Patents

Literature

53 results about "Environmental aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

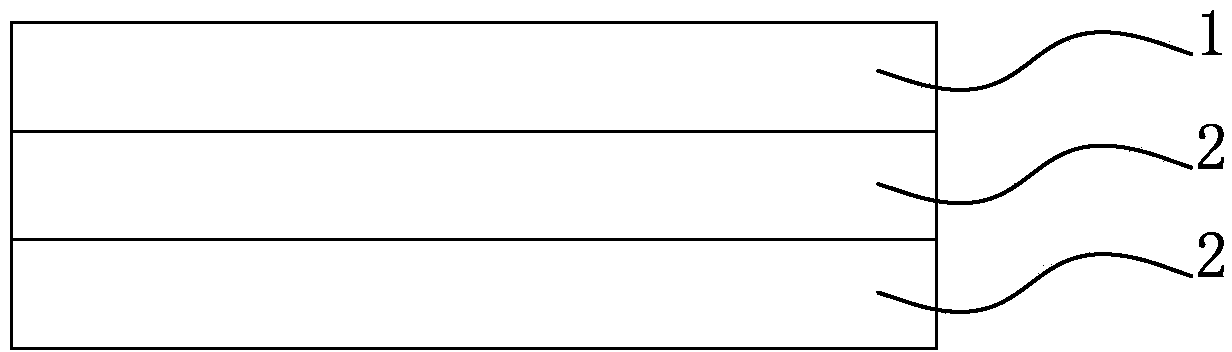

Expanded polytetrafluoroethylene film coating composite material with functions like heat conduction, heat insulation, electric conduction and electromagnetic shielding and preparation method thereof

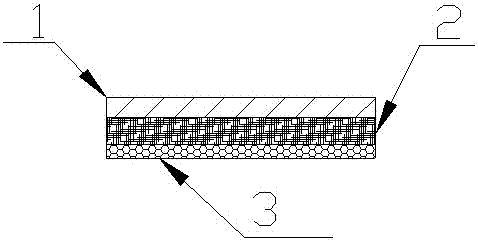

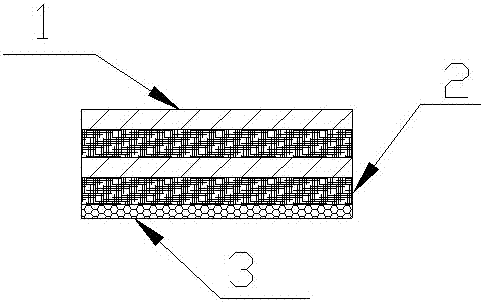

PendingCN107513168AFix stability issuesThe overall thickness is thinSynthetic resin layered productsPolyurea/polyurethane coatingsElectromagnetic shieldingGraphite

The invention discloses an expanded polytetrafluoroethylene film coating composite material with functions like heat conduction, heat insulation, electric conduction and electromagnetic shielding and a preparation method thereof. The composite material comprises at least one expanded polytetrafluoroethylene film layer, a graphene electric-conductive and heat-transfer coating and a silica aerogel coating, wherein the surface of one side of the at least one expanded polytetrafluoroethylene film layer is compounded with the graphene electric-conductive and heat-transfer coating; and the surface of the other side of the at least one expanded polytetrafluoroethylene film layer is compounded with the silica aerogel coating. Thus, the problems of attachment compactness and fastness of the graphene electric-conductive and heat-transfer coating and the heat-insulating silica aerogel coating can be solved; the expanded polytetrafluoroethylene film coating composite material with functions like heat conduction, heat insulation, electric conduction and electromagnetic shielding has the advantages of good softness and bonding properties, strong coating tensile resistance, no cracking, small material thickness and environmental aging resistance; meanwhile, the coating-free surface of the expanded polytetrafluoroethylene has the functions of insulation and isolation.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

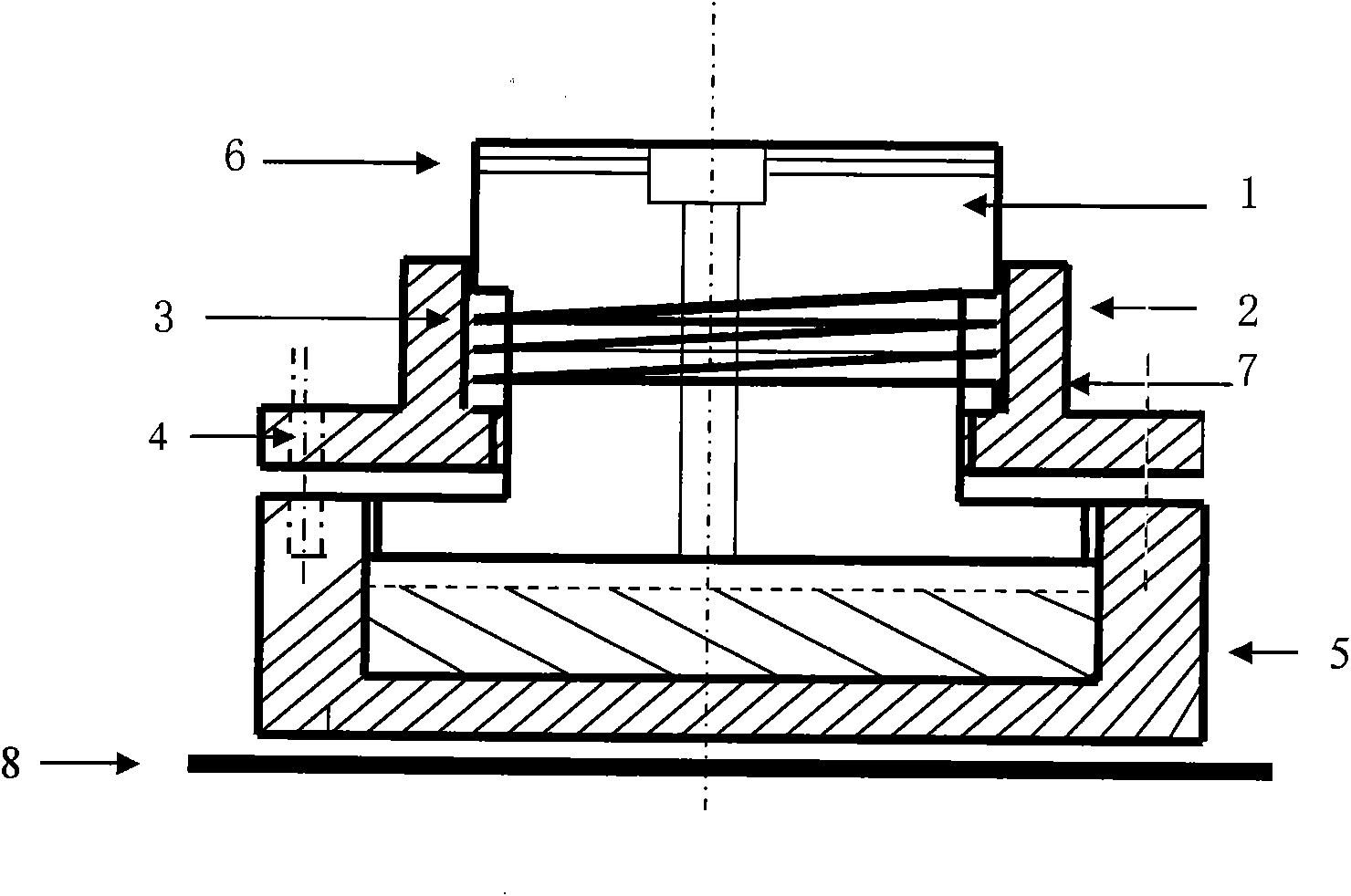

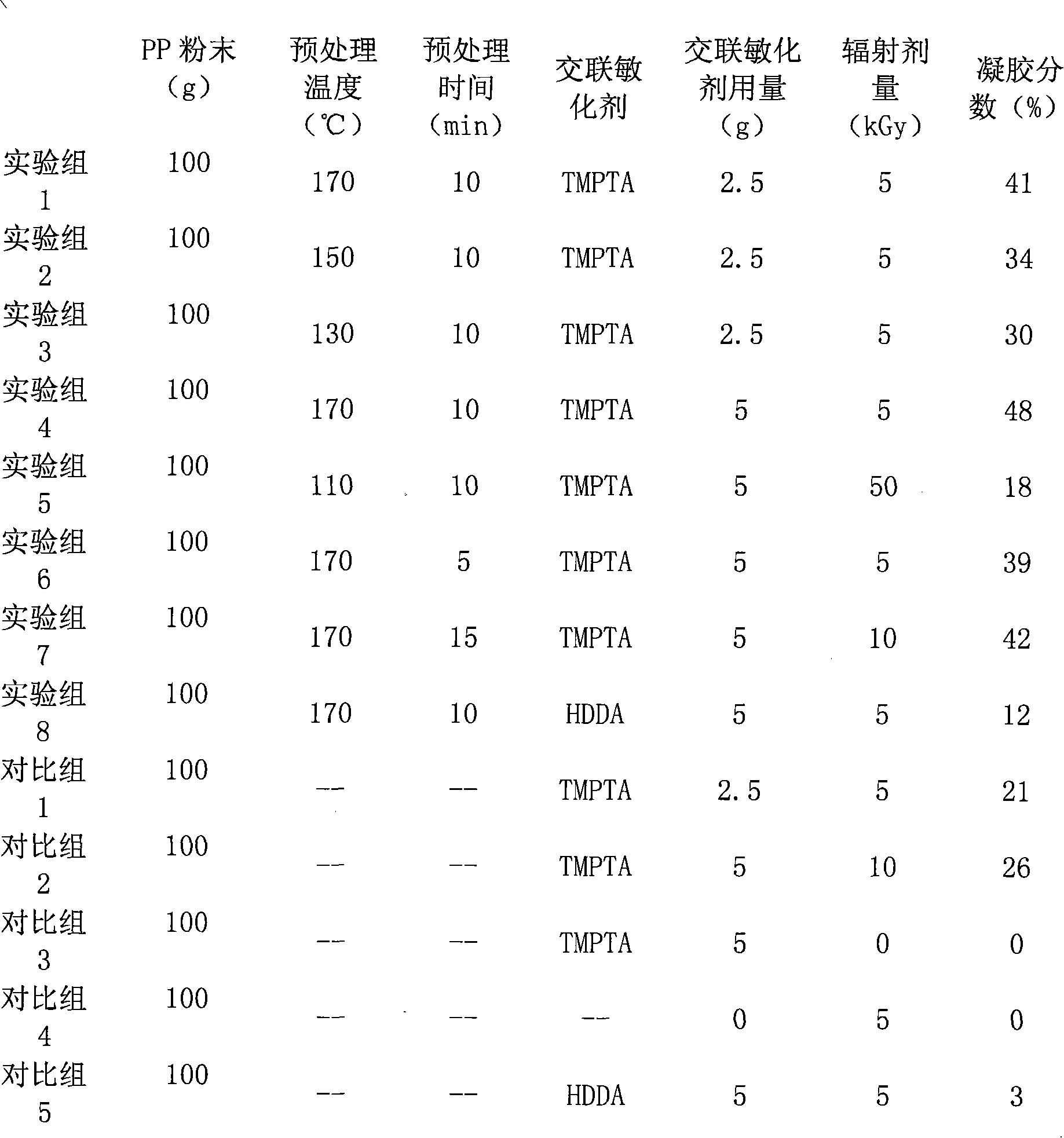

Preparation method of radiation-crosslinked polypropylene

InactiveCN102399390AWell mixedImprove the environmentChemical industryPolymer scienceElectron radiation

The invention discloses a preparation method of radiation-crosslinked polypropylene. According to the invention, polypropylene powder is added to a solution containing a croddlinking auxiliary agent; the mixture is processed through bake-drying, solvent removing and heat treatment; an antioxidant is added to the mixture, and the mixture is milled by using a double-roller mixing mill; the mixture is molded by extrusion or mold-pressing; and the molded polypropylene is irradiated. With the method provided by the invention, polypropylene and the croddlinking auxiliary agent can be sufficiently and uniformly mixed beforehand; the milling time can be shortened; the crosslinking efficiency can be improved; and the heat resistance and the melt strength can both be improved. In the radiation-crosslinking process, no chemical crosslinking agent is used, such that the method is environment-friendly. The crosslinking degree is uniform and controllable. The method is also advantaged in low energyconsumption and high yield. With electron radiation, environmental-aging resisting and temperature resisting performances of the polypropylene foam are substantially improved.

Owner:SICHUAN INST OF ATOMIC ENERGY

Preparation method of cross-linked polymer wax micropowder

The invention belongs to the technical field of polymeric material in fine chemicals, and relates to a preparation method of a cross-linked polymer wax. The method comprises the following steps: a. melting a polymer wax and grafting silane; b. carrying out micronization on the polymer grafted with the silane; c. obtaining a polymer wax micropowder with an average particle size between 1-50 [mu]m; besides, a crosslinking of a micronized graft polymer is finished in water. Before the crosslinking, the polymer wax micropowder prepared by the method is hydrophilic and is conducive to be added into a water-based paint ink; after the crosslinking, the polymer wax micropowder has good water repellency and a much higher molecular weight. Compared with oxidized polyethylene wax micropowder of prior art, the polymer wax micropowder has increased hydrophobicity, heat resistance, and environmental aging resistance, and is wear resistant and stain resistant as well.

Owner:NANJING TIANSHI NEW MATERIAL TECH

Preparation method of modified polyurethane elastomer composite material

The invention discloses a preparation method of an environment-friendly modified polyurethane elastomer composite material. The method comprises the following steps of uniformly agitating polypropylene oxide dibasic alcohol and polypropylene oxide tribasic alcohol, then adding silane modified nano silicon carbide, ultrasonically dispersing, then firstly heating to 105 to 115 DEG C, carrying out vacuum treatment, then lowering a temperature to 80 to 90 DEG C, adding diisocyanate to carry out a polymerization reaction, and further lowering the temperature to 70 to 80 DEG C, adding an antifoamingagent and ethylene-propylene-diene monomer rubber, uniformly agitating, and then adding water as a chain extender, so that the modified polyurethane elastomer composite material which is excellent inhigh-temperature-resistant, wear-resistant and environmental aging-resistant performance. The environment-friendly modified polyurethane elastomer composite material is suitable to use in a large range, and is particularly suitable for an all-weather sports terrace; the method is low in requirement on a device; the process is simple; the reaction procedure is easy to control; the one-step synthesis is achieved, and the waste of a raw material, which is caused due to the failure of calculation, is avoided.

Owner:CENT SOUTH UNIV

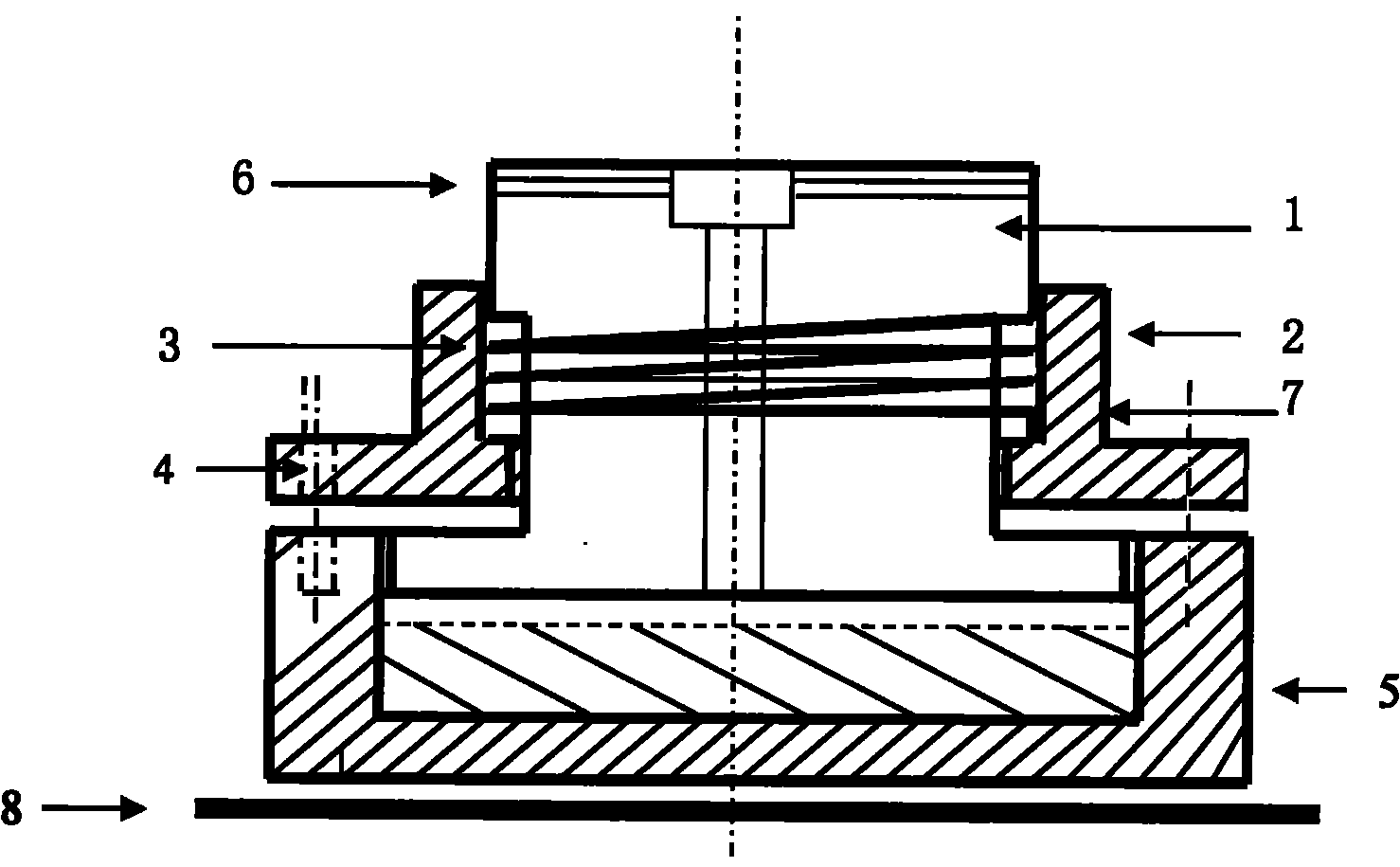

Salt mist system of multifactor environmental aging test device for composite material

InactiveCN102608301ARealize controllableAchieving Settlement UniformityMaterial testing goodsSaline waterCavitation

The invention discloses a salt mist system of a multifactor environmental aging test device for a composite material. The salt mist system comprises a salt mist generating chamber and a test working chamber, wherein the salt mist generating chamber is communicated to the test working chamber, and a salt mist generator is arranged in the salt mist generating chamber. According to the salt mist system of the multifactor environmental aging test device for the composite material, the salt mist generator is an ultrasonic salt mist generator, when the salt mist system works, salt water to be atomized is added into the salt mist generating chamber, and the salt water can be atomized into salt mist with a smaller particle diameter under the action of the acoustic cavitation of the ultrasonic salt mist generator, so that the controllability of the salt mist is realized, and the validity of a salt mist tested result is improved; and the salt mist can be diffused from the salt mist generator to the test working chamber and evenly covered on a sample workpiece, so that the uniformity of the settlement quantity of the salt mist is realized. The salt mist system of the multifactor environmental aging test device for the composite material can serve as a salt mist system to be applied to salt mist test equipment.

Owner:广州合成材料研究院有限公司

Weatherable toughened modified polyethylene cable sheath material

ActiveCN103589039AImprove performanceImprove rigidityPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethylenePhosphoric acid

The invention relates to a cable material, and specifically relates to a weatherable toughened modified polyethylene cable sheath material. the material comprises the following raw materials in parts by weight: 15-19 parts of SG-2 PVC resin, 23-25 parts of POE, 24-28 parts of low-density polyethylene, 14-18 parts of calcined potter's clay, 1-2 parts of silver nitrate, 3-4 parts of sodium chloride, 2-3 parts of silane coupling agnet KH-550, 1-2 parts of zirconium fluoride, 6-8 parts of nanometer titanium dioxide, 2-3 parts of nanometer titanium phosphate, 8-10 parts of dimethyl isooctyl thioglycolate tin, 1-2 parts of anti-aging agent 4010, 12-15 parts of diatomite powder, 2-3 parts of ammonium polyphosphate, 25-30 parts of tributyl citrate and 14-16 parts of an auxiliary agent. The insulating material combines the advantages of low-density polyethylene, POE, PVC resin and the like, the prepared material is good in rigidity, high in toughness, good in mechanical properties, resistant to environmental aging, resistant to heat, resistant to flame, and safe and reliable to use, is widely applicable to preparation of various cable sheath insulating materials, and has wide market demanding prospect.

Owner:TONGXIANG GUANGSHENG PLASTIC IND CO LTD

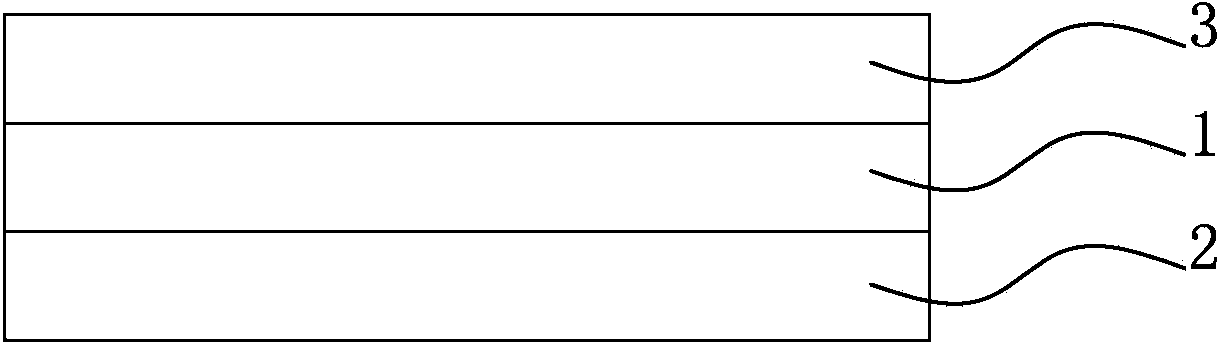

VPF backplane for solar cell and processing process thereof

InactiveCN103660493AImprove performanceSolve layeringSynthetic resin layered productsLaminationEngineeringSolar cell

The invention provides a VPF backplane for a solar cell. The VPF backplane comprises a functional PET layer and a conventional PET layer and is characterized in that the functional PET layer and the conventional PET layer are compounded by using tape casting technology. According to the invention, the tape casting technology is adopted to compound the functional PET layer and the conventional PET layer, so layering of PET layers during glueing is overcome, and service life is prolonged; meanwhile, due to usage of a composite structure of the functional PET layer and the conventional PET layer, integral performance of the VPF backplane is improved; the surface of a fluorine-containing coating in contact with EVA has good ultraviolet aging resistance; the outer air surface of functional PET has double properties consisting of ultraviolet resistance and damp-heat aging resistance; and the backplane has stronger environmental aging resistance.

Owner:JOLYWOOD SUZHOU SUNWATT

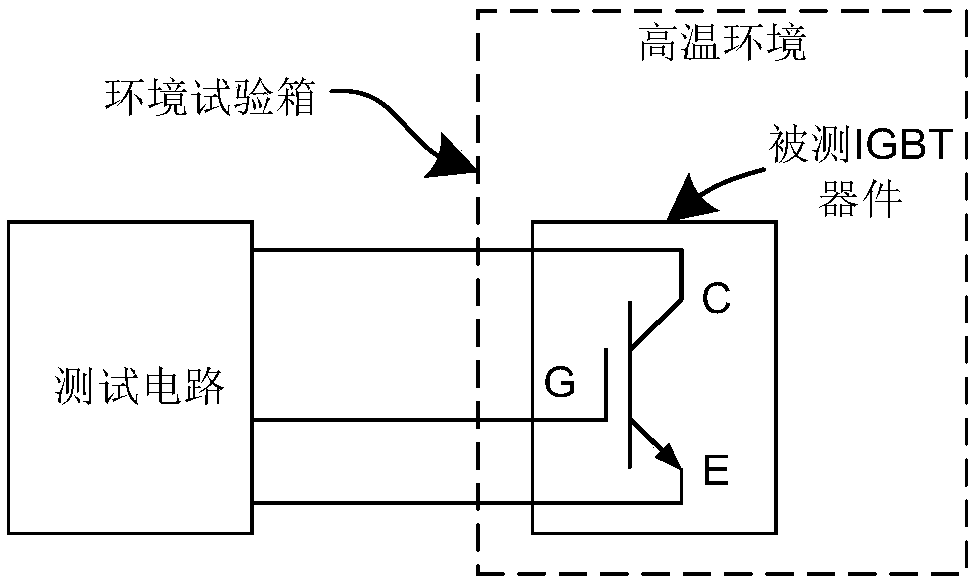

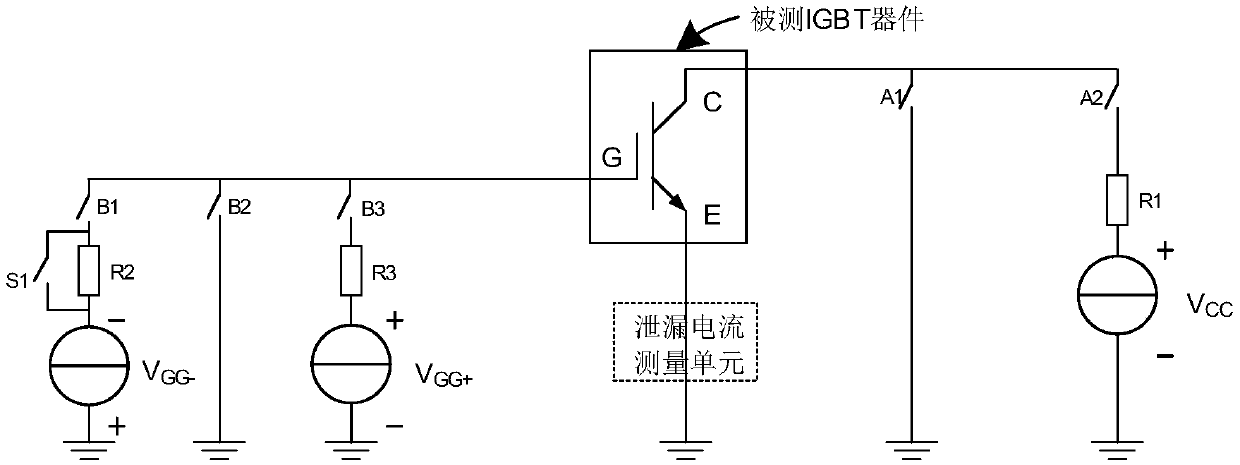

Method and system capable of being compatible with various environmental aging tests

ActiveCN109596964AIncrease profitReduce procurement costsIndividual semiconductor device testingTest powerHigh humidity

The invention relates to a method and a system capable of being compatible with various environmental aging tests. The system comprises a test environment device and a test circuit; the test environment device can be used to provide a test environment required by a to-be-tested power device in the environmental aging test; the test circuit can be used to provide electrical conditions needed by theto-be-tested power device in the environmental aging test, so that a required reverse bias test or grid bias test can be carried out on the to-be-tested power device; the test environment which can be provided by the test environment device includes a low-temperature environment, a high-temperature environment and a high-temperature and high-humidity environment; through cooperation of the test environment provided by the test environment device and / or the electrical conditions loaded by the test circuit, the required environmental aging test can be carried out on the to-be-tested power device; and the various environmental aging tests can be realized at the same time by utilizing the same device, so that the comprehensive utilization rate of the test is improved, and the installation space, the purchasing cost and the follow-up operation and maintenance cost are reduced.

Owner:山东阅芯电子科技有限公司

Cross arm for wire pole wiring

InactiveCN103821402AReduce weightSimple structureTowersGlass/slag layered productsDielectricGlass fiber

The invention discloses a cross arm for wire pole wiring. The cross arm comprises a cross arm supporting layer, glass fibers, a waterproof foamed plastic resistance body filled in the cross arm supporting layer, a first uvioresistant layer and a second uvioresistant layer, the first uvioresistant layer and the second uvioresistant layer are coated on the cross arm supporting layer, the glass fibers are continuously wound on the cross arm supporting layer to form a square tubular object, and the waterproof foamed plastic resistance body filled in the cross arm supporting layer is identical with the glass fibers in dielectric factor to be used as equipment on a wire pole of an overhead power system to support load. By combining multiple insulating materials, the cross arm is enabled to be light in weight and have effect of being resistant to environmental aging and polluting, so that wiring safety and power supply reliability are improved.

Owner:吴新平

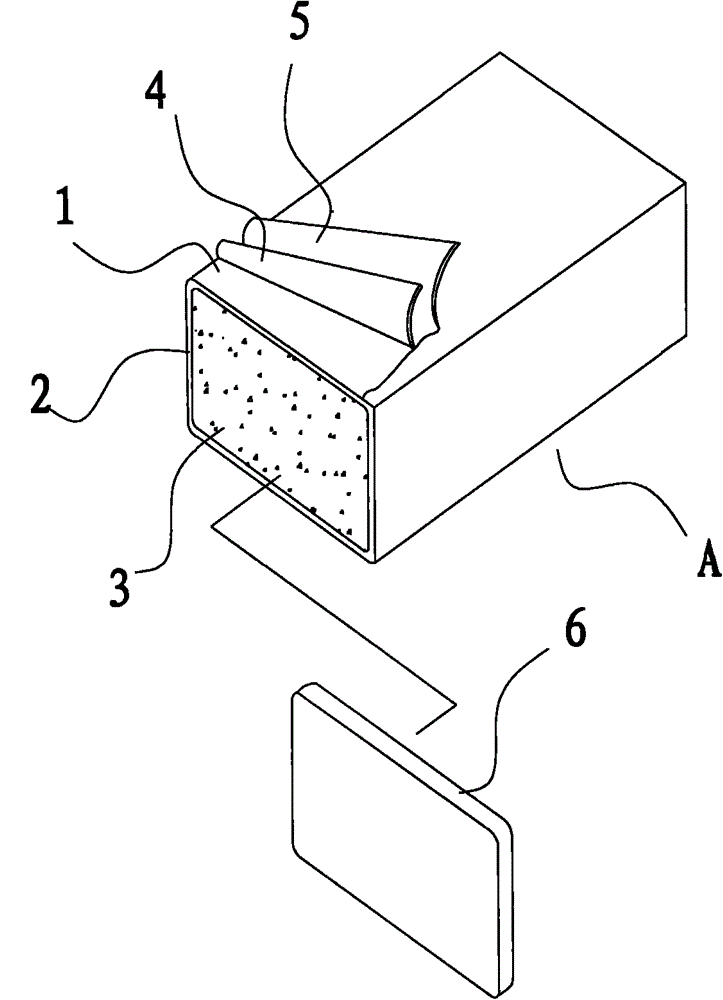

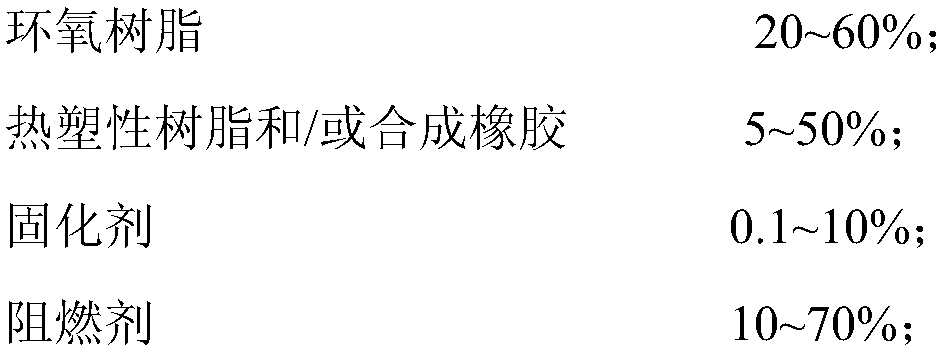

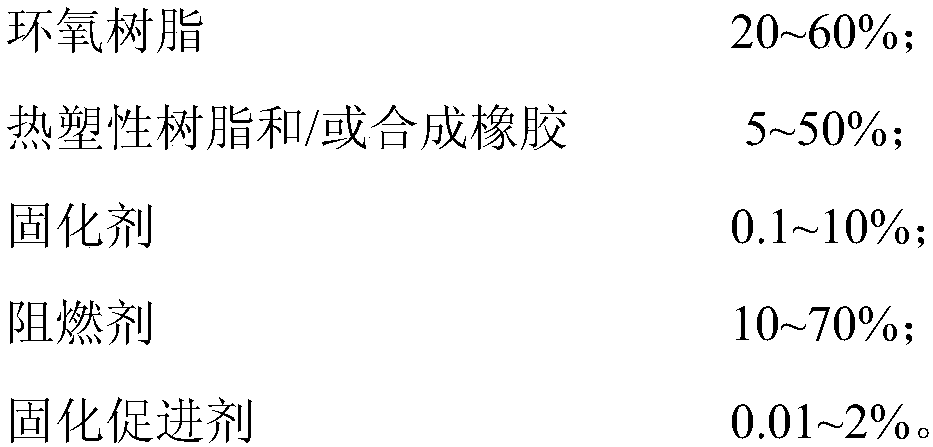

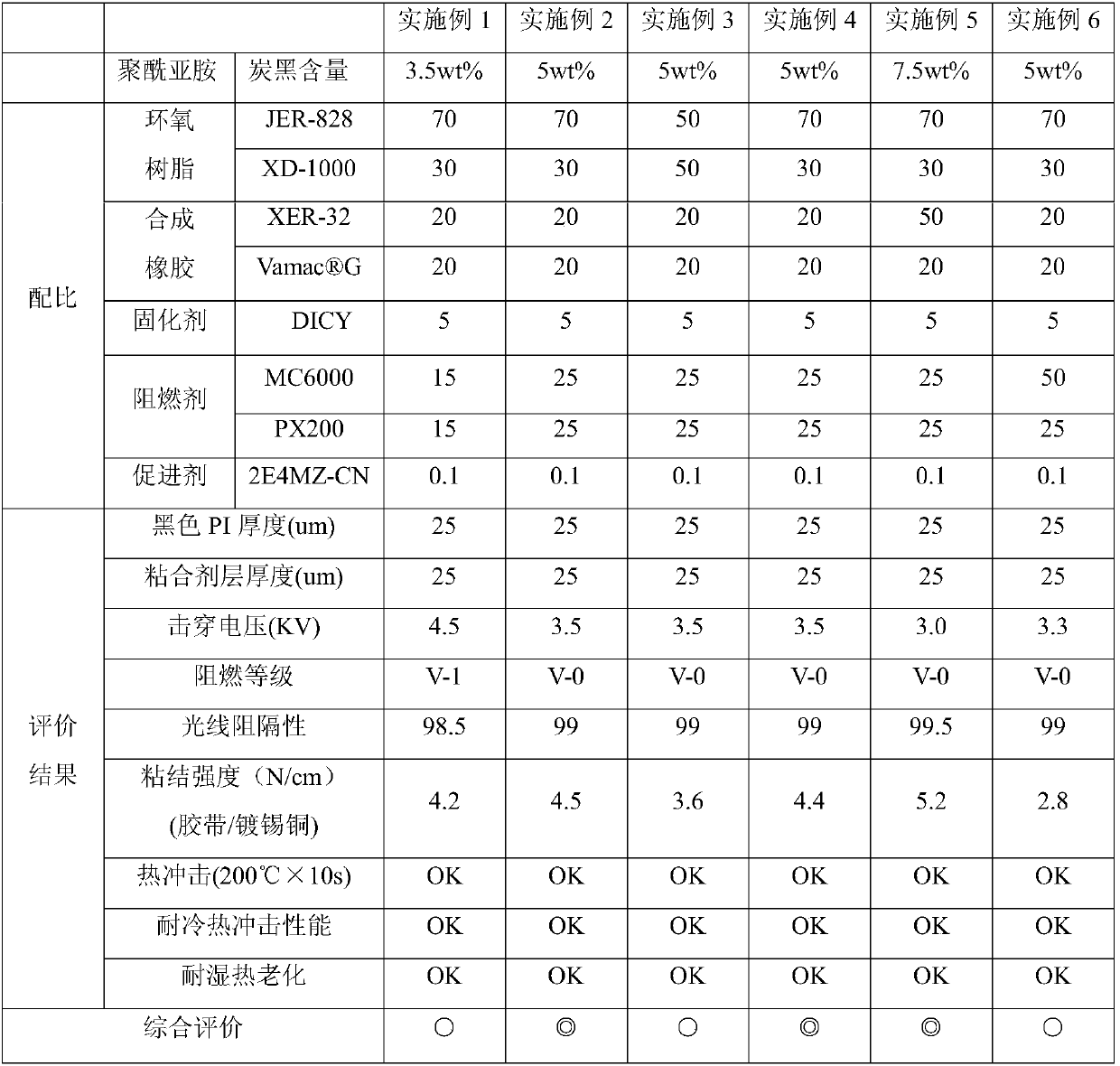

Photovoltaic assembly bus bar insulating tape, bus bar comprising insulating tape, and photovoltaic assembly

InactiveCN107619643AImprove thermal shock resistanceExcellent adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyFire retardant

The invention relates to a photovoltaic assembly bus bar insulating tape, a bus bar comprising the insulating tape, and a photovoltaic assembly. The photovoltaic assembly bus bar insulating tape comprises an insulating substrate layer and an adhesive layer formed on one surface of the insulating substrate layer, wherein the insulating substrate layer is a polyimide layer which contains 2-10% of carbon black and has the light transmittance being lower than 2% in the range of 280-1100 nm; and the adhesive layer comprises the following components as raw materials in percent by mass: 20-60% of epoxy resin, 5-50% of thermoplastic resin and / or synthetic rubber, 0.1-10% of a curing agent and 10-70% of a flame retardant. The insulating substrate layer of the photovoltaic assembly bus bar insulating tape has excellent ultraviolet barrier performance, and the adhesive layer not only has excellent adherence to the insulating substrate layer, but also has excellent adhesion to metal; the photovoltaic assembly bus bar insulating tape has environmental aging properties of ultraviolet resistance, heat shock resistance, cold and heat shock resistance, damp heat resistance and the like; and the photovoltaic assembly bus bar insulating tape is thermally pressed on a metal plate or a metal bus bar and can be used for insulating the photovoltaic assembly bus bar.

Owner:CYBRID TECHNOLOGIES INC

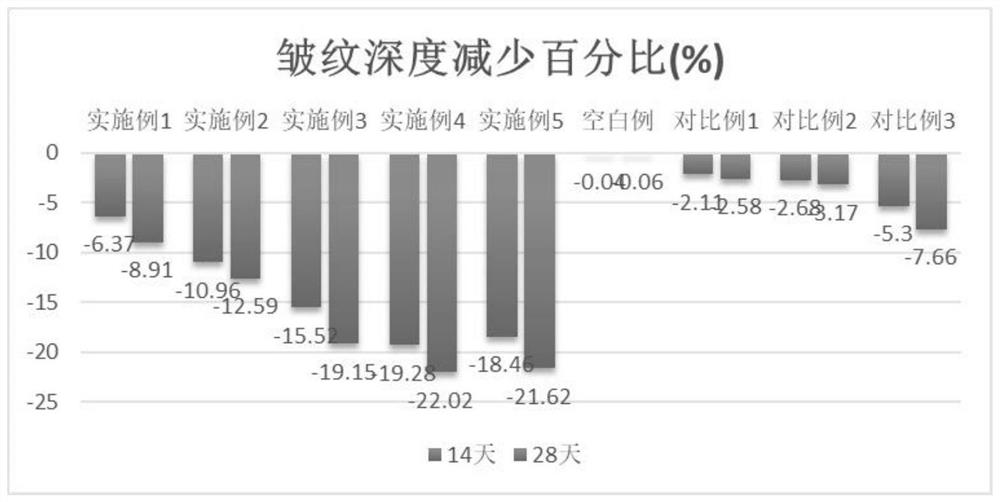

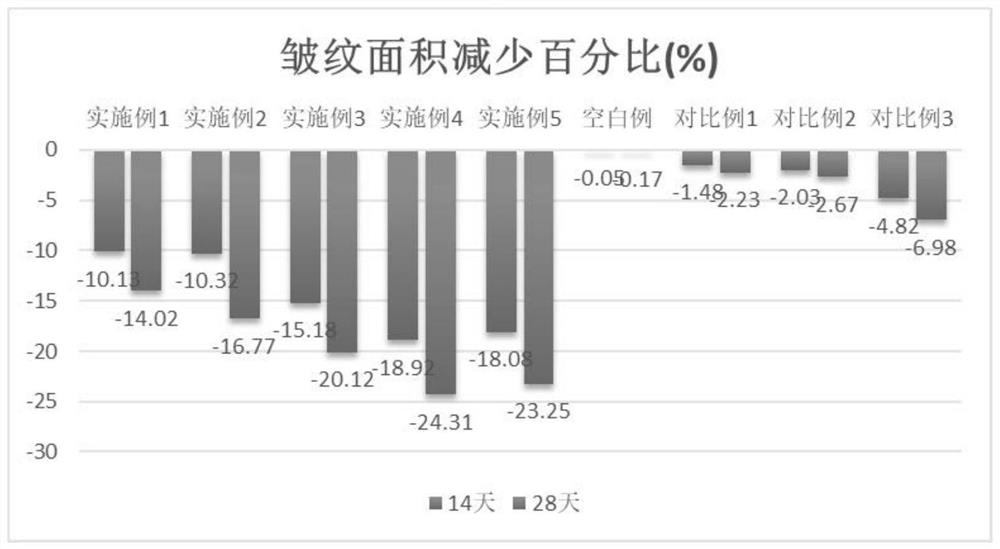

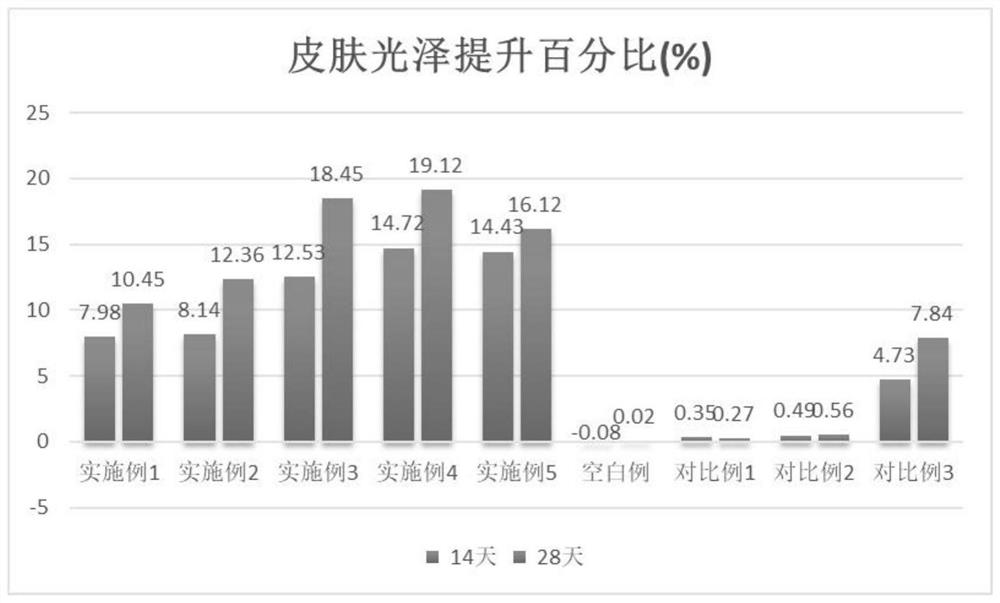

Multi-vitamin anti-wrinkle composition, cosmetic composition and preparation method thereof

ActiveCN113288822AHigh glossMake up for the defect of a single mechanism of actionCosmetic preparationsToilet preparationsBiotechnologyEngineering

The invention discloses a multi-vitamin anti-wrinkle composition, a cosmetic composition and a preparation method thereof, and relates to the technical field of cosmetics, and the multi-vitamin anti-wrinkle composition is prepared from the following raw materials in parts by weight: 0.05-0.2 part of retinol palmitate; 0.02-0.2 part of acetyl tetrapeptide-2; 0.02-0.2 part of acetyl hexapeptide-8; 0.5-5 parts of a bifidus yeast fermentation product lysate; and the balance of auxiliary components. According to the multi-dimensional anti-wrinkle composition disclosed by the invention, by combining multiple reasons of wrinkles generated by skin aging, through targeted functional component design and collocation, the wrinkle fading and anti-wrinkle effects are realized from physiologic aging, mechanical aging and environmental aging in multiple dimensions. The defect that the existing anti-wrinkle product has a single action mechanism is overcome, meanwhile, the four functional components have a synergistic effect, and the effects of more comprehensively and more remarkably reducing the depth and area of wrinkles, smoothing the wrinkles and improving the skin glossiness are achieved.

Owner:SHANGHAI NEW COGI COSMETIC

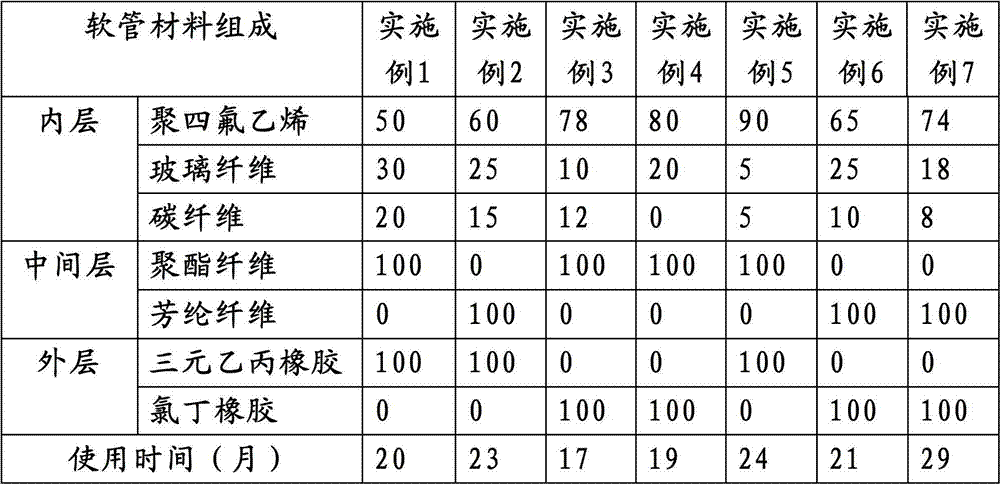

Cooling hose for turbocharger of engine

ActiveCN102734570AImprove high temperature resistanceImprove high pressure performanceMachines/enginesFlexible pipesPolyesterCarbon fibers

The invention discloses a cooling hose for a turbocharger of an engine. The cooling hose consists of an inner layer, an interlayer and an outer layer, wherein the inner layer and the interlayer are bonded by hot-pressing; the interlayer and the outer layer are bonded through a binder; the inner layer is formed by compounding 50 to 90 weight percent of polytetrafluoroethylene, 5 to 30 weight percent of glass fiber and 0 to 20 weight percent of carbon fiber; the interlayer is woven from at least one of polyester fiber and aramid fiber; and the outer layer is formed by extruding and vulcanizing at least one of ethylene-propylene-diene monomer and neoprene. The cooling hose for the turbocharger of the engine is high in heat resistance and pressure resistance, and low in cooling liquid permeability; the problem of environmental aging of the hose is effectively solved; and the cooling hose is simple in structure and easy to manufacture.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

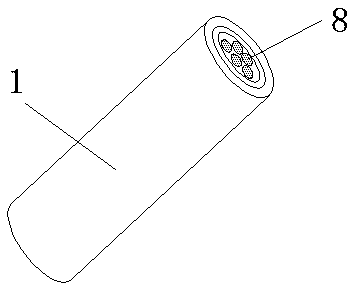

Preparation process of rail transit cable

InactiveCN108831629AHigh temperature resistanceImprove environmental aging resistanceReduction of cables/conductors sizeInsulating conductors/cablesElectrical conductorCopper wire

The invention discloses a preparation process of a rail transit cable. The preparation process of the rail transit cable comprises the steps of (1) conductor drawing; (2) conductor stranding; (3) insulating layer extrusion; (4) preparation of a metal shielding layer outside an insulating wire core; (5) gap filling; and (6) sheath extrusion. The rail transit cable disclosed by the invention has good low-smoke, halogen-free and flame-retardant performance, and is high in temperature resistance level (125 DEG C) and excellent in environmental aging resistance. The cable shielding layer adopts a double-layer shielding structure, thereby being capable of effectively suppressing the occurrence of crosstalk. Meanwhile, the rail transit cable adopts tinned copper wire and aramid fiber braiding, thereby being capable of bearing influences of strong external tension to a certain extent, and playing a role of protecting core wires. The effect of the tensile strength is more prominent especially for cables with a small cross section in the connecting part. The sheath layer of the cable is made of a nylon sheath, and the high wear resistance of the sheath can effectively prevent cable damages caused by friction.

Owner:ANHUI YILI CABLE

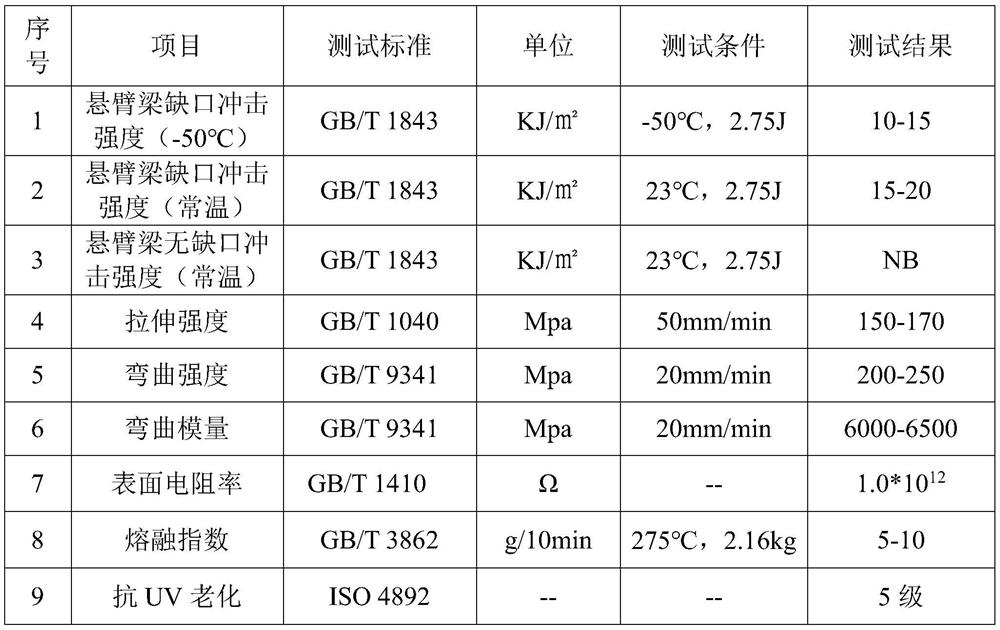

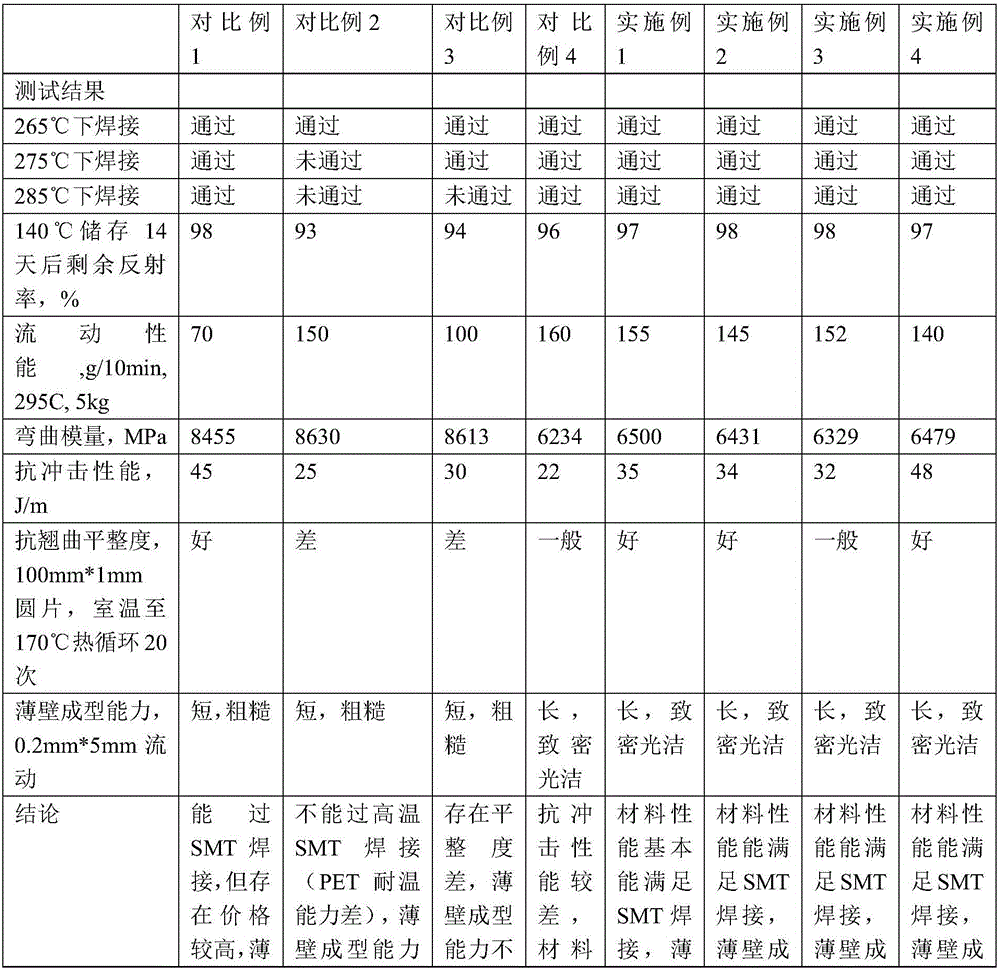

Nylon material for pin type composite insulator cap-shaped connector for power grid power transmission and distribution line and forming method

PendingCN111621149AImprove mechanical propertiesImprove liquidityInsulatorsGlass fiberNylon material

The invention relates to a nylon material of a pin-type composite insulator cap-shaped connector for a power grid power transmission and distribution line and a forming method. The nylon material comprises the following components in percentage by mass: 62%-66% of nylon resin, 28%-33% of glass fiber, 3%-6% of a toughening agent, 0.2%-0.5% of a main antioxidant, 0.2%-0.5% of an auxiliary antioxidant, 0.2%-0.5% of an ultraviolet absorbent, 0.2%-0.5% of a light stabilizer and 1%-3% of a wear-resistant additive, the viscosity of the nylon resin is 3.2 + / -0.01; the grafting rate of the toughening agent is 0.8 to 1.2%; the nylon resin is PA66 polyhexamethylene adipamide, PA6 polyamide 6 or a mixture of the PA66 polyhexamethylene adipamide and the PA6 polyamide 6. After polymerization processing,the material performance is excellent, the mechanical performance, the electrical performance, the environmental aging resistance, the high and low environmental temperature resistance and the material wear resistance of the composite product are excellent, and the safe use condition of the product is met.

Owner:XIAN WEISHI TRANSMISSION & DISTRIBUTION TECH CO LTD

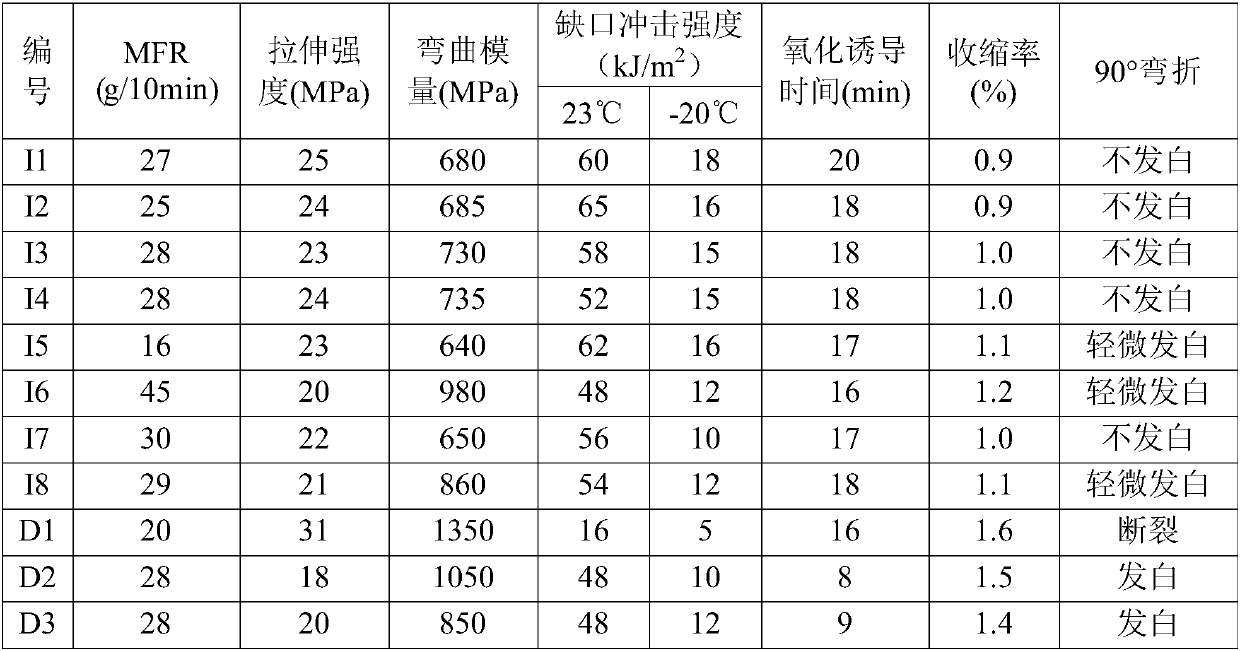

Polypropylene composition, polypropylene material, and applications of polypropylene composition and polypropylene material

The present invention relates to the field of polymers, particularly to a polypropylene composition, a polypropylene material, and applications of the polypropylene composition and the polypropylene material, wherein the polypropylene composition contains, by weight, 64-90% of anti-impact co-polypropylene, 9-35% of a thermoplastic elastomer, and 0.2-1.5% of an antioxidant. According to the presentinvention, the polypropylene material has advantages of good fluidity, good shrinkage, rigidity and toughness balance, heat aging resistance and environmental aging resistance, and cannot produce stress whitening after bending 90 DEG; and the polypropylene composition and / or the polypropylene material are particularly suitable for the preparation of pot seedling cultivation disks.

Owner:CHINA PETROLEUM & CHEM CORP +1

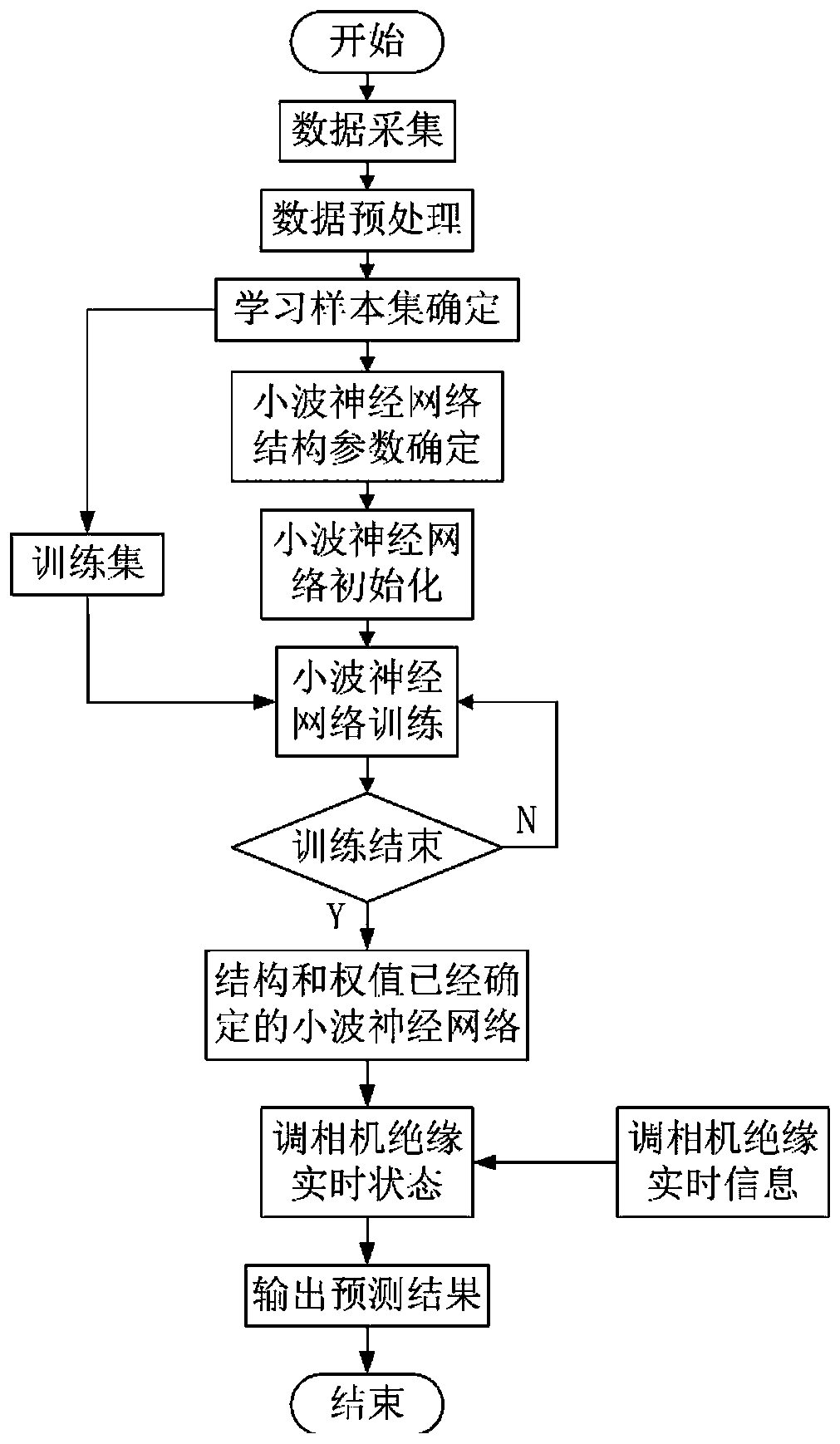

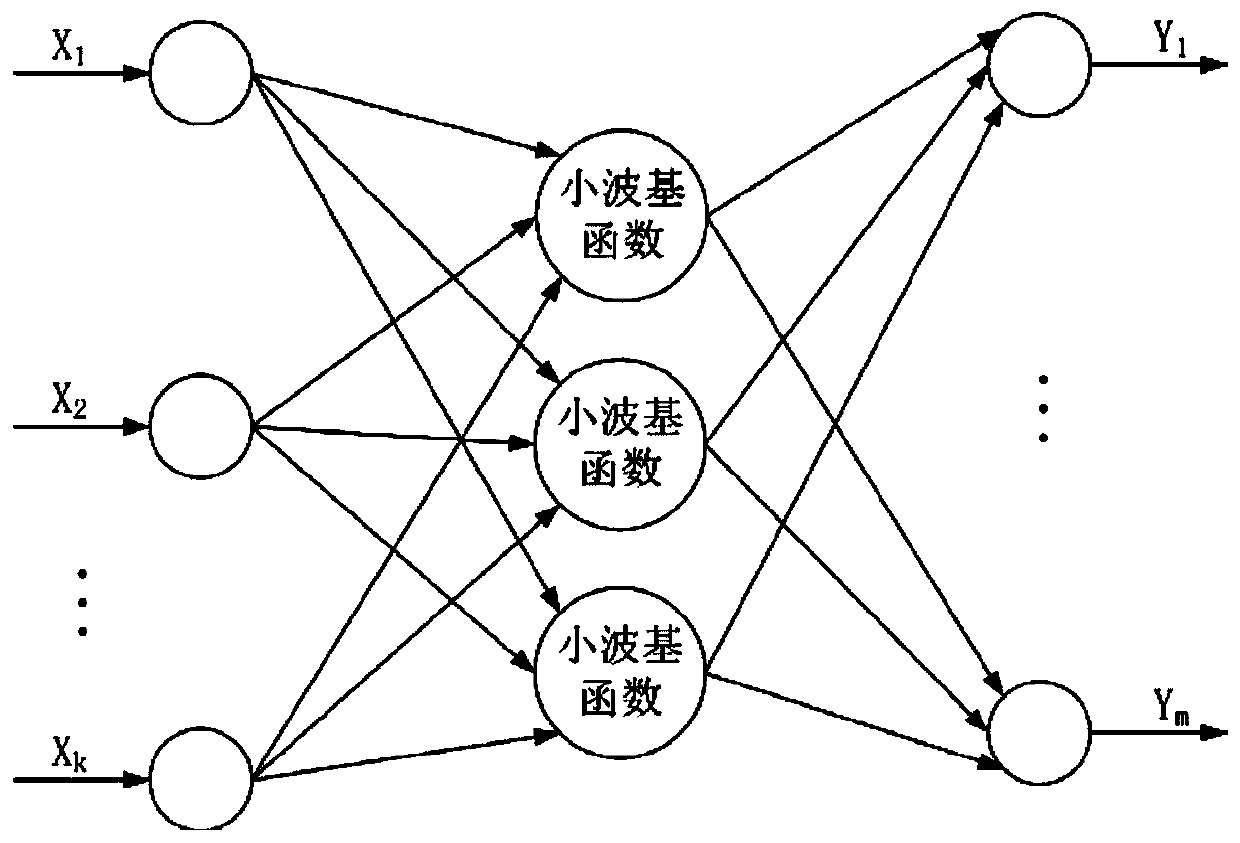

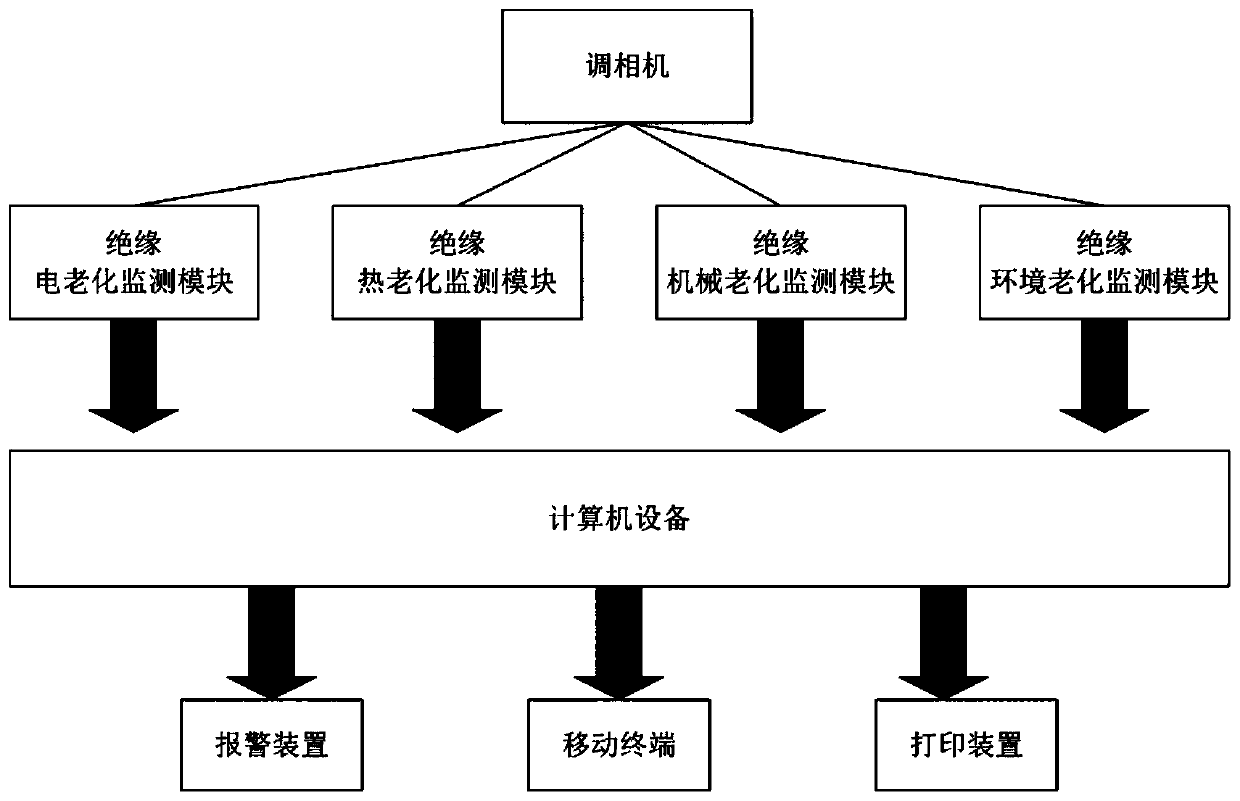

Phase modifier insulation fault prediction method and system

InactiveCN110749810AImproving the Efficiency of Insulation Failure Trend PredictionGuaranteed uptimeTesting dielectric strengthNeural architecturesControl engineeringTrend prediction

The invention provides a phase modifier insulation fault prediction method and system. The method comprises the steps of firstly obtaining electrical aging data, thermal aging data, mechanical aging data and environmental aging data of a diagnosed phase modifier insulation; then performing data preprocessing to eliminate obvious singular points in the data; determining a learning sample set and structural parameters of a neural network; and then starting wavelet neural network modeling and performing network training until a wavelet neural network with a determined structure and weight is obtained. According to the method and the system, for the problem of difficult phase modifier insulation maintenance, insulation state diagnosis analysis of a phase modifier can be performed by integrating phase modifier insulation electrical aging, thermal aging, mechanical aging and environmental aging parameters, so that the phase modifier insulation fault trend prediction efficiency is greatly improved, a guarantee is provided for safe and reliable operation of the phase modifier, the phase modifier insulation operation and maintenance cost is reduced, and the feasibility is provided for intelligent health management of the phase modifier.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

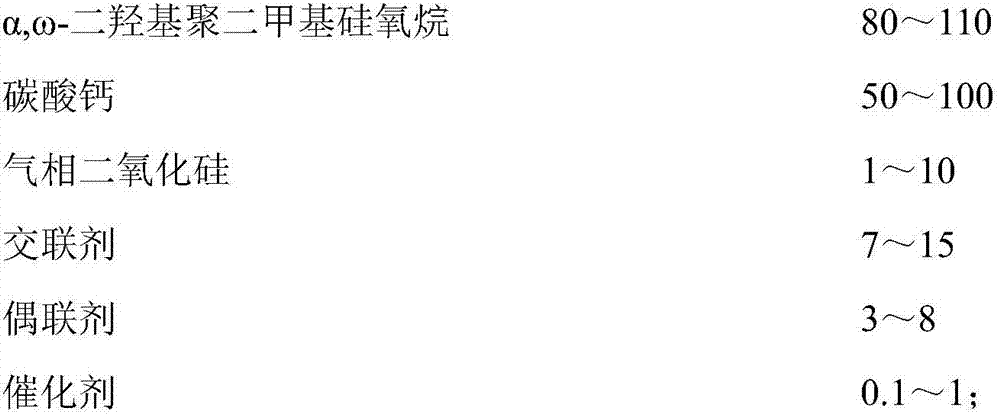

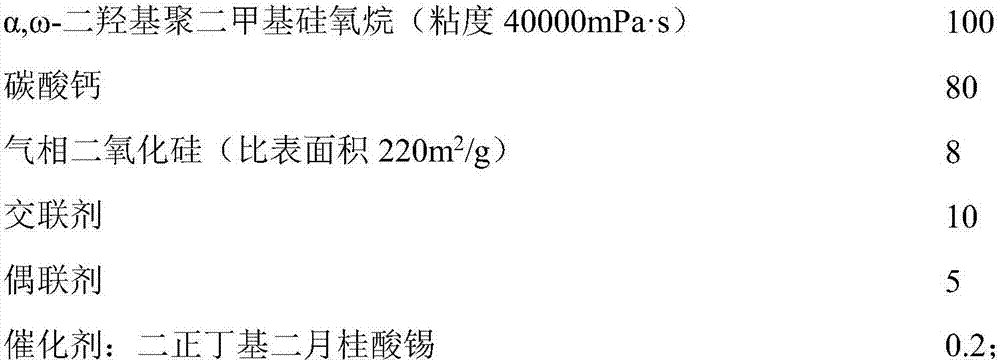

One-component silicone rubber for acrylic bonding and preparation method thereof

The invention discloses a one-component silicone rubber for acrylic bonding. The one-component silicone rubber is composed of alpha, omega-dihydroxy polydimethylsiloxane base materials, calcium carbonate, gas phase silica, a cross-linking agent, a coupling agent and a catalyst. In addition, the invention also discloses a method for preparing the one-component silicone rubber for acrylic bonding. Organic silica gel products with good adhesiveness for acrylic materials with low surface energy are obtained by means of formula design and synthetic compound use of the coupling agent, and weather resistance and environmental aging resistance are excellent, so that more extensive application advantages are brought to the acrylic materials.

Owner:GUANGZHOU HUINA NEW MATERIAL TECH

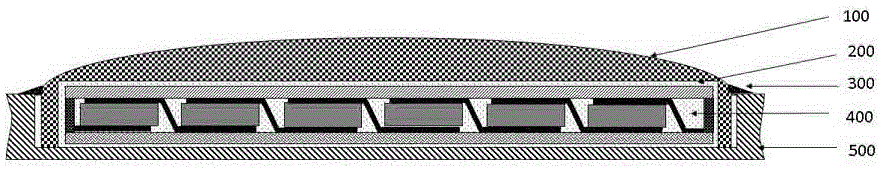

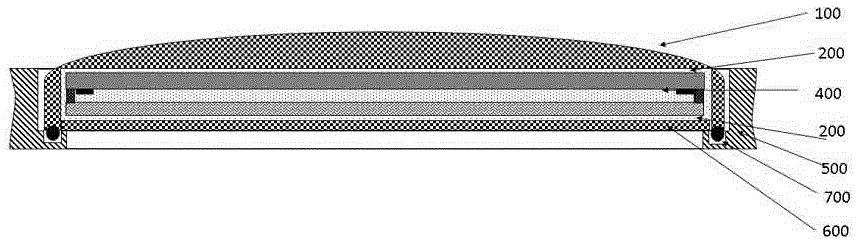

Polycarbonate packaged solar car roof or skylight and manufacturing method thereof

ActiveCN105128943AGuaranteed aestheticsVisible light transmittance is equivalent toSuperstructure subunitsPhotovoltaic energy generationSolar cellSilica gel

The invention discloses a polycarbonate packaged solar car roof or skylight and a manufacturing method thereof. The polycarbonate packaged solar car roof comprises a polycarbonate shell and a car roof body provided with a mounting groove, wherein the outer side surface of the polycarbonate shell is a curved surface, an arrangement cavity having a plane therein is formed in the inner side of the polycarbonate shell, solar cell modules are arranged in the arrangement cavity and are bonded with the plane of the arrangement cavity through light-transmitting organic silica gel, the polycarbonate shell where the solar cell modules are arranged is arranged in the mounting groove formed in the car roof, and a sealing strip is arranged between the open portion of the top of the mounting groove and the polycarbonate shell. After the structure is adopted, the problem that rigid photovoltaic modules cannot be applied to the curved surface is solved, and an attractive car body is kept. Various light-weight solar cell packaging structures can be adopted. The capacity of resisting to environmental aging and mechanical abrasion of the solar car roof can be greatly improved, and the service life of the solar car roof or skylight is ensured.

Owner:NINGBO SANDI SOLARTECH CO LTD

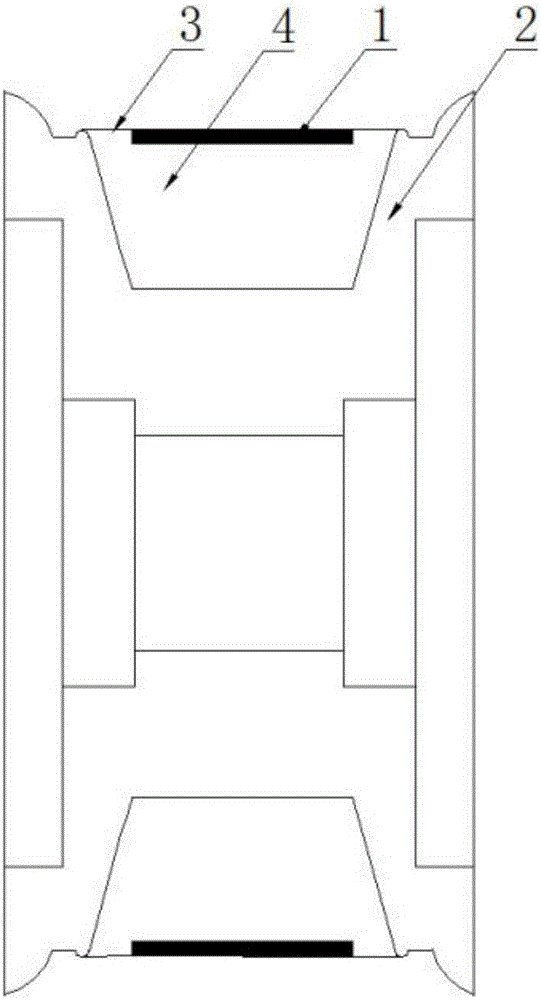

Environmental aging simulation test method for sizing material

ActiveCN105784582AGood correlationSimple methodWeather/light/corrosion resistanceEvery Two WeeksEngineering

The invention relates to an environmental aging simulation test method for a sizing material. The method comprises the following steps: 1) vulcanizing and cutting the sizing material; 2) adhering the cut sizing piece to a central part of a rim groove; 3) installing a tire matched with the size of a rim to obtain a tire, rim and sizing piece assembly; 4) filling compressed air into the tire, keeping stand for more than 24 hours at an ambient temperature if no air leaks, and replacing the compressed air in the tire with a nitrox mixture; 5) putting the tire, rim and sizing piece assembly into an aging oven, aging for 8 weeks at a temperature of 65 DEG C, and re-filling the nitrox mixture once every two weeks; 6) then removing the tire, and taking down the sizing piece from the rim and then carrying out a related physical property test. The method has the beneficial effects that the environmental aging test of the sizing material can be directly carried out, the correlation is good, the method is simple, and the application range is wide.

Owner:SHANDONG LINGLONG TIRE

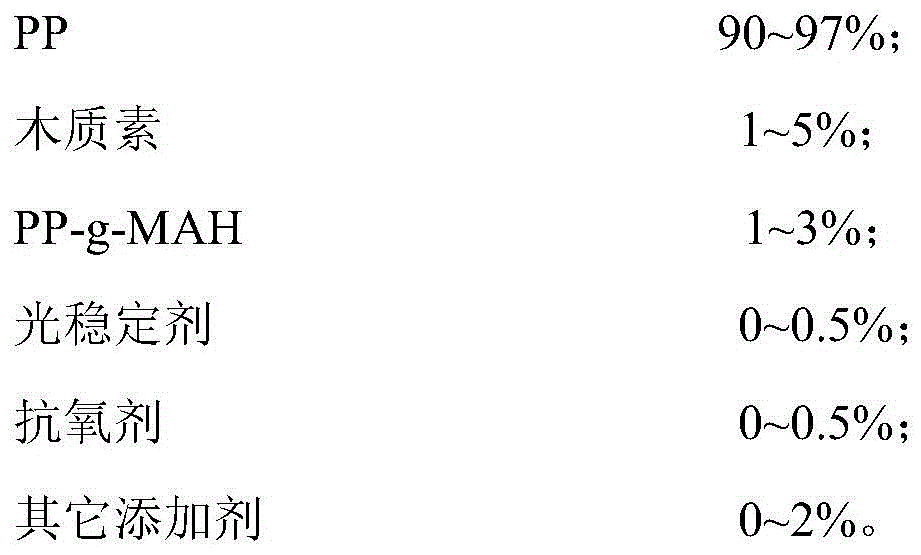

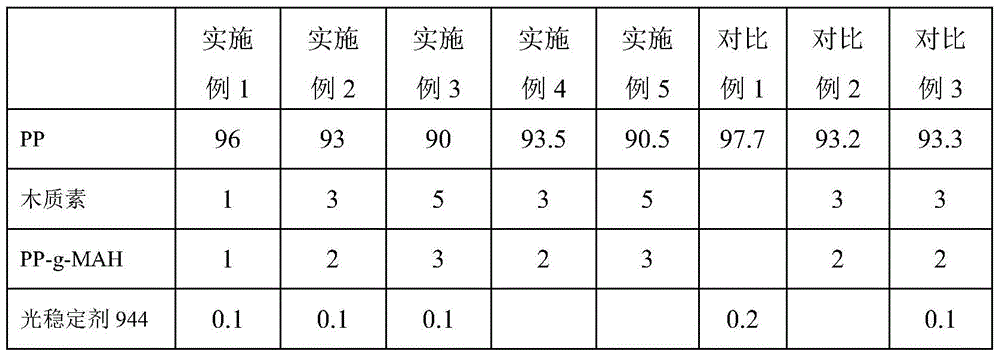

Novel environmental-aging-resistant PP material and preparation method thereof

The invention discloses a novel environmental-aging-resistant PP material and a preparation method thereof. The novel environmental-aging-resistant PP material comprises the following raw materials by the weight percentage: 90-97% of PP, 1-5% of xylogen, 1-3% of PP-g-MAH, 0-0.5% of a light stabilizer, 0-0.5% of an antioxidant, and 0-2% of other additives. The novel environmental-aging-resistant PP material has the advantages: 1, the xylogen can be used for partially or completely replacing traditional additives, and can effectively solves PP surface blooming and emission problems; and 2, the prepared PP material is simple in production process, low in cost and easy to industrialize.

Owner:SHANGHAI PRET COMPOSITES

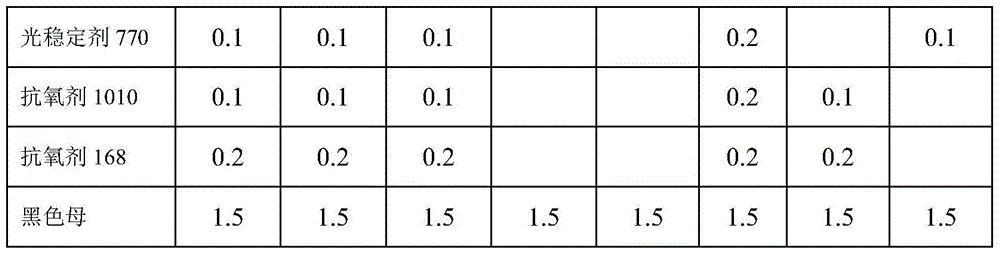

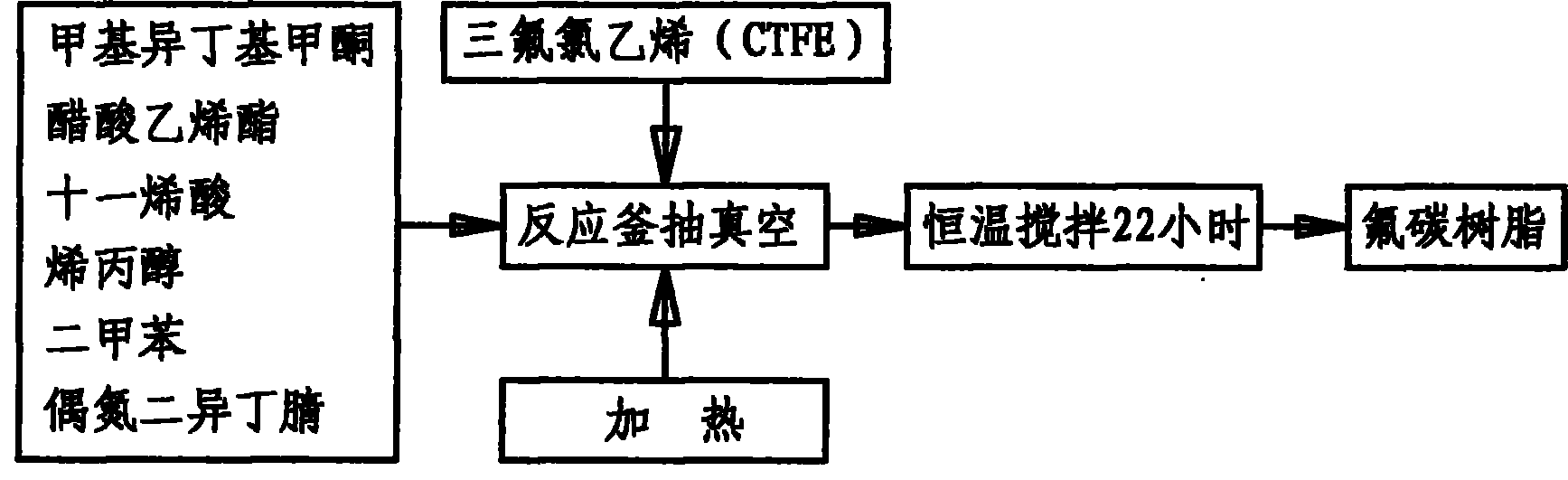

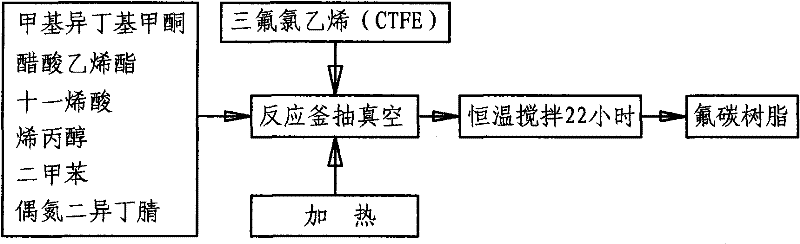

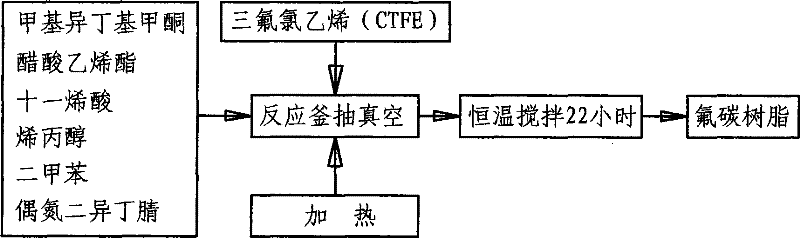

Solvent-based fluorocarbon resin

The invention provides a solvent-based fluorocarbon resin, belonging to the synthesis process of the fluorocarbon resin. The fluorocarbon resin comprises the following components by mass percent: 38.56% of a chlorotrifluoroethylene monomer, 10.44% of methyl isobutyl ketone, 24.38% of dimethylbenzene, 0.832% of azodiisobutyronitrile, 1.024% of undecylenic acid, 2.894% of allyl alcohol and 21.87% of vinyl acetate, wherein, CTFE is the abbreviation for the chlorotrifluoroethylene monomer, and MIBK is the abbreviation for methyl isobutyl ketone. The synthesis process comprises the following steps: preparing, adding raw materials to a polymerization kettle, vacuumizing the polymerization kettle, adding the trifluorochloroethylene chlorotrifluoroethylene monomer raw material to the polymerization kettle, stirring and heating, and finally discharging the fluorocarbon resin. The fluorocarbon resin has durability, weatherability and chemical resistance, and shows special surface properties such as remarkable non-stick property, low surface tension, low friction property, water repellency, oil repellency and the like; and various coatings prepared by the fluorocarbon resin have outstanding high adhesive force and outstanding environmental aging resistance.

Owner:徐州中研科技工业有限公司

Special polyvinyl alcohol butyral resin for 3D printing and preparation method thereof

InactiveCN108440690AImprove flow processabilityEasy to processAdditive manufacturing apparatusPolymer scienceSolvent

The invention belongs to the technical field of 3D printing, and relates to special polyvinyl alcohol butyral resin for 3D printing. The viscosity of the resin in an ethanol solution at a concentration of 10 percent is 40 to 250 Pa.s; the residual butyraldehyde content is less than or equal to 10 ppm, and the residual diethylhexenal content is less than or equal to 1,000 ppm. The invention furtherprovides a preparation method of the polyvinyl alcohol butyral resin. The preparation method comprises the following steps: dissolving polyvinyl alcohol which has a polymerization degree of 300 to 1,000 and an alcoholysis degree of 90 to 99 percent and is used as a raw material, and generating condensation reaction with aldehyde under the catalysis of acid, thereby obtaining polyvinyl alcohol butyral resin powder through neutralization reaction, washing and drying. When the special polyvinyl alcohol butyral resin for 3D printing provided by the invention is applied, no auxiliary resin is required to be added, and no solvent or plasticizer is needed; in a process of producing a 3D printing wire and a 3D printing process, no exhaust gas and odor are generated; and in addition, the product is relatively high in mechanical property and environmental aging resistance.

Owner:ZHEJIANG DECENT PLASTIC

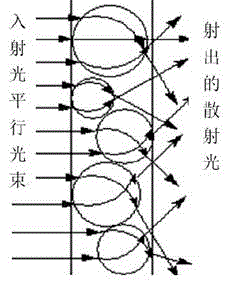

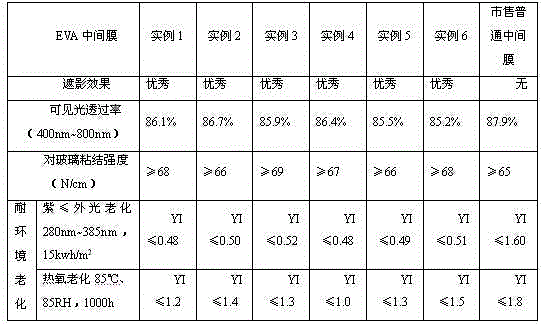

Laminated glass intermediate film with shielding capacity and high transparency as well as preparation method thereof

InactiveCN104098828AAchieve light transmissionAchieve the optical effect of shadingPolymer scienceCross linker

Owner:NANJING KIN YONG FA PLASTIC MFG

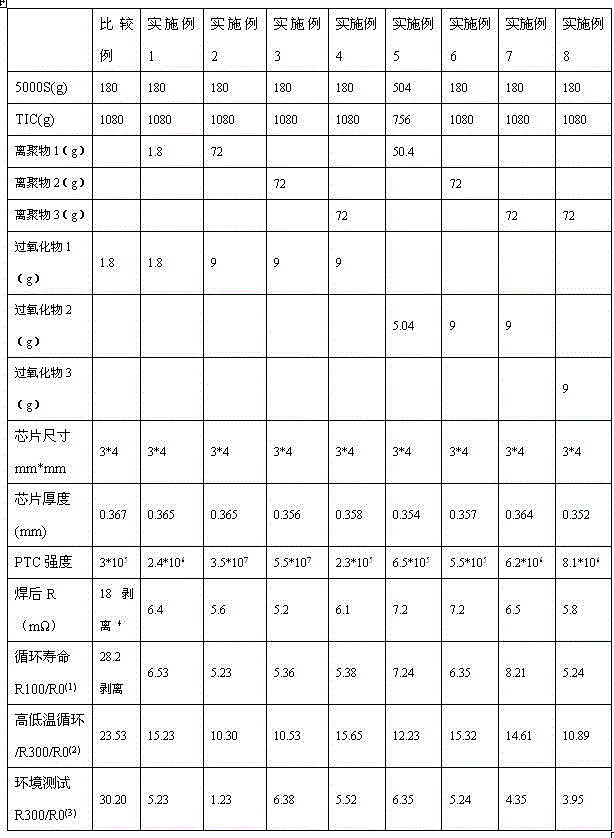

Conductive composite with positive temperature coefficient (PTC), preparation method and application thereof

InactiveCN102942731ALower resistanceImprove impact performanceCurrent responsive resistorsPositive temperature coefficient thermistorsPolymer scienceCross linker

The invention provides a conductive composite with a PTC. The composite comprises a polymer, a conductive filler, an ionomer and a peroxide crosslinking agent. The ionomer and the peroxide are added into the composite, therefore the resistance of a chip can be reduced obviously, good heat shock resistance and environmental aging test performances are provided for a core material, simultaneously, not only the adhesiveness between the polymer and the conductive filler can be improved, but also the resistance can be reduced effectively.

Owner:上海神沃电子有限公司

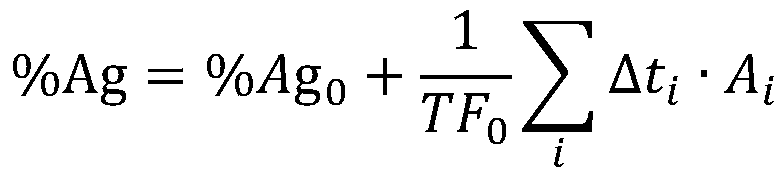

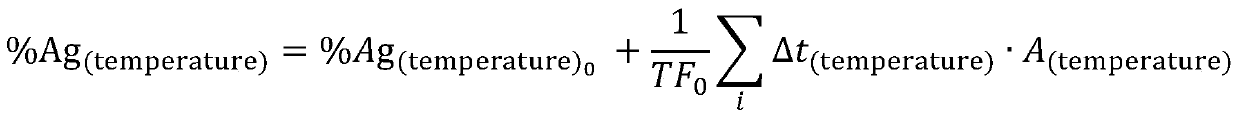

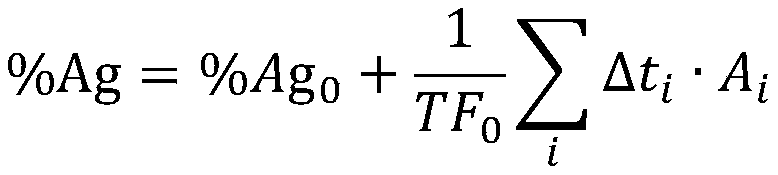

Method for analyzing service life aging of circuit breaker

InactiveCN111458632AEasy to replaceLow failure rateMachine part testingEnvironmental/reliability testsFailure rateProcess engineering

The invention provides a method for analyzing the service life aging of a circuit breaker, and relates to the field of electrical element operation performance. The method comprises the following steps: judging the operation aging of the circuit breaker; calculating the environmental aging of the circuit breaker; calculating thermal aging of a control unit of the circuit breaker; calculating corrosion aging of the control unit of the circuit breaker; calculating the environmental aging of the control unit of the circuit breaker. According to the method for calculating the aging value of a circuit breaker, the aging value of the circuit breaker is calculated by comprehensively considering the operation state of the corresponding circuit breaker according to the temperature, humidity, salt mist environment and / or corrosive gas of the environment, subsequent replacement of an aged circuit device is facilitated, the failure rate of equipment is reduced, and the reliability is improved.

Owner:SICHUAN HABOAT ELECTRIC CO LTD

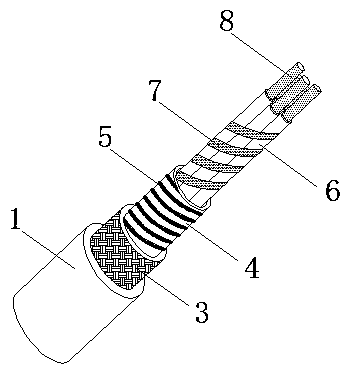

Environmental-aging-resistant polyolefin photovoltaic cable

InactiveCN108899121AImprove structural strengthSimple structureClimate change adaptationInsulated cablesPolyolefinAging resistance

The invention discloses an environmental-aging-resistant polyolefin photovoltaic cable, comprising a polyolefin jacket; a polytetrafluoroethylene layer is fixedly installed on the outer surface of thepolyolefin jacket; a high-temperature-resistant braided cover is fixedly installed on the inner surface of the polyolefin jacket; an insulating protective cover is fixedly installed on the inner surface of the high-temperature-resistant braided cover; a support shaping steel wire is installed on the outer surface of the insulating protective cover in a winding way; five groups of copper core insulating sleeves are fixedly installed on the inner surface of the insulating protective cover. The environmental-aging-resistant polyolefin photovoltaic cable provided by the invention is provided withthe polytetrafluoroethylene layer, the high-temperature-resistant braided cover and the support shaping steel wire, thus being better in environmental aging resistance, and prolonging the service life; high-temperature-resistant protection can be realized, aging caused by the overhigh temperature of the internal insulating protective cover is prevented, and the cable can be protected by supporting and shaping, so that the structural strength of the whole cable is improved; therefore, the environmental-aging-resistant polyolefin photovoltaic cable has certain practicability and brings a betteruse prospect.

Owner:ANHUI DUJIANG CABLE GROUP

High anti-environmental aging and high temperature resistant polyester resin matrix composite material

The invention discloses a high anti-environmental aging and high temperature resistant polyester resin matrix composite material. The composite material is prepared by mixing of the following raw materials by weight percentage: 30-80% of thermoplastic resin, 0.5-15% of modified attapulgite powder, 5-30% of titanium dioxide, 0.1-0.5% of an antioxidant, 0.2-0.5% of a mould release agent, 3-10% of glass fiber, and 5-20% of mineral powder. The composite material provided by the invention has the advantages of high temperature resistance, good aging resistance, high structural strength, high dimensional stability under long-term high temperature use condition, high anti-yellowing performance, and high flow performance under processing condition, and is suitable for application in thin walled parts.

Owner:山东道恩合复新材料有限公司

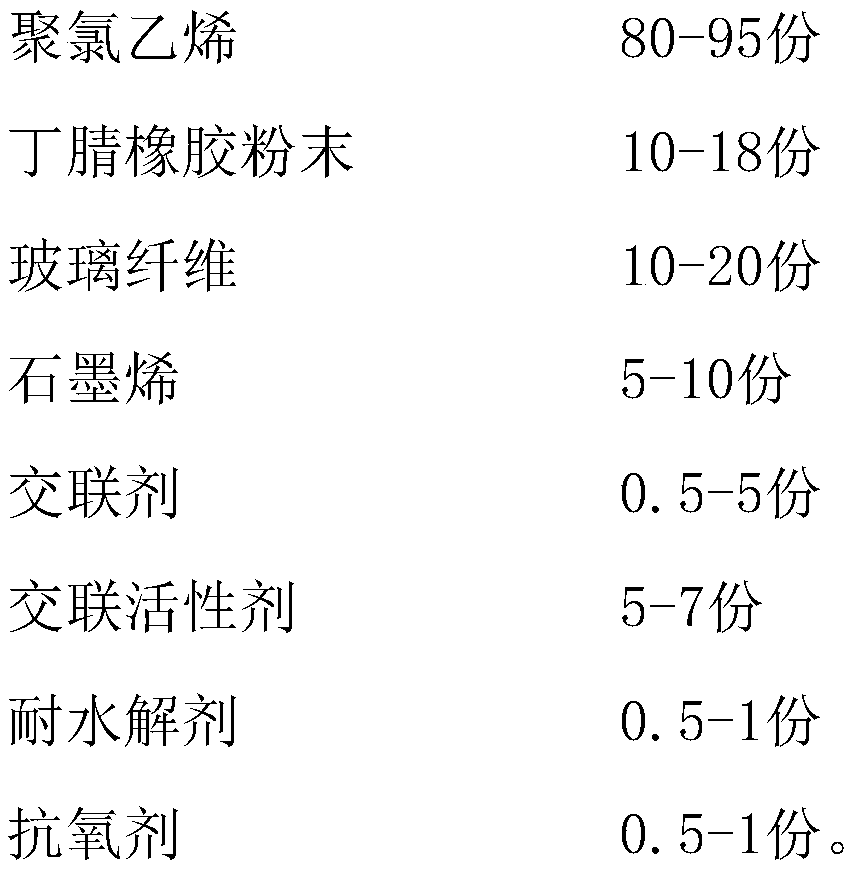

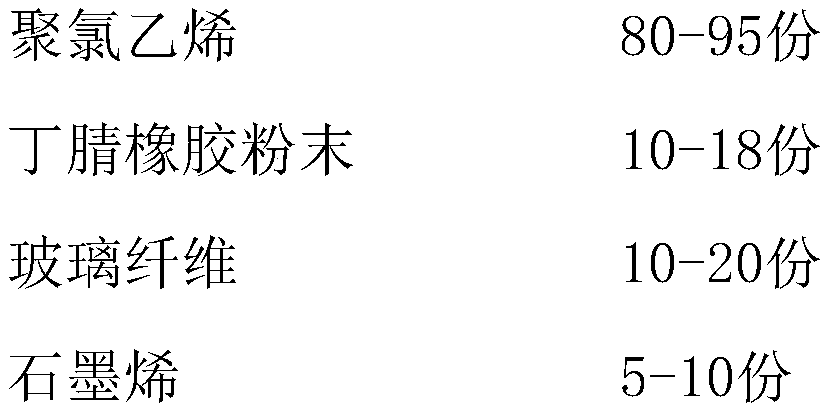

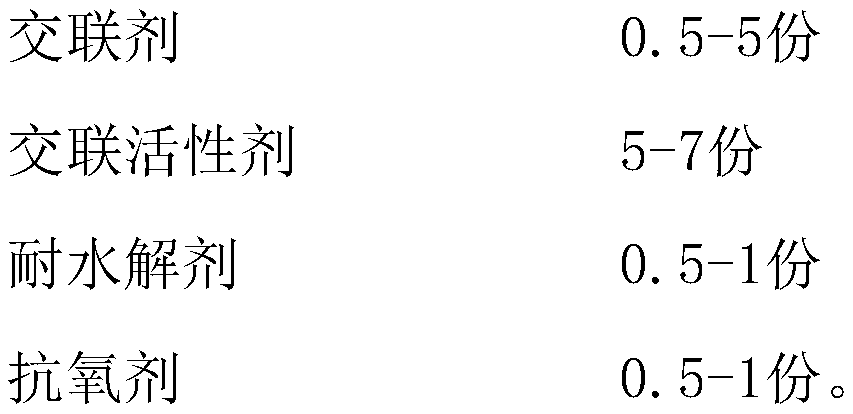

Bridge-cut-off aluminum profile and preparation method thereof

The invention relates to the technical field of bridge-cut-off aluminum profiles, in particular to a bridge-cut-off aluminum profile and a preparation method thereof. The bridge-cut-off aluminum profile comprises a first aluminum alloy component, a second aluminum alloy component and a heat insulation strip arranged between and connected with the first aluminum alloy component and the second aluminum alloy component, wherein hook-shaped embedded blocks extend from the two sides of the heat insulation strip, and the hook-shaped embedded blocks on the two sides of the heat insulation strip are fixedly connected with the first aluminum alloy component and the second aluminum alloy component correspondingly. The heat insulation strip comprises the following raw materials: polyvinyl chloride, nitrile rubber powder, glass fibers, graphene, a cross-linking agent, a cross-linking activating agent, a hydrolysis-resistant agent and an antioxidant. According to the bridge-cut-off aluminum profile, the stability of the bridge-cut-off aluminum profile is improved through the hook-shaped embedded blocks of the heat insulation strip; the heat insulation strip uses polyvinyl chloride as a main rawmaterial, so cost is lower than the cost of a PA66 raw material; and other raw materials are added to jointly improve the heat insulation property, toughness and environmental aging resistance of theheat insulation strip, so the service life and heat insulation effect of the bridge-cut-off aluminum profile are improved.

Owner:广东润盛科技材料有限公司

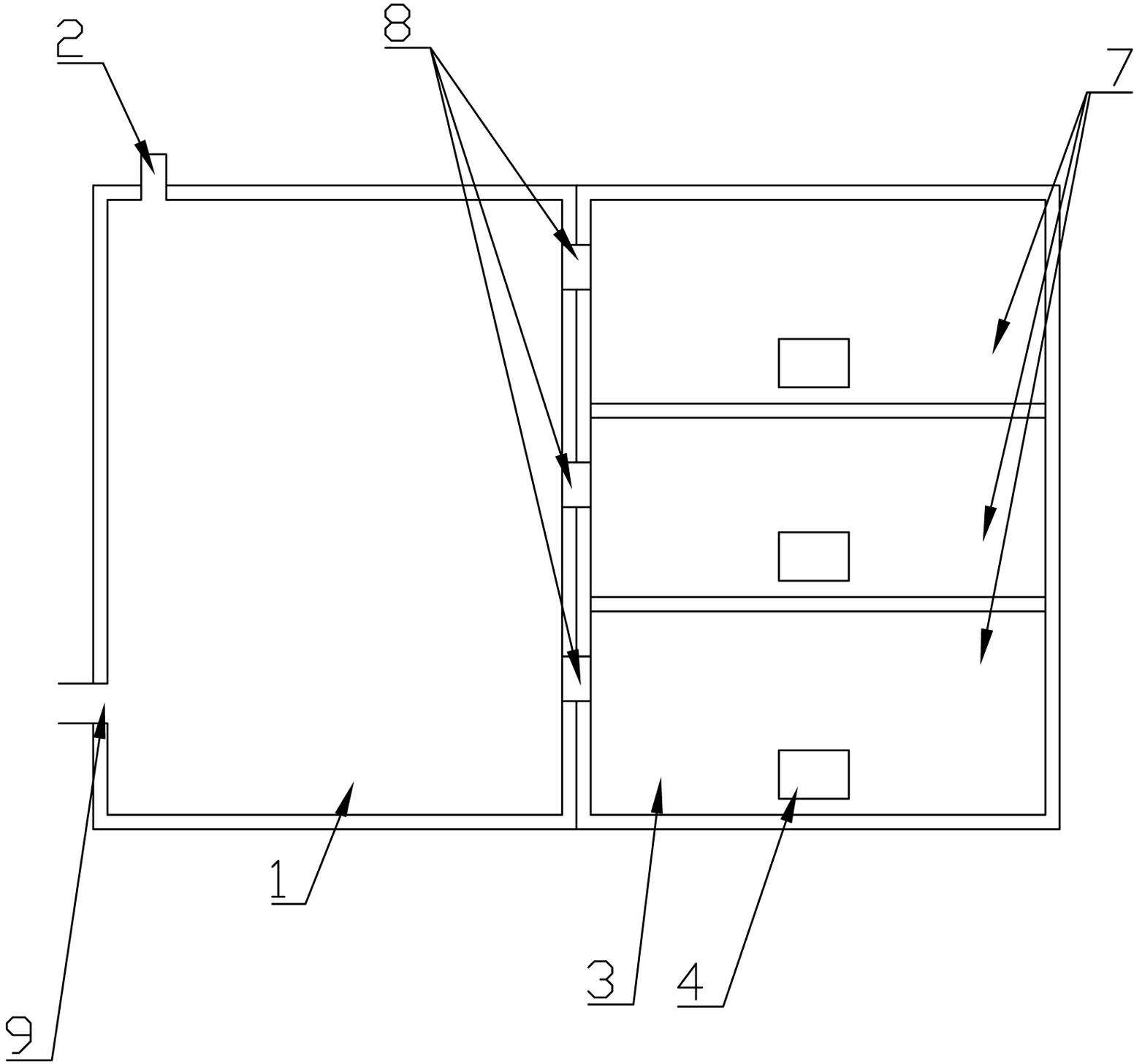

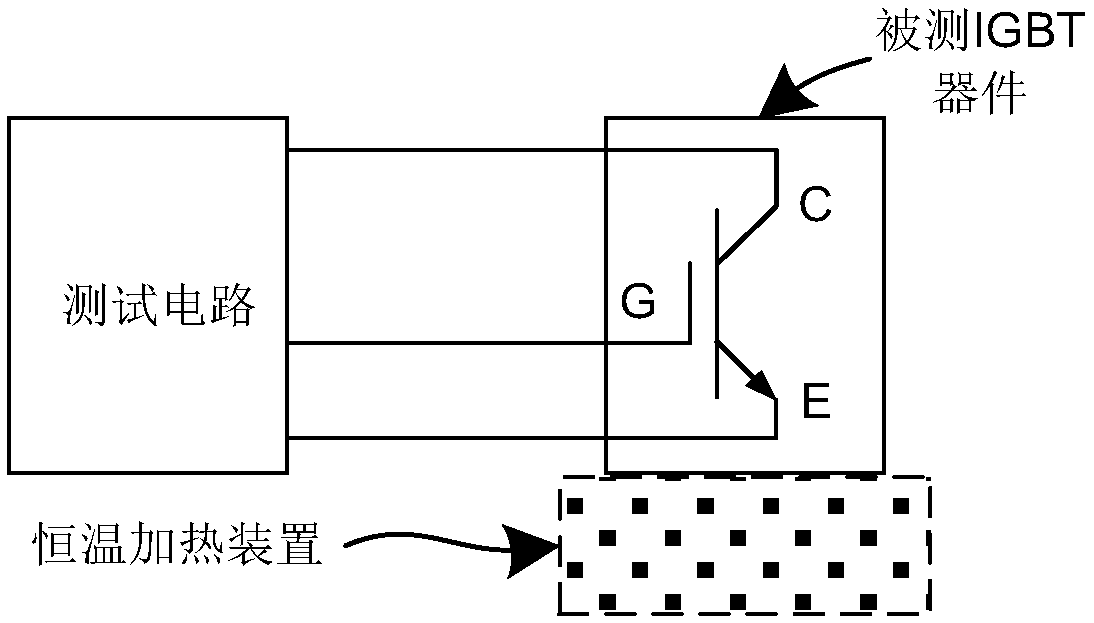

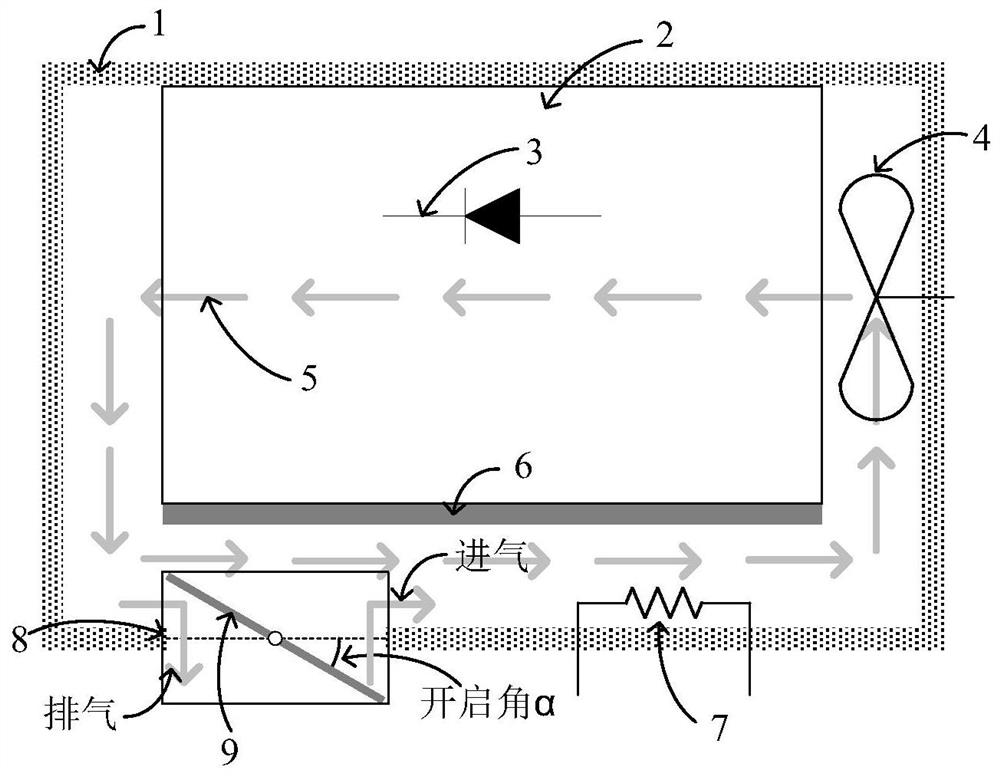

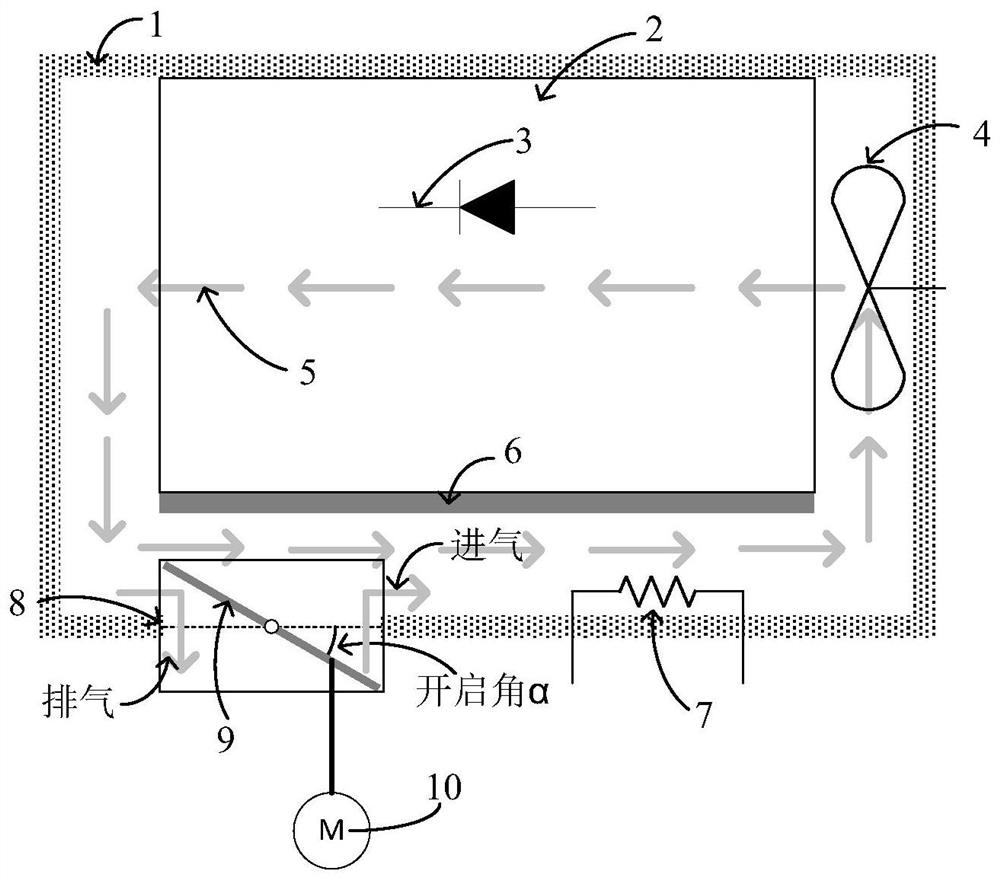

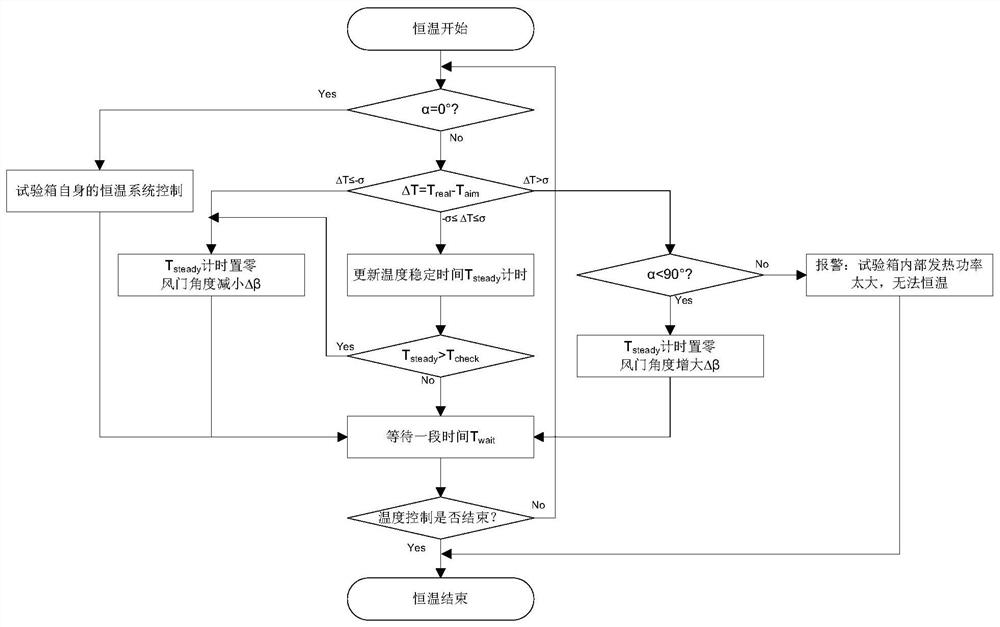

Method and system for increasing the number of test samples in high-temperature environment aging test

ActiveCN109613413BAchieve constant temperaturePrecise and quick adjustment of the opening degreeSemiconductor operation lifetime testingTest chamberDamper

The invention relates to a method and system for increasing the number of test samples in a high-temperature environmental aging test, which includes an environmental test chamber capable of providing the required environment for the environmental aging test of the device under test; State of the damper control mechanism. During the test, according to the current opening angle α of the damper baffle and the current temperature T in the environmental test chamber real , adjust the opening angle α of the air door baffle accurately and quickly through the air door baffle control mechanism, so as to change the maximum allowable heating power of the test system, so that the test system can accommodate more test samples on the one hand, and save electric energy to the greatest extent on the other hand , to ensure the smooth progress of the test.

Owner:PRIME REL ELECTRONIC TECH CO LTD

Solvent-based fluorocarbon resin

The invention provides a solvent-based fluorocarbon resin, belonging to the synthesis process of the fluorocarbon resin. The fluorocarbon resin comprises the following components by mass percent: 38.56% of a chlorotrifluoroethylene monomer, 10.44% of methyl isobutyl ketone, 24.38% of dimethylbenzene, 0.832% of azodiisobutyronitrile, 1.024% of undecylenic acid, 2.894% of allyl alcohol and 21.87% of vinyl acetate, wherein, CTFE is the abbreviation for the chlorotrifluoroethylene monomer, and MIBK is the abbreviation for methyl isobutyl ketone. The synthesis process comprises the following steps: preparing, adding raw materials to a polymerization kettle, vacuumizing the polymerization kettle, adding the trifluorochloroethylene chlorotrifluoroethylene monomer raw material to the polymerization kettle, stirring and heating, and finally discharging the fluorocarbon resin. The fluorocarbon resin has durability, weatherability and chemical resistance, and shows special surface properties such as remarkable non-stick property, low surface tension, low friction property, water repellency, oil repellency and the like; and various coatings prepared by the fluorocarbon resin have outstanding high adhesive force and outstanding environmental aging resistance.

Owner:徐州中研科技工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com