Method for preparing radiation oriental magnetic ring and radiation multipolar magnetic ring

A radiation orientation and multi-pole magnetic ring technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, and the magnetism of inorganic materials, can solve problems such as sintering cracking and uneven shrinkage of magnetic rings, so as to improve the yield and avoid shrinkage Non-uniformity, effect of improving orientation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

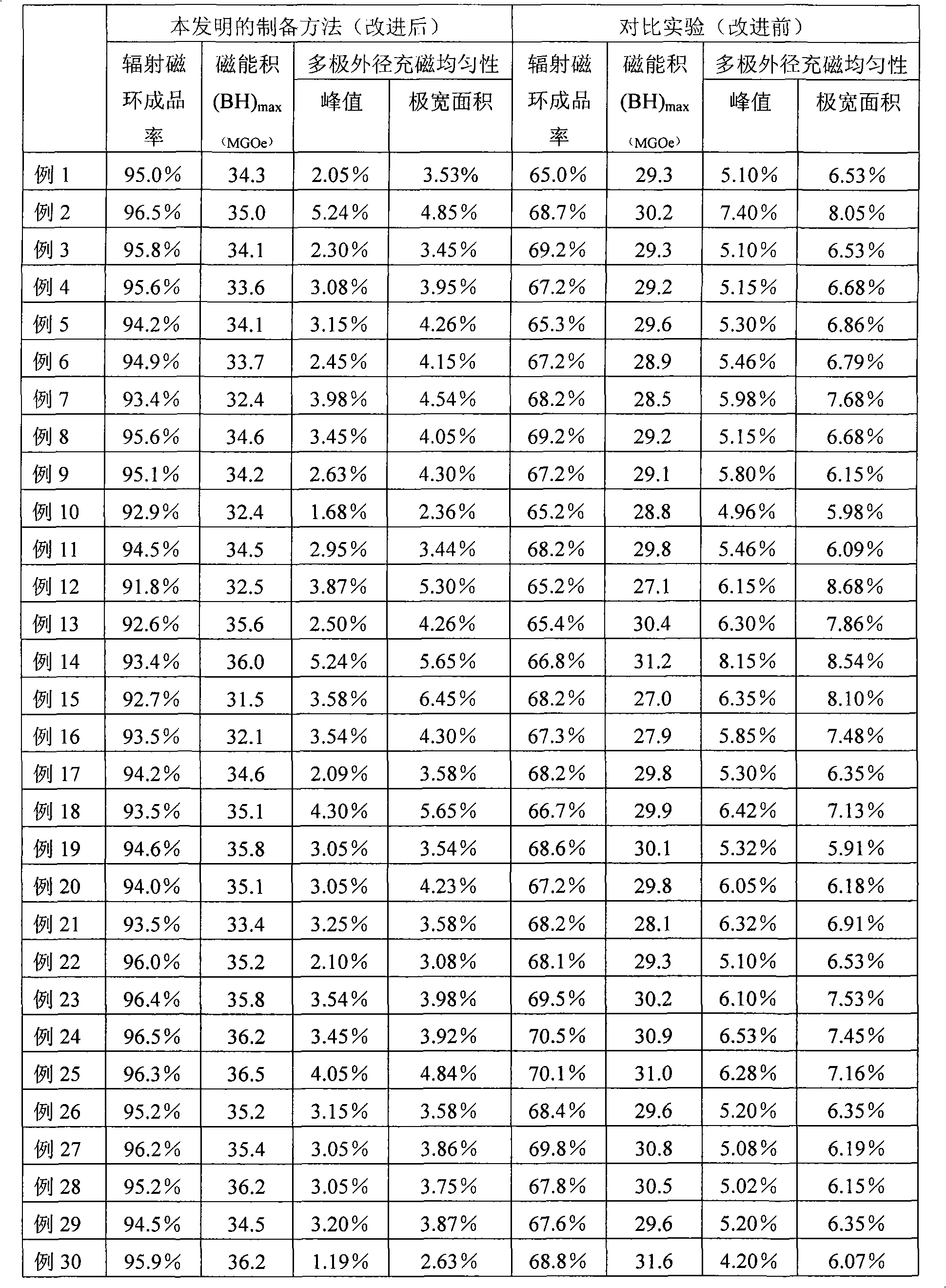

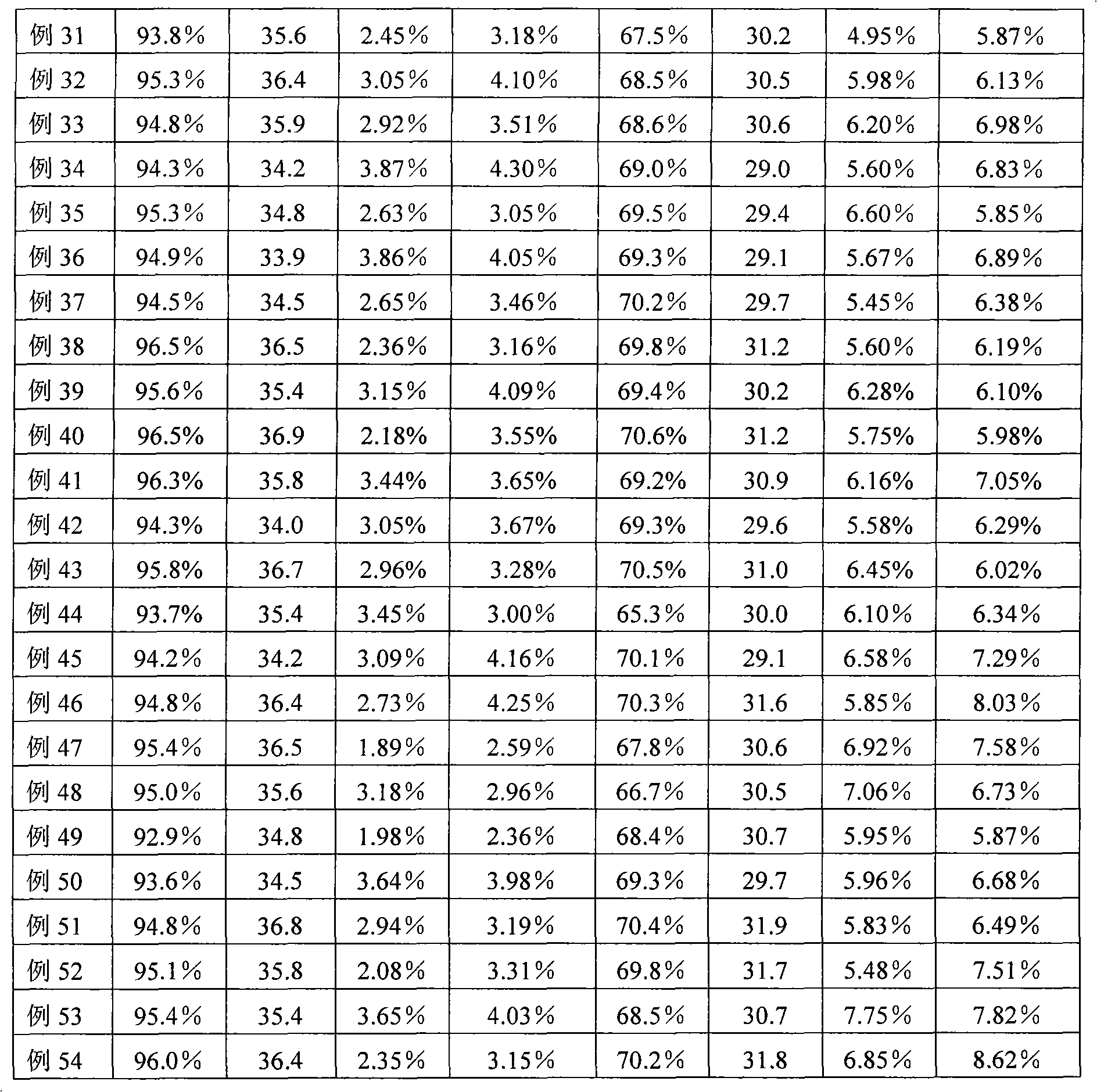

Examples

Embodiment 1

[0039] The raw material alloy is prepared by strip stripping method, and its composition is 5.0Pr-22.0Nd-4.8Dy-0.2Al-0.1Cu-0.5Co-0.2Ga-0.1Zr-1.0B-balance Fe. Then carry out hydrogen crushing treatment, make the raw material alloy hydrogen absorption at room temperature, in Ar 2 Dehydrogenation was performed at 500° C. for 1 hour in an atmosphere. Add 0.1wt.% aluminum stearate and paraffin wax and mix for 1 hour. After jet milling, powder particles with an average particle size of 4 μm are obtained, and then passed through 60 and 300 mesh sieves to obtain powder 1 with uniform particle size distribution.

[0040] Put powder 1 in Ar 2 After annealing at 500° C. for 2 hours in atmosphere, 0.5 wt. % carbonyl iron powder and cyclohexane were added thereto and mixed for 3 hours to obtain powder 2 . Put the powder 2 into a closed rubber container, put it in the magnetic field of the magnetizer to pre-orientate it in one direction, the pre-orientation magnetic field is 0.8T; then sh...

Embodiment 2

[0042] The raw material alloy is prepared by strip stripping method, and its composition is 5.0Pr-22.0Nd-4.8Dy-0.2Al-0.1Cu-0.5Co-0.2Ga-0.1Zr-1.0B-balance Fe. Then carry out hydrogen crushing treatment, make the raw material alloy hydrogen absorption at room temperature, in Ar 2 Dehydrogenation was performed at 500° C. for 1 hour in an atmosphere. Add 0.1wt.% zinc stearate and triglycerides and mix for 1 hour, jet mill to obtain powder particles with an average particle size of 4 μm, and then pass through 60 and 300 mesh sieves to obtain powder 1 with uniform particle size distribution.

[0043] The powder 1 was annealed at 600° C. for 3 hours in a vacuum atmosphere, 1.0 wt. % carbonyl iron powder and cyclohexane were added thereto and mixed for 3 hours to obtain the powder 2 . Put the powder 2 into a closed plastic container, put it in the magnetic field of the press to pre-orientate it in one direction, the pre-orientation magnetic field is 1.5T; then shape the powder 2 on t...

Embodiment 3

[0045] The raw material alloy is prepared by strip stripping method, and its composition is 5.0Pr-22.0Nd-4.8Dy-0.2Al-0.1Cu-0.5Co-0.2Ga-0.1Zr-1.0B-balance Fe. Then carry out hydrogen crushing treatment, make the raw material alloy hydrogen absorption at room temperature, in Ar 2 Dehydrogenation was performed at 500° C. for 1 hour in an atmosphere. Add 0.01wt.% aluminum stearate and paraffin wax and mix for 1 hour, and the average particle diameter obtained after jet milling is 1 μm (the specific surface area is 1.5m 2 / g) powder particles, and then through 60 and 300 mesh sieves to obtain powder 1 with uniform particle size distribution.

[0046] Put powder 1 in Ar 2 After annealing at 500° C. for 2 hours under atmosphere, 0.05 wt. % carbonyl iron powder and cyclohexane were added thereto and mixed for 3 hours to obtain powder 2 . Put the powder 2 into an airtight container made of non-magnetic stainless steel, and put it in the magnetic field of the magnetizer to pre-orient...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com