Patents

Literature

130 results about "Lead naphthenate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chronic lead intoxication was produced by cutaneous application of lead naphthenate solution (80-200 mg Pb/kg body weight) for a period of 8 weeks and chronic selenium intoxication was induced by giving 5 ppm, 10 ppm and 15 ppm selenium in drinking water.

Conductive polyaniline film rust proof oil

InactiveCN1718860AImprove anti-corrosion performanceAchieve anti-corrosion effectParaffin waxButanedioic acid

The film-type antirust oil for iron and steel is proportionally prepared from electrically conductive polyphenylamine, tetradecanyl polymethyl acrylate, tert-butylphenol formaldehyde resin, dibutyl phthalate, lead naphthenate, benzotriazole, 2.6-ditert-butyl p-cresol, paraffin wax, barium soap, barium dinonyl naphthalenesulfonate or dodecenyl butanedioic acid and solvent oil.

Owner:JILIN ZHENGJI TECH DEV

Insulation primer

InactiveCN102977736AFast curingIncrease the resistance valueEpoxy resin coatingsEpoxyBenzoyl peroxide

The invention provides an insulation primer which comprises, by weight, 30 to 45 parts of an epoxy resin, 13 to 16 parts of dimethylaminopropane, 3 to 5 parts of a polyimide resin, 1 to 3 parts of zinc borate, 2 to 6 parts of magnesium carbonate, 2 to 6 parts of talcum powder, 1 to 3 parts of barium metasulfate, 3 to 5 parts of phosphatidylcholine, 2 to 3 parts of epoxidized calcium, 0.5 to 1.5 parts of lead naphthenate, 5 to 12 parts of trimethylol propane, 5 to 8 parts of benzoyl peroxide, 0.5 to 1.5 parts of dimethyl aniline and 20 to 25 parts of a solvent, wherein the solvent is glycol or xylene, and the epoxy resin is one or a mixture of more selected from the group consisting of the epoxy resin E-20, the epoxy resin E-42 and the epoxy resin E-51. According to the invention, a proper amount of a resistance adjusting agent dimethylaminopropane is added into a formula for the insulation primer, so a resistance value of a film formed by the primer is increased, conductive capability is reduced, and an insulation effect is obtained.

Owner:苏州市德莱尔建材科技有限公司

Cold-rolling steel-plate punch drawing lube oil and its production

InactiveCN101029272AImprove adsorption capacityReduce wearAdditivesBase-materialsN-butyl vinyl etherParaffin oils

A cold-rolling steel-plate punch stretch lube oil consists of motor oil 45-55wt%, castor oil 6-10wt%, soya oil 8-12wt%, barium mahogany acid 1-3wt%, lead naphthenate 1-3wt%, chlorinated paraffin 10-20wt%, butyl-octanol zinc salt phosphinothioyl 4-6wt% and poly-n-butyl vinyl ether 6-10wt% and bactericide 0.2-0.3wt%. The process is carried out by adding motor oil into reactor, heating to 90-100degree, adding into barium mahogany acid, lead naphthenate and chlorinated paraffin, agitating at 750-850 / min for 1.5-2.5hrs, lowering temperature to 50-60degree, adding into castor oil, soya oil and bactericide, agitating for 0.5-1.5hrs, lowering to normal temperature, adding into butyl-octanol zinc salt phosphinothioyl and poly-n-butyl vinyl ether and agitating at 85-95 / min for 1.5-2.5hrs. It has better oil-film continuity and adsorption and prevents punch work-piece from being scraped and corrosion.

Owner:DALIAN SANDAAOKE CHEM

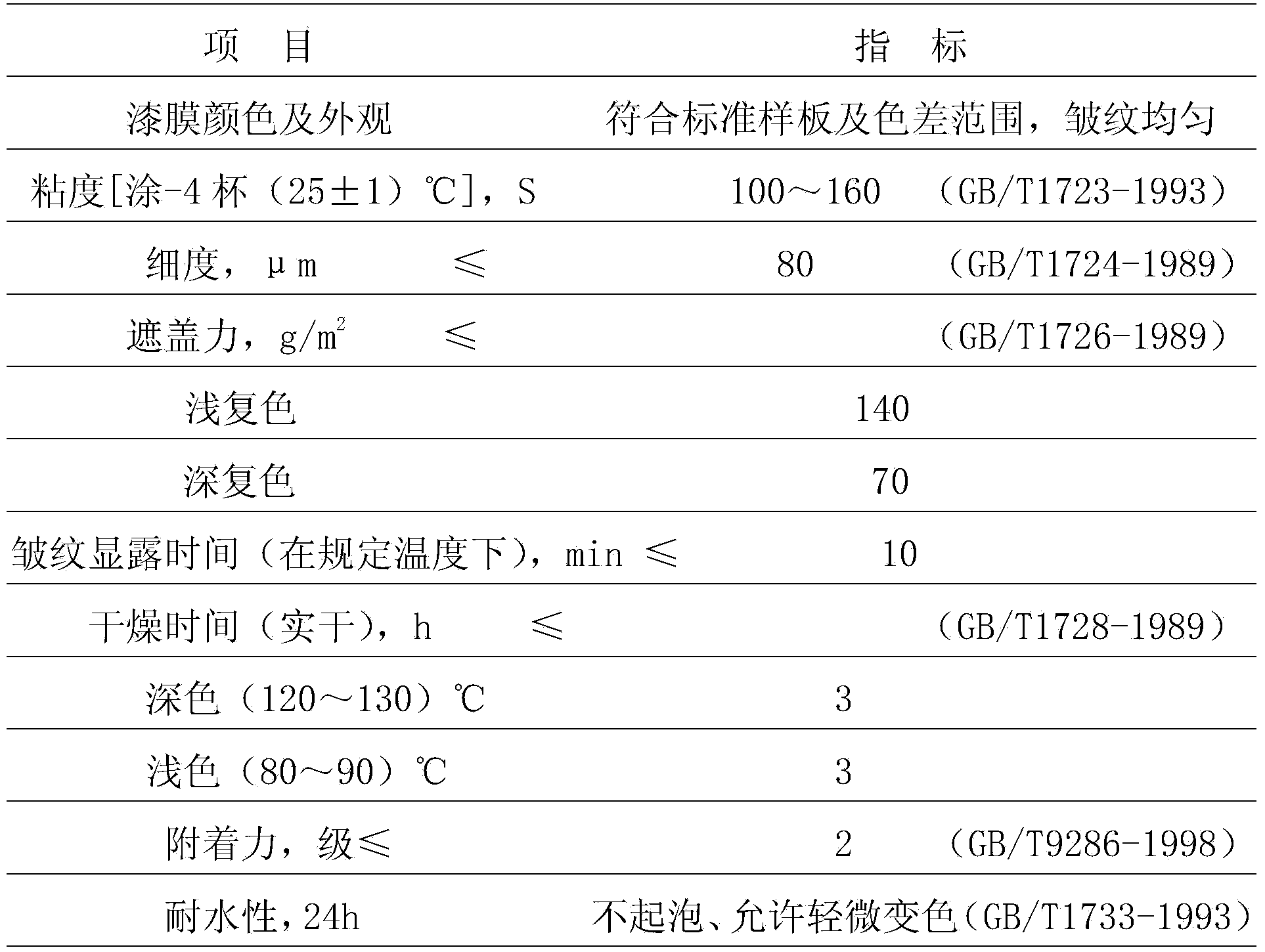

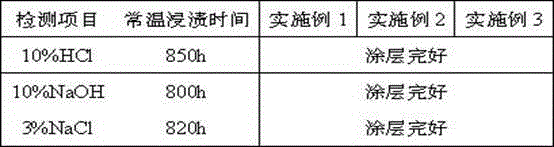

Alcohol acid ripple finish and preparation method thereof

ActiveCN103468106ASimple production processReduce security risksPolyester coatingsCalcium EDTASkin agent

The invention provides alcohol acid ripple finish and a preparation method thereof. The alcohol acid ripple finish comprises, by weight, 50-60 parts of alcohol acid ripple resin (having solid content of 60+ / -3wt%), 5-10 parts of polymerized oil pattern-adjustment resin, 2-3 parts of carbon black, 20-35 parts of light calcium, 0.5-1.5 parts of bentonite HFGEL-40A, 1-2.5 parts of lead naphthenate having the content of 10%, 2-3.5% of cobalt naphthenate having the content of 4%, 0.1-0.3 parts of an anti-skinning agent and 5-10 parts of toluene. The anti-skinning agent is methyl ethyl ketoxime, butyraldehyde oxime or cyclohexanone-oxime and is obtained by mixing. The film of the alcohol acid ripple finish has excellent characters, realizes a flexible change of ripple patterns according to user demands and can be prepared by a simple method.

Owner:天津灯塔涂料工业发展有限公司

Rust proof coating for machinery equipment and preparation method thereof

InactiveCN104130708AEffective protectionExtended service lifeAnti-corrosive paintsBituminous coatingsKaolin clayPhosphoric acid

The invention provides a rust proof coating for machinery equipment and a preparation method thereof. The coating contains the following components by weight: 30-45 parts of coal tar, 8-14 parts of maleic anhydride, 3-6 parts of modified phenolic resin, 10-20 parts of barium borate, 8-15 parts of molybdenum dioxide, 7-14 parts of aluminum tripolyphosphate, 1-3 parts of diatomite, 1-3 parts of kaolin, 1-3 parts of light calcium carbonate, 4-8 parts of propylene glycol, 0.6-1.1 parts of lead naphthenate, and 15-30 parts of deionized water. The coating provided by the invention has excellent rust resistance and wear resistance, hardly peels or blisters, has little environmental pollution, and can effectively protect the mechanical equipment, and prolong the service life of mechanical equipment.

Owner:SUZHOU JUKANG NEW MATERIAL TECH

Metal cutting fluid with high extreme pressure resistance

InactiveCN102757853AStrong resistance to extreme pressureImprove cooling effectLubricant compositionCarboxylic acidOleic Acid Triglyceride

The invention discloses a metal cutting fluid with high extreme pressure resistance, which comprises the following components in part by weight: 16 to 18 parts of barium petroleum sulfonate, 10 to 12 parts of lead naphthenate, 8 to 10 parts of oleic acid, 22 to 28 parts of triethanolamine, 2 to 3 parts of boric acid, 4 to 6 parts of sodium molybdate, 0.5 to 1 part of methyl silicone oil, 3 to 5 parts of borax, 10 to 12 parts of diethanolamine boric acid polycarboxylic acid composite ester, 8 to 10 parts of diethanolamine boric acid maleic anhydride composite ester, 2 to 3 parts of sodium silicate, 3 to 5 parts of nitrobenzoic acid, and 40 to 50 parts of water. A method for synthesizing the diethanolamine boric acid polycarboxylic acid composite ester comprises the step that diethanol amine, polycarboxylic acid and boric acid are subjected to esterification reaction for 2 to 4 h at 150 to 155 DEG C at a mole ratio of 3:1:1. Another method for synthesizing the diethanolamine boric acid maleic anhydride composite ester comprises the step that diethanol amine, maleic anhydride and boric acid are subjected to esterification reaction for 2 to 4 h at 150 to 155 DEG C at a mole ratio of 3:1:1.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Lubricating oil for stamping and stretching stainless steel plate and production method

InactiveCN102585981AWill not cause sticking to the moldPrevents chafing and wearLubricant compositionTert butyl phenolN-butyl vinyl ether

The invention discloses lubricating oil for stamping and stretching a stainless steel plate and a production method. The raw materials are as follows, by mass percentage, 1-6% of chlorcosane, 4-14% of dibutyl phosphite, 1-12% of sulphurized sperm oil, 0.1-1.0% of 2,6-di-tert-butyl phenol, 1-6% of polybutyl vinyl ether, 1-5% of lead naphthenate, 1-16% of oleic acid triethanolamine (1:1.5), 0.1-1.0% of simethicone, 10-30% of transformer oil and the balance machine oil. The production method includes adding the machine oil and the transformer oil into a reaction kettle, heating to 48 to 52 DEG C, starting a blender with rotary speed of 60 turns / minute, adding chlorcosane, dibutyl phosphite, sulphurized sperm oil, lead naphthenate, oleic acid triethanolamine (1:1.5), 2,6-di-tert-butyl phenol, polybutyl vinyl ether, polybutyl vinyl ether and simethicone which are calculated and weighed sequentially into the reaction kettle, stirring for 2-3 hours continuously, dissolving, cooling to room temperature, discharging and packaging.

Owner:DALIAN SANDAAOKE CHEM

High-toughness ceramic nozzle material and preparation method thereof

The invention discloses a high-toughness ceramic nozzle material which is composed of, by weight parts, 70-75 parts of silicon nitride, 26-32 parts of boron nitride, 13-17 parts of nano silicon carbide, 10-14 parts of magnesium fluoride, 18-22 parts of chromium carbide, 15-19 parts of aluminum oxide, 13-17 parts of titanium diboride, 5-8 parts of kaolin, 3-6 parts of halloysite, 1-5 parts of light calcium carbonate, 9-13 parts of magnesium oxide, 1-3 parts of water glass, 5.3-6.0 parts of butyl acetate, 3.5-4.8 parts of carboxymethyl cellulose and 0.8-1.6 parts of lead naphthenate. The invention further discloses a method for preparing the high-toughness ceramic nozzle material. A prepared ceramic nozzle is high in intensity and good in toughness, the deformation resistance of the ceramic nozzle can be greatly improved, the density is high, the washing resistance of the nozzle is improved, and the service life of the nozzle is prolonged.

Owner:扬州北方三山工业陶瓷有限公司

Medical sterilization siloxane coating and preparing method thereof

InactiveCN105694714AImprove the bactericidal effectImprove thixotropyCoatingsDodecaneHexamethylenediamine

The invention discloses a medical sterilization siloxane coating and a preparing method thereof. Raw materials include methyltrimethoxysilane, isopropanol, acetic acid, dodecyl dimethyl benzyl ammonium bromide, silica gel, aluminum powder, water, hexamethylenediamine, lead naphthenate and ammonium persulfate. The medical sterilization siloxane coating is superior in sterilization performance and suitable for coating protection of medical materials, viscosity is 25-35 s, the adhesive force is 1-2 level, flexibility is 1-2 mm, the coating is free of toxin and is good in thixotropic property, the surface drying time is 1-2 h, the solid drying time is 12-16 h, the 45 degree gloss is 85-95%, the water resisting property is 4-8 h without change, the Shore hardness is 30-60, and the elastic elongation is 400-600%.

Owner:SUZHOU BEC BIOLOGICAL TECH

Water type colorful coating

InactiveCN104073066AColorfulBright coating colorMulticolor effect coatingsHydroxyethyl celluloseSodium hydroxide

The invention discloses a water type colorful coating which is prepared from the following raw materials in parts by weight: 100 parts of hydroxyethyl cellulose, 15-25 parts of isopropanol, 20-30 parts of sodium hydroxide, 40-50 parts of xylene, 10-20 parts of sodium carboxymethylcellulose, 5-15 parts of lead naphthenate, 80-90 parts of deionized water, 15-35 parts of cobalt naphthenate, 10-20 parts of pigment, 25-35 parts of modified bentonite, 20-40 parts of sodium polystyrenesulfonate, 10-30 parts of talcum powder, 4-10 parts of plasticizer, 30-40 parts of titanium dioxide, 10-20 parts of naphthalene sulfonic acid and 20-30 parts of zinc phosphate. The product is bright and smooth in color, a coating film is resistant to scrubbing of 12000-13000 times without exposing a substrate, the dispersibility is good, no bobbles are caused and no powder drops off when the product is soaked in water of 20 DEG C for 40-60 days, the consumption of a reciprocating testing machine of 1000 times is 0.004-0.006g / cm<2>, the coating film is bright in color and good in decoration effect after being stored for 6-10 months at 25 DEG C, and thus the coating can be widely produced to constantly replace a conventional material.

Owner:苏州市超邦涂料有限公司

Acrylic resin polyurethane powder coating for ceramics

The invention discloses an acrylic resin polyurethane powder coating for ceramics. The acrylic resin polyurethane powder coating comprises the following raw materials: dimethyl glutarate, methacrylic acid, diethanol amine, lead naphthenate, carbon black, polysiloxane, ultraviolet ray absorber, polycarbodiimide, calcium stearate, azelaic acid, flatting agents, sorbitol anhydride monolaurate, butyl maleic acid, dimethyl dodecyl amine and methyl methacrylate; a melting point of the product is 180-200 DEG C and the density is130-150 g / cm<3>, and the phenomena of bubbling and dropping are avoided after the product is soaked for 40-50 days in water; the tensile strength is 20-40 MPa, the elongation rate is 300-400 percent, and the product is soaked for 25-35 days in a 5% hydrochloric acid solution and the abnormal phenomenon is avoided; the lustrousness is 115-135 percent, and the product is soaked for 20-30 days in saturated calcium hydroxide, and the phenomena of bubbling and wrinkling are avoided; the drying time is 20-30 minutes, and the time of the washing fastness is 1,600-2,000 times.

Owner:苏州非特兄弟新材料科技有限公司

Anti-rust drawing oil and preparation method thereof

InactiveCN102899148AMeet the needs of lubricationMeet the needs of anti-rustAdditivesEnvironmental resistanceBenzotriazole

The invention belongs to the fields of hardware product lubrication and anti-rust technologies, and discloses anti-rust drawing oil and a preparation method thereof. The drawing oil consists of the following components in percentage by weight: 7 percent of barium petroleum sulfonate, 1 percent of benzotriazole tri-n-butylamine, 1-2 percent of lead naphthenate, 15-25 percent of vaseline and 65-76 percent of diesel oil. The drawing oil can meet the requirement of lubrication during stamping (such as drawing or bending), and can also meet the anti-rust requirement between the steps; the anti-rust period of a stamped workpiece is over seven days; and rust protection between the steps is not required additionally. The preparation method comprises the steps of: directly mixing the raw materials; heating through a heating tube; mechanically stirring; and collecting. The preparation method has the advantages of easiness, convenience, environmental friendliness, low cost and easiness in implementation.

Owner:SOUTH CHINA UNIV OF TECH

Alloyed steel work-piece tapping oil and production method

InactiveCN101255373ASmall thermal deformationFast heat conductionAdditivesTert butylLead naphthenate

The invention discloses a tapping oil for alloy steel workpiece that reduces cutting temperature and force for tapping to maximum limit, improves process efficiency of tapping and cutting, ensures precision and surface quality of the workpiece and prolongs life of cutting tool for tapping, reduces cost, satisfies requirements of environmental protection, and method for making the same. Weight percentage of the raw material is 5# high speed oil 38%-42%, 20# machine oil 18%-22%, vulcanized oleic acid 9-13%, paraffinum chloride 18-22%, sulfur phosphorus butanol-octanol zinc salt (T-202) 1-3%, 2,6-Di-tert-butyl-4-methylphenol 0.5-1.5%, lead naphthenate 4-6%, sodium petroleum sulfonate 0.5-1.5%, 2-methyl-3(2H)-Isothiazolone 0.1-0.2%. The production process is synthesis with stirring under condition of normal temperature - high temperature - normal temperature.

Owner:DALIAN SANDAAOKE CHEM

Method for preparing metal cutting fluid with high extreme pressure resistance

InactiveCN102703197AStrong resistance to extreme pressureImprove rust resistanceLubricant compositionCarboxylic acidOleic Acid Triglyceride

The invention discloses a method for preparing a metal cutting fluid with high extreme pressure resistance. The method for preparing the metal cutting fluid with high extreme pressure resistance comprises the following steps of: 1) synthesizing diethanolamine-boric acid-polycarboxylic acid complex ester, namely performing esterification reaction of diethanolamine, polycarboxylic acid and boric acid in a molar ratio of 3:1:1 at the temperature of 150 to 155 DEG C for 2 to 4 hours; 2) synthesizing diethanolamine-boric acid-maleic anhydride complex ester, namely performing esterification reaction of diethanolamine, maleic anhydride and boric acid in a molar ratio of 3:1:1 at the temperature of 150 to 155 DEG C for 2 to 4 hours; 3) raising the temperature of water to 70 to 80 DEG C, sequentially adding lead naphthenate, oleic acid, barium petroleum sulfonate, triethanolamine, borax, sodium silicate and nitrobenzoic acid under stirring, continuing to stir for 20 to 40 minutes, reducing the temperature to 50 to 60 DEG C, adding sodium molybdate and boric acid under the condition of constant stirring, stirring for 20 to 30 minutes, adding methylsilicone oil, and stirring for 10 to 20 minutes; and 4) mixing products obtained in step 1)-3), and stirring at the temperature of 50 to 60 DEG C for 60 to 90 minutes to obtain the metal cutting fluid.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Alkyd resin coating formula

The invention discloses an alkyd resin coating formula which comprises the following raw materials in part by mass: 85-90 parts of 50% alkyd resin, 1-3 parts of carbon black, 0.05-0.1 part of massicot, 1-1.5 parts of 12% lead naphthenate, 1-1.5 parts of 3% cobalt naphthenate, 0.5-0.8 part of 3% manganese naphthenate, 0.6-0.8 part of 2% zinc naphthenate, 0.7-0.9 part of 1% calcium naphthenate, 2-3 parts of bipentene, 2-3 parts of xylene and 5-8 parts of mildew inhibitor. The alkyd resin coating formula is strong in adhesion property, not easy to fall, easy to operate and excellent in overall performance, and has a mildewproof function.

Owner:HAIAN GUOLI CHEM

Stainless steel stamping tension lubricating oil

InactiveCN103756763AImprove the lubrication effectImprove cooling effectLubricant compositionPhosphorous acidTert butyl phenol

The invention discloses a stainless steel stamping tension lubricating oil which comprises the following components in parts by mass: 1-2 parts of glycerin monostearate, 55 parts of LN32 mechanical oil, 8 parts of chlorinated paraffin, 4 parts of dimethyl silicon oil, 19 parts of phosphorous acid di-n-butyl phosphate, 8 parts of lead naphthenate, 23 parts of triethanolamine oleate, 9 parts of poly(n-butyl) vinyl ether, 35 parts of transformer oil, 17 parts of vulcanized whale oil, 2 parts of 2.6-di-tert-butyl phenol and 1 part of hydroxypropyl methyl cellulose. The stainless steel stamping tension lubricating oil is good in lubrication and cooling property and easy to demold, and is capable of preventing a stamped surface from scratch or rusting, ensuring surface smoothness and cleanness, and meeting the direct assembling requirements.

Owner:CHANGSHU MEIERTE METAL PROD

Extreme pressure resistant additive for industrial gear oil

InactiveCN101993764AImprove extreme pressure performanceImprove efficacyAdditivesMethacrylateFatty amine

The invention discloses an extreme pressure resistant additive for industrial gear oil, which is basically characterized by consisting of base oil, antimony dialkyl-dithiocarbamate, phenothiazine, fatty amine, thiadiazole, polyisobutene, polyalkoxy polyamine, a long-chain amino compound, polyalkyl methacrylate, polydimethylsiloxane and metal magnesium powder, namely, 42 to 45 weight percent of lead naphthenate, 3 to 5 weight percent of diarylamine, 3 to 5 weight percent of ethoxyphenol, 3 to 5 weight percent of thiobenzothiazole, 5 to 6 weight percent of dialkyl dithiophosphate, 3 to 4 weight percent of polyisobutene, 2 to 3 weight percent of polyalkoxy polyalcohol, 2 to 4 weight percent of polyalkyl methacrylate, 4 to 5 weight percent of polyacrylate, 3 to 4 weight percent of metal magnesium powder and the balance of base oil. The preparation method of the additive is simple, economic and practical, and the preparation scheme is scientific. The prepared product is applicable to various kinds of industrial gear oil and can improve the extreme pressure resistance of the gear oil by more than 2 times. Besides the extreme pressure resistance of the gear oil, the additive can improve the effects of the gear oil to make the effects of the gear oil exceed national standards and prolong the service life of the gear oil.

Owner:TIANJIN GONGBO SCI TECH DEV

Lubricating grease antioxidant

The invention relates to a lubricating grease antioxidant additive which is basically characterized by comprising the following components in percentage by weight: 42-45 percent of sterically hindered phenol, 3-5 percent of alkylated succinic acid derivative, 3-5 percent of bisalicylpropane diamine, 6-8 percent of alkyl containing phosphate and salt, 4-6 percent of lead naphthenate, 3-5 percent of metal borates, 5-7 percent of polyisobutene and the balance of base oil. The lubricating grease antioxidant additive has the advantages of simple preparation, economy, practicability and low cost, can ensure that the oxidation resistance of common lubricating grease is greatly improved and various properties of the lubricating grease are greatly improved when the oxidation resistance of the lubricating grease is enhanced and the use period is prolonged, has no damage to mechanical equipment and comprehensively improves various effects of the lubricating grease.

Owner:TIANJIN GONGBO SCI TECH DEV

Molybdenum disulfide-added stainless steel wire drawing liquid with good lubricity and preparation method thereof

The invention discloses a molybdenum disulfide-added stainless steel wire drawing liquid with good lubricity, which comprises the following raw materials by weight: 2-3 parts of molybdenum disulfide, 2.5-4 parts of cerium tetrafluoride, 1-2 parts of cobaltous naphthenate, 4-5.5 parts of fatty alcohol polyoxyethylene ether, 3-4 parts of glycol, 2.5-3.5 parts of citric acid, 3-5 parts of sorbitan mo-nooleate, 1-2 parts of lead naphthenate, 3.5-4.5 parts of vulcanized whale oil, 3-4 parts of bobbin oil, 5-7 parts of auxiliary agent and 900-950 parts of deionized water. The added molybdenum disulfide as a lubrication additive is mixed with a surfactant through grinding, powder has the advantages of uniform dispersion as well as stable and uniform quality, and the added auxiliary agent has good antiwear, dispersion, lubrication and film forming ability. The employed aqueous formula has good heat radiation and cleaning performance, the wire drawing liquid has advantages of good lubrication performance, low flow viscosity, good fluidity and stability, and low cost, and is suitable for wire drawing of the stainless steel.

Owner:ANHUI TATSU PRECISION ALLOY

Preparation method of oily iron oxide red antirust paint

The invention discloses a preparation method of an oily iron oxide red antirust paint. The product of the invention is an oily metal antirust paint, and the working principal thereof is that the density of a paint film is improved and the permeability of the paint film is reduced by means of the stability of the antirust paint in physical and chemical properties and excellent filling property of the antirust paint, thus the antirust effect is realized. The antirust paint has the advantages that: the paint film has excellent adhesive force and impact resistance, good oiliness, solvent resistance, water resistance and saline resistance, outstanding compatibility with epoxy type finish, polyurethane type finish and chlorinated rubber finish, and superior interlayer adhesive force. The raw materials adopted for producing the paint are as follows: oil-based phenolic aldehyde paint, iron oxide red, zinc oxide, precipitated barium sulfate, calcium carbonate, 4% of cobalt naphthenate, 3% of manganese naphthenate, 10% of lead naphthenate, zinc stearate, No. 200 paint solvent gasoline, epoxy resin and a polyamide curing agent.

Owner:王胜美

Phenolic resin coating

The invention relates to a phenolic resin coating. The coating comprises, by weight, 70-80 parts of a phenolic interior enamel material, 2-3 parts of a HL assistant agent, 4-6 parts of light calcium carbonate, 6-8 parts of 200# solvent oil, 0.5-0.6 parts of 2% cobalt naphthenate, 0.5-0.6 parts of 2% naphthenic acid, 0.8-1 parts of 10% lead naphthenate, and 6-8 parts of carbon black. The coating of the present invention has the following advantages that: the phenolic resin coating is applicable for the surface finishing of interior metals and wood objects, the use effect is good, and the production cost is low.

Owner:李之洲

Thick-wall bearing steel pipe drawing lubricating emulsifying oil and production method thereof

InactiveCN102585978AImprove adsorption capacityReduce wearLubricant compositionN-butyl vinyl etherTriethylamine phosphate

The invention discloses thick-wall bearing steel pipe drawing lubricating emulsifying oil, which consists of the following raw material components in percentage by mass: 1-15 percent of oleic acid, 1-8 percent of barium mahogany sulfonate, 1-8 percent of lead naphthenate, 10-20 percent of chlorinated paraffin, 10-20 percent of 2,6-butylated hydroxytoluene, 1-4 percent of triethyl phosphate, 1-4 percent of dibutyl phthalate, 1-6 percent of zinc dialkyl dithiophosphate, 1-6 percent of polyvinyl butyl ether and the balance transformer oil. A production method of the emulsifying oil comprises the following steps of: adding the transformer oil into a reaction kettle, and heating to 40-50 DEG C; starting a stirrer and controlling the rotating speed at 40 revolutions per minute; slowly and sequentially adding barium mahogany sulfonate, lead naphthenate, oleic acid, chlorinated paraffin, triethyl phosphate, dibutyl phthalate, T501, T202 and T601 into the reaction kettle, wherein a next raw material is added till a previous raw material is fully dissolved by stirring; after all raw materials are dissolved, continually stirring for 1 hour; and discharging and packaging.

Owner:DALIAN SANDAAOKE CHEM

Phenolic aldehyde varnish

A phenolic aldehyde varnish comprises, by weight, 4-6 parts of light calcium carbonate, 70 parts of phenolic aldehyde paint, 6-8 parts of tung polymerized oil, 6-8 parts of solvent naphtha 200, 0.5-0.6 part of 2% cobaltous naphthenate, 0.5-0.6 part of 2% manganese naphthenate, 0.8-1 part of 10% lead naphthenate and 6-8 parts of pigment scarlet powder. The invention has advantage that the enamel is suitable for surface coating of indoor woodenware in building engineering, traffic tool and machinery equipment, and metal manufacturing; besides the varnish has a good effect and low production cost.

Owner:李之洲

Anti-rust undercoat of mine production machine

InactiveCN109161305AImprove adhesionDry fastAnti-corrosive paintsEpoxy resin coatingsDiacetone alcoholALUMINUM STEARATES

Owner:TONGLING MINGCHENG FOUNDRY

Lubricating grease antirust anticorrosive additive

InactiveCN101988004AImproved anti-rust and anti-corrosion functionImprove anti-rust and anti-oxidationAdditivesHydrogenPhosphate

The invention discloses a lubricating grease antirust anticorrosive additive, which is basically characterized by comprising the following components in percentage by weight: 48 to 53 percent of sodium hydrogen sebacate, 3 to 5 percent of phenothiazine, 3 to 5 percent of bis(salicylidene)-propanediamine, 5 to 7 percent of dialkyl two glucosinolate and phosphate, 3 to 6 percent of lead naphthenate, 2 to 5 percent of calcium carbonate, 5 to 8 percent of polyisobutene, 2 to 4 percent of atactic polypropylene, and the balance of base oil. The preparation method is simple; the preparation scheme is economic and practical; the cost is low; the additive can greatly improve the antirust and anticorrosive functions of common lubricating grease, improve the antirust and antioxidation performance of the lubricating grease and various comprehensive properties of the lubricating grease and prolong the service life of the lubricating grease, and has good protection effect on mechanical equipment.

Owner:TIANJIN GONGBO SCI TECH DEV

Interior wall paint

InactiveCN104356942AImprove stabilityGood acid and alkali resistanceRosin coatingsPolyester coatingsCellulosePhosphoric acid

Interior wall paint comprises components of raw materials in parts by weight as follows: 8-14 parts of zinc oxide, 3-9 parts of talcum powder, 5-7 parts of lead naphthenate, 5-9 parts of carboxymethylcellulose, 5-7 parts of tributyl phosphate, 4-10 parts of titanium dioxide, 3-6 parts of a thickening agent, 3-8 parts of chlorinated paraffin, 2-6 parts of dibutyric acid, 6-10 parts of rosin, 5-8 parts of pentaerythritol, 4-6 parts of alkyd resin and 7-10 parts of mica powder. The interior wall paint has the benefits of good stability, acid-base resistance, high-temperature resistance and good adhesion force.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

Antioxidant lubricating oil for automobile

ActiveCN104388156AExcellent high temperature detergencyExcellent antioxidant stabilityAdditivesPolyolefinAlpha-olefin

The invention discloses antioxidant lubricating oil for an automobile. The antioxidant lubricating oil for the automobile comprises the following raw materials by weight percentage: 1-5% of dialkenyl succinimide, 0.2-2.0% of alkylated diphenylamine, 1-3% of lead naphthenate, 0.5-2.0% of polymethacrylate, 3-15% of petroleum barium borate, 1-3% of poly alpha olefin, 1-3% of methylsilicone oil, 1-3% of anitimony diisopropyl dithio phosphate, 1-3% of glyceryl monooleate and the balance of base oil. Compared with the prior art, the antioxidant lubricating oil for the automobile has the advantages that the high-temperature cleanliness, the anti-oxidation stability, the antifriction and abrasive resistance, and the base value retainability are excellent, the average oil consumption is low, the engine noise and engine vibration are reduced, the automobile runs more stably, and the driving control performance is remarkably improved.

Owner:GUANGZHOU LEARNBER SCI & TECH DEV

Lubricating grease rust-inhibiting additive

InactiveCN101988006AImproved anti-rust and anti-corrosion functionImprove anti-rust and anti-oxidationAdditivesPhenolPolypropylene

The invention relates to a lubricating grease rust-inhibiting additive which comprises the following components in percent by weight: 50-54 percent of alkylsuccinate derivative, 3-5 percent of hindered phenol, 3-5 percent of bis(salicylidene) propanediamine, 6-8 percent of alkyl phosphate salt, 3-5 percent of lead naphthenate, 2-4 percent of metal borates, 3-5 percent of polyisobutene, 2-4 percent of random polypropylene and the balance of base oil. The lubricating grease rust-inhibiting additive has the advantages of simple preparation method, economic and practical preparation scheme and low cost, can ensure that the rust-inhibiting and corrosion-preventing functions of common lubricating grease are greatly improved, improves various comprehensive properties of the lubricating grease while improving the rust-inhibiting and corrosion-preventing functions of the lubricating grease, can prolong the service period of the lubricating grease, and plays a role of protecting various machines and devices.

Owner:TIANJIN GONGBO SCI TECH DEV

Novel flame-retardant type synthetic hydraulic oil for coal mine

InactiveCN105482881AImprove the shortcoming of easy oxidationHigh biodegradation rateBase-materialsDimethyl methylphosphonateBoron carbide

The invention discloses novel flame-retardant type synthetic hydraulic oil for a coal mine. The novel flame-retardant type synthetic hydraulic oil is prepared from the following raw materials in parts by weight: 280 to 285 parts of industrial oleic acid, 12.6 to 13 parts of iodine, 72 to 74 parts of acrylic acid, 134 to 135 parts of TMP (Trimethylolpropane), 15 to 16 parts of toluenesulfonic acid, 15 to 17 parts of nano boron carbide particles, 0.8 to 1 part of span 80, 2 to 3 parts of CMC (Carboxy Methylated Cellulose) sodium, 30 to 32 parts of deionized water, 3.2 to 3.5 parts of hydroxyethyl imidazolidine, 10 to 12 parts of polymethacrylate, 3.5 to 4 parts of zinc dialkyl dithiophosphate, 0.08 to 0.1 part of benzotriazole, 0.07 to 0.08 part of barium dinonyl naphthalene sulfonate, 3 to 4 parts of tricresyl phosphate, 2 to 3 parts of DMMP (Di-methyl Methyl Phosphonate) and 2.5 to 3 parts of lead naphthenate. The novel flame-retardant type synthetic hydraulic oil prepared by the invention is good in rust resistance, corrosion resistance and flame retardancy and is very suitable for being used by hydraulic equipment of a coal mine system.

Owner:WUHU CHUANGYUAN NEW MATERIALS CO LTD

Car glossiness improvement car paint

A car glossiness improvement car paint comprises the following material components by weight: 8-17 parts of butyl acetate, 3-8 parts of 2-hydroxy ethyl methacrylate, 5-9 parts of isobutyl methacrylate, 2-6 parts of silicon oxide powder, 3-7 parts of alkyl phenol polyoxyethylene alcohol sulfate sodium, 2-5 parts of lead naphthenate, 2-7 parts of phenolic resin, 5-10 parts of unsaturated oleic acid, 6-8 parts of pentaerythritol, 1-5 parts of dimethyl ammonium sulfonate, 2-4 parts of calcium zincate, and 1-3 parts of copper cyanide. The beneficial effect is that: the car glossiness improvement car paint enhances car glossiness, improves the car beautiful degree, and has very good alcohol and gasoline resistance.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com