Patents

Literature

40results about How to "Good rigidity balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-modulus and ultrahigh-impact polypropylene composite material and its preparation method

ActiveCN103923381AImprove low temperature toughnessImprove rigidityElastomerPolypropylene composites

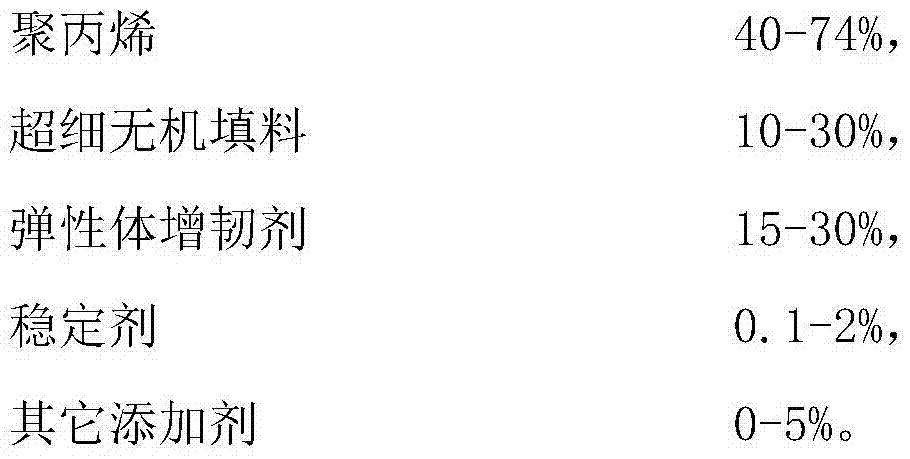

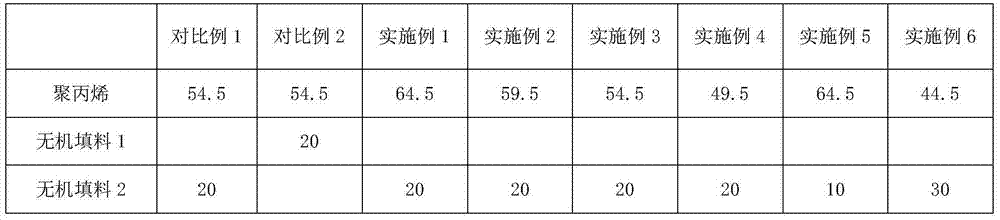

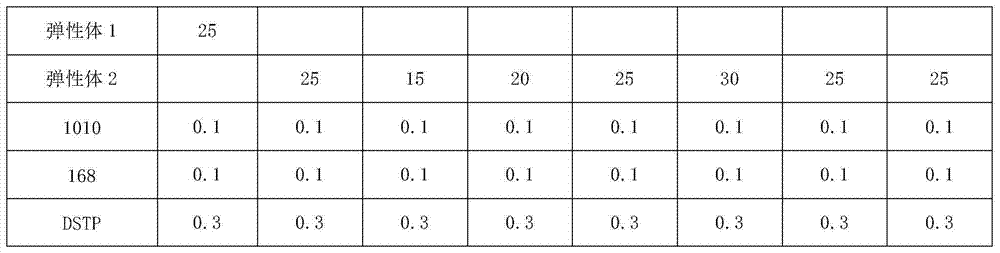

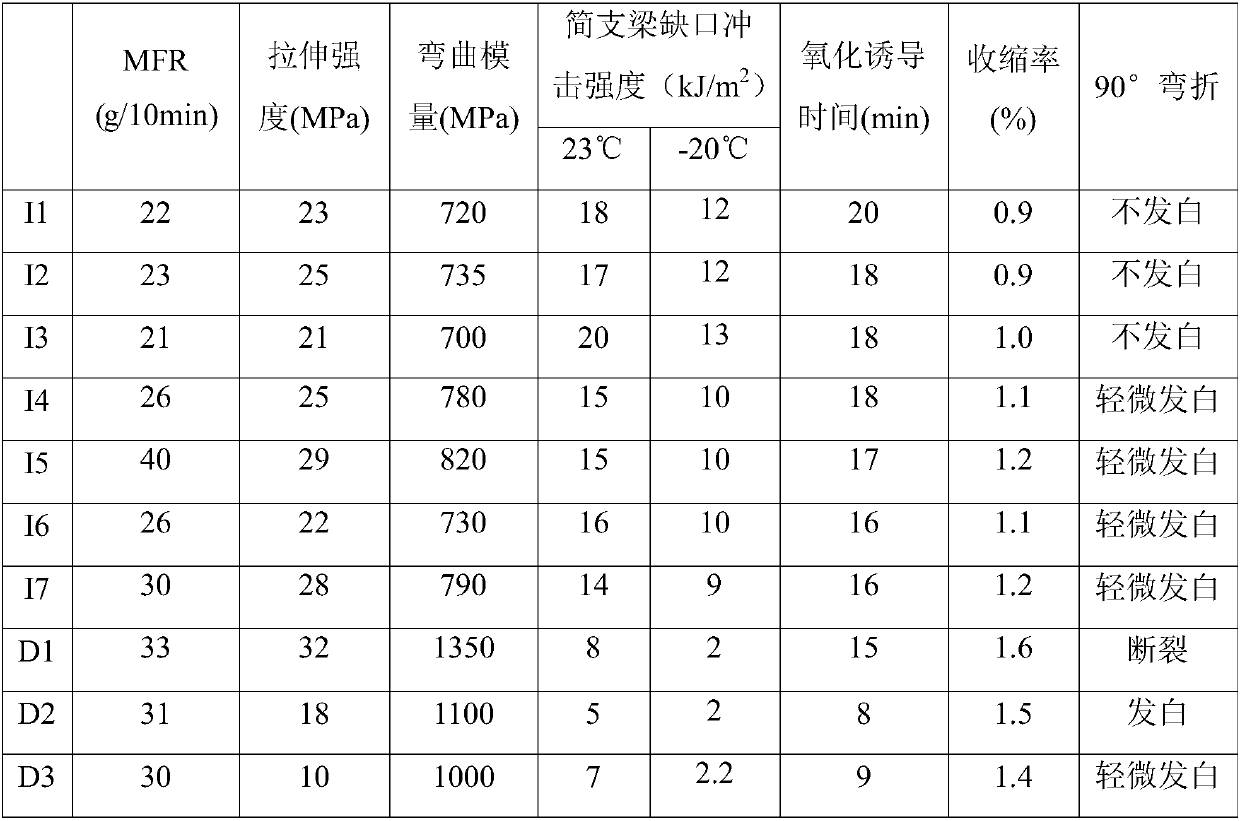

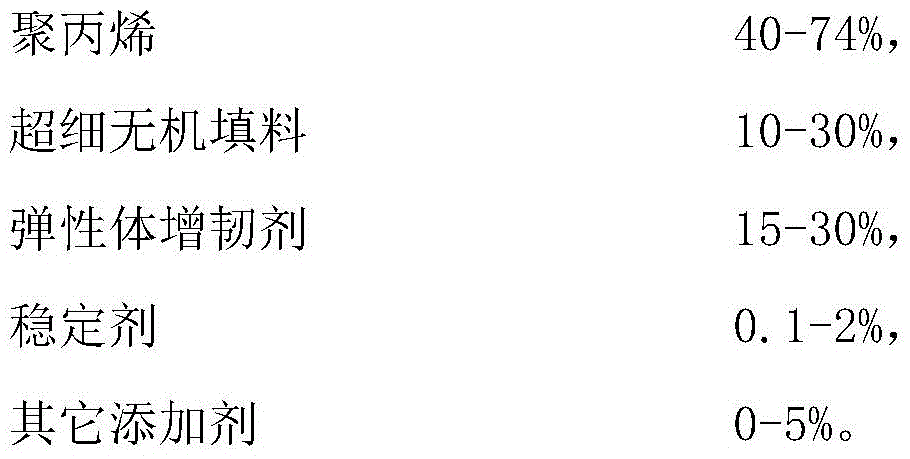

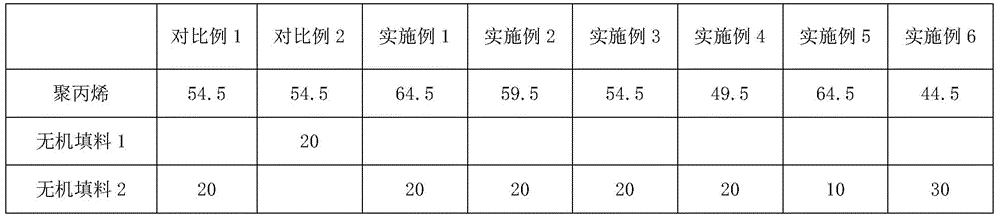

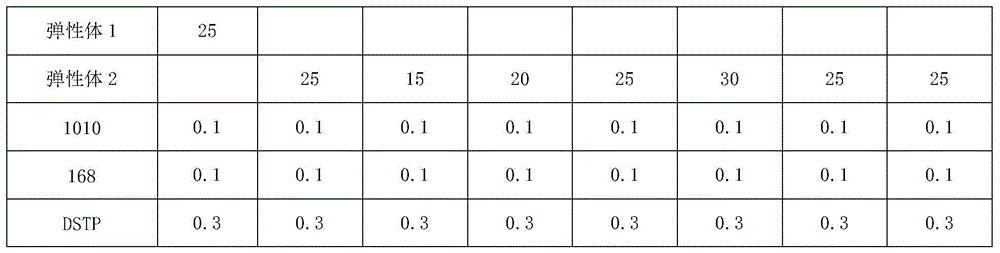

The invention discloses a high-modulus and ultrahigh-impact polypropylene composite material and its preparation method. The composite material comprises 40-74wt% of polypropylene, 10-30wt% of an ultrafine inorganic filler, 15-30wt% of an elastomer flexibilizer, 0.1-2wt% of a stabilizer, and 0-5wt% of other additives. The preparation method comprises the following steps: carrying out dry mixing on raw materials in a high speed mixer for 3-15min, adding the mixed raw materials into a double screw extruder, carrying out melt extrusion, and carrying out cooling granulation. The preparation method has the following advantages:1, a ethylene-butylene copolymer is used as the elastomer flexibilizer, so the polypropylene composite material has better low temperature toughness than traditional toughening modified polypropylene; 2, ultrafine talcum powder is used as the inorganic filler, so the toughness loss can be reduced as much as possible, and the rigidness of the material is greatly improved; and 3, the synergistic effect of the ultrafine talcum powder and the elastomer flexibilizer is utilized, so the polypropylene composite material has more ideal rigidness-toughness balance than the traditional toughening modified polypropylene.

Owner:SHANGHAI PRET COMPOSITES +2

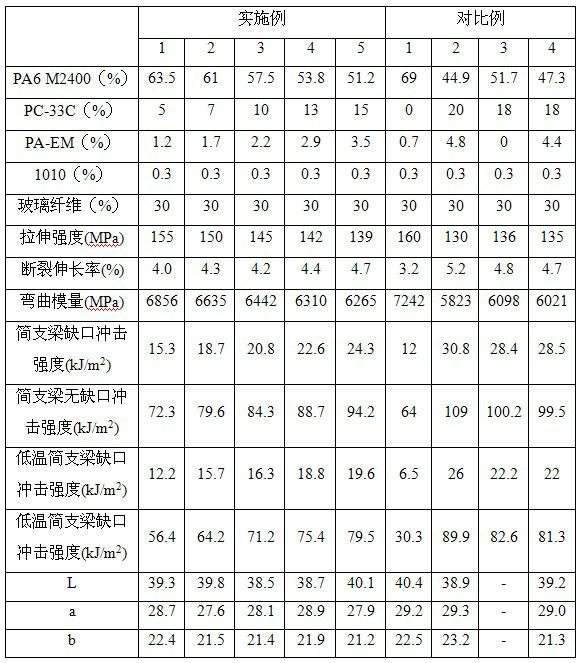

Low temperature resistance stained glass fiber reinforcement nylon 6 and preparation method thereof

ActiveCN102492293AImprove low temperature impact performanceImprove low temperature resistanceGlass fiberPolymer science

The invention discloses low temperature resistance stained glass fiber reinforcement nylon 6 and a preparation method thereof. The low temperature resistance stained glass fiber reinforcement nylon 6 is characterized by being composed of 40-75% of nylon 6, 15-35% of glass fibre, 5-20% of flexibilizer, 0.5-5% of composite dye and 0.1-0.5% antioxygen according to percentages by weight. The preparation method comprises enabling the nylon 6, the flexibilizer, the composite dye and the antioxygen to be evenly mixed and added in a twin-screw extruder, enabling the glass fibre to be added at the position of a dedicated glass fibre port, and cooling, dying and sized dicing after extrusion. The low temperature resistance stained glass fiber reinforcement nylon 6 has the advantages of being bright in color, even in distribution and good in property retention, has good color uniformity, has good toughening balance under normal temperature, and has excellent impact property under low temperature, and the combination property is close to natural color materials.

Owner:SHANGHAI KINGFA SCI & TECH +1

Toughening polyamide combination and prepn method

A toughened polyamide composition is prepared from polyamide and the rubber composition containing of powdered (not greater than 0.3 microns) rubber with cross-linking structure and at least one of unsulfurized rubber, thermoplastic elastomer and the thermoplastic elastomer grafted with polar monomer. Its advantages are controllable form and particle diameter, better toughness and machinability, and good strength and rigidity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified polypropylene material with low molding shrinkage and without buckling deformation and preparation method of modified polypropylene material

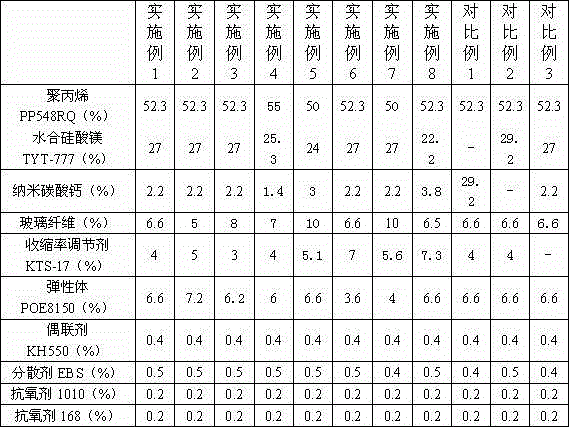

The invention discloses a modified polypropylene material and a preparation method thereof. The modified polypropylene material comprises the following ingredients by mass percentage: 50-55% of polypropylene, 25-30% of filler, 5-10% of glass fiber, 3-8% of shrinkage regulator, 3-8% of elastomer, 0.5-1% of coupling agent, 0.4-1% of dispersing agent, and 0.2-0.5% of antioxidant. The preparation method comprises the steps of mixing weighed PP (polypropylene) resin and the coupling agent in a high speed mixer, adding the other ingredients than the glass fiber for mixing for 5-10min, fusing, mixing, extruding, cooling, drying, pelleting and packaging the mixed material and the glass fiber, and obtaining the modified polypropylene material. According to the polypropylene material and the preparation method, horizontal and vertical flow shrinkages of polypropylene are reduced to below 0.8%, the difference between the shrinkages is very small (below 0.1%), the polypropylene material has excellent processability and rigidity and balanced toughness, a product made of modified polypropylene is free from warpage, no fiber exists on the surface of the product, and the application field of the polypropylene material is expanded greatly.

Owner:GUANGDONG TIANBAO NEW MATERIALS CO LTD

High-performance polypropylene composite material for vehicle seamless airbag instrument board, and preparation method thereof

InactiveCN108546385AImprove mechanical propertiesImprove low temperature toughnessInorganic fillerLow emission

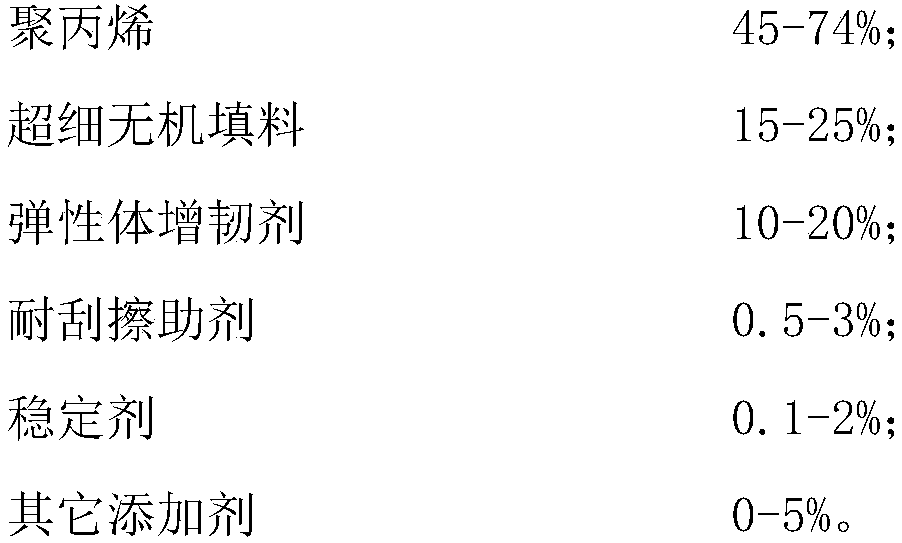

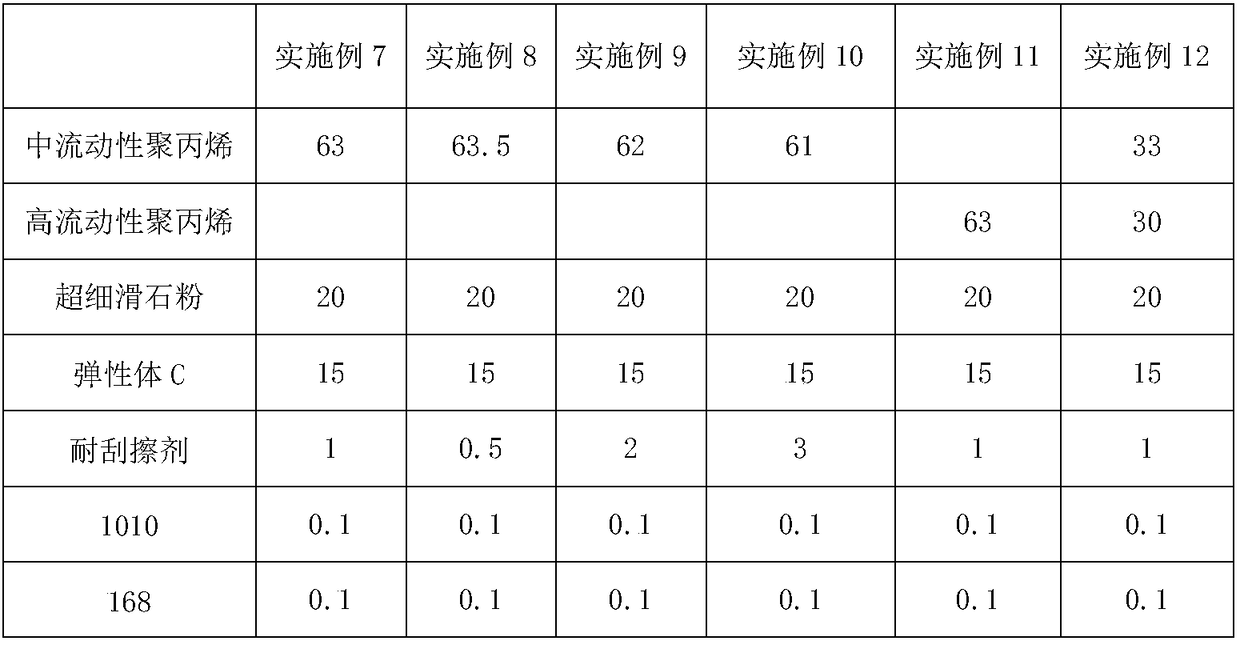

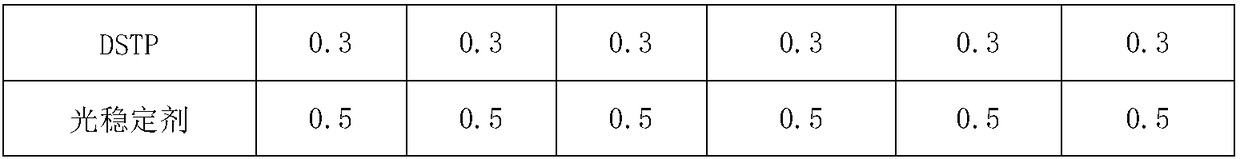

The invention discloses a high-performance polypropylene composite material for a vehicle seamless airbag instrument board, and a preparation method thereof, wherein the high-performance polypropylenecomposite material comprises the following raw materials by weight: 45-74%of polypropylene, 15-25% of an ultrafine inorganic filler, 10-20% of an elastomer toughening agent, 0.5-3% of a scratch-resistant aid, 0.1-2% of a stabilizer, and 0-5% of other additives. According to the present invention, through the synergistic action of the ultrafine inorganic filler and the special-structure elastomertoughening agent, the optimal balance between the rigidity and the ultrahigh toughness can be obtained, and the product integrates low-temperature impact resistance and heat deformation resistance, further has good scratch resistance, no sticking, low emission, continuous-illumination resistance, long-term heat resistance and the like, further has excellent processing property, and is suitable forvehicle hard plastic seamless airbag instrument boards and related components.

Owner:SHANGHAI PRET COMPOSITES +5

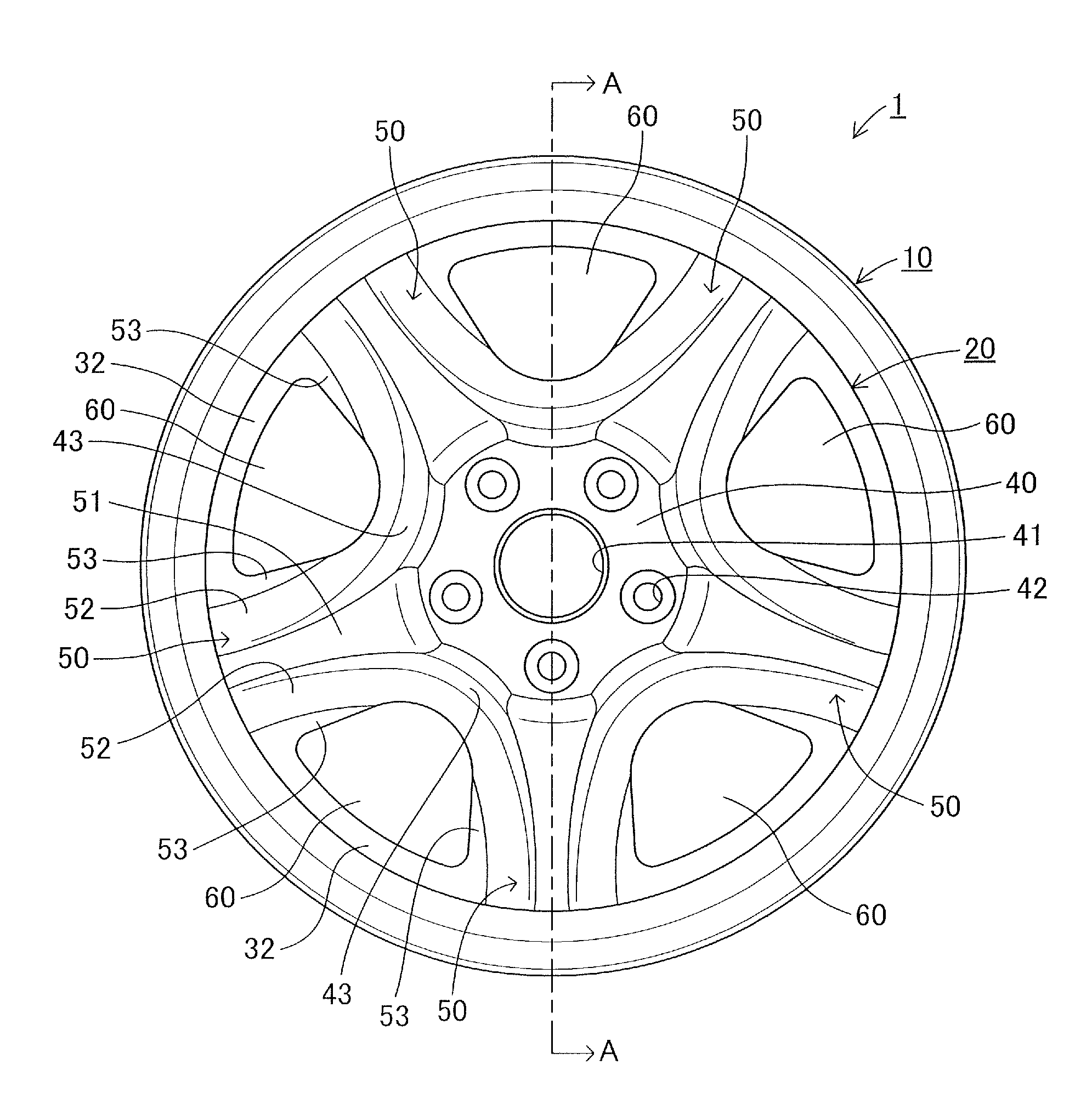

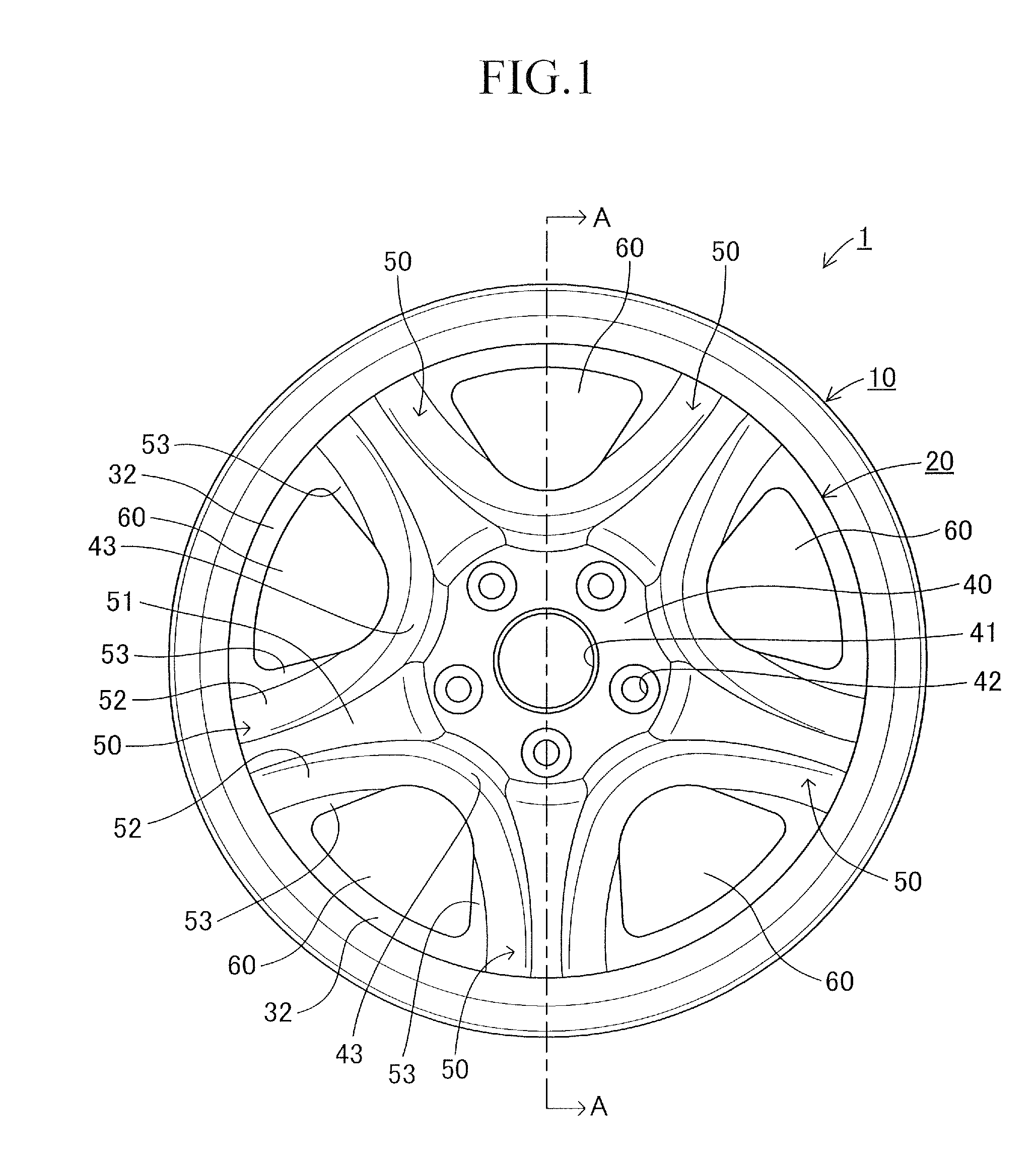

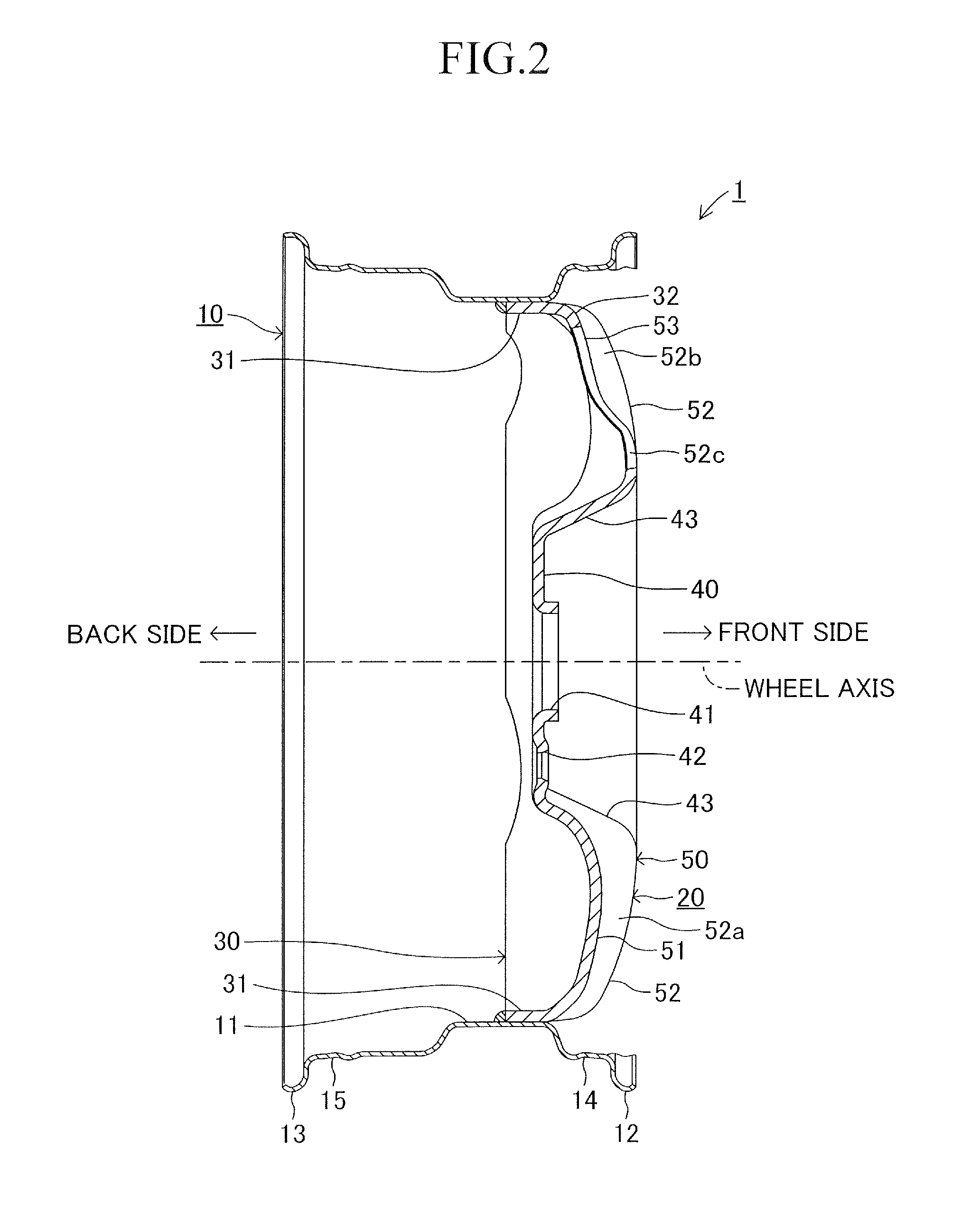

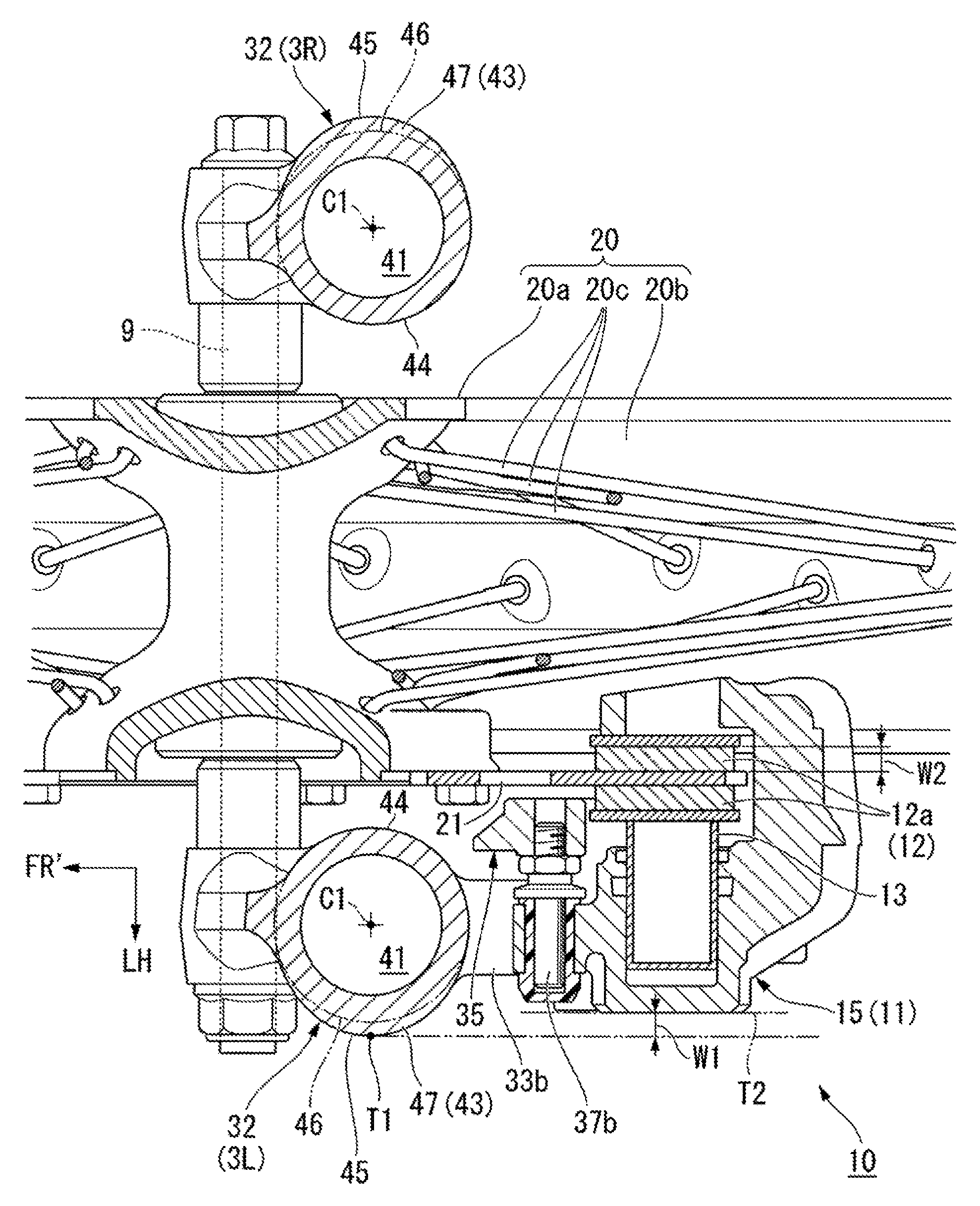

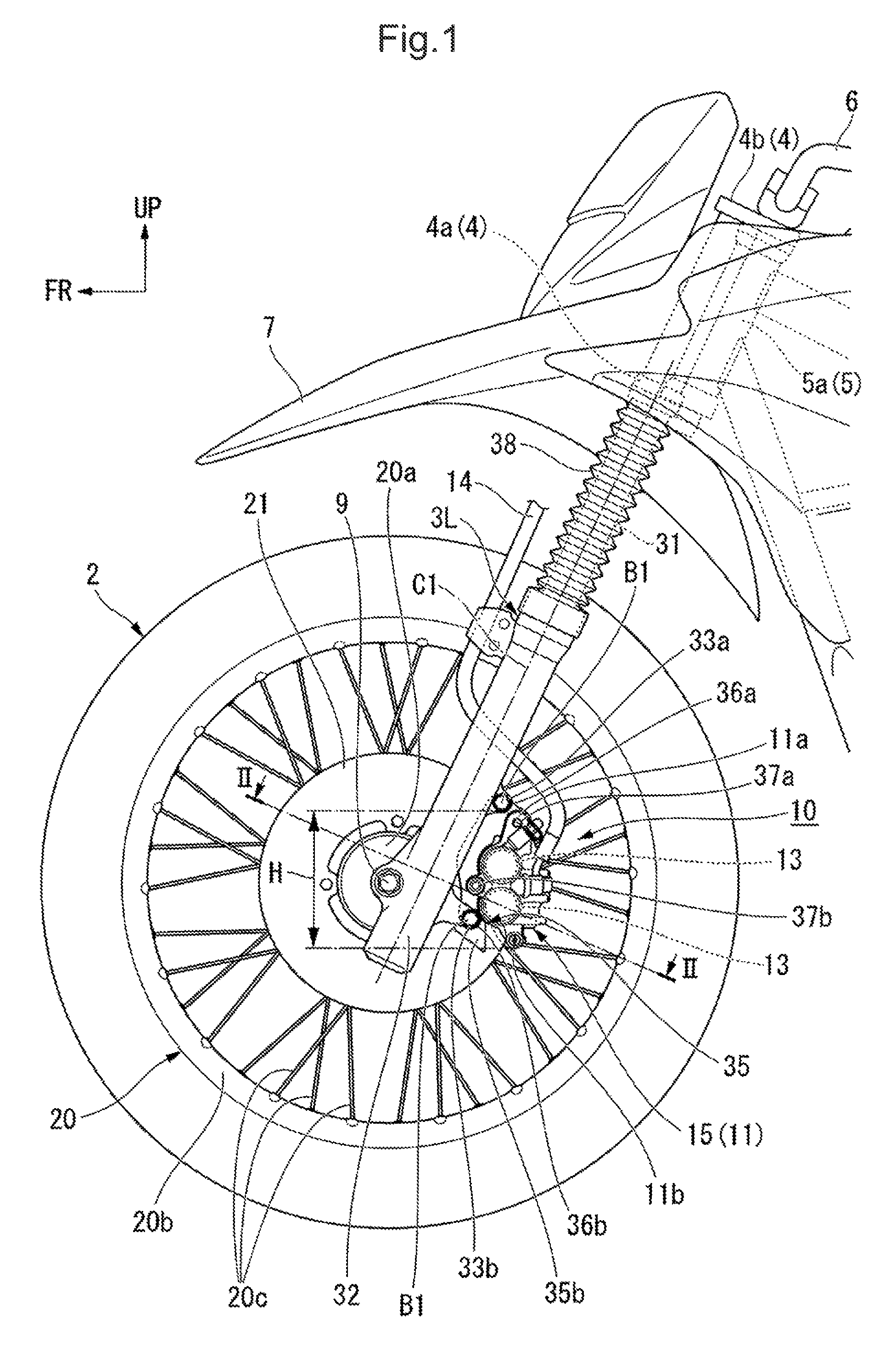

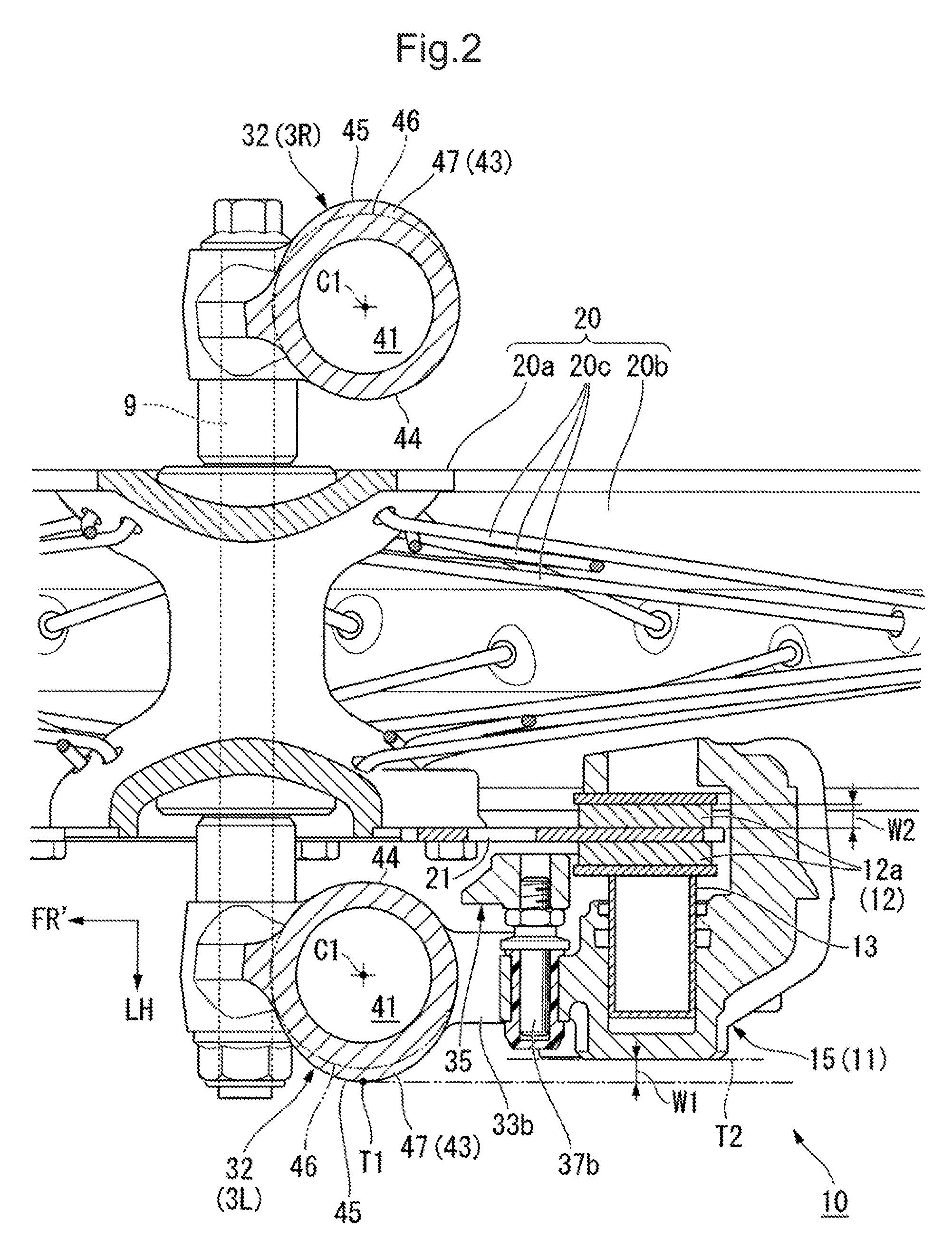

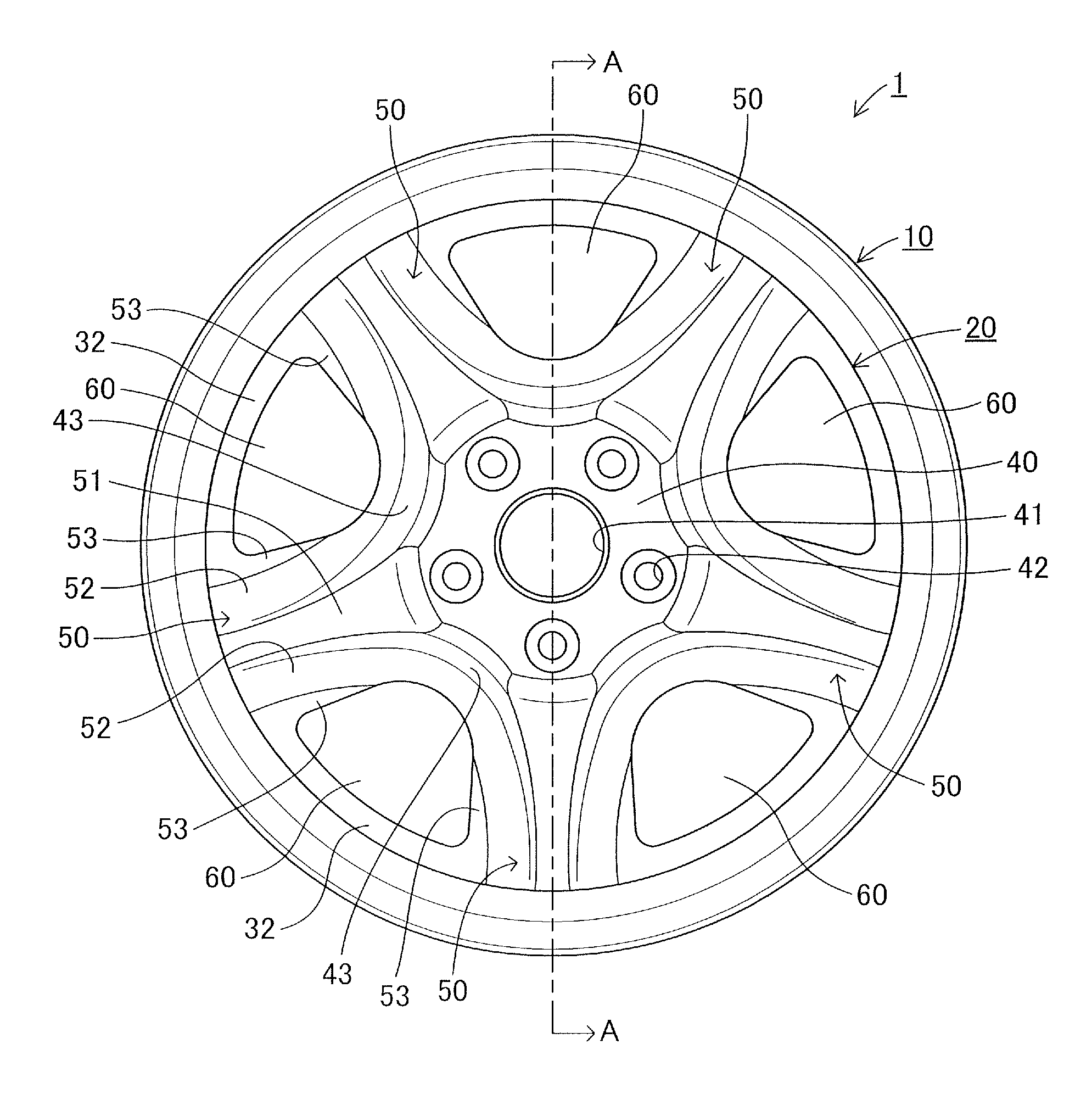

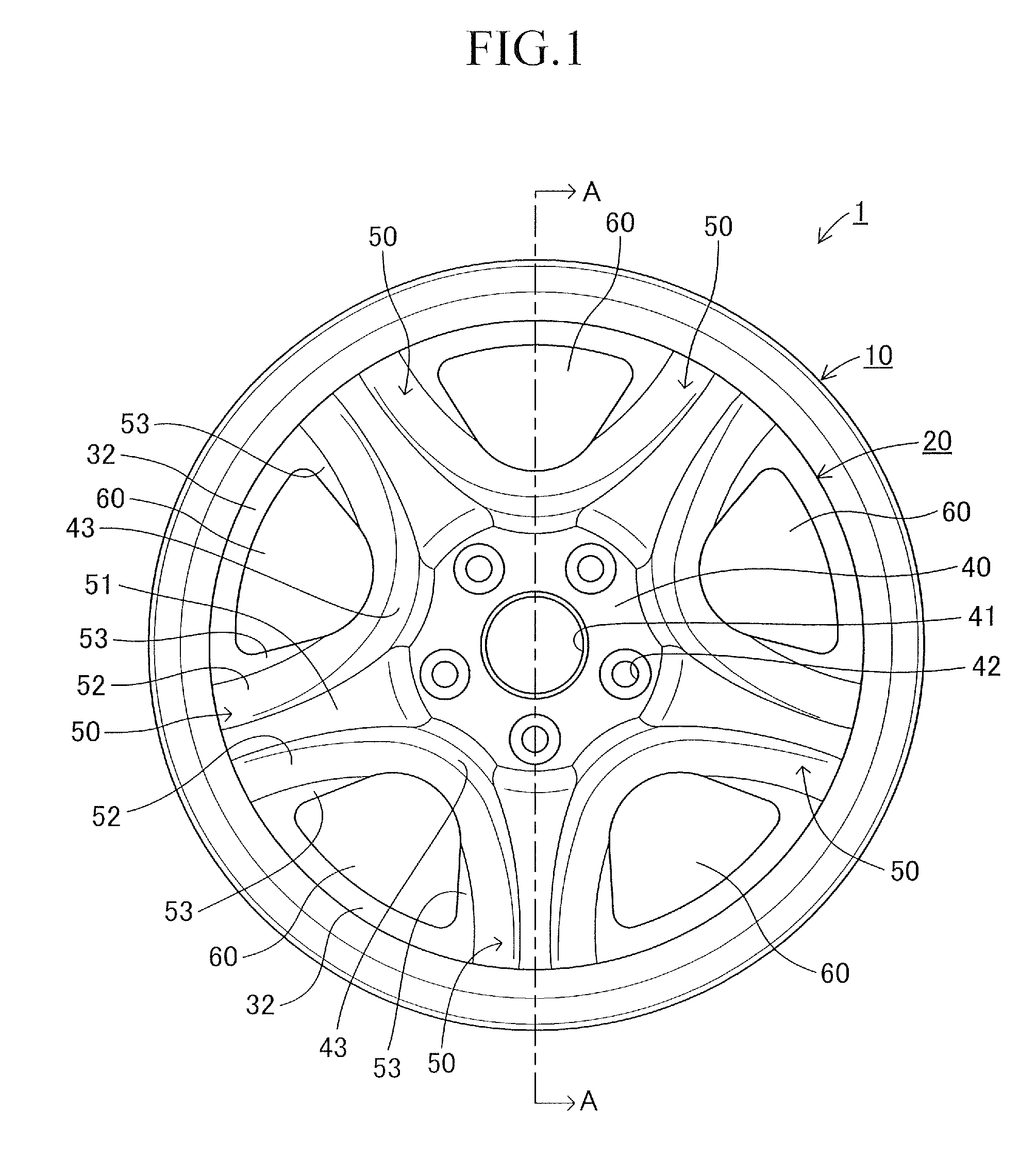

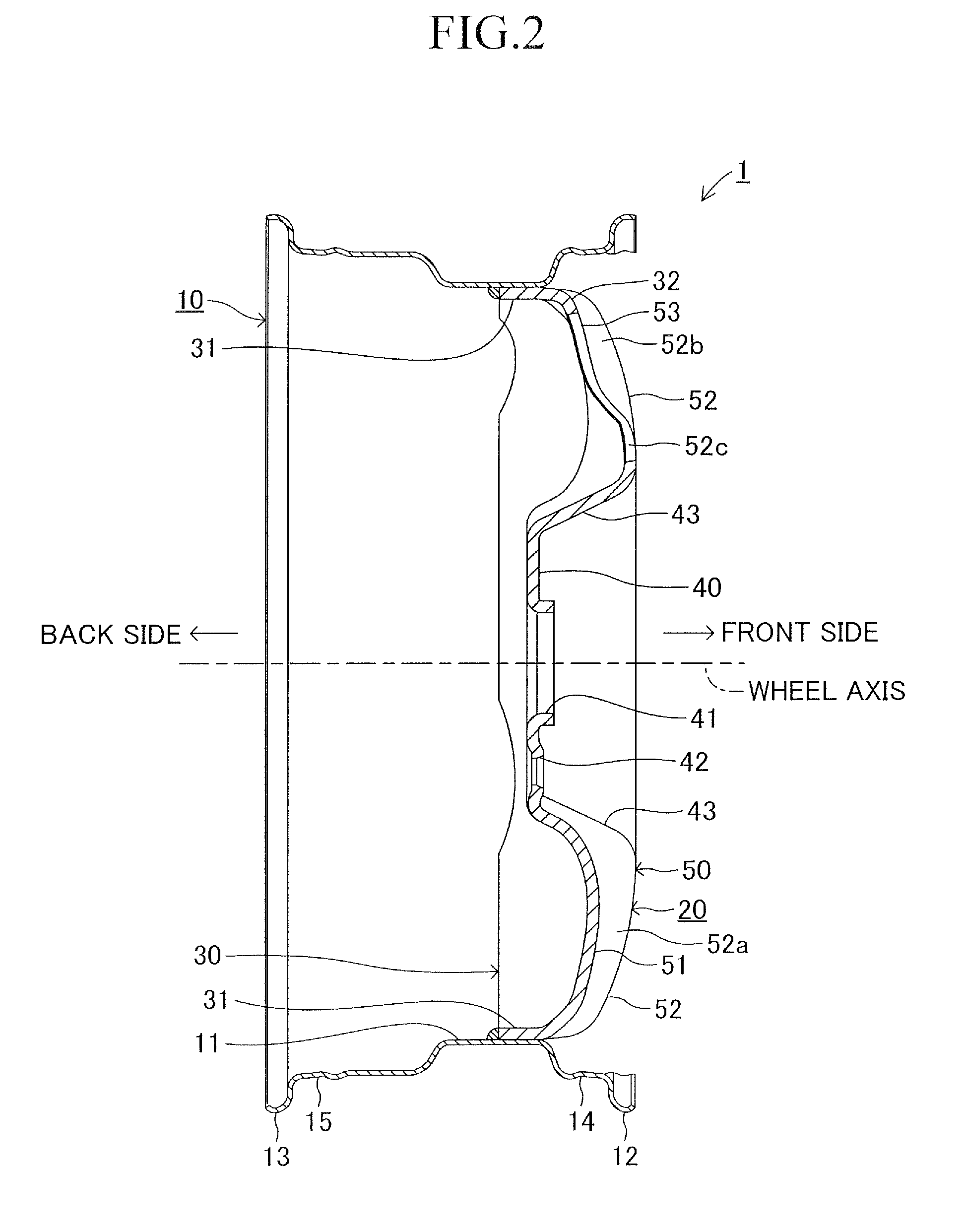

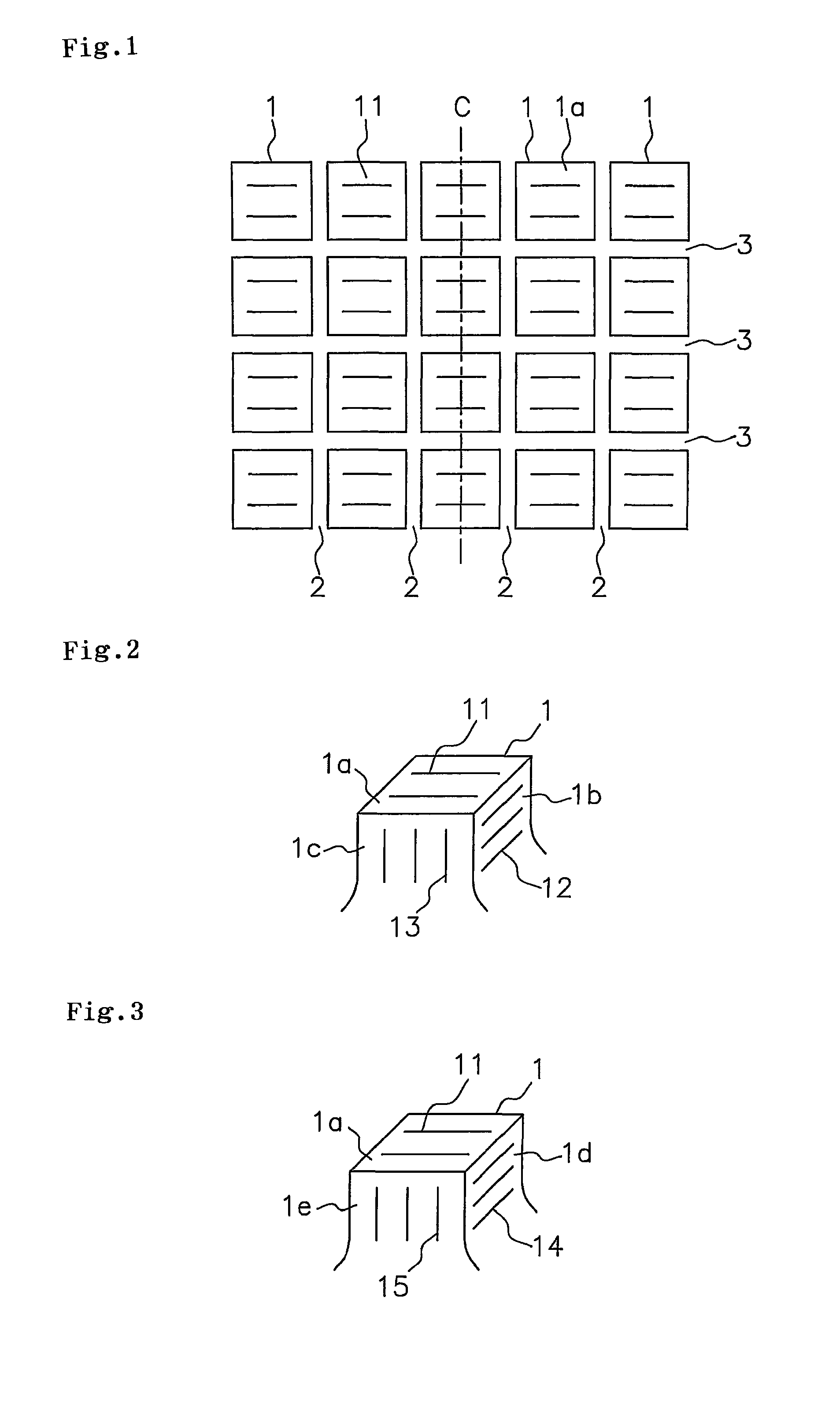

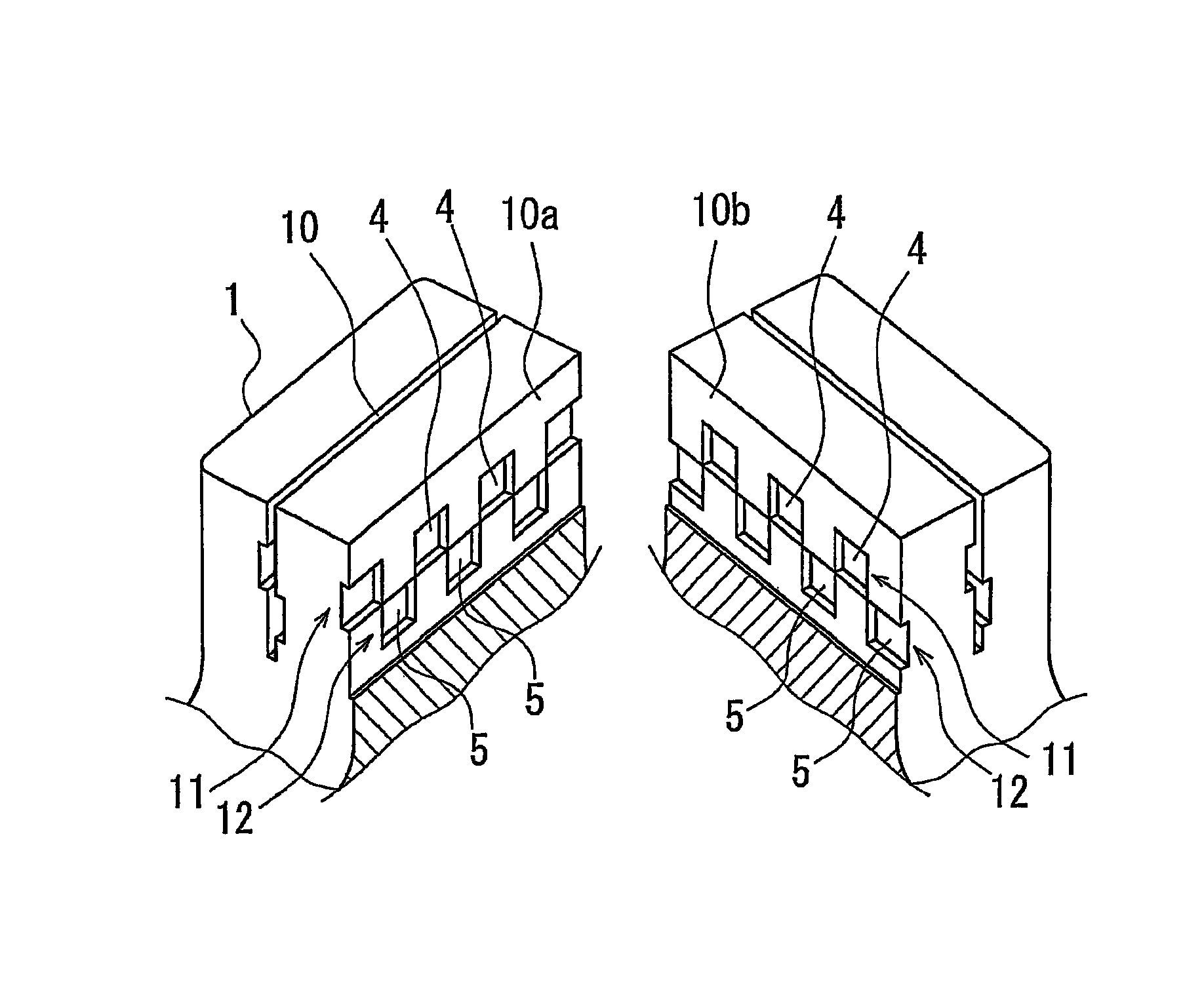

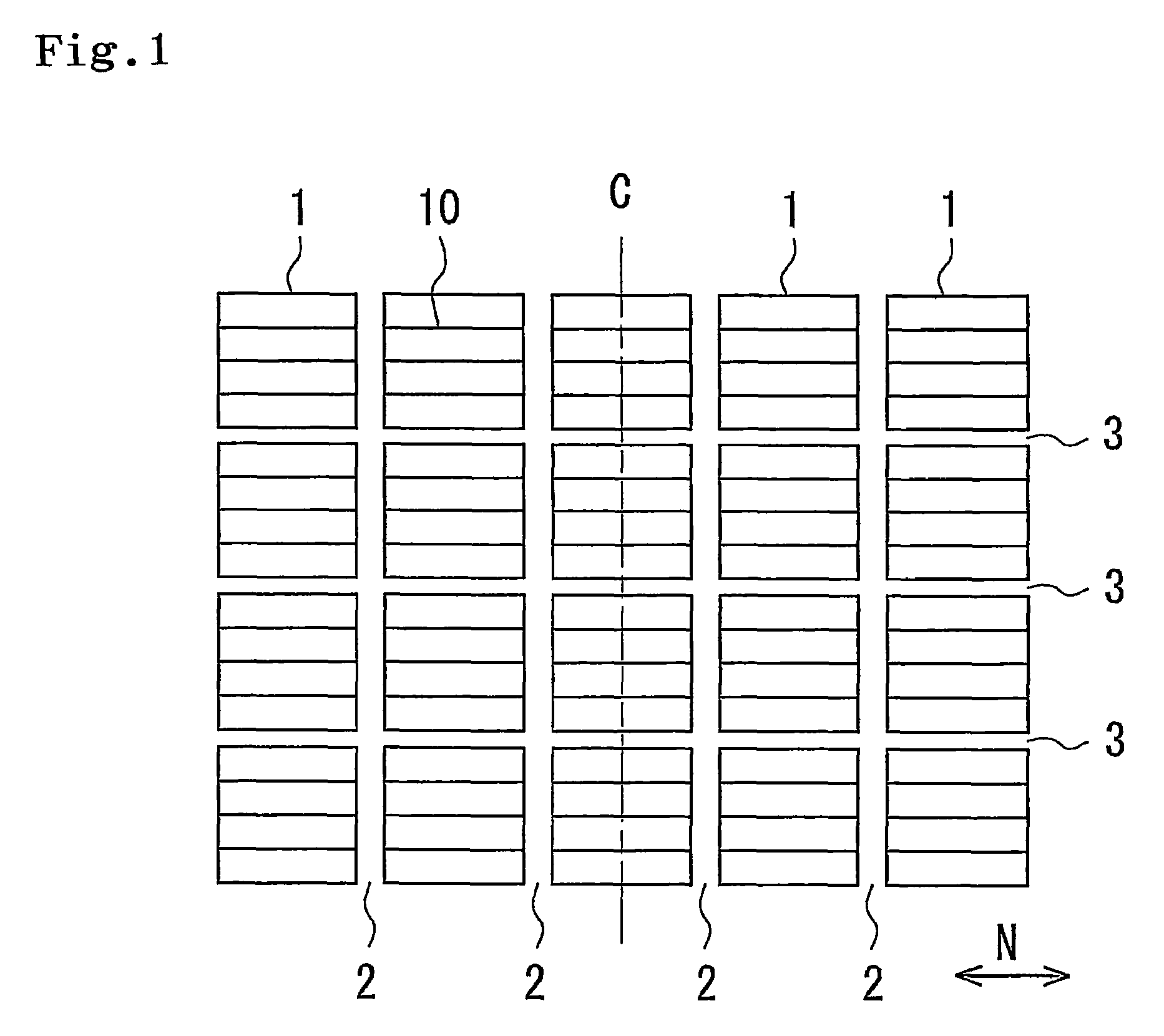

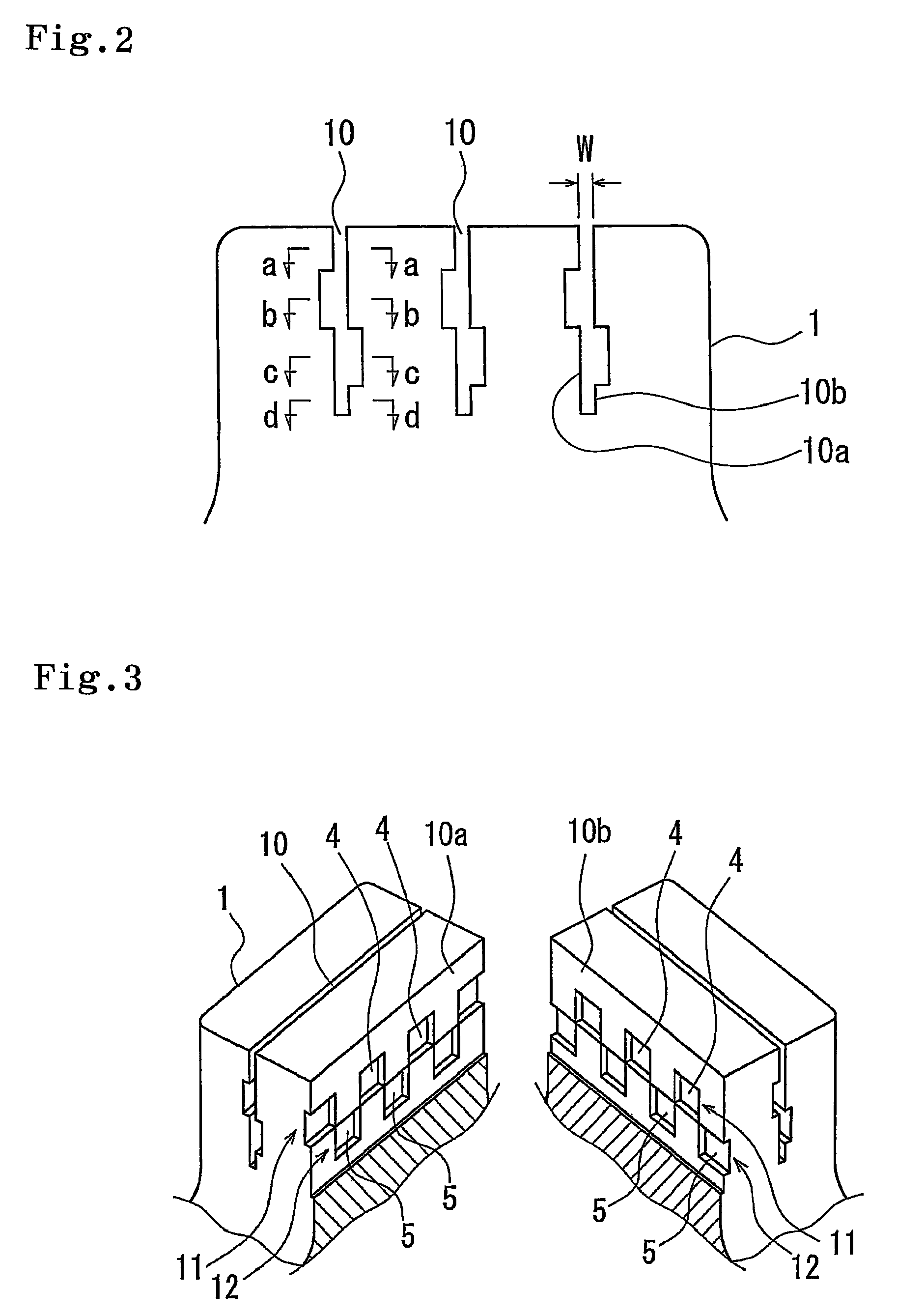

Automobile wheel

ActiveUS20150042150A1Satisfy the rigidity requirementMaintain performanceRoad vehiclesSpoked wheelsEngineeringFlange

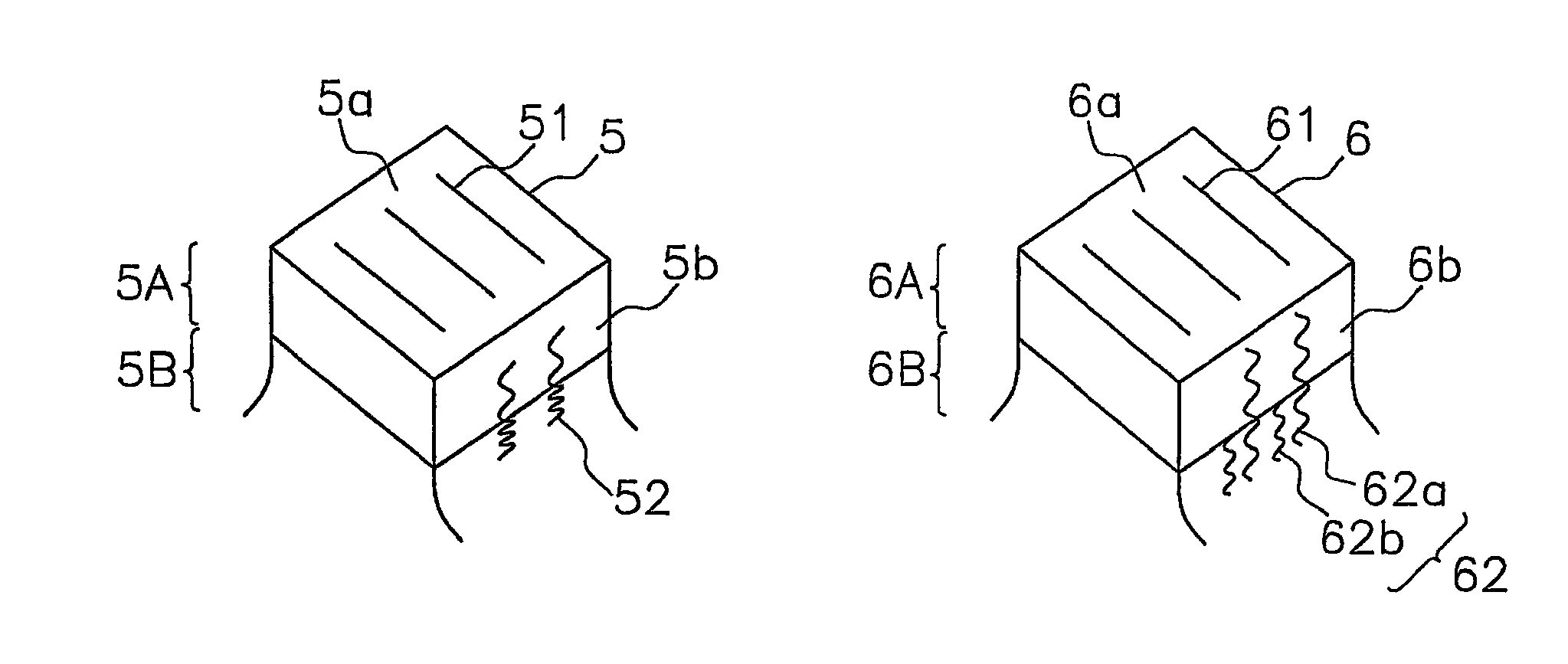

Each spoke portion includes spoke projecting threads on both sides thereof, and a reinforcing plate portion is formed so as to protrude from a side edge of each of the spoke projecting threads outward in a spoke widthwise direction. The reinforcing plate portion is formed continuously with an inter-spoke plate potion extended from a fitting portion of a disc flange portion to a wheel radially inner side, and forms an integral plate surface with the inter-spoke plate portion. With this configuration, it is possible to reduce imbalance of rigidity of the spoke portion in a radial direction, and to increase rigidity of an automobile wheel.

Owner:CENTRAL MOTOR WHEEL CO LTD

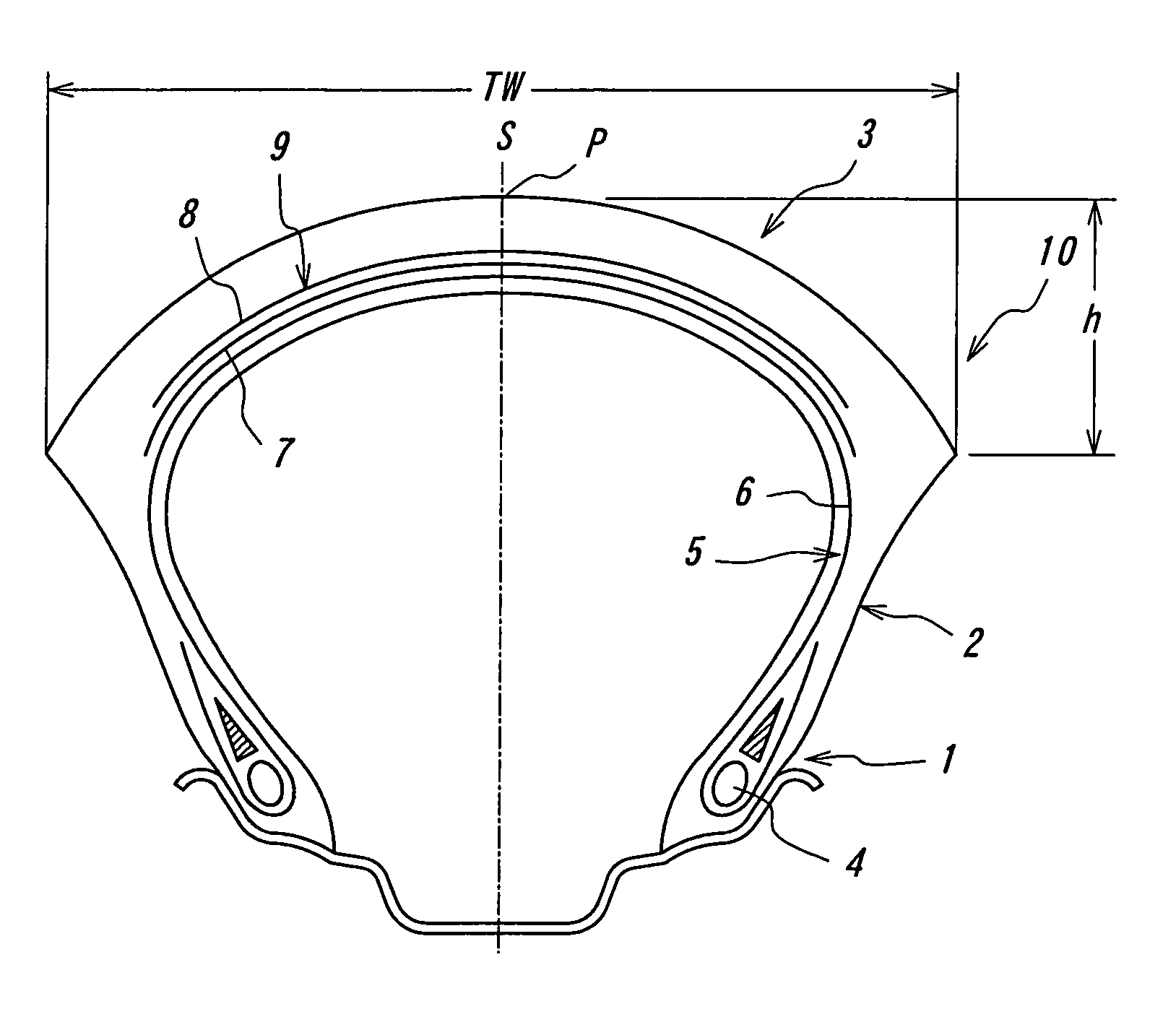

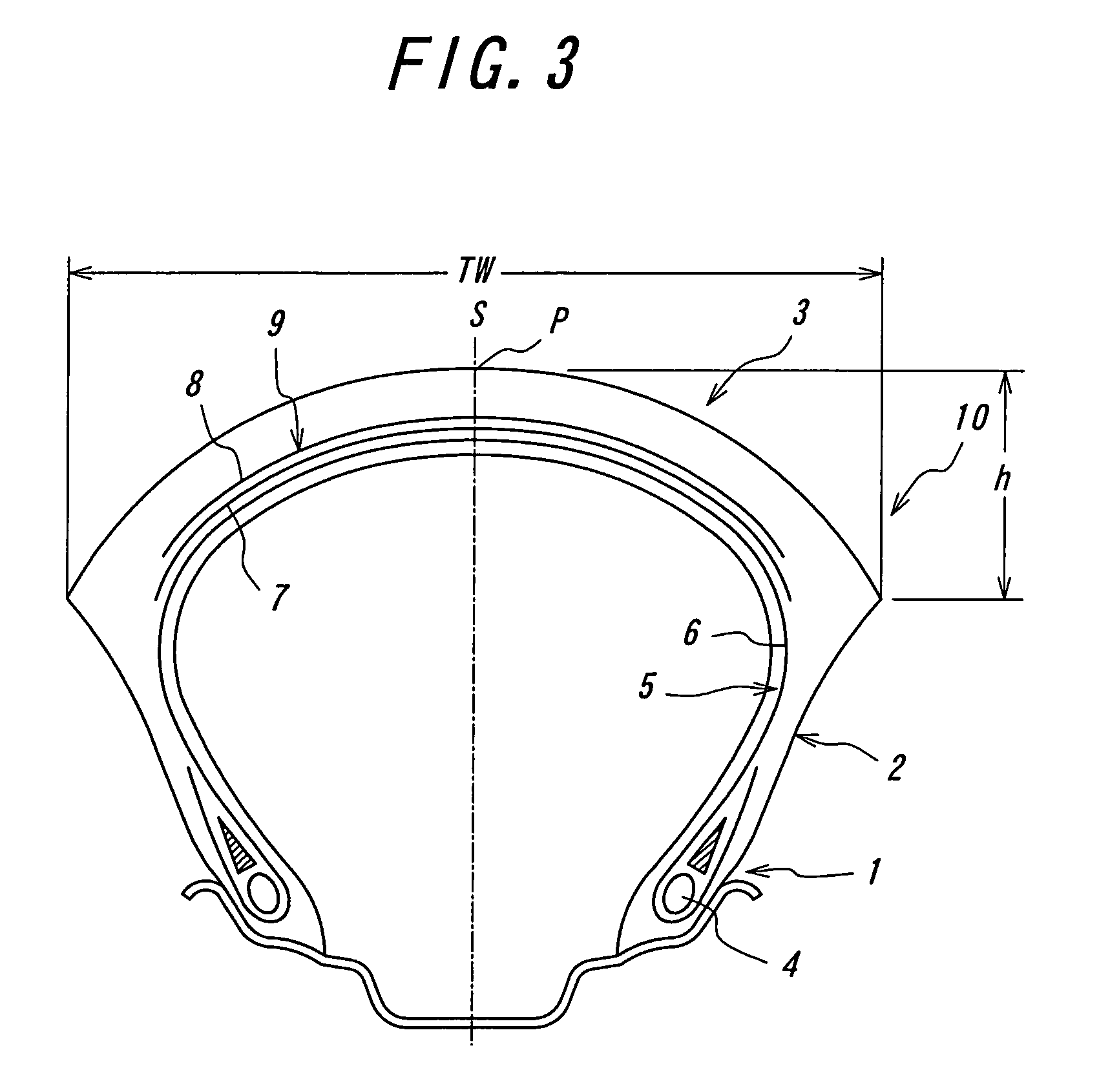

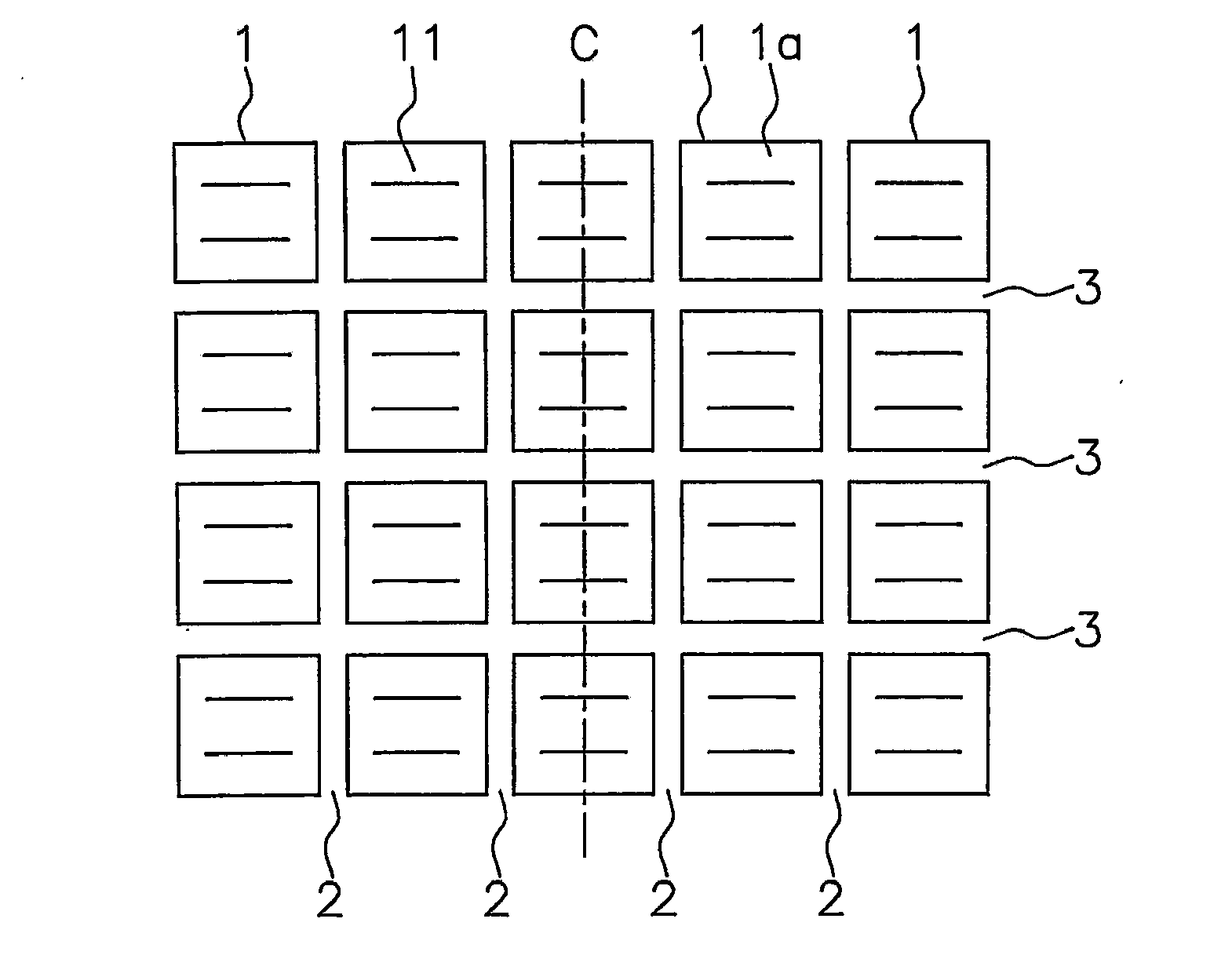

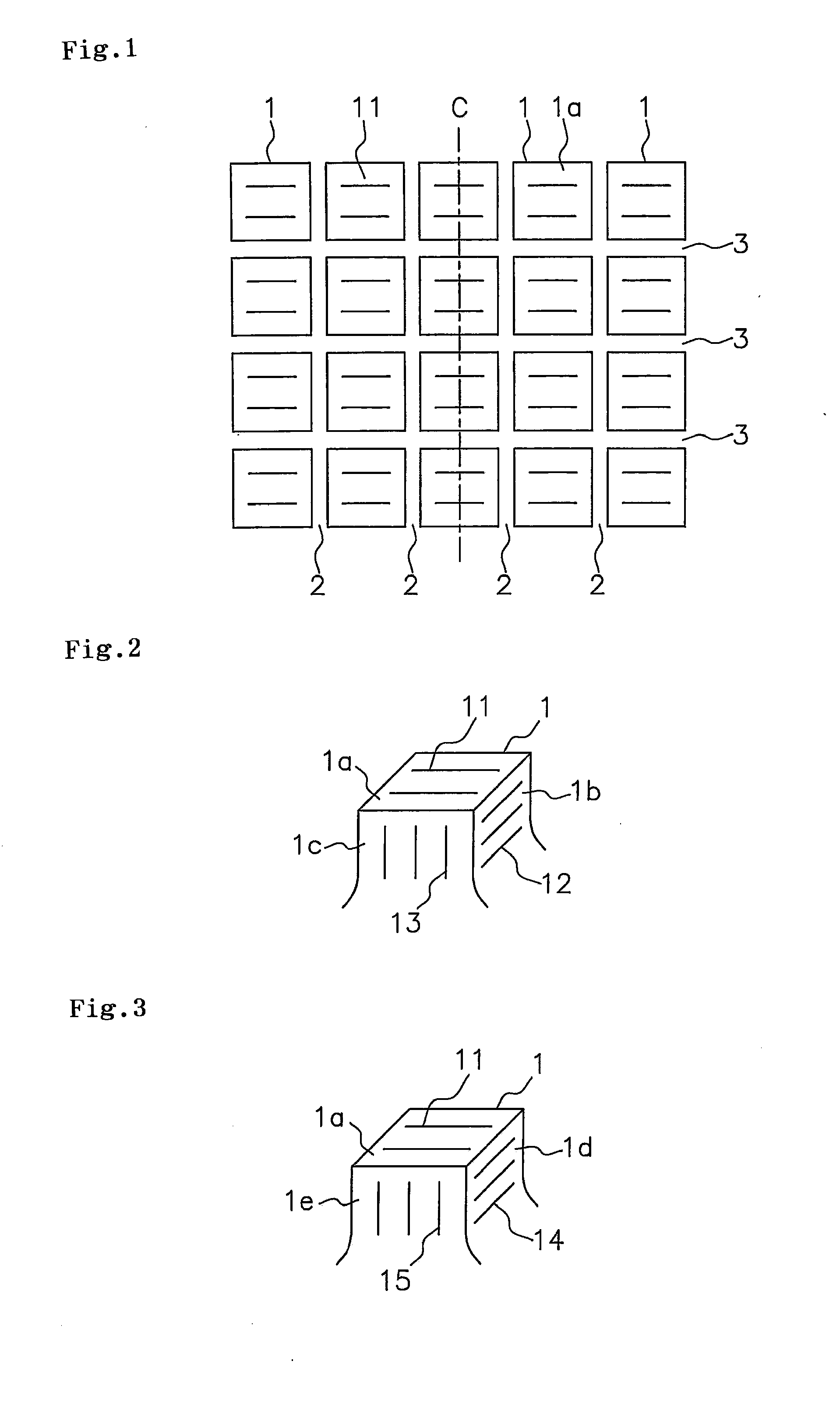

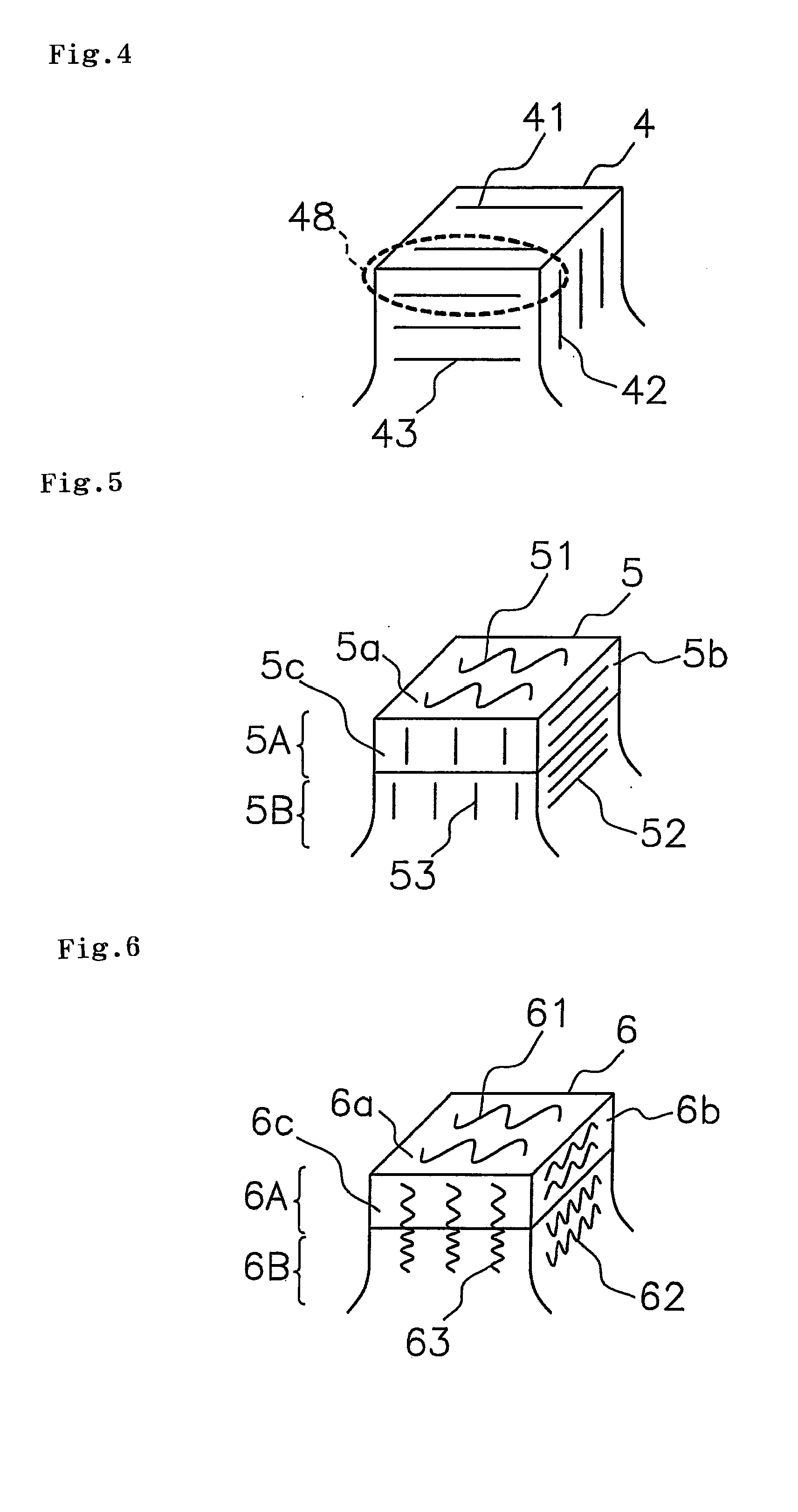

Rubberized fibous material and pneumatic tire

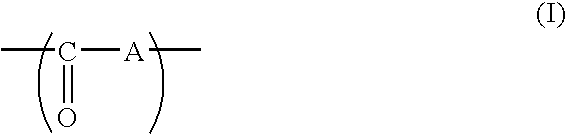

InactiveUS20060213597A1Small differenceGood rigidity balanceSpecial tyresPneumatic tyre reinforcementsFiberPolymer science

A rubberized fiber material is used in a belt reinforcing layer of a pneumatic tire, and comprises polyketone fibers having substantially a repeat unit represented by the following formula (I): (wherein A is a moiety derived from an ethylenically unsaturated compound polymerized through ethylenic linkage, and may be same or different in repeat units) and a coating rubber covering the fibers, in which the coating rubber has a modulus at 100% elongation (room temperature) of not less than 2.5 MPa but not more than 5.5 MPa and a rebound resilience of not less than 60%. Also, a pneumatic tire comprises a belt reinforcing layer made from the rubberized fiber material.

Owner:BRIDGESTONE CORP

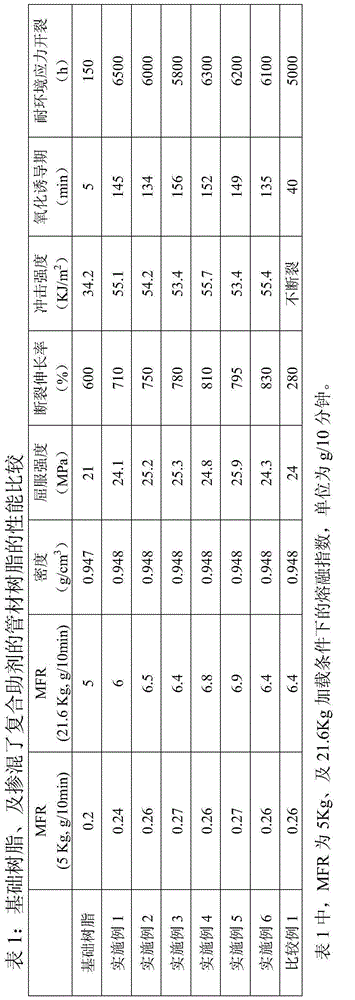

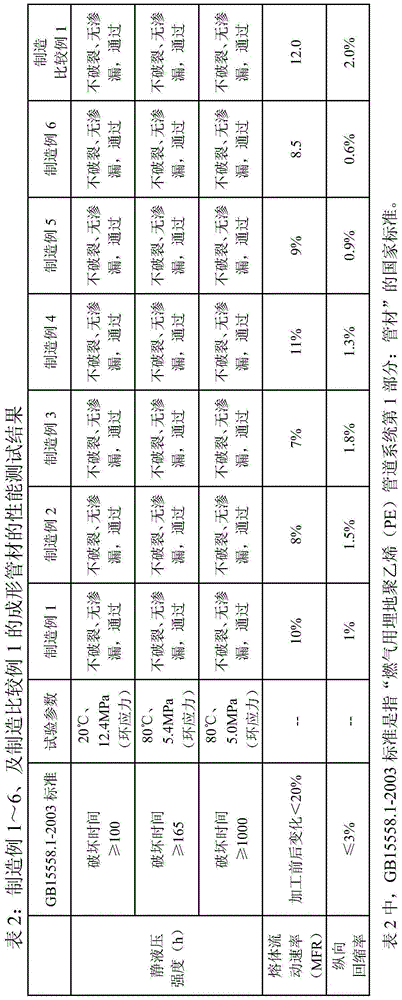

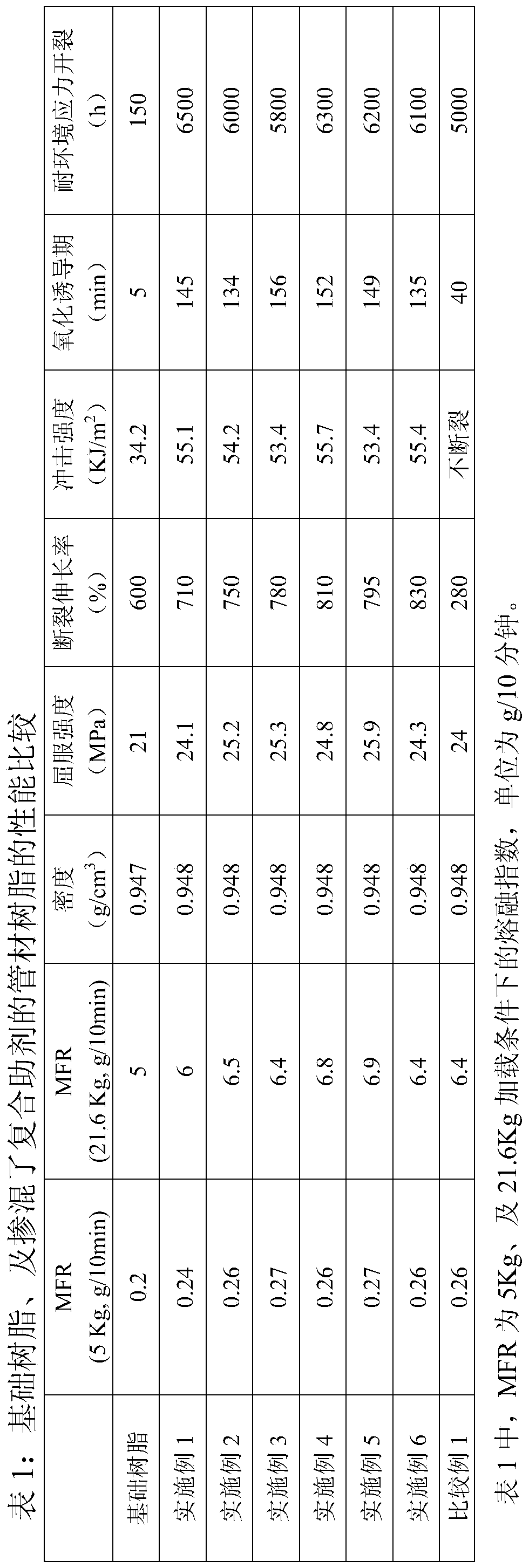

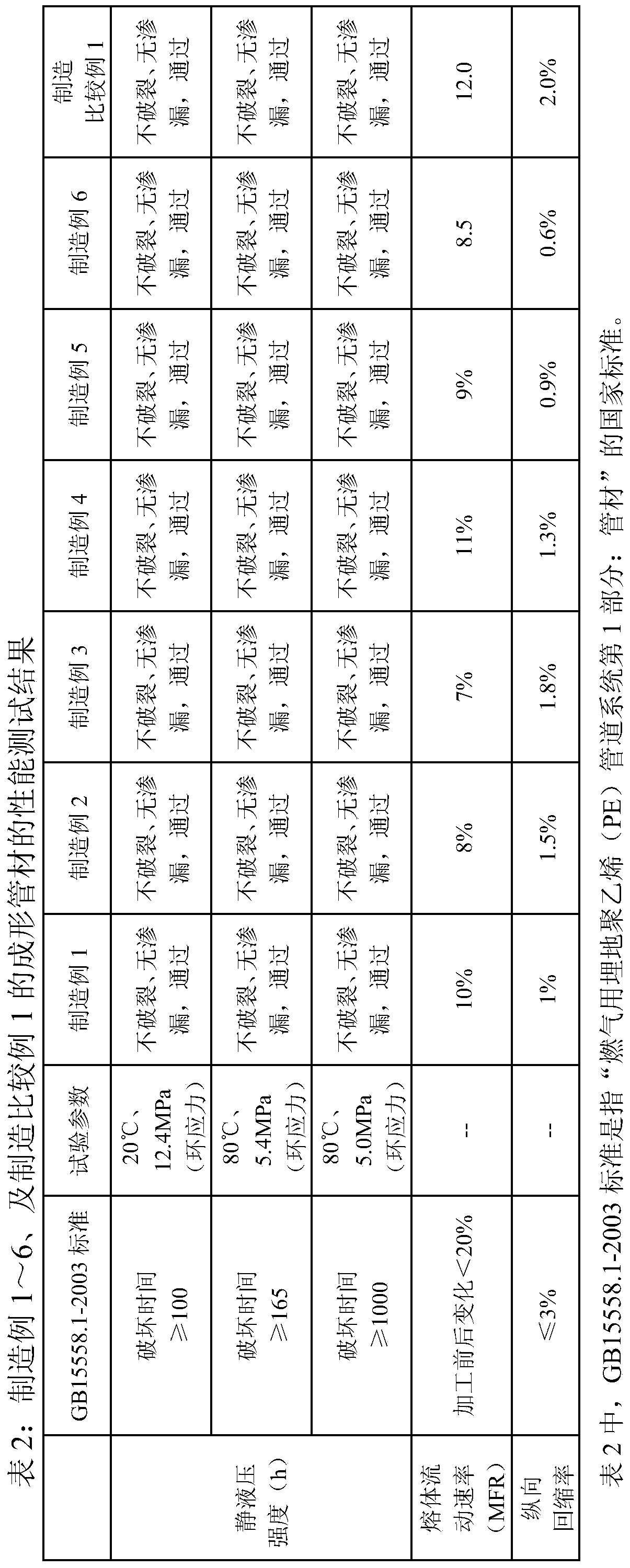

Composite auxiliary agent for high density polyethylene overpressure resistant tubing, preparation method thereof, and resin raw material containing the composite auxiliary agent

ActiveCN105733023AGood environmental stress cracking resistanceImprove pressure resistanceProcedure AgentsAntioxidant

The invention provides a composite auxiliary agent for a high density polyethylene overpressure resistant tubing. The composite auxiliary agent comprises 30-50 parts by weight of a long-term ageing resistant auxiliary agent , 10-30 parts by weight of a thermal stable auxiliary agent, and 10-30 parts by weight of a processing auxiliary agent, wherein the long-term ageing resistant auxiliary agent is at least one selected from a group consisting of hindered phenols antioxidants, amines antioxidants, and phosphorus antioxidants; the thermal stable auxiliary agent is at least one selected from metal soap stabilizers; and the processing auxiliary agent comprises at least a fluoroelastomer. The invention also provides a preparation method of the composite auxiliary agent, and a high density polyethylene overpressure resistant tubing resin raw material containing the composite auxiliary agent. The high density polyethylene overpressure resistant tubing resin raw material containing the composite auxiliary agent has excellent processing performance. The formed tubing has excellent environmental stress crack resistance, ageing resistance, and rigidity-toughness balance.

Owner:PETROCHINA CO LTD

Straddle type vehicle

ActiveUS8991543B2Reduce impactWithout increasing number of componentWheel based transmissionFrictional rollers based transmissionEllipseCalipers

Owner:HONDA MOTOR CO LTD

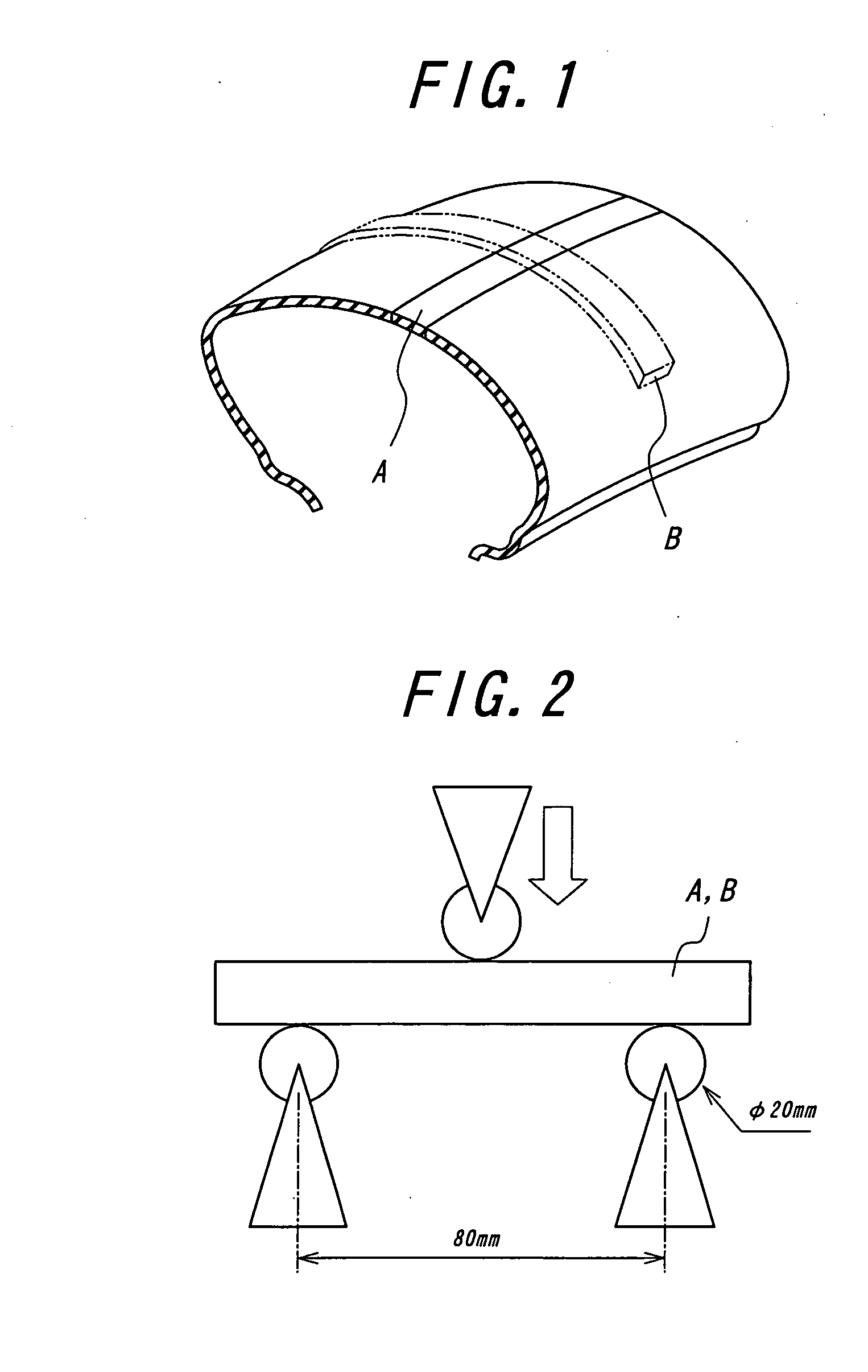

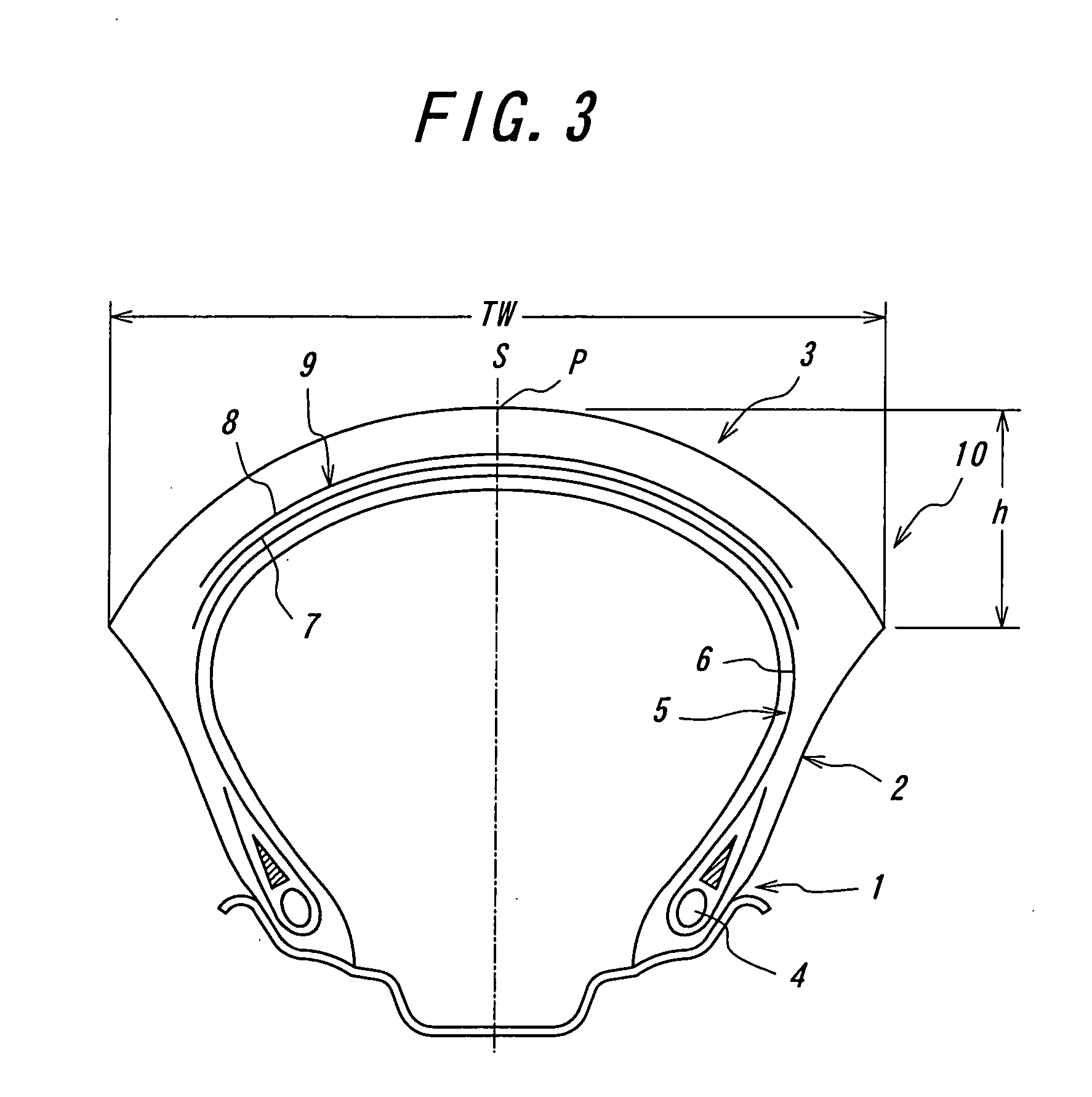

Pneumatic radial tire with specified tread portion bending rigidity ratio

InactiveUS7025101B2Weight increaseLowering straight-runningPneumatic tyre reinforcementsMotorcycle tyresIn planeCamber angle

There is provided a pneumatic radial tire for a motorcycle capable of developing an excellent steering stability in a high-speed cornering subjected to a large camber angle, and having an aspect ratio of 0.50–0.85, in which a tensile strength at break of a carcass ply cord is not less than 980 MPa, and an absolute value of a carcass total rigidity obtained by adding carcass rigidities of carcass plies is not less than 30000, and a tensile strength at break of a belt layer cord is not less than 2350 MPa, and an absolute value of a belt total rigidity obtained by adding belt rigidities of belt layers is not less than 170000, and a bending rigidity ratio as a ratio of out-of-plane bending rigidity to in-plane bending rigidity is within a range of 4.20–9.10.

Owner:BRIDGESTONE CORP

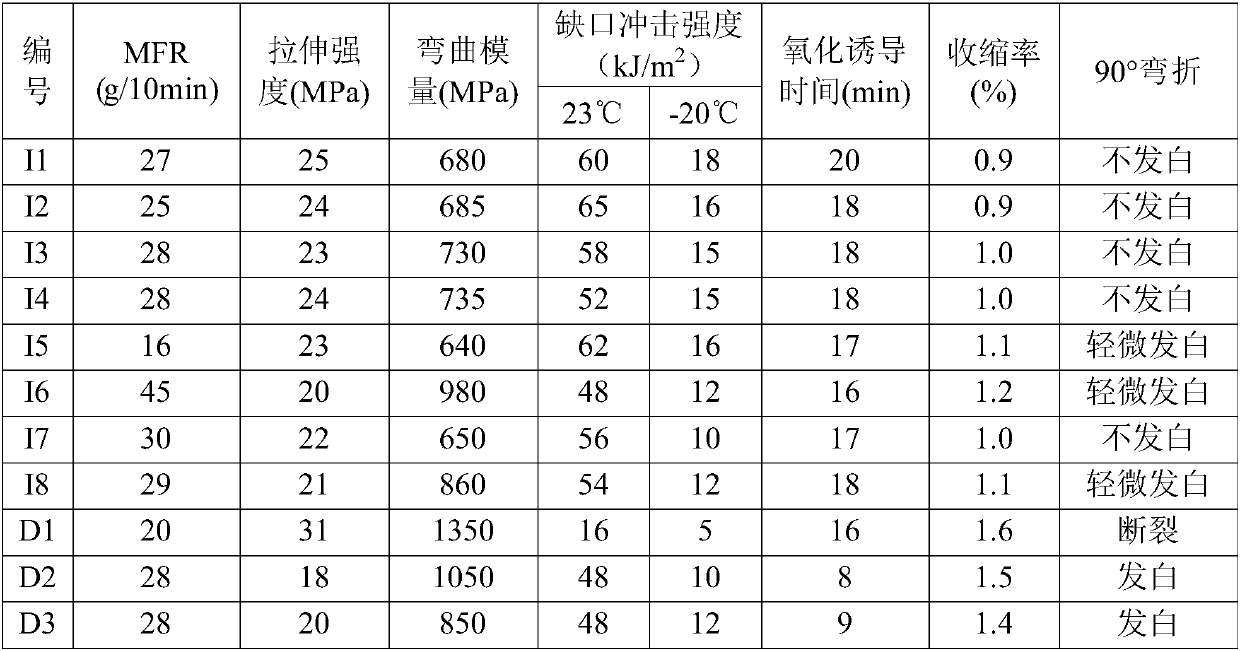

Polypropylene composition, polypropylene material, and applications of polypropylene composition and polypropylene material

The present invention relates to the field of polymers, particularly to a polypropylene composition, a polypropylene material, and applications of the polypropylene composition and the polypropylene material, wherein the polypropylene composition contains, by weight, 64-90% of anti-impact co-polypropylene, 9-35% of a thermoplastic elastomer, and 0.2-1.5% of an antioxidant. According to the presentinvention, the polypropylene material has advantages of good fluidity, good shrinkage, rigidity and toughness balance, heat aging resistance and environmental aging resistance, and cannot produce stress whitening after bending 90 DEG; and the polypropylene composition and / or the polypropylene material are particularly suitable for the preparation of pot seedling cultivation disks.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polypropylene composition, polypropylene material, and applications of polypropylene composition and polypropylene material

The present invention relates to the field of polymers, particularly to a polypropylene composition, a polypropylene material, and applications of the polypropylene composition and the polypropylene material, wherein the polypropylene composition contains, by weight, 64-90% of random co-polypropylene, 9-35% of a polyolefin elastomer, and 0.2-1.5% of an antioxidant. According to the present invention, the polypropylene material has advantages of good fluidity, good shrinkage, rigidity and toughness balance, heat aging resistance and environmental aging resistance, and cannot produce stress whitening after bending 90 DEG; and the polypropylene composition and / or the polypropylene material are particularly suitable for the preparation of pot seedling cultivation disks.

Owner:CHINA PETROLEUM & CHEM CORP +1

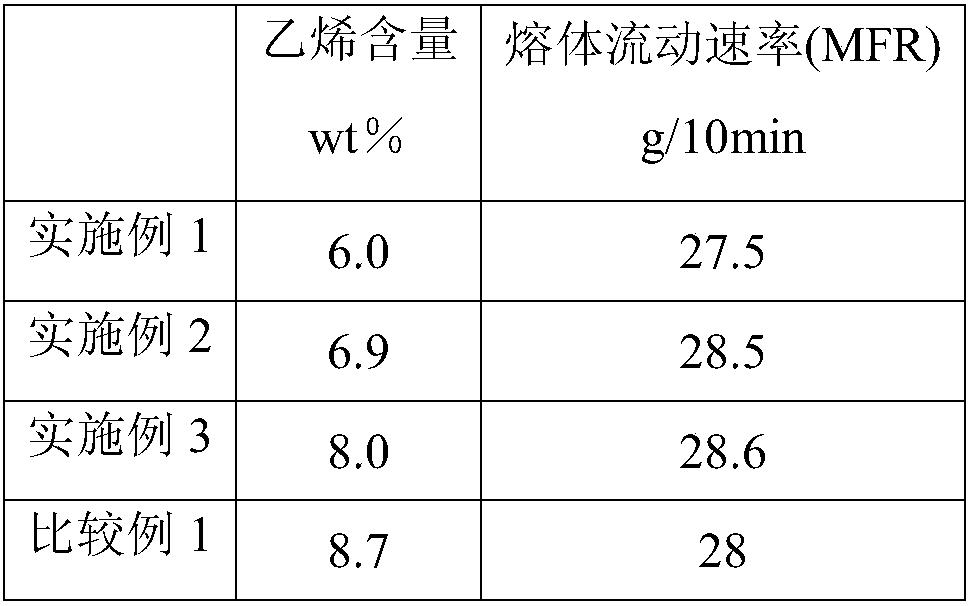

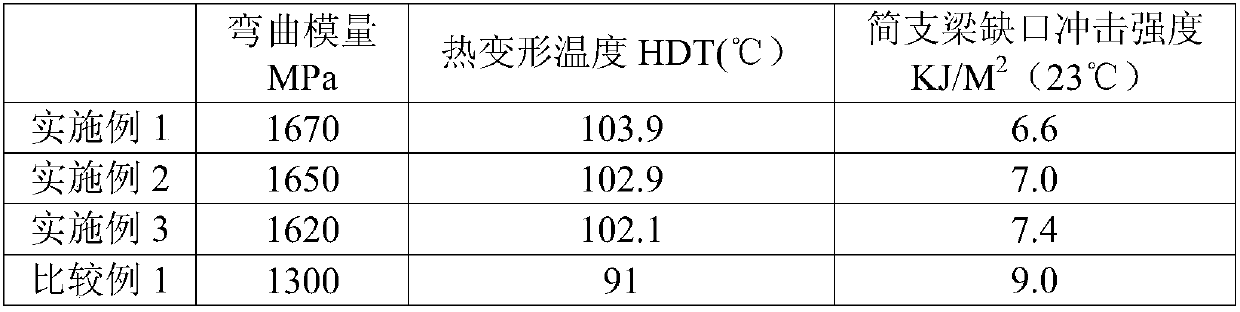

Preparation method of high modulus and high impact polypropylene resin

Belonging to the field of polymer technology, the invention in particular relates to a preparation method of high modulus and high impact polypropylene resin. The method specifically includes the steps of: firstly, conducting propylene homopolymerization in a reactor to obtain homo-polypropylene; then subjecting the homo-polypropylene, propylene and ethylene to multiphase copolymerization in a gasphase reactor to obtain anti-impact polypropylene resin; and finally, mixing the anti-impact polypropylene resin, an antioxidant, an acid neutralizer and a nucleating agent and performing granulationso as to obtain the high modulus and high impact polypropylene resin. Specifically, the nucleating agent is a Milliken novel Narsil nucleating agent. The high modulus and high impact polypropylene resin obtained by the method provided by the invention has the advantages of good heat resistance, rigidity and toughness, especially good rigidity-toughness balance, and is especially suitable for application in automobile interior and exterior decoration modified matrixes.

Owner:CHINA PETROLEUM & CHEM CORP +1

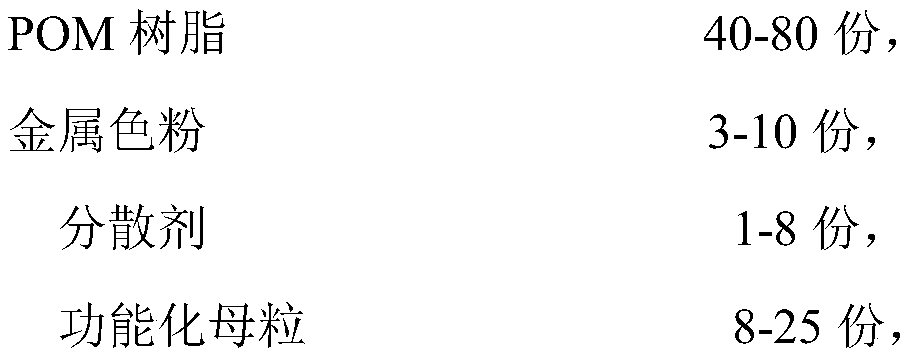

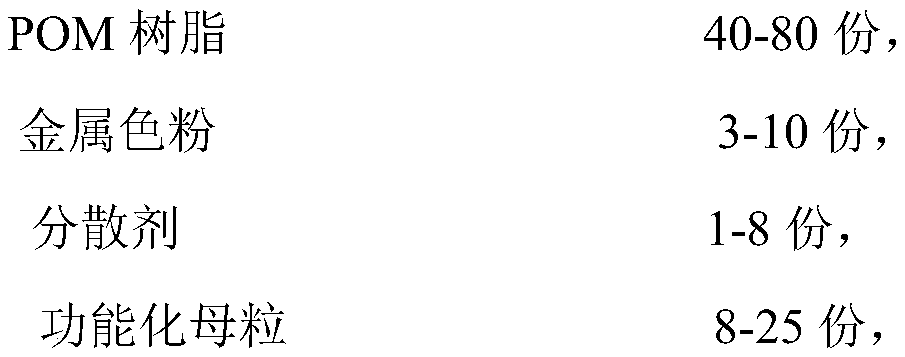

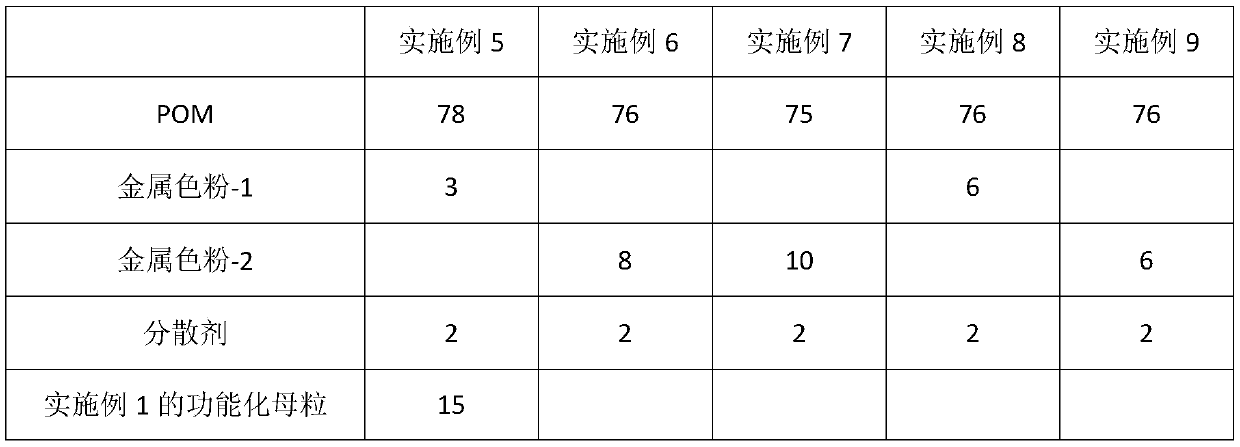

High-performance antibacterial spraying-free POM composite material and preparation method thereof

ActiveCN110819063AHigh content of active ingredientsAchieve broad-spectrum antibacterial effectEscherichia coliIonomer

The invention discloses a high-performance antibacterial spraying-free POM composite material and a preparation method thereof, wherein the high-performance antibacterial spraying-free POM composite material specifically comprises the following raw materials by weight: 40-80 parts of a POM resin, 2-10 parts of metal toner, 1-8 parts of a dispersing agent and 5-15 parts of functionalized master batch, wherein the functionalized master batch comprises, by weight, 2-8 parts of an elastic ionomer, 2-6 parts of a nano-state aerogel and 2-6 parts of a silver ion antibacterial agent. According to theinvention, the key antibacterial agent component and the aerogel with a nanometer mesoporous structure are subjected to effective master batch premixing and adsorption, so that the good spraying-freeeffect is achieved, and the POM material has broad-spectrum antibacterial effect, wherein the long-acting antibacterial rates of the POM material to three different strains (escherichia coli, staphylococcus aureus and aspergillus niger) are respectively more than 99%; and by using the special toughening agent-ionomer, the spraying-free POM composite material has good rigidity and toughness balance.

Owner:华合新材料科技股份有限公司

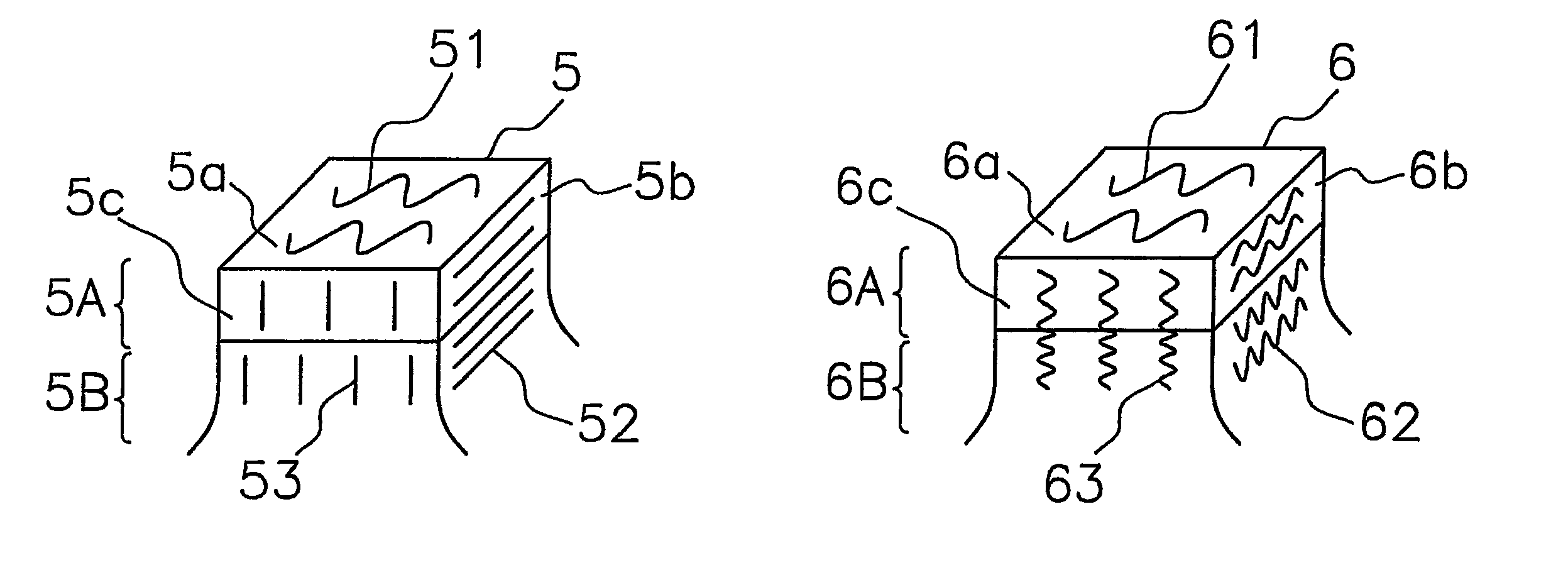

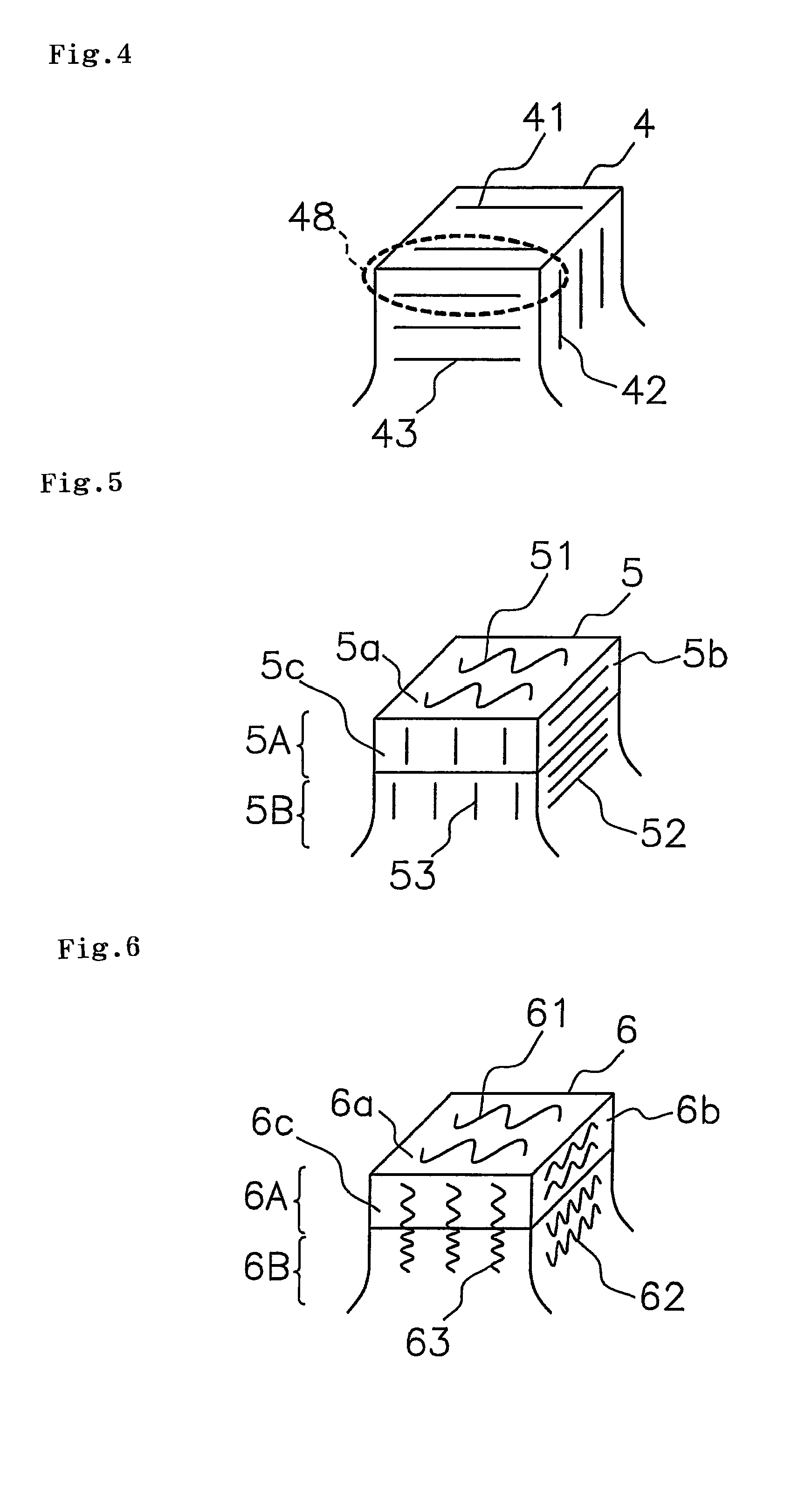

Automobile wheel

ActiveUS9302535B2Reduce imbalance of rigidityImprove rigidityRoad vehiclesSpoked wheelsEngineeringFlange

Each spoke portion includes spoke projecting threads on both sides thereof, and a reinforcing plate portion is formed so as to protrude from a side edge of each of the spoke projecting threads outward in a spoke widthwise direction. The reinforcing plate portion is formed continuously with an inter-spoke plate portion extended from a fitting portion of a disc flange portion to a wheel radially inner side, and forms an integral plate surface with the inter-spoke plate portion. With this configuration, it is possible to reduce imbalance of rigidity of the spoke portion in a radial direction, and to increase rigidity of an automobile wheel.

Owner:CENTRAL MOTOR WHEEL CO LTD

Pneumatic Tire

ActiveUS20090178743A1Lowering too much a rigidity of the blockImprove performanceSpecial tyresTyre tread bands/patternsEngineering

Owner:TOYO TIRE & RUBBER CO LTD

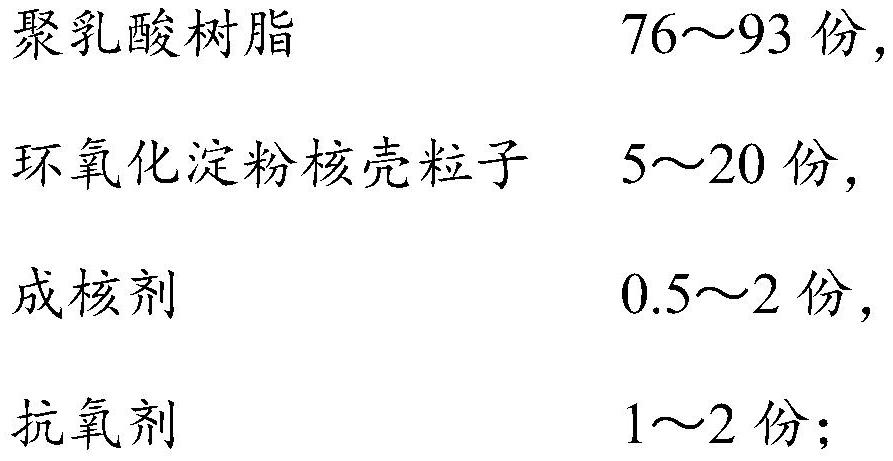

Toughened polylactic acid composite material and preparation method thereof

The invention provides a toughened polylactic acid composite material and a preparation method thereof. The toughened polylactic acid composite material comprises the following raw materials in parts by weight: 76-93 parts of polylactic resin, 5-20 parts of epoxidized starch core-shell particles, 0.5-2 parts of a nucleating agent and 1-2 parts of an antioxidant, the epoxidized starch core-shell particles are core-shell particles prepared by grafting and copolymerizing butyl acrylate and esterified modified starch by adopting an emulsion polymerization method, and the particle size is 200-500nm. The toughened polylactic acid composite material disclosed by the invention has relatively good biodegradable characteristic, the mechanical property is improved, and relatively good rigid-tough balance is obtained.

Owner:江苏尚艾新材料科技有限公司

Pneumatic tire with tread including block having sipes

ActiveUS8132605B2Lowering too much a rigidity of the blockImprove performanceSpecial tyresTyre tread bands/patternsMechanical engineeringTread

Owner:TOYO TIRE & RUBBER CO LTD

A kind of high modulus, ultra-high impact polypropylene composite material and preparation method thereof

ActiveCN103923381BImprove low temperature toughnessImprove rigidityElastomerPolypropylene composites

The invention discloses a high-modulus and ultrahigh-impact polypropylene composite material and its preparation method. The composite material comprises 40-74wt% of polypropylene, 10-30wt% of an ultrafine inorganic filler, 15-30wt% of an elastomer flexibilizer, 0.1-2wt% of a stabilizer, and 0-5wt% of other additives. The preparation method comprises the following steps: carrying out dry mixing on raw materials in a high speed mixer for 3-15min, adding the mixed raw materials into a double screw extruder, carrying out melt extrusion, and carrying out cooling granulation. The preparation method has the following advantages:1, a ethylene-butylene copolymer is used as the elastomer flexibilizer, so the polypropylene composite material has better low temperature toughness than traditional toughening modified polypropylene; 2, ultrafine talcum powder is used as the inorganic filler, so the toughness loss can be reduced as much as possible, and the rigidness of the material is greatly improved; and 3, the synergistic effect of the ultrafine talcum powder and the elastomer flexibilizer is utilized, so the polypropylene composite material has more ideal rigidness-toughness balance than the traditional toughening modified polypropylene.

Owner:SHANGHAI PRET COMPOSITES +2

Pneumatic tire with tread having upper surface sipes and wall surface sipes

ActiveUS8181683B2Lowering too much a rigidity of the blockImprove performanceSpecial tyresTyre tread bands/patternsEngineeringMechanical engineering

Owner:TOYO TIRE & RUBBER CO LTD

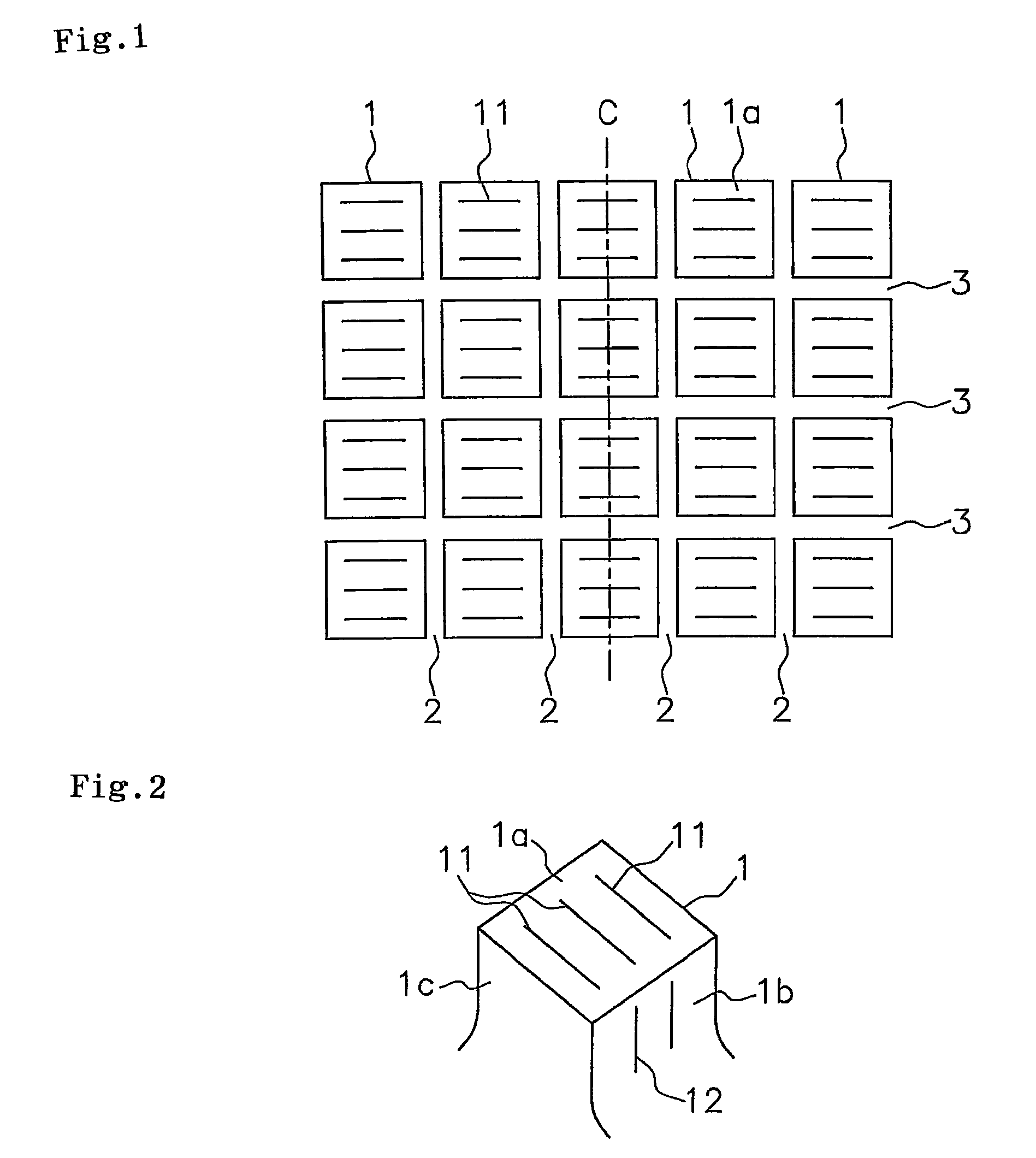

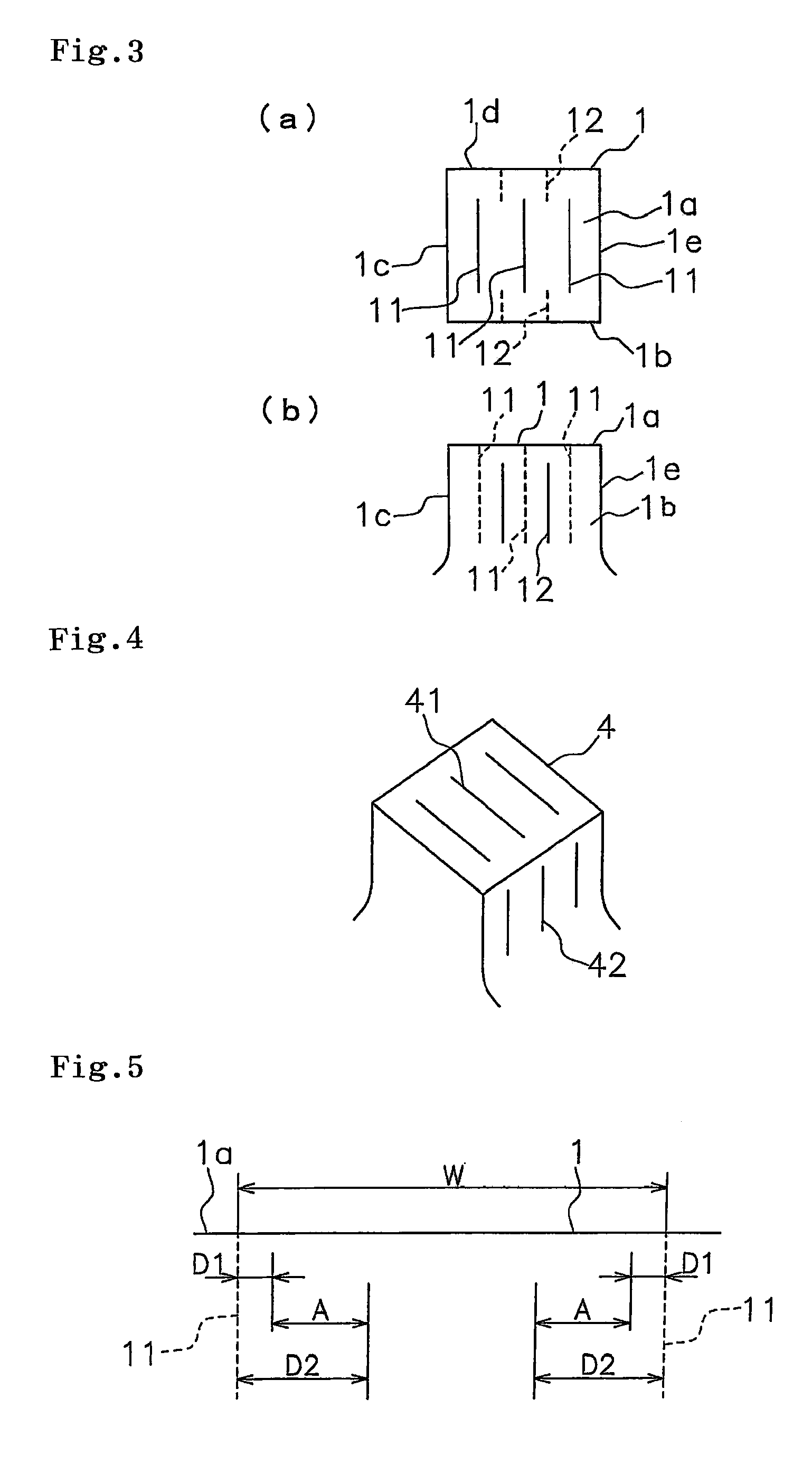

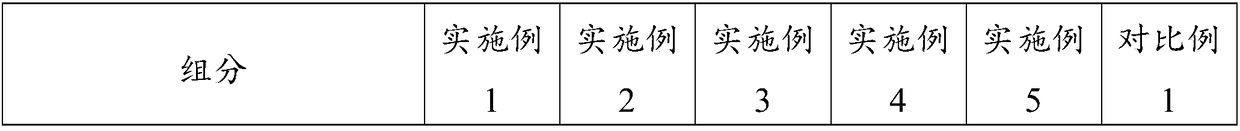

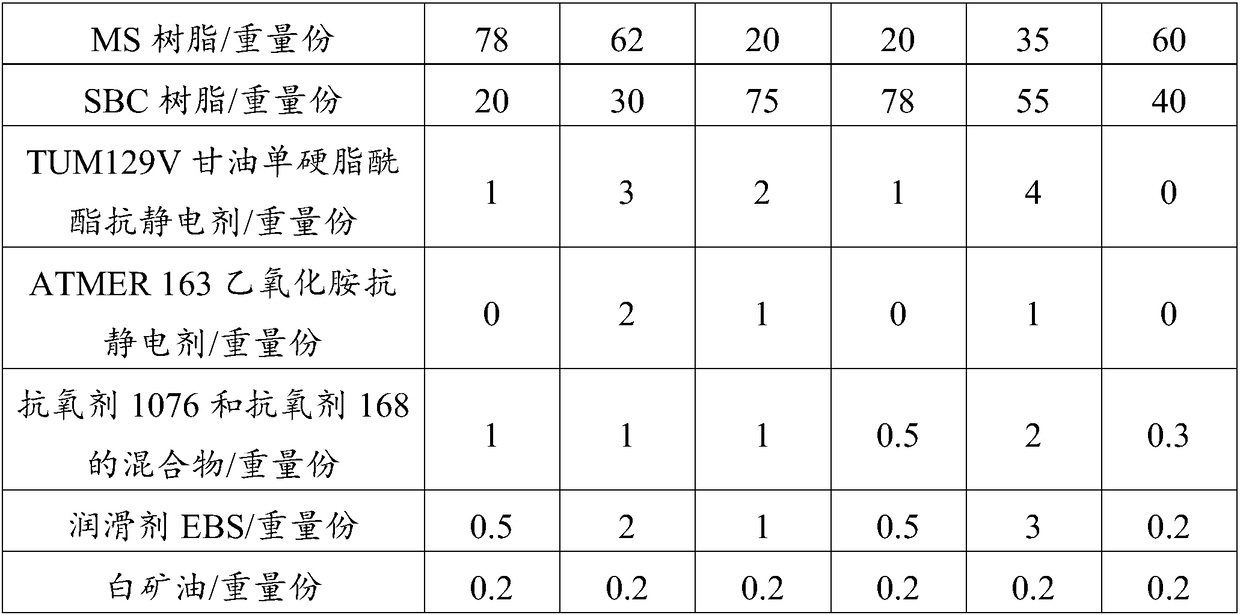

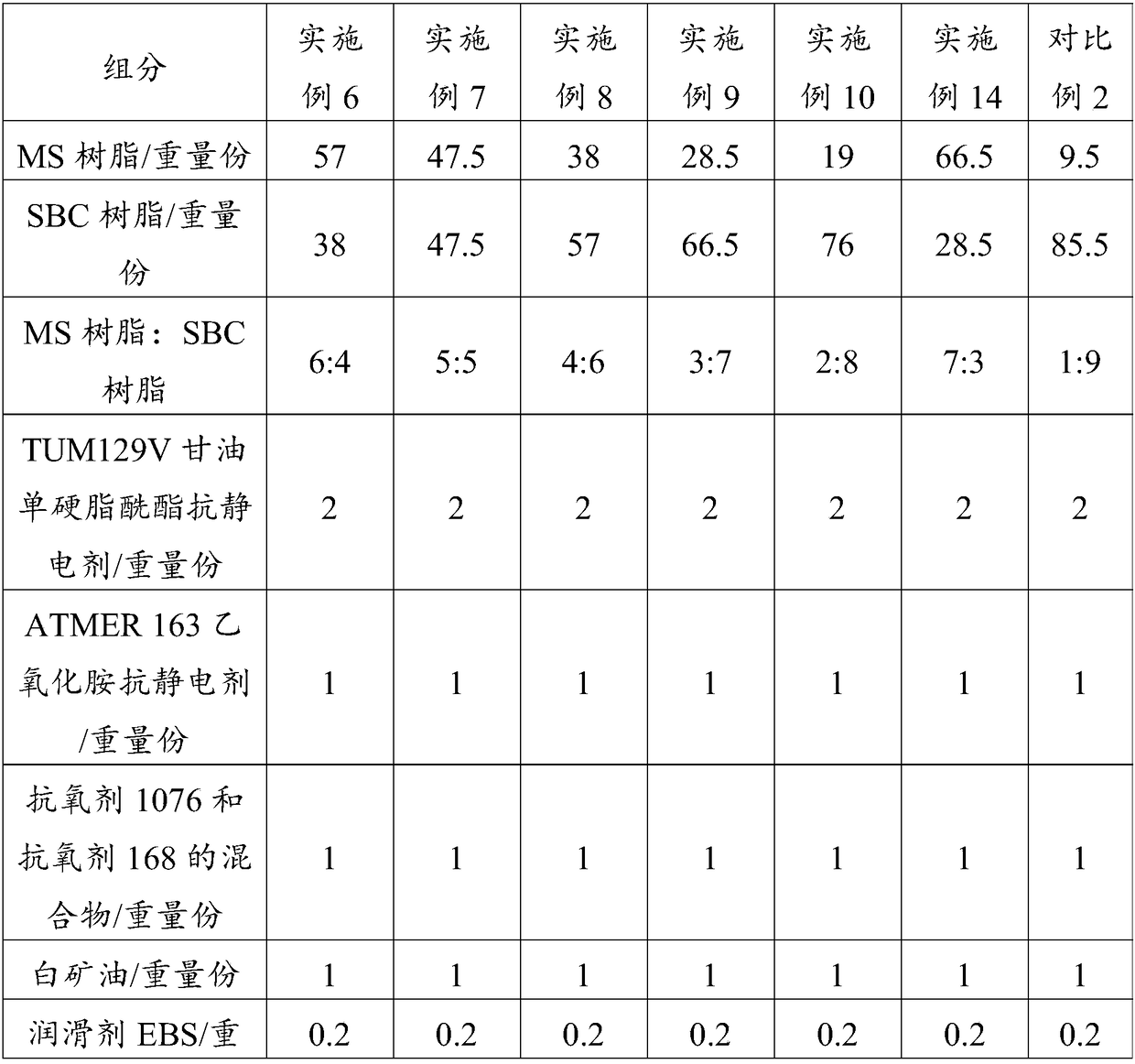

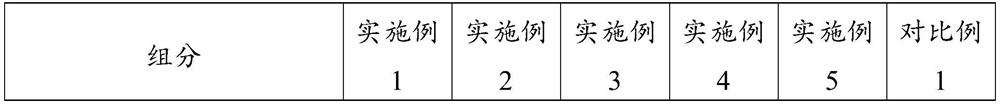

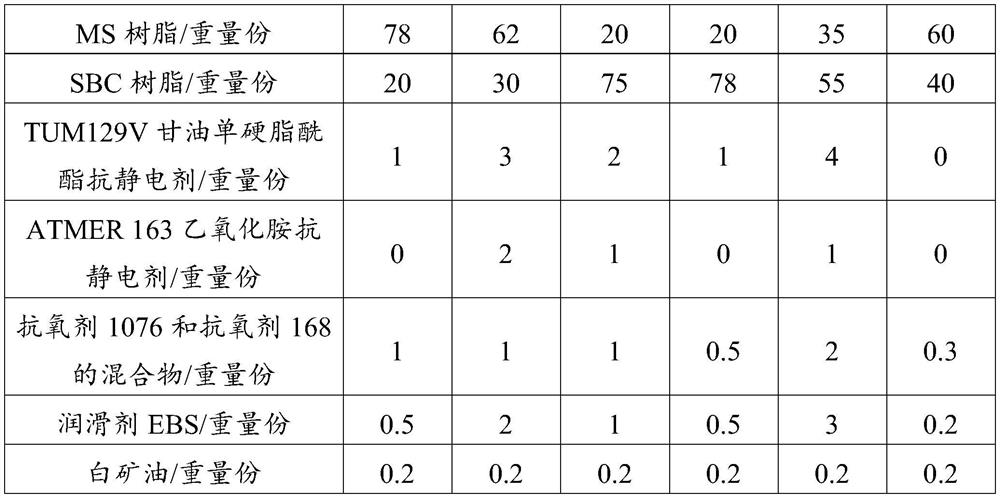

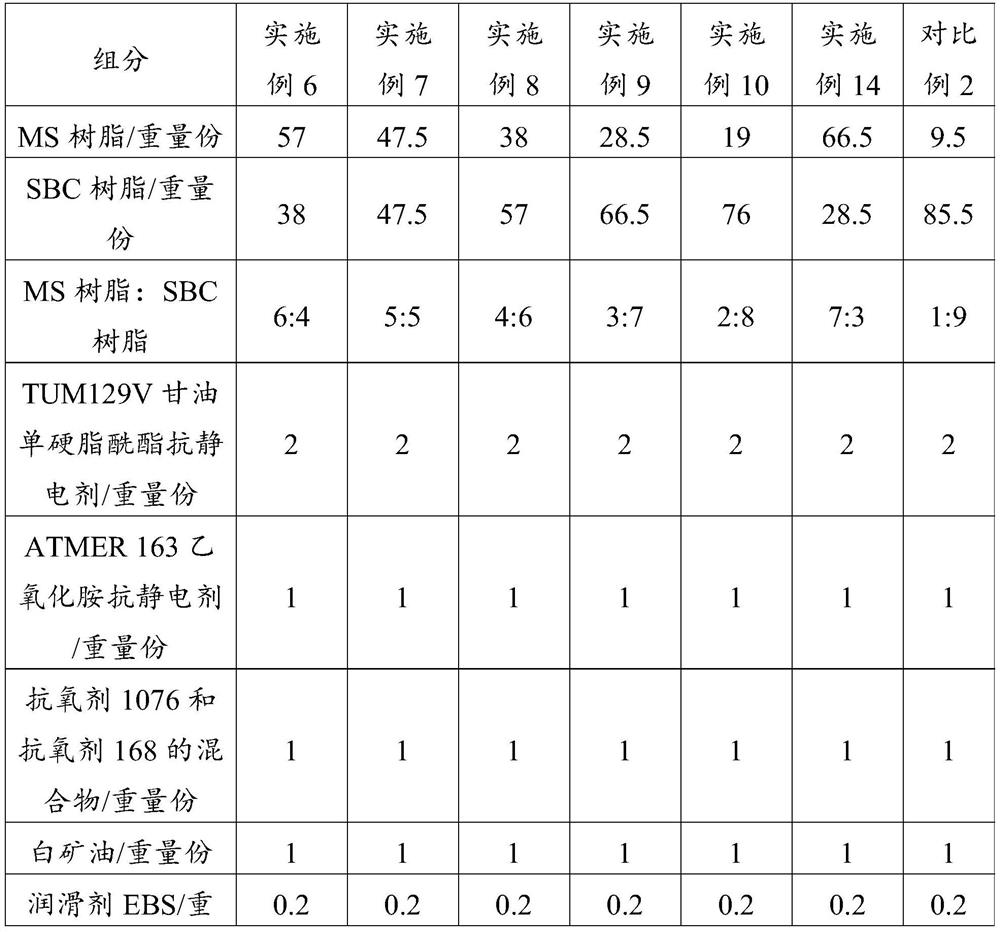

Resin composition for transparent anti-static IC packaging tube

The invention discloses a resin composition for a transparent anti-static IC packaging tube. The resin composition is prepared from the following ingredients in parts by weight: 20 to 78 parts of methyl methacrylate-styrene resin, 20 to 78 parts of styrene-butadiene copolymers and 1 to 5 parts of anti-static agents. The resin composition for the transparent anti-static IC packaging tube uses methyl methacrylate-styrene (MS) as substrate resin, uses styrene-butadiene copolymers (SBC, also called as K glue) as a toughening agent for toughening, and has the advantages that the good rigidity and roughness balance is realized; the anti-static agents are added, so that the obtained resin composition has a good transparent effect and anti-static effects.

Owner:KINGFA SCI & TECH CO LTD

Pneumatic tire with tread having sipes

ActiveUS8640751B2Prevent an excessive collapseAvoid rigidityTyre tread bands/patternsNon-skid devicesEngineeringDepth direction

A pneumatic tire structured such that a sipe is formed in a land portion of a tread surface. The sipe has a wide portion extending along a longitudinal direction at least at one position in a depth direction. The wide portion is structured by alternately arranging concave portions which are smaller in the longitudinal direction and the depth direction than the sipe, in both sides of a sipe wall surface along the longitudinal direction of the sipe.

Owner:TOYO TIRE & RUBBER CO LTD

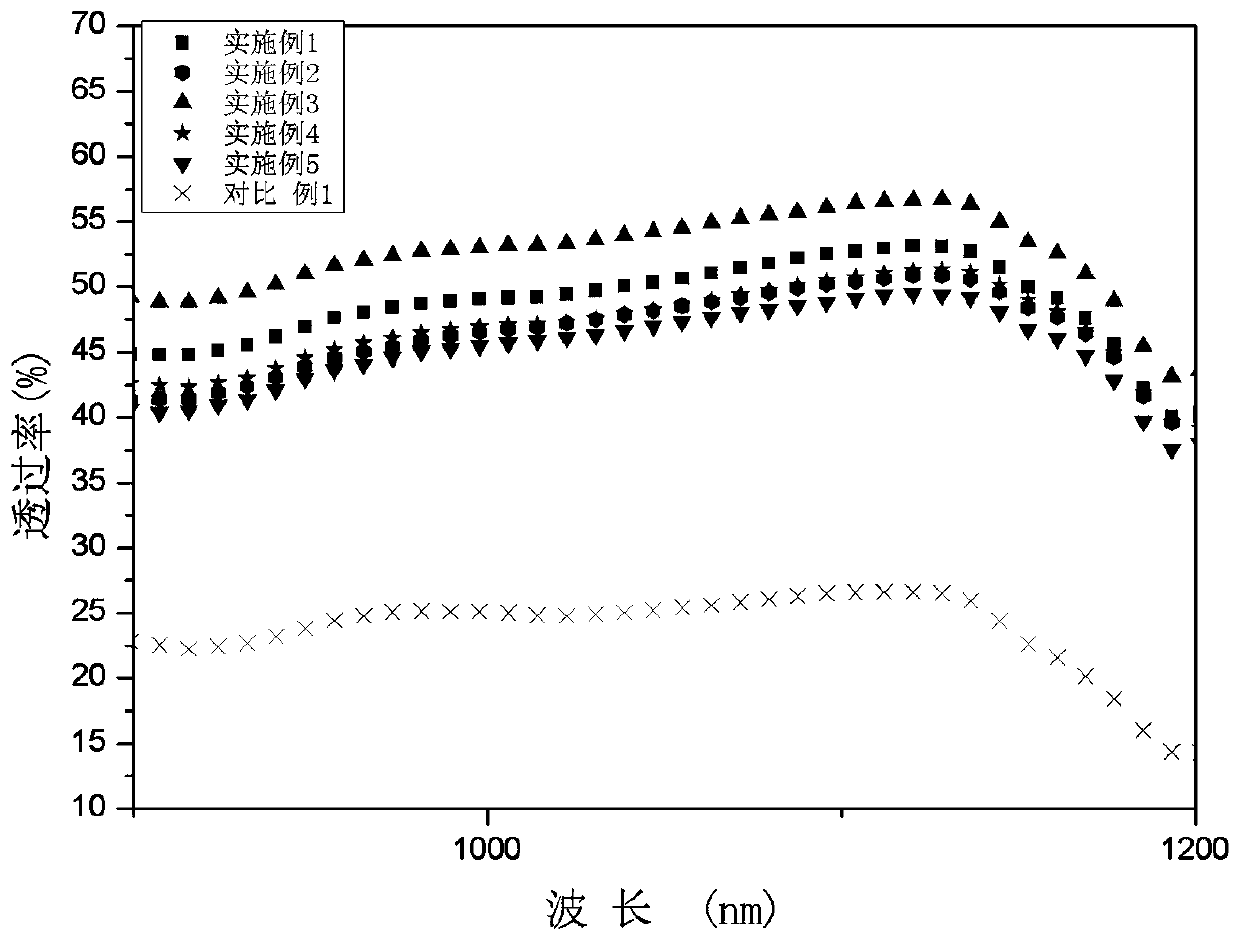

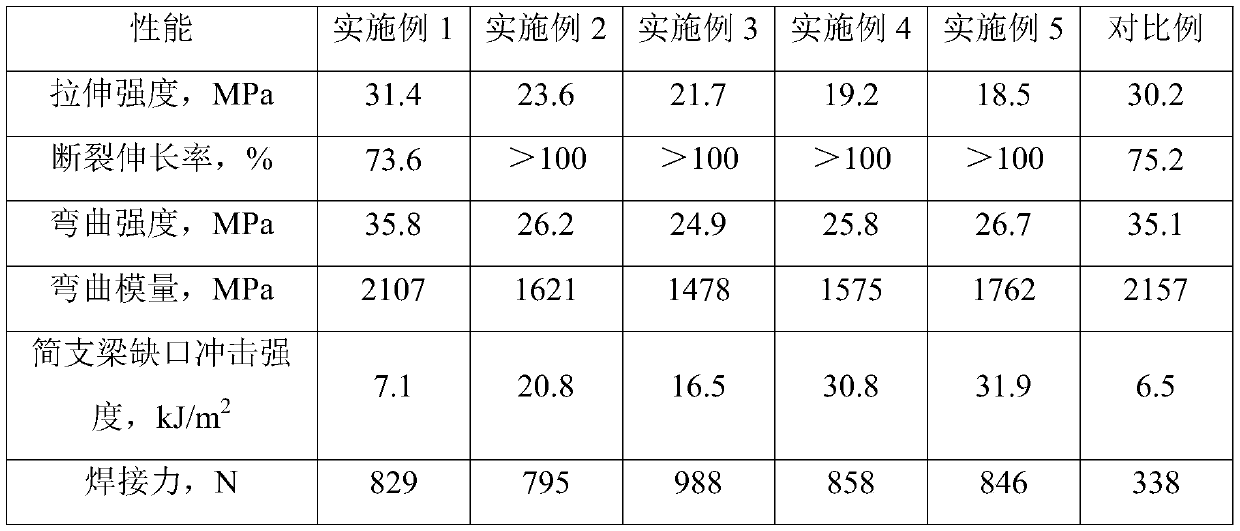

Filling modified polypropylene material and preparation method thereof

The invention relates to a filling modified polypropylene material and a preparation method thereof. The filling modified polypropylene material comprises the following components: co-polypropylene, aflexibilizer A, a flexibilizer B, mica powder, an antioxidant, a light stabilizer and a lubricant. Compared with the prior art, the polypropylene material has good permeability to 900-1100nm near-infrared light and can meet the requirements of laser welding; and more materials with different properties and good laser welding strength can be achieved through formula design due to the addition of the mica powder and the flexibilizer B, the performance bottleneck is broken through and the application field of the laser welding technology in plastic parts on automobiles is greatly broadened.

Owner:SHANGHAI KINGFA SCI & TECH +1

Rubberized fiber material and pneumatic tire

InactiveUS7597128B2Small differenceGood rigidity balanceSpecial tyresPneumatic tyre reinforcementsFiberPolymer science

Owner:BRIDGESTONE CORP

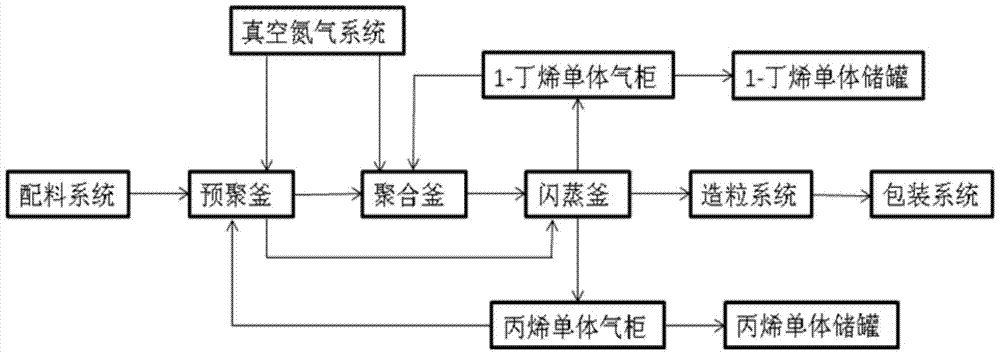

A kind of industrial production method and device of high isotactic polybutene alloy

The application discloses an industrial production method and device for a highly isotactic polybutylene alloy. The production method comprises the following steps: firstly polymerizing propylene in a prepolymerization kettle at -20 to 90 DEG C to form polypropylene particles loaded with active centers, carrying out reduced pressure recovery on the unreacted propylene monomer into a propylene monomer gas cabinet, putting polypropylene loaded with active centers and 1-butene monomer into the polymerization kettle and polymerizing at -10 to 80 DEG C to obtain a granular polybutene alloy, removing partial unreacted monomer under reduced pressure, feeding the materials in the prepolymerization kettle into a flash kettle to further remove unreacted 1-butene, sequentially introducing nitrogen into the flash kettle for replacing air, discharging the granular isotactic polybutene alloy from a discharge valve arranged at the bottom of the kettle, extruding and packaging. The production device comprises a batching system, a polymerization system, a post-treatment packaging system, a vacuum nitrogen system, a degassing flash system and a utility system. By the method and the device, the industrialized synthesis of the polybutylene alloy can be achieved and the method has the advantages of no organic solvent and no waste emissions and belongs to the scope of environment-friendly clean production.

Owner:QINGDAO UNIV OF SCI & TECH +2

A kind of resin composition for transparent antistatic ic packaging tube

ActiveCN108395638BStable extrusion processSuitable for large-scale productionPolymer scienceButadiene Dioxide

Owner:KINGFA SCI & TECH CO LTD

A kind of polypropylene composition and polypropylene material and application thereof

The present invention relates to the field of polymers, particularly to a polypropylene composition, a polypropylene material, and applications of the polypropylene composition and the polypropylene material, wherein the polypropylene composition contains, by weight, 64-90% of random co-polypropylene, 9-35% of a polyolefin elastomer, and 0.2-1.5% of an antioxidant. According to the present invention, the polypropylene material has advantages of good fluidity, good shrinkage, rigidity and toughness balance, heat aging resistance and environmental aging resistance, and cannot produce stress whitening after bending 90 DEG; and the polypropylene composition and / or the polypropylene material are particularly suitable for the preparation of pot seedling cultivation disks.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite auxiliary agent for high-density polyethylene pressure-resistant pipes, preparation method thereof, and resin raw material containing the same

ActiveCN105733023BGood environmental stress cracking resistanceImprove pressure resistanceProcedure AgentsAntioxidant

The invention provides a composite auxiliary agent for a high density polyethylene overpressure resistant tubing. The composite auxiliary agent comprises 30-50 parts by weight of a long-term ageing resistant auxiliary agent , 10-30 parts by weight of a thermal stable auxiliary agent, and 10-30 parts by weight of a processing auxiliary agent, wherein the long-term ageing resistant auxiliary agent is at least one selected from a group consisting of hindered phenols antioxidants, amines antioxidants, and phosphorus antioxidants; the thermal stable auxiliary agent is at least one selected from metal soap stabilizers; and the processing auxiliary agent comprises at least a fluoroelastomer. The invention also provides a preparation method of the composite auxiliary agent, and a high density polyethylene overpressure resistant tubing resin raw material containing the composite auxiliary agent. The high density polyethylene overpressure resistant tubing resin raw material containing the composite auxiliary agent has excellent processing performance. The formed tubing has excellent environmental stress crack resistance, ageing resistance, and rigidity-toughness balance.

Owner:PETROCHINA CO LTD

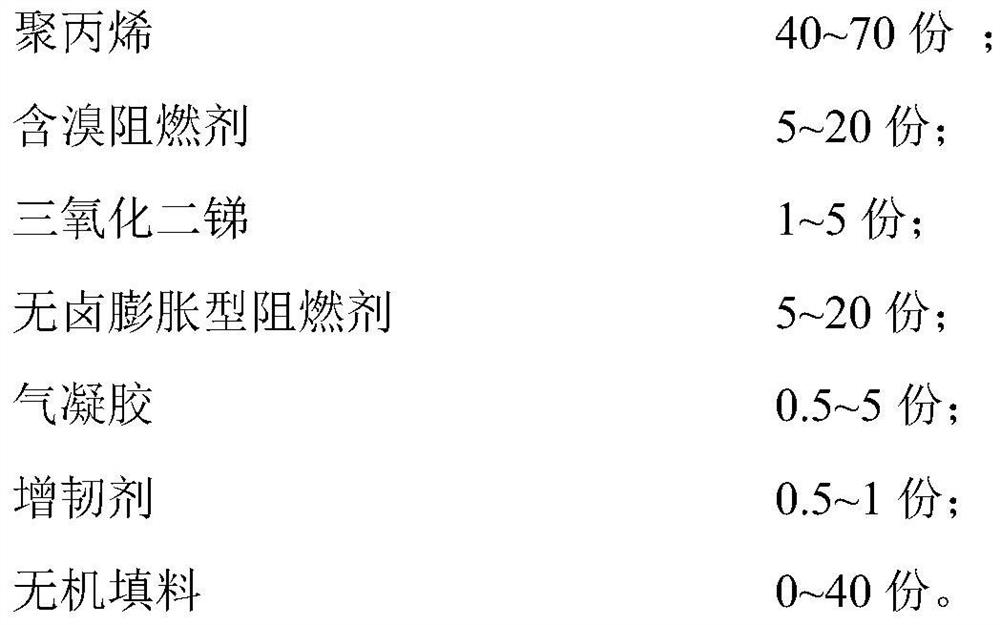

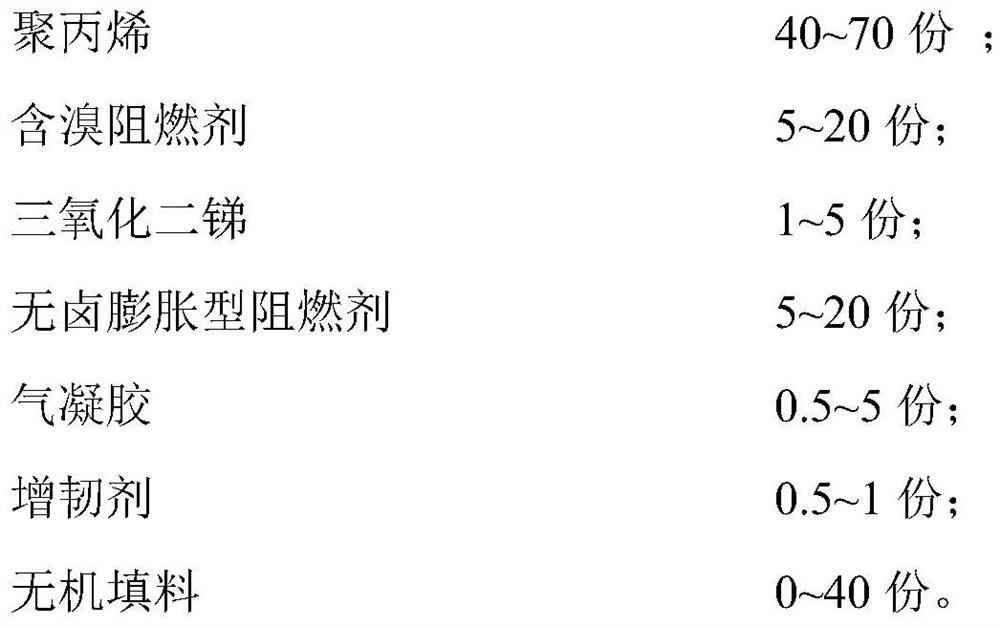

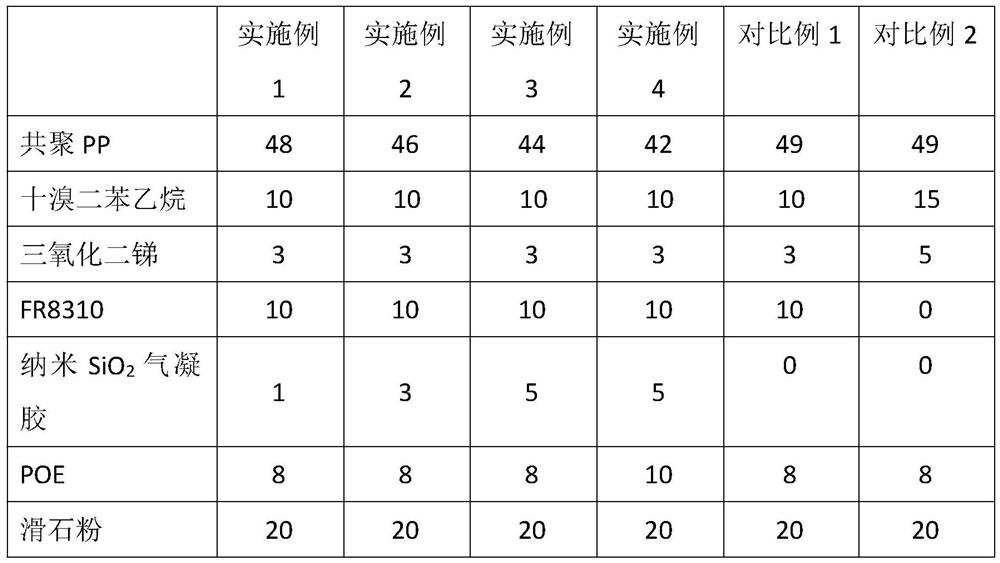

High-impact flame-retardant polypropylene composite material for passenger car interior decoration and preparation method of high-impact flame-retardant polypropylene composite material

The invention belongs to the technical field of polymer flame retardance, and particularly relates to a high-impact flame-retardant polypropylene composite material for passenger car interior decoration and a preparation method of the high-impact flame-retardant polypropylene composite material. The high-impact flame-retardant polypropylene composite material is specifically prepared from the following raw materials in parts by weight: 40-70 parts of polypropylene, 5-20 parts of bromine-containing flame retardant, 1-5 parts of antimony trioxide, 5-20 parts of halogen-free intumescent flame retardant, 0.5-5 parts of aerogel powder, 0-15 parts of flexibilizer. and 0-40 parts of an inorganic filler. The flame-retardant polypropylene composite material obtained by the technical scheme of the invention has excellent mechanical properties, and the toughening agent is added, so that the material has excellent impact resistance, and can be used for parts such as instrument boards, stand columns and the like which need to be blasted; by adopting the nanoscale SiO2 aerogel, smoke in the combustion process of the composite material can be adsorbed, SiO2 can also play a role of a flame-retardant synergist and catalyze charring, the oxygen index and smoke density of flame-retardant polypropylene are synergistically improved, and the flame-retardant polypropylene can be used for passenger car interior materials.

Owner:SHANGHAI PRET COMPOSITES +3

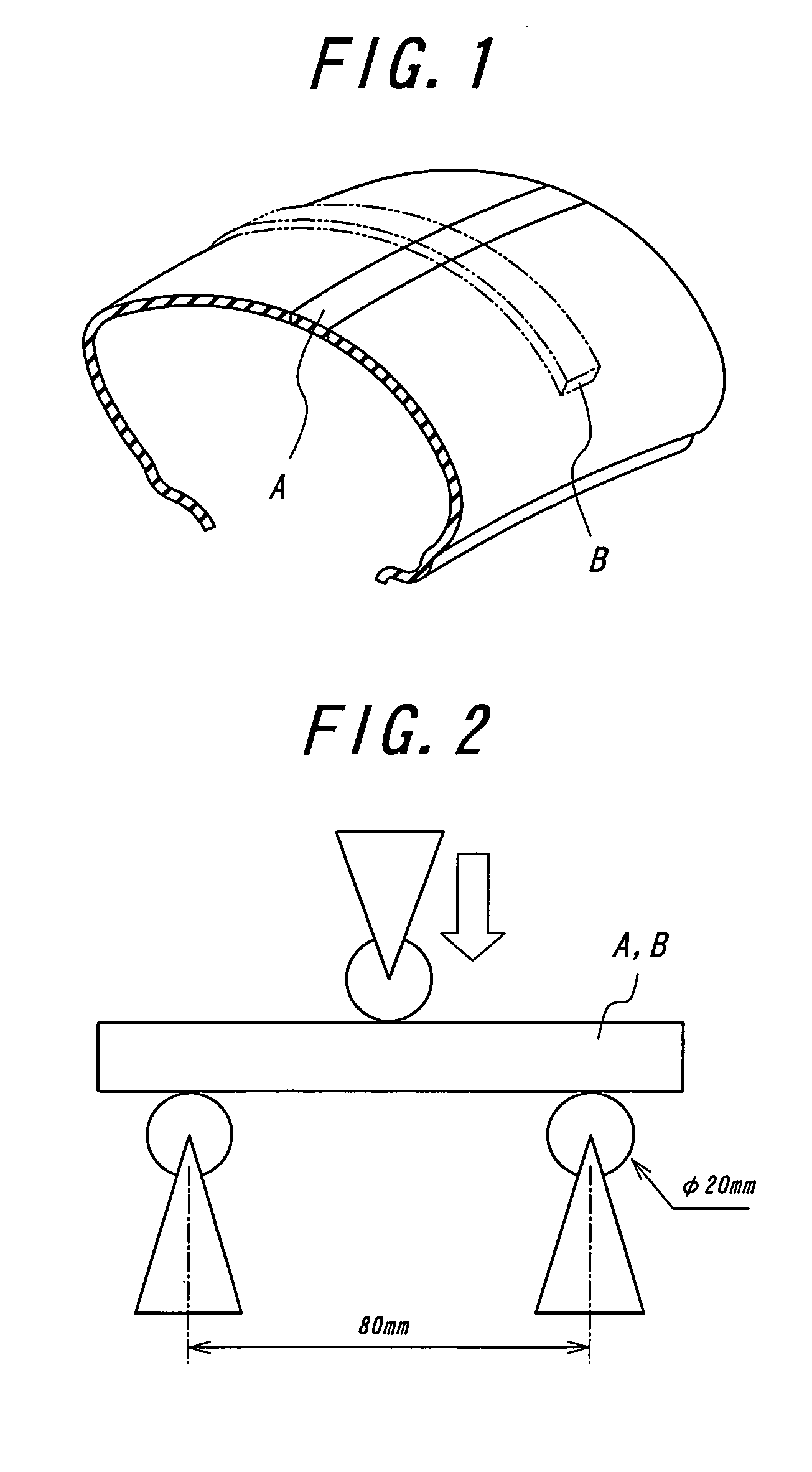

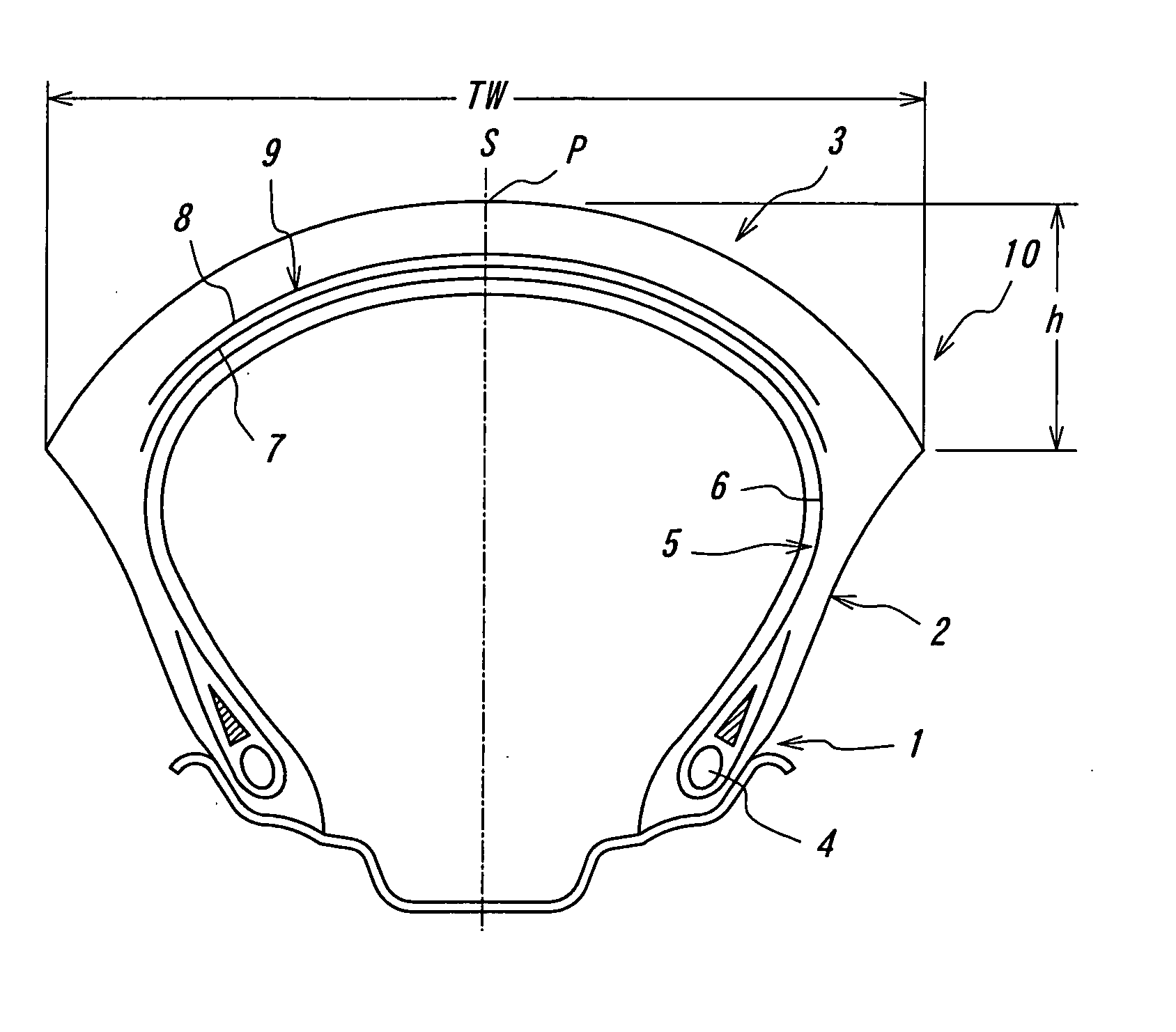

Pneumatic radial tire for motorcycle

InactiveUS20050205188A1Lowering straight-running stabilityGood rigidity balancePneumatic tyre reinforcementsMotorcycle tyresIn planeCamber angle

There is provided a pneumatic radial tire for a motorcycle capable of developing an excellent steering stability in a high-speed cornering subjected to a large camber angle, and having an aspect ratio of 0.50-0.85, in which a tensile strength at break of a carcass ply cord is not less than 980 MPa, and an absolute value of a carcass total rigidity obtained by adding carcass rigidities of carcass plies is not less than 30000, and a tensile strength at break of a belt layer cord is not less than 2350 MPa, and an absolute value of a belt total rigidity obtained by adding belt rigidities of belt layers is not less than 170000, and an out-of-plane bending rigidity in widthwise direction of a tread portion is 0.40-0.70 kg / mm and an in-plane bending rigidity in peripheral direction thereof is 0.05-0.15 kg / mm and a bending rigidity ratio as a ratio of out-of-plane bending rigidity to in-plane bending rigidity is within a range of 4.20-9.10.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com