Coaxial cable and production process thereof

A coaxial cable and inner conductor technology, applied in the direction of coaxial cable/analog cable, insulated cable, conductor/cable insulation, etc., can solve the problem of poor stability and reliability of the transmission line, serious longitudinal scratches on the surface, stability and reliability Poor performance and other problems, to achieve the effect of strong resistance to external electromagnetic interference, good insulation performance, and stable electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

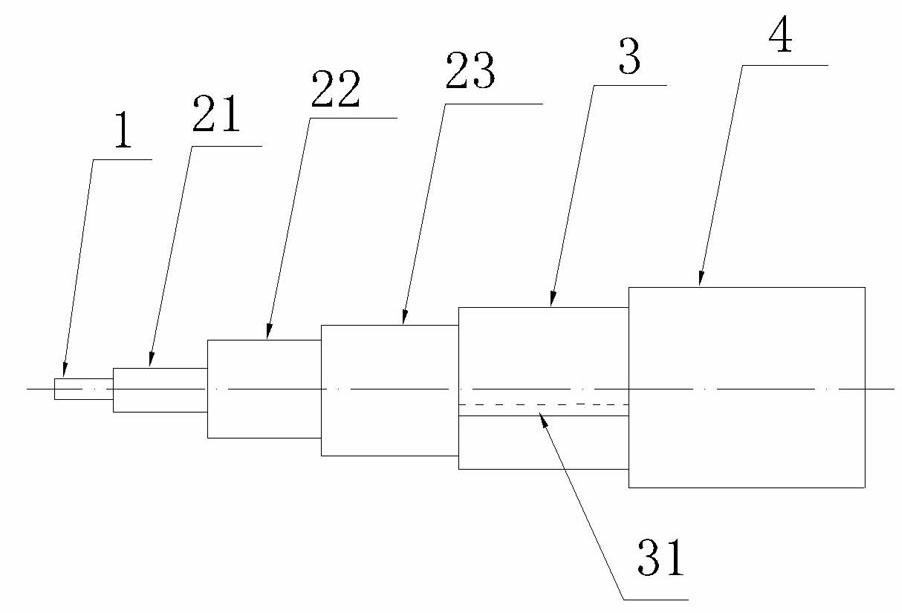

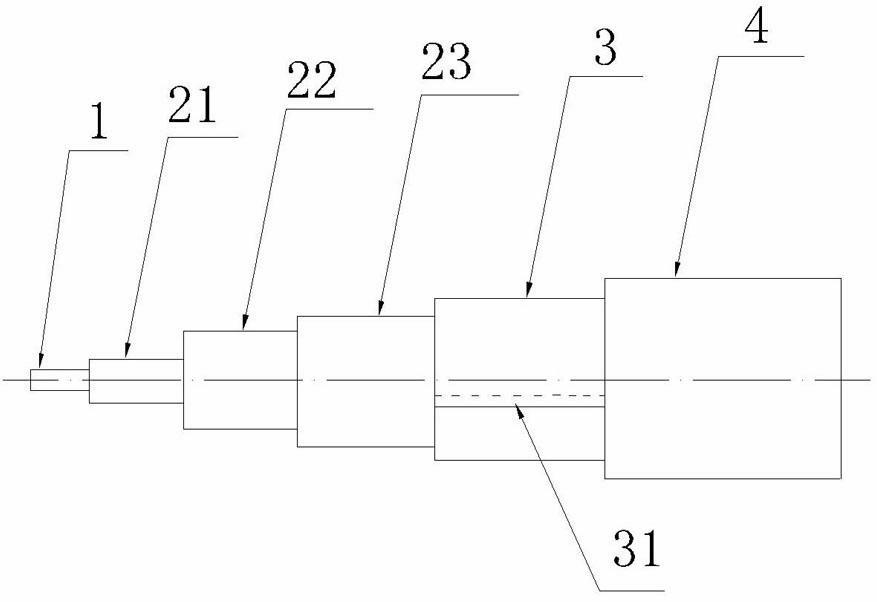

[0024] Such as figure 1 As shown, the coaxial cable of the present invention includes an inner conductor 1, an outer conductor 3, and an outer sheath 4. The coaxial cable further includes a combined insulation layer, and the combined insulation layer includes an inner thin layer. 21. The foamed insulating layer 22, the outer thin layer 23, the inner thin layer 21, the foamed insulating layer 22, and the outer thin layer 23 are sequentially wrapped around the periphery of the inner conductor 1 from the inside to the outside, and the outer layer body 3 is arranged on the periphery of the outer thin layer 23, the outer sheath 4 is wrapped around the outer conductor 3, and the inner thin layer 21, the foamed insulating layer 22 and the outer thin layer 23 are bonded as Integrally form a combined insulating layer. The inner thin layer 21 is bonded to the inner conductor 1 but can be peeled off. This combined structure prevents the inner conductor 1 and the inner thin layer 21 from b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com