High-flash-point alkyd resin protective coating as well as preparation method and application thereof

A high flash point alkyd and alkyd resin technology, used in anti-corrosion coatings, polyester coatings, coatings, etc., can solve problems such as human health threats, environmental pollution, and hidden safety hazards of coatings, and achieve suitable large-scale production and operation. Simple, high-performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

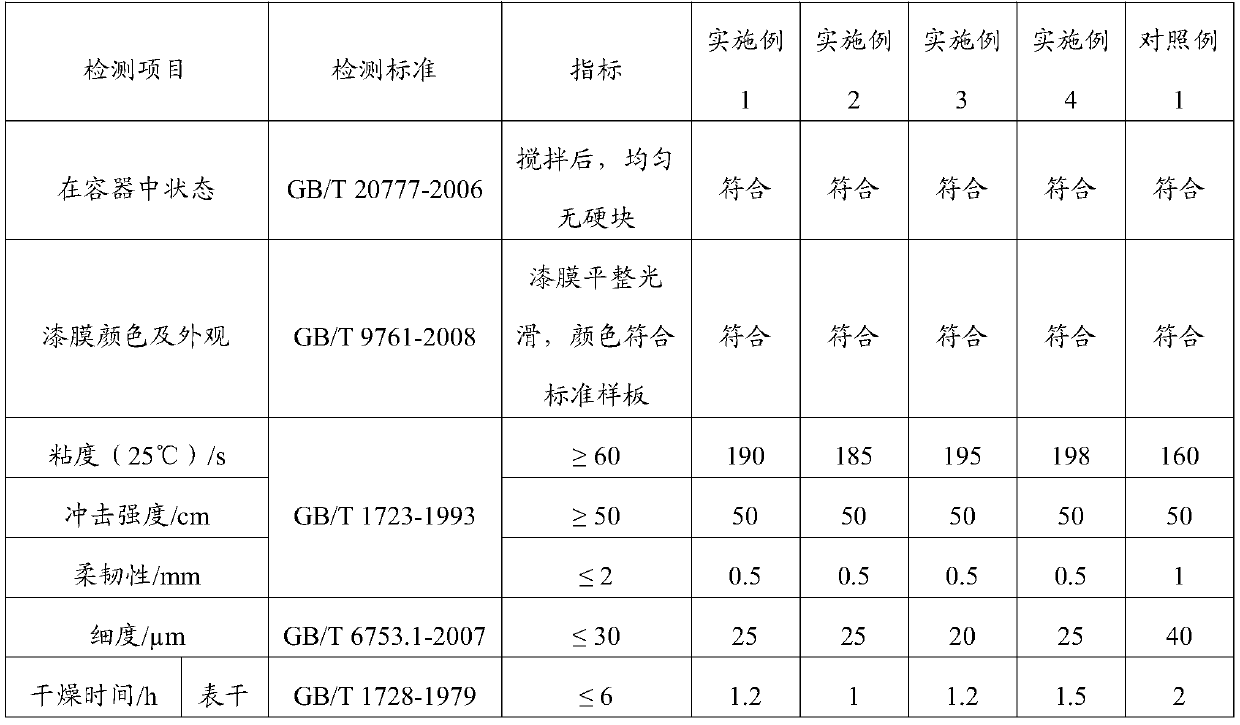

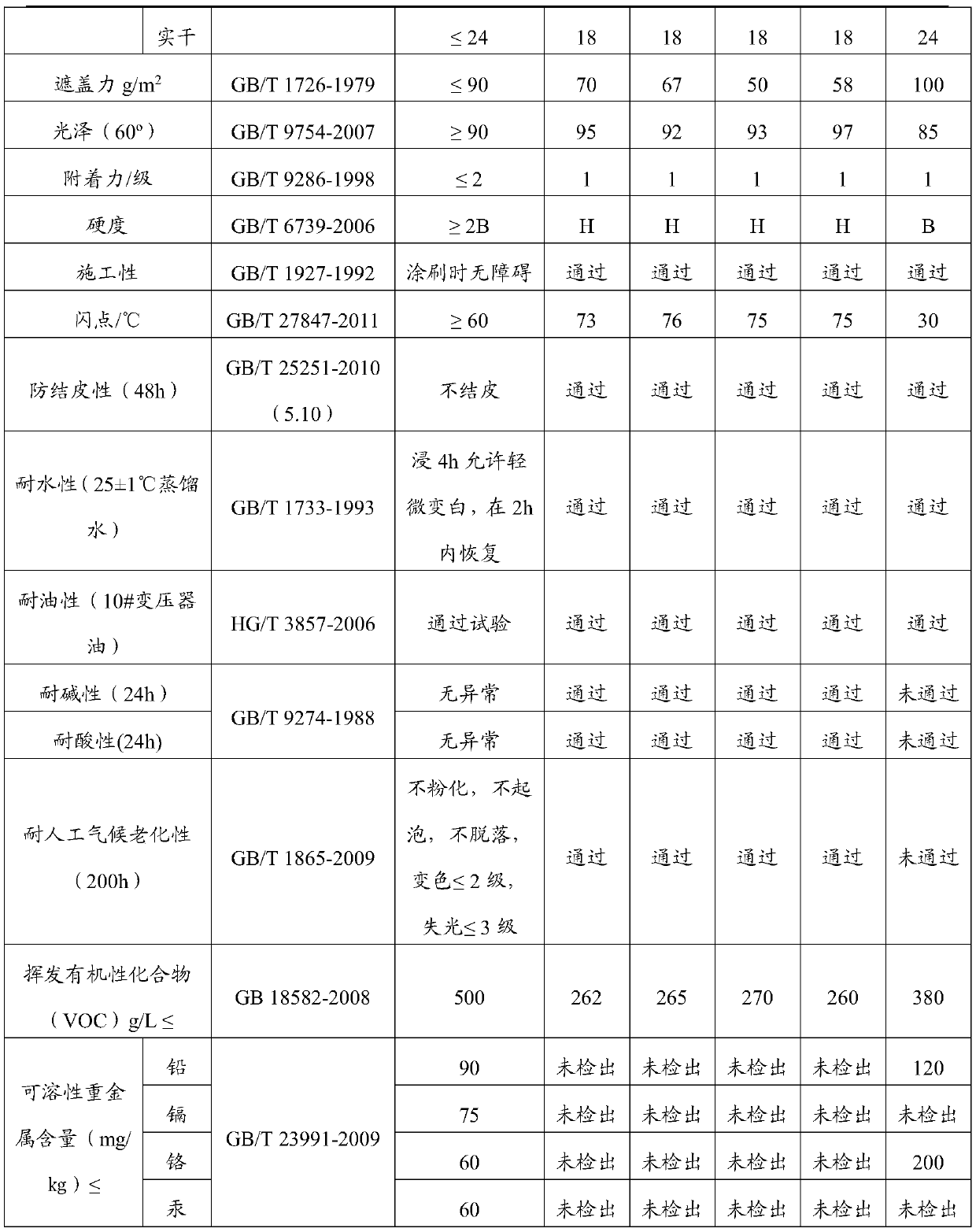

Examples

preparation example Construction

[0052] The present invention also provides a preparation method for the high-flash point alkyd resin protective coating described in the above technical solution, comprising the following steps:

[0053] Mix and grind part of the alcohol ether solvent, part of the alkyd resin, wetting agent, dispersant, fumed silica, titanium dioxide and barium sulfate to obtain a slurry;

[0054] The slurry, the remaining alkyd resin, the drier, the remaining alcohol ether solvent and the anti-skinning agent are mixed to obtain the alkyd resin protective coating.

[0055] In the invention, part of alcohol ether solvent, part of alkyd resin, wetting agent, dispersant, gas phase silicon dioxide, titanium dioxide and barium sulfate are mixed and then ground to obtain slurry.

[0056] In the present invention, the part of the alkyd resin preferably accounts for 65-75% of the total mass of the alkyd resin, more preferably 68-72%, and most preferably 70%. In the present invention, the part of the ...

Embodiment 1

[0069] (1) React soybean oil at 180°C for 14 hours, adjust the resin viscosity to 300s with diethylene glycol butyl ether, and obtain an alkyd resin;

[0070] (2) Pre-dispersion: In parts by weight, add 6.3 parts of mixed alcohol ether solvent and 45.5 parts of alkyd resin into the feeding dispersion tank and stir evenly; add 0.25 parts of wetting agent, 0.5 parts of dispersing agent, and 0.3 parts of gas phase Silica, disperse at high speed for 15 minutes at 1000rpm; then add 15 parts of titanium dioxide and 10 parts of barium sulfate in sequence, and stir at a high speed at 1000rpm until it is in a uniform state; among them, the alcohol ether solvent is diethylene glycol methyl ether , tripropylene glycol methyl ether, the mixed solvent of diethylene glycol ether, the volume ratio of diethylene glycol methyl ether, tripropylene glycol methyl ether, diethylene glycol ether is 4:4:2;

[0071] (3) Grinding: the obtained material is sucked into a sand mill with a diaphragm pump ...

Embodiment 2

[0074] (1) React linseed oil at 190°C for 15 hours, and adjust the resin viscosity to 280s with diethylene glycol butyl ether to obtain an alkyd resin;

[0075] (2) Pre-dispersion: In parts by weight, add 5.8 parts of mixed alcohol ether solvent and 42 parts of alkyd resin into the feeding dispersion tank and stir evenly; add 0.2 parts of wetting agent, 0.4 parts of dispersant, and 0.3 parts of gas phase Silicon dioxide, disperse at high speed for 15 minutes under the condition of 1000rpm; then add 16 parts of titanium dioxide and 15 parts of barium sulfate in sequence, and stir at a high speed under the condition of 1000rpm until it is in a uniform state; among them, the alcohol ether solvent is diethylene glycol butyl ether : the mixed solvent of dipropylene glycol butyl ether, the volume ratio of diethylene glycol butyl ether and dipropylene glycol butyl ether is 3:7;

[0076] (3) Grinding: the obtained material is sucked into a sand mill with a diaphragm pump or a gear pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com