Patents

Literature

438results about How to "Stable and uniform quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

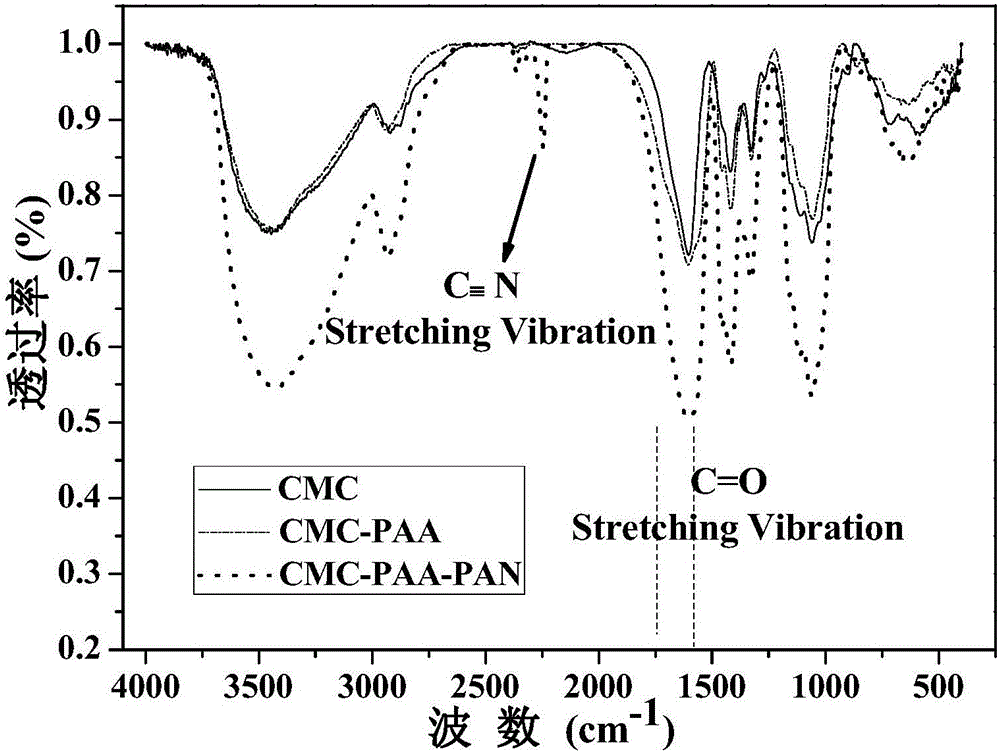

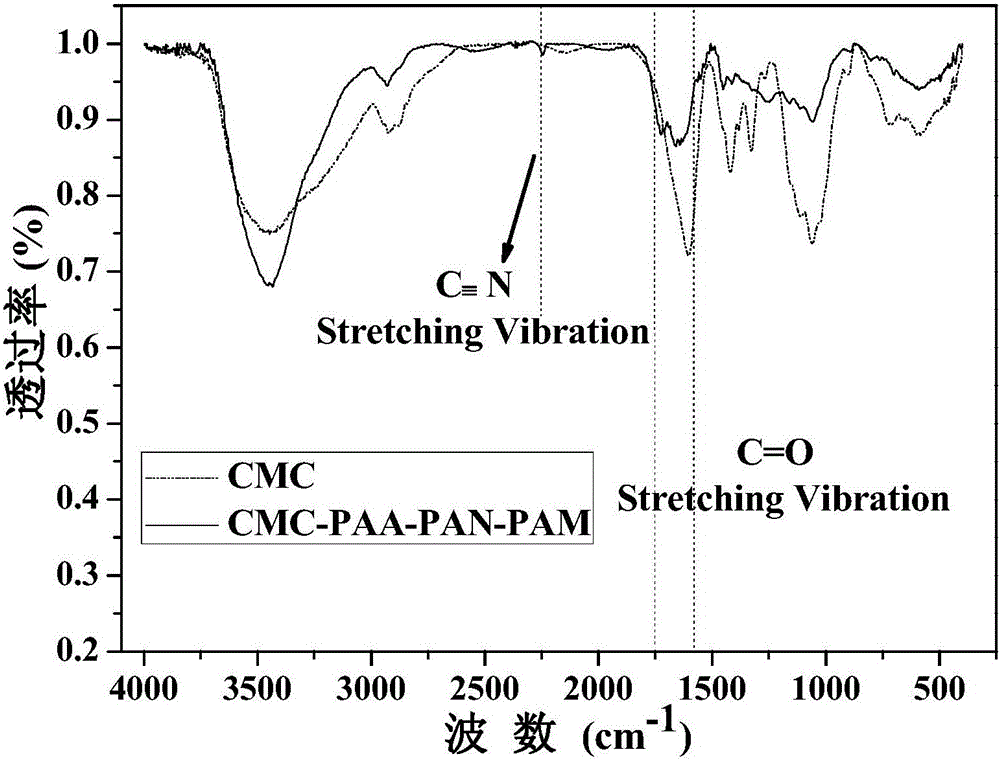

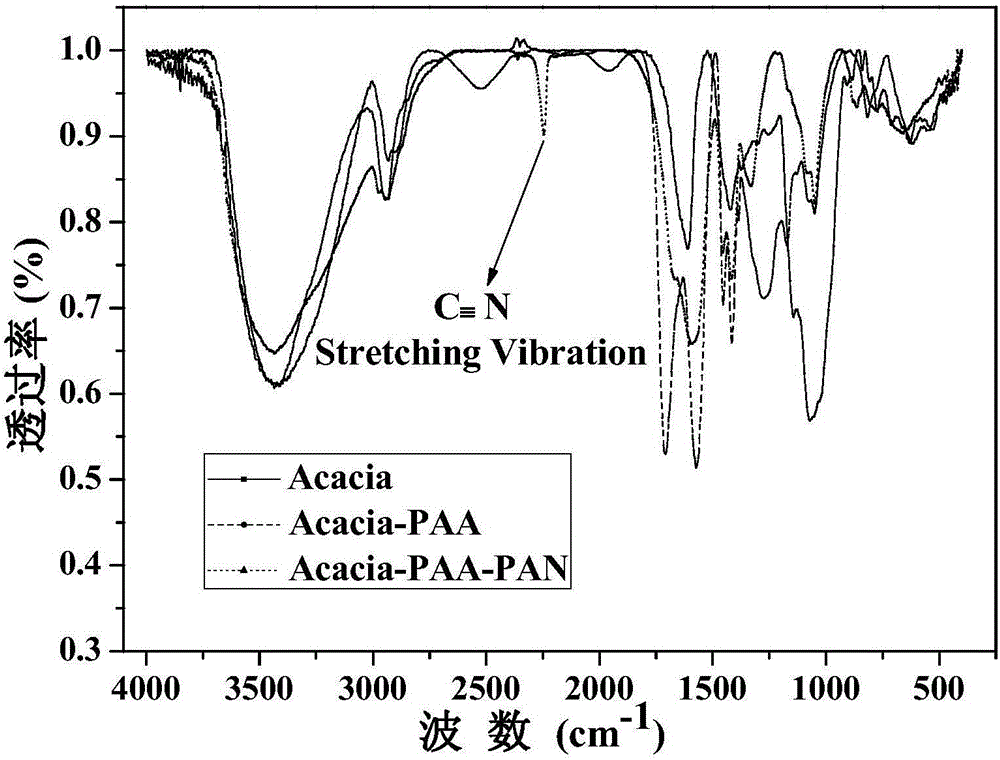

Multielement functional modified polymer binder for lithium ion battery and application of binder in electrochemical energy storage device

ActiveCN105914377AStable and uniform qualityGood overall performanceCyclodextrin adhesivesCellulose derivative adhesivesBiomassAddition reaction

The invention discloses a multielement functional modified binder for a polymer lithium ion battery. The binder takes a biomass polymer or a synthetic polymer as the substrate, takes a hydrophilic monomer and an oleophilic monomer as the functional modified monomer; and then the binder is prepared through a free radical graft copolymerization reaction or a Michael addition reaction in a modification manner. The binder has a multi-branch structured three-dimensional space network body, so that more active sites in contact with the electrode active material can be provided, and the uniformity and the smoothness of the electrode slurry in film-forming can be improved; the peeling strength of the active materials and the conductive agent on the metal substrate is reinforced; and meanwhile, the binder is excellent in elasticity and binding force, can be applied to water / organic solvent and can be applied to the positive electrode and negative electrode of the lithium ion battery; the conduction of electrons / ions in the charging-discharging process can be promoted; the electrochemical interface impedance of the pole piece is lowered; the high rate capacity and the cycling stability of the positive electrode material and the negative electrode material of the lithium battery are relatively improved; in addition, the synthetic raw material is wide in source, so that the cost can be obviously lowered; and therefore, the binder has a wide market prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

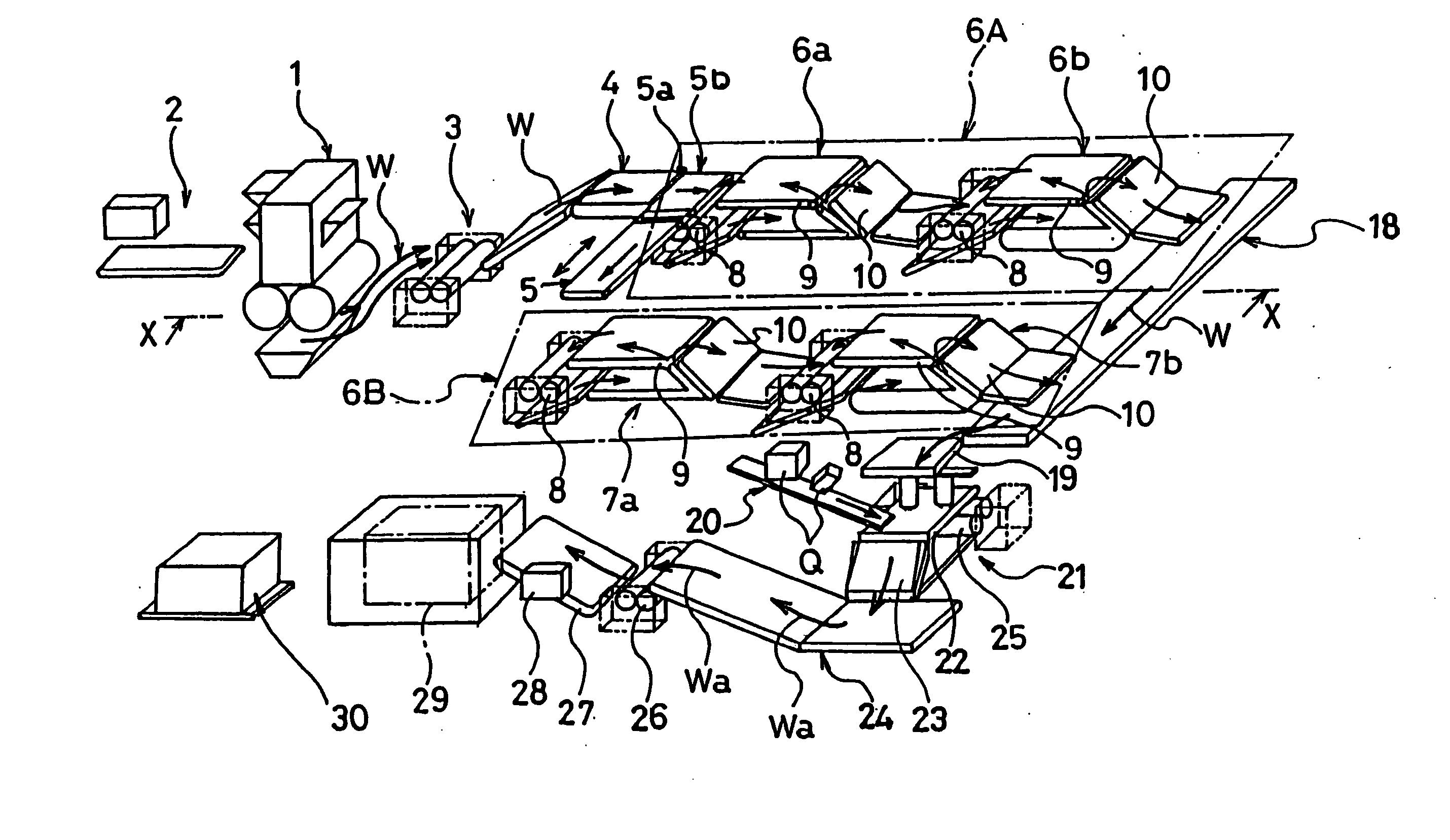

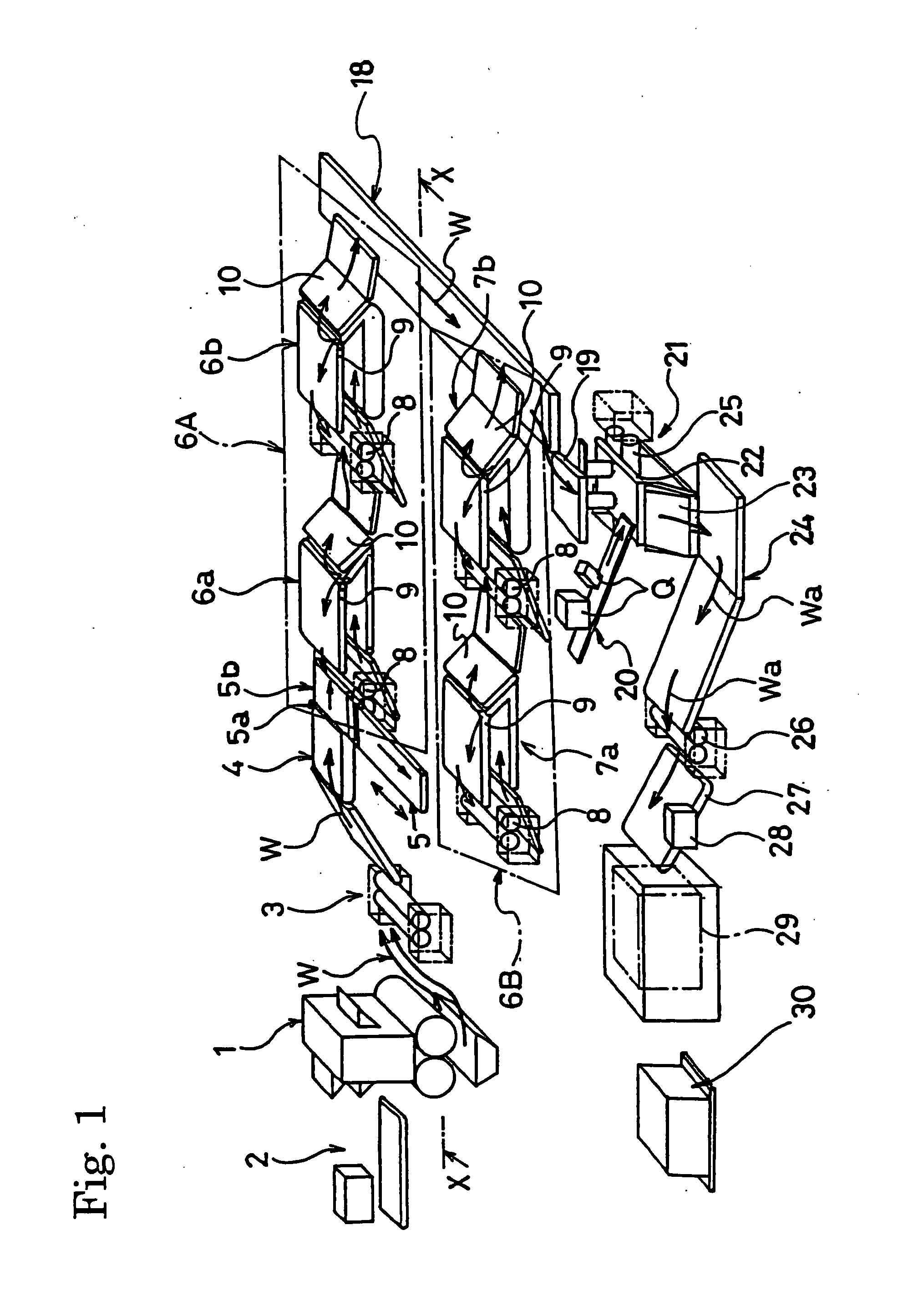

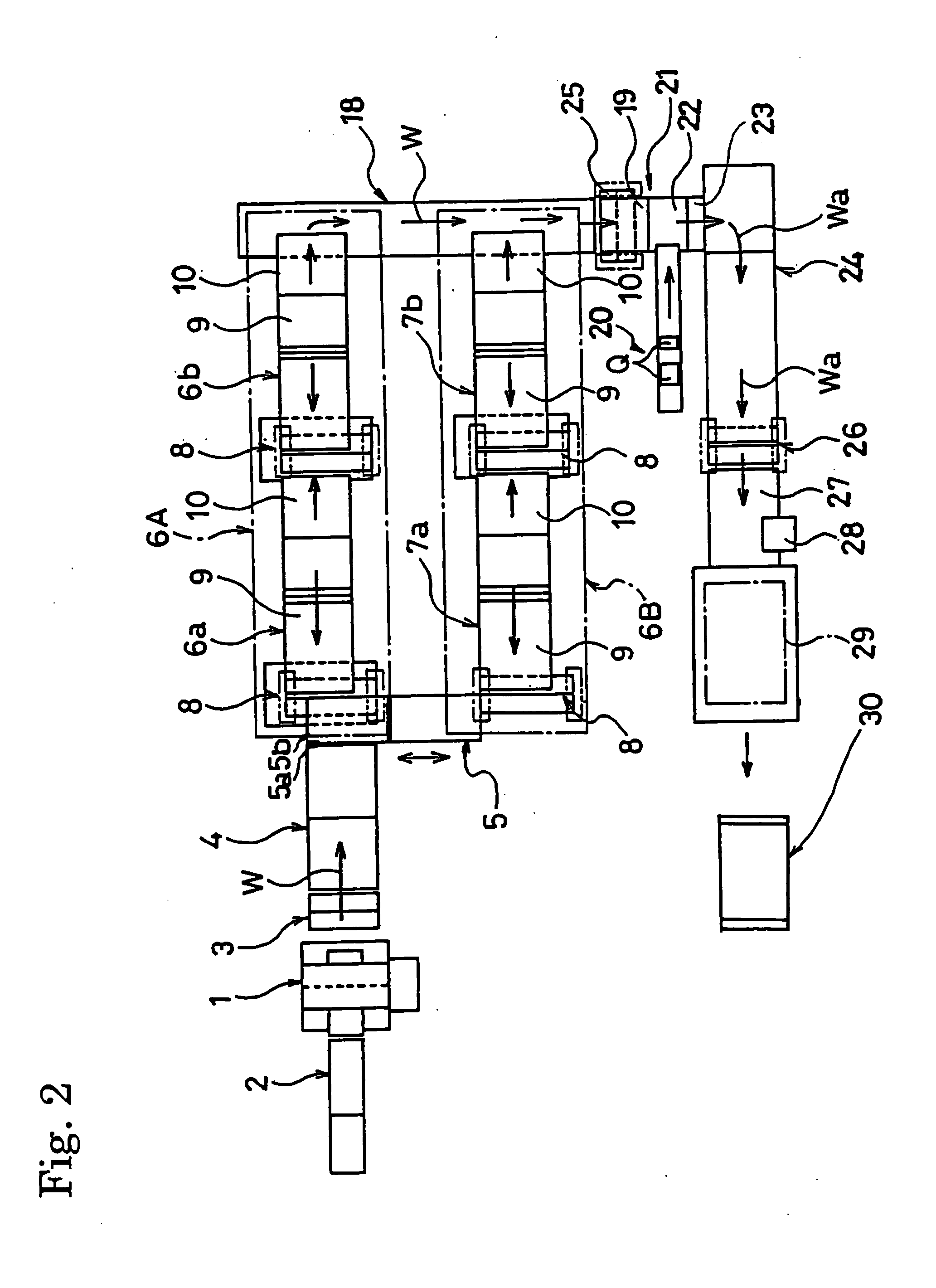

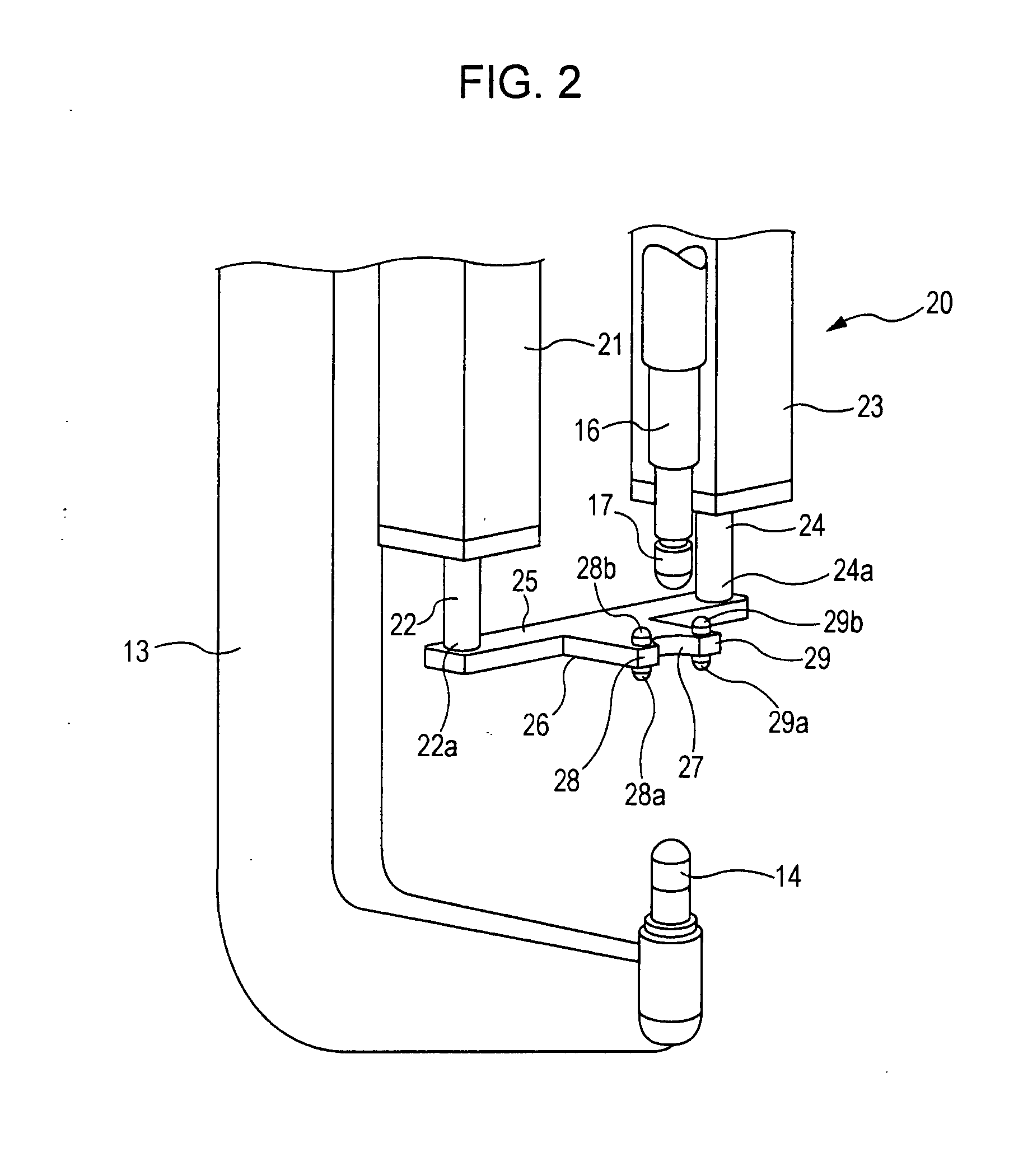

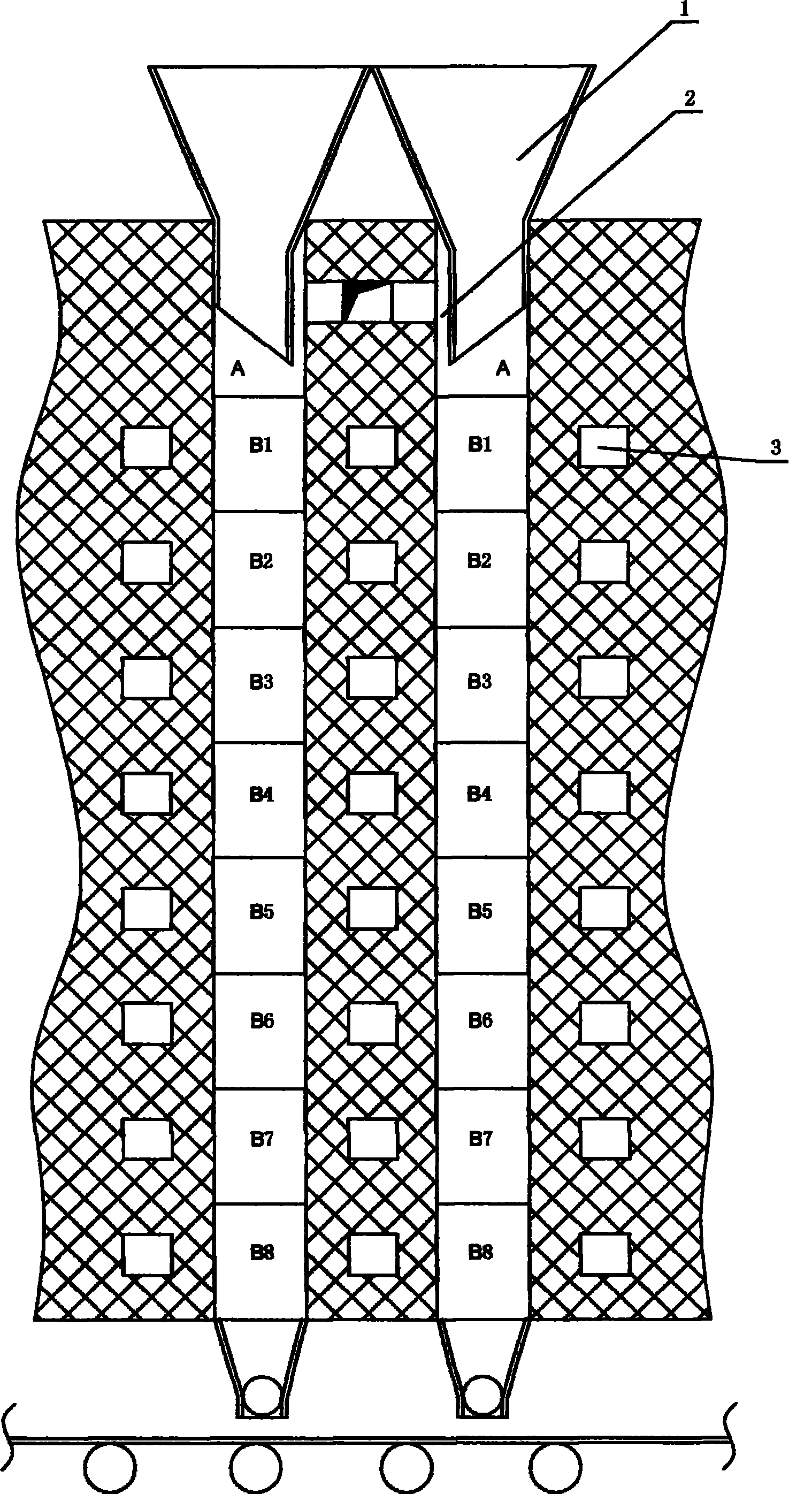

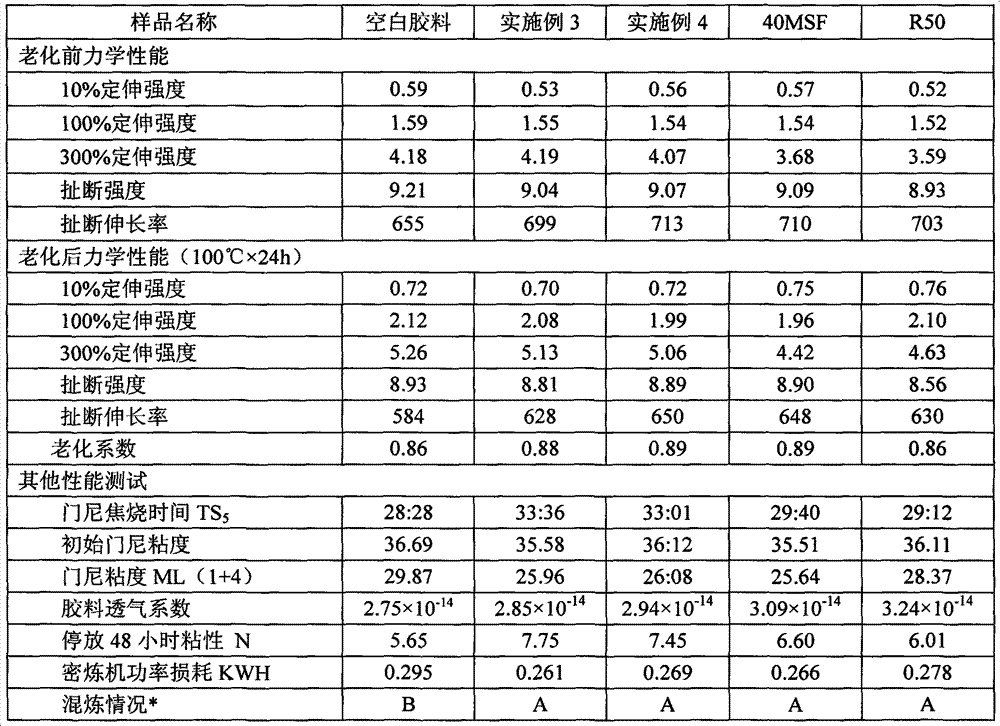

Apparatus for and Method of Kneading Rubber Material

InactiveUS20090238027A1Reduce energy lossLow viscosityDischarging apparatusMixing operation control apparatusRubber materialVulcanization

Disclosed are: an apparatus for kneading a rubber material which continuously performs a series of processes which are kneading a rubber material with a non-vulcanization compounding agent at the beginning, kneading it with a vulcanization compounding agent, and finally obtaining final kneaded rubber; and a kneading method using this kneading apparatus. Preparatory kneaded rubber having been kneaded in one internal mixer is selectively fed, by a distribution conveyor, to a group of kneading lines where at least two kneading lines are provided to be arranged side by side. Each of the kneading line consists of a plurality of open roll mixers serially connected with each other. Intermediate kneaded rubber resulted in having a target viscosity after having been kneaded in the group of kneading lines is kneaded with a vulcanization compounding agent, whereby final kneaded rubber is obtained.

Owner:YOKOHAMA RUBBER CO LTD

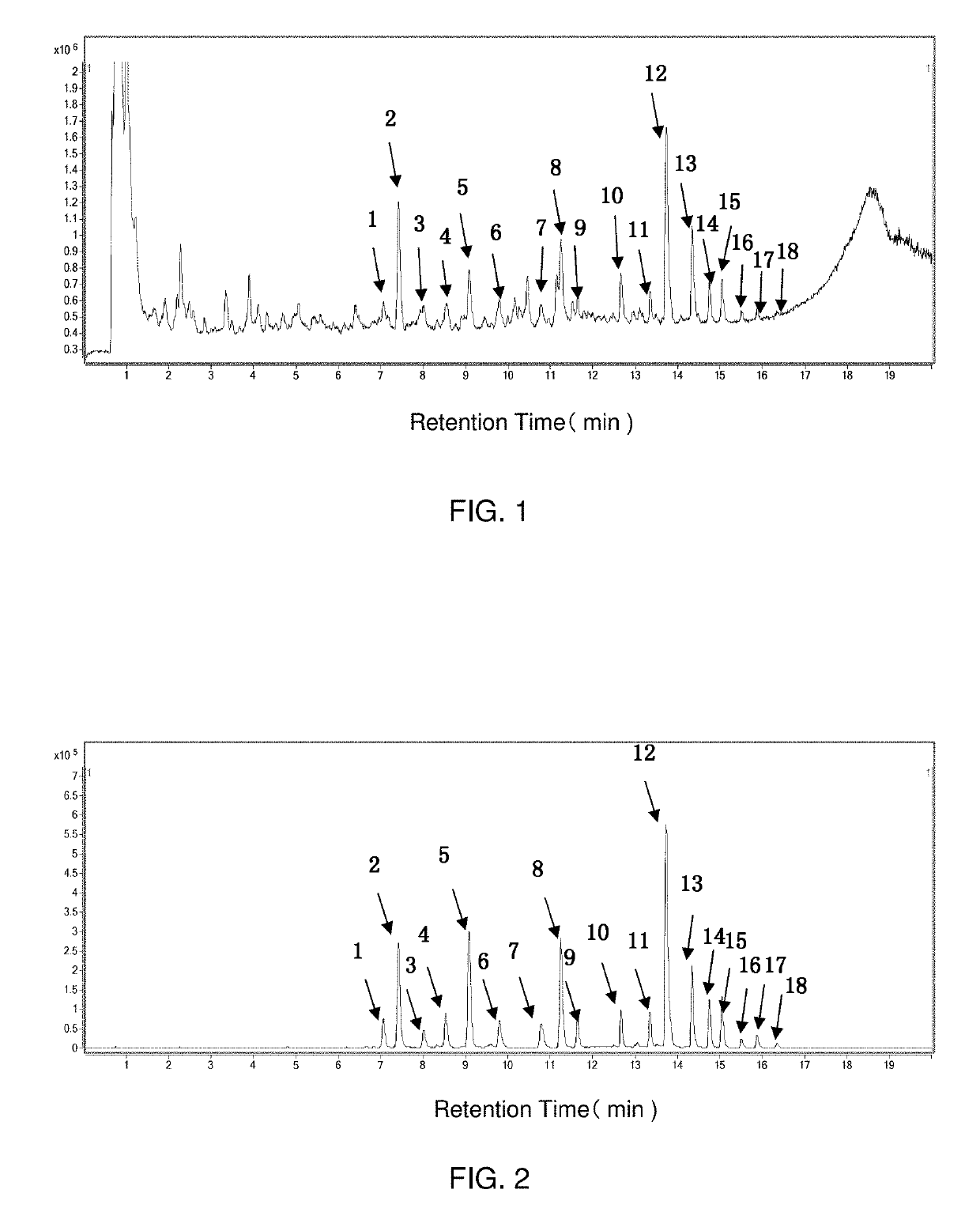

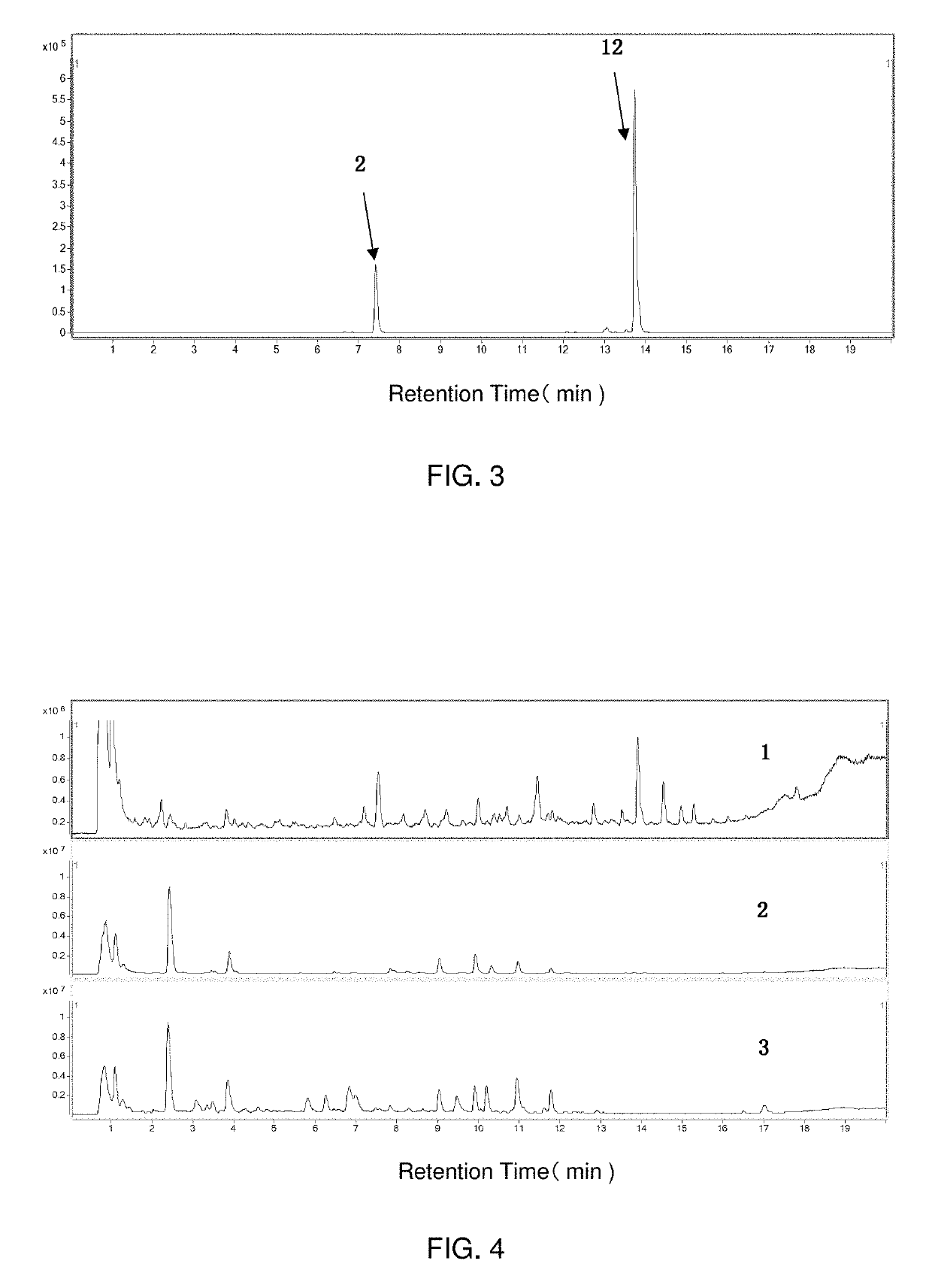

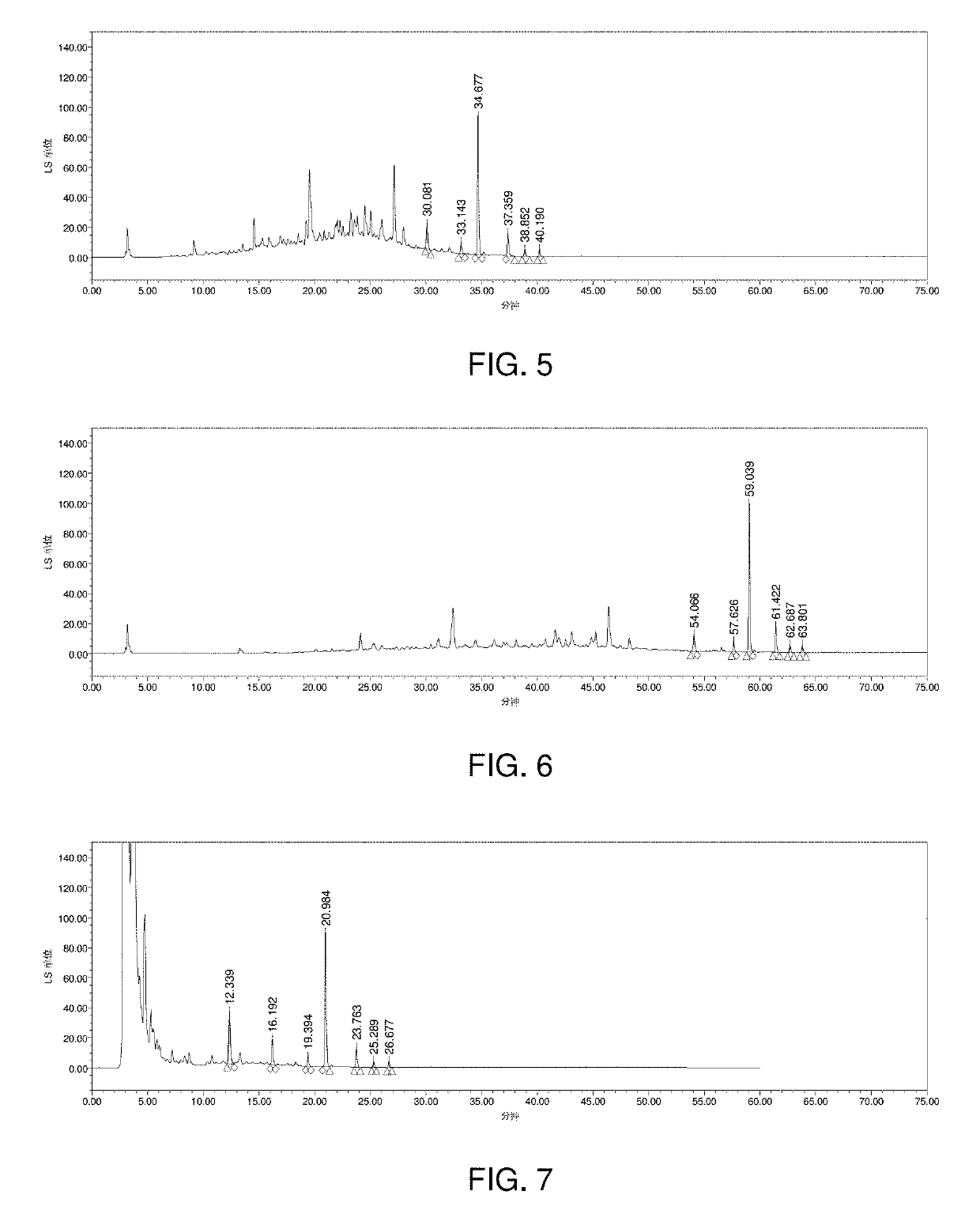

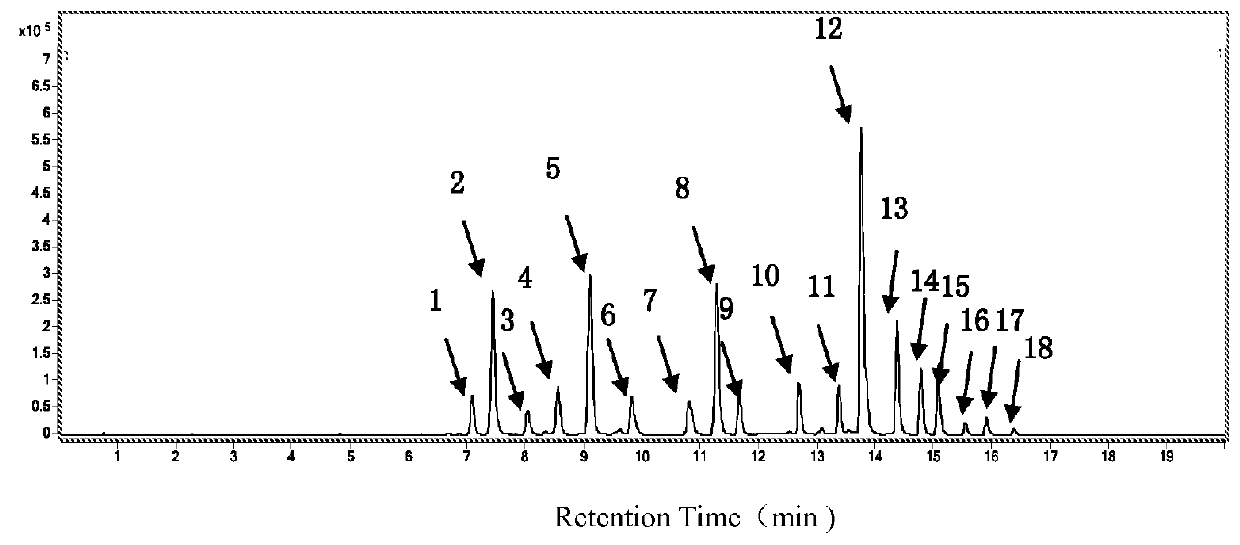

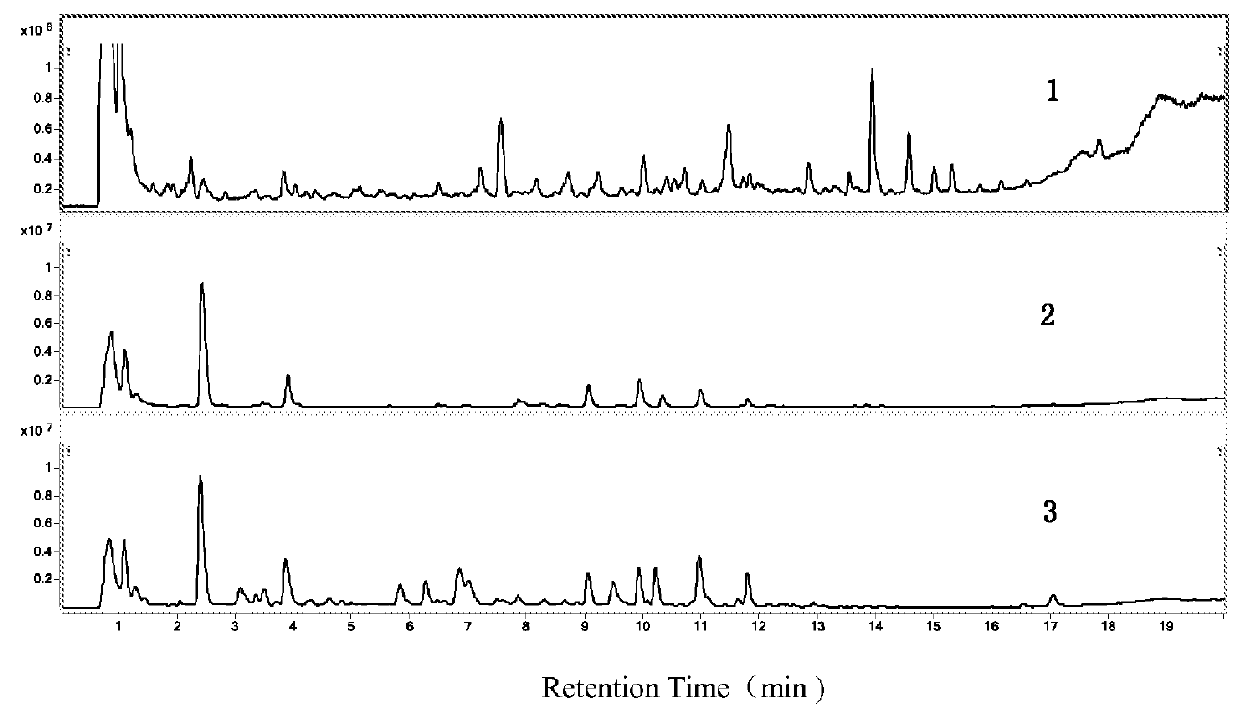

System and Method for Identifying Shenqi Fuzheng Injection

InactiveUS20190219550A1Easy to monitorImprove stabilityComponent separationTesting medicinal preparationsShenqi fuzhengUltra high voltage

A system for identifying Shenqi Fuzheng injection includes a mechanism for establishing a profile of a sample to be tested; a mechanism for establishing a characteristic fingerprint profile of Shenqi Fuzheng injection as a standard fingerprint profile; and a mechanism for comparing the profile of the sample to be tested with the standard fingerprint profile to distinguish between authentic Shenqi Fuzheng injection and counterfeit Shenqi Fuzheng injection.A method for establishing a Shenqi Fuzheng injection fingerprint spectrum, including: employing an ultra-high voltage liquid chromatography mass spectrometer to test the Shenqi Fuzheng injection, the chromatography conditions including: chromatographic column: Agilent Zorbax Eclipse Plus C18, 2.1 mm×100 mm, 1.8 μm; mobile phase: mobile phase A is 0.1% formic acid aqueous solution, and mobile phase B is 0.1% formic acid acetonitrile solution; and employing gradient elution procedure.

Owner:LI MIN PHARM FAB OF LIVZON PHARM GRP

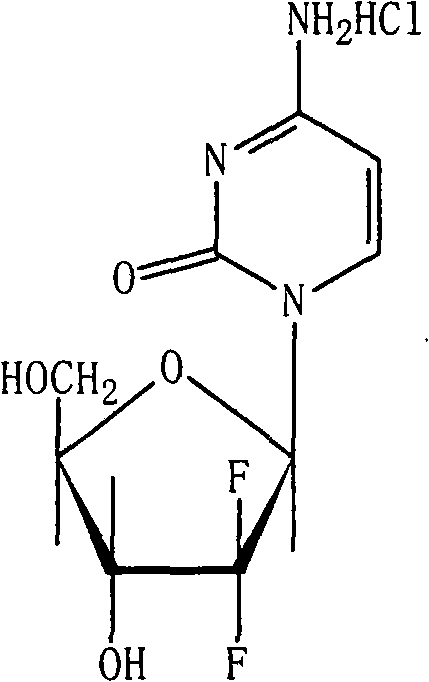

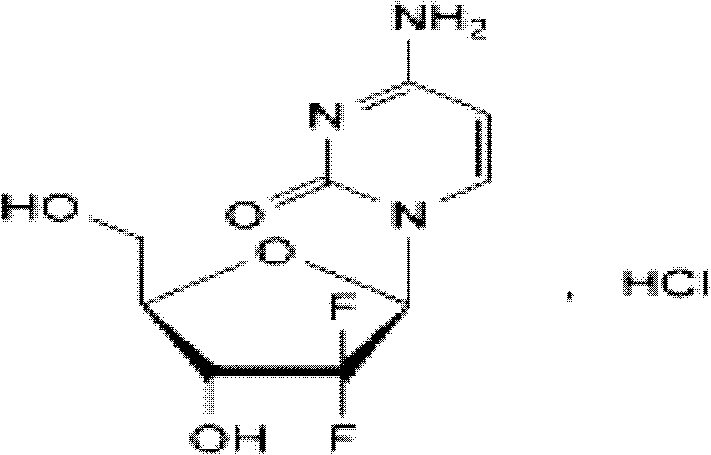

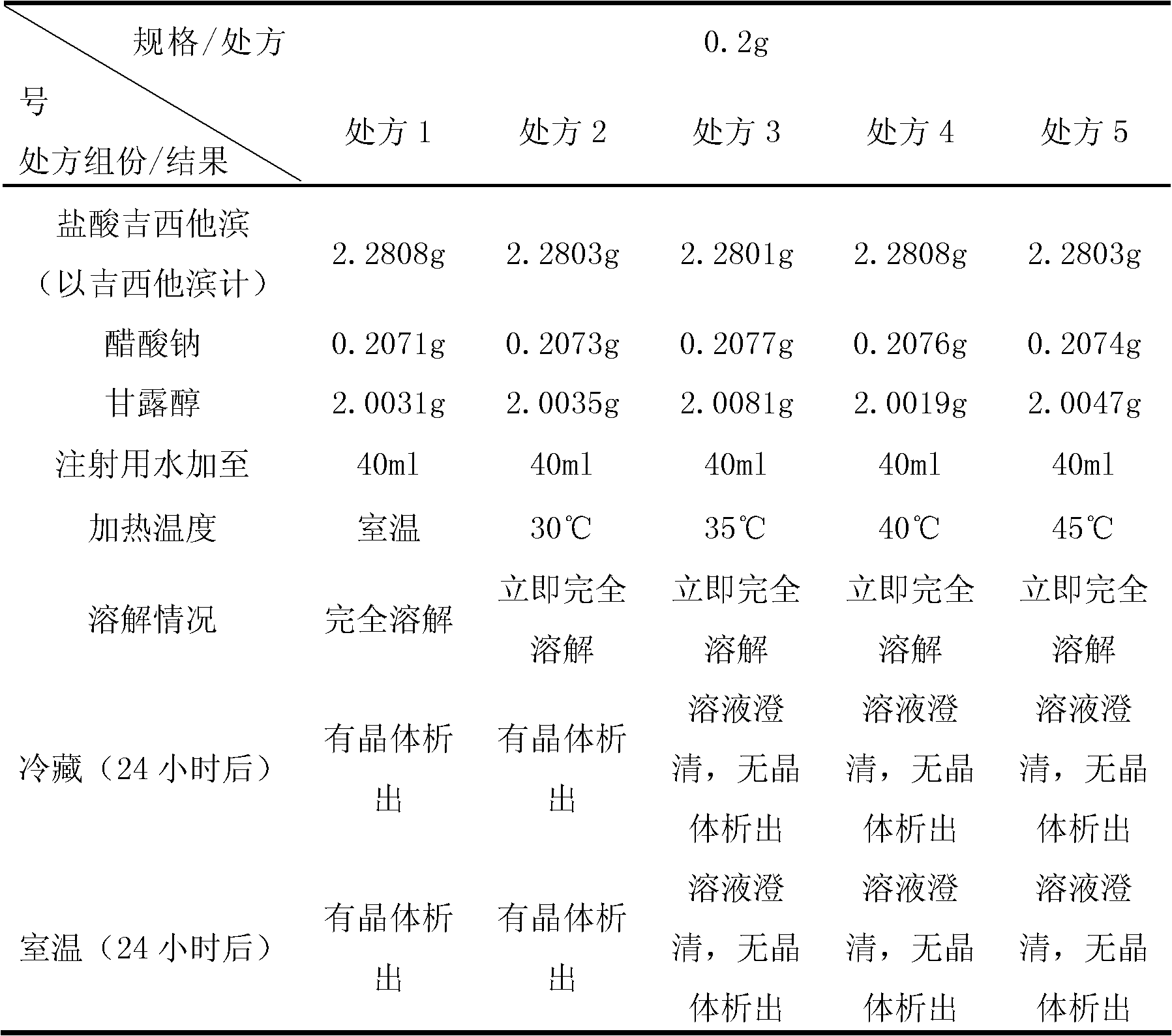

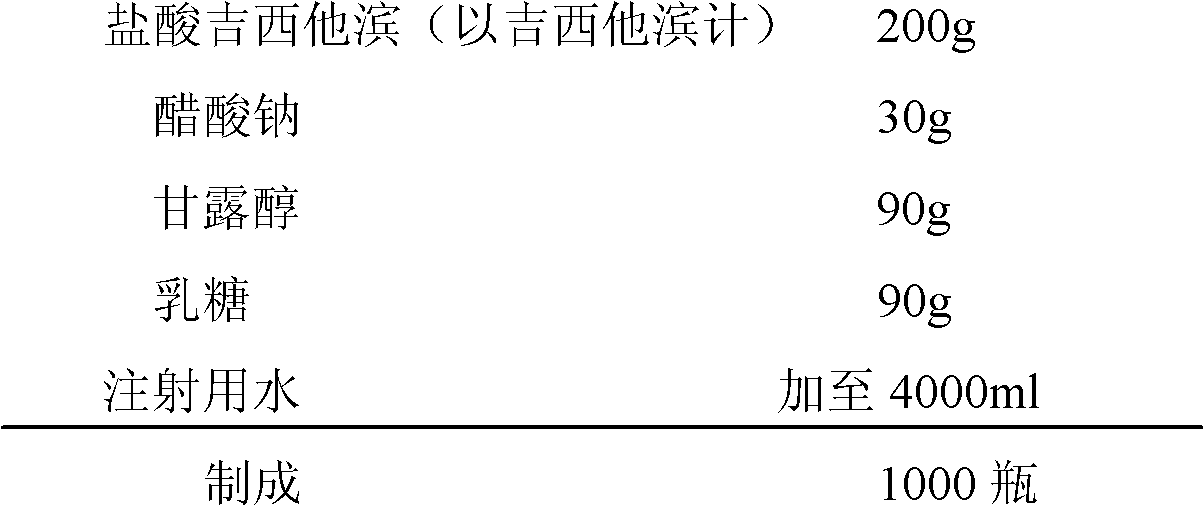

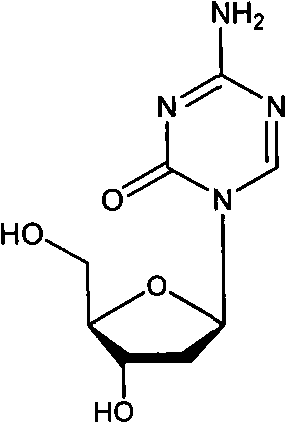

Gemcitabine hydrochloride lyophilized powder injection

ActiveCN101564381AImprove stabilityLow content of related substancesPowder deliveryOrganic active ingredientsPancreas CarcinomaDrug

The invention relates to a gemcitabine hydrochloride lyophilized powder injection and a preparation method thereof. The gemcitabine hydrochloride lyophilized powder injection prepared by the method can be used as a therapeutic medicament for treating middle and late non-small cell lung cancer, pancreatic cancer and the like. The gemcitabine hydrochloride lyophilized powder injection is characterized by consisting of gemcitabine hydrochloride, mannitol and sodium acetate, wherein the weight ratio of the gemcitabine hydrochloride to the mannitol is 1:0.5-5, and the weight ratio of the gemcitabine hydrochloride to the sodium acetate is 1:0.01-0.1. The preparation method comprises the following steps: taking the mannitol and the sodium acetate; dissolving the mannitol and the sodium acetate by adding injection water; adding the gemcitabine hydrochloride to the mixture, stirring and dissolving the mixture, and adjusting the pH to between 2.7 and 3.3; fixing the volume; filtering the product by a 0.22 mu m microporous membrane; filling, dishing up, lyophilizing, and compressing; taking the product out of a box, and tying the product with an aluminum-plastic composite cover; and inspecting the quality, and packaging the product after passing the quality inspection to obtain the gemcitabine hydrochloride lyophilized powder injection.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

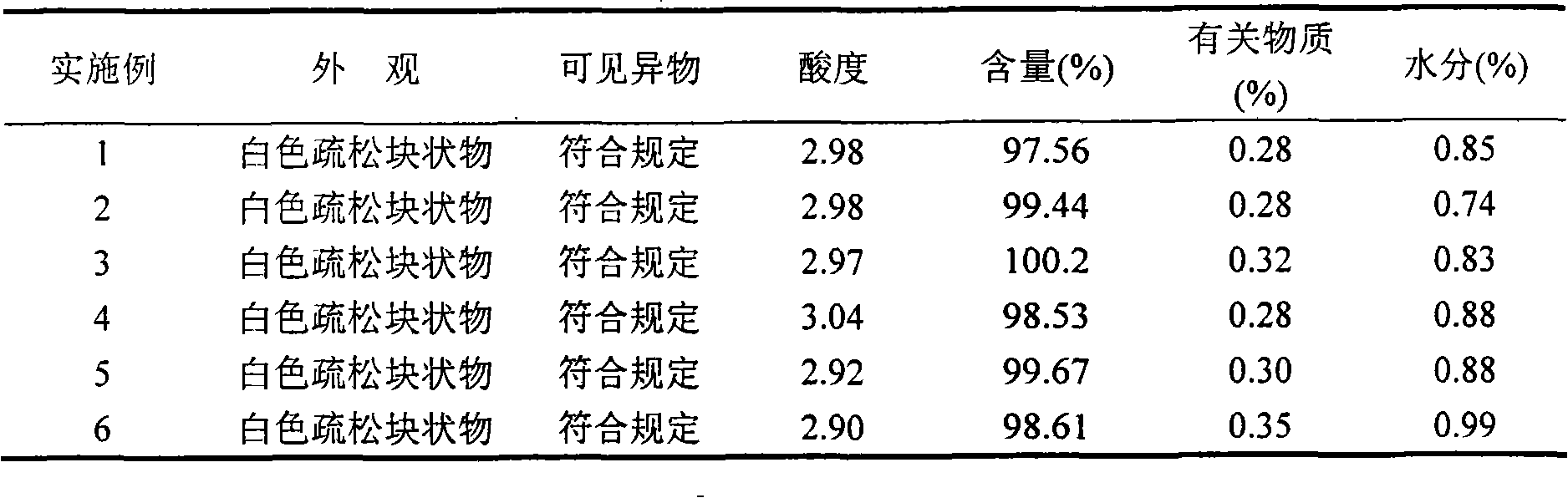

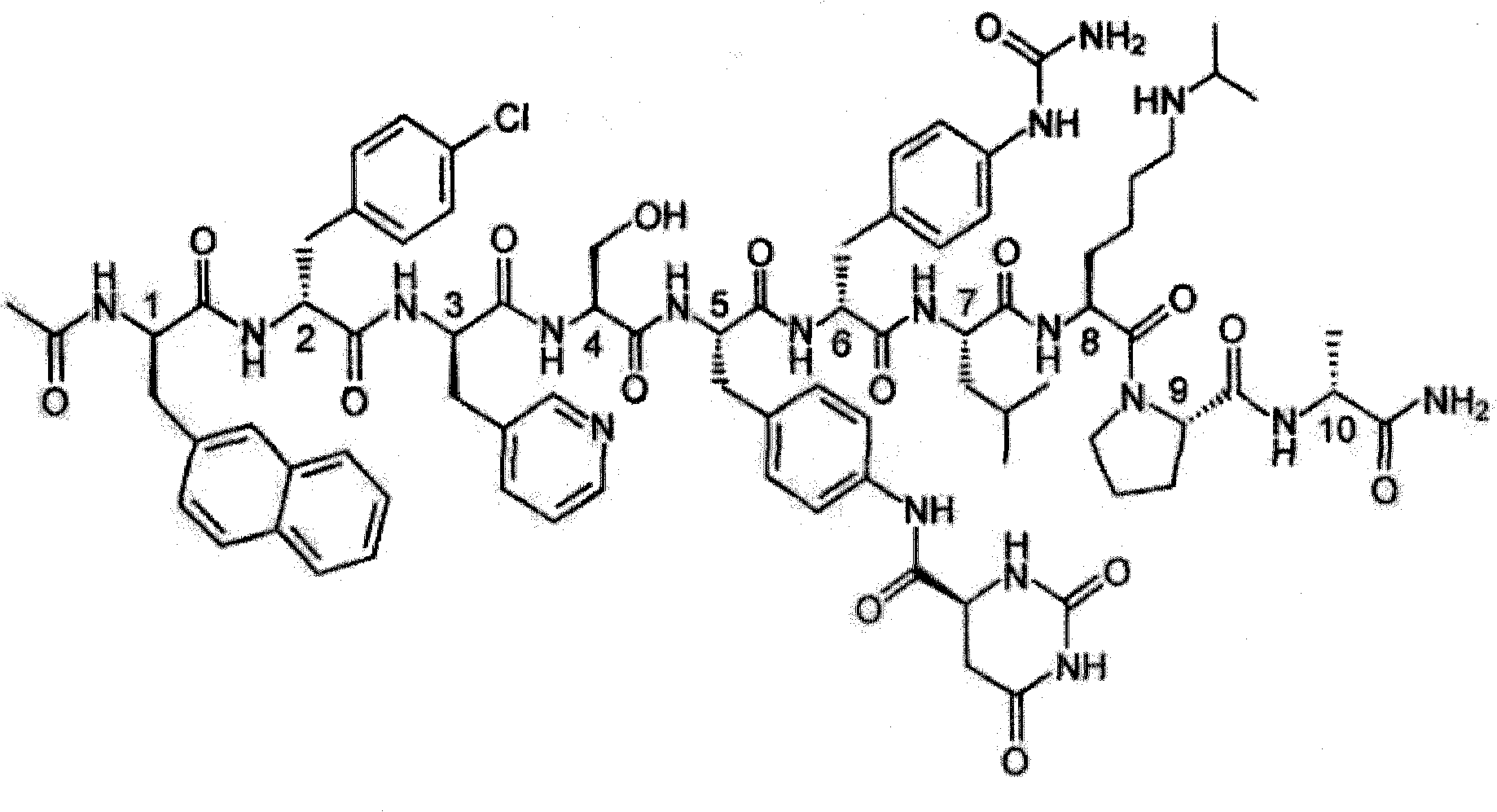

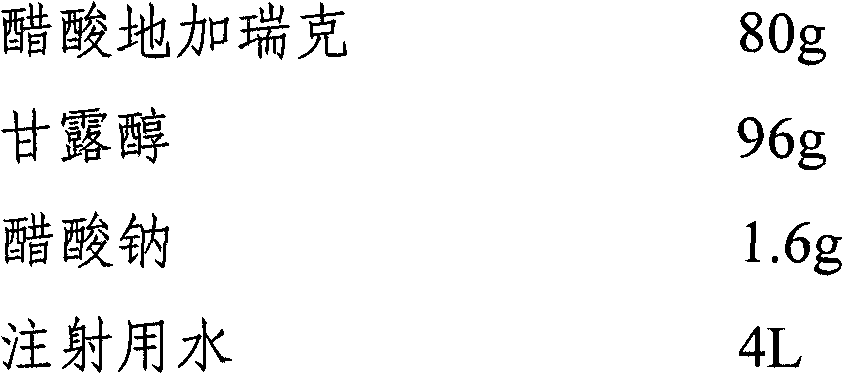

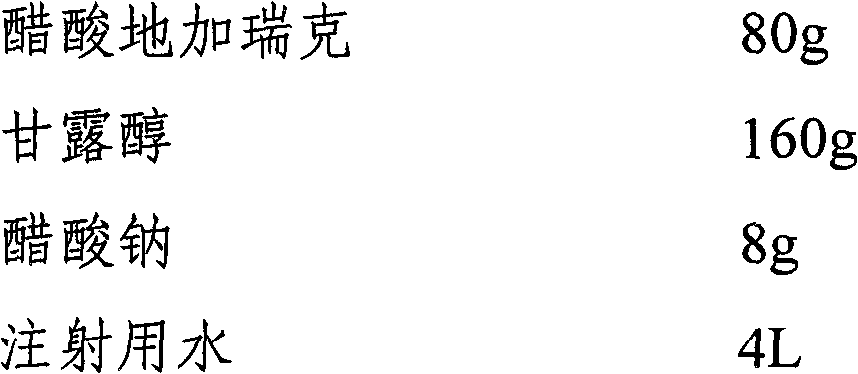

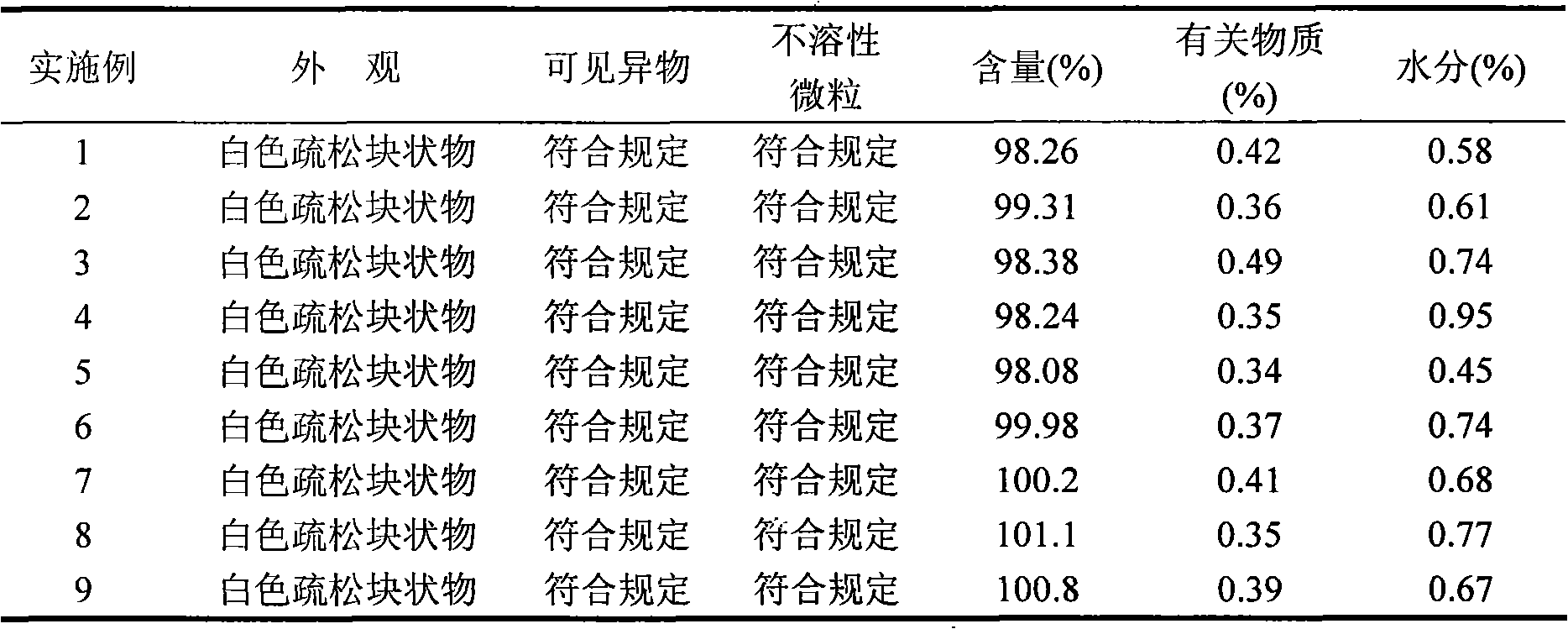

Degarelix acetate lyophilized powder injection and preparation method thereof

ActiveCN102204889AReduce contentUniform and stable qualityPowder deliveryPeptide/protein ingredientsChemistryMoisture

The invention provides a degarelix acetate lyophilized powder injection, which consists of degarelix acetate, mannitol and sodium acetate in the mass ratio of 1:(1.2-2):(0.02-0.1). The lyophilized powder injection is obtained by performing freeze drying on the degarelix acetate, the mannitol and the sodium acetate serving as main medicaments. In the preparation process, the stability and safety of a preparation are ensured strictly. The prepared degarelix acetate lyophilized powder injection has the advantages of low content of relevant substances, uniform and stable mass, complete moisture drying, stability in transportation, storage and using processes, convenience for clinical application, high stability and high biological activity, and the like. The preparation method adopted by the invention is simple and effective, has high repeatability and low production cost, and is easy for industrial production.

Owner:蚌埠丰原涂山制药有限公司

Artificial cultivation method of Collybia albuminosa

ActiveCN104255297AAchieving large-scale plantingIncrease productionCultivating equipmentsMushroom cultivationNutritive valuesFlavor

The invention discloses an artificial cultivation method of Collybia albuminosa and belongs to the technical field of artificial cultivation of wild fungi. The artificial cultivation method of Collybia albuminosa includes steps of termites farming, Collybia albuminosa breeding, Collybia albuminosa planting, fertilizer and water management and harvesting. The artificial cultivation method of Collybia albuminosa achieves large-scale cultivation of Collybia albuminosa by selecting high-quality breeds, simulating the wild conditions of Collybia albuminosa and making full use of the symbiotic relationship of Collybia albuminosa and termites. Under scientific management, the output is greatly improved, the quality is stable and unified, the cultivated Collybia albuminosa approaches those growing in the wild environment in terms of the nutritive value, the medicinal value, taste and flavor, protects the unique biological resource while meeting partial requirements of the market, and prevents the wild Collybia albuminosa from dying out due to over exploitation.

Owner:兴义市太阳雨食用菌栽培农民专业合作社

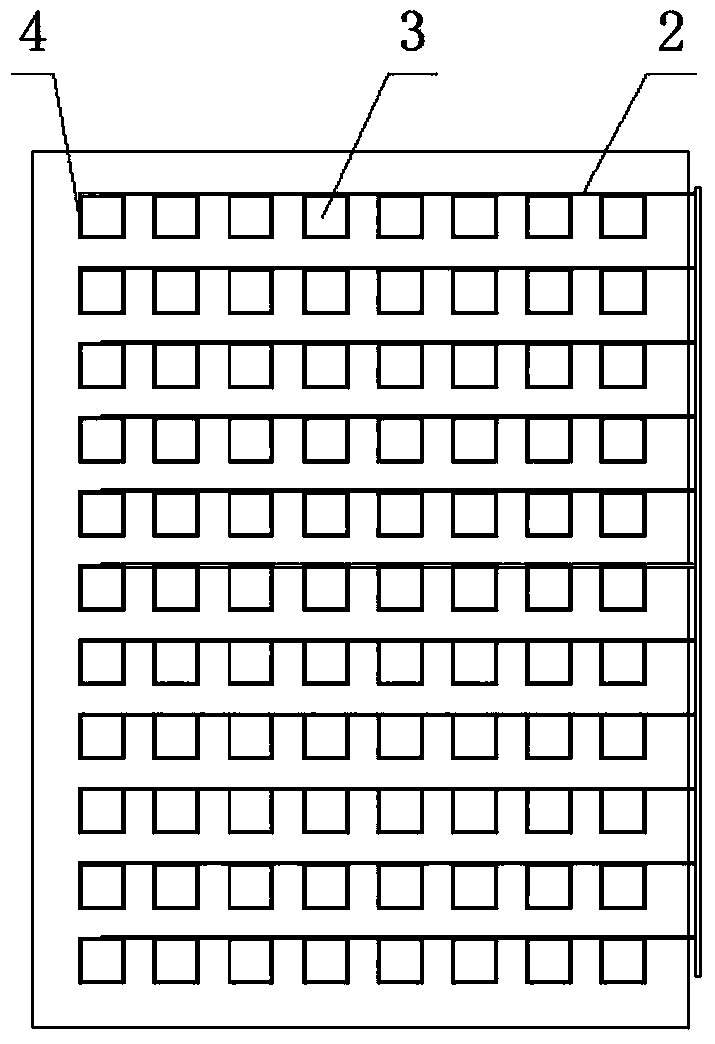

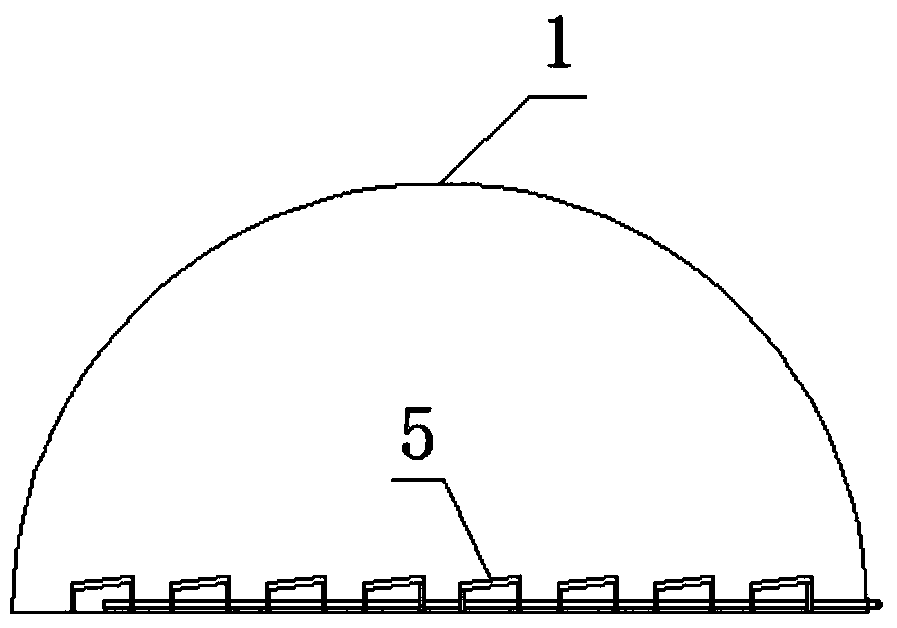

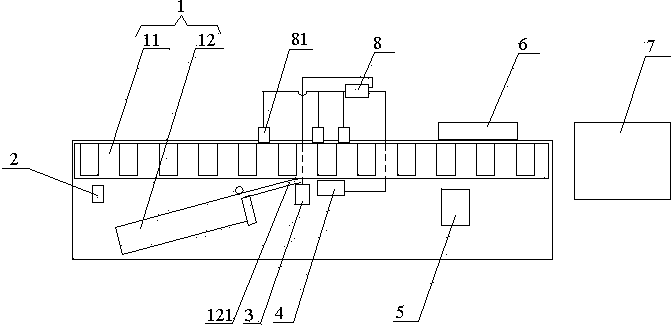

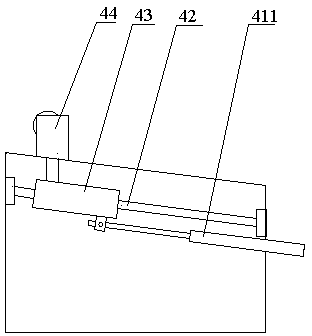

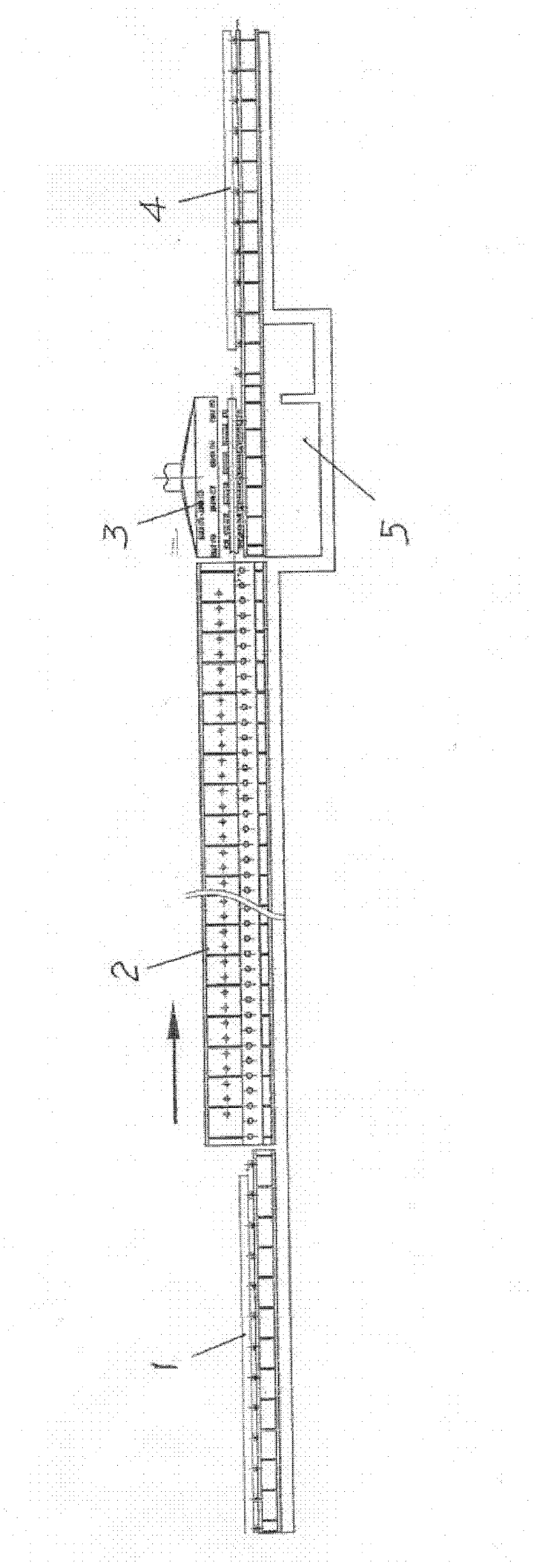

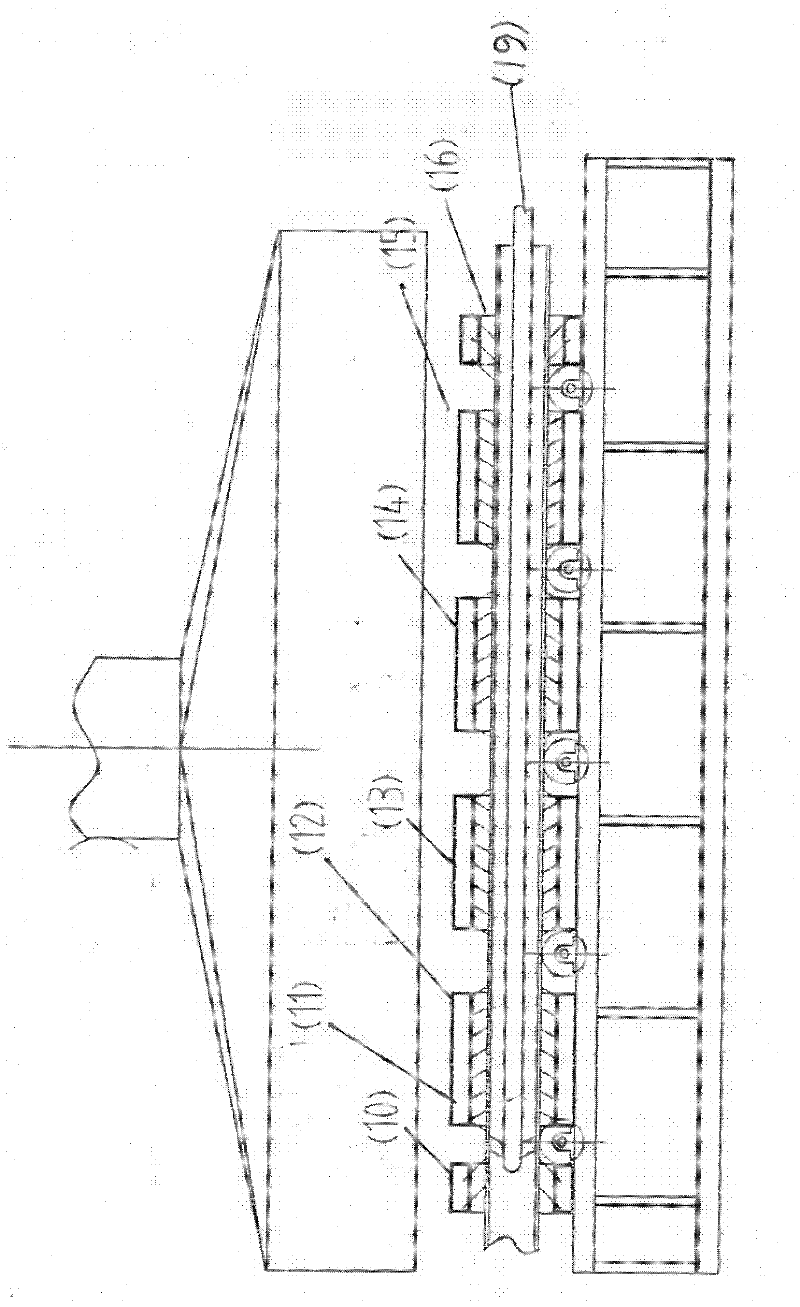

Board splicing machine

The invention discloses a board splicing machine. The board splicing machine comprises a machine frame and a board conveying device installed on the machine frame, wherein the board conveying device comprises a bottom board conveying belt for conveying bottom boards forwards, and a side board conveying groove formed in one side of the bottom board conveying belt, and one side, close to the bottom board conveying belt, of the front end of the side board conveying groove is provided with a side board outlet; a gluing device is arranged beside the inlet end of the bottom board conveying belt; an aligning device corresponding to the side board outlet is arranged in front of the side board outlet, and an induction device corresponding to the aligning device and inducting the positions of the bottom boards is further installed on the portion, beside the bottom board conveying belt, of the machine frame; a nail gun is arranged between the side board outlet and the aligning device; the board conveying device, the aligning device and the nail gun are further connected with a control device, and the input end of the control device is connected with the induction device; a pressing and connecting device for pressing and airing the bottom boards and side boards is arranged in front of the outlet end of the bottom board conveying belt. The board splicing machine is reasonable in structure and convenient to use, the machining efficiency can be substantially improved, consumption of wood can be reduced, and cost can be saved.

Owner:河北简工科技有限公司

Gemcitabine hydrochloride lyophilized powder injection and preparation method thereof

ActiveCN102144981AReduce dosageImprove stabilityPowder deliveryOrganic active ingredientsSodium acetateAdjuvant

The invention relates to a gemcitabine hydrochloride lyophilized powder injection and a preparation method thereof. The lyophilized powder injection comprises the following components in parts by weight: 20-30 parts of gemcitabine hydrochloride, 5-9 parts of mannitol, and 3-10 parts of sodium acetate. The freeze-drying step includes the following three stages: a pre-freezing stage, a primary drying stage and a secondary drying stage, and the entire freeze-drying time is lower than 20 hours. The gemcitabine hydrochloride lyophilized powder injection provided by the invention has the advantages of less types and amounts of adjuvants, easily-controlled technological parameters, simple process route, short freeze-drying time, convenience in operation, good repeatability, low contents of related substances, and controllable quality; and the redissolved lyophilized powder injection has good clarity and forming performance. The lyophilized powder injection has stable and controllable quality, is easy to realize industrial production, and can generate considerable economic and social benefits.

Owner:HAINAN JINRUI PHARMA CO LTD

Decitabine freeze-dried powder injection

ActiveCN101584670AImprove stabilityLow content of related substancesOrganic active ingredientsPowder deliveryPhosphateFreeze-drying

The invention relates to a decitabine freeze-dried powder injection and a preparing method thereof. The prepared decitabine freeze-dried powder injection is used for treating myelodysplastic syndrome (MDS). The decitabine freeze-dried powder injection contains decitabine, utilizes the mixed solvent composed of the tert-butyl alcohol and the injection water in the preparation process, wherein the concentration of the decitabine in the mixed solvents is 2.5-5 mg / ml; and the volume ratio of the solvents is: 5-50% of tert-butyl alcohol and the balance of injection water. The potassium dihydrogen phosphate and the sodium hydroxide may be added for the pH regulator. The preparation process comprises the following steps: measuring tert-butyl alcohol, adding injection water, potassium dihydrogen phosphate and sodium hydroxide, stirring and mixing evenly, cooling to 2-15 DEG C, heat preserving, adding decitabine, stirring to dissolve, filtering, filling, plugging, disking, freeze-drying, pressing plug, out box, tying and packing after quality test qualification.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Probiotics composition with function of improving immunity and preparing method and application of probiotics composition

InactiveCN105641209AGood for healthSimple preparation processUnknown materialsImmunological disordersProbiotic bacteriaBiology

The invention discloses a probiotics composition with the function of improving immunity and a preparing method and application of the probiotics composition. The probiotics composition is prepared from, by mass, 60-70% of dry probiotics powder, 20-30% of radix astragali extract powder and 10-20% of fructus lycii extract powder. Probiotics and traditional Chinese medicine are two internationally-recognized prebiotics substances, are interlinked in action mechanism and can perfectly complement each other in the specific using process to jointly bring the advantages to full play. According to the probiotics composition, probiotics and traditional Chinese medicine are perfectly combined, multiplication of probiotics is promoted through the probiotics increasing function of traditional Chinese medicine, the microecological balance in the intestines is regulated, and thus the effect of improving immunity is achieved.

Owner:WONDERARRAY BIOTECH CO LTD

Environment-friendly polypropylene filament yarn oil agent and production method thereof

The invention discloses a preparation method of an environment-friendly polypropylene filament yarn oil agent, comprising the following steps of: weighing 40 to 60 parts by weight of fatty alcohol ether phosphate potassium salt, 2 to 8 parts by weight of polysiloxane polyether copolymer, 3 to 12 parts by weight of pentaerythritol oleate, 4 to 10 parts by weight of fatty alcohol polyoxyethylene ether, 2 to 12 parts by weight of ethylene oxide-epoxypropane block polyether, 20 to 45 parts by weight of polyethylene glycol laurate, 10 to 20 parts by weight of butter alcohol amine phosphate salt and 5 to 10 parts by weight of high-carbon heterogeneous alcohol phosphate potassium salt, heating to 40 to 80 DEG C, reacting under the stirring condition, then adding 20 to 40 parts of emulsifying agent EL-40, 1 to 5 parts of methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methosulfate, 5 to 15 parts of dimethyl silicon oil, 2 to 40 parts of deionized water and 0.001 to 0.02 part of preservative, reacting under the stirring condition at 50 to 70 DEG C, and separating to obtain the environment-friendly polypropylene filament yarn oil agent.

Owner:青岛荣达新材料研究所

Preparation method of polyvinylidene fluoride-based thin film

The invention relates to a preparation method of a polyvinylidene fluoride (PVDF)-based thin film. According to the thin film forming process, through an extrusion casting and drawing method, PVDF, polymethyl methacrylate (PMMA), a rubber elastomer, titanium dioxide as well as other auxiliaries and fillers are mixed according to a certain ratio and are melted and extruded at certain temperature, and then the PVDF-based thin film is formed under guiding and stretching effects of casting traction equipment. The PVDF-based thin film prepared by the invention is uniform and easily controllable in thickness, good in barrier property as well as excellent in mechanical property and environmental aging resistance, and is easy to realize industrialization; the PVDF-based thin film, through modification treatment, is significantly improved in surface caking property and guarantees good adhesion with a solar cell packaging material; the thin film brings high convenience for assembly of a solar cell backboard film and is compact in structure; and the thin film has good application prospect in solar cell industry.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

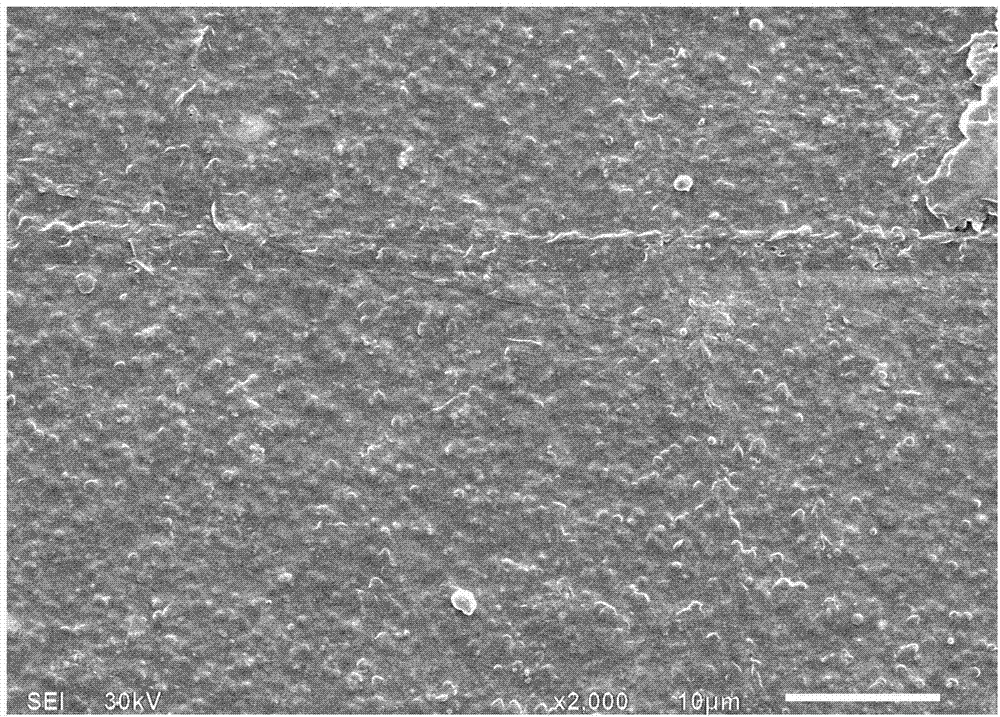

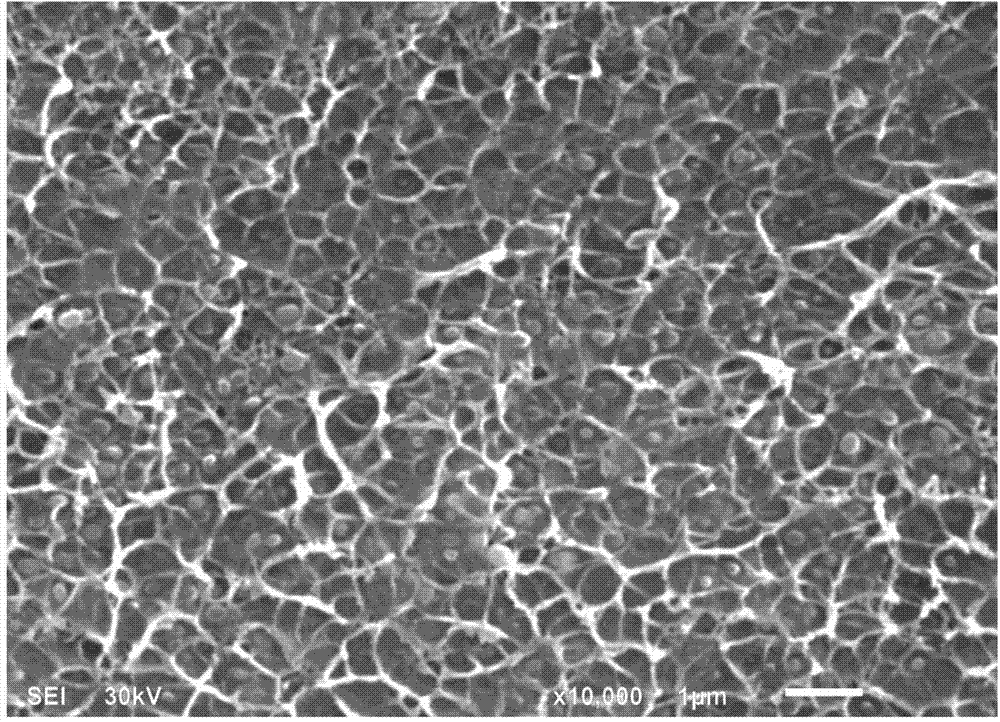

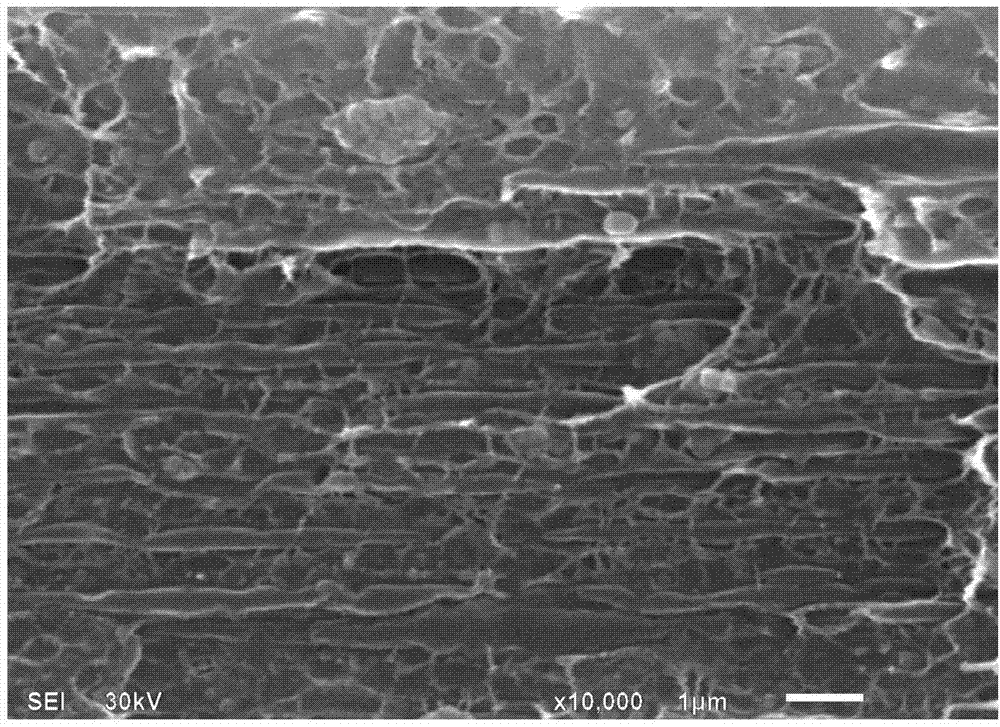

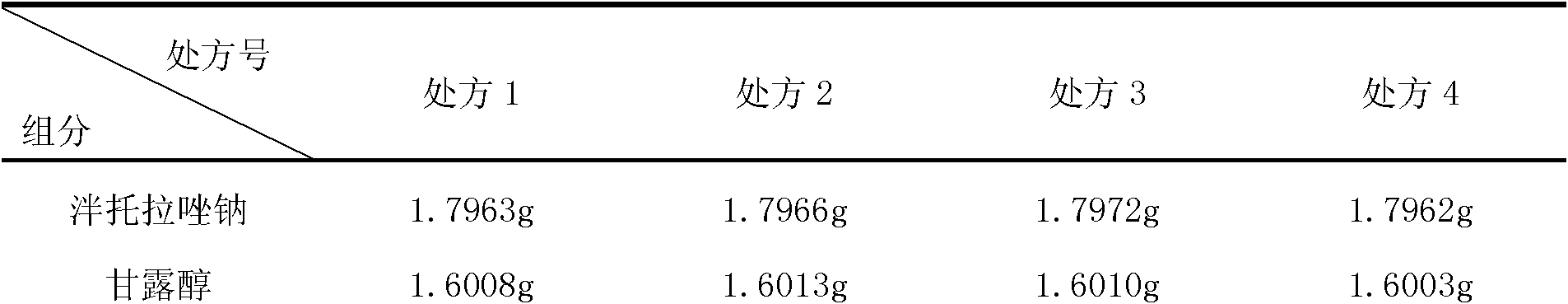

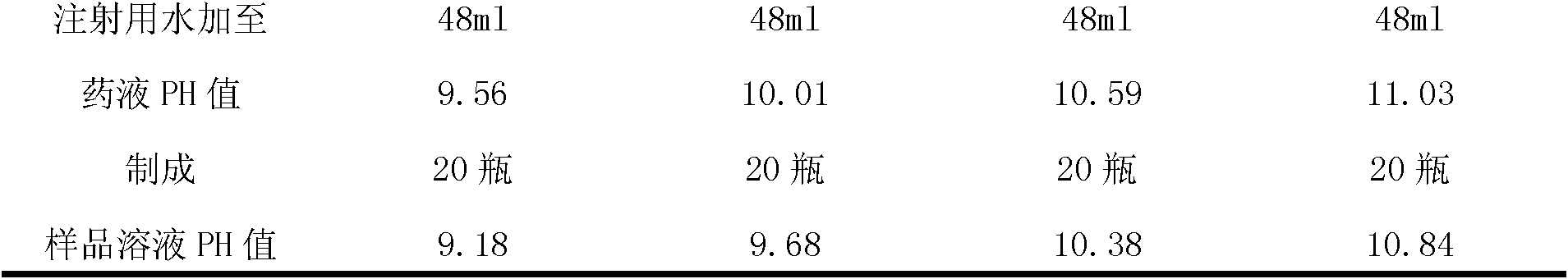

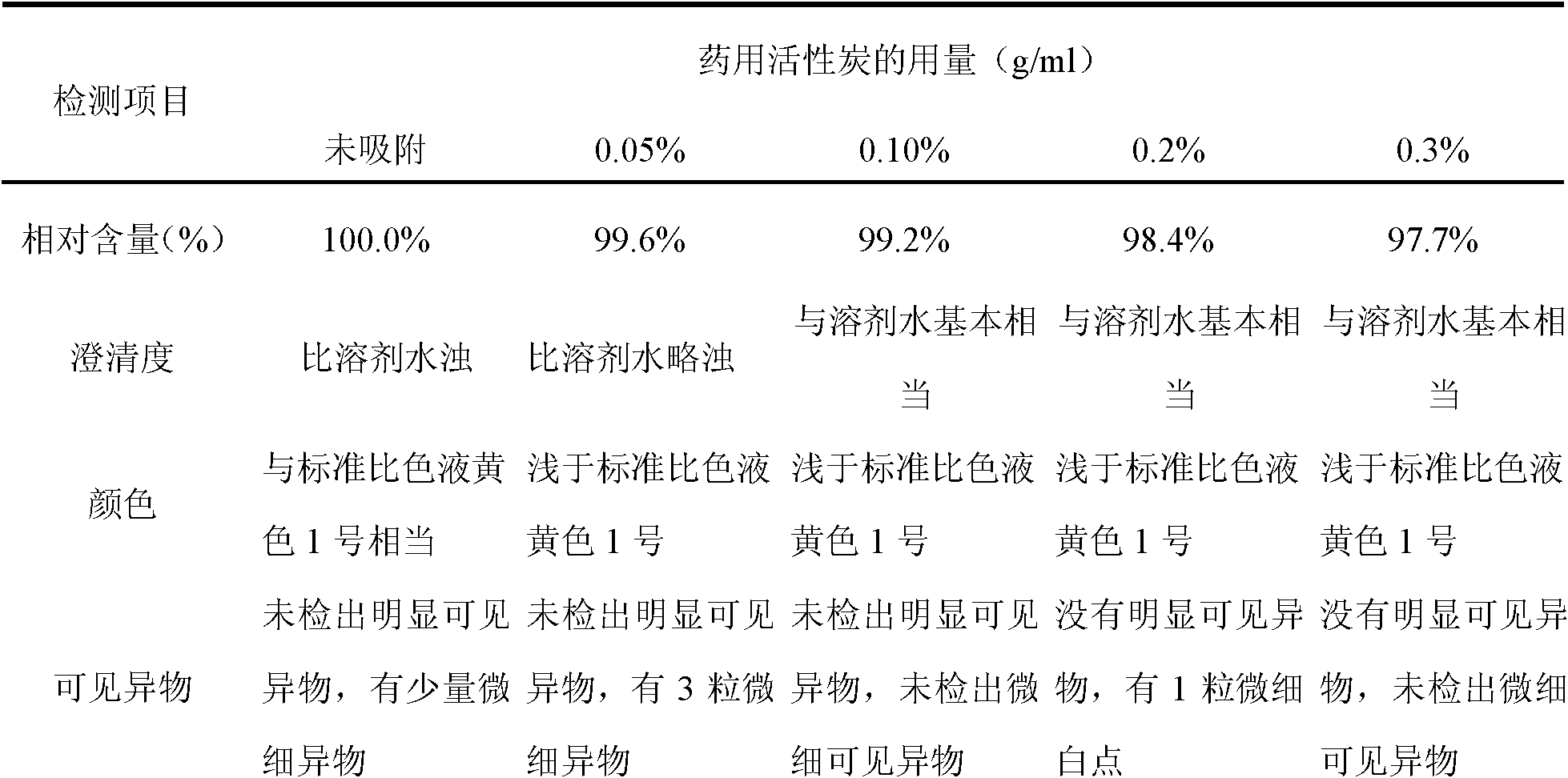

Pantoprazole sodium freeze-dried powder injection and preparation method thereof

ActiveCN102085190AShorten the secondary drying timeGood lookingOrganic active ingredientsPowder deliveryCLARITYFreeze-drying

The invention relates to a pantoprazole sodium freeze-dried powder injection and a preparation method thereof. The powder injection is prepared from pantoprazole sodium and mannitol, wherein the consumption ratio of the pantoprazole sodium to the mannitol is (1:0.8)-(1:1.6), and the PH value is 10.5-11.0. In the invention, by lowering the pre-freezing temperature, properly lowering the freezing temperature, maintaining the lowered freezing temperature for a proper time, properly shortening two-stage drying time and carrying out other adjustment processes, good appearance and quality of the product can be kept under the condition that the content of the mannitol is low, the processes are reliable and feasible, and the effect is obvious. The prepared product has low content of related substances and has controllable quality, and the freeze-dried product has good clarity and formability after being redissolved.

Owner:HAINAN JINRUI PHARMA CO LTD

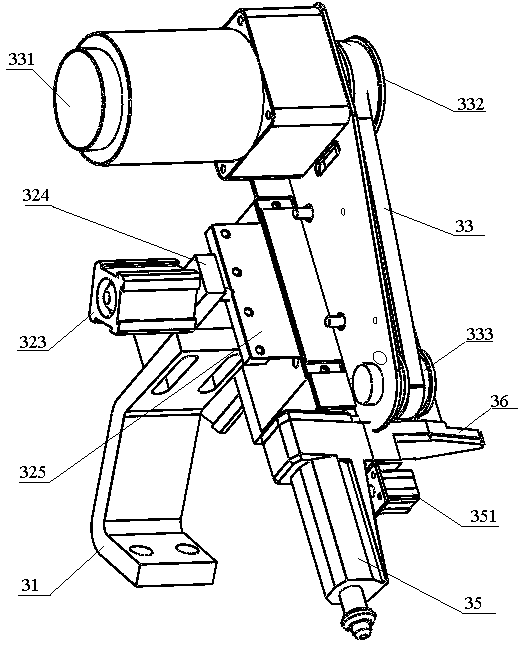

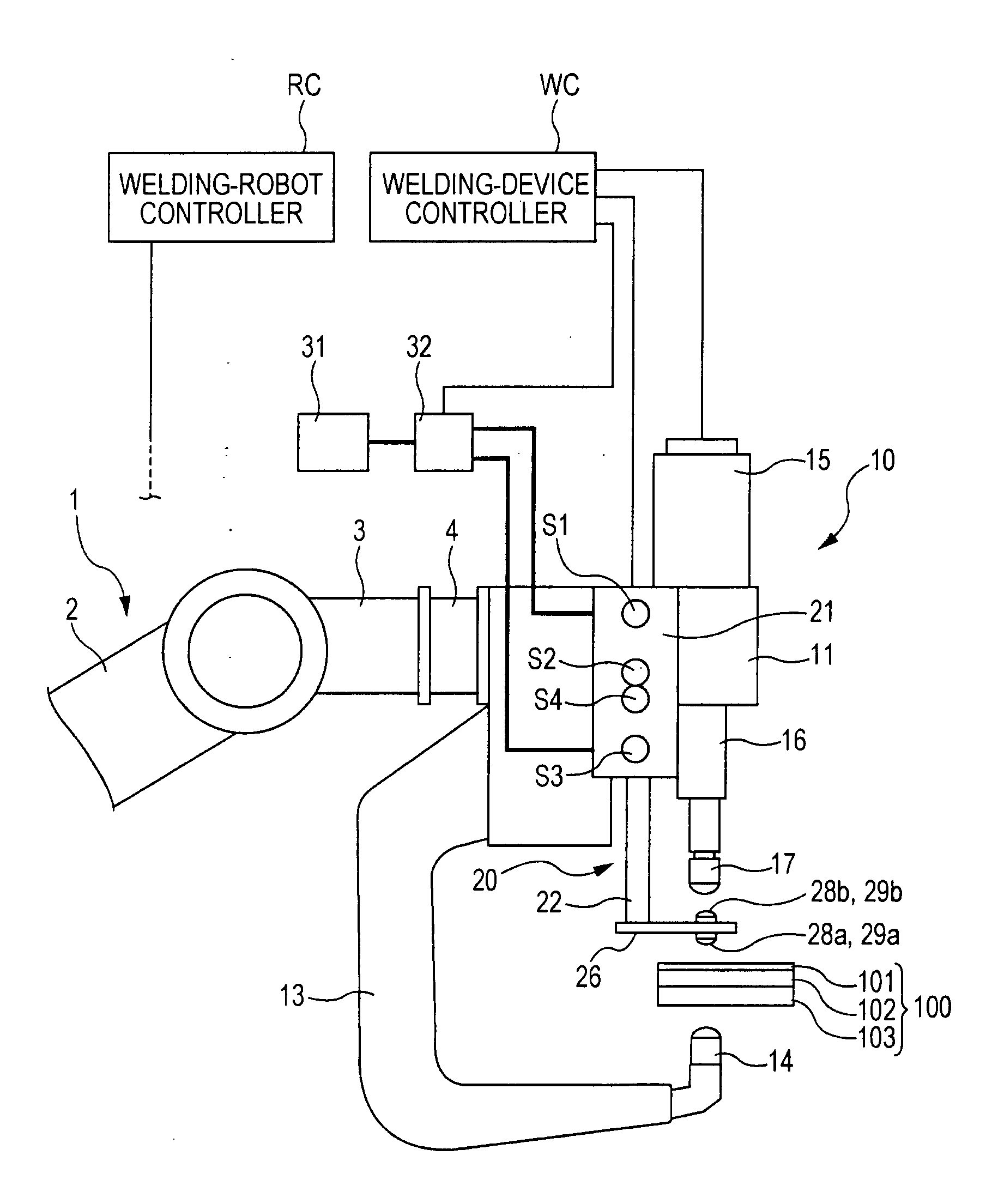

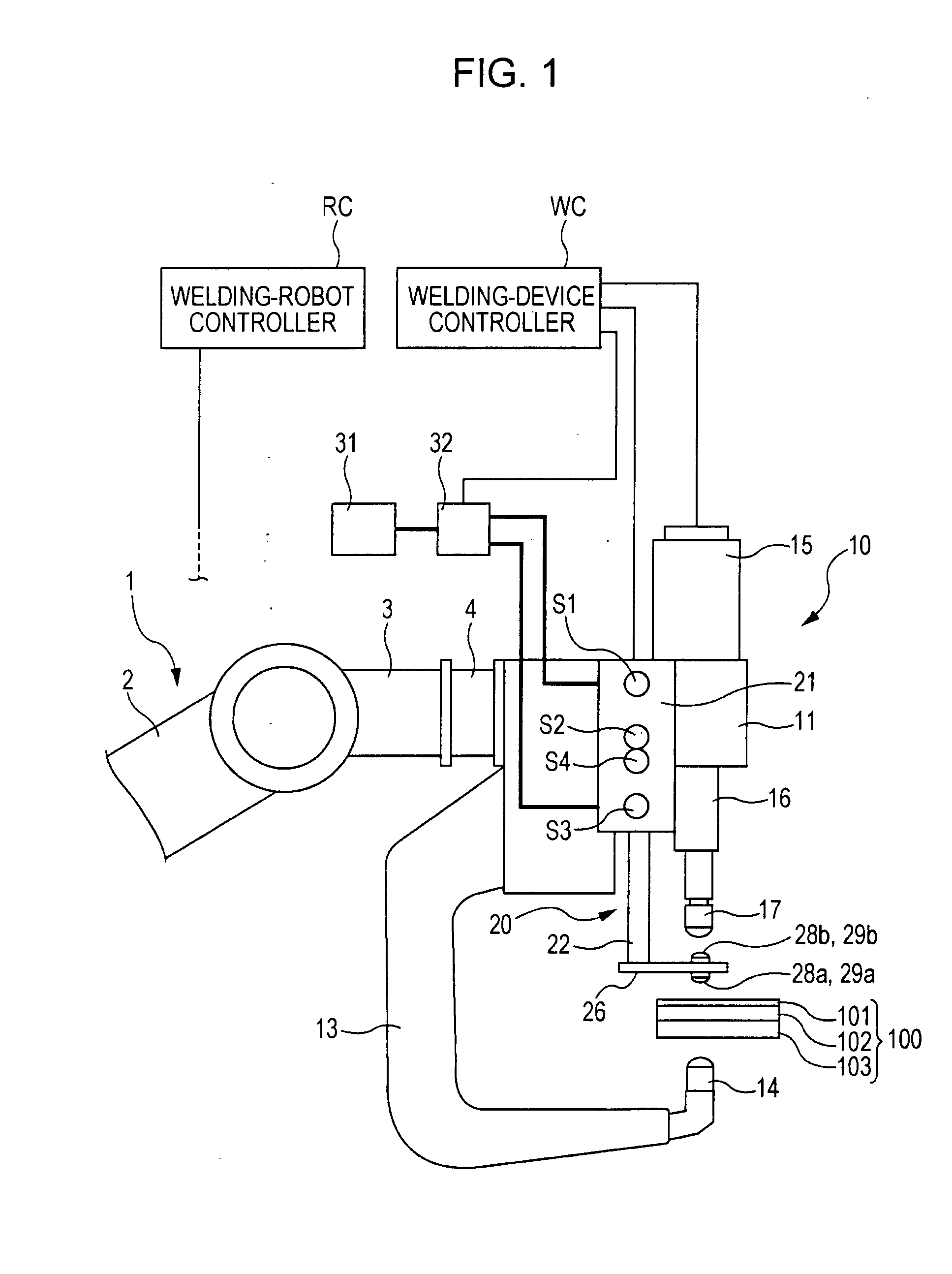

Spot-welding method and spot-welding device

ActiveUS20120055910A1Current densityEnhances weld qualityWelding/cutting auxillary devicesArc welding apparatusEngineeringElectrical and Electronics engineering

When spot-welding a workpiece including a thin plate, a first thick plate, and a second thick plate, the workpiece is clamped by a fixed electrode in contact with the second thick plate, a movable electrode in contact with the thin plate, and control-pressure applying unit set adjacent to the movable electrode and in contact with the thin plate. Pressure is applied to the second thick plate by the fixed electrode, and pressure and control pressure are respectively applied by the movable electrode and the control-pressure applying unit to the thin plate. The pressure from the fixed electrode is controlled to be smaller than the pressure from the movable electrode. The current density between the thin plate and the first thick plate increases.

Owner:SUBARU CORP

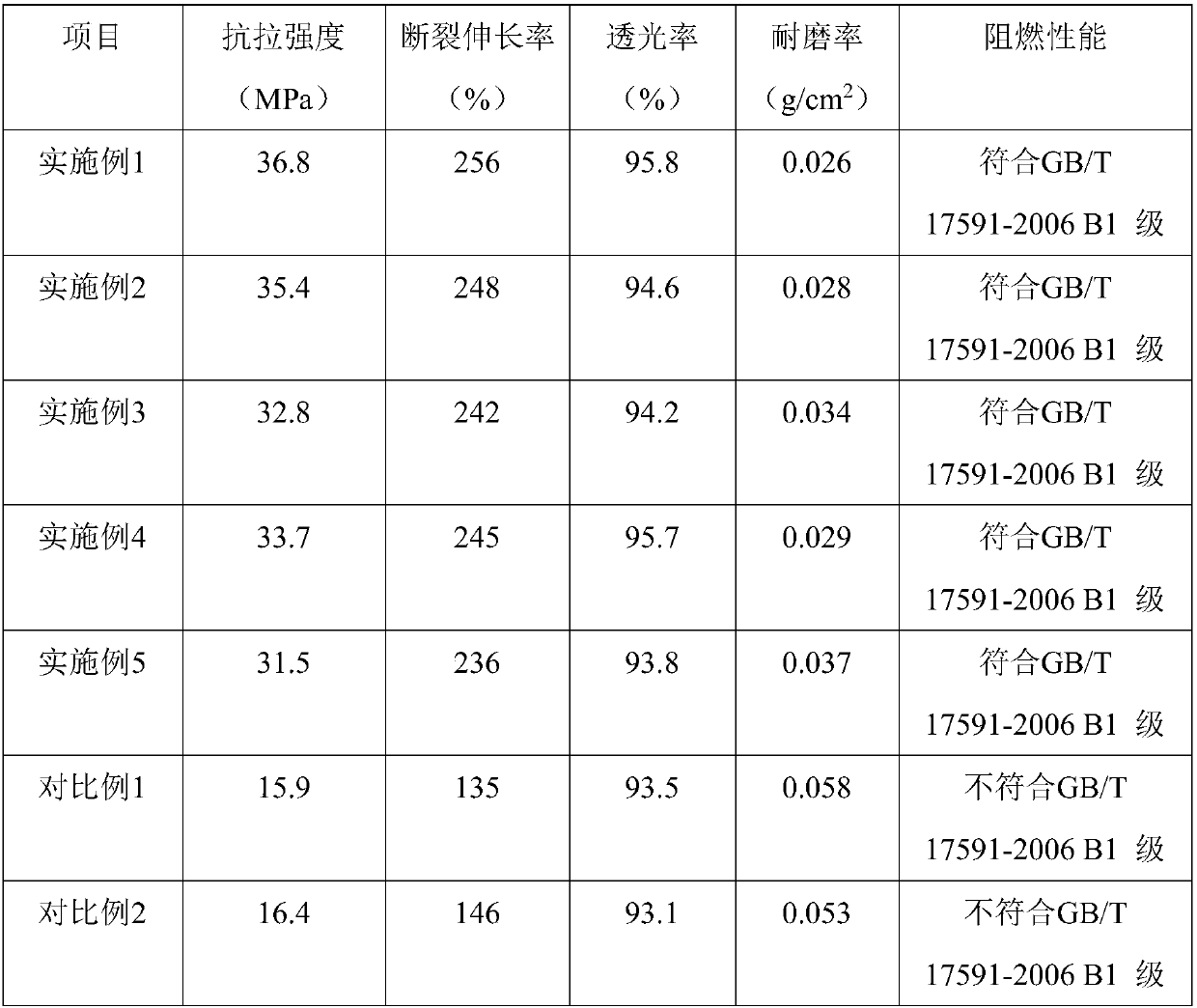

Technology for processing floor films

The invention discloses a technology for processing floor films, and relates to the field of floor film processing. The technology for processing the floor films includes steps of (1),mixing ingredients, to be more specific, weighing, by weight, PVC (polyvinyl chloride) resin powder, impact-resistant MBS (methyl methacrylate) resin, ACR (acrylamide) processing agents, di-iso-decylphthalate, internal lubricants, 3-10 parts of external lubricants and phosphate ester flame retardants, stirring the ingredients at the high speeds, and then carrying out cold stirring on the ingredients to obtain mixed materials; (2), carrying out extrusion, plasticization and calendaring molding on the mixed materials; (3), carrying out cooling and ageing treatment; (4), carrying out traction, winding and packaging. The technology has the advantages that the floor films are reasonable in composition proportion, high in light transmittance and suitable for large-scale industrial production, the technology isreasonable in design, and the toughness, the abrasion resistance, the flame retardance and the temperature resistance of the floor films can be enhanced.

Owner:安徽嘉阳新材料科技有限公司

Electric furnace production process of high-purity non-quenched and tempered steel for crankshaft

ActiveCN104372263AUltrasonic flaw detection qualifiedReduce anisotropyElectric furnaceProcess efficiency improvementElectric arc furnaceTempering

The invention relates to an electric furnace production process of high-purity non-quenched and tempered steel for a crankshaft. The steel comprises the following components in percentage by weight: 0.45%-0.48% of C, 1.02%-1.12% of Mn, less than or equal to 0.025% of P, 0.020%-0.030% of S, 0.20%-0.30% of Si, 0.05%-0.25% of Cr, 0.015%-0.035% of Alt, 0.07%-0.12% of V, less than or equal to 0.025% of Ti, less than or equal to 0.20% of Ni, 0.04%-0.15% of Cu, 0.01%-0.05% of Mo, 0.0080%-0.0140% of N, less than or equal to 0.0020% of O and 0.88%-0.96% of Ceq. The electric furnace production process comprises the following steps of: preparation of scrap steel, hot charging of molten iron, electric-arc furnace smelting, LF refining, VD vacuum degassing treatment and continuous casting. The steel is uniform in steel component and macrostructure and low in anisotropy and has no need of quenching and tempering treatment.

Owner:NANJING IRON & STEEL CO LTD

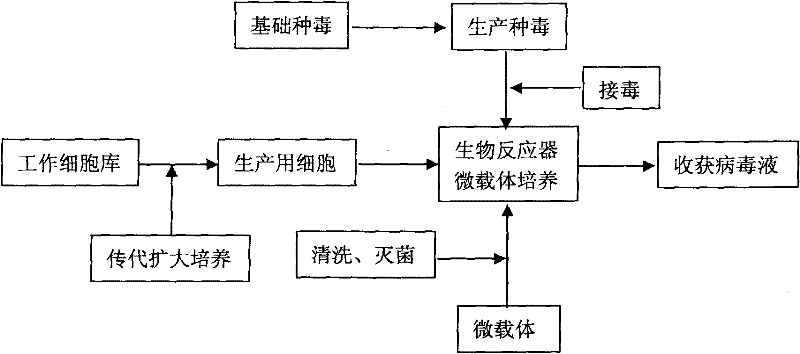

Method for production of porcine epidemic diarrhea virus

The invention discloses a technology for the production of porcine epidemic diarrhea virus by means of the microcarrier culture of VREO cells using a bioreactor, and comprises the technology for the production of different porcine epidemic diarrhea virus strains. The technology comprises the following technical steps: (1) selection of VERO cells as cell line for vaccine; (2) passage and culture of cells for vaccine; (3) propagation of seed culture of the porcine epidemic diarrhea virus; (4) microcarrier suspension culture of the VERO cells in the bioreactor; (5) propagation of porcine epidemic diarrhea virus antigen; and (6) treatment of acquired virus antigen liquid. The production method can remarkably lower production cost and enhance output-input ratio by 5 to 10 times, and has the advantages of short production period, small occupied space, great easiness for enlarging production scale rapidly, little environmental pollution, easy processing, high automation degree, a small number of staff, easy implementation of even and stable quality, obviously lowered production cost and enhanced yield and quality of vaccine.

Owner:成都史纪生物制药有限公司

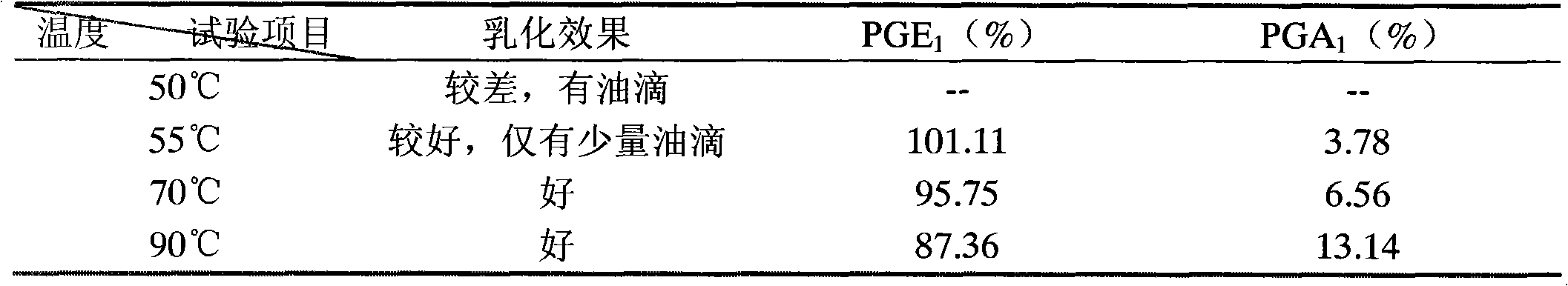

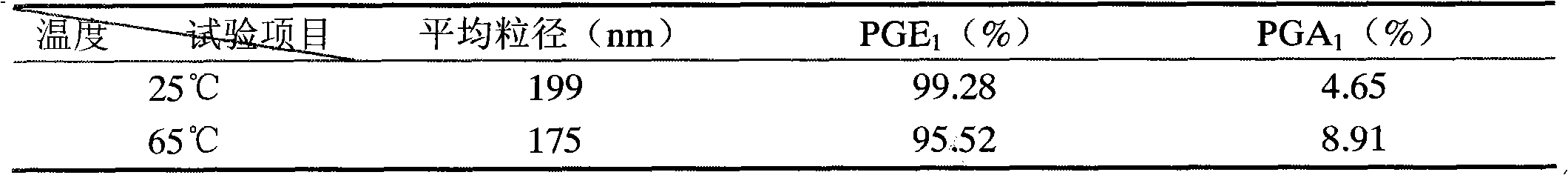

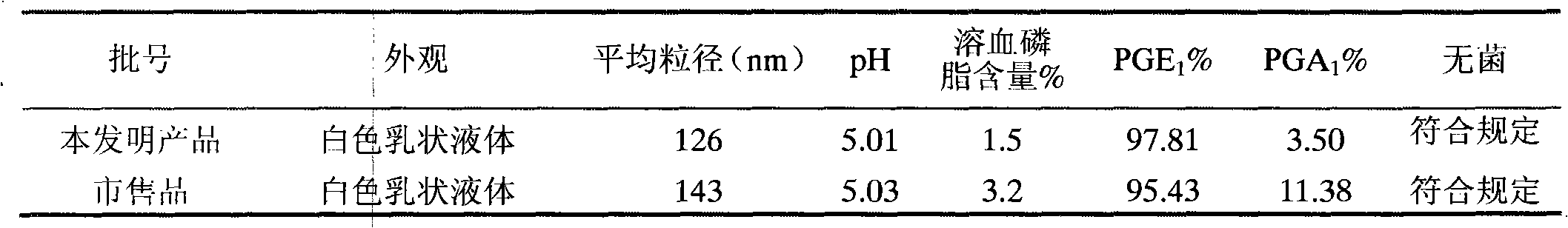

Preparation method of alprostadil injection

ActiveCN101627968AQuality assuranceReduce incidenceOrganic active ingredientsDigestive systemMedicineAlprostadil Injection

The invention relates to a preparation method of an alprostadil injection. The alprostadil injection consists of alprostadil, oil for injection, emulsifier, stabilizer and other agents, pH regulator and water for injection. Compared with the commercially available products, the quality standard of the prepared product is significantly improved, and the safety of clinical medication is increased.

Owner:辽宁中海康生物制药股份有限公司

Method for processing Congou black tea

InactiveCN103039637AThe processing method is scientific and reliableQuality is easy to controlPre-extraction tea treatmentProcess qualityBlack tea

The invention discloses a method for processing Congou black tea. The method comprises steps of selecting tea leaves, withering the leaves, rolling the leaves, fermenting the leaves, baking the leaves and potting the leaves. Through controlling fermentation and baking of the Congou black tea and other key steps, the whole processing method of the Congou black tea is guaranteed to be scientific and reliable, the production process quality is controllable, the quality is stable and balanced, strip shapes of the processed tea leaves are tight and straight, the color is black and oily, endoplasm aromas are rich, the taste is mellow, the liquor color is bright red, and leaf bottoms are red and uniform.

Owner:平阳县天韵茶叶有限公司

Process for calcining petroleum coke

The invention discloses a process for calcining petroleum coke. The calcination of the petroleum coke is carried out in a tank type calcining furnace, and the tank body of the tank type calcining furnace is provided with a preheating zone and 6-8 calcining zones sequentially from top to bottom, wherein the calcining temperature of the first calcining zone at the uppermost part is controlled in the maximum calcining temperature interval allowed by the petroleum coke; the calcining temperature of the second calcining zone in the downstream position of the first calcining zone is kept in the maximum calcining temperature interval and is not higher than the calcining temperature of the first calcining zone; starting from the third calcining zone, the calcining temperature of each calcining zone gradually reduces relative to the calcining temperature of the adjacent calcining zone in the upstream position; and in the undermost calcining zone, the calcining temperature is reduced to the discharging temperature. In the invention, when the petroleum coke is calcined, the high temperature zone is positioned at the top end of the calcining furnace, thereby relieving the high temperature deformation phenomenon of the furnace body, being more favorable for overflow of combustible gas in the petroleum coke, reducing the corrosion of the combustible gas on wall bricks, and being favorable for prolonging the service life of the tank type furnace.

Owner:WEIFANG LIANXING NEW MATERIAL TECH

Environment-friendly rubber plasticizing homogenizing agent and preparation method thereof

ActiveCN102850674AImprove production safetyFew reaction stepsBuilding insulationsPolycyclic aromatic hydrocarbonCarcinogenic Polycyclic Aromatic Hydrocarbon

The invention discloses a rubber plasticizing homogenizing agent and a preparation method thereof. The method comprises the following steps: reacting 70-100 parts of heavy traffic petroleum asphalt, 0-30 parts of optional hydrocarbon compound and derivatives thereof and 0.1-9 parts of catalyst with modifier at 90-180 DEG C, keeping the reaction at 100-180 DEG C for 0.5-3 hours, and carrying out vacuum distillation until the softening point of the product is 80-130 DEG C, thereby obtaining the rubber homogenizing agent. By modifying the heavy traffic petroleum asphalt and hydrocarbon compound and derivatives thereof with the modifier, the preparation method disclosed by the invention obviously lowers the content of cancerigenic polycyclic aromatic hydrocarbons, and overcomes the defects of high bubbling tendency and kettle overflow in production in the prior art, thereby enhancing the production safety. The rubber plasticizing homogenizing agent disclosed by the invention can mix the rubber materials with different polarities and different viscosities more homogeneously and sufficiently, and is beneficial to powder dispersion, so that the rubber materials in different batches have stable and homogeneous quality.

Owner:BEIJING RED AVENUE INNOVA

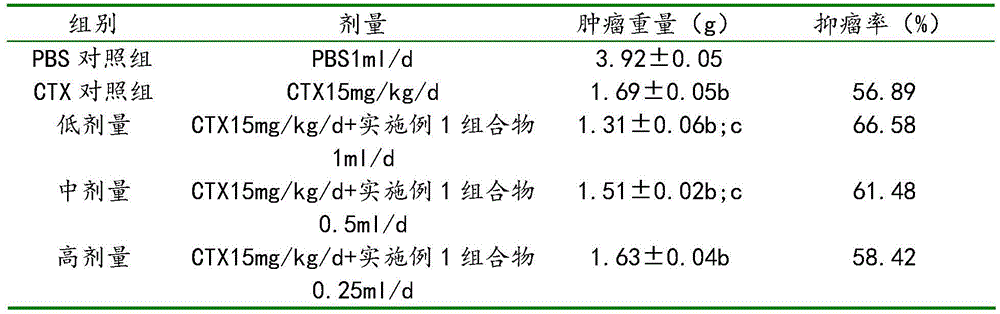

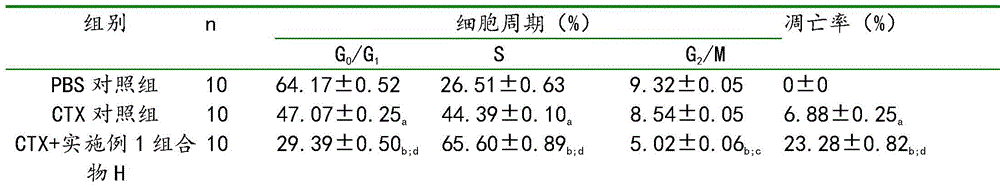

Probiotic composition with anti-tumor function as well as preparation method and application thereof

InactiveCN105535650AHave healthGood for healthUnknown materialsAntineoplastic agentsAsparagus extractMechanism of action

The invention discloses a probiotic composition with an anti-tumor function as well as a preparation method and application thereof. The probiotic composition comprises the following components in mass percent: 60-70% of probiotic dry powder, 20-30% of astragalus root extract powder and 10-20% of asparagus extract powder. Probiotics and traditional Chinese medicines belong to two types of internationally recognized probiotic substances, and the probiotics and the traditional Chinese medicines are similar in mechanism of action and can perfectly complement each other in a concrete use process so as to jointly exert advantages. According to the probiotic composition disclosed by the invention, the probiotics and the traditional Chinese medicines are perfectly combined, and proliferation of the probiotics is promoted by virtue of the probiotic proliferation action of the traditional Chinese medicines so as to enhance the immune function of organisms and inhibit the proliferation of tumor cells, thereby achieving an anti-tumor effect.

Owner:WONDERARRAY BIOTECH CO LTD

Sodium rebeprazole freeze-dried injection

InactiveCN101249078ASmall irritation to human bodyImprove securityPowder deliveryOrganic active ingredientsVialAdjuvant

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

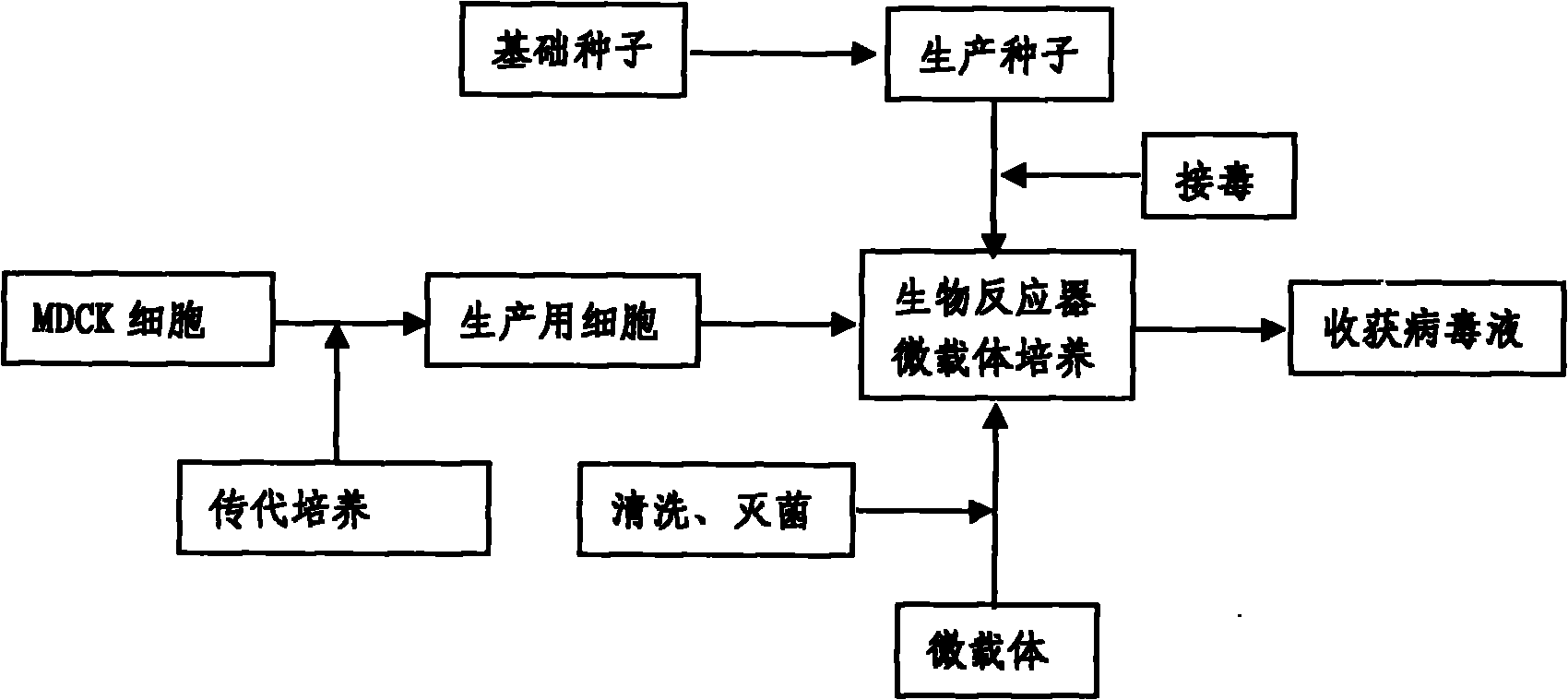

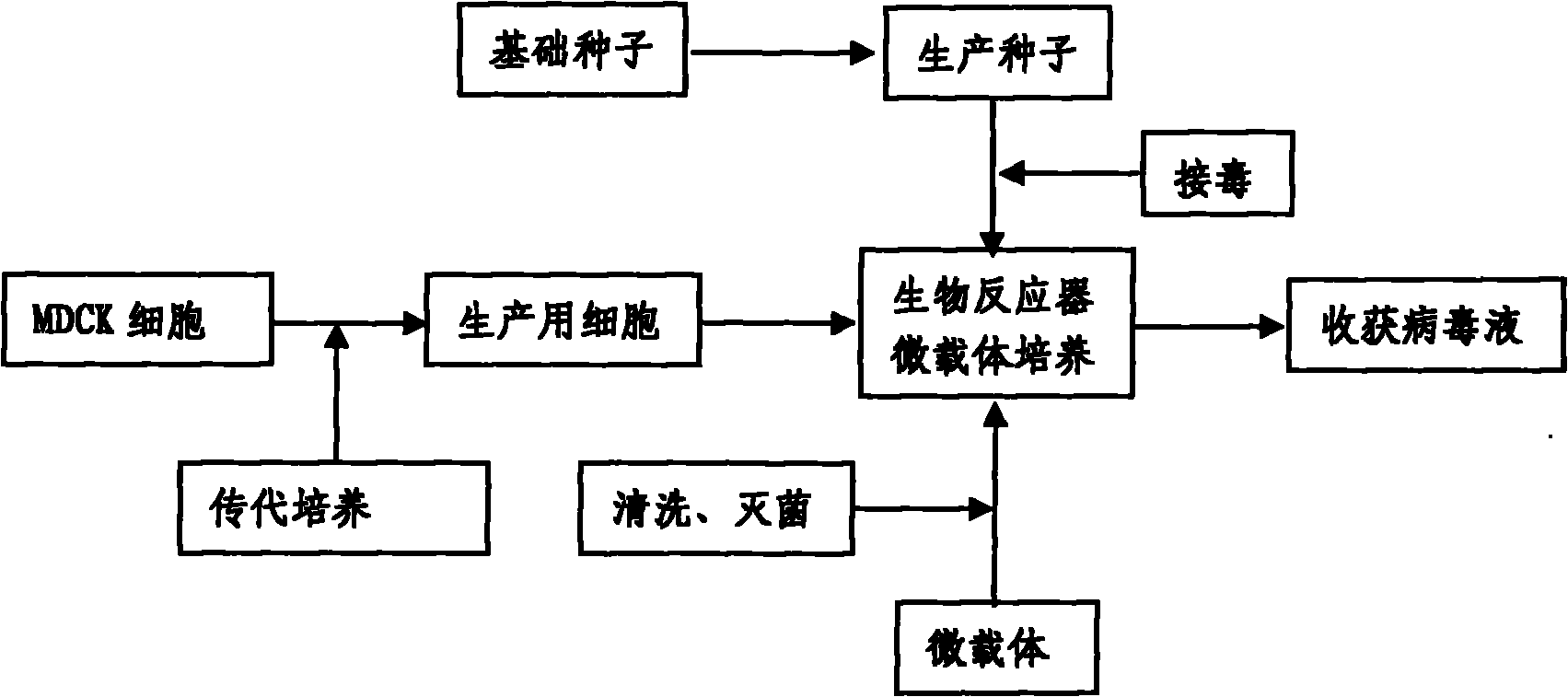

Production method for influenza virus vaccines

InactiveCN101818131ASolve yourselfSolve pollutionAntiviralsViruses/bacteriophagesEquine influenza vaccineBioreactor

The invention discloses a production method for vaccines of avian influenza virus and other influenza virus such as swine influenza, dog influenza and equine influenza, which comprises the following steps of: (1) transfer of culture and cultivation of vaccine-made cells; (2) reproduction of vaccine-made virus seeds; (3) microcarrier suspension culture of MDCK cells in a bioreactor; (4) reproduction of vaccine-made virus liquid; and (5) harvest of the virus liquid. The production method has the advantages of reducing the production cost greatly and improving the yield and quality of the vaccines obviously, along with short production period, no restriction to raw material supply, small occupied area, easy and quick expansion of production scale, light environmental pollution, easy processing, high automaticity, low employment and easy realization of balanced and stable quality.

Owner:成都史纪生物制药有限公司

Continuous esterification production method for mixed dibasic acid dimethyl ester

InactiveCN101891610AFully contactedImprove conversion rateOrganic compound preparationCarboxylic acid esters preparationRoom temperatureEsterification reaction

The invention discloses a continuous esterification production method for mixed dibasic acid dimethyl ester. The method comprises the following steps of: (1) pre-esterifying, namely, mixing dibasic acid and methanol in a mole ratio of 1:2-3 and performing pre-esterification at the normal temperature and normal pressure to obtain a pre-esterified material; (2) pre-heating the methanol, namely, pressurizing and pre-heating the methanol to form overheated methanol gas with the temperature of between 145 and 155 DEG C; and (3) continuously esterifying, namely, adding the pre-esterified material into a continuous esterification reactor, of which the middle part is provided with a catalyst reaction bed, from the top, adding the overheated methanol gas into the continuous esterification reactor from the bottom, performing a reverse flow reaction on the ascending methanol gas and the descending pre-esterified material on the catalyst reaction bed, and continuously discharging the mixed dibasic acid dimethyl ester which is generated by the esterification from the bottom of the esterification reactor.

Owner:WEIFANG YUANLI CHEM

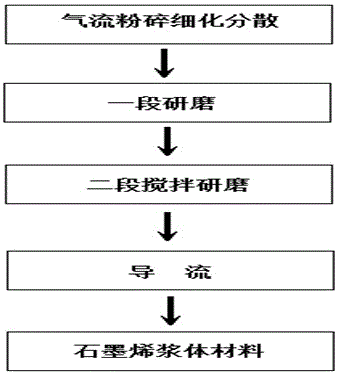

Graphene paste material and preparation method thereof

The invention provides a graphene paste material, and belongs to the field of graphene preparation. Through the collection and enrichment effect of a chelating agent, through two-stage grinding under a liquid grinding condition, particles reaching the graphene level float on the liquid surface through the chelating agent and are continuously guided out and collected through a diversion groove, so the graphene level can not be reached; the chelating agent can not be chelated and collected, so the chelating agent continues to circulate for grinding in a grinding device. By means of a method, particles reaching the graphene level are collected in time, yield is high, graphene is effectively prevented from being excessively ground and damaged, and collected graphene is uniform and stable in quality. Graphene is in a chelating state, is stable in dispersion and free of sedimentation and coagulation in paste and is graphene paste which can be directly added. The material is applied to a battery conductive agent, conductive coating, anticorrosion coating and thermal conductive coating. The green, clean and large-scale production, application and development of the graphene industry are further promoted.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Continuous Quenching Line for Large Diameter Tube and Bar

ActiveCN102268523ALow costImprove product quality performanceFurnace typesHeat treatment furnacesAutomatic controlAutomated control system

A continuous quenching line for large-diameter tube and bar materials is provided. Along the moving direction of tube and bar materials, a V-shaped inclined roll transmission continuous heating furnace is connected to an end of an automatic material charging machine; a multifunctional quenching machine is connected to an end of the V-shaped inclined roll transmission continuous heating furnace; the multifunctional quenching machine is connected to an automatic material discharging machine; a water collecting pool is disposed at the lower part of the multifunctional quenching machine; an automatic control system controls the devices from the automatic material charging machine to the automatic material discharging machine; continuous horizontal heat processing of alloy steel, stainless steel, light alloy bar and tube materials with a diameter of 100-800 mm and a length of above 2000 mm (a wall thickness of below 100 mm) can be performed. During the heating and quenching processes, the material both moves forward and performs self-rotation, does not bend or deform, is heated and quenched uniformly, and has a deep quenched layer, and the invention has the functions of performing quenching, solid solution treatment, normalization processing, annealing processing and the like of alloy tool steel tube and bar materials, alloy structure steel tube and bar materials, heat resistant steel tube and bar materials, various stainless steel tube and bar materials, aluminium alloy tube and bar materials, and the like.

Owner:ARES IND FURNACE TIANJIN

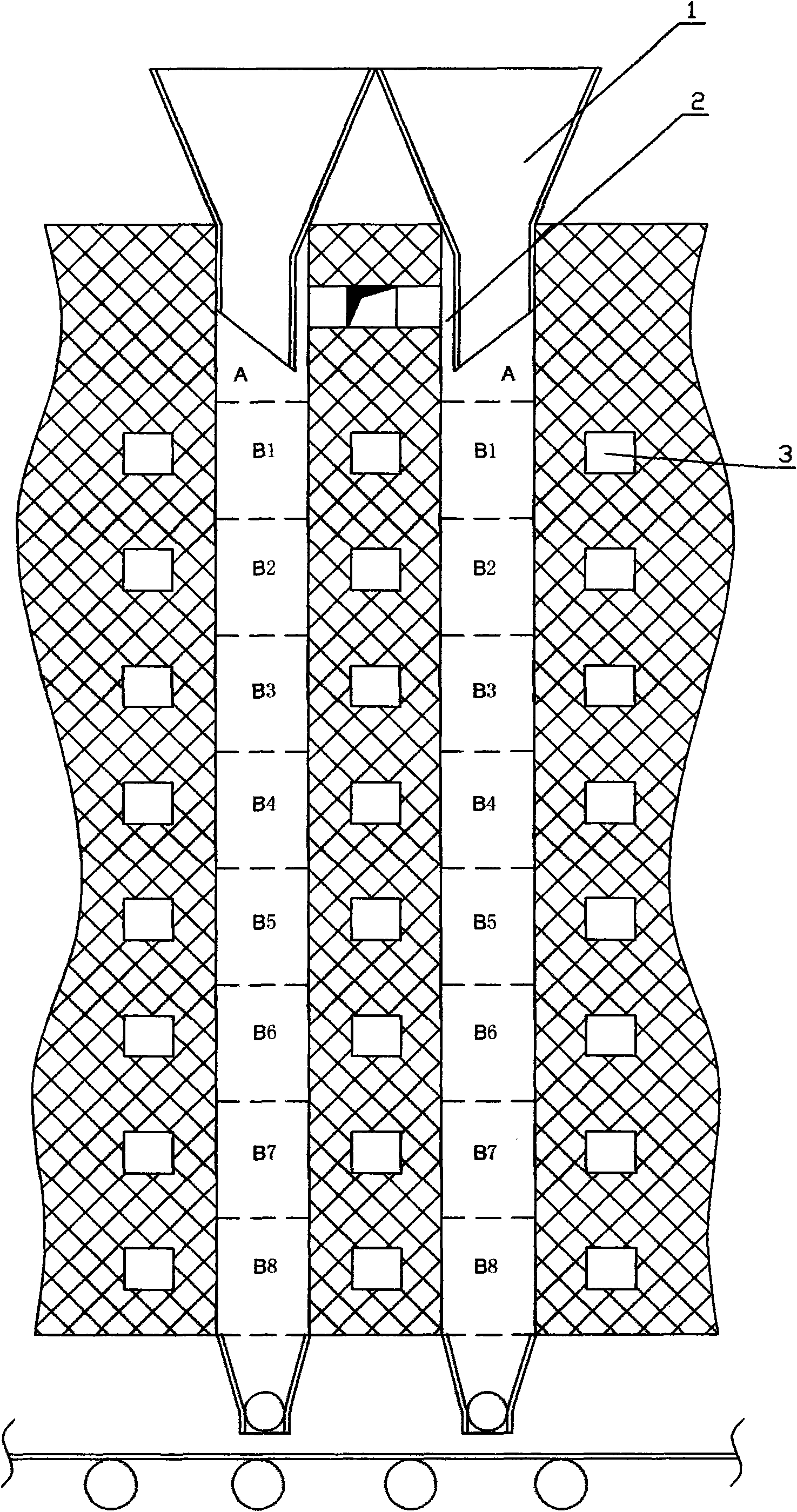

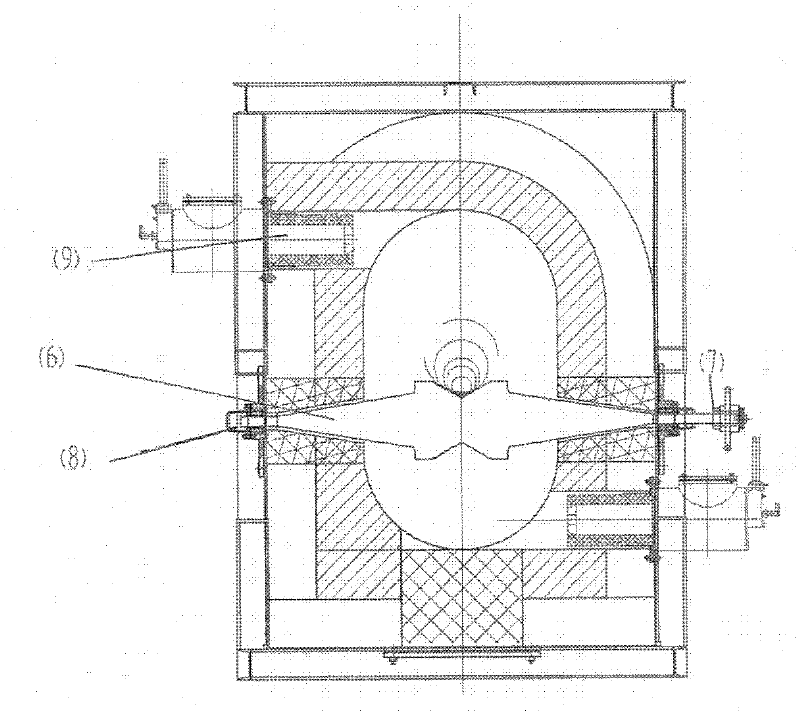

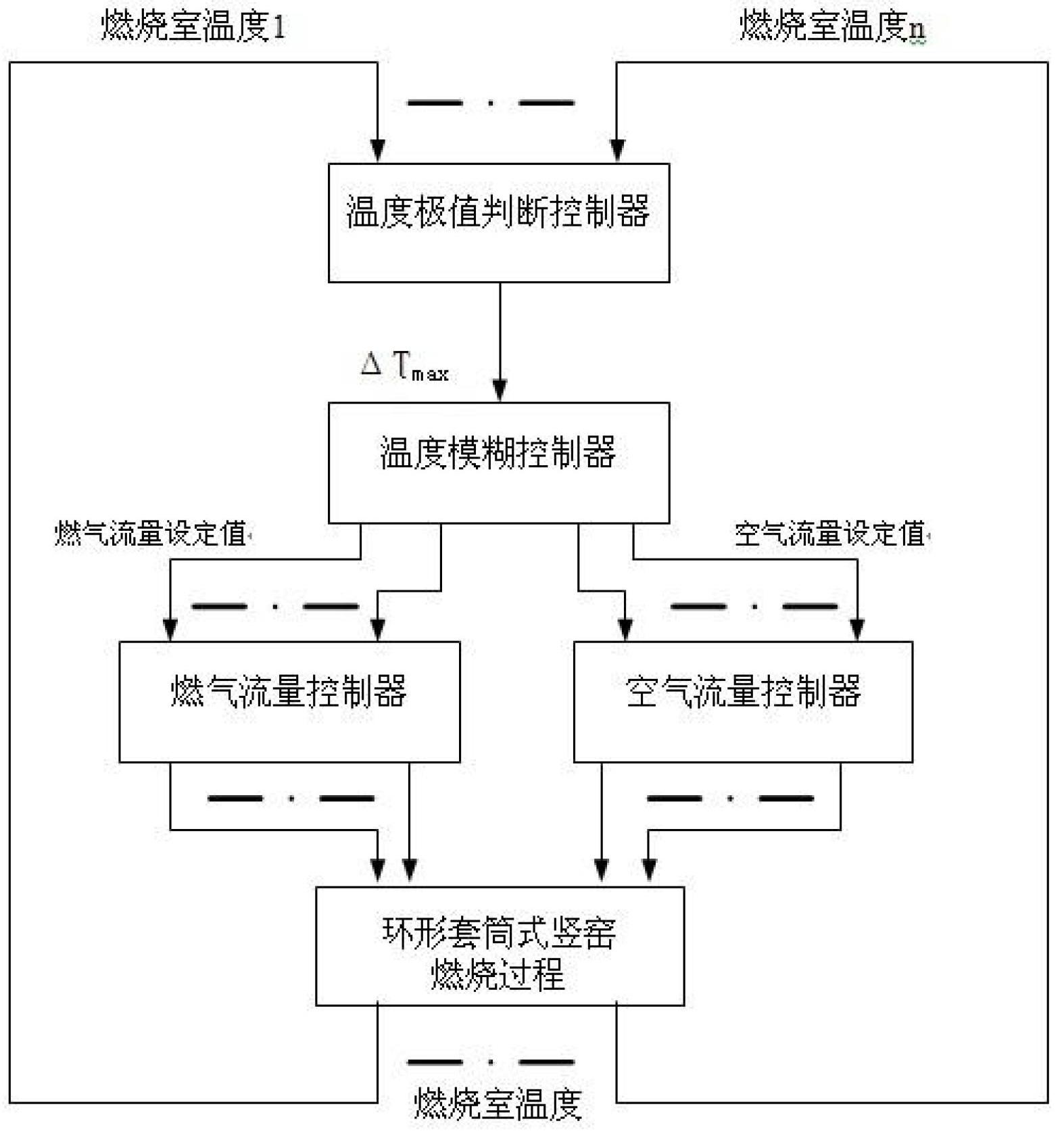

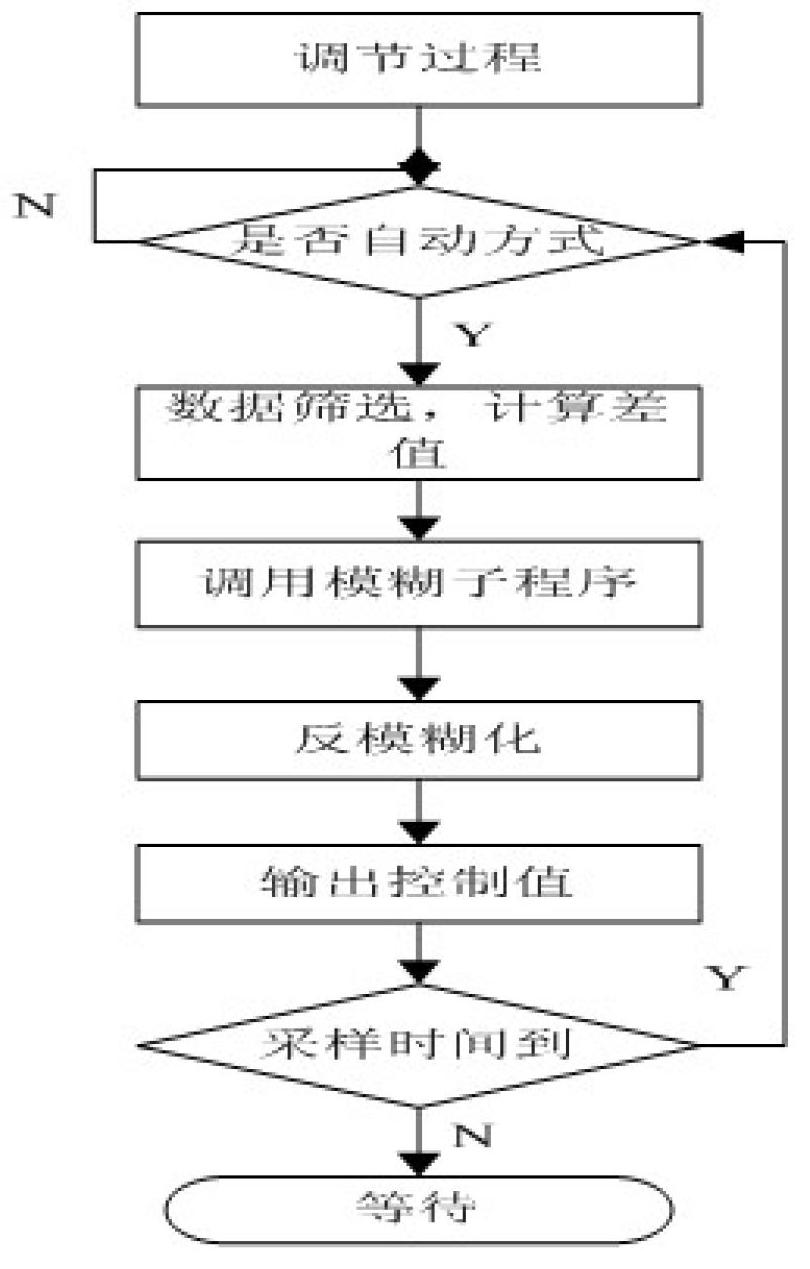

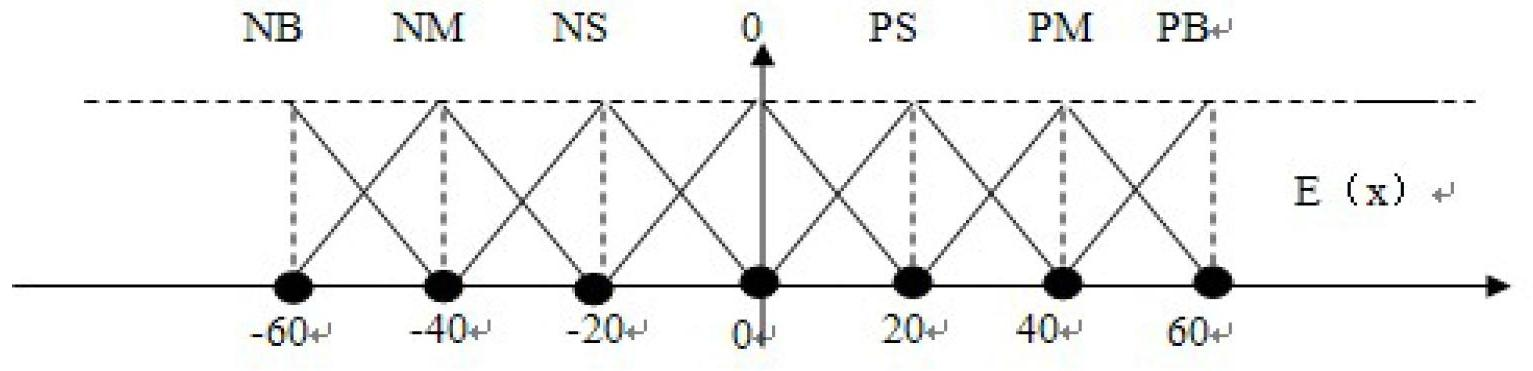

Automatic control method for improving uniformity of temperature of sleeve kiln

ActiveCN102692124AImprove uniformityStable and uniform qualityVertical furnacesCombustion chamberAutomatic control

The invention relates to an automatic control method for improving the uniformity of the temperature of a sleeve kiln and belongs to the technical field of industrial automation. According to the method, on the basis of a fuzzy control principle, the variation of the temperature of each combustion chamber of the ring-shaped sleeve vertical kiln is tracked by an industrial control computer so as to control the temperature of the ring-shaped sleeve vertical kiln. A temperature extreme value judgment controller, a temperature fuzzy controller, a gas flow regulation controller and a combustion air flow controller are arranged in a programmable logic controller (PLC) machine; and the temperature of the sleeve kiln is controlled and regulated by judging the variation of the temperature of each combustion chamber, automatically regulating a distribution coefficient of gas in each combustion chamber and regulating the gas flow and the combustion air flow of each combustion chamber according to the coefficient. According to the method provided by the invention, due to the adoption of the automatic control method, the uniformity of the temperatures of the combustion chambers can be improved, the product quality is improved and refractory materials inside the sleeve kiln are protected.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH +2

Integrated processing and preparing method in production place for wine rhizoma polygonati

InactiveCN107296891AStable and uniform qualityStrong antioxidant activityComponent separationPlant ingredientsRoom temperatureIntegrated processing

The invention discloses an integrated processing and preparing method in a production place for wine rhizoma polygonati. The integrated processing and preparing method in the production place for the wine rhizoma polygonati comprises the following steps: taking a fresh rhizoma polygonati medicinal material, removing impurities and non-medicinal parts, and washing; scalding the washed rhizoma polygonati in boiled water for 3 to 10 minutes, then, directly cutting the scalded rhizoma polygonati into thick pieces, and spreading and drying to half-dry; spraying yellow wine on the cut thick rhizoma polygonati pieces, and moistening for 1 to 5 hours; steaming the moistened rhizoma polygonati in a steaming container for 12 hours, braising for 12 hours, spreading for 24 hours at room temperature, and steaming, braising and drying for 2 to 9 times repeatedly to obtain finished wine rhizoma polygonati. The process disclosed by the invention integrates processing in the production place and a wine rhizoma polygonati process; the produced wine rhizoma polygonati is stable and uniform in quality; the production period can be effectively shortened; the energy consumption and human cost can be reduced; continuous production can be realized; the integrated processing and preparing method in the production place for the wine rhizoma polygonati can be applied to industrial large-scale production well, and meanwhile, the antioxidant activity of the wine rhizoma polygonati which is prepared according to the method disclosed by the invention is remarkably better than commercially available rhizoma polygonati.

Owner:SHAANXI UNIV OF CHINESE MEDICINE

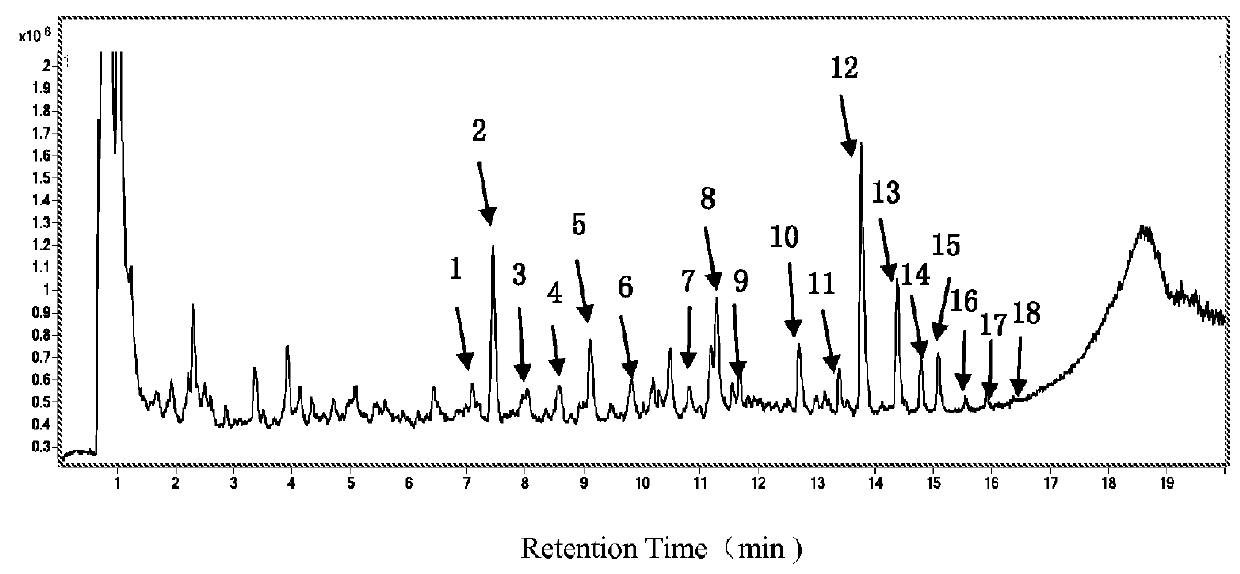

Method for establishing shenqi fuzheng injection fingerprint spectrum

InactiveUS20160054276A1Easy to monitorImprove stabilityComponent separationTesting medicinal preparationsChromatographic columnShenqi fuzheng

A method for establishing a Shenqi Fuzheng injection fingerprint spectrum, comprising: employing an ultra-high voltage liquid chromatography mass spectrometer to test the Shenqi Fuzheng injection, the chromatography conditions including: chromatographic column: Agilent Zorbax Eclipse Plus C18, 2.1 mm×100 mm, 1.8 μm; mobile phase: mobile phase A is 0.1% formic acid aqueous solution, and mobile phase B is 0.1% formic acid acetonitrile solution; employing gradient elution procedure as follows: 0-0.5 min, 95% of mobile phase A, and 5% of mobile phase B; 0.5-10 min, 95%-75% of mobile phase A, and 5%-25% of mobile phase B; 10-15 min, 75%-45% of mobile phase A, and 25%-55% of mobile phase B; 15-18 min, 45%-0% of mobile phase A, and 55%-100% of mobile phase B; and 18-20 min, 0% of mobile phase A, and 100% of mobile phase B.

Owner:LI MIN PHARM FAB OF LIVZON PHARM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com