Low-temperature-resistant polyolefin grafted maleic anhydride flexibilizer used for nylon and preparation method of flexibilizer

A technology of grafting maleic anhydride and maleic anhydride, which is applied in the field of toughening agent and preparation of polyolefin grafted maleic anhydride for low temperature resistant nylon. Improvement and other issues, to achieve the effect of improving low temperature impact performance, improving compatibility, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

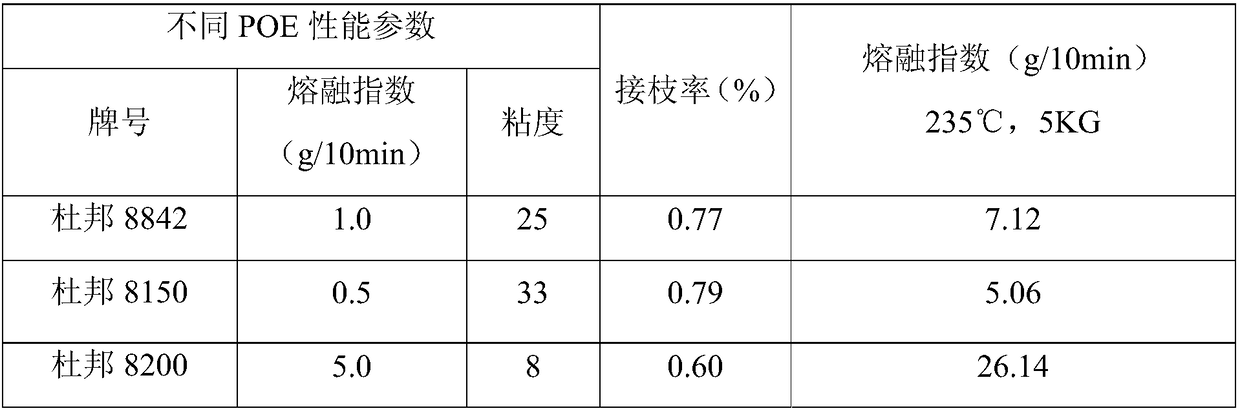

[0027] The following experiments are used to further verify different POE products.

[0028]Take 100 parts of polyolefin elastomer, 1.0 part of maleic anhydride, 4 parts of ionic polymer, 1.5 parts of polypropylene powder, 0.1 part of graft polypropylene, 0.2 part of zinc stearate, and 0.3 part of phthalate, Take different grades of polyolefin elastomers according to Table 1, mix them evenly in a high-speed mixer, and put them into a twin-screw extruder at 180°C in the first zone, 185°C in the second zone, 190°C in the third zone, and 195°C in the fourth zone. Five zones 200°C, six zones 200°C, seven zones 195°C, eight zones 190°C, nine zones 185°C, head 220°C, each zone dwell time 5 seconds, screw speed 590rpm, 0.075 parts of initiator DCP from the second zone The section cylinder is added, 0.075 parts of initiator BPO is added from the third section cylinder, 0.2 parts of antioxidant (antioxidant is a mixture of 1010 and 168, the mixing weight ratio is 1.5:1) is fed from the...

Embodiment 2

[0033] The dosage of initiator is further verified by experiments below.

[0034] Take 100 parts of polyolefin elastomer (DuPont 8842), 1.0 part of maleic anhydride, 4 parts of ionic polymer, 1.5 parts of polypropylene powder, 0.1 part of grafted polypropylene, 0.2 part of zinc stearate, 0.3 part of phthalate Formate, mix evenly in a high-speed mixer, take the initiator doses according to Table 2, and put them into a twin-screw extruder. The first zone is 180°C, the second zone is 185°C, the third zone is 190°C, the fourth zone is 195°C, and the fifth zone is 195°C. Zone 200°C, six zone 200°C, seven zone 195°C, eight zone 190°C, nine zone 185°C, head 220°C, dwell time of each zone 5 seconds, screw speed 590rpm, initiator DCP and BPO from the second section It is added with the third section cylinder (weight ratio of DCP and BPO is 1:1), 0.2 part of antioxidant (the mixture of antioxidant is 1010 and 164, the mixing weight ratio is 1.5:1) is fed from the side, after Stranding,...

Embodiment 3

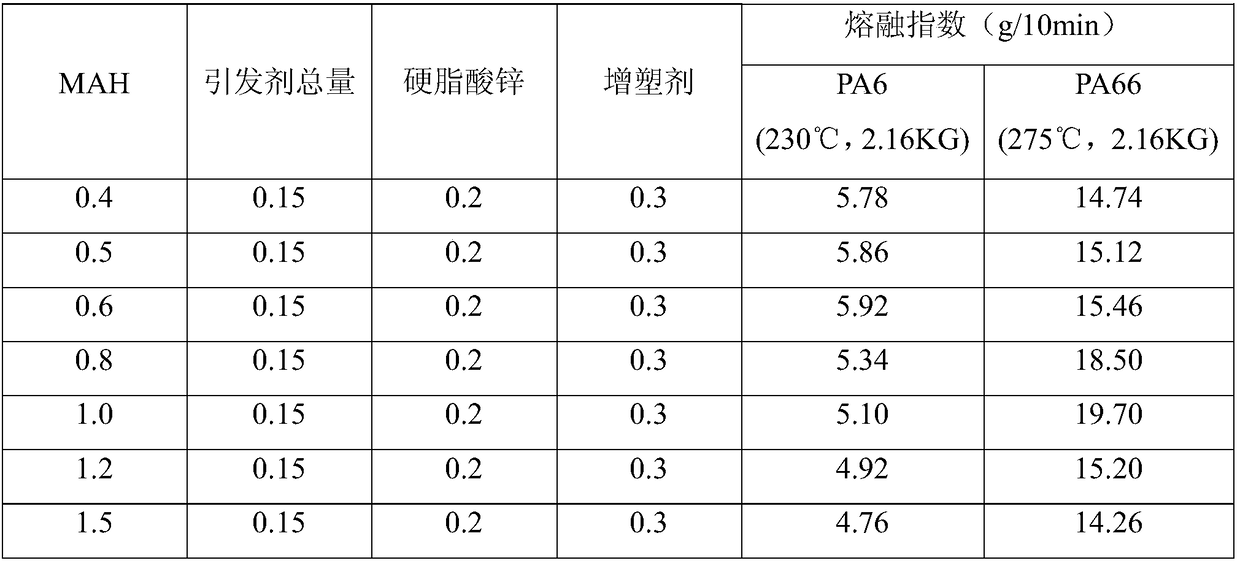

[0039] The dosage of maleic anhydride is further verified by experiments below.

[0040] Take 100 parts of polyolefin elastomer (DuPont 8842), 4 parts of ionic polymer, 1.5 parts of polypropylene powder, 0.1 part of grafted polypropylene, 0.2 part of zinc stearate, 0.3 part of phthalate, according to the table 3. Take the amount of maleic anhydride and mix them evenly in a high-speed mixer. Extrusion process: After the materials are mixed evenly, they are put into a twin-screw extruder. Zone 195°C, five zone 200°C, six zone 200°C, seven zone 195°C, eight zone 190°C, nine zone 185°C, head 220°C, dwell time of each zone 5 seconds, screw speed 590rpm, 0.075 parts of initiator DCP is added from the second cylinder, 0.075 parts of initiator BPO is added from the third cylinder, and 0.2 parts of antioxidant (antioxidant is a mixture of 1010 and 1076, the mixing weight ratio is 1.5:1) is fed from the side , after pulling, cooling and dicing;

[0041] Nylon was prepared as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com