Flexible bonding rare-earth permanent magnet and manufacturing method thereof

A technology of rare earth permanent magnets and manufacturing methods, applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., can solve problems such as high fluidity requirements and magnetic performance decline, and achieve good corrosion resistance and easy to overcome Effects of embrittlement and deformation, good flexibility and surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]Magnet formula (weight ratio): NdFeB magnetic powder 91.55%, 3-glycidoxypropyltrimethoxysilane (coupling agent) 0.45%, polyurethane-based thermoplastic elastomer (binder) 6%, stearin Acid (lubricant) 0.5%, dioctyl phthalate (plasticizer) 0.3%, epoxy soybean oil (plasticizer) 0.5%, AO-3[B-(4-hydroxy-3,5- Di-tert-butylphenyl) propionate n-octadecyl ester] (antioxidant) 0.7%.

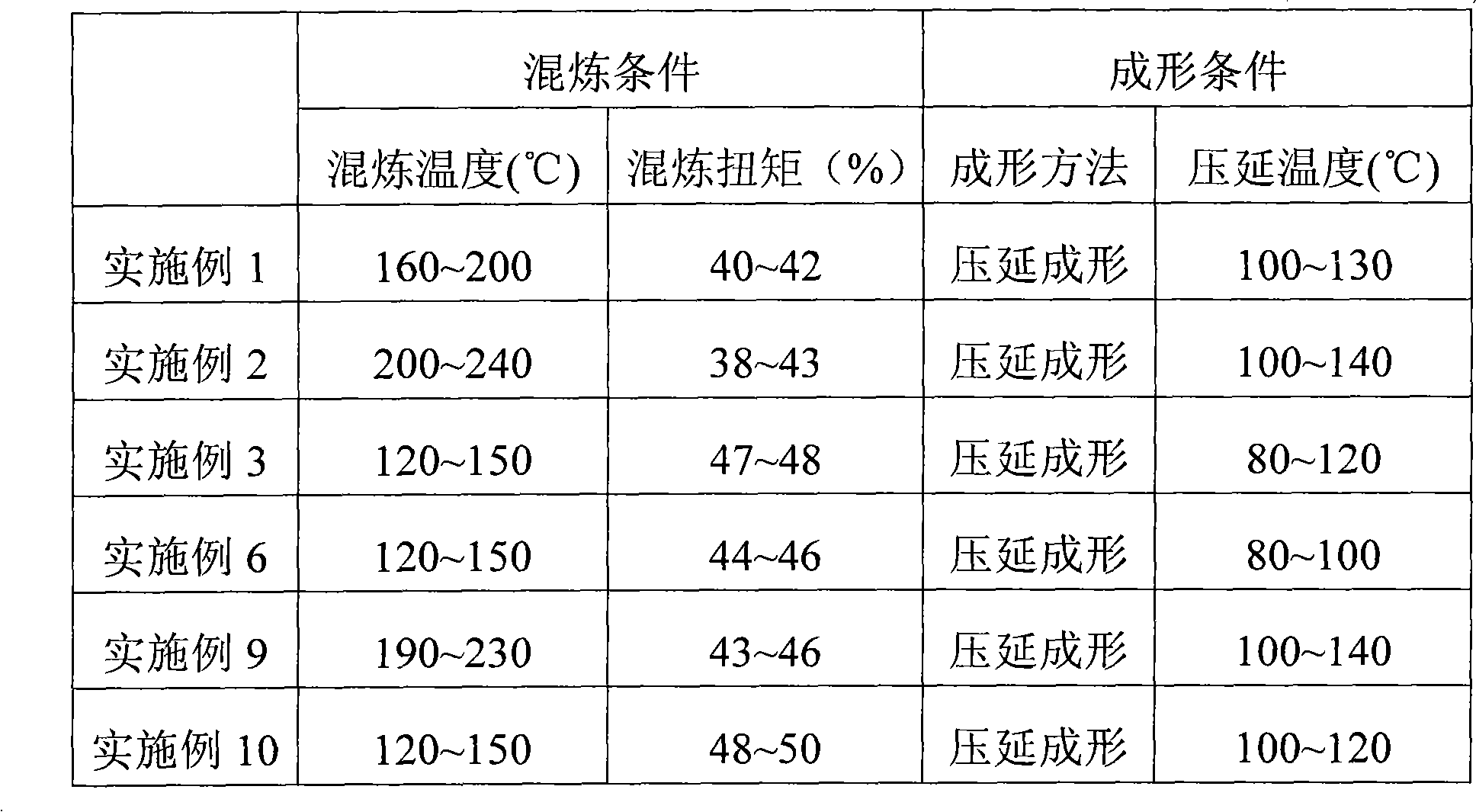

[0027] First, the magnetic powder is coupled with 3-glycidoxypropyltrimethoxysilane coupling agent and dried, and then the above-mentioned magnetic powder, binder and additive mixture are mixed evenly with a high-speed mixer, and then the mixture is mixed with an open mill The mixture was kneaded at a certain temperature and load until uniform, and then granulated, and finally made into a magnetic sheet with a thickness of 2 mm on a calender.

Embodiment 2

[0029] Magnet formula (weight ratio): NdFeB magnetic powder 94.5%, γ-mercaptopropyltriethoxysilane (coupling agent) 0.5%, polystyrene is the thermoplastic elastomer (binding agent) 3.9% of base material, silicone oil ( lubricant) 0.3%, diisononyl phthalate (plasticizer) 0.5%, WS-245 [triethylene glycol bis(β-(3-tert-butyl-4-hydroxy-5-methyl phenyl) propionate) (antioxidant) 0.3%.

[0030] Firstly, the magnetic powder is coupled with γ-mercaptopropyltriethoxysilane coupling agent and dried, then the magnetic powder, binder and other additives are mixed uniformly in a high-speed mixer, and then mixed with a twin-screw mixer The mixture was uniformly kneaded and granulated under a certain temperature and load, and a magnetic sheet with a thickness of 1 mm was formed by a calender.

Embodiment 3

[0032] Magnet formula (weight ratio): NdFeB magnetic powder 92.4%, γ-aminopropyltriethoxysilane (coupling agent) 0.5%, polyamide-based thermoplastic elastomer (binder) 5.5%, stearic acid and zinc stearate (lubricant) 0.5%, dioctyl phthalate (plasticizer) 0.3%, epoxy soybean oil (plasticizer) 0.4%, AO-27 (N, N'-binaphthalene Base-p-phenylethylamine) (amine antioxidant) 0.4%.

[0033] First, the magnetic powder is coupled with γ-aminopropyltriethoxysilane coupling agent and dried, then the magnetic powder, binder and other additives are mixed uniformly in a high-speed mixer, and then the mixture is mixed with an open mill After uniform mixing under a certain temperature and load, it is granulated, and finally a magnetic sheet with a thickness of 1.4 mm is made on a calender.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com