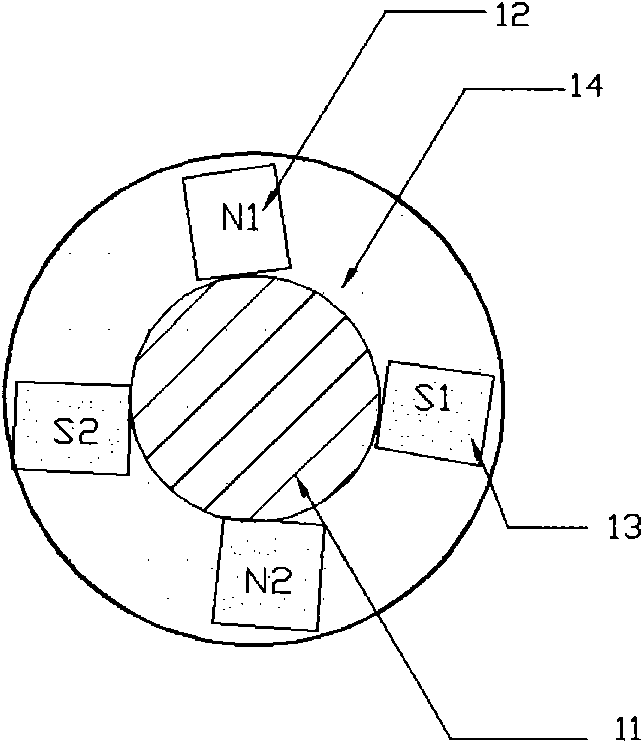

[0053] A magnetic roller, structured as figure 1 As shown, there are four magnetic poles, and one magnetic pole N1 is composed of an isotropic bonded NdFeB magnet 12 . 11 is the mandrel of magnetic roller, and all the other magnetic poles are made up of ferrite permanent magnet 13, and 14 is the resin for filling.

[0054] The magnetic pole N1 is composed of an isotropic bonded NdFeB magnet, and the ratio of each component of the magnet is as follows (weight):

[0055] Bonded NdFeB permanent magnet powder 86%,

[0056] Ferrite permanent magnet powder 10%

[0057] Bonding resin 4%

[0058] The particle size of the bonded NdFeB permanent magnet powder is about 70-100 μm;

[0059] The particle size of ferrite magnetic powder is 0.9~1.2μm;

[0060] The binding resin is selected from polyamide resin nylon 6 and nylon 12, and the weight ratio of nylon 6 and nylon 12 is 1:1;

[0061] Said isotropic bonded NdFeB magnets are prepared as follows:

[0062] Firstly, the above raw m...

Embodiment 2

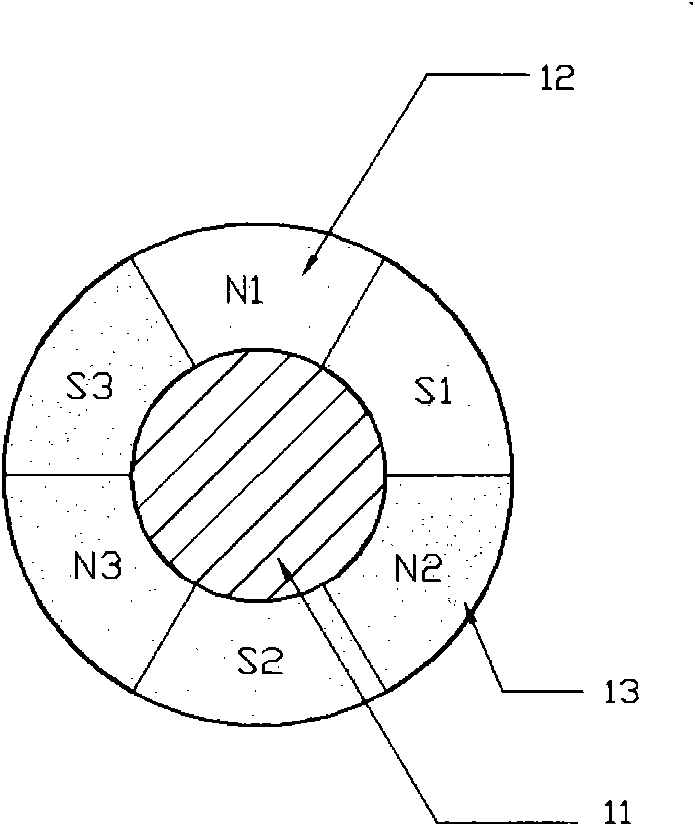

[0068] A magnetic roller, structured as figure 2 , with 6 magnetic poles, two of which, N1 and S1, are composed of isotropic bonded NdFeB magnets. 11 is the mandrel of magnetic roller, and residual magnetic pole is made up of ferrite permanent magnet 13.

[0069] The magnetic poles N1 and S1 are composed of isotropic bonded NdFeB magnets, and the ratio of each component of the magnets is as follows: (weight)

[0070] Bonded NdFeB permanent magnet powder 78%,

[0071] Ferrite permanent magnet powder 15%

[0072] Bonding resin 7%

[0073] The particle size of the bonded NdFeB permanent magnet powder is about 70-100 μm;

[0074] The particle size of ferrite magnetic powder is 0.9~1.2μm;

[0075] The binding resin is selected from nylon 6, nylon 12 and nylon 6-12, and the weight ratio of nylon 6, nylon 12 and nylon 6-12 is 1:1:1;

[0076] Said isotropic bonded NdFeB magnets are prepared as follows:

[0077] Firstly, the above raw materials are accurately weighed according ...

Embodiment 3

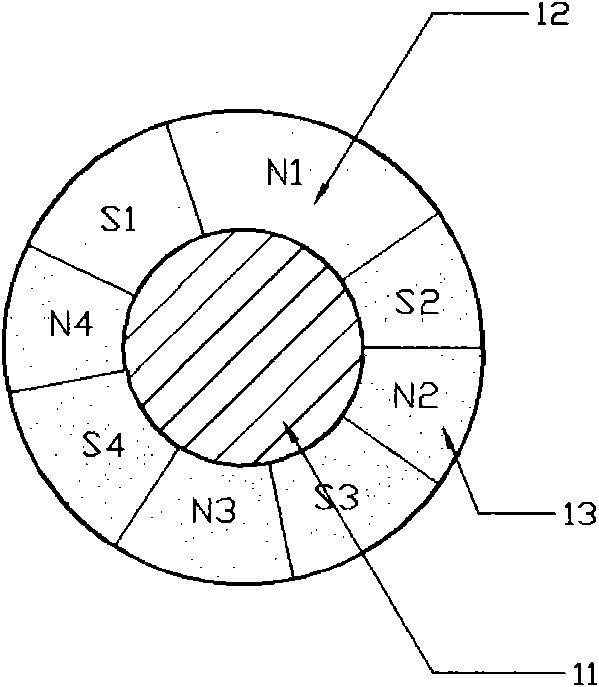

[0083] A magnetic roller, structured as image 3 , There are 8 magnetic poles, two of which, N1 and S1, are composed of isotropic bonded NdFeB magnets. 11 is the mandrel of magnetic roller, and residual magnetic pole is made up of ferrite permanent magnet 13.

[0084] The magnetic poles N1 and S1 are composed of isotropic bonded NdFeB magnets, and the ratio of each component of the magnets is as follows: (weight)

[0085] Bonded NdFeB permanent magnet powder 70%,

[0086] Ferrite permanent magnet powder 20%

[0087] Bonding resin 10%

[0088] The particle size of the bonded NdFeB permanent magnet powder is about 70-100 μm;

[0089] The particle size of ferrite magnetic powder is 0.9~1.5μm;

[0090] The binding resin is selected from nylon 6, nylon 66 and nylon 12, and the weight ratio of nylon 6, nylon 66 and nylon 12 is 2:1:1;

[0091] Said isotropic bonded NdFeB magnets are prepared as follows:

[0092] Firstly, the above raw materials are accurately weighed according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com