Non-tempered N80 steel-grade petroleum casing pipe and preparation method thereof

An oil casing, non-quenched and tempered technology, applied in the metallurgical field, can solve the problem that the non-quenched and tempered N80-1 steel grade oil casing cannot meet the matching requirements of high strength and impact toughness, and avoid excessive grain growth. , High rolling elongation and diameter reduction, the effect of improving low temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

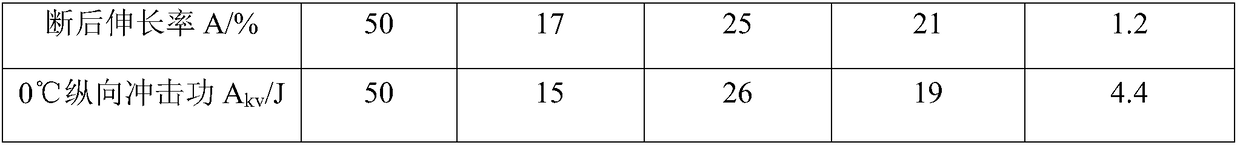

Examples

Embodiment 1

[0044] The embodiment of the present invention provides a non-quenched and tempered N80 steel grade petroleum casing, the chemical composition of which is:

[0045] C 0.28%, Si 0.32%, Mn 1.55%, P 0.006%, S 0.004%, Nb 0.016%, V 0.05%, Ti 0.013%, Al 0.040%, N 0.015%, Cr 0.05%, Ni 0.03%, Cu 0.01 %, As 0.020%, Sn0.005%, Pb 0.002%, Sb 0.004%, Bi 0.001%, and the balance is Fe.

[0046] The preparation steps of the above-mentioned non-quenched and tempered N80 steel grade petroleum casing are as follows:

[0047] Step 1. Using steel scrap as raw material, after electric arc furnace smelting, LF refining, and continuous casting, a continuous casting round billet with a specification of Φ180mm is obtained;

[0048] Step 2, after the continuous casting round billet is heat-treated in an annular furnace, it is perforated to obtain a capillary tube;

[0049] The furnace temperature of the heating furnace is: the temperature of the preheating section is 700°C, the temperature of the firs...

Embodiment 2

[0054] The embodiment of the present invention provides a non-quenched and tempered N80 steel grade petroleum casing, the chemical composition of which is:

[0055] C 0.30%, Si 0.40%, Mn 1.70%, P 0.015%, S 0.005%, Nb 0.011%, V 0.06%, Ti 0.007%, Al 0.025%, N 0.013%, Cr 0.08%, Ni 0.10%, Cu 0.06 %, As 0.002%, Sn 0.02%, Pb 0.001%, Sb 0.01%, Bi 0.002%, and the balance is Fe.

[0056] The preparation steps of the above-mentioned non-quenched and tempered N80 steel grade petroleum casing are as follows:

[0057] Step 1. Using steel scrap as raw material, after electric arc furnace smelting, LF refining, and continuous casting, a continuous casting round billet with a specification of Φ180mm is obtained;

[0058] Step 2, after the continuous casting round billet is heat-treated in an annular furnace, it is perforated to obtain a capillary tube;

[0059] The furnace temperature of the heating furnace is: the temperature of the preheating section is 650°C, the temperature of the first...

Embodiment 3

[0064] The embodiment of the present invention provides a non-quenched and tempered N80 steel grade petroleum casing, the chemical composition of which is:

[0065] C 0.32%, Si 0.25%, Mn 1.63%, P 0.002%, S 0.008%, Nb 0.020%, V 0.08%, Ti 0.010%, Al 0.010%, N 0.017%, Cr 0.02%, Ni 0.04%, Cu 0.10 %, As 0.006%, Sn0.003%, Pb 0.01%, Sb 0.002%, Bi 0.01%, and the balance is Fe.

[0066] The preparation steps of the above-mentioned non-quenched and tempered N80 steel grade petroleum casing are as follows:

[0067] Step 1. Using steel scrap as raw material, after electric arc furnace smelting, LF refining, and continuous casting, a continuous casting round billet with a specification of Φ180mm is obtained;

[0068] Step 2, after the continuous casting round billet is heat-treated in an annular furnace, it is perforated to obtain a capillary tube;

[0069] The furnace temperature of the heating furnace is: the temperature of the preheating section is 750°C, the temperature of the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com