Reinforced bar glass fiber resin concrete pipe and producing method thereof

A glass fiber resin and concrete pipe technology, applied to chemical instruments and methods, pipes, rigid pipes, etc., can solve the problems of high use cost, polluted water quality, long cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

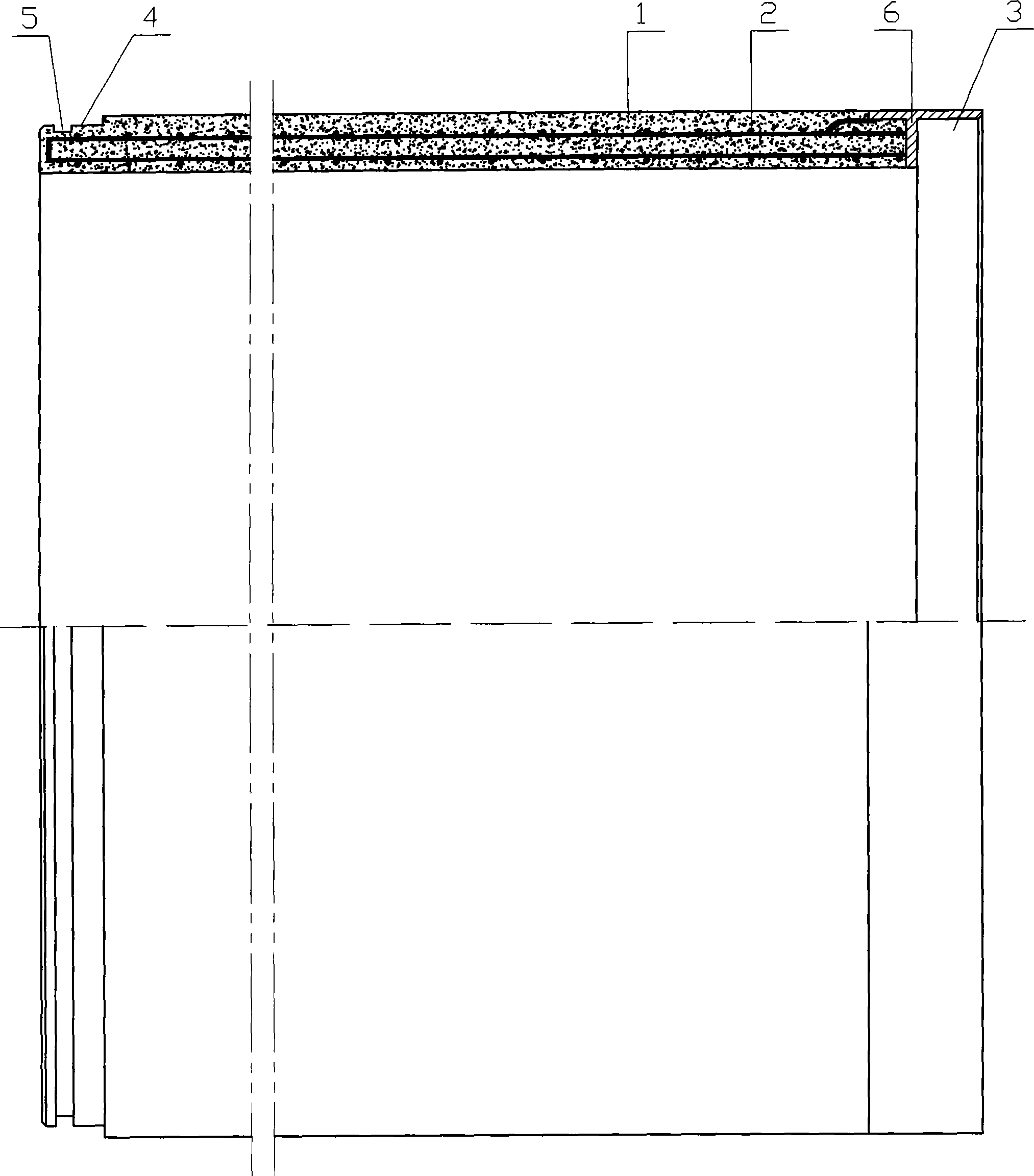

Image

Examples

Embodiment 1

[0020] The production methods of reinforced glass fiber resin concrete pipes are as follows:

[0021] (1), steel mesh production: according to the size of the reinforced glass fiber resin concrete pipe, make the steel mesh 2 poured in the pipe wall of the reinforced glass fiber resin concrete pipe into a round tubular steel mesh 2 with steel bars, and one end of the steel mesh 2 is welded with a T shape A steel sleeve 3 made of steel 6 circles;

[0022] (2), mould-loading: the circular tubular steel mesh 2 is put into the tubular mould, which is composed of an inner mold and an outer mold;

[0023] (3), batching: batching by weight percentage: glass fiber 4%, model is TM-196SP edible grade unsaturated polyester resin 23%, accelerator 1%, epoxy resin curing agent 2% and quartz sand 70%;

[0024] (4) Mixing material: Stir unsaturated polyester resin, epoxy resin curing agent and accelerator together to form a resin mixture according to the above formula, add quartz sand and gla...

Embodiment 2

[0031] The production methods of reinforced glass fiber resin concrete pipes are as follows:

[0032] (1), steel mesh production: according to the size of the reinforced glass fiber resin concrete pipe, make the steel mesh 2 poured in the pipe wall of the reinforced glass fiber resin concrete pipe into a round tubular steel mesh 2 with steel bars, and one end of the steel mesh 2 is welded with a T shape A steel sleeve 3 made of steel 6 circles;

[0033] (2), mould-loading: the circular tubular steel mesh 2 is put into the tubular mould, which is composed of an inner mold and an outer mold;

[0034] (3), batching: batching by weight percentage: glass fiber 6%, model is 10% of unsaturated polyester resin of 192#, accelerator 0.8%, epoxy resin curing agent 1.2% and quartz sand 82%;

[0035] (4) Mixing material: Stir unsaturated polyester resin, epoxy resin curing agent and accelerator together to form a resin mixture according to the above formula, add quartz sand and glass fibe...

Embodiment 3

[0041] The production methods of reinforced glass fiber resin concrete pipes are as follows:

[0042] (1), steel mesh production: according to the size of the reinforced glass fiber resin concrete pipe, make the steel mesh 2 poured in the pipe wall of the reinforced glass fiber resin concrete pipe into a round tubular steel mesh 2 with steel bars, and one end of the steel mesh 2 is welded with a T shape A steel sleeve 3 made of steel 6 circles;

[0043] (2), mould-loading: the circular tubular steel mesh 2 is put into the tubular mould, which is composed of an inner mold and an outer mold;

[0044] (3), batching: batching by weight percentage: glass fiber 8%, model is 12% of unsaturated polyester resin of 192#, accelerator 1.5%, epoxy resin curing agent 2.5% and quartz sand 76%;

[0045] (4) Mixing material: Stir unsaturated polyester resin, epoxy resin curing agent and accelerator together to form a resin mixture according to the above formula, add quartz sand and glass fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com