Patents

Literature

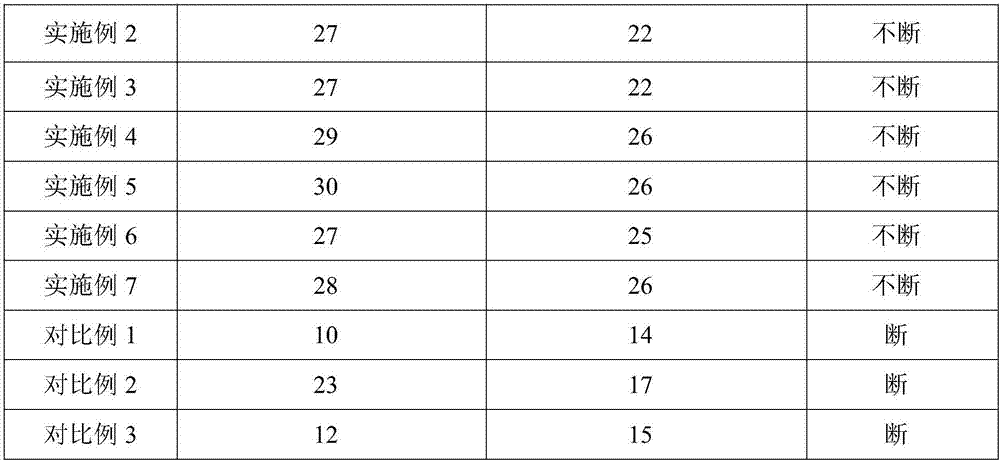

88results about How to "Improve low temperature impact performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

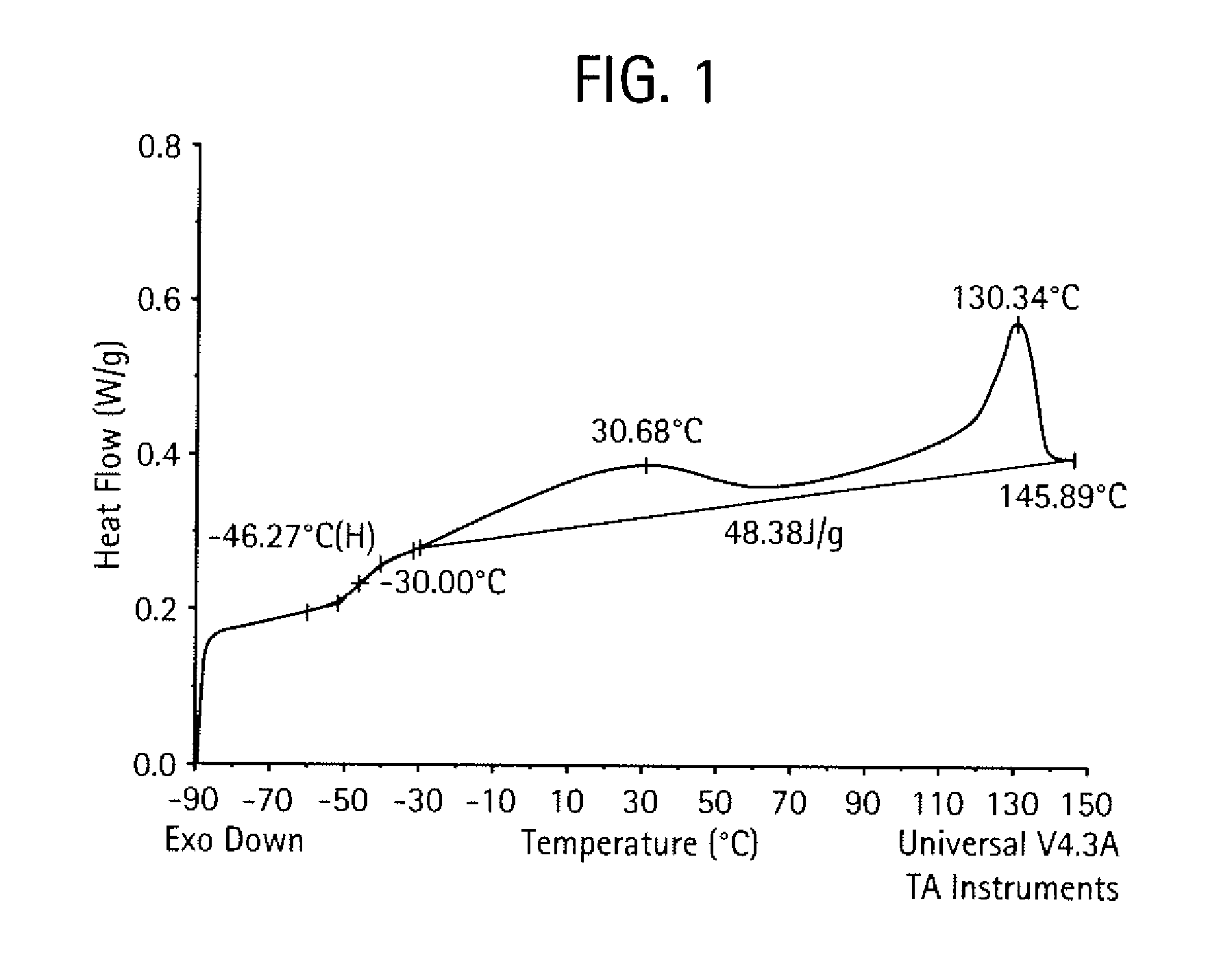

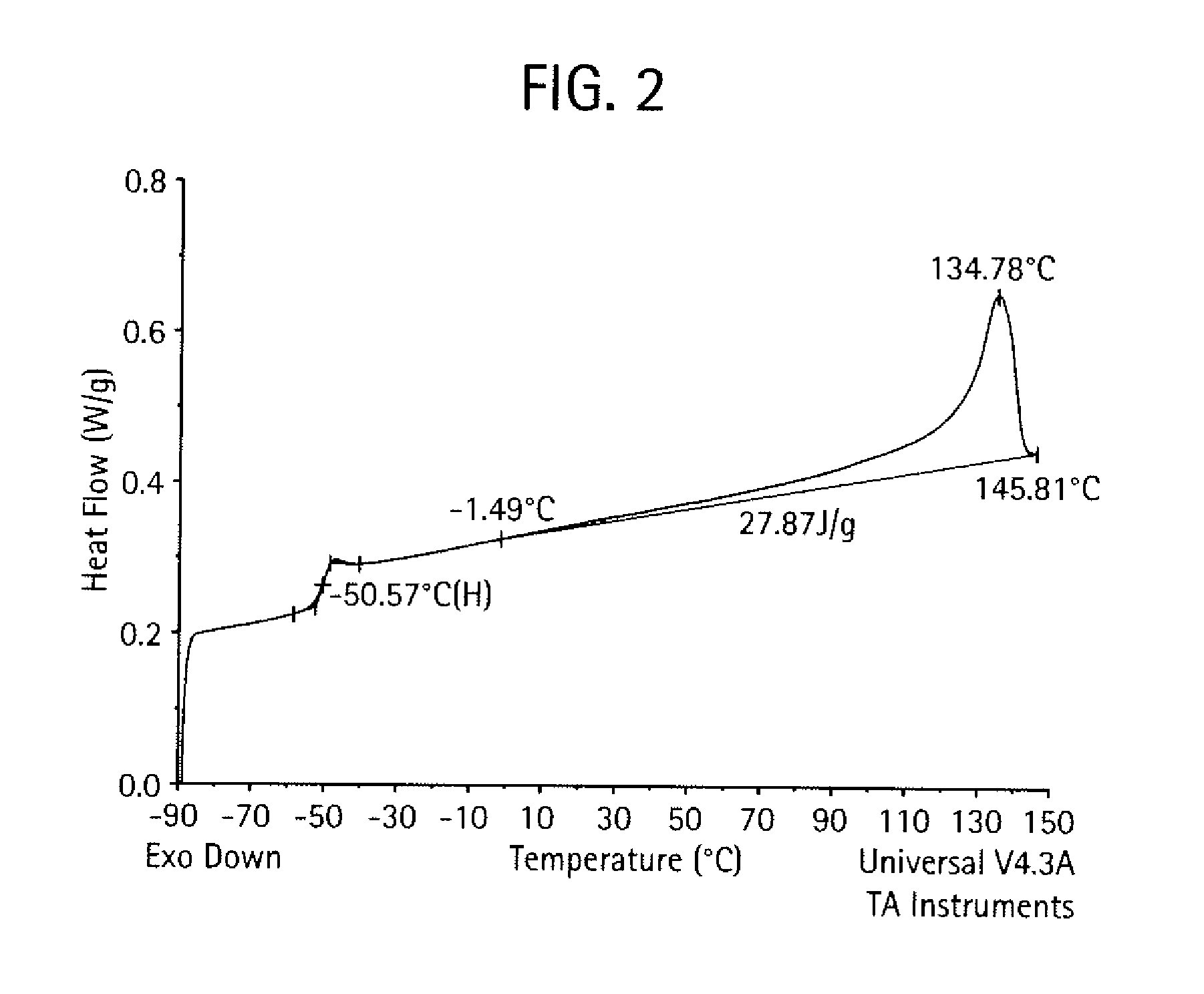

Block composites in soft compounds

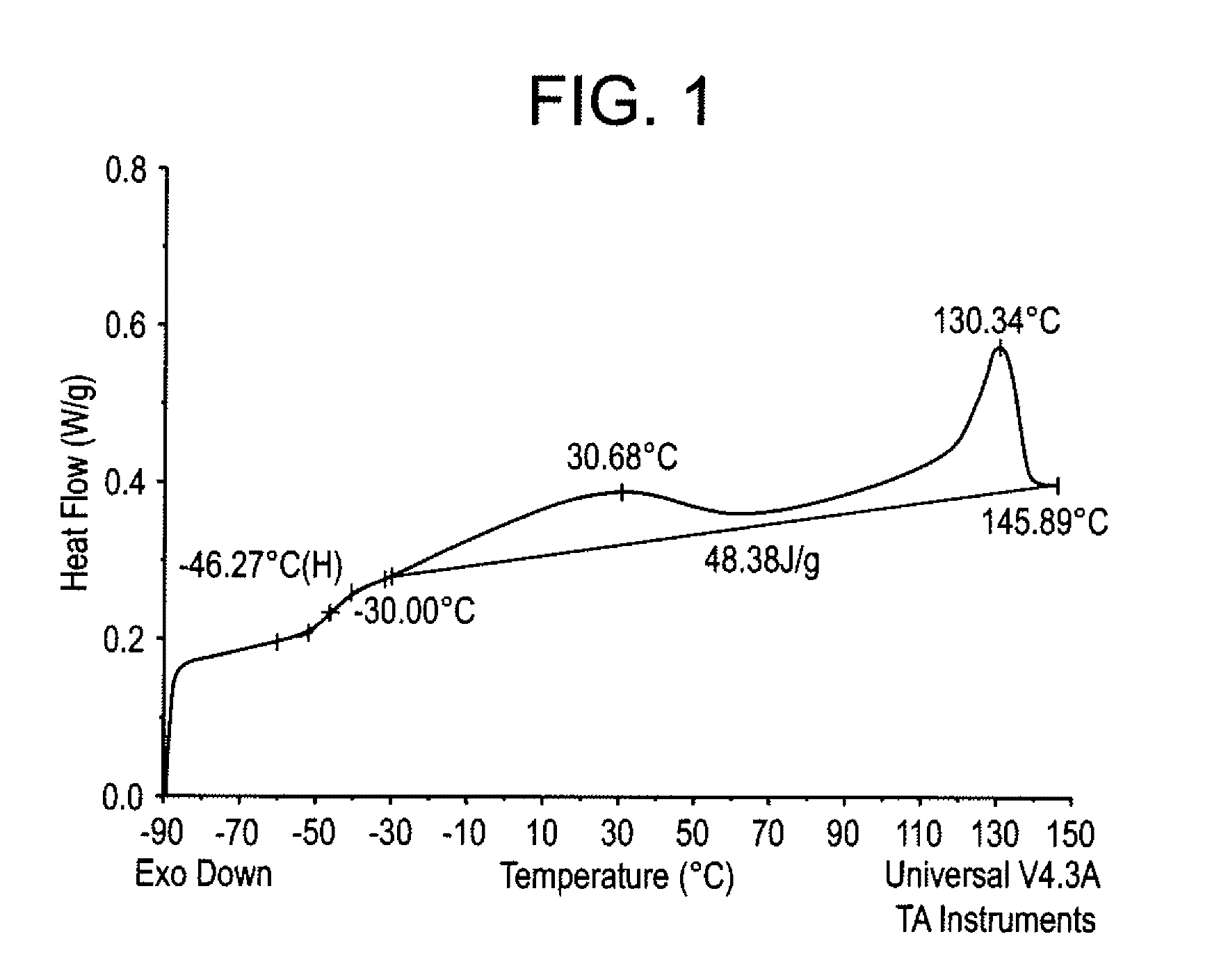

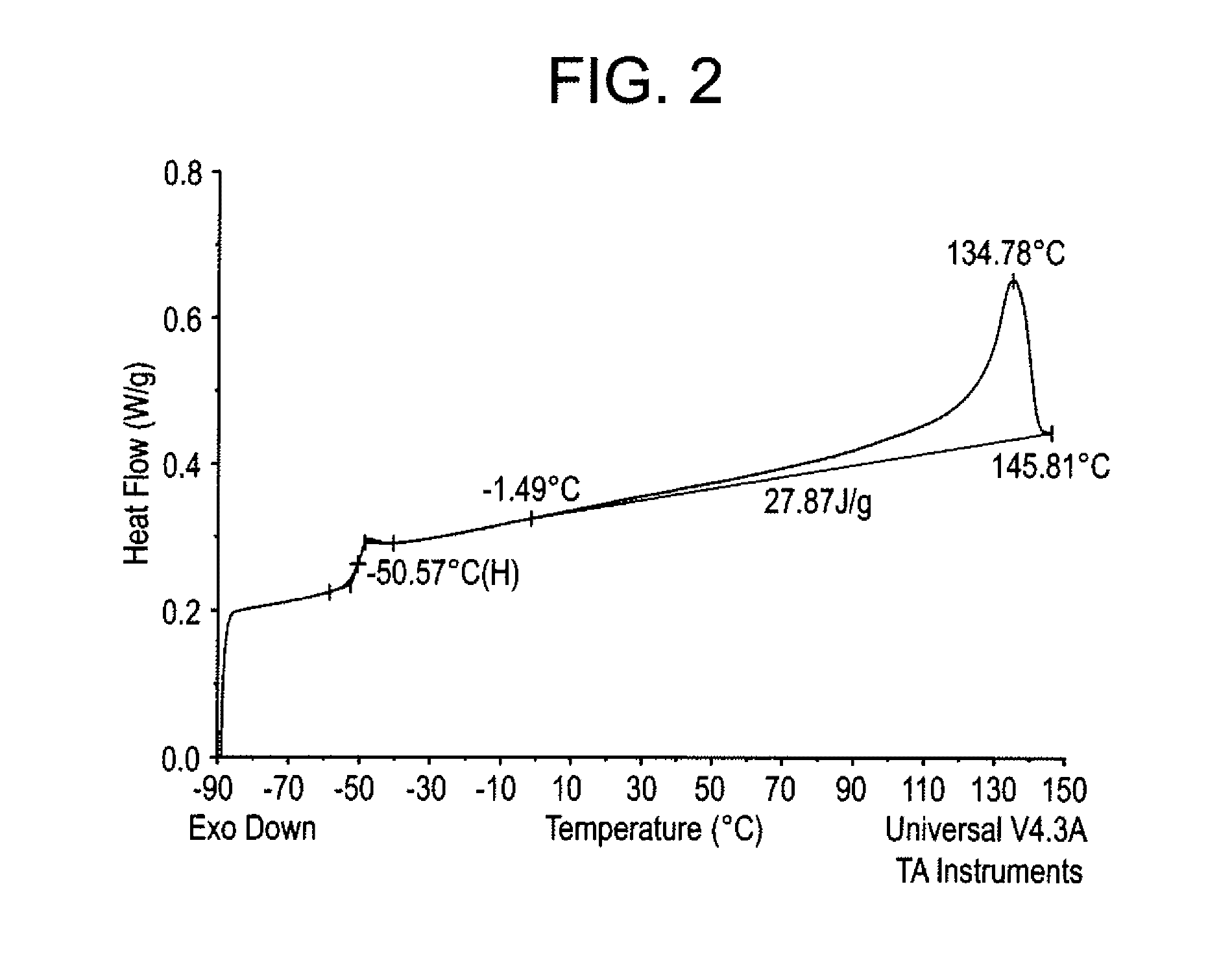

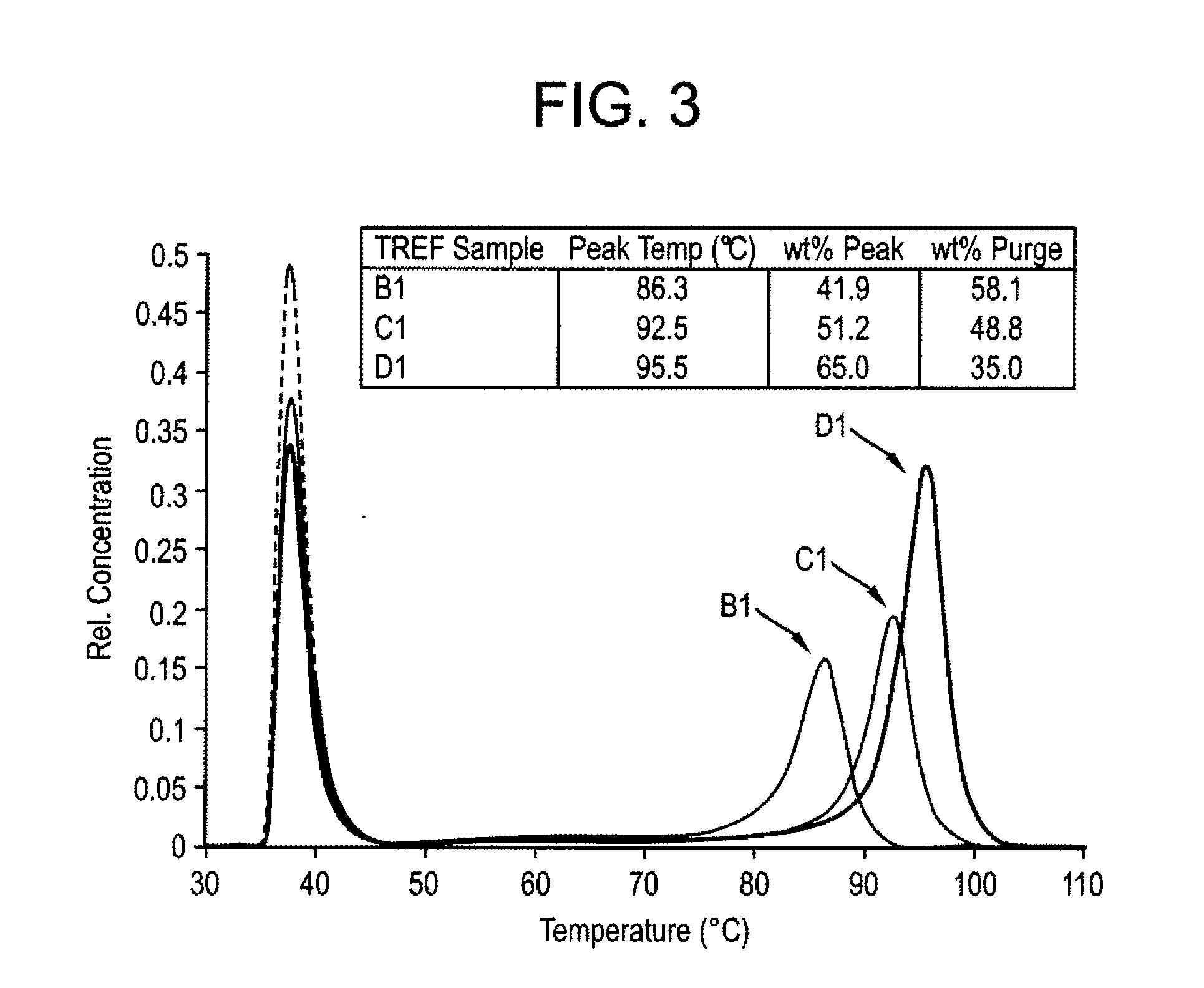

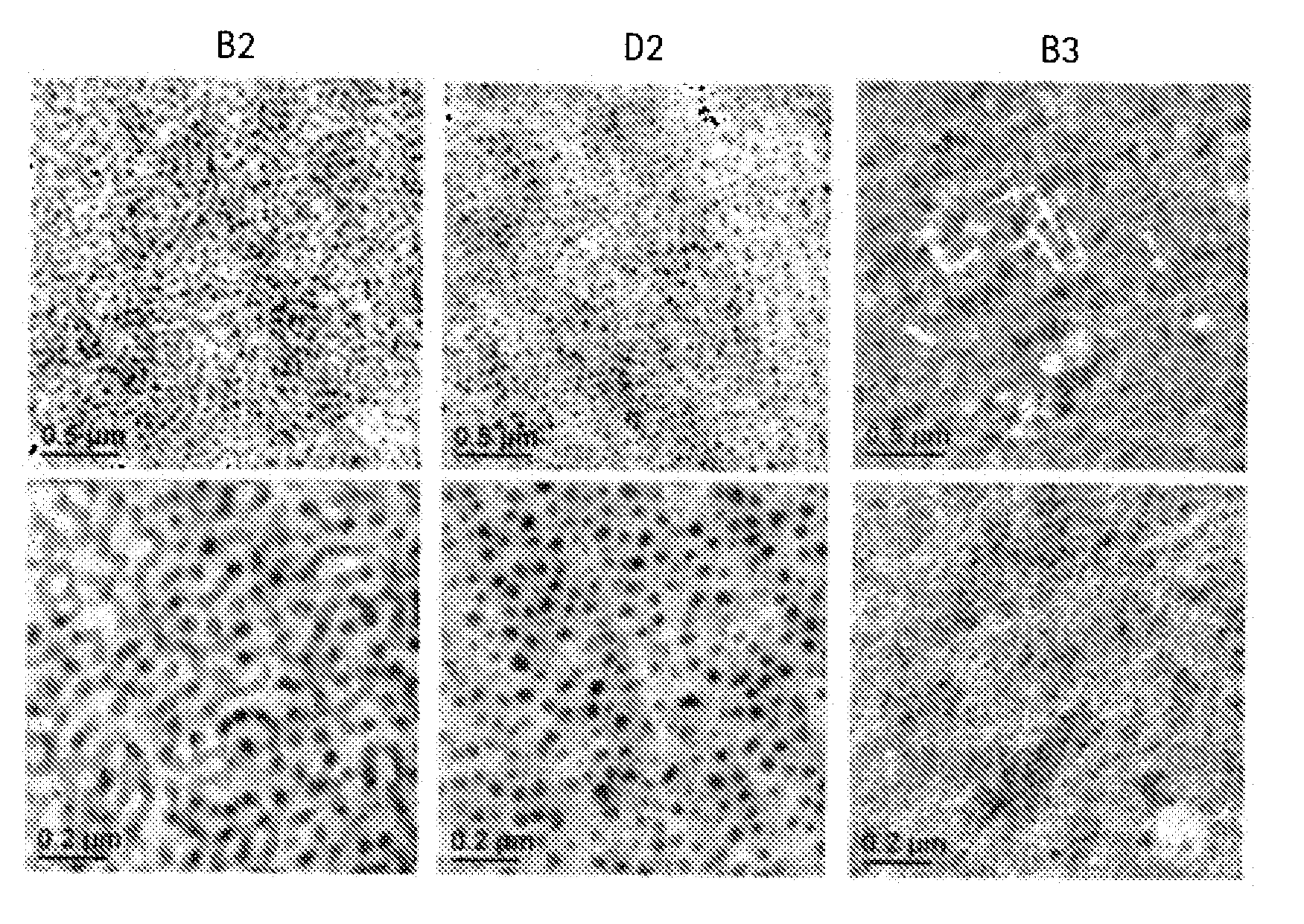

ActiveUS20110082249A1Improve low temperature impact performanceModulus improvementFilm/foil adhesivesMixingMaterials science

Owner:DOW GLOBAL TECH LLC

Block composites and impact modified compositions

Owner:DOW GLOBAL TECH LLC

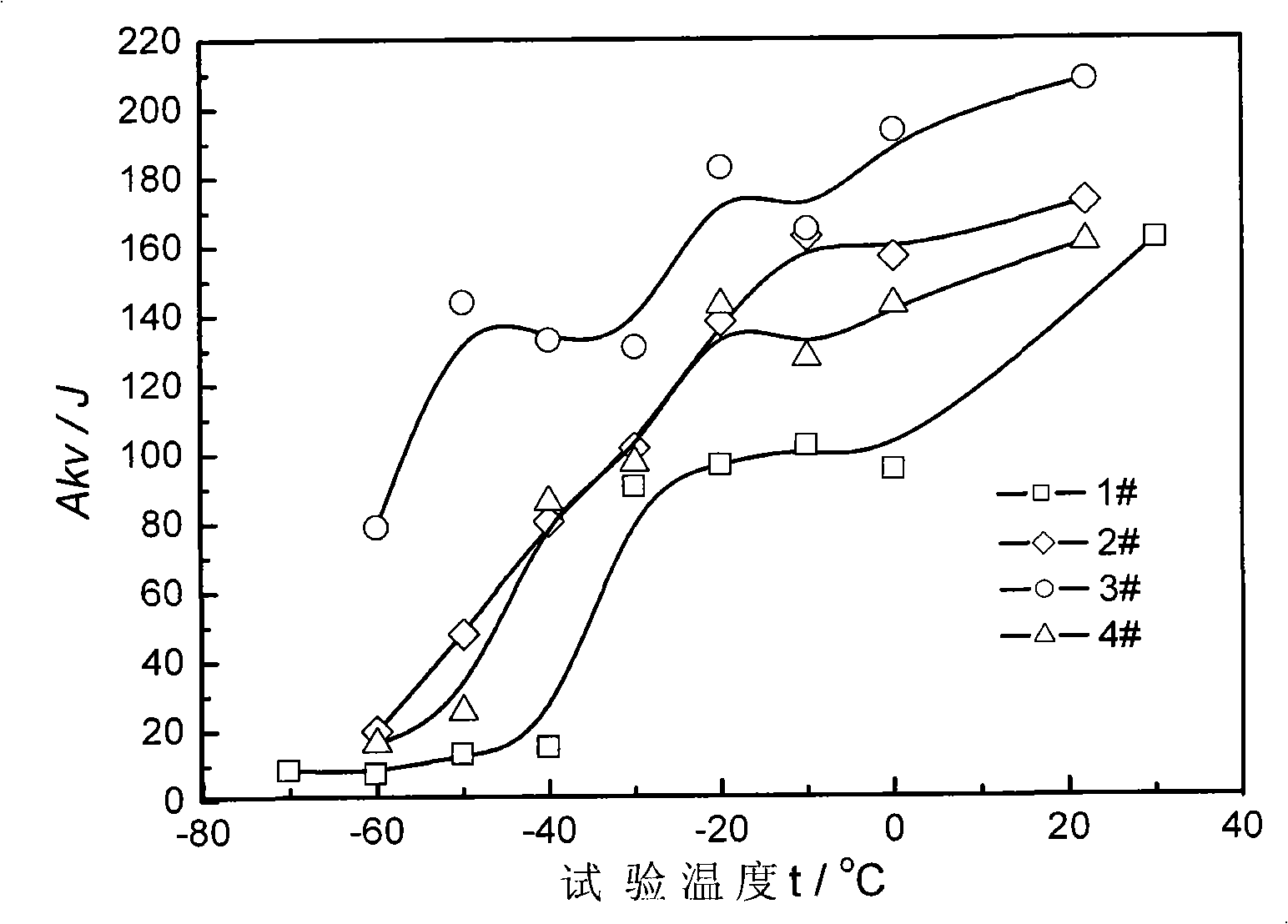

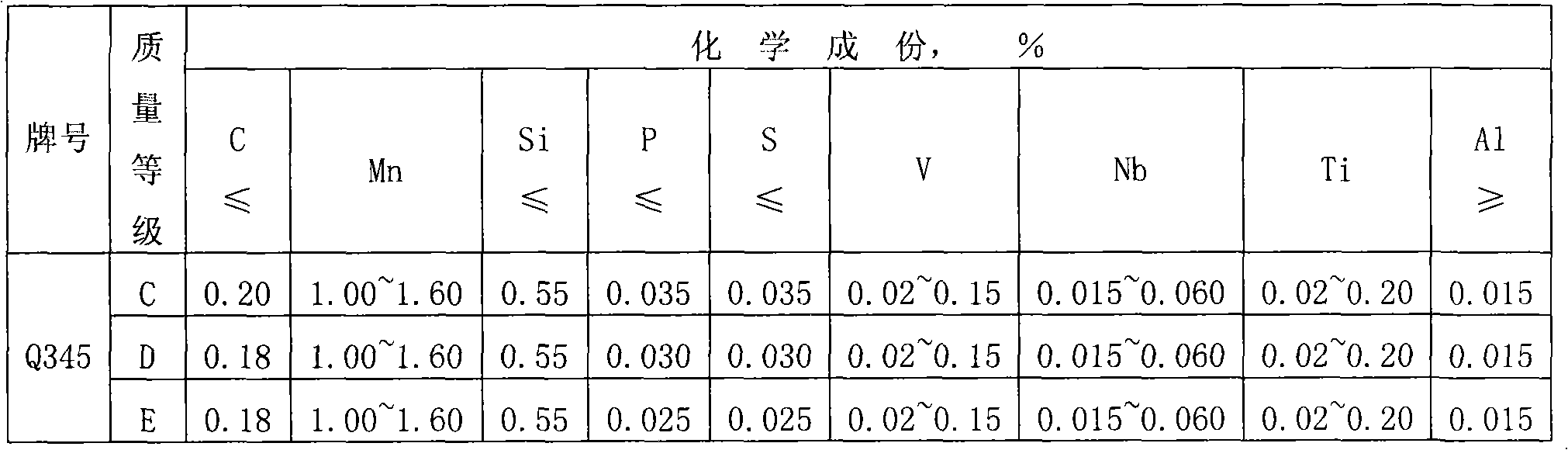

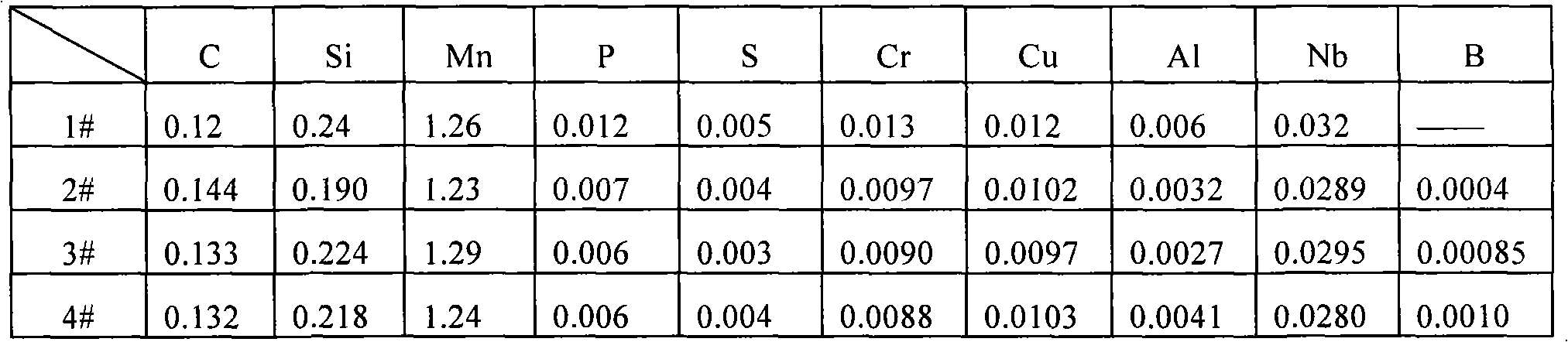

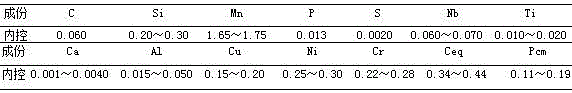

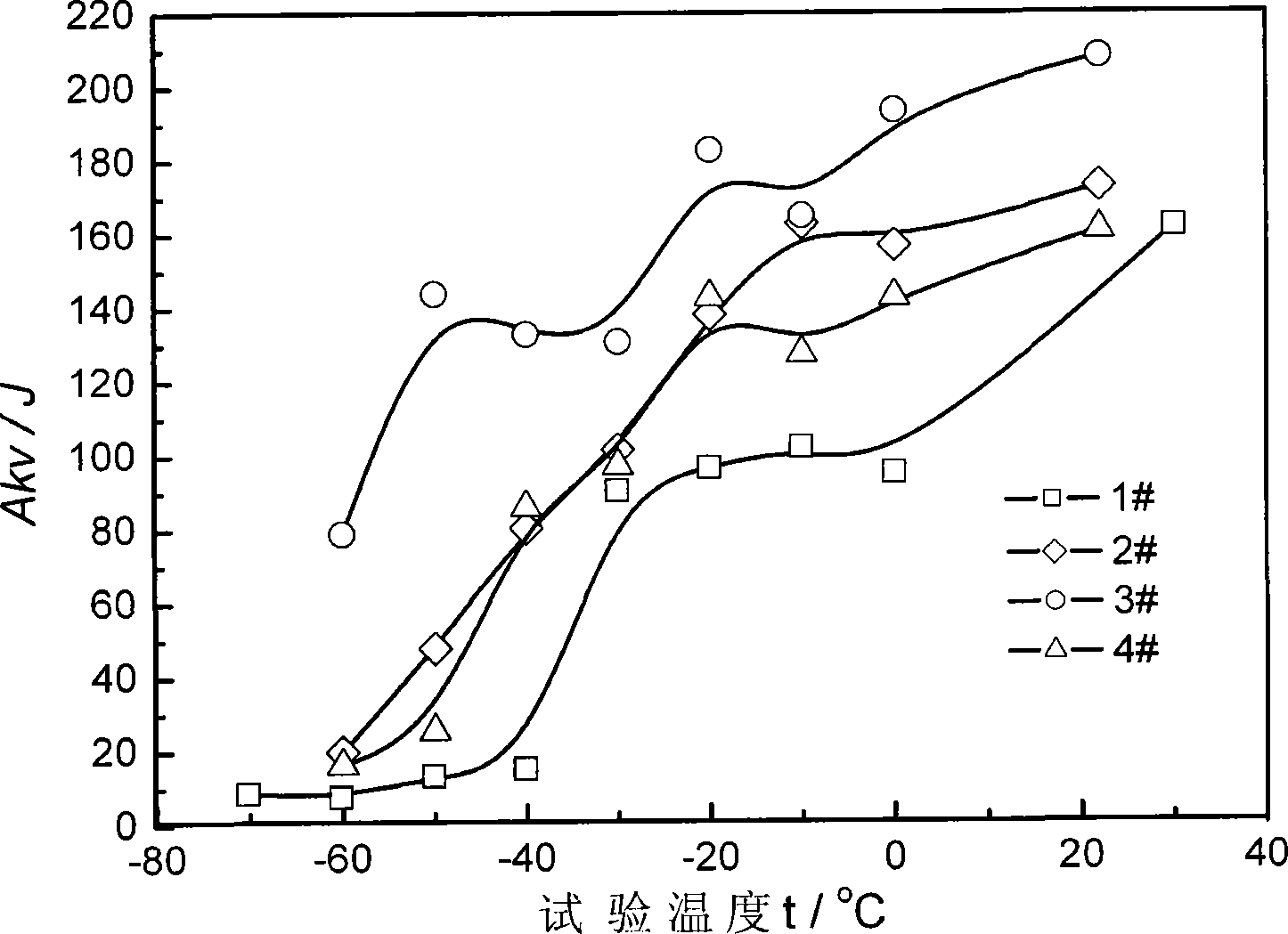

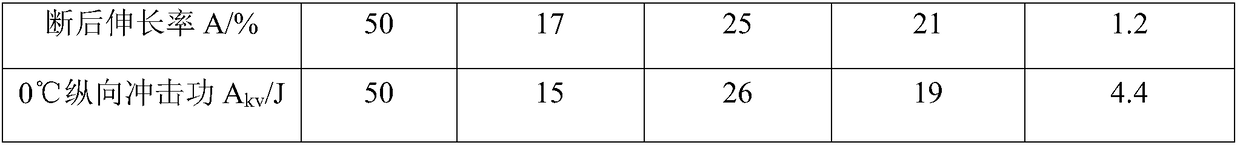

Boron-modified H-shape steel having well low-temperature impact flexibility and preparation method thereof

InactiveCN101255527AImprove mechanical propertiesImproved low temperature impact propertiesMetallurgyBoron

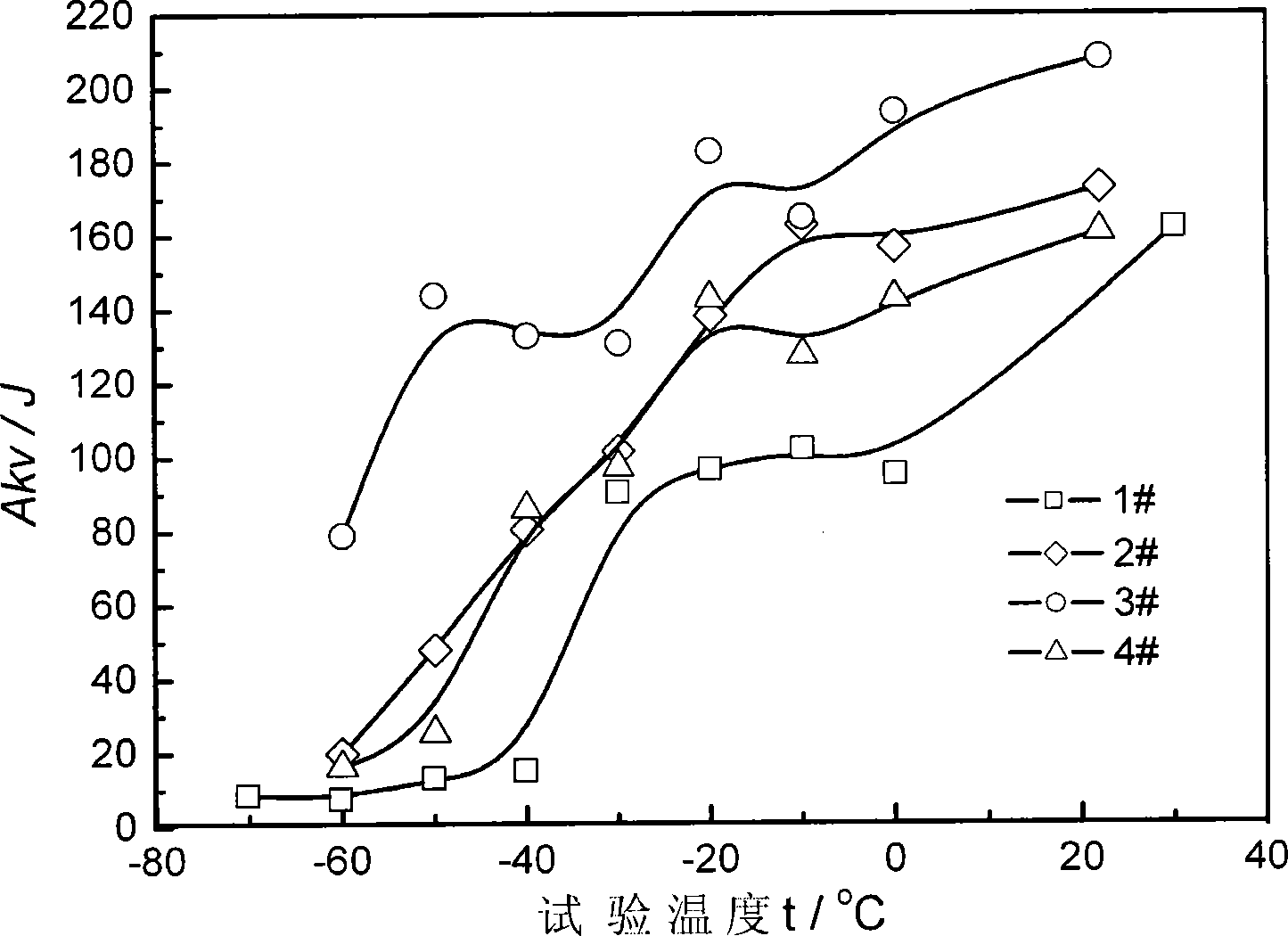

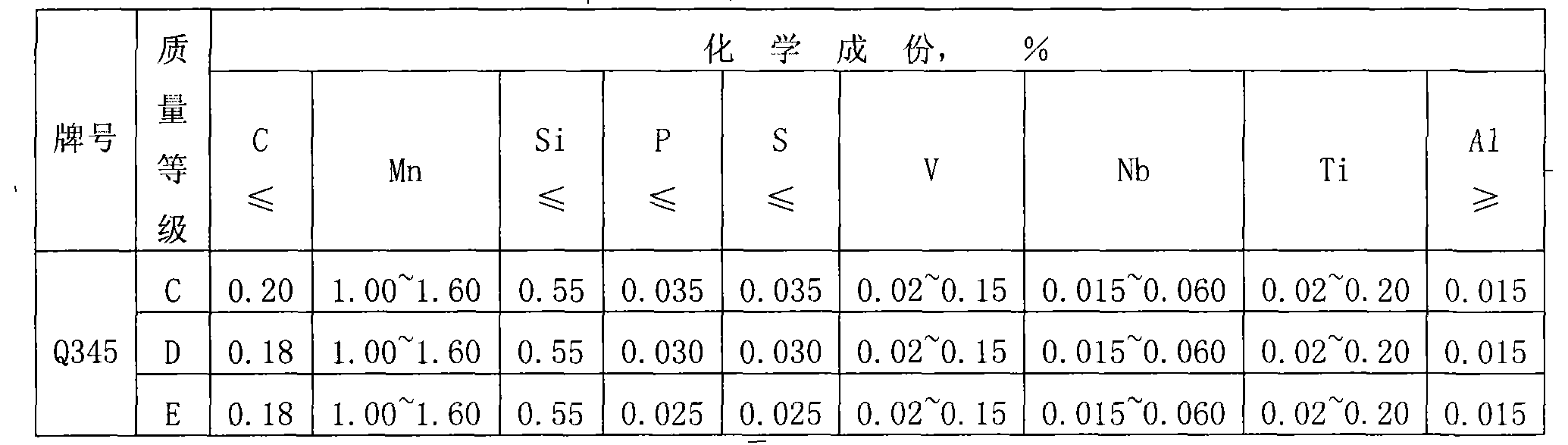

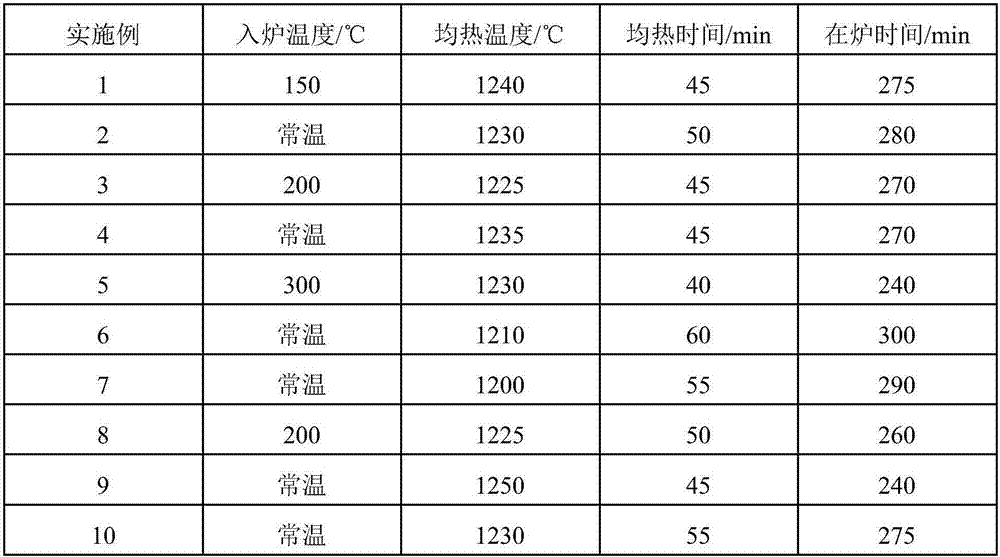

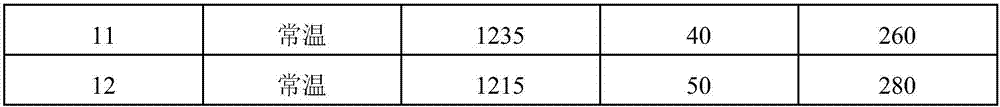

The invention relates to a boron-modified H type steel having good low-temperature impact toughness and the preparing method thereof. The steel is composed of 0.08 to 0.20 by weight percentage of C, 1.00 to 1.60 by weight percentage of Mn, 0.10 to 0.55 by weight percentage of Si, no more than 0.25 by weigh percentage of P, no more than 0.025 by weight percentage of S, 0.015 to 0.035 by weight percentage of Nb, 0.0005 to 0.0012 by weight percentage of B, and the balance Fe and trace impurity. During melting process, the gas content is controlled: no more than 0.004% of N, and no more than 0.0085% of O. According to the invention, the low-temperature impact toughness of Q345 H type steel is greatly improved; compared with Chinese standard, -40 DEG C AKV has a large surplus, the product quality is easy to be guaranteed; the Q345 H type steel can also be applied to regions having more severe condition.

Owner:SHANDONG IRON & STEEL CO LTD

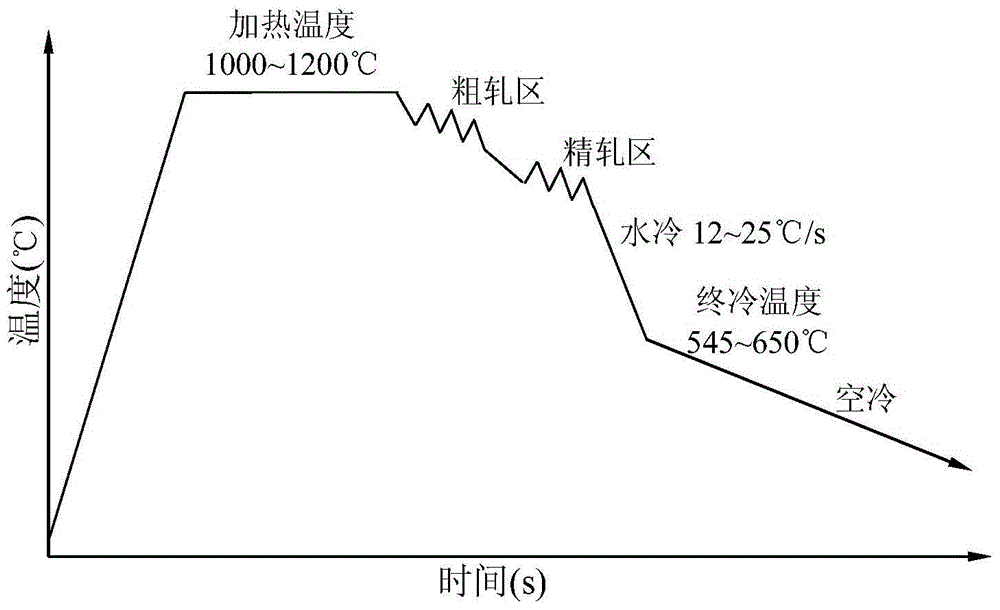

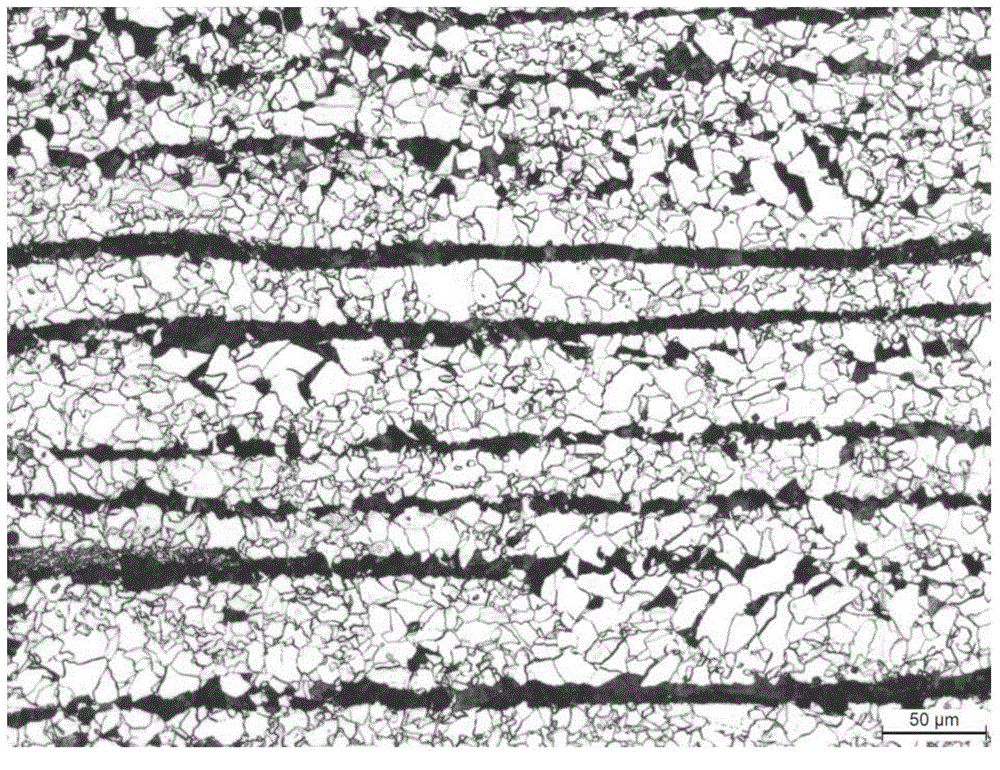

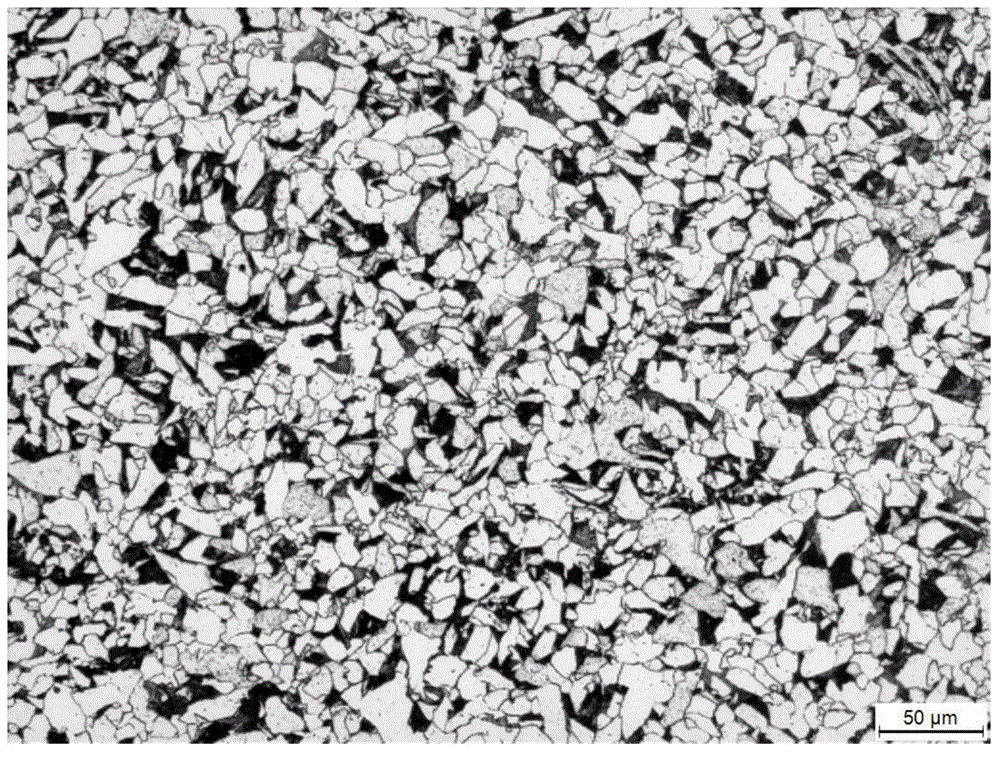

V-N microalloyed Q550 grade medium plate and preparation method thereof

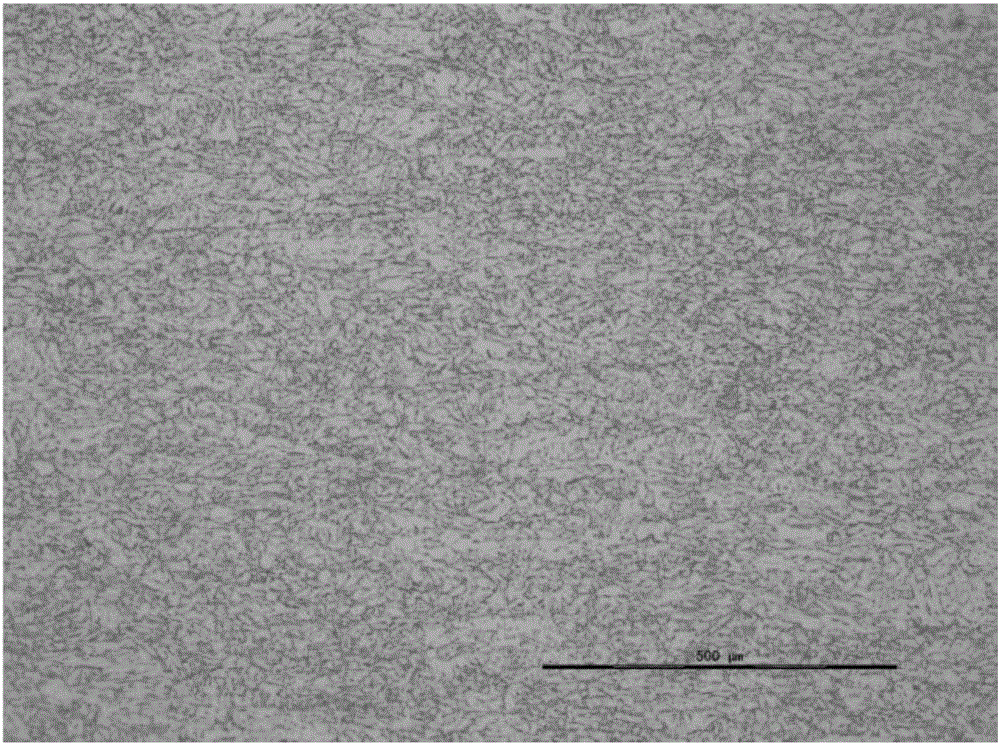

The invention aims at providing a V-N microalloyed Q550 grade medium plate and a preparation method thereof which are specific to the condition that in the prior art, the Q550 grade medium plate expensive alloy is in large consumption and the preparation process is complex. The chemical constitutions of the steel are as follows by weight percentage: 0.06 to 0.12 percent of C, 1.20 to 2.00 percent of Mn, 0.10 to 0.50 percent of Si, 0.002 to 0.01 percent of S, 0.003 to 0.01 percent of P, 0.01 to 0.05 percent of Al, 0.06 to 0.15 percent of V, 0.01 to 0.02 percent of N and the balance of Fe and other unavoidable impurities; the preparation method comprises the steps of heating a steel billet to 1000 to 1200 DEG C along with a furnace and performing heat preservation for 3 to 4 hours, and further carrying out hot rolling on the steel billet to form a hot rolled plate being 20 to 50mm in thickness, wherein the beginning temperature and the finishing temperature in a rough rolling stage are respectively 1030 to 1150 DEG C and 980 to 1020 DEG C, and the beginning temperature and the finishing temperature in a finish rolling stage are respectively 908 to 925 DEG C and 820 to 845 DEG C; cooling the plate by water to 545 to 650 DEG C after the hot rolling, and then cooling by air to room temperature. The plate is a high-toughness ultra-low-carbon medium-manganese medium plate, and the metallographic structure of the plate is a fine crystalline ferrite, a pearlite and an acicular ferrite; the method is simple in operation process, has no need of quenching and tempering treatment, and is easy to realize industrial production.

Owner:NORTHEASTERN UNIV LIAONING

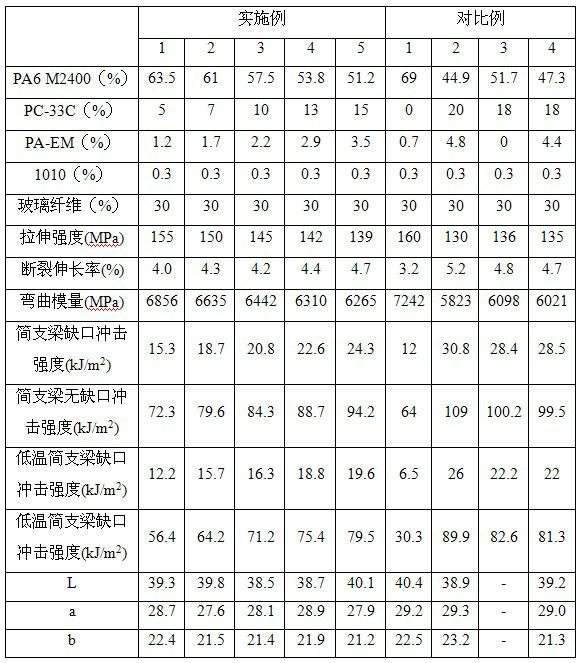

Low temperature resistance stained glass fiber reinforcement nylon 6 and preparation method thereof

ActiveCN102492293AImprove low temperature impact performanceImprove low temperature resistanceGlass fiberPolymer science

The invention discloses low temperature resistance stained glass fiber reinforcement nylon 6 and a preparation method thereof. The low temperature resistance stained glass fiber reinforcement nylon 6 is characterized by being composed of 40-75% of nylon 6, 15-35% of glass fibre, 5-20% of flexibilizer, 0.5-5% of composite dye and 0.1-0.5% antioxygen according to percentages by weight. The preparation method comprises enabling the nylon 6, the flexibilizer, the composite dye and the antioxygen to be evenly mixed and added in a twin-screw extruder, enabling the glass fibre to be added at the position of a dedicated glass fibre port, and cooling, dying and sized dicing after extrusion. The low temperature resistance stained glass fiber reinforcement nylon 6 has the advantages of being bright in color, even in distribution and good in property retention, has good color uniformity, has good toughening balance under normal temperature, and has excellent impact property under low temperature, and the combination property is close to natural color materials.

Owner:SHANGHAI KINGFA SCI & TECH +1

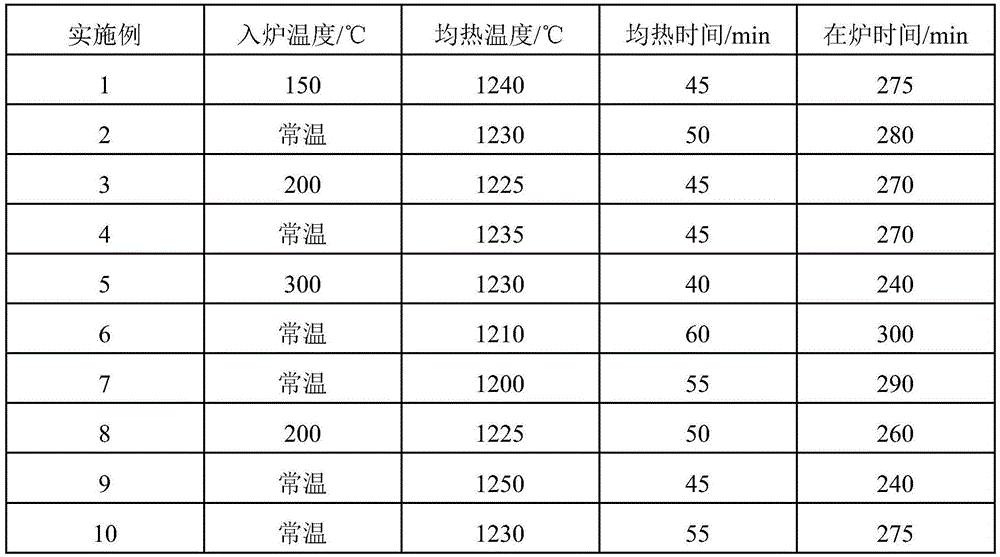

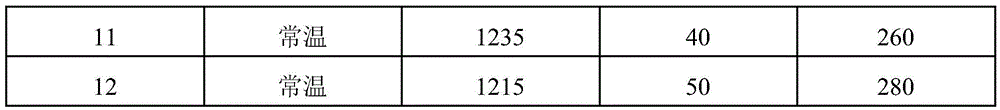

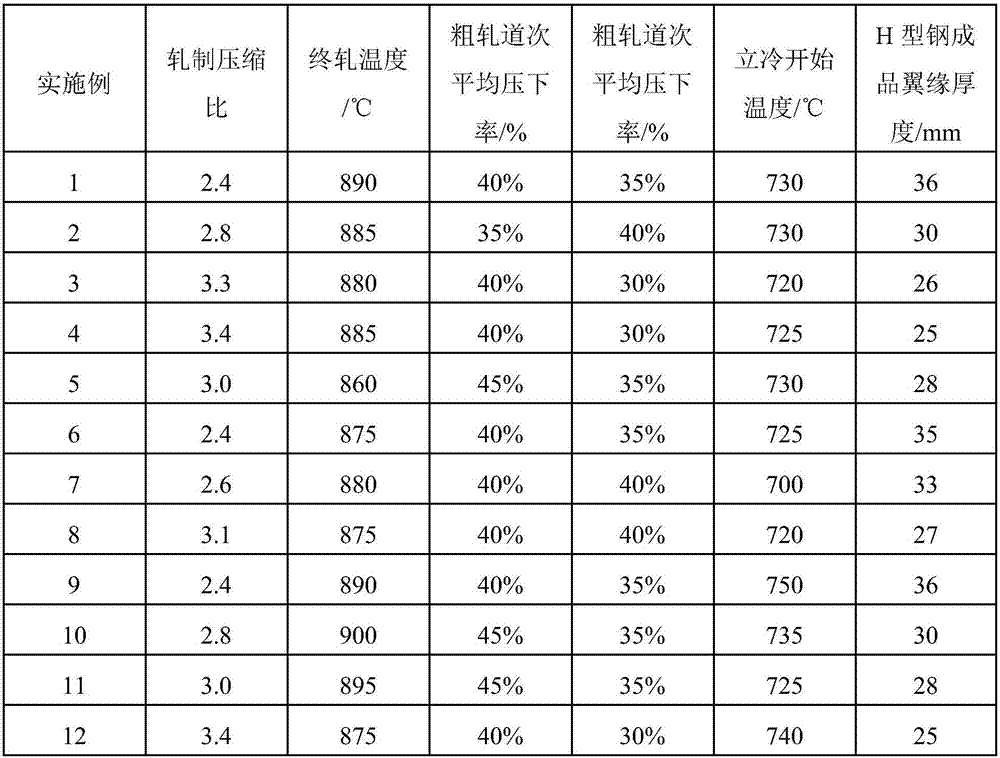

Ultra-thick hot-rolled H-shaped steel with low ductile-brittle transition temperature and production method thereof

ActiveCN105586534AImprove low temperature resistanceRaise the roughening temperatureWater coolingUltimate tensile strength

The invention belongs to the technical field of steel and particularly relates to ultra-thick hot-rolled H-shaped steel with a low ductile-brittle transition temperature and a production method thereof. The hot-rolled H-shaped steel is composed of, by mass, 0.08%-0.15% of C, 0.10%-0.40% of Si, 1.0%-1.5% of Mn, 0-0.015% of P, 0-0.008% of S, 0.020%-0.070% of V, 0.005%-0.025% of Ti, 0.006%-0.015% of N, 0.10%-0.50% of Ni, and the balance Fe and residual trace impurities. The flange thickness of the H-shaped steel is between 25 mm and 36 mm. The web height of the H-shaped steel is between 700 mm and 1000 mm. The rolling compression ratio of the H-shaped steel is lower than 3.5. The H-shaped steel is produced through a hot rolling process (instead of processes such as water cooling, ultrafast cooling and heat treatment). As for a final product, the yield strength reaches 420 Mpa or more, the tensile strength reaches 500 Mpa or more, the ductile-brittle transition temperature is lower than -65 DEG C, and the final product has good resistance to Charpy impact energy at the low temperature of -45DEG C to -65DEG C.

Owner:SHANDONG IRON & STEEL CO LTD

Block copolymers in soft compounds

InactiveUS20120208946A1Improve low temperature impact performanceModulus improvementMaterial nanotechnologyFilm/foil adhesivesMedicineCopolymer

Owner:DOW GLOBAL TECH LLC

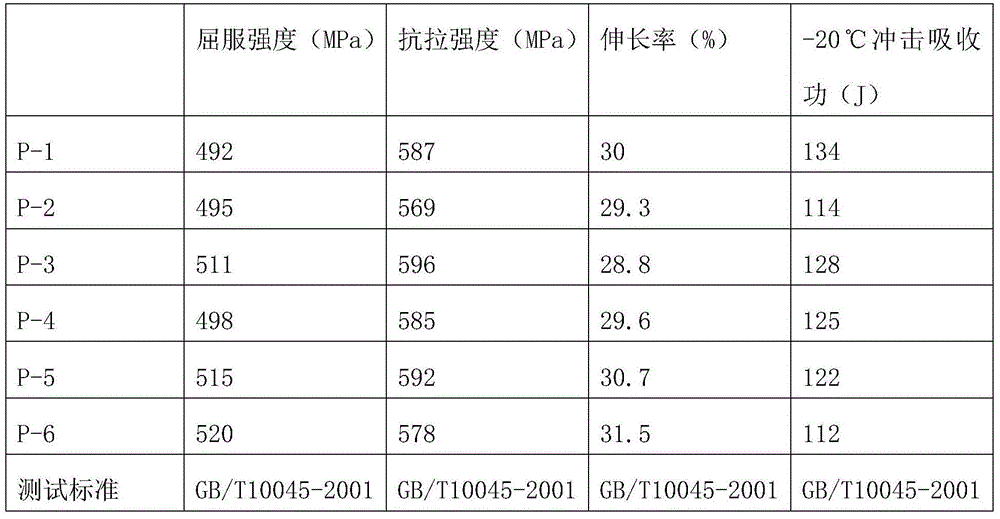

Gas shield solid welding wire for high corrosion resistance type weathering resistant steel

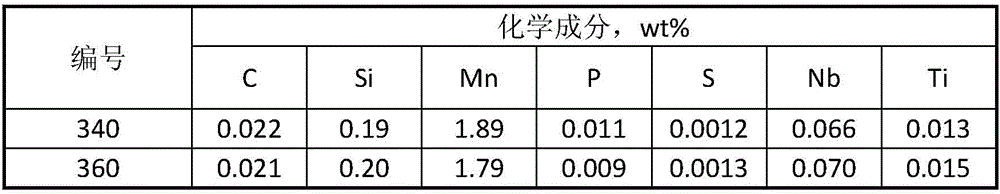

ActiveCN105234584AImprove low temperature impact performanceSolve the problem of slow melting speedArc welding apparatusVehicle componentsSheet steelChemical composition

The invention belongs to the technical field of welding materials, and particularly provides a gas shield solid welding wire for high corrosion resistance type weathering resistant steel. The gas shield solid welding wire comprises, by mass, the following chemical components of 0.01% of C or less, 0.40%-0.60% of Si, 0.5%-1.0% of Mn, 1.25%-1.55% of Cr, 3.0%-4.0% of Ni, 0.17%-0.30% of Cu, 0.02%-0.06% of Ti, 0.002%-0.006% of B, 0.005%-0.015% of S, 0.010% of P or less and the balance iron and inevitable impurities. The chemical components are reasonably designed, and therefore the gas shield solid welding wire has the beneficial effects that corrosion resistance is good, the deposited metal strength is moderate, welding joints are good in low-temperature impact toughness and attractive in forming, small splashing is achieved, and the welding technology is excellent in performance; and meanwhile rich-chlorine gas shield welding is adopted in the solid welding wire, the relative corrosion rate of the solid welding wire is smaller than or equal to 10% by taking an S450EW steel plate as a reference, and the solid welding wire can be suitable for welding of high corrosion resistance type weathering resistant steel plates of the 650MPa level.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Flange for wind power drum and manufacturing technique thereof

ActiveCN103045960APrevent precipitationGuaranteed corrosion resistanceFlanged jointsTemperingChemical composition

The invention provides a flange for a wind power drum, and a manufacturing technique thereof. The flange comprises the chemical compositions in percentage by weight: 0.15-0.22 percent of C, 0.55-0.65 percent of Si, 0.65-0.75 percent of Mn, 5-8 percent of Ni, 4-6 percent of Cr, 0.65-0.85 percent of Nb, 0.25-0.45 percent of Cu, 0.05-0.07 percent of N, 0.05-0.07 percent of Mo, 0.7-0.9 percent of Al, 0.02-0.03 percent of S, 0.08-0.09 percent of Ti, 0.01-0.04 percent of V, 0.002-0.003 percent of B, 1-2 percent of rare earth lanthanide series and the balance of Fe. According to the invention, with the heating processing procedures of two-time normalization and two-time tempering, the excellent corrosion resistance of the flange is ensured, and meanwhile, high tensile strength and high yield strength are achieved; and the flange is ensured to have smaller surface roughness, more uniform and stable tissue, and less air holes and sand holes.

Owner:WUXI HUAERTAI MACHINERY MFG

Low-carbon X80 pipeline steel plate roll and manufacturing method thereof

InactiveCN106834932AImprove welding effectImproved anti-HIC performanceChemical compositionSheet steel

The invention provides a low-carbon X80 pipeline steel plate roll. The chemical components of the low-carbon X80 pipeline steel plate roll comprise, by mass percentage (wt%), C<=0.035%, 1.60%<=Mn<=1.90%, Si<=0.30%, 0.050%<Nb<=0.075%, 0.010%<=Ti<=0.020%, 0.20%<=Mo<=0.30%, 0.20%<=Ni<=0.60%, 0.15%<=Cu<=0.30%, 0.15%<=Cr<=0.30%, S<=0.0025wt%, P<=0.0100wt%, and N<=0.0040wt%, wherein 0.60%<=Mo+Cr+Ni+Cu<=1.10%; the microscopic structure contains more than 90% of acicular ferrite and smaller than 5% of granular bainite; and the typical value of the yielding strength is 580 MPa, the typical value of the tensile strength is 680 MPa, and the typical value of the Charpy V type impact energy under -30 DEG C is 400 J.

Owner:MAANSHAN IRON & STEEL CO LTD

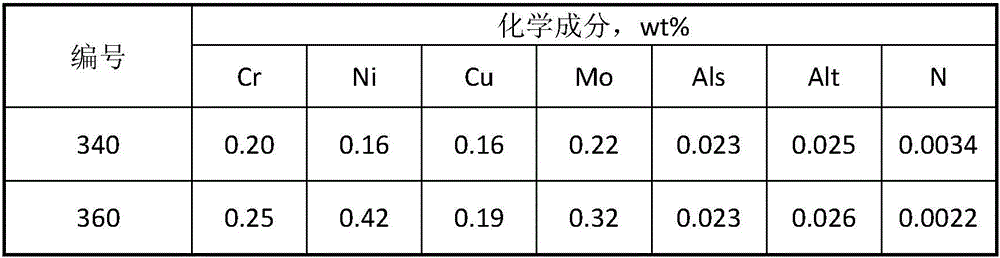

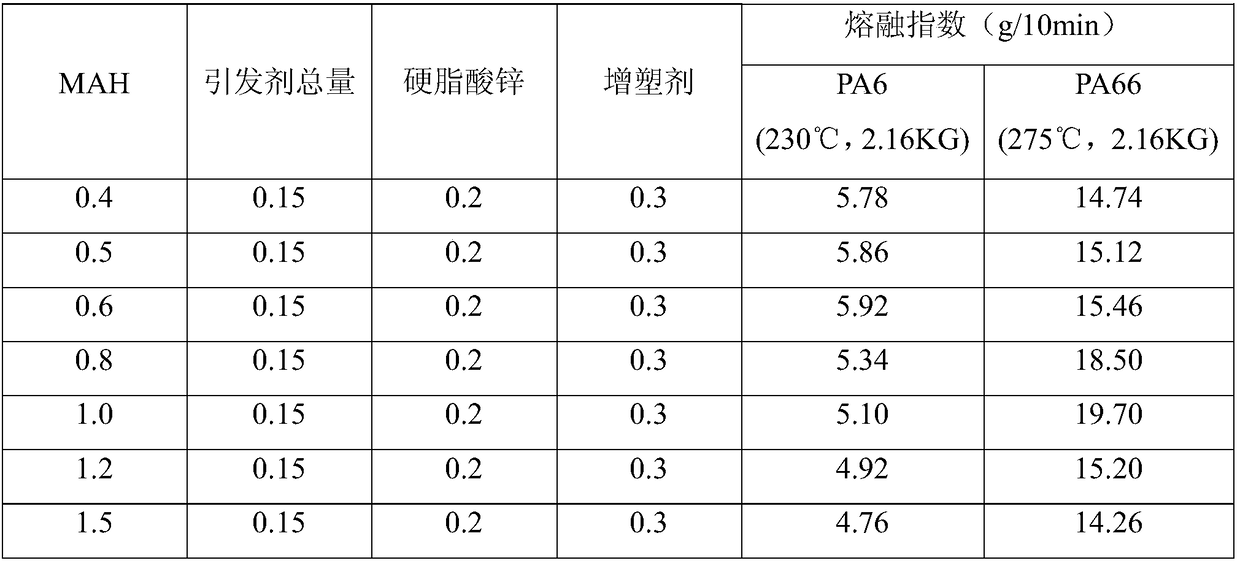

Low-temperature-resistant polyolefin grafted maleic anhydride flexibilizer used for nylon and preparation method of flexibilizer

ActiveCN108129833AImprove low temperature impact performanceGood compatibilityElastomerNylon material

The invention belongs to the field of polymer materials, and in particular relates to a low-temperature-resistant polyolefin grafted maleic anhydride flexibilizer used for nylon and a preparation method of the flexibilizer. The flexibilizer comprises the following raw materials in parts by weight: 100 parts of a polyolefin elastomer, 0.3-1.5 parts of maleic anhydride, 2-6 parts of an ionic polymer, 1.0-2.0 parts of polypropylene powder, 0.05-0.15 part of graft polypropylene, 0.05-0.25 part of a lubricant, 0.1-0.3 part of a plasticizer, 0.05-0.2 part of an initiator, and 0.1-0.3 part of an antioxidant. According to the flexibilizer provided by the invention, the maleic anhydride is grafted through the polyolefin elastomer, the polarity of the polyolefin elastomer is enhanced, and the grafted polyolefin elastomer can be used as a flexibilizer, an interfacial modifier and a compatibilizer of the nylon; and the flexibilizer can obviously improve the compatibility of the polyolefin elastomer and a strong-polarity nylon material, and can effectively improve the low-temperature impact performance.

Owner:SHENYANG KETONG PLASTIC

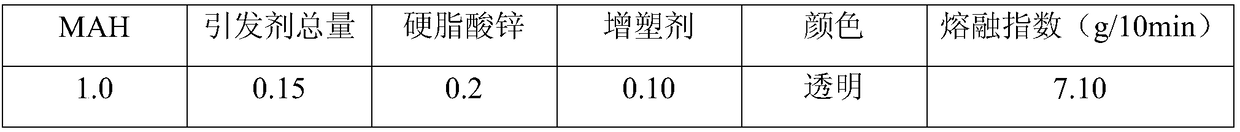

PVC (polyvinyl chloride) composite modified material and preparation method thereof

InactiveCN105602160AImprove creep resistanceImprove low temperature impact performanceRough surfacePolymer science

The invention relates to a PVC (polyvinyl chloride) modified material and a preparation method thereof, particularly a PVC composite modified material and a preparation method thereof. The invention aims to solve the following problem: the molecular chain of the existing PVC modified material has a certain amount of unsaturated double bonds which can form active centers, thereby causing poor ductility and high melt crushing tendency, and further causing rough surface and no gloss of the product. The PVC composite modified material is prepared from a PVC resin, a low-temperature toughener, an impact modifier, processing aids, a surfactant, a composite stabilizer, a covering agent, an initiator and a crosslinking agent according to parts by weight. The preparation method comprises the following steps: 1. weighing; 2. premixing to obtain a premix; 3. carrying out multi-step mixing to obtain a multi-step mixture; 4. carrying out final mixing to obtain a final mixture; and 5. carrying out extrusion granulation to obtain the PVC composite modified material. The method is mainly used for preparing the PVC composite modified material.

Owner:HARBIN ZHONGDA PROFILE TECH

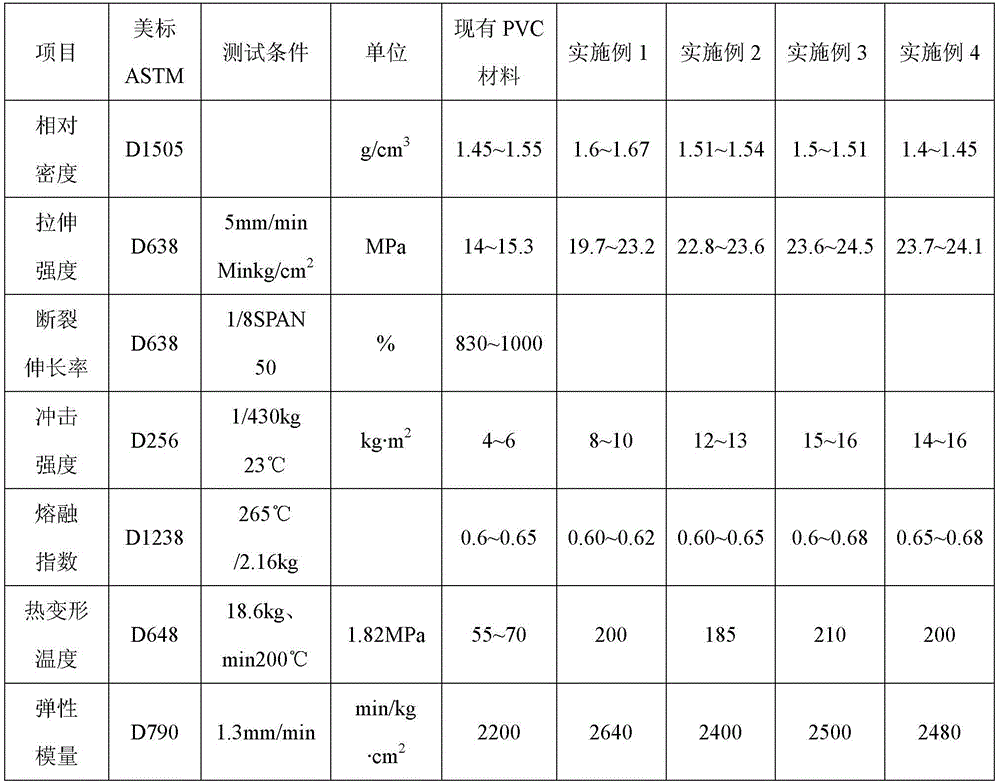

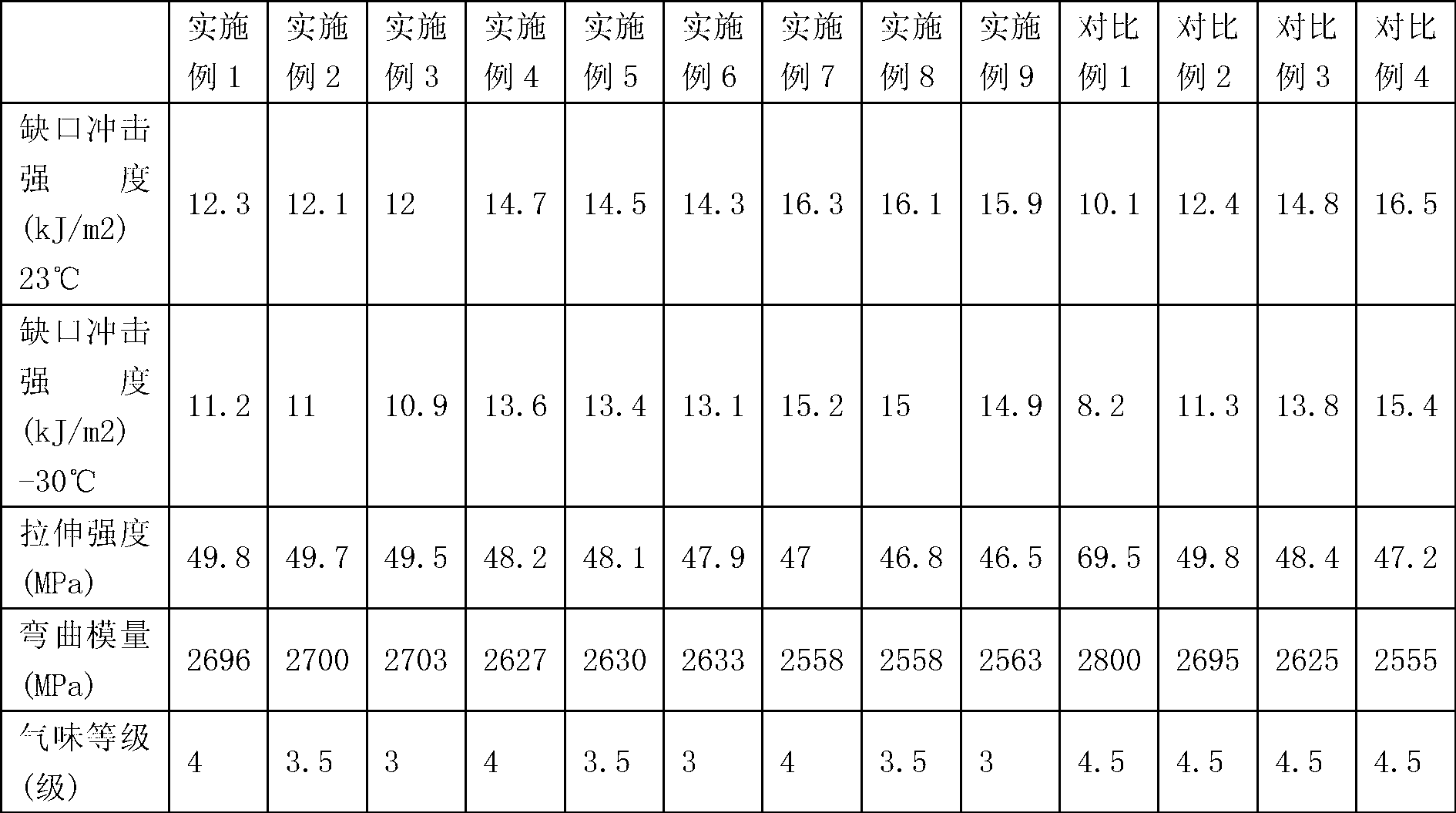

Low-odor high-tenacity polyformaldehyde material and preparation method thereof

The invention discloses low-odor high-tenacity polyformaldehyde material and a preparation method thereof. The low-odor high-tenacity polyformaldehyde material is composed of the following raw materials by weight, polyformaldehyde 83-94%, flexibilizer 5-11%, antioxygen 0.1-2%, odor inhibitor 0.5-5% and color toner or color master batch 0-2%. The low-odor high-tenacity polyformaldehyde material has the advantages that the flexibilizer and the odor inhibitor are adopted, odor of the polyformaldehyde is effectively lowered, a low-temperature impact property is effectively improved, the odor inhibitor is simple and easy to get and capable of effectively adsorbing a plurality of volatile components, accordingly obvious effect of absorbing odors is achieved, the preparation method of the low-odor high-tenacity polyformaldehyde material is simple in preparation process and low in production cost.

Owner:SHANGHAI PRET COMPOSITES

Low-cost high-strength steel plate for shipbuilding and manufacturing method thereof

ActiveCN102828108AImprove low temperature impact performanceReduce manufacturing costRoll mill control devicesMetal rolling arrangementsPhosphateHigh pressure water

The invention provides a low-cost high-strength steel plate for shipbuilding and a manufacturing method thereof. The steel plate comprises the following chemical ingredients of: by weight, 0.05-0.16% of C, 0.10-0.50% of Si, 0.90-1.50% of Mn, P being less than or equal to 0.020%, S being less than or equal to 0.015%, and the balance Fe and unavoidable impurities. The manufacturing method comprises steps of smelting, continuous casting and hot rolling, and is characterized in that heating temperature of a casting blank is 1100-1150 DEG C; high pressure water is used to remove phosphate before the casting blank enters a rolling mill; initial rolling temperature is 1120-1050 DEG C; continuous rolling is carried out for 3-5 passes; pass reduction is greater than 20%; finishing temperature during the first stage is 970-1000 DEG C; temperature waiting thickness is 2-3 times the thickness of a finished product; initial temperature during the second stage is 920-950 DEG C; rolling is carried out for 5-10 passes; accumulative deformation is greater than 50%; finishing temperature is 800-900 DEG C; cooling is rapidly carried out for 5-10 s at the cooling rate of 30-40 DEG C / s after rolling; and re-reddening temperature is 580-650 DEG C. Without the addition of Nb, V and Ti, performance of the steel plate reaches requirements of 315N / mm<2> strength-grade steel for shipbuilding by the adoption of controlled rolling and ultra-rapid cooling technologies.

Owner:ANGANG STEEL CO LTD

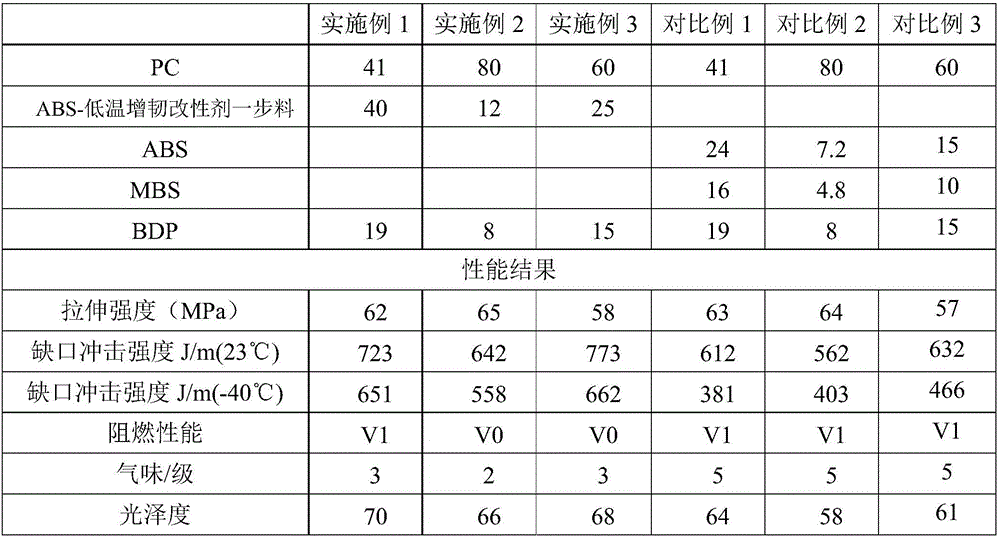

High-glossiness low-odor high-low-temperature-toughness flame-retardant PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) composition

The invention provides a high-glossiness low-odor high-low-temperature-toughness flame-retardant PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) composition which is prepared from the following raw materials in percentage by mass: 30-90% of PC, 5-25% of phosphorus-containing flame retardant and 5-50% of ABS-low-temperature toughening modifier one-step material, totaling 100%. The ABS-low-temperature toughening modifier one-step material is prepared from the following raw materials in percentage by mass: 50-80% of ABS and 20-50% of low-temperature toughening modifier. The selected ABS material and the produced ABS-low-temperature toughening modifier one-step material are proportionally mixed with the flame retardant and PC to perform modification in an extruder, thereby obviously improving the problems of the odor of the PC / ABS composition, the defects in the compacting process and the like.

Owner:TIANJIN KINGFA NEW MATERIAL

Manufacturing method of thick-wall and large-caliber high-grade pipeline steel

The invention discloses a manufacturing method of thick-wall and large-caliber high-grade pipeline steel. The purity of molten steel is improved through calcium treatment process improvement, five-hole water port use and middle ladle sampling position optimization; the macrostructure of a casting blank is improved through low-temperature and constant-pulling-speed casting; the heating temperature of the casting blank is reasonably selected to set open rolling temperatures in the first phase and the second phase; the reasonable final rolling temperature guarantees different deformation storage energy and grain boundary migration rates; organization grains are effectively refined through the final rolling temperature; the water feeding temperature, the final cooling temperature and the cooling speed are reasonably matched to guarantee fine ferrite structures and to guarantee strength and toughness of steel plates; and a reasonable reduction schedule guarantees the stability of structures and performances to satisfy the performance requirements of the thick-wall and large-caliber pipeline steel.

Owner:NANJING IRON & STEEL CO LTD

Acrylic copolymers with improved low temperature performance

InactiveUS7314893B2Improve low temperature impact performanceImproving the low temperature impact properties of an engineering plasticCoatingsCore shell2-ethylhexyl acrylate

This invention relates to a core / shell impact modifier having as a core a copolymer or terpolymer having from 25 to 75 percent by weight of 2-ethylhexyl acrylate (2-EHA) monomer units with from 25 and 75 percent by weight of n-octyl acrylate (n-OA) monomer units. This core-shell impact modifier is used in performance polymers to improve low temperature impact performance.

Owner:ARKEMA INC

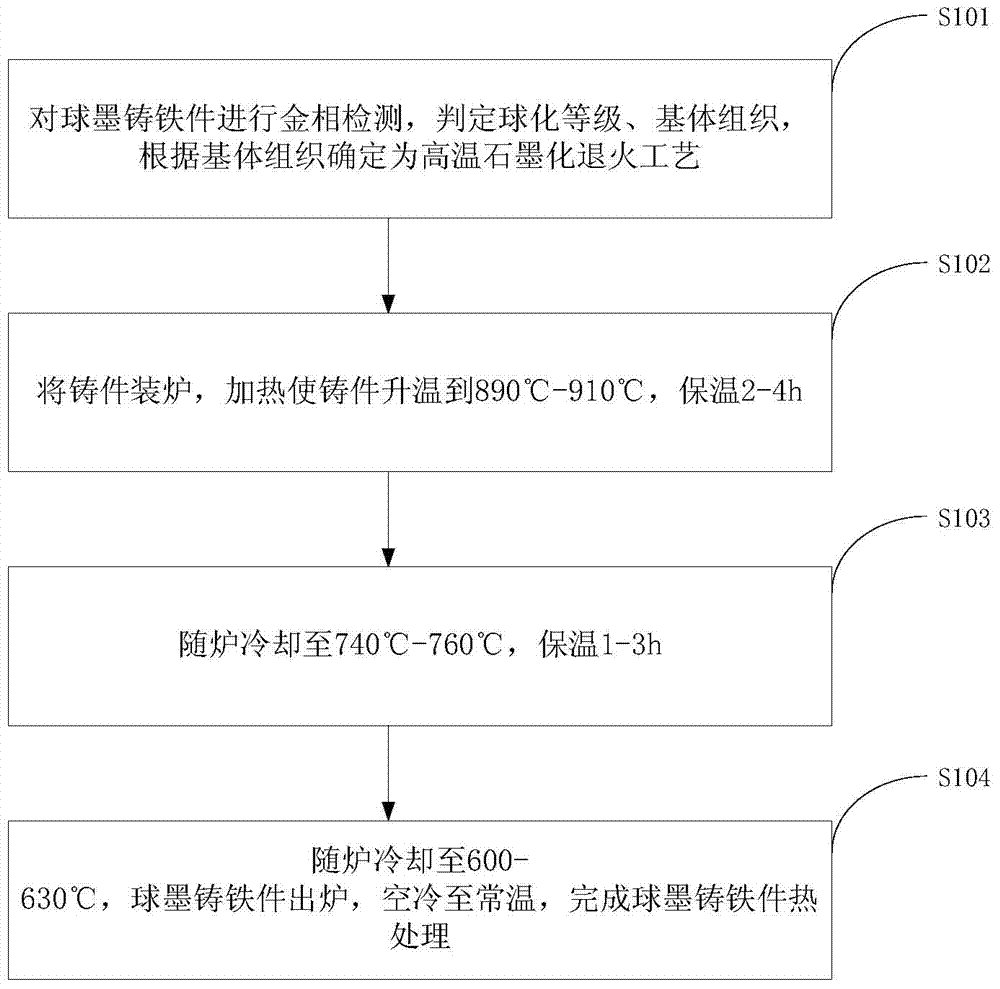

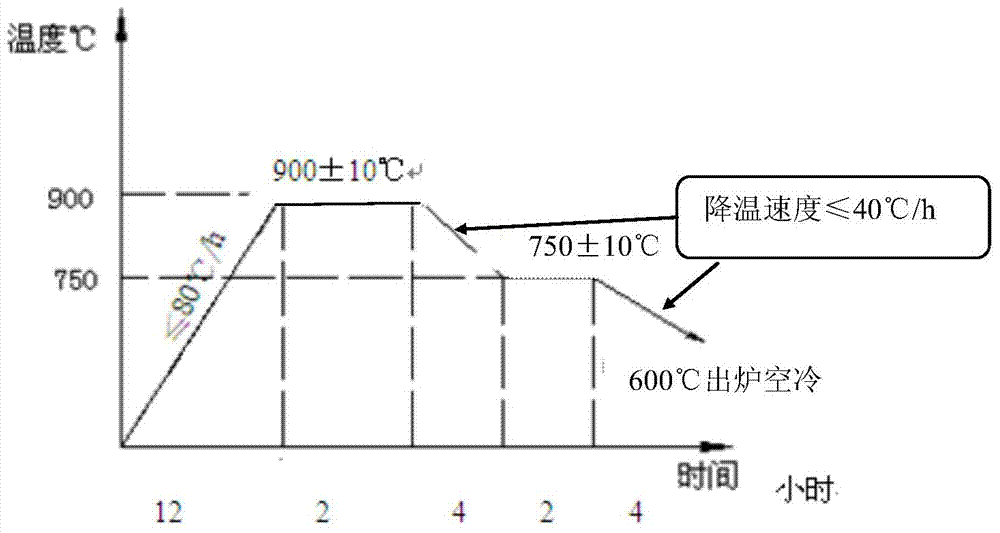

Method for performing heat treatment on nodular iron casting in nodular cast iron production

InactiveCN104726658AEliminate carbidesEnhanced low temperature impact capabilityHardnessMachinability

The invention discloses a method for performing heat treatment on a nodular iron casting in a nodular cast iron production. The method comprises the following steps: performing metallography detection on the nodular iron casting, judging the nodulizing grade and the matrix structure, and determining the high-temperature graphitization annealing process according to the matrix structure; loading the casting into a furnace, heating the casting to the temperature of 890-910 DEG C and keeping the temperature for 2-4h; cooling in the furnace to 740-760 DEG C and keeping the temperature for 1-3h; cooling in the furnace to the temperature of 600-630 DEG C, discharging the nodular iron casting, and performing air cooling to room temperature to finish the nodular iron casting heat treatment. By adopting the method for performing heat treatment on the nodular iron casting in the nodular cast iron production, the grain crystal is refined, the carbide generated in the freezing cold part is eliminated, the low-temperature impact of the nodular iron casting is reinforced, the hardness is reduced, the machinability is improved, various performances of the low-temperature nodular cast iron can be reached by the material, various property indices are obtained by a stable process, the volume production is realized and the cost is reduced.

Owner:山西清慧机械制造有限公司

Halogen-free flame retardant cold-resistant conductive polycarbonate/carbon fiber composite material and preparation method thereof

The invention discloses a halogen-free flame retardant cold-resistant conductive polycarbonate / carbon fiber composite material and a preparation method of the halogen-free flame retardant cold-resistant conductive polycarbonate / carbon fiber composite material. The halogen-free flame retardant cold-resistant conductive polycarbonate / carbon fiber composite material comprises 55-85 parts of PC resin, 10-30 parts of carbon fiber, 5-10 parts of cold-resistant flexibilizer, 0.08-1 part of fire retardant, 0.5-5 parts of synergistic fire retardant, 0.4-2 parts of antioxygen, 0.2-0.5 part of ultraviolet light absorber and 0.3-1 part of lubricant, wherein the melt flow rate MFR of the PC resin is 10-40g / 10min, and the carbon fiber is subjected to surface modification and is a chopped carbon fiber with the length of 3-12mm. The preparation method provided by the invention is simple and is easy in processing, the low-temperature impact property, the flame retardant property, the conductive property and the mechanical property of the product are further improved under the condition that the original properties of the PC resin are kept, and the halogen-free flame retardant cold-resistant conductive polycarbonate / carbon fiber composite material and the preparation method of the halogen-free flame retardant cold-resistant conductive polycarbonate / carbon fiber composite material are applicable to the fields of industries, transportation, military projects, areospace and the like with severe requirements.

Owner:聚石化学(苏州)有限公司

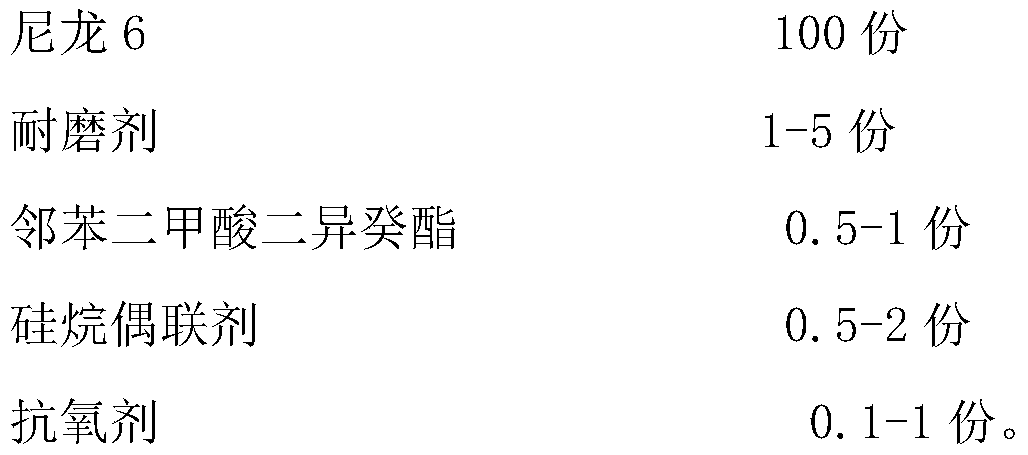

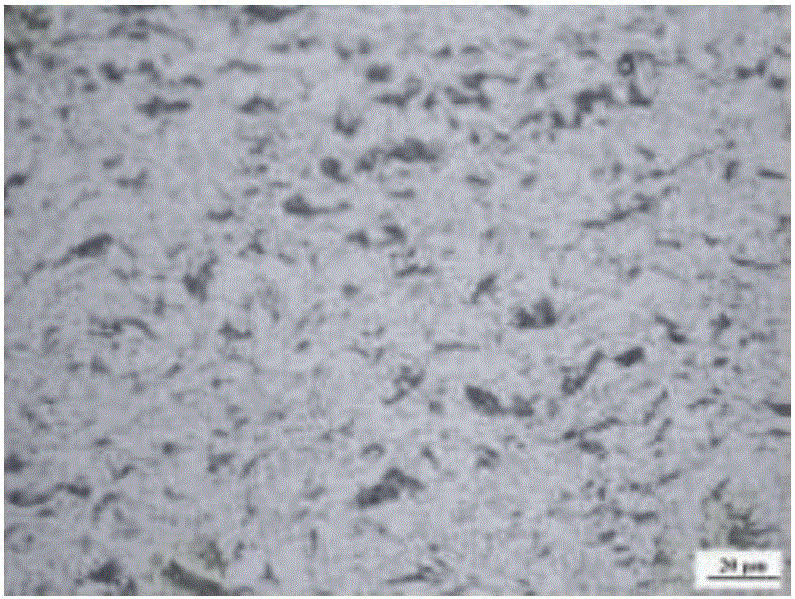

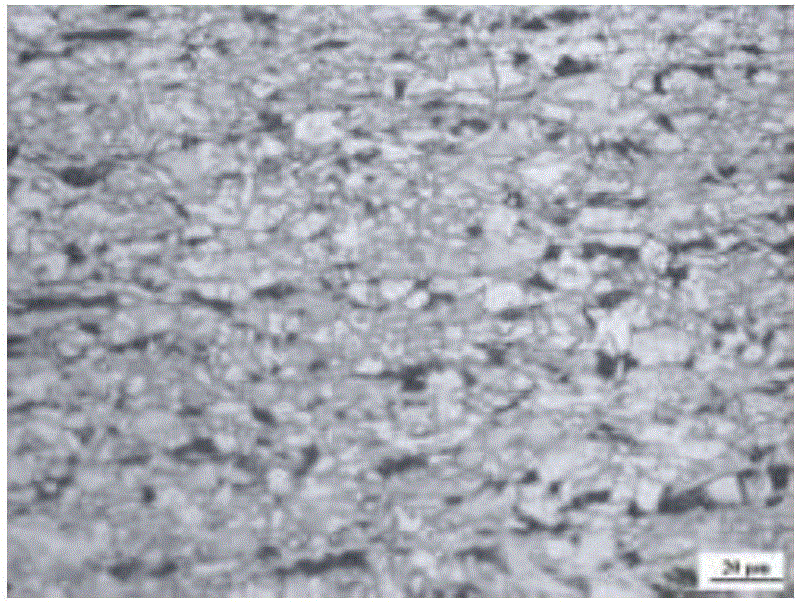

Nylon 6 composition with excellent wear resistance and preparation method of nylon 6 composition

ActiveCN110079077AImprove wear resistanceImprove low temperature impact performanceWear resistantNylon 6

The invention provides nylon 6 composition with excellent wear resistance and a preparation method of the nylon 6 composition. 100 parts of nylon 6, 1-5 parts of a wear-resistant agent, 0.5-1 part ofDIDP (di-iso-decyl phthalate) (which is 0 when not added), 0.5-2 parts of a silane coupling agent and 0.1-1 part of an antioxidant are added to a mixer to be stirred for 30-40 s at normal temperatureat low speed, and the obtained mixture after uniform mixing is added to a twin-screw extruder; granulation is performed after melt extrusion, and the nylon 6 composition with excellent wear resistanceis prepared. The used wear-resistant agent has a better wear-resistant effect than single wollastonite and alumina and excellent wear-resistant effect than common molybdenum disulfide, polytetrafluoroethylene and graphite wear-resistant agents in the market.

Owner:河北易牛工程塑料有限公司

Atmosphere corrosion resisting steel belt for railroad car and preparation method of atmosphere corrosion resisting steel belt

The invention discloses an atmosphere corrosion resisting steel belt for a railroad car. The atmosphere corrosion resisting steel belt for the railroad car comprises, by mass, 0.05-0.07% of C, 0.15-0.25% of Si, 1.2-1.4% of Mn, no more than 0.015% of P, no more than 0.006% of S, 0.22-0.32% of Cu, 0.008-0.018% of Ti, 0.20-0.30% of Ni, 0.40-0.50% of Cr, and 0.025-0.035% of Nb. The invention further discloses a preparation method of the atmosphere corrosion resisting steel belt for the railroad car. The steel belt obtained through the method has good comprehensive mechanical performance and welding performance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Boron-modified H-shape steel having well low-temperature impact flexibility and preparation method thereof

InactiveCN101255527BImprove mechanical propertiesImproved low temperature impact propertiesMetallurgyBoron

The invention relates to a boron-modified H type steel having good low-temperature impact toughness and the preparing method thereof. The steel is composed of 0.08 to 0.20 by weight percentage of C, 1.00 to 1.60 by weight percentage of Mn, 0.10 to 0.55 by weight percentage of Si, no more than 0.25 by weigh percentage of P, no more than 0.025 by weight percentage of S, 0.015 to 0.035 by weight percentage of Nb, 0.0005 to 0.0012 by weight percentage of B, and the balance Fe and trace impurity. During melting process, the gas content is controlled: no more than 0.004% of N, and no more than 0.0085% of O. According to the invention, the low-temperature impact toughness of Q345 H type steel is greatly improved; compared with Chinese standard, -40 DEG C AKV has a large surplus, the product quality is easy to be guaranteed; the Q345 H type steel can also be applied to regions having more severe condition.

Owner:SHANDONG IRON & STEEL CO LTD

A kind of extra-thick hot-rolled H-shaped steel with low ductile-brittle transition temperature and its production method

ActiveCN105586534BImprove low temperature resistanceRaise the roughening temperatureChemical compositionWater cooling

The invention belongs to the technical field of steel and particularly relates to ultra-thick hot-rolled H-shaped steel with a low ductile-brittle transition temperature and a production method thereof. The hot-rolled H-shaped steel is composed of, by mass, 0.08%-0.15% of C, 0.10%-0.40% of Si, 1.0%-1.5% of Mn, 0-0.015% of P, 0-0.008% of S, 0.020%-0.070% of V, 0.005%-0.025% of Ti, 0.006%-0.015% of N, 0.10%-0.50% of Ni, and the balance Fe and residual trace impurities. The flange thickness of the H-shaped steel is between 25 mm and 36 mm. The web height of the H-shaped steel is between 700 mm and 1000 mm. The rolling compression ratio of the H-shaped steel is lower than 3.5. The H-shaped steel is produced through a hot rolling process (instead of processes such as water cooling, ultrafast cooling and heat treatment). As for a final product, the yield strength reaches 420 Mpa or more, the tensile strength reaches 500 Mpa or more, the ductile-brittle transition temperature is lower than -65 DEG C, and the final product has good resistance to Charpy impact energy at the low temperature of -45DEG C to -65DEG C.

Owner:SHANDONG IRON & STEEL CO LTD

Mixed-gas protection high-tenacity carbon steel flux-cored wire

ActiveCN104625462AReduce the amount addedReduce burning lossWelding/cutting media/materialsSoldering mediaNiobiumPotassium

The invention relates to a mixed-gas protection high-tenacity carbon steel flux-cored wire. A flux core comprises, by mass, 32% to 49% of rutile, 20% to 25% of iron powder, 14.5% to 17% of silicon manganese alloy, 1.0% to 1.5% of low-carbon ferromanganese, 2% to 4% of quartz, 2.5% to 3.5% of aluminum oxide, 2.5% to 5% of zircon sand, 2% to 3.8% of fluoride, 3% to 6% of alloy elements and 2% to 5% of rare elements. The fluoride is one or more kinds of barium fluoride, calcium fluoride and aluminum fluoride. The alloy elements are any combination of titanium, potassium, nickel and chrome. The rare elements are one or two kinds of vanadium, niobium, boron and molybdenum. According to the mixed-gas protection high-tenacity carbon steel flux-cored wire in the formula, the adding quantity of slagging components and the adding quantity of other functional components in the flux core are optimized and coordinated; as the adding amount of the silicon manganese alloy is controlled, the adding quantity of the alloy elements is reduced, and burning losses of the alloy elements are reduced, the microelements such as the boron in the formula are accurately controlled, and the mechanical property of deposited metal is more stable; particularly, the low-temperature impacting property is greatly improved, and the impacting property can further be more stable.

Owner:JIANGSU ZHONGJIANG WELDING WIRE

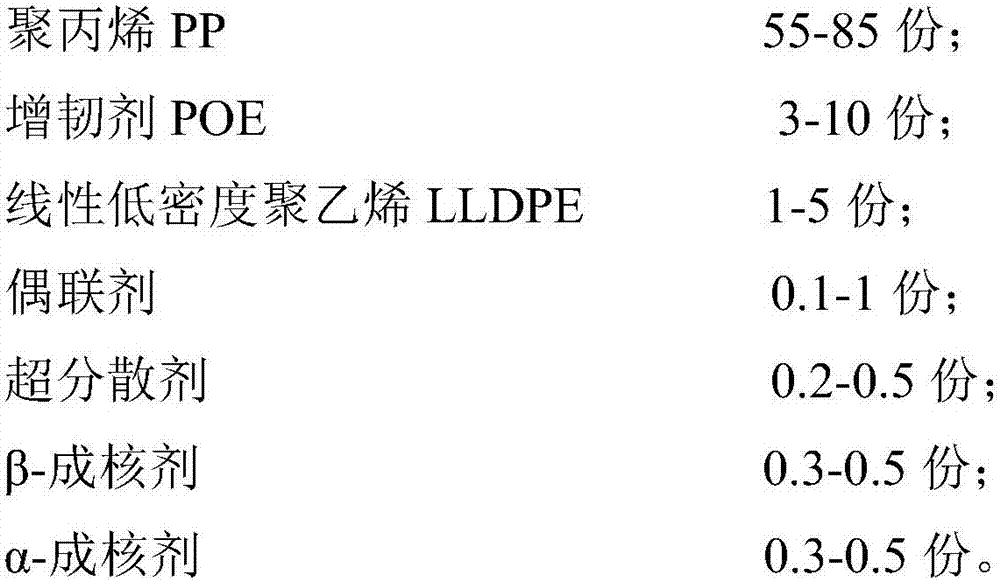

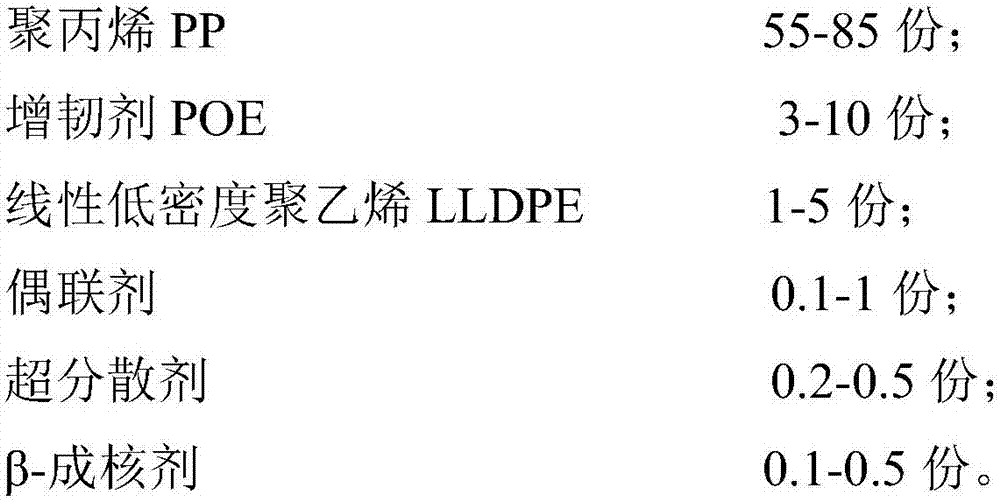

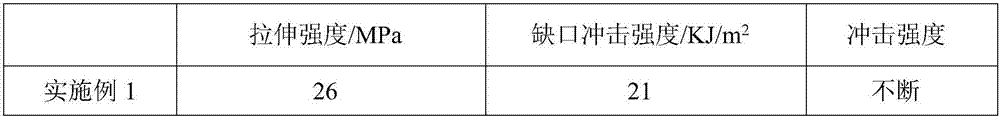

Modified polypropylene for handles of ceilings of automobiles

InactiveCN107254101ARaise the crystallization temperatureHigh crystallinityElastomerLinear low-density polyethylene

The invention discloses modified polypropylene for handles of ceilings of automobiles. The modified polypropylene which is a composite material comprises, by weight, 55-85 parts of polypropylene (PP), 3-10 parts of toughening agents POE (polyolefin elastomers), 1-5 parts of linear low-density polyethylene (LLDPE), 0.1-1 part of coupling agents, 0.2-0.5 part of hyper-dispersants, 0.1-0.5 part of beta-nucleating agents and 0.1-0.5 part of alpha-nucleating agents. The modified polypropylene has the advantages of high rigidity and toughness and wide application range.

Owner:SUZHOU SUNWAY POLYMER

Steel gas protection welding wire for railway vehicle welding

InactiveCN107350657AImprove corrosion resistanceSolve the strength problemWelding/cutting media/materialsSoldering mediaImpact energyGas protection

The invention discloses a steel gas protection welding wire for railway vehicle welding. The steel gas protection welding wire comprises chemical components, by mass, of 0.04-0.10% of C, 0.35-0.65% of Si, 1.30-1.60% of Mn, 0.020% or less of P, 0.010% or less of S, 0.20-0.50% of Cr, 0.30-0.80% of Ni, 0.19-0.40% of Cu and the balance Fe and inevitable impurities. According to the steel gas protection welding wire, the comprehensive property is good, the tensile strength is 620 MPa or over, impact energy of minus 40 DEG C is 124 J or over, and the anti-corrosion property is outstanding.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Non-tempered N80 steel-grade petroleum casing pipe and preparation method thereof

ActiveCN109136786AMake up for the defect of reduced strengthRaise the ratioFurnace typesHeat treatment process controlPetroleumMaterials science

The invention relates to the technical field of metallurgy, and particularly discloses a non-tempered N80 steel-grade petroleum casing pipe and a preparation method thereof. The non-tempered N80 steel-grade petroleum casing pipe comprises the following components in percent by weight: 0.28-0.32% of C, 0.25-0.40% of Si, 1.55-1.70% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.008% of S, 0.011-0.020% of Nb, 0.05-0.08% of V, 0.007-0.013% of Ti, 0.010-0.040% of Al, 0.013-0.017% of N, smaller than 0.10% of Cr, smaller than or equal to 0.10% of Ni, smaller than or equal to0.10% of Cu, smaller than or equal to 0.020% of As, smaller than or equal to 0.020% of Sn, smaller than or equal to 0.01% of Pb, smaller than or equal to 0.01% of Sb, smaller than or equal to 0.01% ofBi, smaller than or equal to 0.035% of Sn, As, Pb, Sb and Bi and the balance of Fe. Through component adjustment and technology optimization, design requirements on the tensile strength, the yield strength, the elongation and the impact energy of the N80 steel-grade petroleum casing pipe are met; the non-tempered N80 steel-grade petroleum casing pipe is stable in performance; compared with the tempering technology, the preparation method provided by the invention has the advantages as follows: the same quality requirements are met, the production process is shortened, energy is saved, the manufacturing cost is low, and the production efficiency is improved.

Owner:DALIPAL PIPE

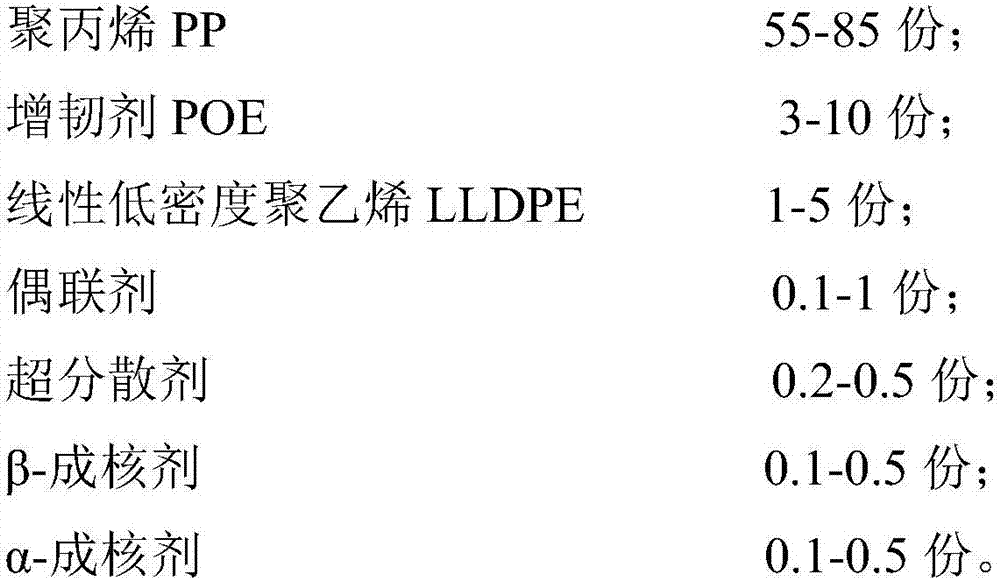

Low-temperature-impact-resistant modified polypropylene

InactiveCN107163391AImprove low temperature impact performanceGood compatibilityLinear low-density polyethylenePolymer science

The invention discloses low-temperature-impact-resistant modified polypropylene composed of, by weight, 55-85 parts of polypropylene PP, 3-10 parts of a toughening agent POE, 1-5 parts of linear low density polyethylene (LLDPE), 0.1-1 part of a coupling agent, 0.2-0.5 parts of a super-dispersant, and 0.1-0.5 parts of a beta-nucleating agent. The low-temperature-impact-resistant modified polypropylene has good low-temperature-impact resistance and has a larger application range.

Owner:SUZHOU SUNWAY POLYMER

Low-temperature-resisting fireproof polypropylene material easy to shape

InactiveCN105733101AImprove low temperature impact performanceImprove performanceInjection mouldingPolypropylene

The invention provides a low-temperature-resisting fireproof polypropylene material easy to shape. The low-temperature-resisting fireproof polypropylene material easy to shape is prepared from, by weight, 20-50 parts of ternary polymerization polypropylene, 20-50 parts of random copolymerization polypropylene, 5-30 parts of halogenated flame retardant, 5-30 parts of synergetic flame retardant, 25-40 parts of inorganic filler and 0.5-2 parts of nucleating agent. The obtained low-temperature-resisting fireproof polypropylene material easy to shape has good flame retardant performance, can still keep high performance in the low-temperature environment and is extremely good in shaping performance, and injection shaping is easier when the low-temperature-resisting fireproof polypropylene material easy to shape is applied to large products.

Owner:FOSHAN MAGIC CHEM TECH CO LTD

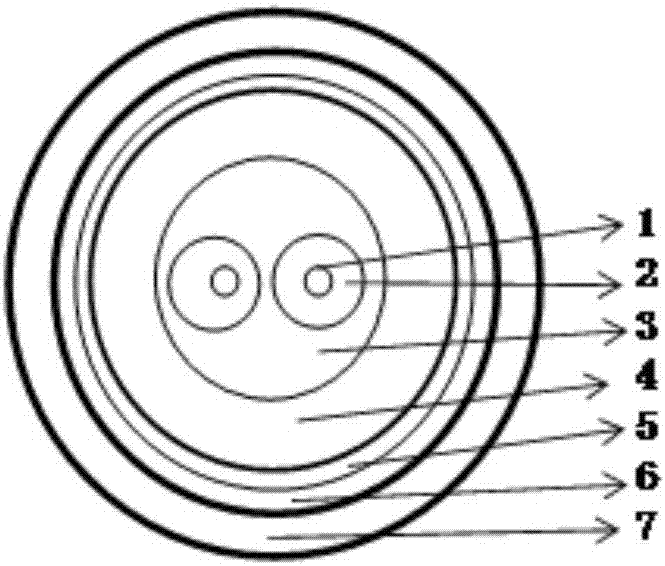

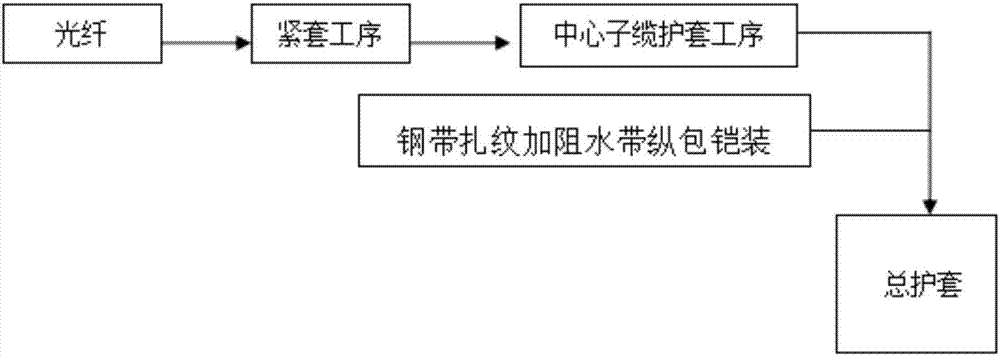

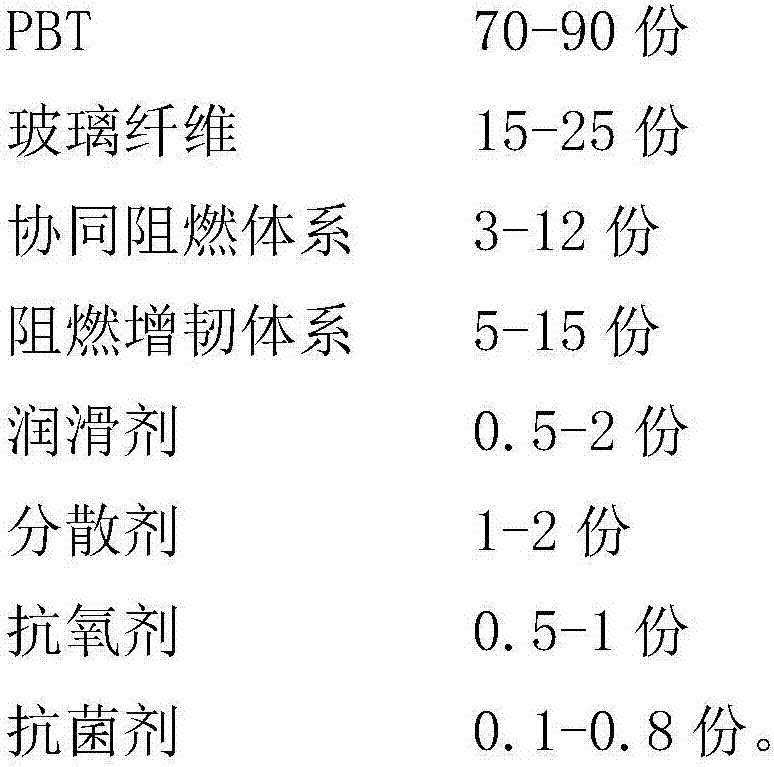

Radio frequency remote optical cable for ratproof and monkeyproof base station capable of conducting thunder and lightning and preparation method thereof

InactiveCN107286597AHigh tensile strengthHigh compressive strengthFibre mechanical structuresGlass fiberEngineering

The invention discloses a radio frequency remote optical cable for a ratproof and monkeyproof base station capable of conducting thunder and lightning. The optical cable successively comprises a tight tube optical fiber, an aramid fiber reinforcing piece, a waterproof band, a steel tape armoring layer and an outer protective layer from inside to outside, wherein the tight tube optical fiber comprises an optical fiber and a PBT tight material arranged on the outer side of the optical fiber, and the PBT tight material comprises 70-90 parts of PBT, 15-25 parts of glass fibers, 3-12 parts of a synergistic flame retardant system, 5-15 parts of a flame retardant toughening system, 0.5-2 parts of a lubricant, 1-2 parts of a dispersant, 0.5-1 part of an antioxidant and 0.1-0.8 part of an antibacterial agent. By means of a novel structural design and a process manufacturing method, stick grain longitudinal wrapping armoring of the steel tape enhances the tensile strength and compressive strength of the optical cable, and the erosion resistance is improved and the service life is prolonged. The radio frequency remote optical cable is a relatively good ratproof method, and as the tensile strength is enhanced, the optical fiber is prevented from breaking as monkeys climb and drag the optical cable.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com