Resin composition for transparent anti-static IC packaging tube

A resin composition and antistatic technology, which is applied in the field of transparent antistatic IC packaging tubes, can solve the problems of expensive raw materials, low modulus, and high difficulty in extrusion molding, and achieve stable extrusion production process and good antistatic Effect, the effect of a good balance of rigidity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

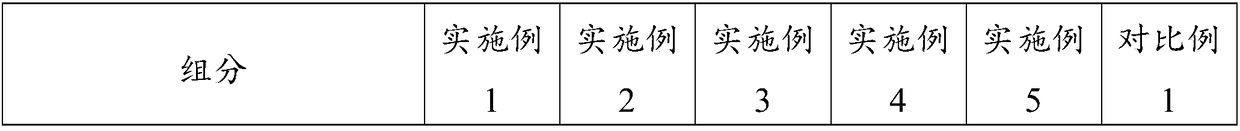

Embodiment 1

[0033] An embodiment of the transparent antistatic IC packaging tube resin composition of the present invention, in this embodiment, the refractive index of the methyl methacrylate-styrene resin is 1.54, and the styrene-butadiene The refractive index of the copolymer is 1.56. In the methyl methacrylate-styrene resin, the molar ratio of methyl methacrylate to styrene monomer is: methyl methacrylate: styrene=1:1, so In the styrene-butadiene copolymer, the molar ratio of styrene to butadiene monomer is: styrene:butadiene=1:1. The composition of the transparent antistatic IC packaging tube resin composition is shown in Table 1.

Embodiment 2

[0035] An embodiment of the transparent antistatic IC packaging tube resin composition of the present invention, in this embodiment, the refractive index of the methyl methacrylate-styrene resin is 1.56, and the styrene-butadiene The refractive index of the copolymer is 1.57. In the methyl methacrylate-styrene resin, the molar ratio of methyl methacrylate to styrene monomer is: methyl methacrylate: styrene=3:7, so In the styrene-butadiene copolymer, the molar ratio of styrene to butadiene monomer is: styrene:butadiene=7:3. The composition of the resin composition for the transparent antistatic IC packaging tube described in this embodiment is shown in Table 1.

Embodiment 3

[0037] An embodiment of the transparent antistatic IC packaging tube resin composition of the present invention, in this embodiment, the refractive index of the methyl methacrylate-styrene resin is 1.56, and the styrene-butadiene The refractive index of the copolymer is 1.57. In the methyl methacrylate-styrene resin, the molar ratio of methyl methacrylate to styrene monomer is: methyl methacrylate: styrene=3:7, so In the styrene-butadiene copolymer, the molar ratio of styrene to butadiene monomer is: styrene:butadiene=7:3. The composition of the resin composition for the transparent antistatic IC packaging tube described in this embodiment is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com