Graphene electric-conduction concrete

A technology of conductive concrete and graphene, which is applied in the field of concrete materials, can solve the problems that conductive concrete cannot balance mechanics and conductivity, performance requirements, and poor durability, and achieve the effects of good durability, good conductivity, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described in conjunction with the following examples.

[0017] The graphene conductive concrete of the present embodiment includes Portland cement and sand, and graphene is added as a conductive phase to form graphene conductive concrete. The percentage of each component relative to the total mass of Portland cement and sand is: graphene 0.05~ 3. 0.5-6 for graphene dispersant, 0-0.75 for concrete superplasticizer.

[0018] Wherein, the graphene is a few-layer graphene oxide powder, and the parameters of the graphene are: the purity is greater than 95wt%, the thickness range is 1.0-1.77nm, the sheet diameter range is 10-50um, and the layer number range is 1-5. The specific surface area is 360-450m2 / g.

[0019] The Portland cement in this embodiment is 42.5 ordinary Portland cement.

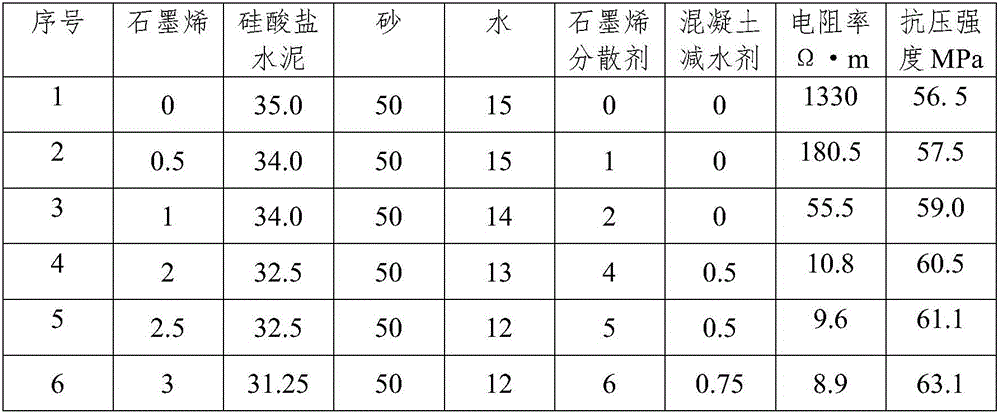

[0020] Referring to Table 1, the raw materials and proportions of graphene conductive concrete and the corresponding resistivity and compressive strength a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com