Patents

Literature

372results about How to "No rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

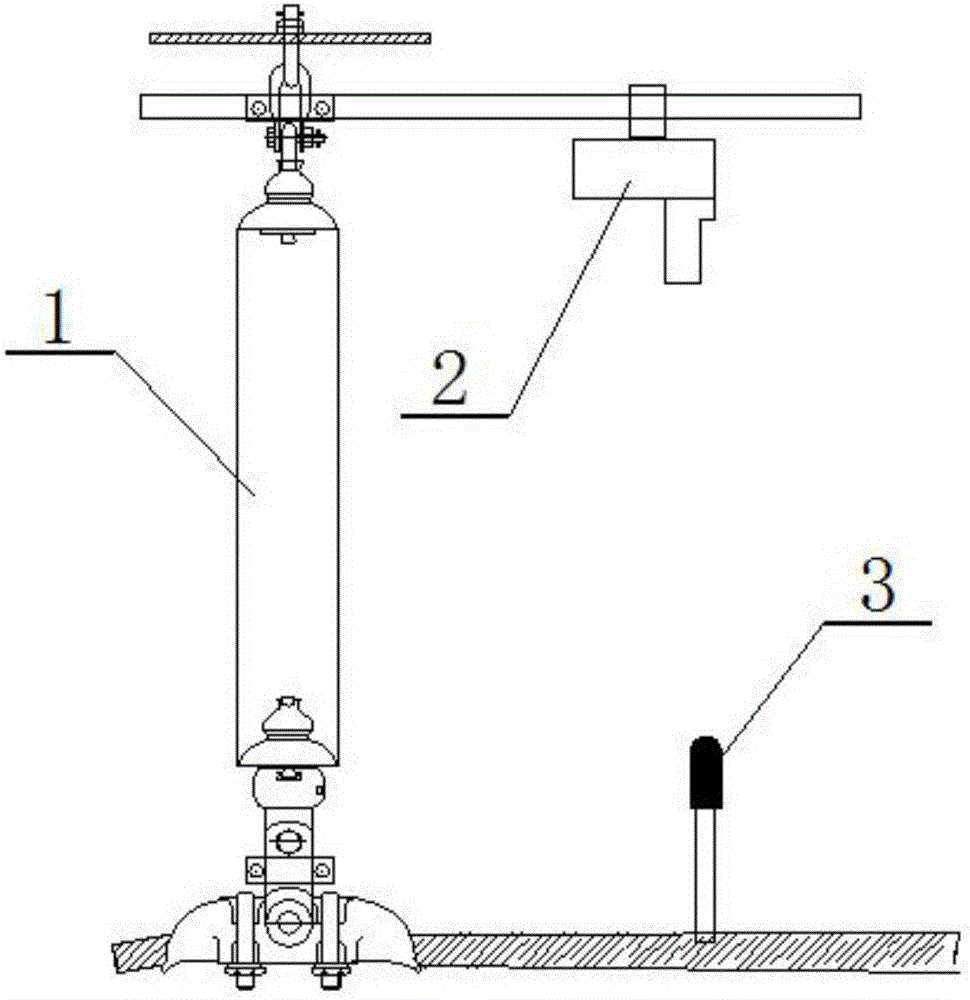

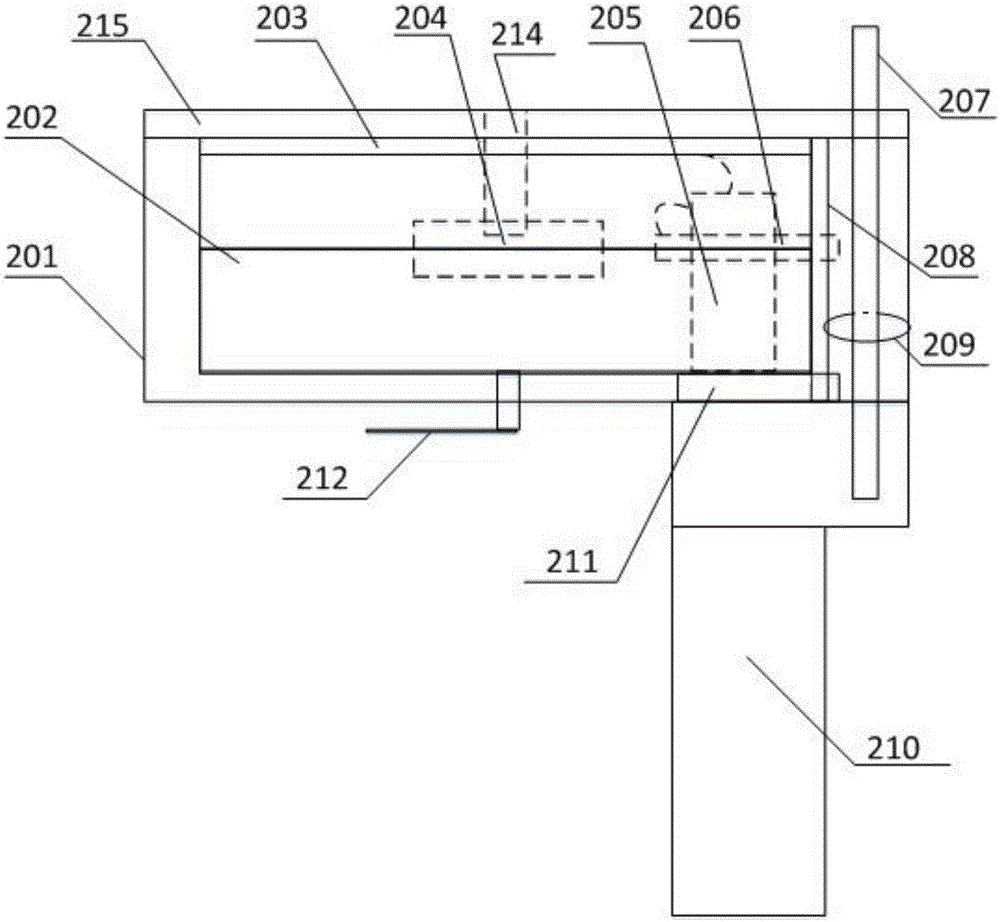

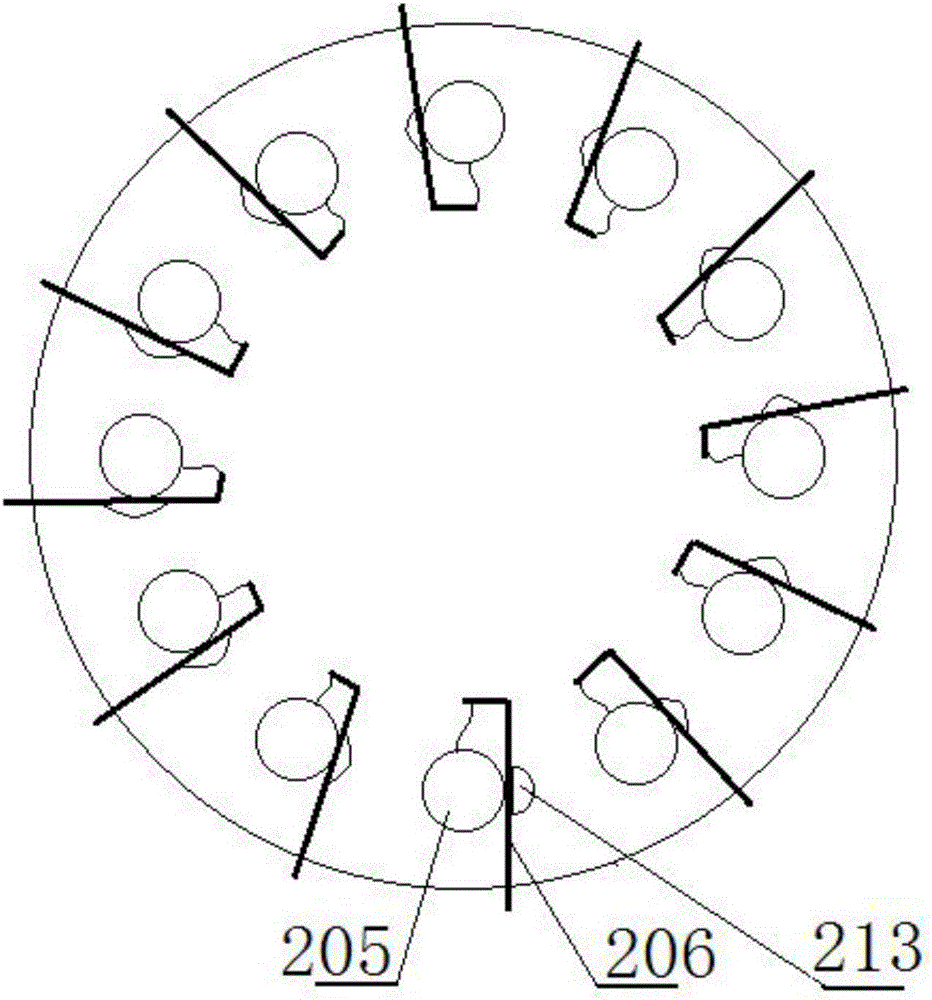

Thunder-lightening induced solid-phase arc-extinguishing lightning arrester

ActiveCN106451077AReliable rotationReliable stopSpark gap detailsDischarge by conduction/dissipationEngineeringMetal

The invention discloses a thunder-lightening induced solid-phase arc-extinguishing lightning arrester. The thunder-lightening induced solid-phase arc-extinguishing lightning arrester mainly consists of a lightning arrester shell, an arc-extinguishing rotary table, an electric conduction metal plate, a starting rod, a clamping rod, an induction coil, an arc-extinguishing barrel and a counting pointer; the arc-extinguishing rotary table is arranged inside the lightning arrester shell, and a flat spiral spring for pushing the arc-extinguishing rotary table to rotate is arranged at the central position of the arc-extinguishing rotary table; the electric conduction metal plate is arranged at the upper part of the arc-extinguishing rotary table; the arc-extinguishing rotary table is provided with a plurality of arc-extinguishing gas pills in the peripheral direction; one side of each arc-extinguishing gas pill is provided with a trigger electrode and a groove respectively, one end of each trigger electrode is connected with one of trigger ends of the corresponding arc-extinguishing gas pill through a lead, and the other ends of the trigger electrodes extend out of the edge of the arc-extinguishing rotary table; and the other of the trigger ends of the corresponding arc-extinguishing gas pill is connected with the electric conduction metal plate through a lead. The thunder-lightening induced solid-phase arc-extinguishing lightning arrester is simple in structure, reasonable in design, high in arc-extinguishing ability and stable and reliable to work, and the arc-extinguishing gas pills are changed quickly and conveniently.

Owner:王巨丰 +1

Semi-synthesis cutting fluid for magnesium alloy, preparation method and application method

ActiveCN102732363AFire Hazard PreventionAvoid difficult issuesLubricant compositionWater solubleHard water

The invention discloses a semisynthesis cutting fluid for magnesium alloy. According to the invention, the hidden danger of fire hazard in the process of magnesium alloy processing is totally avoided by using an environment-friendly water-soluble system; excellent reasonable proportioning of additives and combined application of corrosion inhibitors effectively prevent the surface of processed magnesium alloy from corrosion and blackening; designing of a low foam type formula enables generation of foam in the cutting fluid for the magnesium alloy to be totally inhibited; application of a delicate low-foam surfactant enables the problem of difficult cleaning of workpiece surface due to excessive oil stains to be overcome; application of an additive with resistance to hard water enables hard water-resistance of the fluid to be effectively improved, the fluid has hard water-resistance of 15000 ppm, allowing the service life of the fluid to be prolonged, all the indexes of the fluid reach or exceed relevant indexes in GB6144-2010, anti-rust performance lasts for more than 72 h per sheet, and the life cycle of the fluid is more than 8 months, 3 to 6 times the life cycle of magnesium alloy cutting fluid on the market; and reasonable design of an environment-friendly formula enables the problems of difficulty in treating waste liquid and the like to be effectively overcome.

Owner:AMER TECH CO LTD

Rust-proof emulsified type metal cutting fluid

The invention discloses rust-proof emulsified type metal cutting fluid which is prepared from, by weight, 40-50% of base oil, 5-15% of an anionic surfactant, 0.5-2.0% of a nonionic surfactant, 3-5% of a black metal inhibitor, 5-10% of a coupling agent, 0.5-1.0% of a copper alloy inhibiter, 3-10% of a lubricating agent, 1-2% of a bactericide, 0.2-0.5% of a defoaming agent and the balance water.The black metal inhibitor is added into the emulsified type cutting fluid formula, excellent interprocess dust-proof protection is provided, and it is ensured that corrosion is avoided before a machined workpiece is transferred to the next process; by adding the lubricating agent and the compound of the anionic and nonionic surfactants, the excellent lubricating performance and corrosion resistance and the outstanding hard water resistance are obtained; the working fluid is long in service life, contains no nitrite, phenols and other toxic and harmful substance, and is beneficial to health of environmental protection and workers.

Owner:DONGGUAN NASHENG LUBRICATING OIL TECH CO LTD

Neodymium-iron-boron magnet of aluminum or aluminum alloy composite coating and preparation method thereof

ActiveCN102031522AImprove processing efficiencyLow costVacuum evaporation coatingSputtering coatingHigh humidityAlloy composite

The invention discloses a neodymium-iron-boron magnet of an aluminum or aluminum alloy composite coating and a preparation method thereof. An aluminum or aluminum alloy film is deposited on the neodymium-iron-boron magnet by adopting multi-arc ion plating technology, and then phosphate treatment is performed. The coating is uniform and dense, and is well combined with a matrix. The neodymium-iron-boron magnet applied with the aluminum composite coating with thickness of 10 to 20 microns tolerates high pressure and high humidity (100 to 130 DEG C, 2 to 2.6atm, and 95 to 100 percent RH) for over 200 hours, and tolerates NaCl salt fog corrosion (3.5 to 5 weight percent of NaCl and 25 to 35 DEG C) for over 500 hours. The coating process has high efficiency and low cost; and the prepared composite coating has good corrosion resistance and adhesion performance, and has no influence on the magnetism of the neodymium-iron-boron matrix (mainly small-size magnet).

Owner:北京钐元新材料股份有限公司

Flexible bonding rare-earth permanent magnet and manufacturing method thereof

ActiveCN101783219AImprove flexibilityNice appearanceInorganic material magnetismInductances/transformers/magnets manufacturePolyesterPlasticizer

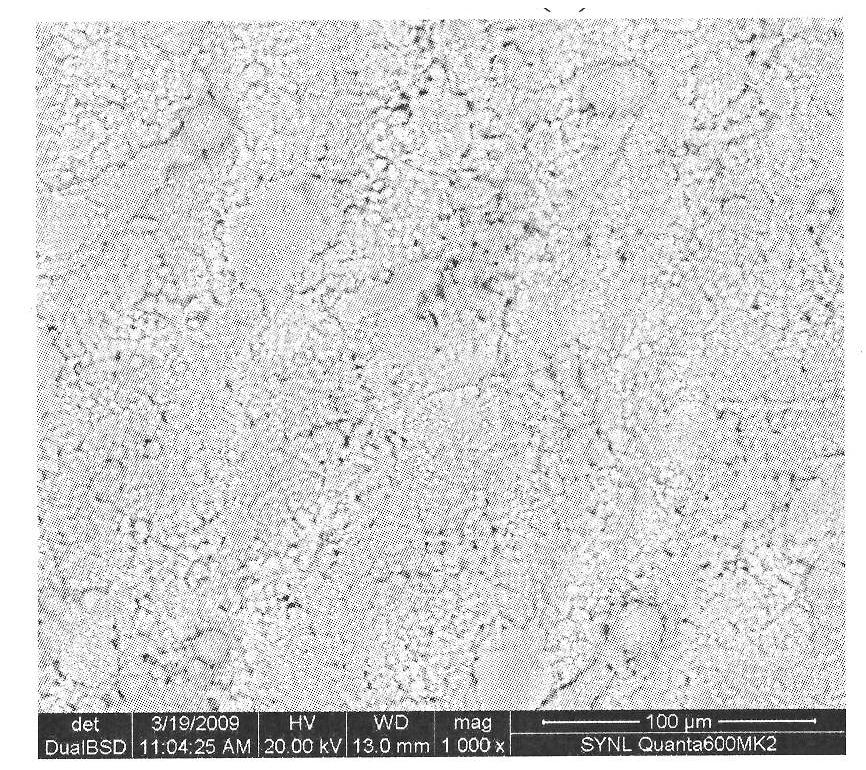

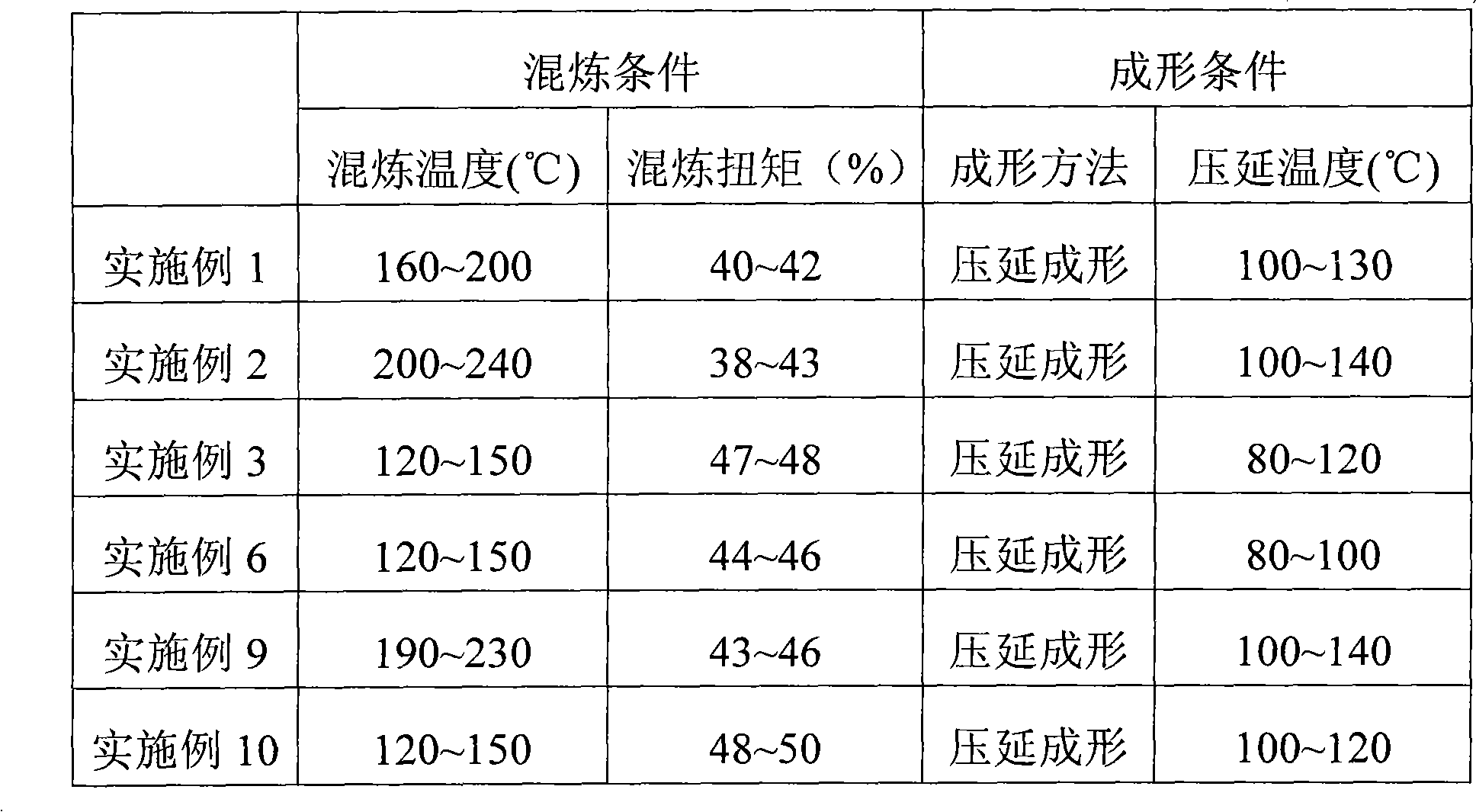

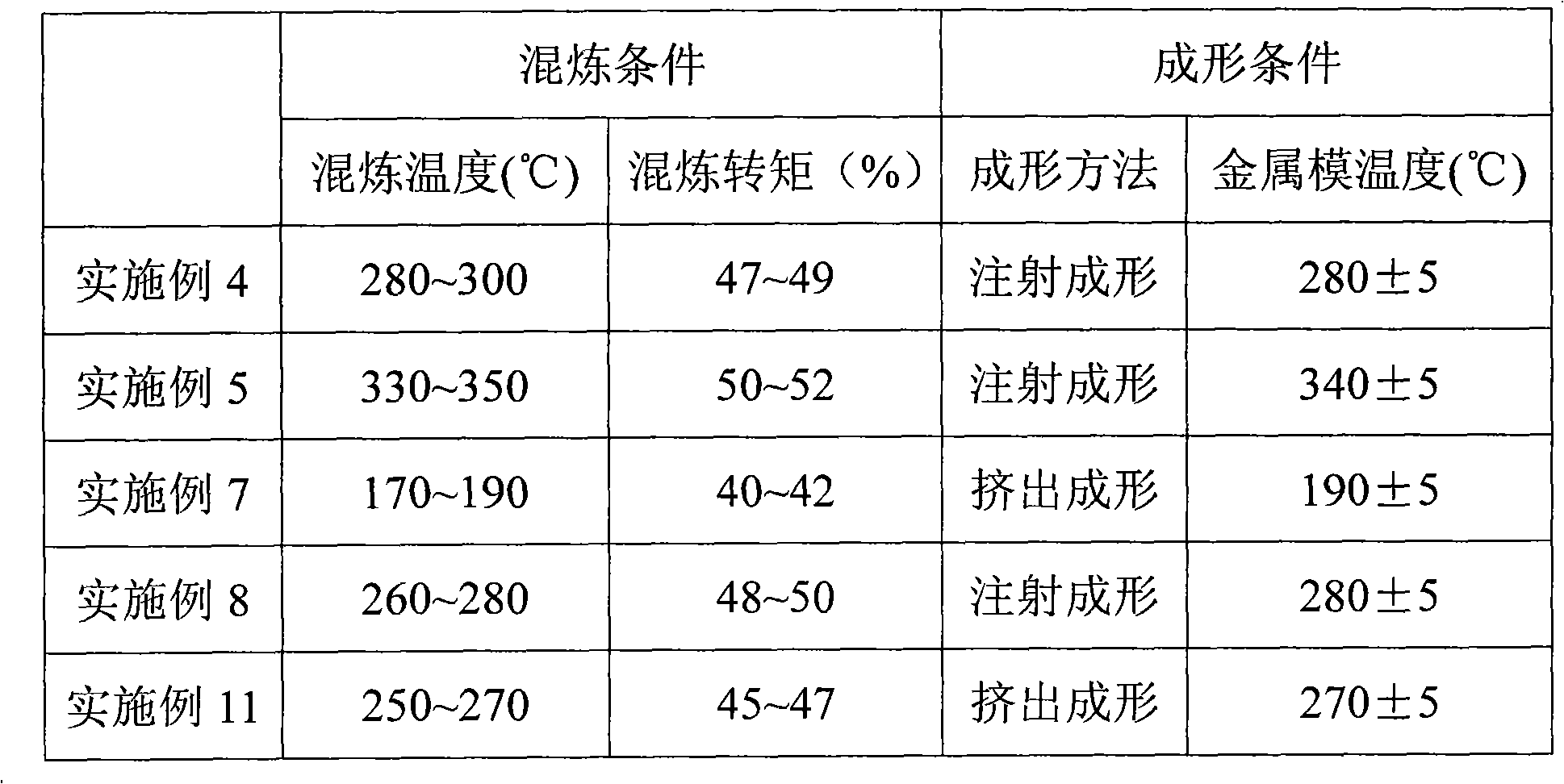

The invention provides a flexible bonding rare-earth permanent magnet and a manufacturing method thereof. The flexible bonding rare-earth permanent magnet comprises the following components in percentage by weight: 84.6 to 96.5 percent of NdFeB magnetic powder, 2.5 to 12 percent of bonder of a thermoplastic elastomer with properties of engineering plastics and 1 to 3.4 percent of processing aid, wherein the bonder is a blend of two or three composites of the single thermoplastic elastomers which take polyurethane, polystyrene, polyamide, polyester and polyimide as base materials; and the processing aid comprises a coupling agent, a lubricant and a plasticizer. In the permanent magnet of the invention, the packing ratio of the magnetic powder reaches 96.5 weight percent; the tensile strength, namely the flexibitity, for calendering to form the magnet is more than 3MPa; and while the deficiency of quick magnetic ageing of the flexible magnet at a high temperature is overcome, the shortcomings of easy crack and deformation at a high temperature are also overcome.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

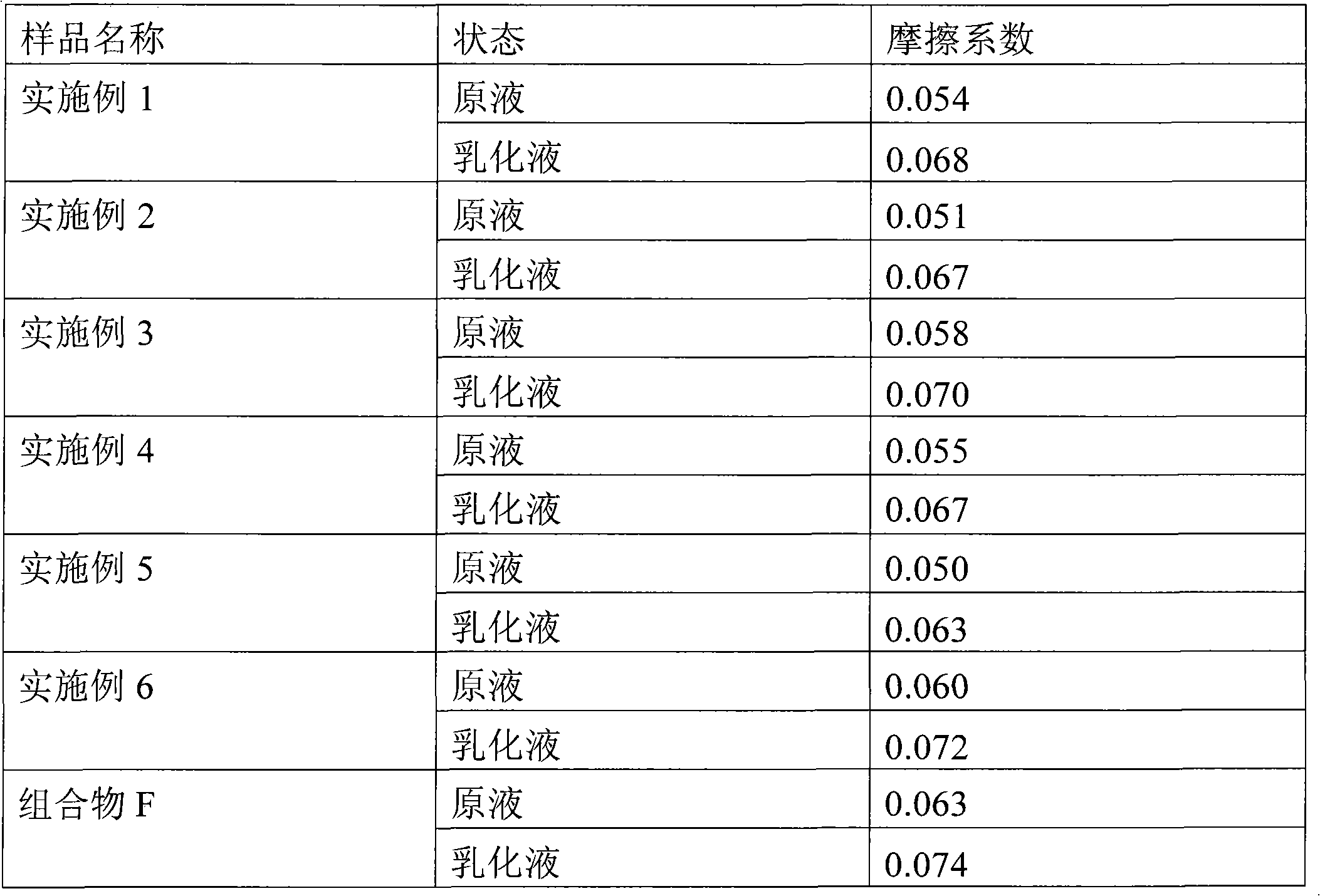

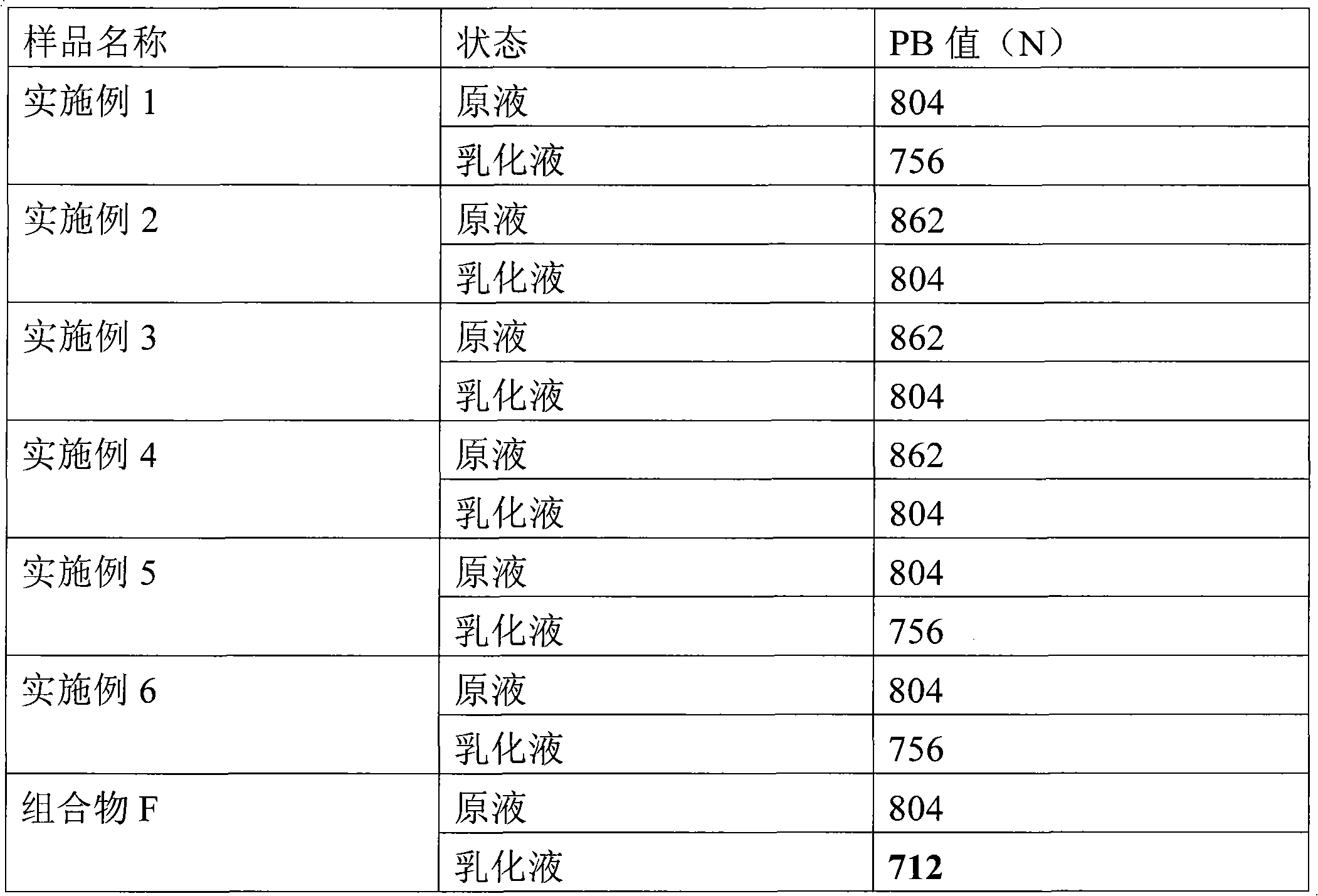

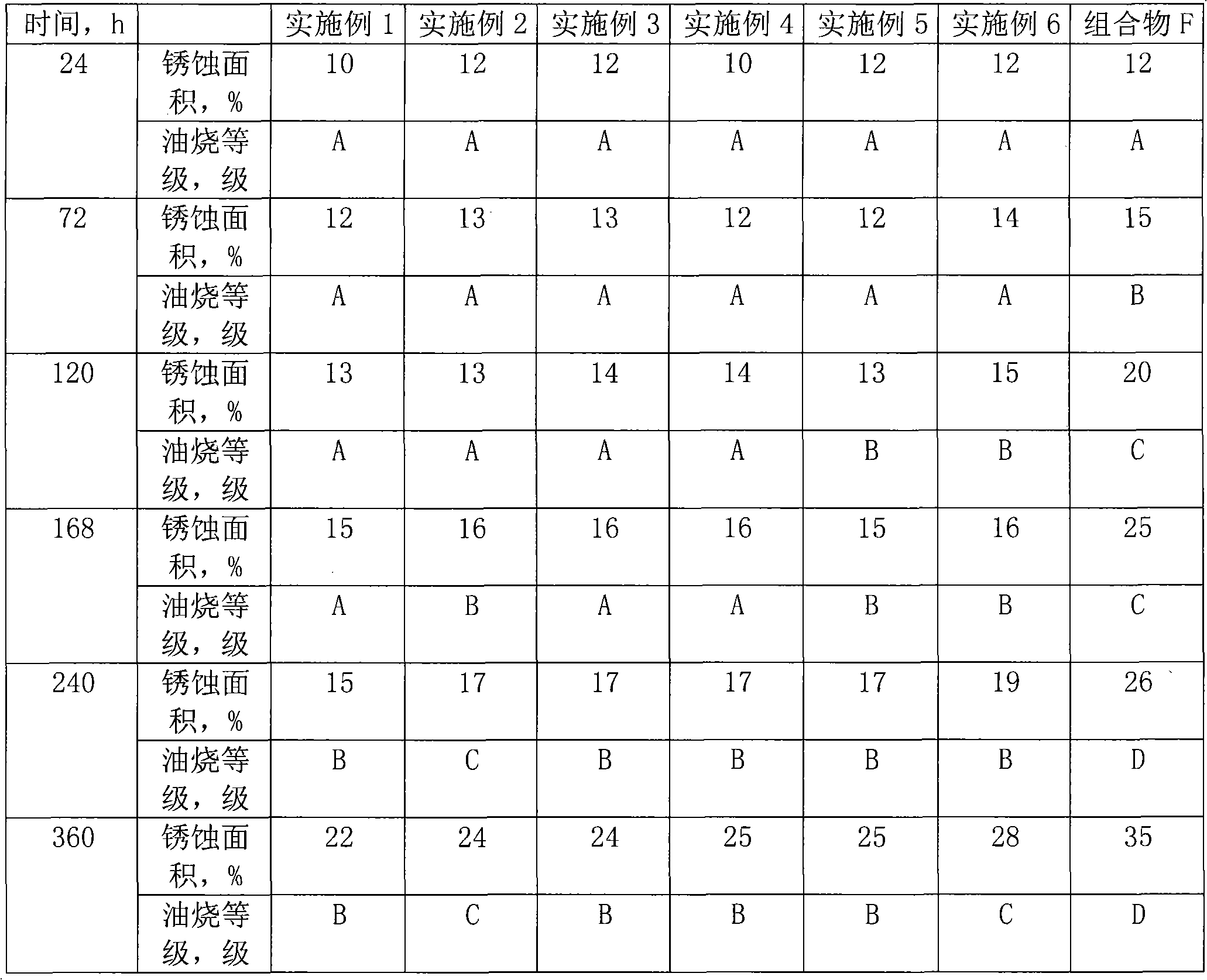

Cold rolled silicon steel rolled oil composition

The invention discloses a cold rolled silicon steel rolled oil composition. The composition comprises the following components in percentage by weight: 60 to 90 percent of alcohol ester oiliness agent, 5.0 to 12 percent of animal and vegetable oiliness agent, 2.0 to 12.0 percent of nonionic surfactant, 0.6 to 8 percent of phosphate antiwear additive and 0.5 to 8 percent of antirust additive. The rolling lubricating property of the cold rolled silicon steel rolled oil composition is high; the cleanness of the rolling environment and a memorial archway is good; and the degreasing property, the rust-proof performance and the anti-oil burn property are high.

Owner:CHINA PETROCHEMICAL CORP +1

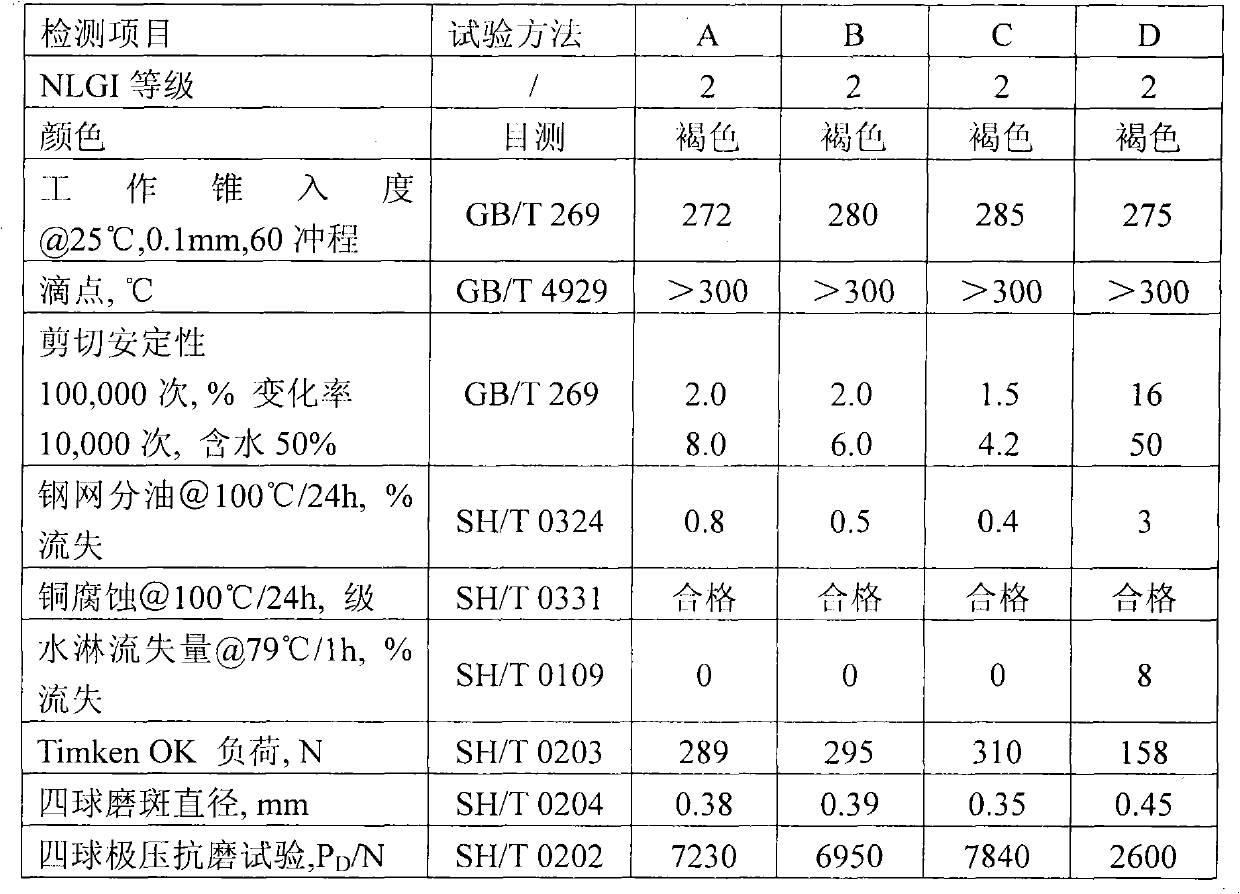

Synthetic high-temperature lubricating grease and preparation method thereof

ActiveCN101921653AGood high temperature performanceSmall oil separationLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to synthetic high-temperature lubricating grease and a preparation method thereof, in particular to lubricating grease generated by taking high-base number compound calcium sulfonate as a thickening agent and high-viscosity synthetic oil as base oil. The synthetic high-temperature lubricating grease comprises the following components in percentage by mass: 30%-80% of the synthetic base oil, 15%-30% of high-base number compound calcium sulfonate, 2%-10% of 12-hydroxyl stearic acid, 1%-5% of boric acid, 1%-4% of acetic acid, 0.5%-2% of water, 1%-3% of calcium hydroxide and0.1%-0.5% of antioxidants. The produced high-temperature lubricating grease has the advantages of excellent high temperature and water spraying resistance, very well extreme pressure abrasion resistance, cutting safety, rust protection, and the like and is very suitable for the production parts of steel mills, cement plants, power plants, and the like, which have high temperature, heavy loads andlarge quantities of cooling water.

Owner:北京奥力助兴石化科技有限公司

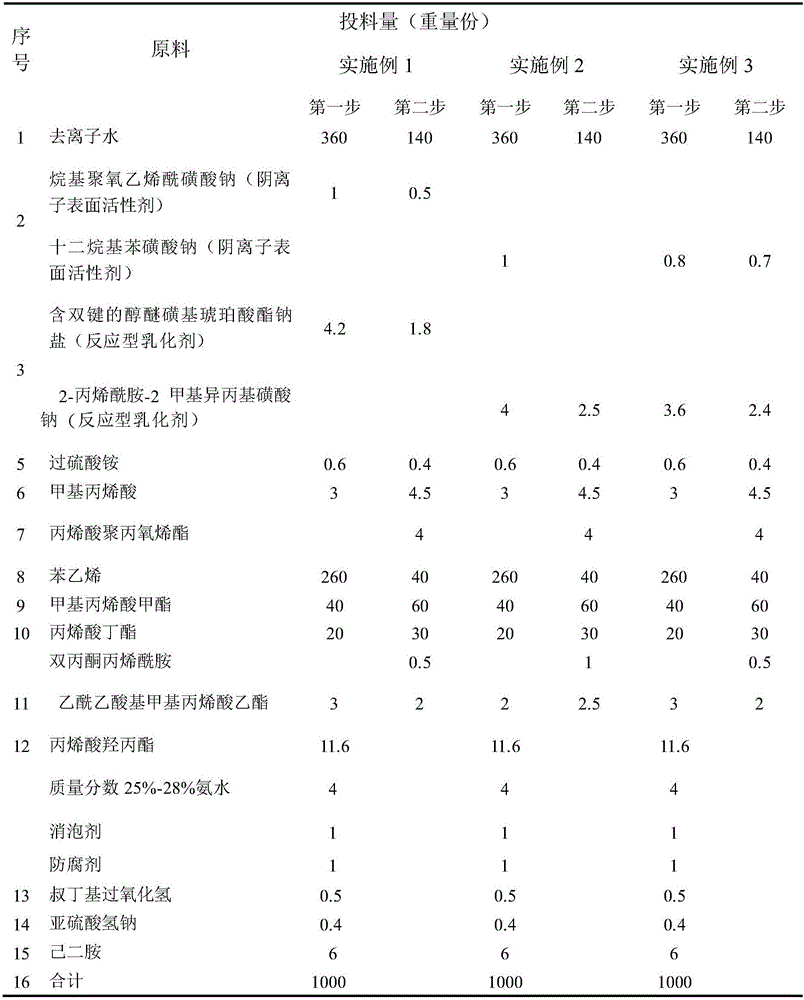

Acrylate copolymer emulsion, and aqueous industrial anticorrosive paint adopting acrylate copolymer emulsion as film forming substance

ActiveCN105859936AReduce the temperatureGuaranteed compactnessAnti-corrosive paintsCross-linkSodium bisulfate

The invention discloses an acrylate copolymer emulsion, and belongs to the technical field of aqueous coatings. The acrylate copolymer emulsion comprises, by weight, 450-550 parts of deionized water, 1-2 parts of an anionic surfactant, 5-8 parts of a reactive emulsifier, 3-15 parts of hydroxypropyl acrylate, 50-160 parts of methyl methacrylate, 20-75 parts of butyl acrylate, 200-410 parts of styrene, 5-10 parts of methacrylic acid, 3-10 parts of an adhesion function monomer, 2-9 parts of a cross-linking monomer, 3-10 parts of a cross-linking agent, 0.1-3 parts of an antifoaming agent, 0.8-2 parts of an initiator, 3-5 parts of ammonia water, 0.8-2 parts of an antiseptic, 0.1-1 part of tert-butyl hydroperoxide and 0.1-0.8 parts of sodium bisulfate. The invention also discloses an aqueous industrial anticorrosive coating adopting the acrylate copolymer emulsion as a film forming substance. The coating has the advantages of high adhesion to a substrate, high water resistance and high salt spray resistance.

Owner:HENGSHUI XINGUANG CHEM

Self-layered low-surface energy antifouling paint

InactiveCN101434805AStrong adhesionTight molecular structureAntifouling/underwater paintsPaints with biocidesEpoxyOrganic solvent

The invention provides an antifouling coating which can be self-layered and solidified, has low surface energy and consists of component A and component B, wherein, according to the weight formula, the component A consists of 50-100 parts of epoxy resin, 0-50 parts of epoxy-capped esserbetol, 60-240 parts of polymethyl siloxane resin, 0-20 parts of pigment, and 0-70 parts of organic solvent; component B consists of 25-40 parts of amine curing agent, 2-16 parts of organic silicone cross-linking agent, 0-0.5 part of organic silicon-crosslinked catalyst and 0-5 parts of organic solvent. The coating uses a principle that the epoxy resin and the organic silicon resin are incompatible in each other, and can be automatically layered during the film-forming process; and the epoxy resin deposits at the bottom and the organic silicon resin is exposed on the external surface. The antifouling coating with low surface energy has the characteristics of excellent adhesion of epoxy resin and low surface energy of the organic silicon and has certain antifouling effect.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

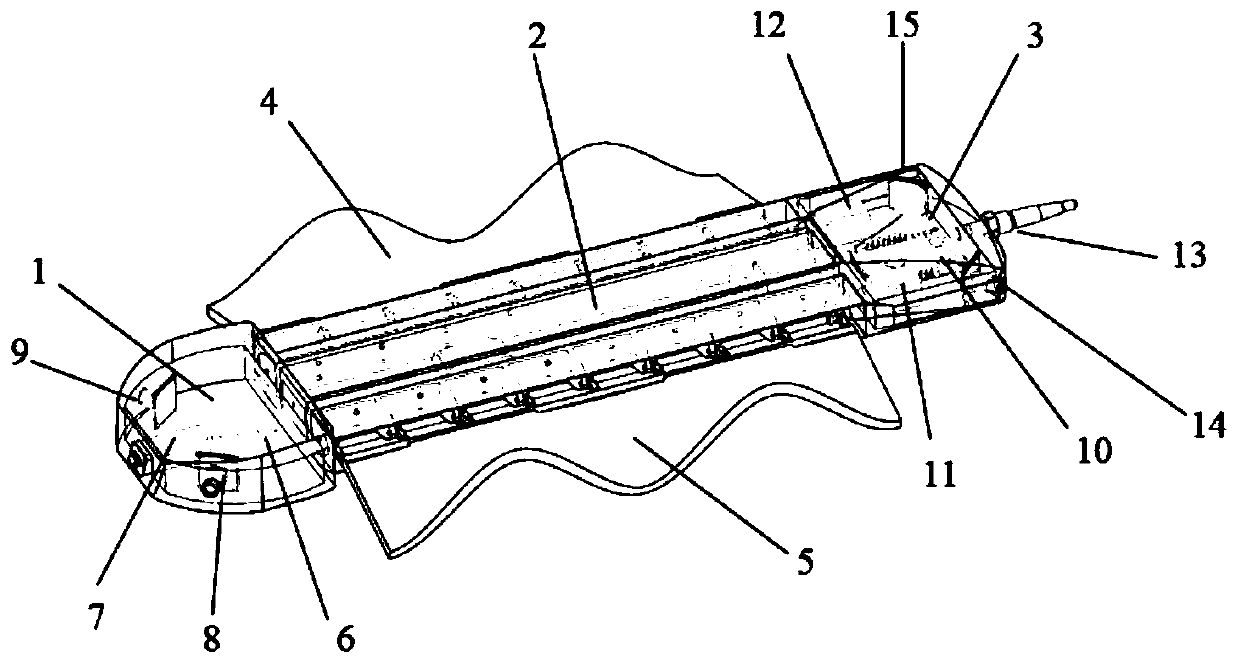

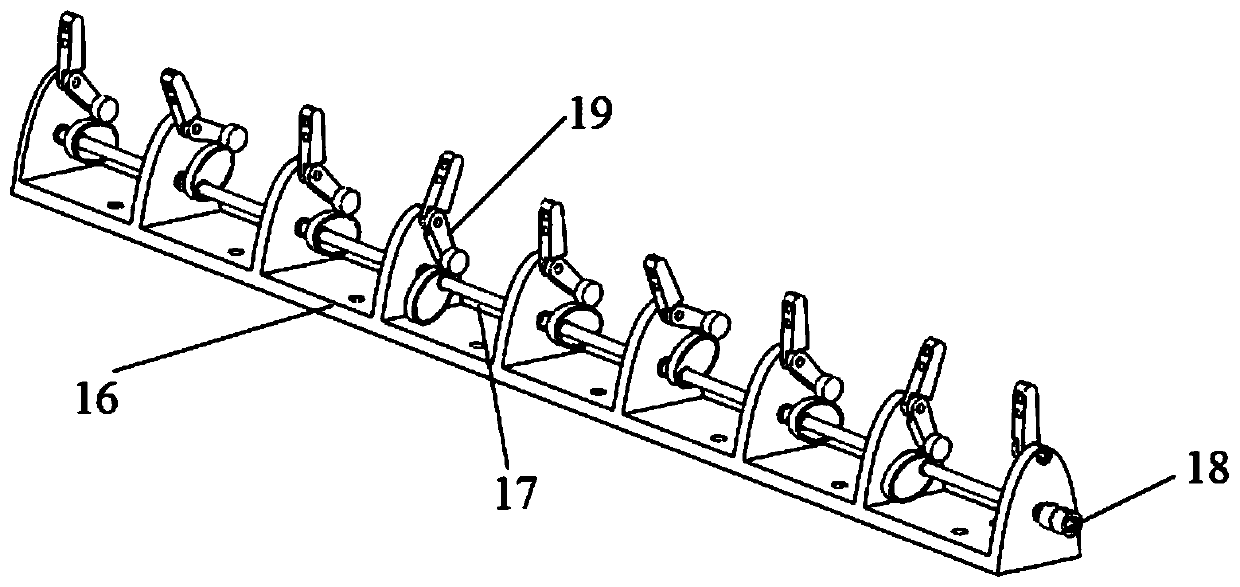

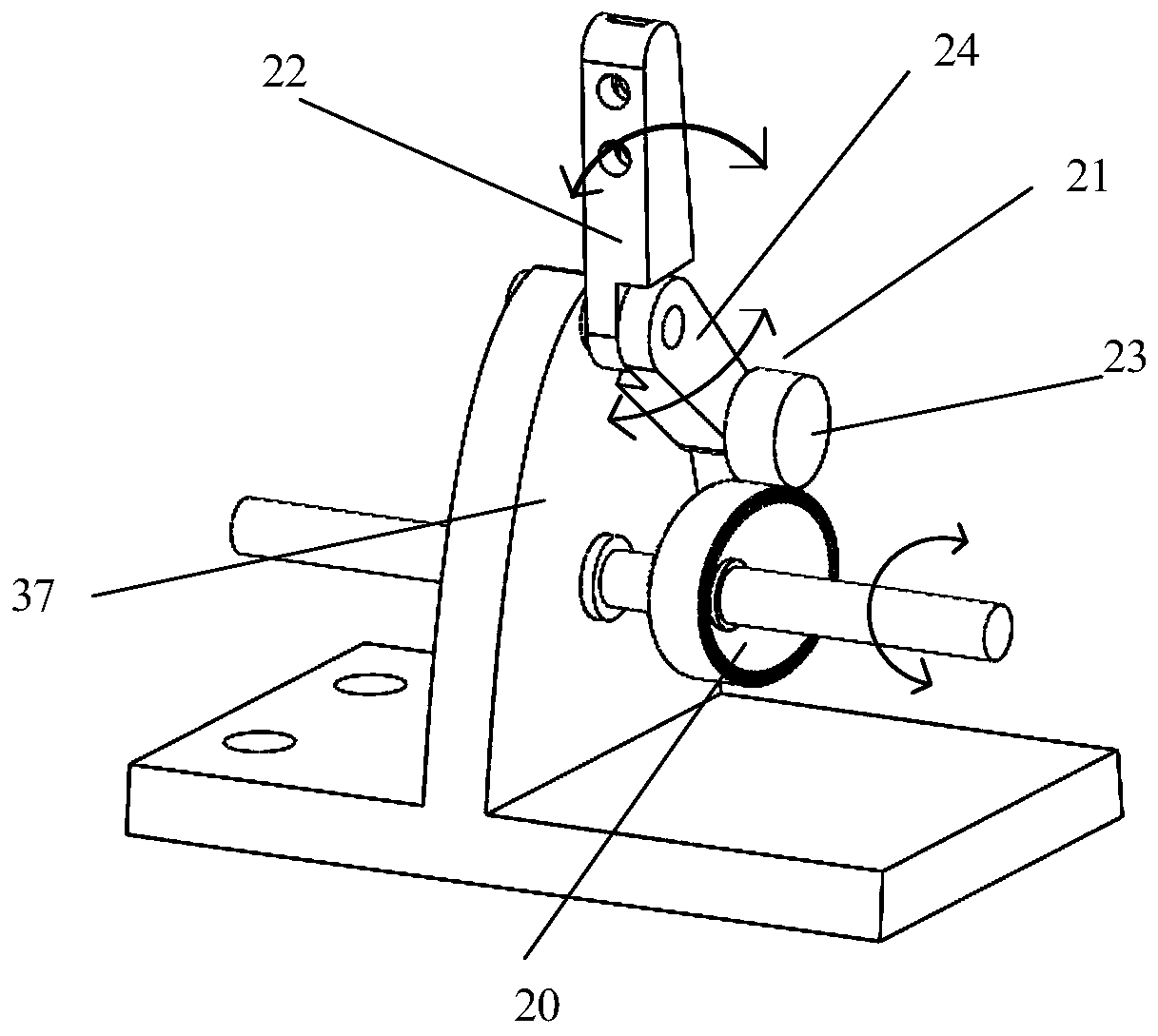

Underwater multipurpose robot propelled by bionic undulating fins

PendingCN111422334APropulsion mode quietImprove concealmentMeasurement devicesPropulsive elements of non-rotary typeClassical mechanicsUltrasonic doppler

The invention discloses an underwater multipurpose robot propelled by bionic undulating fins. The underwater multipurpose robot comprises a head, a middle, a tail, a left bionic undulating fin propelling mechanism and a right bionic undulating fin propelling mechanism which are arranged in sequence. The bionic undulating fin propelling mechanisms on the left side and the right side with a cam swing arm driving structure as the core are adopted for driving the fin strips to drive the flexible fin faces to generate continuous undulating deformation, the fin strips act with water to generate advancing thrust, through cooperation with a sinking and floating adjusting mechanism in the middle, multi-dimensional movement such as straight moving, turning and floating and diving of the underwater robot can be achieved, and good maneuverability is achieved. Meanwhile, the sensing flow field speed data and the self orientation data can be obtained according to an ultrasonic Doppler current meterarranged at the head part and a USBL underwater acoustic positioning system; motion of the underwater robot is planned, the underwater robot is selected to operate on a channel with constant flow velocity and small flow resistance, the underwater robot has the capacity of sensing and reducing underwater surge interference in advance, and the underwater robot has good reliability and robustness.

Owner:XI AN JIAOTONG UNIV

Reinforced bar glass fiber resin concrete pipe and producing method thereof

InactiveCN101482204AHigh strengthLow costMixing operation control apparatusCeramic shaping apparatusSteel tubeRebar

The invention discloses a reinforcement fiberglass resin concrete tube used for burying and a production method thereof, aiming at providing a reinforcement fiberglass resin concrete tube used for burying and a production method thereof with the advantages of corrosion resistance, high intensity, small resistance, low manufacture and use cost, simple manufacture technique and convenient construction. The reinforcement fiberglass resin concrete tube comprises a circular tube cast by the concrete composed by unsaturated resin and quartz sand; and connecting ports which are mutually inserted are manufactured at the two ends of the circular tube. The invention is characterized in that a tubular reinforcement mat is arranged in the circumferential wall of the circular tube; and the concrete comprises fiberglass. The production method thereof is as follows: manufacturing the reinforcement mat, diefilling, dosing, mixing, casting, solidifying, demoulding, correcting, and warehouse-in inspection. The reinforcement fiberglass resin concrete tube a lower cost than a steel tube, can not generate rustiness, and has longer service life compared with the steel tube. The mutual connection is not welded; moreover, the reinforcement fiberglass resin concrete tube is a burying jacking perfusion tube which can be broadly applied to a drinking tube or a drainage tube with the advantages of high intensity, low cost, safety and sanitation and convenient construction.

Owner:姚春贤

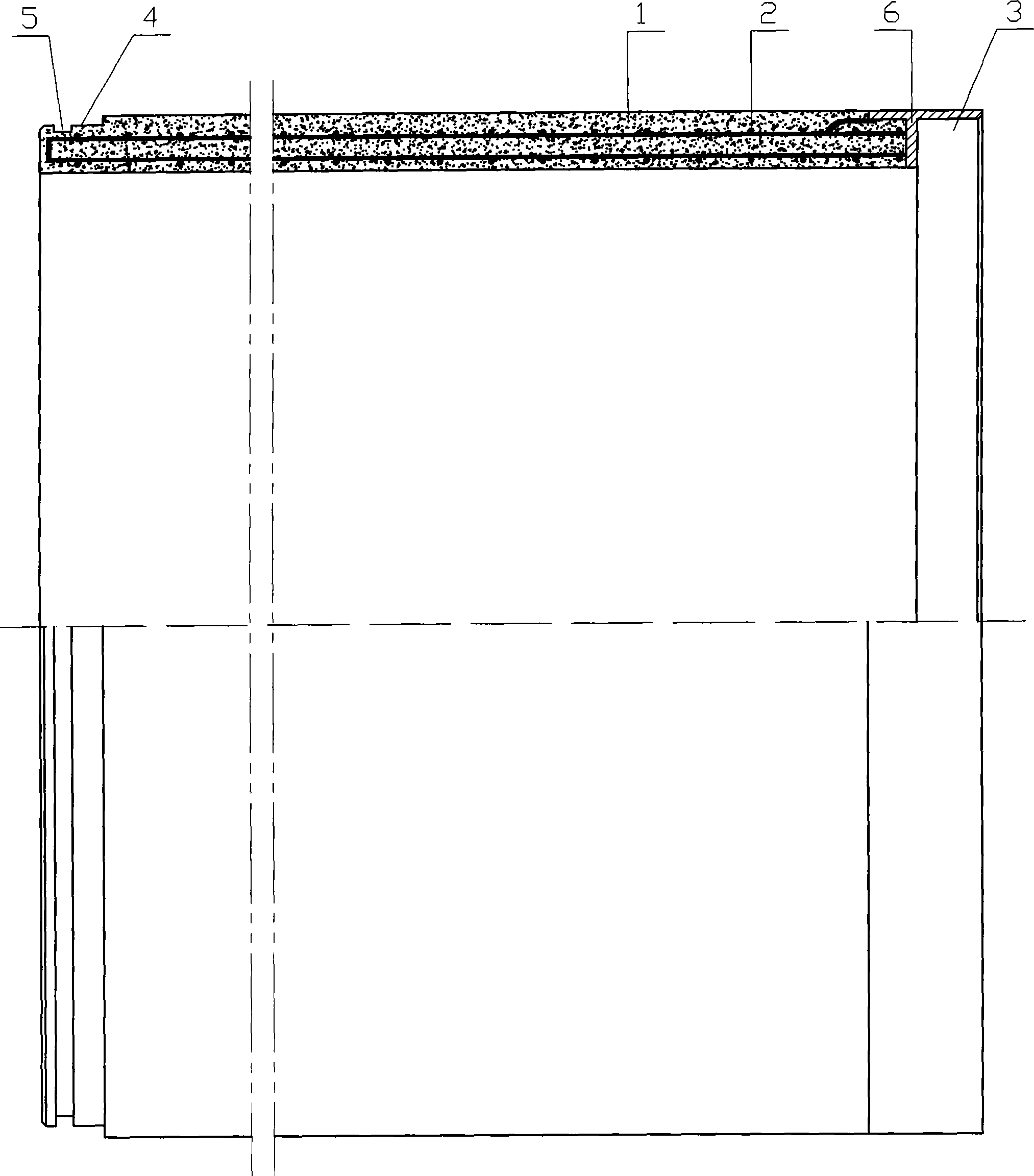

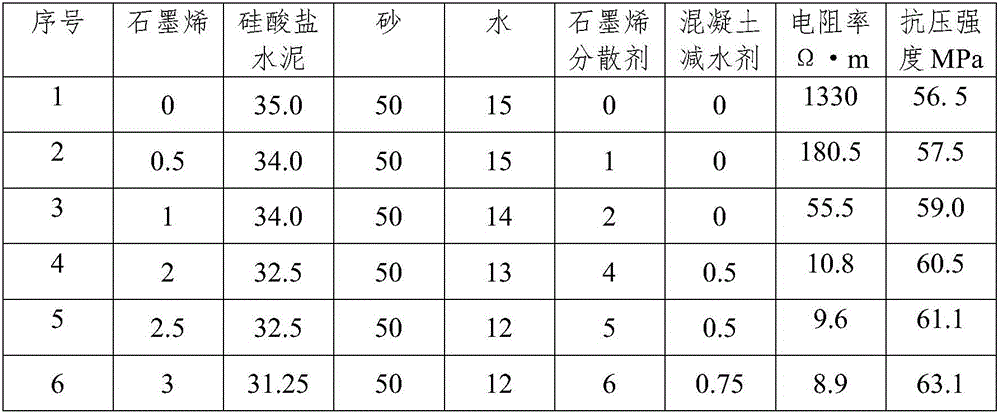

Graphene electric-conduction concrete

Provided graphene electric-conduction concrete comprises silicate cement and sand, and is characterized in that the graphene electric-conduction concrete is formed by adding graphene as an electric conduction phase, and the compositions comprise, relative to the total mass of cement and sand, 0.05-3 parts of graphene, 0.5-6 parts of a graphene dispersant, and 0-0.75 part of a water reducer for concrete. The graphene electric-conduction concrete possesses characteristics of good electric conductivity, high mechanical strength, stable electrical resistivity and good durability, and is applicable to electric heating ground surfaces, floors, and snow and ice thawing and the like.

Owner:GUANGZHOU UNIVERSITY

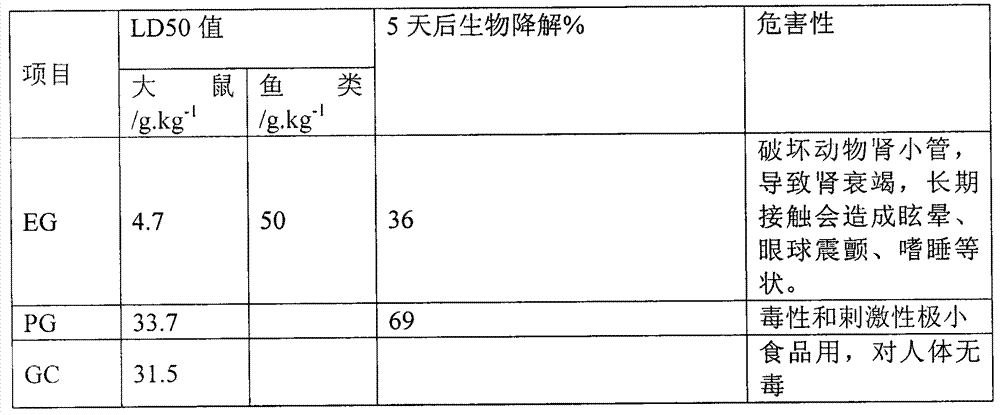

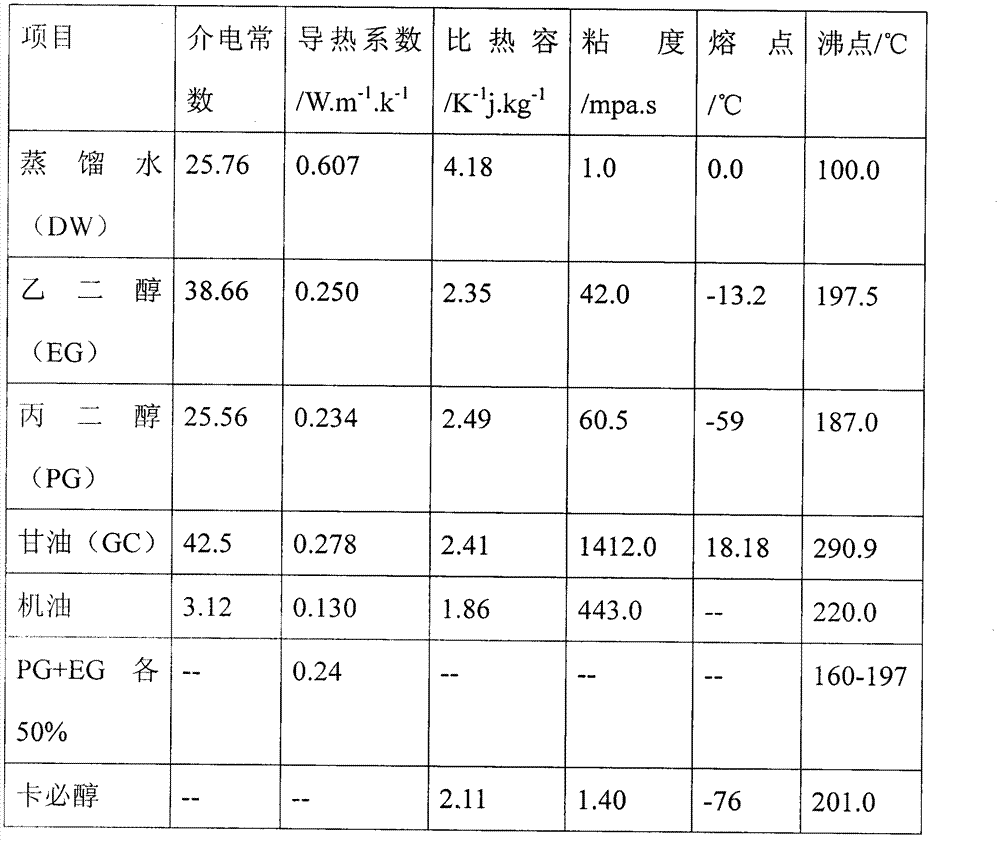

Nano long-acting liquid coolant

InactiveCN104263326AReliability benefitsHigh boiling pointHeat-exchange elementsFluorescenceCarbon nanotube

The invention discloses a nano long-acting liquid coolant. The nano long-acting liquid coolant comprises the following components of a base liquid which is composed of diatomic alcohol and a diluent, metal nanoparticles with a particle size of 3-100nm or carbon nano tube particles with a tube diameter of 8-100nm and length of 100-600nm, a dispersing agent, a corrosion inhibition additive, a pH regulator and a fluorescence colorant. The nano long-acting liquid disclosed by the invention is high in heat conductivity coefficient, good in heat transfer performance, good in liquidity and low in cost.

Owner:陈德全

Dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid

ActiveCN101718297AImprove wear resistanceAccelerated corrosionBearing componentsSliding contact bearingsWater basedCarrying capacity

The invention discloses a dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid, which comprises a bearing sleeve, wherein a flange is arranged at one end of the bearing sleeve, and external threads are arranged at the other end of the bearing sleeve; a ceramic shaft sleeve is assembled at the outer layer of the bearing sleeve; a ceramic shaft bushing which comprises a special liquid cavity and a liquid hole structure is arranged outside the ceramic shaft sleeve; a shaft bushing sleeve with the special liquid cavity and the liquid hole structure is assembled at the outer layer of the ceramic shaft bushing; and the bearing of the invention also comprises a bearing end cover, wherein a ceramic ring is assembled at the inner end of the bearing end cover, and internal threads matched with the external threads of the bearing sleeve are arranged on the inner ring of the bearing end cover. The bearing of the invention can improve the wear resistance and the corrosion resistance, can operate in the poor water condition where sandy solid particles are contained, can be lubricated by the water-based lubricating liquid formed by adding other additives into water or water-based liquid; at the same time, the bearing has larger carrying capacity and rigidity, and can ensure a safe and stable operating state, thereby greatly prolonging the operation life.

Owner:TIANJIN UNIV

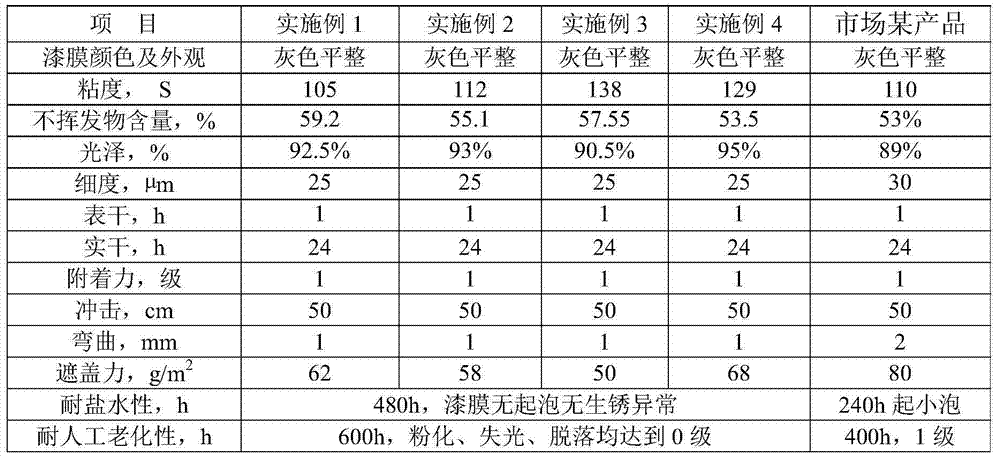

Preparation method of waterborne alkyd enamel

Owner:成都拜迪新材料有限公司

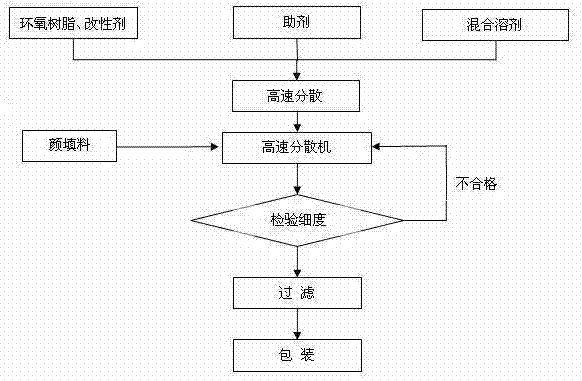

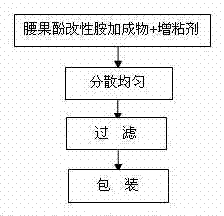

High-performance high-solid general modified epoxy antirust paint and preparation method thereof

ActiveCN102363690AHas acid and alkali resistanceNo acid and alkali resistanceAnti-corrosive paintsEpoxy resin coatingsLife ProlongationSlurry

The invention discloses a general modified epoxy antirust paint with high performances and high solids and a preparation method thereof. The paint comprises a component A and a component B, wherein the component A comprises 10-20 parts of an E44 epoxy resin, 10-20 parts of an NPPN-631 epoxy resin, 5-15 parts of a terpene resin, 4-18 parts of a cumarone resin, 0.1-1.0 parts of a BYK antifoaming agent, 0.1-1.0 part of an HX leveling agent, 0.1-1.5 parts of a rheological assistant, 5-20 parts of active silica, 10-20 parts of a mixed solvent and 10-30 parts of a pigment-filler; and the component B comprises 10-40 parts of cardanol modified amine and 0.5-3 parts of a modified silane coupling agent. The antirust paint of the invention has the advantages of compact coating, low viscosity, good compatibility and fast curing of a curing agent, high tough strength and strong adhesion of the coating, coating number reduction during the thick slurry curing, construction efficiency improvement, construction cost reduction, and anticorrosion life prolongation.

Owner:XIAMEN SUNRUI SHIP COATING

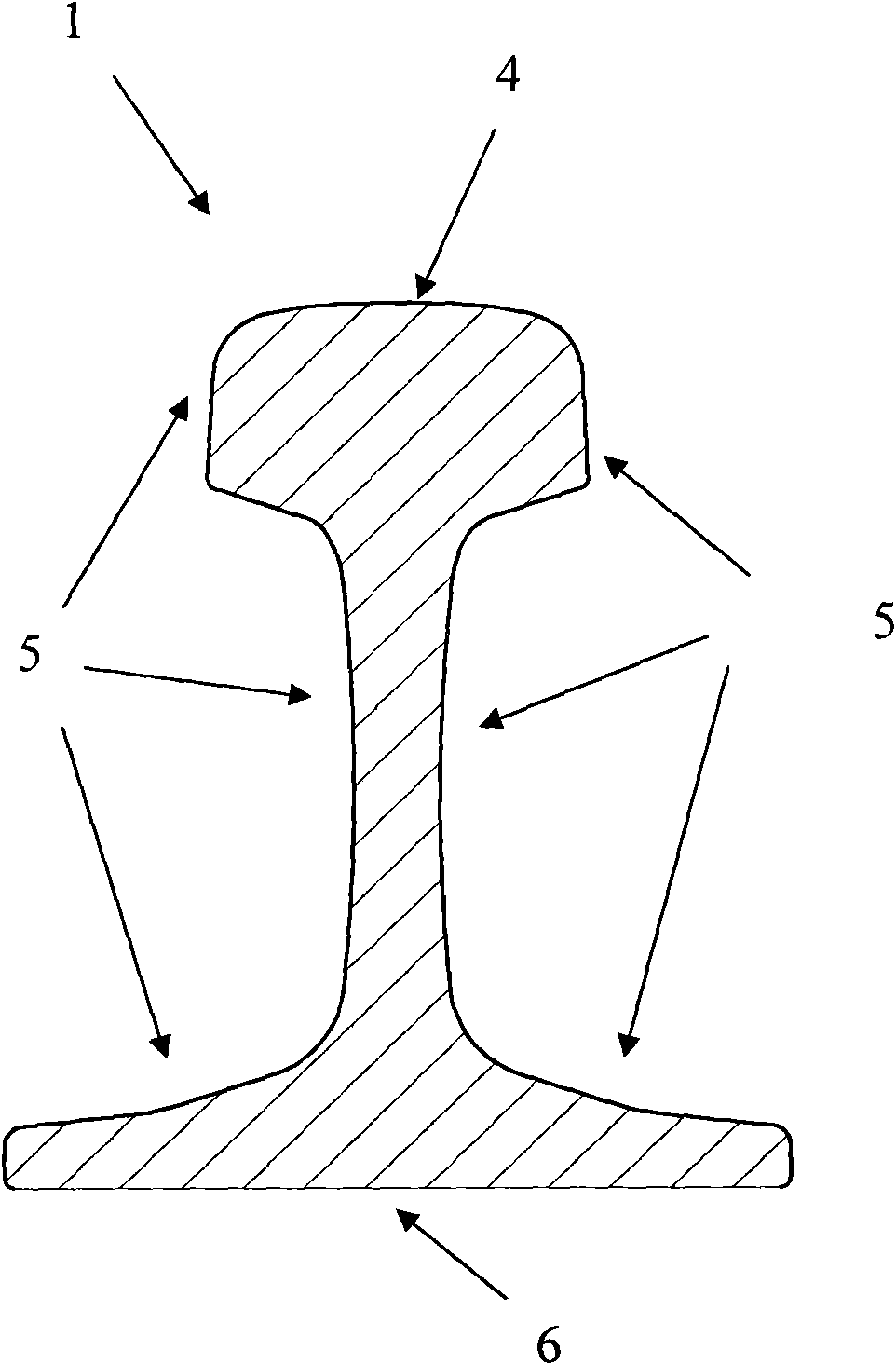

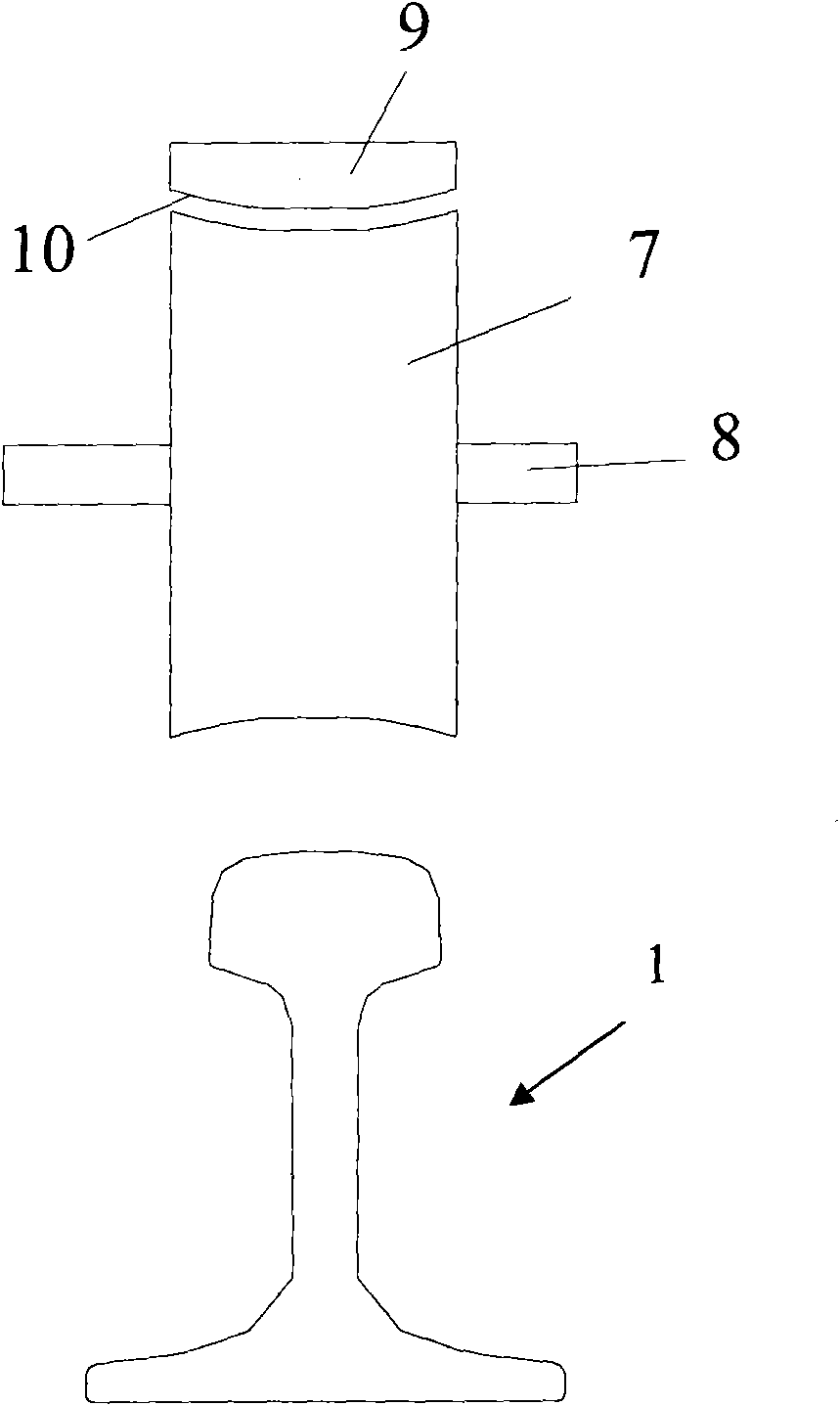

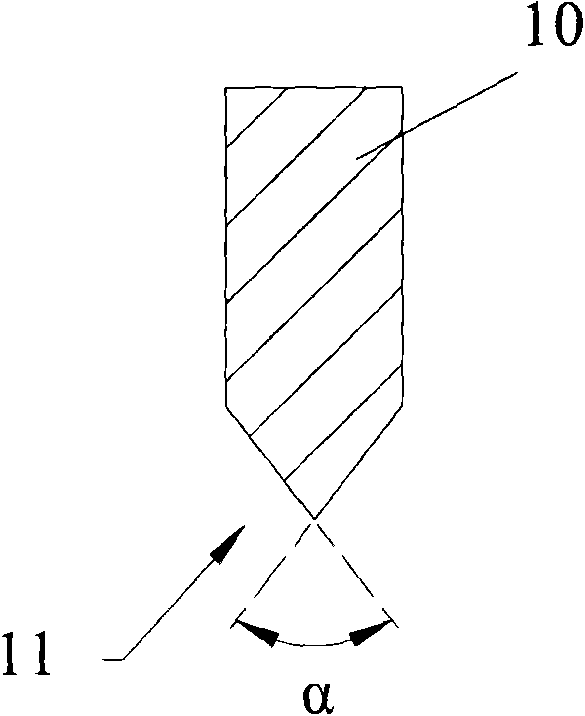

Device for coating steel rail and method thereof

InactiveCN102059185ANo rustEvenly distributedLiquid surface applicatorsLiquid spraying apparatusEngineeringCoating

The invention discloses a device for coating steel rail. The device comprises a machine frame, a coating roller and an anti-rusting agent supplying device, wherein the coating roller is used for contacting at least one surface of the top surface, the side surface and the bottom surface of the steel rail; and the anti-rusting agent supplying device comprises an anti-rusting agent container used for storing an anti-rusting agent, and a nozzle connected with the anti-rusting agent container through a pump and a conveying pipeline. A method for using the coating device to coat the anti-rusting agent on the steel rail comprises the following steps of: spraying the anti-rusting agent onto at least one surface of the top surface, the side surface and the bottom surface of the steel rail and rolling the surface coated with the anti-rusting agent by a coating roller; or when rolling at least one surface of the top surface, the side surface and the bottom surface of the steel rail by the coating roller, supplying the anti-rusting agent to the coating roller and / or the surface of the steel rail, which contacts the coating roller. Through the device, the steel rail coated with the anti-rusting agent is not rusted in transportation and air storage processes and the anti-rusting agent on the steel rail is relatively uniformly distributed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +3

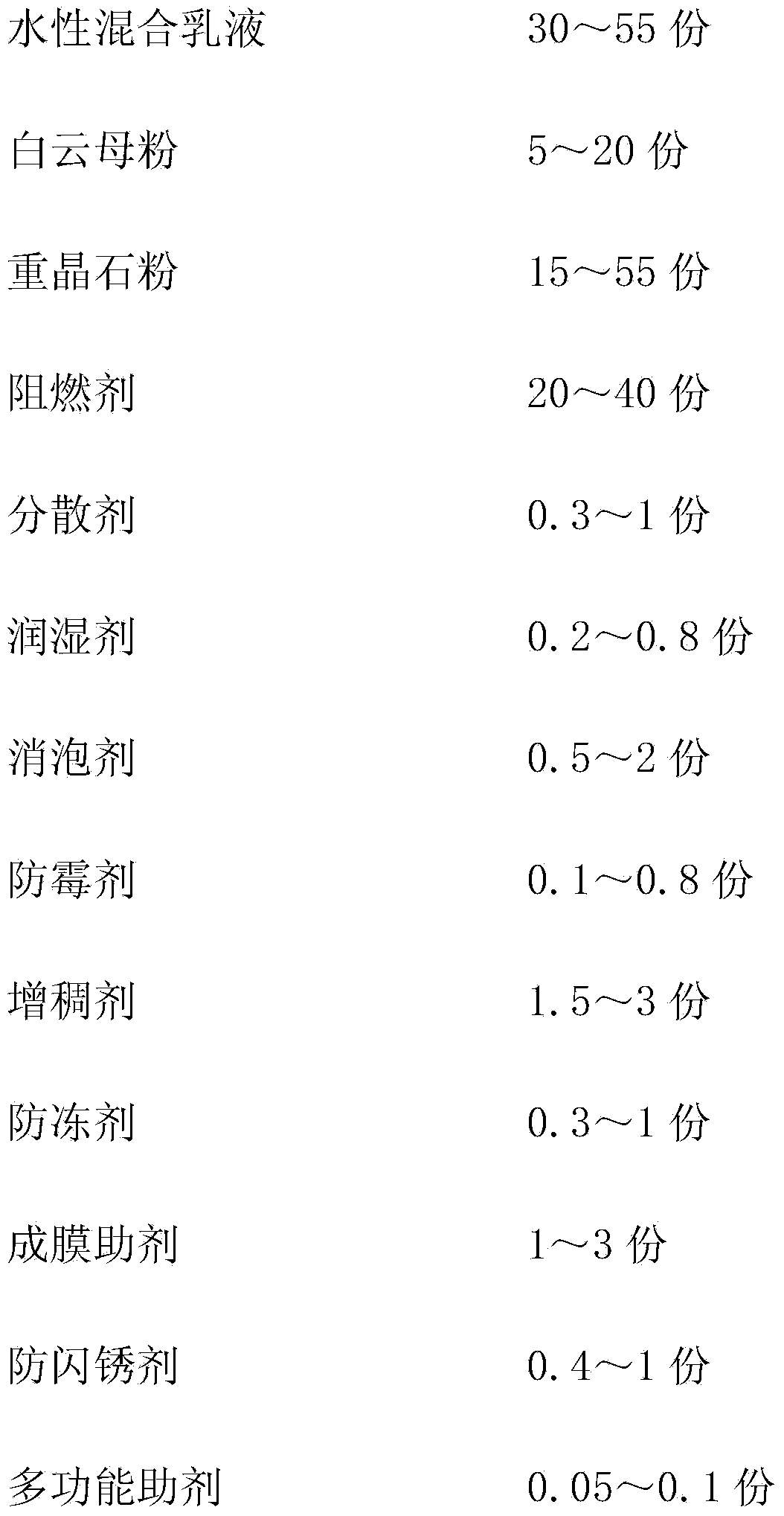

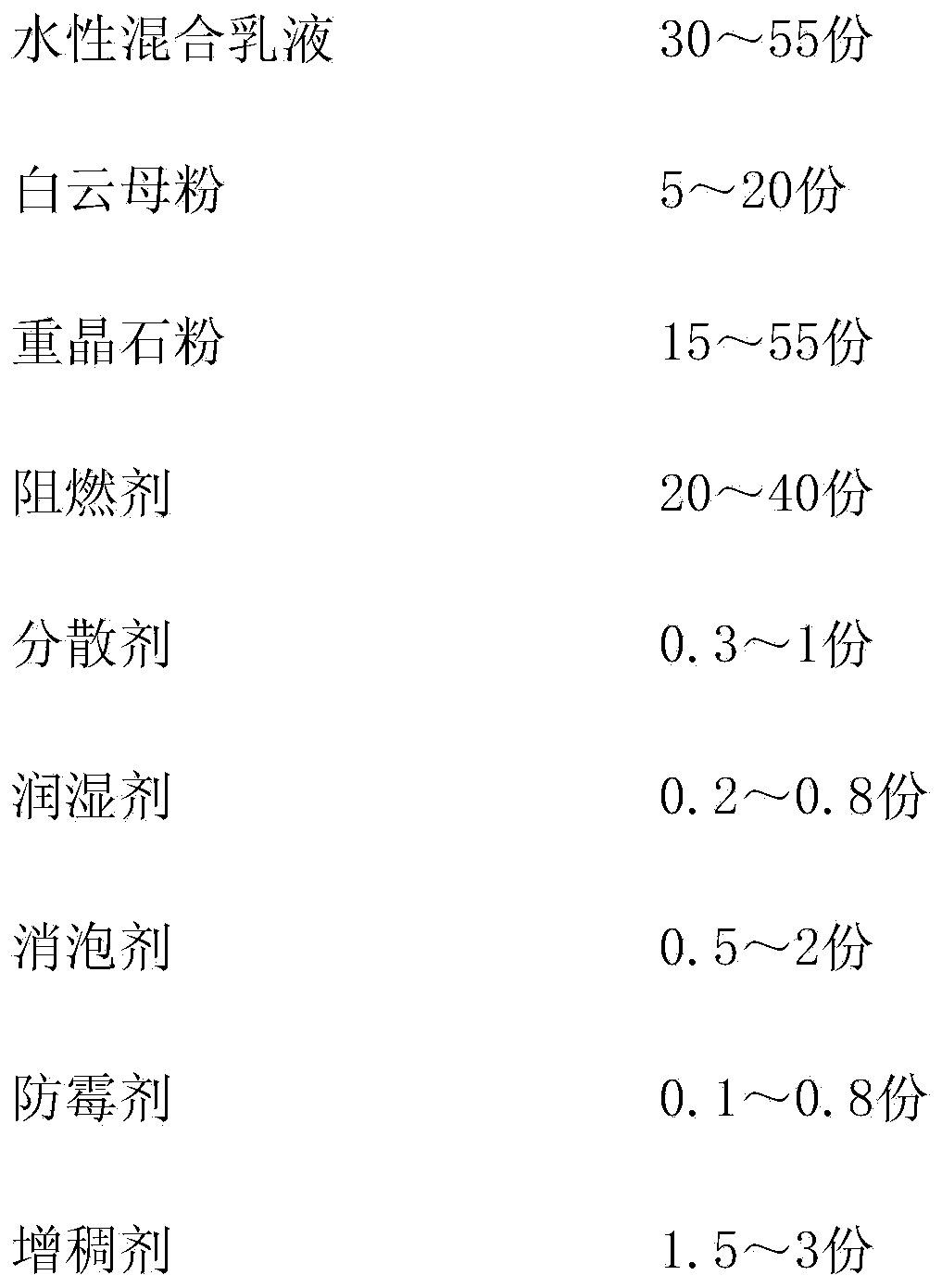

Water-borne sound-insulating damping coating for ship and preparation method thereof

InactiveCN104004418AImproved damping propertiesGood flame retardant performanceAnti-corrosive paintsSteel platesEmulsion

The invention provides a water-borne sound-insulating damping coating for a ship. According to the water-borne sound-insulating damping coating for the ship, water-borne mixed emulsion is used as film forming matter, inorganic filter is used as main filler, and coating aids are added. The water-borne sound-insulating damping coating for the ship mainly comprises, by weight, 30 parts to 55 parts of water-borne styrene-acrylic emulsion which is of an interpenetrated network structure, 30 parts to 60 parts of the inorganic filler and 20 parts to 40 parts of fire retardants. The water-borne sound-insulating damping coating for the ship is prepared by preparing the water-borne mixed emulsion, adding the filler and the aids, and conducting paint mixing, white mica powder is used as functional damping filler, and blanc fixe is used as functional sound-insulating filler. The water-borne sound-insulating damping coating for the ship has the advantages that the recombination loss factor is high, and the sound insulation coefficient is high; the performance of being rapidly dried at normal temperature can be achieved; the adhesive force to a steel plate is high; the fire retardant property is high, and the shipment use requirement is met; the steel plate is free of rust; the workability is high; no hazardous substances exist, and environmental friendliness is achieved.

Owner:太仓市兰燕新材料有限公司

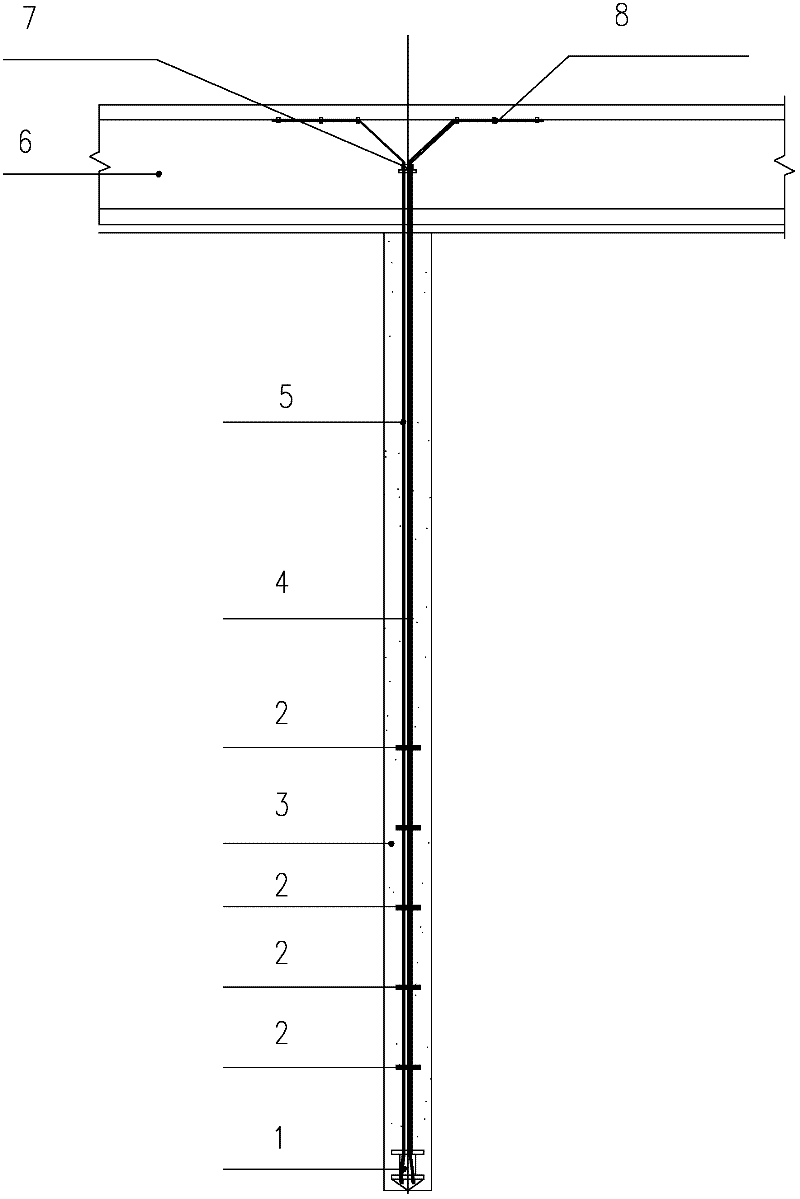

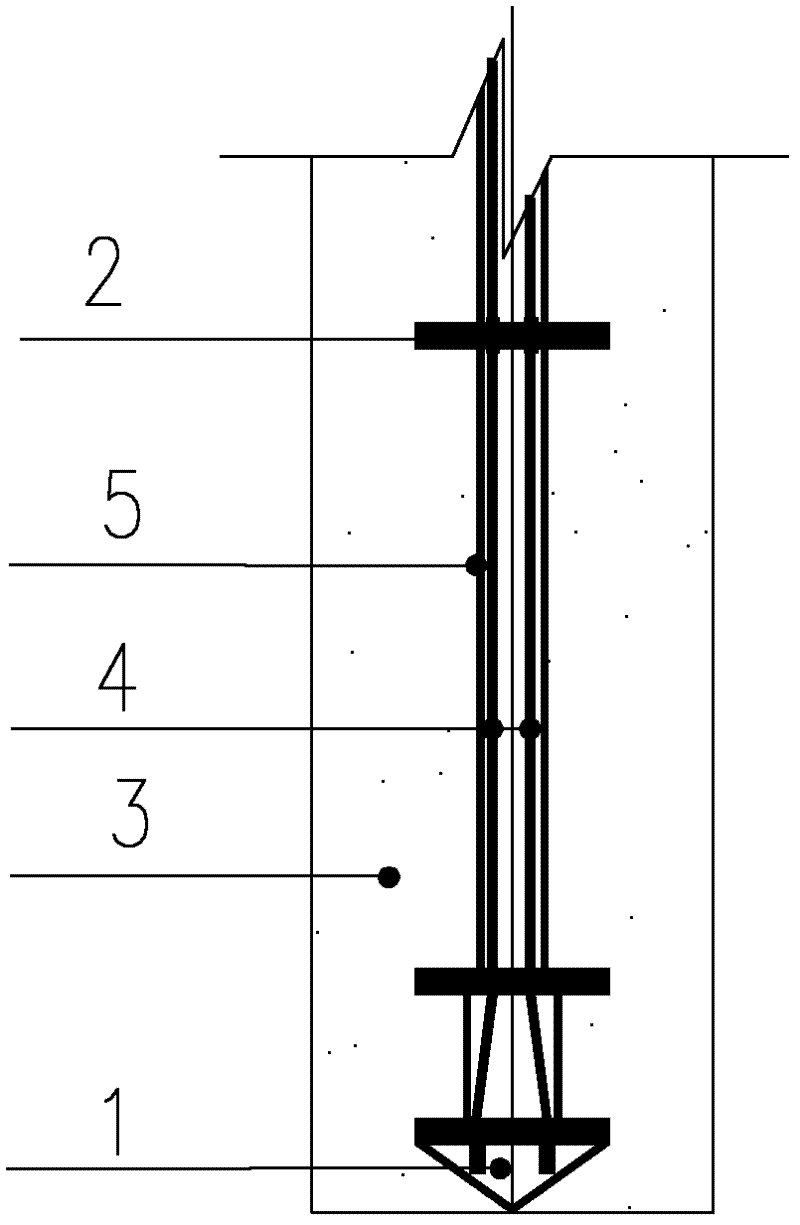

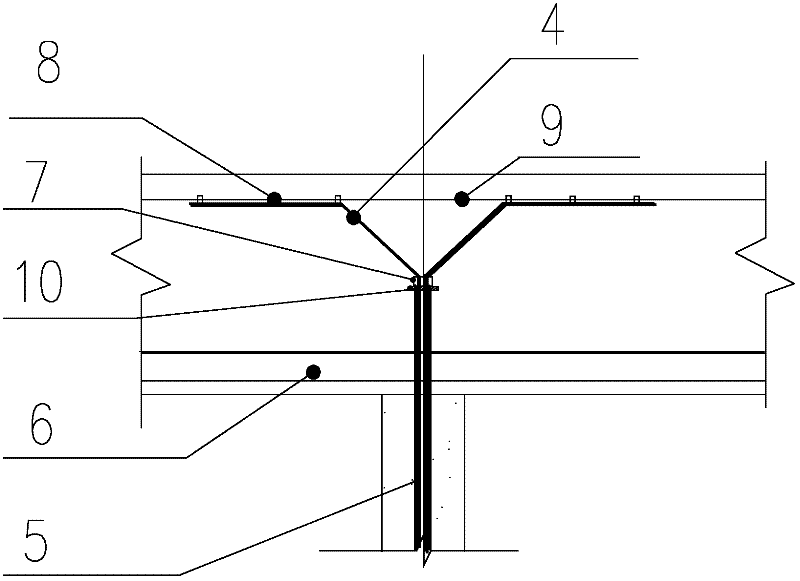

Novel energy-saving anti-floating pile

The invention provides a novel energy-saving anti-floating pile, which comprises a cement pile body. An anti-pulling rib body, a pile tip, anchoring plates and a protective tube are embedded in the pile body, and are connected together; the anti-pulling rib body is connected with a base plate of a structure, and transmits the anti-floating force provided by the anti-floating pile to the base plate of the structure to realize the anti-floating of an underground building. Large anti-floating force can be acquired through large friction force between a large-diameter rotary-jet mixing pile body and foundation soil. The protective tube is adopted to protect the anti-pulling rib body, and the durability of the anti-pulling rib body is greatly improved; and the anti-pulling rib body is made of a high-strength material, so steel can be saved. In addition, the anti-floating rib material is connected with a plurality of anchoring plates, and the binding power between the anti-floating rib material and the rotary-jet mixing pile body is greatly increased, so that several problems of the conventional anti-floating pile are effectively solved, the construction period is effectively shortened,and the engineering cost is reduced.

Owner:SHANGHAI STRONG FOUND ENG

Thick film phosphating method

InactiveCN102534591AHigh film thicknessSmooth surfaceMetallic material coating processesTitaniumPhosphate

The invention discloses a thick film phosphating method. The method comprises the following steps of: removing oil stain on the surface of a workpiece and washing with water; washing the surface subjected to oil stain removal by using acid; washing the workpiece with water; carrying out surface conditioning on the workpiece by using a titanium salt; putting the workpiece subjected to surface conditioning in a phosphating solution for phosphating processing; and washing the workpiece. The workpiece provided by using the thick film phosphating method has higher film forming thickness, smooth and fine surface and no rust after a salt spray test; meanwhile the thick film phosphating method disclosed by the invention has the advantages of short reaction time and strong corrosion resistance, can meet the thickness requirements of different phosphate films, and is suitable for the phosphating requirements of the workpiece with high corrosion and high hardness; and the workpiece can meet the process requirements in a small-scale test and an intermediate-scale test.

Owner:ANHUI QIMING SURFACE TECH

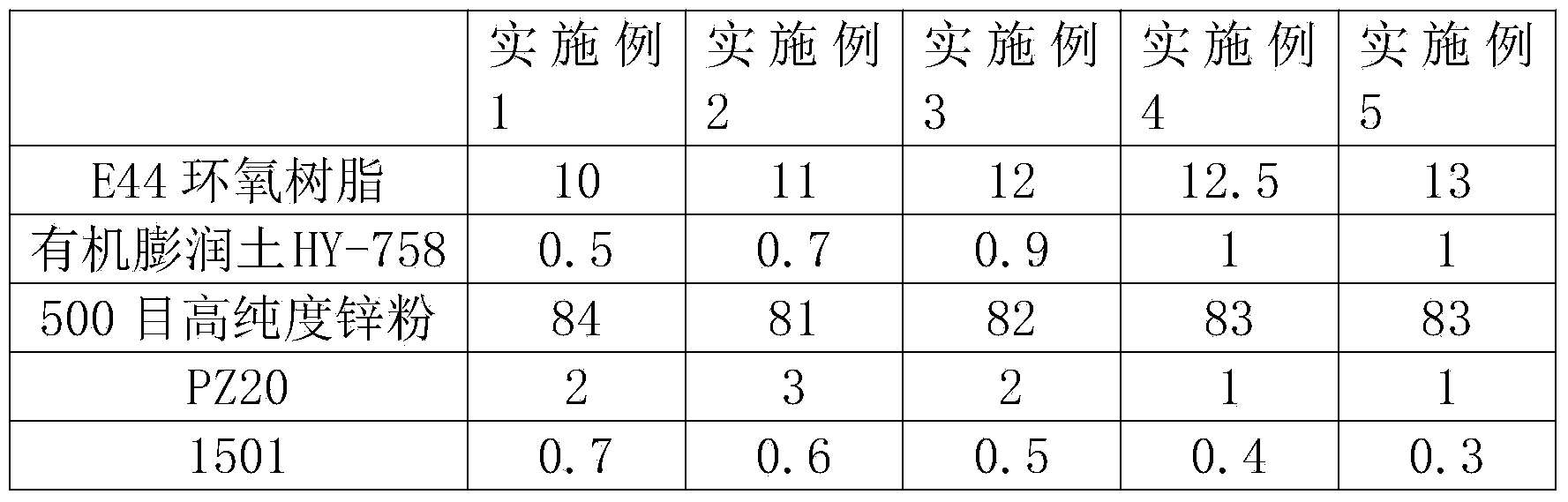

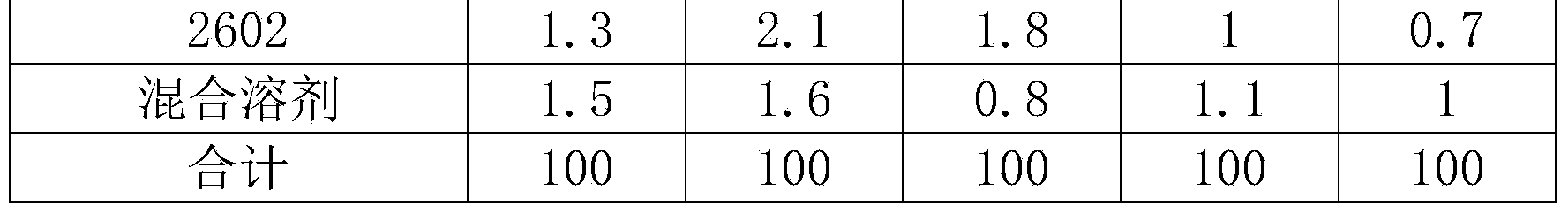

High-specific-weight high-zinc-content heavy-duty epoxy zinc-rich primer and preparation method thereof

InactiveCN104140735ANon-foamingNo rustAnti-corrosive paintsEpoxy resin coatingsZinc phosphateSodium Bentonite

The invention provides a high-specific-weight high-zinc-content heavy-duty epoxy zinc-rich primer. The primer contains a component A and a component B and is characterized in that the component A contains epoxy resin, high-purity zinc powder, environment-friendly zinc phosphate, an assistant A / B, organic bentonite and a mixed solvent; the component B contains cardanol modified polyamide resin, an assistant C and a mixed solvent. The product provided by the invention has the characteristics of salt mist resistance and high specific weight, the solid content reaches 95%, the zinc content reaches 80%, the primer solid proportion reaches 3.0g / ml, and the salt mist resistance can achieve that a primer film is free from bubbling, rusting and peeling for more than 5,000 hours; the product can be extensively applied to the field of metallic heavy-duty products in relatively adverse climates and seaboards, such as bridges, steel structures, ships and petroleum pipelines.

Owner:成都拜迪新材料有限公司

High-temperature-resistant corrosion-resistant coating for engineering machinery tail gas pipe

InactiveCN102190940AImprove toughnessImproved counteracting stressAnti-corrosive paintsEpoxy resin coatingsCorrosion resistantAluminium

The invention discloses a high-temperature-resistant corrosion-resistant coating for an engineering machinery tail gas pipe. The coating comprises the following components in percentage by weight: 55 to 65 percent of organic silicon epoxy resin polymer, 1 to 2 percent of salt mist resistant aid, 6 to 10 percent of copper ferrochrome black, 2 to 5 percent of nano zinc oxide, 6 to 3 percent of flaky mica powder, 7 to 4 percent of aluminium trippolyhosphate, 0.1 to 0.4 percent of leveling agent, 0.2 to 0.6 percent of defoaming agent, 0.2 to 0.6 percent of dispersing agent, 4 to 6 percent of talcpowder and 18.5 to 3.4 percent of dimethylbenzene. The bond strength of the coating to a substrate is obviously improved; high temperature resistance can reach 500 DEG C; the coating can resist salt mist corrosion for 48 to 72 hours; and the coating is still black and is slightly faded after being roasted at the temperature of 500 DEG C for 100 hours. The coating is convenient to construct and operate, has wide material sources, and can be applied to resisting corrosion on the outer surfaces of various kinds of steel structure high-temperature equipment, engineering machinery tail gas pipes and steel structure high-temperature chimneys.

Owner:江苏山力漆业有限公司

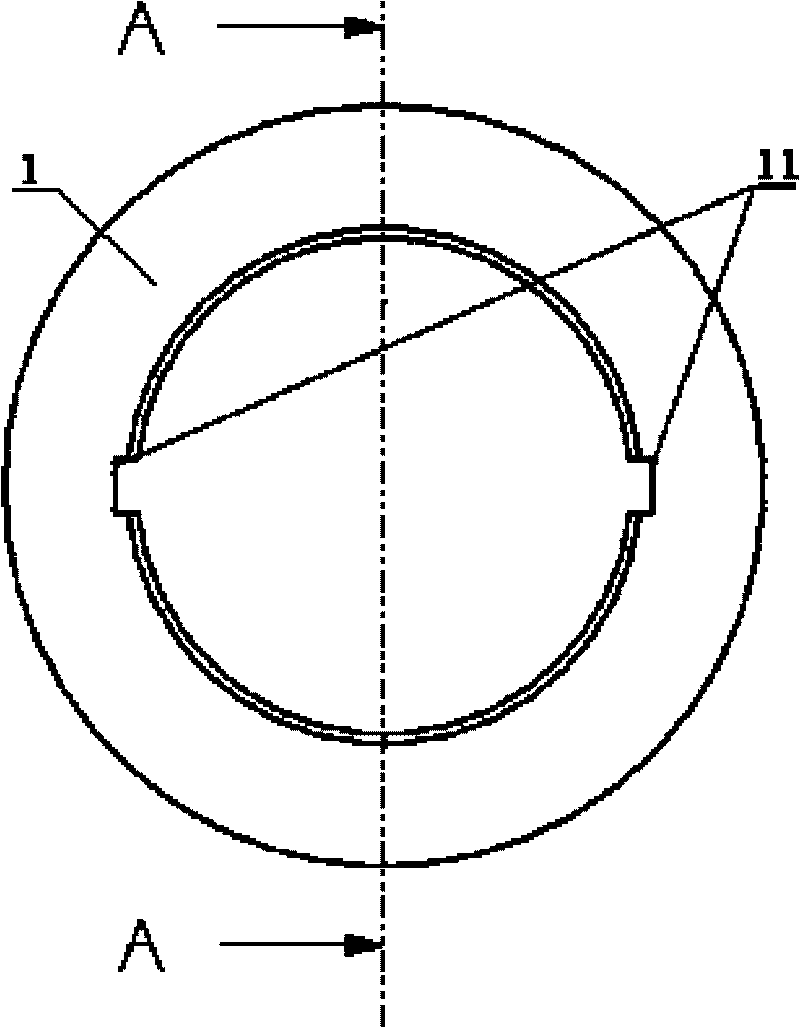

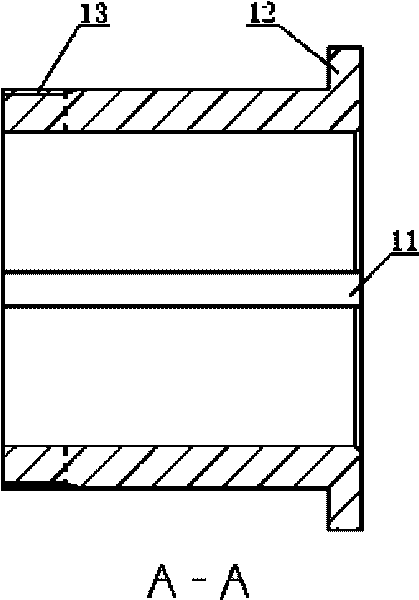

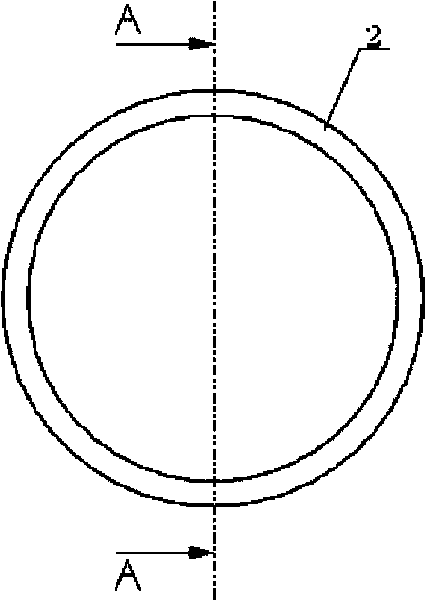

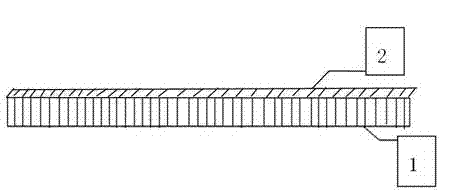

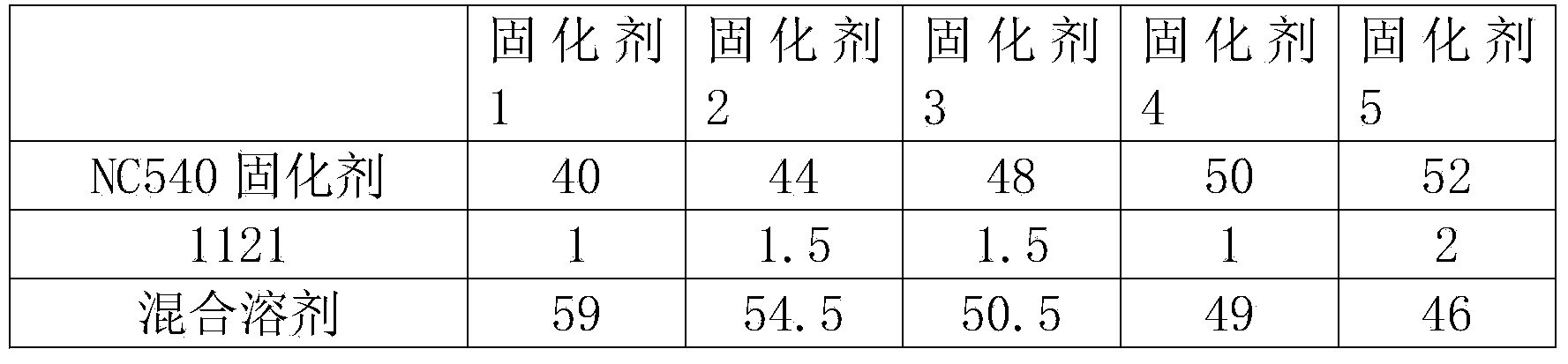

Coaxial cable and production process thereof

InactiveCN102222545AImprove electrical performancePrevent oxidationCoaxial cables/analogue cablesInsulated cablesCoaxial cableElectrical conductor

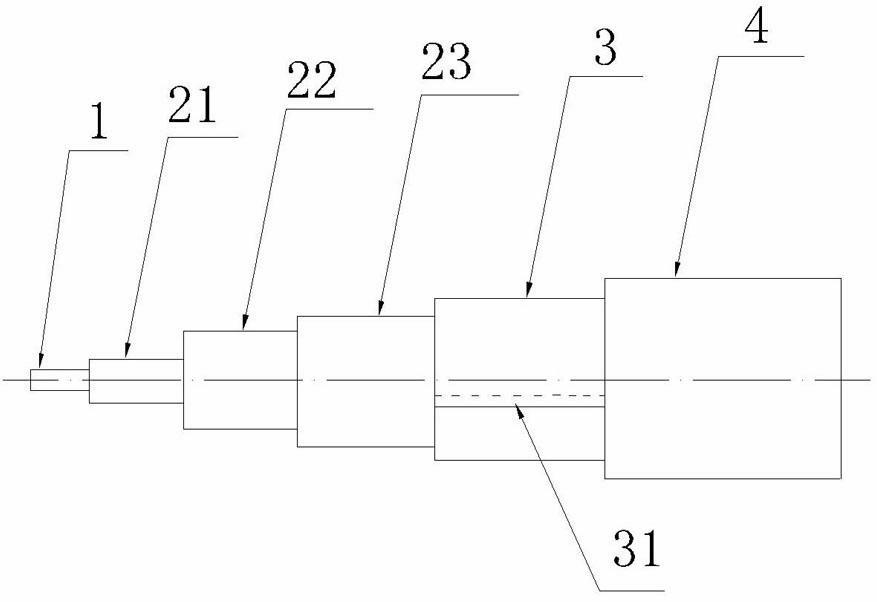

The invention discloses a coaxial cable and a production process thereof, and aims to provide a coaxial cable which is prevented from being damped easily and has stable transmission quality and high electric performance, and a production process thereof. The coaxial cable comprises an inner conductor (1), an outer conductor (3), an outer jacket (4) and a combined insulating layer, wherein the combined insulating layer comprises an inner thin layer (21), a foamed insulating layer (22) and an outer thin layer (23); the inner thin layer (21), the foamed insulating layer (22) and the outer thin layer (23) are sequentially coated at the periphery of the inner conductor (1) from inside to outside; the outer conductor body (3) is arranged at the periphery of the outer thin layer (23); and the outer jacket (4) is coated outside the outer conductor (4). The invention can be widely applied to the fields of coaxial cables and production thereof.

Owner:ZHUHAI YUXUN COAXIAL CABLE

Marine water-based damping coating and preparation method thereof

InactiveCN103897508AMeets flammability requirementsImprove flame retardant performanceCoatingsEmulsionInterpenetrating polymer network

The invention provides a marine water-based damping coating and a preparation method thereof. A water-based styrene-acrylic emulsion with an interpenetrating polymer network structure is used as a film forming matter, mica powder with a laminated structure is used as a filler and coating additives are added. The marine water-based damping coating comprises the following main components in parts by weight: 40-65 parts of water-based mixed emulsion, 35-60 parts of filler and 20-40 parts of flame retardants. The marine water-based damping coating is prepared by mixing water-based emulsions, adding the filler and the additives and mixing the coating. The marine water-based damping coating disclosed by the invention has construction performances, high complex loss factor, strong adhesion to steel plates and good flame retardance, can be quickly dried under normal temperature, can ensure the steel plates not to rust after being applied and is environmentally friendly.

Owner:SHANGHAI UNIV

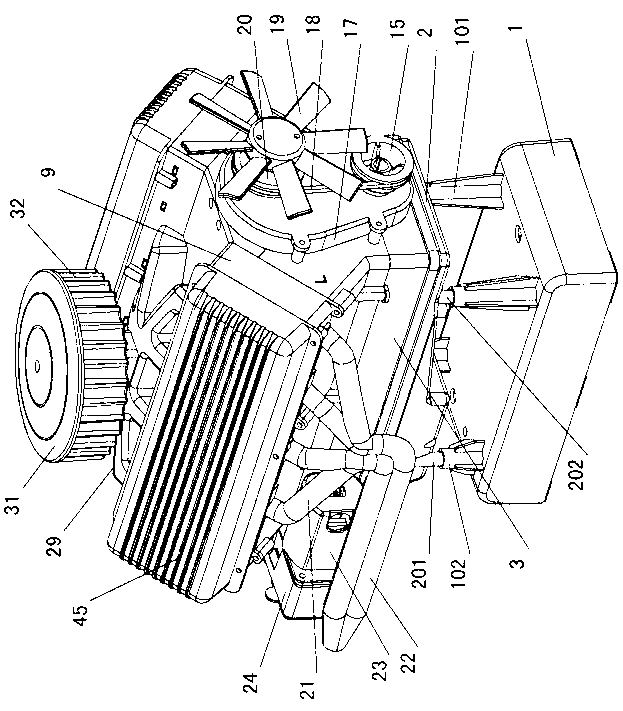

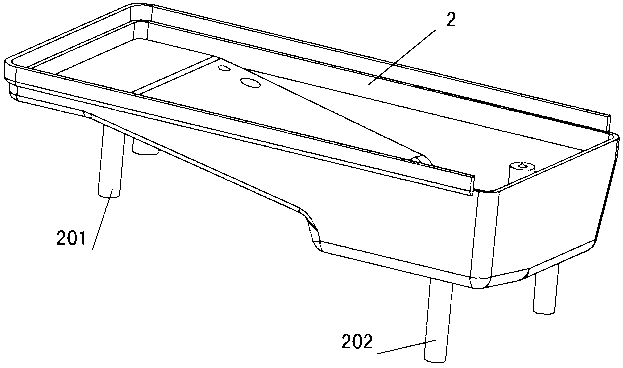

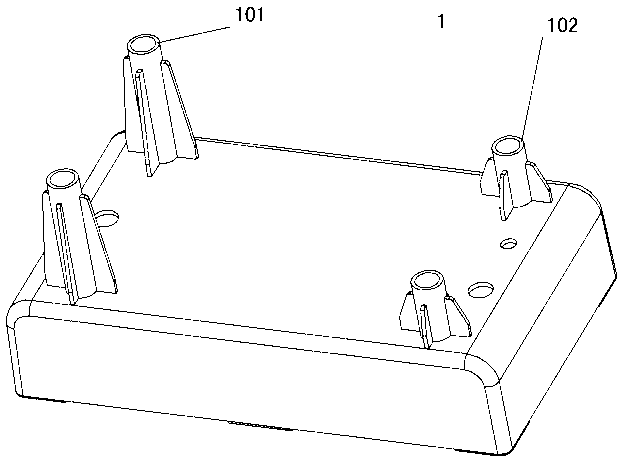

Plastic assembled engine model

The invention relates to a plastic assembled engine model. A V type eight-cylinder automobile engine is taken as a simplified version, the structure is integral, the simulation is strong, an engine mount, a sump panel, a low crankcase, a crankshaft, a connecting rod, a connecting rod head, a piston pin, a piston, a cylinder seat, a cylinder top plate, a cylinder cover, a valve rod, a valve top, a crankshaft gear, a crankshaft belt pulley, a camshaft gear, a cam, a camshaft, a cam-pushed rocker, a rocker arm fixed seat, a rocker sleeve, a rocker arm, a rocker cover, a gear cover, a fan belt pulley, the crankshaft belt pulley, a fan, an exhaust pipe, a lower cover of the exhaust pipe, a gearbox housing, a top cover, a filter, a filter cover and other parts are made of plastic, the processing is labor-saving, the price is low, rust dirt caused by oil can be avoided, and the plastic assembled engine model is clean and sanitary; the working of a transmission mechanism constituted by the crankshaft, the connecting rod, the piston, a cylinder and the like is in line with the requirements of an actual product, so that the plastic assembled engine model is conductive to understanding the engine by trainees and improving mechanical knowledge; and the motor is used for driving the rotation in reverse direction, and the operation is safe and has no danger.

Owner:徐正才

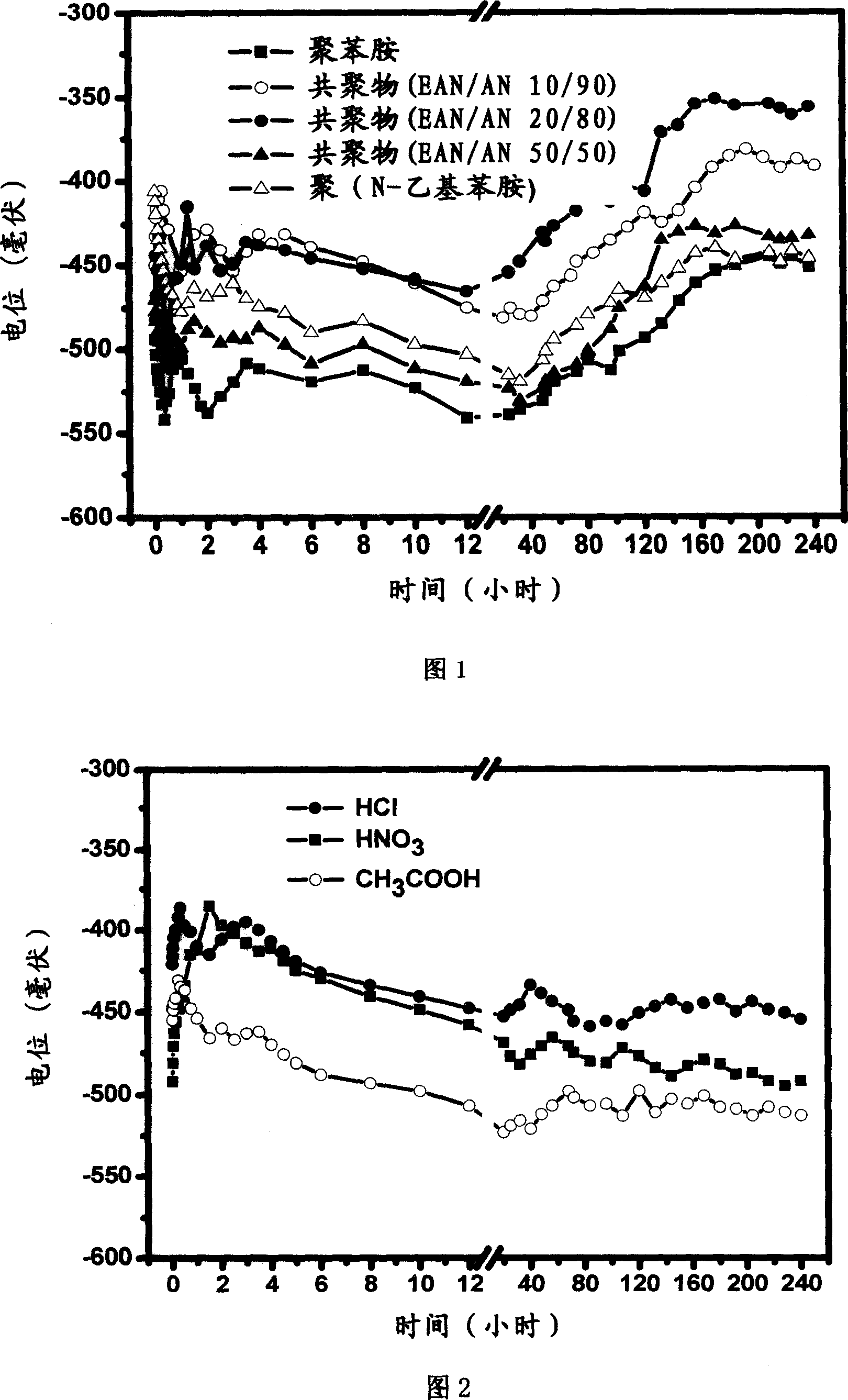

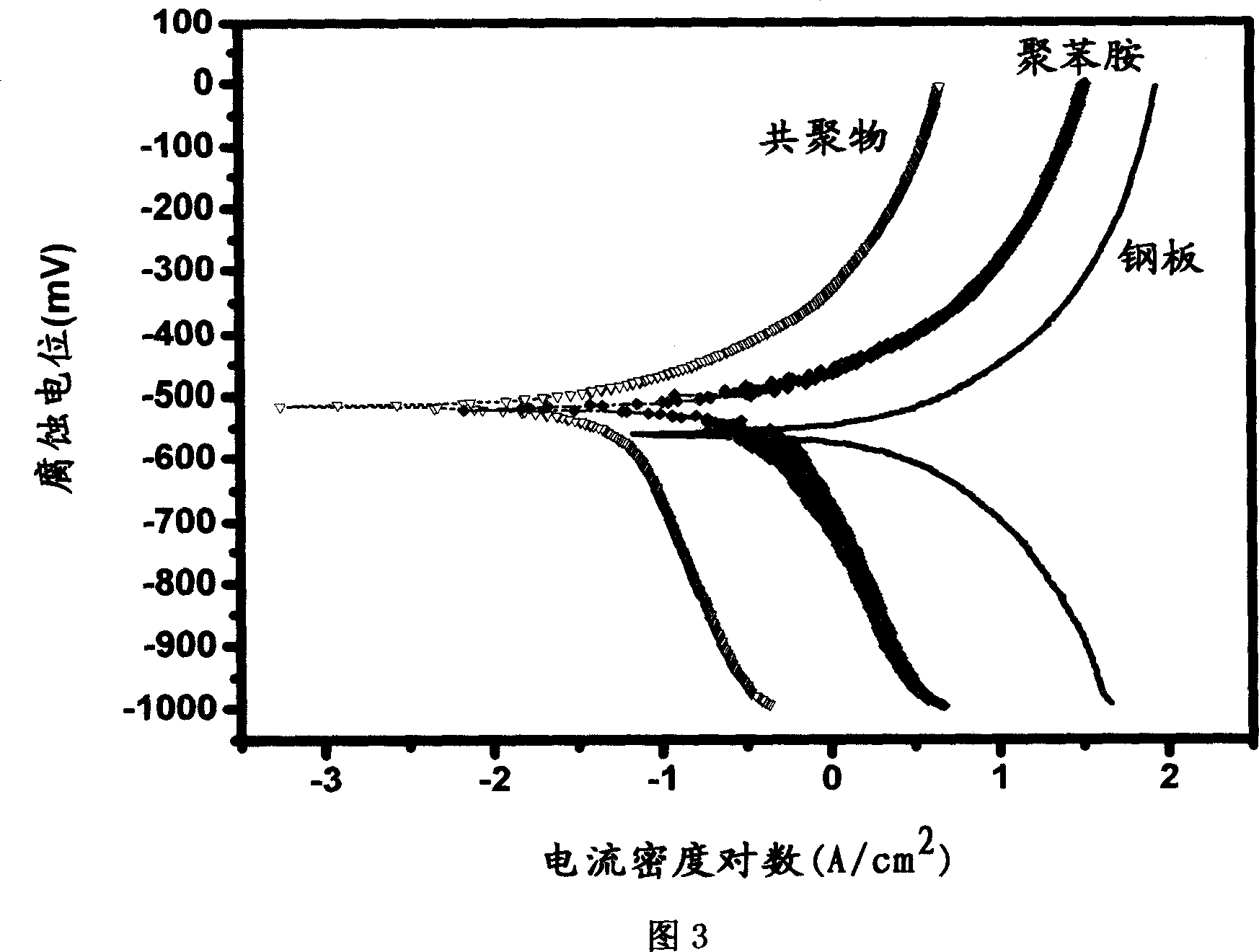

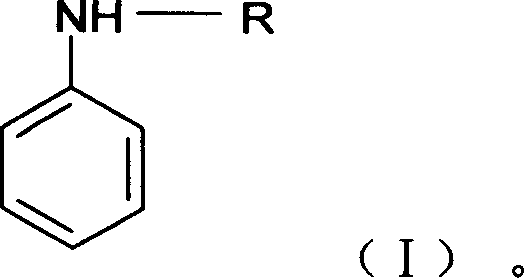

Anticorrosion paint containing aniline copolymer and its preparation and use

InactiveCN101007925AEasy to synthesizeImprove solubilityLiquid surface applicatorsAnti-corrosive paintsSolubilityEpoxy

The invention discloses a high- performance metal corrosion resistant paint and the method for preparing the same. The said aniline polymer- containing corrosion resistant paint is polymer organic solution formed by dissloving copolymer of aniline and N- alkylaniline into proper solvent. The utilization comprises following steps: brushing coating liquid on metal surface, drying, forming polymer coating after solvent volatilization, taking this ploymer coating as corrosion resistant priming coating, then adding epoxy resin coating on it as corrosion resistant surface coating. The invention is characterized in that it polymerizes aniline and N- alkylaniline and gets conductive corrosion resistant coating with better dissloving performance than polyaniline, and the adhesion force to steel plate is greatly increased and the corrosion resistant performance is aslo dramatically improved.

Owner:TONGJI UNIV

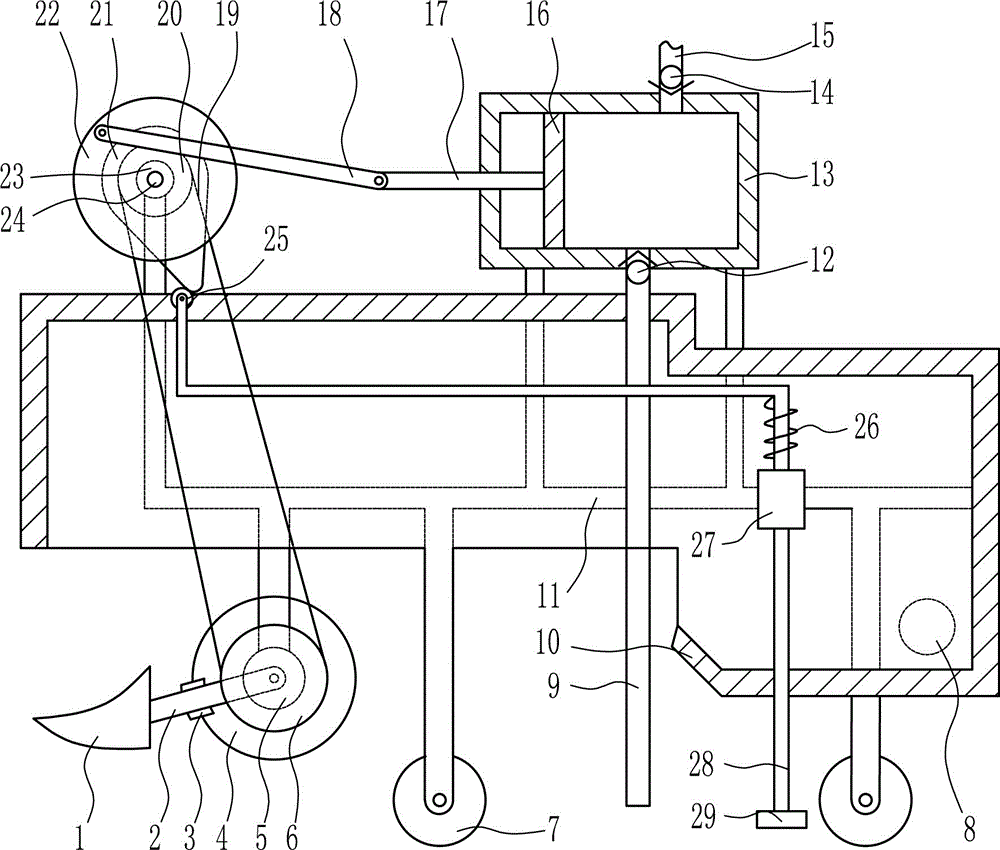

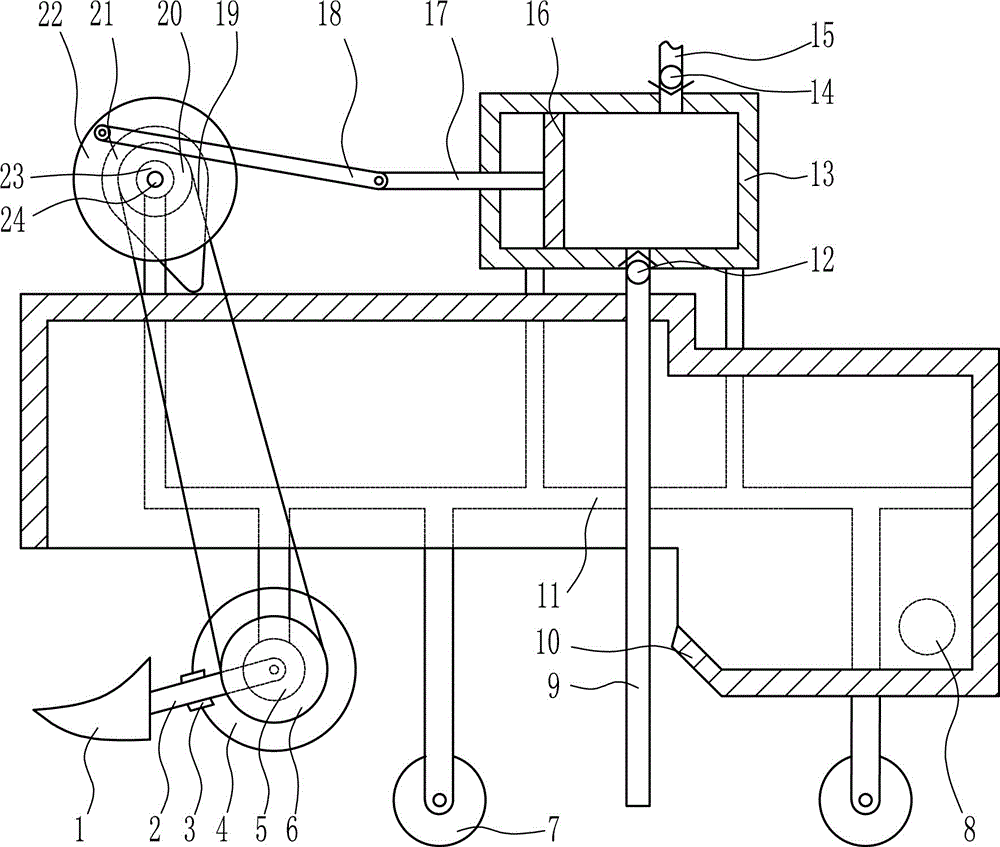

High-efficiency ditching drainage device for farmland

ActiveCN106759176AAvoid oxidation, rust and corrosionEasy to useConstructionsSoil drainageEngineeringPulley

The invention relates to a ditching drainage device, in particular to a high-efficiency ditching drainage device for farmland and aims at achieving the technical purpose of providing the high-efficiency ditching drainage device for the farmland, wherein during ditching, dug soil will not fill a ditched furrow again, a large amount of accumulated water will not be left in the ditched furrow, and as the bottom of the ditched furrow is smooth, the situation that the water in the furrow cannot be drained easily in rainy days is avoided. To achieve the technical purpose, the high-efficiency ditching drainage device for the farmland is provided and comprises a ditching spoon, a first connecting rod, an annular sliding block, a round sliding rail, a motor, a first belt pulley, wheels, a liquid inlet pipe, a conveying box, a vehicle plate, a first one-way valve and the like. The conveying box is arranged on the front side of the vehicle plate. The high-efficiency ditching drainage device for the farmland achieves the effects that during ditching, dug soil will not fill the ditched furrow again, a large amount of accumulated water will not be left in the ditched furrow, and as the bottom of the ditched furrow is smooth, the situation that the water in the furrow cannot be drained easily in rainy days is avoided.

Owner:徐州市宝盛新田农业机械有限公司

Steel bar anti-rust treating liquid and treating method

InactiveCN101660151ANo expiration dateEasy to useMetallic material coating processesAtmospheric airAluminium hydroxide

The invention provides a steel bar anti-rust treating liquid and a treating method, wherein the steel bar anti-rust treating liquid is prepared by the following steps of: adding 50 to 100g of aluminium hydroxide, 3 to 5g of zinc oxide, 3 to 5g of nickel oxide or / and chromic oxide or / and manganese oxide in every 1L of phosphoric acid, raising temperature, heating the mixed solution to 250 to 300 DEG C, leading fixed raw materials to be mixed and dissolved in phosphoric acid, cooling to room temperature, adding water for dilution according to volume ratio of 1:10 to 20 and obtaining the steel bar anti-rust treating liquid without toxicity and odor and invalid period. The invention has convenient use and good anti-rust effect, also is economical, delays the phenomenon that the surface of thehot rolled ribbed steel bar is rusted under the atmosphere to a greater extent, namely can not be rusted by wind-blowing, raining and sun-drying for more than two months under the atmosphere, does nothave influence to the mechanical performance and welding performance of the steel bar, and fundamentally solves the problems that the existing hot rolled ribbed steel bar is rusted seriously so as tohave influence on the bearing capability and durability and the like of the steel bar concrete members.

Owner:WUKUN STEEL

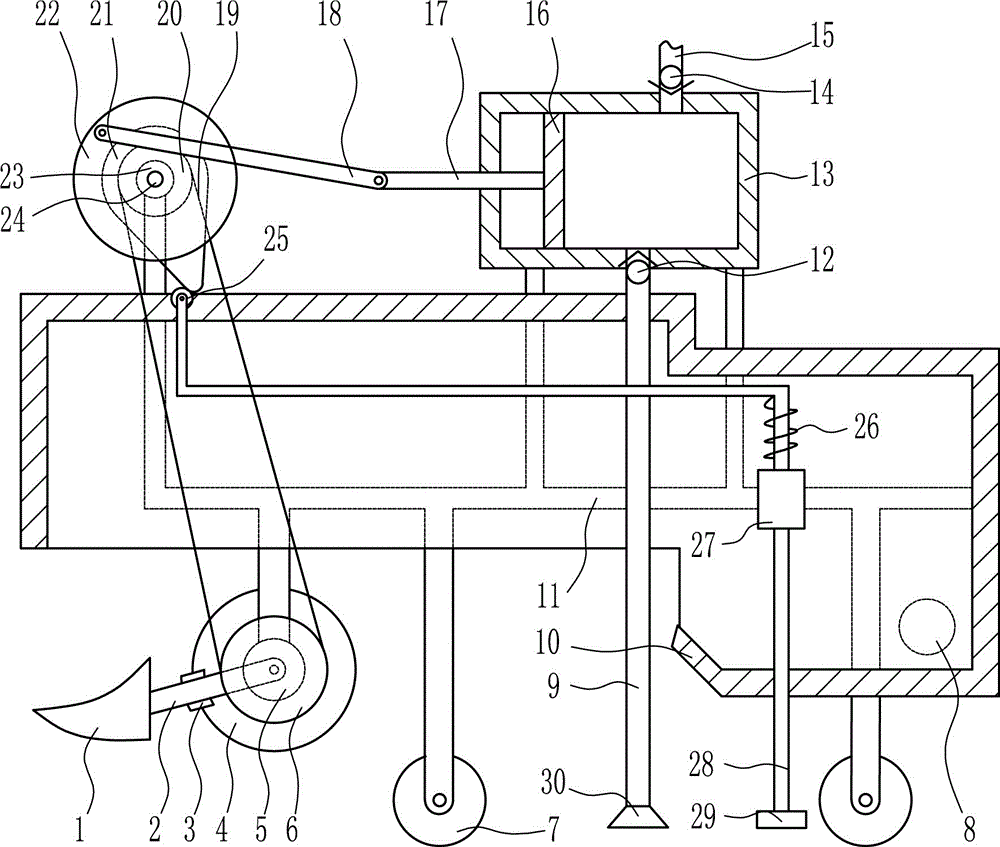

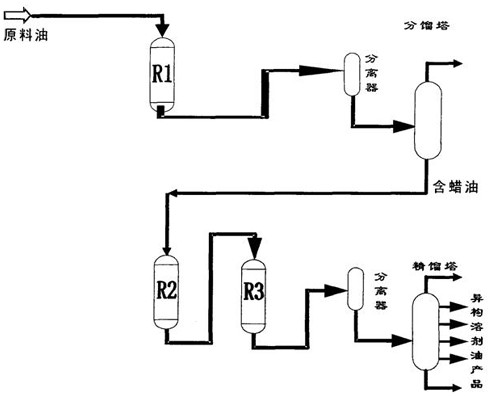

High-performance volatile fin punching oil and preparation method thereof

PendingCN112048359AStrong emulsificationGood emulsifying effectLubricant compositionAlkaneActive agent

The invention relates to high-performance volatile fin punching oil, which consists of isoparaffin base oil, a surfactant, an acid trapping agent, an oiliness agent, an extreme pressure anti-wear agent, a defoaming agent and an antirust agent. The invention further provides a preparation method of the fin stamping oil. According to the invention, the excellent lubricity of the fin during processing is ensured, the fin has a certain flash point, the safety of the fin is ensured, and a processed part can be completely volatilized at room temperature within a short time without being heated and baked, so that no residue is left. The high-performance volatile fin punching oil does not contain water, chlorine, sulfur and other corrosives, and does not corrode or rust various metal materials. The pH value of the working solution prepared from isoparaffin is 6.5-7.0, and the product waste liquid is also neutral, does not cause anaphylactic reaction to skin, does not generate acidification reaction, does not have heavy metal ions, has good biodegradability and completely meets the environmental protection requirements.

Owner:上海中孚油品集团有限公司

Diffusion zincizing coating method

InactiveCN103668043APrevent oxidationStabilized Zinc SourceSolid state diffusion coatingPre treatmentZinc

The invention relates to a diffusion zincizing coating method and belongs to the technical field of surface coating techniques of steel materials. The method comprises the steps of precoating the surface of a steel product with a zinc deposition layer according to a traditional mechanical zinc coating method, burying the steel product in anti-oxidation filling and putting in a diffusion coating furnace or an incubator, or applying an anti-oxidation coating on a workpiece with a pre-coated zinc layer, drying and putting in the diffusion coating furnace or the incubator for heat preservation, and allowing zinc iron atoms to diffuse mutually to form a diffusion zincizing layer with a zinc-iron alloy structure. With the adoption of the method, diffusion zincizing uncoating caused by pretreatment and reoxidation can be avoided basically, the quality of the diffusion zincizing layer is ensured, and the yield of a product is greatly improved.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com