Preparation method of polyvinylidene fluoride-based thin film

A polyvinylidene fluoride, film technology, applied in the field of polymer material processing, can solve the problems of poor performance and high cost

Active Publication Date: 2015-02-04

DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

View PDF8 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The purpose of the present invention is to solve the problems of the above-mentioned fluorine-containing films such as poor performance or high cost, and provide a method for preparing a PVDF-based film with simple procedures, good overall performance and low cost. Uniformity, good adhesion, excellent aging resistance, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0009] scope

[0010] All ranges cited herein are inclusive of endpoints unless expressly stated to the contrary. For example, dissolving the surface treatment agent in "0%-40% alcohol solution" means that the concentration range a of the alcohol solution is 0%≤a≤40%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

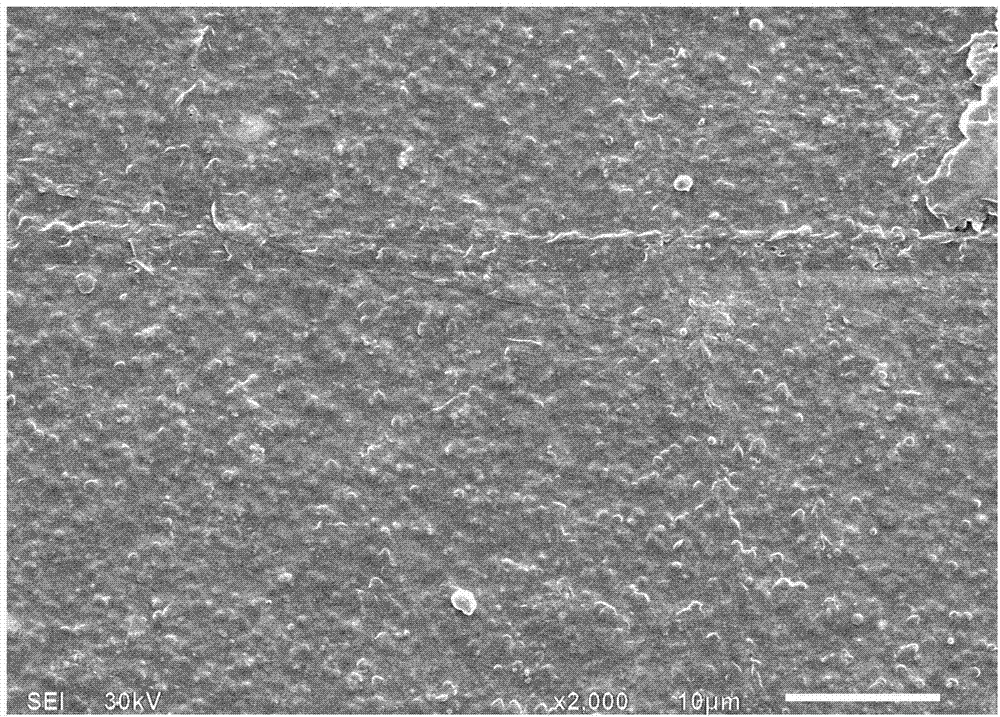

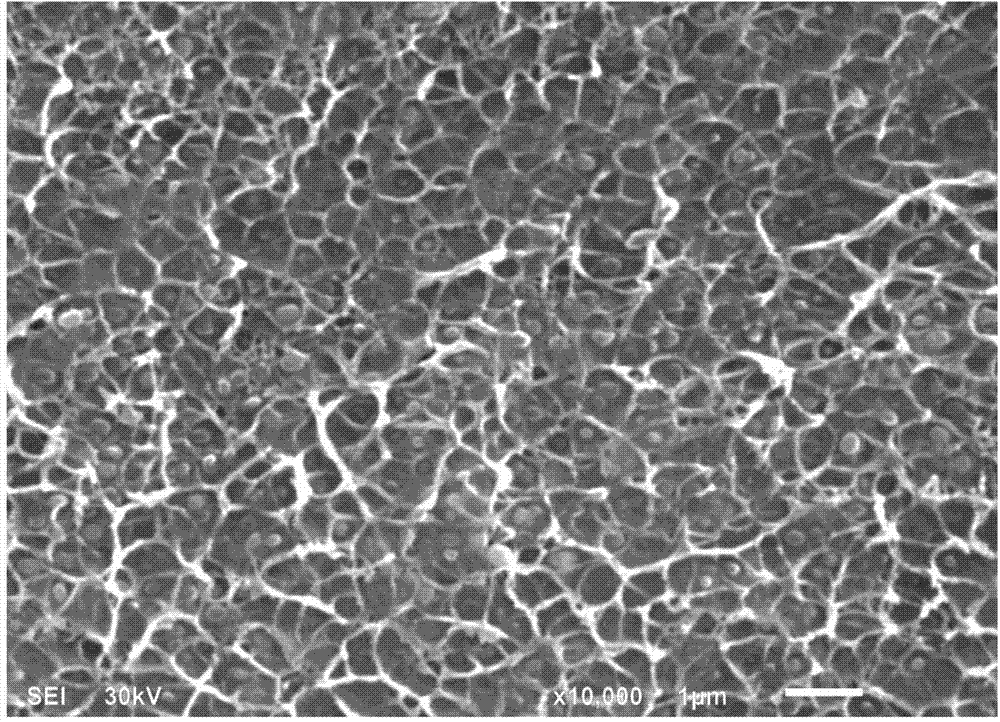

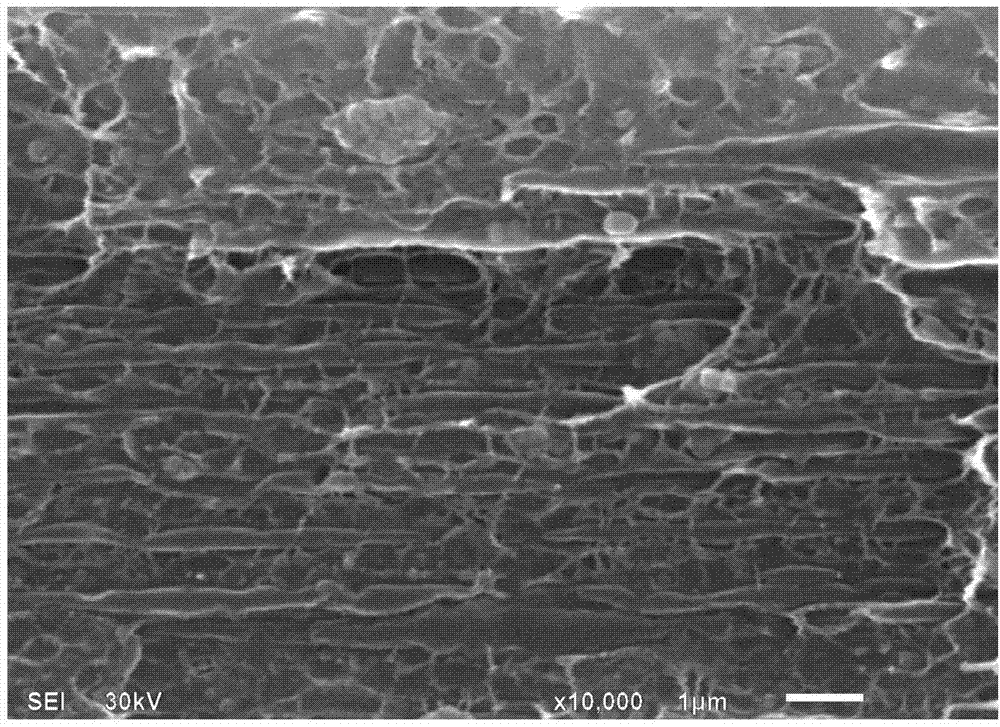

The invention relates to a preparation method of a polyvinylidene fluoride (PVDF)-based thin film. According to the thin film forming process, through an extrusion casting and drawing method, PVDF, polymethyl methacrylate (PMMA), a rubber elastomer, titanium dioxide as well as other auxiliaries and fillers are mixed according to a certain ratio and are melted and extruded at certain temperature, and then the PVDF-based thin film is formed under guiding and stretching effects of casting traction equipment. The PVDF-based thin film prepared by the invention is uniform and easily controllable in thickness, good in barrier property as well as excellent in mechanical property and environmental aging resistance, and is easy to realize industrialization; the PVDF-based thin film, through modification treatment, is significantly improved in surface caking property and guarantees good adhesion with a solar cell packaging material; the thin film brings high convenience for assembly of a solar cell backboard film and is compact in structure; and the thin film has good application prospect in solar cell industry.

Description

technical field [0001] The invention relates to the field of polymer material processing, in particular to a preparation method of a polyvinylidene fluoride-based film, which is applied to a back plate protective film material in the solar cell industry. Background technique [0002] With the gradual depletion of non-renewable energy and various environmental pollution problems caused by the production and use of mineral resources, countries are using policy and legal means to gradually increase the development and utilization of renewable energy and clean energy, and strive to Increase its share in overall energy use. Among these clean and renewable energy sources, solar energy is one of the most important energy sources. In recent years, the governments of various countries have increased investment in the solar photovoltaic industry in terms of capital, technology and policies, and have taken the development of the solar photovoltaic industry as one of the strategic goal...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L33/12C08L27/16C08K13/06C08K3/22C08J5/18C08J7/12

Inventor 李义涛程丛汤诚李林杨华军栗彦娜许才盛

Owner DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com