Flame-retardant acrylic resin coating material capable of slowly releasing negative oxygen ions, and preparation method thereof

A technology of acrylic resin and negative oxygen ions, which is applied in the direction of fireproof coatings, coatings, latex paints, etc., can solve the problems of large influence on film mechanical properties and uneven flame retardant effect, and achieve low cost, good flame retardant effect, and excellent The effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

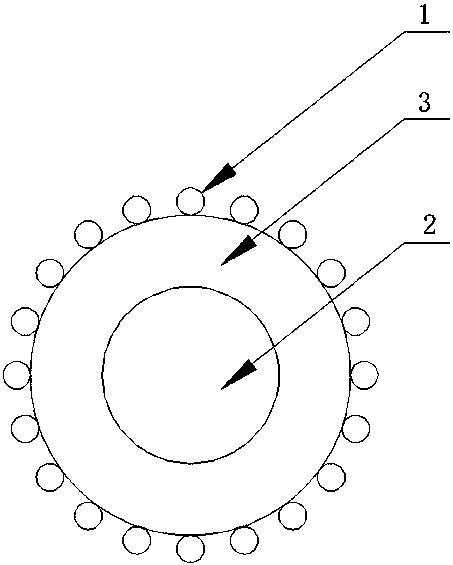

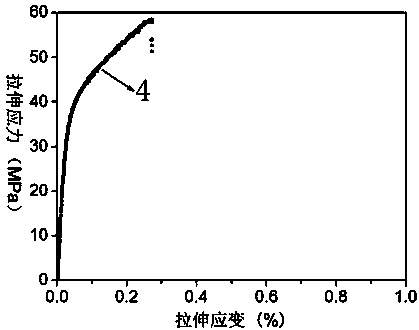

Image

Examples

Embodiment 1

[0022] A flame-retardant acrylic resin coating for slow release of negative oxygen ions and a preparation method thereof, comprising the following steps and process conditions:

[0023] (1) Preparation of reactive flame retardant molecular modification precursor solution: add 80% water, 2% nitrogen and phosphorus series flame retardants including 1% ammonium polyphosphate and 1% melamine polyphosphate to the reaction vessel in sequence , 2% of the flame retardant synergist diethylaluminum phosphate, 1% of the char-forming agent polyamide resin, and high-speed stirring and mixing to obtain the precursor solution;

[0024] (2) Preparation process of flame retardant modified emulsion: Add 0.1% emulsifier alkylphenol polyoxyethylene ether and 0.1% dispersant sodium dodecylbenzene sulfonate to the reaction precursor in step (1), and Add 25% cyclic phosphate flame retardant, 1% melamine, and 2% protective colloid hydroxyethyl cellulose drop by drop during the emulsification process ...

Embodiment 2

[0034] A flame-retardant acrylic resin coating for slow release of negative oxygen ions and a preparation method thereof, comprising the following steps and process conditions:

[0035] (1) Preparation of reactive flame retardant molecular modification precursor solution: add 90% water, 3% nitrogen and phosphorus series flame retardants including 2% ammonium polyphosphate and 1% melamine polyphosphate to the reaction vessel in sequence , 2% of the flame retardant synergist diethyl aluminum hypophosphite, 1% of the char-forming agent polyamide resin, and high-speed stirring and mixing to obtain the precursor solution;

[0036] (2) Preparation process of flame retardant modified emulsion: Add 0.1% emulsifier alkylphenol polyoxyethylene ether and 0.2% dispersant sodium dodecylbenzenesulfonate to the reaction precursor in step (1), and Add 25% cyclic phosphate flame retardant, 1% melamine, and 2% protective colloid hydroxyethyl cellulose drop by drop during the emulsification proc...

Embodiment 3

[0042] A flame-retardant acrylic resin coating for slow release of negative oxygen ions and a preparation method thereof, comprising the following steps and process conditions:

[0043] (1) Preparation of reactive flame retardant molecular modification precursor solution: add 80% water, 2% nitrogen and phosphorus series flame retardants including 1% ammonium polyphosphate and 1% melamine polyphosphate to the reaction vessel in sequence , 2% of the flame retardant synergist diethyl aluminum hypophosphite, 2% of the carbon forming agent polyamide resin, and high-speed stirring and mixing to obtain the precursor solution;

[0044] (2) Preparation process of flame retardant modified emulsion: Add 0.1% emulsifier alkylphenol polyoxyethylene ether and 0.1% dispersant sodium dodecylbenzene sulfonate to the reaction precursor in step (1), and Add 25% cyclic phosphate flame retardant, 1% melamine, and 1% protective colloid hydroxyethyl cellulose drop by drop during the emulsification p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com