Method for preparing high-coercivity SmCoFeCuZr (samarium-cobalt-ferrum-copper-zirconium) high-temperature permanent magnet by doping nano-Cu powder

A high-coercivity, nano-technology, applied in the direction of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of reducing saturation magnetization, increasing coercive force, and reducing the maximum magnetic energy product of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

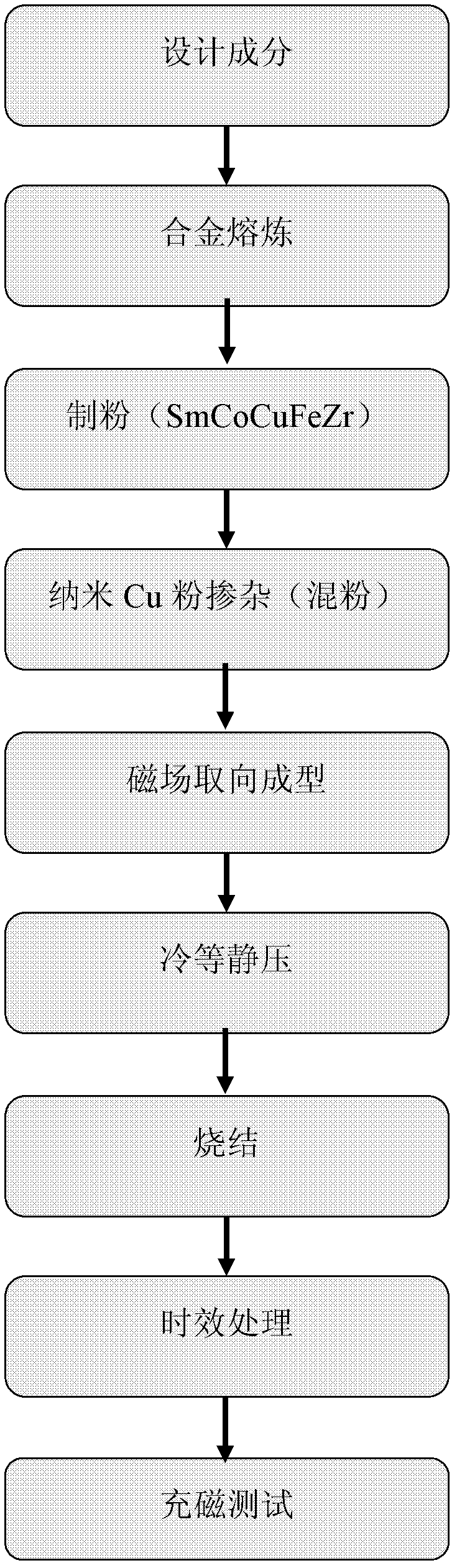

Image

Examples

Embodiment 1

[0019] The weight ratio of 0.25wt.% nanometer Cu powder (average particle size is 20 nanometers) and SmCoFeCuZr powder A are uniformly mixed, and sintered after orientation molding in a 2T magnetic field.

[0020] Sintering process: pre-fired in vacuum at 1180°C for 0.5 hours, then sintered at 1220°C under argon protection for 1.5 hours, then solid solution treated at 1180°C for 3.5 hours, and then air-cooled to room temperature before being released from the furnace.

[0021] Aging heat treatment process: heat preservation at 840°C for 10 hours, then cool to 400°C at a cooling rate of 0.4°C / min, keep heat for 10 hours, and then cool naturally to room temperature. The magnetic properties of the obtained magnets are shown in Table 1.

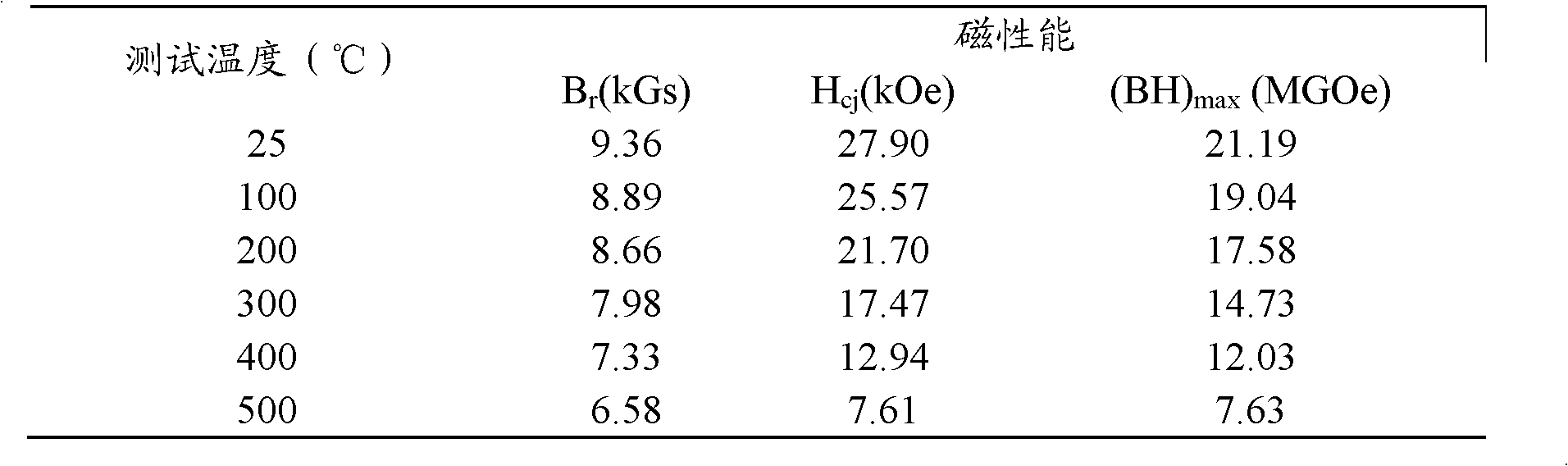

[0022] Magnetic properties of SmCoFeCuZr sintered magnets doped with 0.25wt.% nano Cu powder in the composition of Table 1A

[0023]

Embodiment 2

[0025] Mix 0.5wt.% nanometer Cu powder (average particle size is 50 nanometers) with SmCoFeCuZr powder A, sinter after magnetic field orientation molding.

[0026] Sintering process: Pre-fired in vacuum at 1180°C for 0.5 hours, then sintered at 1230°C under argon protection for 1.5 hours, then solid solution treated at 1185°C for 3.5 hours, and then air-cooled to room temperature before being released from the furnace.

[0027] Aging heat treatment process: heat preservation at 840°C for 12 hours, then cool to 420°C at a cooling rate of 0.5°C / min, keep heat for 10 hours, and then cool naturally to room temperature. The magnetic properties of the obtained magnets are shown in Table 2.

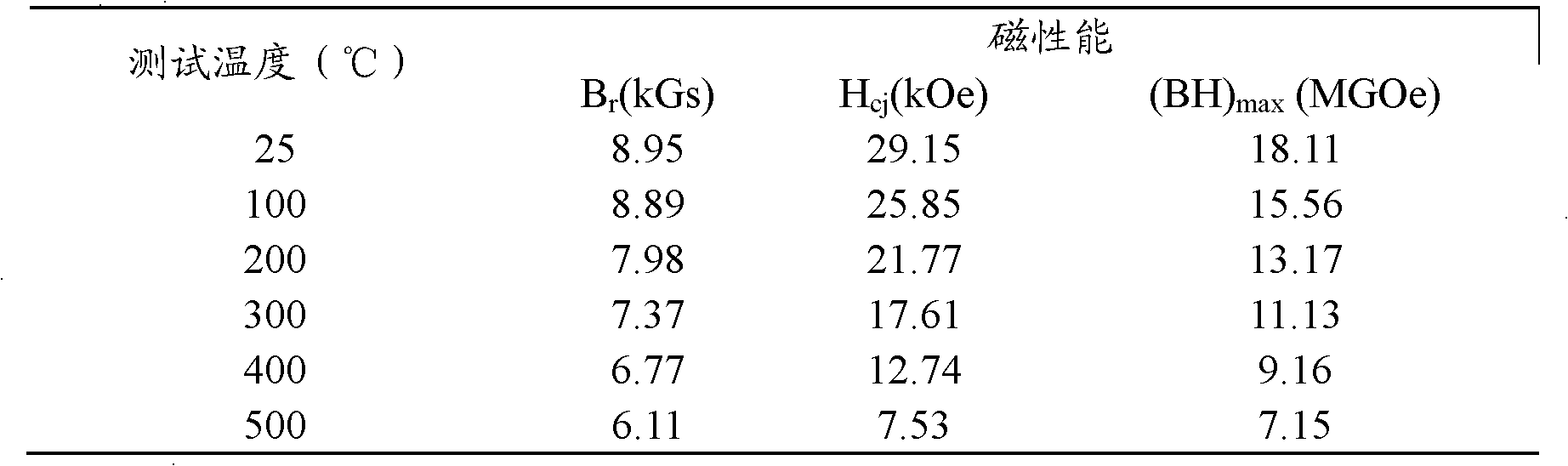

[0028] Magnetic properties of SmCoFeCuZr sintered magnets doped with 0.5wt.% nanometer Cu powder in the composition of Table 2A

[0029]

Embodiment 3

[0031] Mix 0.75wt.% nanometer Cu powder (average particle size is 100 nanometers) with SmCoFeCuZr powder A, sinter after magnetic field orientation molding.

[0032] Sintering process: Pre-fired in vacuum at 1190°C for 0.5 hours, then sintered at 1230°C under argon protection for 1.5 hours, then solid solution treated at 1180°C for 3.5 hours, and then air-cooled to room temperature before being released from the furnace.

[0033] Aging heat treatment process: heat preservation at 840°C for 10 hours, then cool to 420°C at a cooling rate of 0.6°C / min, keep heat for 10 hours, and then cool naturally to room temperature. The magnetic properties of the obtained magnets are shown in Table 3.

[0034] Magnetic properties of SmCoFeCuZr sintered magnets doped with 0.75wt.% nano Cu powder in the composition of Table 3A

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com