Patents

Literature

200 results about "Skin agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating and excipient agent for oral or dermal dosage forms

InactiveUS6624210B1Good effectQuick releaseSuppositories deliveryNon-macromolecular organic additionMeth-Excipient

The invention relates to a method for the production of a coating and excipient agent for oral or dermal dosage forms, consisting of (a) 35-98% by weight of a copolymer consisting of radically polymerized C1-C4 esters of acrylic or methacrylic acid and additional (meth)acrylate monomers having functional tertiary ammonium groups and (b) 1-50% by weight of a softener and 1-15% by weight of an emulgator with an HLB value of less than 14, wherein constituents (a), (b) and (c) are mixed with or without adding water and optionally adding a pharmaceutical active substance and other conventional additives and the coating and excipient agent is produced by melting, casting, spreading or spraying. The invention is characterized in that the copolymer (a) is applied in powder form with a mean particle size of 1-40 mum.

Owner:EVONIK ROEHM GMBH

Hard wax oil and preparation method thereof

ActiveCN101974292AGood weather resistanceImprove UV absorption performanceWax coatingsRosin coatingsVegetable oilUltraviolet

The invention provides hard wax oil prepared from the following components in parts by weight: 40-80 parts of vegetable oil, 3-15 parts of biological wax, 5-15 parts of rosin glycerol resin, 0.2-1.0 part of drier, 0.1-0.5 part of anti-skinning agent, 0.1-0.3 part of mixed UV (Ultra-Violet) absorber and 0.1-0.3 part of defoaming agent. The preparation method of the hard wax oil, which is provided by the invention, comprises the steps of generating bodied oil with relatively smaller molecular weight under the action of nitrogen protection and adding an oil-based UV absorber with synergy and a hindered amine light stabilizer, and thus the UV absorption performance of the hard wax oil is improved. The prepared hard wax oil is suitable for outdoor woodenware products, has good weatherability, favorable water resistance and ideal durability effect under the condition that sunlight and UV rays exist, and the hard wax oil hardly sags and has tough firm formed in coating construction, belongs to natural coatings, accords with the environmental protection requirement and can be also used for decorating private indoor rooms.

Owner:CARPOLY CHEM GRP

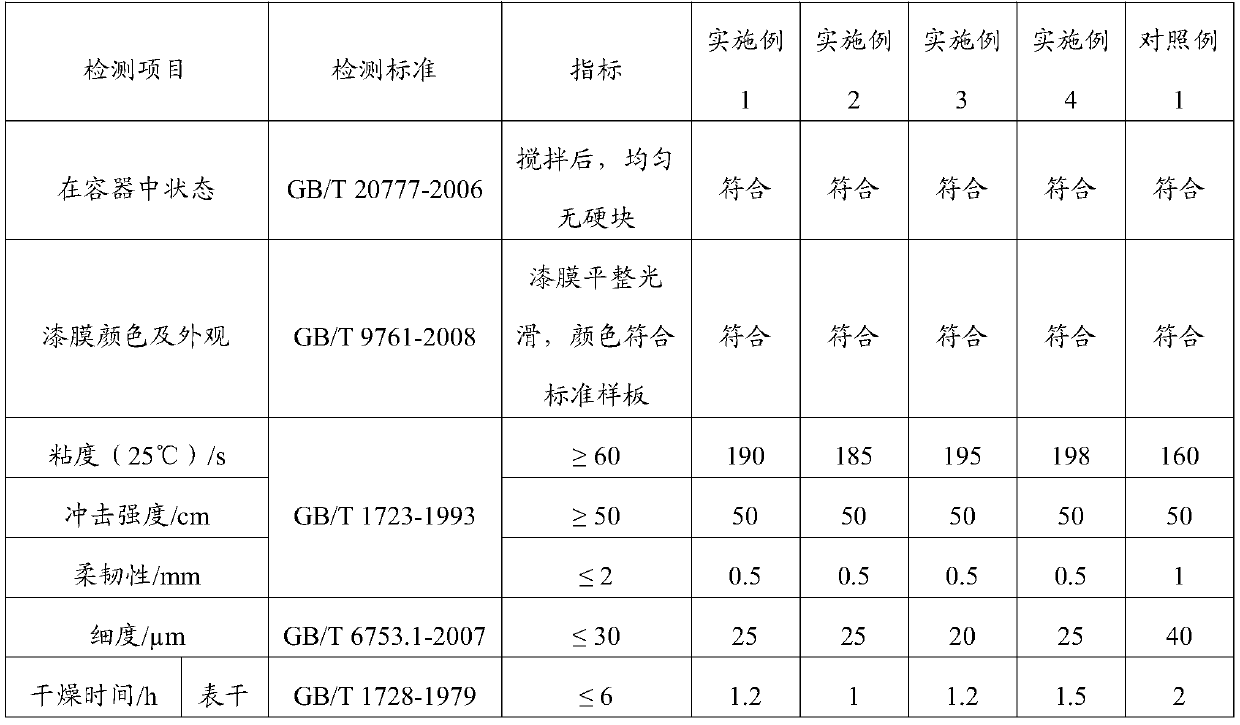

Quick-dry type acrylic modified alkyd paint and preparation method thereof

The invention relates to quick-dry type acrylic modified alkyd paint which is characterized by comprising the following components in parts by weight: 35-65 parts of acrylic modified alkyd resin, 15-25 parts of pigment, 10-25 parts of filling, 0.5-2.0 parts of anti-settling agent, 0.3-1.0 part of dispersant, 0.3-0.6 part of flatting agent, 0.3-0.6 part of antifoaming agent, 2-5 parts of drier, 0.1-0.3 part of anti skinning agent, 10-20 parts of heavy aromatic, 10-20 parts of xylene and 5-15 parts of prime city naphtha. The preparation method comprises the following steps of: adding the front four raw materials of the acrylic modified alkyd resin, and the like into a burdening pot; evenly stirring a mixture, dispersing the mixture for 20 minutes at high speed; grinding the mixture in a sand grinder into fineness of 30micron; filling pigment paste into a paint mixing tank; adding the last seven raw materials; evenly stirring; and filtering. The invention has the beneficial effects that various colors of acrylic modified alkyd paint is prepared by using the acrylic modified alkyd resin as a base material; and a paint film is quickly dried, and has the characteristics of good light retention property, weather resistance and recoatability, high decoration performance, and greatly improved comprehensive physical and chemical properties.

Owner:天津灯塔涂料工业发展有限公司

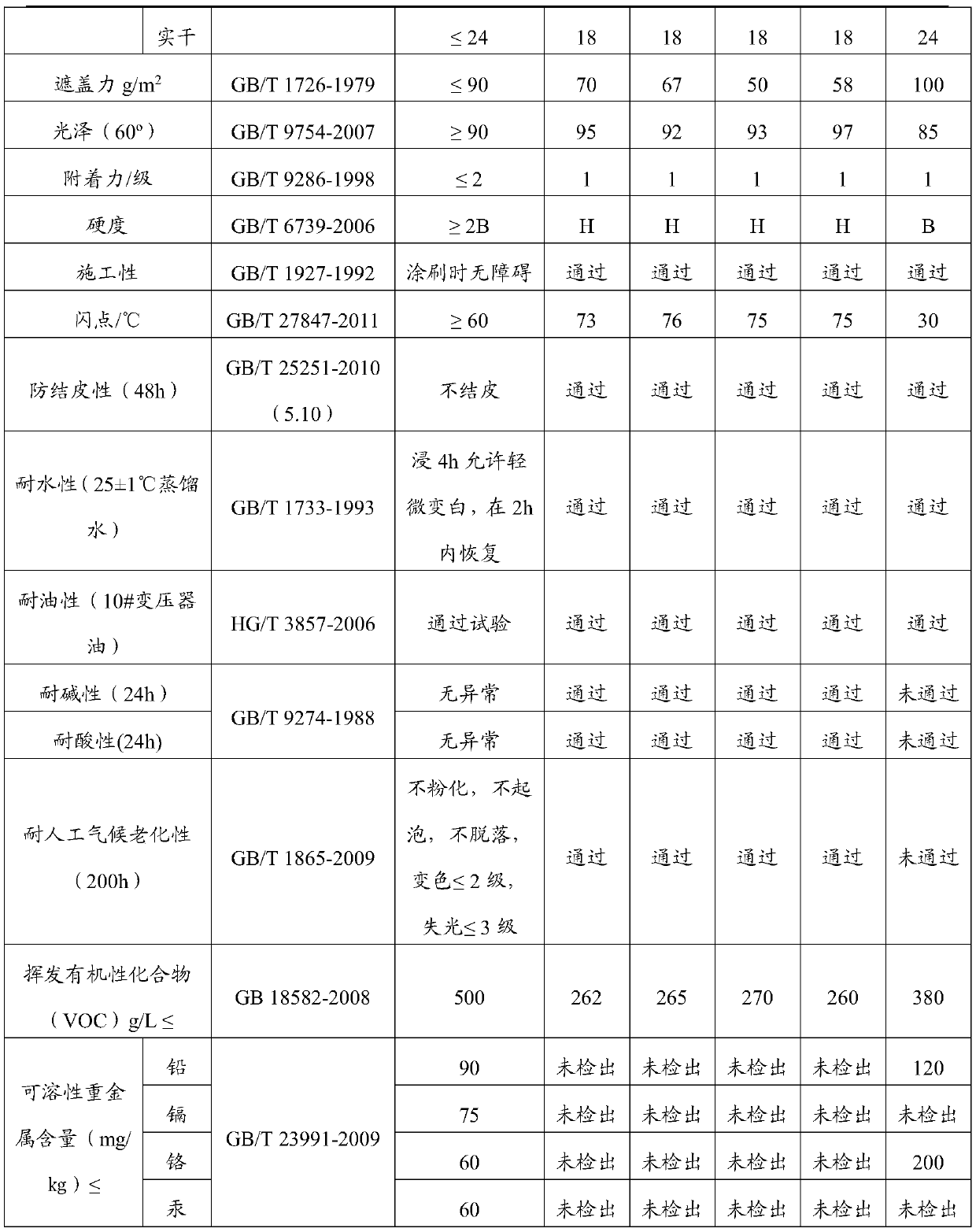

High weather resistant leadless catalyst alkyde resin top-coat

The invention relates to highly weather-resistant lead-free catalyst alkyd resin finish, which comprises the following compositions with the contents (weight): 55 to 75 percent of alkyd resin, 10 to 20 percent of pigment, 3 to 5 percent of a film forming additive, 3 to 5 percent of a drier, 0.3 to 1.0 percent of an anti-skinning agent, and the balance being a petroleum solvent (based on 100 percent of the total weight). Compared with the prior art, the alkyd resin finish has excellent weather resistance, can be repaired in an on-line mode, more adapts to flow coating of the prior containers, and forms a continuous coating membrane when the finish is coated on the outer surfaces of the containers; and the coating membrane has more excellent weather resistance and more durable color retention, and is more environment-friendly due to the fact that used film forming materials do not contain heavy metals.

Owner:中涂化工(上海)有限公司

Environment-friendly and durable wax oil and preparation method thereof

The invention relates to the field of wood coatings, and particularly relates to environment-friendly and durable wax oil and a preparation method thereof. The environment-friendly and durable wax oil is prepared from the following raw materials in parts by weight: 50-80 parts of vegetable oil, 5-20 parts of biological wax, 5-10 parts of gum dammar, 5-10 parts of isopropanol, 5-10 parts of ethyl ester, 3-5 parts of nanosilicon dioxide, 3-5 parts of sodium silicate, 3-5 parts of calcium sulfate, 2-5 parts of silicone emulsion, 2-5 parts of polyvinyl butyral, 0.5-1 part of a dryer, 0.1-0.3 part of an anti-skinning agent, 0.1-0.3 part of an ultraviolet light absorber, and 0.1-0.3 part of a mould inhibitor. The vegetable oil is a mixture of 15-30 parts of tung oil and 40-60 parts of turpentine. The product is good in durability, low-temperature resistant, fire-proof, less in peeling possibility, good in abrasive resistance, and good in glossiness, and can be widely applied to coating protection of woodwork. Guarantee is provided for the product by the preparation method.

Owner:HANGZHOU EABY ENVIRONMENTAL PROTECTION TECHCO

Organosilicon-modified alkyd resin paint composite and preparation method thereof

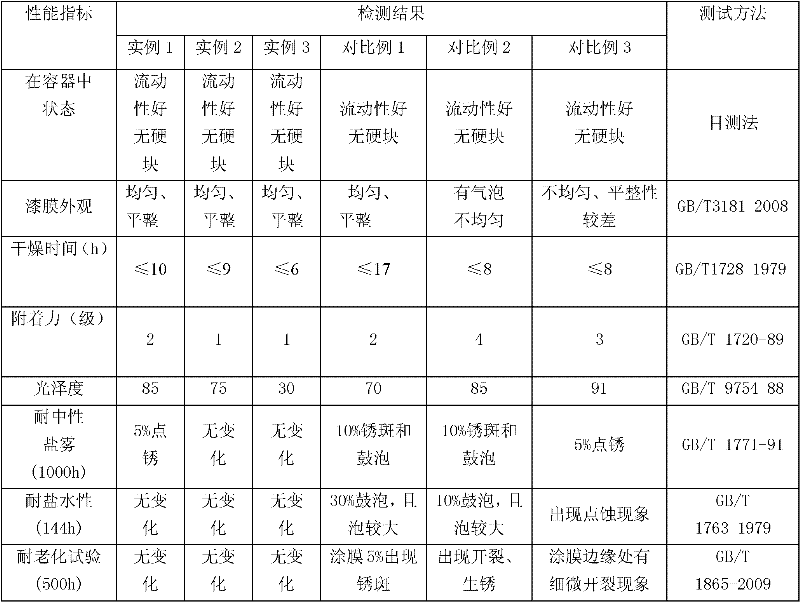

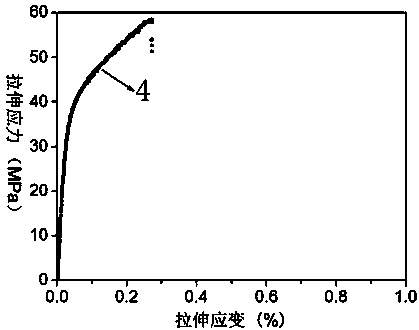

InactiveCN102174291AStrong adhesionImprove aging resistanceAnti-corrosive paintsLow speedAging resistance

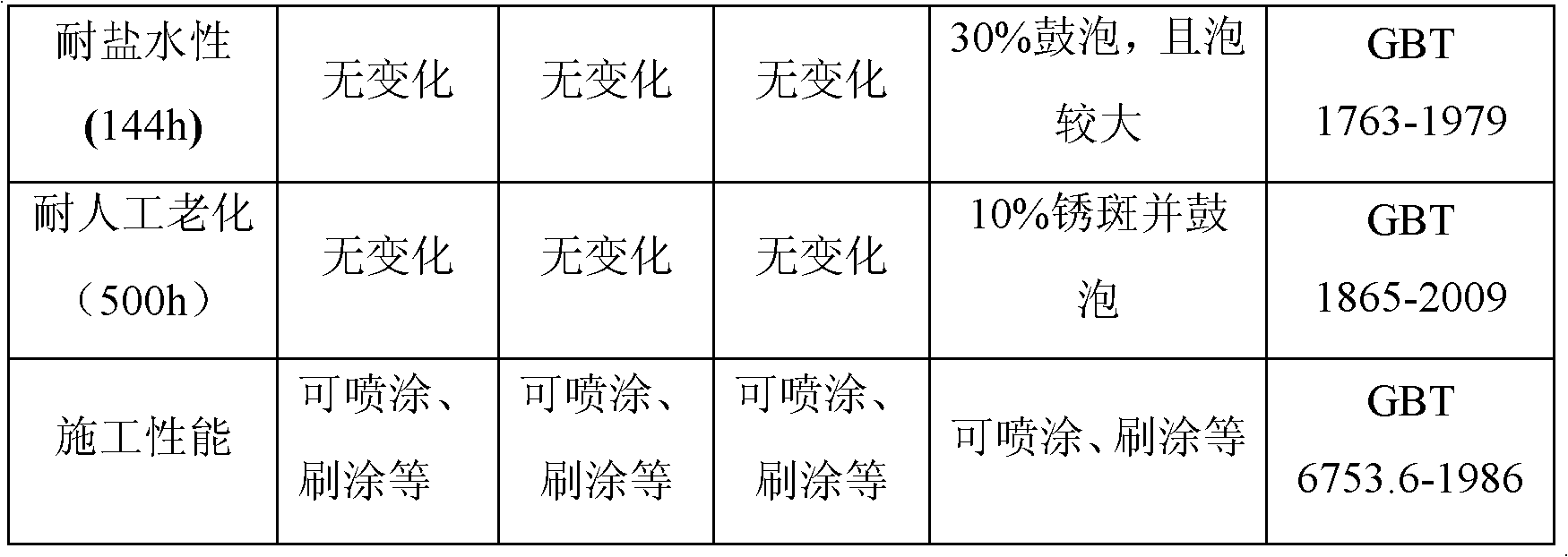

The invention discloses an organosilicon-modified alkyd resin paint composite and a preparation method thereof. The paint comprises the following components in parts by weight: 20-60 parts of organosilicon-modified alkyd resin, 15-35 parts of solvent, 15-40 parts of pigment and filler, 0.1-1 part of leveling agent, 1-5 parts of wetting dispersant, 0.5-2 parts of drier and 0.2-0.35 part of anti-skinning agent. The preparation method of the paint composite comprises the following steps: stirring, grinding and dispersing the solvent, the pigment and filler, the organosilicon-modified alkyd resin and the wetting dispersant; adding the leveling agent, the anti-skinning agent and the drier in abrasive; and dispersing at a low speed to obtain the paint composite. The paint composite has good comprehensive properties such as good adhesion, salt fog resistance, saline resistance and aging resistance, and is suitable for the anticorrosion of a steel structure.

Owner:CHINA ELECTRIC POWER RES INST +1

Water alcohol acid rust-having anti-corrosive paint and preparation method thereof

The invention discloses a water-borne alkyd with anti-corrosive paint and a process for preparation, which solves the problems that the existing water-borne price of coating material is high, technique is difficult to achieve mechanization and stream mode and the like, and has the advantages that the invention achieves water-borne, reduces the dosage of organic solvent, meanwhile, the invention releases construction workers form heavy and hostile environment and the like. The components which are measured according to parts by weight are that waterborne alkyd resin 290 parts, iron oxide red 110 parts, filling material 310 parts, active pigment 10 parts, anti-settling agent 3 parts, penetrating agent 22 parts, surface activator 5 parts, deionized water 200 parts, aliphatic hydrocarbon solution 33 parts, drier 16 parts and anti-skinning agent 1 part.

Owner:山东奔腾漆业股份有限公司

White wood wax oil for woodware and preparation method thereof

ActiveCN102284990AMeet environmental protection requirementsSafe and non-toxic natural propertiesWood impregnation detailsWaxVegetable oil

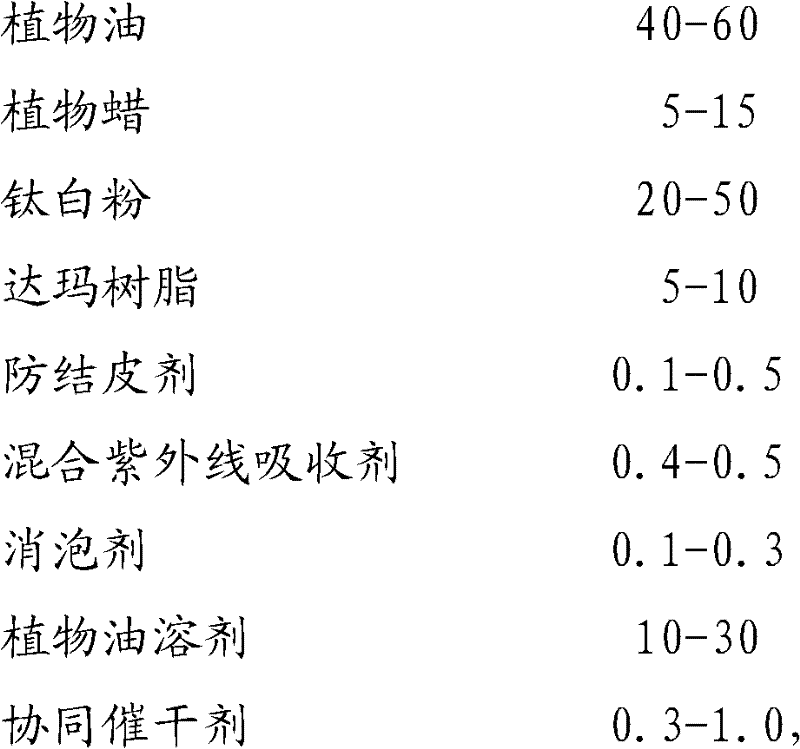

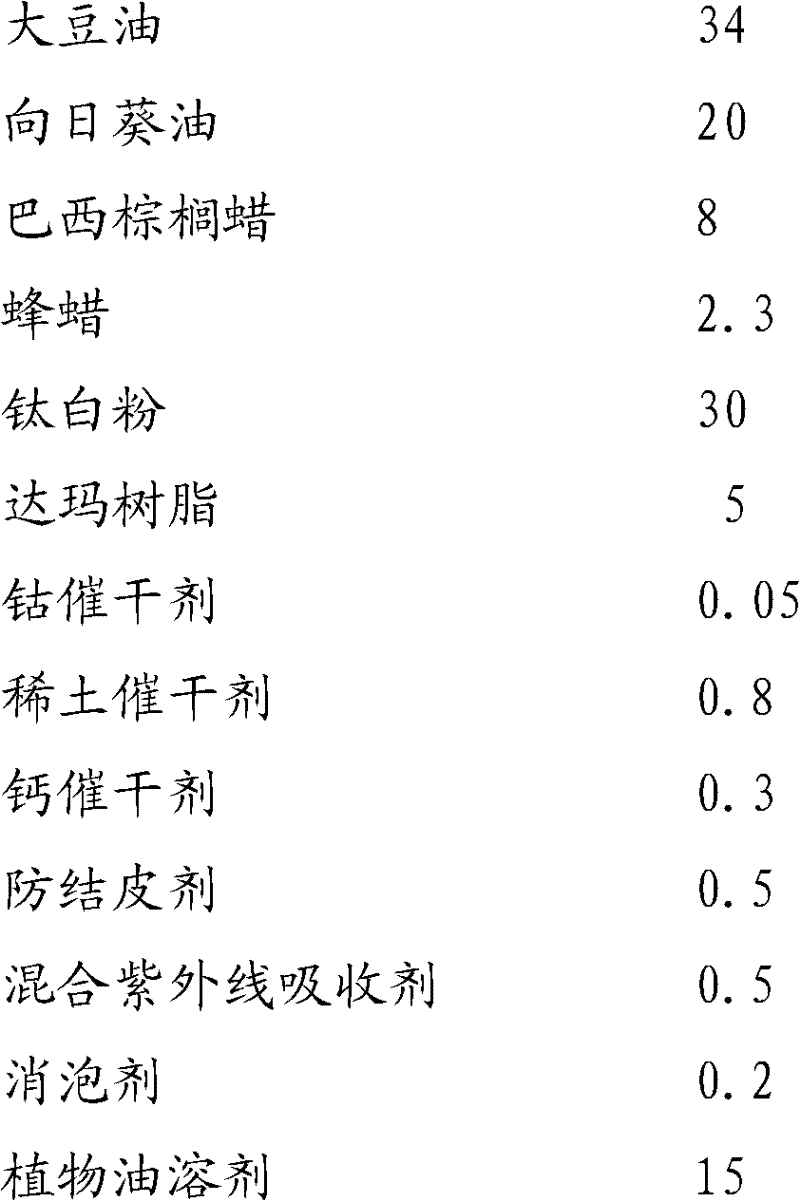

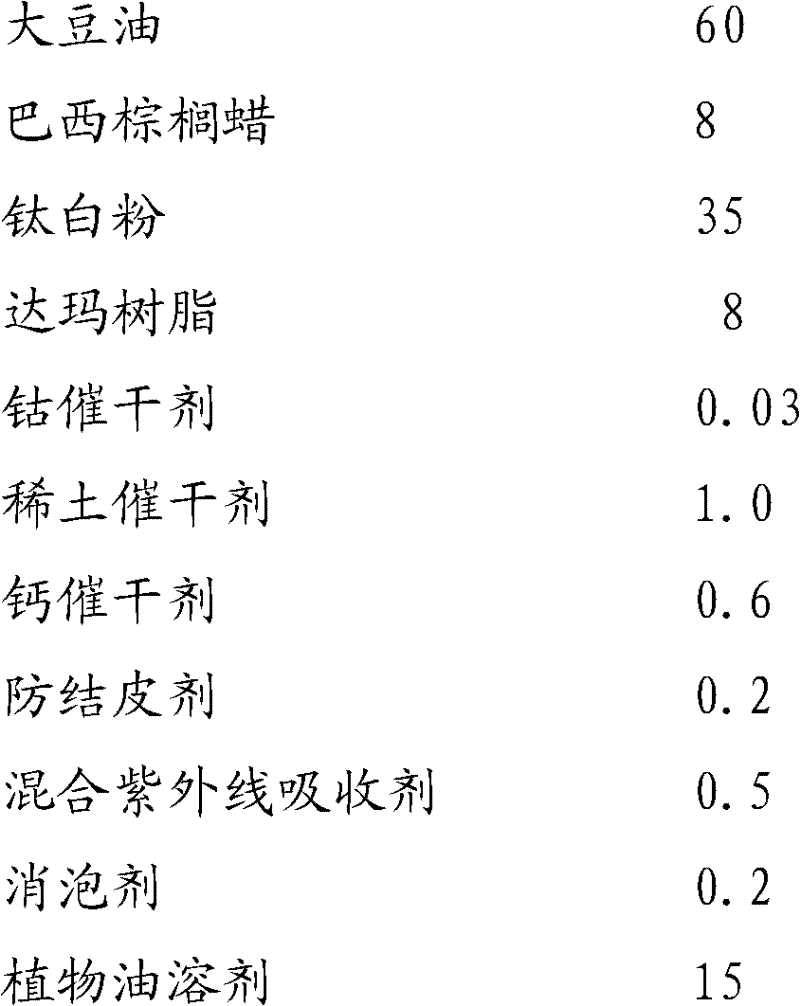

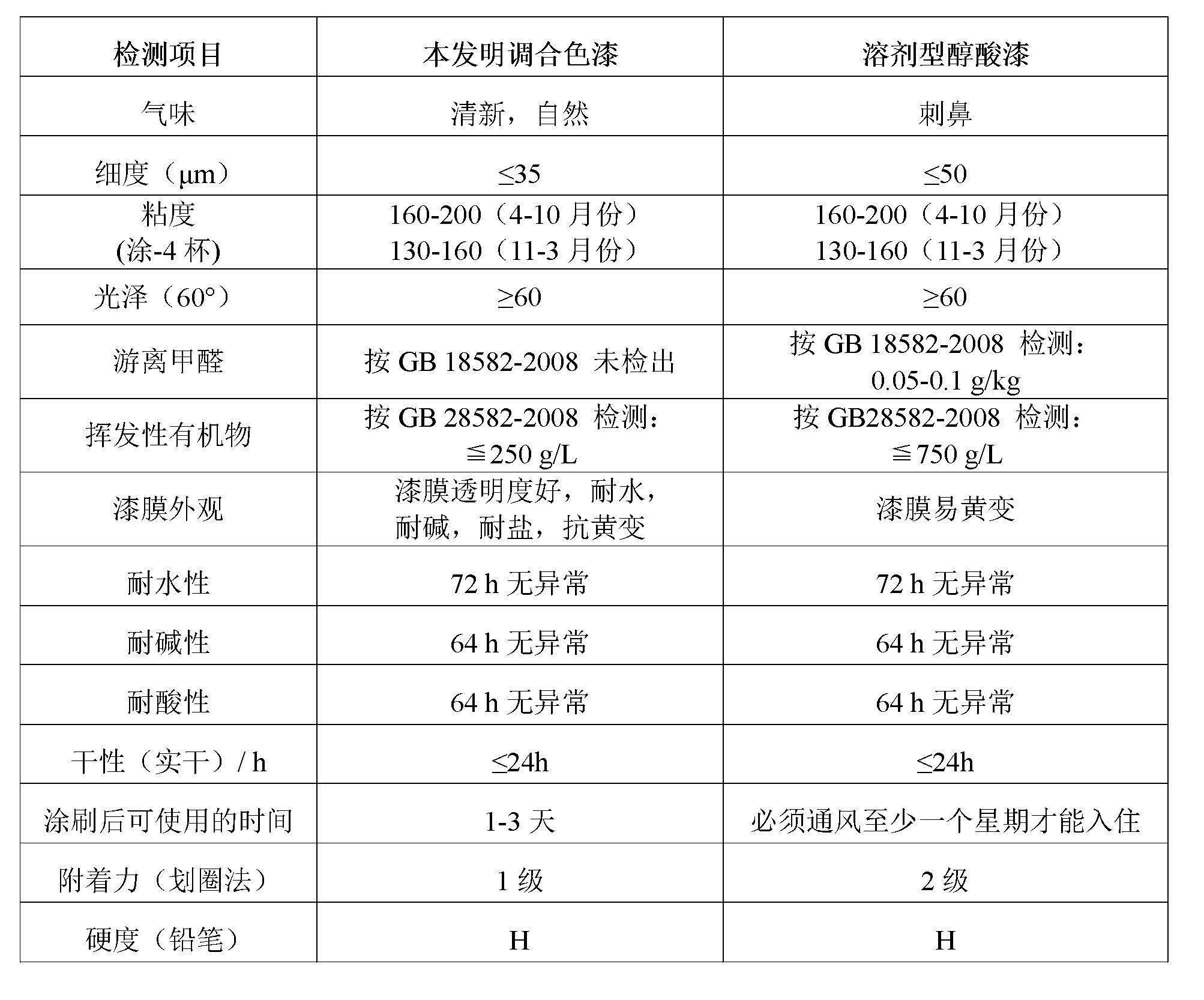

The invention discloses white wood wax oil for woodware and a preparation method thereof. The white wood wax oil comprises the following components in parts by weight: 40-60 parts of vegetable oil, 5-15 parts of vegetable wax, 20-50 parts of titanium white, 5-10 parts of dammar resin, 0.1-1.6 parts of composite drier, 0.3-1.0 part of synergistic drier, 0.1-0.5 part of anti-skinning agent, 0.1-0.5 part of mixed ultraviolet absorber, 0.1-0.3 part of defoamer and 10-30 parts of vegetable oil solvent. The white wood wax oil belongs to natural paints of an ultralow VOC (Volatile Organic Compounds) emission type, has the natural properties of safety, non-toxicity, harmlessness and healthiness, and is not only suitable for outdoor decoration but also an ideal choice for indoor private habitable room decoration.

Owner:广东嘉宝莉科技材料有限公司

Aqueous dispersed alkyd blend colored paint and preparation method thereof

ActiveCN102690589AIncreasing the thicknessDry fastPolyester coatingsWater dispersibleOrganic solvent

The invention discloses aqueous dispersed alkyd blend colored paint and a preparation method thereof. The aqueous dispersed alkyd blend colored paint is made of, by weight, 40%-46% of alkyd resin, 2%-6% of petroleum resin, 10%-28% of color filler, 0.3%-0.8% of defoaming agent, 0.4%-0.8% of organic clay, 0.3%-0.6% of wetting agent, 0.5%-1% of drier, 0.1%-0.3% of anti-skinning agent, 20%-35% of cosolvent and 5%-10% of organic solvent. The aqueous dispersed alkyd blend colored paint is fresh and natural in smell and has excellent gloss, bonding force, flexibility, water resistance, corrosion resistance and outdoor durability.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Anti-acne skin agent for external use

InactiveUS20080299159A1Raise security concernsHigh transparencyCosmetic preparationsToilet preparationsHas active ingredientMedicine

It is an object of the present invention to provide an anti-acne skin agent for external use which comprises highly safe protein nanoparticles having high transparency due to the small particle size, moisturizing properties, and high permeability into skin. The present invention provides an anti-acne skin agent for external use, which comprises protein nanoparticles containing an active ingredient.

Owner:FUJIFILM CORP

Composition to enhance permeation of topical skin agents

This invention relates to compositions and methods for enhancing the penetration of topical skin agents into the skin wherein said compositions contain at least one active ingredient, a skin conditioner and a polymeric emulsifier.

Owner:KUNG JOHN +2

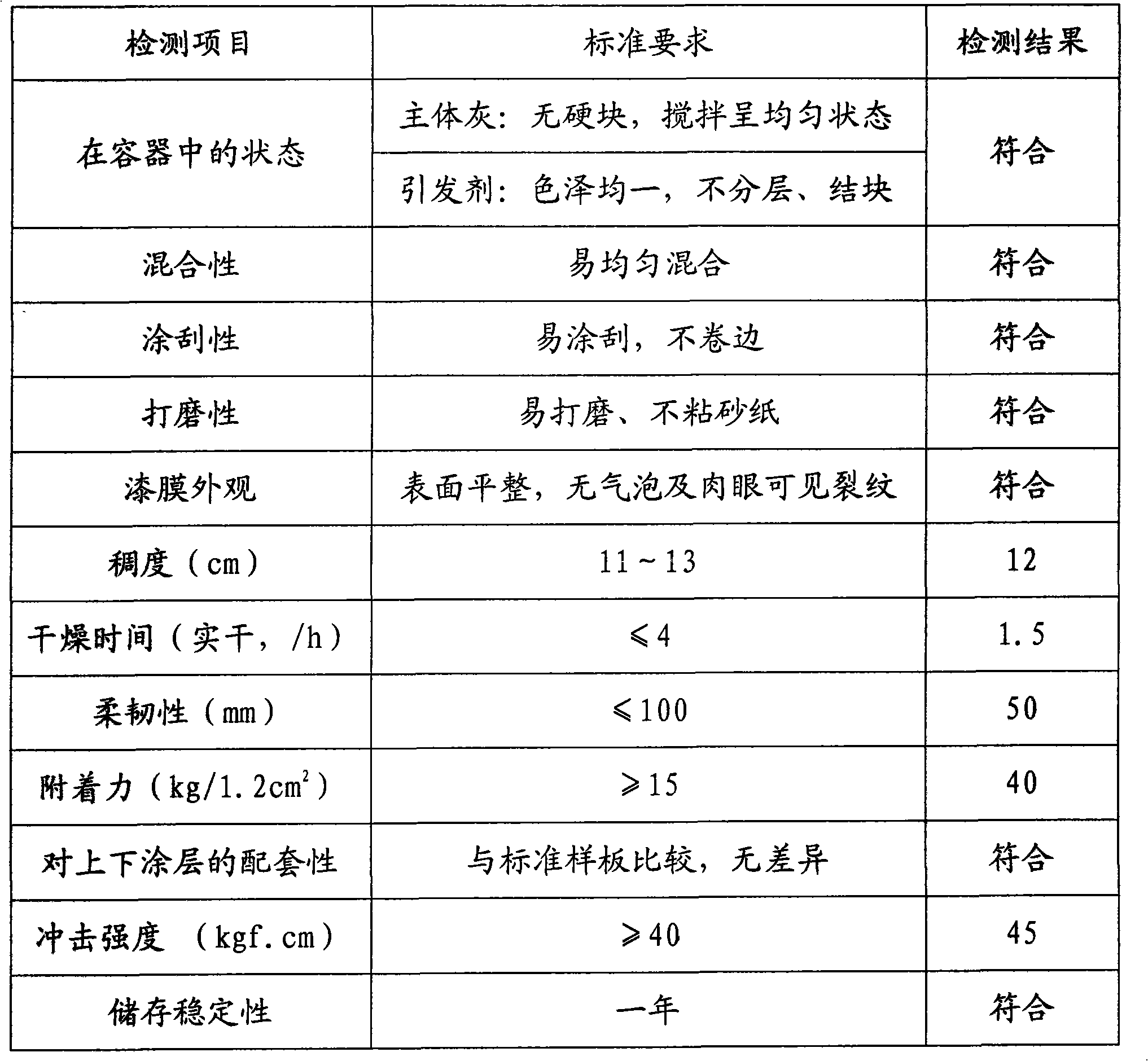

Environment-friendly aqueous putty

An environment-friendly aqueous putty consists of main putty and an initiator. The putty is obtained by evenly mixing the main putty and the initiator at required weight ratio. The main putty consists of the following components: an air-drying water-born unsaturated polyester resin, deionized water, an anti-shrinking agent, a promoter, a wetting dispersant, an anti-skinning agent, an anti-settling agent, an adhesion promoter, an anti-mildew agent, a structure reinforcing agent and packing. The initiator consists of the following components: benzoyl peroxide, dibutyl phthalate and silicon dioxide. The putty has the advantages that air-drying performance of a product is hardly affected by temperature of construction environment; the product has high environmental protection performance, good service performance in construction, special structure reinforcing agent and high overcoatability for use.

Owner:GUANGDONG SANVO CHEM IND TECH

Atomic ash special for wood decoration

The invention relates to a polymeric putty, in particular to an atomic ash specialized for carpentry decoration. The invention is specialized for meeting the using requirements of the carpentry furniture production and the interior decoration and fitment industry. The invention consists of two compositions: main ash and an evocating agent; the weight percentage of the main ash and the evocating agent is 100:2; when the invention is used, two compositions are evenly mixed according to mixture ratio. The main ash consists of the following compositions in percentage by weight: 35 to 45 portions of unsaturated polyester resin, 5 to 10 portions of saturated polyester resin, 0.003 to 0.005 portion of anti skinning agent, 8 to 12 portions of styrene, 0.3 to 1.2 portions of accelerant, 0.2 to 0.5 portion of wetting agent, 1 to 2 portions of thixotropic agent, 1 to 3 portions of zinc stearate, 5 to 8 portions of titanium pigment, 5 to 8 portions of permanent white, 20 to 35 portions of talcum powder and 8 to 12 portions of atomic powder. The evocating agent consists of the following compositions in percentage by weight: 45 to 55 portions of cyclohexanone peroxide or methyl ethyl ketone peroxide, 35 to 48 portions of dibutyl phthalate and 4 to 9 portions of SiO2. The atomic ash specialized for carpentry decoration has the following advantages that: the atomic ash has good adhesive force with various carpentry materials, good construction and flexility and shrinkage resistance and rapid drying speed and can fill up large holes or cracks; the putty film is exquisite, smooth and good in air-drying property and can be matched with wood lacquer in the market for use.

Owner:GUANGDONG SANVO CHEM IND TECH

High-flash-point alkyd resin protective coating as well as preparation method and application thereof

InactiveCN110591523AEasy to operateSuitable for large-scale productionAnti-corrosive paintsPolyester coatingsFumed silicaSilicon dioxide

The invention provides a high-flash-point alkyd resin protective coating as well as a preparation method and an application thereof, and belongs to the technical field of coatings. The high-flash-point alkyd resin protective coating provided by the invention comprises the following components in parts by weight of 60-65 parts of alkyd resin, 15-20 parts of titanium dioxide, 5-15 parts of barium sulfate, 5-10 parts of an alcohol ether solvent, 0.3-0.4 parts of fumed silica, 0.2-0.4 parts of a wetting agent, 0.3-0.5 parts of a dispersing agent, 0.7-1 part of a drier, and 0.2-0.3 parts of an anti-skinning agent. According to the coating, alkyd resin is used as a main body, and the alcohol ether solvent, titanium dioxide, barium sulfate and fumed silica are added, and the obtained alkyd resinprotective coating has high flash point and is safer in the production, transportation and use processes under the action of the wetting agent, the dispersing agent, the drier and the anti-skinning agent; and the alkyd resin protective coating has excellent performances such as acid resistance, alkali resistance, weather resistance and the like, and is low in toxicity, green and environmentally friendly.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

High-saline-resistance lead red alcohol acid antirust paint and its preparing method

InactiveCN1775880AReduce manufacturing costExcellent salt resistanceAnti-corrosive paintsPolyester coatingsSodium BentoniteAlcohol

The invention discloses high salt- water resistance red lead alkyd antirust paint and the manufacturing method that belongs to antisepsis material field. It contains the following material: alkyd resin 27-33 portions, red lead powder 35-42 portions, silicon oxide powdered aluminum 3-9 portions, barium sulfate precipitated 8-14 portions, talcum powder 9-15 portions, bentonite 0.1-0.6 portion, anti skinning agent 0.4-1.0 portion, drying agent 0.1-1 portion, 200 mark solvent petrol 3-9 portions. The invention could be used in steel structure building, chemical device, and pipeline fields.

Owner:浙江川科防保材料发展有限公司

Micropore type coating sizing and preparation method thereof

InactiveCN102817244ACrust is not easy to appearGood moisture permeabilityFibre treatmentArray data structureEmulsion

The invention provides micropore type coating sizing and a preparation method of the micropore type coating sizing. The micropore type coating sizing is characterized by comprising the following components in parts by weight: 100 parts of polyurethane resin, 15-25 parts of toluene, 15-25 parts of butanone, 2-6 parts of bridging agent, 1-5 parts of anti-skinning agent, 1-5 parts of waterproof agent and 30-60 parts of water. The preparation method of the micropore type coating sizing is characterized by comprising the following steps of: weighing, adding the raw materials, stirring and sealing up for safekeeping. The invention has the benefits as follows: the bridging agent, the anti-skinning agent and the waterproof agent are used as assistants in a formula and sequentially added in a mixture of polyurethane resin, toluene and butanone, so that the prepared sizing forms a white emulsion system which is stable and can be kept for long time; and the sizing is coated on a textile by a scraper and has a specific micropore structure, so that the prepared fabric has good moisture penetrability and waterproofness.

Owner:CTA HI TECH TEXTILES

Alkyd paint and preparation method thereof

The invention discloses alkyd paint and a preparation method thereof. The alkyd paint is prepared from the following raw materials in percentage by weight: 32-40 parts of alkyd resin, 8-12 parts of petroleum resin liquid, 8-15 parts of pigment, 30-38 parts of filler, 0.2-1.0 part of a dispersant, 0.1-2.0 parts of an anti-settling agent, 8-12 parts of a water emulsion, 0.8-2.0 parts of a drier, 0.1-0.5 part of an anti-skinning agent, and 1-10 parts of a solvent. The method disclosed by the invention is simple in process and easily-obtained in raw materials, and the VOC (volatile organic compound) content of the prepared alkyd paint is less than 300 g / L, thereby greatly reducing the environmental hazards. Used 200# solvent oil does not contain aromatic hydrocarbons, therefore, the alkyd paint is low in toxicity, and environment-friendly; part of the solvent is replaced with tap water, therefore, the alkyd paint has the characteristics of low cost, low toxicity, low pollution, and the like; the alkyd paint is dried quickly, the surface drying time is less than 4h, and the hard drying time is less than 24h; the glossiness is good, and more than 85%; the alkyd paint is good in application property and decoration property, and a product paint film is smooth, and excellent in hardness and glossiness.

Owner:西北永新涂料有限公司

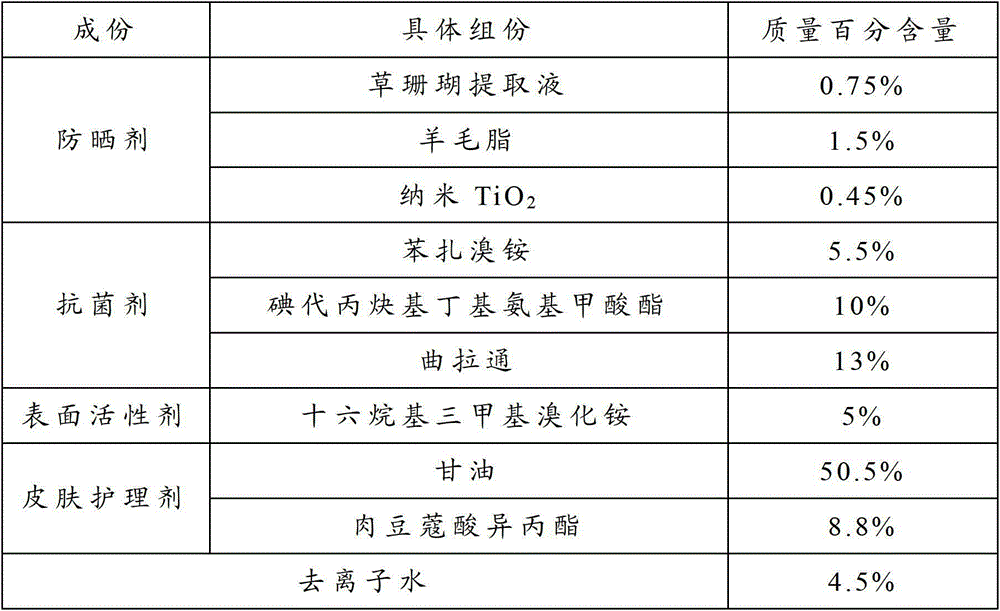

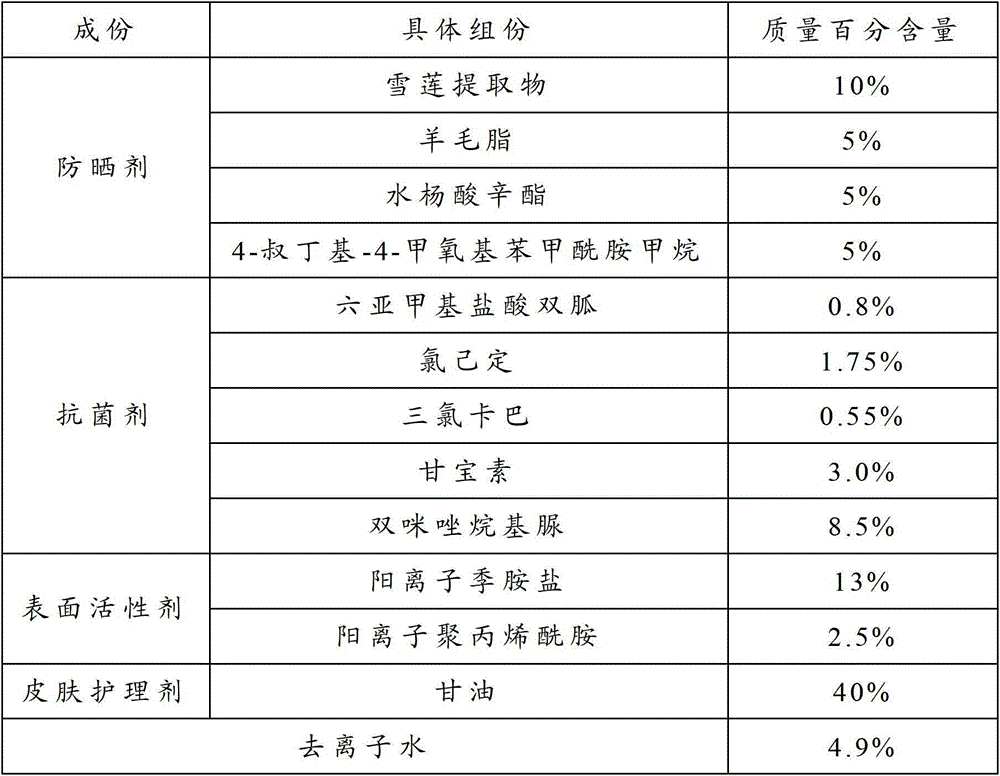

Skin care composition and facial tissue employing same

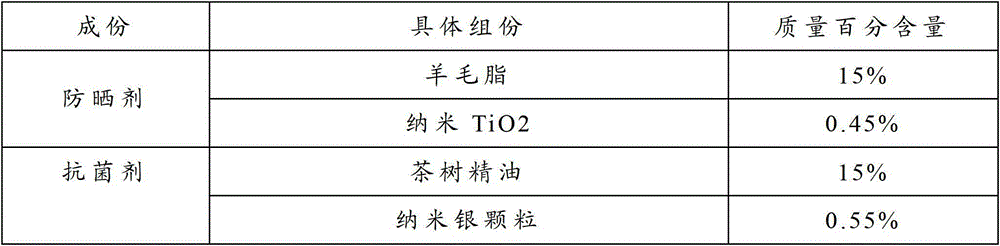

InactiveCN103142419AWith sweat and moisture absorptionWith sun protection functionCosmetic preparationsToilet preparationsSunscreen agentsMass ratio

A skin care composition contains at least one sun-screening agent, at least one antibacterial agent, at least one surfactant and at least one skin care agent, wherein the mass ratio of the sun-screening agent to the antibacterial agent to the surfactant to the skin care agent is (0.1-25): (0.1-20): (0.1-25): (10-60). The invention also provides a facial tissue employing the skin care composition. The facial tissue provided by the invention has the functions of wiping sweat and absorbing moisture, protecting against sunshine and inhibiting bacteria.

Owner:GOLD HONG YE PAPER

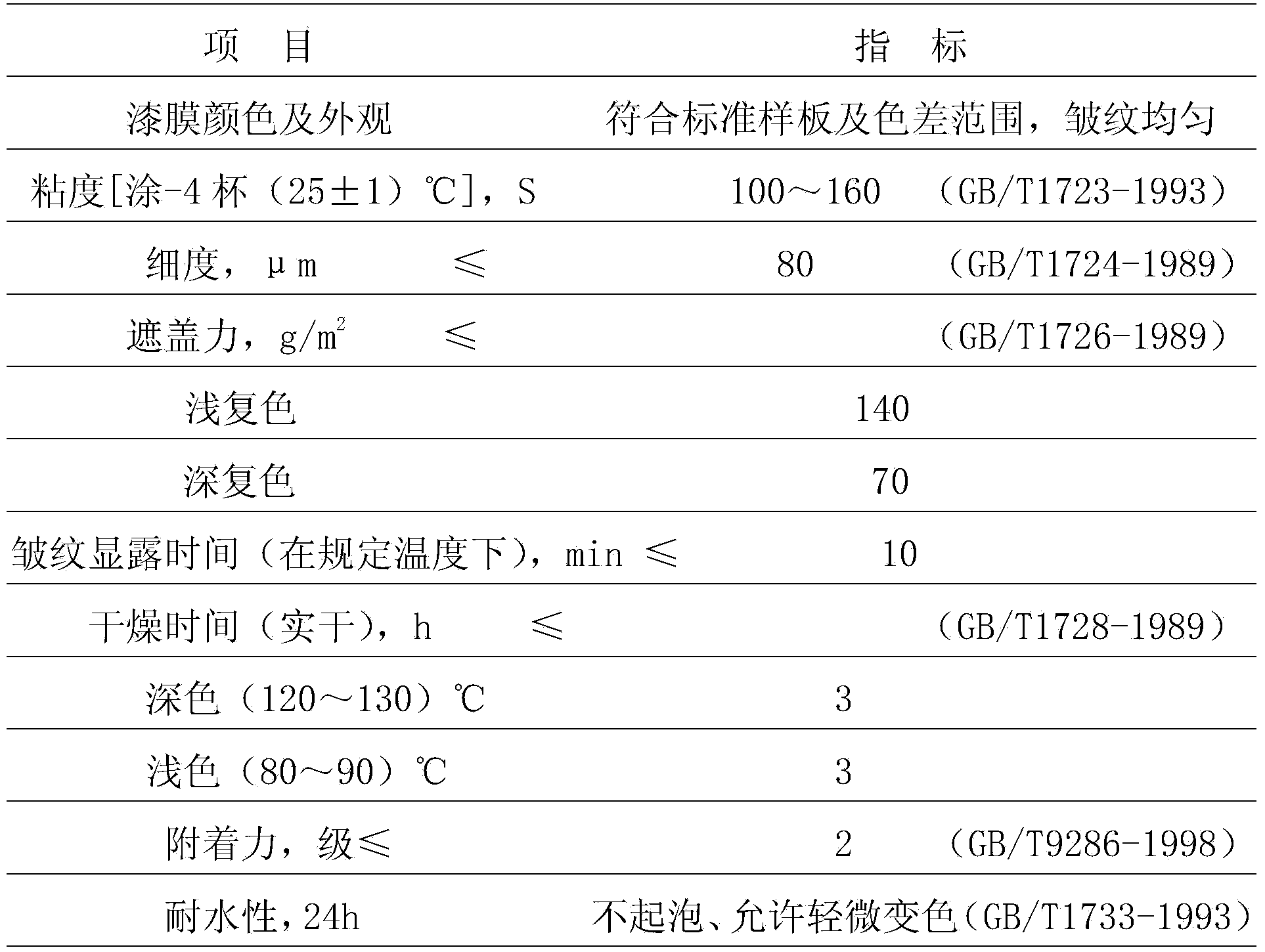

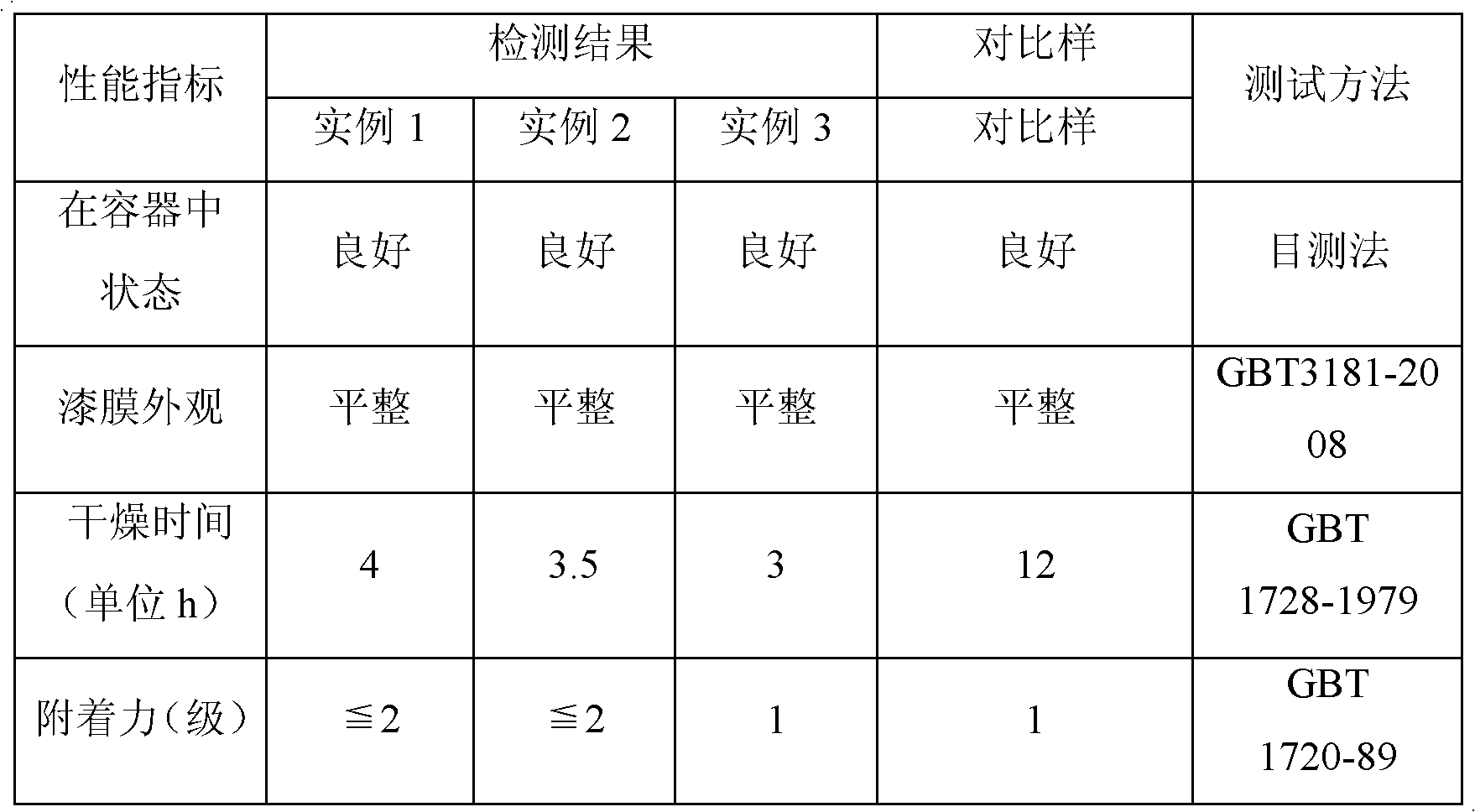

Alcohol acid ripple finish and preparation method thereof

ActiveCN103468106ASimple production processReduce security risksPolyester coatingsCalcium EDTASkin agent

The invention provides alcohol acid ripple finish and a preparation method thereof. The alcohol acid ripple finish comprises, by weight, 50-60 parts of alcohol acid ripple resin (having solid content of 60+ / -3wt%), 5-10 parts of polymerized oil pattern-adjustment resin, 2-3 parts of carbon black, 20-35 parts of light calcium, 0.5-1.5 parts of bentonite HFGEL-40A, 1-2.5 parts of lead naphthenate having the content of 10%, 2-3.5% of cobalt naphthenate having the content of 4%, 0.1-0.3 parts of an anti-skinning agent and 5-10 parts of toluene. The anti-skinning agent is methyl ethyl ketoxime, butyraldehyde oxime or cyclohexanone-oxime and is obtained by mixing. The film of the alcohol acid ripple finish has excellent characters, realizes a flexible change of ripple patterns according to user demands and can be prepared by a simple method.

Owner:天津灯塔涂料工业发展有限公司

All-solid environment-friendly protective paint and preparation method thereof

InactiveCN105038538AAvoid corrosionNo shipping costsAnti-corrosive paintsPolyester coatingsSolventMaterials science

The invention relates to all-solid environment-friendly protective paint and a preparation method thereof. The paint is prepared from the following raw materials: 10-40% of all-solid alkyd resin, 5-30% of mineral wax, 20-50% of drying oil, 5-20% of a sulfonate based preservative, 5-15% of calcium carbonate, 1-5% of fatty acid ester, 1-10% of a thickening agent, 5-20% of a petroleum resin, 0.1-0.5% of a drying agent and 0.2-0.5% of an anti-skinning agent. The preparation process for the protective paint comprises the following steps: adding drying oil, mineral wax and petroleum resin into a reaction kettle, rising the temperature to be 100-110 DEG C, stirring at the rotating speed of 10-20 rpm, and stirring at the speed of 30-35 rpm after the mixture is fully molten to uniformly mix the mixture; stopping heating, adding all-solid alkyd resin, fatty acid ester, the sulfonate based preservative, the thickening agent, the drying agent and the anti-skinning agent in sequence under the stirring condition; discharging when the temperature is reduced to be 40 DEG C. Compared with the conventional protective paint, the protective paint provided by the invention has the advantages of being free of solvent, environment-friendly, good in safety and stability, high in preservative efficiency, and the like.

Owner:苏州讯鼎光电科技有限公司 +1

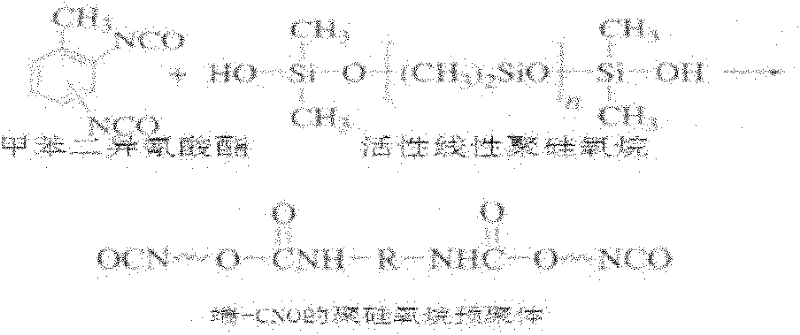

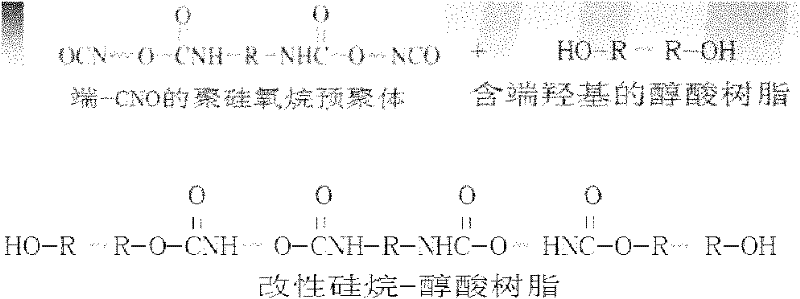

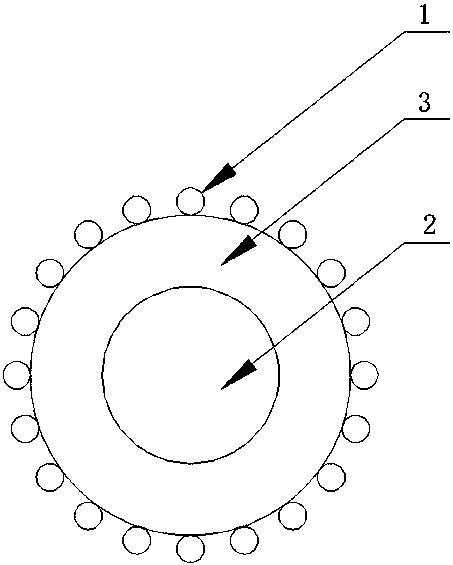

Organic silicon polyurethane composite modified alkyd resin coating composition and preparation method thereof

ActiveCN102134441AAvoid separationImprove stabilityPolyurea/polyurethane coatingsComposition BResin coating

The invention discloses an organic silicon polyurethane composite modified alkyd resin coating composition and a preparation method thereof. The double-component coating composition contains the components in parts by weight: 0.3 to 1.2 parts of A and 6 parts of B, wherein the component A is modified active polysiloxane; the component B comprises alkyd resin, solvent, pigment and filler, wetting dispersant, leveling agent and anti-skinning agent; and when in use, the component A and the component B are mixed uniformly according to the proportion. The composition B is prepared by the following steps of: 1) uniformly mixing, abrading and dispersing the raw materials; and 2) adding the leveling agent and the anti-skinning agent to the abrasive. The coating composition disclosed by the invention has excellent comprehensive properties including good adhesion, salt spray resistance, salt water resistance, ageing resistance and the like, and is suitable for heavy-duty coating protection of a steel structure.

Owner:CHINA ELECTRIC POWER RES INST +1

Offset ink and preparation method thereof

InactiveCN103173065ASolve the problem of sticking ink rollerImprove work efficiencyInksWaxCarbon chain

The invention provides offset ink and a preparation method thereof, and belongs to the field of offset printing. The offset ink comprises the following components in parts by weight: 65-80 parts of connecting materials, 1-2 parts of cerate, 15-25 parts of pigments, 0.1-0.3 part of anti-skinning agents and 1-10 parts of auxiliary agents A, wherein the cerate comprises flax oil, mineral oil and bee waxes; and the bee waxes contain polar and non-polar groups, carbon chains are unequal in length, and thus the cerate has both internal lubrication action and external lubrication action. Above all, the offset ink provided by the invention effectively solves the problem that the offset ink is adhered with an ink roller under the precondition of not influencing gelation because the prepared cerate is discovered to equilibrize the internal and external lubrication action under the combined action of the flax oil, the mineral oil and the bee waxes, and can effectively enhance the printing quality, reduce the cleaning and maintaining cost of a printing machine and increase the working efficiency of the printing machine; and the preparation method provided by the invention has the advantages of simple preparation step and low process cost.

Owner:ZHEJIANG KEXIN INK

Non-cement-based caulking compound and construction method thereof

The invention relates to a non-cement-based caulking compound. The non-cement-based caulking compound is prepared from the following raw materials by weight: 10 to 20 parts of acrylic acid copolymerization emulsion, 40 to 60 parts of heavy calcium carbonate, 28 to 40 parts of quartz powder, 3 to 5 parts of metakaolin, 0.06 to 0.1 part of hydroxypropyl methyl cellulose ether, 4 to 5 parts of titanium dioxide, 0.4 to 0.6 part of a water reducer, 0.2 to 0.3 part of a water repellent, 0.2 to 0.3 part of a liquid antifoaming agent, 0.4 to 0.6 part of an antiseptic, 0.1 to 0.3 part of a wetting dispersant, 0.2 to 0.5 part of aluminum-magnesium silicate and 0.1 to 0.2 part of an anti-skinning agent. According to the invention, since various properties of the caulking compound are improved through addition of proper additives, disadvantages of traditional cement-based caulking compounds are overcome, problems of a reactive resin type caulking compound are perfectly solved, and the caulking compound disclosed in the invention has excellent resistance to corrosion, mildew, permeation, water, scrubbing, wear and contamination, excellent shrinkage deformation capability and other excellent properties and enables cost to be saved; and in construction, the caulking compound can be applied in a manner resembling squeezing of toothpaste out of a tube, so production and construction steps are simplified.

Owner:FOSHAN JIAMITE WATERPROOF MATERIAL CO LTD

Vacuum gold-plated primer

InactiveCN104559746ARaw materials are easy to getLow costPolyurea/polyurethane coatingsSolventSkin agent

The invention discloses a vacuum gold-plated primer which comprises the following components in percentage by mass: 55 to 60 percent of alcohol acid modified urethane oil, 20 to 25 percent of rosin modified phenolic resin, 1 to 2 percent of a dryer, 1 to 2 percent of an anti-skinning agent, 0.3 to 0.4 percent of organic modified nano SiO2, 0.2 to 0.3 percent of organic modified nano graphene and 11 to 22 percent of No.200 solvent oil. The alcohol acid modified urethane oil is prepared from the following components in percentage by mass: 5 to 10 percent of linseed oil, 1 to 5 percent of soybean oil, 10 to 15 percent of stillingia oil, 5 to 10 percent of pentaerythritol, 15 to 20 percent of toluene diisocynate and 40 to 64 percent of No.200 solvent oil. The vacuum gold-plated primer disclosed by the invention has the advantages of low cost, good adhesive force, high hardness, excellent heat resistance, controllable curing time, bright and full surface, high convenience in construction and the like and is suitable for industrial production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Quick-drying wax oil and preparation method thereof

The invention discloses quick-drying wax oil. The wax oil is prepared from the following components in by weight percent: 56-64 percent of alkyd resin, 8-12 percent of vegetable wax and / or animal wax, 4.5-5.5 percent of a cosolvent, 0.08-0.12 percent of a drier, 0.4-0.6 percent of a drier additive, 22-28 percent of a drying assisted solvent and 0.05-0.15 percent of an anti-skinning agent. Furthermore, the invention discloses a method for preparing quick-drying wax oil. The quick-drying wax oil is paint prepared from environment-friendly raw materials, and has the advantages of quick drying, proper viscosity, good stability, good wet permeability, relatively good yellowing resistance and the like; and the raw materials are sufficiently and uniformly mixed by adopting a stepwise mixing method according to properties of the raw materials, and the quick-drying wax oil has low mixing temperature and short mixing time, so that energy and time can be saved, and the preparation cost is reduced.

Owner:黄兴财

Dry towel and processing method and application thereof

PendingCN110025597AImprove the safety of useKeep aliveCosmetic preparationsToilet preparationsFiberWound dressing

The invention discloses a dry towel and a processing method and an application thereof. The dry towel comprises a base fabric carrier layer and a lyophilized film layer attached to the base fabric carrier layer in a freeze-dried form, the base fabric carrier layer and the lyophilized film layer are contacted with 0.0001 ml / cm<2> to 0.1 ml / cm<2> of water, and the lyophilized film layer can be dissolved. The lyophilized film layer comprises a lyophilized efficacy object, or further comprises one or both of a lyophilized skin agent and lyophilized fiber. The dry towel is in contact with water, the lyophilized film layer is dissolved, and when rubbed against the skin, the lyophilized film layer is peeled off from the base fabric carrier layer to form a film on the skin. The dry towel can be used as a skin care product, a makeup-removing cleansing product, a transdermal absorption external paster or a wound dressing paster.

Owner:李和伟

Anti-corrosion paint for low heavy metal automobile parts and method for preparing same

The invention relates to an anti-corrosion paint for low heavy metal automobile parts and a method for preparing the same, wherein the anti-corrosion paint comprises the following components in part ratio(part): 30 to 40 parts of resin specially used for an anti-corrosion primer, 10 to 20 parts of zinc phosphate, of which the zinc content is lower than 20mg / kg, 10 to 20 parts of solution of nitrocotton resin, 5 to 15 parts of talc powder, 5 to 10 parts of calcium carbonate, 3 to 6 parts of carbon black, 3 to 6 parts of anti skinning agent, 0.5 to 1.0 part of dispersing agent YB-201A, 20 to 35parts of mixed solvent, 0.5 to 1 part of anti-settling agent bentonite, 0.3 to 0.6 part of defoaming agent and 3 to 5 parts of dryer; and the preparation method comprises the following steps of: adding the raw materials in a stirring container in sequence and evenly stirring, dispersing the mixture at a high speed, grinding the mixture by grinding equipment until the fineness of the mixture is below 35mum, and adding the solution of nitrocotton resin, the dryer and the mixed solvent and evenly stirring. The anti-corrosion paint has the advantages of having excellent adhesive force, covering force, decorative property, stability and construction application, withstanding salt fog for 600 hours, meeting higher use requirements on environmental protection and also meeting the requirements oflimiting amount of four types of soluble heavy metals in the national mandatory standards.

Owner:天津灯塔涂料工业发展有限公司

Flame-retardant acrylic resin coating material capable of slowly releasing negative oxygen ions, and preparation method thereof

PendingCN109836954ASimple processImprove performanceFireproof paintsEmulsion paintsAcrylic resinOxygen

The invention discloses a flame-retardant acrylic resin coating material capable of slowly releasing negative oxygen ions, and a preparation method thereof. According to the present invention, an acrylic resin is functionally modified with organic and inorganic active molecules, such that the generated core-shell structure polyacrylic resin has characteristics of remarkable fire resistance, waterresistance, high film forming strength and high solid content (not lower than 67%); the prepared fireproof polyacrylic resin aqueous emulsion is used as a film-forming agent, and is added with a dispersant, a drying agent, an anti-settling agent, an antifoaming agent, a preservative, an anti-skinning agent, a leveling agent, a pigment and other auxiliary materials, and an oxygen negative ion emission agent to prepare the high-performance fireproof aqueous acrylic resin coating material capable of releasing negative oxygen ions; and the prepared coating material has characteristics of environmental protection, negative oxygen ion releasing, fire resistance, fire retardation and low cost, and can be widely used in woodware, metals, plastics, glasses, building surfaces and other materials.

Owner:南京新莱尔材料科技有限公司

Quick-drying anticorrosive dipping prime paint with low viscosity as well as preparation and application method thereof

InactiveCN103232796ALow viscosityGood anti-sag performanceRubber derivative coatingsAnti-corrosive paintsEtherDiluent

The invention discloses a quick-drying anticorrosive dipping prime paint with low viscosity as well as preparation and application methods of the prime paint and belongs to the technical field of dipping paints. The preparation method comprises the following steps of: mixing alkyd resin, dimethylbenzene, methylbenzene, acetic ether, thixotropic agent, pigments and padding and anticorrosive pigments; grinding in a grinder; dispersing the thixotropic agent and the round slurry again; adding chlorinated rubber, an anti-skinning agent, a drying agent and an anti-sag agent and uniformly stirring to obtain the dipping prime paint. The dipping prime paint is mixed with diluent to form dipping paint, and a workpiece is dipped by the dipping paint, the prime paint has low requirement on drying and can be dried at a low temperature or constant temperature. The prime paint is of a single-component type, has low viscosity and high anti-sag performance and is convenient in construction; dipping construction is directly carried out after the prime paint is diluted; the prime paint is not affected by seasons; a dried coating film is flat and compact, and a paint film is plump.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com