Polypropylene composition, polypropylene material, and applications of polypropylene composition and polypropylene material

A polypropylene composition and polypropylene technology, applied in the polymer field, can solve the problems of inability to use injection-molded thin-walled products, poor toughness, and low shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

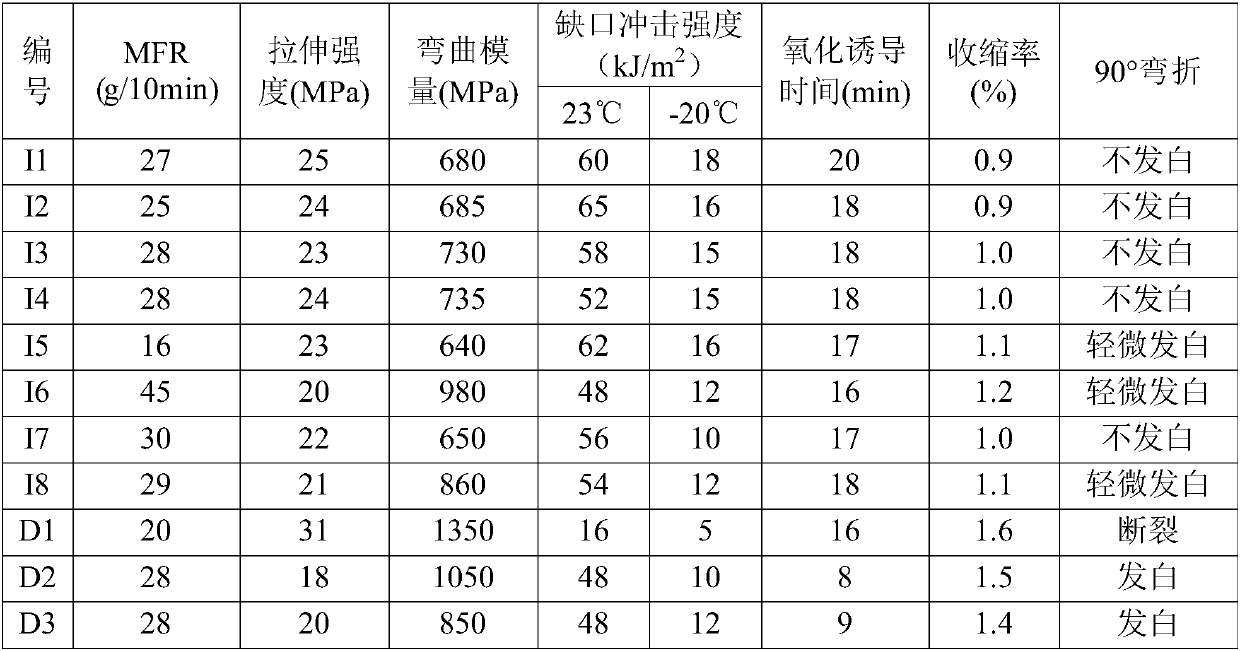

Examples

preparation example Construction

[0035] In the preparation process of the polypropylene material, in order to obtain a more uniform polypropylene material, a step of uniformly mixing the polypropylene composition is preferably included before the melt extrusion molding. The methods and conditions for uniformly mixing the polypropylene composition are well known to those skilled in the art. For example, the polypropylene composition can be added to various existing mixing equipment and stirred uniformly, wherein the mixing equipment Examples include mixers, kneaders, mills, internal mixers, and the like. The temperature and time of stirring and mixing are well known to those skilled in the art. For example, the temperature of stirring and mixing can be 25-65°C, the time of stirring and mixing can be 1-30 minutes, and the rotating speed of stirring and mixing can be 300-3000 rpm .

[0036] According to a specific manner of the present invention, the preparation method of the polypropylene material of the prese...

Embodiment 1

[0041] (1) Based on the total weight of the polypropylene composition, the components and their percentages are:

[0042] Impact copolymer polypropylene resin (at 230°C, the melt mass flow rate MFR under the load of 2.16kg is 30g / 10min, the content of ethylene structural unit is 7% by weight, and the content of rubber phase is 12% by weight), 78.95% by weight %;

[0043] Hydrogenated styrene-butadiene block copolymer (Shore hardness D is 45, the content of SEBS is 85% by weight, mineral oil oil extension is 10% by weight), 18% by weight;

[0044] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, 0.2% by weight;

[0045] Tris(2,4-di-tert-butylphenyl)phosphite, 0.15% by weight;

[0046] The polymer of succinic acid and 4-hydroxy-2,2,6,6-tetramethyl-1-piperidinol (light stabilizer 622, BASF, Germany, UV366), 0.2% by weight;

[0047] Hydrogenated palm oil glycerides, oleic acid glycerides and polyglycerides are compounded in a weight ratio of 1:1:1...

Embodiment 2

[0052] (1) Based on the total weight of the polypropylene composition, the components and their percentages are:

[0053] Impact copolymer polypropylene resin (the melt mass flow rate MFR under the action of 2.16kg load at 230°C is 28g / 10min, the content of ethylene structural unit is 9% by weight, and the content of rubber phase is 24% by weight), 76.7% by weight %;

[0054] Hydrogenated styrene-butadiene block copolymer (Shore hardness D is 40 degrees, the content of SEBS is 80% by weight, and mineral oil oil extension is 15% by weight), 20% by weight;

[0055] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, 0.2% by weight;

[0056] Tris(2,4-di-tert-butylphenyl)phosphite, 0.2% by weight;

[0057]Dilauryl thiodipropionate, 0.25 parts by weight;

[0058] Bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 0.25% by weight;

[0059] Oleamide, 0.4% by weight;

[0060] Masterbatch, 2% by weight.

[0061] (2) The preparation method of polypropylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com